Haier AS18ND1HRA-WHITE, HSU18VHGL-G, 1U18FE2ERA, HSU18VHGL-W, AS24BS4HRA Service Manual

...Page 1

SERVICE MANAUL

Wall Mounted Type

DC Inverter FREE MATCH N-Series

AS18ND1HRA-WHITE

HSU18VHGL-G

Model No.

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or

Repair the product or products dealt with in this service information by anyone else could result in serious injury or death

WARNING

2014 (Qingdao Haier Air Conditioner General corp. , Ltd)

All rights reserved. Unauthorized copying and distribution is a violation of law

Haier Group

Version:V1 Date:2014-05-25

Page 2

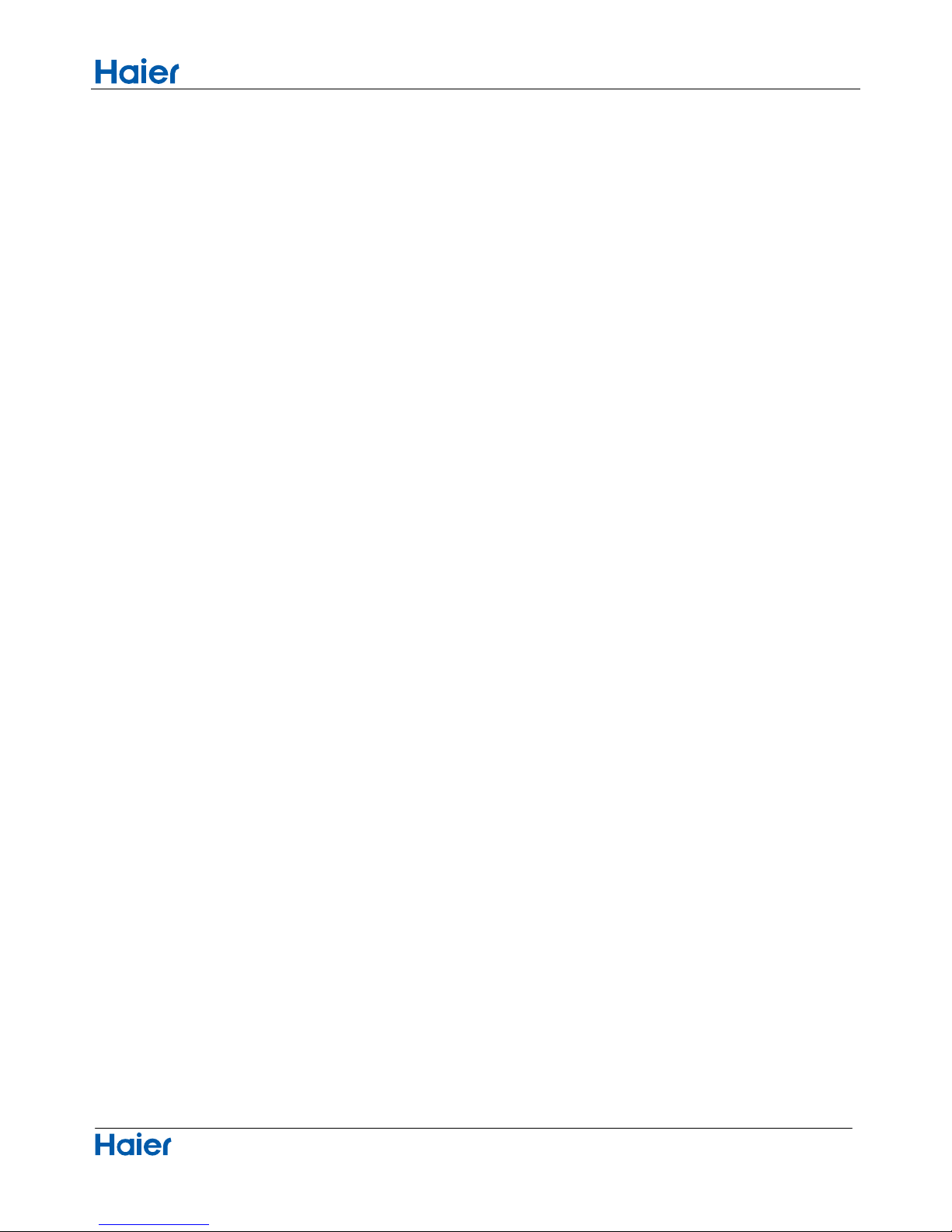

Table of contents

Domestic air conditioner

Contents

1. Introduction ............................................................................................ 1

2. Features ................................................................................................ 7

3. Specifications ........................................................................................ 8

4. Sensors list............................................................................................ 9

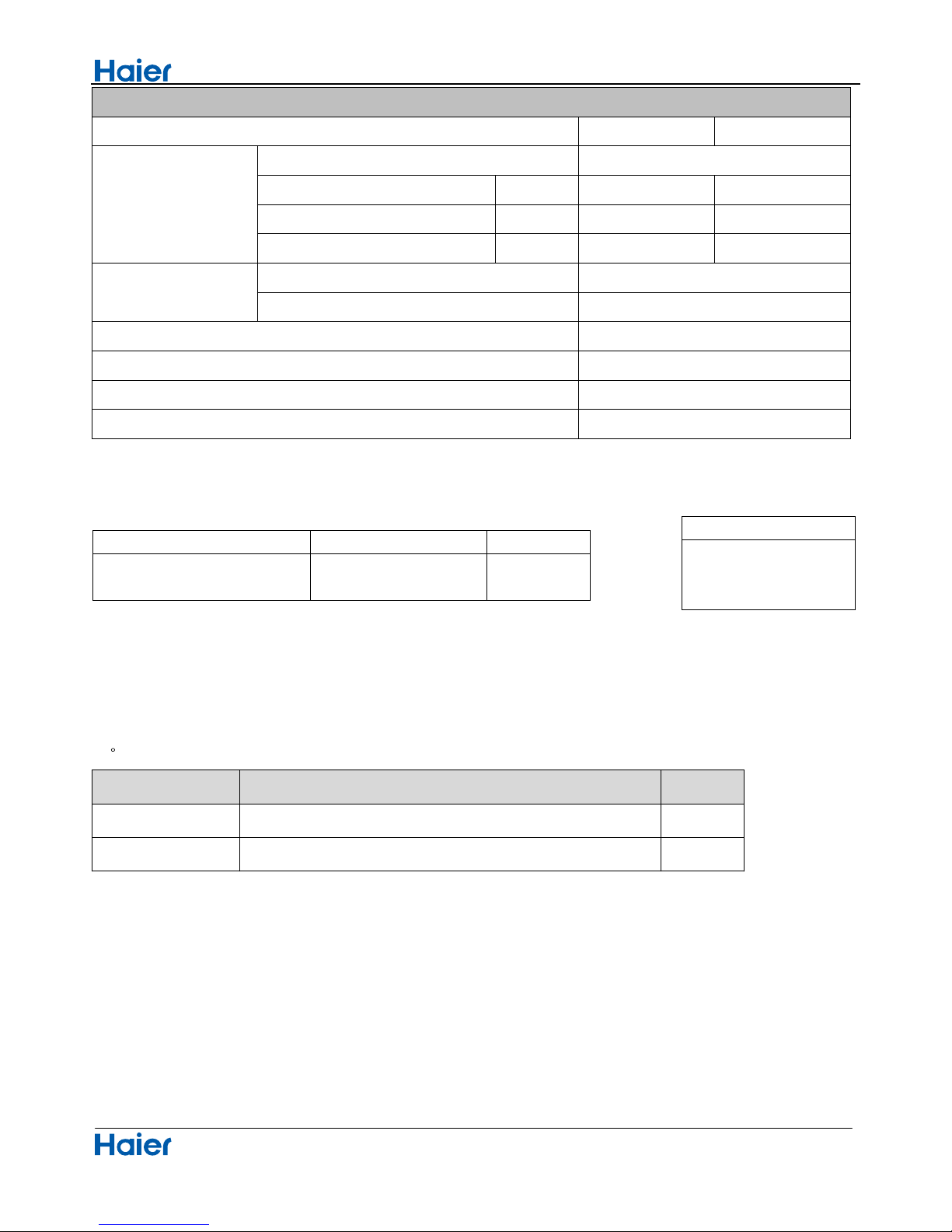

5. Piping diagrams .....................................................................................10

6. Printed Circuit Board Connector Wiring Diagram..................................11

7. Functions and Control ...........................................................................

8. System configuration.............................................................................

9. Dimensional drawings ...........................................................................

10. Conter of gravity..................................................................................

11. Service Diagnosis ................................................................................

12. Circuit diagrams

..................................................................................

14

59

43

42

42

25

Page 3

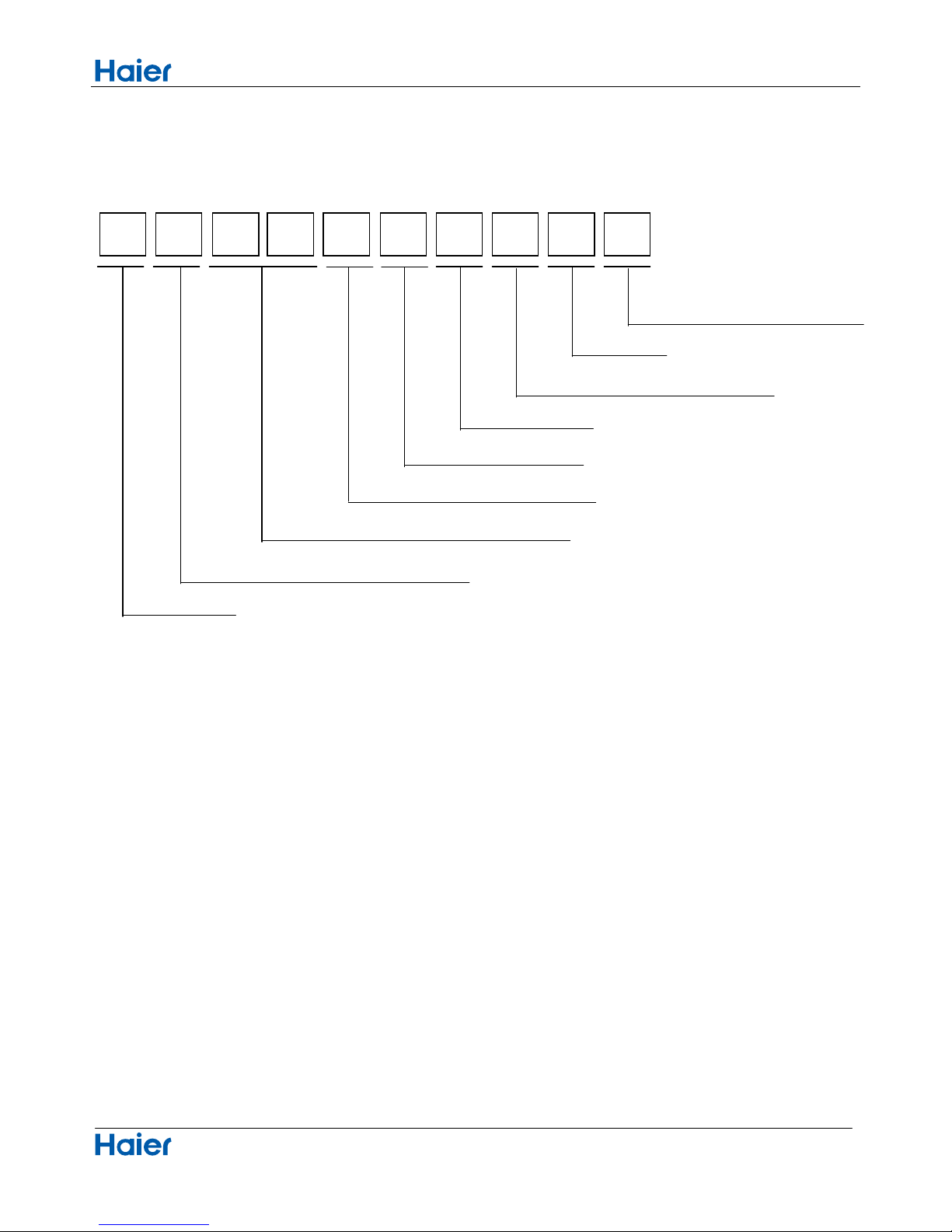

Introduction

Domestic air conditioner

1 Introduction

1.1 Model name explanation

A S 1 8 N D 1 H R A

Indoor unit

Type of indoor unit: S (wall-mounted)

Nominal cooling capacity (18000BTU/h)

Version number

Heat pump & R410A refrigerant

DC inverter

Apply toT1; 208~230V60HZ/1ph

1

Platform of indoor units: N (N platform)

50N Platform

Page 4

Intuoduction

Domestic air conditioner

1.2 Safety Cautions

Be sure to read the following safety cautions before conducting repair work.

The caution items are classified into “Warning” and “Caution”. The “Warning” items are especially important

since they can lead to death or serious injury if they are not followed closely. The “Caution” items can also lead

to serious accidents under some conditions if they are not followed. Therefore, be sure to observe all the safety

caution items described below.

About the pictograms

△ This symbol indicates an item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

○ This symbol indicates a prohibited action.

The prohibited item or action is shown inside or near the symbol.

● This symbol indicates an action that must be taken, or an instruction.

The instruction is shown inside or near the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the equipment operates

Normally, and explain the cautions for operating the product to the customer.

1.2.1 Caution in Repair

Warning

Be sure to disconnect the power cable plug from the plug socket before disassembling the equipment for

a repair.

Working on the equipment that is connected to a power supply can cause an electrical shook.

