Page 1

Manuel d’utilisation

Manual para el usuario

RDE350AW/RDG350AW/CRDE350AW

Gas and Electric Clothes Dryers

Sécheuses électriques et à gaz

Secadoras de ropa a gas y eléctricas

User Manual

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ................................................................. 2

Gas Dryer Precautions .................................................................................................. 2

Installation Safety Precautions ..................................................................................... 3

General Safety Precautions .......................................................................................... 4

PARTS AND FEATURES ....................................................................................... 5

INSTALLATION INSTRUCTIONS .......................................................................... 6

Tools Needed .................................................................................................................6

Additional Parts Required ..............................................................................................6

Location Requirements .................................................................................................7

Electrical & Gas Supply Requirements .......................................................................... 8

Exhaust System Requirements ...................................................................................11

Mobile Home - Additional Requirements ..................................................................13

STEP BY STEP INSTRUCTIONS .......................................................................... 14

Step 1 - Unpack the Dryer ...........................................................................................14

Step 2 - Attach a Power Cord to the Dryer (Electric Dryer Only) ..............................14

Step 2 - Connect to a Gas Supply Line (Gas Dryer Only) ...........................................16

Step 3 - Connect to an Exhaust System .....................................................................18

Step 4 - Level the Dryer ..............................................................................................19

Step 5 - Complete the Installation ..............................................................................19

CONTROL PANEL AND FEATURES .................................................................... 20

OPERATING INSTRUCTIONS ............................................................................. 22

Step 1 - Prepare and Sort Laundry .............................................................................22

Step 2 - Clean the Lint Screen ....................................................................................22

Step 3 - Load the Dryer ............................................................................................... 23

Step 4 - Start the Dryer ...............................................................................................23

CARE AND CLEANING GUIDE ............................................................................ 24

Cleaning and Maintenance ..........................................................................................24

Vacationing Precautions .............................................................................................25

Moving or Storage Preparation ...................................................................................25

TROUBLESHOOTING ........................................................................................ 26

LIMITED WARRANTY ........................................................................................ 28

RECORD KEEPING

Thank you for purchasing this Haier

product. This user manual will help you

get the best performance from your

new dryer.

For future reference, record the model

and serial number located on back of

the dryer, and the date of purchase.

Staple your proof of purchase to this

manual to aid in obtaining warranty

service if needed.

___________________________________

Model number

___________________________________

Serial number

___________________________________

Date of purchase

1

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING

To reduce the risk of fire, electric shock, or injury to persons when using

your appliance, follow the basic precautions, including the following:

NOTE: The dryer is designed in compliance with ANSI Z21.5.1 or ANSI/UL

2158 - CAN/CSA C22.2 No. 112-97 (latest editions) for HOME USE ONLY.

This dryer is not recommended for commercial application such as restaurants and beauty salons.

• The dryer must be electrically grounded in accordance with local codes,

or in the absence of local codes, with the National Electrical Code, ANSI/

NFPA 70 or Canadian Electrical Code, CSA C22.1.

• Read all of the instructions before using this appliance.

• This appliance must be properly installed and located in accordance with

the installation instructions before it is used.

• Use this appliance only for its intended purpose as described in this user

manual.

• Do not use the dryer for commercial clothes drying.

GAS DRYER PRECAUTIONS

WARNING

For your safety, the information in this manual must be followed to

minimize the risk of fire or explosion or to prevent property damage,

personal injury or loss of life.

• Installation must be performed by a qualiÞ ed or licensed contractor,

plumber, or gas Þ tter qualiÞ ed or licensed by the state, province, or

region where this appliance is being installed.

• Combustible materials, gasoline, and other ß ammable vapors and liquids

must not be stored near the dryer.

2

Page 4

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch. Do not use any phone in your

building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the Fire Department.

INSTALLATION SAFETY PRECAUTIONS

DANGER

Before you throw away your old appliance, remove the door or lid so

that children cannot hide or get trapped inside your old appliance.

• The dryer must be installed by a qualiÞ ed appliance technician.

• Do not install or store this appliance where it will be exposed to water

and/or to the weather.

• The appliance must be properly grounded to conform with all electrical

codes and ordinances. See “Electrical Requirements” section.

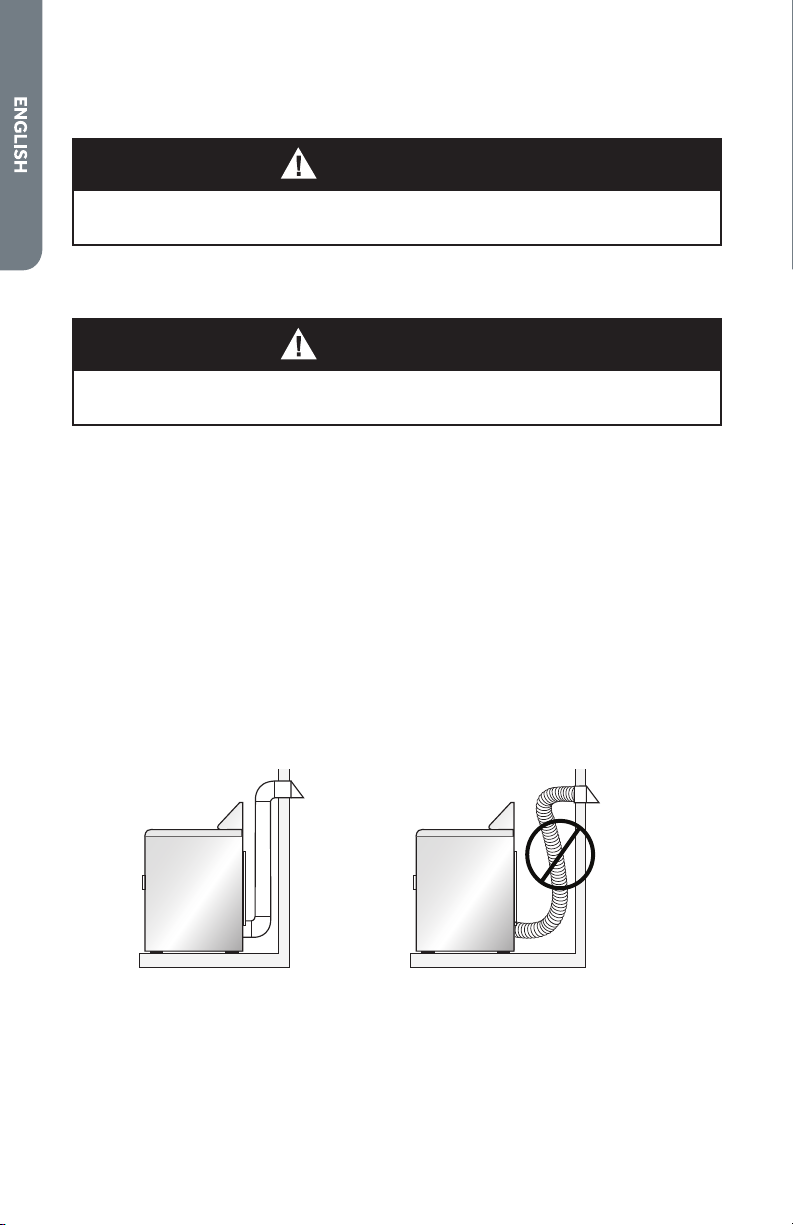

• Do not install this dryer to an exhaust system with plastic or metal foil

ß exible ducting. Flexible ducting can collapse, easily be crushed, and trap

lint. These conditions will obstruct clothes dryer airß ow and increase the

risk of Þ re.

3

Page 5

GENERAL SAFETY PRECAUTIONS

• Keep area around the exhaust opening and adjacent surrounding areas

free from the accumulation of lint, dust and dirt.

• Keep the dryer area clear and free from items that would obstruct

the ß ow of combustion and ventilation air through the louvered panel

located on the rear of the dryer.

• Close supervision is necessary if this appliance is used by or near

children. Do not allow children to play on, with, or inside this appliance.

• Do not dry items that have been previously cleaned in, washed in,

soaked in, or spotted with gasoline, dry-cleaning solvents or other

ß ammable explosive substances, since they give o vapors which could

ignite or explode.

• Do not place items exposed to cooking oils in your dryer. Items

contaminated with cooking oil may contribute to a chemical reaction

than could cause a load to catch Þ re.

• If material has been used with any ß ammable liquids or solids, it should

not be dried in the dryer until all traces of ß ammable liquids and fumes

have been removed.

• Do not reach into the appliance if the drum is moving.

• Do not tamper with the controls.

• Do not use fabric softeners or products to eliminate static unless

recommended by the manufacturers of the fabric softener or product.

• Do not use heat to dry items containing foam rubber or similarly

textured rubber-like materials.

• Clean the lint screen before or after each load.

• The interior of the appliance and the exhaust duct should be cleaned

periodically by qualiÞ ed service personnel.

• To minimize the possibility of electric shock, unplug this appliance from

the power supply before attempting any maintenance or cleaning.

NOTE: Turning the cycle selector knob to the “O ” position does NOT

disconnect the appliance from the power supply.

• Never unplug your dryer by pulling on the power cord. Always grasp the

plug Þ rmly and pull straight out from the outlet.

• Do not attempt to service, repair or replace any part of the appliance

unless speciÞ cally recommended in this user manual or in published

repair instructions that you understand and have the skills to carry out.

• Before discarding or removing from service, remove the door to the

drying compartment.

SAVE THESE INSTRUCTIONS

HOUSEHOLD USE ONLY

4

Page 6

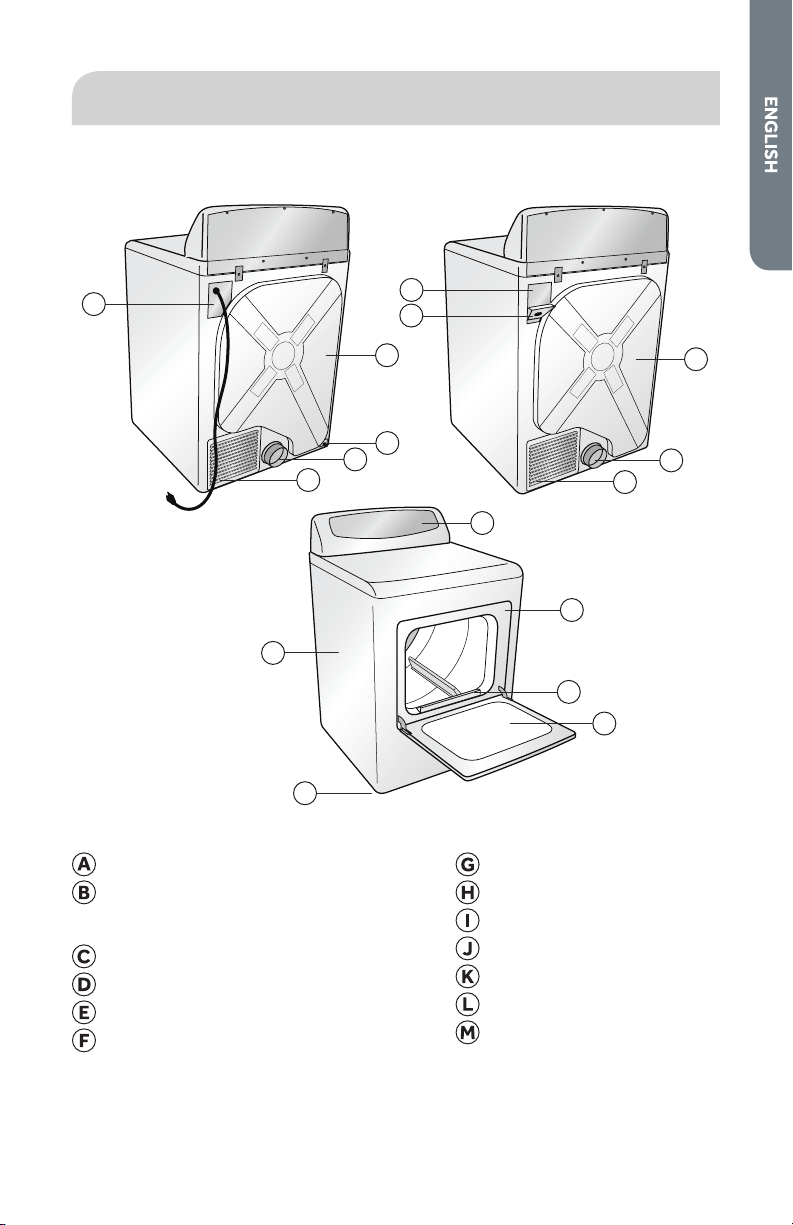

PARTS AND FEATURES

Gas Dryer Electric Dryer

A

D

G

E

F

M

L

Power Cord (120 volt/60 Hz)

Strain Relief Mounting Bracket

(Canadian electric model has a 240 volt/

60 Hz power cord attached.)

Terminal Block Access Cover

Access Panel

Exhaust Outlet

Louvered Ventilation Panel

C

B

D

E

F

H

I

J

K

Gas Inlet Pipe

Control Panel

Door Safety Switch

Lint Screen

Dryer Door

Leveling Feet

Dryer Cabinet

5

Page 7

INSTALLATION INSTRUCTIONS

WARNING

Risk of Fire

Clothes dryer installation must be performed by a qualified installer.

Install the clothes dryer according to the manufacturer's instructions

and local codes.

To reduce the risk of severe injury or death, follow all installation

instructions.

TOOLS NEEDED

• Phillips Screwdriver

• Flat-Blade Screwdriver

• Channel-Lock Adjustable Pliers

• ½" Open-End Wrench

• Carpenter’s Level

• Measuring Tape (12 ft. [3.7 m] min.)

For gas installations only:

• Pipe Wrench

• 2 Adjustable Wrenches

ADDITIONAL PARTS REQUIRED

• 4" (10.2 cm) Rigid or Flexible Metal Exhaust Ducting

• Vent Clamps

• Duct Tape

• Power Cord (US Electric Dryer Only)

- A power supply cord kit must be purchased to meet local electrical codes.

- UL Listed Strain Relief

• Gas Hookup Parts (Gas Dryer Only)

- !" NPT Elbow

- !" NPT Flare Adapter Fitting

- !" Flexible Gas Connector

- Pipe-Joint Compound

• Mobile Home Installation Kit (Gas Dryer for Mobile Home Only)

The dryer must use a 3 or 4-wire NEMA 14-30 or 10-30 type SRDT or ST

(as required) power supply cord rated at 120/240 volt AC minimum,

30 amp, with 3 open-end spade lug connectors with upturned ends or

closed loop connectors and marked for use with clothes dryers.

6

Page 8

LOCATION REQUIREMENTS

WARNING

Do not install the dryer where gasoline or other flammables are kept or

stored. If the dryer is installed in a garage, it must be a minimum of

18 inches (45.7 cm) above the floor. Failure to do so can result in death,

explosion, fire or burns.

