Haier H2SM-(9+9)HRA03/R2, H2SM-(9+9)HEA03/R2, H2SM-(9+12)HEA03/R2, H2SM-(9+12)HRA03/R2, H2SM-(9+9)HEK03/R2 Installation Manual

...

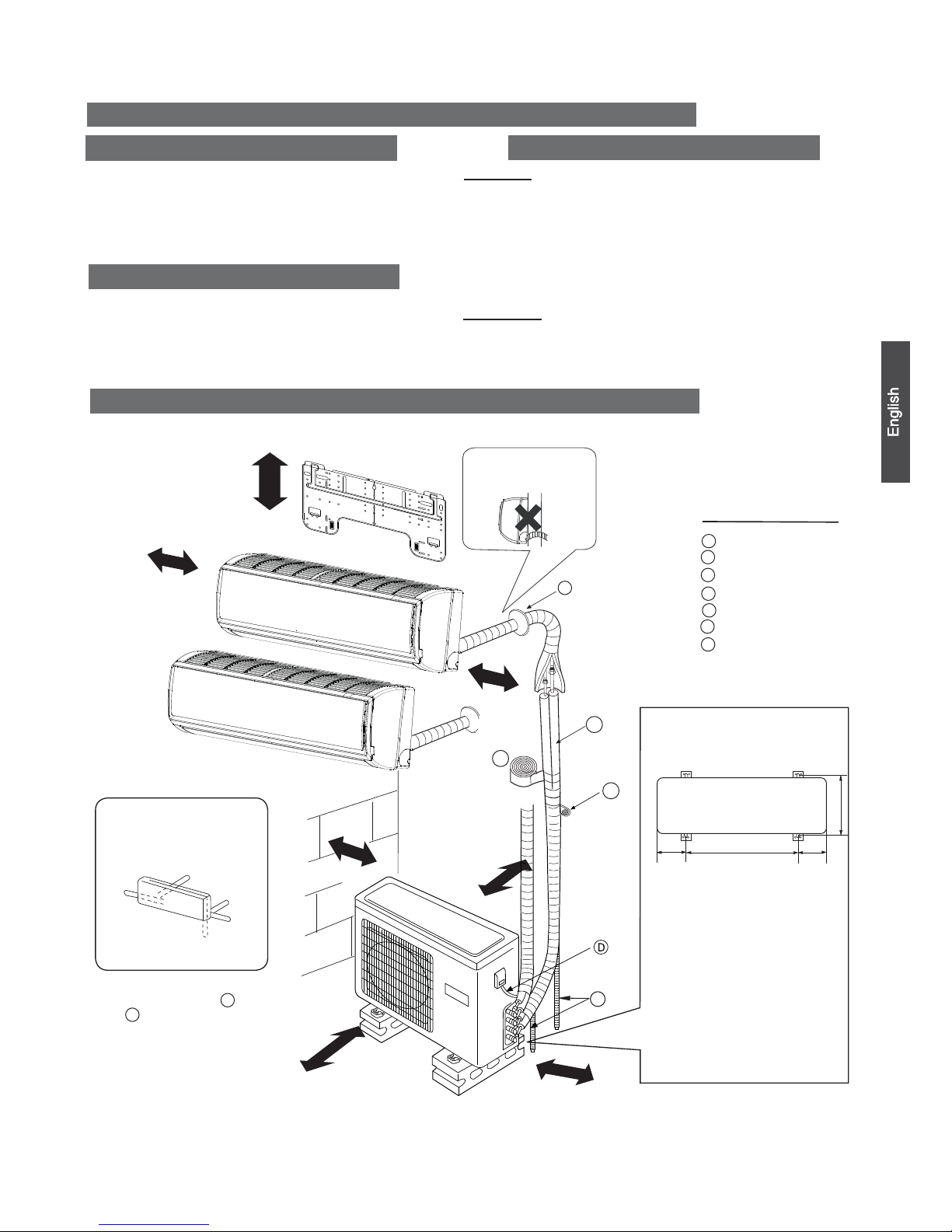

Drawing for the installation of indoor and outdoor units

Necessary Tools for Installation

Driverƽ

Torque wrench

ƽ

(17mm,2 2mm, 26mm)

Nipperƽ

Reamerƽ

Hacksawƽ Pipe cutterƽ

Gas leakage detector orƽ

soap-and-water solution

Hole core drillƽ Flaring toolƽ

Spanner(17,19 and 26mm)ƽ Knifeƽ

Measuring tapeƽ

Indoor Unit

Place, robust not causing vibration, where the body can be supported sufficiently.ƽ

Place, not affected by heat or steam generated in the vicinity, where inlet and outlet of the

unit are not disturbed.

