Page 1

Air Conditioner

REVISION 0

CAUTION

READ THIS MANUAL CAREFULLY TO

DIAGNOSE TROUBLE CORRECTLY

BEFORE OFFERING SERVICE .

SERVICE MANUAL

Edition:2006/1/10

Air Conditioners

THIS MANUAL IS USED BY

QUALIFIED APPLIANCE

TECHNICIANS ONLY. HAIER

DOES NOT ASSUME ANY

RESPONSIBILITY FOR PROPERTY

DAMAGE OR PERSONAL INJURY

FOR IMPROPER SERVICE

PROCEDURES DONE BY ONE

UNQUALIFIED PERSON.

MODEL: H2SM-(9+12)H03/R2

Page 2

Air Conditioner

Edition:2006/1/10

IMPORTANT INFORMATION

MODEL: H2SM-(9+12)H03/R2

ƽҏFeatures

ƽҏComfortable: wide-angle airflow

ƽhealth air purifying

ƽquiet operation

ƽҏsuper energy efficient

ƽMain Specification

ƽCooling CapacityΚ 2900/3300/5800W

ƽRated Power/Current(cooling)Κ960/1020/2050W/4.6/4.8/9.0A

ƽEER: 3.02/3.23/2.82W/W

ƽHeating CapacityΚ 2800/3300/6000W

ƽRated Power/Current(heating): 900/980/1760W/4.5/4.6/8.0A

ƽCOP: 3.11/3.36/3.4

3

ƽAir Volume(Indoor): 400/500m

ƽPower: 1PH 220-230V~ 50 Hz

/h

Page 3

Air Conditioner

Edition:2006/1/10

Safety Information

General Information

This Service Manual describes the operation,disassembly,troubleshooting,and repair of Haier Room Air

Conditioners,etc. It is intended for use by authorized servicers who troubleshoot and repair these units.

NOTE:It is assumed that users of this manual are familiar with the use of tools and equipment used to

troubleshoot and repair electrical,mechanical,and refrigeration systems;and understand the terminology

used to describe and discuss them.

Haier urges you read and follow all safety precautions and warnings contained in this manual. Failure

to comply with safety information may result in severe personal injury or death.

Related Publications

This is a base service manual,covering a range of similar models.It is intended to be used in

conjunction with the Parts Manual and Technical Sheet covering specific model being serviced.

General Precautions and Warnings

To avoid risk of personal injury or death due to electrical shock,disconnect electrical power to unit

before attempting to service the unit.

WARNING

WARNING

To avoid risk of personal injury or death due to electrical shock,DO NOT,under any circumstances,alter

the grounding plug .Air conditioner must be grounded at all times.Do not remove warning tag from power

cord.If a two-prong (non-grounding) wall receptacle is encountered,contact a qualified electrician and

have the receptacle replaced with a properly grounder wall receptacle in accordance with the National

Electrical Code.

To av oid risk of personal injury or death due to electrical shock,grounding wires and wires colored like

groundi ng wires are NOT to be used as current carrying conductors.The standard accepted color coding

for ground wires is green or green with a yellow stripe.Electrical components such as the compressor

and fan motor are grounded through an individual wire attached to the electrical component and to

another part of the air conditioner.Groundi ng wires should not to be removed from individual components

while servicing,unless the component is to be removed and replaced.It is extremely important to replace

all removed grounding wires before completing service.

WARNING

WARNING

To avoid risk of heat exposure,which may cause death or severe illness,air conditioner must be

monitored when malf unctions or shuts down.

Page 4

Air Conditioner

Edition:2006/1/10

CONTENTS

1. SPECIFICATION....................................1

2. ELECTRICAL CONTROL..............................3

. TROUBLE SHOOTING.................................27

3

. INSTALLA TION....................................32

4

5

. CIRCUIT AND WIRING DIAGRAM.......................42

Page 5

Air Conditioner

Edition:2006/1/10

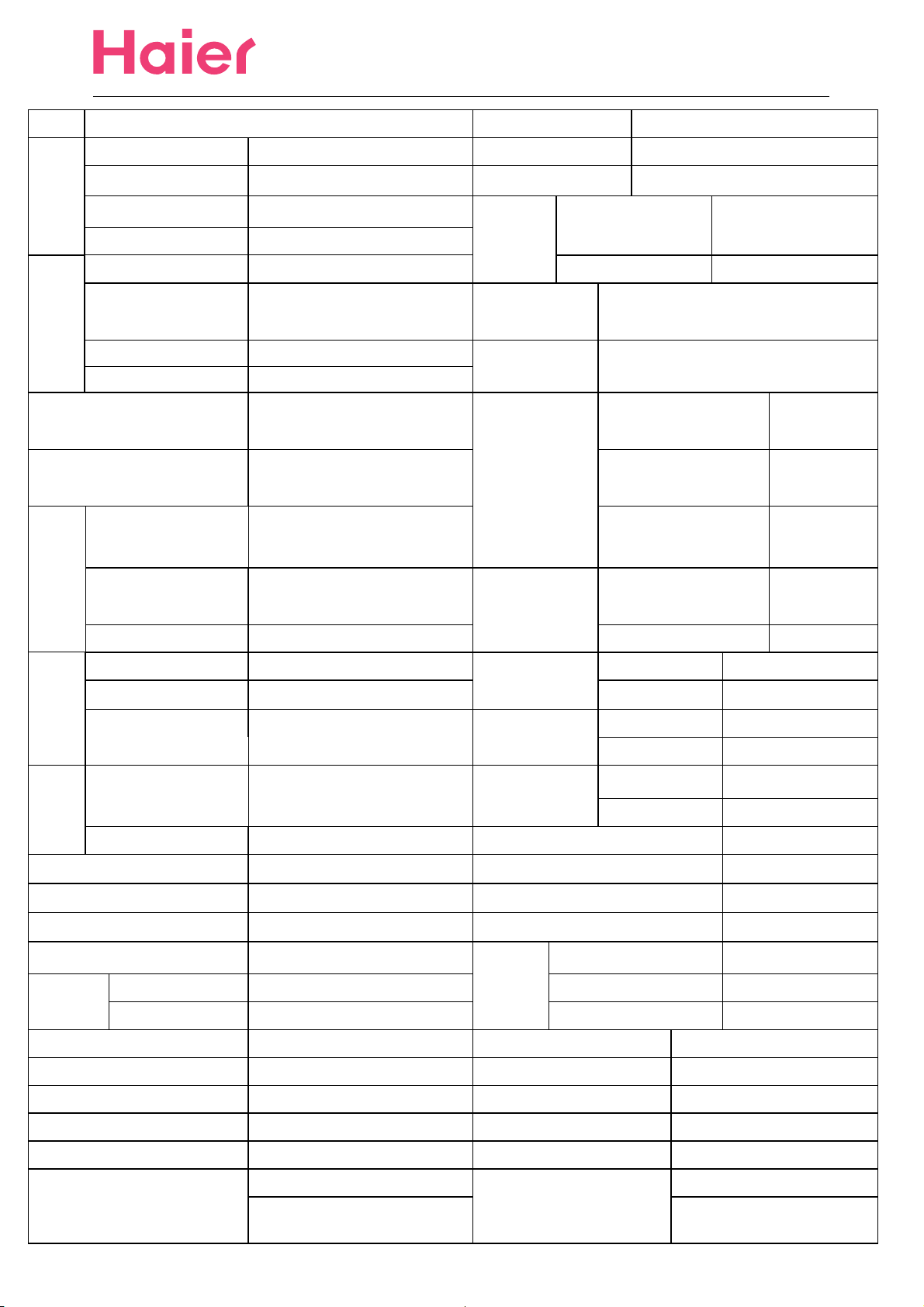

SPECIFICATION

1

Page 6

13.0A

Oilcharge

Air Conditioner

HUARUN(09)/CRV113

MEIZHI(12)/PA118

350/350ml

850g(09)

1150g(12)

400(09)/

1.2/

0010707668

0010707669

Max.running

Edition:2006/1/10

Model˖

H2SM-(9+12)H03/R2

Cooling Capacity˖

Rated Power/Current˖

2900/3300/5800W

960/1020/2050W/9.0A

Cooling

2400W/12.4A

2800/3300/6000W

900/980/1760W/8.0A

Heating

Max Power/Current˖

R 3.02/3.23/2.82W/W

EE

Heating Capacity˖

Rated Power/Current˖

Max Power/Current˖ 2520W/

COP 3.11/3.36/3.40

Power/Current of

----- Type/NetCharge˖

Electric Heating˖

Operating temp. range -7OC-43OC

1180 r/min

1050 r/min

Indoor

Velocity

H˖

M˖

Brand Mark˖

Frequency Range˖

1PH 220-230V~ 50 Hz

Power

Model×Sectional Area˖

Power Cord

Refer. No.˖ --------

Compressor

manufacturer/Type

Compressor

Additional Charge for

Refrigerant

exhausting air.

Charge if over Standrad

Pipe Lenth

Lenth×Internal/External

Capilary

Diametre

-----

50Hz

--------

R410A

0g

50g/m

2.7*1.4

Outdoor

Velocity

L˖

H˖ 840 r/min Indoor˖ 1.30 mm

920 r/min

Height of rising

H˖ ---- r/min

radiator slice

H˖ ---- r/minNet˖

Refer No.˖

Outdoor˖ 1.37 mm

8.8kg

Indoor Weight

10.6kg

57kg

Air

Gross˖

Net˖

Outdoor Weight

Vol ume

(High)

Indoor˖ 500(12) m3/h

Outdoor˖ ----- m

Capacitor of Fan Motor˖

Class of electric Shock Protection

3

/hIndoor Dimension(L×W×H)˖ 795×265×182 mm

……

ĉ

Gross˖

Indoor Packaging Dimension(L×W×H) 865x272x330 mm

Outdoor Dimension (L×W×H)˖

66kg

810×288×680 mm

Class of Water Proof˖ IP 24 Outdoor Packaging dimension(L×W×H) 960×405×760 mm

Moisture Removal˖

2.4×10

/h

liquid /Gas pipe Diametre

ij6.35/9.52 mm

-3m3

Refrigerant

: YR-

Remote

Model

Controller Refer. No.˖

H10 standard Lenth

0010401628

Pipe

Max Lenth 15 m

5m

Remote Controller Bracket˖ ----- Lenth/Diametre of Drain Hose ----

Appearance˖ ----- Max. pressure at warm side˖ 4.15 MPa

Climate Type˖ T1 Max.pressure at cool side˖ 4.15MPa

Installation Bracket Type˖ ----- Plug Type(spec.)˖ ---

Area available for clooling/heating

15-23 m

2

Ammeter spec.˖ ---

Dry/Wet ball(indoor)˖ 32℃/ 223 ćDry/Wet ball(indoor):27 /ć --ć

Max.running

temperature(cooling):

Dry/Wet ball(outdoor)˖ 43 / 26 ćć

temperature(heating):

2

Dry/Wet ball(outdoor):24℃/18℃

Page 7

Air Conditioner Edition:2005/11/18

3

ELECTRICAL CONTROL

Page 8

Air ConditionerEdition:2006/1/10

4

One. Temperature Control Function

In temperature control function, the operation frequency of outdoor unit is determined based on room

temperature and the set temperature.

