Ductless Split Heat Pump

Installation Manual

Indoor

AM24LP2VHA

AM36LP2VHA

AM48LP2VHA

AL24LP2VHA

AL36LP2VHA

AL48LP2VHA

AW24LP2VHA

AW36LP2VHA

Outdoor

1U24LP2VHA

1U36LP2VHA

1U48LP2VHA

Nomenclature

T

able of Cont

............................................................................................................................... 2

ents

................................................................................................................... 3

ety ........................................................................................................................................... 4

Saf

Section A - Outdoor Unit Installation ............................................................................................ 7

Section B - Indoor Unit Installation - Wall Mount ......................................................................... 13

Section C - Indoor Unit Installation - Cassette ............................................................................. 17

Section D - Indoor Unit Installation - High ESP Duct ................................................................... 23

Section E - Wir

ed Controller YR-E17 ............................................................................................ 29

Section F - Wireless Remote Controller ....................................................................................... 37

ENGLISH

1 U 24 LP 2 V H A

1 U 18 ES 2 V H A

Unit Type

A = Indoor Unit

1 = Single Zone Outdoor

2 = Two Zone Outdoor

3 = Three Zone Outdoor

4 = Four Zone Outdoor

Nomenclature

Nomenclature

Product Revision

Unit Type

U = Outdoor

B = Casse e Type Indoor

D = High ESP Duct Type Indoor

M=High Static Duct Type Indoor

W = Wall Mount Type Indoor

L = Large Cassette Type Indoor

Nominal Capacity

In Btu/hr (x 1000)

