Page 1

FLEXFIT SINGLE SPECIFICATION GUIDE

FLEXIT SINGLE - DEVIS DESCRIPTIF / GUÍA DE ESPECIFICACIÓN DEL FLEXIT SIMPLE

31-5000407 Rev. 0 06-19 GEA

Page 2

ENGLISH

2 31-5000407 Rev. 0

Page 3

TABLE OF CONTENTS

OUTDOOR UNIT DIMENSIONS ....................................................................................4

INDOOR UNIT DIMENSIONS ......................................................................................5

DUCTED UNIT DIMENSIONS ......................................................................................6

CASSETTE UNIT DIMENSIONS ....................................................................................7

CLEARANCES ....................................................................................................8

SYSTEM .........................................................................................................9

Part 1: General ......................................................................................................9

Part 2: Performance and Operating Range ...........................................................................9

Part 3: Installation Requirements ...................................................................................13

Part 4: Electrical Requirements .....................................................................................13

OUTDOOR UNIT .................................................................................................14

Part 1: General .....................................................................................................14

Part 2: Installation .................................................................................................14

Part 3: Components ...............................................................................................14

WALL MOUNT INDOOR UNIT .....................................................................................15

Part 1: General .....................................................................................................15

Part 2: Installation Requirements ...................................................................................15

Part 3: Electrical Requirements .....................................................................................15

Part 4: Components ...............................................................................................16

DUCTED INDOOR UNITS ........................................................................................17

Part 1: General .....................................................................................................17

Part 2: Installation Requirements ...................................................................................17

Part 3: Electrical Requirements .....................................................................................17

Part 4: Components ...............................................................................................18

Part 5: Supply and Return Air Panels ................................................................................18

CASSETTE INDOOR UNITS ......................................................................................19

Part 1: General .....................................................................................................19

Part 2: Installation Requirements ...................................................................................19

Part 3: Electrical Requirements .....................................................................................19

Part 4: Components ...............................................................................................20

CASSETTE INDOOR PANELS .....................................................................................20

Part 1: PB-700IB 2x2 Compact Cassette Panel ......................................................................20

Part 2: PB-950KB 3x3 Large Cassette Standard Panel ................................................................21

Part 3: PB 950MB 3x3 Large Cassette Panel with Intelligent Eye ......................................................21

CONTROLS AND ACCESSORIES ..................................................................................22

Part 1: Wireless Control ............................................................................................22

Part 2: Wired Controllers ...........................................................................................22

Part 3: QAWF01A WiFi Adapter .....................................................................................23

Part 4: WK-B Interface Kit ..........................................................................................23

LIMITED WARRANTY ........................................................................................... 25

ENGLISH

31-5000407 Rev. 0 3

Page 4

ENGLISH

)

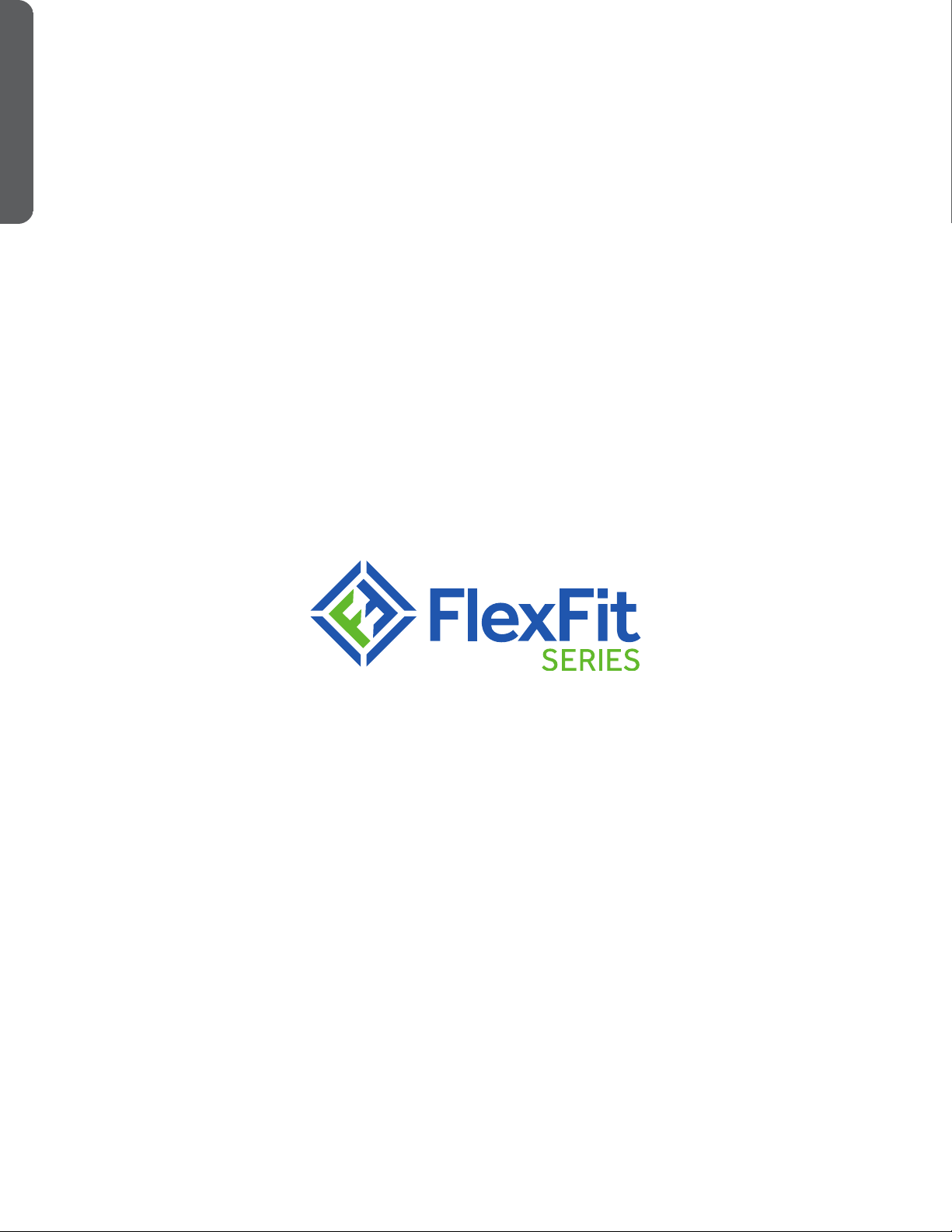

OUTDOOR UNIT DIMENSIONS

1U12LC2VHA

21 1/4 (540)

1U18LC2VHA

27 1/8 (688)

30 3/4 (780

31 7/8 (810)

1U36LP2VHA

9 5/8 (245

)

11 3/8 (288)

)

38(967)

37 3/8(950)

23 5/8(600)

15 5/8(396)

15 7/8(404)

21 1/4(450)

1U48LP2VHA

37 3/8(950)

53 1/8(1350)

15 5/8(396

1U24LP2VHA

38(967)

37 3/8(950)

23 5/8(600)

15 5/8(396)

15 7/8(404)

21 1/4(450)

23 5/8(600)

15 7/8(404)

17 3/4(450)

4 31-5000407 Rev. 0

Page 5

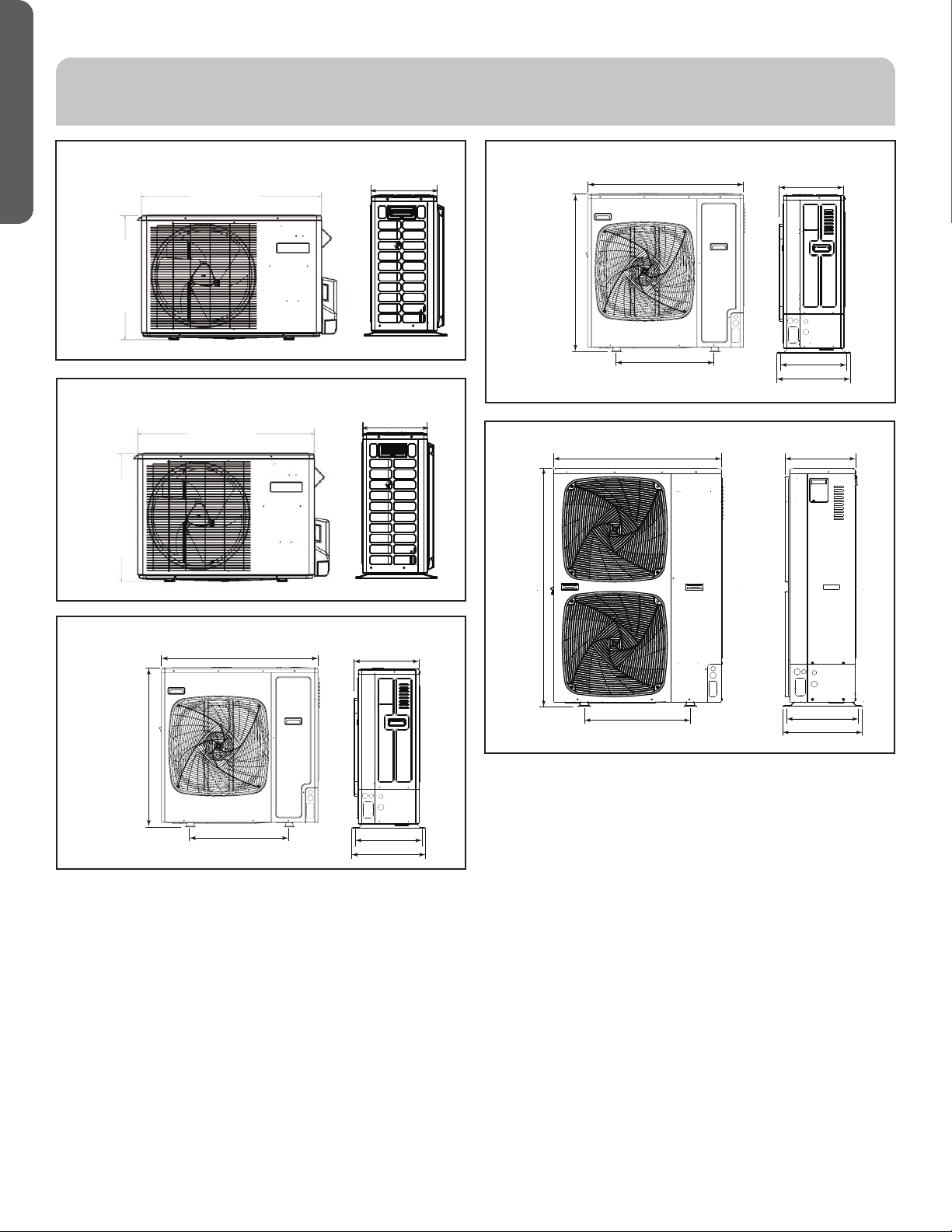

INDOOR UNIT DIMENSIONS

AW12LC2VHB

11(280)

AW18LC2VHB

)

13 1/8 (332

33 5/8 (855

39 1/4 (997

AW24LP2VHA

ENGLISH

)

13 1/4(336)

8 (204)

43 7/8(1115)

9 5/8(243)

AW36LP2VHA

)

14 3/8(365)

9 1/4 (235)

51 3/4(1316)

10 7/8(275)

31-5000407 Rev. 0 5

Page 6

ENGLISH

DUCTED UNIT DIMENSIONS

AD12SL2VHB

16 1/2 (420)

14 1/2 (369)

air flow

7 1/4 (184)

34 3/4 (880)

AD18SL2VHB

33 1/2 (850)

30 3/4 (780)

air flow

25 1/4 (640)

35 1/8 (892)

3 1/2

(30)

1 1/4

47 3/4(1213)

46 1/8(1170)

43 1/4(1100)

(90)

air flow

2 3/4(70)

2 3/4(70)

6 (152)

AM36LP2VHA

25 3/4(653)

air flow

9 7/8(251)

28 3/8(720)

AM48LP2VHA

59(1500)

56 1/2(1435)

air flow

50 5/8(1286)

61 514(1556)

59(1500)

56 1/2(1435)

6 5/8(168)

air flow

9 1/4(235)

16 1/2(420)

14 1/2 (369)

air flow

7 1/4(185)

17 3/4 (450)

AM24LP2VHA

23 1/2 (595)

air flow

37 3/4(960)

3 1/2(90)

1 1/8(30)

41 3/8 (1050)

39 (990)

33 1/2(849)

air flow

air flow

air flow

25 3/4(653)

50 5/8(1286)

61 514(1556)

air flow

6(152)

9 7/8(251)

28 3/8(720)

6 5/8(168)

air flow

9 1/4(235)

31 3/8 (797)

air flow

9 7/8 (250)

28 3/8 (720)

37 5/8 (957)

5 7/8 (148)

air flow

8 7/8 (226)

6 31-5000407 Rev. 0

Page 7

CASSETTE UNIT DIMENSIONS

AB12SC2VHA / AB18SC2VHA

More than 59 (1500) to wall on all sides

10 1/4 (260)

1 (25)

1 inch recess between ceiling surface and bottom

of unit without panel on.