In automatic fan speed mode, indoor fan is controlled based on the need of temperature control

In heating mode, indoor fan is controlled based on the temperature of coil.

1-1-1.Specification of Indoor Ambient Temperature Sensor

In case of short circuit or open circuit, indicator lamp alarms and indoor fan stops. When normal condition is resumed,

fan will automatically restart and operate normally.

Short Circuit:

Temperature: over 126

Normal Temperature:

Temperature: 25

Open Circuit:

Temperature: below -31

0.15V.

B Parameter = 4200 R (25

1-1-2 Specification of Indoor Coil Temperature Sensor

B Constant Number = 3700 R (25

1-1-3 When heating operation starts and indoor fan stops or when within 30s of indoor fan starts after

heating operation starts, the resistant of indoor ambient temperature sensor is ignored. (to avoid the

impact of heat exchanger temperature over it.)

When forced operation ends after start-up, temperature zone control begins.

1-2. Set Temperature Correction

Set temperature is corrected according to unit model, operation mode, fan speed and whether it is in

power operation.

Fan speed correction is available only during low and mid heating operation.

1-3. Temperature Zone Control

1-3-1.Error

Temperature zone error is calculated as per the following formula

In Heating Mode: E = (Remote Control Set Temperature + Correction Value) – Indoor Temperature

In Cooling & Dehumidification Mode: E = Indoor Temperature - (Remote Control Set Temperature +

Correction Value)

1-3-2 Compressor Shutdown

E is negative and |E|>∆T

o

C, Hexadecimal System: over F8H, Resistance: below 0.65K,Voltage: over 4.85V.

o

C, Hexadecimal System: 40H, Resistance: 23K, Voltage: 2.33V.

o

C, Hexadecimal System: below 08H, Resistance: below 620K Voltage: below

o

C) = 23K

o

C) = 10KΩ

:

Heating Cooling

∆T TCHAHL 0.67 TCHACL 0.33

After change of ∆T TCHAHH 0.67 TCHACH 1

∆T Change Condition When operation starts E ≥ 3.0℃,

Compressor shuts down after continuous testing for 120s,

At the beginning of operation, with reference to the conditions given in above table, it operates based

on the parameters after change of ∆T until compressor shuts down for the first time. In the time period

between compressor shutdown and restart, it operates based on ∆T. (except in dehumidification mode)

Compressor starts at the beginning of operation or upon switch of operation mode (except standby ends)

or when E (error) > -∆T.

When compressor is operating, remote control set temperature is changing towards the direction of

compressor shutdown and when it is below –∆T, compressor will shut down.

1-3-3. Compressor Operation

Compressor restarts when E (error) > -△T+0.67℃ and when 3 mins standby is over.

Page 9

Air ConditionerEdition:2006/1/10

5

wo. Indoor Fan Control

T

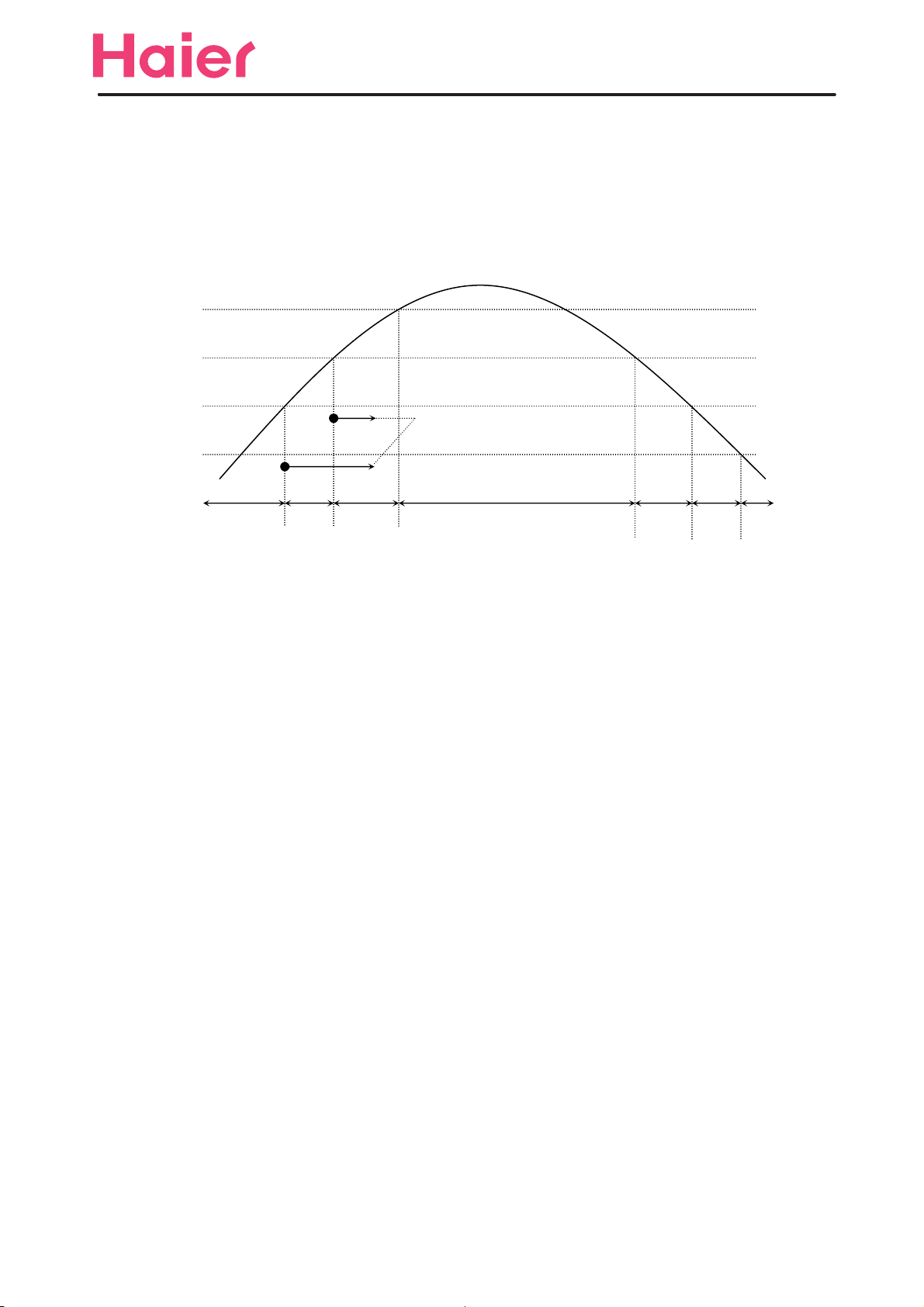

2-1. Heating

2-1-1. Warm Start

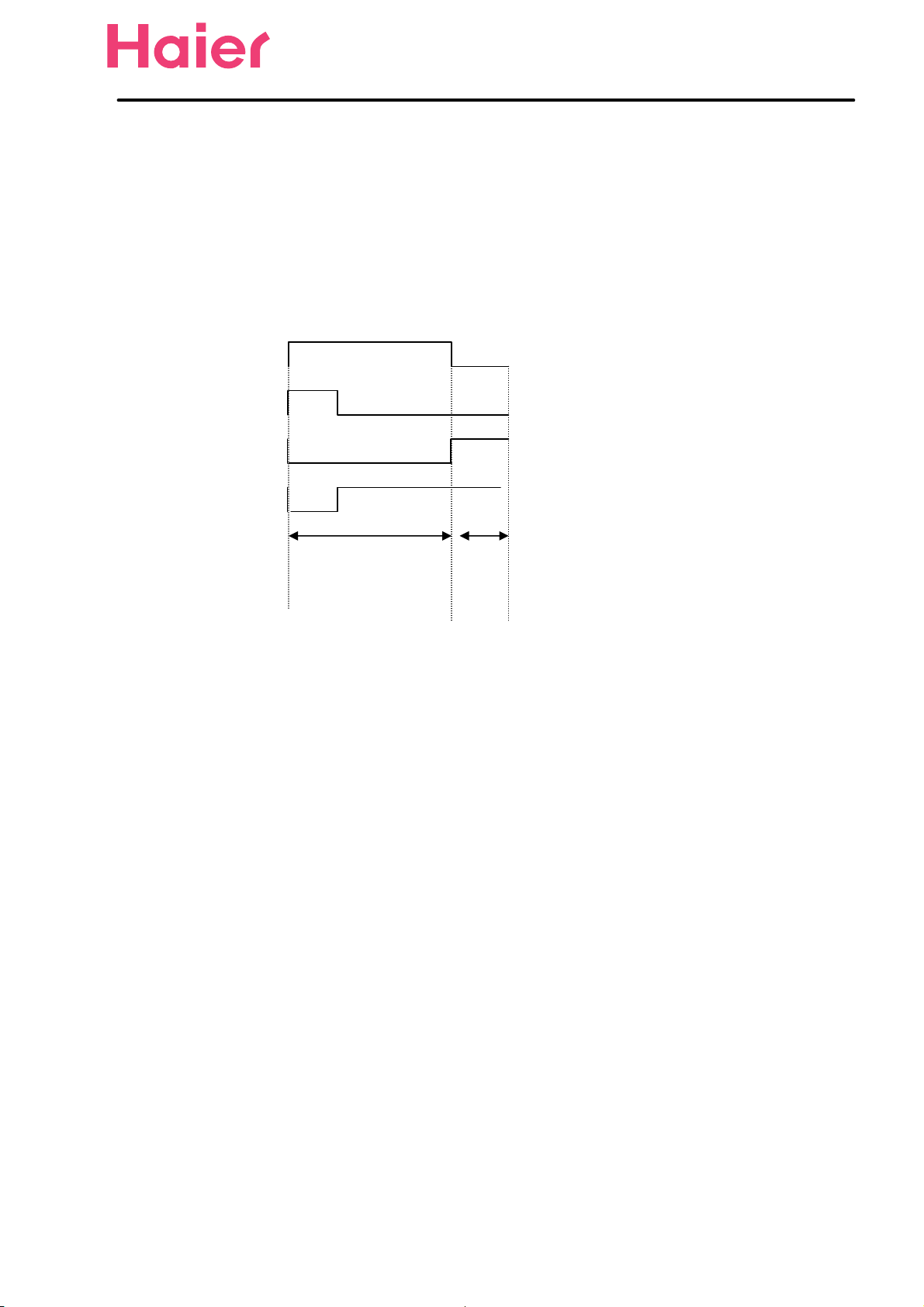

Cold Air Control in Heating Mode

Heat Exchange Temperature:

THHOT3

37.0℃

THHOT2

35.2℃

THHOT1

25.2℃ 4mins

THHOTR

16℃

Stop SLO LO Set LO SLO Stop

Conduct indoor fan control as per the above diagram and the heat exchange temperature.

1. Judge wind speed when heat exchange temperature is rising:

Fan is at super low level when heat exchange temperature is below 35.2℃.(Fan will stop upon

initially energized into heating mode or after defrosting, or when heat exchange temperature is lower

than 25.2℃. Fan is at super low level when temperature is higher than 25.2℃ but lower than

35.2℃.);

Fan is at low level when heat exchange temperature is between 35.2℃ and 37℃;

Fan will operate as per setting when heat exchange temperature is above 37℃.

2. Judge wind speed when heat exchange temperature is falling:

Fan is at low level when heat exchange temperature is below 35.2℃ but above 25.2℃;

Fan is at super low level and will maintain the mode when heat exchange temperature is lower than

25.2℃(Fan is at super low level upon initially energized into heating mode or after defrosting, or

heat exchange temperature is lower than 25.2℃ but higher than 16℃; Fan will stop when heat

exchange temperature falls below 16℃.)

3. Wind speed is at super low or low level when heat exchange temperature is rising. If heat exchange

temperature fails to enter the next temperature zone after 4 mins while wind speed rises to the next

stage, it is necessary to maintain the set wind speed for 4 mins before it is adjusted based on heat

exchange temperature.

4. When heat exchange temperature is falling, wind speed will return to set speed if low wind level is

maintained for over 4 mins.

2-1-2. 3 mins standby period when compressor shutdown.

1. When compressor shuts down(temperature sensor is off), airflow is low for the initial 20s then

reduced to super low (When in silent operation, it is SSLO);

2. Wind is maintained at super low level in the standby period in heating mode(Compressor stops during

mode switch.).

3. Remote control shut down and stop indoor fan.

2-1-3. Compressor Restart

When warm start, airflow is at remote control set level.

When in automatic airflow mode, airflow is determined based on temperature.

Refers to temperature zone control functions.

2-2 Cooling

Airflow is different when airflow is set at high, mid and low level.

When in automatic airflow mode, airflow is determined as per temperature. Refers to temperature control

functions. (Refers to 2-4-8)

2-3. Dehumidification

Page 10

Air ConditionerEdition:2006/1/10

6

2-3-1. Compressor is off and is in 3 mins standby.

Fan will stop if compressor stops

Fan is at super low level upon the end of 3 mins standby.

Compressor is on after 3 mins standby.

2-3-2. Compressor is on.

When airflow is set at high, mid or low level, fan will operate as per the setting.

When in automatic airflow mode, airflow is determined as per temperature.

Three. Air Refreshing

Up reception of remote control signal, negative ion generator will start operation to emit negative ion if

fan is operating.

If fan stops, negative ion generator is off.

When negative ion generator is off, if air-refreshing feature is set and fan restarts then negative ion

generator is on.

Four. Timed Operation

Time counting will start based on the difference of timer clock and current clock.

In timed operation, display panel timer lamp is on.

4-1. Timer Off

When timer off is set, panel timer lamp is on and unit will stop operation as per the timing.

4-2. Timer On

If timer on is set, when unit is off, panel timer lamp will be on and unit will resume operation as per the

timing and in set mode.

Execution sequence is based on the setting.

Five. Sleep Operation

When remote control set sleep mode, timer lamp is on.

o

5-1. In cooling/dehumidification mode, set temperature will rise 1

o

C after the second hour. The unit will stop after another 6 hours.

1

5-2. In heating mode, set temperature will fall 2

o

and will rise 1

C after another 3 hours and the unit will stop after another 3 hours.

o

C after 1 hour and another 2 oC after the second hour

C after 1 hour operation and another

5-3 If airflow of indoor fan is high before setting sleep mode, then it will turn into mid level after sleep

mode is set. If airflow of indoor fan is mid before setting, it will turn into low level after setting. If airflow of

indoor fan is low before setting, then it will not change after setting.

Six. Automatic Operation

Automatic operation consists of two features of automatic and full automatic, which can be realized

through EEPROM selection.

6-1. Automatic Operation Mode:

On entering this mode, main control unit will decide the corresponding operation mode as per room

temperature to maintain the set temperature(Set temperature is 23℃in heating mode and 26℃ in

cooling mode.).

Upon initial startup, the unit will enter heating mode if room inlet air temperature is equal to or lower

than 23℃ or it will enter cooling mode if temperature is higher than 23℃.

When entering heating mode, the unit will operate as per heating program(set temperature is 23℃)

Upon reaching temperature where compressor stops operation, compressor will stop and standby for 3

mins. In case it detects that inlet air temperature is higher than 27 15 mins after compressor stops, the ℃

unit will enter cooling mode. Otherwise, the unit will remain in heating mode.

When entering cooling mode, the unit will operate as per cooling program(set temperature is 26℃).

Temperature difference compensation is automatically cancelled. Upon reaching temperature where

compressor stops operation, compressor will stop and standby for 3 mins. In case it detects that inlet air

temperature is equal to or lower than 23℃ 15 mins after compressor stops, the unit will enter heating

mode. Otherwise, the unit will remain in cooling mode.

If the unit changes into automatic mode from any other mode and if the operation mode is changed

Page 11

Air ConditionerEdition:2006/1/10

7

(detect before operation), the unit will stop for 3 mins and it will operate based on inlet air temperature

after 3 mins.

Seven. Trial Operation

Trial operation will end after 30 mins, after which unit shuts down. In trial operation, the unit will quit trial

operation mode upon reception of signal.

Low load protection will not start.

Constant Frequency Multi-split Unit( Single, Double Compressors ) Low Load Protection

(Anti-freeze)Function:

Anti-freeze protection feature is available (Invalid in trial operation and heating mode):

Avoid freeze of indoor heat exchanger(in cooling and dehumidification mode)Compressor will stop

when temperature of indoor coil ≤ 0℃ and when compressor operates for over 5 mins. Compressor will

restart when temperature of indoor coil rises to over 7℃ (It must meet the needs of 3-min delay.).

In case high load protection is actuated twice within 30 mins, high load protection will alarm.

In case heat exchange temperature does not reach "THHEAT[2]", normal temperature zone control will

resume. .

Adopt the lower of either high load frequency or zone frequency as operation data.

Constant Frequency Multi-split Unit(single, double compressor)High Load Protection Control:

1. Fan Stop Protection: Indoor unit only sends A/D value to outdoor unit and outdoor unit exerts control;

2. Compressor Stop Protection:

Eight. Heating Low Temperature Treatment

In case it is unable to switch the four-way valve or in case the temperature of heat exchanger is below

"THHOTLTH"(-4.5℃)for "TMHOTLTH"(90s), compressor will stop and standby for 3 mins. Compressor

will restart when heat exchange temperature is above "THHOTLTH"(-4.5℃).

Fourteen. Communication

8-1 Communication between Indoor & Outdoor Unit

Note: This communication mode is compatible with three unit models of constant frequency

double-compressor multi-split, constant frequency single-compressor multi-split and inverter-controlled

multi-split.

8-1-1 Communication Sequence

Communication starts 2s after power is supplied. Indoor unit will send out signal first and transmission

will maintain at LO of 5ms then it starts to receive signal. In case, signal cannot be received within 2s,

another signal will be sent out. Upon reception of signal, another signal will be sent out after 10ms.

While indoor unit is waiting for signal input, its signal transmission is HI.

Error transmission occurs when indoor unit is unable to receive signal for 10 attempts (20s) after the

previous signal reception. In case of time reduction and shutdown, it is not considered as error

transmission.

Communication treatment will be engaged upon reception of correct HAD signal.

At the end of signal reception, communication data and reverse data will be compared and all the data

will be discarded in case of any error.

Outdoor unit will wait for signal from indoor HEADER HDR (81H) when power is supplied.

When sending signal, signal with header of C3H will be sent first.

During signal transmission, data"1" will output HI of 9MS and LO of 2MS, while data "0" outputs HI of

2MS and LO of 9MS.

Received signal is treated based on the majority of 5, 6 and 7MS.

Signal is only treated when correct HRD signal is received.

Nine. EEPROM Control

When outdoor unit is supplied with power, if there is any inconsistency between EEPROM parameter and

Page 12

Air ConditionerEdition:2006/1/10

8

checksum, EEPROM error.

When indoor unit receives EEPROM error signal from outdoor unit, it will display outdoor unit EEPROM error.

At this time, control and emergency operation are not acceptable.

It can only be cancelled through power off.

Ten. Error Record

There is no display when no error code record exists.

Error display mode automatically ends in 10s.

Only stop signal is accepted by remote control. Error record display mode ends corresponding to switch or

remote control stop signal.