ƽ

Place, possible to drain easily, where piping can be connected with the outdoor unit.ƽ

Place,wherecoldaircanbespreadin a roomentirely.ƽ

Place, nearby a power receptacle, with enough space around. (Refer to drawings).ƽ

Place where the distance of more than lm from televisions, radios, wireless apparatuses

and fluorescent lamps can be left.

ƽ

In the case of fixing the remote controller on a wall, place where the indoor unit can

receivesignalswhenthefluorescent

ƽ

lampsintheroomarelightened.

Outdoor Unit

Place, which is less affected by rain or direct sunlight and is sufficiently ventilated.ƽ

Place,possibletobeartheunit,wherevibrationandnoisearenotincreased.ƽ

Place, where discharged wind and noise do not cause a nuisance to the neighbors.ƽ

Place, where a distance markedƽ

is available as illustrated in the above figure.

Before inserting power plug into receptacle, check the voltage without fail.

The power

sourceisthesameasthe

ƽ

correspondingnameplate.

Install an exclusive branch circuit of the power.

ƽ

Areceptacleshallbesetupin a distancewherethepowercablecanbe

reached.

Donotextendthecablebycuttingit.

ƽ

Power Source

Preparation

Read this manual before installation

Explain sufficiently the operating means to the user according to this manual.

NO.0010531114

Installation Manual of Room Air Conditioner

F

A

C

E

Optional parts for piping

Non-adhesive tape

Adhesive tape

Saddle (L.S) with screws

Connecting electric cable

for indoor and outdoor

Drain hose

Heating insulating material

Piping hole cover

Floor fixing dimensions of the

outdoor unit (Unit:mm)

Fixing of outdoor unit

Fix the unit to concrete or blockƽ

withbolts(10mm)andnutsfirmly

and horizontally.

When fitting the unit to wall

ƽ

surface, roof or rooftop, fix

a supporter surely with nails

or wires in consideration of

earthquake and strong wind.

If vibration may affect the

ƽ

house, fix the unit by attaching a

vibration-proof mat.

The marks from to

in the figure are the

parts numbers.

Thedistancebetween

the indoor unit and the

floor should be more

than 2m.

ThemodelsadoptHFCfreerefrigerantR410A

more than

10cm

more than 5cm

more than 10cm

more than 10cm

more than

10cm

more than15cm

more than

60cm

A

G

ƽ

ƽ

A

F

C

E

D

G

B

Arrangement of piping

directions

Rear left

Left

Rear

right

Right

Below

G

Please be subject to the actual product purchased , the above picture is just for your reference.

Attention must be paid to

the rising up of drain hose

113.5

583

113.5

5

.

913

Selection of Installation Place

Unit A

Unit B

To unit A

To unit B

Indoor unit

Fixtosidebarandlintel a mountingbar,Whichisseparatelysold,andthen

ƽ

fasten the plate to the fixed mounting bar.

Refer to the previous article, “ When the mounting plate is

ƽ

position of wall hole.

Make a hole of 60 mm in diameter, slightly descending to outside the wall.