• The dryer must be installed on a solid ß oor. A concrete ß oor is the best.

• The ß oor should be level with maximum slope of 1" (2.5 cm) under entire dryer.

• A suitable location is protected from direct sunlight and heat sources such as

radiators, baseboard heaters, or cooking appliances.

• Do not install on carpeting.

• The location must have the appropriate electrical and gas supply outlets. See

“Electrical & Gas Supply Requirements” section for details.

• Do not install the dryer in an area where the dryer will come into contact with

curtains, thick carpet, or anything that might obstruct the ß ow of combustion

and ventilation air.

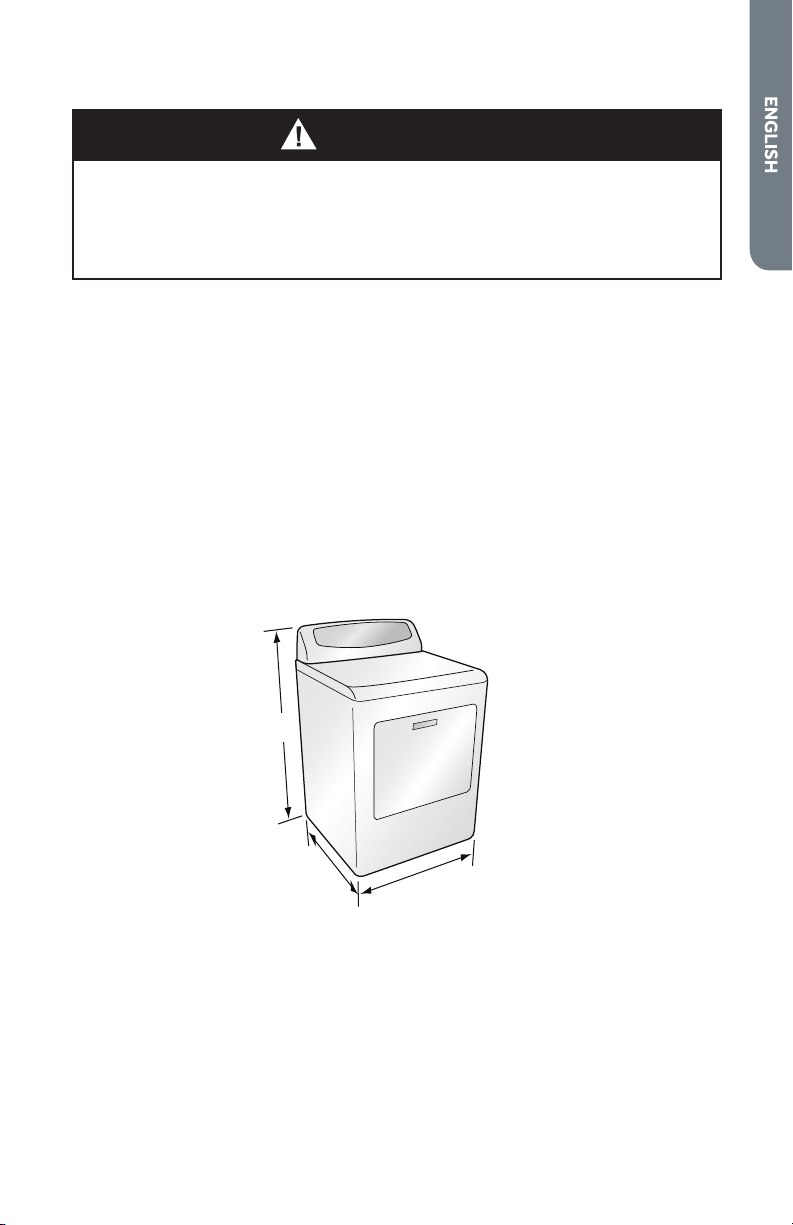

DRYER DIMENSIONS

42¹⁄₂"

(108 cm)

28¹⁄₄"

(72.4 cm)

27"

(68.6 cm)

7

Page 9

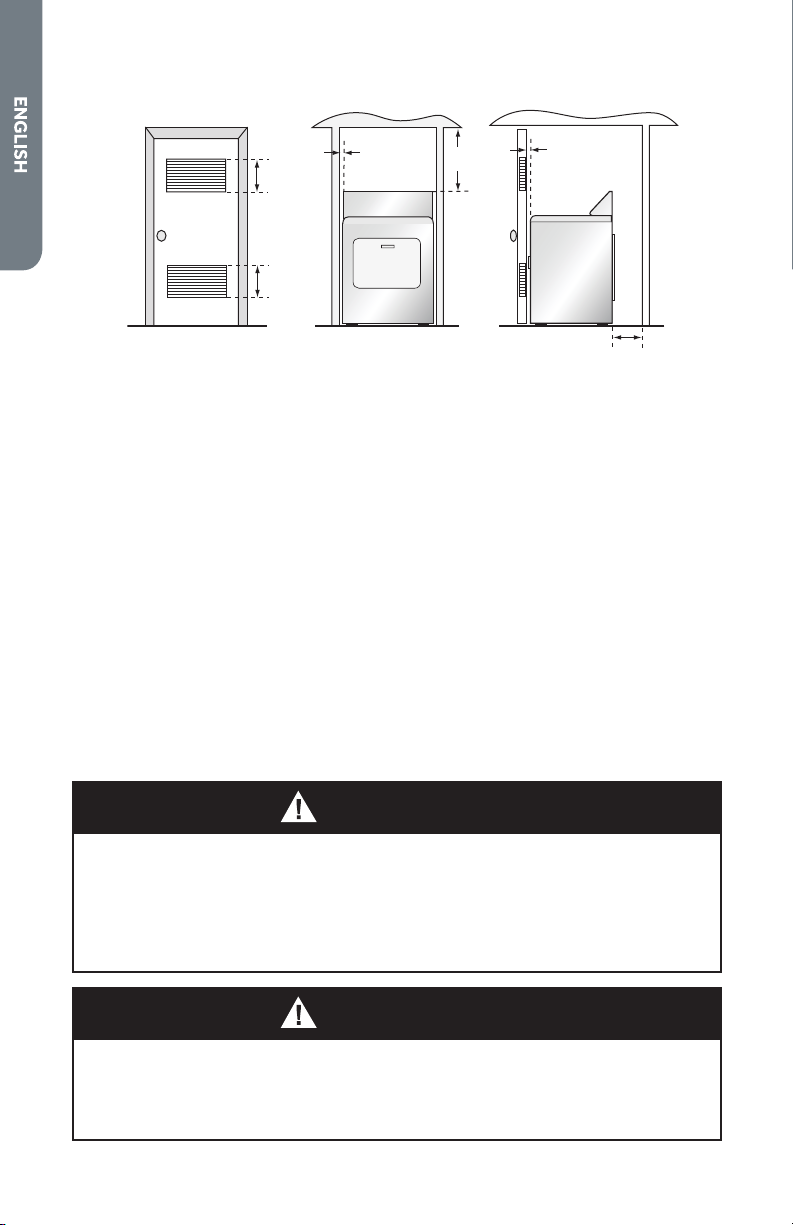

ALCOVE OR CLOSET REQUIREMENTS

1"

(2.5 cm)

5½"

(14 cm)

2

60 in.

(387.1 cm2)

2

60 in.

(387.1 cm2)

1"

(2.5 cm)

15"

(38.1 cm)

MINIMUM CLEARANCES

• Dimensions shown are the recommended minimum clearance allowances.

• Space on the sides of the dryer is required to avoid noise transfer.

• Space at the rear of the dryer is necessary to accommodate exhaust ducting.

OTHER REQUIREMENTS

• This dryer must be vented to the outdoors.

• Do not install the dryer in a closet with a solid door.

• A closet door must be louvered or vented with a minimum of 120 sq. in.

(774.2 sq. cm) of opening equally divided at the top and bottom of the door. The

airß ow must not be obstructed in any way.

• No other fuel-burning appliance shall be installed in the same closet as the gas

dryer.

ELECTRICAL & GAS SUPPLY REQUIREMENTS

ELECTRIC DRYER (U.S. ONLY)

WARNING

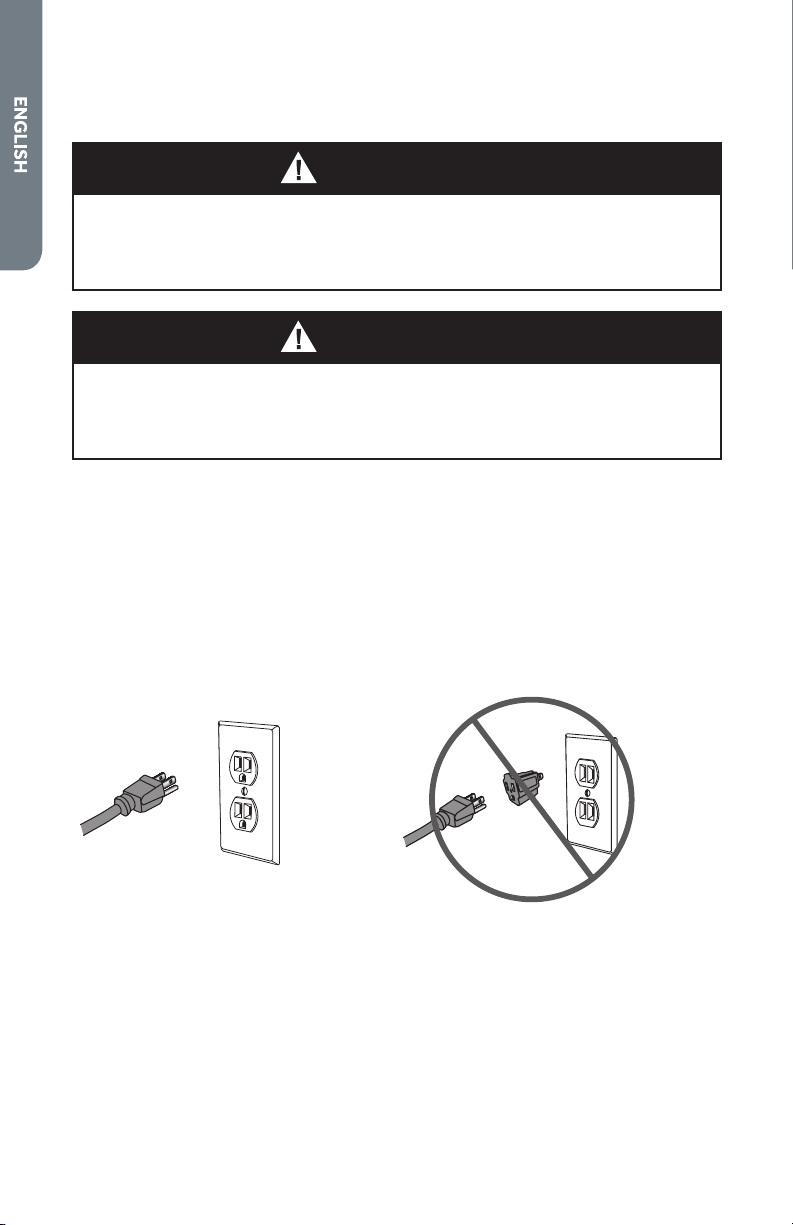

The dryer must be plugged into a properly grounded 3 or 4-wire, single

phase, 120/240 volt (or 120/208 volt), 60Hz, AC-only electrical outlet

connected to an individual 30-amp circuit, fused with a 30-amp

time-delay fuse or circuit breaker. Do not operate a washer and dryer

on the same circuit.

WARNING

This appliance must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape route for the electrical current.

8

Page 10

NOTE: The electrical supply for the dryer must conform with local codes and

ordinances and the latest edition of the National Electrical Code, ANSI/NFPA 70.

• If the electrical supply available in the intended dryer location does not meet the

above requirements, contact a licensed electrician.

• A dryer operating on a 208 volt power supply will have longer drying times than if

it were operating on a 240 volt power supply.

• The dryer is not equipped with a power cord. A kit that meets local electrical

codes must be purchased separately. The dryer can be Þ tted with a 3 or

4-wire NEMA 14-30 or 10-30 type SRDT or ST (as required) power cord rated

at 120/240 volt AC minimum, 30 amp, with 3 open-end spade lug connectors

with upturned ends or closed loop connectors and marked for use with clothes

dryers.

• A UL listed strain relief must be attached to the dryer to hold the power cord.

• Do not use an aluminum wire receptacle with copper-wired power cord and plug

(or vice versa). The proper wiring and receptacle is a copper-wired power cord

with a copper-wired receptacle.

• The electrical outlet should be located so that the power cord is accessible when

the dryer is in the installed position.

ELECTRIC DRYER (CANADA ONLY)

WARNING

The dryer must be plugged into a properly grounded 4-wire, single

phase, 120/240 volt, 60Hz, AC-only electrical outlet connected to an

individual 30-amp circuit, fused with a 30-amp time-delay fuse or

circuit breaker. Do not operate a washer and dryer on the same circuit.

WARNING

This appliance must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape route for the electrical current.

NOTE: The electrical service to the dryer must conform with local codes and

ordinances and the latest edition of the CSA C22.1 Canadian Electrical Code Part 1.

• If the electrical supply available in the intended dryer location does not meet the

above requirements, contact a licensed electrician.

• Do not use an aluminum wire receptacle with copper-wired power cord and plug

(or vice versa). The proper wiring and receptacle is a copper-wired power cord

with a copper-wired receptacle.

• The electrical outlet should be located so that the power cord is accessible when

the dryer is in the installed position.

9

Page 11

GAS DRYER

ELECTRICAL SUPPLY REQUIREMENTS

WARNING

The gas dryer must be plugged into a properly grounded 3-wire, single

phase, 120 volt, 60Hz, AC-only electrical outlet, fused with a 15-amp

time-delay fuse or circuit breaker.

WARNING

This appliance must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape route for the electrical current.

• The dryer is equipped with a power cord that has a 3 prong plug. Do not cut or

remove the grounding prong from the power cord.

• The power cord must be plugged into a mating, 3 prong outlet, grounded in

accordance with local codes and ordinances. If a mating outlet is not available,

contacted a licensed electrician to have one installed.

• If you are not sure if your outlet is properly grounded, contact a licensed

electrician.

• Do not use a 3 prong plug adapter.

• Do not use an extension cord.

GAS SUPPLY REQUIREMENTS

NOTE: The gas service to the dryer must conform with local codes and ordinances

and the latest edition of the National Fuel Gas Code, ANSI Z223.1 or in Canada,

CAN/CGA B149.1.

Natural Gas

• The dryer is equipped for use with Natural gas.

LP (Liquid Propane) Gas

• The dryer can be converted for use with LP gas.