For unit with EEPROM, record is saved when power is reset.

Eleven. Error Detect Method

1-1. Indoor Temperature Sensor Error

1

In operation, an error occurs if the temperature is above 126

o

C or below – 31oC.

Operation will resume automatically when temperature is outside the above range.

1-2. Heat Exchange Temperature Sensor Error

1

In operation, an error occurs if the temperature is above 196

o

C or below – 53oC.

Operation will resume automatically when temperature is outside the above range.

In error condition, low load protection is cancelled.

11-3. High Load

After high load and high limit is actuated, if the same operation recurs within 30 mins, a high load and high limit

error occurs.

11-4. Outdoor Temperature Sensor Error

On receiving error code of defrosting, air discharge temperature, base pane or outdoor temperature sensor,

indoor unit will display outdoor temperature sensor error.

Operation will resume automatically when receiving signal of removal of outdoor temperature sensor error.

In the error period, low load protection is cancelled.

1-5. Outdoor Unit Protection & Control Function

1

Indoor unit will display error when receives the following error codes:

Compressor Discharge Duct High Temperature Protection, DC Over Current, CT Disconnection, AC Over

Current, Power Module High Temperature Protection, Power Module Over Current Protection, Low Voltage

Protection, Outdoor Unit EEPROM Error, Compressor Operation Error.

Error conditions will be cancelled by stopping operation when outdoor unit receives 17654=0001,13=0 error

removal signal.

11-6. Transmission Error

Based on the condition of communication between indoor and outdoor unit, in case outdoor unit fails to

receive signal within 20s after indoor unit sends out signal, transmission is abnormal. (except in the period of

first 2 mins when power is supplied.). It is confirmed as transmission error when outdoor unit receive the error

signal.

Transmission error is removed by stopping operation.

Twelve. Special Function

1

2-1. Independent Operation of Indoor Unit

a. Entry Condition: First set remote control as heating high wind, 30

o

C, initial energization, press sleep key 6

times in 7s and there will be 6 sounds.

b. On entering independent operation of indoor unit, indoor unit will operate as per the following procedures:

Indoor unit will operate and communicate as per setting. Communication signal form outdoor unit will not be

treated by indoor unit while it will send signals to outdoor unit continuously.

c. Exit Condition: On receiving remote control or emergency shut down signal, it will exit independent

operation of indoor unit. Furthermore, it will exit independent operation of indoor unit after power off and power

on again. During independent operation of indoor unit, it may simulate outdoor unit and send the following

Page 13

Air ConditionerEdition:2006/1/10

9

signals to indoor unit:

2-2. Power-Off Compensation

1

a Entry Condition: Press sleep key 10 times in 7s and buzzer gives out 4 sounds and save the current status

into indoor unit EEPROM upon the entry.

b. On entering power-off compensation operation, indoor unit operates as per the following procedures:

Remote control emergency signal, and operates as per condition set by remote control and emergency setting

and save the current status into indoor unit EEPROM.

Main unit will operate as per condition set on panel board. And save the current status into indoor unit

EEPROM.

c. Exit Condition: Press sleep key 10 times in 7s and buzzer gives out 2 sounds

d. If timer and sleep features are set under power-off compensation condition, main unit memory is in a state

of shut-off if power is off and on again.

T

hirteen. Emergency Switch

When shutdown, press emergency switch down for less than 5s, the unit will start emergency operation.

When shutdown, press emergency switch down for more than 5s but less than 10s, the unit will start trial

operation.

When shutdown, press emergency switch down for more than 10s but less than 15s, it will demonstrate

the previous error.

When shutdown, press emergency switch down, the panel will display automatic operation.

When shutdown, press emergency switch down for less than 15s, or remove hand from emergency

switch, the unit will not accept remote control signal.

Unit enters shutdown condition after 15s.

Unit can receive remote control signal after 15s.

Press emergency switch during operation, air-conditioner will shut down.,

During operation, if error occurs, press emergency switch to shut down the unit to clear error condition.

During error presentation, press emergency switch and error presentation will end.

During operation, if emergency switch is pressed continuously (press and hold) in normal or abnormal

condition (such as tact switch short circuit) or in error presentation condition, the unit can also receive

remote control signal.

Error Record Presentation Mode:

When press and hold switch for 10s it gives out 3 sounds, release switch to enter error record

presentation mode. Press and hold switch for 15s, panel display is off and error record presentation

mode is cancelled.

Previous alarm information will be sent to display panel for status display.

Error record presentation mode is cleared after 10s. (Error record presentation mode is only displayed

for 10s.)

During the presentation, no remote control signal except shutdown signal is accepted.

There is no presentation when no error occurs, only buzzer utters sound.

Page 14

Air Conditioner

10

1. Definition of chip tubes’ pins

Chips are used in this manual and their pins are defined as follows:

Edition:2006/1/10

Chip’s Pins Definition of Function Chip’s

Definition of Function

Pins

GND GND P37AIN5 CTA signal input

XIN XIN P36AIN4 CTB signal input

XOUT XOUT P35AIN3 tube temperature A

TEST GND P34AIN2 tube temperature B

VDD +5V P33 AIN1 Outdoor ambient temperature

P21 Alarm light

(to be connected with pull resistance)

reuse for self-checking/contracting

P22 Serial communication output

(to be connected with pull resistance)

RESET Reset P30 EEPROM--SCL

P20 4-way valve A P12 EEPROM--SDA

P00 4-way valve B P11 -INT1 Communication input A

P01 High air flowrate P10 -INTO Communication input B

P02 Mid air flowrate P07 Communication output A

P03 Low air flowrate P06 Communication output B

P04 Compressor B P05 Compressor A

P32 AIN0

P31

P32 P31 Model selection

0 0 Model 1

0 1 Model 2

1 0 Model 3

1 1 Model 4

2. Communication format

Note: This communication format is compatible with 3 models, i.e., double-compressor one-drive-two

without converter, single-compressor one-drive-two without converter and one-drive-two with

converter.

2.1. Sequence of communication

Communication begins 2 seconds after the power supply inputs. The indoor unit first gives out a

signal and outputs the LO which remains at 5 ms, then changes to receive signal. If it fails to

receive signal 2 seconds after the signal is given out, it will give out a signal once again. After the

signal is received, it will give out a signal once more 10 ms later. When the indoor unit is waiting

for the signal input, the signal output is HI. If the indoor unit fails to receive signals in normal

condition in times (20 seconds) after the previous signal has been received, the transmission is

abnormal. But time shortage and being halted are not of abnormal transmission. Communication is

carried out when a correct HDA signal is received. After the signal has been received, the

communication data is compared with the inverter data. When incorrect, all the data will be given

up. The outdoor unit waits to receive signal HEADER HDR(81H) from the indoor unit after the

power supply inputs. After the signal has been received, the communication data is compared with

the inverter data. When incorrect, all the data will be given up.

Page 15

Air Conditioner

11

Edition:2006/1/10

The outdoor unit waits to receive signal HEADER HDR(81H) from the indoor unit after the power

supply inputs. When transmitting signal, HEADER is C3H. When a signal is first transmitted at the

head, data "1" outputs HI of 9MS and LO of 2MS and data "0" outputs HI of 2MS and LO of 9MS.

When receiving signal, the signal reception is carried out depending on the majority of the 5th, 6th

and 7th 5,6,7MS.

The signal reception will not take place until a correct HDR signal is received.

Output 1:

0:

Input 1:

0:

9ms 2ms

2.2. Checkout of errors

The signal reception does not take place until the outdoor unit receive signal HDR from the indoor

unit. At the completion of the signal reception, the data is compared with the inverter data. When

incorrect, all the data is given up. If it is incorrect in 20 seconds of comparison, the compressor,

4-way valve and outdoor fan turn off, giving the abnormal condition and sending out the

corresponding error codes for the abnormalcy of signal delivery and transmission.

2.3. Tim er for communication data input /output

After the power supply inputs, the outdoor communication output is HI, waiting for the indoor unit

to send signal.

The timer counter is cleared 0 at the decline of communication, regarding 3 times of 5,6,7 ms.

The status of the communication input PORT determines input signals. When in the next decline of

communication, the timer counter is cleared one again.

HEADER 8 bits, the data and inverter data 48 bits, and the total is 56 bits. After the data has been

received, LO of 10 ms is ready to send signal. The 0 clearance of the timer counter during the

sending takes place in a 1 ms interruption.

HEADER 8 bits, the data and inverter data 48 bits, and the total is 56 bits. After the data has been

sent, Both output LO of 5 ms and output HI of 5ms are ready to receive signal 4 and

communications

Page 16

Air Conditioner

12

Edition:2006/1/10

A7-6 A5-3 A2-0 C7-0 E7 E6 E5 E4 E3 E2-0

Protocol

8 2 3 3 8 1 1 1 1 1 3 LSB

MSB

READER Oper

ation

mode

Not

in

use

Section Heat

excha

nge

Not

in

use

Trouble

record

Set

oper

ation

Capa

city

Time

short

age

temp.