ƽ

Install piping hole cover and seal it off with putty after installation

ƽ

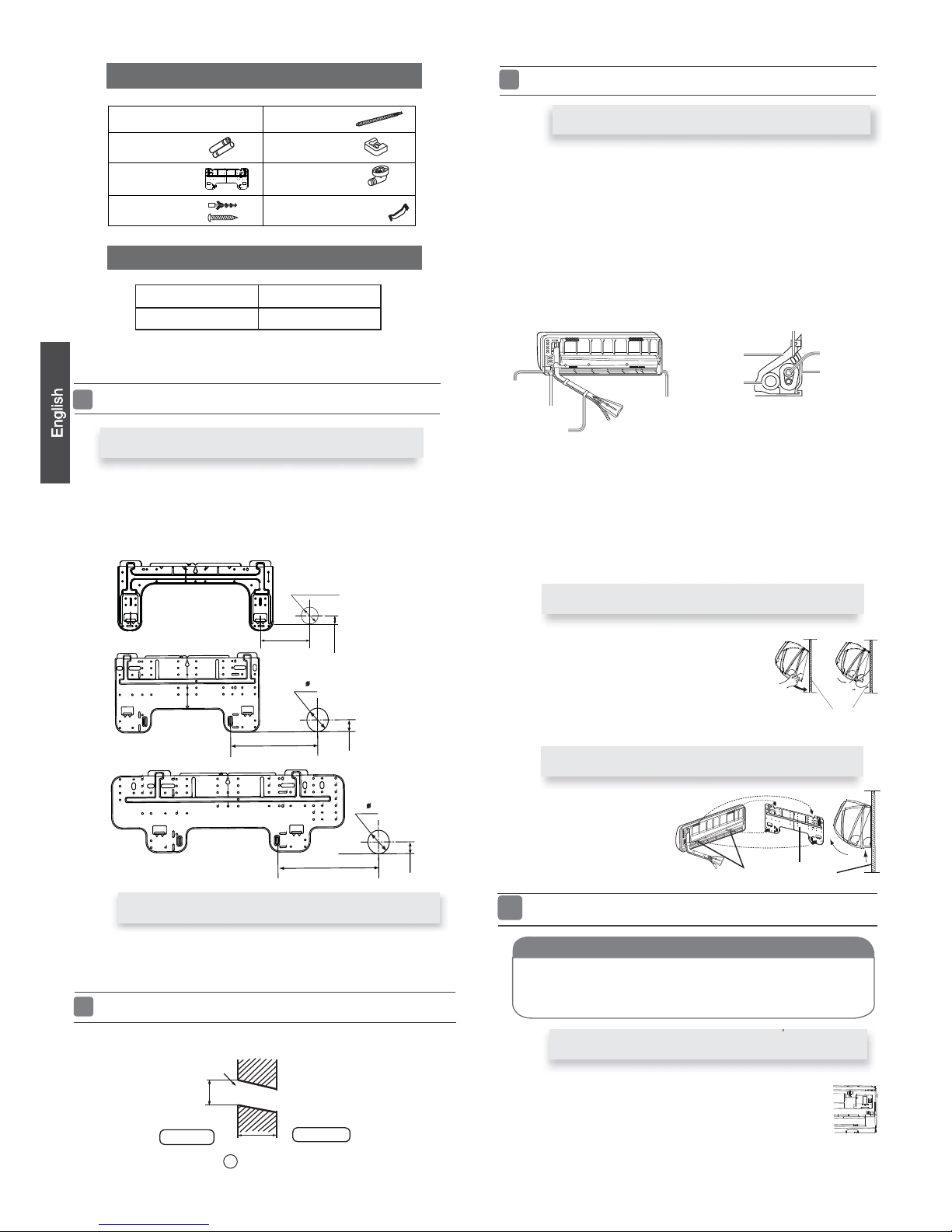

When the mounting plate is first fixed

1. Carry out, based on the neighboring pillars or lintels, a

to be fixed against the wall, then

temporarily fasten the plate with one steel nail.

2. Make sure once more the proper level of the plate, by

hanging a thread with a

weight from the central top of the plate, then fasten securely the plate with the

attachment steel nail.

3. Find the wall hole location A using a measuring tape

When the mounting plate is fixed side bar and lintel

Indoor side

Outdoor side

Fitting of the Mounting Plate and

Positioning of the wall Hole

Ø60mm

Wall hole

Thickness of wall

(Section of wall hole) Piping hole pipe

Lid for right

piping

Lid for under piping pipe

Fixwithadhesivetape

Lid for left piping

Heat insulation

material

Drain hose

Piping

Pipe supporting

plate

Indoor/outdoor electric cable

Indoor/outdoor electric cable and drain hose must be bound with refrigerant

ƽ

piping by protecting tape.