Suspending Rods 22 7/16(570)

Ceiling Opening 23-23 7/8 (585-605)

11 1/4 (285)

6 7/8 (175)

less than 1/2 (12)

No object closer than 39 (1000)

Unit Body 22 7/8 (580)

Panel 24 3/8 (620)

22 7/8 (580)

Ø 4 (100)

ENGLISH

3/4 (20)3/4 (20)

8 1/4 (210)

less than 1/2 (12)

AL24LP2VHA / AL36LP2VHA / AL48LP2VHA

More than 59 (1500) to wall on all sides

4 3/8 (110)

7 (179)

1 (25)

1 inch recess between ceiling and bottom of unit without panel on.

3 1/2 (90)

5 (126)

8 (204)

Ceiling Opening 34 1/4 - 35 (870-890)

3 1/2 (90)

Less than 1 (25)

No object closer than 39 (1000)

Suspending Rods 30 1/8 (765)

Unit Body 33 1/8 (840)

Panel 37 3/8 (950)

33 1/8 (840) 1 3/4 (45)1 3/4 (45)

2 5/8 (68)

Ø 3 (75)

4 3/8 (110)

3 1/2 (90)

Less than 1 (25)

31-5000407 Rev. 0 7

Page 8

ENGLISH

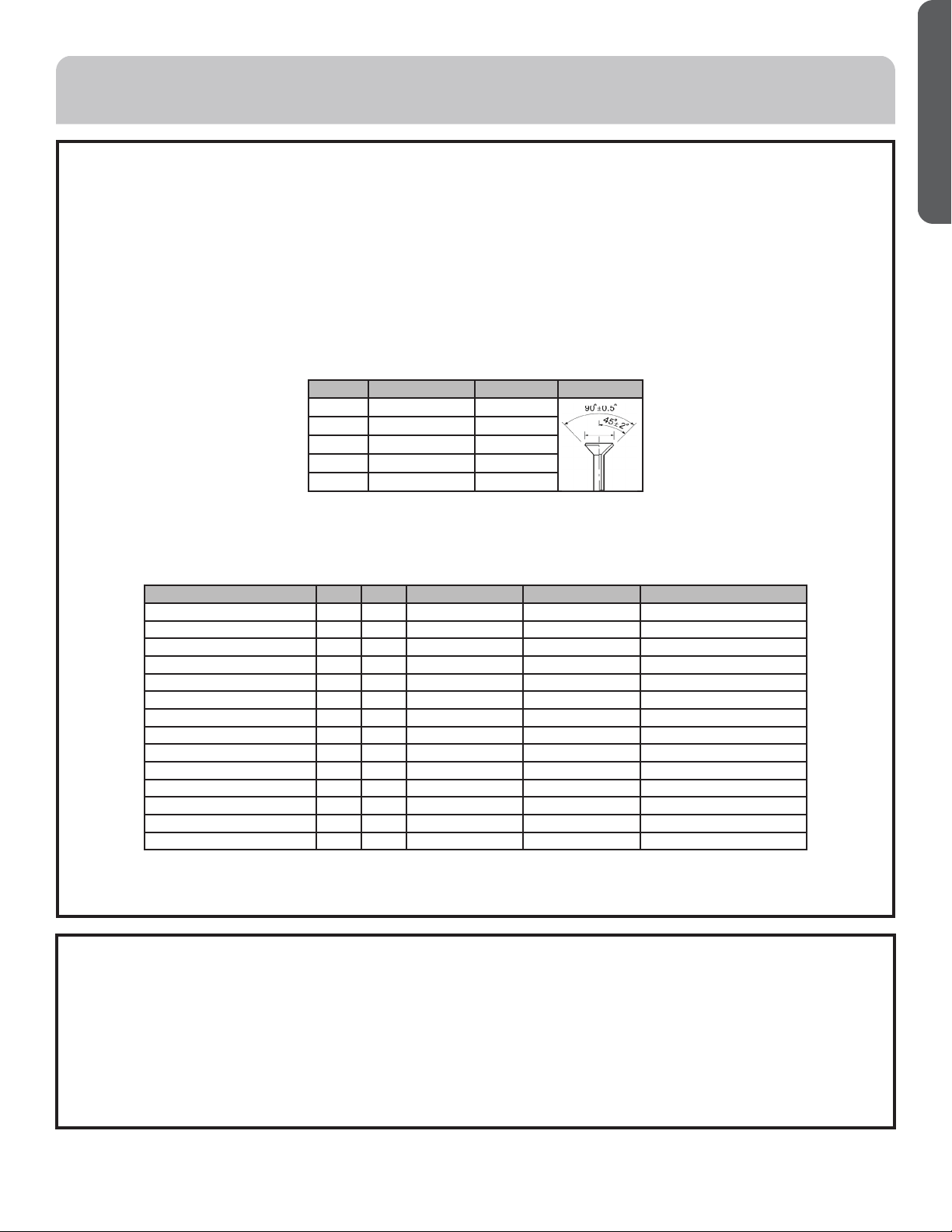

SYSTEM CLEARANCES

MINIMUM CLEARANCES

(Appearance may vary)

This picture is for reference only, as your product may look different. Read your manual before installation. Explain the

operation of the unit to the user according to this manual.

more than 4in.

more than

4in.

Attention must be paid to

the pitch of drain hose

Cassette

1 ft.

Thedistancebetween

theindoorunitandthe

ĥòor should be more

than 6 feet.

more than 24in.

more than 4in.

more than 6in.

unit:

more than 4in.

more than 6in.

B

> 6 in

5 ft.

5 ft.

8 ft. Over

Ducted

> 12 in

> 12 in

Air Flow

> 12 in

8 31-5000407 Rev. 0

Page 9

SYSTEM

Part 1: General

1.1 Description

A. The Haier Flexfit Single heat pump air conditioner shall be a variable capacity, mini-split type system

comprised of a single outdoor and a single indoor unit.

1.2 Toxicity

A. The heat pump system shall participate in RoHS compliance and listed in the directory.

Part 2: Performance and Operating Range

2.1 Operating Range

A. The heat pump unit shall provide cooling temperature range of 0°~115°F (-18°C~46°C).

B. The heat pump system shall be capable of providing greater than 70% capacity at -22°F (-30°C) outdoor

ambient temperature.

C. The heat pump system connected to 1U24LP2VHA, 1U36LP2VHA or 1U48LP2VHA outdoor shall be capable of

providing 100% cooling capacity at 0°F (-18°C) outdoor ambient temperature.

D. The heat pump shall operate normally with voltages between 187~253V.

2.2 Performance

The system shall perform within the specified operating window found on the following table.

A. Cooling performance rating shall be verified following AHRI 210/240 standards of 80°F DB/67°F WB (27°/19°C)

indoor temperature and 95°F DB/75°F WB (35°/24°C) outdoor temperature.

B. Heating performance rating shall be verified following AHRI 210/240 standards of 70°F DB/60°F WB (21°/16°C)

indoor temperature and 47°F DB/43°F WB (8°/6°C) outdoor temperature.

ENGLISH

31-5000407 Rev. 0 9

Page 10

ENGLISH

SYSTEM

Model

Name and

operating

range

System Type Wall Mount

Outdoor 1U12LC2VHA 1U18LC2VHA 1U24LP2VHA 1U36LP2VHA

Indoor AW12LC2VHB AW18LC2VHB AW24LP2VHA AW36LP2VHA

Cooling °F(°C) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46)

Heating °F(°C) 5~75(-15~24) 5~75(-15~24) -4~75(-20-24) -4~75(-20-24)

Power Supply Voltage, Cycle, Phase V/Hz/- 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1

Wire Size between ID and OD 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded

Maximum Fuse Size A 15 20 25 30

Minimum Circuit Amp A 14 17 21 26

Cooling Rated Capacity Btu/hr 12,000 17,000 24000 35000

Capacity Range Btu/hr 4,780-13,300 5,100-19,000 6800-30700 8500-37500

Rated Power Input W 1,180 1,530 2,182 3,500

SEER 18.0 18.0 17.0 17.0

EER 10.5 11.0 10.0 8.6

Moisture Removal Pt./h 3.38 4.23 4.10 5.1

Heating "Rated Heating Capacity

Outdoor Unit Outdoor Noise Level dB 53 54 47 52

Indoor Unit Indoor Sound dB (Turbo/ High/Med/

Airflow (Turbo/High/Med/Low/

Refrigerant

Lines

Maximum Line Length Ft / m 50/15 83/25 165/50 165/50

Btu/hr"

"Heating Capacity Range

Btu/hr"

Rated Power Input W 1,200 1,485 2700 3700

HSPF 9.5 9.0 10.0 10.0

Dimension: Height in (mm) 21 1/4 (540) 27 (688) 38 (965) 38 (965)

Dimension: Width in (mm) 30 3/4 (780) 31 7/8 (810) 37 3/8(950) 37 3/8(950)

Dimension: Depth in (mm) 9 5/8 (245) 11 5/16 (288) 14 5/8(370) 14 5/8(370)

Weight (Ship/Net)- lbs (kg) 75.4/68.8 (34.2/31.2) 100.3/94.8 (45.5/43) 202.8/ 176.4 (92/80) 207.2/180.7 (94/82)

Low/Quiet)

Quiet) CFM

Dimension: Height in (mm) 11(280) 12 3/4 (322) 13 1/4(336) 14 3/8(365)

Dimension: Width in (mm)

Dimension: Depth in (mm) 8 1/16 (204) 9 1/4 (235) 9 9/16(243) 10 7/8(275)

Max. Ext. Static in.W.G (Pa) NA NA NA NA

Drainpipe Size O.D. in NA NA NA NA

Internal Condensate Pump NA NA NA NA

Max. Drain-Lift in (mm) NA NA NA NA

Grill Model NA NA NA NA

Grill Size: H×W×D in (mm) NA NA NA NA

Weight (Ship/Net)-lbs (kg) 26.9/22.05 (12.2/10) 35.3/28.7 (16/13) 45.4/37.5(20.6/17) 55.1/46.3(25.5/21)

Connections Flare Flare Flare Flare

Liquid/Suction O.D. in 1/4 3/8 1/4 1/2 3/8 5/8 3/8 5/8

Factory Charge Oz 42.3 45.9 88.2 88.2

Maximum Height Ft / m 33/10 50/15 100/30 100/30

13,500 18,000 27000 37000

5,120-13,990 5,400-20,400 6800-34100 8500-41000

41/40/34/27/23 46/45/40/35/25

353/294/277/259/230 636/530/483/430/383 710/650/560/440/410 720/660/570/450/420

33 5/8 (855) 39 1/4 (997) 43 7/8(1115) 51 13/16(1316)

