Haier CI0193AANC, CI0316AANB, CI0247AANB, CI0247AANC, CI0316AANC Installation, Operation And Technical Manual

...

Air Cooled Semi-hermetic Screw Chiller

Installation, operation and technical manual

Heat pump

R22 refrigerant

193KW~1265KW

3PH, 380V~400V, 50Hz

Haier Commercial Air Conditioning

MANUAL CODE: SYJS-007-08REV. 2008-030 -20

HAIER CHILLER

2

TABLE OF CONTENTS

1. Nomenclature…………………………………………………………………………………………………….3

2. Product character………………………………………………………………………………………………..4

3. Specifications…………………………………………………………………………………………………….6

4. Dimension data………………………………………………………………………………………………….10

5. Installation………………………………………………………………………………………………………..19

6. Unit statup and stop..…………………………………………………………………………………………...26

7. Maintenance……………………………………………………………………………………………………..28

8. General maintenance…………………………………………………………………………………………...30

9. Control device. …………………………………………………………………………………………………..34

10. Wiring diagram…………………………………………………………………………………………………...36

11. Control system…………………………………………………………………………………………………. ..39

HAIER CHILLER

3

1. Nomenclature

Note: Haier air-cooled screw (heat pump) chiller is module-structured. The chiller assembly is a flexible

combination of the basic modules of 1 the catalog, models of above 316KW

are some typical module-combined products recommended by Haier.

For example: CI0740AANB chiller is composed of one CI0247AANB and two CI0247AANC chillers.

Capacity Regulation Mode

Step Capacity Regulation Mode: Each compressor has four steps of capacity regulation: 100% - 75% -

50% - 25%, among which 25% step is for the startup of compressor.

Compressor

Qty.

Startup Capacity Regulation During Chiller Operation

Regulation

Steps

1 Compressor 25% 50%,75%,100% 4

2 Compressor 12.50% 25%,37.5%,50%,62.5%,75%,87.5%,100% 8

3 Compressor 8.30% 16.7%,25%,33.3%,41.7%,50%,58.3%,66.7%,75%,83.3%,91.7%,100% 12

4 Compressor 6.25%

12.5%,18.8%,25%,31.3%,37.5%,43.8%,50%,56.3%,62.5%,68.8%,75%,

81.3%,87.5%,93.8%,100%

16

1 3456

chiller

system

C

C

1069 R22 Aair cooled A

100-115V, 60Hz 1

fixed frequency A-G

air cooled 0237 R407C B water cooled W

220-240V, 50Hz 2

inverter H-Q

water cooled 0 0 1 2 R132 C earth source E

115-220V, 50/60Hz 3

DC inverter R-Z

earth source R134a D

220-220V, 60Hz 4

A

R410a E

110V, 50-60Hz 5

H

R22 M

220V, 50-60H

z

6

R

R407C N

127V, 60Hz 7

W

R123 O

240V, 50Hz 8

Cassatte

B

R134a P

110-220V, 50/60Hz 9

Duct

D

R410a Q 330V, 50Hz A

Cabinet

P

400V, 50Hz B

Wall mounted

S

3300V, 50Hz

C

6600V, 50Hz D

380-400V, 50Hz N

415V, 50Hz M

Code Explanation for chiller

compressor type

capacity (for

Centrifugal chiller:

Rt; other: KW)

product type unit character

2

7

89

heat

pump

cooling

only

10

I

Air-cooled module chiller

suitable voltage design number

Light

chiller

Water-cooled cabinet chiller

Hydronic

system

Centrifugal chiller

Screw

chiller

single-packaged

split-packaged

93KW, 247KW and 316KW. In

HAIER CHILLER

4

2. Product character

Haier air-cooled (heat pump) chiller is a comprehensive product developed by Haier. This product series

adopt compressors, system parts and electrical components of well-known brands and they are characterized

by compact structure, cutting-edge technology, reliable control, cost-effective operation and convenient

installation. The computer-controlled system can not only improve control precision and reliability, but also

realize multi-step energy adjustment, through which the balance of chiller capacity and customer load is

optimized and thus to effect economical operation. The chiller is under continuous control by means of large

volume information display. Unattended and energy-saving operation can be realized using the preset

operation mode and operation program. The computer-controlled system can be connected to master computer

so as to render network-based automatic management of the whole building. The air-cooled integral structure

is dispensed with such components as cooling tower and cooling pump and can save project construction cost.

This product can serve as central air-condition system for hotels, stores and office buildings and can meet the

technological air-conditioning requirements in textiles, chemical, metallurgical, pharmaceutical and power

industries.

2.1 Motor

The compressor motor is 3-phase scal perator induction type, and the operation voltage will be confirmed

as per the nameplate.

The inner refrigerant suction system is cooled by the refrigerant.

Started up by Y -△ type

2.2 Compressor

The compressor is equipped with the protection device of discharging temperature, discharging pressure,

suction pressure, motor coil temperature, motor coil, etc.

The unit adopts screw type compressor. Within 3 minutes after startup, the compressor is in the transitional

period.

Note: 1) To avoid the compressor start/stop frequency, once shut off, please do not start up the compressor

in 3 minutes. 2) When several compressors are installed, the time difference of the compressor startup needs to

be set.

The capacity adjustment will be realized by the refrigerant driving the slide valve.

In the compressor there is high efficiency oil segregator.

The screw axis and the rotor are one complete unit in the mold.

2.3 SHELL&TUBE heat exchanger

In cooling mode, SHELL&TUBE heat exchanger is as evaporator, while, in heating mode, it is as

condenser.

The SHELL&TUBE heat exchanger adopts high efficiency copper pipe.

In the SHELL&TUBE heat exchanger, the freezed water will flow out of the copper pipe, while the

refrigerant flow in the copper pipe.

Out of the SHELL&TUBE heat exchanger, there is the heat insulation material.

2.4 Condenser

Condenser adopts the pinned coil type structure, and adopts the high efficiency copper pipe. The condenser

fan motor is with low noise.

HAIER CHILLER

5

2.5 Electric control

Adopt the PCB to control the operation.

The unit can realize remote operation .

The control of water temperature will act according to the water outlet temperature.

The unit can realize compulsorily unit quantity control and compulsorily capacity control for the unit with

several compressors.

When failure occurs, the normal compressor can continue running (for the unit with several compressors).

When abnormal, the unit can monitor the current water temperature, operation time.

In operation, the unit can monitor the water temperature, capacity state, and operation time.

On the crystal touch screen, you can control the unit.

When abnormal, the failure information will display on the crystal touch screen automatically.

The unit can realize the interlock between the cooling .

Note: Do not damage the power cable.

The following items can be tested if abnormal: high pressure, low pressure, compressor motor coil

temperature, compressor discharging temperature, anti-freeze, reverse power supply, etc.

2.6 Safety Device

For the requirement of safety, there is solenoid valve on the discharging pipe to discharge the gas when the

pressure is too high. Must not install any stop valve on the pipe with safety relief valve.

The unit is equipped with safety device to confirm the safe operation. When one safety device acts, the

failure indicator will light, and the corresponding function will stop, while the other function is normal.

Suggestion: Once one section occurs abnormal phenomenon, you should shut off the unit to check

the reason to avoid the worse damage.

safety device Protection point Set value Action reasons

Delay time when

shut off

The interval time between

compressor stops and restart up

15minutes Compressor startup/stop frequently

Refrigerant charged too much

Ambient temperature too high

Condenser blocked, bad ventilation

High pressure

sensor

Discharging pressure protection

2.4Mpa

Non-condensing gas in system

Chilled water temperature too low Water temperature

sensor

Anti-freezed protection for chilled

water

5℃

Set temperature too low

Because of leakage, refrigerant too little

Solenoid valve of compressor heat exchanging pipe

shut off because of failure

Discharging

temperature

sensor

Discharging temperature

protection

in:100±2.5℃

out:89±2.5℃

Stop valve on condenser outlet shutoff

Motor overheat

protection

Compressor motor protection

in:105±5℃

out:88±11℃

Identical with high pressure switch (high

pressure protection)

Expansion valve shutoff because of failure

Stop valve on condenser outlet shutoff

Chilled water flow too low

Low pressure

sensor

Suction pressure protection

0.35Mpa (cooling)

0.1Mpa (heating)