Product Family

- LP:LP=FlexFit Pro Series

System Type

H = Heat Pump

C = Cool Only

Compressor Speed

V = Variable Speed

Voltage

1 = 115V

2 = 230V

PAGE 2

INTRODUCTION

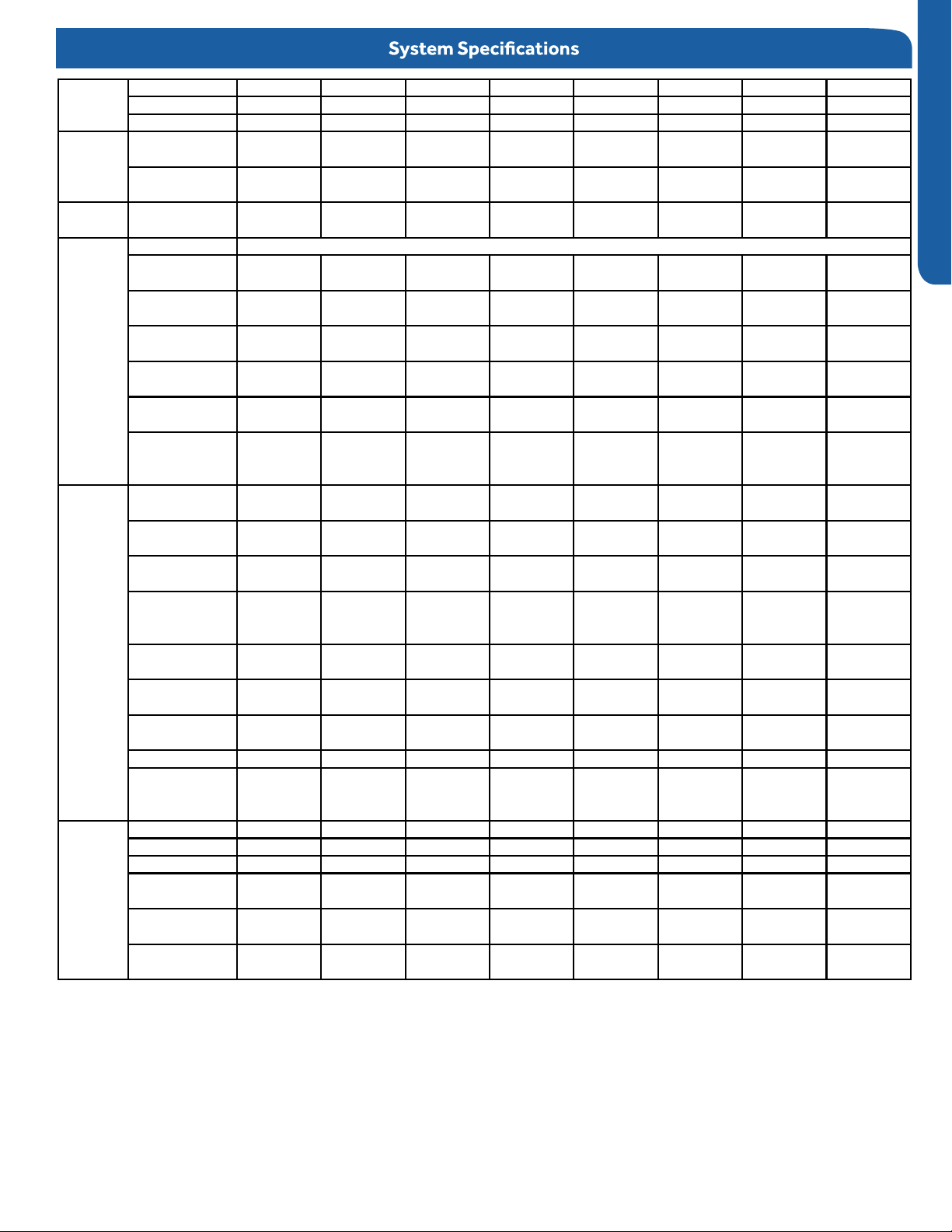

Model

Name

Operating

Range

Power

Supply

Outdoor

Unit

Indoor Unit

Refrigerant

Line

System AW24LP AW36LP AM24LP AM36LP AM48LP AL24LP AL36LP AL48LP

Outdoor

Indoor AW24LP2VH AW36LP2VH AM24LP2VH AM36LP2VH AM48LP2VH AL24LP2VH AL36LP2VH AL48LP2VH

Cooling

Heating

Voltage, Cycle,

Maximum Fuse

Minimum Circuit

Height

Width

Depth

(Ship/Net)-

°F(°C)

°F(°C)

Phase

V/Hz/-

Compressor

Size

A

Amp

A

Dimension:

in (mm)

Dimension:

in (mm)

Dimension:

in (mm)

Weight

(kg)

Dimension:

Height

in (mm)

Dimension:

Width

in (mm)

Dimension:

Depth

in (mm)

Max. External

Static Pressure

1U24LP2VH 1U36LP2VH 1U24LP2VH 1U36LP2VH 1U48LP2VH 1U24LP2VH 1U36LP2VH 1U48LP2VH

0~115

(-18~46)

-4~75

(-20~24)

208-

230/60/7

25.0 30 25.0 30 40 25.0 30 40

21.0 26.0 21.0 26.0 35.0 21.0 26.0 35.0

38 (965) 38 (965) 38 (965) 38 (965) 53 1/8 (1350) 38 (965) 38 (965) 53 1/8 (1350)

37 3/8(950) 37 3/8(950) 37 3/8(950) 37 3/8(950) 37 3/8(950) 37 3/8(950) 37 3/8(950) 37 3/8(950)

14 5/8(370) 14 5/8(370) 14 5/8(370) 14 5/8(370) 14 5/8(370) 14 5/8(370) 14 5/8(370) 14 5/8(370)

202.8/ 176.4

lbs

(92/80)

13 1/4(336) 14 3/8(365) 9 7/8 (250) 9 7/8 (250) 9 7/8 (250) 9 5/8 (246) 9 5/8 (246) 11 3/8 (288)

43 7/8(1115)

9 9/16(243) 10 7/8(275) 25 3/4 (655) 28 3/8 (720) 28 3/8 (720) 33 1/8(840) 33 1/8(840) 33 1/8(840)

