Page 1

Q uality

U ser M a n ua l a nd In s ta lla tio n Ins tru ctio ns

G a s & Ele ctric D r y e r

G uid e d’ utilisa tio n et in s tr u ction s

d ’ ins ta lla tio n éch eu s e à g a z e t éle ctr iq u e

M a nua l pa r a e l u su a r io e ins tr u ccion e s de

ins ta la ción . Se ca do r a a g a s y eléctr ica

y

t

u

e

e

D

r

y

F

v

s

a

s

e

e

H

r

P

l

a

m

r

o

N

s

e

t

i

Wh

y

r

e

V

e

r

o

M

l

a

m

r

o

N

s

s

e

L

p

m

a

D

e

l

mb

u

T

d

n

e

t

x

E

t

a

e

H

o

N

(Picture for illustration purposes only. A ctual model may vary per model purcha sed. )

(La imagen tiene un propósito meramente ilustrativo. El modelo real puede variar

según el modelo adquirido.)

(L’image est à but d’illustration uniquement. Le modèle réel peut varier selon le

modèle acheté. )

M odel # / M o d éle # / P a r a M od el o de #

G DE / G DG 75 0 A W , G DE/ G D G 9 5 0 AW

n

Innovation n Style

Page 2

English

TABLE OF CONTENTS

PAGE

SAFETY INSTRUCTIONS ............................................................2-4

INSTALLATION INSTRUCTIONS ..............................................5-17

Tools and Materials Required ............................................................ 5

Electrical Requirements ..................................................................... 5

Unpacking Your Dryer ..................................................................... 6

Exhaust System Requirements ........................................................... 7

Gas Supply Requirements ................................................................ 9

Location of Your Dryer ................................................................... 10

Manufactured (Mobile) Home Instruction .........................................11

Electrical Installation ...................................................................... 12

3-Wire Cord Connections ..............................................................13

4-Wire Cord Connections ..............................................................14

Gas Connections ..........................................................................15

Replacement Parts .........................................................................17

OPERATING INSTRUCTIONS ............................................... 18-28

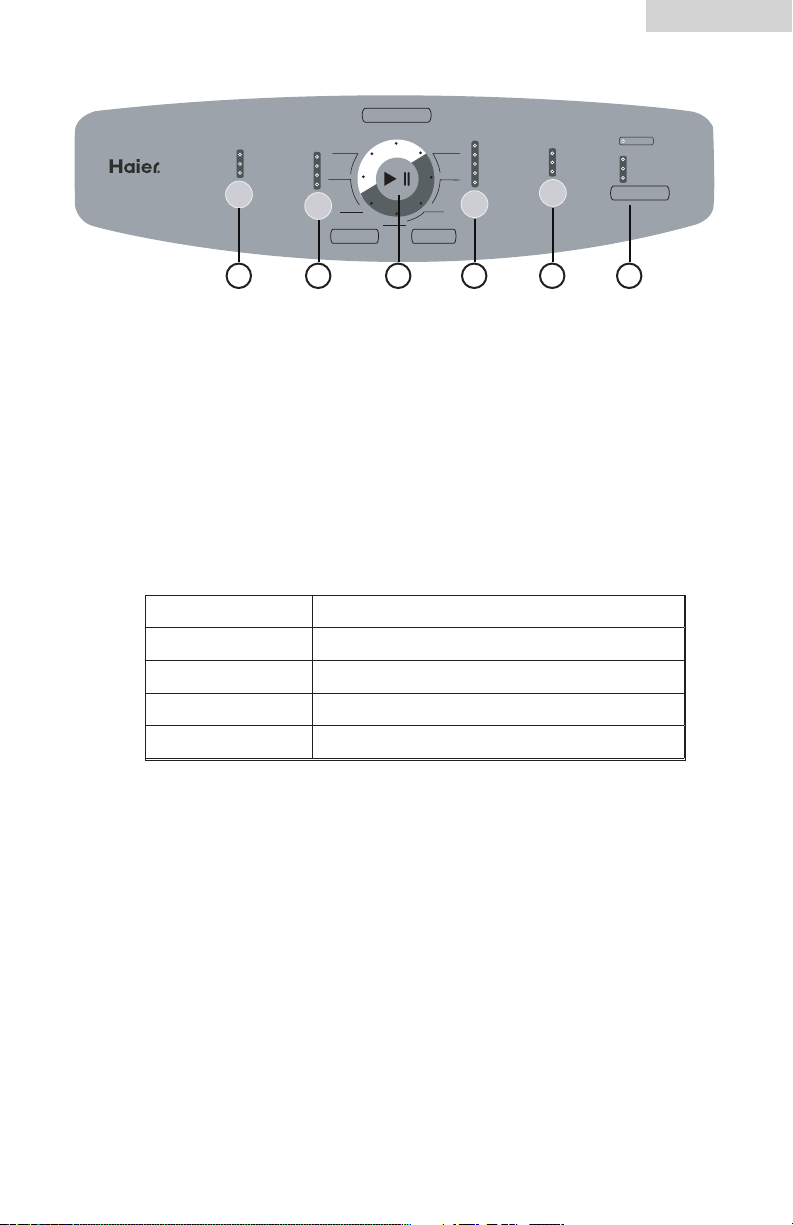

Understanding the Control Panel ......................................................18

Preparations before Drying .............................................................21

Load clothes into Dryer ................................................................... 22

Auto Dry Cycle ..............................................................................22

Timed Dry Cycle ............................................................................ 25

Rack Dry Cycle .............................................................................. 26

Other Features .............................................................................. 27

Normal Operating Sounds .............................................................. 28

Tips .............................................................................................. 28

CARE AND CLEANING GUIDE .......................................................28

TROUBLESHOOTING .................................................................. 29

WARRANTY................................................................................30

Page 3

English

ADVERTENCIA

ADVERTISSMENT

IMPORTANT SAFETY INSTRUCTIONS

Before beginning installation, carefully read these instructions. This will simplify

the installation and ensure the dryer is installed correctly and safely.

NOTE: The electrical service to the dryer must conform with local codes and

ordinances and the latest edition of the National Electrical Code, ANSI/

NFPA 70 or in Canada, CSA C22.1 Canadien Electrical Code Part 1.

NOTE: The gas service to the dryer must conform with local codes and

ordinances and the latest edition of the National Fuel Gas Code, ANSI

Z223.1 or in Canada, CAN/CGA B149.1.

NOTE: The dryer is designed under ANSI Z21.5.1 or ANSI/UL 2158 - CAN/

CSA C22.2 No. 112-97 (latest editions) for HOME USE ONLY. This

dryer is not recommended for commercial application such as restaurants,

beauty salons, etc.

Combustible materials, gasoline, and other flammable vapors and

liquids must not be stored near the dryer.

WHAT TO DO IF YOU SMELL GAS

1. Do not try to light any appliance

2. Do not touch any electrical switch. Do not use any phone in

your building.

3. Clear the room, building, or area of all occupants.

4. Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

5. If you cannot reach your gas supplier, call the Fire Department.

Installations must be performed by a qualified or licensed

contractor, plumber, or gasfitter qualified or licensed by the state,

province, or region where this appliance is being installed.

For your safety the information in this manual must be

followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or loss

of life.

21

Page 4

English

IMPORTANT SAFETY

INSTRUCTIONS

WARNING - To reduce the risk of fire, electric shock, or

injury to persons when using your appliance, follow the

basic precautions, including the following:

1. Read all of the instructions before using this appliance.

2. Don’t dry articles that have been previously cleaned in, washed in,

soaked in, or spotted with gasoline, dry clean solvents or other

flammable explosive sub stains as they give off vapors which could

ignite or explode.

3. Do not allow children to play on or in the appliance. Close

supervision of children is necessary when the appliance is used

near children.

4. Before the appliance is removed from service or discarded, remove

the door to the drying compartment.

5. Do not reach into the appliance if the drum is moving.

6. Do not install or store this appliance where it will be exposed to

water and/or to the weather.

7. Do not tamper with controls.

8. Do not repair or replace any part of the appliance or attempt any

servicing unless specifically recommended in the user-repair

instructions that you understand and have skills to carry out.

9. Do not use fabric softeners or products to eliminate static unless

recommended by the manufacturers of the fabric softener or product.

10. Do not use heat to dry articles or products to eliminate static unless

recommended by the manufacturers of the fabric softener or product.

11. Clean lint screen before or after each load.

12. Keep area around the exhaust opening and adjacent surrounding

areas free from the accumulation of lint, dust and dirt.

13. Keep the dryer area clear and free from items that would obstruct

the flow of combustion and ventilation air through the louvered panel

located on the rear of the dryer.

14. The interior of the appliance and the exhaust duct should be cleaned

periodically by qualified service personnel.

3

Page 5

English

15. Do not place items exposed to cooking oils in your dryer. Items

contaminated with cooking oil may contribute to a chemical reaction

than could cause a load to catch fire.

16. If material has been used with any flammable liquids or solids, it

should not used in the dryer until all terraces of flammable liquids

and its fumes have been removed.

17. This dryer must be properly installed in accordance with the

installation instructions before it is used. See grounding instructions in

the installations sections.

18. Proper grounding must be ensured to reduce the risk of electric shock

and force. Check with a qualified electrician or service personnel if

you are in doubt as to whether the dryer is properly grounded.

19. Use the dryer only for its intended purpose: drying clothes.

20. Always disconnect dryer from electrical supply before attempting any

service. Disconnect power cord by grasping the plug, not the cord.

21. Replace worn power cord and/or loose plugs.

22. To reduce the risk of electric shock or fire, do not use extension cords

or adapters to connect dryer electrical power source.

SAVE THESE

INSTRUCTIONS

DANGER

Risk of child entrapment. Before you throw away your old dryer,

take off the door so that children may not get trapped inside.

Thank you for using our Haier

product. This easy-to-use manual

will guide you in getting the best

use of your dryer.

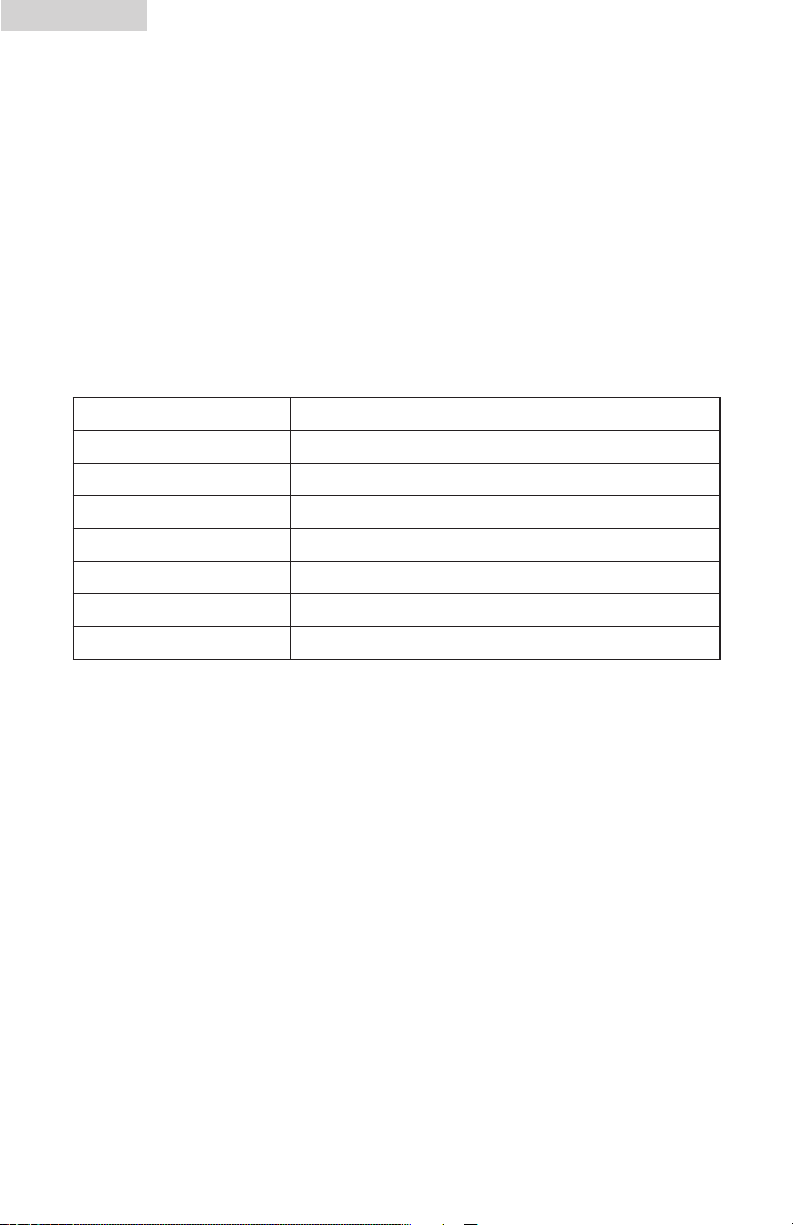

Remember to record the model and

serial number. They are on a label

in back of the dryer.