Evaporator blocked

Reverse phase

protection

Compressor motor reverse protection P hase s equenc e

correct

Power wiring incorrect

Over current relay

Compressor motor over current

protection

According to the

compressor

Motor over current

/ master cold water pump and the and remote control unit

and passive element starup/stop control

HAIER CHILLER

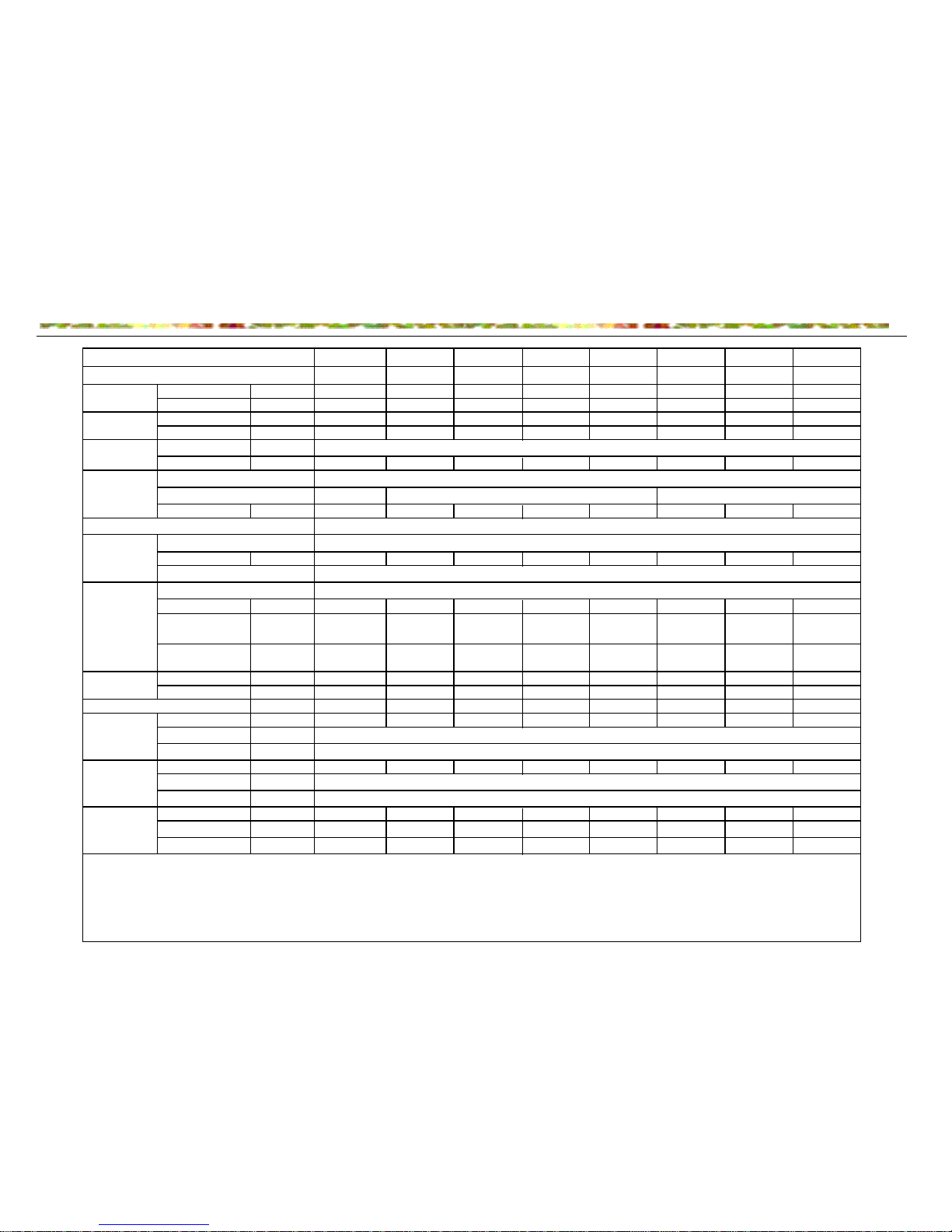

3. Specifications

CI0193AANB CI0193AANC CI0247AANB CI0247AANC CI0316AANB CI0316AANC CI0386AANB CI0493AANB CI0563AANB

A B C D E F A+B C+D E+D

R22 kW 193.1 193.1 246.6 246.6 316.3 316.3 386.2 493.2 562.9

X104Kcal/h 16.6 16.6 21.2 21.2 27.2 27.2 33.2 42.4 48.4

R22 kW 221 221 282.6 282.6 362.9 362.9 442 565.2 645.5

X104Kcal/h 19 19 24.3 24.3 31.2 31.2 38 48.6 55.5

tyep

total kW 71.6 71.6 79.8 79.8 90.9 90.9 143.2 159.6 170.7

input power kW 66.4 66.4 72 72 83.1 83.1 132.8 144 155.1

fan power kW 4*1.3 4*1.3 6*1.3 6*1.3 6*1.3 6*1.3 8*1.3 12*1.3 12*1.3

rated water flow m3/h 33 33 42.4 42.4 54.4 54.4 66 84.8 96.8

water inlet/outlet

pipe dimension

DN 80 80 100 100 100 100 80*2 100*2 100*2

water side

resistance

kPa 45 45 45 45 45 45 45 45 45

type R22 R22 R22 R22 R22 R22 R22 R22 R22 R22

charge Kg 68 68 90 90 100 100 136 180 190

dB(A) 68 68 68 68 71 71 73 74 74

unit length mm 2285 2285 3250 3250 3250 3250 4570 6500 6500

unit width mm

unit height mm

unit length mm 2535 2535 3500 3500 3500 3500 5070 7000 7000

unit width mm

unit height mm

unit weight kg 2450 2450 2800 2800 3300 3300 4900 5600 6100

operation weight kg 2600 2600 2965 2965 3430 3430 5200 5930 6395

shipping weight kg 2500 2500 2850 2850 3350 3350 5000 5700 6200

Note:

1.cooling condition: water outlet temperature 7℃, water inlet temperature 12℃, ambient temperature 35℃.

2.heating condition: water outlet temperature 45℃, ambient temperature: DB 7℃, WB 6℃.

3.noise level is the average value measured at 2 meter to the unit, 1.5 meter high to the gound.

4.unit total capacity is counted in the cooling condition.

5. the length of multi-module chiller is not included the 450mm maintenance space between modules.

2140

25%、50%、75%、100%

high efficiency, heat exchanging pipe cross the hydrophilic aluminum foil

axial fan with low noise

12

3PH, 5-wire, 380V, 50HZ

compressor

type semi-hermetic screw type specially for heat pump type compressor

quantity

model

cooling

capacity

heating

capacity

power supply

combination

2608

capacity control

air side heat

exchanger

dry type shell&shell heat exchanger

water side

heat

exchanger

fan type

type

type

weight

shipping

dimension

2235

2650

refrigerant

noise level

exterior

dimension

HAIER CHILLER

CI0633AANB CI0740AANB CI0810AANB CI0879AANB CI0949AANB CI1056AANB CI1196AANB CI1265AANB

E+F C+D*2 E+D*2 E+F+D E+F*2 E+D*3 E+F*2+D E+F*3

R22 kW 632.6 739.8 809.5 879.2 948.9 1056.1 1195.5 1265.2

X104Kcal/h 54.4 63.6 69.6 75.6 81.6 90.8 102.8 108.8

R22 kW 725.8 847.8 928.1 1008.4 1088.7 1210.7 1371.3 1451.6

X104Kcal/h 62.4 72.9 79.8 86.7 93.6 104.1 117.9 124.8

tyep

total kW 181.8 239.4 250.5 261.6 272.7 330.3 352.5 363.6

2

input power kW 166.2 216 227.1 238.2 249.3 229.1 321.3 332.4

fan power kW 12*1.3 18*1.3 18*1.3 18*1.3 18*1.3 24*1.3 24*1.3 24*1.3

rated water flow m3/h 108.8 127.2 139.2 151.2 163.2 181.6 205.6 217.6

water inlet/outlet

pipe dimension

DN 100*2 100*3 100*3 100*3 100*3 100*4 100*4 100*4

water side

resistance

kPa 45 45 45 45 45 45 45 45

type R22 R22 R22 R22 R22 R22 R22 R22 R22

charge Kg 200 270 280 290 300 370 390 400

dB(A) 76 74 75 75 76 76 76 78

unit length mm 6500 9750 9750 9750 9750 13000 13000 13000

unit width mm

unit height mm

unit length mm 7000 10500 10500 10500 10500 14000 14000 14000

unit width mm

unit height mm

unit weight kg 6600 8400 8900 9400 9900 11700 12700 13200

operation weight kg 6860 8895 9360 9825 10290 12325 13255 13720

shipping weight kg 6700 8550 9050 9550 9550 11900 12900 13400

shipping

dimension

25%、50%、75%、100%

high efficiency, heat exchanging pipe cross the hydrophilic aluminum foil

axial fan with low noise

dry type shell&shell heat exchanger

2140

2608

2235

Note:

1.cooling condition: water outlet temperature 7℃, water inlet temperature 12℃, ambient temperature 35℃.

2.heating condition: water outlet temperature 45℃, ambient temperature: DB 7℃, WB 6℃.

3.noise level is the average value measured at 2 meter to the unit, 1.5 meter high to the gound.

4.unit total capacity is counted in the cooling condition.

5. the length of multi-module chiller is not included the 450mm maintenance space between modules.

type

refrigerant

noise level

exterior

dimension

weight

26

model

combination

cooling

capacity

heating

capacity

capacity control

air side heat

exchanger

type

fan type

power supply

compressor

type

quantity

3PH, 5-wire, 380V, 50HZ

semi-hermetic screw type specially for heat pump type compressor

43

water side heat

exchanger

50

HAIER CHILLER

63

68

58

73

78

8:<4446

427

426

425

424

423

32<

32;

32:

73

68

78

63

58

426

425

424

423

32<

32;

8:<4446

LVaW^a\R]TV TdaeVb

A^^[Z]X TR_RTZch T^aaVTcZ^] WRTc^a TdaeV

A^aaVTcZ^] WRTc^a ^W T^^[Z]X TR_RTZch

AYZ[[Va PRcVa Kdc[Vc NV\_VaRcdaV

AYZ[[Va PRcVa Kdc[Vc NV\_VaRcdaV

j

?\SZV]c NV\_VaRcdaV

A^^[Z]X _^fVa Z]_dc T^aaVTcZ^] WRTc^a TdaeV

A^aaVTcZ^] WRTc^a ^W _^fVa Z]_dc

?\SZV]c NV\_VaRcdaV

48

:

1:

148

68 73 78 83

425

424

423

32<

32;

32:

329

:

48

1:

148

425

424

423

32<

32;

32:

329

68 73 78 83

AYZ[[Va PRcVa Kdc[Vc NV\_VaRcdaV

AYZ[[Va PRcVa Kdc[Vc NV\_VaRcdaV

FVRcZ]X TR_RTZch T^aaVTcZ^] WRTc^a TdaeV

A^aaVTcZ^] WRTc^a ^W YVRcZ]X TR_RTZch

?\SZV]c NV\_VaRcdaV

3

3

_^fVa Z]_dc T^aaVTcZ^] WRTc^a TdaeV

A^aaVTcZ^] WRTc^a ^W _^fVa Z]_dc

?\SZV]c NV\_VaRcdaV

8

FVRcZ]X

HAIER CHILLER

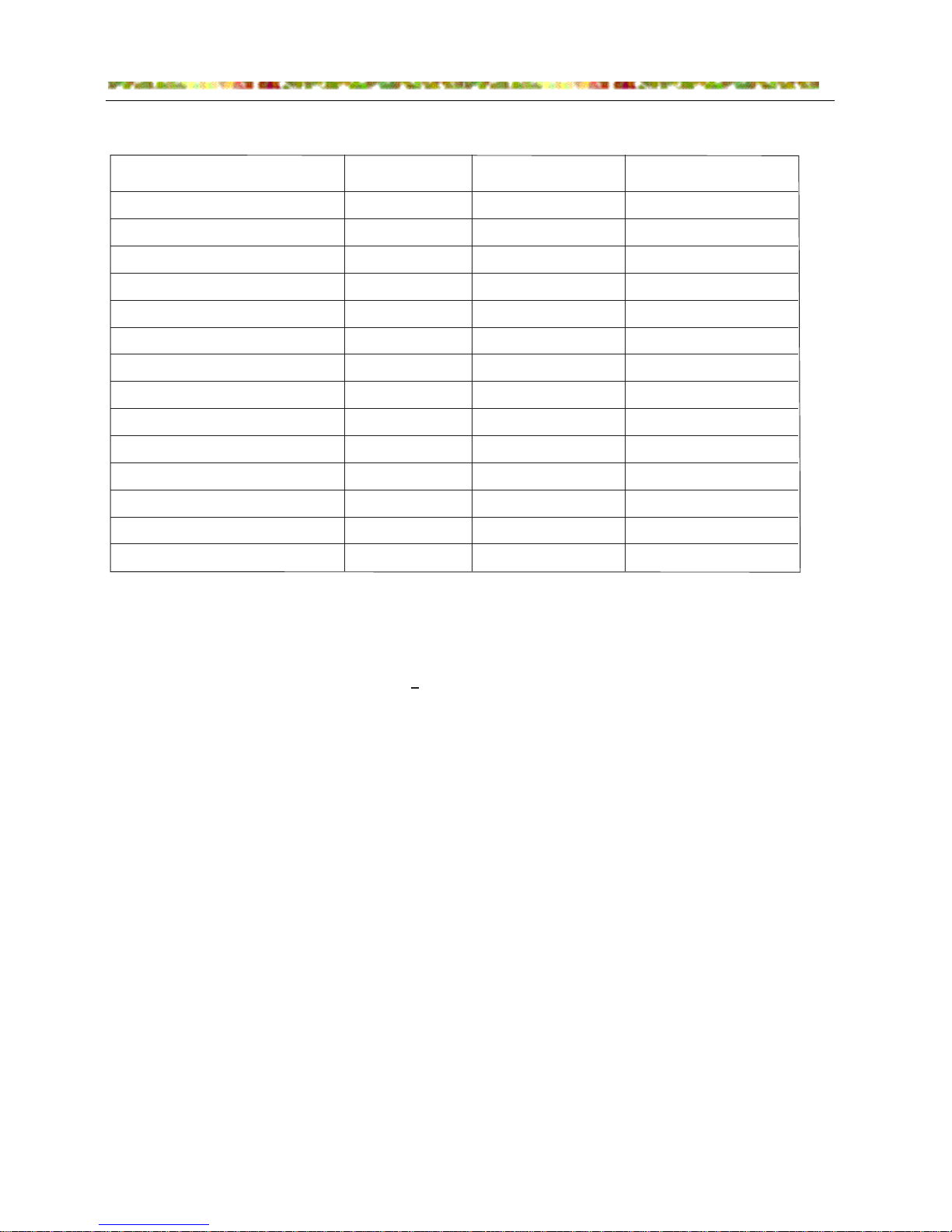

+123304 -30/542/.3 ,.5.

DS` KaiWd -]Q.

527R8

527R:

527R:

527R<

527R56

527R56

527R56

527R5<

527R5<

527R5<

527R5<

527R68

527R68

527R68

5:9

659

694

774

874

8:9

944

:89

:<4

;59

;94

<=9

=:9

5444

KaiWd Q[dW M[lW -__6.

7R;4

7R=9

7R=9

6-7R;4.

6-7R=9.

7R=9/7R=9

6-7R=9.

7-7R=9.

6-7R=9./-7R=9.

7R=9/6-7R=9.

7-7R=9.

7-7R=9./-7R=9.

-7R=9./7-7R=9.

8-7R=9.

HSj JbWdSf[`Y

AgddW`f -?.

HaVW^

AF45=7??I@ AF45=7??IA

AF468;??I@ AF468;??IA

AF475:??I@ AF475:??IA

AF47<:??I@

AF48=7??I@

AF49:7??I@

AF4:77??I@

AF4;84??I@

AF4<54??I@

AF4<;=??I@

AF4=8=??I@

AF549:??I@

AF55=:??I@

AF56:9??I@

IafW>

52NZW V[S_WfWd aX Ydag`V i[dW eZag^V TW 6 e[lWe e_S^^Wd fZS` fZW baiWd i[dW2 -LWXWd fa fZW 81UadW W^WUfd[US^ i[dW efS`VSdVe.

62Ff [e SVh[eST^W fa eW^WUf UabbWd UadW ^WSV i[dW Ua`Xad_[`Y fa `Sf[a`S^ efS`VSdV @P ad @PL ad PP1FGP baiWd UST^W2

72Oe[`Y eWbSdSfW KPA b[bW Xad WSUZ ^[`W aX [`Ua_[`Y baiWd UST^W0 S`V V[XXWdW`f baiWd ^[`We _Sk `af TW _[jWV gb [` a`W KPA b[bW2

82QZW` Ua``WUf[`Y i[dWe0 Y[hW SVWcgSfW Ua`e[VWdSf[a` fa fZSf fZW ^W`YfZ aX i[dW i[^^ USgeW bdWeegdW Vdab2 C`egdW fZW baiWd egbb^k

fa fZW UZ[^^Wd Ua`Xad_e fa fZW bSdS_WfWde> 7m0 7<4

/ 54+P0 94El2

9

HAIER CHILLER

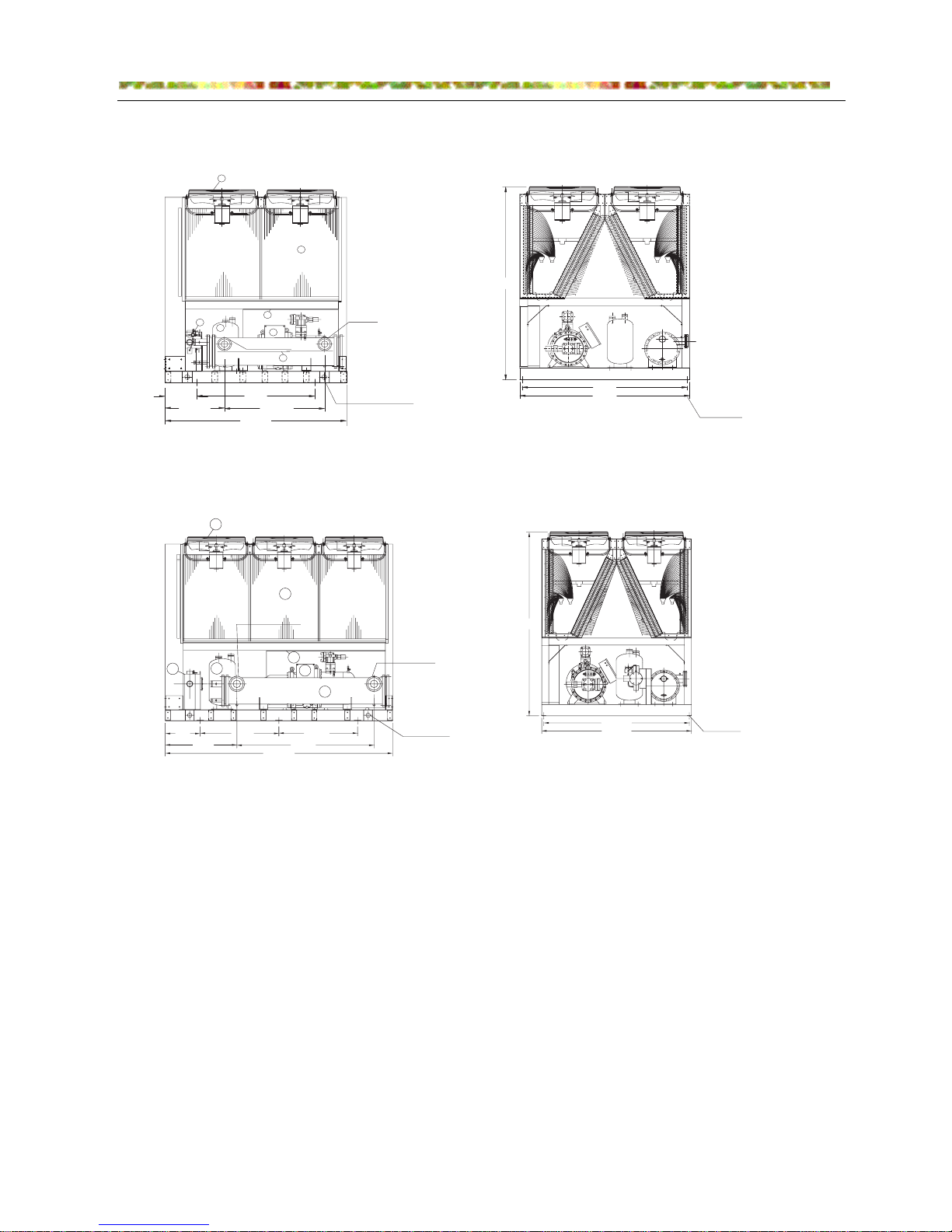

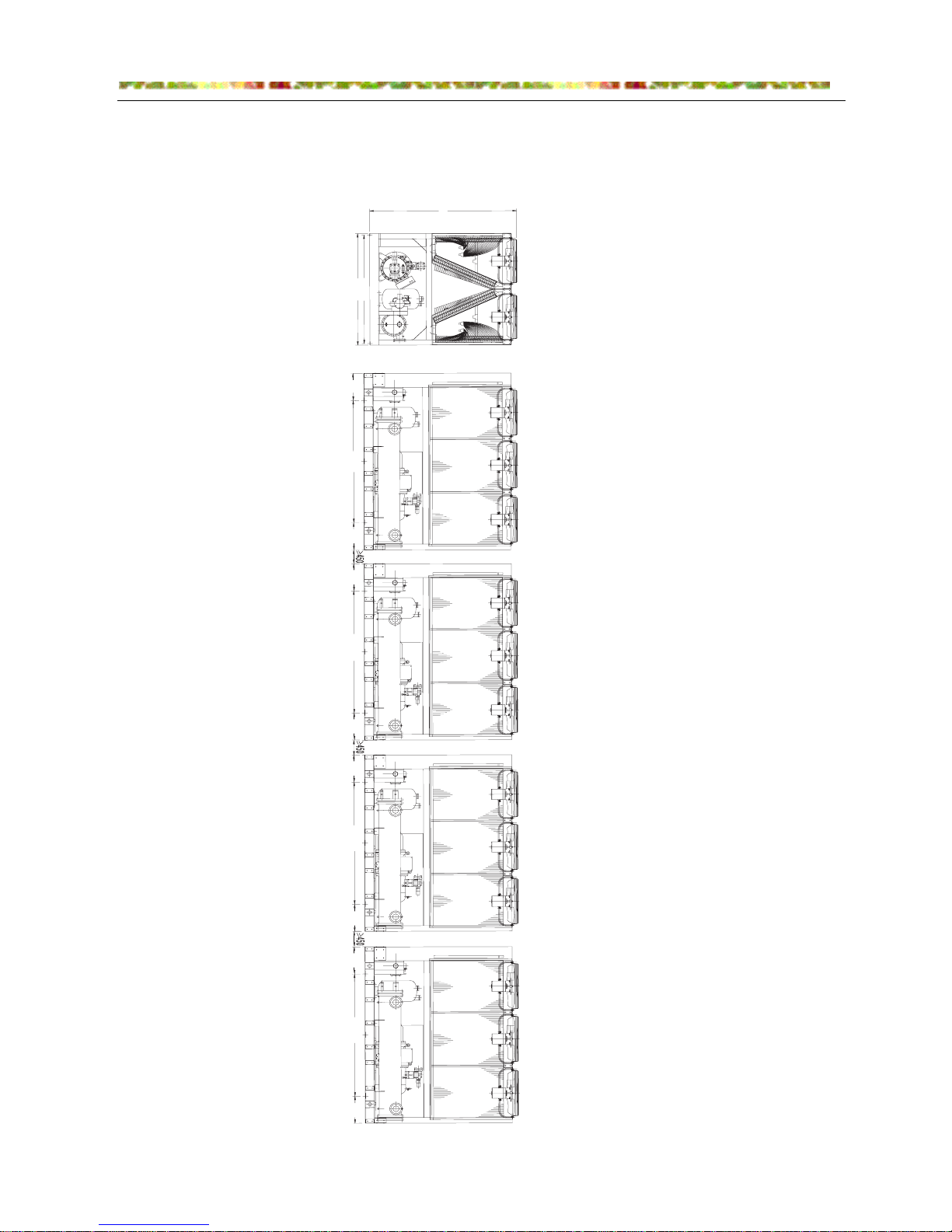

4. Dimension data

PRcVa ^dc[Vc

PRcVa G][Vc

AYZ[[Va F^ZbcZ]X

F^[V

AYZ[[Va DZgZ]X

F^[V

:

PRcVa G][Vc

PRcVa ^dc[Vc

AYZ[[Va F^ZbcZ]X

F^[V

AYZ[[Va DZgZ]X

F^[V

J^cV=

42 LRacb JR\V= -4. DR]0 -5. A^]UV]bVa0 -6. D^da1fRh OR[eV0 -7. ERb , HZ`dZU MV_RaRc^a

-8. C[VTcaZTR[ A^]ca^[ ARSZ]Vc0 -9. A^\_aVbb^a0 -:. VeR_^aRc^a

52 HVReV Rc [VRbc 5\ Ra^d]U cYV TYZ[[Va W^a eV]cZ[RcZ^] R]U bVaeZTZ]X _da_^bV>

72 D^a d]ZUV]cZWZVU _Racb Z] R \d[cZ1T^\_aVbb^a TYZ[[Va0 _[VRbV aVWVa c^ cYV SRbZT \^Ud[Vb>

82 PYV] T^\SZ]X \^Ud[Vb0 cYV b_RTV SVcfVV] \^Ud[Vb bY^d[U SV \^aV cYR] 783\\ W^a eV]cZ[RcZ^]0

bVaeZTZ]X R]U \RZ]cV]R]TV2

47;8

4593

4

8

3

:7;2;

73323

7

BJ;3

6

4

8

3

4

71k97

:

9

8

BJ;3

5

593;

53;3

5473

71k4;

483

483

55;8

833

4357

6583

BJ433

4458

4<93

4458

BJ433

6

7

9

8

71k97

5

4

593;

547323

53;323

91k4;

CI0193AANB (Module A) and CI0193AANC (Module B)

CI0247AANB (Module C) and CI0247AANC (Module D)

CI0316AANB (Module E) and CI0316AANC (Module F)

3. The multi-compressor chiller is normally composed of six basic modules A, B, C,

D, E and F.

For ezample, CI1056AANB(E+D*3) means the chiller is composed of

three D modules and

one E module;

10

HAIER CHILLER

11

593;

53;3

5473

483

483

833

5583

833

833

5583

833

448833

448833

448833

5583

833

833

593;

5473

53;3

47;8

4

8

3

4

8

3

733 733

47;8

4

8

3

4

8

3

733

733i783

448833

448833

448833

448833

448833

448833

593;

5473

53;3

783

833

5583

833

5583

833

833

CI0386AANB (A+B)

CI0493AANB (C+D)

CI0563AANB (E+D)

CI0633AANB (E+F)

CI0740AANB (C+D*2)

CI0810AANB (E+D*2)

CI0879AANB (E+F+D)

CI0949AANB (E+F*2)

HAIER CHILLER

593;

5473

53;3

44

88

33

44

88

33

44

88

33

5583

833

833

44

88

33

44

88

33

44

88

33

5583

833

833

44

88

33

44

88

33

44

88

33

44

88

33

44

88

33

44

88

33

833

5583

833

5583

833

833

CI1056AANB (E+D*3)

CI1196AANB (E+F*2+D)

CI1265AANB (E+F*3)

12

HAIER CHILLER

13

Part name

25%—50%—75% compressor capacity

regulation solenoid valve, control the

movement of capacity piston by oil

pressure drop so that the compressor can

adjust the capacity flexibly according to the

actual capacity.

Filter drier, used to remove moisture

and impurit

y

in the refrigerant.

HAIER CHILLER

14

4-way valve, reverse

when electrify is complete

in heating mode

Refrigerant spray hole, enter the

middle of compressor and

reduce the dischar

g

e temp..

Capacity regulation capillary

Oil inlet connector

Oil pressure drop switch,

used to inspect the

pressure drop of the two

side of oil filter

Compressor crankcase

heater, used to heat up

Oil inspect glass, used to

observe the oil lower level

of compressor

Oil outlet connector

Solenoid valve before 4way valve, used to control

the reverse of 4-wa

y

valve.

HAIER CHILLER

15

By-pass valve, when the

compressor is run in part

capacity, move the

refrigerant from discharging

Low pressure sensor, used

to detect the compressor

suction pressure and

protect when the suction

p

ressure is too low

HAIER CHILLER

16

Liquid spray solenoid valve,

used for compressor

refrigerant spray protection,

prevent the motor of

compressor overheat and

discharging temp. too high.

Thermostatic expansion

valve, control the spray of

refrigerant by liquid-spray

solenoid valve and

discharging temperature

which is detected by the

thermostat.

Thermal expansion

thermostat,fixed on the

discharging pipe.

One-way valve, used

to prevent refrigerant

flow back.

Discharging temp. sensor,

used to detect the

compressor discharging

temp. and prevent

discharging temp. from too

high.

Safety valve, used to decrease

the pressure when the system

pressure is too high.

HAIER CHILLER

17

Spherical valve, install at the each

side of filter drier, which is used to

close the system when maintain

the

filter drier.

Thermostatic expansion

valve, used to throttle

the refrigerant and

decrease the

p

ressure.

HAIER CHILLER

Dag`VSf[a` VdSi[`Y

18

AF45=7??I@ AF45=7??IA

AF468;??I@ AF468;??IA

AF475:??I@ AF475:??IA

AF47<:??I@

AF48=7??I@

AF49:7??I@

AF4:77??I@

AF4;84??I@

AF4<;=??I@

AF4<54??I@

AF4=8=??I@

AF549:??I@

AF55=:??I@

AF56:9??I@

HaVW^

B[_W`e[a`

58<9 5694

6694

6694

6694

5894

5894

5894

6694 5894

6694 5894 6694 5894

844

944

844

944

944

66<9

7694

9464

:=94

54:94

58794

58<9

6694

58<9

6694

6694

6694

TUVWXYZ \[

844

944

844

944

944

944

S

6694 5894 6694 5794 58<9944 844 =:<9

944

IafW>

52 NZW UZ^^Wde eZag^V TW [`efS^^WV a` fZW Sbbdabd[Sf[hW Ua`UdWfW Xag`VSf[a`0 fZW d[Y[V bWVWefS^-egUZ Se YdaahW efWW^.

US` TW geWV [` ebWU[S^ Ua`V[f[a`2

62 NZW Ua`UdWfW Xa`VSf[a` ad d[Y[V bWVWefS^ eZag^V TW TWSd fZW iW[YZf aX fZW UZ[^^Wd [` abWdSf[a`2

72 NZW STahW Xag`VSf[a` VdSi[`Y [e \gef Xad dWXWdW`UW0 fZW VWfS[^ [`efS^^ _WfZaV [e TSeWV a` fZW XSUfgS^ Ua`V[f[a`e282

NZW STahW V[_W`e[a`e [`U^gVW fZW 894__ _S[`fW`S`UW ebSUW TWfiWW` UZ[^^Wde2

[

64<4

6884

:4

544

WSdfZ aX fZW UZ[^^Wd daa_

H5:

X

\

T

S

W

VU

Z

Y

HAIER CHILLER

19

5. Installation

5.1 Inspection & Acceptance

When the chiller is shipped to the place of delivery in accordance with the contract, the client shall engage in

inspection and acceptance.

a. Check the completeness of documents shipped with the chiller;

b. Check the model, specification and accessory to the chiller against the above-mentioned documents;

c. Check the chiller for any broken parts and the completeness of spare parts;

d. Check if there is any leakage of refrigerant charged into the equipment.

Please timely notify us or our business branch in case of any broken parts or any doubt, so that we can

handle it with a proper manner.

After inspection of the equipment, it is advisable to adopt proper protective measures. Do not hastily remove

the package so as to avoid possible damage to the equipment.

5.2 Handling & Hoisting

All the chillers have gone through rigid testing and inspection procedures before leaving the factory to

ensure their quality and performance. Please handle the equipment with extreme care to avoid damage to

the control and piping system.

1) Transport the equipment to a location as close to the installation site as possible before removing the

outer package and stand the equipment on its end. When transporting chiller without package, it needs to

follow the procedures given below:

A. Move the chiller with rollers. Insert three identical rollers under the base of chiller. The roller should be

a little bit wider than the chiller bracket to maintain its balance.

B. Lift up the chiller with forklift truck. Insert the fork under the chiller base and lift it up with extreme care.

The fork should be in fast contact with the two longitudinal beams on the base.

The client may make by its own two hoisting racks and place them on top of the chiller to expand the

steel cable so as to avoid damage to the chiller panel. The strength of the steel wire should be at least 3

times of the weight of the chiller. The hoisting hole on the chiller should be fast. When hoisting, no

personnel may stand under the chiller. Weight of the chiller is indicated in the rating plate. (Refer to

Diagram 1)

(Diagram 1)

HAIER CHILLER

5.3 Installation

q{~*szz~*y|{ y{~*}+t*y|{~ w|} py}ot||zvu rt}v, txyzzv}

52 ES[Wd ?[d1Uaa^WV MUdWi AZ[^^Wd US` TW [`efS^^WV a` fZW daaX0 b^SfXad_0 WSdfZ WfU2 S`kiZWdW WSek fa [`efS^^2

62 F`efS^^ fZW UZ[^^Wd a` efST[^W0 X[d_ S`V X^Sf Ua`UdWf Xag`VSf[a` ad _WfS^ efWW^ TdSU]Wf0 S`V fZW egbbadf[`Y egdXSUW

US` TWSd fZW abWdSf[`Y iW[YZf aX fZW g`[f2

72 LWUa__W`V fZSf _S[`fW_S`UW ebSUW S_a`Y g`[fe eZag^V TW ahWd 894__2

82 NZWdW eZS^^ TW ahWd 6_ ebSUW Sdag`V fZW g`[f fa TW Ua`hW`[W`f Xad hW`f[^Sf[a`2

92 Ndk fa ]WWb fZW g`[f SiSk Xda_ eg`eZ[`W S`V dS[`0 [f [e dWUa__W`VWV fa UahWd fZW g`[f i[fZ eZWV0 Tgf TW egdW

fZWdW [e S ebSUW ahWd 7_ STahW fZW S[d agf^Wf Xad dW^WSe[`Y ZWSf WSe[^k2

:2 ?` S`f[1h[TdSf[a` UgeZ[a` eZS^^ TW Wcg[bbWV TWfiWW` fZW g`[f S`V fZW Xag`VSf[a`2