NA NA 0.6(150) 0.6(150) 0.6(150) NA NA NA

0~115

(-18~46)

-4~75

(-20~24)

208-

230/60/10

207.2/180.7

(94/82)

51

13/16(1316)

0~115

(-18~46)

-4~75

(-20~24)

208-

230/60/8

202.8/ 176.4

(92/80)

37 5/8 (957) 59 (1500) 59 (1500) 33 1/8(840) 33 1/8(840) 33 1/8(840)

0~115

(-18~46)

-4~75

(-20~24)

208-

230/60/11

DC Inverter Driven Rotary

207.2/180.7

(94/82)

0~115

(-18~46)

-4~75

(-20~24)

208-

230/60/13

260.1/231.5

(118/105)

0~115

(-18~46)

-4~75

(-20~24)

208-

230/60/9

202.8/ 176.4

(92/80)

0~115

(-18~46)

-4~75

(-20~24)

208-

230/60/12

207.2/180.7

(94/82)

(-18~46)

(-20~24)

230/60/14

260.1/231.5

(118/105)

in.W.G(Pa)

Drainpipe Size

in

O.D.

Internal

Condensate

Max. Drain-Lift

height

in(mm)

Grill Model NA NA NA NA NA PB-950KB PB-950KB PB-950KB

Weight

(Ship/Net)-

lbs

(kg)

Connections Flare Flare Flare Flare Flare Flare Flare Flare

Liquid O.D.

Suction O.D.

Factory Charge

in

in

Oz

Maximum Line

Length

Ft / m

Maximum Height

Ft / m

NA NA 1 1/4 1 1/4 1 1/4 1 1 1

NA NA Standard Standard Standard Standard Standard Standard

NA NA 27 9/16(700) 27 9/16(700) 27 9/16(700) 39 3/8 (1000) 39 3/8 (1000) 39 3/8 (1000)

45.4/37.5(20.

6/17)

3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8

5/8 5/8 5/8 5/8 5/8 5/8 5/8 5/8

88.2 88.2 88.2 88.2 131 88.2 88.2 131

165 (50) 165 (50) 165/50 165/50 230/75 165/50 165/50 230/75

100/30 100/30 100/30 100/30 100/30 100/30 100/30 100/30

55.1/46.3(25.

5/21)

81.1/68.8

(36.8/31.2)

130.1/121.3

(59/55)

132.3/114.6

(60/52)

79.4/68.3

(36/31)

79.4/68.3

(36/31)

83.8/70.5

ENGLISH

0~115

-4~75

208-

(38/32)