Staple your receipt to your manual.

You will need it to obtain warranty service.

Model number

Serial number

Date of purchase

4

Page 6

WARNING

ADVERTENCIA

ADVERTENCIA

ADVERTISSMENT

PRECAUCIÓN

ATTENTION

CAUTION

English

INSTALLATION INSTRUCTIONS

1. Clothes dryer installation must be performed by a

2. Install the clothes dryer according to the manufacturer’s

3. To reduce the risk of severe injury or death, follow all installation

Risk of Fire:

qualified installer.

instructions and local codes.

instructions.

SAVE THESE INSTRUCTIONS

Tools and materials required

• Phillips-Head and flathead screwdrivers

• Channel-lock adjustable pilers

• 1/2-inch open-end wrench

• Carpenter’s level

• Measuring tape (12ft. min.)

• Duct tape

• Pipe thread sealer (Gas)

• Rigid or flexible metal 4 inch (102cm) duct

• Vent hood

Safety Warning:

1. Before starting installation, make sure that the gas shut off valve is in the

off position.

2. All old gas connectors and gas piping should be discarded.

ELECTRICAL REQUIREMENTS

Electric Dryer: (GDE750AW and GDE950AW)

C ircuit

Individual 30 Amp branch circuit fused with 30 Amp time-delay fuses or circuit

breakers. Use seperately fused circuits for washers and dryers, and DO NOT operate

a washer and dryer on the same circuit.

P ower Supply

3 or 4 wire, 240 Volt, 1 Phase, 60Hz, AC

(Canada - 240 Volt, 1 Phase, 60 Hz, AC)

P ower Supply Cord Kit

(Not supplied when sold in US. Must be purchased to meet local electrical codes.)

The dryer MUST employ a 3-conductor power supply cord NEMA 10-30 Type SRDT

rated at 240 Volt AC minimum, 30 Amp, with 3 open end spade lug connectors with

5

Page 7

upturned ends or closed loop connectors and marked for use with clothes dryers.

(When sold in Canada - 4-wire power supply cord provided

and attached on dryer)

Dryers being installed in a manufactured (mobile) home MUST employ a 4-

wire power supply cord NEMA 14-30 type SRDT or ST (as required) rated to

240 Volt AC minimum, 30 Amp, with 4 open-end spade lug connectors with

upturned ends or closed loop connectors and marked for use with clothes

dryers. See Electrical Connections for more information on a 4-wire system.

O utlet Receptacle

NEMA 10-30R receptacle should be located so the power supply cord is

accessible when the dryer is in the installed position. (Canada - NEMA

14-30R receptacle)

ELECTRICAL REQUIREMENTS

Gas Dryer: (GDG750AW and GDG950AW)

C ircuit

Individual 15 Amp branch circuit fused with 15-Amp maximum time delay fuse

or circuit breakers.

P ower Supply

3 wire, 120 Volt, 1 Phase, 60Hz, AC

P ower Supply Cord

The dryer is equipped with a 120 Volt 3-wire power supply cord.

English

Note: This dryer is equipped with a three-prong grounding plug for your

protection against shock hazard and should be plugged into a properly

grounded three-prong receptacle. Do not under any circumstance cut or

remove grounding prong from plug.

Unpacking Your Dryer

1. Remove all packaging material. This includes the foam base and all adhesive

tape holding the dryer accessories inside and outside.

2. Inspect and remove any remains of packaging, tape or printed materials

before using the dryer.

6

Page 8

English English

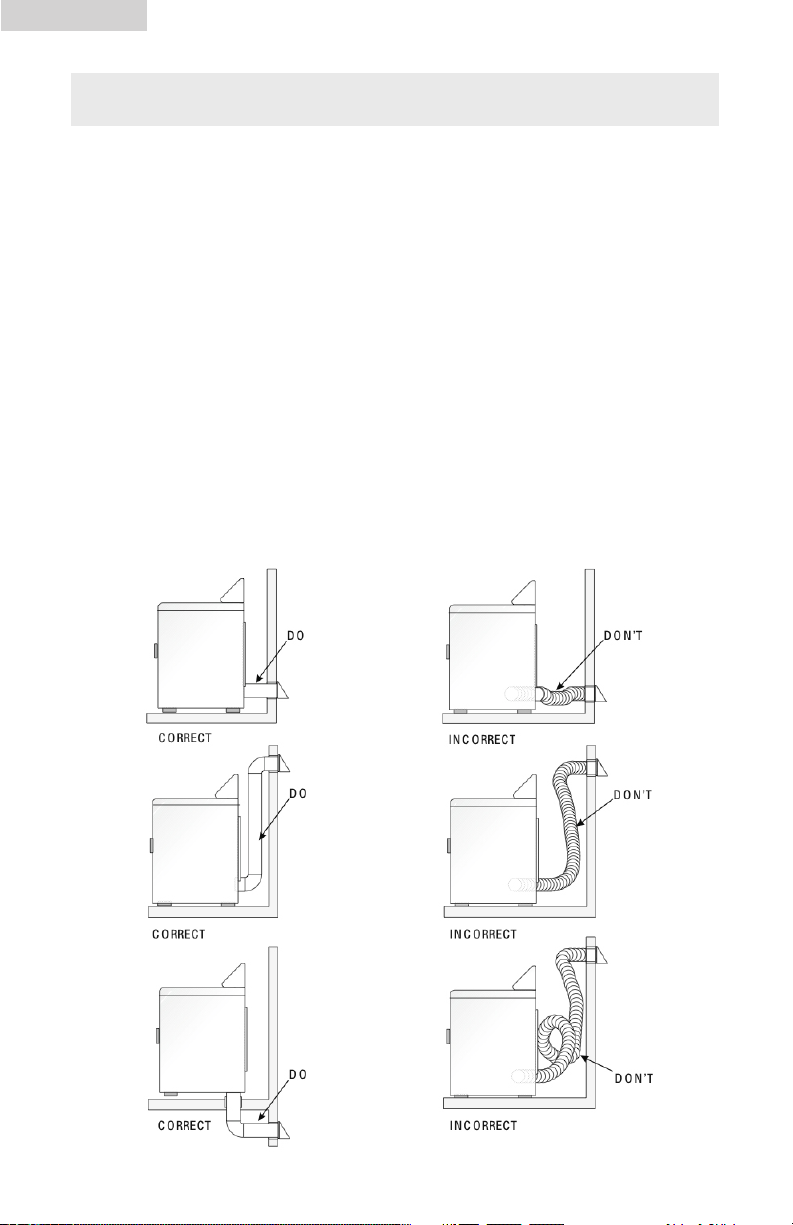

EXHAUST SYSTEM REQUIREMENTS

WARNING

The following are specific requirements for

proper and safe operation of your dryer. Failure

to follow these instructions can create excessive

drying times and fire hazards.

1. Do not use plastic flexible duct to exhaust the dryer. Excessive lint can build up

inside exhaust system and create a fire hazard and restrict air flow. Restricted

air flow will increase drying time. If your present system is made up of plastic

duct or metal foil duct, replace it with a rigid or flexible metal duct. Ensure

present duct is free of any lint prior to installing dryer duct.

2. The dryer must not be exhausted into any gas vent, chimney, wall, ceiling or

any concealed space of a building. The dryer exhaust system MUST be

exhausted to the outdoors. If the dryer is not exhausted outdoors, some

fine lint will be expelled into the laundry area. An accumulation of lint in any

area of the home can create a health and fire hazard.

3. Exceeding the length of duct pipe or number of elbows allowed in the

“Maximum Length” chart can cause an accumulation of lint in the exhaust

system. Plugging the system could create a fire hazard, as well as increase

drying times.

4. Do not screen the exhaust ends of the vent system. Lint can become caught in

the screen, increasing drying time. Use an approved vent hood to terminate the

duct outdoors, and seal all joints with duct tape.

5. All male duct pipe fittings must be installed downstream with the flow of air.

6. Exhaust duct must not be connected or secured with screws or other fastening

devices which extend into the interior of the duct.

7. Do not allow combustible material (clothing, draperies/curtains, paper, etc.) to

come in contact with exhaust system.

Explosion hazard:

Do not install the dryer where gasoline or other flammables are kept or

stored. If the dryer is installed in a garage, it must be a minimum of 18

inches (45.7cm) above the floor. Failure to do so can result in death,

explosion, fire or burns.

Exhaust Requirements:

Use only 4 inch (10.2cm) diameter (minimum) rigid of flexible metal duct and

approved vent hood which has a swing-out damper hat open when the dryer is

in operation. When the dryer stops, the dampers automatically close to prevent

drafts and the entrance of insects and rodents. To avoid restricting the outlet,

7

Page 9

maintain a minimum of 12 inches (30.5cm) clearance between the vent hood

and the ground or any other obstruction. The vent flap should be able to move

freely, although vertical orientation of the exhaust system is acceptable. Certain

extenuating circumstances could affect the performance of the dryer:

1. Only rigid metal duct work should be used.

2. Venting vertically through a roof may expose the exhaust system to down

drafts causing an increase in vent restriction.

3. Running the exhaust system through an uninsulatedarea may cause

condensation and faster accumulation of lint.

4. Compression of crimping of the exhaust system will cause an increase in

vent restriction.

The exhaust system should be inspected and cleaned a minimum of every 12

months with normal usage. The more the dryer is used the more often you

should check the exhaust system and vent hood for proper operation.

