Page 1

Automatic Drum

Washing Machine

HA1000TE HA800TE HA600TE

Table of Contents

Before using

Names of Parts---------------------------------inside front cover

Matters Needing Attention-------------------------------------1-3

Installation---------------------------------------------------------4-5

Control Panel--------------------------------------------------------6

Operational Functions-----------------------------------------6-7

During using

Program Selection-------------------------------------------------8

Preparation----------------------------------------------------------9

Washing Methods--------------------------------------------10-11

Other Function----------------------------------------------------12

Maintenance

Maintenance ------------------------------------------------------13

Trouble Shooting-------------------------------------------------14

Wiring Circuit------------------------------------------------------15

Technical Specification---------------------------------- --------16

Page 2

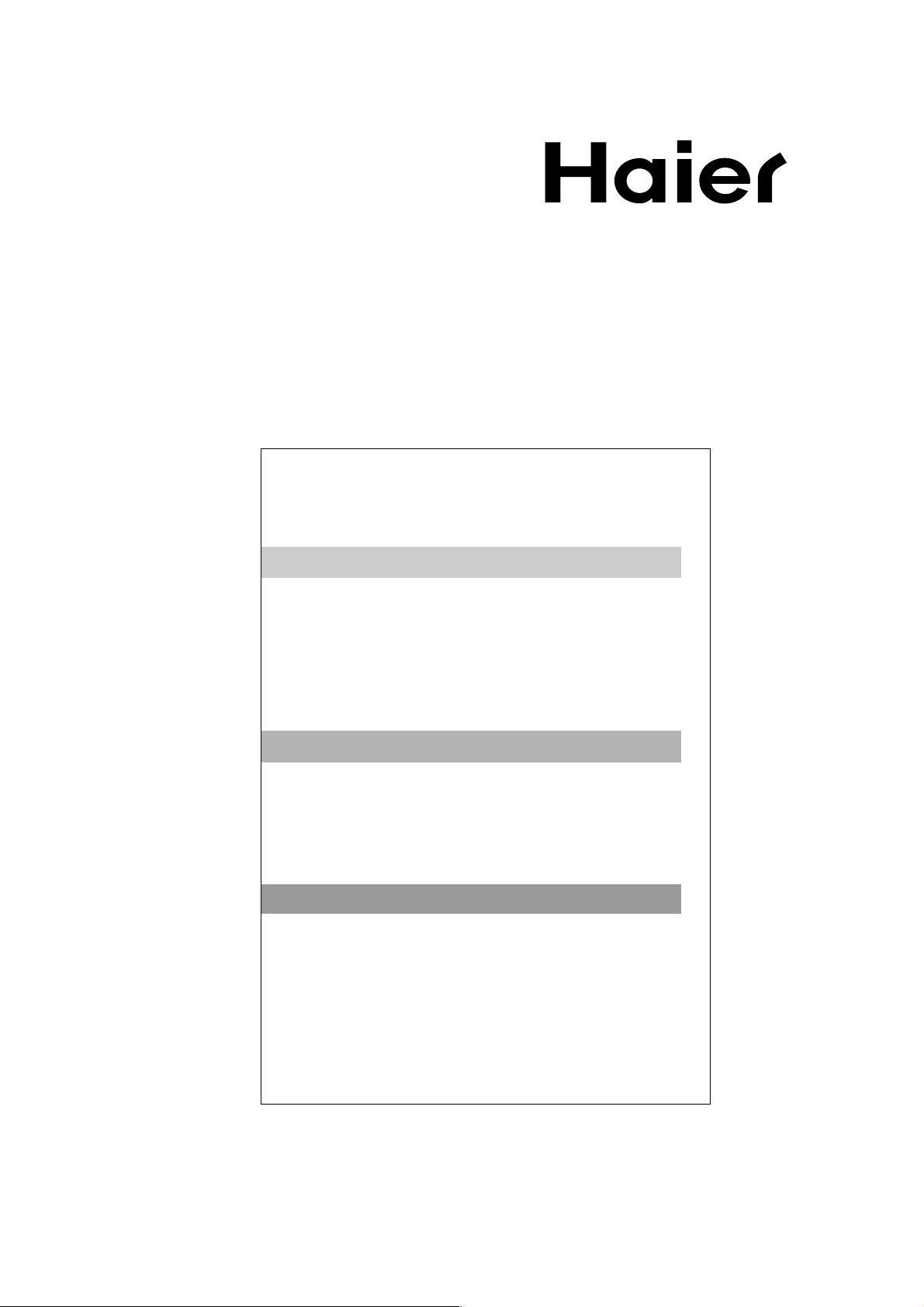

Names of Parts

Washing Allocating box

Wash Door

Observing Glass Window

Power supply cable

Table Cover

Operation Button

Program Knob

Temperature knob

Earth terminal

Back plate screw (3)

Drainage hose

Drainage hose clip

Packing bolt (3)

Back plate

Caution and Warning symbols

For your safety, any instructions in this manual with this "Warning" sign

shall be strictly followed.

For your safety and to prevent damages to the washing machine, any

instructions in this manual with this "Stop" sign shall be strictly followed.

This diagram may vary slightly with the layout of the washing machine you have just purchased due

to technical improvements.