[ Other direction piping ]

Cut away, with a nipper, the lid for piping according to the piping direction and

ƽ

then bend the pipe according to theposition of wall hole. When bending, be

careful not to crash

pipes.

Connect beforehand the indoor/outdoor electric cable,

ƽ

andthenpulloutthe

connected to the heat insulation of connecting part specially.

proper leveling for the plate

first fixed “, for the

Making a Hole on the Wall and Fitting the Piping Hole Cover

G

Drawing of pipe

Installation of the Indoor Unit

[Rearpiping ]

Drawpipesandthedrainhose,thenfastenthemwiththeadhesivetape

ƽ

[Left・Left-rear piping ]

In case of left side piping, cut away, with a nipper, the lid for left piping.

ƽ

In case of left-rear piping, bend the pipes according to the piping direction to

ƽ

the mark of hole for left-rear piping which is marked on heat insulation materials.

1. Insert the drain hose into the dent of heat insulation

materials of indoor unit.

2. Insert the indoor/outdoor electric cable from backside of

indoor unit, and pull it

out on the front side, then connect them.

3.Coattheflaringsealfacewithrefrigerantoilandconnect

pipes.

Cover the connection part with heat insulation materials closely, and make sure

fixingwithadhesivetape

Fixing the indoor unit body

Hang surely the unit body onto the upper notches of the

ƽ

mountingplate.Movethebodyfromsidetosidetoverifyits

secure fixing.

Inordertofixthebodyontothemountingplate,holdup

ƽ

thebodyaslantfromtheundersideandthenputitdown

perpendicularly.

Connecting the indoor/outdoor Electric Cable

Removing the wiring cover

Remove terminal cover at right bottom corner of indoor unit, then takeƽ

off wiring cover by removing its screws.

mounting plate

When you unload the indoor unit,please use

then lift the bottom of the body outward

slightly and lift the unit aslant until it

leaves the mounting plate.

agraffe

mounting plate

Unloading of indoor unit body

ƽ

your hand to arise the body to leave agraffe,

Remote controller (1)

R-03 dry battery (2)

Mounting plate (1)

Drain hose (1)

Ø4X25 Screw

(4)

Plastic cap (4)

Drain-elbow (1)

Cushion (4)

Pipe supporting plate (1)

Accessory parts

Liquid pipe (Ø) 6.35mm(1/4”)

Gaspipe(Ø)

9.52mm(3/8”)

NOTE˖The thickness of the pipe must be 0.8mm at least.

Selection of pipe

2

A=145mm

B=

60mm

mm

03

A=150mm

B=

60mm

m

m

03

A=145mm

B=

60mm

Ø

30mm

CAUTION

For multi model , the indoor units A and B should be

connected with corresponding valves A and B of outdoor exactly. Any mixed connection is forbidden.

ƽ

3

Note

When connecting the cable, confirm the terminal number of indoor and

outdoorunitscarefully.Ifwiringisnotcorrect,properoperationcannot

be carried out and will cause defect.

1.Ifthesupplycordisdamaged,itmustbereplacedbythemanufacturerorits

service agent or a similar qualified person. The type of connecting wire is H05RN-F

or H07RN-F.

2. If the fuse on PC board is broken please change it with the

type of T. 3.15A/250V.

3.Thewiringmethodshouldbeinlinewiththelocalwiringstandard.

4. After installation, the power plug should be easily reached.

5. A breakershouldbeincorporatedintofixedwiring.Thebreakershouldbeall-pole

switch and the distance between its two contacts should be not less than 3mm.

Outdoor unit

Install according to Drawing for the installation of indoor and

outdoor units

Tobend a pipe,givetheroundnessaslargeaspossiblenottocrushthepipe,

ƽ

andthebendingradiusshouldbe30to40

mm or longer.

Connecting the pipe of gas side first makes working easier.

ƽ

TheconnectionpipeisspecializedforR410A.ƽ

Installation of Outdoor Unit

Half union

Flare nut

Tor que wr enc h

Becarefulthatmatters,suchaswastesofsands,etc.shallnotenterthepipe.