;2 NZW [`efS^^Sf[a` S`V fZWd_S^ [`eg^Sf[a` aX fZW iSfWd b[bWe aX fZW S[d Ua`V[f[a`[`Y ekefW_ eZS^^ TW VWe[Y`WV S`V

[`efdgUfWV Tk fZW bdaXWee[a`S^e S`V eZS^^ [_b^W_W`f fZW dW^WhS`f dWYg^Sf[a`e aX fZW F`efS^^Sf[a` MfS`VSdV Xad EP ,

?A2

<2 NZW WjfWd`S^ iSfWd b[bW ekefW_ _gef TW Wcg[bbWV i[fZ S`f[1h[TdSf[a` ZaeW0 iSfWd X[^fWd0 W^WUfda`[U iSfWd U^WS`Wd0a`W1

iSk hS^hW0 V[eUZSdY[`Y hS^hW0 efab hS^hW S`V WjbS`e[a` fS`]0 WfU2 fZWd_a_WfWd S`V bdWeegdW YSgYW eZag^V TW

[`efS^^WV fa fZW b[bW ekefW_ Xad aTeWdhW UZ[^^Wd S`V fZW iZa^W g`[f abWdSf[a` Ua`V[f[a` Ua`hW`[W`f^k2

=2 NZW Ua^V iSfWd bg_b eZag^V TW [`efS^^WV a` fZW iSfWd [`^Wf b[bW aX ekefW_0 S iSfWd X[^fWd _gef TW Wcg[bbWV a`

iSfWd [`^Wf b[bW S`V geW fZW _WeZ i[fZ 5:m841_WeZ X[^fWd fa YgSdS`fWW fZW iSfWd cgS^[fk2

542 NZW S`f[1h[TdSf[a` ZaeW _gef TW geWV TWfiWW` iSfWd [`^Wf b[bW S`V iSfWd b[bW aX ekefW_2 ?f fZW eS_W f[_W0 fZW

b[bWe S`V fZW iSfWd bg_b eZS^^ ZShW TdSU]Wf fa bdWhW`f fZW g`[f Xda_ dWUW[h[`Y XadUW2

552 AWS`[`Y S`V ZWSf bdWeWdhSf[a` aX ekefW_ _gef TW Va`W TWXadW Ua``WUf[`Y fZW b[bW i[fZ fZW g`[f2

20

HAIER CHILLER

a. Location

The unit should be located on the place where you clean and maintain easily. The concerning data and the

required space will be displayed in the exterior figure. Firstly, the air ventilation should be taken into

consideration. Because the air around the unit will make heat exchanging with the material in the condenser,

and the air will bring away the heat energy, so the ventilation should be good. If this basic condition can be met,

the condensing temperature will increase, further more, the operation efficiency and the power consumption will

rise, as a result, the unit will be damaged. The unit can be located in the place where the scream, hot air or

much smoke exists. Another considerate question is the place far away from the noisy area and measures must

be taken to avoid the transition of noise and vibration. The unit should be installed out of the gallery, the public

area or the rest area. To proper airflow, the distance from the unit to the wall or obstacle should be less than

1.5m. On the top of the unit, there is no obstacle.

b. Foundation

For normal operation, the foundation must be horizontal. If installed on the building top, the building must be

strong enough to bear the great weight. If installed on the ground, suggest that the concrete ground will be better,

such as following figure.

If the area cannot permit the vibration, the unit bottom should be equipped with the anti-vibration device.

Please select the rubber shock absorber or spring shock absorber as per the actual supporting point. When the

shock absorber is used, the connection between the unit and water pipe should be equipped with the flexible

joint against the connector break.

Note: The performance of the flexible joint pipe must be accordant with the liquid and the pressure, which

flow through the joint pipe. All the exterior pipes connected to the unit must use the flexible cord when being

suspended; while when being passed through the wall, the ceiling, or the floor, the pipe connected to the flexible

pipe must be added the sleeve pipe to prevent the vibration being transferred into the building.

The flexible joint also is needed between the unit and the power supply wires.

c. Maintenance & Ventilation Space

The chiller should be properly ventilated. A minimum space of 2m should be left between the chiller and

other objects. It is desirable to build a herringbone shelter 2m over the highest point of the chiller to avoid

sunshine and rain. Please take note of the 2m minimum space requirement if a shelter is built. At least 450mm

space should be left beteen the chillers for easy maintenance.

21

HAIER CHILLER

The supporting points and foundation

5.4 Maintenance of water side

After the bottom plate is horizontal, connect the water pipe of SHELL&TUBE heat exchanger. Because the

SHELL&TUBE heat exchanger will be cleaned or changed, the exterior pipe should be disassembled. The

discharging valve should be installed on the higher position to ensure the air can be exhausted completely. The

water relief valve is installed on the lower position to discharge water easily.

On the water circuit, there is the temperature indicator and the pressure indicator. In order to

disconnect the unit and the exterior pipe in maintenance, the stop valve is installed on the water circuit. To

reduce the block in the evaporator, it is important to deal with water before the chilled water enters the

evaporator. After the whole system is full of water, startup the pump to exhaust the air in the system.

Even if the cool load changes, heat pump unit also need to operate under the stable water flow. Generally,

the unit can operate normally under the design water flow with tolerance of plus/minus 10%. The changing water

flow can result in unstable operation control, especially for the control of cool/hot water inlet/outlet temperature.

3400

2080

1125

575

1125

E

C

140

A

B DF

300

Note:

1.The above supporting points do not include the weight of water circuit

out of the unit and the exterior power cable brac ke t

2.The foundation must be plane

3.The installer can adopt the expansion bolt M16 or embedded foundation

bolt, the embedded depth is about 240mm(for referen ce) an d th e

extention length is about 50mm(for reference)

4.When used rubber shock absorber, there need not joint among the unit,

the foundation and the rubber shock absorber, only to place the shock

absorber between the unit and the foundation

5.When used spring shock absorber, there is joint between the unit and

the absorber,while we suggest no joint between t he ab so rber and the

foundation. After the absorber is installed, please adjust it until the bottom

plate is horizontal.

577

474

649

A

kg

300 300

Model

481

584

640

512 508

615 611

675 634

591

488502

605

2965

3583

2600

kgBkgCkg

D

supporting points

total

weight

kg

F

kg

E

kg

2080

2434.8

475

300

1484.8

B D

300

A

140

300

C

CI0193AANB CI0193AANC

electric control box side

water inlet/outlet side

concret

electric control box side

water inlet/outlet side

concret

CI0247AANB CI0247AANC

CI0316AANB CI0316AANC

CI0193AANB

CI0193AANC

CI0247AANB

CI0247AANC

CI0316AANB

CI0316AANC

22

HAIER CHILLER

AZ[^^WV iSfWd ekefWd_

NZWdW SdW e[Y` a` fZW Ua``WUf[`Y bSdf aX WSUZ b[bW0 b^WSeW Va Se fZW e[Y` eZaie0 fZW Xa^^ai[`Y [fW_e eZag^V

TW Va`W iZW` Ua``WUf b[bWe>

52 NZW Ua``WUfad ad X^S`YW aX S^^ b[bWe eZag^V TW Se `WSd Se baee[T^W fa fZW UZ[^^Wde Xad WSek V[eSeeW_T^W

iZW` `WUWeeSdk2

62 NZW Ua``WUfad aX UZ[^^WV iSfWd [`^Wf3agf^Wf b[bW eZag^V geW X^Wj[T^W ZaeW \a[`f2

72 MWf fZW iSfWd X^ai ei[fUZ S`V Ua_bdWeead Ua`fda^ i[dW iZ[UZ [`efS^^WV a` fZW iSfWd b[bW [`fWd^aU] fa [`egdW

fZW iSfWd X^ai2

IafW>

52 QSfWd X^ai ei[fUZ _gef TW [`efS^^WV hWdf[US^^k a` fZW efdS[YZf

bSdf aX iSfWd agf^Wf b[bW2 fZW ^W`YfZ aX efdS[YZf b[bW TWe[VW fZW

ei[fUZ [e 9 f[_We fZS` fZW b[bW V[S_WfWd2

62NZW SddaiZWSV aX ei[fUZ _gef ba[`f fa fZW iSfWd X^ai V[dWUf[a`2

72JSd1hS`W fkbW iSfWd X^ai ei[fUZ [e geWV [` fZW abWdSf[a`

bdWeegdW [e 54TSd YSgYW bdWeegdW2

WhSbadSfad

ad

Ua`VW`eWd

iSfWd [`^Wf

iSfWd egbb^k Za^W

VdS[`SYW

Za^W

ahWdX^ai

Za^W

.0

./

...-

..

6./5.

432

1/

/

1

.

0

.1 .2

fWd_[`S^

51 X^Wj[T^W ZaeW \a[`f

61 bdWeegdW YSgYW

71 fafS^ iSfWd agf^Wf fW_b2 eW`ead [`efS^^ bS^UW-T^[`V b[bW0 dWXWd fa D[Y2 ?.

81 fZWd_a_WfWd

90 550 59 1 efab hS^hW

:1 Tk1bSee hS^hW

;1 a`W1iSk hS^hW

<1 iSfWd bg_b

=1 iSfWd efdS[`Wd

541 W^WUfd[US^ iSfWd bdaUWeead

561 Sgfa V[eUZSdY[`Y S[d hS^hW-Z[YZWef [` fZW iSfWd ekefW_.

571 WjbS`e[a` iSfWd fS`]

581 VdS[`SYW hS^hW

2

:4__

54__

TWfiWW` 89 1579

iSfWd agf^Wf

.

T^[`V b[bW

D[Y2 ?

23

HAIER CHILLER

water inlet to air

conditioner

SHELL&TUBE

heat exchanger

Planform for master unit Planform for slave unit

P

T

P

T

P

pressure gauge

water temperature

sensor

FS

FS

FS

flow switch

master unit

slave unit

Multiple units are combined, the water pipes out of unit connection figure:

master control box

water outlet

water inlet

slave control box

SHELL&TUBE

heat exchanger

water inlet

water outlet

water outlet to

air conditioner

Technical requirement:

1.Temperature sensor must be installed on the main water pipe of the unit.

2.Temperature sensor should be installed at the place far from the electric

box <15m.

3.In the sleeve of temperature sensor should be filled with appropriate

sleeve

hole with the sealant.

4.The communication wire between two units can not be over 50m.

5.5 Installation for water pump

Must install stop valve at the water inlet/outlet to make the general maintenance conveniently.

Suggest that the thermometer and pressure gauge are installed at the water inlet/outlet of heat exchanger in

order to check or maintain the unit easily.

Suggest that the filter is installed close to water inlet joint of evaporator to prevent the dirt into the heat

exchanger.

Chilled water pump on the pipe should be installed on the water inlet pipe of the evaporator. Other object

except for the unit can control the pump.