HDR A B C D E F

10000001 00000000 11111111 00000000 11111111 00000000 11111111

HDR: READER indoor unit→outdoor unit 81H 10000001

Communic

ation

Letter

A

C

E

Communication Byte Communication Content Remark

A7, A6

A5

A4

A3

A2A1A0

C7-0

E7 Not in use

E6

E5

E4 Not in use

00 stop 01 cooling

10 dehumidify 11 heating

0: normal 1: trial

operation

0: normal

1: timer on operation in

heating

0 ordinary

1 timer on operation in

cooling

Variable

000:0

001:1

~

110:6

111:7

00000000: - infinite

00000001: -53℃

~

10000000: 54℃

11111111:368℃

0: normal

1: trouble record

indication

0: normal

1: set operation

frequency: [set

temp.- room

temp.] section

Fixed frequency:

000: Off

Other: On

Indoor unit heat

exchange

temperature

Operation mode

Abnor

mal

informa

tion

Page 17

Air Conditioner

13

0: normal

E3

E2 E1

E0 Not in use Can not be used

B,D,F: inverter data of A,C and E respectively 8 Bits each

1: time shortage

operation

00 double-compressor

one-drive-two without

inverter

01 single-compressor

one-drive-two without

inverter

10 One-drive-two with

inverter

Edition:2006/1/10

G7-0 I7-4 I3 I21 I0 K76 K54 K3-0

Protocol

8 8 4 1 2 2 2 4 LBS

MSB

HEADER Output

Frequency

Error

code

Err

3 minute

or

standby

Operation

mode

ide

ndi

ty

HDR G H I J K L

11000011 00000000 11111111 00000000 11111111 00000000 11111111

HDA: HEAD 8BIT outdoor unit→indoor unit C3H 11000011

Communi

cation

Letter

G G7-G0 00000000:OHZ

Communicat

ion Byte

Communication Content Remark

│

11111111:255HZ

Variable frequency: output

frequency

Oper

ation

sign

al

Moni

tor

signa

l

Page 18

Air Conditioner

14

Edition:2006/1/10

I I7-I4 0000: compressor operation abnormal

0001: normal

0010: discharge pipe temperature over-rise

protection

0011: DC wave crest current

0100: outdoor EEPROM abnormal

0101: AC wave crest current(AC current too

high)

0110: not in use

0111: communication abnormal

1000: CT disconnected

1001: undervoltage protection

1010: outdoor thermistor abnormal

1011: not in use

1100: outdoor base plate temperature

over-rise protection

1101: outdoor ambient temperature sensor in

trouble

1110: outdoor coil sensor

1111: not in use

I3 0: normal

1: error identity

Black indicates the trouble in the

unit with inverter

Red indicates the trouble in the

unit without inverter

Note:

1. Outdoor AC current too high,

i.e., original transformer

troubles A and B.

2. The troubles A and B in the

coil and transformer of previous

outdoor units are separate. Now

the troubles in the outdoor coil

and transformer are no longer

differentiated by A and B.

In case of 1, it indicates error.

K

I2,I1 00: data abnormal

01: normal

10: defrosting operation

11: not in use

I0 0: normal

1: 3 minute standby

K7,K6 00: stop 01: cooling

10: dehumidifying 1 1: hea ting

K5, 0: not double-compressor heating 1:

double-compressor heating

K4 0: normal 1: rated operation

K3 0: normal 1: abnormal operation

K2-0 000: normal

1**: RC heating at the non-communication

side starts in the timer

*1*: RC cooling at the non-communication

side starts in the timer

**1: both units are in operation

In case of 10, the air blower

control operation during

defrosting takes place.

H, J, L: inverter data of G, I and K respectively 8 bits each

Page 19

Air Conditioner

15

Edition:2006/1/10

3. Single-unit cooling operation

3.1. When the single unit’s indoor unit gives a cooling signal, the corresponding outdoor

compressor carries out cooling operation. During the operation, the outdoor fan operates 1

second before the compressor operates.

3.2. When changed from heating to cooling, the compressor stands by for 3 minutes, the outdoor

fan operates to blow off remaining heat and stops 30 seconds later.

3.3. When the outdoor ambient temperature T1≥38℃, the outdoor fan runs at the high speed.

There is a return difference of 2℃ for the change between high and medium speed.

When the outdoor ambient temperature T1≤26℃, the outdoor fan runs at the low speed. There

is a return difference of 2℃ for the change between low and medium speed.

When the outdoor ambient temperature T1≤8℃, the outdoor fan is in a cycle of 1 minute stop

and 3 minute run. There is a return difference of 2℃ for the change between low speed and run

and stop.

3.4. Once the fan operates in a mode, it must operate for more than 45 seconds.

There is a temperature cut-off protection: when the indoor coil temperature higher than T_CPS (68

℃) and maintains for 10 seconds, both the compressor and outdoor fan stop. The compressor will

not restart in 3 minutes until the coil temperature lower than T_CP R(50℃). The indoor fan is

controlled the same as the thermostat is OFF.

4. Double-unit cooling operation

4.1. When the indoor unit gives out a double unit cooling signal, outdoor compressor A starts

cooling operation. During the operation, the outdoor fan runs 1 second before compressor A

operates, 20 seconds later, outdoor compressor B starts cooling operation.

4.2. Once a compressor starts, the other compressor will not start in 20 seconds from the start.

4.3. When changed from heating to cooling, the compressor stands by for 3 minutes. When both

compressors are in the strand-by status, the outdoor fan stops. Otherwise, it operates. The status

of the fan depends on the number of the compressors that operate.

4.4. When the outdoor ambient temperature T1≥30℃, the outdoor fan runs at the high speed.

There is a return difference for the change between high and medium speed;

When the outdoor ambient temperature T1≤23℃, the outdoor fan runs at the low speed. There

is a return difference for the change between low and medium speed;

When the outdoor ambient temperature T1≤5℃, the outdoor fan is in a cycle of 1 minute stop

Page 20

Air Conditioner

16

Edition:2006/1/10

and 3 minute run. There is a return difference of 2℃ for the change between low speed and run

and stop.

4.5. Once the fan operates in a mode, it must operate for more than 45 seconds.

4.6. There is a temperature cut-off protection: when a indoor coil temperature higher than T_CPS

(68℃) and maintains for 10 seconds, the corresponding compressor stops. The compressor will

not restart in 3 minutes until the coil temperature lower than T_CP R(50℃). The indoor fan is

controlled the same as the thermostat is OFF.

4.7. In the case of double-unit cooling, one compressor stops and it changes to the single-unit

operation. The fan is controlled in the single-unit operation mode. It stops 30 after blowing off

the remaining heat only if both compressors turn off at the same time.

5. Single unit heating operation:

5.1. When the single unit’s indoor unit gives a heating signal, the corresponding outdoor

compressor carries out cooling operation. During the operation, the outdoor fan and 4-way valve

operate 1 second before the outdoor fan operates.

5.2. When changed from cooling to heating, the compressor stands by for 3 minutes, the outdoor

fan stops.

5.3. When the outdoor ambient temperature T1≤3℃, the outdoor fan runs at the high speed. There

is a return difference of 2℃ for the change between high and medium speed.

When the outdoor ambient temperature T1≥13℃, the outdoor fan runs at the low speed. There is a

return difference of 2℃ for the change between low and medium speed.

5.4. Once the fan operates in a mode, it must operate for more than 45 seconds.

5.5. There is a high temperature protection and a temperature cut-off protection.

High temperature protection: When the indoor coil temperature higher than T_OFS (56℃), the

outdoor fan stops; when the coil temperature falls to T_OFR (52℃), the outdoor fan restarts. The

outdoor fan stops for more than 45 seconds.

High temperature cut-off protection: When the indoor coil temperature higher than T_CPS (68℃)

and maintains for 10 seconds, both the compressor and outdoor fan stop, and the indoor fan operates

as the thermostat is Off. The compressor will not restart in 3 minutes until the coil temperature

lower than T_CP R(50℃).

6. Double-unit heating operation

6.1. When the double-unit’s indoor unit gives out a heating signal, outdoor compressor A starts

Page 21

Air Conditioner

17

Edition:2006/1/10

heating operation. During the operation, outdoor compressor A and the 4-way valve operate 1

second before the fan starts, 20 seconds later, outdoor compressor B starts heating operation.

6.2. Once an outdoor compressor starts, the other compressor will not start in 20 seconds from the

start.

6.3. When changed from cooling to heating, the compressor stands by for 3 minutes. When both

compressors are in the strand-by status, the outdoor fan stops. Otherwise, it operates. The status

of the fan depends on the number of the compressors that operate.

6.4. When the outdoor ambient temperature T1≤10℃, the outdoor fan runs at the high speed.

There is a return difference for the change between high and medium speed;

When the outdoor ambient temperature T1≥20℃, the outdoor fan runs at the low speed. There

is a return difference for the change between low and medium speed.

6.5. Once a fan operates in a mode, it must operate for more than 45 seconds.

7. Cooling and heating operations take place at the same time:

7.1. When one of the indoor units gives out a cooling signal and another unit gives out a heating

signal at the same time, the outdoor fan operates at the low speed.

7.2. When the indoor unit gives the value of coil temperature, the outdoor fan runs at the low speed if

the heating outdoor unit judges high load.

7.3. When outdoor ambient temperature T1≥28℃, there is no heating operation.

7.4. When outdoor ambient temperature T1≤7℃, there is no cooling operation.

7.5. Once a compressor starts, the other compressor will not start in 20 seconds from the start.

8. Single-unit heating operation with heat load:

8.1. In the single-unit heating operation, the indoor unit gives out the value of the coil temperature,

and the outdoor unit judges whether to start in the high load protection operation based on the

value of the coil temperature it has received. If the conditions for high load protection are met, the

outdoor fan stops immediately. It will restart 45 seconds later if the signal for the outdoor heat load

disappears. Otherwise, the outdoor fan will continue to stop until the signal for the outdoor heat

load disappears. The signal for heat load is as follows:

High temperature protection: When the indoor coil temperature higher than T_OFS (56℃), the

outdoor fan stops; when the coil temperature falls to T_OFR (52℃), the outdoor fan restarts. The

outdoor fan stops for more than 45 seconds.

Page 22

Air Conditioner

18

Edition:2006/1/10

High temperature cut-off protection: When the coil temperature higher than T_CPS (68℃) and

maintains for 10 seconds, both the compressor and outdoor fan stop, and the indoor fan operates as the

thermostat is Off. The compressor will not restart in 3 minutes until the coil temperature lower than

T_CP R(50℃).

8.2. In the single-unit heating operation, the current in the compressor is larger than 5.8A, and the

outdoor fan stops. 45 seconds later, the current in the compressor is less than 5.3A, and the outdoor fan

operates in normal condition(the compressor does not detect current within 30 seconds after its start),

the current in the compressor is larger than 5.3Aand less than 5.8A, and the outdoor fan does not

restore.

9. Double-unit heating operation with heat load

9.1. In the double-unit heating operation, the indoor unit gives out the value of the coil temperature,

and the outdoor unit judges whether to start in the high load protection operation based on the

value of the temperature it has received. If the conditions for high load protection are met, the

outdoor fan stops immediately. It will restart 45 seconds later if the signal for the outdoor heat load

disappears. Otherwise, the outdoor fan will continue to stop until the signal for the outdoor heat

load disappears. The signal for heat load is as follows:

High temperature protection: When the indoor coil temperature higher than T_OFS (56℃), the

outdoor fan stops; when the coil temperature falls to T_OFR (52℃), the outdoor fan restarts. The

outdoor fan stops for more than 45 seconds.