49/47/42/36/34 50/48/44/38/36

10 31-5000407 Rev. 0

Page 11

SYSTEM

Model

name and

operating

range

Power

Supply

Cooling Rated Capacity Btu/hr 11,000 16,000 24000 35000 47000

Heating "Rated Heating Capacity

Outdoor

Unit

Indoor Unit Indoor Sound dB (Turbo/

Refrigerant

Lines

System Type Slim Duct High Static Duct

Outdoor 1U12LC2VHA 1U18LC2VHA 1U24LP2VHA 1U36LP2VHA 1U48LP2VHA

Indoor AD12SL2VHB AD18SL2VHB AM24LP2VHA AM36LP2VHA AM48LP2VHA

Cooling °F(°C) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46)

Heating °F(°C) 5~75(-15~24) 5~75(-15~24) -4~75(-20-24) -4~75(-20-24) -4~75(-20-24)

Voltage, Cycle, Phase V/

Hz/-

Wire Size between ID and OD14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded

Maximum Fuse Size A 15 20 25 30 40

Minimum Circuit Amp A 14 17 21 26 35

Capacity Range Btu/hr 4,000~12,000 5,000~18,000 6800-30700 8500-37500 11900-54500

Rated Power Input W 1,200 1,700 2,182 3,500 4,476

SEER 16.0 15.0 17.0 17.0 17.0

EER 9.0 9.0 11.0 10.0 10.5

Moisture Removal Pt./h 2.65 3.85 5.1 6.8 11.0

Btu/hr"

"Heating Capacity Range

Btu/hr"

Rated Power Input W 1,400 1,600 2,089 3,283 4,407

HSPF 8.2 9.5 11.0 10.5 10.0

Outdoor Noise Level dB 53 54 47 52 53

Dimension: Height in (mm)

Dimension: Width in (mm) 30 3/4 (780) 31 7/8 (810) 37 3/8(950) 37 3/8(950) 37 3/8(950)

Dimension: Depth in (mm) 9 5/8 (245) 11 5/16 (288) 14 5/8(370) 14 5/8(370) 14 5/8(370)

Weight (Ship/Net)- lbs (kg) 75.4/68.8 (34.2/31.2) 100.3/94.8 (45.5/43) 202.8/ 176.4 (92/80) 207.2/180.7 (94/82) 260.1/231.5 (118/105)

High/Med/Low/Quiet)

Airflow (Turbo/High/Med/

Low/ Quiet) CFM

Dimension: Height in (mm) 7 5/16 (185) 7 5/16 (185) 9 7/8 (250) 9 7/8 (250) 9 7/8 (250)

Dimension: Width in (mm)

Dimension: Depth in (mm) 16 9/16 (420) 16 9/16 (420) 25 3/4 (655) 28 3/8 (720) 28 3/8 (720)

Max. Ext. Static in.W.G (Pa) 0.16 (40) 0.16 (Pa) 0.6(150) 0.6(150) 0.6(150)

Drainpipe Size O.D. in 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4

Internal Condensate Pump Standard Standard Standard Standard Standard

Max. Drain-Lift in (mm) 27 9/16 (700) 27 9/16 (700) 27 9/16(700) 27 9/16(700) 27 9/16(700)

Grill Model NA NA NA NA NA

Grill Size: H×W×D in (mm) NA NA NA NA NA

Weight (Ship/Net)-lbs (kg) 47.2/36.8 (21.4/16.7) 62.4/51.4(28.3/23.3) 81.1/68.8 (36.8/31.2) 130.1/121.3 (59/55) 132.3/114.6 (60/52)

Connections Flare Flare Flare Flare Flare

Liquid/Suction O.D. in 1/4 3/8 1/4 1/2 3/8 5/8 3/8 5/8 3/8 5/8

Factory Charge Oz 42.3 45.9 88.2 88.2 131.0

Maximum Line Length

Ft / m

Maximum Height Ft / m 33/10 50/15 100/30 100/30 100/30

208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1

12,000 17,000 26500 37500 52000

5,000 ~ 13,000 6,000~19,000 6800-34100 8500-41000 13600-64800

21 1/4 (540) 27 (688) 38 (965) 38 (965) 53 1/8 (1350)

38/35/29/26/23 31/29/23/29/25 38/35/32/29 32/28/25/23 41/36/33/31

400/353/282/247/218 540/500/447/365/306 845/670/530/470 1100/950/735/675 1350/1150/930/765

33 7/16 (850) 46 1/16 (1170) 37 5/8 (957) 59 (1500) 59 (1500)

50/15 83/25 165/50 165/50 230/75

ENGLISH

31-5000407 Rev. 0 11

Page 12

ENGLISH

SYSTEM

Model

name and

operating

range

Power

Supply

Cooling Rated Capacity Btu/hr 11,000 16,000 24000 35000 45000

Heating "Rated Heating Capacity

Outdoor

Unit

Indoor Unit Indoor Sound dB (Turbo/

Refrigerant

Lines

System Type Compact Cassette Large Cassette

Outdoor 1U12LC2VHA 1U18LC2VHA 1U24LP2VHA 1U36LP2VHA 1U48LP2VHA

Indoor AB12SC2VHA AB18SC2VHA AL24LP2VHA AL36LP2VHA AL48LP2VHA

Cooling °F(°C) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46)

Heating °F(°C) 5~75(-15~24) 5~75(-15~24) -4~75(-20-24) -4~75(-20-24) -4~75(-20-24)

Voltage, Cycle, Phase V/

Hz/-

Wire Size between ID and OD14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded

Maximum Fuse Size A 15 20 25 30 40

Minimum Circuit Amp A 14 17 21 26 35

Capacity Range Btu/hr 4,000~12,000 5,000~18,000 6800-27000 8500-37500 11900-52800

Rated Power Input W 1,150 1,690 2,087 3,500 4,286

SEER 16.0 16.0 17.0 17.0 17.0

EER 10.0 9.0 11.5 10.0 10.5

Moisture Removal Pt./h 2.65 3.85 5.1 6.3 11.0

Btu/hr"

"Heating Capacity Range

Btu/hr"

Rated Power Input W 1,400 1,600 2,281 3,253 4,533

HSPF 9.0 9.0 10.0 10.3 10.5

Outdoor Noise Level dB 53 54 47 52 53

Dimension: Height in (mm)

Dimension: Width in (mm) 30 3/4 (780) 31 7/8 (810) 37 3/8(950) 37 3/8(950) 37 3/8(950)

Dimension: Depth in (mm) 9 5/8 (245) 11 5/16 (288) 14 5/8(370) 14 5/8(370) 14 5/8(370)

Weight (Ship/Net)- lbs (kg) 75.4/68.8 (34.2/31.2) 100.3/94.8 (45.5/43) 202.8/ 176.4 (92/80) 207.2/180.7 (94/82) 260.1/231.5 (118/105)

High/Med/Low/Quiet)

Airflow (Turbo/High/Med/

Low/ Quiet) CFM

Dimension: Height in (mm) 10 1/4 (260) 10 1/4 (260) 9 5/8 (246) 9 5/8 (246) 11 3/8 (288)

Dimension: Width in (mm)

Dimension: Depth in (mm) 22 7/16(570) 22 7/16(570) 33 1/8(840) 33 1/8(840) 33 1/8(840)

Max. Ext. Static in.W.G (Pa) NA NA NA NA NA

Drainpipe Size O.D. in 1 1/4 1 1/4 1 1 1

Internal Condensate Pump Standard Standard Standard Standard Standard

Max. Drain-Lift in (mm) 47.2(1200) 47.2(1200) 39 3/8 (1000) 39 3/8 (1000) 39 3/8 (1000)

Grill Model PB-700IB PB-700IB PB-950KB PB-950KB PB-950KB

Grill Size: H×W×D in (mm) 2 3/8 × 27 9/16 × 27 9/16(60×700×700) 2 × 37 3/8 × 37 3/8 (50×950×950)

Weight (Ship/Net)-lbs (kg) 61.3/47 (27.8/21.3) 61.3/47.0 (27.8/21.3) 79.4/68.3 (36/31) 79.4/68.3 (36/31) 83.8/70.5 (38/32)

Connections Flare Flare Flare Flare Flare

Liquid/Suction O.D. in 1/4 3/8 1/4 1/2 3/8 5/8 3/8 5/8 3/8 5/8

Factory Charge Oz 42.3 45.9 88.2 88.2 131.0

Maximum Line Length

Ft / m

Maximum Height Ft / m 33/10 50/15 100/30 100/30 100/30

208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1

12,000 16,000 27300 36500 49000

5,000 ~ 13,000 6,000~19,000 6800-30500 8500-38500 13600-61000

21 1/4 (540) 27 (688) 38 (965) 38 (965) 53 1/8 (1350)

42/40/36/32/25 45/42/40/36/32 36/33/29/26 45/42/38/34 41/36/33/31

410/365/305/265/205 470/410/365/295/252 740/630/480/400 990/900/776/700 1147/941/847/705

22 7/16(570) 22 7/16(570) 33 1/8(840) 33 1/8(840) 33 1/8(840)

50/15 83/25 165/50 165/50 230/75

12 31-5000407 Rev. 0

Page 13

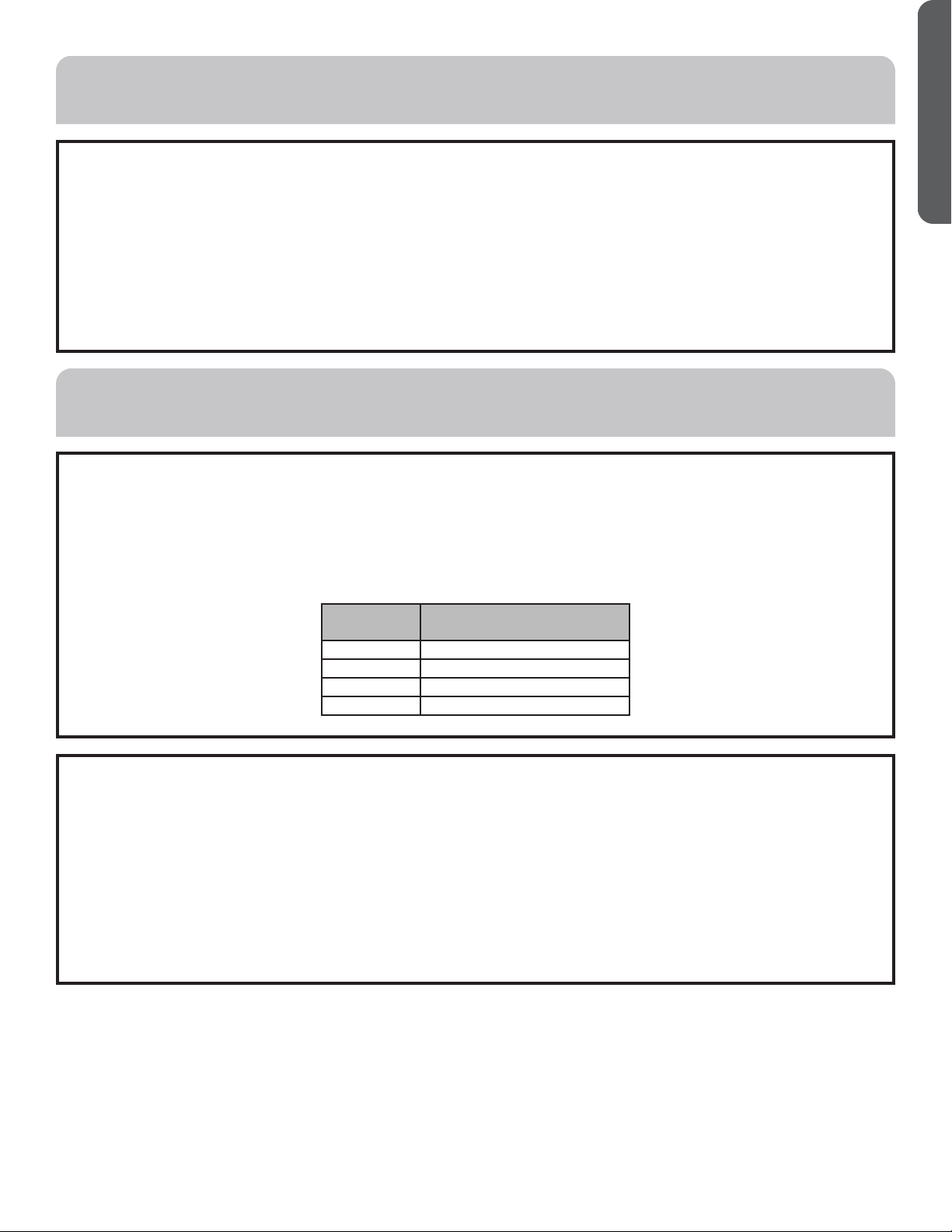

SYSTEM

Part 3: Installation Requirements

3.1 Lineset

A. The connecting refrigerant lines between the indoor and outdoor units are to be supplied by the installer.

B. The tubing must be annealed ACR-type copper, meeting ASTM B280 standards.

C. The connecting tubing between the outdoor and indoor units shall be continuous in all possible situations.

D. The tubing ends must be reamed inside and out, and must be flared using a 45° flaring tool approved for

R-410A.