Suggest that all the pipes connected to the unit should be equipped with the anti-vibration device. If the unit

has the shock absorber, the unit and the pipe should be connected in cross type.

On the lower points of the pipes, the drainage joint can be set, while on the higher position, the air

discharging joint can be set.

Before the water pipe is put the heat preservation and the unit is filled with water, please check the pipe

leakage.

Must install the required flow switch.

When the project needs to install the dirt removal system, please avoid the water inlet/outlet pipe of the heat

exchanger, otherwise, that will affect the efficiency.

5.6 Control of Water Quality

When industrial water is used as chilling water, there is little scale formed. When water from well or river is

used, more sediment such as scale or sand will settle down in the evaporator, which will reduce the water flow

and leads to freezing of pipes. So the water should be filtered and softened with chemicals before being supplied

to chilling water system. It is necessary to analyze the PH value, conductivity, the concentration of chlorine ion

and sulfuric ion.The following is the water quality standards adopted by Haier:

Evaporator Water Quality Standard:

24

glycerin. After the sensor has been inserted in the sleeve, seal the

HAIER CHILLER

Alkaline Ion ≤50ppm

Total Hardness ≤50ppm

Sulfuric Ion None

Ammonia Ion None

Silicon ≤30ppm

Sodium Ion Not Required

Note:

1) Do not install the chiller indoor. or leave at least 1.5m between air vent and the ceiling if have to and equip

the chiller with proper ventilation equipment so that the heat generated by the chiller during operation can quickly

dissipate.

2) The refrigerant R22 for the unit is nontoxic and non-flammable. it will permeate near the ground if leakage

occur for R22 is heavier than air. So the ventilation must be will if install the chiller inside in an enclosed room to

avoid suffocation.

3) Stop the chiller immediately and contact with the technician in time if leakage occurs. Naked fire is

prohibited in the site, or the refrigerant will be reduced to harmful gases.

4) Connect water systems between modules in parallel when applying multi-module. Each module should

have a flow switch and a minimum 450mm space should be left between modules for maintenance.

5) Use cuprum-core soft cable which can meet the current requiement of chiller as power supply cable, the

cable should be connected with cuprum block directly when enter electric box and setted away from weak

electrical wire, otherwise, it is forbidden to install or maintain when power is on.

6) Confirm if the electrical connection is well before debugging. The connection may become flexible during

transport, so fix the connection again before debugging.

7) The dip switch on the P control module is forbidden to be changed.

5.7 Installation of electric control

Install the power cable (3-phase, 4-wire type)

Check if the local power supply (voltage, frequency) can meet the requirement of the unit.

Please install residual circuit circuit-breaker.

Note: For the safety, the unit must be grounded.

Fix the chilled water inlet/outlet temperature sensor: It is placed on the exterior pipes vertically (less than

450mm to the unit).

Fix the chilled water inlet/outlet pressure drop controller: high pressure side is connected to the inlet; low

pressure side is connected to the outlet.

25

PH Value 6.5-8.0

Conductivity ≤200uv/cm(25°)

Chlorine Ion ≤50ppm

Sodium Ion ≤50ppm

Total Ferrous Content ≤0.3ppm

CB

HAIER CHILLER

6. Unit startup and stop

6.1 Check before startup

6.1.1 Water circuit

Confirm if the water circuit has leakage and if the water flow direction is correct.

Open all the water valves.

Start up the chilled water pump.

Exhaust the air in the water circuit of heat exchanger.

Check the water side resistance consumption of heat exchanger and if the water flow volume is correct.

Confirm the temperature sensor is fixed correctly.

6.1.2 Wiring circuit

Cut off the main power switch, and check all the startup circuit and control circuit.

Confirm the switch is at OFF state.

Check the power supply if the voltage fluctuation (within ±10%), the phase voltage unbalance (within ±

2%), and the power frequency fluctuation (within ±2%) are in the permitted range.

Check if there is enough power supply capacity to meet the requirement of startup and full load operation.

Water switch is fixed as per the circuit diagram.

For multi-compressor system, please wire the communication cables as per the group control wiring

diagram.

Confirm that all the wires and the fuses are the proper specs matching with the unit.

Confirm all the accessories and the control device operate normally, and at the first operation, their cooling

capacity can meet the operation requirement.

Though the electric circuit such as control box and the sensors, etc. has been tested before out of factory.

Because in the transportation, there are some uncertain effects, please check the unit carefully again before the

unit is put into use.

6.1.3 System section

Confirm if the compressor oil heater has been electrified for 24 hours.

Through the liquid sight glass of the oil segregator, if you can observe the oil level, please add the oil.

Check the fan-driving device, if there is corrosion or rust and if the fan needs to be cleaned, etc. For the

problems, maintain or adjust the unit.

Open the manual stop valve of the liquid spray pipe fully.

Open the suction, discharging stop valves, and then turn 1/2 circle in clockwise.

Open the liquid supplying valve fully.

Open the chilled water pump.

6.2 Unit startup and stop

1.Close the exterior main power switch, and enter the unit operation surface, that is the auto startup

program.

2.If the unit occurs failure in running, the control box can alarm automatically or cut off the power supply,

meanwhile, on the screen there is the failure information.

3.Parameters in the cooling standard condition:

26

HAIER CHILLER

Parameter Standard value Fluctuation range

Condensing pressure 18kg/cm2 ±2kg/cm2

Evaporating pressure 4.2kg/cm2 ±0.5kg/cm2

Discharging temp. 80℃ ±10℃

Suction temp. 12℃ ±5℃

Liquid supply temp. 45℃ ±3℃

The above value is the basic value in the operation.

4. Parameters in the heating standard condition:

Parameter Standard value Fluctuation range

Condensing

pressure

18kg/cm2 ±2kg/cm2

Evaporating

pressure

3.5kg/cm2 ±0.5kg/cm2

Discharging temp. 80℃ ±10℃

Suction temp. 4℃ ±5℃

Liquid supply temp. 45℃ ±3℃

The above value is the basic value in the operation.

Note: You had better not use EMERGENCY if not necessary. Only after the failure is eliminated, the unit can

start up.

6.3 Stop for long time

If the unit does not run for long time, the following measures will be taken:

Close the liquid supply stop valve, and operate the compressor to extract the refrigerant, then stop the unit.

Close the compressor suction, discharging stop valve, and stop the water pump.

Shut off all the power supply.

Make the emergency at OFF state.

All the shut-off switches must be marked the sign as warning. Only after the compressor suction,

discharging stop valve and liquid supply stop valve, also and the liquid spray stop valve are open, the unit can be

started up.

27

HAIER CHILLER

28

7 Maintenance

Must not make the maintenance in operation.

7.1 System maintenance

To ensure the unit can operate normally with full load, and do not occur the failure, the below clauses should

be checked on period.

Check the humidity of the liquid sight glass on the liquid supply pipes. Confirm there is full of liquid and the

humidity indicator is dry state. If the humidity is too high or there is air bubble in the glass, even though the unit

has enough refrigerant, you had better change the filter drier core.

7.2 Electric control maintenance

Note: Before any maintenance for electric control, shut off the power of whole electric control box.

The electric parts need not special maintenance and only need to be fixed the wring every month

appropriately.

If the wiring is not performed as per the requirement, the guarantee will be invalid. The fuse shutoff or the

breaker acting shows short circuit or overload. Before changing fuse or restart the compressor, you must find out

the failure and repair it. The control box must be repaired by the experienced engineer. For any damage because

of any modification of control box, the manufacturer will not take any responsibility.

7.3 Recommended daily checking items

Time Position Checking items Correct value

1.oil heater Check if the electric heater is

electrified when stop

Start the electric heater

2.liquid sight glass of oil segregator Oil level Ensure the oil level of the

glass should be over 1/3.

3.manual stop valve of the liquid spray pipe Chec k if the valve is open fully Open the valve

4.voltage of power supply To check with a voltmeter Not over rated value±10%

Before

startup

5.ambient temperature(outdoor) To check with a thermometer ≤40℃

1.liquid sight glass of side cover Check the wheel rotation Wiring as per EY302947

2.solenoid valve on the liquid spray pipe When startup, check if it is open

Startup

3.vibration and noise To feel and listen No abnormal vibration

and noise

1.liquid sight glass of oil segregator Oil level Recharge refrigerant oil*

2.solenoid valve on the liquid spray pipe Check if sprayi ng oil

3.discharging pressure Check high pressure gauge 1.1~1.8MPa

4.suction pressure Check low pressure gauge 0.3~0.6MPa

5.suction pressure drop among the

running compressors

Check low pressure gauge ≤0.05MPa

6.hot water outlet temperature (in heating) To check with thermometer 30~45℃

Operation

7.chilled water outlet temperature (in

cooling)

To check with thermometer 5~10℃

HAIER CHILLER

29

8.discharging pressure drop among the

running compressors

Check high pressure gauge ≤0.1MPa

1.refrigerant volume Check liquid sight glass No air bubble in the

liquid of the pipe

Every

season

2.lubracation oil volume Oil level In the permitted range

Note: The additional oil volume cannot be over 10 liter.

7.4 Recommended maintenance period

Running time(h)

Item

1000 2500

Electric insulation △ △ △ △

Motor △ △ △ △

Liquid spray control valve △ △

Solenoid valve △ △

Suction filter △ △ △ △ ○

Oil filter △ △ △ △ ○

Filter of the liquid spray pipe △ △ △ △ ○

Refrigerant oil ○ ○

Note: △check ○change

5000 10000 35000

HAIER CHILLER

8. General maintenance

Checking the cycling water: discharge the water from the heat exchanger. If the water is dirty, the cooling

efficiency will reduce, at the time, the water in the system should be changed.

8.1 Check of heat exchanger and pipes

8.1.1 Check of evaporator

The dirty surface of heat exchanger will reduce the working efficiency. The material of the SHELL&TUBE

heat exchanger is steel and copper pipe, and the heat exchanger can be used for the water system which has

been treated. In some area, the water quality is very hard, therefore the evaporator will be blocked, and will result

that the system stop because of failure or the operation is not economical. In the condition, please consult the

specialist to get the high quality water.

8.1.2 Check of condenser

In the operation, if the environment air is dirty and the dirt on the condenser is much, please often clean the

condenser. With the dirt condenser, the unit will run under high pressure, as a result, the system will not meet the

satisfied effect. Please clean the coil with soft brush and cool water or ask for the professional person. Do not

clean with hot water or cream. Otherwise, the inner pressure of the system will increase. Before the seasonal

startup, clean the condenser surface. As per the cleanness, confirm the periodic cleaning.

8.1.3 Checking the pipes

The periodic checking of pipes mainly is to remove and clean. And then check the leakage of the welding

gap, the flange, the sealed cushion, the thread type, etc.