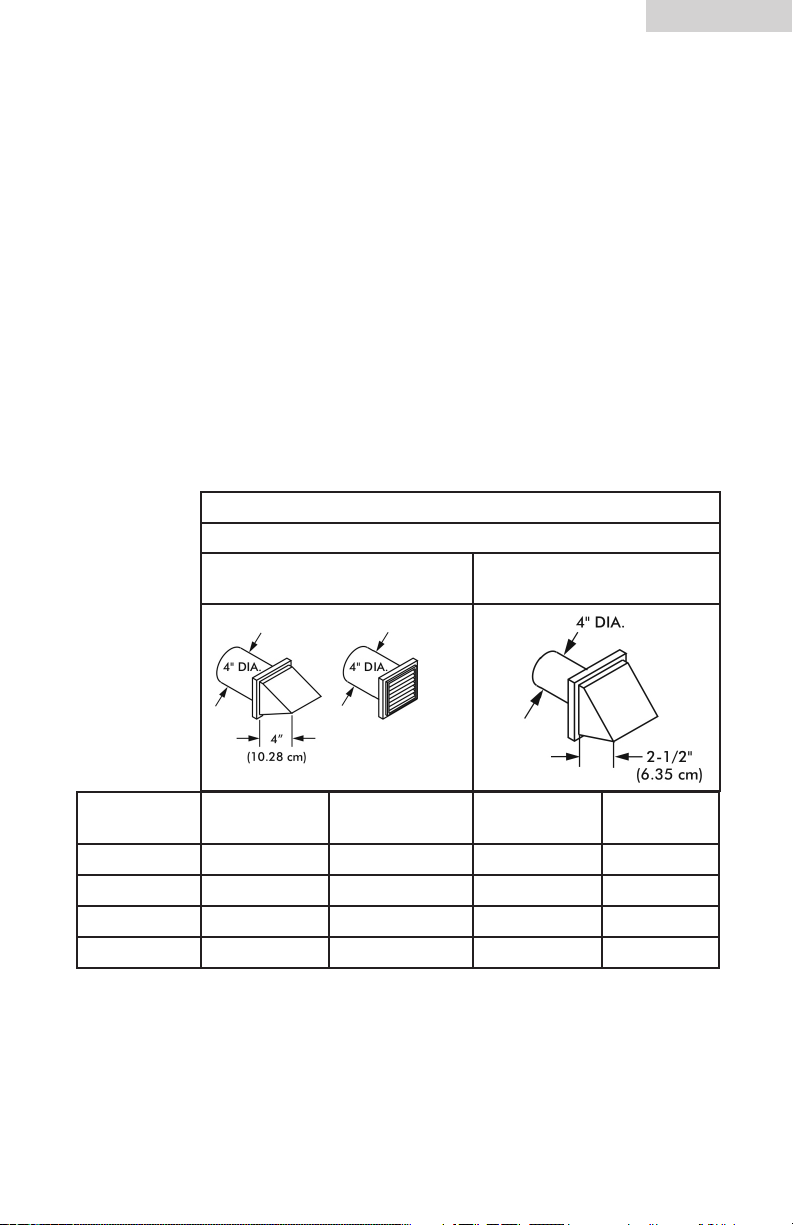

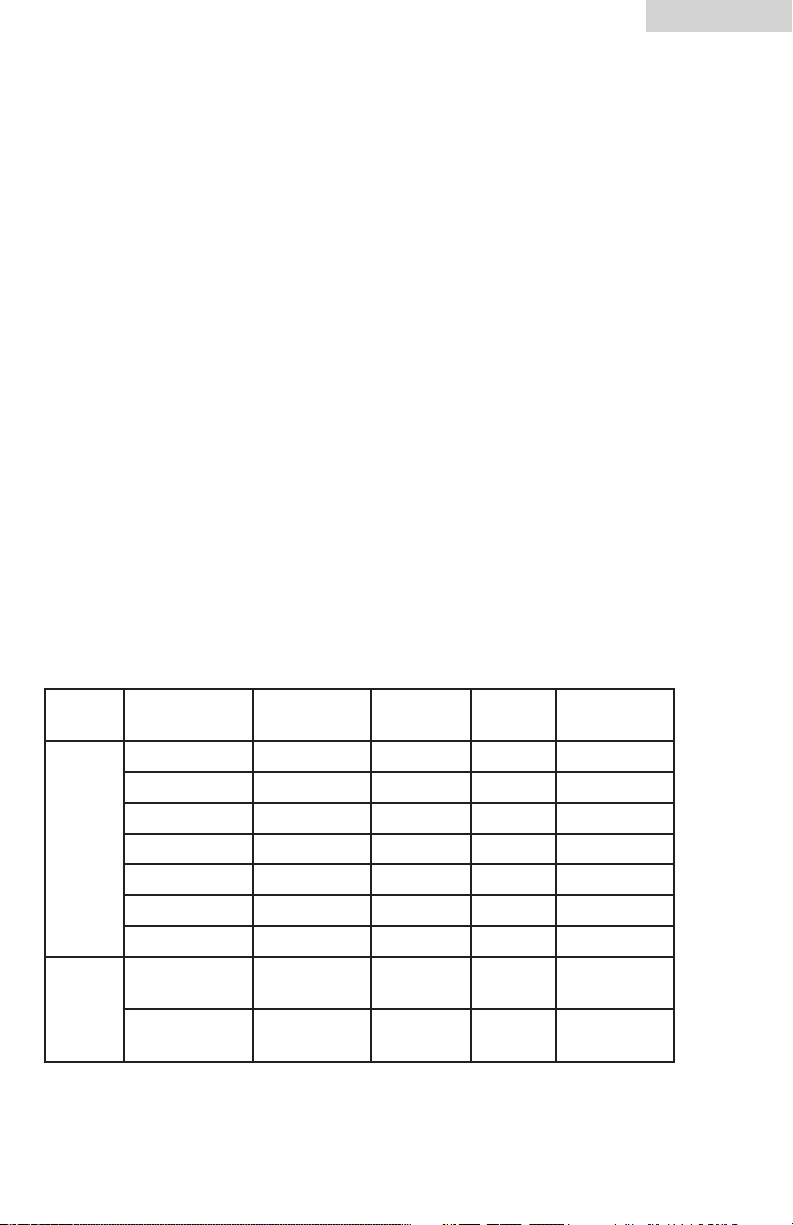

RECOMMENDED MAXIMUMM

Exhaust Hood Types

Recommended Use only for short

run installations

No. of 90º

elbows

0 90 ft. 55 ft. 60 ft. 45 ft.

1 60 ft. 40 ft. 45 ft. 30 ft.

2 45 ft. 30 ft. 35 ft. 20 ft.

3 35 ft. 20 ft. 25 ft. 15 ft.

Rigid Metal Flexible Metal Rigid Metal Flexible

Metal

8

Page 10

English English

ADVERTENCIA

ADVERTISSMENT

GAS SUPPLY REQUIREMENTS

Replace copper connecting pipe that is not plasticcoated. Stainless steel or plastic-coated brass MUST

be used.

1. Installation MUST conform with local codes. In the absence of local codes,

installation must conform with the National Fuel Gas Code, ANSI Z223.1 (latest

edition) or in Canada, the current CAN/CGA B149.1

2. The gas supply line should be 1/2 inch (1.27cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect your dryer to the

gas supply line. The tubing MUST be constructed of stainless steel or plasticcoated brass.

4. The gas supply line MUST have an individual manual shutoff valve installed

within 6 feet (183cm) of the dryer in accordance with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

In Canada, an individual manual shut-off valve MUST be installed in

accordance with the B149.1, Natural Gas and Propane Installation Code.

5. A 1/8 inch (0.32cm) N.P.T. plugged tapping, accessible for test gauge

connection, MUST be installed immediately upstream of the gas supply

connection to the dryer.

6. The dryer MUST be disconnected from the gas supply piping system during

any pressure testing of the gas supply piping system at test pressures in excess

of 1/2 psig (3.45kPa).

7. The dryer MUST be isolated from the gas supply piping system during any

pressure testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

9

Page 11

LOCATION OF YOUR DRYER

Do Not Install Your Dryer:

1. In an area exposed to dripping water or outside weather conditions.

2. In an area where it will come in contact with curtains, thick carpet, or anything

that will obstruct the flow of combustion and ventilation air.

3. On carpet, floor must be solid with a maximum slope of 1inch (2.54 cm). Any

floor unevenness should be corrected with leveling legs located on the bottom

of the dryer.

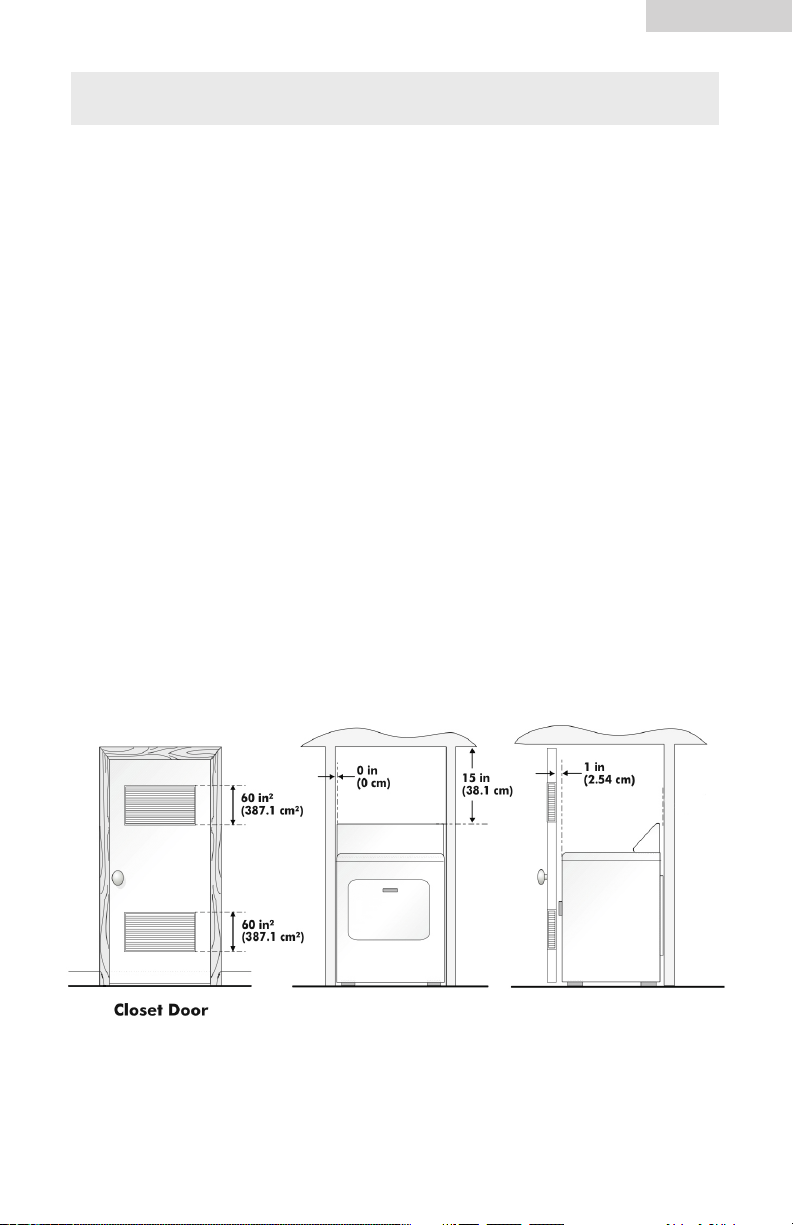

Installation in Alcove or Closet:

1. DO NOT install your dryer in a closet with a solid door.

2. A dryer installed in a bedroom, bathroom, alcove or closet MUST be

exhausted outdoors.

3. No other fuel burning appliance shall be installed in the same closet as the

gas dryer.

4. Refer to the images on this page to ensure the installation provides the

minimum amount of clearance required for ventilation.

5. When installing the dryer in a closet with a door, a minimum of 120 square

inches (774.2 square cm) of ventilation in the door is required. Openings must

be equally divided at the top and bottom of the door and airflow must be

unobstructed. A louvered door with equivalent air openings for the length of

the door is acceptable.

10

Page 12

English

MANUFACTURED (MOBILE) HOME INSTALLATION

1. Dryer MUST be exhausted outside (outdoors, not beneath the manufactured

home) using metal ducting that will not support combustion. Metal ducting must

be 4 inch (10.16 cm) in diameter with no obstructions. Rigid metal duct

is preferred.

2. If dryer is exhausted through the floor and area beneath the manufactured

home is enclosed, the exhaust system MUST terminate outside the enclosure

with the termination securely fastened to the mobile home structure.

3. When installing a gas dryer into a manufactured home, a provision must be

made for outside make up air. This provision is to be not less than twice the

area of the dryer exhaust outlet.

4. This dryer MUST be fastened to the floor using P/N 0030807899

Manufactured Home Installation Kit. Follow the instructions supplied with

the kit.

5. Refer to previous sections for other important venting requirements.

6. Installation must conform to current Manufactured Home Construction & Safety

Standard (which is a Federal Regulation Title 24 CFR-Part 32-80) or when

such standard is not applicable, with American National Standard for Mobile

Homes. In Canada, the CSA Z240 is applicable.

Page 13

English

ADVERTENCIA

ADVERTISSMENT

ELECTRICAL INSTALLATION

WARNING

The following are specific requirements for proper

and safe electrical installation of your dryer.

Failure to follow these instructions can create

electrical shock and/or fire hazard.

ELECTRIC Dryer (GDE750AW and GDE950AW)

1. This appliance must be properly grounded. Electrical shock can result if the

dryer is not properly grounded. Follow the instructions in this manual for

proper grounding.

2. Do not use an extension cord with this dryer. Some extension cords are not

designed to withstand the amounts of electrical current this dryer utilizes and

can melt, creating electric shock and/or fire hazard. Locate the dryer within

reach of the receptacle for the length power cord to be purchased, allowing

some slack in the cord. Refer to the electrical requirements in this manual for

the proper power cord to be purchased.

3. A UL approved strain relief must be installed onto power cord. If the strain

relief is not attached, the cord can be pulled out of the dryer and can be cut

by any movement of the cord, resulting in electrical shock.

4. Do not use an aluminum wire receptacle with copper-wired power cord and

plug (or vice versa ). A chemical reaction occurs between copper and

aluminum and can cause electrical shorts. The proper wiring and receptacle

is a copper-wired power cord with a copper-wired receptacle.

Note: Dryers operating on 208 Volt power supply sill have longer drying times

than operation on 240 Volt power supply.

Improper connection of the equipment grounding conductor can

result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is

properly grounded.

GAS Dryer (GDG750AW and GDG950AW)

1. Gas dryers are equipped with a factory installed three-prong 15 Amps ~120

Volts (grounding) plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong receptacle. Do not cut

or remove the grounding prong from this plug.