E. Connections to the indoor and outdoor units shall be made with flare nuts that are supplied with the individual

units.

F. The flare nuts must be attached to indoor and outdoor units using a torque wrench and

back-up wrench.

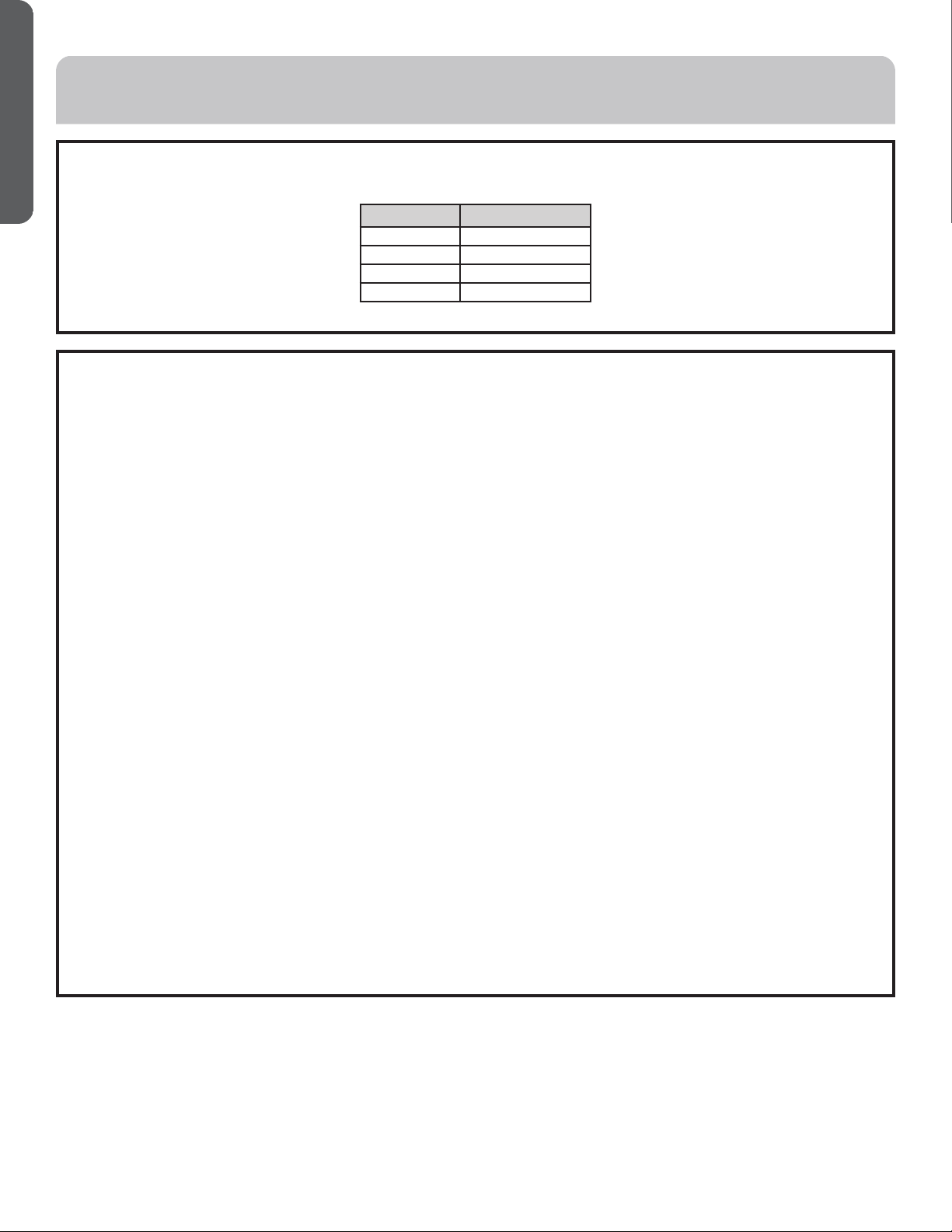

Pipe Size Torque A (inch) Flare Shape

1/4 12 lb/ft 16.3 Nm 0.327-0.343

3/8 27 lb/ft 36.6 Nm 0.472-0.488

1/2 40 lb/ft 54.2 Nm 0.488-0.654

5/8 50 lb/ft 67.8 Nm 0.732-0.748

3/4 80 lb/ft 108.5 Nm 0.902-0.917

G. Each tube must be insulated with a minimum of 1/2 inch (12.7mm) closed-foam insulation that is UV resistant

and meets ASTM Standard E84 25/50 flame spread/smoke development.

H. The lineset between the indoor and outdoor must not exceed the listed maximum length and maximum height

difference. See chart below.

System Models Liquid Vapor Minimum Length Maximum Length Maximum Height Difference

1U12LC2VHA / AB12SC2VHA

1U12LC2VHA/ AD12SL2VHB

1U12LC2VHA / AW12LC2VHB

1U18LC2VHA / AB18SC2VHA

1U18LC2VHA / AD18SL2VHB

1U18LC2VHA / AW18LC2VHB

1U24LP2VHA / AL24LP2VHA

1U24LP2VHA / AM24LP2VHA

1U24LP2VHA / AW24LP2VHA

1U36LP2VHA / AL36LP2VHA

1U36LP2VHA / AM36LP2VHA

1U36LP2VHA / AW36LP2VHA

1U48LP2VHA / AL48LP2VHA

1U48LP2VHA / AM48LP2VHA

1/4 in 3/8 in 6ft (1.8m) 66ft (20m) 50 ft (15 m)

1/4 in 3/8 in 6ft (1.8m) 66ft (20m) 50 ft (15 m)

1/4 in 3/8 in 6ft (1.8m) 66ft (20m) 50 ft (15 m)

1/4 in 1/2 in 6ft (1.8m) 83ft (25.3m) 50 ft (15 m)

1/4 in 1/2 in 6ft (1.8m) 83ft (25.3m) 50 ft (15 m)

1/4 in 1/2 in 6ft (1.8m) 83ft (25.3m) 50 ft (15 m)

3/8 in 5/8 in 6ft (1.8m) 165ft (50m) 100 ft (30 m)

3/8 in 5/8 in 6ft (1.8m) 165ft (50m) 100 ft (30 m)

3/8 in 5/8 in 6ft (1.8m) 165ft (50m) 100 ft (30 m)

3/8 in 5/8 in 6ft (1.8m) 165ft (50m) 100 ft (30 m)

3/8 in 5/8 in 6ft (1.8m) 165ft (50m) 100 ft (30 m)

3/8 in 5/8 in 6ft (1.8m) 165ft (50m) 100 ft (30 m)

3/8 in 5/8 in 6ft (1.8m) 230ft (75m) 100 ft (30 m)

3/8 in 5/8 in 6ft (1.8m) 230ft (75m) 100 ft (30 m)

ENGLISH

A

I. The lineset connected to 1U24LP2VHA and 1U36LP2VHA shall be capable of being up to 165ft (50m) long.

J. The lineset connected to a 1U48LP2VHA shall be capable of being up to 230ft (70m) long.

Part 4: Electrical Requirements

4.1 Electrical Supply

A. The operating electrical requirements shall be 208/230 volts AC, single-phase, 60 hertz. Voltage supplied to

the outdoor unit must be between 187-253 volts.

B. Power supply must be installed in accordance to NEC standards.

4.2 Connecting Wire to Indoor

A. Connecting cable between the indoor unit(s) must be made with 4 conductor - 14 AWG stranded copper wire.

B. Connecting wire must be continuous (without break) unless local code requires power disconnect next to

indoor unit. See indoor electrical section 3.1 for the specification.

31-5000407 Rev. 0 13

Page 14

ENGLISH

OUTDOOR UNIT

Part 1: General

1.1 Outdoor Unit

A. The Haier Flexfit Single outdoor unit shall be comprised of a condenser coil with all components and controls

necessary to perform the rated operation.

1.2 Warranty

A. The outdoor unit shall be covered by a manufacturer's parts warranty. See Appendix for details.

1.3 Sound Pressure Rating

Model Sound Pressure Rating dB (A)

1U12LC2VHA 53

1U18LC2VHA 54

1U24LP2VHA 47

1U36LP2VHA 52

1U48LP2VHA 53

Part 2: Installation

2.1 Condensate

A. The installer must adhere to local building codes for managing condensate water produced by the outdoor unit.

2.2 Clearances

A. The installer must follow the recommended clearances provided in the Installation Manual.

Part 3: Components

3.1 Coil

B. Coils shall be helium pressure tested at the factory within a range of 600 - 650 PSI.

C. Outdoor unit shall be factory charged with R-410A refrigerant for 25 feet of lineset.

3.2 Fan Motor

A. The outdoor fan motor shall be a brushless, variable speed DCV motor type.

B. The fan motor shall be molded with heat-hardened resin.

C. The fan motor shall have permanently lubricated SRC bearings.

3.3 Fan Blade

A. The outdoor fan blade shall be a UL flame rated plastic-resin design.

3.4 Compressor

A. The compressor shall be a DC rotary type and A-PAM inverter-driven for stable operation in lower and higher

B. The compressor shall be vairable speed, variable capacity.

C. The compressor shall have an internal overload protection device.

D. The compressor shall use PVE (FV50S) refrigerant oil for better anti-wear effectiveness, superior resistance to

3.5 4WV

A. The outdoor unit shall contain a four-way reversing valve (4WV) to change system mode from cool to heat.

3.6 EEV

A. The refrigerant flow shall be regulated by an electronic expansion valve (EEV).

B. The outdoor control shall monitor the refrigerant flow through the EEV using a pulse-operated coil.

C. The EEV shall maintain the target of 10°F (5.5°C) of superheat.

3.7 Base Pan

A. The base pan shall be constructed of commercial grade DC51/DC52 hot-dip galvanized steel with coating.

B. The outdoor unit shall ship with a drain port adapter sized for 1/2 inch tubing to manage condensate run off.

A. The outdoor coil shall be made with a blue colored hydrophilic coating on the aluminum fins and packed with internally

кхттщизжтууихчшемскчтмсжхидцичлииййижчмщилидчиыжлдскицшхйджидхидеь"%]хицшпчмскмслмклихийймжмисжмицдсз

shorter defrost cycles (approx. 29%.)

B. The fan blade shall be factory balanced in quiet performance and enhanced velocity.

frequency.

capillary tube blockage and no hydrolysis compared to POE oil.

14 31-5000407 Rev. 0

Page 15

OUTDOOR UNIT

Part 3: Components (continued)

3.9 Copper Piping

A. All internally connected copper tubing shall conform to ASTM B280 tubing tolerances.

3.10 Outdoor Enclosure Materials

A. The outdoor cabinet shall be constructed of commercial grade DC51/DC52 hot-dip galvanized steel with coating.

3.11 Defrost

A. The outdoor unit shall have a reverse-cycle (hot gas) defrost system to maximize heat pump operation and minimize

energy consumption.

3.12 Accumulator

A. The accumulator shall be connected to the compressor return line to prevent liquid refrigerant from entering the

compressor during operation.