If it is necessary to supply power to the equipment to conduct the repair or inspecting the circuits, do not

touch any electrically charged sections of the equipment.

If the refrigerant gas discharges during the repair work, do not touch the discharging refrigerant gas .The

refrigerant gas can cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at the welded section, release the

refrigerant gas completely at a well-ventilated place first.

If there is a gas remaining inside the compressor , the refrigerant gas or refrigerating machine oil

discharges when the pipe is disconnected, and it can cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area. The refrigerant gas can generate

toxic gases when it contacts flames.

The step-up capacitor supplies high-voltage electricity to the electrical components of the outdoor unit.

Be sure to discharge the capacitor completely before conducting repair work . A charged capacitor can

cause an electrical shock.

Do not start or stop the air conditioner operation by plugging or unplugging the power cable plug.

Plugging or unplugging the power cable plug to operate the equipment can cause an electrical shock or

fire.

2

Page 5

Intuoduction

Domestic air conditioner

Warning

Do not repair the electrical components with wet hands . Working on the equipment with wet hands can

cause an electrical shock

Do not clean the air conditioner by splashing water. Washing the unit with water can cause an electrical

shock.

Be sure to provide the grounding when repairing the equipment in a humid or wet place, to avoid

electrical

shock.

Be sure to turn off the power switch and unplug the power cable when cleaning the equipment. The

internal fan rotates at a high speed, and cause injury.

Do not tilt the unit when removing it. The water inside the unit can spill and wet the furniture and floor.

Be sure to check that the refrigerating cycle section has cooled down sufficiently before conducting

repair

work. Working on the unit when the refrigerating cycle section is hot can cause burns.

Use the welder in a well-ventilated place. Using the welder in an enclosed room can cause oxygen

deficiency.

1.2.2 Cautions Regarding Products after Repair

Warning

Be sure to use parts listed in the service parts list of the applicable model and appropriate tools to

conduct repair work. Never attempt to modify the equipment. The use of inappropriate parts or tools can

cause an electrical shock, excessive heat generation or fire.

When relocating the equipment, make sure that the new installation site has sufficient strength to

withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation work is not conducted

securely, the equipment can fall and cause injury.

Be sure to install the product correctly by using the provided standard installation frame.

Incorrect use of the installation frame and improper installation can cause the equipment to fall, resulting

in injury.

For

integral

units only

Be sure to install the product securely in the installation frame mounted on a window frame.

If the unit is not securely mounted, it can fall and cause injury.

For

integral

units only

3

Page 6

Intuoduction

Domestic air conditioner

Warning

Be sure to use an exclusive power circuit for the equipment, and follow the technical standards related to

the electrical equipment, the internal wiring regulations and the instruction manual for installation when

conducting electrical work.

Insufficient power circuit capacity and improper electrical work can cause an electrical shock or fire.

Be sure to use the specified cable to connect between the indoor and outdoor units. Make the

connections securely and route the cable properly so that there is no force pulling the cable at the

connection terminals.

Improper connections can cause excessive heat generation or fire.

When connecting the cable between the indoor and outdoor units, make sure that the terminal cover

does

not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section can cause an electrical shock,

excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable can cause an electrical shock or fire. Placing heavy items on the

power cable, and heating or pulling the power cable can damage the cable.

Do not mix air or gas other than the specified refrigerant (R-410A / R22) in the refrigerant system.

If air enters the refrigerating system, an excessively high pressure results, causing equipment damage

and injury.

If the refrigerant gas leaks, be sure to locate the leak and repair it before charging the refrigerant. After

charging refrigerant, make sure that there is no refrigerant leak.

If the leak cannot be located and the repair work must be stopped, be sure to perform pump-down and

close the service valve, to prevent the refrigerant gas from leaking into the room. The refrigerant gas

itself

is harmless, but it can generate toxic gases when it contacts flames, such as fan and other heaters,

stoves and ranges.

.

When replacing the coin battery in the remote controller, be sure to disposed of the old battery to prevent

children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

4

Page 7

Intuoduction

Domestic air conditioner

Caution

Installation of a leakage breaker is necessary in some cases depending on the conditions of the

installation site, to prevent electrical shocks.

Do not install the equipment in a place where there is a possibility of combustible gas leaks.

If a combustible gas leaks and remains around the unit, it can cause a fire.

Be sure to install the packing and seal on the installation frame properly. If the packing and seal are not

installed properly, water can enter the room and wet the furniture and floor.

1.2.3 Inspection after Repair

Warning

Check to make sure that the power cable plug is not dirty or loose, then insert the plug into a power outlet

all the way.

If the plug has dust or loose connection, it can cause an electrical shock or fire.

If the power cable and lead wires have scratches or deteriorated, be sure to replace them.

Damaged cable and wires can cause an electrical shock, excessive heat generation or fire.

Warning

Do not use a joined power cable or extension cable, or share the same power outlet with other electrical

appliances since it can cause an electrical shock, excessive heat generation or fire.

5

Page 8

Intuoduction

Domestic air conditioner

Caution

Check to see if the parts and wires are mounted and connected properly, and if the connections at the

soldered or crimped terminals are secure. Improper installation and connections can cause excessive

heat generation, fire or an electrical shock.

If the installation platform or frame has corroded, replace it. Corroded installation platform or frame can

cause the unit to fall, resulting in injury.

Check the grounding, and repair it if the equipment is not properly grounded. Improper grounding can

cause an electrical shock.

Be sure to measure the insulation resistance after the repair, and make sure that the resistance is 1 M

ohm or higher.

Faulty insulation can cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage can cause the water to enter the room and wet the furniture and floor.

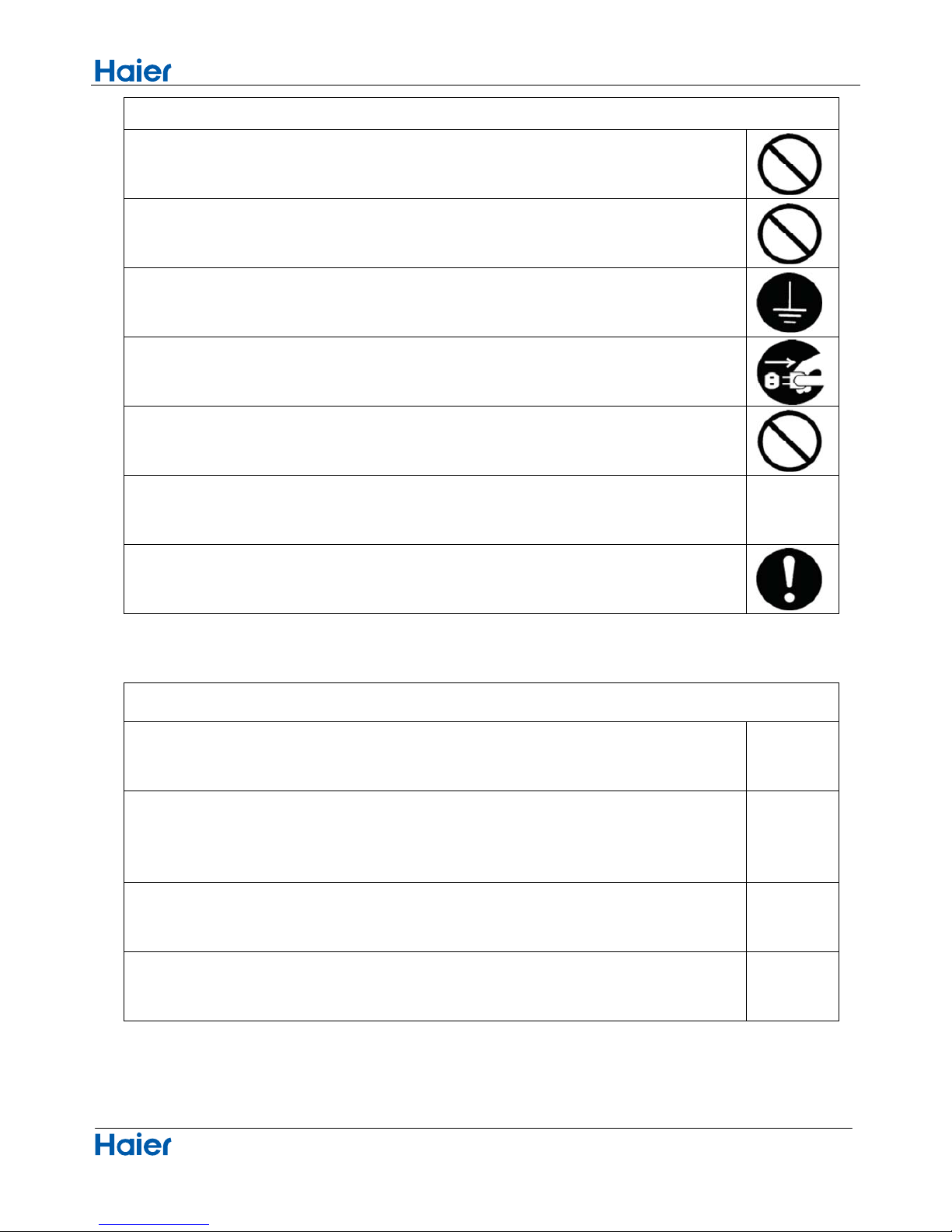

1.2.4 Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each icon is described in

the table below:

1.2.5 Using Icons List

Icon Type of Information Description

Note

Note

A “note” provides information that is not indispensable, but may

nevertheless be valuable to the reader, such as tips and tricks.

Caution

Caution

A “caution” is used when there is danger that the reader, through

incorrect manipulation, may damage equipment, loose data, get

an

unexpected result or has to restart (part of) a procedure.

Warning

Warning

A “warning” is used when there is danger of personal injury.

Reference

A “reference” guides the reader to other places in this binder or in

this manual, where he/she will find additional information on a

specific topic.

6

Page 9

Specifications

Domestic air conditioner

2.Features

7

Super quiet: Lower noise operation condition

A-PAM DC inverter:With adoption of S-TYPE,S-PAM and PHASE control technology to works more

stably at low-frequency,and is more energy-saving,mor powerful at high frequency.

Long distance air supplying:

5 F° Heating: When 5 °F can still heating natural

50 °F heating maintenance:Heating Holding 50°F temperature

Confortable sleep:The setting temperature and the indoor noise can be adjusted to a more comfortable

level when you set the “sleep mode” during night sleep.

Super match:One outdoor unit can match two or more indoor unit.

DIY auto mode: Adjust the last fixed operation mode automatically.

Turbo mode: Quick cooling or heating

Auto restart: Automatic return to previous operation conditions after sudden power blackout

24 hours timer: Use the timer function to set on,or off,or from on to off,or from off to on.

Intergr

ative valve cover:The valve cover is Intergrative.

2-way piping design: The pipe can shoot out both from left or right side.

Easy clean design: The panel is easy to wash and the airflow vents can be detached easily

Double 8 display:The display is Double 8 mode.

Page 10

Specifications

Domestic air conditioner

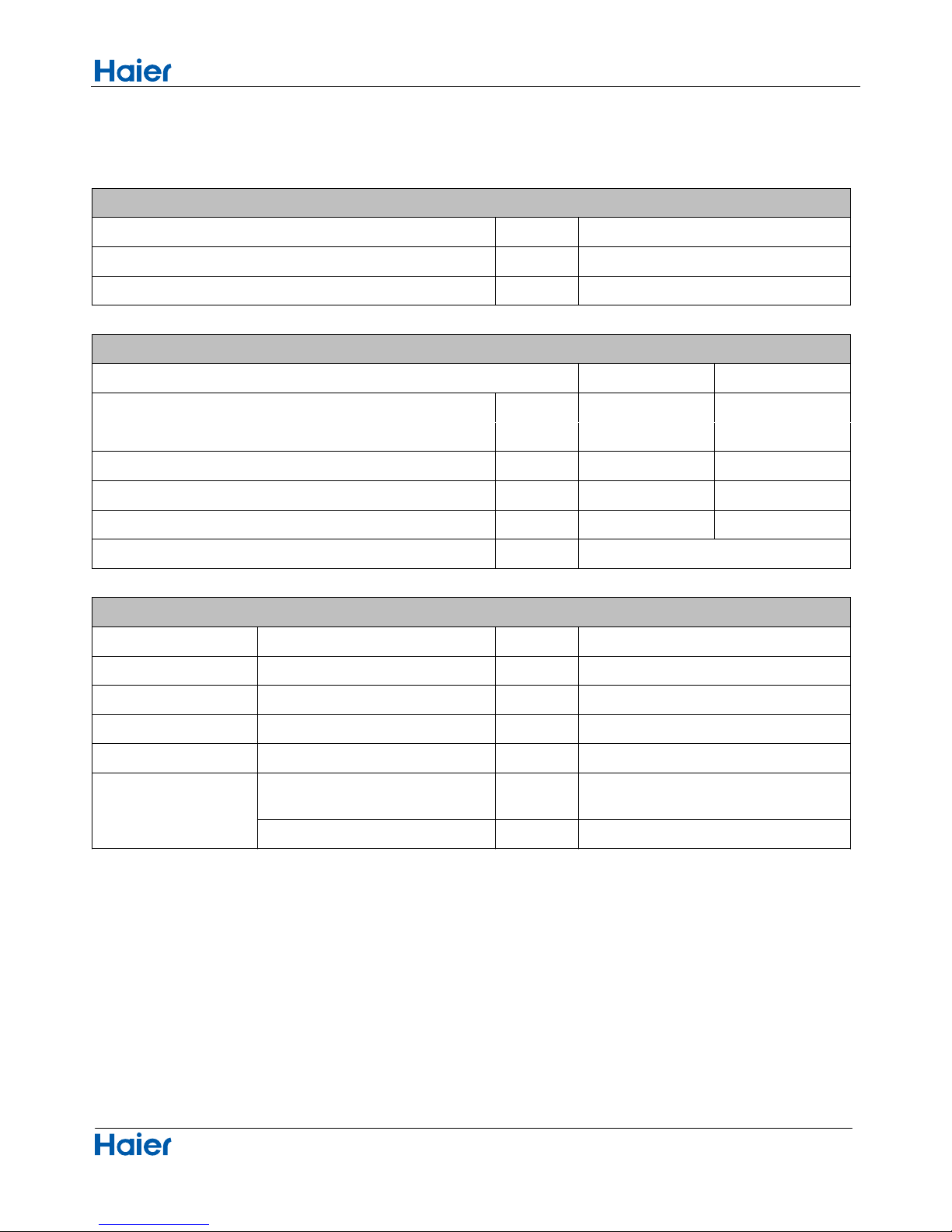

3 Specifications

NOMINAL DISTRIBUTION SYSTEM VOLTAGE

1/esahP

05zHycneuqerF

032VegatloV

NOMINAL CAPACITY and NOMINAL INPUT

cooling heating

Capacity rated

Btu/h

17000(4780-13300) 18000(5120-13990)