• Conversion to LP gas must be made by a qualiÞ ed technician.

10

Page 12

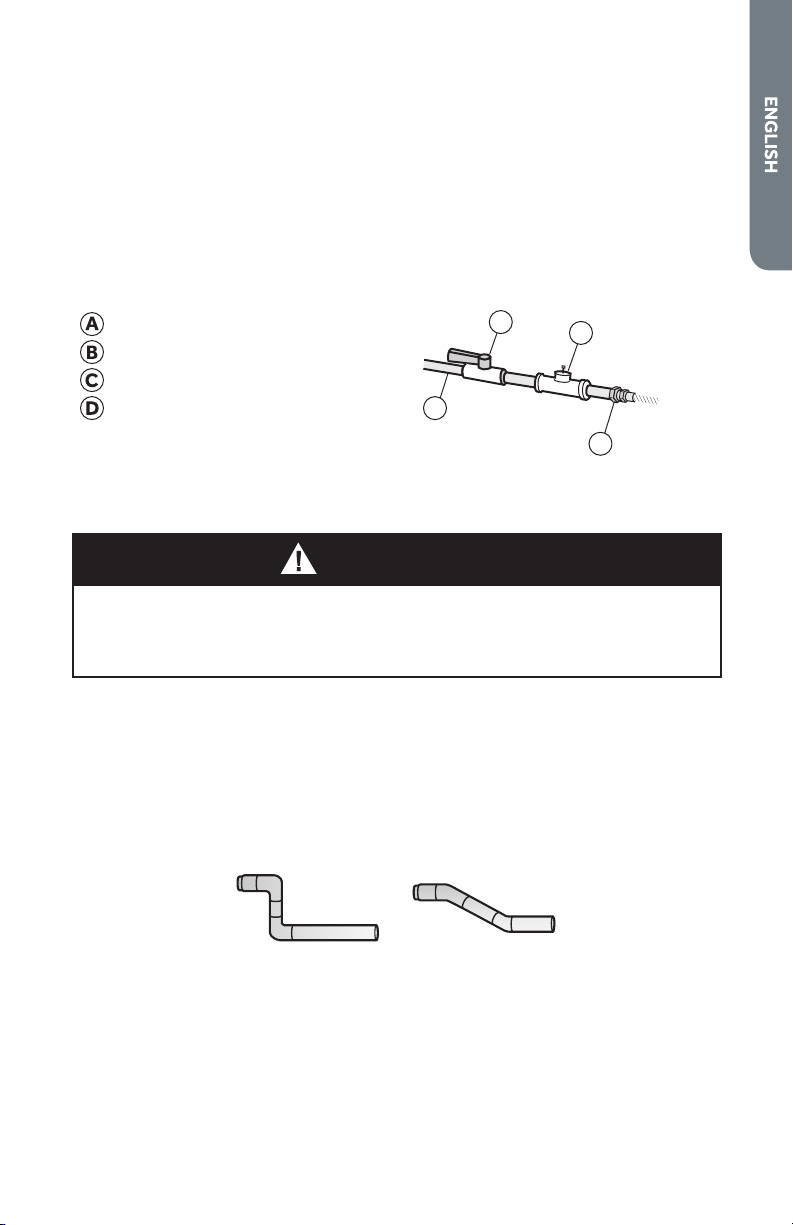

Gas Supply Line

• The gas supply line should be ½" (1.3 cm) pipe and must have an individual

manual shut-o valve installed within 6 ft. (183 cm) of the dryer in accordance

with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or in Canada with the

Natural Gas and Propane Installation Code, B149.1.

• The shut-o valve should be easy to reach for opening and closing.

• A "" NPT minimum plugged tapping must be installed immediately upstream of

the shut-o valve. This Þ tting is used to check the gas pressure.

• The supply line should terminate with a !" NPT ß are adapter Þ tting.

¹⁄₂" NPT Gas Supply Line

Gas Shut-O Valve

¹⁄₈" NPT Minimum Plugged Tapping

!" NPT Flare Adapter Fitting

B

C

A

D

EXHAUST SYSTEM REQUIREMENTS

WARNING

This section describes the requirements for a safe and efficient exhaust

system. Failure to follow these instructions can result in poor dryer

performance, damage to the dryer, and a fire hazard.

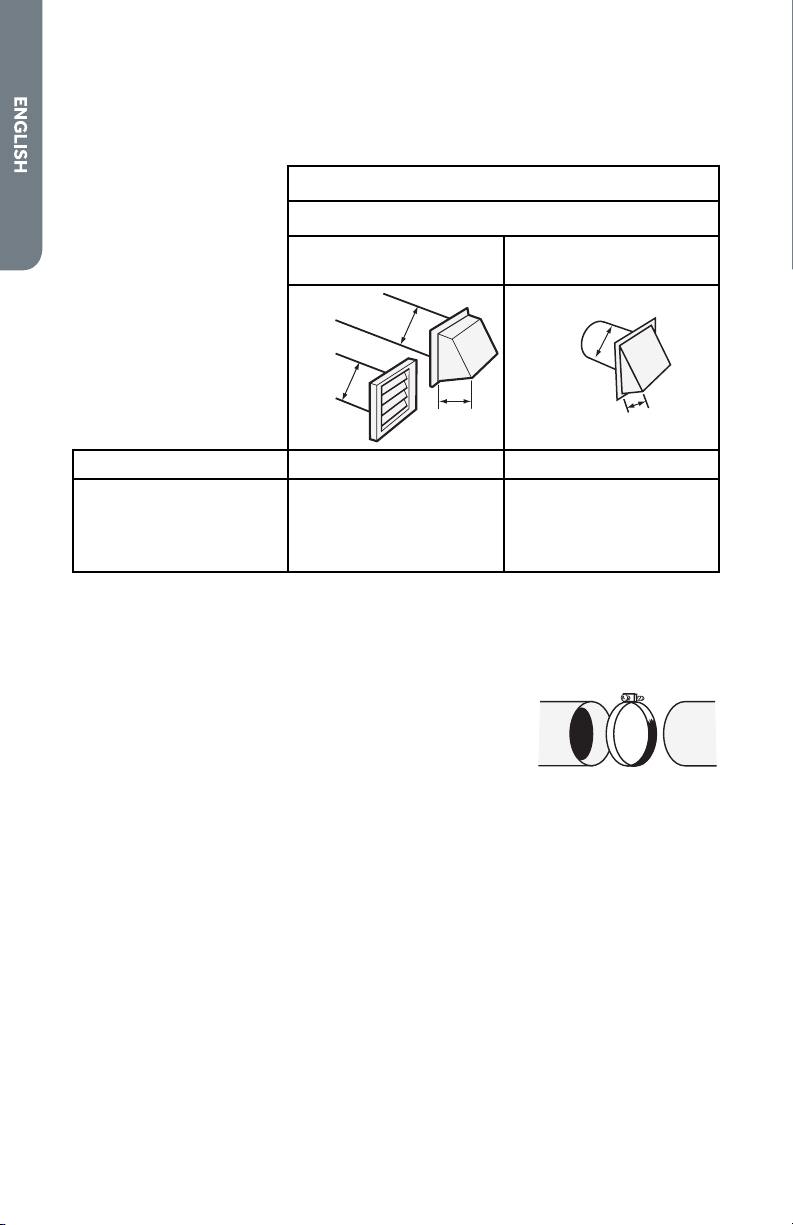

DUCTING

• If your current exhaust system is constructed of plastic or metal foil ß exible

ducting, replace it with rigid metal ducting.

• Use only 4” (10.2 cm) diameter rigid metal ducting.

• When making turns in the ductwork, use 45° elbows rather than 90° elbows. This

provides better airß ow and can reduce the accumulation of lint in the exhaust

system.

90° - Good 45° - Better

11

Page 13

• Do not exceed the length of duct pipe for the number of elbows shown in the

chart below. Doing so can cause an accumulation of lint, increase drying time,

and create a Þ re hazard.

• Two 45° elbows equal one 90° elbow.

Recommended Maximum Exhaust Length

Exhaust Hood Types

Recommended Use Only For Short Run

Installations

4"

(10.2 cm)

dia.

4"

(10.2 cm)

dia.

4"

(10.2 cm)

4"

(10.2 cm)

dia.

2½"

(6.4 cm)

No. of 90° Elbows Rigid Metal Rigid Metal

0

1

2

3

90 feet

60 feet

45 feet

35 feet

60 feet

45 feet

35 feet

25 feet

• All joints should be tight to avoid air leaks. The male end of each section of

ducting must point away from the dryer.

• Use clamps or duct tape to connect and seal all joints.

Do not connect with screws or other fasteners that

extend into the interior of the duct as they will create a

collection point for lint.

Clamp

• Avoid running the exhaust system through an unheated area as this will

cause condensation to form inside the duct and accelerate the rate of lint

accumulation.

• Avoid running the exhaust system vertically through a roof as this may expose

the exhaust system to down drafts, causing an increase in air restriction.

• Avoid sagging, compression or crimping of the exhaust system as this will result

in reduced airß ow and poor dryer performance.

• Do not screen the end of the exhaust system. Lint will accumulate and

eventually clog the screen. Use an approved exhaust hood to terminate the duct

outdoors.

12

Page 14

EXHAUST HOOD

• Use an approved exhaust hood with a swing-out damper that opens when the

dryer is in operation. When the dryer stops, the damper automatically closes to

prevent drafts and the entrance of insects and rodents.

• Louvered or box hood styles are recommended. Angled hood styles are

acceptable, but should be used only for short run installations. See the

“Recommended Maximum Exhaust Length” chart for more information.

• To avoid restricting air ß ow, maintain a minimum of 12” (30.5 cm) clearance

between the vent hood and the ground or any other obstruction.

MOBILE HOME - ADDITIONAL REQUIREMENTS

• The installation must conform to current Manufactured Home Construction and

Safety Standard, Title 24 CFR-Part 3280 or the Canadian Manufactured Home

Standard CAN/CSA-Z240 MH.

• Special provisions must be made for outside makeup air. The opening should be

at least twice as large as the dryer exhaust outlet.

• If the dryer is exhausted through the ß oor and into an enclosed area beneath the

mobile home, the exhaust system must terminate outside the enclosure with

the termination securely fastened to the mobile home structure.

GAS DRYER ONLY (MOBILE HOME ONLY)

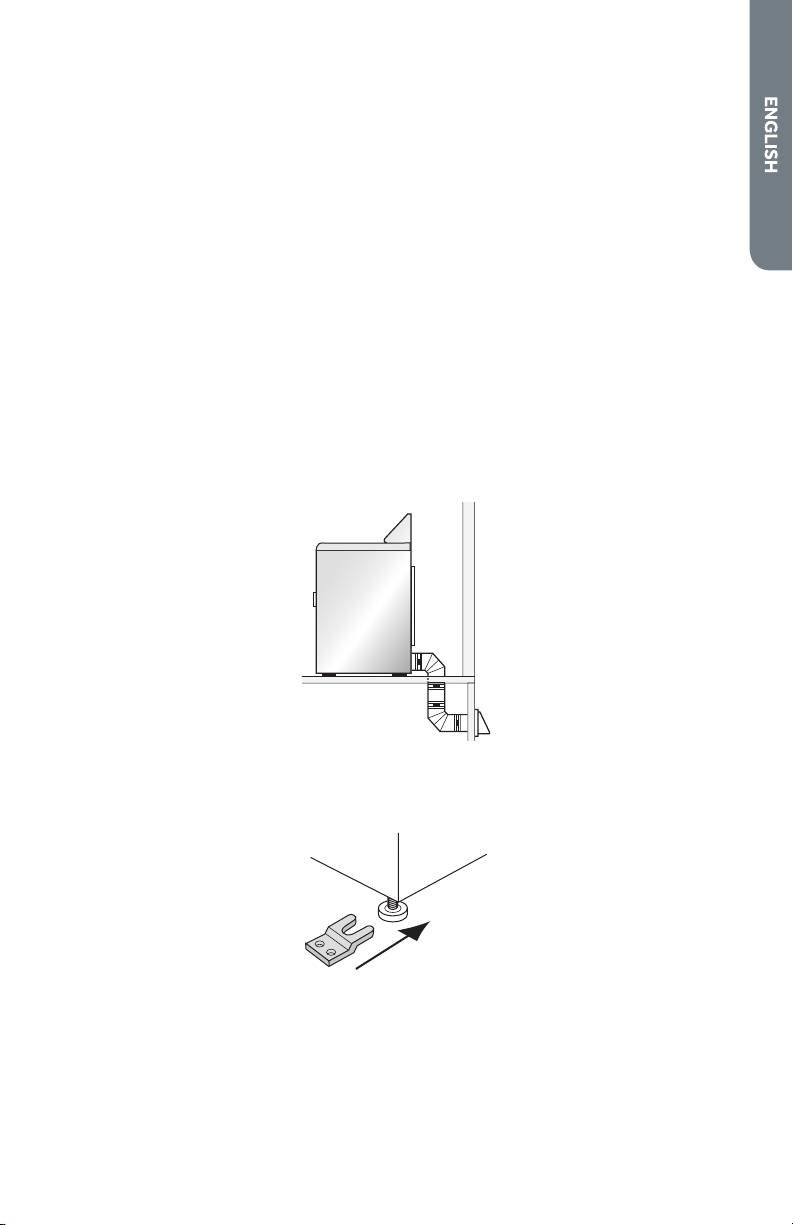

• The dryer must be fastened to the ß oor using a mobile home installation kit.

Follow the instructions supplied with the kit.

13

Page 15

STEP BY STEP INSTRUCTIONS

INSTALLING YOUR DRYER

We recommend that your new dryer be installed by a qualiÞ ed appliance technician.

If you feel that you have the skills to install the dryer, please read the installation

instructions carefully before installing.

CAUTION: If, after completing these steps, you are unsure that the dryer is properly

installed, contact a qualiÞ ed appliance technician.

STEP 1 - UNPACK THE DRYER

1. Remove all packing materials. This includes the foam base and all adhesive tape

holding the dryer accessories inside and outside.

2. Inspect and remove any remains of packing, tape or printed materials before

using the dryer.

WARNING

To avoid danger of suffocation, keep plastic bag and other packing

material away from babies and children. Do not use this bag in cribs,

carriages and playpens. The plastic bag could block nose and mouth

and prevent breathing. This bag is not a toy.