WALL MOUNT INDOOR UNIT

Part 1: General

1.1 Description

A. The wall mounted indoor section completes the system when connected to the matching outdoor unit and

field-supplied piping and wiring.

1.2 Warranty

A. The wall mounted indoor unit shall be covered by a manufacturer's parts warranty. See Appendix for detail.

1.3 Sound Pressure Rating

Model Blower Pressure Sound Rating dB(A)

(Turbo/High/Medium/Low/Quiet)

AW12LC2VHB 41/40/34/27/23

AW18LC2VHB 46/45/40/35/25

AW24LP2VHA 49/47/42/36/34

AW36LP2VHA 50/48/44/38/36

ENGLISH

Part 2: Installation Requirements

2.1 Condensate

A. The wall mouted indoor shall be shipped with a insulated polyethylene condensate tubing (5/8" ID) attached from the factory.

B. The wall mounted indoor unit shall ship with a 6.5 ft (2m) corrugated drain tube that connects to the insulated drain tube.

C. The wall mounted indoor unit shall be a gravity drain.

2.2 Clearances

A. The installer must follow the minium clearances illustrated in the Installation Manual when installing the indoor unit.

2.3 Mounting

A. The wall mounted indoor unit shall ship with a galvanized metal wall bracket.

B. The wall bracket shall have multiple anchor points to provide the installer with many options to firmly attach the wall

mounted indoor unit to the wall.

C. The field-supplied mounting hardware must be sufficient to adequately support the indoor unit.

31-5000407 Rev. 0 15

Page 16

ENGLISH

WALL MOUNT INDOOR UNIT

Part 3: Electrical Requirements

3.1 Electrical Disconnect

A. Connecting wire must be continuous (without break) unless local code requires a disconnect at the indoor unit.

Model Fan Motor Rating (HP)

AW12LC2VHB 0.054

AW18LC2VHB 0.054

AW24LP2VHA 0.094

AW36LP2VHA 0.094

B. If a disconnect is required by local code, it must be a 3-pole, single-throw type.

Part 4: Components

4.1 Coil

A. The indoor coil shall be made with a blue colored hydrophilic coating on the aluminum fins and packed with internally

grooved copper tubing, to increase the effective heat exchange surface area by 25%.

B. Copper tubing shall have inner micro-grooves to increase effective heat transfer capabilities.

C. Coils shall be pressure tested at 600~650 PSI using helium leak detection.

D. The coil shall be charged with dry nitrogen for shipping at 70~100 PSI.

4.2 Fan Motor

A. The fan motor shall be a sealed DC multiple-speed resin-packed motor

B. The fan motor shall have permanently lubricated bearings.

C. The AW12LC2VHB shall have an optimized fan motor and blower design to enable up to 40 feet of air flow.

D. The AW18LC2VHB, AW24LP2VHA and AW36LP2VHA models shall have an optimized fan motor and blower design to

enable up to 60 feet of air flow.

4.3 Fan Blade

A. The fan blade shall be a corrosion-resistant cross-flow blower.

B. The fan shall be designed with optimized diameter and surface area to deliver quiet and even air flow.

4.4 Copper Piping

A. The coil shall be connected to a length of insulated annealed copper.

B. The ends of the tubing shall have male flare connections.

4.5. Air Louvers

A. The supply air shall be distributed by horizontal and vertical motorized louvers.

B. Air Louvers shall provide wide angle of operation for both horizontal (120°) and vertical (90° from top to down) airflow

movement to provide room comfort for each corner.

4.6 Display

A. The wall mounted indoor unit shall have a 4.5 x 1.1-inch backlit temperature display capable of showing set or room

temperatures.

B. The display shall also have colored icons representing set mode.

C. The display can be turned off from the wireless remote control.

4.7 WiFi

A. The wall mounted indoor unit shall be capable of connecting to WiFi using an adapter.

4.8 Filter

A. The wall mounted indoor unit shall have removable air filters.

B. The air filters shall be washable and reusable.

4.9 Control

A. The wall mounted indoor unit shall ship with a hand-held infrared remote control (YR-HG).

B. The wall mounted indoor unit shall be compatible with YR-E17, YR-E16B and QACT17A wired controls. The adapter,

WK-B, shall be used with the indoor unit when connected to a wired controller.

4.10 Installation Clip

A. The wall mounted indoor unit shall have a built-in clip that swings out and acts as a kick stand to allow for easier

access to the rear of the unit during installation repair.

16 31-5000407 Rev. 0

Page 17

DUCTED INDOOR UNITS

Part 1: General

1.1 Description

A. The ducted indoor unit completes the system when connected to the matching outdoor unit and field-supplied

piping and wiring.

1.2 Warranty

A. The ducted indoor unit shall be covered by a manufacture parts warranty. See appendix for full warranty detail.

1.3 Sound Pressure Rating

Model Blower Pressure Sound Rating dB(A)

(turbo/high/medium/low/quiet)

AD07SL2VHB 35/33/29/26/21

AD09SL2VHB 35/33/29/26/22

AD12SL2VHB 38/35/29/26/23

AD18SL2VHB 31/29/23/29/25

AM24LP2VHA 38/35/32/29/-AM36LP2VHA 32/28/25/23/-AM48LP2VHA 41/36/33/31/--

Part 2: Installation Requirements

2.1 Condensate

A. The ducted indoor unit shall ship with an insulated drain tube adapter that is sized for 3/4-inch PVC on one end.

B. The ducted indoor unit shall have gravity drain ports on both sides of the unit.

2.2 Clearances

A. The installer must follow the minimum clearances illustrated in the installation manual when installing the

indoor unit.

2.3 Mounting

A. The ducted indoor unit shall have 4 hanging brackets that are sized for 3/8 threaded rod.

B. The installer must use 3/8 threaded rod to suspend the ducted indoor unit from the building structure.

C. The installer must install the unit upright and level in all directions.

ENGLISH

Part 3: Electrical Requirements

3.1 Electrical Disconnect

A. Connecting wire must be continuous, without break, unless local code requires power disconnect next to

indoor unit.

Model Fan Motor Rating (HP)

AD07SL2VHB 0.066

AD09SL2VHB 0.066

AD12SL2VHB 0.085

AD18SL2VHB 0.114

AM24LP2VHA 0.362

AM36LP2VHA 0.617

AM48LP2VHA 0.617

B. If a disconnect is required by local code, it must be a 3-pole, single-throw type.

31-5000407 Rev. 0 17

Page 18

ENGLISH

DUCTED INDOOR UNITS

Part 4: Components

4.1 Coil

A. Coil shall be painted with a hydrophilic coating to increase airflow efficiency.

B. Copper tubing shall have inner micro grooves to increase effective heat transfer capabilities.

C. Coils shall be pressure tested at 600~650 PSI using Helium leak detection.

D. The coil shall be charged with dry nitrogen for shipping at 70~100 PSI dwelling pressure.

4.2 Fan Motor

A. The ducted fan motor shall be a sealed DC resin-packed motor.

B. The fan motor shall have permanently lubricated bearings

4.3 Fan Blade

A. The fan blade shall be a noncorrodible centrifugal fan blower.

4.4 Copper Piping

A. The coil shall be connected to a length of insulated annealed copper.

B. The ends of the tubing shall have female flare connections.

4.5 Filter

A. The ducted indoor unit shall have removable air filters.

B. The air filters shall be washable and reusable.

4.6 Control

A. The ducted indoor unit shall ship with a wall mountable control (YR-E17).

B. The ducted indoor unit shall be compatible with YR-E17, YR-E16B and QACT17A wired controls.

Part 5: Supply and Return Air Panels

5.1 Supply Grille Panel

A. For models AD07SL2VHB, AD09SL2VHB, AD12SL2VHB shall be compatible with the air supply panel

PAD0890SA.

B. The PAD0890SA air supply shall be distributed by horizontal and vertical motorized louvers.

C. For AD18SL2VHB shall be compatible with the air supply panel PAD1210SA.

D. The PAD1210SA air supply shall be distributed by horizontal and vertical motorized louvers.

5.2 Return Grille Panel

A. For models AD07SL2VHB, AD09SL2VHB, AD12SL2VHB shall be compatible with the air return panel

PAD0890RA.

B. The PAD0890SRA air return panel shall have a customer removable air filter that can be washed and reused.

C. For AD18SL2VHB shall be compatible with the air supply panel PAD1210RA.

D. The PAD1210RA air return panel shall have a customer removable air filter that can be washed and reused.

18 31-5000407 Rev. 0

Page 19

CASSETTE INDOOR UNITS

Part 1 General

1.1 Description

A. The cassette indoor unit completes the system when connected to the matching outdoor unit and field-

supplied piping and wiring.

1.2 Warranty

A. The cassette indoor unit shall be covered by a manufacture parts warranty. See appendix for full warranty detail.

1.3 Sound Pressure Rating

Model Blower Pressure Sound Rating dB(A)

(turbo/high/medium/low/quiet)

AB09SC2VHA 42/40/36/32/25

AB12SC2VHA 42/40/36/32/25

AB18SC2VHA 45/42/40/36/32

AL24LP2VHA 38/35/32/29/-AL36LP2VHA 45/42/38/34/-AL48LP2VHA 41/36/33/31/--

Part 2 Installation Requirements

2.1 Condensate

A. The cassette indoor unit shall ship with an insulated drain tube adapter that is sized for 3/4-inch PVC on one

end.

B. The cassette indoor unit shall have gravity drain port.

2.2 Clearances

A. The installer must follow the minimum clearances illustrated in the installation manual when installing the

indoor unit.

2.3 Mounting

A. The cassette indoor unit shall have 4 hanging brackets that are sized for 3/8 threaded rod.

B. The installer must use 3/8 threaded rod to suspend the cassette indoor unit from the building structure.

C. The installer must install the unit upright and level in all directions.

ENGLISH

Part 3 Electrical Requirements

3.1 Electrical Disconnect

A. Connecting wire must be continuous, without break, unless local code requires power disconnect next to

indoor unit.

Model Fan Motor Rating (HP)

AB09SC2VHA 0.033

AB12SC2VHA 0.033

AB18SC2VHA 0.033

AL24LP2VHA 0.161

AL36LP2VHA 0.161

AL48LP2VHA 0.161

B. If a disconnect is required by local code, it must be a 3-pole, single-throw type.

31-5000407 Rev. 0 19

Page 20

ENGLISH

CASSETTE INDOOR UNITS

Part 4 Components

4.1 Coil

A. Coil shall be painted with a hydrophilic coating to increase airflow efficiency.

B. Copper tubing shall have inner micro grooves to increase effective heat transfer capabilities.

C. Coils shall be pressure tested at 600~650 PSI using Helium leak detection.

D. The coil shall be charged with dry nitrogen for shipping at 70~100 PSI dwelling pressure.

4.2 Fan Motor

A. The cassette fan motor shall be a sealed DC resin-packed motor.

B. The fan motor shall have permanently lubricated bearings

4.3 Fan Blade

A. The fan blade shall be a noncorrodible axial fan blower.

4.4 Copper Piping

A. The coil shall be connected to a length of insulated annealed copper.

B. The ends of the tubing shall have female flare connections.

4.5 Panel

A. A panel must be ordered separately.

B. The cassette must be installed with a 1 inch recess beyond the ceiling surface to allow the panel to properly fit

flush against the ceiling and to allow the panel gasket to seal against the cassette.

4.6 Control

A. The compact cassette indoor units with model numbers that start with AB shall ship with a hand-held control

(YR-HG)

B. The large cassette indoor units with model numbers that start with AL shall ship with a hand-held control (YR-

HBS01).

C. The cassette indoor unit shall be compatible with YR-E17, YR-E16B and QACT17A wired controls.

CASSETTE INDOOR PANELS

Part 1 PB-700IB 2x2 Compact Cassette Panel

1.1 General

A. The PB-700IB panel must be ordered separately when ordering the indoor cassette unit.

1.2 Compatibility

A. The PB-700IB panel shall be compatible with FlexFit Compact Cassette indoor units, AB09SC2VHA,

AB12SC2VHA and AB18SC2VHA.