INTRODUCTION

PAGE 3

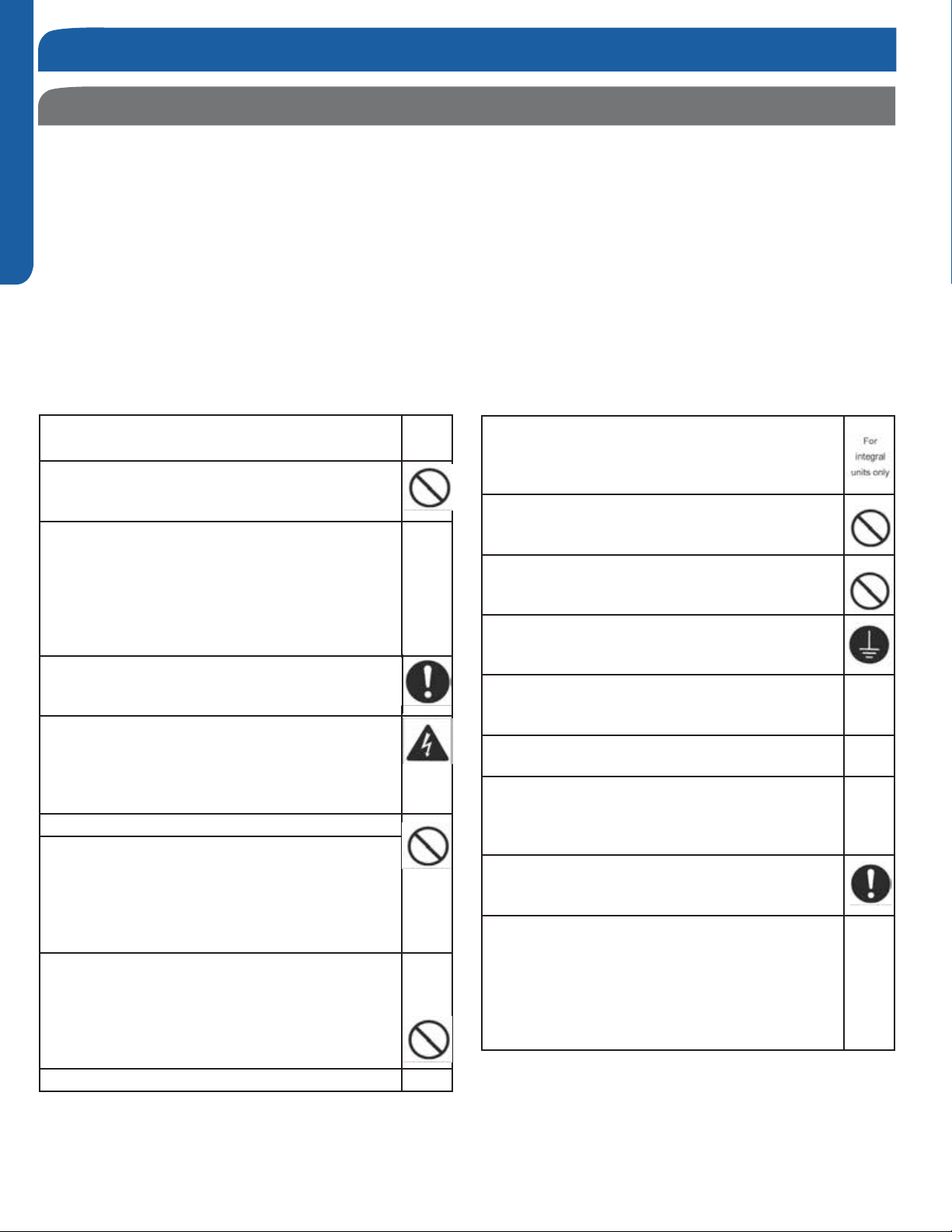

SAFETY OVERVIEW

Read These Safety Precautions

Be sure to read the safety precautions before conducting work. The items are classified into “Warning” and “Caution.” The

“Warning" items are especially important since they can lead to death or serious injury if not followed closely. Under certain

conditions, the "Caution" items can also lead to accident or injury if they are not followed. Therefore, be sure to observe all

ENGLISH

safety precautions listed here.

∆ This symbol means be careful when doing this procedure or touching this equipment.

ᴏ This symbol indicates a prohibited action.

• This symbol means that an action must be taken; the action will be listed next to the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the equipment operates properly;

explain the safety precautions for operating the equipment to the customer.

Warning

Disconnect the power cable from electrical supply

before disassembling equipment for repair.

If the refrigerant discharges during the repair work,

DO NOT touch the discharging refrigerant. The

refrigerant can cause frostbite.

Before disconnecting the suction or discharge

pipe of the compressor at the brazed connections,

recover the refrigerant in a well-ventilated area. If

refrigerant remains inside the compressor, the

refrigerant or the refrigerating machine oil will

discharge when the pipe is disconnected and may

cause injury.

If the refrigerant leaks during the repair work,

ventilate the area. The refrigerant can generate

toxic gases when it contacts ames.

The step-up capacitor supplies high-voltage

electricity to the electrical components of the

outdoor unit. Be sure to discharge the capacitor

completely before conducting repair work. A

charged capacitor can cause electrical shock.