1211

Page 14

English

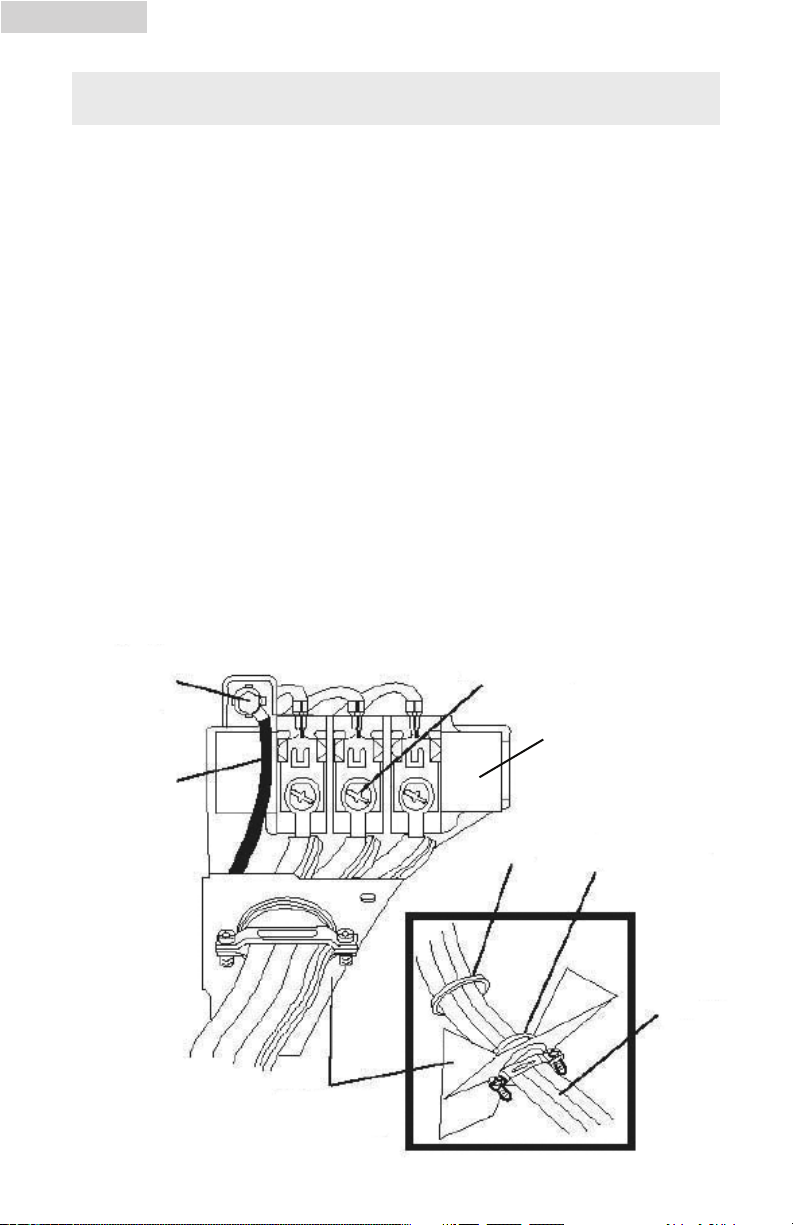

ELECTRICAL CONNECTIONS

ELECTRIC Dryer (GDE750AW and GDE950AW)

3-Wire System (US models only)

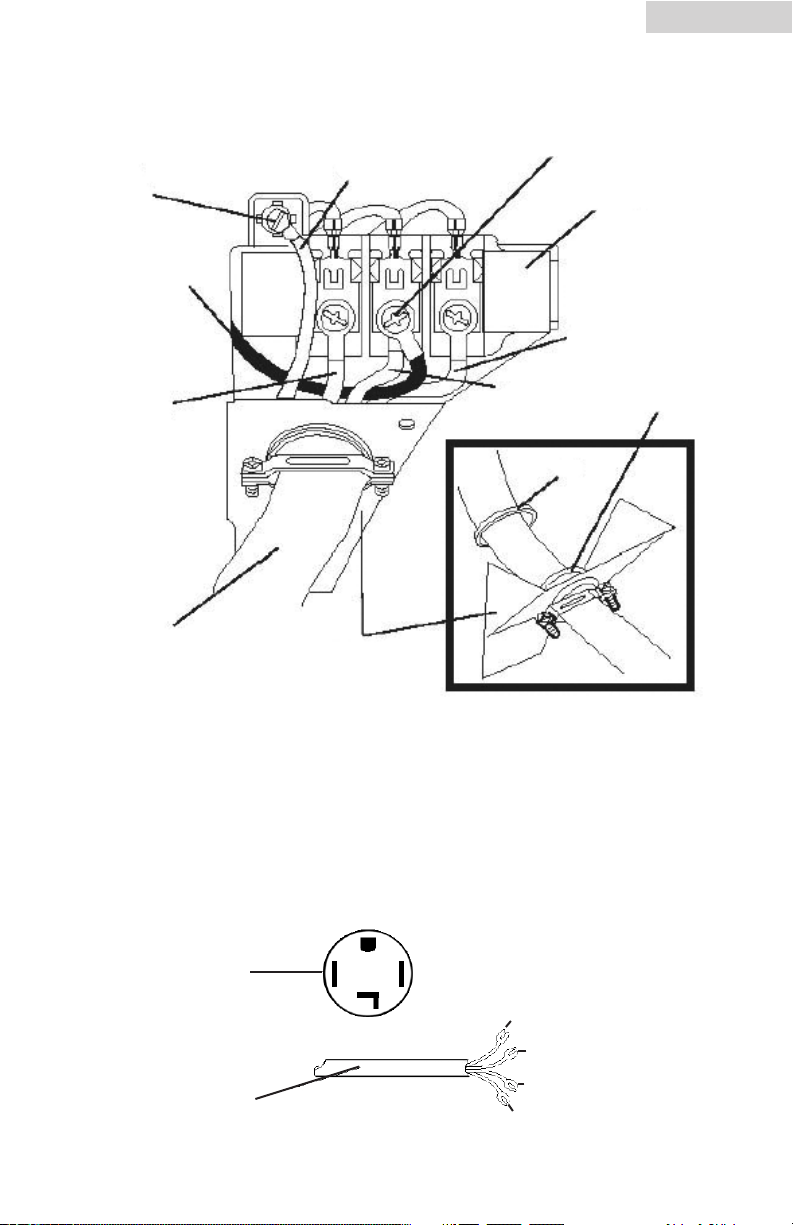

1. Remove the screws securing the terminal block access cover and the strain

relief mounting bracket located on the back of the dryer’s upper corner.

2. Install a U.L. approved strain relief into the power cord entry hole of the

mounting bracket. Finger tighten the nut only at this time.

3. Thread a U.L. Approved 30 Amp. Power cord, NEMA 10-30 Type SRDT,

through the strain relief.

4. Attach the power cord neutral (center wire) conductor to the brass colored

center terminal on the terminal block. Tighten the screw securely.

5. Attach the remaining two power cord outer conductors to the outer brass

colored terminals on the terminal block. Tighten both screws securely.

Warning: Do not make a sharp bend or crimp wiring/conductor

at connections.

6. Reattach the strain relief mounting bracket to the back of the dryer with two

screws. Tighten screws securely.

7. Tighten the screws securing the cord restraint firmly against the power cord.

8. Tighten the strain relief nut securely so that the strain relief does not turn.

9. Reinstall the terminal block cover.

Green Ground

Screw

Neutral

Ground Wire

13

Strain Relief

Mounting Bracket

Brass Terminal

Terminal Block

Nut

Tighten Nut to

These Threads

Power Cord

Page 15

ELECTRIC Dryer (GDE750AW and GDE950AW)

4-Wire Cord Connections (US Models Only)

Green Ground

Screw

Neutral

Ground Wire

Red

Green Power Cord

Ground Wire

Brass Terminal

White

Nut

English

Terminal Block

Black

Tighten Nut to

These Threads

Power Cord

Strain Relief

Mounting Bracket

1. Remove the screws securing the terminal block access cover and the strain

relief mounting bracket located on the back of the dryer upper corner.

2. Install a UL approved strain relief into the power cord entry hole of the

mounting bracket . Finger tighten the nut only at this time.

3. Remove the green neutral ground wire from the green ground screw located

above the terminal block.

Typical Conductor

Receptacle

Black 240V

White Neutral

Typical 4

Conductor Cord

Green Ground

Red 240V

14

Page 16

English

WARNING

ADVERTENCIA

ADVERTENCIA

ADVERTISSMENT

PRECAUCIÓN

ATTENTION

CAUTION

4. Thread a U.L. approved 30 Amp power cord. NEMA 14-30 type ST or SRDT

through the strain relief.

5. Attach the green power cord ground wire to the cabinet with green ground screw.

6. Attach the white (neutral) power cord conductors to the outer cord and the

green ground wire from the dryer harness to the brass-colored center

terminal on the terminal block. Tighten the screw securely.

7. Attach the red and black power cord conductors to the outer brass-colored terminals

on the terminal block.

Warning: Do not make a sharp bend or crimp the wiring /conductor at

connections.

8. Tighten the screws securing the cord restraint firmly against the power cord.

9. Tighten the strain relief nut securely so that the strain relief does not turn.

10. Reinstall the terminal block cover.

GAS CONNECTIONS

GAS Dryer (GDG750AW and GDG950AW)

NOTE: DO NOT connect the dryer to L.P. gas service without converting

1. Remove the shipping cap from gas pipe at the rear of the dryer.

2. Connect a 1/2 inch (1.27cm) I.D. semi-rigid or approved pipe from gas supply line to

3. Open the shutoff valve in the gas supply line.

4. Test all connections by brushing on a soapy water solution. NEVER TEST FOR GAS

5. Connect the exhaust duct to the outside exhaust system. Use duct tape to seal

6. With the dryer in its final position, adjust one or more of the legs until the dryer is

7. Plug the power cord into a grounded outlet. NOTE: check to ensure power is OFF at

8. Turn on the power at the circuit breaker/fuse box.

9. Run the dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is necessary for the gas line to be

NOTE: Follow instructons supplied with kit.

15

the gas valve. An L.P. Conversion Kit must be installed by a

qualified gas technician.

the 3/8 inch (0.96cm) pipe located on the back of the dryer. Use a 1/2 inch to 3/8

inch (1.27cm to 0.96cm) reducer for a connection. Apply an approved thread sealer

that is resistant to the corrosive action of liquified gases on all pipe connections.

LEAKS WITH AN OPEN FLAME.

all joints.

resting solid on all four legs. Place a level on top of the dryer. THE DRYER MUST

BE LEVEL AND RESTING SOLID ON ALL FOUR LEGS.

circuit breaker/fuse box before plugging the power cord into the outlet.

Before operating the dryer, make sure the dryer area is clean and free

from combustible materials, gasoline, and other flammable vapors. Also

see that nothing (such as boxes, clothing, etc.) obstructs the flow of

combustion and ventilation air through the louvered panel located on the

rear of the dryer.

bled of air. If the burner does not light within 45 seconds the first time the dryer

is turned on, the safety switch will shut the burner off. If this happens, turn the

dryer to “OFF” and wait 5 minutes before making another attempt to light.

Page 17

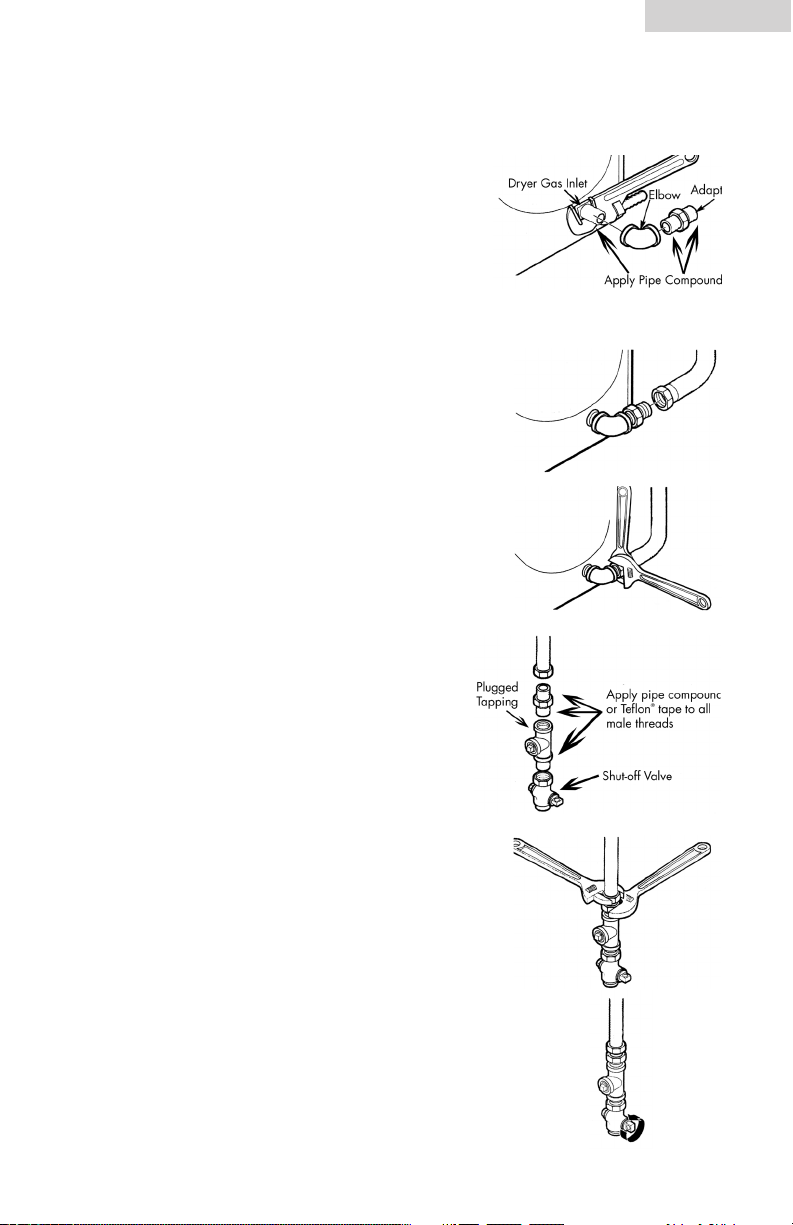

CONNECTING THE DRYER TO THE GAS SUPPLY

A) Connect female 3/8” NPT elbow to gas

inlet on dryer. Then connect 3/8” flare

union adapter to female elbow.