Thestandardpipelengthis5m.Ifitisover7m,thefunctionoftheunitwillbe

affected. If the pipe has to be lengthened, the refrigerant should be charged,

according to 20 g/m. But the charge of refrigerant must

be conducted by professional air conditioner engineer. Before adding additional refrigerant, perform air

purging from the refrigerant pipes and indoor unit using a vacuum pump,then

Spanner

Forced fastening without careful centering may

damage the threads and cause a leakage of gas.

Pipe Diameter(ǿ) Fastening torque

Liquid side6.35mm(1/4") 18N.m

Liquid/Gas side9.52mm(3/8") 42 N.m

Gas side 12.7mm(1/2") 55N.m

Gas side 15.88mm(5/8") 60 N.m

Connection of pipes

charge additional refrigerant.

Use the same method on indoor unit. Loosen the screws onƽ

terminal block and

inserttheplugsfullyinto terminalblock,thentightenthescrews.

Insertthecableaccordingto terminalnumberinthesamemannerastheindoor

unit.

ƽ

If wiring is not correct, proper operation can not be carried out and controller

may be damaged.

ƽ

Fix the cable with a clamp.ƽ

CAUTION

Max.Elevation:

●

In case the elevation A is more

●

than 5m, oil trap shoud be

installed every 5~7m

Max. Length:

●

In case the pipe length B is

●

more than 7m, the refrigerant

should be charged, according

to 20 g/m.

Connection

If the drain-elbow is used,ƽ

please attach it as figure. (Note:

Onlyforheatpumpunit.)

Detach the service port’s cap of

1.

3-wayvalve,thevalverod’scapfor2-wayvalve

and 3-way’s, connect the service port into the

projection of charge hose (Iow)

for gaugemanifold.

Then connect

the projection of charge hose (center) for gau-

gemanifold

into vacuum pump.

Open the handle at Iow in

2.

gaugemanifold, operate

vacuum pump. If the scale-

moves of gause (Iow) reach vacuum condition in a moment, check 1. again.

Attaching Drain-Elbow

Purging Method:To use vacuum pump

A1max=10m

B1max=15m

A

B

Outdoor unit

Indoor unit

A1

B1

Indoor unit

A2

B2

Outdoor unit

Indoor unit

Oil trap

Outdoor unit

Indoor unit

A1

B1

Indoor unit

A2

B2

A2max=10m

B2max=15m

Insert the cable from the backƽ

side of the unit, then pull it out

on the front side.

Loosen the screws and insert

ƽ

thecableendsfullyinto

terminal block, then

tighten the screws.

Pull the cable slightly to

ƽ

make sure the cables have

been properly inserted and

tightened.

After the cable connection,

ƽ

neverfailtofastentheconnectedcablewiththe

wiring cover.

When connecting the cable before installing the indoor unit

Power cable:

3G2.5mm

Outdoor unit

R

E

W

O

P

1

3

2

1

2

Indoor unit A

Indoor unit B

{

4G0.75mm

2

4G0.75mm

2

ı

ı

L

N

1

)

(

2

)

(

H2SM-(9+9)HEA03/R2

H2SM-(9+12)HEA03/R2

H2SM-(9+9)HRA03/R2

H2SM-(9+12)HRA03/R2

H2SM-(9+12)HEK03/R2

(C)

3

(C)

1.Insertfromoutsidetheroomcableintoleftside of thewall

hole,inwhichthepipehasalreadyexisted.

2. Pull out the cable on the front side, and connect the cable

making a loop.

When connecting the cable after installing the indoor unit

H2SM-(9+9)HEK03/R2

CAUTION

For multi model , the indoor units A and B should be

connected with corresponding valves A and B of outdoor exactly. Any mixed connection is forbidden.

ƽ

Open

No gas leakage?5.

Detachthechargehose6.

from the service port,

open 2-way valve and 3-way. Turn

thevalverodanticlockwise until hitting lightly.

In case of gas leakage, tighten parts of pipe connection. If

leakagestops,thenproceed6.steps

If it does not stop gas leakage, discharge whole refrigerants

from the service

port.Afterflaring workagainandvacuumize,fillupprescribed

refrigerantfromthegascylinder.