STEP 2 - ATTACH A POWER CORD TO THE DRYER

(ELECTRIC DRYER - U.S. ONLY)

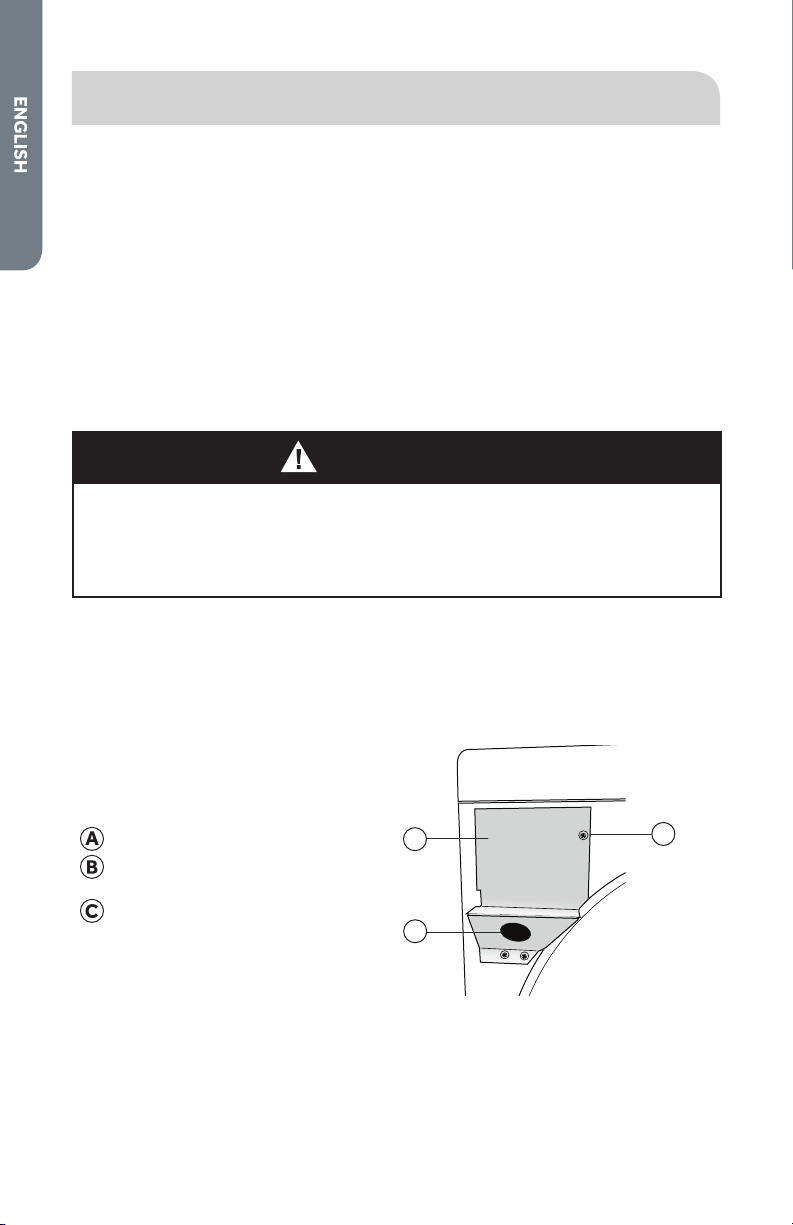

1. Remove the screw securing the terminal block access cover, located on the back

of the dryer’s upper corner.

Terminal Block Access Cover

Hole in Strain Relief Mounting

Bracket

Remove This Screw

14

A

B

C

Page 16

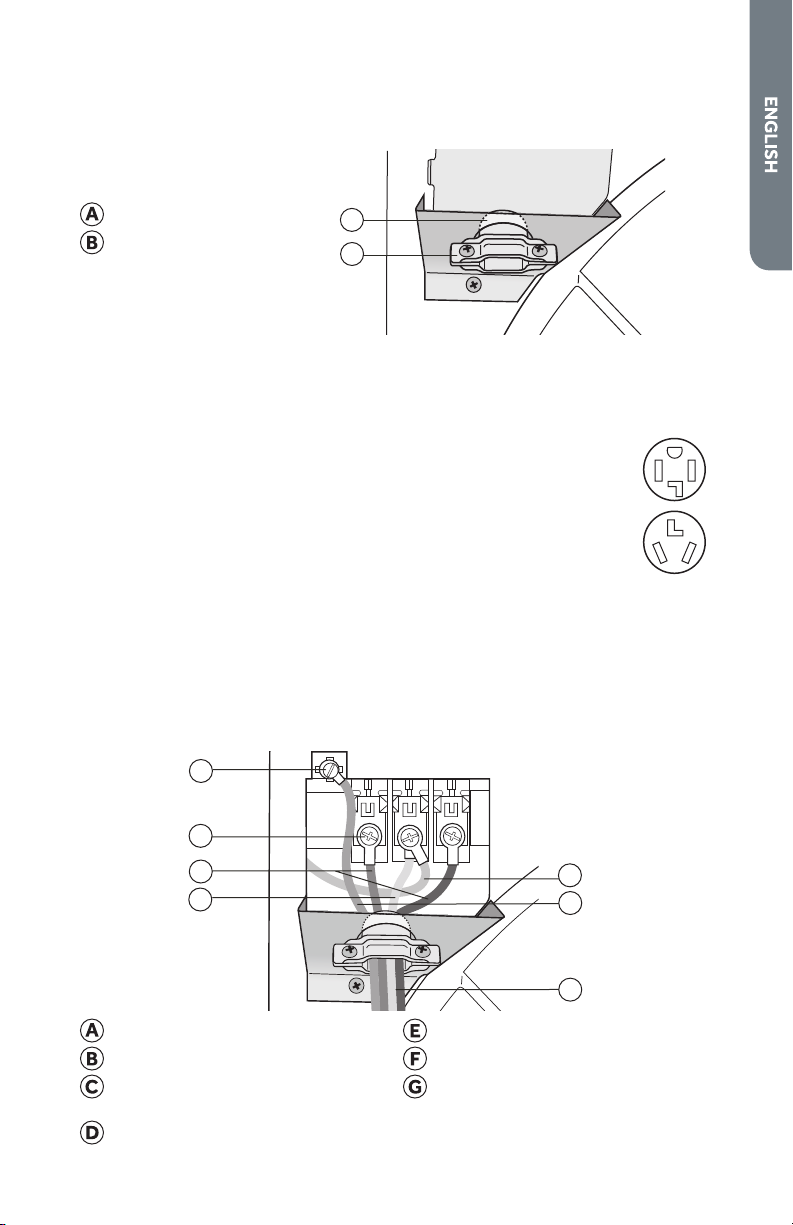

2. Insert a UL listed strain relief into the mounting bracket hole. Position the strain

relief so that one tab is pointing up and one tab is pointing down. Tighten the

strain relief screws just enough to hold the two halves together.

Tab

Strain Relief

3. Insert a power cord into the strain relief. Take care to ensure that the wire

insulation of the power cord is inside the strain relief.

4. Connect power cord wires following Part A for a 4-wire power cord

connection or Part B for a 3-wire power cord connection.

4-wire (recommended) if your home has a 4-wire receptacle (NEMA

14-30 type SRDT or ST):

3-wire (if 4-wire is not available) if your home has a 3-wire receptacle

(NEMA 10-30 type SRDT):

CAUTION: A 4-wire connection is required for mobile homes and

where local codes do not permit the use of 3-wire connections.

5. Tighten strain relief screws.

6. Be sure that none of the wires are touching the dryer drum inside the dryer

cabinet.

7. Reinstall the terminal block cover.

A

B

PART A - 4-WIRE POWER CORD

A

B

C

D

Green Ground Screw

Terminal Block Screw

Power Cord Wires (One Red; One

Black)

White (Neutral) Power Cord Wire

G

F

E

Power Cord

Green Power Cord Ground Wire

Green (Neutral) Ground Wire From

the Dryer Harness

15

Page 17

A1. Remove the green (neutral) ground wire from the green ground screw located

above the terminal block.

A2. Attach the green power cord ground wire to the cabinet with the green ground

screw. Tighten the screw securely.

A3. Attach the green (neutral) ground wire from the dryer harness and the white

(neutral) power cord wire to the center terminal block screw. Tighten the screw

securely.

A4. Attach each of the remaining 2 power cord wires (red and black) to one of the

outer terminal block screws. Either wire can be attached to either screw. Tighten

both screws securely.

IMPORTANT: Do not make a sharp bend or crimp the wires at connections.

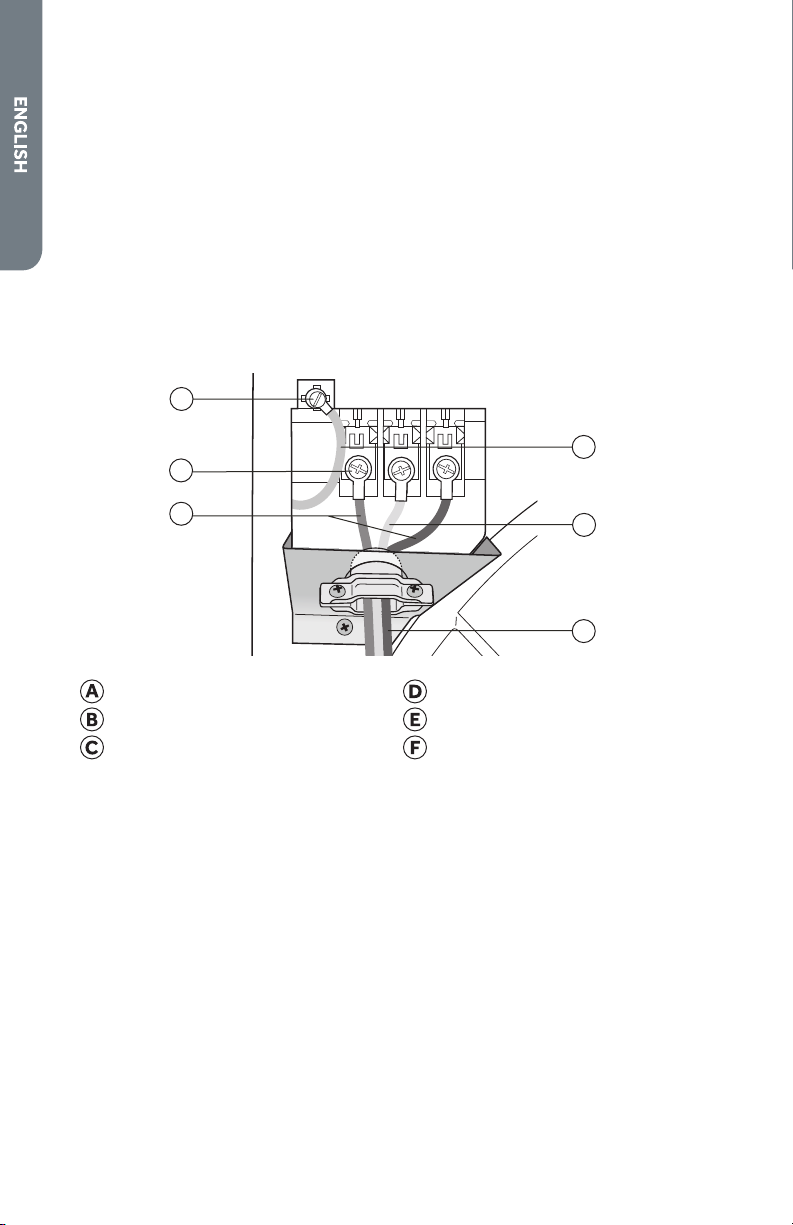

PART B - 3-WIRE POWER CORD

A

F

B

C

E

D

Green Ground Screw

Terminal Block Screw

Outer Power Cord Wires

B1. Attach the center (neutral) power cord wire to the center terminal block screw.

Tighten the screw securely.

B2. Attach each of the remaining 2 power cord wires to one of the outer terminal

block screws. Either wire can be attached to either screw. Tighten both screws

securely.

IMPORTANT: Do not make a sharp bend or crimp the wires at connections.

Power Cord

Center (Neutral) Power Cord Wire

Green (Neutral) Ground Wire

From the Dryer Harness

STEP 2 - CONNECT TO A GAS SUPPLY LINE

(GAS DRYER ONLY)

NOTE: Do not connect the dryer to an LP gas line without Þ rst converting the

dyer with a conversion kit. An LP conversion kit must be installed by a qualiÞ ed

technician.

NOTE: Apply a pipe-joint compound that that is resistant to the action of LP gas to

all males threads. Do not use plumber’s tape.

16

Page 18

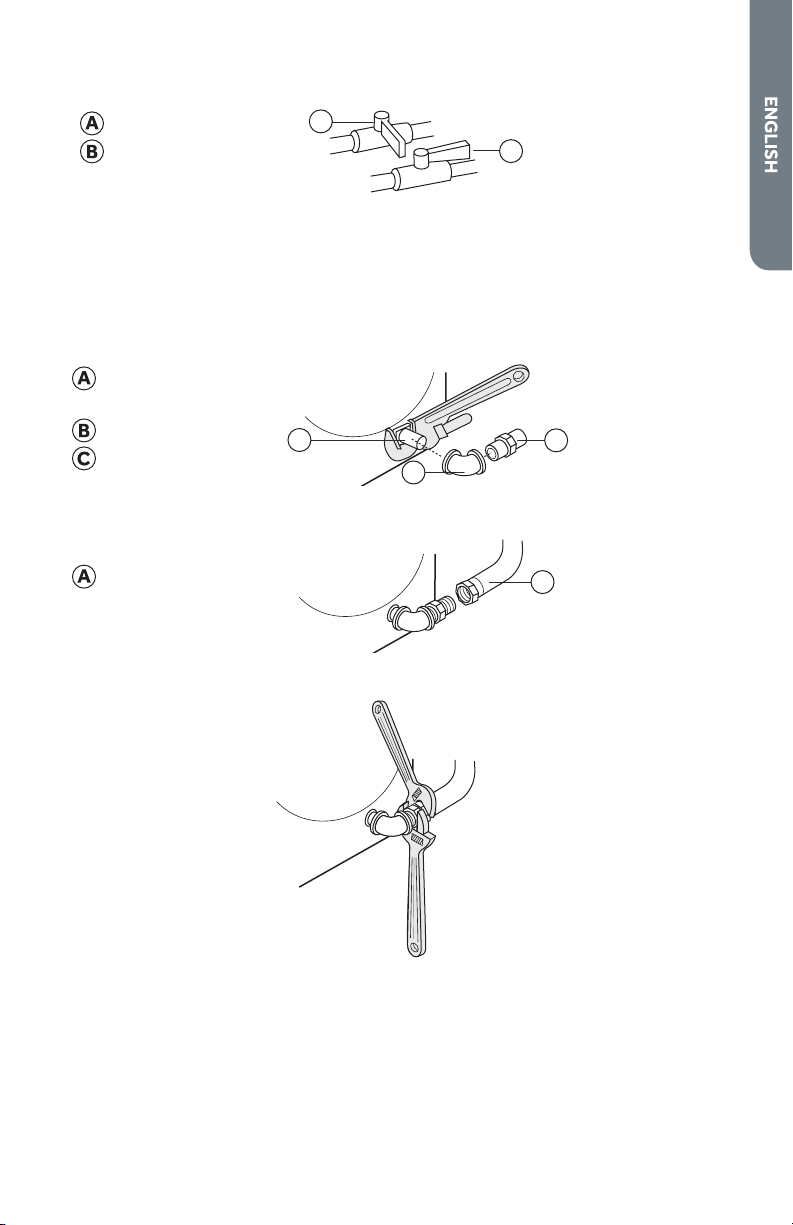

1. Turn the gas supply o by moving the shut-o valve to the closed position.

Closed Valve

Open Valve

2. Disconnect and discard old ß exible gas connector. Replace with a new

CSA(AGA) approved ß exible gas connector.