Page 3

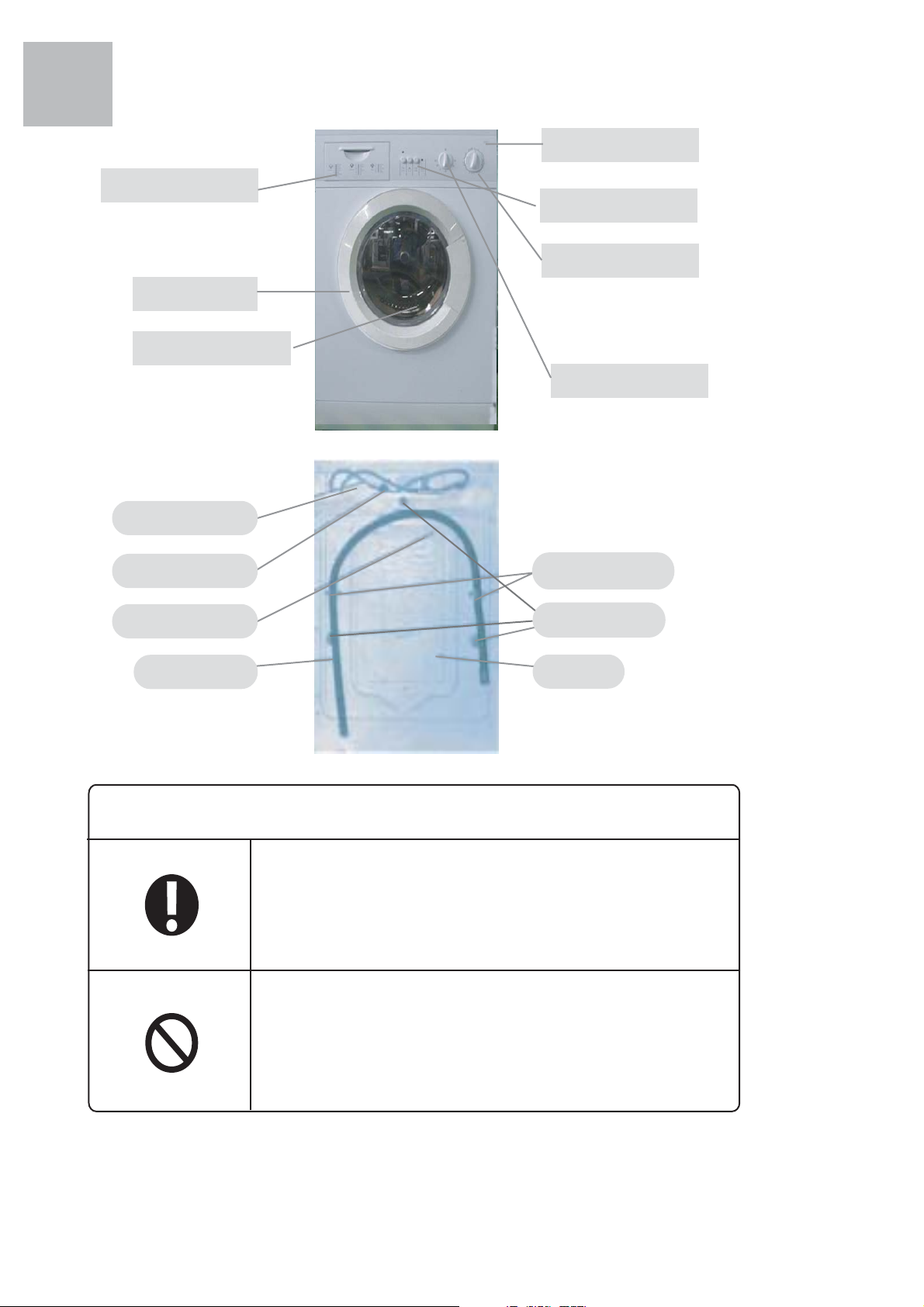

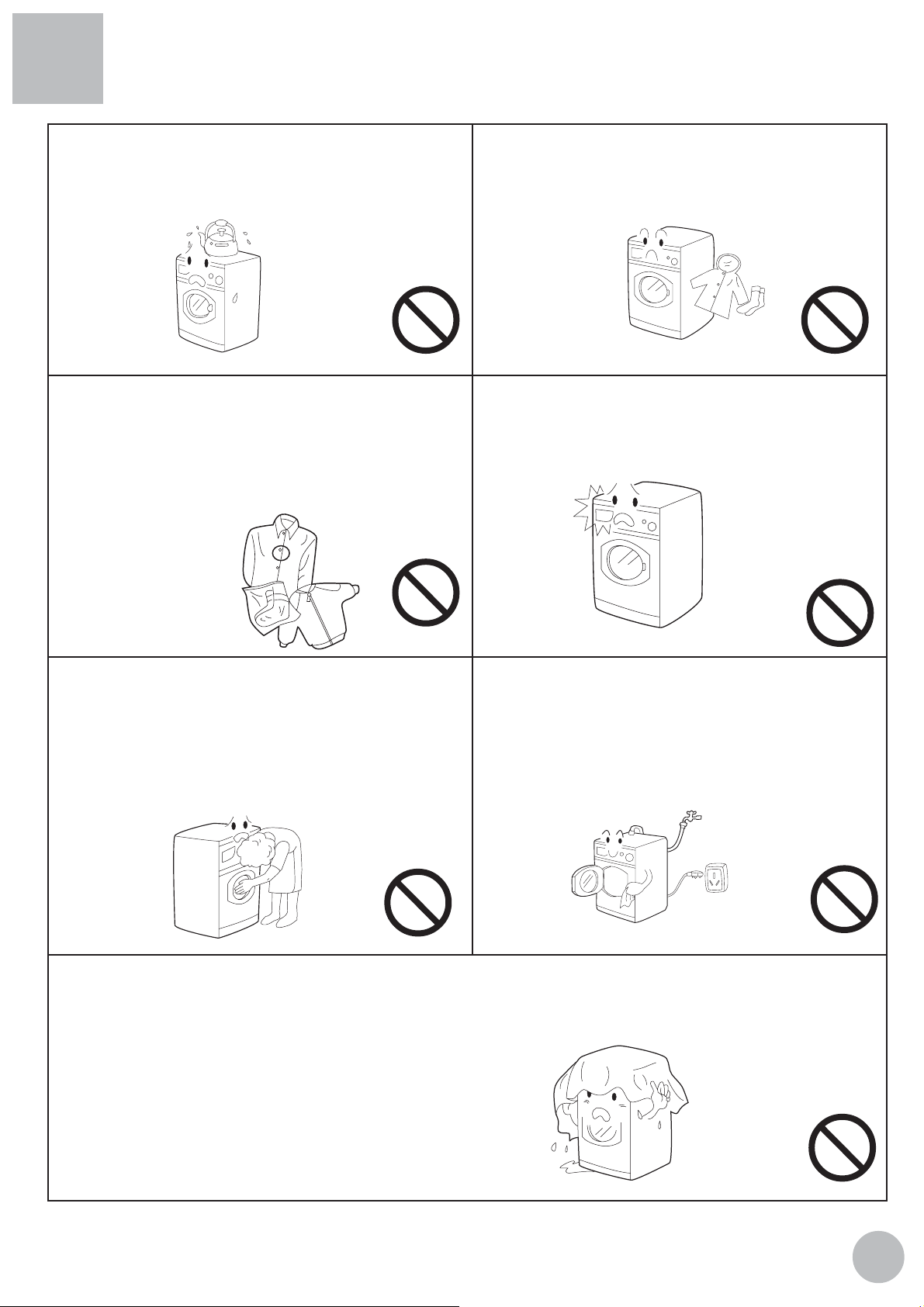

Matters Needing Attention

ƽ

Safety

1. A separate earthed socket is required

for the power supply. After installation of

the washing machine,the power plug

should be accessible during the normal

wash.

3. Fuses in the power circuit should be rated

for 15A. Refer to a washing machine technician or a Haier designated service point for

power cable replacement.

2. Hold the plug and not the electric cable

when unplugging the washing machine.

4. For your safety, dry hands before touching the washing machine and wear appropriate footwear .

5. Do not use flammable detergent or dry

cleaning agent; do not use flammable

spray in close vicinity to the washing

machine; do not remove or insert the plug

in the presence of flammable gas.

7. Do not allow children play with the packing materials after unpacking.

6. The door of the washing machine will become hot during the water heating process.

Avoid contact with the door during the heating process. For safety, keep children away

from the washing machine.