IMPORTANT: To prevent the inlet from

twisting, please use a pipe

wrench to secure the dryer

gas inlet. Affix Teflon®

tape or pipe compound to

adapter and gas inlet.

B) Attach the flexible metal gas line connector

to the adapter.

C) Make sure flexible gas line seal is secure.

Use two wrenches for the best possible

connection.

English

D) To check gas inlet pressure, attach 1/8”

NPT plugged tapping to dryer gas line shutoff valve. Then connect flare union adapter

to plugged tapping. Affix Teflon® tape

to the threads of the adapter and plugged

tapping to ensure seal.

E) Use two adjustable wrenches to tighten

every connection.

IMPORTANT: Do not overtighten!

F) Open gas shut-off valve.

16

Page 18

English English

WARNING

ADVERTENCIA

ADVERTENCIA

ADVERTISSMENT

PRECAUCIÓN

ATTENTION

CAUTION

ADVERTENCIA

ADVERTISSMENT

ADVERTENCIA

ADVERTISSMENT

REPLACEMENT PARTS

Replacement parts and accessories for US and Canada can be purchased

through Haier America at 1-800-313-8495

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. Check

unit for proper operation after servicing.

Discard or destroy the carton and plastic bags after the dryer is

unpacked. Children should not be allowed to use them to play with.

Cartons covered in rugs, bedspreads or plastic sheets can become

an airtight chamber and cause suffocation leading to death. Make

all packing materials inaccessible to children.

The instructions in this manual and all other literature included with

this dryer can not cover every possible condition and situation that

may occur. Good safe practice and caution must be applied when

installing, operating, and maintaining any appliance. If you are in

doubt after installing, call a certified electrician to install and wire

the dryer.

17

Page 19

Super C a pacity

Heavy Duty

Normal

W hites

Bulky

Press Free

Delicate

Touch Up

Custom

Timed Dry

Rack Dr y

Dry W rinkle Saver

Cool Down Remaining Time

Cycle Co mpleted E xtended Tumble

High

Medium

Low

No Hea t

Louder

Softer

Off

Ve ry

More

Normal

Less

Damp

Auto

Dry

Cycles

Timed

Dry

Cycles

Less

Time

More

Time

Wri nkle

Saver

Sensor

Dry

Level

Temp

Signal

Off

Start

Pause

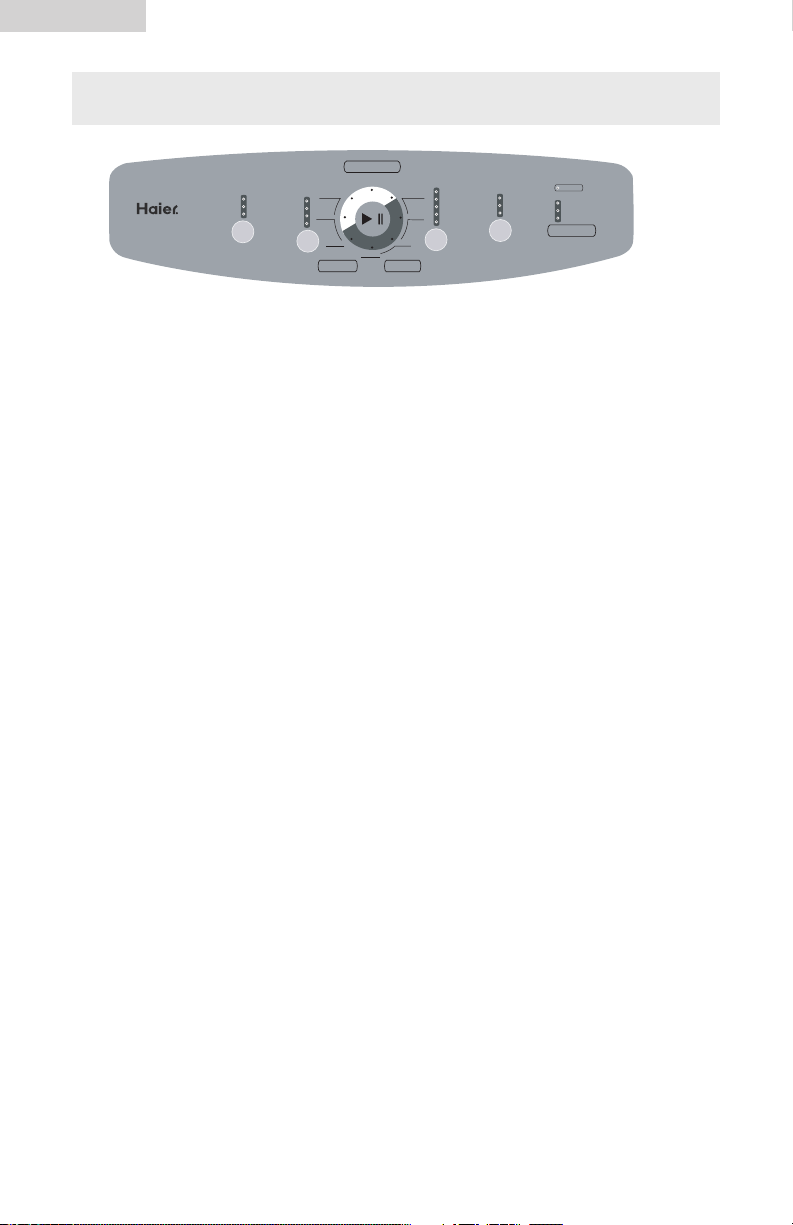

OP E R ATING INS T R UC TIONS

Understanding the C ontrol Panel

G DE/ G DG 950A W

3

6

10

7

8

9

11

45

N o te : Fea tures ma y vary per model.

S ta r t/ P a us e Butto n: (1)

• Press the button to turn the dryer O N . Press this button once to start the dry

process. Press this button once again to pause the activity during the dry cycle.

O ff B utton: (2)

• Press the button to turn dryer off.

S igna l B utto n: (3 )

• S elects buzz ing volume or turns off the buzzer. You can choose louder, softer,

or off.

Te mp Bu tto n : (4)

• Used to set drying temperature. There are 4 available drying temperatures:

High, Medium, Low, and N o H ea t (A ir Dry).

S e ns o r Dr y Le ve l B u tto n: (5 )

• Used to set drying level of auto-programs. If no auto-progra m is selected,

pressing the button will cause the chime to sound. There are 5 selections: Very,

More, Normal, Less, Damp.

W r in k le Sa ver Butto n: (6)

• This convenient feature helps keep wrinkles from setting when you cannot

unload the dryer at the end of a cycle. The dryer will stop a nd then tumble

for a brief period every few minutes. Press the wrinkle sa ver button to choose

the number of hours required, from 3 to 2 4 . Stop the setting at any time by

pressing the wrinkle saver button or opening the dryer door.

• If not set, the wrinkle saver indica tor is off and remaining time indicator is on.

• The LED displa y indica tes the remaining time of non-reserved program. If setting

“W rinkle Sa ver” in standby status, the LED displa y indica tes 3 hr, which will

increa se by 1 hr with each press until 24 hours is reached It will then return to

3. If held for 1. 5 seconds, the LED displa y indica ted value will

increa se continuously.

2

1

1 8

Page 20

English

More Time & Less Time Button: (7)

• Used to set time from 0 to 180 minutes when Timed Dry or Rack Dry

cycle selected.

Timed-Dry Cycles Button: (8)

• The “Timed-Dry Cycles” button will let you select your desired dry mode.

Timed Dry: You can set status of “Temp”, “Signal” and dry time with “More Time”

and “Less Time” by yourself.

Rack Dry: This program is used to dry articles like sport shoes.

Auto-Dry Cycles Button: (9)

• “Auto-Dry cycles” button will let you select your desired dry cycles. For your

convenience, there are seven fabric care dry cycles programmed in this

mode: Heavy Duty, Normal, Whites, Bulky, Press-Free, Delicate, Touch-up,

and Custom.

Heavy Duty Heavy weight material such as jeans or bath towels.

Normal Normal drying

Whites For clothes such as linens and sheets..

Bulky Drying bulky clothing, such as bed sheets.

Press Free For wrinkle-free, permanent press, and knits..

Delicate Drying small quantity clothes and delicate fabric.

Touch Up Used to select wrinkle-remove function.

Custom The drying program defined by user and stored.

Status lights: (10)

• Status lights note which part of the cycle the machine is in.

Digital display: (11)

• Indicates the remaining time (min) during cycle operation. Also indicates

remaining wrinkle saver time (hr).

Note: If door is opened during running cycle, the display will show “E2” and

sound an alarm.

Function Light Indicator:

• The function “display light” indicates selected feature is “ON” or the cycle is

about to begin.

• During the dry cycle, “flashing light” indicates current running program.

• Rapidly flashing light indicates that the dryer is not operating properly.

19

Page 21

Normal

1 2 3 4

5

6

English

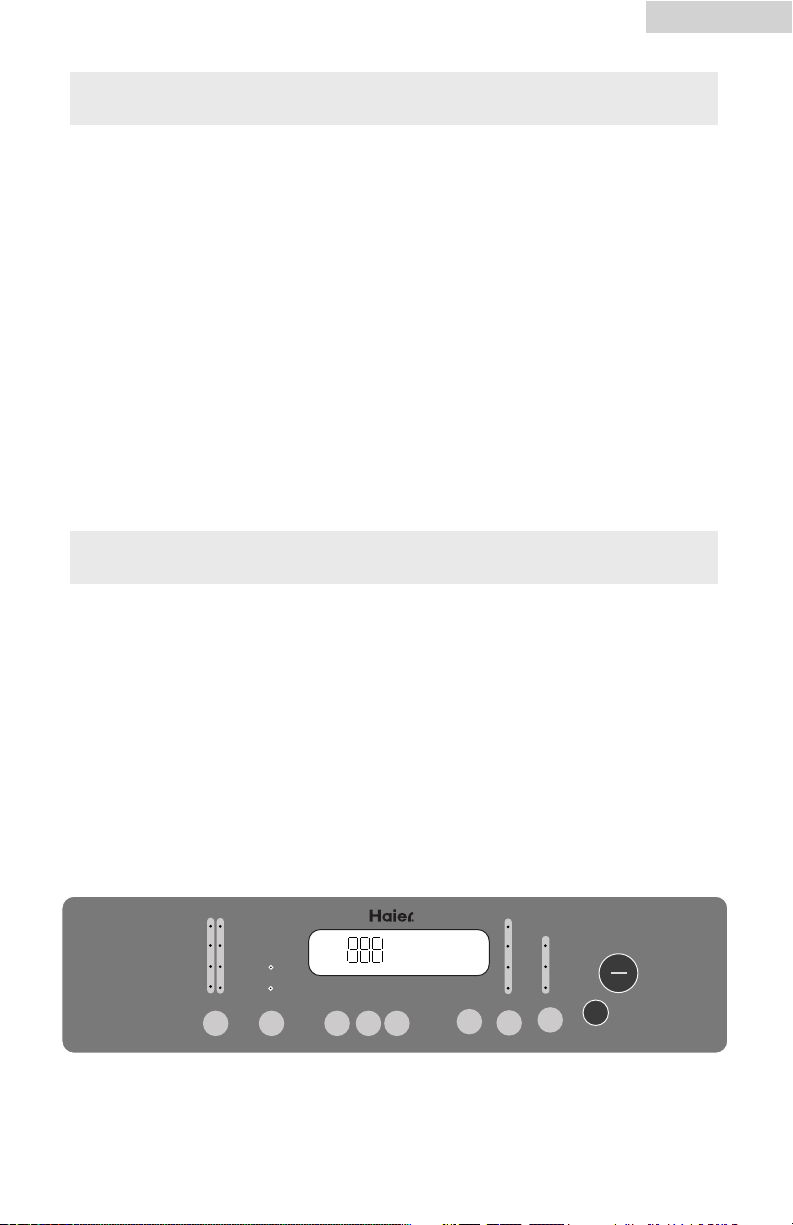

Cycle Select

Delicates

Off

Auto DryTimed Dry

More

Less

Dry

Level

Timed Dry Heavy Duty

High

Medium

Low

Rack Dr y Normal

No Heat

Temp

Touch Up Whites

Timed Dry

90

60

30

20

10

Louder

Softer

Off

Signal

Clean Lint

Drying

Cool Down

Wrinkle Saver

Cycle Process

Note: Features may vary per model.

Dry Levels: (1)

• Used to set drying levels of auto programs. There are 3 selections: More,

Normal, and Less

Temp Button: (2)

• Used to set drying temperatures. There are four available drying temperatures to

choose from: High, Medium, Low, and No Heat.

Start/Pause, Cycle Select Button: (3)

• Select the from 4 Auto-Dry cycles (Heavy Duty, Normal, Whites and Delicates),

Touch Up, Time Dry, or Rack Dry Cycle.

Heavy Duty Heavyweight material such as jeans or bath towels.