Anti countercurrent joint

Gaugemanifold(for

R410A)

2-way valve Liquid Side

3-wayvalveGasSide

Vacuum pump(for R410A)

Tube(for R410A)

Close

2-way valve

3-way valve

Open 90

O

2-way valve

3-way valve

2-way valve

3-way valve

Valve rod cap

Valve rod cap

Service port cap

To prevent the gas

leakage, turn the service

port’s cap, the valve

rod’s cap for 2-way

valve and 3-way’s a little more

than the point where the torque increases suddenly

After attaching the each

caps, check the gas

leakagearoundthecaps.

7.

8.

Step 1.

Step 2.

Step 3.

Step 7.

Step 6.

Step 4.

The power source must be exclusively used for air

ƽ

conditioner. (Over I0A)

In the case of installing an air conditioner in a moist place,

ƽ

pleaseinstallanea-

For installation in other places, use a circuit breaker as far

ƽ

as possible.

Pipe cutting is carried out with a pipe cutter and burs must

ƽ

be removed.

Afterinsertingtheflarenut,flaring workiscarriedout.

ƽ

Power Source Installation

CuttingandFlaringWorkofPiping

Flare tooling die

1.Cut pipe

2.Remove burs

FlaretoolforR410A Conventionalflaretool

Clutch-type clutch-type(Rigid-type) Wing-nut type (Imperial-type)

A 0~ 0.5mm 1.0~1.5mm 1.5~2.0mm

rth leakage breaker.

Lean

Damage of flare Crack Partial Too outside

Correct Incorrect

On Drainage

It becomes

high midway.

The gap with the

ground is too small.

There is the bad

smell from a ditch

It waves.

The end is immersed in water.

Pleaseinstallthedrainhosesoastobedownwardslopewithoutfail.

Pleasedon’tdothedrainageasshownbelow.

ƽ

ƽ

Please pour water in the drain pan of the indoor unit, and

ƽ

is carried out surely to outdoor.

In case that the attached drain hose is in a room, please

ƽ

applyheatinsulationto

Less than

5cm

confirm that drainage

it without fail.

4

2-way valve

3-way valve

2-way valve

3-way valve

Iftherefrigerant of theairconditionerleaks,itisnecessarytodischargeallthe

ƽ

refrigerant. Vacuumize first, then

charge the liquid refrigerant into air conditioneraccordingtotheamountmarkedonthenameplate.

Please do not let other cooling medium, except specified one (R410A), or air

ƽ

enterintothecoolingcirculationsystem.Otherwise,therewillbeabnormal

highpressureinthesystemtomakeitcrackandleadtopersonalinjuries.

CAUTION

Each indoor unit musts to be vacuumed , according to the above steps.

ƽ

1

1+2=

kg

R410A

2

kg

2=

1=

B

C

D

FE

kg

A

This product contains fluorinated greenhouse gases covered by

the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type:R410A

GWP* value:1975

GWP=global warming potential

Please fill in with indelible ink,

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged in the field and

• 1+2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product

charging port (e.g. onto the inside of the stop value cover).

A contains fluorinated greenhouse gases covered by the Kyoto

Protocol

B factory refrigerant charge of the product: see unit name plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

Refrigerant charge labelƵ

Check Items for Test Run

Put check mark

in boxes

Gasleakfrompipeconnecting?

Heat insulation of pipe connecting?

Are the connecting wirings of indoor and outdoor firmly

Istheconnectingwiring of indoorandoutdoorfirmlyfixed?

Is drainage securely carried out?

Is the earth line securely connected?

Istheindoorunitsecurelyfixed?

Is power source voltage abided by the code?

Is there any noise?

Isthelampnormallylighting?

Arecoolingandheating(wheninheatpump)performednormally?

Is the operation of room temperature regulator normal?

Please kindly explain to our customers how to operate

throughtheinstructionmanual.

Check for Installation and Test Run

Ƶ

inserted to the terminal block?

Ƶ

Vacuumize for over 15min.And check the level gauge which should read -0.1MPa

3.