Power Consumption(Ra 50685222Btu)det

38/BtuBtuPOC/REE

hWKnoitpmusnocygrenelaunnA 999950 6252250

h/³inlavomeRerutsioM 70.62*10 ³

TECHNICAL SPECIFICATIONS

1.06×0.77×3.21inD*W*HsnoisnemiD

1.32×1.08×3.56inD*W*HsnoisnemiDdegakcaP

28.6lb/thgieW

35.2lb/thgiewssorG

etihW//roloC

Sound level

Sound

peessure(high/medium/low)

dB

Sound power(high) dB

8

-

57/54/51

38

/

Page 11

Specifications

Domestic air conditioner

TECHNICAL SPECIFICATIONS-PARTS

cooling heating

Fan

nafwolfssorCepyT

136.5WtuptuorotoM

Air flow rate(high) in³/h 31779 31779

Speed(high/middle/low) rpm 950/850/750 900/ 800/700

Heat exchanger

Type

ML fin-φ7HI-HX tube

4.1*81*3hctif*egats*tnemgeS

hgiRlortnocnoitceridriA t,Left,Horizontal,Downward

Air filter

Removable/Washable/Mildew Proof

Temperature control

Microcomputer Control

HD01-RYledomrellortnocetomeR

Note: the data are based on the conditions shown in the table below

htgnelgnipiPgnitaehgnilooc

16.4in

4.Sensors list

type Description Qty

1erutarepmetmoorgnitcetedrofdesustIrosnesmooR

Pipe sensor Its used for detecting temperature of evaporator 1

Conversation formulae

Kcal/h= KW×860

Btu/h= KW×3414

cfm=m³/min×35.3

9

136.5

Indoor:

80.6°

F

DB/66.2°

F

W B

Outdoor: 95°

F

DB/75.2°FW B

Indoor:68°

F

D B

Ou t doo r: 44.6°

F

D B / 42.8°

F

W B

Page 12

Piping diagrams

Domestic air conditioner

5.Pinping diagrams

10

Page 13

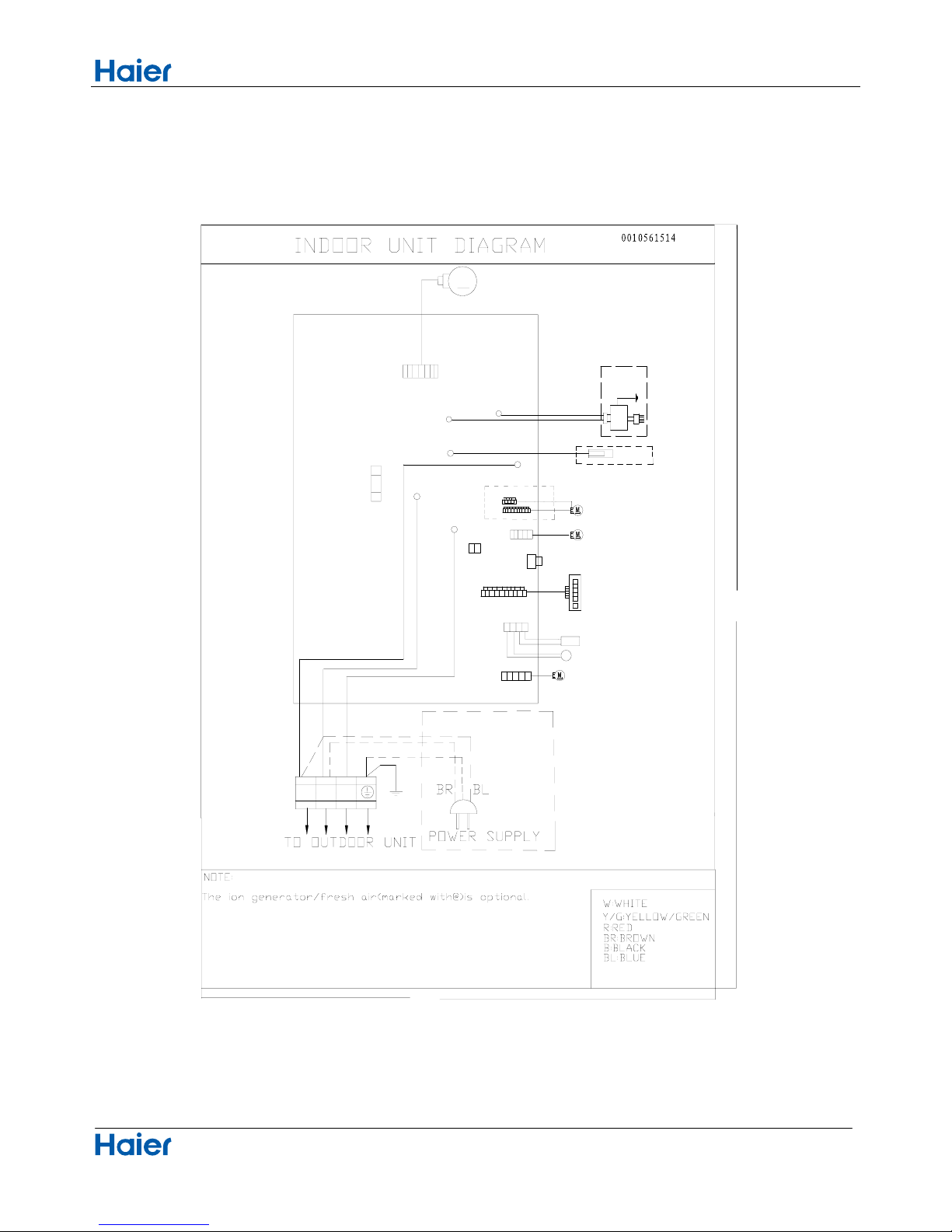

Connector Wiring diagrams

Domestic air conditioner

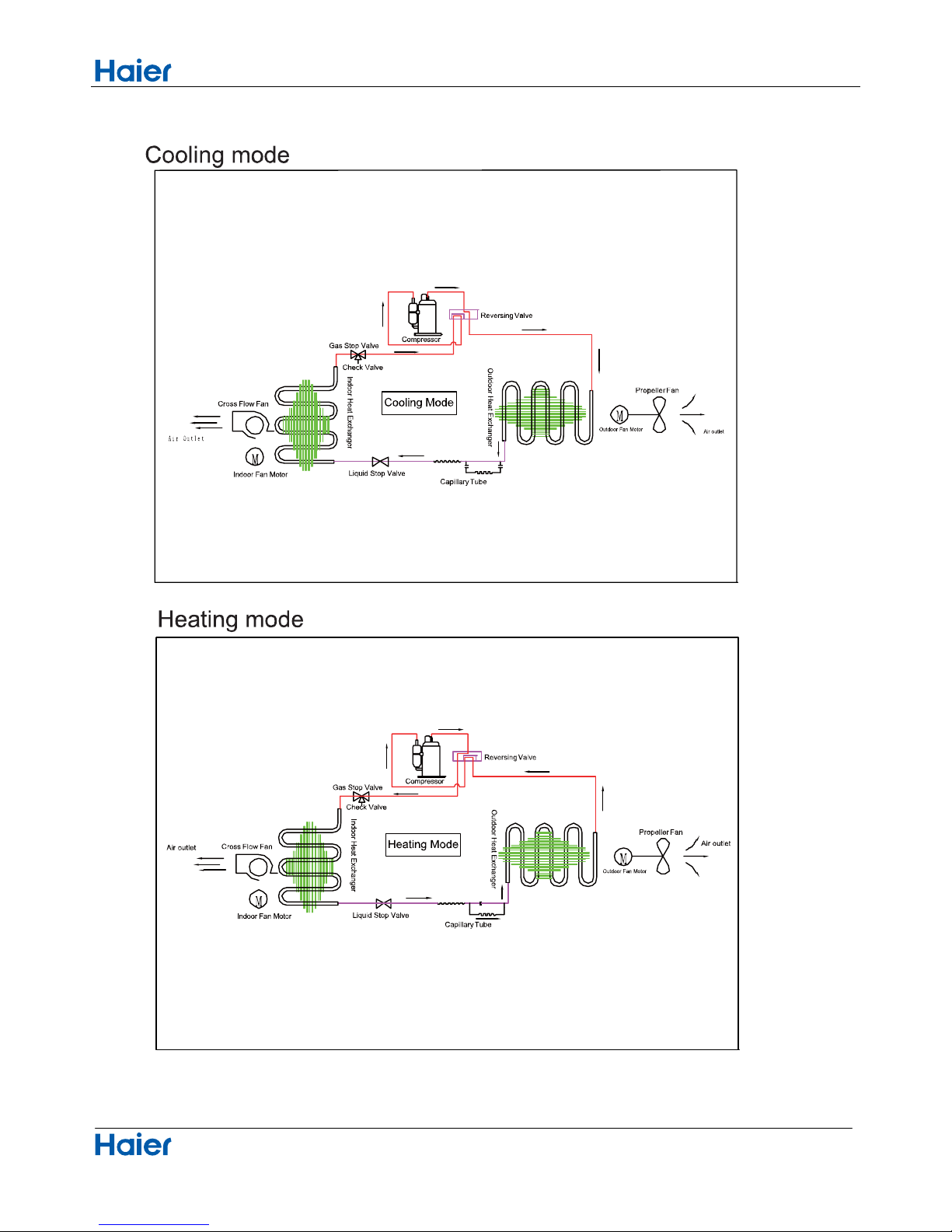

6. Printed Circuit Board Connector Wiring Diagram

11

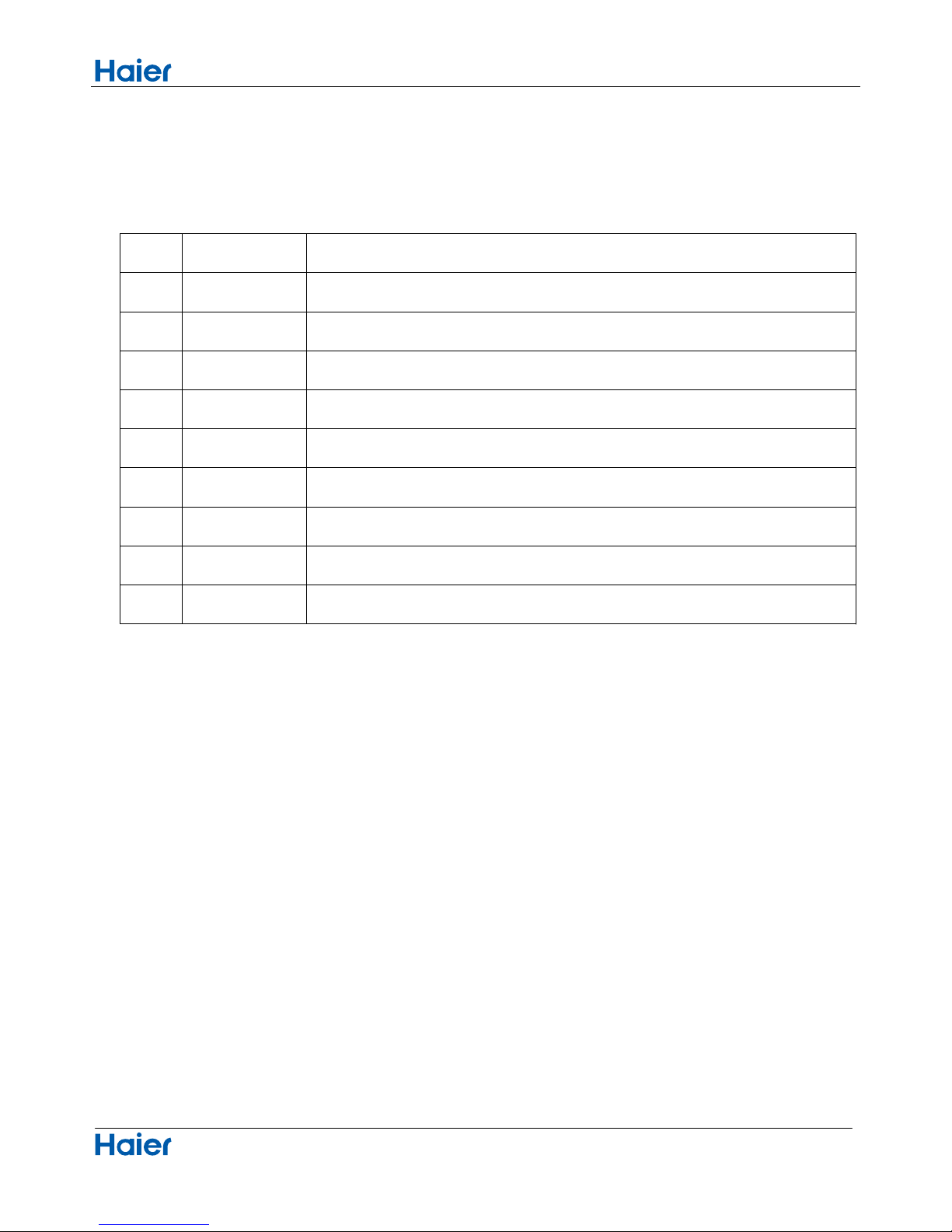

Connectors

PCB(1) (Control PCB)

daolhtiwtcennoC

rotcennocBCPseires

1 CN9

Connector for fan motor

2 CN6

Connector for heat exchanger thermistor and Room temperature thermistor

3

CN5

Connector for UP&DOWN STEP motor

4 CN21

Connector for power N wire

5 CN52

Connector for power L

6 CN27

7 CN7

8 CN23 Connector for communicate between the indoor board and the outdoor board

9 CN34

Connector for power GRN

Connector for display board

Note: Other designations

PCB(1) (Indoor Control PCB)