1

Page 4

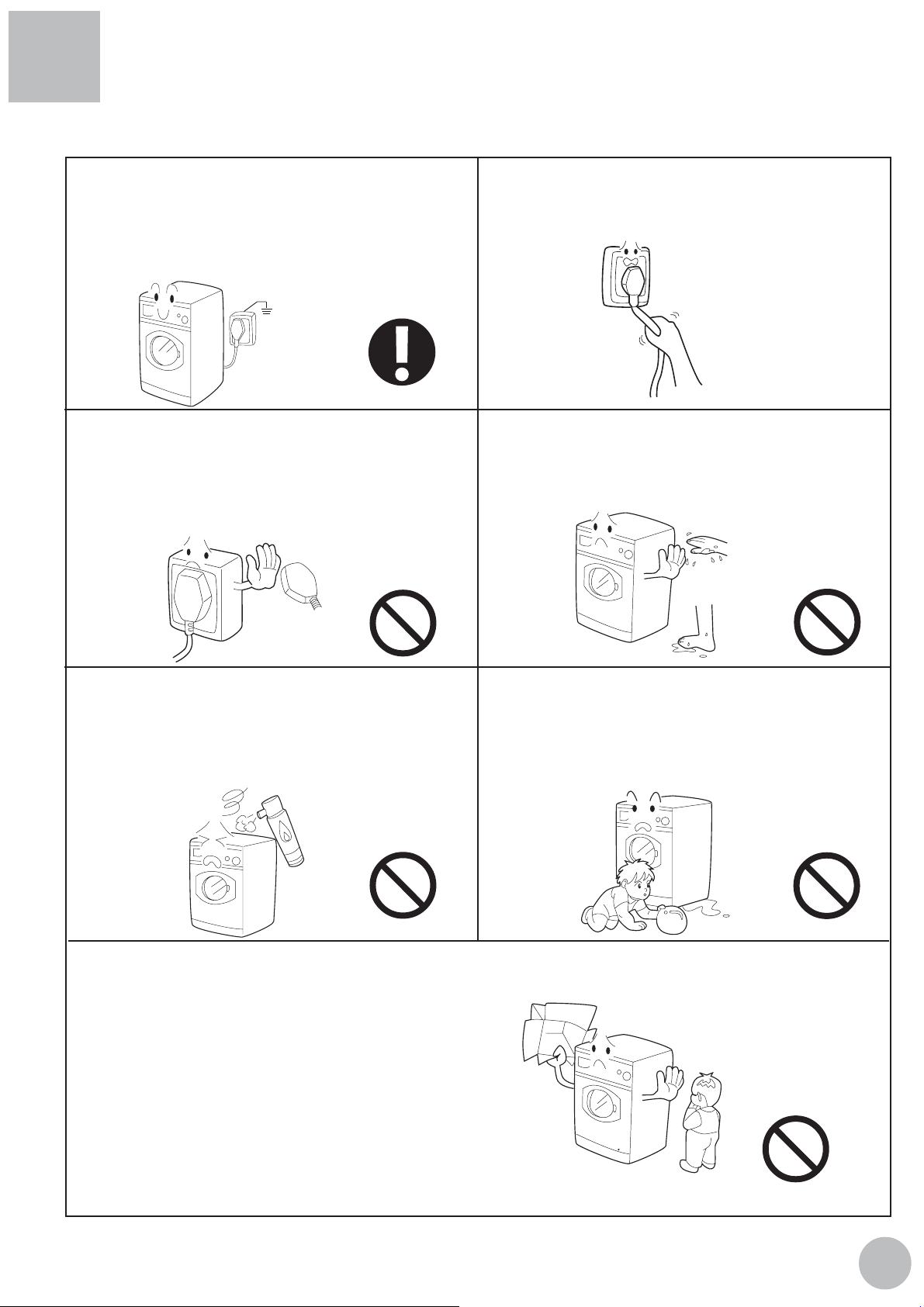

Matters Needing Attention

ƽ

Use

2

Page 5

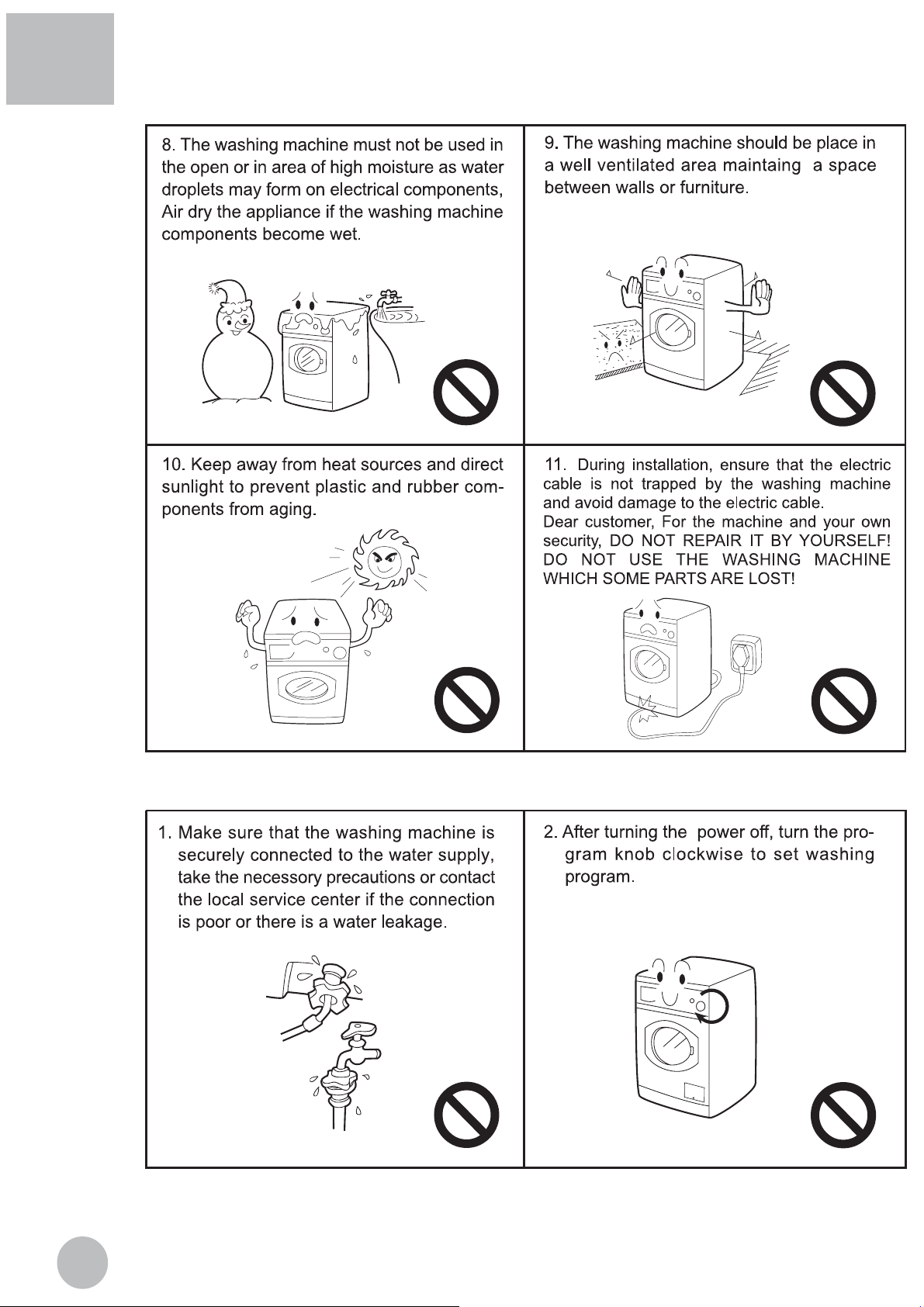

Matters Needing Attention

3. Never place heavy objects ,a heating

applianceor a water container on the top panel

of the washing machine.

5. Before washing, do up zippers, buttons ,

laces and repair damaged areas,underwear or small articals should be placed

in the laundry bag or a pillowslip.

Do not wash clothes containing wire

frames.

4. Do not wash foam rubber or similar sponge

materials.

6. Do not open the detergent box during

the wash cycle.

7. The door is fitted with a self-lock device and

will not open until 2~3 minutes after the washing machine stops. Do not force the door

open. Do not open the door when water level

reaches the port hole.

9. Keep the door slightly open when the washing machine is not being used. Never cover the

machine with a plastic sheet.

8. After washing, turn off the tap to prevent

leakage; unplug the washing machine

and wipe clean the lower part of the port

hole.