Normal Normal drying

Whites For whites such as linens and sheets

Delicate Drying small quantity clothes and delicate fabric.

Touch Up Used to select wrinkle-remove function.

Timed Dry: (4)

• When Cycle Select dial is on Time or Rack Dry, the “Timed Dry” button can be

used to select the amount of time required for the dry program.

Signal: (5)

• This feature selects the buzzing volume or turns off the buzzer entirely. There

are three choices: Louder, Softer, or Off.

Cycle Process: (6)

• This indicates the process the cycle is currently in. The “Clean Lint” indicator is

lit when the dryer is powered on. This is a reminder to clean the lint filter before

the dry program starts.

20

Page 22

English

PREPARATIONS BEFORE DRYING

• Sort clothes of the same kind (cotton, synthetics, woolen) to dry.

• Dark and light colored clothes should be separately dried. Fabrics prone to

losing lint and those prone to adhering lint shall be separately dried. Clothes

prone to falling lint should be turned inside out before putting into the dryer.

• Make sure buttons and ornaments on the clothes are high temperature

resistant and won’t damage drum surface. Before loading, the clothes should

have their zippers zipped up, buttons and hooks done up and belts tied so as to

avoid entanglement or other obstacles.

• If possible, turn out the clothes pockets for uniform drying.

• Check if clothes remain soiled. If so, wash them again, otherwise soils may be

permanently set.

• Small articles should be collected in a mesh bag before loading and drying, so

as to avoid entanglement and ensure easy removal.

• Make sure the power socket is reliably grounded. The grounding terminal should

not be connected to gas or tap water pipelines.

• Make sure exhaust duct has been properly connected.

• Make sure lint filter is clean and properly installed. If lint filter is not in place,

tumbling items could enter the exhaust system and cause damage to the dryer.

Note: Applies to Auto Dry cycle and Timed Dry cycle.

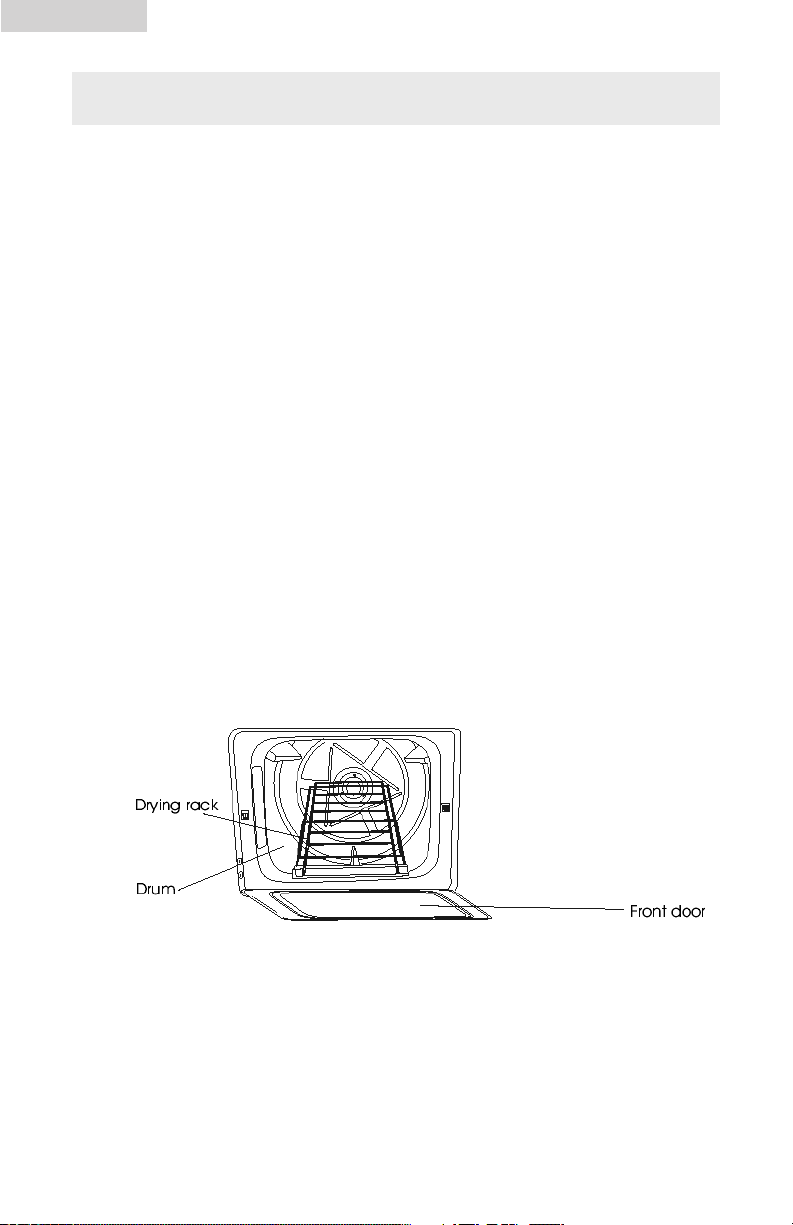

• For Rack Dry cycle, remove the lint filter and assemble the drying rack with its

rear end slightly downward inclined. The configuration is as shown in the

following figure:

Page 23

LOAD CLOTHES INTO DRYER

Super Capacity

Heavy Duty

Normal

Whites

Bulky

Press Free

Delicate

Touch Up

Custom

Timed Dry

Rack Dry

Dry Wrinkle Saver

Cool Down Remaining Time

Cycle Completed Extended Tumble

High

Medium

Low

No Heat

Louder

Softer

Off

Ver y

More

Normal

Less

Damp

Auto

Dry

Cycles

Timed

Dry

Cycles

Less

Time

More

Time

Wrinkle

Saver

Sensor

Dry

Level

Temp

Signal

Off

Start

Pause

• The appropriate load should be 1/3 ~ 1/2 of the drum volume. Avoid too

much load, as space is needed to allow clothes free rotation for uniform and

wrinkle-proof drying.

• When drying big articles, only 2-3 pieces should be loaded at a time and

supplemented with small and medium-sized articles.

• For delicate clothes or less load, two towels may be added to get better

drying and wrinkle-proof effects.

• Do not excessively dry clothes to avoid wrinkles, shrinkage, roughness,

electro-static charge accumulation, and/or more lint.

Rack Dry cycle

• This program is designed specially for articles like sport shoes. During drying,

please make sure the articles are placed on the rack with no risk of

entangling the baffles while the drum is rotating.

Note: If drying rack is not in place, rolling inner tub could collide with drying

rack and causes damage to the dryer and drying rack.

AUTO DRY CYCLE

English

GDE/GDG 950AW

1. Press any button except “Off” button to power on.

• Turn on the power switch. The computer board will beep once and the dryer

will change from off status to the initial operating status (Heavy Duty program).

• If the “Start/Pause” button is not pressed in 5 min after powering on, it

automatically cuts off power and returns to off status.

• The dryer returns to off status immediately upon end of each cycle. Regardless,

the status of the control panel, pressing OFF will stop all operations.

• The default status is “Heavy Duty” program.

2221

Page 24

English English

Cycle Signal Softer

Wrinkle Care Off

Cycles Heavy Duty

LED display Indicates current program remaining time. Initial display time is 60 minutes.

Temp High

Sensor Dry Level More Dry

Timed/Cycles Auto-program

2. Press “Auto-Dry Cycles” button to select a suitable full automatic cycle.

• The Heavy Duty program will be automatically selected after powering on. If

another full automatic program is desired, press “Auto-Dry Cycles” button until

corresponding indicator turns on.

This is subject to change depending on the moisture level in the dry load.

Auto-Dry Cycles

Heavy Duty

Normal

Whites

Bulky

Press Free

Delicate

Touch Up

Custom

• To select your desired settings, the “Custom” function should be chosen.

• The dryer can memorize programs defined by user and display the previous

program upon next application of this function.

Use details are as follows (Features may vary per model purchased):

After powering on, press “Auto-Dry Cycles” until ”Custom” status, then set

“Timed-Dry Cycles” to Timed Dry or Rack Dry and set status of other buttons.

Press “Start/Pause” button or after half a minute, the program defined by user will be

stored and will be directly displayed upon next use.

Note: The“Sensor Dry Level” button will be inactive during use of “Custom” function

and “Touch Up” cycle.

3. Press “Sensor Dry Level” button to select a suitable drying level.

• After powering on, the clothes dryer automatically sets dryness at “very”, which

means a longer drying time. If other drying level is desired, press “Sensor Dry

Level” button to select.

4. Press “Temp” button to set a suitable drying temperature.

• After switching on, the dryer sets the corresponding temperature adapting to

different cycles selected. If other drying temperature is wanted, press “Temp”

button to enable such a selection. There are 4 available drying temperatures:

High, Medium, Low, and No Heat.

23

Page 25

5. Press “Signal” button, and the buzzer will sound upon end of a cycle.

• After switching on, the dryer automatically sets buzzer at “Softer”. The user may

define three prompt sound conditions: “Louder”, “Softer” and “Off”.

6. Press the “Wrinkle Saver” button to select a suitable reserved drying program.

• This convenient feature helps keep wrinkles from setting when you cannot unload the

dryer at the end of a cycle. The dryer will stop and then tumble for a brief period

every few minutes. Press the wrinkle saver button to choose the number of hours you

want, from 3 to 24. Stop the setting at any time by pressing the wrinkle saver button

or opening the dryer door.

• If not set, the wrinkle saver indicator will be off and remaining the time indicator will

be displayed.

• The LED display indicates remaining time of a non-reserved program. If setting

“Wrinkle Saver” in standby status, the LED display indicates 3 hr, which will

increase by 1 hr with each press (until 24 and return to 3). If held for 1.5 seconds,

LED display indicated value will increase continuously.

7. Press “Touch Up” button to select wrinkle-proof drying mode.

• Use the “Touch Up” cycle to continue drying if clothes are still damp after the

Automatic cycle.

• You can also use the “Touch Up” cycle to remove wrinkles from clean clothes

packed tightly in a suitcase or closet.

8. Press “Start/Pause” button

• When starting the machine, first close the door and then press this button.

• If pause is needed during machine operating, press this button. Pressing again will

resume operation.

Autodry Cycle Remain Time Sensor

Dry Level

Heavy Duty 60 very High Softer

Normal 52 very High Softer

Whites 65 very High Softer

Start/

Pause

0-180

minutes

• Wrinkle saver 3-24 hours

• Sensor Dry Levels: Very, More, Normal, Less, Damp

• Temp Levels: High, Medium, Low, No Heat

• Signal: Louder, Softer, Off

Bulky 62 very High Softer

Press Free 35 very Medium Softer

Delicate 35 very Low Softer

Touch Up 25 N/A Low Softer

Custom Timed

Dry

Pass for Rack

Dry

40 N/A High Softer

60 N/A Air Dry Softer

Temp Signal

24

Page 26

Super Capacity

Heavy Duty

Normal

Whites

Bulky

Press Free

Delicate

Touch Up

Custom

Timed Dry

Rack Dry

Dry Wrinkle Saver

Cool Down Remaining Time

Cycle Completed Extended Tumble

High

Medium

Low

No Heat

Louder

Softer

Off

Ver y

More

Normal

Less

Damp

Auto

Dry

Cycles

Timed

Dry

Cycles

Less

Time

More

Time

Wrinkle

Saver

Sensor

Dry

Level

Temp

Signal

Off

Start

Pause

English English

AUTO DRY CYCLE

GDE/GDG 750AW

1. Turn the knob to any program except “OFF” to power on. The control panel will beep

once and the dryer will change from “OFF” to the operating status.

2. Set the cycle select dial to required auto dry cycle. The signal, temperature, and dry

levels are preprogrammed. To change this setting:

• Press the “Dry Level” button to select suitable drying level after powering on the

dryer. There are 3 options to choose from: More, Normal, or Less.

• Press the “Temp” button to set a suitable drying temperature.

• After powering on and selecting the cycle, the dryer selects the pre-programmed

temperature. If a different drying temperature is required, press the “Temp” button

to select. There are four available drying temperatures: High, medium, Low, and

No Heat.

• Press the “Signal” button, and the buzzer will sound upon end of cycle.

• After switching on, the dryer automatically sets buzzer at “Softer”. The user

can choose from Louder, Softer, or OFF.

• Press Start/Pause button.

• When starting the machine, close the door first, then press this button.

• If a pause is needed during drying, press this button. Pressing again will

resume operation.

Note: Your dryer has a preprogrammed wrinkle saver cycle. At the end of the autodry

cycle, the beeper will signal that the load is dry. If ignored, the drum will turn

for about one minute out of every five minutes, up to one hour. When the door

is opened, the feature shuts off.

TIMED DRY CYCLE

GDE/GDG 950AW

1. Press any button except “Off” button to power on.

2. Press “Timed-Dry Cycles” button and select “Timed Dry” cycle.

• After powering on, press “Timed-Dry Cycle” button to select “Timed Dry” program.