1.3 Installation

A. The cassette must be installed with a 1 inch recess beyond the ceiling surface to allow the panel to properly fit

flush against the ceiling and to allow the panel gasket to seal against the cassette.

1.4 Filter

A. The cassette indoor unit shall have a removable air filter.

B. The air filters shall be washable and reusable.

1.5 Air Flow Control

A. The PB-700IB shall have vertical and horizontal louvers on all side to direct the air flow.

20 31-5000407 Rev. 0

Page 21

CASSETTE INDOOR PANELS

Part 2 PB-950KB 3x3 Large Cassette Standard Panel

2.1 General

A. The PB-950KB panel must be ordered separately when ordering the indoor cassette unit.

2.2 Compatibility

A. The PB-950KB panel shall be compatible with FlexFit Pro Large Cassette indoor units, AL24LP2VHA,

AL36LP2VHA and AL48LP2VHA.

2.3 Installation

A. The cassette must be installed with a 1 inch recess beyond the ceiling surface to allow the panel to properly fit

flush against the ceiling and to allow the panel gasket to seal against the cassette.

2.4 Filter

A. The cassette indoor unit shall have a removable air filter.

B. The air filters shall be washable and reusable.

2.5 Air Flow Control

A. The PB-950KB shall have horizontal louvers on all sides to direct the air flow.

B. The PB-950KB shall have individual louver control.

Part 3 PB-950MB 3x3 Large Cassette Panel with Intelligent Eye

3.1 General

A. The PB-950MB panel must be ordered separately when ordering the indoor cassette unit.

3.2 Compatibility

A. The PB-950MB panel shall be compatible with FlexFit Pro Large Cassette indoor units, AL24LP2VHA,

AL36LP2VHA and AL48LP2VHA.

3.3 Installation

A. The cassette must be installed with a 1 inch recess beyond the ceiling surface to allow the panel to properly fit

flush against the ceiling and to allow the panel gasket to seal against the cassette.

3.4 Filter

A. The cassette indoor unit shall have a removable air filter.

B. The air filters shall be washable and reusable.

3.5 Air Flow Control

A. The PB-950MB shall have horizontal louvers on all sides to direct the air flow.

B. The PB-950MB shall have individual louver control.

3.6 Intelligent Eye

A. The PB-950MB shall have a heat mapping sensor.

B. The heat mapping sensor shall map 24.5ft (7.5m) in all directions.

C. The PB-950MB shall set the louvers to avoid heat signatures when set to ‘Evade’ when using the YR-HBS01

controller.

D. The PB-950MB shall set the louvers to follow heat signatures when set to ‘Follow’ when using the YR-HBS01

controller.

ENGLISH

31-5000407 Rev. 0 21

Page 22

ENGLISH

CONTROLS AND ACCESSORIES

Part 1: Wireless Control

1.1 General

A. The Haier wireless control, YR-HG, shall be compatible with Haier wall mounted and cassette indoor units.

B. The Haier wireless control, YR-HBS01, shall be compatible with Haier large cassette indoor units.

C. The wireless control (YR-HG) shall come packaged with wall mounted and compact cassette indoor units.

D. The wireless control (YR-HBS01) shall come packaged with large cassette indoor units.

1.2 Connection

A. The wireless control shall be infrared.

1.3 Compatibility

A. The wireless controls shall be compatible with all wall mounted and cassette indoor models.

1.4 Warranty

A. The warranty shall also cover all defects in workmanship or material for the unit accessory for a period of 1 year. Haier will

provide a new or refurbished controller, at its sole discretion

1.5 YR-HG Features

A. The YR-HG wireless control shall have a power button, individual mode buttons (heat, cool, dehumidify), temperature +/-,

fan speed, vertical and horizontal louver adjust.

B. The YR-HG wireless control shall be capable of setting a precise temperature of ±1°F (±0.5°C).

C. The YR-HG wireless control shall have a backlight.

D. The YR-HG wireless control shall have vertical and horizontal louver control.

E. The YR-HG wireless control shall have a child lock function.

F. The YR-HG wireless control shall have the ability to turn on/off the indoor unit display.

G. The YR-HG wireless control shall have Fahrenheit and Celsius temperature functions.

1.6 YR-HBS01 Features

A. The YR-HBS01 wireless control shall have a power button, individual mode buttons (heat, cool, dehumidify), temperature

+/-, fan speed, louver selector and horizontal louver adjust.

B. The YR-HBS01 wireless control shall have a large display with clock.

C. The YR-HBS01 wireless control shall have an on/off timer control.

D. The YR-HBS01 wireless control shall be capable of setting a precise temperature of ±1°F (±0.5°C).

E. The YR-HBS01 wireless control shall have a backlight.

F. The YR-HBS01 wireless control shall have vertical and horizontal louver control.

G. The YR-HBS01 wireless control shall have a child lock function.

H. The YR-HBS01 wireless control shall have the ability to turn on/off the indoor unit display.

I. The YR-HBS01 wireless control shall have Fahrenheit and Celsius temperature functions.

Part 2: Wired Controllers

2.1 General

A. The wired controller shall be a wall-mounted.

2.2 Connection

A. The wired controller shall connect to an indoor unit using the supplied cable.

B. Two wired controllers can connect to one indoor unit.

C. A single wired controller shall be able to connect up to 16 of the same model type of indoor units. The connected units shall

2.3 Compatability

2.4 Warranty

A. The warranty shall cover all defects in workmanship or material for a period of 1 year. Haier will provide a new or refurbished

2.5 YR-E17 Features

A. The wired controller shall operate power, mode (heat, cool, dry), temperature +/-, fan speed.

B. The wired controller shall be capable of setting a precise temperature of ±1°F (±0.5°C).

C. The wired controller shall have a backlight.

D. The wired controller shall have vertical and horizontal louver control.

E. The wired controller shall have a child lock function.

F. The wired controller shall display either Fahrenheit or Celsius.

G. The wired controller shall have the ability to display indoor ambient temperature.

H. The wired controller shall have a Clean Filter reminder.

I. The wired controller shall display error codes.

work in unison as a single zone.

A. The wired controller shall be compatible with all Haier indoor units. Connection to a wall mounted unit requires a WK-B adapter. If

multiple indoor units are connected to the controller, a WK-B adapter is required for each indoor unit.

controller, at its sole discretion.

22 31-5000407 Rev. 0

Page 23

CONTROLS AND ACCESSORIES

Part 2: Wired Controllers (continued)

2.7 QACT17A Features

A. The wired controller shall have large physical buttons for easy operation.

B. The wired controller shall have a power button, a mode button (heat, cool, dry), a fan speed button, a temperature up button

C. The wired controller shall be capable of setting a precise temperature of ±1°F (±0.5°C).

D. The wired controller shall have a backlight.

E. The wired controller shall have vertical and horizontal louver control.

G. The wired controller shall display either Fahrenheit or Celsius.

H. The wired controller shall have the ability to display indoor ambient temperature.

I. The wired controller shall have a Clean Filter reminder.

J. The wired controller shall display error codes.

K. The wired controller shall have an infrared receiver that can receive commands from a Haier hand-held remote

2.6 YR-E16B Features

A. The controller shall have a color display.

B. The wired controller shall have a power button, individual mode buttons (heat, cool, dry), temperature +/-, fan speed, vertical

C. The wired controller shall be capable of setting a precise temperature of ±1°F (±0.5°C).

D. The wired controller shall have a backlight.

G. The wired controller shall display either Fahrenheit or Celsius.

H. The wired controller shall have the ability to display indoor ambient temperature.

I. The wired controller shall have a Clean Filter reminder.

J. The wired controller shall display error codes.

K. The wired controller shall be able to be programmed for daily or weekly settings.

and a temperature down button.

F. The wired controller shall have a child lock function.

control.

and horizontal louver adjustments.

F. The wired controller shall have a child lock function.

ENGLISH

Part 3: QAWF01A WiFi Adapter

3.1 General

A. The QAWF01A WiFi adapter shall connect to a smart device app that will provide the user the ability to set mode,

3.2 Connection

A. The WiFi adapter shall connect to the indoor wall mounted unit via the USB port.

B. The WiFi adapter shall have an app that is compatible with both iOS and Android.

C. The WiFi adapter shall be paired with existing 2.4gHz network

D. The WiFi adapter shall comply with Part 15 of the FCC rules.

3.3 Compatibility

A. The WiFi adapter shall be compatible with all wall mounted indoor units.

3.4 Warranty

A

3.5 Features

A. The WiFi adapter shall be Google Home compatible.

B. The WiFi adapter shall be Amazon Alexa compatible.

C. The homeowner shall have the ability to install and configure the WiFi adapter.

temperature, and fan speed of the indoor unit.

.

The warranty shall cover all defects in workmanship or material for a period of 1 year. Haier will provide a new or refurbished

controller, at its sole discretion.

Part 4: WK-B Interface Kit

4.1 General

A. The WK-B adapter shall be used when connecting a wired controller to a wall mounted indoor unit.

4.2 Connection

A. The WK-B adapter shall connect to the indoor unit with a supplied 3-wire cable.

B. The wired controller shall connect to the WK-B with a supplied 3-wire cable.

4.3 Compatibility

A. The WK-B adapter shall be compatible with all Haier mini-split and multi-split wall mounted indoor units.

B. The WK-B adapter shall be compatible with YR-E17, YR-E16B, and QACT17A Haier wired controllers.

4.4 Warranty

A. The warranty shall cover all defects in workmanship or material for a period of 1 year. Haier will provide a new or

refurbished controller, at its sole discretion.

31-5000407 Rev. 0 23

Page 24

ENGLISH

NOTES

24 31-5000407 Rev. 0

Page 25

LIMITED WARRANTY

For the product models listed on Attachment 1 (the “Product”), this Standard Limited Warranty is provided to the Original

Owner of the Product:

For The Period Of: Haier Will Replace:

5 year limited parts

warranty

From the date of the original

purchase

7 year compressor

warranty

the original purchase

from the date of

WHAT IS THE DATE OF PURCHASE

The “Date of Purchase” is the date that the original installation is complete and all product start-up procedures have been

properly completed and verified by the installer’s invoice. If the installation date cannot be verified, then the Date of Purchase

will be sixty (60) days after the manufacture date, as determined by the Product’s serial number. You should keep and be able

to provide your original sales receipt from the installer as proof of the Date of Purchase. In new construction, the Date of

Purchase will be the date the owner purchased the residence from the builder.

WHO IS COVERED

This limited warranty cover all defects in workmanship or material for the mechanical and

electrical parts contained in the Product (“Defective Parts”) for a period of 5 years from the

Date of Purchase. Haier will provide new or refurbished parts, or a replacement for all or part

of the unit, at its sole discretion, to your licensed HVAC technician installer. This warranty also

covers all defects in workmanship or material for the unit controller for a period of 1 year. The

remote controller is covered by 1-year accessory warranty. The ductless system is covered

by standard warranty. Haier will provide a new or refurbished controller, at its sole discretion.

The compressor contained in this product is warrantied for a period of 7 years from the Date

of Purchase. Haier will provide a new or refurbished compressor, or a replacement for all or

part of the unit, at its sole discretion, to your licensed HVAC technician installer.

ENGLISH

ENGLISH

Owner occupied: The “Original Owner” of this product, which means the original owner (and his or her spouse) of the residence

where the Product was originally installed. Subject to the law of the state or province where the Product is installed, this warranty

is not transferable to subsequent owners or if the product is moved to a different residence after the initial installation. Nonowner occupied: This limited warranty is provided for product 1) installed in a) single family or multi-family non-owner occupied

residential buildings, or b) non-industrial commercial applications, (such as office buildings, retail establishments, hotels/motels)

where the product is not subjected to an atmosphere with corrosives or high levels of particulates (such as soot, aerosols, fumes,

grease), and 2) if the product is maintained annually by a licensed HVAC technician (proof of annual maintenance is required).