3. Remove the shipping cap from the gas inlet pipe at the rear of the dryer.

4. Connect a !" NPT elbow to the gas inlet pipe on the dryer. Then connect a ß are

adapter to the elbow.

IMPORTANT: Use a pipe wrench to keep the dryer gas inlet pipe from twisting.

Gas Inlet Pipe on

the Dryer

³⁄₈" NPT Elbow

³⁄₈" NPT Flare Adapter

5. Connect the dryer to the gas supply line with a ß exible gas connector.

Flexible Gas Connector

6. Tighten the ß exible gas connector using two adjustable wrenches.

A

B

A

C

B

A

7. Turn the gas supply on by moving the shut-o valve to the open position. The

valve is open when the handle is parallel to the gas pipe.

17

Page 19

8. Check all connections for leaks by applying a noncorrosive leak-detection

solution. Bubbles will identify leaks. If leaks are found, close the shut-o valve,

retighten the joint, open the shut-o valve, and check again.

WARNING

Never use an open flame to test for gas leaks.

STEP 3 - CONNECT TO AN EXHAUST SYSTEM

WARNING

To reduce the risk of fire, this dryer must be exhausted outdoors.

1. Make sure that the exhaust system is free and clear of old lint accumulation prior

to connecting the dryer.

2. Use 4” (102 mm) rigid or ß exible metal ducting to connect the dryer exhaust

outlet to the exhaust system.

3. Use clamps to seal and secure all joints. Exhaust ducting must not be connected

with screws or other fastening devices which extend into the interior of the duct.

NOTES:

Do not use plastic or metal foil ß exible ducting. Excessive lint can build up inside

•

the ductwork, restrict airß ow, and create a Þ re hazard. Restricted air ß ow will

increase drying time.

The dryer must not be exhausted into a gas vent, chimney, wall, ceiling or other

•

concealed space of a building. The dryer must be exhausted to the outdoors.

If the dryer is not exhausted outdoors, some Þ ne lint will be expelled into the

laundry area. An accumulation of lint in any area of the home can create a health

and Þ re hazard.

18

Page 20

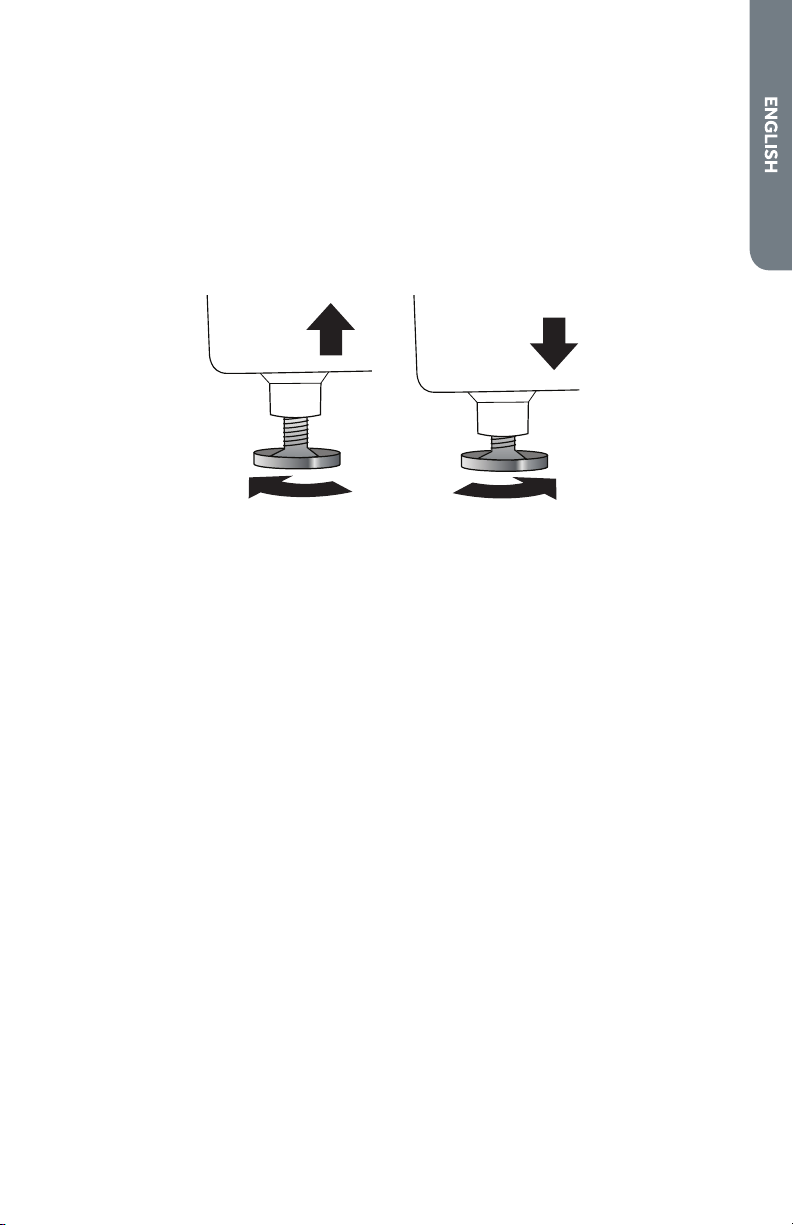

STEP 4 - LEVEL THE DRYER

1. Place the dryer in its Þ nal location. Take care not to crush or kink the exhaust

vent. Make sure that all four feet are Þ rmly in contact with the ß oor and that the

dryer rests solidly in position.

NOTE: For a gas dryer, make sure that there are no kinks in the ß exible gas line.

2. Using a carpenter’s level, check to make sure the dryer is level from side to side

and from front to back.

3. If the dryer is not level, adjust the leveling feet. Turn clockwise to extend (raise

the dryer) or counterclockwise to retract (lower the dryer).

STEP 5 - COMPLETE THE INSTALLATION

1. Plug the dryer power cord into an appropriate outlet.

2. Resume power to the outlet. Check to make sure the circuit breaker is switched

on.

3. Dispose of/recycle all packaging materials.

4. Make sure the dryer area is clean and free from combustible materials, gasoline,

and other ß ammable vapors. Also see that nothing (such as boxes, clothing, etc.)

obstructs the ß ow of combustion and ventilation air through the louvered panel

located on the rear of the dryer.

5. Test dryer operation by selecting a Timed Dry heated cycle. See the “Operating

Instructions” section.

NOTE: On gas dryers, before the burner will light, it is necessary for the gas line to

be bled of air. If the burner does not light within 45 seconds, the Þ rst time the dryer

is turned on, the safety switch will shut o the burner. If this happens, turn the dryer

to “OFF” and wait 5 minutes before making another attempt to light the burner.

19

Page 21

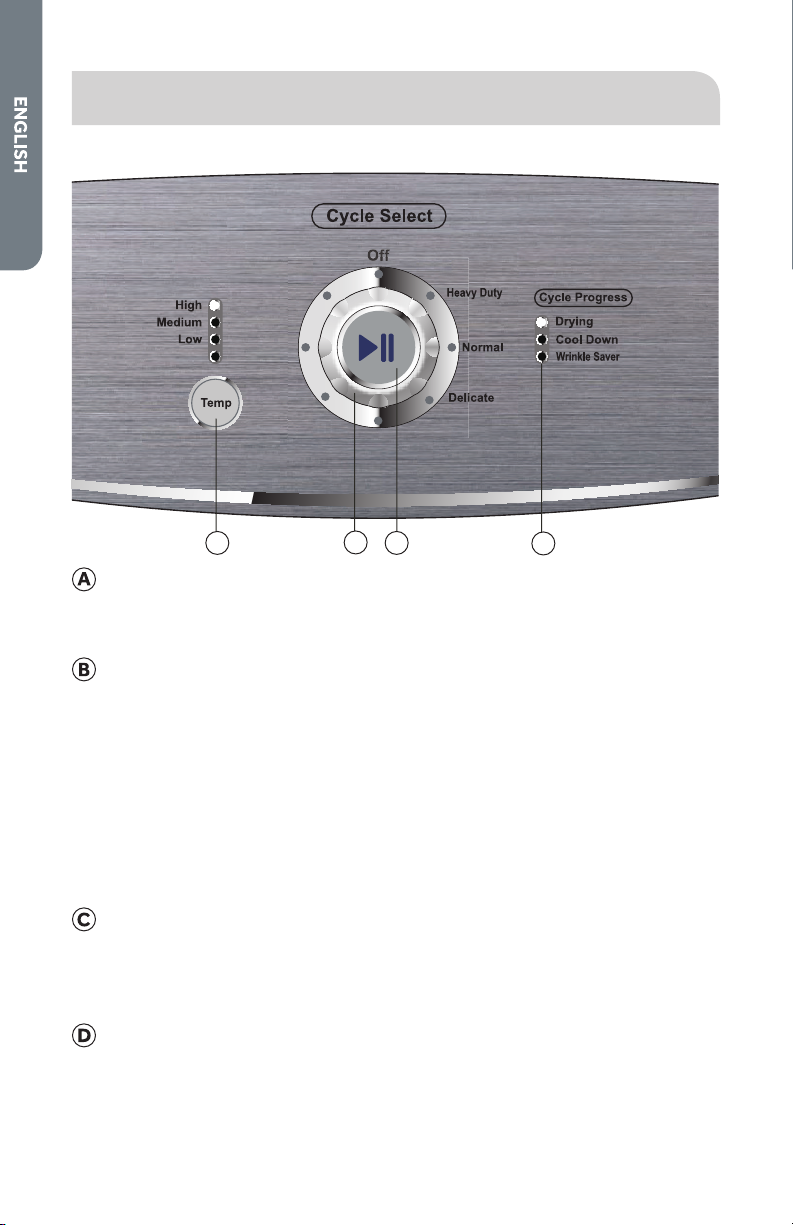

CONTROL PANEL AND FEATURES

CONTROL PANEL

Air Fluff

A

Timed Dry

120 min

90 min

60 min

30 min

B

Automatic

C

D

TEMP BUTTON

Use to select a drying temperature. There are 4 available drying

•

temperatures to choose from: High, Medium, Low, and Air Flu .

CYCLE SELECTION KNOB

Turn the dryer on by rotating the Cycle Selection Knob.

•

NOTE: If the dryer is not started, it will automatically turn o after 5 mins.

There are 3 Automatic Cycles and 4 selections for Timed Dry:

•

Heavy Duty - Use this cycle for heavy garments like jeans and towels.

Normal - Use this cycle for permanent press, synthetics, casual clothes.

Delicate - Use this cycle to dry small loads and delicate fabrics.

Timed Dry - 30, 60, 90 or 120 minute cycles.

START/PAUSE BUTTON

Press this button to start a selected cycle or to pause an operating cycle.

•

NOTE: After starting the dryer, you must pause an operating cycle to

change the Temp setting.

CYCLE PROGRESS INDICATORS

When the dryer is Þ rst powered on, the Cycle Progress lights indicate all of

•

the stages of the selected cycle.

As a stage is completed, the light will turn o , indicating that the next stage

•

is operating.

20

Page 22

FEATURES

END OF CYCLE SIGNAL

A signal will sound at the end of the cool down cycle to alert you that the load is

•

complete.

WRINKLE SAVER

At the end of the cool down cycle, the dryer will periodically tumble for 1 hour to

•

prevent wrinkles from setting in your garments.

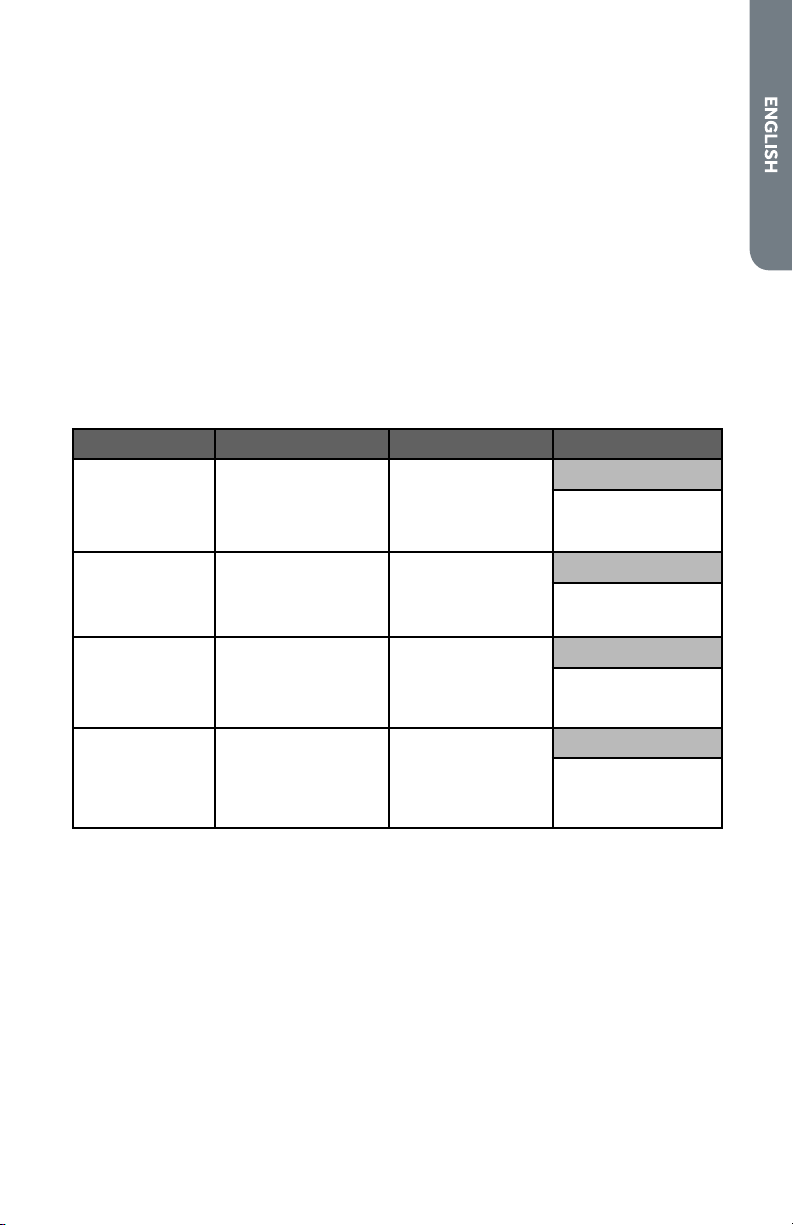

CYCLE GUIDE

NOTE: To protect your garments, all options and settings are not available for all

cycles. The shaded boxes indicate the default settings for each cycle.