High temperature cut-off protection: When the coil temperature higher than T_CPS (68℃) and

maintains for 10 seconds, both the compressor and outdoor fan stop, and the indoor fan operates as

the thermostat is Off. The compressor will not restart in 3 minutes until the coil temperature lower

than T_CP R(50℃).

9.2. When the outdoor single-unit gives out the heat load signal, the outdoor fan stops immediately,

45 minutes later, the heat load signal disappears, and the outdoor fan operates.

9.3. In heating operation, any of the current in the compressor is larger than or equal to 5.8A , and

the outdoor fan stops. The current in the compressor is less than or equal to 5.3A, and the outdoor

fan restores (the compressor does not detect current within 30 seconds after its start), the current in

the compressor is larger than 5.3A and less than 5.8A, and the outdoor fan does not restore.

10. Current peak protection

Page 23

Air Conditioner

19

Edition:2006/1/10

10.1. The current in the compressor is larger than 10 Afor more than 5 seconds, The compressor which

has the highest current will stop(the compressor does not detect current within 10 seconds after its

start) and 3 minutes later it will continue to operate.

10.2. The compressor will no longer operate if overcurrent protection occurs 4 times in a row within

30 minutes, and the output transformer signal fails. In the double-unit operation, if one of the

compressors stops due to the current too high, the other system is a single system.

11. Single-unit defrosting operation (outdoor judgement)

Defrosting control

11.1. Conditions for starting in the defrosting operation

The heating compressor starts and operate continuously for 10 minutes. After the compressor has

been operating for 45 minutes in total (the defrosting operation ends, or when starting in the

cooling mode, the compressor totals the operating time for zero clearance), detecting the

defrosting sensor TE (detecting the frosting of the outdoor heat exchanger) and the outdoor

ambient temperature sensor TA for straight 2 minutes, provided the following conditions are met,

it will start for the defrosting operation: TE≤C×TA-α

Where,

C: TA<0℃

C=0.8

TA≥0℃

C=0.6

αcan be selected according to the data of EEPROM as follows:

Selection of

Jumper

L M H

α(℃) 10 8 6

In the place where it tends to frost, it is preferred to choose H. In the place where it does not intend to

frost, it is preferred to choose L. It is set M at delivery.

During the defrosting operation, the temperature control starts -15℃≤C×TA-α≤-2℃

Note: If the result of the calculation from C×TA-α is less than -15℃, -15℃ applies. If the result

of the calculation from C×TA-α is larger than -2℃, -2℃ applies.

11.2. Interval of defrosting

Page 24

Air Conditioner

20

Edition:2006/1/10

When the result of the calculation from C×TA-α falls in the range of -15℃≤C×TA-α, the

interval between two defrosting operations is 45 minutes.

When the result of the calculation from C×TA-α falls in the range of C×TA-α<-15℃, the

interval between two defrosting operations is 55 minutes.

11.3. Defrosting operation

At the beginning of defrosting, the compressor is halted for the first one minute, but the outdoor fan

operates, 50 seconds later, the 4-way valve is OFF.

During the defrosting operation, such protections as the compressor’s current protection are available.

The compressor may be interrupted for its protection or due to a trouble, and restore after 3 minutes. If

it remains in the defrosting period, it will still start to defrost. The start of the compressor is made by

the rules for the start of the defrosting compressor. (if it cannot restore 3 times in a row, it will be dealt

with as in trouble and cancel defrosting.)

11.4. Once starting to defrost, the compressor must be guaranteed at least 2 minutes of operation

before canceling defrosting. As for the conditions to cancel defrosting, it will restore to the heating

operation from the defrosting operation as long as any of the following conditions is met.

(1) . The outdoor heat exchanger temperature is above 7 degrees for consecutive 80 seconds.

(2) . The outdoor heat exchanger temperature is above 5 degrees for consecutive 12 seconds.

(3) . The defrosting operation has lasted 9 minutes.

11.5. After the conditions for cancellation of defrosting are met, the following operations will follow:

The compressor stops, the outdoor fan starts, 50 seconds later, the 4-way valve is engaged, and 60

seconds later, the compressor operates.

12. Double-unit defrosting operation (outdoor judgement)

After receiving the signal to stop the indoor unit during the defrosting period, the unit must not be

turned off until the outdoor defrosting lasts more than 2 m inutes.

When the double units are activated for defrosting, the activation of compressor B is 20 minutes later

than that of compressor A.

Conditions for ending defrosting: It will restore to the heating operation from the defrosting operation

as long as any of the following conditions is met.

(1) . The temperatures on both outdoor heat exchangers are above 7 degrees for consecutive 80

seconds.

(2) . The temperatures on both outdoor heat exchangers are above 5 degrees for consecutive 12

Page 25

Air Conditioner

21

Edition:2006/1/10

seconds.

(3) . The defrosting operation has lasted 9 minutes.

The starting conditions and control process for the double-unit are same as that for single-unit

defrosting, the only difference is that the activation of compressor B lags that of compressor A.

13. Alarming operation

1. When the whole unit is in normal operation, the alarm light is always on, but does not flash.

2. When the outdoor temperature sensor short-circuited or disconnected, the outdoor fan always

operates at the medium speed and will restore automatically after the sensor comes to normal.

3. When the temperature sensors on the pipes A and B short-circuited or disconnected, the double

unit will not carry out defrosting operation. During heating, this signal is sent to the indoor unit,

but no sending for other operating conditions. When sent to the indoor unit, the whole unit stops.

The signal is sent to the indoor unit which coil is operating abnormally, and the corresponding

indoor unit indicates trouble.

4. When the temperature sensor short-circuited or disconnected or the current transformer fails, the

alarm light flashes in the following manner; when the current transformer fails, the signal is sent

to the indoor unit that operates abnormally, and the corresponding indoor unit indicates trouble:

Page 26

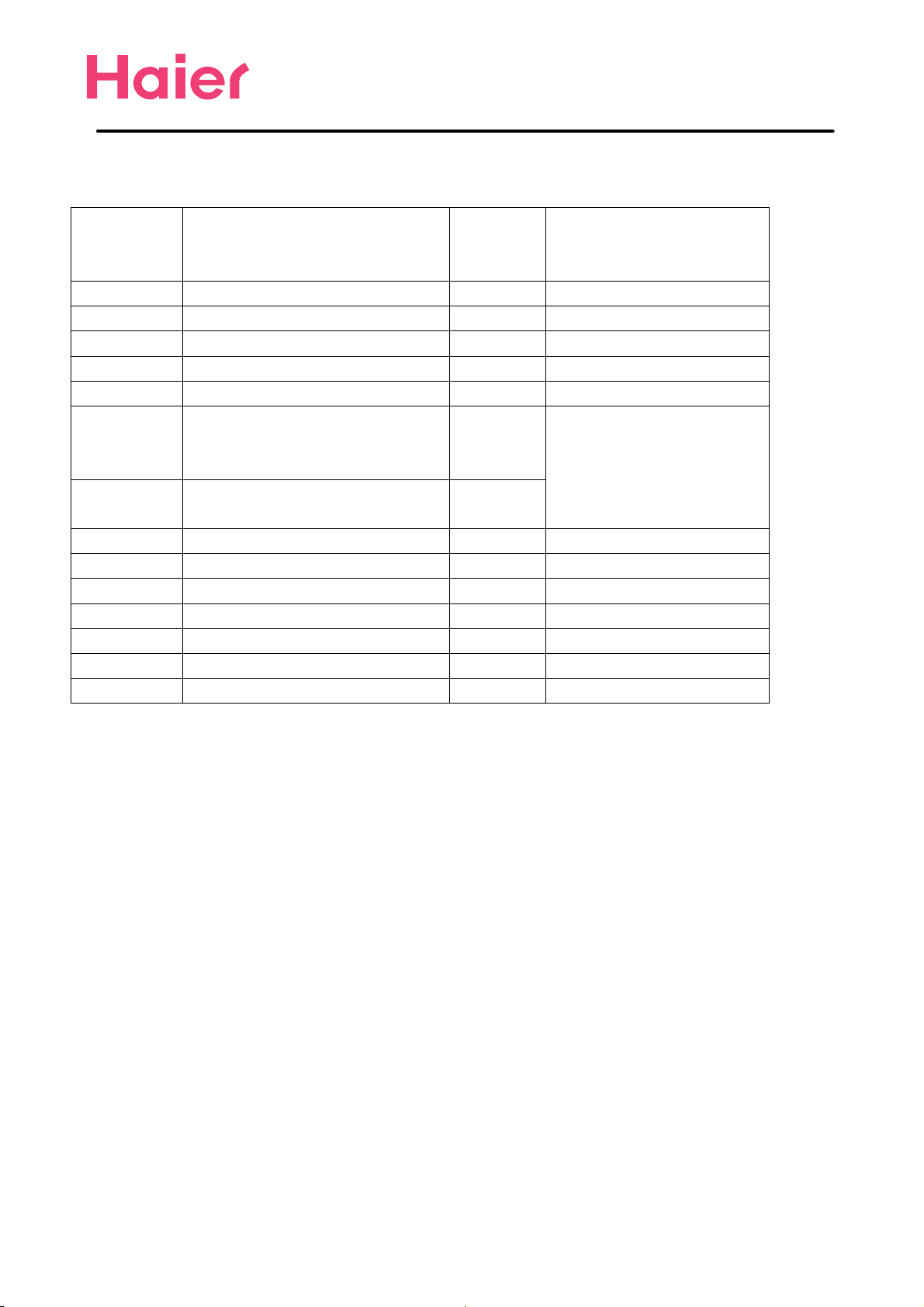

Codes and Description

H2SM-14/18C03/R2

Code indication

Description

indoor

Indoor

Malfunction

Power timer operate

Operate heating cooling

★ ■ ■

★ □ □

★ □ ★

■ □ ★

Room temperature sensor failure --

Heat-exchange sensor failure --

Indoor EEPROM error ---

Indoor fan motor malfunction --

■ ■ ★ Communication Error (between indoor and outdoor unit)

Outdoor

Malfunction

★ □ ■ Outdoor Senistor Error

outdoor EEPROM error 1

outdoor unit A’s coil sensor failure

outdoor unit B’s coil sensor failure

explanation □on★flash■off

Trouble Shooting

★ ■ ■: Room temperature sensor failure CN8

★ □ □: Heat-exchange sensor failure CN8

Pull the sensor out of the mainboard

1) Measure the value of resistance Between its two

jumpers

2) Measure the temperature at the room temperature

sensing head.