(76 cm Hg) at Iow

pressure side. After the

completion of vacuumizing, close the

handle ‘Lo’ in gaugemanifold and stop the operation of the vacuum pump. Check

condition of the scale and hold it for 1-2min. If the scale-moves back in spite of

tightening, make flaring work again, the return to the beginning of 3 .

Openthevalverodforthe2-wayvalvetoanangle of4.

anticlockwise90degrees.

After 6 seconds, close the

2-wayvalveandmakethe

inspection of gas leakage.

Check Items for Test Run

3.Insert the flare nut

4.Flare pipe

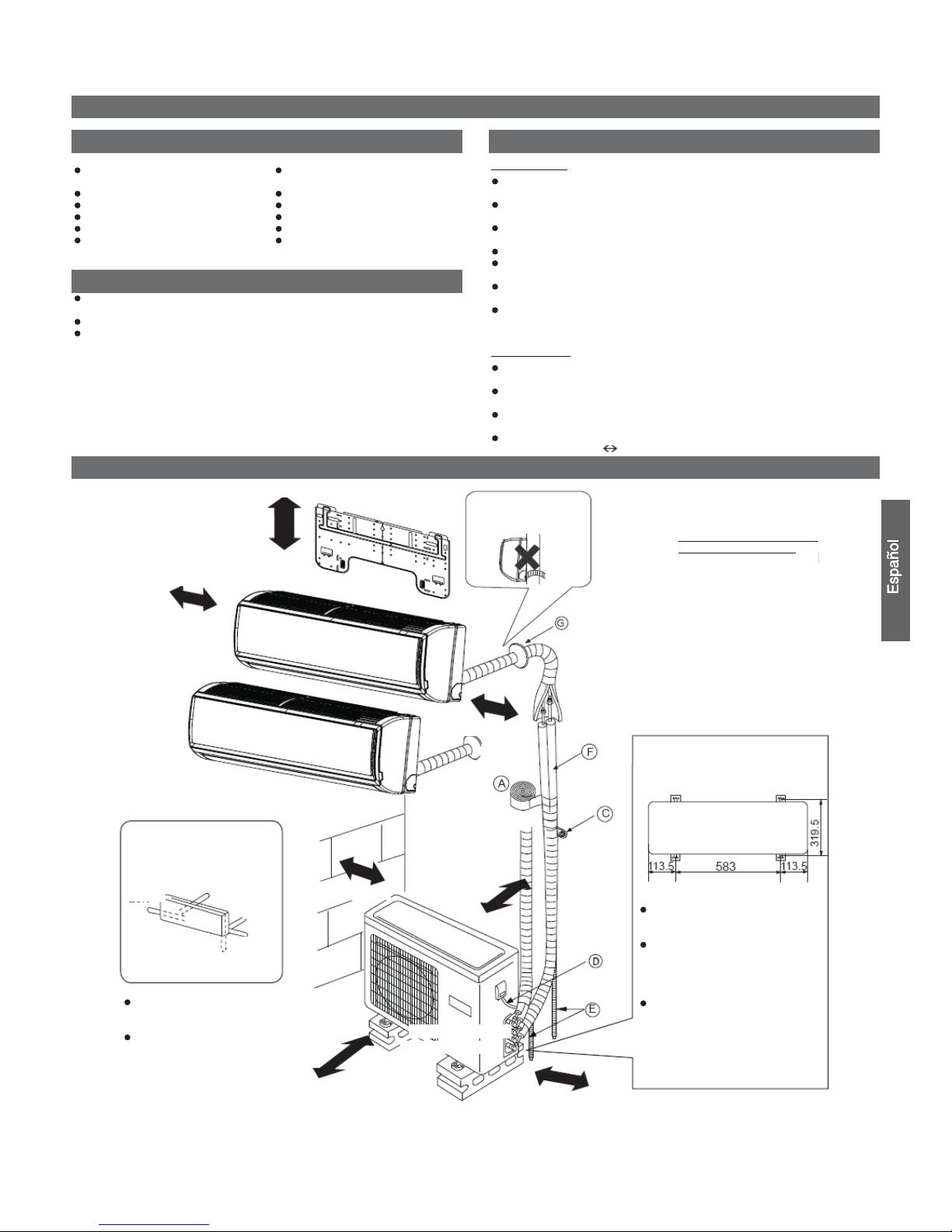

Manual de instalación de aparato de aire acondicionado

Preparación

Herramientas necesarias para realizar la instalación

Destornillador Llave dinamométrica (17mm, 22mm,

26mm)