1) CN14 Connector for Forced operation ON / OFF switch

2) SW2 1 Select remote code A or B,2 Select room card able or disable , 3-4 Select 23,26,33,or 35

3) RV1 Varistor

4) FUSE1 Fuse 3.15A/250VAC

Connector for long-range control

Page 14

Connector Wiring diagrams

Domestic air conditioner

12

PCB(1)

C23

CN21

CN7

CN14

CN6

CN52

CN34

CN9

CN5

CN27

Page 15

Connector Wiring diagrams

Domestic air conditioner

Wiring diagrams

13

up-down stepmoter

ION GENERATIOR

Y/G

C0N2

C0N3

DC FAN MOTOR

M

FUSE1

SW1

EMERGENCY SWITCH

RECEIVER

DISPLAY

CN7

T3.15A/250V AC

80

120

1

(N)

(C)

3

(L)

2

W

B

Y/G

Y/G

GND

CN14

AMBIENT TEMP SENSOR

PIPING TEMP SENSOR

CN6

CN10

Right stepmoter

left stepmoter

CN11

CN5

CN5-1 CN5-2

R

C0N1

BL

Fresh air

(L)

CN21

N

S

CN51

Room card

R

W

@

@

CN9

CN52

CN23

Page 16

Functions and Control

Domestic air conditioner

7.Funcitions and Control

7.1 Main functions and control specification

7.1.1 Automatic operation

When the running mode is turned to automation after starting the system, the system will first determine

the running mode according to the current room temperature and then will run according to the determined

mode. Tr in the following selection conditions means room temperature, Ts means setting temperature, Tp

means temperature of indoor coil pipe

Tr 73.4°F Choose Cooling Mode

Tr

Choose Heating Mode

After turning to the automation mode, the running mode can be switched between cooling mode, fan

mode and heating mode according to the change of the indoor ambient temperature. But the automatic

conversion between cooling mode and heating mode must be conducted after 15 minutes.

7.1.2 Cooling operation mode

Temperature control range: 60.8°F---86°F

Temperature difference: 33.8°F/30.2°F

* Control features: When Tr

input airflow >Ts set temperature °F, the compressor will be opened, the indoor

fan will operate at the set speed and the mode signal will be sent to the outdoor system. When Tr

input

airflow

Ts set temperature °F, the compressor will be opened, the indoor fan will operate at the set speed

and the mode signal will be sent to the outdoor system. The system will keep the original status if Tr= Ts.

Airflow speed control: (temperature difference 33.8°F)

Automatic: When Tr

Ts+37.4°F, high speed.

When Ts+33.8°F

Tr<Ts+37.4°F, medium speed

When Tr<Ts+33.8°F , low speed

When the sensor is off, low speed

When the airflow speed has no delay from the high to low switching, the speed should be delayed for 3

minutes (remain at high speed for 3 minutes.) before the next switch.

Manus: When the system is operating, you can set the high, medium or low speed manually. (When the

sensor is on or off, the system will change the speed 2 seconds after receiving the signal.)

*Airgate location control: the location for the airgate can be set according to your needs.

*Defrosting function: preventing the frosting on the indoor heat exchanger (when cooling or dehumidifying).

When the compressor works continuously for 1/6 minutes (adaptable in EEPROM) and the temperature of

the indoor coils has been below zero centigrade

for 10 seconds, the compressor will be stopped and the

malfunction will be recorded in the malfunction list. The indoor system will continue to run. When the

temperature of the indoor coil is raised to 46°F, the compressor will be restarted again (the requirement of 3

minutes’ delay should be satisfied.)

* timing system on/off function.

* Dormant control function.

14

73.4°F

Page 17

Functions and Control

Domestic air conditioner

7.1.3 Dehumidifying mode.

* temperature control range:

60.8---86 F

* temperature difference:

30.2/33.8°F

Control feature: send the dehumidifying signal to the outdoor system.

When Tr>Ts+35.6°F , the compressor will be turned on, the indoor fan will operate at the set speed.

When Tr is between the Ts and Ts+35.6°F , the outdoor system will operate at the high dehumidifying

frequency for 10 minutes and then at the low dehumidifying mode for six minutes. The indoor fan will

operate at low speed.

When Tr< Ts, the outsystem will be stopped, the indoor fan will be stopped for 3 minutes and then turned to

the low speed option.

All the frequency converses have a 30.2/33.8°F difference.

* Wind speed control: Automatic:

When Tr

Ts+41°F , high speed.

When Ts+37.4°F Tr< Ts+41°F , medium speed.

When Ts+35.6°F Tr< Ts+37.4°F, low speed.

When Tr<Ts+35.6°F, light speed.

If the outdoor fan stopped, the indoor fan will be paused for 3 minutes.

If the outdoor fan stopped for more than 3 minutes and the outdoor system still operates, the system will be

changed into light speed mode.

When the airflow speed has no delay from the high to low switching, the speed should be delayed for 3

minutes (remain at high speed for 3 minutes.) before the next switch.

Manual: When the sensor is off or Tr< Ts+37.4°F, the manual operation can not be made. (obligatory automatic

operation.)

*Airgate location control: the location for the airgate can be set according to your needs.

*Defrosting function: preventing the frosting on the indoor heat exchanger (when cooling or dehumidifying).

When the compressor works continuously for 1/6 minutes (adaptable in EEPROM) and the temperature of

the indoor coils has been below zero centigrade for 10 seconds, the compressor will be stopped and the

malfunction will be recorded in the malfunction list. The indoor system will continue to run. When the

temperature of the indoor coil is raised to 44.6°F, the compressor will be restarted again (the requirement of 3

minutes’ delay should be satisfied.)

* Coil protection (synchronic overheating protection) are installed for the four directions latch malfunctions

when dehumidifying.

* Timing system on/off function.

* Dormant control functio

n.

7.1.4 Heating operation mode.

*

temperature control range: 60.8---86 F

* temperature difference: 30.2/33.8°F

* control feature: the temperature compensation is automatically added and the system will send the heating

signals to the outdoor system.

If Tr

Ts, the outdoor compressor is turned on, the indoor fan will be at the cold air proof mode.

If Tr>Ts+35.6°F, the outdoor system is turned off, the indoor fan will be at the heat residue sending mode.

If Tr<Ts+35.6°F, the outdoor system will be turned on again, the indoor fan will be at the cold air proof mode.

15

<

<

Page 18

Functions and Control

Domestic air conditioner

*Indoor fan control

manual control: You can choose high, medium, low and automatic speed control.

Automatic: When Tr<Ts, high speed.

When Ts

Tr Ts+35.6°F, medium speed.

When Tr> Ts+35.6°F, low speed.

When the airflow speed has no delay from the high to low switching, the speed should be delayed for 3

minutes (remain at high speed for 3 minutes.) before the next switch.

*Airgate location control: the location for the airgate can be set according to your needs.

Coldair proof operation

1. The indoor operation within 4 minutes after the start up is as the following diagram, the air speed can be

raised only after the speed has reached a certain level.

2. 4 minutes after the start up of the indoor fan, the light airflow and the low airflow will be turned to the set

speed airflow.

3. In the cold air proof operation, the fan won’t stop after the start up.

4. During the cold air proof operation, the indoor system will continuously send ‘indoor high speed’ signals to

the outdoor system.

* Resi

due heat sending. The indoor fan will send the residue heat at a low speed for 12 seconds.

If other conditions are satisfied, when the compressor stops, the indoor system will operate at a light speed.

The indoor fan will stop when the coil temperature is below the ‘heat start temp 4’.

* Defrosting. When the system receives the defrosting signal from outdoors, the indoor fan will stop and the

indoor temperature display won’t change. At the time, any indoor coil malfunctions will be neglected. When

the outdoor defrosting finishes, the coil malfunction will still be neglected until the compressor has been

started up for 30 seconds. The indoor temperature display will not change and the system operates at the

cold air proof mode.

* Automatic heating temperature compensation: when the system enters the heating mode, the temperature

compensation (4) will be added. When the status is switched off, the compensation will be erased.

7.1.5 Strength operation

The system enters the mode after receiving the ‘strength signal’.

Send strength operation signal to the outdoor system.

The mode change finishes the strength operation.

Entering ‘mute’, you can have normal operation or signal control such as timing to finish the strength

operation.

When the system is at the automatic option with the strength/ mute function, if the system enters the cooling

Heat start temp 1

Heat start temp

2

Heat start temp

3

Heat start temp

4

Set speed

Low speed

Light speed

Fan/off

Fan/off

Keep the hig

h

speed. The fa

n

doesn’t stop

16

Page 19

Functions and Control

Domestic air conditioner

mode, the cooling strength/ mute function will be offered; if the system enters the heating mode, then the

heating strength/ mute function will be offered; if the system enters the airflow mode, there will be no

strength/ mute function.

7.1.6 Mute operation

The system enters the mode after receiving the ‘mute signal’.

a. Mute heating: the airflow speed is slight, the system sends the mute signal to the outdoor system.

b. mute cooling: the airflow speed is slight, the system sends the mute signal to the outdoor system.

When the compressor operates, the airflow speed is mute speed. EEPROM is adaptable.

Mute operation can not work under the dehumidifying and airflow-sending operation.

7.1.7 Air refreshing

After receiving the signal from the remote control, (HV series: the background light of the ‘health’ logo is

green. HS series: the ‘health’ indicator will be lighted). If the fan operates, the Nano-Aqua operates to realize

the ions sending function.

If the indoor fan stops, the Nano-Aqua is turned off.

When the Nano-Aqua is turned off, if the air refreshing system is turned on, the Nano-Aqua will be turned on

when the fan operates.

7.1.8 Timing

You can set 24 hours’ on/off timing accordingly. After the setting, the timing indicator will be lightened. Also,

the light will be turning off after the timing is finished. The followings are several timing methods.

1.system /on timing: The timing indicator will be lightened and the indoor system is under the waiting mode.

The light will be turned off when the timing is finished and the rest of the system will operate under a normal

condition. The timing starts since the last reception of the timing signal.

2.system /off timing: When the system is turned on, the timing indicator is lightened, the rest of the system

will operated under a normal condition. When set time comes, the indicator light will be turned off and the

system will be turned off. If you have set the dormant functions, the order of your settings will be operated

according to the timing settings.

3 .system /on and off timing: The settings will be completed according to the orders..

7.1.9 Dormant operation

The dormant timing is an eight hours unadaptable one. The timing signs are shown on the V series board.

(RC series show the dormant signal, the timing light is lighted on the 6 lights board).

2.1 Under the cooling/ dehumidifying operation, after the setting of the dormant operation, the set

temperature will be raised for 1 centigrade after 1 hour’s operation and will be raised for 1 centigrade 1 hour

later. The system will keep this status for 6 hours and then close.

2.2 Under the heating mode, after the setting of the dormant operation, the setting temperature will fall 2

centigrade after 1 hour’s operation and will fall 2 centigrade 1 hour later. 3 hours after the preceding

operations, the set temperature will be raised for 1 centigrade and the system will keep this status for 3 hours

and then close down.

2.3 During the dormant time, except the change of the system mode or a new press on the dormant setting

17

Page 20

Functions and Control

Domestic air conditioner

keys, the timing of the 8 hours dormancy will take the first timing as the start time, any presses on other keys

will not affect the original timing.

2.4 Indoor fan control under the dormant operation.

If the indoor fan is at the high speed before the dormant operation setting, the speed will be turned to medium

after the setting. If the fan is at the medium speed before the dormant setting, the speed will be turned to low

after the setting. If the fan is at the low speed before the dormant setting, the speed will not change.

7.1.10 Urgent on/off input

Press the urgency button the buzzer will ring. The system will enter the automatic mode if you don’t press the

button for more than 5 seconds.

Under the system off mode, if you press the urgency key for 5 to 10 seconds, the system will start the test

operation.

Under the system off mode, if you press the urgency key for 10 to 15 seconds, the

display screen will show

the resume of the last malfunction.

If the system is under operation, the press on the urgency key will stop it.

Under the system off mode, the display screen will show automatic running sign.

Under the system off mode, the system will not receive the remote control signal if the press on the urgency

key doesn’t last for 15 seconds or if the key is loosened.

Urgency operation: If you press the urgency key for less than 5 seconds, the buzzer will ring when you press

the on/off key. The system will enter the urgency operation when the urgency key is loosened. The urgency

operation is fully automatic.

Test operation.