Be sure to use parts listed in the service parts

of the applicable model and appropriate tools to

conduct repair work. Never attempt to modify

the equipment. The use of inappropriate parts or

tools can cause electrical shock, excessive heat

generation, or re.

When relocating the equipment make sure that

the new installation site has sufficient strength to

withstand the weight of the equipment. If the new

installation site does not have sucient strength

and if the installation work is no

securely, the equipment can fall and cause injury.

t conducted

Be sure to install the product correctly by using the

standard installation frame provided. Incorrect use

of the installation frame and improper installation

can cause equipment to fall, resulting in injury.

Do not repair the electrical components with wet

hands. Working on equipment with wet hands can

cause electrical shock.

Do not clean the equipment by splashing water.

Washing the unit with water can cause an electrical

shock.

Make sure that the unit is grounded when reparing

the equipment in a wet or humid place to avoid

electrical shocks.

Be sure to turn o the power switch when cleaning

the equipment; the internal fan rotates at a high

speed and may cause injury.

Do not tilt the unit when removing it. Water inside

the unit can spill, wetting the oor.

Be sure to check that the refrigeration cycle section

has cooled down suciently before conducting

repair work. Working on the unit when the

refrigerating cycle is hot can cause burns.

Use the brazing equipment in a well-ventilated

place. Using the brazing equipment in an enclosed

room can cause oxygen deficiency.

Be sure to use a dedicated power circuit for the

equipment; follow appropriate technical standards

for the electrical equipment, the internal wiring

regulations, and the instruction manual for

installation when conducting electrical work.

Insucient power circuit capacity and improper

electrical work can cause an electrical shock or re.