Alicate Sierra de tubos

Sierra para metales Herramienta de conicidad

Broca de tubo Cuchilla

Llave (17, 19 y 26 mm) Metro

Detector de fugas de gas o agua

jabonosa

Avellanador

Fuente de alimentación

Antes de insertar el enchufe de alimentación en la toma, compruebe que el voltaje

no falla. La fuente de alimentación es la que figura en la placa de datos nominales.

Instale el aparato en un circuito dedicado de alimentación.

Debe existir una toma al alcance del cable de alimentación. No prolongue el cable

cortándolo.

Selección del lugar de instalación

Unidad interior

Coloque la unidad sobre una superficie que pueda soportarla correctamente y no

provoque vibraciones.

Asegúrese de que el lugar no se ve afectado por calor o vapor generado en las

cercanías y donde las tomas de entrada y salida no estén obstruidas.

Asegúrese de que el lugar permita un drenaje sencillo y en el que puedan

conectarse los tubos a la unidad exterior.

Asegúrese de que el aire frío pueda distribuirse uniformemente por la sala.

Coloque la unidad interior cerca de una toma de suministro eléctrico con espacio

suficiente alrededor. (Consulte los diagramas).

Coloque la unidad interior de modo que se encuentre a más de 1m de televisiones,

radios, aparatos inalámbricos y lámparas fluorescentes.

En el caso de fijar el control remoto a una pared, colóquelo donde la unidad interior

pueda recibir su señal mientras estén encendidas las lámparas fluorescentes de la

sala.

Unidad exterior

Seleccione el lugar menos afectado por la lluvia o la luz solar directa y

suficientemente ventilado.

Elija un lugar que permita soportar el peso de la unidad y que no amplifique el

ruido y las vibraciones.

Seleccione un lugar en el que los residuos y el viento generado por la unidad no

cause una molestia a los vecinos.

Coloque la unidad en un lugar en el que pueda disponerse de la distancia de

separación marcada

en la figura anterior.

Diagrama para la instalación de aparatos interiores y exteriores

Recuerde que la ilustración anterior podría no reflejar fielmente el producto adquirido y debe utilizarse únicamente como referencia.

Lea este manual antes de la instalación

Explique el uso del aparato al usuario siguiendo las instrucciones de este manual.

Los modelos cumplen la norma R410A sobre refrigerantes libres de HFC

más de 5cm

más de 10cm

Unidad A

Unidad B

Organización de la dirección

de los tubos

Izquierda

Izquierda trasera

Derecha

trasera

Derecha

Inferio

r

Las marcas de A a G que se

muestran en la figura

representan los componentes.

La distancia entre la unidad

interior y el suelo debe ser

superior a 2m.

Debe prestarse atención a la

pendientedelamanguerade

drenaje

más de 10cm

más de 10cm

más de 10cm

más de

60cm

a la unidad interior A

a la unidad interior B

más de 15cm

Componentes opcionales para

la instalación de los tubos

ƻ

A Cinta no adhesiva

ƻ

B Cinta adhesiva

ƻ

C Soporte (L.S) con tornillos

ƻ

D Conexión de cable

eléctrico para interior y

exterior

ƻ

E Manguera de drenaje

ƻ

F Material aislante de calor

ƻ

G Cubierta de orificio de

entubación

Dimensiones de fijación al suelo de

la unidad exterior (Unidad:mm)

Fijación de la unidad exterior

Fije la unidad a un bloque de

cemento con pernos (10mm) y

tuercas firme y horizontalmente.

Si instala la unidad sobre una pared,

techo o tejado, instale un soporte

con clavos o cables considerando la

posibilidad de terremotos o viento

fuerte.

Si la vibración afectase a la casa, fije

la unidad instalando una alfombra

de absorción de vibraciones.

5

Loading...

Loading...