The inlet temperature sensor doesn’t work, the indoor fan and the indoor air direction board motor works

synchronically. High speed airflow, cooling, outdoor system on, etc, will send the ambient temperature 30

centigrade and coil temp

erature 16 centigrade information to the outdoor system.

Test operation

The defrost protection of the evaporator doesn’t work.

The temperature control doesn’t work.

The test operation will be finished in 30 minutes.

The test operation can be stopped by the relative commands from the remote control.

7.1.11 Low load protection control

In order to prevent the frosting of the indoor heat interaction device, the outdoor system will be stopped if the

indoor heat interaction temperature is below zero centigrade for 5 minutes, but the fan will continue to

operate. The outdoor system will be started again when the heat interaction temperature is above 7

centigrade and the system has been stopped for 3 minutes. The malfunction will be stored in the malfunction

resume and will not be revealed.

7.1.12 High load protection control

The outdoor system will be stopped if the coil temperature is above 149°F for 2 minutes. The indoor fan will be

controlled by the thermostat. The outdoor system can be restarted when the coil temperature is below 107.6°F

and the system has been stopped for 3 minutes. The malfunction will be stored in the malfunction resume

18

Page 21

Functions and Control

Domestic air conditioner

and will not be revealed.

7.1.13 Abnormal operation of indoor system

When the outdoor system operates, if the indoor system operation differs from the outdoor system, the

abnormal operation malfunction will be reported. 10s after the report, the indoor system will be closed.

Outdoor system mode Indoor system mode conflicts

cooling heating yes

cooling cooling no

cooling airflow no

heating heating no

heating airflow yes

heating cooling yes

7.1.14 Malfunction list resume.

Nothing is presented if there is no code list.

The malfunction display will automatically finish in 10 seconds.

The remote control only receives the signals for stop. According to the signals, the malfunction resume

presentation finishes.

The resume restores after the power supply restores.

7.1.15 Abnormality confirmation approaches

1. indoor temperature sensor abnormality:

Under the operation, the normal temperature ranges from 248°F to -22°F. When the temperature

goes beyond this range, the

abnormality can be confirmed. If the temperature goes back into the range, the

system will automatically resume.

2 .indoor heat interaction sensor abnormality:

Under the operation, the normal temperature ranges from 248°F to -22°F. When the temperature

goes beyond this range, the abnormality can be confirmed. If the temperature goes back into the range, the

system will automatically resume.

3 .indoor malfunction:

Out door malfunction: When the indoor system receives the outdoor malfunction codes, it will store the code

into E2 for the malfunction list resume. The indoor system will continue to operate according to the original

status, the malfunction code will not be revealed or processed.

4. transmission abnormality:

If the indoor system can’t receive the outdoor system for 8 minutes, the communication abnormality can be

confirmed and reported and the outdoor system will be stopped.

7.1.16 Single indoor system operation

* Enter condition: First, set the high speed airflow and 86°F set temperature, then press the dormant

keys for 6

times within 7 seconds, the system will feedback with 6 rings.

* After the system enters the separate indoor system operation mode, the indoor system will operate

19

Page 22

Functions and Control

Domestic air conditioner

according to the set mode and neglect the communication signals of the outdoor system. However, it has to

send signals to the outdoor system.

* Quitting condition: This mode can be quitted after receiving the quitting signal from the remote control or

urgency system. The indoor system thus can quit the single operation mode.

7.1.17 Power cut compensation

* Entering condition: Press dormant button 10 times within 7 second, the buzzer will ring 4 times and the

present system status will be stored into the EEPROM of the indoor system.

* After entering the power cut compensation mode, the processing of the indoor system should be as the

followings:

Remote control urgency signal: operate according to the remote control and the urgent conditions, the

present status will be stored into the EEPROM of the indoor system.

* Quitting conditions: Press dormant button 10 times within 7 seconds and the buzzer will ring twice.

7.1.18 Fixed frequency operation

1. Fixed cooling: a. under G code condition: high speed cooling, set 60.8°F , press temperature ‘-‘ key and the

set key at the same time. The system will enter the fixed frequency operation after the buzzer rings twice.

b. The proceeding programs are as the follows:

Entering the fixed frequency operation, you can set the fixed strength location 1 and send the cooling signal

to the outdoor system. Meanwhile, you can fix the indoor system at high speed mode, the location of the

airflow direction board can be switched to the maximal position.

c. Quitting condition: The fixed frequency cooling can be quitted after receiving the remote signal, and the

system will enter the remote setting status.

2. Fixed heating: a. under G code condition: high speed heating, set 86°F, press temperature ‘+‘ key and the

set key at the same time. The system will enter the fixed frequency operation after the buzzer rings twice.

b. The proceeding p

rograms are as the follows:

Entering the fixed frequency operation, you can set the fixed strength location 1 and send the heating signal

to the outdoor system. Meanwhile, you can fix the indoor system at high speed mode, the location of the

airflow direction board can be switched to the maximal position.

c. Quitting condition: The fixed frequency heating can be quitted after receiving the remote signal, and the

system will enter the remote setting status.

7.1.19 Test program

First, connect the test program terminal on the mainboard. Then connect the system to the power circuit. The

test program will operate as follows.

HV series display: The buzzer rings for one time—the signal will be sent to outdoor system for 0.5 second—

the violet is sent for 0.5-- the background light turns to white—the back ground light turns to white—the

background light turns to white—the background li

ght is fully lighted for 0.5 second—LED screen lights for

0.5 second— the step-in motor fully output for 0.5 second—then the motor doesn’t output for 0.5

second—the motor fully output again for 0.5 second. The test program finishes.

20

Page 23

Functions and Control

Domestic air conditioner

7.1.20 Time cutting function:

Connect the test program terminal on the mainboard after connecting the system to the power circuit. The

CPU of the main control will be 60 times faster.

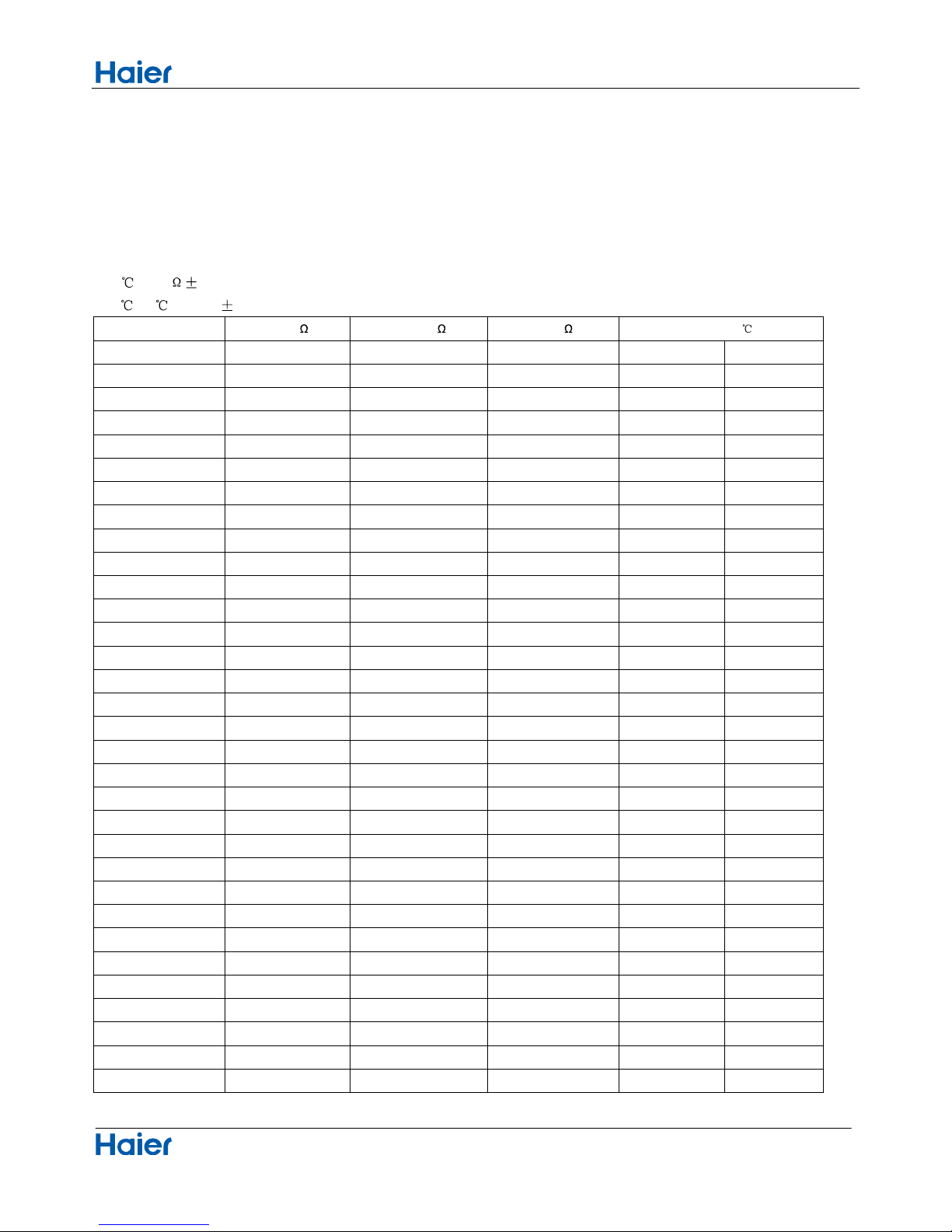

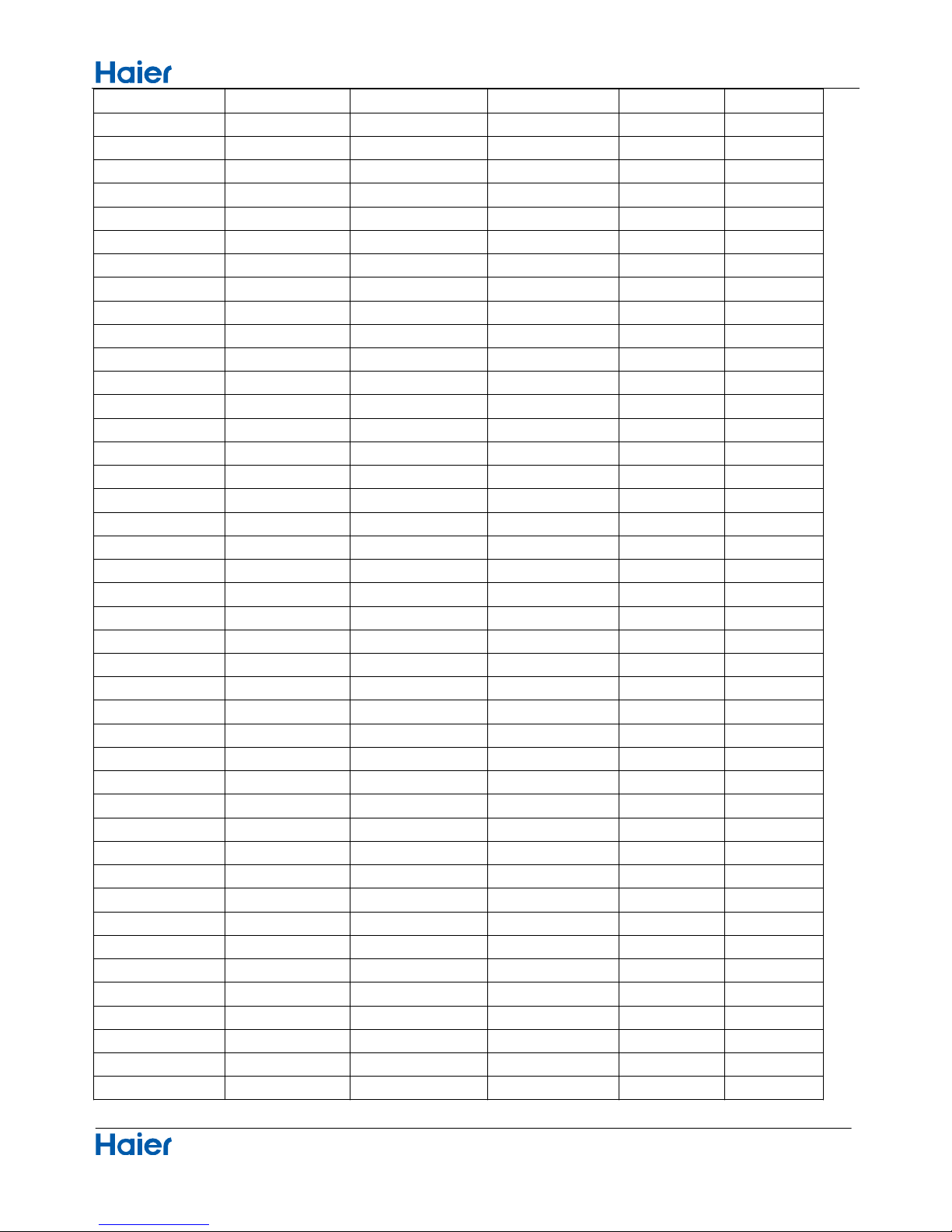

7.2 Value of thermistor

Room sensor and Pipe Sensor

R25 =10K 3%

B25

/50 =3700K 3%

Temp.(( °F ))

Max.(K

) Normal(K ) Min.(K )

Tolerance(

)