The “Original Owner” of the product, means the original owner of the building where the product was originally installed. For

new construction, the purchaser of the building from the builder will also be considered an original owner. This warranty is not

transferable to subsequent owners or if the product is moved to a different location after the initial installation.

HOW CAN YOU GET SERVICE

Contact your licensed HVAC technician installer. All installation and service must be performed by a licensed HVAC

technician. Failure to use a licensed HVAC technician for installation of this Product voids all warranty on this Product..

THIS WARRANTY DOES NOT COVER

• Damage from improper installation.

• Damage in shipping.

• Defects other than from manufacturing (i.e.,

workmanship or materials).

• Damage from misuse, abuse, accident, alteration, lack

of proper care and/or regular maintenance, or incorrect

electrical voltage or current.

• Damage resulting from floods, fires, wind, lightning,

accidents or similar conditions.

• Damage from installation or other services performed by

other than a licensed HVAC technician.

• Labor and related services for repair or installation of the

Product.

• A Product purchased from an online retailer.

31-5000407 Rev. 0 25

• Damage as a result of subjecting Product to an

atmosphere with corrosives or high levels of particulates

(such as soot, aerosols, fumes, grease).

• A Product sold and/or installed outside of the 50 United

States, the District of Columbia, or Canada.

• Batteries for the controller and other accessories

provided with the Product for installation (e.g., plastic

hose).

• Normal maintenance, such as cleaning of coils, cleaning

filters, and lubrication.

• For Product installed in non-owner occupied applications,

Product that has not been maintained annually by a

licensed HVAC technician (proof required).

date is needed to obtain service under the warranty.

Staple your receipt here. Proof of the original purchase

Page 26

ENGLISH

LIMITED WARRANTY

10 YEAR STANDARD REGISTERED LIMITED WARRANTY

All “Indoor and Outdoor Products,” identified in Attachment 1, registered by the installer or the Original Owner within 60 days

of the Date of Purchase shall receive a Standard Registered Limited Warranty, which shall be identical to the Standard Base

Warranty, except that the Limited Parts Warranty shall be for a term of 10 Years and the Limited Compressor Warranty shall be

for a term of 10 years. All Product not registered within 60 days of the Date of Purchase shall be subject to the Standard Base

Warranty. Some states and provinces do not allow warranty terms to be subject to registration; in those states and provinces the

longer terms for Limited Parts Warranty and the Limited Compressor Warranty apply.

THIS LIMITED WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy provided in this warranty is exclusive and is granted in lieu of all other remedies. This warranty does not cover

incidental or consequential damages. Some states and provinces do not allow the exclusion of incidental or consequential

damages, so this limitation may not apply to you. Some states and provinces do not allow limitations on how long an implied

warranty lasts, so this limitation may not apply to you. This warranty gives you specific legal rights and you may also have other

rights which vary by state and province. This warranty covers units within the 50 United States, the District of Columbia and

Canada. This warranty it provided by GE Appliances a Haier company, Louisville, KY 40225.

ATTACHMENT 1

The “Product” is defined as Haier brand Ductless Split Units. The “Product” contains 2 sub-categories of goods: “Indoor and

Outdoor Products” and “Selected Installation Products,” which are further defined below: “Indoor and Outdoor Products” can

further be identified by the following model number descriptions: 1U*, 2U*, 3U*, 4U*, AB*, AD*, AL*, AM*, AW*, AF*, MVA*

MVH* “Selected Installation Products,” identified by the following model number descriptions: PB-* FQG-*, AH1-*, MS1-* and

MS3-*

26 31-5000407 Rev. 0

Page 27

TABLE DES MATIÈRES

DIMENSIONS DE L’UNITÉ EXTÉRIEURE ...........................................................................28

DIMENSIONS DE L’UNITÉ MURALE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

DIMENSIONS DE L’UNITÉ À CONDUITS ...........................................................................30

DIMENSIONS DE L’UNITÉ À CASSETTE ...........................................................................31

DÉGAGEMENTS DU SYSTÈME ....................................................................................32

SYSTÈME .......................................................................................................33

Partie 1 : Généralités ...............................................................................................33

Partie 2 : Plage de fonctionnement et rendement ...................................................................33

Partie 3 : Exigences d’installation ...................................................................................37

Partie 4 : Exigences électriques .....................................................................................37

UNITÉ EXTÉRIEURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Partie 1 : Généralités ...............................................................................................38

Partie 2: Installation ................................................................................................38

Partie 3 : Composants .............................................................................................38

UNITÉ INTÉRIEURE MURALE .....................................................................................39

Partie 1 : Généralités ...............................................................................................39

Partie 2 : Exigences d’installation ...................................................................................39

Partie 3 : Exigences électriques .....................................................................................39

Partie 4 : Composants .............................................................................................40

UNITÉS INTÉRIEURES À CONDUITS

Partie 1 : Généralités ...............................................................................................41

Partie 2 : Exigences d’installation ...................................................................................41

Partie 3 : Exigences électriques .....................................................................................41

Partie 4 : Composants .............................................................................................42

Partie 5: Panneaux d’admission et de retour d’air ....................................................................42

UNITÉS INTÉRIEURES À CASSETTE ..............................................................................43

Partie 1 : Généralités ...............................................................................................43

Partie 2 : Exigences d’installation ...................................................................................43

Partie 3 : Exigences électriques .....................................................................................43

Partie 4 : Composants .............................................................................................44

UNITÉS INTÉRIEURES À CASSETTE ..............................................................................44

Partie 1: Panneau à cassette compact 2x2 PB-700IB ................................................................44

Partie 2: Panneau standard à cassette large 3x3 PB-950KB ...........................................................45

Partie 3: Panneau à cassette large 3x3 PB-950MB avec œil intelligent ................................................45

COMMANDES ET ACCESSOIRES .................................................................................46

Partie 1 : Télécommande ...........................................................................................46

Partie 2 : Commandes câblées ......................................................................................46

Partie 3 : Adaptateur Wi-Fi QAWF01A ...............................................................................47

Partie 4 : Trousse d’interface WK-B .................................................................................47

GARANTIE LIMITÉE ............................................................................................. 49

..............................................................................41

FRANÇAIS

31-5000407 Rev. 0 27

Page 28

DIMENSIONS DE L’UNITÉ EXTÉRIEURE

)

1U12LC2VHA

1U18LC2VHA

FRANÇAIS

21 1/4 (540)

27 1/8 (688)

30 3/4 (780

31 7/8 (810)

1U36LP2VHA

9 5/8 (245

)

11 3/8 (288)

)

38(967)

37 3/8(950)

23 5/8(600)

15 5/8(396)

15 7/8(404)

21 1/4(450)

1U48LP2VHA

37 3/8(950)

53 1/8(1350)

15 5/8(396

1U24LP2VHA

38(967)

37 3/8(950)

23 5/8(600)

15 5/8(396)

15 7/8(404)

21 1/4(450)

23 5/8(600)

15 7/8(404)

17 3/4(450)

28 31-5000407 Rev. 0

Page 29

DIMENSIONS DE L’UNITÉ MURALE

AW12LC2VHB

11(280)

AW18LC2VHB

)

13 1/8 (332

33 5/8 (855

39 1/4 (997

AW24LP2VHA

)

13 1/4(336)

8 (204)

43 7/8(1115)

9 5/8(243)

AW36LP2VHA

)

14 3/8(365)

9 1/4 (235)

51 3/4(1316)

10 7/8(275)

FRANÇAIS

31-5000407 Rev. 0 29

Page 30

DIMENSIONS DE L’UNITÉ À CONDUITS

AD12SL2VHB

AD18SL2VHB

FRANÇAIS

16 1/2 (420)

air flow

7 1/4 (184)

14 1/2 (369)

34 3/4 (880)

33 1/2 (850)

30 3/4 (780)

air flow

25 1/4 (640)

35 1/8 (892)

3 1/2

(90)

(30)

1 1/4

47 3/4(1213)

46 1/8(1170)

43 1/4(1100)

air flow

2 3/4(70)

2 3/4(70)

6 (152)

AM36LP2VHA

25 3/4(653)

air flow

9 7/8(251)

28 3/8(720)

AM48LP2VHA

59(1500)

56 1/2(1435)

air flow

50 5/8(1286)

61 514(1556)

59(1500)

56 1/2(1435)

6 5/8(168)

air flow

9 1/4(235)

16 1/2(420)

14 1/2 (369)

air flow

7 1/4(185)

17 3/4 (450)

AM24LP2VHA

23 1/2 (595)

air flow

37 3/4(960)

3 1/2(90)

1 1/8(30)

41 3/8 (1050)

39 (990)

33 1/2(849)

air flow

air flow

air flow

25 3/4(653)

50 5/8(1286)

61 514(1556)

air flow

6(152)

9 7/8(251)

28 3/8(720)

6 5/8(168)

air flow

9 1/4(235)

31 3/8 (797)

air flow

7/8 (250)

37 5/8 (957)

/8 (148)

air flow

/8 (226)

30 31-5000407 Rev. 0

Page 31

DIMENSIONS DE L’UNITÉ À CASSETTE

AB12SC2VHA / AB18SC2VHA

Barre de suspension 22 7/16(570)

Corps de l'unité 22 7/8 (580)

Ouverture de toit 23-23 7/8 (585-605)

Plus de 59 (1500) à mur de tous les côtés.

Panneau 24 3/8 (620)

10 1/4 (260)

1 (25)

1 pouce en retrait entre la surface du toit

et le bas de l'unité sans panneau dans

AL24LP2VHA / AL36LP2VHA / AL48LP2VHA

11 1/4 (285)

6 7/8 (175)

moins de 1/2 (12)

Ningún objeto más cercano

que 39 (1000

22 7/8 (580)

3/4 (20)3/4 (20)

Ø 4 (100)

moins de 1/2 (12)

Pas plus au-dessus du sol que 106 (2700)

8 1/4 (210)

FRANÇAIS

Barre de suspension 30 1/8 (765)

Corps de l'unité 1/8 (840)

Ouverture de toit 34 1/4 - 35 (870-890)

Plus de 59 (1500) à mur de tous les côtés.

4 3/8 (110)

7 (179)

1 (25)

1 pouce encastré entre le plafond et le bas de l'unité sans panneau

31-5000407 Rev. 0 31

3 1/2 (90)

8 (204)

5 (126)

3 1/2 (90)

Moins de 1 (25)

Ningún objet à vendre plus

de 39 (1000)

Panneau 37 3/8 (950)

33 1/8 (840) 1 3/4 (45)1 3/4 (45)

2 5/8 (68)

Ø 3 (75)

Installer entre 98-144 (2500-3658) sur le sol

4 3/8 (110)

3 1/2 (90)

Moins de 1 (25)

Page 32

DÉGAGEMENTS DU SYSTÈME

DÉGAGEMENTS MINIMAUX

(L’aspect peut varier)

Cette illustration est pour référence seulement. L’aspect de votre produit peut être différent. Lisez votre manuel avant

l’installation. Expliquez le fonctionnement de l’appareil à l’utilisateur selon ce manuel.

ЮсидччисчмтсзтмчƯчхи

Ùïøöçè$óò¤! "æð¥

Ùïøöçè$óò¤! "æð¥

утхчŻиƑпдуисчизш

ĥиымепизđŻщджшдчмтс

Cassette

1 ft.

FRANÇAIS

Ùïøöçè$óò¤! "æð¥

ХдзмцчдсжиисчхипđшсмчŻ

мсчŻхмишхиичпиупдсжлих

зтмчƯчхицшуŻхмишхиƑ

&умизц¤!(#р¥

Ùïøöçè"$óò¤&!æð¥

installation à l'unité (unité: in. (mm.))

unit:

arrière

Ùïøöçè$óò¤! "æð¥

Ùïøöçè&óò¤!%"æð¥

Ùïøöçè&óò¤!%"æð¥

devant

B

> 6 in

5 ft.

Sortie d’air

8 pi au-dessus

8 ft. Over

Conduits

Circulation d’air

Air Flow

dos et côté

en haut

d’air

Sortie d’airEntrée

5 ft.