PAGE 4

INTRODUCTION

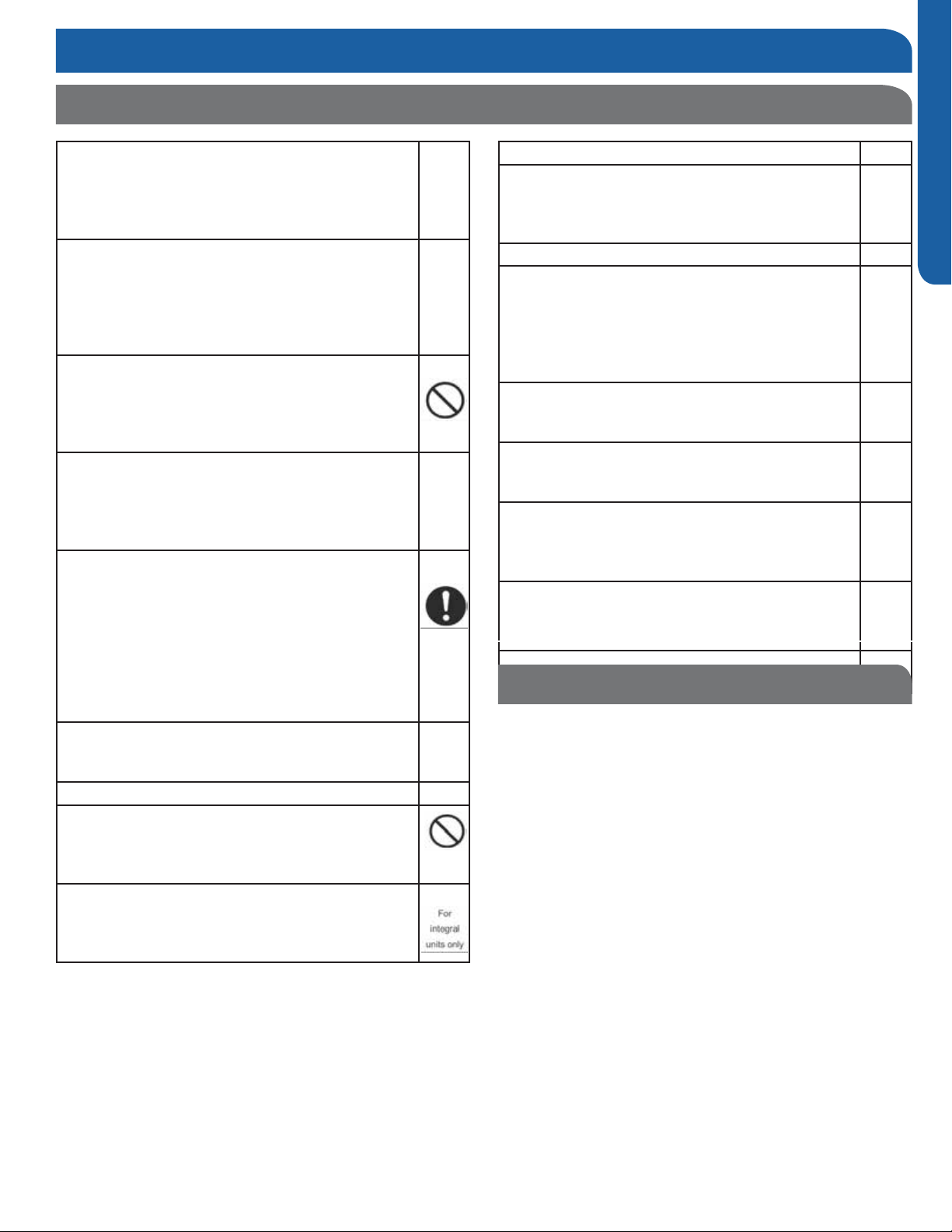

SAFETY OVERVIEW

Read These Safety Precautions

Be sure to use the specied cable to connect

between the indoor and outdoor units. Make the

connections securely and route the cable properly

so that there is no force pulling the cable at the

connection terminals.

When connecting the cable between the indoor and

outdoor units make sure that the terminal cover

does not lift o or dismount because of the cable.

If the cover is not mounted properly, the terminal

connection section can cause an electrical shock,

excessive heat generation, or re.

Do not damage or modify the power cable.

Damaged or modied power cables can cause

electrical shock or re. Placing heavy items on the

power cable and heating or pulling the power cable

can damage the cable.

Do not introduce air into the refrigerant system. If

air enters the refrigerant system, an excessively

high pressure results, causing equipment damage

and injury.

If the refrigerant leaks, be sure to locate the leak

and repair it before charging the system with

additional refrigerant. If the leak cannot be located

and the repair work cannot be stopped, be sure to

perform pump-down and close the service valve to

prevent the refrigerant from leaking into the room.

The refrigerant itself is harmless, but it can

generate toxic gases when it contacts a heat

source such as another appliance or an open flame.

When replacing the remote control battery, be

sure to safely dispose of the battery.

Do not install the equipment in a place where

there is a possibility of combustable gas leaks. If

combustible gas leaks and remains near the unit, it

may cause a re.

Be sure to install the packing and seal on the

installation frame correctly. If the packing and

seal are not properly installed, water can spill out,

wetting furniture and the oor.

ENGLISH

Replace power cables and lead wires if they are

scratched or deteriorated. Damaged cable and

wires can cause electrical shock, excessive heat

generation, or re.

Check to see if the parts are mounted correctly,

that the wires are connected correctly, and that

connections at soldered or crimped terminals are

secure. Improper installation and connections can

cause excessive heat generation, electrical shock,

and re.

If the installation platform or frame has deteriorated

or corroded, replace it. Corroded platform or frames

can cause the unit to fall, resulting in injury.

Check to make sure that the equipment is grounded.

Repair it if it is not properly grounded. Improper

grounding can cause an electrical shock.

Be sure to measure the installation resistance of

the repair. Be sure that the resistance is 1 M ohm

or higher. Faulty installation can cause an electric

shock.

Be sure to check the drainage of the indoor unit after

the repair. Faulty drainage can cause a water leak

from indoor unit and could cause property damage.

Important Safety Related

Installation Information

Indoor Clearances: If noncompliant may lead to temperature

control complaints.