-22 165.2170 147.9497 132.3678 28.51 35.15

-20.2 155.5754 139.5600 125.0806 28.53 35.13

-18.4 146.5609 131.7022 118.2434 28.56 35.11

-16.6 138.1285 124.3392 111.8256 28.60 35.08

-14.8 130.2371 117.4366 105.7989 28.63 35.06

-13 122.8484 110.9627 100.1367 28.67 35.04

-11.2 115.9272 104.8882 94.8149 28.71 35.01

-9.4 109.4410 99.1858 89.8106 28.74 34.99

-7.6 103.3598 93.8305 85.1031 28.76 34.95

-5.8 97.6556 88.7989 80.6728 28.80 34.93

-4 92.3028 84.0695 76.5017 28.83 34.92

-2.2 87.2775 79.6222 72.5729 28.87 34.88

-0.4 82.5577 75.4384 68.8710 28.90 34.86

-1.4 78.1230 71.5010 65.3815 28.94 34.83

-3.2 73.9543 67.7939 62.0907 28.98 34.79

-5 70.0342 64.3023 58.9863 29.01 34.77

-6.8 66.3463 61.0123 56.0565 29.05 34.74

-8.6 62.8755 57.9110 53.2905 29.08 34.72

-10.4 59.6076 54.9866 50.6781 29.12 34.68

-12.2 56.5296 52.2278 48.2099 29.16 34.65

-14 53.6294 49.6244 45.8771 29.19 34.63

15.8 50.8956 47.1666 43.6714 29.23 34.59

17.6 48.3178 44.8454 41.5851 29.28 34.56

19.4 45.8860 42.6525 39.6112 29.32 34.52

21.2 43.5912 40.5800 37.7429 29.35 34.50

23 41.4249 38.6207 35.9739 29.39 34.47

24.8 39.3792 36.7676 34.2983 29.43 34.43

26.6 37.4465 35.0144 32.7108 29.46 34.39

28.4 35.6202 33.3552 31.2062 29.52 34.36

30.2 33.8936 31.7844 29.7796 29.55 34.32

32 32.2608 30.2968 28.4267 29.59 34.30

33.8 30.7162 28.8875 27.1431 29.62 34.27

21

Page 24

Functions and Control

Domestic air conditioner

35.6 29.2545 27.5519 25.9250 29.68 34.23

37.4 27.8708 26.2858 24.7686 29.71 34.20

39.2 26.5605 25.0851 23.6704 29.75 34.16

41 25.3193 23.9462 22.6273 29.79 34.12

42.8 24.1432 22.8656 21.6361 29.84 34.09

44.6 23.0284 21.8398 20.6939 29.88 34.05

46.4 21.9714 20.8659 19.7982 29.93 34.02

48.2 20.9688 19.9409 18.9463 29.97 33.96

50 20.0176 19.0621 18.1358 30.00 33.93

51.8 19.1149 18.2270 17.3646 30.06 33.89

53.6 18.2580 17.4331 16.6305 30.09 33.85

55.4 17.4442 16.6782 15.9315 30.15 33.82

57.2 16.6711 15.9601 15.2657 30.18 33.78

59 15.9366 15.2770 14.6315 30.24 33.73

60.8 15.2385 14.6268 14.0271 30.27 33.69

62.6 14.5748 14.0079 13.4510 30.33 33.66

64.4 13.9436 13.4185 12.9017 30.36 33.62

66.2 13.3431 12.8572 12.3778 30.42 33.57

68 12.7718 12.3223 11.8780 30.45 33.53

69.8 12.2280 11.8126 11.4011 30.51 33.49

71.6 11.7102 11.3267 10.9459 30.54 33.44

73.4 11.2172 10.8634 10.5114 30.60 33.40

75.2 10.7475 10.4216 10.0964 30.65 33.35

77 10.3000 10.0000 9.7000 30.65 33.35

78.8 9.8975 9.5974 9.2980 30.63 33.37

80.6 9.5129 9.2132 8.9148 30.56 33.34

82.4 9.1454 8.8465 8.5496 30.49 33.49

84.2 8.7942 8.4964 8.2013 30.43 33.55

86 8.4583 8.1621 7.8691 30.36 33.62

87.8 8.1371 7.8428 7.5522 30.29 33.67

89.6 7.8299 7.5377 7.2498 30.24 33.75

91.4 7.5359 7.2461 6.9611 30.16 33.80

93.2 7.2546 6.9673 6.6854 30.09 33.87

95 6.9852 6.7008 6.4222 30.02 33.93

96.8 6.7273 6.4459 6.1707 29.97 34.00

98.6 6.4803 6.2021 5.9304 29.89 34.05

100.4 6.2437 5.9687 5.7007 29.82 34.12

102.2 6.0170 5.7454 5.4812 29.75 34.20

104 5.7997 5.5316 5.2712 29.68 34.25

105.8 5.5914 5.3269 5.0704 29.61 34.32

107.6 5.3916 5.1308 4.8783 29.53 34.39

109.4 5.2001 4.9430 4.6944 29.46 34.45

111.2 5.0163 4.7630 4.5185 29.39 34.52

22

Page 25

Functions and Control

Domestic air conditioner

113 4.8400 4.5905 4.3500 29.32 34.59

114.8 4.6708 4.4252 4.1887 29.25 34.65

116.6 4.5083 4.2666 4.0342 29.17 34.72

118.4 4.3524 4.1145 3.8862 29.10 34.79

120.2 4.2026 3.9686 3.7443 29.03 34.86

122 4.0588 3.8287 3.6084 28.94 34.92

123.8 3.9206 3.6943 3.4780 28.87 34.99

125.6 3.7878 3.5654 3.3531 28.80 35.06

127.4 3.6601 3.4416 3.2332 28.72 35.13

129.2 3.5374 3.3227 3.1183 28.63 35.20

131 3.4195 3.2085 3.0079 28.56 35.28

132.8 3.3060 3.0989 2.9021 28.49 35.33

134.6 3.1969 2.9935 2.8005 28.40 35.40

136.4 3.0919 2.8922 2.7029 28.33 35.47

138.2 2.9909 2.7948 2.6092 28.26 35.55

140 2.8936 2.7012 2.5193 28.17 35.62

141.8 2.8000 2.6112 2.4328 28.09 35.69

143.6 2.7099 2.5246 2.3498 28.00 35.76

145.4 2.6232 2.4413 2.2700 27.93 35.83

147.2 2.5396 2.3611 2.1932 27.84 35.91

149 2.4591 2.2840 2.1195 27.75 35.98

150.8 2.3815 2.2098 2.0486 27.68 36.05

152.6 2.3068 2.1383 1.9803 27.59 36.12

154.4 2.2347 2.0695 1.9147 27.52 36.21

156.2 2.1652 2.0032 1.8516 27.43 36.28

158 2.0983 1.9393 1.7908 27.34 36.36

159.8 2.0337 1.8778 1.7324 27.27 36.43

161.6 1.9714 1.8186 1.6761 27.18 36.50

163.4 1.9113 1.7614 1.6219 27.09 36.57

165.2 1.8533 1.7064 1.5697 27.00 36.64

167 1.7974 1.6533 1.5194 26.91 36.73

168.8 1.7434 1.6021 1.4710 26.82 36.81

170.6 1.6913 1.5528 1.4243 26.74 36.88

172.4 1.6409 1.5051 1.3794 26.65 36.95

174.2 1.5923 1.4592 1.3360 26.56 37.04

176 1.5454 1.4149 1.2942 26.47 37.11

177.8 1.5000 1.3721 1.2540 26.38 37.18

179.6 1.4562 1.3308 1.2151 26.29 37.27

181.4 1.4139 1.2910 1.1776 26.20 37.35

183.2 1.3730 1.2525 1.1415 26.11 37.42

185 1.3335 1.2153 1.1066 26.02 37.51

186.8 1.2953 1.1794 1.0730 25.92 37.58

188.6 1.2583 1.1448 1.0405 25.83 37.67

23

Page 26

Functions and Control

Domestic air conditioner

190.4 1.2226 1.1113 1.0092 25.74 37.74

192.2 1.1880 1.0789 0.9789 25.65 37.83

194 1.1546 1.0476 0.9497 25.56 37.90

195.8 1.1223 1.0174 0.9215 25.45 37.99

197.6 1.0910 0.9882 0.8942 25.36 38.07

199.4 1.0607 0.9599 0.8679 25.27 38.16

201.2 1.0314 0.9326 0.8424 25.16 38.23

203 1.0030 0.9061 0.8179 25.07 38.32

204.8 0.9756 0.8806 0.7941 24.98 38.39

206.6 0.9490 0.8558 0.7711 24.87 38.48

208.4 0.9232 0.8319 0.7489 24.78 38.55

210.2 0.8983 0.8088 0.7275 24.67 38.64

212 0.8741 0.7863 0.7067 24.58 38.73

213.8 0.8507 0.7646 0.6867 24.48 38.80

215.6 0.8281 0.7436 0.6672 24.39 38.89

217.4 0.8061 0.7233 0.6484 24.28 38.98

219.2 0.7848 0.7036 0.6303 24.19 39.06

221 0.7641 0.6845 0.6127 24.08 39.15

222.8 0.7441 0.6661 0.5957 23.97 39.24

224.6 0.7247 0.6482 0.5792 23.88 39.33

226.4 0.7059 0.6308 0.5632 23.77 39.42

228.2 0.6877 0.6140 0.5478 23.67 39.49

230 0.6700 0.5977 0.5328 23.56 39.58

231.8 0.6528 0.5820 0.5183 23.47 39.67

233.6 0.6361 0.5667 0.5043 23.36 39.76

235.4 0.6200 0.5518 0.4907 23.25 39.85

237.2 0.6043 0.5374 0.4775 23.14 39.94

239 0.5891 0.5235 0.4648 23.04 40.01

240.8 0.5743 0.5100 0.4524 22.93 40.10

242.6 0.5600 0.4968 0.4404 22.82 40.19

244.4 0.5460 0.4841 0.4288 22.71 40.28

246.2 0.5325 0.4717 0.4175 22.60 40.37

248 0.5194 0.4597 0.4066 22.50 40.46

24

Page 27

System configuration

Domestic air conditioner

8 System configuration

8.1System configuration

After the installation and test operation of the room air conditioner have been completed, it should be

operated and handled as described below. Every user would like to know the correct method of operation

of the room air conditioner, to check if it is capable of cooling(or heating) well, and to know a clever method

of using it. In order to meet this expectation of the users, giving sufficient explanations taking enough time

can be said to reduce about 80% of the requests for servicing. However good the installation work is and

however good the functions are, the customer may blame either the room air conditioner or its installation

work because of improper handling. The installation work and handing over of the unit can only be

considered to have been completed when its handling has been explained to the user without using

technical terms but giving full knowledge of the equipment.

8.2 Instruction

25

Page 28

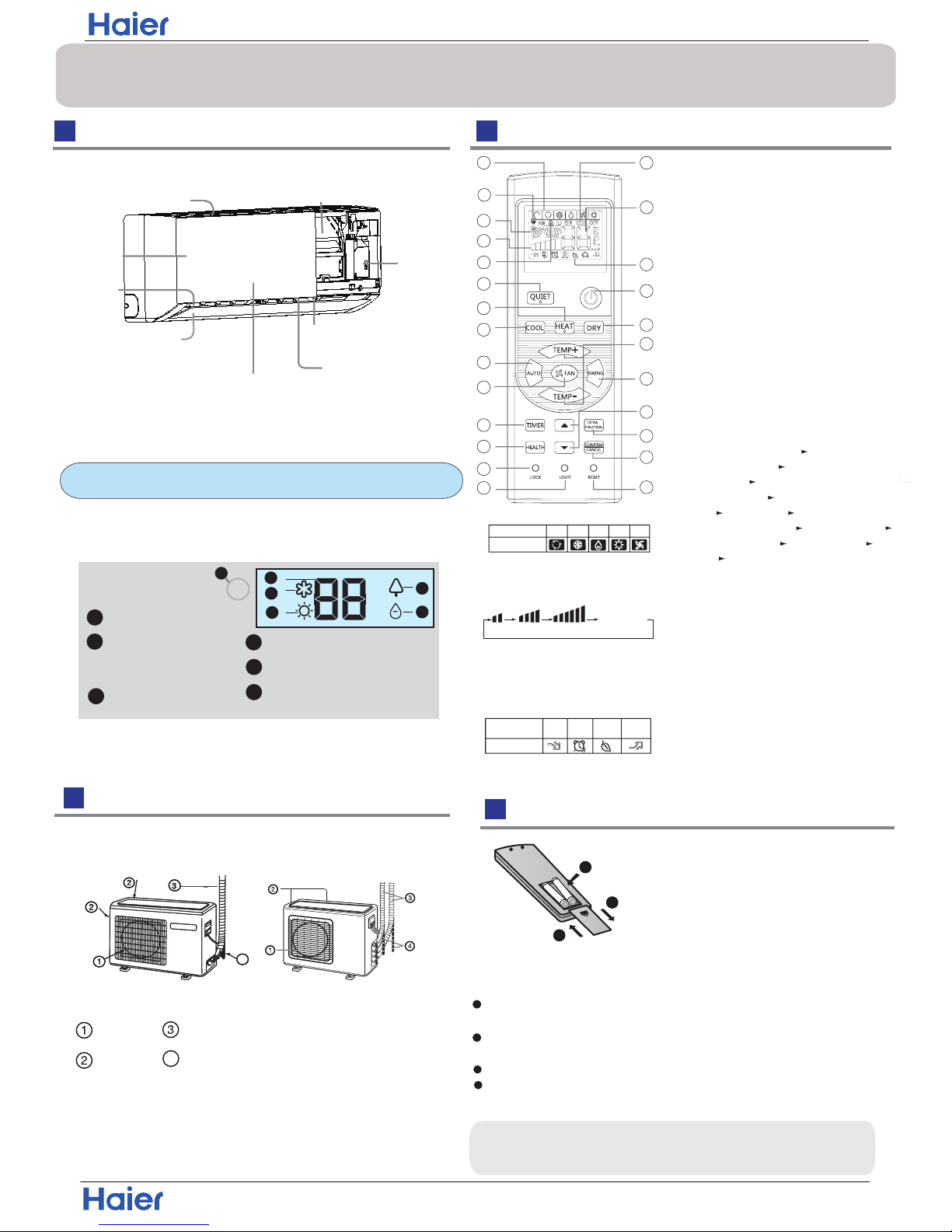

Display board

Signal receiver hole

COOL display

HEALTH display

4

2

3

1

5

DRY display

6

Ambient temp.display

When receiving the remote

control signal, display the set

temperature.