> 12 in

> 12 in

> 12 in

la hauteur des

barrières est

inférieure à

celle de l'unité

extérieure

avant et arrière

en haut

en haut

en hauten haut

quand des barrières existent au dessus de l'unité

en haut 6(150)

en haut

en haut

en haut

en haut

en haut

32 31-5000407 Rev. 0

Page 33

SYSTÈME

Partie 1 : Généralités

1.1 Description

A. Le climatiseur à thermopompe Flexfit Single de Haier doit être de type bi-blocs à capacité variable composé

d’une unité extérieure et d’une unité intérieure murale.

1.2 Toxicité

A. La thermopompe doit adhérer à la directive RoHS et figurer dans son registre.

Partie 2 : Plage de fonctionnement et rendement

2.1 Plage de fonctionnement

A. La thermopompe doit générer des températures de climatisation allant de 0 °F à 115 °F (-18°C à 46 °C).

B. La thermopompe doit générer une capacité supérieure à 70 % à une température extérieure de -22 °F (-30 °C).

C. Le système à thermopompe connecté aux modèles 1U24LP2VHA, 1U36LP2VHA ou 1U48LP2VHA à l’extérieur

doivent générer 100 % de la capacité de climatisation à une température extérieure de 0 °F (-18 °C).

D. La thermopompe doit fonctionner normalement à une tension de 187 à 253 V.

2.2 Rendement

Le rendement du système doit se situer dans le créneau de fonctionnement présenté dans le tableau suivant.

A. Le rendement de climatisation doit être vérifié selon les normes AHRI 210/240 pour des températures

intérieures de 80 °F ts / 67 °F tm (27°/19 °C) et des températures extérieures de 95 °F ts / 75 °F tm (35°/24 °C).

B. Le rendement de chauffage doit être vérifié selon les normes AHRI 210/240 pour des températures intérieures

de 70°F ts / 60 °F tm (21°/16°C) et des températures extérieures de 47 °F ts / 43 °F tm (8°/6 °C).

FRANÇAIS

31-5000407 Rev. 0 33

Page 34

SYSTÈME

Nom de

modèle et

plage de

fonctionnement

Alimentation Tension, Cycle, Phase V/Hz/ - 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1

Climatisation Capacité nominale Btu/h 12,000 17,000 24000 35000

Chauffage Capacité chauffage nominale Btu/h 13,500 18,000 27000 37000

Unité extérieure Intensité sonore extérieure dB 53 54 47 52

FRANÇAIS

Unité intérieure Intensité sonore intérieure (Turbo/

réfrigérant

Tuyaux

Type de système Montage mural

Extérieur 1U12LC2VHA 1U18LC2VHA 1U24LP2VHA 1U36LP2VHA

Intérieur AW12LC2VHB AW18LC2VHB AW24LP2VHA AW36LP2VHA

Climatisation °F (°C) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46)

Chauffage °F (°C) 5~75(-15~24) 5~75(-15~24) -4~75(-20-24) -4~75(-20-24)

Calibre des fils entre D.I. et D.E. 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded

Calibre fusible max. A 15 20 25 30

Intensité circuit min. A 14 17 21 26

Plage de capacités Btu/h 4,780-13,300 5,100-19,000 6800-30700 8500-37500

Puissance d'entrée nominale W 1,180 1,530 2,182 3,500

Taux rendement énergétique

saisonnier

Taux rendement énergétique 10.5 11.0 10.0 8.6

Suppression d’humidité pintes/h 3.38 4.23 4.10 5.1

Plage des capacités de chauffage

Btu/h

Puissance d'entrée nominale W 1,200 1,485 2700 3700

Coefficient de performance

saisonnière

Dimension : Hauteur po (mm) 21 1/4 (540) 27 (688) 38 (965) 38 (965)

Dimension : Largeur po (mm) 30 3/4 (780) 31 7/8 (810) 37 3/8(950) 37 3/8(950)

Dimension : Profondeur po (mm) 9 5/8 (245) 11 5/16 (288) 14 5/8(370) 14 5/8(370)

Poids (Exp./Net) – lb (kg) 75.4/68.8 (34.2/31.2) 100.3/94.8 (45.5/43) 202.8/ 176.4 (92/80) 207.2/180.7 (94/82)

Haut/Moy/Bas/Silence) dB

Débit d’air (Turbo/Haut/Moy/Bas/

Silence) pi3/min

Dimension : Hauteur po (mm) 11(280) 12 3/4 (322) 13 1/4(336) 14 3/8(365)

Dimension : Largeur po (mm)

Dimension : Profondeur po (mm) 8 1/16 (204) 9 1/4 (235) 9 9/16(243) 10 7/8(275)

Pression statique ext. max., pouces

de colonne d’eau (Pa)

Tuyau de vidange D.E. po NA NA NA NA

Pompe à condensat intérieure NA NA NA NA

Rehauss. max. drain po (mm) NA NA NA NA

Modèle de grille NA NA NA NA

Dim. grille : H x L x P po (mm) NA NA NA NA

Poids (Exp./Net) – lb (kg) 26.9/22.05 (12.2/10) 35.3/28.7 (16/13) 45.4/37.5(20.6/17) 55.1/46.3(25.5/21)

Raccords Flare Flare Flare Flare

Liquide/Aspiration D.E. po 1/4 3/8 1/4 1/2 3/8 5/8 3/8 5/8

Charge d’usine oz

Long. conduite max. pi / m 50/15 83/25 165/50 165/50

Hauteur max. pi / m 33/10 50/15 100/30 100/30

18.0 18.0 17.0 17.0

5,120-13,990 5,400-20,400 6800-34100 8500-41000

9.5 9.0 10.0 10.0

41/40/34/27/23 46/45/40/35/25 49/47/42/36/34 50/48/44/38/36

353/294/277/259/230 636/530/483/430/383 710/650/560/440/410 720/660/570/450/420

33 5/8 (855) 39 1/4 (997) 43 7/8(1115) 51 13/16(1316)

NA NA NA NA

42.3 45.9 88.2 88.2

34 31-5000407 Rev. 0

Page 35

SYSTÈME

Nom de

modèle et

plage de

fonctionnement

Alimentation Tension, Cycle, Phase V/

Climatisation Capacité nominale Btu/h 11,000 16,000 24000 35000 47000

Chauffage Capacité chauffage

Unité extérieure Intensité sonore extérieure

Unité intérieure Intensité sonore intérieure

Tuyaux

réfrigérant

Type de système

Extérieur

Intérieur

Climatisation °F (°C)

Chauffage °F (°C)

Hz/ -

Calibre des fils entre D.I.

et D.E.

Calibre fusible max. A 15 20 25 30 40

Intensité circuit min. A 14 17 21 26 35

Plage de capacités Btu/h 4,000~12,000 5,000~18,000 6800-30700 8500-37500 11900-54500

Puissance d'entrée

nominale W

Taux rendement

énergétique saisonnier

Taux rendement

énergétique

Suppression d’humidité

pintes/h

nominale Btu/h

Plage des capacités de

chauffage Btu/h

Puissance d'entrée

nominale W

Coefficient de performance

saisonnière

dB

Dimension : Hauteur po

(mm)

Dimension : Largeur po

(mm)

Dimension : Profondeur

po (mm)

Poids (Exp./Net) – lb (kg) 75.4/68.8 (34.2/31.2) 100.3/94.8 (45.5/43) 202.8/ 176.4 (92/80) 207.2/180.7 (94/82) 260.1/231.5 (118/105)

(Turbo/Haut/Moy/Bas/

Silence) dB

Débit d’air (Turbo/Haut/

Moy/Bas/Silence) pi3/min

Dimension : Hauteur po

(mm)

Dimension : Largeur po (mm)

Dimension : Profondeur

po (mm)

Pression statique ext. max.,

pouces de colonne d’eau

(Pa)

Tuyau de vidange D.E. po 1 1/4 1 1/4 1 1/4 1 1/4 1 1/4

Pompe à condensat

intérieure

Rehauss. max. drain po

(mm)

Modèle de grille NA NA NA NA NA

Dim. grille : H x L x P po

(mm)

Poids (Exp./Net) – lb (kg) 47.2/36.8 (21.4/16.7) 62.4/51.4(28.3/23.3) 81.1/68.8 (36.8/31.2) 130.1/121.3 (59/55) 132.3/114.6 (60/52)

Raccords Flare Flare Flare Flare Flare

Liquide/Aspiration D.E. po 1/4 3/8 1/4 1/2 3/8 5/8 3/8 5/8 3/8 5/8

Charge d’usine oz

Long. conduite max. pi / m 50/15 83/25 165/50 165/50 230/75

Hauteur max. pi / m 33/10 50/15 100/30 100/30 100/30

1U12LC2VHA 1U18LC2VHA 1U24LP2VHA 1U36LP2VHA 1U48LP2VHA

AD12SL2VHB AD18SL2VHB AM24LP2VHA AM36LP2VHA AM48LP2VHA

0~115(-18~46) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46) 0~115(-18~46)

5~75(-15~24) 5~75(-15~24) -4~75(-20-24) -4~75(-20-24) -4~75(-20-24)

208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1 208-230/60/1

14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded 14/4 AWG Stranded

5,000 ~ 13,000 6,000~19,000 6800-34100 8500-41000 13600-64800

21 1/4 (540) 27 (688) 38 (965) 38 (965) 53 1/8 (1350)

30 3/4 (780) 31 7/8 (810) 37 3/8(950) 37 3/8(950) 37 3/8(950)

9 5/8 (245) 11 5/16 (288) 14 5/8(370) 14 5/8(370) 14 5/8(370)

38/35/29/26/23 31/29/23/29/25 38/35/32/29 32/28/25/23 41/36/33/31

400/353/282/247/218 540/500/447/365/306 845/670/530/470 1100/950/735/675 1350/1150/930/765

7 5/16 (185) 7 5/16 (185) 9 7/8 (250) 9 7/8 (250) 9 7/8 (250)

33 7/16 (850) 46 1/16 (1170) 37 5/8 (957) 59 (1500) 59 (1500)

16 9/16 (420) 16 9/16 (420) 25 3/4 (655) 28 3/8 (720) 28 3/8 (720)

0.16 (40) 0.16 (Pa) 0.6(150) 0.6(150) 0.6(150)

Standard Standard Standard Standard Standard

27 9/16 (700) 27 9/16 (700) 27 9/16(700) 27 9/16(700) 27 9/16(700)

Conduit étroit Conduit à statique élevée

1,200 1,700 2,182 3,500 4,476

16.0 15.0 17.0 17.0 17.0

9.0 9.0 11.0 10.0 10.5

2.65 3.85 5.1 6.8 11.0

12,000 17,000 26500 37500 52000

1,400 1,600 2,089 3,283 4,407

8.2 9.5 11.0 10.5 10.0

53 54 47 52 53

NA NA NA NA NA

42.3 45.9 88.2 88.2 131.0

FRANÇAIS

31-5000407 Rev. 0 35

Page 36

SYSTÈME

modèle et

plage de

fonctionnement

Alimentation Tension, Cycle, Phase V/

Climatisation Capacité nominale Btu/h 11,000 16,000 24000 35000 45000

Chauffage Capacité chauffage

FRANÇAIS

Unité extérieure Intensité sonore extérieure

Unité intérieure Intensité sonore intérieure

réfrigérant

Nom de

Tuyaux

Type de système

Extérieur

Intérieur

Climatisation °F (°C)

Chauffage °F (°C)

Hz/ -

Calibre des fils entre D.I.

et D.E.

Calibre fusible max. A 15 20 25 30 40

Intensité circuit min. A 14 17 21 26 35

Plage de capacités Btu/h 4,000~12,000 5,000~18,000 6800-27000 8500-37500 11900-52800

Puissance d'entrée

nominale W

Taux rendement

énergétique saisonnier

Taux rendement

énergétique

Suppression d’humidité

pintes/h

nominale Btu/h

Plage des capacités de

chauffage Btu/h

Puissance d'entrée

nominale W

Coefficient de performance

saisonnière

dB

Dimension : Hauteur po

(mm)