3

Page 6

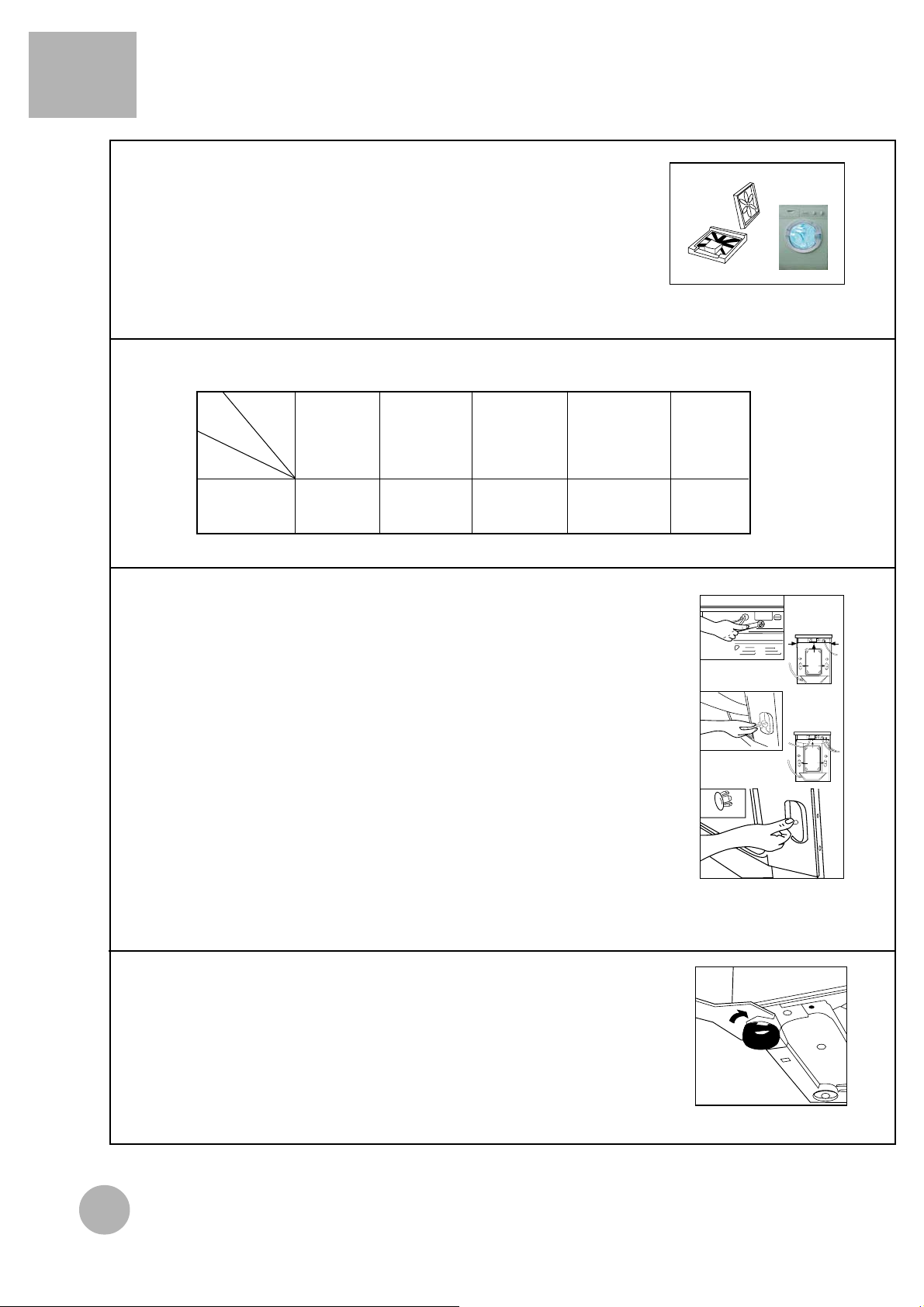

Installation

As shown in figure1 remove all the packing materials

ƽ

(including the foam base).

Upon opening of the package, water drops may be seen on

the plastic bag and the porthole. This in normal phenomenon

resultingfrom water test in the factory.

ƽ

Check attachments and materials.

Fig 1

Name

Qty

Model

HA1000TE

HA800TE

HA600TE

Remove the packing screws as shown in figure 2.

ƽ

The packing bolts protect the appliance from shock during transportation The steps below should be followed before using the

appliance,

1. Remove the rear panel of the washing machine;

2. Remove the three packing bolts from the rear panel of the washing machine,the rubber hose and then the shock absorption channel steel;

3. Reinstall the back plate;

4. Fill the holes left by the packing bolts with plastic plugs.

(Attention: the packing bolts and rubber hose should be kept in a

safe place for later use)

Operational

manual

1

Quality

certificate

Water

hose

1

Drainage

holder

11

Plastic

plugs

3

Adjusting the position of the washing machine .There are ad-

ƽ

justable feet under the bottom of the washing machine. Before use,

the washing machine should be adjusted, as shown in figure 3, so

that it is level.