CYCLE FABRIC TYPE DRY PROCESS TEMPERATURE

High

n/a

Automatic

Heavy Duty

Heavily soiled,

durable colorfast

fabrics

Heat

Cool Down

Wrinkle Saver

Automatic

Normal

Automatic

Delicate

Timed Dry

Cottons, linens, and

mixed garments

Lingerie, sheer

fabrics with lace

trim

Cottons, linens, and

mixed garments

Heat

Cool Down

Wrinkle Saver

Heat

Cool Down

Wrinkle Saver

Heat

Cool Down

Wrinkle Saver

High

Medium

Low

Low

n/a

Medium

High

Low

Air Flu

21

Page 23

Status lights indicate the progress of an operating drying cycle.

OPERATING INSTRUCTIONS

STEP 1 - PREPARE AND SORT LAUNDRY

Check garment labels for manufacturers’ drying instructions.

•

Where possible, turn pockets inside out for uniform drying.

•

Tie strings and sashes so they don’t tangle.

•

Close zippers, snaps and hooks to avoid snagging.

•

Make sure buttons and ornaments on the clothes are high temperature resistant

•

and will not damage drum surface.

To avoid permanently setting stains or soils, check that all stains and soils have

•

been removed during the wash cycle. If not, wash them again.

To avoid entanglement and ensure easy removal, small articles should be

•

collected in a mesh bag before loading.

Separate fabrics that attract lint from fabrics that give o lint. Clothes prone to

•

linting should be turned inside out before being put into the dryer.

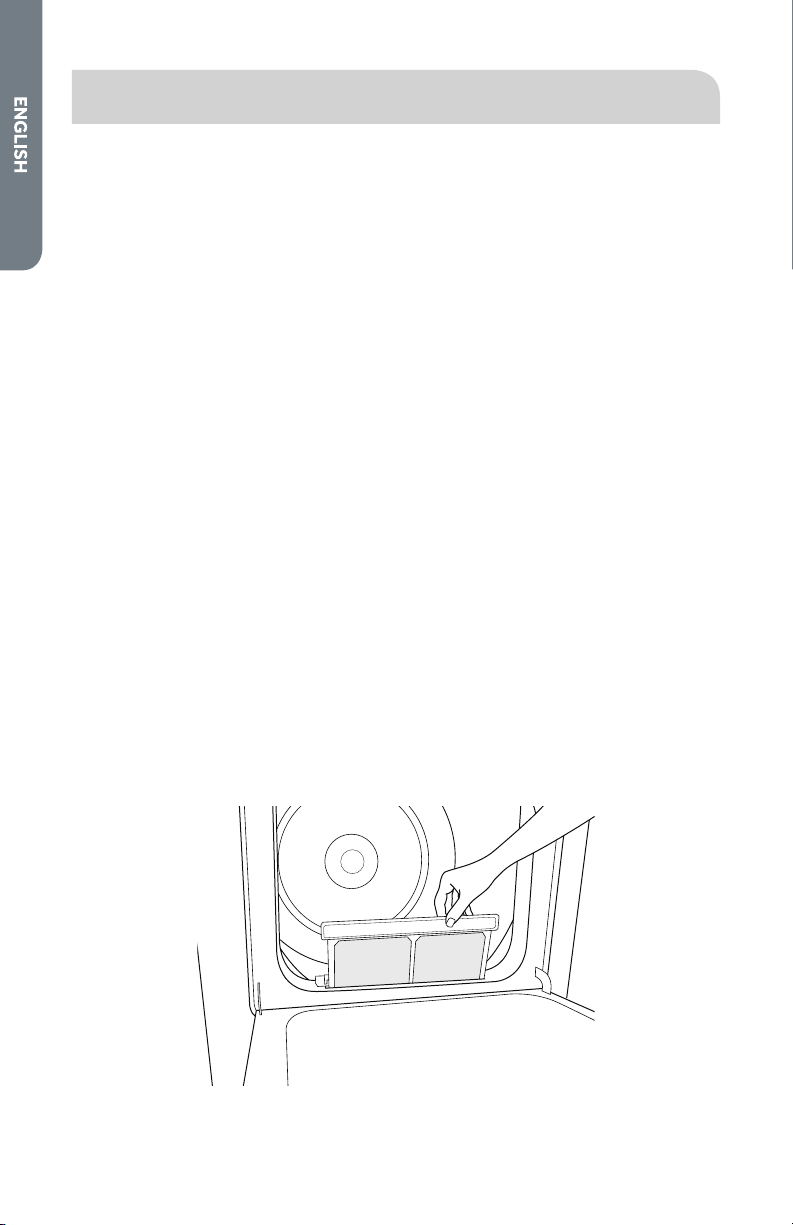

STEP 2 - CLEAN THE LINT SCREEN

1. Clean the lint screen before each use. The Þ lter can be removed by pulling on the

handle of the lint screen located inside the dryer door.

2. Use your Þ ngers to roll the accumulated lint o of the lint screen. Do not rinse or

wash the lint screen to remove lint.

3. Slide the lint screen back into place.

NOTES:

Do not operate the dryer without the lint screen in place. Without the screen,

•

tumbling garments could enter the exhaust system and cause damage to the

dryer.

Lint buildup on the screen will restrict airß ow and cause longer drying times.

•

22

Page 24

STEP 3 - LOAD THE DRYER

1. Load damp garments loosely into the dryer drum.

2. Close the dryer door.

NOTES:

Do not pack the dryer full of garments.

•

An appropriate load should be 1/3 to 1/2 of the drum volume. Allow space for

•

clothes to tumble freely for uniform and wrinkle-free drying.

When drying large bulky items, only 2-3 pieces should be loaded at a time along

•

with a few small and medium-sized garments.

For delicate clothes or small loads, adding a couple towels will help to ensure

•

that garments are tumbled. This will produce even drying and reduce wrinkles.

STEP 4 - START THE DRYER

1. Turn the dryer on by rotating the CYCLE SELECTION KNOB.

2. Select a dry cycle.

3. Modify the default settings and options if desired.

4. Press the START/PAUSE BUTTON on the face of the knob to start the dryer.

NOTE:

Opening the door will pause the operating cycle. Close the door and press the

•

START/PAUSE BUTTON to resume.

23

Page 25

CARE AND CLEANING GUIDE

WARNING

Always unplug your dryer to avoid electric shock before cleaning.

Ignoring this warning may result in death or injury.

Before using cleaning products, always read and follow manufacturer’s

instructions and warnings to avoid personal injury or product damage.

CLEANING AND MAINTENANCE

Only use a damp or sudsy cloth for cleaning the control panel.

•

If you spill liquid/powdered softener, bleach or detergent on the cabinet, wipe

•

the cabinet immediately to avoid damage to the Þ nish.

Do not use abrasive cleansers, harsh chemicals, ammonia, chlorine bleach,

•

concentrated detergent, or solvents to clean the washer. These chemicals may

dissolve, damage, or discolor the dryer.

Do not use any type of spray cleaner when cleaning the dryer interior.

•

Hazardous fumes or electric shock could occur. If dryer drum becomes stained,

clean the drum with a damp cloth. Remove any residue before drying next load.

CLEANING THE LINT SCREEN

Laundry detergent and fabric softener residue can build up on the lint screen.

•

This buildup can cause longer drying times, or cause the dryer to stop before

your load is completely dry.

Wash the lint screen every 6 months, or sooner, if it becomes clogged due to a

•

residue buildup.

Steps to Wash the Lint Screen:

1. Remove the normal accumulation of lint with your Þ ngers.

2. Wet both sides of lint screen with hot water.

3. Apply liquid detergent with water and scrub with a nylon brush.

4. Thoroughly rinse the lint screen with hot water.

5. Completely dry the lint screen before reinstalling and using the dryer.

24

Page 26

REMOVING ACCUMULATED LINT

Inside the Dryer Cabinet

Lint should be removed every 2 years, or more often, depending on dryer usage.

•

Cleaning should be done by a qualiÞ ed person.

The Exhaust System

The exhaust system should be inspected and cleaned at least every 12 months

•

with normal usage. The more the dryer is used, the more often you should check

the exhaust system and outdoor exhaust hood for proper operation.

VACATIONING PRECAUTIONS

Unplug the dryer from the electrical outlet or disconnect the power.

•

Clean lint screen. See the “Cleaning the Lint Screen” section.

•

(For gas dryers only): Close shuto valve in gas supply line.

•

MOVING OR STORAGE PREPARATION

In addition to performing the steps in “Vacationing Precautions,” complete the

following additional steps.

Disconnect the dryer from the exhaust system.

•

Turn the leveling feet so that they are fully retracted into the dryer cabinet.

•

Use masking tape to secure dryer door.

•

Move and store your dryer in an upright position only.

•

NOTE: For gas dryers, turn o the gas being supplied to the dryer. Disconnect the

dryer from the gas supply line and remove Þ ttings attached to the dryer’s gas inlet

pipe. Cap the gas supply line.

25

Page 27

TROUBLESHOOTING

NORMAL OPERATING SOUNDS

The following sounds are normal during the operation of the dryer.

•

Tumbling sound: This is normal as the heavy, wet clothes in the dryer are

•

continuously being tossed around.

Air rushing noise: This happens as the dryer drum spins and the air is rushing

•

through the dryer drum.

DRYER DOES NOT OPERATE

Check that the dryer is plugged in. The plug may have come loose.

•

Check that the electrical wall receptacle is of proper voltage. Electric dryers

•

require a 240 volt power supply.

Check if the circuit breaker needs to be reset, or if the fuse needs to be replaced.

•

Check that the Cycle Select knob is in the “O ” position. Press the Start/Pause

•

button again.

Check that the dryer door is Þ rmly shut.

•

CLOTHES ARE NOT DRYING

Dryer may be overloaded. Wet clothes should not Þ ll more than ½ of the drum

•

volume.

Check the exhaust ducting and exhaust hood. The entire exhaust system should

•

be free of obstructions.

The exhaust system should be maintained, and cleaned regularly.

•

Dryer load may need to be sorted. Heavyweight clothes should be separated

•

from lightweight clothes.

Bulky items may require repositioning.

•

Check the lint screen. Lint screen should be cleaned before each load.

•

Check that the dryer is not set on the Air Flu (no heat) temperature setting.

•

For gas dryers, check that the gas supply line is open.

•

26

Page 28

DRYER IS MAKING NOISE

Rattling or clanking noises:

Foreign objects may be in the dryer drum. Stop the dryer and check for foreign

•

objects such as loose change, keys and heavy objects.

Vibration noises:

Load may be uneven. Stop the dryer and rearrange the load.

•

Dryer may not be level. Check that all 4 leveling feet are resting Þ rmly on the

•

ß oor and that the dryer is level.

See the “Normal Operating Sounds” section.

•

Static:

Caused by over-drying. Adjust for shorter drying time and use a fabric softener

•

or a dryer sheet.

Loads are wrinkled:

The load may have been left in the dryer too long at the end of the cycle. Be sure

•

to remove clothes promptly after the load ends.

Dryer may be overloaded. The dryer drum should be at most half full.

•

Odors:

Wet clothes left in the washer and or dryer may develop an odor. Drying will not

•

remove this odor. Rewash clothes before drying them.

The electric heating element may have an odor when the dryer is used for the

•

Þ rst time. The odor will be gone after the Þ rst cycle.

27

Page 29

LIMITED WARRANTY

IN HOME SERVICE

FULL ONE YEAR WARRANTY

For 12 months from the date of original retail

purchase, Haier will repair or replace any part

free of charge including labor that fails due to

a defect in materials or workmanship.

LIMITED WARRANTY

After one year from the original retail

purchase date, Haier will provide a part at

no cost, as indicated below, to replace said

part as a result of a defect in materials or

workmanship. Haier is solely responsible for

the cost of the part. All other costs, such as

labor, trip charge, etc., are the responsibility

of the owner.

Second through Fifth Year

Haier will provide all replacement parts if

defective in material or workmanship.

NOTE: This warranty commences on the

date the item was purchased, and the original

purchase receipt must be presented to the

authorized service representative before

warranty repairs are rendered.

Exceptions: Commercial or Rental Use

Warranty

90 days labor from date of original purchase

90 days parts from date of original purchase

No other warranty applies.

FOR WARRANTY SERVICE

Contact your nearest authorized service

center. All service must be performed by

a Haier authorized service center. For the

name and telephone number of the nearest

authorized service center, please call

1-877-337-3639.

Before calling please have available the

following information:

Model number and serial number of your

appliance. The name and address of the

dealer you purchased the unit from and the

date of purchase.

A clear description of the problem.

A proof of purchase (sales receipt).

This warranty covers appliances within

the continental United States, Puerto Rico

and Canada. What is not covered by this

warranty:

Replacement or repair of household fuses,

circuit breakers, wiring or plumbing.

A product whose original serial number has

been removed or altered.

Any service charges not speciÞ cally identiÞ ed

as normal such as normal service area or

hours.

Damage to clothing.

Damage incurred in shipping.

Damage caused by improper installation or

maintenance.

Damage from misuse, abuse accident, Þ re,

ß ood, or acts of nature.

Damage from service other than an

authorized Haier dealer or service center.

Damage from incorrect electrical current,

voltage or supply.

Damage resulting from any product

modiÞ cation, alteration or adjustment not

authorized by Haier.

Adjustment of consumer operated controls

as identiÞ ed in the owner’s manual.

Hoses, knobs, lint trays and all attachments,

accessories and disposable parts.

Labor, service transportation, and shipping

charges for the removal and replacement of

defective parts beyond the initial 12-month

period.

Damage from other than normal household

use.

Any transportation and shipping charges.

THIS LIMITED WARRANTY IS GIVEN

IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE

The remedy provided in this warranty is

exclusive and is granted in lieu of all other

remedies.

This warranty does not cover incidental

or consequential damages, so the above

limitations may not apply to you. Some

states do not allow limitations on how long

an implied warranty lasts, so the above

limitations may not apply to you.

This warranty gives you speciÞ c legal rights,

and you may have other rights, which vary,

from state to state.