3. Press “More Time” and “Less Time” buttons to set a suitable time.

• After setting “Timed-Dry Cycle” to “Timed Dry,” you can press these two buttons

to increase or decrease drying time as you desire.

4-6. Press buttons “Temp,” “Cycle Signal,” and “Wrinkle Saver” to define your desired

program.

25

Page 27

Note: For “Timed Dry” program, use of buttons “Temp,” “Cycle Signal,” and “Wrinkle

Saver” is the same as for auto-programs. “Sensor Dryness Level” is inactive, and a

beep will sound if pressed.

7. Press “Start/Pause” button.

TIM E D DR Y C Y C LE

Cycle Select

Off

More

Normal

Less

Dry

Level

Timed Dr y Heavy Duty

High

Medium

Low

Rack Dry Normal

No Heat

Temp

Touch Up Whites

Delicates

90

60

30

20

10

Timed Dry

Auto DryTimed Dry

GDE/GDG 750AW

1. Turn the knob to any program except “OFF” to power on. The control panel

will beep once and the dryer will change from “OFF” to the operating status. If

Start/Pause button is not pressed five minutes after powering on, the dryer will

automatically return to OFF status.

2. Set the cycle select dial to Timed Dry Cycle.

3. Press “Timed Dry” button to set the required drying time.

4-6. Press “Temp” and “Signal” to define the required programs. Note: For “Timed Dry”

program use of “Temp” and “Signal” buttons is the same as for auto-programs. “Dry

Level” is inactive.

Clean Lint

Louder

Drying

Softer

Cool Down

Off

Wrinkle Saver

Signal

Cycle Process

R AC K DR Y C YC LE

Super Capacity

1. Press any button except “Off” button to power on.

2. Press “Timed-Dry Cycles” button and select “Rack Dry” cycle.

• After powering on, press “Timed-Dry Cycle” button to select “Rack Dry” program.

3. Press “More Time” And “Less Time” buttons to set a suitable time.

• After setting “Timed-Dry Cycle” to “Rack Dry”, you can press these two buttons

to increase or decrease drying time as you desire.

4-7. Press buttons “Temp,” “Signal,” “Wrinkle Saver,” and “Touch Up” to define

your desired program.

Notes : For “Rack Dry” program, use of buttons “Temp,” “Signal,” “Wrinkle Saver,” and

“Touch up” is the same as for auto-programs. “Sensor Dry Level” is inactive, and

a beep will sound if pressed.

8. Press “Start/Pause” button.

Heavy Duty

Press Free

Normal

Delicate

Whites

Touch Up

Bulky

Custom

Auto

Dry

Cycles

Timed Dry

Rack Dry

Timed

Dry

Cycles

Dry W rinkle Saver

Cool Down Remaining T ime

Cycle Completed Extended T umble

Less

More

Wrinkle

Time

Time

Saver

High

Ve ry

More

Louder

Medium

Normal

Less

Softer

Low

Damp

No Heat

Sensor

Dry

Temp

Level

Start

Pause

Off

Off

Signal

26

Page 28

English English

R AC K DR Y C YC LE

Cycle Select

Off

More

Normal

Less

Dry

Level

Timed D ry Heavy Duty

High

Medium

Low

Rack Dry Normal

No Heat

Temp

Touch Up Whites

Delicates

90

60

30

20

10

Timed Dry

Auto DryTimed Dry

Signal

GDE/GDG 750AW

1. Turn the knob to any program except “OFF” to power on. The control panel

will beep once and the dryer will change from “OFF” to the operating status.

If Start/Pause button is not pressed five minutes after powering on, the dryer

will automatically return to OFF status.

2. Set the cycle select dial to Rack Dry Cycle.

3. Press “Timed Dry” button to set the required drying time.

4-6. Press “Temp” and “Signal” to define the required programs.

Note: For “Rack Dry” program use of “Temp” and “Signal” buttons is the

same as for auto-programs. “Dry Level” is inactive.

Clean Lint

Louder

Drying

Softer

Cool Down

Off

Wrinkle Saver

Cycle Process

Other Features

Your dryer also has the following features for your convenience:

Lint Filter:

• All dryers come with a lint filter that needs to be cleaned before or after every

use (read “Care and Cleaning Guide” Section).

Leveling Legs:

• Your dryer has four leveling legs which are located in the front and rear corners

of your dryer. After installing your dryer in its final position, you can level your

dryer.

• Leveling legs can be adjusted by turning them clockwise to raise your dryer or

by turning them counterclockwise to lower your dryer.

27

Page 29

NORMAL OPERATING SOUNDS

The following sounds are normal during the operation of the dryer.

• Tumbling sound: this is normal as the heavy wet clothes in the dryer are

continuously being tossed around.

• Air rushing noise: this happens as the dryer drum spins at very high RPM and

the air is rushing through the dryer drum.

Tips

• For best drying results, clean the lint filter before or after every use.

• Do not overload the dryer.

• Balance the dryer load evenly throughout the dryer for the best result.

• Drying time depends on many variables: load size, type of fabric and

moisture in it, heat and moisture in the room, electric voltage, length of the

exhaust duct, etc.

• To eliminate guessing and to conserve energy,it is recommend for certain

clothes to dry on an auto-drying setting.

• Always follow the fabric care instructions supplied by the garment manufacturer.

CARE AND CLEANING GUIDE

• Lint filter needs to be cleaned before

or after each use for your unit to

operate at optimum efficiency. The

filter can be removed by pulling on

the tabs located on the inside of the

dryer door. The filter may be washed

or vacuumed. Remove the excess

water from the filter by gently shaking the filter. This will remove dust and

particles trapped in the filter. Lint built up in screen will restrict airflows, which

causes longer drying times. After cleaning, slide the filter back in place. Do not

use your dryer without the lint filter.

• Do not use any type of spray cleaner when cleaning the interior.

• Hazardous fumes or electric shock could occur. If dryer drum becomes stained,

clean the drum with damp cloth. Remove any residue before drying next load.

• Clean the cabinet with mild soap and water. Do not use harsh or abrasive

cleaners, as this could damage the dryer.

• Clean the duct and the vent on a regular basis to avoid clogging which could

affect the efficiency of the dryer.

Lint Filter

28

Page 30

English English

TROUBLESHOOTING

Dryer does not operate:

• Check if unit is plugged in. The plug may have come loose.

• Check if the electrical wall receptacle is of proper voltage.

• Check if the circuit breaker needs to be reset, or if the fuse needs to

be replaced.

• Check if the unit is in the “off” mode. Press start button again.

• Check if the door is open.

Dryer is working but not drying the clothes:

• Unit may be overloaded. The dryer drum should be at most half full.

• Check exhaust ducts and vents. Vents should be free of obstruction.

• Duct should be dust - and lint - free, and cleaned regularly.

• Dryer load need to be resorted. Heavy clothes may need to be separated

from regular clothes.

• Bulk clothes may require repositioning.

• If the clothes dries unevenly a higher dry setting may be required, or clothes

in the dryer need to be resorted.

Dryer makes noise when drying:

• Check for coins, loose change, buttons and other heavy objects that could be

causing the noise.

• Dryer may need to be leveled.

• Read operating guide for normal operating sounds.

Static:

• Caused by over drying. Adjust for shorter drying time.

• Mixed with synthetics fabric. Sort and separate different fabric.

• Use a fabric softener.

29

Page 31

LIMITED WARRANTY

Full ONE Year Warranty

For 12 months from the date of original retail

purchase, Haier will repair or replace any part

free of charge including labor that fails due to a

defect in materials or workmanship.

Limited Warranty

After only year from the original retail purchase

date Haier shall provide a part at no cost, as

indicated below, to replace said part as a result

or a defect in materials or workman ship, Haier

is solely responsible for the cost of the part.

All other costs such as the cost of the part. All

other costs such as labor trip charge, etc are the

responsibility of the owner.

Second through Fifth Year.

NOTE: This warranty commences on the date

the item was purchased and the original

purchase receipt must be presented to the

authorized service representative before

warranty repairs are rendered.

Exceptions: Commercial or Rental Use

warranty.

90 days labor from date of original purchase.

90 days parts from date of original purchase

NO OTHER WARRANTY APPLIES.

For Warranty Service

Contact your nearest authorized service center.

All service must be performed by a Haier

authorized service center. For the name and

telephone number of the nearest authorized

service center please call

1-877-337-3639.

Before calling please have available the

following information:

Model number and serial number of your

appliance( found on the rear of the unit on the

upper left hand side).

The name and address of the dealer you

purchased the unit from and the date of

purchase.

A clear description of the problem.

A proof of purchase (sales receipt).

This warranty covers appliances within the

continental united States. Puerto Rico and

Canada .

What is not covered by this warranty:

Replacement or repair of household fuses, circuit

breakers, wiring or plumbing.

A product whose original serial number has

been removed or altered.

Any service charges not specifically identified as

normal such as normal service area or hours.

Damage to clothing.

Damage incurred in shipping

Damage caused by improper installation

or maintenance.

Damage from misuse, abuse accident, fire,

flood, or acts of nature.

Damage from service other than on authorized

Haier dealer or service center.

Damage from incorrect electrical current,

voltage or supply.

Damage resulting from any product

modification, alteration or adjustment not

authorized by Haier.

Adjustment of consumer operated controls as

identified in the owners manual.

Hoses, knobs, lint trays and all attachments,

accessories and disposable parts.

Labor, service transportation, and shipping

charges for the removal and replacement of

detective parts beyond the initial

12-month period.

Damage from other than normal household use.

Any transportation and shipping charges.

THIS LIMITED WARRANTY IS GIVEN IN LIEU

OF ALL OTHER WARRANTIES EXPRESSED

OR INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE

The remedy provided in this warranty is

exclusive and is granted in lieu of all

other remedies.

This warranty does not cover incidental or

consequential damages so the above limitations

may not apply to you .Some states do not allow

limitations on how long on implied warranty

lasts, so the above limitations may not

apply to you.

This warranty gives you specific legal rights,

and you may have other rights, which vary,

from state to state.

Haier America

New York, NY 10018

30

Page 32

Français Français

TABLE DES MATIERES

PAGE

CONSIGNES DE SÉCURITÉ ................................................... 32-34

INSTRUCTIONS D’INSTALLATION ....................................... 35-37

Outils et matériel nécessaires ..........................................................35

Exigences électriques ......................................................................35

Déballage de votre sécheuse ..........................................................36

Exigences du système d’évacuation .................................................37

Exigences d’alimentation en gaz ....................................................39

Emplacement de votre sécheuse ....................................................40

Instruction pour une maison mobile ................................................. 41

Installation électrique ..................................................................... 42

Raccordements cordon à 3 fils .......................................................43

Raccordements cordon à 4 fils .......................................................44

Raccordements gaz .......................................................................45

Pièces de remplacement ................................................................ 47

INSTRUCTIONS DE FONCTIONNEMENT ............................. 48-58

Comprendre le tableau de commande..............................................48

Préparations avant séchage ............................................................51

Mettre les vêtements dans la sécheuse .............................................. 52

Cycle séchage automatique ............................................................ 52

Cycle séchage minuté ..................................................................... 55

Cycle Étagère ................................................................................ 56

Autres caractéristiques ................................................................... 57

Bruits de fonctionnement normal ......................................................58

Conseils ........................................................................................ 58

GUIDE DE NETTOYAGE ET ENTRETIEN .......................................58

PROBLÈMES ET SOLUTIONS ......................................................59

GARANTIE LIMITÉE ..................................................................... 60

Page 33

CONSIGNES DE SÉCURITÉ IMPORTANTES

ADVERTISSMENT

Avant de commencer l’installation, lisez attentivement ces instructions. Cela

simplifiera l’installation et assurera que la sécheuse est installée correctement et en

toute sécurité.

NOTE : Le service électrique de la sécheuse doit être conforme aux codes et

règlements locaux et la dernière édition du National Electrical Code,

ANSI/NFPA 70 ou au Canada, CSA C22.1 Canadian Electrical

Code Part 1.

NOTE : Le service du gaz de la sécheuse doit être conforme aux codes et

règlements locaux et la dernière édition du National Fuel Gas Code,

ANSI Z223.1 ou au Canada, CAN/CGA B149.1.

NOTE : La sécheuse est conçue selon ANSI Z21.5.1 ou ANSI/UL 2158 – CAN/

CSA C22.2 No. 112-97 (dernières éditions) pour UNE UTILISATION

DOMESTIQUE UNIQUEMENT. Cette sécheuse n’est pas recommandée

pour une utilisation commerciale comme dans les restaurants, les salons

de beauté, etc.

Ne rangez pas et n’utilisez pas d’essence ou d’autres vapeurs et

liquides inflammables près de cet appareil électroménager ou d’un autre.

CE QU’IL FAUT FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

1. N’essayez pas d’allumer un quelconque appareil électroménager.

2. Ne touchez aucun commutateur électrique; n’utilisez pas le téléphone

de votre bâtiment.