8.2 Refrigerant charge

When lack of refrigerant (adjusted on the standard condition: cooling: ambient temperature 35℃, water

outlet temperature 7℃; heating: ambient temp 7℃, water outlet temp 45℃. In running, the liquid sight glass must

be clear.), firstly please check the leakage position and amend it. If there is non-condensing air, firstly evacuate

the system and then add refrigerant.

Procedure of charging refrigerant:

a. Close the compressor discharging valve, condenser liquid supply valve, liquid spray valve(single screw

unit), and separate condenser.

b. Connect the hose with the accumulator, and tighten the nut. Then connect the hose with refrigerant

charging valve, temporarily do not tighten the nut. Open the accumulator valve a little to discharge the air until

the refrigerant go out of the hose, then tighten the nut of hose connector on the refrigerant charging valve.

c. Open the big refrigerant charging valve of condenser slowly. By the pressure drop, fill the refrigerant into

the condenser automatically until it meets the admired volume.

d. After the pressure is in balance (weight of accumulator no change), if the refrigerant still does not meet

the admired volume, heat the lower section of the accumulator to ensure the refrigerant can be charged

continuously. Once it meets the admired volume, stop heating at once and close the valve of accumulator.

e. Close the refrigerant charging valve, and disassemble the refrigerant charging pipe.

f. If one bottom of refrigerant cannot meet the requirement, please change the accumulator, and repeat the

above procedure until it meets the requirement.

g. If lack of refrigerant, and the refrigerant weight in the system is unknown, please perform the No 1, No2

and then start up the unit (liquid supply stop valve had better not to open largely). Open the refrigerant

30

HAIER CHILLER

charging valve of the condenser slowly, and observe how the liquid sight glass and the condensing pressure

change. If there is refrigerant foam in the liquid sight glass, or the pressure and the admired pressure on the

condition cannot be accordant, that shows the system is lack of refrigerant. As per the actual situation, perform

No3, No4. Until the light glass and the pressure gauge resume normal, shut off the refrigerant charging valve,

and open the liquid supply stop valve slowly. If there is refrigerant foam in the liquid sight glass, or the pressure

and the admired pressure on the condition cannot be accordant, open the refrigerant charging valve to charge

the refrigerant. Repeat the above the procedure, when the liquid supply stop valve is fully open, If there is

refrigerant foam in the liquid sight glass, or the pressure and the admired pressure on the condition can be

accordant, that shows the refrigerant has been charged well. Perform No 5, and record the refrigerant volume.

8.3 Troubleshooting

Section Phenomenon Reason Solution

Shutoff time over 3s 1.the hole of the valve plug side is blocked 1.Remove the dirt in the hole and install a

filter in front of the valve

1.Voltage is below 85% 1.adjust the voltage within ±10%

After powered on, the

valve can not open

2.The coil has been burnt out or the

connector falls off

2.If necessary, open the valve to check or change

the coil. New coil must be dipped and dried, and fill

a layer of glue made of quartz and pitch (the weight

proportion 3:1) between the coil and the shell.

1.the hole of the valve plug side is blocked 1.Remove the dirt in the hole

2.The sealed loop of valve plug is worn

out or distorted.

2.change the sealed loop

The gap between the

valve plug and the

valve bracket is not

sealed, there is

leakage

3.Pressure drop between the pressure before

and after the valve is lower 10% than the

weighed pressure.

3.Comply with the requirement

1.sealed cushion is not placed well. 1.place the sealed cushion and tighten firmly

and evenly

The sealed section

between the static

part and movable part

is not sealed well.

2.sealed cushion is worn out or distorted. 2.change the sealed part

1.pressure relief hole is dirt 1.Eliminate the dirt in the hole

Solenoid

valve

After electrified, the

valve plug does not

start up

2.the improper medium, and the bad

viscosity

2.bad viscosity, enlarge the pressure relief

hole

1.Main switch cannot close 1.close the switch Compressor Compressor not

startup

2.fuse is burnt out, and the circuit switch is

not close

2. check if the wiring circuit and the motor coil have

been grounded or in short circuit. check if it is

overload (after troubleshooting),change the fuse

or close the switch to check if the connection is

loose or rusty.

31

HAIER CHILLER

3.overheat protection disconnection 3.auto reset of overload protection. Before

the overheat protection resumes normal,

please eliminate the problem.

4.contactor or solenoid valve failure 4.modify or change

5.safety device acts, then the unit stops

5.confirm the stop type and reason. Before

the safety function has resume, please

eliminate the problem.

6.no heat load 6.wait for the heat load

7.modify or change the solenoid valve

8.check if the motor is in short circuit, in cut

circuit or burnt out.

9.check all the wiring terminals, and tighten the

screws.

10.make the safety switch reset

1. wrong wiring 1. check and re-wring

2. low voltage 2. check the power voltage

3. starter invalid 3. change

Compressor cannot

operate and be

noisy

4. compressor damaged 4. change

1. too much refrigerant enters the

compressor

1. check the expansion valve set value Compressor is noisy

and vibrates greatly

2. compressor damaged 2. change

1. capacity control failure 1. change

2. load reducing device failure 2. change

3. the thermostat grade occurs failure or the

wire is broken down

3. change

Compressor can add

or reduce the load

4. grade set not reasonable 4. re-set

1. the water thermostat is abnormal 1. change The interval between

compressor adding

and reducing load is

too short

2. water flow is not adequate 2. adjust the water flow

1. the operation condition exceeds the

designed range

1.change the condition to the admired range

2. discharging valve is not open fully 2.open the valve

The compressor

heat-sensitive

protection switch is

broken down

3. motor abnormal 3.change the compressor

1. when in great load, the voltage is too

low

1. check if the power voltage drop is too

high

motor

Motor overload, relay

broken down

2. the motor coil damaged 2. change the compressor

32

HAIER CHILLER

3. power cable is loose 3. check all the connection and tighten

them

4. condensing temperature too high 4. lower the discharging pressure

5. abnormal power cable result in the

voltage unbalance

5. check the power voltage, do not start up

the compressor until the trouble is

eliminated

6. overload relay damaged, ambient

temperature too high

6. improve the ventilation to get good

radiator

1. there is non-condensing gas in the

system

1. discharge the non-condensing gas

2. too much refrigerant 2. extract the redundant refrigerant

3. discharging stop valve not open 3. open the discharging stop valve

Discharging pressure

too high

4. air outlet temperature of condenser

too high

4. check if the installation is proper and

the fin is blocked

1. condensing temperature not

adjusted properly

1. check the condenser control and

operation process

2. suction stop valve not open fully 2. open the suction stop valve

3. lack of refrigerant 3. check the leakage and maintain, charge

the refrigerant

4. suction pressure too low

Discharging pressure

is too low

1. oil filter inlet is blocked 1. clean

2. liquid type refrigerant enters the oil

segregator

2. check the electric heater, adjust the

overheat value of expansion valve.

Check the liquid supply solenoid valve

to adjust the water flow

3. oil pressure gauge is not correct 3. modify or change, close the valve. Open it

until there is reading.

unit

Oil supply abnormal

4. oil lever too low 4. add the oil

33

HAIER CHILLER

9. Control device

The core component adopts touching type

screen; the surface is dialog type, easy to operate.

The whole control device is highly automatic and highly

reliable.

9.1 System diagram

1. air-liquid segregator 2. 4-way valve 3. safety valve 4. high pressure sensor 5. high temperature

expansion valve 6. compressor 7. expansion valve 8. liquid supply solenoid valve 9. evaporator

10. thermostatic expansion valve for cooling 11. one-way valve 12. filter drier 13. ball valve 14. corner

valve 15. thermostatic expansion valve for heating 16. one-way valve 17. condenser 18. ball valve

19. one-way valve 20. one-way valve 21. thermostatic expansion valve for heating 22. liquid spray solenoid

valve 23. low pressure sensor

The compressor takes in low-pressure superheat refrigerating gas from the dry-type evaporator and

compresses it into high-pressure, high-temperature steam-gas. The steam-gas discharges heat to the ambient

environment when going through the condenser and is condensed into saturated or super-cool refrigerating

liquid, which flow is regulated and pressure reduced through expansion valve. Then, the liquid flows into the

dry-type evaporator, where it absorbs heat from cold water, gasifies and is again taken in by the compressor to

start a new cycle. Thus, the cold water passing the dry-type evaporator is cooled down and flows into the

air-conditioning area.

In heat pump cycle, the direction of refrigerant flow is switched over by means of four-way valve. After being

compressed by the compressor, the high-pressure, high-temperature refrigerating gas is directly discharged into

the shell and tube heat exchanger (dry-type evaporator) and heat is released to cold water in this process to

realize heating. The condensed refrigerant flows through expansion valve, where its flow is regulated and

pressure reduced and then evaporates in the air-cool condenser by absorbing ambient heat. The gas is then

34

HAIER CHILLER

taken in by the compressor to start a new cycle.

9.2 Daily maintenance:

In order to maintain the unit performance and life, please check the below items in daily maintenance:

1.Check if the high/low pressure switch data is in accordant with the requirement.

2.Observe the refrigerant oil level.

3.Observe the refrigerant oil color, if is seems brown or black, please change the oil.

4.Observe the pressure gauge, and confirm if the high/low pressure is correct and the working points have

tolerance, record the operation data.

5.Measure if the working current of the compressor is correct.

6.Check if the unit is stable and if the unit can run continuously.

7.Confirm if the unit and the condenser is noisy.

8.Confirm if the drainage is OK.

9.Confirm if the refrigerant charge is proper.

10.If the condenser fan motor is running normally and the rotation direction is correct.

11.If the wire has been bitten, worn, over hot, aged and if the connector is loose.

12.The leakage of electric system.

13.If the electric parts are insulated, bad radiator, or over heat, etc. phenomenon.

14.Check if the condenser is blocked by the dirt or sundries. If yes, please clear immediately.

15.If there is tough, collision or friction among pipes, please adjust or add the rubber.

16.If the refrigerant pipe and welding point are rusty, please remove the rust with the tender sand paper and

cloth, then paint the anti-rust varnish.

17.If the frame and other steel shell are rust, remove the rust with the rough sand paper and the cloth, then

paint the anti-rust lacquer with the same color.

35

HAIER CHILLER

10. Wiring diagram

t and slave control diagram, each diagram included

diagram are used for any combination, because the quantity of fan motor and address of input/output are

defferent, wiring diagram of the six basic modules is not completely same, but the basic control is similar.

Take CI0386AANB as example:

1. Combination type: CI0386AANB=CI0193AANB+CI0193AANC one is used

2. Control 4 condensing fan motor, which is divided to 2 groups and controlled by contactor and relay, the wiring

digram is as following:

10.1 Main control circuit

1) 386 main control return circuit: it is the sketch map for compressor, fan motor and PCB power supply mostly.