4

Fig 2

Fig 3

Page 7

Installation

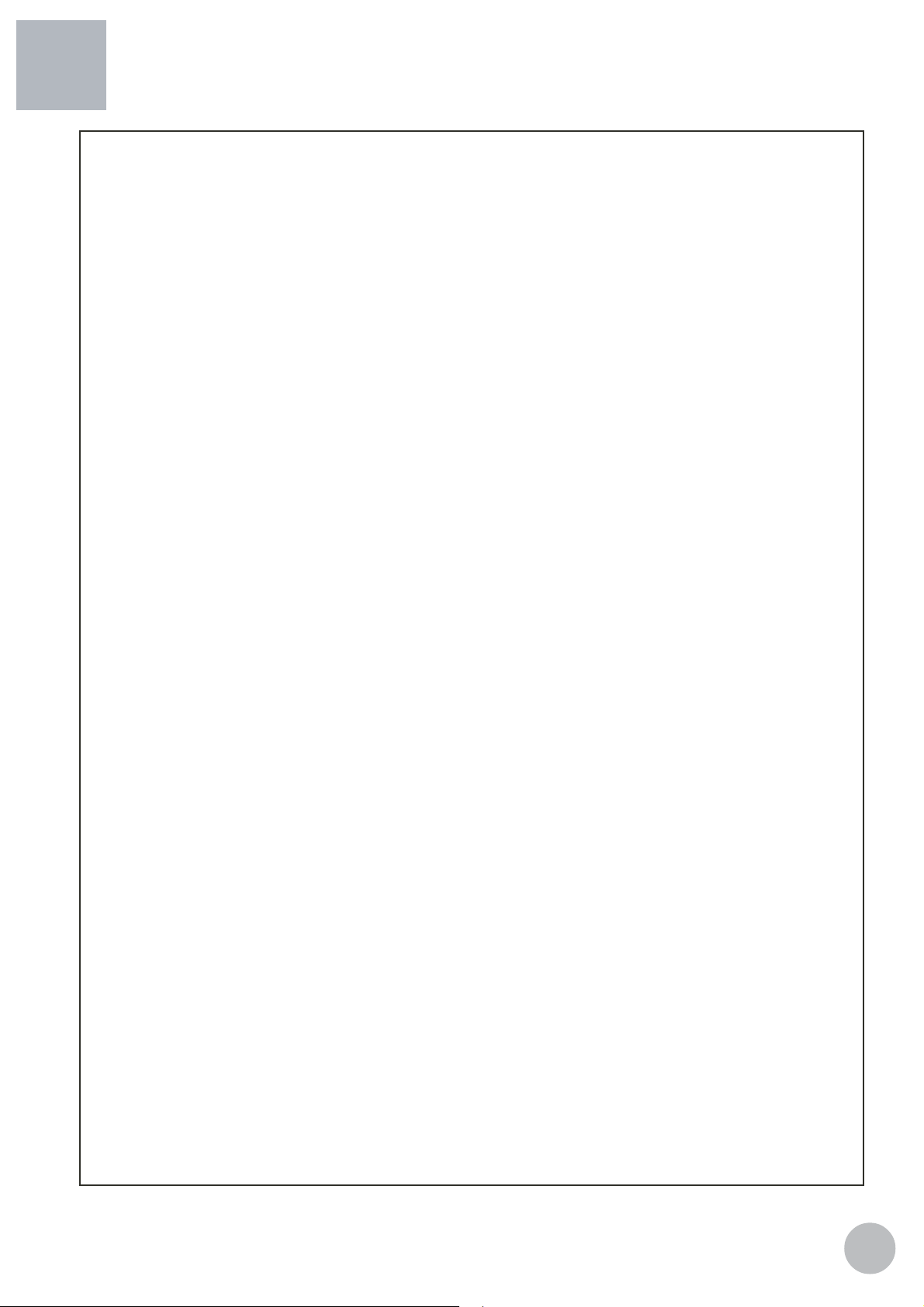

Connection of water inlet hose and washing machine

.

Waterdrainagehose

The height of the terminal of the water drainage

hose should be between 80cm-100cm, the water

drainage hose must be securely placed on the clip

on the back of the washing machine.

Use the water drainage support supplied as an

accessory for proper installation of the water drainage hose .fix the water drainage hose support with

waterproof sring.Do not use an excessively long water drainage hose and contract the authorized technician if the water drainage hose needs to be

extended.the water drainage hose should not be extended more than250cm.(longer extension will result

in concurrent water inflow and outflow).The diameter of the extension hose should be the same as

the original hose.

caution:water drainage hose must not be immersed

in water.the original and extension hoses should be

tightly connected .

100cm

80cm

Connection of power supply

Check the following items before connection to the power supply.

The socket conforms to the maximun power load(The maximum current load of the socket and

power supply cable should not be less than 15A).

Power supply voltage conforms to the required value.

The power supply socket and the plug of the washing machine compatible,if they are compatible ,Refer to a washing machine technician or a Haier designated service point for power cable

replacement.The washing machine should be connected to an earth before use.

Supplementary earth cable should not be necessary if the socket is connected to the earth.

Supplementary earth cable should be installed on the upper back of the washing machine

andconnected to an earth if the power supply socket has no earth connection.

5

Page 8

Control Panel

H

0

15

14

90

80

70

60

13

30

12

40

11

50

10

1

2

3

4

5

6

7

9

8

Turn the knob at "0", then turn off the power and

turn the program knob for setting desired wash program.

The program knob will not rotate with the programmed washing

process.

0

1

15

14

13

12

11

10

90

80

70

2

3

4

5

6

7

9

8

30

40

50

60

6

Page 9

Operational Functions

Economic Wash button

Soak Button

For the synthetics cycle and the wool cycle, push the

button down, th e anticrease fu ntion will b e skiped and

automatically enter into the next step;Release the

button,the anti-crease funtion willwork again.

It reduces water and power consumption when

rinsingifthemachinedoesnothaveafullload.

Note: Select this function when "Cotton" "Synthetics", "Wool" or "Silk"