3. Videz la pièce, l’immeuble ou la zone de tous ses occupants.

4. Appelez immédiatement votre fournisseur de gaz du téléphone d’un

voisin. Suivez les instructions du fournisseur de gaz.

5. Si vous ne pouvez pas joindre votre fournisseur de gaz, appelez

les pompiers.

Les installations doivent être effectuées par un installateur qualifié,

un plombier, le service après-vente ou le fournisseur de gaz agréé et

détenteur d’une licence de l’état ou de la province, ou la région où cet

appareil est installé.

Pour votre sécurité, si l’information contenue dans ces

instructions n’est pas suivie exactement, il pourrait

y avoir un incendie ou une explosion causant des

dégâts matériels, des blessures personnelles ou

la mort.

3231

Page 34

Français Français

CONSIGNES DE SÉCURITÉ

IMPORTANTES

AVERTISSEMENT - Afin d’éviter les risques d’incendie, de choc

électrique ou de blessures lors de l’utilisation de cet appareil

respectez les précautions d’utilisation de base, dont les suivantes

:

1. Lisez toutes les instructions attentivement avant d’utiliser

l’appareil.

2. Ne séchez pas des articles qui ont été lavés, nettoyés, trempés ou

détachés avec de l’essence, des solvants secs ou d’autres produits

inflammables car leurs vapeurs peuvent créer un départ de feu ou

une explosion.

3. Ne laissez pas les enfants jouer sur ou dans l’appareil. Surveillez-les

attentivement lorsque vous utilisez cet appareil près d’enfants.

4. Retirez la porte de l’appareil avant de le réviser ou de vous

en débarrasser.

5. Ne tendez pas la main vers l’intérieur de l’appareil lorsque le tambour est

en marche.

6. N’installez pas et ne rangez pas cet appareil là où il sera exposé à l’eau

et/ou aux conditions climatiques.

7. Ne jouez pas avec les contrôles.

8. Ne réparez pas et ne remplacez aucune pièce de l’appareil ou ne tentez

pas de réparer sans que cela ne soit spécifié dans les instructions et que

vous comprenez et avez les compétences nécessaires.

9. N’utilisez pas d’assouplissants ou de produits anti-statiques à moins que

cela ne soit recommandé par les fabricants de l’adoucissant ou

produit anti-statique.

10. N’utilisez pas la chaleur pour sécher des articles contenant du caoutchouc

mousse ou des matériaux avec une texture similaire.

11. Nettoyez l’écran à peluches avant ou après chaque séchage.

12. Gardez les zones autour des ouvertures sans peluches, poussière et saleté.

13. Gardez la zone de la sécheuse sans articles qui pourraient obstruer le flot

de combustion et de ventilation de l’air à travers le panneau à persiennes

situé à l’arrière de la sécheuse.

14. L’intérieur de l’appareil et les conduites d’évacuation doivent être

nettoyées régulièrement par du personnel qualifié.

33

Page 35

15. Ne mettez pas des éléments exposés à de l’huile de cuisson dans votre

sécheuse. Les éléments contaminés avec de l’huile peuvent créer une

réaction chimique pouvant créer un incendie.

16. Si un tissu a été utilisé avec des liquides ou solides inflammables il ne

doit pas être utilisé dans la sécheuse jusqu’à ce que toutes les traces de

liquides inflammables et leurs vapeurs aient disparues.

17. Cette sécheuse doit être installée conformément aux instructions

d’installation avant d’être utilisée. Voir les instructions de mise à la terre

dans la section Installation.

18. Une bonne mise à la terre doit être effectuée pour réduire les risques

de choc électrique et de force. Vérifiez avec un électricien agréé si vous

avez des doutes quant à la bonne mise à la terre de la sécheuse.

19. Utilisez uniquement la sécheuse pour l’usage pour laquelle elle est

conçue : sécher les vêtements.

20. Débranchez toujours la sécheuse avant d’essayer de la réparer.

Débranchez le cordon par la fiche, pas le cordon lui-même.

21. Remplacez le cordon d’alimentation usé et/ou les fiches lâches.

22. Afin d’éviter tout risque de choc électrique, n’utilisez pas de rallonges ou

d’adaptateurs pour connecter l’unité à une source électrique.

CONSERVEZ CES

INSTRUCTIONS

DANGER

Risque de suffocation et de confinement des enfants. Avant de jeter

votre vieille sécheuse, retirez la porte pour que les enfants ne puissent

pas grimper à l’intérieur facilement.

Merci d’avoir choisi ce produit

Haier. Ce guide facile à utiliser

vous permettra d’utiliser votre

sécheuse au maximum de ses

capacités.

N’oubliez pas de noter le modèle

et le numéro de série. Ils sont au

dos de votre sécheuse.

Agrafez votre reçu à votre manuel.

Vous en aurez besoin pour faire valoir votre garantie.

Numéro du modèle

Numéro de série

Date d’achat

34

Page 36

ADVERTISSMENT

ATTENTION

Français Français

INSTRUCTIONS D’INSTALLATION

1. L’installation de la sécheuse doit être faite par un installateur agréé.

2. Installez la sécheuse selon les instructions du fabricant et les codes locaux.

3. Afin de réduire le risque de blessure grave ou de mort, suivez toutes les

Risque d’incendie :

instructions d’installation.

CONSERVEZ CES INSTRUCTIONS

Outils et matériaux nécessaires

• Tournevis Philips et tournevis à tête plate

• Pinces réglables

• Clé anglaise de 1,3 cm (1/2 pouce)

• Niveau de menuisier

• Mètre à ruban de 3,65 mètres minimum (12 pieds minimum)

• Ruban adhésif en toile

• Pâte à joint (Gaz)

• Conduit rigide ou flexible en métal de 10,2 cm (4 pouces)

• Hotte d’évacuation

Avertissement de sécurité :

1. Avant de commencer l’installation, assurez-vous que la valve de fermeture

du gaz est sur la position off.

2. Tous les vieux connecteurs de gaz et la tuyauterie de gaz doivent être mis

au rebut.

EXIGENCES ÉLECTRIQUES

Sécheuse électrique : (GDE750AW et GDE950AW)

C ircuit

Circuit terminal à fusible individuel de 30 Ampères avec fusibles temporisés ou

disjoncteurs. Utilisez séparément les circuits pour laveuses et sécheuses et NE FAITES

PAS fonctionner une laveuse et une sécheuse sur le même circuit.

Alimentation

3 ou 4 fils, 240 volts, 1 phase, 60Hz, CA

(Canada - 240 volts, 1 phase, 60Hz, CA)

K it de cordon d’alimentation

(non fourni quand vendu aux États-Unis) La sécheuse DOIT utiliser un cordon

35

Page 37

d’alimentation NEMA 10-30 à 3 conducteurs de type SRDT avec une tension

minimum de 240 volts, 30 ampères avec 3 connecteurs à cosse à fourche à

bout ouvert avec des bouts renversés ou des connecteurs en circuit fermé et

marqués pour être utilisés avec des sécheuses.

(Quand vendu au Canada – cordon d’alimentation à 4 fils

fourni et attaché à la sécheuse.)

Les sécheuses installées dans une maison mobile, DOIVENT utiliser un

cordon d’alimentation NEMA 14-30 à 4 conducteurs de type SRDT ou ST

(comme exigé) avec une tension minimum de 240 volts, 30 ampères avec

4 connecteurs à cosse à fourche à bout ouvert avec des bouts renversés

ou des connecteurs en circuit fermé et marqués pour être utilisés avec des

sécheuses. Voir Raccordements électriques pour un système à 4 fils, pour plus

d’information.

P rise Murale

Une prise murale NEMA 10-30R doit être située de façon à ce que le cordon

d’alimentation soit accessible quand la sécheuse est dans sa position installée.

(Canada – prise murale NEMA 14-30R).

EXIGENCES ÉLECTRIQUES

Sécheuse à gaz : (GDG750AW et GDG950AW)

C ircuit

Circuit terminal à fusible individuel de 15 Ampères avec un fusible temporisé de

15 ampères maximum ou des disjoncteurs. .

A limentation

3 fils, 120 volts, 1 phase, 60Hz, CA

C ordon d’alimentation

La sécheuse est équipée d’un cordon d’alimentation à 3 fils d’une tension de

120 volts.

Note : Cette sécheuse est équipée d’une fiche polarisée avec trois lames pour

votre protection contre d’éventuels chocs électriques. Ne coupez ou

retirez en aucun cas la troisième lame du cordon d’alimentation.

Déballage de votre sécheuse

1. Retirez tous les matériaux d’emballage dont la mousse et les adhésifs qui

retiennent les accessoires à l’intérieur de la sécheuse et à l’extérieur.

2. Vérifiez et retirez tous les restes d’emballage, adhésif ou documentation avant

d’utiliser la sécheuse.

36

Page 38

Français Français

EXIGENCES DU SYSTEME D’EVACUATION

AVERTISSEMENT

Les instructions suivantes sont des exigences

spécifiques pour un fonctionnement correct et en toute

sécurité. Ne pas suivre ces instructions peut créer des

temps de séchage excessifs et des dangers d’incendie.

1. N’utilisez pas un conduit flexible en plastique pour évacuer la sécheuse. Un

excès de peluches peut se former à l’intérieur du système d’évacuation et

créer un risque d’incendie et restreindre la circulation de l’air. Une mauvaise

circulation d’air augmentera le temps de séchage. Si votre système actuel est

fait d’un conduit en plastique ou d’un conduit en feuille de métal, remplacez-le

avec un conduit rigide ou flexible en métal. Assurez-vous que le conduit actuel

ne contient aucune peluches avant d’installer le conduit de la sécheuse.

2. La sécheuse ne doit pas être évacuée dans un purgeur de gaz, une cheminée,

un mur, un plafond ou tout espace ferme d’un immeuble. Le système

d’évacuation de la sécheuse DOIT être évacué à l’extérieur. Si la

sécheuse n’est pas évacuée à l’extérieur, de fines peluches seront envoyées

dans la zone où vous utilisez la machine. Une accumulation de peluches dans

n’importe quelle partie de votre habitation peut poser un problème de santé et

un risque d’incendie.

3. Dépasser la longueur du conduit ou le nombre de coudes autorisés dans

les tableaux de la « Longueur maximale » peut causer une accumulation de

peluches dans le système d’évacuation. Boucher le système pourrait créer un

risque d’incendie et augmenter les durées de séchage.

4. Ne cachez pas les extrémités d’évacuation du système de ventilation, n’utilisez

pas des vis ou des rivets pour assembler le système d’évacuation. Les peluches

peuvent s’accrocher à l’écran et augmenter les durées de séchage. Utilisez une

hotte à évacuation pour raccorder le conduit à l’extérieur et scellez tous les

joints avec du ruban adhésif.

5. Toutes les ferrures mâles du conduit doivent être installées en aval de la

circulation de l’air.

6. Le conduit d’évacuation ne doit pas être connecté ou sécurisé avec des vis ou

autres outils de fixation qui s’étendent dans l’intérieur du conduit.

7. Ne mettez pas de matériaux combustibles (par exemple : vêtements, rideaux,

draperies, le papier) en contact avec le système d’évacuation.

Danger d’explosion :

N’installez pas la sécheuse dans un lieu ou de l’essence ou d’autres

matières inflammables sont gardées ou entreposées. Si la sécheuse est

installée dans un garage, elle doit être à au moins 18 pouces (45,7 cm) du

sol. Ne pas suivre cette consigne peut conduire à la mort, un incendie ou

des brûlures.

37

Page 39

Exigences d’évacuation :

Utilisez uniquement un conduit rigide ou flexible en métal de 4 pouces (10.2

cm) et une hotte de ventilation approuvée qui a un amortisseur à balancement

ouvert quand la sécheuse est en marche. Lorsque la sécheuse s’arrête,

l’amortisseur se ferme automatiquement pour empêcher les courants d’air

et l’entrée d’insectes et de rongeurs. Afin d’éviter la restriction de la prise,

maintenez une distance minimum de 12 pouces (30,5 cm) entre la hotte de

ventilation et le sol ou toute autre obstruction. Le clapet d’air doit pouvoir

bouger librement, cependant une orientation verticale du système d’évacuation

est acceptable. Certaines circonstances atténuantes peuvent affecter la

performance de la sécheuse :

1. Seul un conduit rigide en métal devrait être utilisé.

2. Ventiler verticalement à travers un toit peut exposer le système d’évacuation

à des courants d’air causant une augmentation dans la restriction de l’évent.

3. Faire fonctionner le système d’évacuation à travers un lieu non isolé peut

causer de l’humidité et une accumulation de peluches plus rapide.

4. Compression ou sertissage du système d’évacuation causera une

augmentation dans la restriction de l’évent.

Le système d’évacuation devrait être inspecté et nettoyé au moins tous les 18

mois avec une utilisation normale. Plus la sécheuse est utilisée plus le système

d’évacuation et la hotte de ventilation doivent être vérifiés pour un

bon fonctionnement.

MAXIMUM RECOMMANDÉ

Types de hottes à évacuation