Wire Sizing: If noncompliant may lead to communication errors

and inverter irregular operation.

Splices in Field Wiring: Splices between the wires that connect

between the outdoor and indoor unit should be avoided.

Sealing Penetrations: If penetrations at back of unit are not

sealed, unconditioned air may be drawn into the back of the

indoor wall mount unit. Temperature control and capacity

complaints may occur.

INTRODUCTION

PAGE 5

[This page intentionally left blank.]

Section A - Outdoor Unit Installation

Step 1 - Installation of the Outdoor Unit

Attaching Drain Elbow to Outdoor Unit

(Heat Pump models only)

1.1

Step - 1.1

If attaching the supplied drain elbow to the outdoor unit,

do so prior to attaching the refrigerant lines and wiring.

Extension piping to attach to this tting is eld supplied.

Electrical Connections for the Outdoor Unit

1.2

Step - 1.2

Remove the cover plate of the outdoor unit to expose the

terminal block connections.

1.3

Step - 1.3

Connect the wiring for both the power source and indoor

wiring.

Wire the system according to applicable national / local

codes.

Verify that the wiring connections for the indoor unit match

wire for wire.

(1-1, 2-2, 3-3, Gnd-Gnd). Failure to wire the system correctly

may lead to improper operation or component damage.

Step 1.1

Step 1.3

ENGLISH SECTION A

Step1.2

Step 1.4

1.4

Step - 1.4

Replace the cover plate.

Step 2 - Connecting the Indoor Unit

*See indoor section A, B, or C for electrical connections.

Piping

The standard lineset length is 25ft. If the installation length is

different, adjust the refrigerant charge by 0.5oz/ft.for the

24k,36k,42k and 48k model. (Illustration 4)

Cut the lineset to length, are and attach the piping to the

outdoor unit valves.

Torque the ttings to the specications shown in the torque

chart.

2.1

Step - 2.1

Refrigerant piping connections at the indoor unit are made

utilizing flare joints. Follow standard practices for creating

pipe flares. When cutting and reaming the tubing, use caution

to prevent dirt or debris from entering the tubing. Remember

to place the nut on the pipe before creating the flare.

CAUTION

Outdoor unit

Outdoor unit

Outdoor unit

Indoor unit

B

A

Max. Elevation: A Max.

●

= 100ft / 30m (24k / 36k)

In case the height of A is more than

●

Oil trap

B

Indoor unit

A

15ft / 5m, an oil trap should be

installed every 16-23ft /5-7m

●

Max. Length: B Max

= 165ft / 50m (24k / 36k)

B

Indoor unit

A

Illustration 4

2.2

Step - 2.2

To join the lineset piping together, directly align the piping

are to the tting on the other pipe, then slide the nut onto

the tting and tighten. Misalignment may result in a leaking

connection.