The indoor PCB is broken, replace with new indoor PCB

22

whether terminal CN8 on

indoor PCB contact wellt?

YES

Check the value of the

sensor to see whether the

sensor is dama

ged or not?

YES

NO

NO

Pull out the terminals on the indoor mainboard and

reinsert them

Sensor is broken,replace it with new sensor

Outdoor led1

blinks times

3 or 7

2

5

9

Page 27

H2SM-14/18C03/R2

★ □ ★: Indoor EEPROM error: Replace the PCB of indoor unit

■ □ ★:Indoor fan motor malfunction

whether terminal CN7

and CN11 on indoor PCB

well inserted or not?

YES

Pull out and reinsert the terminals

Electrify the machine again and turn it on in the cooling

operation, Measure voltage between the positions 1 ( red

wire)

and 5( black wire) of Terminal CN1 on the indoor PCB

NO

. the voltage is about

90-200vac

NO

the indoor pcb is damaged and need replace

check whether motor

can run when

turn on the unit

Yes

NO

the indoor motor is damaged and need

replace

Yes

When motor is running Measure

whether there is voltage

pulse(0-5VDC) between the

positions 2 (middle wire) and

black wire) of Terminal CN7

3(

on the indoor PCB

NO

the indoor motor is damaged and need

replace

the indoor pcb is damaged and need replace

23

Page 28

H2SM-14/18C03/R2

LED1 of outdoor pcb flashes once: outdoor EEPROM error: Replace the PCB of outdoor unit,

★ □ ■

LED1of outdoor pcb flashes twice: Outdoor ambient Sensor failure CN1,

whether terminal CN1 on

outdoor PCB contact well?

NO

Pull out the terminals on the outdoor mainboard and

reinsert them

YES

Pull the sensor out of the mainboard

3) Measure the value of resistance Between its two

jumpers

4) Measure the temperature of

Outdoor ambient

Check the value of the

sensor to see whether the

sensor is dama

ged or not?

NO

Sensor is broken,replace it with new sensor

YES

The outdoor PCB is broken, replace a new one

24

Page 29

H2SM-14/18C03/R2

■ ■ ★ :Communication fault between indoor and outdoor system

Yes

Check whether the linking cable

between the indoor and outdoor

is not well connected

Reconnect the linking cable;

NO

If unit A have error , please turn

Yes

on A and B both,check whether B

is fine

NO

YES

please check whether the

connecting of L or N is reversed of

the two units

NO

YES

Check whether the LED1

on the outdoor pcb is on

NO

check whether the voltage of

NO YES

CN7 in outdoor pcb is about

198-253VAC

NO

YES NO

NO

check whether the voltage of

CN4

in outdoor pcb is about 12VAC

YES

the outdoor PCB is damaged

please reverse the outdoor

connecting wires A(C) and B (C)

between unit A and B,

reconnect the L and N wires

the outdoor PCB is damaged

check whether fuse of outdoor

pcb is broken

check whether the wire from

terminal block to out pcb is well

connected

the transformer is bad

if A is error and B is fine, indoor

unit A PCB is damaged

if A is fine and B has error,the

outdoor unit main PCB is damaged

reaplace the fuse with

T3.15A 250V

Reconnect the linking

wire

25

Page 30

H2SM-14/18C03/R2

LED1 of outdoor pcb flashes 5 or 9 times outdoor unit A or B’s coi sensor failure CN2

whether terminal CN2 on

outdoor PCB contact well?

NO

Pull out the terminals on the outdoor mainboard and

reinsert them

YES

Pull the sensor out of the mainboard

5) Measure the value of resistance Between its two

jumpers

6) Measure the temperature of

B’s coi

outdoor unit A or

Check the value of the

sensor to see whether the

sensor is dama

ged or not?

NO

Sensor is broken,replace it with new sensor

YES

The outdoor PCB is broken, replace a new one

26

Page 31

Air Conditioner Edition:2005/11/18

TROUBLE SHOOTING

27

Page 32

Air Conditioner

2006/1/10

Trouble shooting

Before asking for service, check the following first.

Normal

Performance

inspection

Phenomenon

The system does not restart

immediately.

Noise is heard

Smells are generated.

Mist or steam are blown out.

Cause or check points

When unit is stopped, it won't restart

immediately until 3 minutes have elapsed

to protect the system.

When the electric plug is pulled out and

reinserted, the protection circuit will work

for 3 minutes to protect the air conditioner.

During unit operation or at stop, a swishing

or gurgling noise may be heard. At first 2-3

minutes after unit start, this noise is more

noticeable. (This noise is generated by

refrigerant flowing in the system.)

During unit operation, a cracking noise may

be heard. This noise is generated by the

casing expanding or shrinking because of

temperature changes

Should there be a big noise from air flow in

unit operation, air filter may be too dirty.

This is because the system circulates smells

from the interior air such as the smell of

furniture, cigarettes.

During COOL or DRY operation, indoor unit

may blow out mist. This is due to the sudden

cooling of indoor air.

Application temp. range of air conditioner -7oC~43oC.

Multiple

check

Does not work at all.

Poor cooling

Is power plug inserted?

Is there a power failure?

Is fuse blown out?

Is the air filter dirty? Normally it should be

cleaned every 15 days.

Are there any obstacles before inlet and outlet?

Is temperature set correctly?

Are there some doors or windows left open?

Is there any direct sunlight through the

window during the cooling operation?(Use

curtain)

Are there too much heat sources or too many

people in the room during cooling operation?

28

Page 33

Abnormality Diagnosing

Air Conditioner

Edition:2006/1/10

Number

1

2

3

4 Not heating

Trouble

phenomenon

Not work with

remote

controller

Outdoor fan

motor

doesn’t work

Indoor fan

motor

doesn’t work

Description

Use the

remote

controller to

boot

machine

and it

doesn’t

work

Outdoor

fan motor

doesn’t run

when

cooling or

heating

Indoor fan

motor

doesn’t run

when

cooling or

heating

Cooling but

not heating

Parts that may appear problems

and the Cause

7805,transformer, piezo

resistance, fuse,remote controller,

receiver. If it can be booted by

using manual emergency switch,

that indicate the power cable and

wiring board are electriferousˈ

remote controller or receiver isn’t

well˗else check whether piezo

resistance ,fuse and 7805 are

wellDŽ

Optical SCR, indoor P.C. board.

Check the 2# and 4# terminal

block of indoor unit, if it has 220V

voltage, wiring board is normal,

then check whether the optical

SCR is good, replace it if it has

flaw˗else check whether there are

something wrong with connecting

lineˈoutdoor fan motor capacitor

and coil assemblyDŽ

Optical SCRˈindoor P.C. board DŽ

Check whether indoor fan motor

has 80-170V voltageˈif it hasˈ

wiring board is normal, then check

whether the optical SCR is good,

replace it if it has flaw˗else check

whether there are something

wrong with connecting lineˈindoor

fan motor capacitor and coil

assemblyDŽ

Indoor P.C. board , four-way valve

coil, body of four-way valveˈCheck

the 2# and 3# terminal block of

indoor unit, if it has 220V voltage

when heating but no when cooling,

then P.C. board is abnormal; else

check whether four-way valve coil

and the body of four-way valve are

damagedDŽ

Prepared parts

and tools

7805,transfor

mer, fuse,

piezo

resistance,

remote

controller,

receive,avome

ter

Optical SCR,

indoor P.C.

board ,

outdoor fan

motor

capacitor,

outdoor fan

motor,avomet

er

Optical SCRˈ

indoor P.C.

board , indoor

fan motor

capacitor,

indoor fan

motor,avomet

er

Indoor P.C.

board ,

four-way valve

coil, body of

four-way

valve,

avometer

Applicable

machine

invariable

frequency

split unit

invariable

frequency

split unit

invariable

frequency

split unit

invariable

frequency

split unit

29

Page 34

Air ConditionerEdition:2006/1/10

5

6

make water

Compressor

doesn’t work

The outdoor

7

compressor

The outdoor

8

runs but the

compressor

Indoor unit

fan motor

and

don’t work

fan motor

doesn’t run

Oriented

wind panel

or drain

pan makes

water when

used

running

indicator

lights upˈ

but

compressor

doesn’t

work

The

running

lamp of air

conditioner

lights but

the outdoor

fan motor

and

compressor

don’t run

The running

lamp of air

conditioner

lights ,the

outdoor fan

motor works,

but the

compressor

doesn’t work

Drain pan, drain hose. Check

whether the indoor unit is installed

horizontal, drain hose of indoor

unit is leveled off ,the hole is over

high ˈfilter and drain hose is dirty

and walled upǃdrain pipe is

underwaterDŽ

Indoor P.C. board , startup capacity

for compressor, overheat protector,

compressor. Check the 1# and 2#

terminal block of indoor unit

whether it has single AVˈif not then

examine the power relay of P.C.

board ˈelse check overheat

protector, startup capacity for

compressor and compressor itself

Remote controller ǃelectrolytic

capacitor of 2500UFǃ7805ǃ

outdoor heat exchanger sensor

and ambient temperature sensor.

Use temperature key of remote

controller to watch how much

times the timing lamp glitters and

judge what’s the trouble .If there is

no glitter we should check the

terminal block to see if there is AC

voltage about 220V.Check the

electrolytic capacitor of 2500UF

and see if there is current about

310V.Examine the output of the

7805 and switch transformer

together with the resistance of the

sensor.