Touch screen 24V DC power Control part of strong power

Main control 193 have have

Slave control 193 none none

same

R2 S2 T2

V1

M1-2

COM

14

1

NO

12

11

NC

100

YX Z

KM3

U1

S11

ABJ1-14

R

R11

6

T4S

5

T11

FU6

FU5

FU7

R

T

S

PA

95

A

PE

FR1

U

VW

M

KM1 KM2

FR2

KM4

S1

QF1

R1 T1

QF2

M3-4

W1 V2U2 W2

DR

GP

+

205

60

102

V+

V-

N

L

-

0

R5 T5

R3 S3 T3

FR3

KM5

66

KM7

65

QF3 QF5

H1

FU4FU3

DF0

R1

KM2

R30

SEM

Q1

67

KM1

R10

KM1

200

201

fan

FJ

FU2

R21

FU1

BT

T21

T31

powe r indicator

electric heater

liquid supply

solenoid valve

emergency b utton

heater

No.2 fan

motor

No.1 fan

motor

compressor

power

supply

3

R31

The wiring diagram can be devided as main control circui

three parts: main control return circuit, PCB circuit and terminal connection diagram. The two type wiring

, one is used as main control, the other

as slave control, the main configuration differenceis as following:

6

HAIER CHILLER

2) 386 PCB circuit: it is the input/output control of PCB mostly.

AI3

AI2

AI0

AI1

D14

D12

D13

32

K2

31

X22

X20

X19

X21

DF3

DF4

X13

D10

D9

D8

D11

29

KM5KM4

28 30

KM6

X16

X15

X14

X17

D7

D6

D5

COM2

KM7

25

2726

X12

X11

X10

PCB

X9

13 141211109

(24V+)

DF1

42

KM3

41

KM2

X3

D1

COM1

D4

D3

D2

2321

KM1

22

KM2

X7

X6

X4

X5

COM0

NL

D0

20

KM3

X2

(24V+)

X0

X1

0

205

FG

(24V-)

100

4 876531 2

102

X8

24

DF2

AI4

15

9391

485A

D25

D23

D22

D24

H2

34

CN2

CN1

CN3

COM5

D20

D19

D21

33

K1

485B

AI7

AI6

AI5

9290

K1 K2

18

1716

X18

COM3

DF6DF5

X23

D15

COM4

D16

D18

D17

Note: In the fig u re, is the exterior w irin g terminal.

Parts in dashed frame does not exist in the control box.

No1 condensing fan motor

No2 condensing fan motor

No3 condensing fan motor

auxiliary electric heat

liquid-spray solenoid valve

4-way valve

by-pass solenoid valve

compressor capacity

solenoid valve 75%

compressor capacity

solenoid valve 50%

compressor capacity

solenoid valve 25%

failure alarm

cycling water pump

compressor control

heater

cycling pump startup/stop switch

auxiliary heating startup/stop switch

compressor oil pressure

drop controller

remote control

cycling water flow protection

compressor electronic protection

compressor oil level protection

power supply protection

compressor overload

No.1 fan motor overload

No.2 fan motor overload

No.3 fan motor overload

address setting

cycling water inlet

touch screen

cycling water outlet

main control water outlet

discharging temperature

fin temperature

discharging pressure

suction pressure

37

38

) 386 terminal connection diagram: it is the connection for external control mostly.

Note:

1.Parts in dashed frame will be prepared by the customer.

2.Temperature sensor adopts the 3-core shielded wire RVVP3x0.5.

10.2 Slave control circuit

1) 386 slave control return circuit: the most difference between the main control circuit is there are no power

and touch screen .

2) 386 PCB circuit: the most difference with the main control circuit is that 3 ports are not used: X7(No. 3 fan)

he connection for external control mostly.

HAIER CHILLER

supply

motor overload); AI2(main control water outlet) and D10(No. 3 condensing fan motor).

3) 386 terminal connection diagram: it is t

3

26

201

0

0

200

10

15

10

FR1

U

V

W

Z

X

Y

KM1 KM2

V1

1

U1

5

U2

V1U1W1

W1

U2W2W2

V2V266

65

17

25

4

31

0

100

32

15

3

20

14

30

12

18

11

18

181615

18

35

10

Q

90

18

40

93

100

9

91

92

45

100

50

PE

PE

18

13

18

compressor control

cycling water flow switch

interlock passive element of

auxiliary heating

interlock passive element of

cycling water pump

cycling water outlet temperature

cycling water inlet temperature

compressor oil pressure drop controller

compressor oil level

4-way solenoid valve

liquid-spray solenoid valve

liquid-supply solenoid valve

crankcase heater

compressor capacity solenoid valve 75%

compressor capacity solenoid valve 50%

compressor capacity solenoid valve 25%

power supply

No1 condensing fan motor

No2 condensing fan motor

No3 condensing fan motor

No4 condensing fan motor

heater

by-pass solenoid valve

remote control

cycling water outlet temperature

of main control

NO.1 compresso r electronic

protection

discharging temperature

fin temperature

discharging pressure

suction pressure

0

R

STPE

2

MC1

M1LN

205

0

1

M2

23

5

25

24

0

100

HAIER CHILLER

39

11. Control system

11.1 Electric control function for chille r P CB 0 0 10 45 29 32

1. Cooling mode:

Startup: After pressing ON button, the cycling pump works firstly, the 25% solenoid valve will start 1

minute(revisable) later, 10 seconds later the main and Y contactor of compressor start, 5 seconds(revisable)

later, Y-△ conversion begins, Y contactor will close and △ contactor will open, 10 seconds later, the 25%

solenoid valve will be open and start the 50% solenoid valve, the startup is complete, enter energy regulation

process.

Energy regulation: when cycling water outlet temp. > setting temp. + download temp. difference, the

chiller will upload from 25% to 100%, or will keep the original energy. When cycling water outlet temp. <

setting temp. - download temp. difference, the chiller will download from 100%~25% until stop working. The

condensed fan started by steps, start of stop the fan by comparing the setting pressure with the detect value,

the started pressure of fist group fans is P1(can be setted between 1.45-1.75MPa), the started pressure of

second group fans is P2(can be setted between 1.65-1.95MPa), the started pressure of third group fans is

P3(can be setted between 1.85-2.15MPa), the pressure difference for each group fan is 0.3MPa. After the

chiller works for 100%, the chiller will download compulsively to 75% when the discharging pressure is over

2.25MPa(revisable) until the pressure resume to 2.0MPa(revisable), then upload to 100% again. (Note: once

the fan starts, run 10 seconds compulsively and then judge if the fan stops by pressure; judge pressure and

restart fan motor after the fan motor has stopped for 5 seconds) When compressor run in 50% lasts for over 30

minutes, compressor will unload to 75% compulsively, then upload or download by adjusting temp. condition.

The chiller will download to 75% compulsively when the discharging pressure is over 2.25MPa(revisable) and

will not upload to 100% unless the pressure resume to 2.0MPa(revisable).

Stop the chiller: the current capacity change to 25% operation when stop the chiller, 1 minute later the

compressor stops, 10 seconds later the fan motors stop in turn, 5 seconds later stop the 25% valve, another 1

minute(revisable) later stop the water pump.

2. Heat mode:

Startup: After pressing ON button, the cycling pump works firstly, the 1# condensing fan motor will start

and 4-way valve open after 1 minute(revisable), 3 seconds later 2# condensing fan motor start, 3 seconds later

3# condensing fan motor start, 5 seconds later 25% solenoid valve start, 10 seconds later the main and Y

contactor of compressor start, 5 seconds(revisable) later, Y-△ conversion begins, Y contactor will close and △

contactor will open, 10 seconds later, the 25% solenoid valve will be open and start the 50% solenoid valve, the

startup is complete, enter energy regulation process.

Energy regulation: when cycling water outlet temp. > setting temp. + download temp. difference, the

chiller will upload from 25% to 100%, or will keep the original energy. When cycling water outlet temp. <

setting temp. - download temp. difference, the chiller will download from 100%~25% until stop working. The

condensed fan started all without be controlled by pressure. When compressor run in 50% lasts for over 30

minutes, compressor will unload to 75% compulsively, then upload or download by adjusting temp. condition.

The chiller will download to 75% compulsively when the discharging pressure is over 2.25MPa(revisable) and

will not upload to 100% unless the pressure resume to 2.0MPa(revisable).

Stop the chiller: the current capacity change to 25% operation when stop the chiller, 1 minute later the

compressor stops, 10 seconds later the fan motors stop in turn, fan motors stop at 5 seconds interval in turns,

5 seconds later stop the 25% valve and 4-way valve, another 1 minute(revisable) later stop the water pump.

Defrost: there are two types to defrost: pressure defrost and temp. defrost.

a. When the suction pressure is less than the defrost pressure setted value, judge if the defrost interval is

met, enter defrost if it meets the interval and quit defrost compulsively if reach the max. defrost time. when

during defrost, the condensing fan motor stops and 4-way valve reverse when the compressor download to

HAIER CHILLER

50%, at the same time by-pass valve is connected, some times later the compressor energy up to 75%, some

times later the compressor energy up to 100%. When quit defrost, the compressor download to 50% firstly,

4-way valve reverse and close the by-pass valve, run in heating mode.

b. When the fin temp. enter the defrost temp. setted value, judge if the defrost interval is met, enter defrost if it

meets the interval, quit defrost compulsively if the chiller do not reach the defrost quit temp. when at the max.

defrost time, the defrost action is the same with pressure defrost.

Quit defrost if one of the below conditions is met:

1. Meet the max. defrost time;

2. Both the discharging pressure and fin temp. meet the defrost quit condition.

Note: start to time the defrost time interval only when defrost once, the first defrost after compressor

startup is not limited by the defrost interval.

3. Upload condition: 1. Cycling water outlet temp. meets the condition;

2. Meet the min. time of chiller stops;

3. Upload according to upload/download interval.

Upload procedure: 1# chiller25%→1# chiller 50%→1# chiller 75%→1# chiller 100%→1# chiller 75%

→2# chiller 25%→2# chiller 50%→2# chiller 75%→1# chiller 100%→2# chiller 100%→1# chiller 75%→2#

chiller 75%→3# chiller 25%→3# chiller 50%→3# chiller 75%→1# chiller 100%→2# chiller 100%→3# chiller

100%→1# chiller 75%→2# chiller 75%→3# chiller 75%→4# chiller 25%→4# chiller 50%→4# chiller 75%→1#

chiller 100%→2# chiller 100%→3# chiller 100%→4# chiller 100%

4. Download condition: 1. Cycling water outlet temp. meets the condition;

2. Meet the min. time of chiller stops;

3. Download according to upload/download interval.

Download procedure: 1# chiller 100%→1# chiller 75%→2# chiller 75%→3# chiller 75%→4# chiller 75

%→1# chiller 50%→2# chiller 50%→3# chiller 50%→4# chiller 50%→1# chiller 25%→2# chiller 25%→3#

chiller 25%→4# chiller 25%→1# chiller stop→2# chiller stop→3# chiller stop→4# chiller stop

Before the later chiller startup, the former chillers which have started will download to 75% and then start