(programs 1-12) is selected.

7

Page 10

Program Selection

HA1000TE/HA800TE/HA600TE

Program Setting Laundry Temperature

-30-40-50-60

1

Intense

Very heavy soil

*

-70-80-90

Silk

2

3

4

5

6

7

8

9

10

11

12

Prewash

Normal

Middle

Delicate

Normal

Middle

Delicate

Normal

Delicate

Normal

Delicate

Heavy soil

Soiled cotton

Non-fade and medium

soiled cotton

Fading and medium

soiled cotton

Non-fade heavily

soiled chemical fiber

Non-fade and medium

soiled chemical fiber

Fading and medium

soiled chemical fiber

Non-fade heavily soiled

woolen fabrics

Fading and medium

soiled woolen fabrics

Non-fade heavily soiled

silk fabrics

Fading and medium

soiled silk fabrics

-30-40-50-60

*

-30-40-50-60

*

-30-40

*

*

-30-40-50-60

*

-30-40

*

*

-30-40

*

*

-30

*

*

13

14

Quick

Rinse

Medium-soiled lanudry

-30

*

*

15

0

NOTE: " " means softener liquid detergent canbe added when necessary.

" " means detergent can be added when necessary.

" " means no detergent can be added.

Spin

End

*

Turn the program knob at "0" position and turn off the power. The wash

program ends and the washing machine stops operation.

8

Page 11

Preparation

2. Water supply

1. Power supply

Plug in the power supply

220V~240V/50Hz.

Turn on the tap ensure that the water is clear.

Caution: Before staring the washing machine turn on the

water faucrt to ensure that the water faucet and the water

inlet hose are connected correctly and do not leak.

4. Detergent selection

Only special low foam detergent

should be used in automatic

drum washing machine, form

blended or wool fabrics special

detergent should be used. dry

cleaning solvent should not be

used such as trichhloroethylene

or alike (caution :load the required amount of detergent only).

3. Laundry treament

sort out clothes according to type and extent of dirt.

ƽ

There are three types of clothes: cotton, synthetical and

woolen (silk) fabrics.

separate white clothes from colored. If whites and

ƽ

coloreds are combined for one load, make sure the

coloreds are colorfast.

-Remove all objects from pockets that may cause dam-

age to the machine, such as keys and coins.

-Clothing with frayed edges or yarns should be put in a

wash bag or special bag before washing.

-Repaire damaged clothing,lose buttons or damaged zips

and hooks before washing.

-Bed sheets and table ware should be loosely loaded and

not folded.

This washing machine is for household use and de-

ƽ

signed for mechanically washable clothes. When washing,

separate unwashable clothes with reference to clothes

labels.