Haier America

New York, NY 10018

28

Page 30

TABLE DES MATIÈRES

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ .................................................. 30

Sécheuse à gaz - Précautions à prendre ....................................................................30

Précautions de sécurité concernant l’installation .....................................................31

Précautions générales de sécurité .............................................................................31

PIÈCES ET CARACTÉRISTIQUES ....................................................................... 33

INSTRUCTIONS D’INSTALLATION .................................................................... 34

Outils nécessaires .......................................................................................................34

Autres pièces nécessaires ..........................................................................................34

Critères d’emplacement .............................................................................................35

SpéciÞ cations de l’alimentation électrique et de l’alimentation en gaz ................... 36

Critères du système d’évacuation ..............................................................................40

Résidence mobile - Autres critères ............................................................................40

INSTRUCTIONS ÉTAPE PAR ÉTAPE ................................................................... 43

Étape 1 - Déballage de la sécheuse ............................................................................43

Étape 2 - Pose d’un cordon d’alimentation électrique sur la sécheuse

(sécheuse électrique [É.-U. Uniquement]) ................................................................. 43

Étape 2 - Raccordement à une canalisation d’alimentation en gaz

(sécheuse à gaz uniquement) ..................................................................................... 46

Étape 3 - Raccordement à un système d’évacuation ................................................48

Étape 4 - Nivellement de la sécheuse ......................................................................... 49

Étape 5 - Fin de l’installation .......................................................................................49

TABLEAU DE COMMANDE ET FONCTIONS ....................................................... 50

INSTRUCTIONS D’UTILISATION .......................................................................52

Étape 1 - Préparation et tri du linge ............................................................................ 52

Étape 2 - Nettoyage du Þ ltre à peluches ....................................................................52

Étape 3 - Chargement de la sécheuse ....................................................................... 53

Étape 4 - Démarrage de la sécheuse .......................................................................... 53

GUIDE D’ENTRETIEN ET DE NETTOYAGE .......................................................... 54

Nettoyage et entretien ................................................................................................ 54

Précautions à prendre avant un départ ...................................................................... 55

Préparation avant un entreposage ou un déménagement ....................................... 55

DÉPANNAGE ..................................................................................................... 56

GARANTIE LIMITÉE ........................................................................................... 58

DOCUMENTS À CONSERVER

Merci d’avoir acheté ce produit Haier. Ce

manuel d’utilisation vous aidera à obtenir

la meilleure performance possible de

votre nouvelle sécheuse.

Pour référence ultérieure, inscrire le

numéro de plaque signalétique situé

au dos de la sécheuse, ainsi que la date

d’achat.

Pour faciliter l’obtention d’un service

sous garantie, agrafer la preuve de la date

d’achat à ce manuel.

___________________________________

Numéro de modèle

___________________________________

Numéro de série

___________________________________

Date d’achat

29

Page 31

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT

Afin de réduire le risque d’incendie, de choc électrique ou de blessures

corporelles lors de l’utilisation de cet appareil, observer certaines

précautions fondamentales, notamment :

REMARQUE : Cette sécheuse est conforme à la version la plus récente des

normes ANSI Z21.5.1 ou ANSI/UL 2158 - CAN/CSA C22.2 No. 112-97 pour

un USAGE DOMESTIQUE UNIQUEMENT. Cette sécheuse n’est pas

recommandée pour un usage commercial comme une utilisation dans un

restaurant ou un institut de beauté.

• La sécheuse doit être correctement reliée à la terre en conformité

avec les codes locaux en vigueur, ou en l’absence de tels codes, avec

le National Electrical Code, ANSI/NFPA 70 ou le Code canadien des

installations électriques, CSA C22.1.

• Lire toutes les instructions avant d’utiliser cet appareil.

• Avant d’être utilisé, cet appareil doit être correctement installé et placé

dans la pièce, conformément aux instructions d’installation.

• Utiliser cet appareil uniquement dans le but auquel il est destiné et tel

que décrit dans le présent manuel d’utilisation.

• Ne pas utiliser la sécheuse pour le séchage de vêtements à usage

commercial.

SÉCHEUSE À GAZ - PRÉCAUTIONS À PRENDRE

AVERTISSEMENT

Pour votre sécurité, il est important de respecter les informations

fournies dans ce manuel pour minimiser les risques d’incendie ou

d’explosion, ou pour éviter tout dommage matériel ou corporel ou

encore tout accident mortel.

• L’installation doit être réalisée par un prestataire de services, plombier

ou tuyauteur qualiÞ é ou agréé par l’État, la province ou la région dans

laquelle cet appareil est installé.

• On ne doit pas entreposer de matériaux combustibles, essence et

autres vapeurs et liquides inß ammables à proximité de la sécheuse.

30

Page 32

QUE FAIRE EN CAS DE DÉTECTION D’UNE ODEUR DE GAZ

• Ne pas tenter d’allumer un quelconque appareil.

• Ne pas toucher de contacteur électrique. Ne pas utiliser de téléphone

situé dans votre immeuble.

• Faire évacuer tous les occupants de la pièce, du bâtiment ou de la zone

concernée.

• Appeler immédiatement le fournisseur de gaz à partir du téléphone d’un

voisin. Suivre les instructions du fournisseur de gaz.

• Si le fournisseur de gaz n’est pas joignable, appeler les pompiers.

PRÉCAUTIONS DE SÉCURITÉ CONCERNANT

L’INSTALLATION

DANGER

Avant de jeter votre ancien appareil, retirer la porte ou le couvercle de

façon à ce que les enfants ne puissent pas se cacher ou être coincés

dans l’ancien appareil.

• Cette sécheuse doit être installée par un technicien d’appareils

électroménagers qualiÞ é.

• Ne pas installer ou remiser cet appareil dans un endroit où il sera exposé

à l’eau ou aux intempéries.

• L’appareil doit être correctement relié à la terre, conformément à tous

les critères des codes et règlements locaux régissant les installations

électriques. Voir la section “SpéciÞ cations électriques”.

• Ne pas raccorder cette sécheuse à un système d’évacuation

comportant des conduits ß exibles en plastique ou en papier métallisé.

Des conduits ß exibles peuvent s’a aisser, s’écraser facilement et retenir

les peluches. Ces situations obstrueront le débit d’air de la sécheuse à

linge et augmenteront le risque d’incendie.

PRÉCAUTIONS GÉNÉRALES DE SÉCURITÉ

• La zone située autour de l’ouverture d’évacuation et les zones

adjacentes doit être exempte de peluches et de poussière.

• Dégager l’emplacement de la sécheuse de façon à ce qu’il soit libre de

tout élément susceptible d’entraver le débit d’air de combustion et de

ventilation par le panneau à persiennes situé à l’arrière de la sécheuse.

• Une surveillance attentive s’impose lorsque cet appareil est utilisé par

ou à proximité d’enfants. Ne pas laisser des enfants jouer avec l’appareil,

ni jouer dessus ou à l’intérieur.

31

Page 33

• Ne pas sécher d’articles précédemment nettoyés, trempés ou tachés

avec de l’essence, des solvants pour nettoyage à sec ou d’autres

substances inß ammables explosives car ces substances dégagent des

vapeurs qui pourraient s’enß ammer ou exploser.

• Ne pas placer d’articles tâchés d’huile de cuisson dans la sécheuse. Les

articles ayant été au contact d’huile de cuisson peuvent provoquer une

réaction chimique susceptible d’enß ammer la charge de vêtements.

• Si certains articles ont été au contact de substances liquides ou solides

inß ammables, ils ne doivent pas être séchés dans la sécheuse avant que

toute trace de liquide ou vapeur inß ammable n’ait été éliminée.

• Ne pas accéder à l’intérieur de la sécheuse lorsque le tambour est en

mouvement.

• Ne pas e ectuer d’intervention non autorisée sur les commandes.

• Ne pas utiliser d’assouplissants pour tissu ou de produits visant à

éliminer l’électricité statique à moins que cela ne soit recommandé par

le fabricant de l’assouplissant pour tissu ou du produit.

• Ne pas utiliser de chaleur pour sécher des articles contenant du

caoutchouc mousse ou des matières similaires.

• Nettoyer le Þ ltre à peluches avant ou après chaque charge.

• L’intérieur de l’appareil et le conduit d’évacuation doivent être nettoyés

régulièrement par un personnel d’entretien qualiÞ é.

• AÞ n de réduire le risque de choc électrique, débrancher cet appareil

de l’alimentation électrique avant d’e ectuer un dépannage ou un

nettoyage.

REMARQUE : Le fait de tourner le bouton de sélection de programme

à la position “d’arrêt” ne permet PAS de déconnecter l’appareil de

l’alimentation électrique.

• Ne jamais débrancher la sécheuse en tirant sur le cordon d’alimentation.

Toujours saisir la Þ che de branchement fermement pour l’extraire de la

prise de courant.

• Ne pas tenter d’e ectuer l’entretien, la réparation ou le remplacement

d’une quelconque pièce de l’appareil, sauf si cette intervention est

expressément recommandé(e) dans ce manuel d’utilisation ou dans

les instructions de réparation fournies, que vous comprenez ces

instructions et êtes capable de les exécuter.

• Retirer la porte du compartiment de séchage avant de jeter l’appareil ou

de le rendre inutilisable.

CONSERVER CES INSTRUCTIONS

USAGE DOMESTIQUE EXCLUSIF

32

Page 34

PIÈCES ET CARACTÉRISTIQUES

Sécheuse à gaz Sécheuse électrique

A

C

B

D

G

E

F

M

L

Cordon d’alimentation électrique

(120 volts/ 60 Hz)

Support de montage pour serre-câble

(un cordon électrique de 240 volt/60 Hz

est Þ xé aux modèles électriques canadiens)

Couvercle d’accès du boîtier de connexion

Panneau d’accès

Sortie d’évacuation

Panneau de ventilation à persiennes

D

E

F

H

I

J

K

Canalisation d’arrivée de gaz

Tableau de commande

Contacteur de sécurité de la porte

Filtre à peluches

Porte de la sécheuse

Pieds de nivellement

Caisse de la sécheuse

33

Page 35

INSTRUCTIONS D’INSTALLATION

AVERTISSEMENT

Risque d’incendie

L’installation de la sécheuse à linge doit être effectuée par un

installateur qualifié.

Installer la sécheuse à linge conformément aux instructions du

fabricant et aux codes locaux.

Afin de réduire le risque de blessure grave ou de décès, suivre toutes les

instructions d’installation.

OUTILS NÉCESSAIRES

• Tournevis Phillips

• Tournevis à lame plate

• Pince multiprise réglable

• Clé plate de ½"

• Niveau

• Mètre-ruban (12 pi [3,7 m] min.)

Installations pour appareils à gaz

uniquement :

• Clé à tuyauterie

• 2 clés à molette

AUTRES PIÈCES NÉCESSAIRES

• Conduit d’évacuation métallique rigide ou ß exible de 4" (10,2 cm)

• Bride de conduit

• Ruban adhésif pour conduit

• Cordon d’alimentation (sécheuse électrique utilisée aux É.-U. uniquement)

- On doit acheter une trousse de cordon d’alimentation pour que l’appareil

- Serre-câble homologué UL

• Pièces de raccordement au gaz (sécheuses à gaz uniquement)

- Coude NPT de "

- Raccord conique NPT de "

- Connecteur de gaz flexible de "

- Composé d’étanchéité pour tuyauteries

• Trousse d’installation pour maison mobile (sécheuse à gaz pour résidence

mobile uniquement)

34

soit en conformité avec les codes locaux régissant les installations

électriques. La sécheuse doit utiliser un cordon d’alimentation électrique

à 3 ou 4 conducteurs NEMA 14-30 ou 10- 30 de type SRDT ou ST (comme

nécessaire) de 120/240 VCA minimum et 30 A, terminé par 3 cosses

rondes ou en fourche à pointes relevées et approuvé pour utilisation avec

les sécheuses à linge.

Page 36

CRITÈRES D’EMPLACEMENT

AVERTISSEMENT

Ne pas installer la sécheuse dans un endroit ou de l’essence ou d’autres

substances inflammables sont conservées ou entreposées. Si la

sécheuse est installée dans un garage, elle doit se trouver à 18 po

minimum (45,7 cm) au-dessus du plancher. Le non-respect de ces

instructions peut entraîner un décès, une explosion, un incendie ou des

brûlures.

• La sécheuse doit être installée sur un plancher résistant. Un plancher en béton

est idéal.

• Le plancher doit être de niveau avec une pente maximale de 1” (2,5 cm) sous

l’ensemble de la sécheuse.

• L’appareil doit être placé dans un emplacement protégé de la lumière directe du

soleil et de sources de chaleur comme des radiateurs, plinthes électriques ou

appareils de cuisson.

• Ne pas installer l’appareil sur de la moquette.

• L’emplacement doit comporter des robinets d’alimentation électrique et

d’alimentation en gaz adéquats. Voir la section “SpéciÞ cations de l’alimentation

électrique et de l’alimentation en gaz” pour plus de détails.

• Ne pas installer la sécheuse dans une zone où elle sera au contact de rideaux,

d’une moquette ou d’un tapis épais ou de tout autre matériau susceptible

d’entraver le ß ux d’air de combustion et de ventilation.

DIMENSIONS DE LA SÉCHEUSE

42¹⁄₂"

(108 cm)

28¹⁄₄"

(72,4 cm)

27"

(68,6 cm)

35

Page 37

SPÉCIFICATIONS POUR ALCÔVE OU PLACARD

1"

(2,5 cm)

5½"

(14 cm)

2

60 in.

(387,1 cm2)

2

60 in.

(387,1 cm2)

1"

(2,5 cm)

15"

(38,1 cm)

DÉGAGEMENTS MINIMUMS

• Les dimensions indiquées correspondent aux dégagements minimaux

nécessaires.

• Il faut laisser un dégagement sur chaque côté de la sécheuse aÞ n d’éviter tout

transfert de bruit.

• Il faut laisser un dégagement à l’arrière de la sécheuse pour permettre le

passage du conduit d’évacuation.

AUTRES CRITÈRES

• L’évacuation de cette sécheuse doit se faire à l’extérieur.

• Ne pas installer cette sécheuse dans un placard avec porte pleine.

• Une porte de placard doit comporter des ouvertures d’aération avec une surface

d’ouverture minimale de 120 in

2

(774,2 cm2) également répartie entre le sommet

et le bas de la porte. Le ß ux d’air ne doit être entravé en aucune manière.

• Aucun autre appareil avec fonctionnement à base de combustible ne doit être

installé dans le même placard que la sécheuse à gaz.