2

3

5

6

4

HEAT display

1

Outlet

Horizontal flap

Display board

(adjust up and down air flow

Don't adjust it manually)

(adjust left and

ow)

Vertical blade

Emergency

Switch

right air fl

Inlet

Air Purifying Filter

(inside)

Inlet grille

Anion generator

(inside)

(inside)

Actual inlet grille may vary from the one shown in the

manual according to the product purchased

The unit pictured above is for reference only.

Your product may appear different.

4

Outdoor Unit

4

Inserting the Battery

Parts and Functions

Indoor Unit

OUTLET

INLET

CONNECTING PIPING AND ELECTRICAL WIRING

DRAIN HOSE

Remote Control

Hint:

Remove the batteries if the unit won't be in use for a long period. If

there is any display after taking-out the batteries, just press reset key.

1. Mode display

2. Signal sending display

4. FAN SPEED display

5. LOCK display

6. TIMER OFF display

TIMER ON display

LO MED HI

7.TEMP display

16. LOCK button

Used to lock buttons and LCD display.

25. RESET button

If the remote is not functioning properly,

use a pen point or similar object to

depress the button to reset the remote

22. HOUR button

Operation mode

NAFOTUA COOL DRY

Remote controller

HEAT

1

2

3

4

5

9

10

11

12

13

14

15

16

17

22

23

24

25

19

20

21

8

18

7

6

Control the lightening and extinguishing

of the indoor LED display board.

3. SWING display

8

.

9. QUIET button

10. HEAT button

11. COOL button

12. AUTO button

13. FAN button

14. TIMER button

15. HEALTH button

17. LIGHT button

18. POWER ON/OFF button

19. DRY button

20. TEMP button

21. SWING button

23. EXTRA FUNCTION button

24.CANCEL/CONFIRM button

AUTO

Function: Setting and cancel to the

timer and other additional functions.

Display

circulated

Operation mode

Remote controller

QUITE

POWER

SLEEP

HEALTH

Additional functions display

Healthy function is not available for some units.

1

2

3

4

Remove the battery cover;

Insert the batteries as illustrated.

2 AAA batteries.

+ -.

Then put on the cover again.

Note:

1

2

3

Be sure battery polarity is

correct

The distance from the remote to the receiver should be less than

23 feet (7 meters) with no obstructions.

Fluorescent lights or cordless telephones will reduce the range

of the remote.

If the display is dim the remote batteries may need to be replaced.

Remote malfunctions can sometimes be corrected by removing

the batteries for a few minutes and then replacing them.

Function:Fan Mode— Healthy

airflow upwarder — Healthy airflow

downwarder— Reset the healthy

airflow position — Right & left airflow

setting— A-B yard— 50

°F

low

temperature heating— Sleep Mode—

Electrical Heating— Refresh Air—

Power — Fahrenheit/Celsius mode

shift on unit and remote

Remark:A-B yard, Right & left airflow

setting, 50

°F low temperature heating,

Electrical Heating, Refresh Air functions

are not available for this mini split series.

Installation

Domestic air conditioner

26

Page 29

Operation

Air Flow Direction Adjustment

Press FAN button. For each press, fan speed

follows:

Remote controller:

Press

button

Every time the button is pressed, temp.setting

increase 1

o

C / 2 F, if kept depressed, it will

increase rapidly

Every time the button is pressed, temp.setting

decrease 1

o

C / 2 F, if kept depressed, it will

decrease rapidly

Select a desired temperature.

4.Fan speed selection

3.Select temp.setting

The air conditioner will be running at the speed shown

in the display.

When FAN is set to AUTO, the air conditioner

automatically adjusts the fan speed according to room

temperature.

1. Unit start

Press ON/OFF on the remote controller, unit starts.

/

Basic Operation

at air outlet if all vertical louvers are

right.

Note:

changes as

COOL/DRY:

HEAT:

Initial state

o

Beep-Beep

stereoscopic air flow

Display

circulated

LOW

MED HI

AUTO

Remote controller

1.Status display of air flow

When restarting the unit after it has been turned off,

the unit will keep the swing position before it stops

working.

2.Left and right air flow adjustment

(manual)

Cautions:

When adjusting the louver by hand,turn off the unit.

When humidity is high,condensate water might occur

adjusted to left or

It is advisable not to keep horizontal louver at

downward position for a long time in COOL or DRY

mode ,otherwise, condensate water might occur.

Emergency Operation and Test Operation

Operation

Mode

Remote

Controller

Note

In DRY mode , when room temperature is 2 C/4 F degrees

o

less than the temperature set point, the unit will run

intermittently at LOW speed regardless of FAN setting.

Under the mode of auto operation, air conditioner will

automatically select Cool or Heat operation according to

room temperature. When FAN is set to AUTO the air

conditioner automatically adjusts the fan speed according

to room temperature.

In FAN operation mode , the unit will not operate in COOL or

HEAT mode but only in

FAN mode, AUTO is not available in

FAN mode. And temp. setting is disabled. In FAN mode,

sleep operation is not available.

Emergency Operation:

Use this operation only when the remote controller is defective

or lost, and with function of emergency running, air conditoner

can run automatically in few seconds.

When power switch is turned on for the first time and

emergency operation starts, the unit will run automatically in

the following modes:

Room

temperature

Designated

temperature

Timer

mode

Fan

speed

Operation

mode

Above 23℃/73℉ 26℃ / 79℉

Below 23℃/73℉ 23℃ / 73℉

No

AUTO

AUTO

COOL

HEAT

No

During emergency operation it is impossible to change the

settings of temp. and fan speed,It is also not possible to

operate in Timer or Dry mode.

the room

temperature is below 16

℃ / 60℉

,

Test Operation:

Use this switch in the test operation when

do not use it in the normal operation.

Test ope ration switch is the same as emergency switch.

Under this operation mode,the fan motor of indoor

unit will run in high speed.

1

4

3

3

2. Select operation mode

2

COOL button:Cooling mode

HEAT button: Heating mode

DRY button: Dehumidify mode

Beep

DRY

COOL

AUTO

HEAT

FAN

In HEAT mode, warm air will blow out after a short

period of the time due to cold-draft prevention function.

When FAN is set to AUTO, the air conditioner automatically

adjusts the fan speed according to room temperature.

When the emergency operation switch is pressed, the unit

beeps once, which starts the operation.

from the switch: the cooling operation

Continue to press the test operation

switch for more than 5 seconds.After

you hear two beeps, release your finger

starts with the air flow speed "HI".

Move the vertical louver by a knob on air

to adjust left and right direction to achieve

stereoscopic air flow as the figure below.

conditioner

o

o

Installation

Domestic air conditioner

27

Page 30

Operation

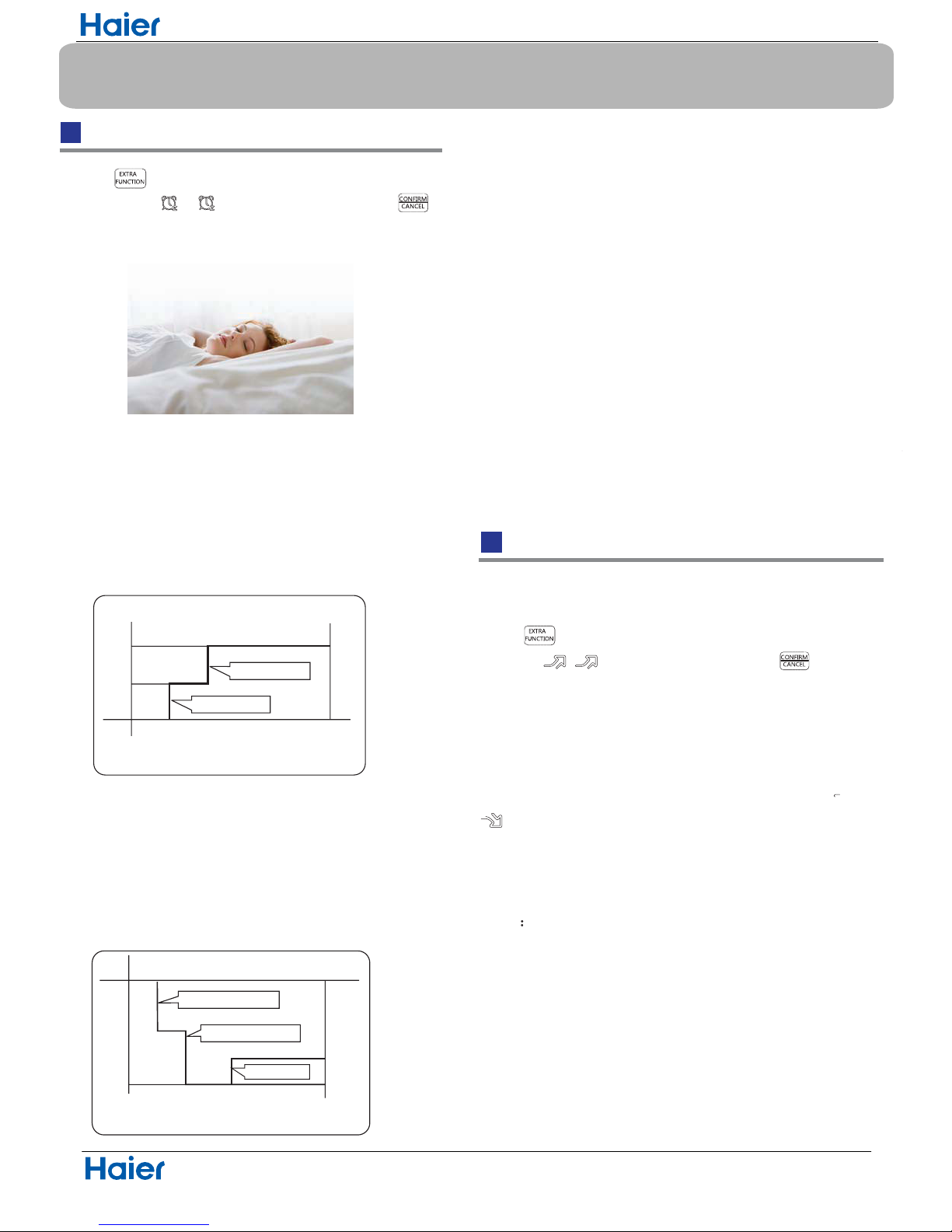

Sleep Operation

5.Fan Speed in Sleep Mode

When the unit is set to sleep mode, the fan speed

will be set to low speed and it cannot be changed.

Operation Mode

1. In COOL,DRY mode

SLEEP operation starts SLEEP operation stops

SLEEP

operation starts

SLEEP

operation stops

Approx.6hrs

1 hr

1 hr

1 hr

3 hrs

3 hrs

Rises 1OC/ 2 F

Rises 1

O

C/ 2 F

Rises 1OC/ 2 F

Temp.setting

Temp.setting

Unit stop

Unit stop

In COOL, DRY mode

In HEAT mode

Decreases 2OC/ 4 F

Decreases 2

O

C/ 4 F

1 hr

2.

3.

In HEAT mode

In AUTO mode

4. In FAN mode

It has no SLEEP function.

Note

When TIMER function is set, the sleep function can’t be

set up .After the sleep function is set up, if user set up

TIMER function, the sleep function will be cancelled; the

machine will be in the state of timing-on.

Power/Quiet Operation

1 hour after SLEEP mode starts,temp.will become

higher than temp.setting.After another 1 hour,temp.rises

by 1 / 2 F futher. The unit will run for an additional 6

hours then stops Temp. is higher than temp.setting so

that room temperature won’t be too low for your sleep.

1 hour after SLEEP mode starts,temp will become 2

4 F lower than temp.setting.After another 1 hour,temp

decrease by 2

C / 4 F futher.After more another 3 hours,

temp.

rises by 1 C / 2 F futher.The unit will run for an

additional 3 hours then stops.Temp.is lower than temp.

setting so that room temperature won’t be too high for

your sleep.

If the unit is running cooling, the sleep mode will follow

the function as in cool mode, while follow as in heat mode.

O

C

O

O

1

O

C/2 F

O

C /

Press button to enter additional options, cycle

the display to , will flash. And then press

enter for sleep function.

(1)

Power Operation

(2)

Quiet Operation

Note

When you need rapid heating or cooling, you can use this function.

You can use this function when silence is needed for rest or

Running the unit in QUIET mode for a long period may

cause the room temperature to not reach the set

temperature. If this occurs, cancel QUITE mode and set

the fan speed to a higher setting.

reading.Press QUIET button, the remote controller will show

, and then achieve to the quiet function. To cancel this

function, press the QUIET button.

Press button to enter additional options, cycle the

display to , will flash,and then press ,enter to

power function. To cancel this function, please select a

different option.

O

O

O

O

O

O

O

O

O

O

Installation

Domestic air conditioner

28

Page 31

Operation

1.After unit starts, select your desired operation mode.

2.Press TIMER button to change TIMER mode. Every

time the button is pressed, display changes as follows:

Remote controller:

BLANK

TIMER ON TIMER OFF TIMER ON-OFF

Then select your desired TIMER mode (TIMER ON or

TIMER OFF or TIMER ON-OFF). " "or " "will flash.