5.Wash Load

Type

Max load

Non-fade cottons

5kg 2kg 1kg

Delicate fabrics

Woolen fabrics

Blending fabrics

2.5kg

9

Page 12

Washing Methods

1. Laundry loading

Evenly load the laundry in the

washing machine and then tightly

close the door of the washing

machine

Note: 1) When first using the

washing machine, let it run unloaded for one program to prevent the laundry from being

tainted by oil or dirty water from

the washing machine. 2) Do not

overload the washing machine.

2. Use of detergent

Overalls

ƽ

(cotton 950g)

ƽ

Blended

fabric clothes

(800g)

shirt

ƽ

(cotton

300g)

ƽ

Single bed

sheets

(cotton 800g)

Reference loading

ƽ

Woolen blankets

(3000g)

ƽ

Jeans (800g)

ƽ

Pajamas (200g)

ƽ

Shirts

(300g)

ƽ

Underwear

(blended fabrics 70g)

ƽ

Socks

(blended fabrics 50g)

ƽ

Jackets

(cotton 800g)

Pull out the detergent drawer, put required detergent, softening agent and bleaching agent into the corresponding boxes.

Push back the drawer gently.

Caution: 1) Do not add liquid detergent into box 1 and 2

2) For pre-washing program, detergent should

be added to both box 1 and 2; for other

programs, do not add detergent to box 1

3) Do not overuse softening agent as this may

damage artificial fabrics.

3. Washing program setting

Set the wash program correctly in accordance with the laundry load. The methods for

setting wash programs are indicated on the handle of the distributor on the washing

machine. Turn the program knob to the desired program.

Caution: If you want to choose another program, first t

urn the program knob at "0", then

turn off the power and turn the program knob for setting desired program.

10

Page 13

Washing Methods

4. Washing temperature Setting

Set the washing temperature as required, otherwise, set at position * when heating is not

needed.

5. Selecting the function button

Select function buttons as required (refer to the directions printed on the control panel) ,

otherwise keep all the button released.

6. Washing

Press the power button and the washing machine will automatically commence the programmed washing process.

Caution: The program knob will not rotate with the programmed washing process.

7. End

Wait 2-3 minutes after the washing process is finished , press the power button again to cut

off the power supply. Open the door to take out the laundry. Turn off the tap and unplug the

washing machine.

Caution: When the washing program finishes, the door lock light will glitter before the door can

be opened.

Additional information

Energy and water saving during wash process

1. Collect clothes for one full wash load.

2. Do not overload the washing machine.

3. Prewash heavily soiled clothes.

4. Reduce the amount of detergent or choose fast or minimal washing programs for lightly

soiled clothes dirty.

O

5. Choose a proper washing temperature. Only exceed 60

6. Do not use more detergent than required.

7. Softening agent makes clothes feel softer and easier to iron.

C for heavily soiled clothes.

11

Page 14

Other Functions

1. Power-off memory funtion:

This machine has a power-off menmory funtion. In case of abrupt power failure

or the power must be cut off during a program cycle, the present settings will be

saved, and operation will resume when the power is switched on again.

2. Trouble messages: judge the malfunctions from door lock light

Error 1: The door lock light does not illuminate.

Cause: Door is not properly shut.

Correction: Shut the door properly.

Error 2: The door lock light glitters 2 times and stops 4 seconds repeatedly.

Cause: Drainage error, water not emptied within 4 minutes.

Correction: Clean the filter and check the drain hose for blockage. If error still

exists, please contact the maintenance personnel.

Error 3: The door lock light glitters 3 times and stops 4 seconds repeatedly.

Cause: Temperature sensor not properly connected or damaged.

Correction: Contact the maintenance personnel.

Error 4: The door lock light glitters 4 times and stops 4 seconds repeatedly.

Cause: Heating coil damage or overload of laundry that leads to a failure to

reach the set temperature within the specified time (This message is display

at the end of a program).

Correction: Reduce load and then start washing again or contact the

maintenance personnel.

Error 5: The door lock light glitters 5 times and stops 4 seconds repeatedly.

Cause: Water level not met in 8 minutes.

Correction: Make sure that tap is turned on, and water pressure is normal.

If problem still exists, please contact the maintenance personnel.

Error 6: The door lock light glitters 6 times and stops 4 seconds repeatedly.

Cause: Timing control silicon damage.

Correction: Contact the maintenance personnel.

Error 7: The door lock light glitters 7 times and stops 4 seconds repeatedly.

Cause: Motor overheat protection or damage.

Correction: Contact the maintenance personnel.

Error 8: The door lock light glitters 8 times and stops 4 seconds repeatedly.

Cause: Water exceeds protective level.

Correction: Contact the maintenance personnel.

12

Page 15

Maintenance

1. Turn of the water and electricity supply after every wash. Open the door to prevent the

formation of moisture and odors. If the washing machine is left idle for a long period, drain

any remaining water in the machine and replace the drainage hose.

4.

2. Unplug the machine during cleaning and

maintenance. Use a soft cloth dampened

with soapy liquid to clean the machine case

and rubber components. Do not use corrosive or abrasive chemicals or solvents.

4. To prevent blockages to the water

supply or the ingress of contaminants,

clean the water inlet and inlet water

filter regularly.

6. If the washing machine is left

idle for a long period turn off the

water and electricity supply and

open the door slightly to prevent

the formation of moisture and

odors.

13

5. If the machine is to be moved a distance location,

replace the vibration mounting locks which were removed during installation as shown below.

Remove the back

cover.

Tighten the bolts with a

spanner.

Replace the rubber

plugs.

Insert the bolts.

Replace the back

cover.

Page 16

Trouble shooting

The following circumstances do not constitute problems. Do not contact the

maintenance service until the problem has been confirmed.