SPÉCIFICATIONS DE L’ALIMENTATION ÉLECTRIQUE ET

DE L’ALIMENTATION EN GAZ

SÉCHEUSE ÉLECTRIQUE (É.-U. UNIQUEMENT)

AVERTISSEMENT

La sécheuse doit être branchée à une prise électrique à 3 ou 4 fils,

correctement mise à la terre et délivrant une tension monophasée CA

uniquement de 120/240 V (ou 120/208 V) à 60 Hz, reliée à un circuit

individuel protégé par fusible temporisé ou disjoncteur de 30 A. Ne pas

faire fonctionner une sécheuse et une laveuse sur le même circuit.

36

Page 38

AVERTISSEMENT

Cet appareil doit être relié à la terre. Au cas où un court-circuit se

produirait, la liaison à la terre réduit le risque de choc électrique, en

permettant au courant de s’échapper directement vers la terre.

REMARQUE : L’alimentation électrique de la sécheuse doit être conforme aux codes

et règlements locaux et à la version la plus récente du code national de l’électricité,

ANSI/NFPA 70.

• Si l’alimentation électrique fournie à l’emplacement d’installation prévu pour la

sécheuse ne répond pas aux critères ci-dessus, contacter un électricien agréé.

• Le temps de séchage fourni par une sécheuse fonctionnant sur un circuit

d’alimentation de 208 volts sera plus long que celui fourni par une sécheuse

fonctionnant sur un circuit de 240 volts.

• La sécheuse n’est pas équipée de cordon d’alimentation. On doit acheter

séparément une trousse de cordon d’alimentation conforme aux codes locaux

régissant les installations électriques. La sécheuse doit utiliser un cordon

d’alimentation électrique à 3 ou 4 conducteurs NEMA 14-30 ou 10-30 de type

SRDT ou ST (comme nécessaire) de 120/240 VCA minimum et 30 A, terminé par

3 cosses rondes ou en fourche à pointes relevées et approuvé pour utilisation

avec les sécheuses à linge.

• Un serre-câble homologué UL doit être Þ xé à la sécheuse comportant le cordon

d’alimentation.

• Ne pas utiliser de prise secteur à conducteurs en aluminium avec un cordon

et une Þ che d’alimentation à conducteurs en cuivre (et inversement). Le

raccordement correct est un cordon à conducteurs en cuivre et une prise

secteur à conducteurs en cuivre.

• La prise électrique doit être située de façon à ce que le cordon d’alimentation

soit accessible une fois la sécheuse installée.

SÉCHEUSE ÉLECTRIQUE (CANADA UNIQUEMENT)

AVERTISSEMENT

La sécheuse doit être branchée à une prise électrique à 4 fils,

correctement mise à la terre et délivrant une tension monophasée CA

uniquement de 120/240 V à 60 Hz, reliée à un circuit individuel protégé

par fusible temporisé ou disjoncteur de 30 A. Ne pas faire fonctionner

une laveuse et une sécheuse sur un même circuit.

37

Page 39

AVERTISSEMENT

Cet appareil doit être relié à la terre. Au cas où un court-circuit se

produirait, la liaison à la terre réduit le risque de choc électrique, en

permettant au courant de s’échapper directement vers la terre.

REMARQUE : L’alimentation électrique à la sécheuse doit être conforme aux

codes et règlements locaux et à la dernière édition de la norme CSA C22.1 du Code

canadien de l’électricité partie 1.

• Si l’alimentation électrique fournie à l’emplacement d’installation prévu pour la

sécheuse ne répond pas aux critères ci-dessus, contacter un électricien agréé.

• Ne pas utiliser de prise secteur à conducteurs en aluminium avec un cordon

et une Þ che d’alimentation à conducteurs en cuivre (et inversement). Le

raccordement correct est un cordon à conducteurs en cuivre et une prise

secteur à conducteurs en cuivre.

• La prise électrique doit être située de façon à ce que le cordon d’alimentation

soit accessible une fois la sécheuse installée.

SÉCHEUSE À GAZ

SPÉCIFICATIONS DE L’ALIMENTATION ÉLECTRIQUE

AVERTISSEMENT

La sécheuse à gaz doit être branchée à une prise électrique à 3 fils

correctement mise à la terre, délivrant une tension monophasée CA

uniquement de 120 V à 60 Hz et protégée par fusible temporisé ou

disjoncteur de 15 A.

AVERTISSEMENT

Cet appareil doit être relié à la terre. Au cas où un court-circuit se

produirait, la liaison à la terre réduit le risque de choc électrique, en

permettant au courant de s’échapper directement vers la terre.

• Cette sécheuse comporte un cordon d’alimentation électrique à 3 broches. Ne

pas couper ou ôter la broche de terre du cordon d’alimentation.

• Le cordon d’alimentation doit être branché sur une prise de courant de

conÞ guration correspondante, à 3 alvéoles, reliée à la terre et installée

conformément à tous les codes et règlements locaux. En l’absence de prise de

courant de conÞ guration correspondante, contacter un électricien agréé pour

installer une prise adéquate.

• En cas de doute quant à la qualité de la liaison à la terre de la prise, consulter un

électricien agréé.

38

Page 40

• Ne pas utiliser d’adaptateur à trois broches.

• Ne pas utiliser de câble de rallonge.

SPÉCIFICATIONS DE L’ALIMENTATION EN GAZ

REMARQUE : L’alimentation en gaz à la sécheuse doit être conforme aux codes et

règlements locaux et à la dernière édition de la norme ANSI Z223.1 du National Fuel

Gas Code ou CAN/CGA B149.1 au Canada.

Gaz naturel

• La sécheuse est équipée pour une utilisation au gaz naturel.

Gaz propane

• La sécheuse peut être convertie pour une utilisation au gaz propane.

• L’opération de conversion au gaz propane doit être exécutée par un technicien

qualiÞ é.

Canalisation d’alimentation en gaz

• La canalisation d’alimentation en gaz doit comporter un diamètre de ½”

(1,3 cm) et comporter un robinet d’arrêt individuel manuel installé à 6 pi (183 cm)

maximum de la sécheuse conformément au code national de l’électricité, ANSI

Z223.1/NFPA 54 ou au Natural Gas and Propane Installation Code, B149.1 pour

le Canada.

• Le robinet d’arrêt doit être facilement accessible pour les manœuvres

d’ouverture et de fermeture.

• Un connecteur obturé NPT de !" doit être installé immédiatement en amont de

la vanne d’arrêt. Ce raccord sert à vériÞ er la pression du gaz.

• La canalisation d’alimentation doit se terminer par un raccord conique NPT de

".

Canalisation d’alimentation en gaz

NPT de ½"

Robinet d’arrêt de gaz

Connecteur obturé (Þ letage NPT de

!" minimum)

Raccord conique NPT de "

B

C

A

D

39

Page 41

CRITÈRES DU SYSTÈME D’ÉVACUATION

AVERTISSEMENT

Cette section décrit les critères à respecter pour un système

d’évacuation sécuritaire et efficace. Le nonrespect de ces instructions

peut entraîner un risque d’incendie, une mauvaise performance de la

sécheuse et endommager l’appareil.

CONDUITS

• Si le système d’évacuation existant est composé de conduits ß exibles en

plastique ou en métal, les remplacer par des conduits métalliques rigides.

• Utiliser uniquement des conduits métalliques rigides de 4" (10,2 cm) de

diamètre.

• Pour réaliser des changements de direction avec les conduits, utiliser des

coudes à 45° plutôt qu’à 90°. Cela permet un meilleur débit de ventilation et peut

permettre de réduire l’accumulation de peluches dans le système d’évacuation.

90° - Bon 45° - Mieux

• Ne pas dépasser la longueur de conduits relativement au nombre de coudes

indiqué dans le tableau ci-dessous. Cela pourrait entraîner une accumulation de

peluches, augmenter la durée de séchage et créer un risque d’incendie.

• Deux raccords 45° produisent le même freinage qu’un raccord 90°.

Longueur d’évacuation maximale recommandée

Types de clapets d’évacuation

Recommandé Utiliser uniquement pour

les circuits courts

4"

4"

(10,2 cm)

de

diamètre

(10,2 cm)

de

diamètre

4"

(10,2 cm)

4"

(10,2 cm)

de

diamètre

Nombre de coudes à 90° Métallique rigide Métallique rigide

0

1

2

3

90 pi

60 pi

45 pi

35 pi

60 pi

45 pi

35 pi

25 pi

40

2½"

(6,4 cm)

Page 42

• Toutes les jointures doivent être étanches aÞ n d’éviter toute fuite d’air.

L’extrémité mâle de chaque section doit être orientée dans la direction opposée

de la sécheuse.

• Utiliser des brides ou du ruban adhésif en toile pour

sceller toutes les jointures. Ne pas utiliser de vis ou

autres dispositifs de Þ xation qui se prolongeraient à

l’intérieur du conduit pour sécuriser l’évacuation car

cela peut retenir les peluches.

• Éviter d’acheminer le système dans une zone non chau" ée car cela entraînera

la formation de condensation à l’intérieur du conduit et accélèrera le rythme

d’accumulation des peluches.

• Éviter de faire passer le circuit d’évacuation verticalement par un toit pour éviter

tout risque de courants d’air descendants susceptibles de gêner la circulation

d’air.

• Éviter que le système d’évacuation ne s’a" aisse, ne soit compressé ou

coincé car cela réduira le débit de ventilation et a" ectera la performance de la

sécheuse.

• Ne pas grillager l’extrémité du circuit d’évacuation. En s’accumulant, les

peluches Þ niront par colmater le grillage. Utiliser une bouche d’évacuation

homologuée à l’extrémité du conduit à l’extérieur.

Bride

CLAPET D’ÉVACUATION

• Utiliser une bouche d’évacuation homologuée à clapet oscillant qui s’ouvre

lorsque la sécheuse est en fonctionnement. Lorsque la sécheuse s’arrête, le

clapet se ferme automatiquement pour empêcher les rongeurs et insectes

d’entrer dans le domicile, et pour empêcher les courants d’air.

• On recommande l’emploi de clapets à persiennes ou de type boîte. On peut

utiliser des clapets inclinés, mais ils ne doivent être utilisés que pour des

installations courtes. Voir le tableau “Longueur maximale recommandée du

système d’évacuation” pour plus d’information.

• AÞ n d’éviter d’entraver le débit de ventilation, maintenir un dégagement

minimal de 12" (30,5 cm) entre le clapet d’évacuation et le plancher ou tout autre

obstacle éventuel.

41

Page 43

RÉSIDENCE MOBILE - AUTRES CRITÈRES

• L’installation doit répondre aux critères de la version en cours de validité de la

Manufactured Home Construction and Safety Standard, Titre 24 CFR, partie

3280 ou de la Canadian Manufactured Home Standard CAN/CSA-Z240 MH.

• Des dispositions particulières doivent être prises pour l’air d’appoint extérieur.

L’ouverture d’entrée d’air doit être au moins deux fois plus grande que la sortie

d’évacuation de la sécheuse.

• Si l’évacuation d’air de la sécheuse se fait par le plancher dans un espace conÞ né

sous la résidence mobile, le circuit d’évacuation doit se terminer à l’extérieur de

cet espace et la bouche d’extrémité doit être solidement Þ xée à la structure de

la résidence mobile.

SÉCHEUSE À GAZ UNIQUEMENT

(RÉSIDENCE MOBILE UNIQUEMENT)

• La sécheuse doit être Þ xée au plancher à l’aide d’une trousse d’installation pour

résidence mobile. Suivre les instructions fournies avec la trousse.

42

Page 44

INSTRUCTIONS ÉTAPE PAR ÉTAPE

INSTALLATION DE LA SÉCHEUSE

Nous recommandons que l’installation de votre nouvelle sécheuse soit réalisée par

un technicien d’appareils électroménagers qualiÞ é. Si vous pensez être capable

d’installer la sécheuse, lire attentivement les instructions d’installation avant de

procéder à l’installation.

MISE EN GARDE : Si vous n’êtes pas certain que la sécheuse est correctement

installée après avoir suivi ces étapes, contacter un technicien d’appareils

électroménagers qualiÞ é.

ÉTAPE 1 - DÉBALLAGE DE LA SÉCHEUSE

1. Enlever tous les matériaux d’emballage. Cela comprend la base en polystyrène

et tous les adhésifs maintenant les accessoires pour sécheuse en place, à la fois

à l’intérieur et à l’extérieur.

2. Inspecter la sécheuse et retirer tout emballage, ruban adhésif ou documents

avant d’utiliser l’appareil.

AVERTISSEMENT

Afin d’éviter tout risque d’étouffement, conserver le sac en plastique et

autres matériaux d’emballage hors de portée des bébés et des enfants.

Ne pas utiliser ce sac dans des berceaux, poussettes ou parcs pour

enfants. Le sac en plastique peut bloquer les orifices du nez et de la

bouche et empêcher la respiration. Ce sac n’est pas un jouet.

ÉTAPE 2 - POSE D’UN CORDON D’ALIMENTATION

ÉLECTRIQUE SUR LA SÉCHEUSE

(SÉCHEUSE ÉLECTRIQUE [É.-U. UNIQUEMENT])

1. Ôter la vis Þ xant le couvercle d’accès du boîtier de connexion située à l’arrière de

l’angle supérieur de la sécheuse.

Couvercle d’accès du boîtier de

connexion

Trou dans le support de montage

pour serre-câble

Retirer cette vis

A

B

C

43

Page 45

2. Insérer un serre-câble homologué UL dans le trou du support de montage.

Positionner le serre-câble de façon à ce qu’un onglet soit orienté vers le haut

et l’autre vers le bas. Serrer les vis du serre-câble juste assez pour maintenir

ensemble les deux moitiés.

Onglet

Serre-câble

3. Insérer un cordon d’alimentation dans le serre-câble. VériÞ er que la gaine

d’isolement du câble d’alimentation pénètre à l’intérieur du serre-câble.

4. Pour le raccordement d’un cordon d’alimentation à 4 conducteurs,

suivre les instructions de la partie A. Pour le raccordement d’un

cordon d’alimentation à 3 conducteurs, suivre les instructions de la

partie B.

4 Þ ls (recommandé) si la résidence est équipée d’une prise secteur à

4 conducteurs (NEMA 14-30 type SRDT ou ST) :

3 Þ ls (en l’absence de câblage 4 Þ ls) si la résidence est équipée d’une

prise secteur à 3 conducteurs (NEMA 10-30 type SRDT) :

MISE EN GARDE : Un raccordement à 4 Þ ls est obligatoire pour

les maisons mobiles et lorsque les codes locaux n’autorisent pas

l’utilisation de raccordements à 3 Þ ls.

5. Serrer les vis du serre-câble.

6. Veiller à ce qu’aucun conducteur ne touche le tambour de la sécheuse à

l’intérieur de la caisse de la sécheuse.

7. Réinstaller le couvercle du boîtier de connexion.

A

B

44

Page 46

PARTIE A - CORDON D’ALIMENTATION À 4 CONDUCTEURS

A