3.Press / button to set time.

It can be adjusted within 24 hours.

Hints:

After replacing batteries or a power failure happens, time

setting should be reset.

According to the Time setting sequence of TIMER ON or

TIMER OFF, either Start-Stop or Stop-Start can be achieved.

Timer On/Off On-Off Operation

Healthy Airflow Operation

1.Press to start

Setting for comfortable conditions.

2.The setting of healthy airflow function

Note:

1.After setting the healthy airflow function, the position

louver is fixed.

4.In cooling and dry, using the air conditioner for a long

time under the high air humidity, condensate water may

occur at the grille .

3.To cancel of the healthy airflow function

Notice: Do not direct the horizontal louver by hand. This

may cause the louver to run incorrectly and not match the

display. If the louver is not running correctly, stop the unit

for a minute and then restart and adjust remote

controller.

2.In heating, it is better to select the

3.In cooling, it is better to select the

mode.

mode.

TIMER OFF-ON

0.5h

0.5h 0.5h

0.5h

Press the button for each time, setting time in the first

12 hours increased by 0.5 hour every time, after 12

hours,increased by 1 hour every time.

Press the button for each time, setting time in the first

12 hours decreased by 0.5 hour every time, after 12

hours,decreased by 1 hour every time.

After adjusting the time,press button and confirm

the time the ON or OFF button will not flash any more.

4.Confirm timer setting

5.Cancel timer setting

Press the timer button until the time display eliminated.

Press button to enter additional options,Press this

button continuously, the louvers location will cycle between

the following three locations, to choose the swing location

what you want, then button to confirm.

Press button to enter additional options,Press this

button continuously, the louvers location will cycle between

the three locations again, then button to cancel.

Healthy

airflow

upwarder

Healthy

airflow

downwarder

Present

position

Domestic air conditioner

29

Installation

Page 32

Maintenance

Setting of proper room

temperature

Close doors and windows

during operation

If the unit is not to be used

for a long time, turn off the

power supply main switch.

Use the timer effectively

Use the louvers effectively

Do not block the air inlet

or outlet

Proper

temperature

During cooling operation

prevent the penetration

of

direct sunlight with

curtain or blind

OFF

Remote Controller Indoor Unit

1.Open the lnlet Grille

2.Detach the Standard Air Filter

3.Attach Air Purifying Filter

4.Attach the standard air filter

(Necessar

y installation)

5.Close the Inlet Grille

Close the inlet grille securely

Slide the knob slightly up

ward to

release the filter, then withdraw it.

Put air purifying filter into the

right and left filter frames.

NOTE:

The photocatalyst air purifying filter will be solarized in fixed

time. In normal use, it will be solarized every 6 months.

Prop up the inlet grille by using the

grille-support located an the right

ATTENTION:

Please keep the bacteria-killing medium air purifying filter

The bacteria-killing medium air purifying filter will be used

for a long time,no need for replacement. But in the period

of using them ,you should remove the dust frequently by

side of the indoor unit.

using vacuum cleaner or flapping them lightly,otherwise ,

its performance will be affected.

cool and dry. Avoid long term exposure to sunlight when not

in use as its ability to sterilize will be reduced.

For Smart Use of The Air Conditioner

Replacement of Air Purifying Filter

The white side of the photocatalyst air purifying filter

faces outside,and the black side faces the unit The green

side of the bacteria-killing medium air purifying filter faces

outside,and the white side faces the unit.

Do not use water, wipe the remote

with a dry cloth. Do not use glass

cleaner or a chemicals.

Wipe the air conditioner by using a

soft and dry cloth.For serious stains,

use a neutral detergent diluted with

water.Wring the water out of the

cloth before wiping,then wipe off the

detergent completely.

Air Filter Cleaning

Open the inlet grille by pulling it upward.

Remove the filter.

Clean the filter.

Attach the filter.

Close the inlet grille.

Push up the filter's center tab slightly until it is

from the stopper, and remove the filter do

wnw

ard.

Use a vacuum cleaner to remove dust, or wash the filter with

water.After washing, dry the filter completely before putting it back in

Attach the filter correctly so that the "FRONT" indication

facing to the front.Make sure that the filter is

fixed behind the stopper.If the right

attached correctly, that

Do not use the following for cleaning

Gasoline,benzine, thinner or cleanser

ay

damage the coating of the unit.

Hot water over 40

O

C(104OF) may

discoloring or deformation.

Once every

two weeks

m

cause

released

is

completely

and left filters are not

may cause defects.

Detach old Air Purifying Filter

the unit.

Installation

Domestic air conditioner

30

Page 33

the power supply cord.

2.

Do not install in the place where there is any

possibility of inflammable gas leakage around

the unit.

3.Do not get the unit exposed

to vapor or oil steam.

Cautions

Connect the earth

cable.

earthing

WARNING

If something abnormal occurs immediately

stop the operation button and contact service

technician.

OFF

Connect to a single

circuit outlet.

ENFORCEMENT

Connect power supply cord

to the outlet completely

Use the proper voltage

Do not use power supply

cord in a bundle.

Take care not to damage

the power supply cord.

1.Do not use extension cords or plug adapters.

STRICT

ENFORCEMENT

STRICT

STRICT

ENFORCEMENT

PROHIBITION

PROHIBITION

PROHIBITION

PROHIBITION

Do not start or stop the

operation by disconnecting

Do not channel the air flow directly

at people.

Do not attempt to repair the

unit. Call for an authorized

service technician.

Do not place or store any objects on the

indoor unit.

CAUTION

Take fresh air occasionally especially

when gas appliance is running at the

same time.

PROHIBITION

STRICT

ENFORCEMENT

Do not operate the switch with

wet hand.

PROHIBITION

PROHIBITION

PROHIBITION

PROHIBITION

PROHIBITION

Do not install the unit near a fireplace

or other heating apparatus.

Install the outdoor unit securely on a

base.

Do not pour water onto the unit

for cleaning

PROHIBITION

Do not place animals or plants in

the direct path of the air flow

Do not place any objects on or

climb on the outdoor unit.

Do not place flower vase or water

containers on the top of the unit.

Do not insert objects into the air inlet or outlet of

the outdoor unit..

PROHIBITION

PROHIBITION

PROHIBITION

STRICT

ENFORCEMENT

Check proper

installation of the

drainage securely

WARNING

Do not install the air conditioner by yourself improper installation may cause fire, water

This system must be installed by a qualified HVAC professional.

leakage, personal injury or death.

Domestic air conditioner

31

Installation

Page 34

Trouble shooting

Normal

performance

inspection

Noise is heard

Phenomenon

Cause or check points

The system

immediately.

Odors are present

Mist or steam are

Multiple

check

Poor cooling

When unit is stopped, it won't restart

elapsed to protect the system.

When the electric plug is pulled out

and reinserted, the protection circuit

During unit operation or at stop,

a swishing or gurgling noise may

(This noise is generated by

refrigerant flowing in the system.)

Should there be a big noise from

filter may be too dirty.

The system circulates any remaining

odors.

During COOL or DRY operation,

This is due to the sudden cooling

Is the power chord correctly position in

the outlet?

Is there a power failure?

Has a fuse or circuit breaker been

tripped?

Is the air filter dirty?

Are there any obstacles in front of

Is temperature set correctly?

Are there some doors or

Is there any direct sunlight

through the window during the

Are there too many heat sources or too

many people in the room during cooling?

In dry mode,

fan

speed can’t be

changed.

In DRY mode, when room temperature

setting+35.6

o

F,unit will run

regardless of FAN setting.

cooling operation?(Use curtain)

windows left open?

inlet and outlet?

Normally it should be cleaned

every 14 days.

intermittently at LOW speed

becomes lower than temp.

indoor unit may blow out mist.

of indoor air.

air flow in unit operation, air

be heard.At first 2-3 minutes after

unit start, this noise is more noticeable.

will work for 3 minutes to protect the

air conditioner.

immediately until 3 minutes have

Cautions

Do not obstruct or cover the ventilation

conditoner.Do not put fingers

inlet/outlet and

swing louver.

Do not allow children to play with the air

conditioner

case should children be

allowed to sit on the outdoor unit.

1.Applicable ambient temperature range:

Specifications

The machine is adaptive in following

situation

The power plug and connecting cable

acquired the local

2. If the power supply cord is damaged, it

must be replaced

manufacturer

3. All electrical wiring must be done to applicable local and state codes.

4. An electrical outlet must be within distance of the indoor unit.

5. When replacing batteries, the batteries removed should be disposed

of properly.

6. Assure that the proper outlet is being used with the power cord.

8. In order to protect the units,please turn off the unit first, wait 30

seconds and turn off the power.

7.

grille of the air

or any objects into the

.In no

or its service agent.

must have

Before calling for service, check the following

first.

blown out.

does not restart

by the

attestation.

The refrigerating circuit is a sealed system.

Cooling

Indoor

Maximum:D.B/W.B

Maximum:D.B/W.B

D.B

Maximum:D.B

D.B

Minimum:D.B/W.B

Maximum:D.B/W.B

Minimum:D.B/W.B

Outdoor

Indoor

Outdoor

Heating

89.6 /73.4

75 /65

115 /75

80.6

67 /57

Outdoor

Maximum:D.B/W.B

Minimum:D.B

5

(INVERTER)

32

Minimum:

Minimum:

67 /57

75 /65

19.4

Installation

Domestic air conditioner

32

Page 35

Drawing for the installation of indoor and outdoor units

Necessary Tools for Installation

●

Torque wrench

●

(0.67 in,0.87in ,1.02in)

Nipper

●

Reamer●

Hacksaw●

Pipe cutter●

Gas leakage detector or●

soap-and-water solution

Hole core drill●

Flaring tool●

Spanner(0.67,0.75 and 1.02in )●

Knife●

Measuring tape●

●

Selection of Installation Place

Power Source

Preparation

The above picture is for reference only. Your product may look different.

Read this manual before installation

Explain the operation of the unit to the user according to this manual

Installation Manual of Room Air Conditioner

F

A

C

E

D

Optional parts for piping

Non-adhesive tape

Adhesive tape

Saddle (L.S) with screws

Connecting electric cable

for indoor and outdoor

Drain hose

Insulating material

Piping hole cover

Floor fixing dimensions of the outdoor unit

Fixing of outdoor unit

Fix the unit to concrete or block●

with bolts

(10mm) securely.

When fitting the unit to wall

●

surface, roof or

rooftop, fix the unit securely in consideration

of

earthquake and strong wind.

If vibration may affect the

●

house, fix the unit

by attaching a

vibration-proof mat.

The marks from to

in the figure are the

name of the parts.

The distance between

the indoor unit and the

floor should be more

than 2m or 6 feet.

The models adopt HFC free refrigerant R410A

more than

10cm

more than 5cm

more than

more than10cm

more than 15cm

more than 60cm

A

G

●

●

A

F

C

E

D

G

B

Arrangement of piping

directions

Rear left

Left

Rear

right

Right

Below

G

Attention must be paid to

the pitch of drain hose

X Y X

Z

Dimensions(inches)

Model

x y z

Hammer

●

●

●

●

Place where the distance of more than lm from televisions, radios, wireless apparatuses

and fluorescent lamps 3 feet or approximately.

●

In the case of fixing the remote controller on a wall, place where the indoor unit can

receive signals when the fluorescent

●

lamps in the room are in use.

●

●

●

A distance marked

●

is available as illustrated in the below figure.

Indoor Unit - Select a location that is

Outdoor Unit - Select a location that is

Robust not causing vibration, where the unit can be supported s ufficiently.

Not affected by heat or steam generated in the vicinity, and where the inlet and outlet of

the unit are not disturbed.

Possible to drain easily, and where piping can be connected with the outdoor unit.

Where conditioned air can be spread in a room evenly.

Less affected by rain or direct sunlight and is sufficiently ventilated.

Strong enough to bear the unit, where vibration and noise are not increased.

Not causing a nuisance to neighbors due to discharged air or noise.

(Unit: inch)

5 1/2

19 2/3

10 1/16

(2 inches)

(4 inches)

(4 inches)

(4 inches)

more than10cm

(4 inches)

(5 7/8 inches)

(24 inches)

All wiring to the unit must be in accordance with the National Electric code

and local ordinances.

HSU12VHGL-W

System configuration

Domestic air conditioner

33

10cm

Page 36

Indoor unit

Make a hole of B mm / inches

in diameter, slightly descending

to outside the wall.

●

Install piping hole cover and seal it off with putty after installation

●

When the mounting plate is first fixed

1. Carry out, based on the wall studs or lintels, a

to be fixed against the wall, then temporarily fasten the plate with one nail.

2. Ensure

the proper level of the plate, by

hanging a thread with a

weight from the central top of the plate, then fasten the plate.

3. Find the wall hole location A using a measuring tape

1

Fitting of the Mounting Plate and

Positioning of the wall Hole

Lid for right

piping

Lid for under piping pipe

Fix with adhesive tape

Lid for left piping

Indoor/outdoor electric cable and drain hose must be bound with refrigerant

●

piping with adhesive.

[ Other direction piping ]

Cut away, with a nipper, the lid for piping according to the piping direction and

●

then bend the pipe according to theposition of wall hole. When bending, be

careful not to crush

pipes.

Make sure that the wires connecting the indoor and outdoor units are not covered

by the refrigeration piping insulation and are long enough to connect to the terminal

block on the indoor unit.

●

proper leveling for the plate

2

Making a Hole on the Wall and Fitting the Piping Hole Cover

Drawing of pipe

3

Installation of the Indoor Unit

[ Rear piping ]

Draw pipes and the drain hose, then fasten them with the adhesive tape

●