Problem

The washing machine fails to

operate

Washing machine does not fill

with water

The water supply and

drainage do not stop

Possible Cause

ƽ

Poor connection to power supply

ƽ

Power failure

ƽ

Door is not properly closed

ƽ

Machine has not been switched on

ƽ

Water is not turned on

ƽ

Water pressure is less than 0.03MPa

ƽ

The inlet hose is kinked

ƽ

Water supply failure

ƽ

The program knob is not properly set

ƽ

The door is not properly closed

ƽ

Check that the height of the water hose is below

80cm

Drainage failure

Strong vibration during spin

Operation stops before completion of the wash cycle

Excessive foam in the drum

ƽ

Drainage hose is blocked

ƽ

Drainage hose end is below 100cm above the

floor level

ƽ

Some packing fixing bolts removed

ƽ

Washing machine on a uneven surface

ƽ

Water or electricity failure

ƽ

The detergent is not a low foam type

Excessive detergent has been used

14

Page 17

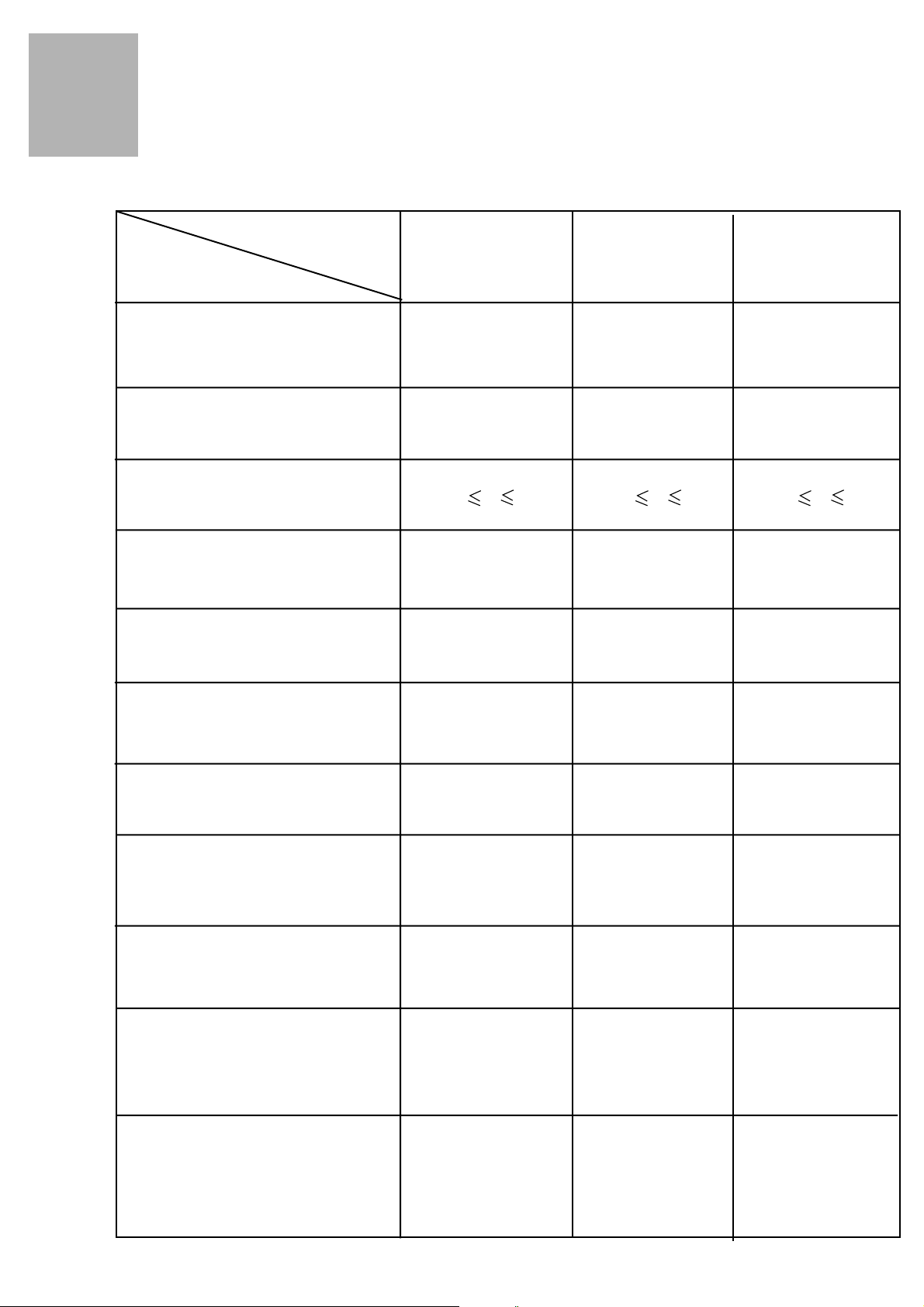

Technical Specification

Model

Item

HA1000TE

HA800TE

HA600TE

Power supply

Maximum working current (A)

Water pressure (MPa)

Washing power (W)

Spinning power (W)

Max. washing load (kg)

220V~240V/50Hz

15

0.03 P 1

230

400

5

220V~240V/50Hz

0.03 P 1

15

230

380

5

220V~240V/50Hz

15

0.03 P 1

230

340

5

Spinning speed (r/min)

Washing program

Maximum power (W)

Size (mm)

W eight (kg)

Net

1000

15

2000

850x520x595

65

800

15

2000

850x520x595

65

600

15

2000

850x520x595

65

Page 18

Wiring Circuit

Motor

MR

EVF

EVP

MRN

MRL

MRC

R

M1

CN1-2 CN2-1 CN1-3 CN1-1

CN2-2

CON3

CN2-3

CN2-4

CN2-5

EVC

M2

M3 M5

PCB

CN2-6 CON3 CN3-3 CN3-4

PS

T

M8

CN3-1

CN6-4

S

M7

CN3-3

NTC

CN6-3

SW

CON2

CON1

12

13

R

14

11

P

FA

N

G

L

PCB-Printed Circuit Board

MR-Door Lock

PS-Drain Pump

EVP,EVF-Cold water Valve

FA-Interference Suppresser

SW-Power Switch

Motor-Motor

R-Heating Element

P-Pressure Switch

EVS-Hot Water Valve

NTC-Temperature Sensor

Motor-Motor

16

Loading...

Loading...