Power modelǃswitch transformerǃ

compressor. Check the temperature key

of remote controller to watch how many

times the timing lamp glitters and judge

what’s the trouble. Examine the two

ends of PN to see if there is DC voltage

about 310V.Four group DC power

resource of 15V.Check the triphase coil

assembly of the compressor and see if

they are the same.

drain pan,

drain hose

Indoor P.C.

board , startup

capacity for

compressor,

overheat

protector,

compressor,av

ometer

Remote

controller ,elec

trolytic

capacitor of

2500UFǃ

7805ǃ

outdoor heat

exchanger

sensor and

ambient

temperature

sensorǃ

avometer

Power modelǃ

switch

transformerǃ

compressorǃ

avometer

invariable

frequency

split unit

invariable

frequency

split unit

Little split

unit of

frequency

conversion

Little split

unit of

frequency

conversion

30

Page 35

Air ConditionerEdition:2006/1/10

Outdoor P.C. Boardǃ4 way valve

coilǃ 4 way valve body. Examine

The air

conditioner

Don’t make

9

heat

can

refrigerate

but can’t

make heat

the CN204 at Outdoor P.C. Board

and watch if there is 220V

voltage .If there doesn’t have we

can judge that the P.C. Board is

bad. If there has, we need to

connect and check the whether the

4 way valve coil and the 4way

valve body have been damaged .

Outdoor P.C.

Boardǃ4way

valve coilǃ 4

way valve

bodyǃ

avometer.

Little split

unit of

frequency

conversion

10 Show error

code E8

shows error

11 Can’t start

12

Show error

code F11

conditioner

can’t start

When the

conditioner

the indoor

unit shows

code F11.

The

machine

doesn’t

work and

code E8

The air

air

has run

about

5minutes

the error

Multimeter negative generatorǃ

indoor P.C. board ǃconnecting and

inserting lines .Check if the

Multimeter negative generator is

plane and the grounding (CF) is

touching well, then examine not

only whether the indoor P.C. Board

and control board have been

damaged or not but also the

connecting lines are good.

Transformerǃindoor

microcomputer plateǃfuse. Check

if the transformer has been

burned. power wave filterǃ

LX102.Check whether the fuse

and indoor microcomputer plate

have been damaged.

The system pressureǃoutdoor P.C.

BoardǃPower source voltageǃ

power modelǃthe connecting lines

of compressor. The cause is that

protective action has been taken

when it runs with large burden,

there is more refrigerant than it

should be .Examine the outdoor

P.C. BoardǃPower source voltageǃ

power model and see whether they

have been damaged and the

connecting lines touch well, if not,

adjust it to be normal.

Multimeter

negative

generatorǃ

indoor P.C.

Boardǃ

control

board ǃ

grounding

(CF)ǃ

avometer.

Transformerǃ

power wave

filterǃindoor

microcompute

r plateǃfuseǃ

avometer.

outdoor P.C.

BoardǃPower

source

voltageǃpower

model .

The series

of

frequency

fixed

cabinet

type

The series

of

frequency

fixed

cabinet

type

The

machine of

frequency

conversion

split unit

31

Page 36

Air Conditioner Edition:2005/11/18

INSTALLATION

32

Page 37

Air Conditioner

33

Edition:2006/1/10

12

12

C

8

D

15

E

Page 38

Air Conditioner

34

Edition:2006/1/10

3/8

Page 39

Air Conditioner

35

Edition:2006/1/10

Page 40

Air Conditioner

36

Edition:2006/1/10

Page 41

Air Conditioner

37

Edition:2006/1/10

Indoor unit A

Indoor unit B

YEL/GRN

RED

1 2 3

1 2 3

BLK

WHT

YEL/GRN

RED

BLK

WHT

WHT

BLK

WHT

BLK

RED

RED

POWER

YEL/GRN

YEL/GRN

BRN

BLU

{

YEL/GRN

1(L)

2(N)

3(R)

1(L)

2(N)

3(R)

1(L)

2(N)

Outdoor unit

5

Page 42

Air Conditioner

38

Edition:2006/1/10

Page 43

Air Conditioner

39

Edition:2006/1/10

3.The purging Method of the indoor unit B is the same as the indoor unit A.

The unit A and unit B are seperated and disconnected connected for the different compress.

9.52

3/8

9.52

3/8

Page 44

Air Conditioner

40

Edition:2006/1/10

1.Cut pipe

3.Insert the flare nut

4.Flare pipe

2.Remove burs

Flare tool for R410A

Clutch-type

0~0.5mm 1.0~1.5mm 1.5~2.0mm

clutch-type(Rigid-type)

Conventional flare tool

Wing-nut type (Imperial-type)

Page 45

Air Conditioner

41

Edition:2006/1/10

Page 46

Air Conditioner

42

Edition:2005/11/18

CIRCUIT AND WIRING DIAGRAM

Page 47

H2SM-14/18C03/R2

CN4

CN8

1

2

3

4

+5V

SJ20-07WX

C49

R83

2.2K

LED1

IC2

SDA

6

SCL

7

8 1

24C02

RL1

CN5

GREEN

220V-N

8

1

2

3

4

61

5

6

53

7

52

51

D8

D6

45

3

2

CON1(red)

1

CON2(white)

1

C38

102/50V

C25

102/50V

C27

102/50V

C26

102/50V

1N4007

1N4007

R84

6.8K 2W

D

C

1

CON5

B

N

1

A

+5

BEEP-PKM13EPY-4002

BUZ1

+12v

R11

10K

R49

100

Q5

2SC2412

R28 1K

+5

C1

102

R37

R36

4

3

2

CN6

1

+5V

R57

220

2

1

R10 10K

1

2

3

R66 27

SW1

+5

220V-L

C39

2UF 450V

R42

L1

125uH

R13 10K R12

+5

R27 10K

R30

10K

R31

10K

C2 104

R50

R14 1K

C43

103

C24

0.01u/275V120 1W

Q10

2SC2412

10K

Q1

2SC2412

R59

4.7K

Q2

2SC2412

+5V

R2

10K

R3

1K

+5V

51K

C16

102

Q3

220V-N

2SC2412

IC10

TLP3526

D

CN9

+12V

C

CN7

CN1

B

1

2

3

A

C29

104/50v

R54

680

R43

3.3K

10K

1K

+5V

C5 102

R20 10K

SW3

CN13

R15

10k

2SC2412

+5V

R4 4.7K

R38 10K

R39 4.7K

5v

R91

4.7K

+12

+5

R16

10k

R17

10k

Q11

2SC2412

Q4

R41

R9

R29 10K

R5

Q8

10K

2SB1197

3.3K

R51

R52

C13

10K

104

R40

+5V

R64 10K

+5

+5

R21 10K

R73

R58 10K

10K

R8922K

89

C19

104

10111213141516

12345

C36

103/50v

R93

10K

1234567

R65

10k

R18

4.7k

C12

102

1K

02 IRQ

4.7K

07

PTF3/TBCH3

11

PTF5

12

PTF6

48

PTH1/KBD3

49

PTH1/KBD4

08

PTF4/TBCH0

03

RST

21

VSS GND

45

56

VSSA GND

60

PTC0

10

PTF7

57

CGMXFC

09

NC

13

PTE0/TXD

14

PTE1/RXD

15

PTE2/TACH0

25

10K

PTG2/KBD2

16

PTE3/TACH1

17

PTE4/SS

18

PTE5/MISO

23

PTG0/KBD0

24

PTG1/KBD1

35

PTB1/ATD1

26

PA0

27

PA1

28

PA2

29

PA3

D

30

PA4

31

C

PA5

32

B

PA6

33

A

PA7

38 PTB4

50 PTD4

IC4

2003

R25

R32

10K

10K

470UF/16V

GNDAVSS/VRE

MC68HC908AB32

E15

PTB2/ATD2

PTB3/ATD3

PTF0/TACH2 04

PTC1

PTC5

PTC3

PTC2/MCLK

PTD7

PTD6/TACLK 52

OSC1

OSC2

VREFH

VDDA

PTE6/MOSI

PTE7/SPSCK

PTF2/TBCH2

PTF1/TACH3

VDDAREF 44

PTD2

PTD1

PTD0

PTB7/ATD7

PTD6/ATD6

PTB5/ATD5

PTB0/ATD0

7805

C17

104

22

VDD

36

37

61

64

63

62

53

51PTD5

59

58

55

54

19

20

06

05

47PTD3

46

43

42

41

40

39

01

PTC4

34

1N4007

IC9

R92

10K

C15

102

C35

104

100u/25v

C18

104/50V

R1

1M

R46

+12+5

E9

+5

C10

102

C41

102

13

XT1

8M

+5

R24

10K

1K

1

2

ZJ1

E8

2200UF/25V

+12

E5

100u/16v

C9

102

2

R47 560 1/4W

C42

104/50V

C4

104

C22

102

R6

10K

D1-D4

IN4007

R86

R95

R96

10K

10K

C28

104/50V

+5

C3

103

R85 2.2K 1/4W

10K 1/4W

R98

R33

10K

10K

5v

CN3

0-171825-3

+5

E4

100u/16v

R87

10K 1/4W

Q9

2SC2412

+5

C6

103/50V

R26

10K

5v

SW2

D5

R97

10K

7654321

CN2

104/275V

T1

C40

RTB-1.5-2P

R45 1K

R44 1K

R34

20K 1%

R35 3.3K 1%

R69 10K

R68 10K

R67 10K

+5

R82

330 1/4W

+5

1

24

R80

2.2k 1/4W

4

3

C7

TLP421

104/50V

+5V

R7

R8

C14

104

D7

RLS4148

.

561K

Z1

E7 4.7UF/50V

E6

C47

104/50V

6

IC14

TLP371

+5

IC12

10K

10K

FUSE

3.15A

4.7UF/50V

R53 1K

R88 560

R70 560

R71 560

R72 560

R81

330K 1/4W

+12

+5V

E13

100u/25v

5

1

103/50V

2

B2P3-VH-A

+5

JQ1A-12V

1 2 3 4 5 6 78

43

Page 48

Air Conditioner

38

44

WIRING DIAGRAM

Edition:2006/1/10

Page 49

Air Conditioner

45

WIRING DIAGRAM

Edition:2006/1/10

W:

Page 50

Air Conditioner

Edition:2006/1/10

Sincere Forever

Haier Group

Haier Industrial Park, No.1, Haier Road

266101, Qingdao, China

http://www.haier.com

Loading...

Loading...