INSTALLATION

Step 2.2Step 2.1

PAGE 7

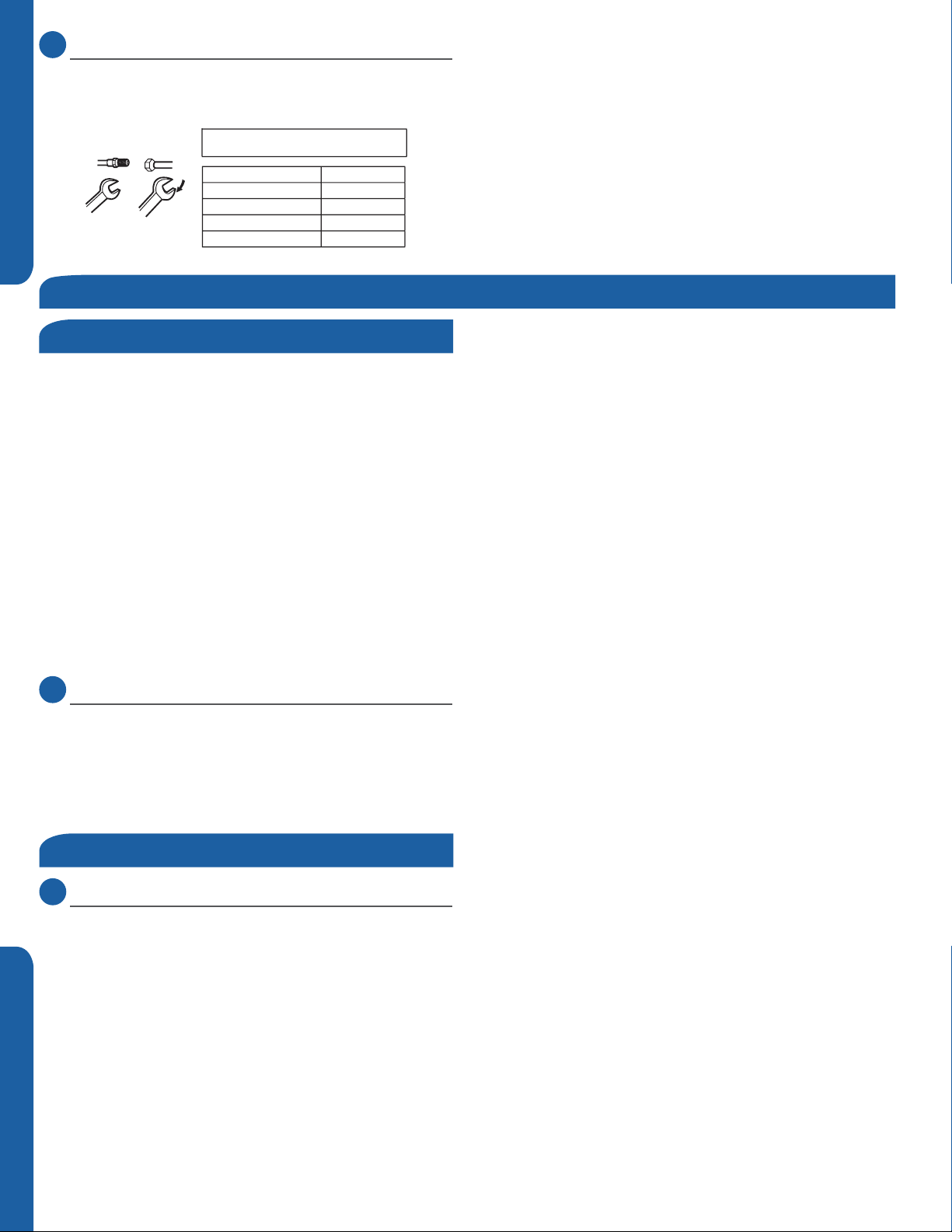

2.3

Step - 2.3

Two wrenches are required to join the are connections, one

standard wrench, and one torque wrench. See Table 1 for the

specic torque per piping diameter.

Forced fasteningwithout carefulcentering may

damagethe threads and cause a leakageofgas.

Pipe Diameter(ǿ)Fastening torque

Liquid side6.35mm(1/4") 18N.m/13.3Ft.lbs

Liquid/Gas side9.52mm(3/8") 42 N.m/30.1Ft.lbs

Gasside12.7mm(1/2") 55N.m/40.6Ft.lbs

Gasside15.88mm(5/8") 60 N.m/44.3Ft.lbs

ENGLISHSECTION A

Half union

Spanner

Flarenut

Torque wrench

Table 1

Step 3 - Leak Test and Evacuation

Leak Test

Hazard of Explosion! Never use an open flame to detect

refrigerant leaks.. Explosive conditions may occur. Use a leak

test solution or other approved methods for leak testing.

Failure to follow recommended safe leak test procedures

could result In death or serious injury or equipment or

property damage.

Use only dry nitrogen with a pressure regulator for

pressurizing unit. Do not use acetylene, oxygen or

compressed air or mixtures containing them for pressure

testing. Do not use mixtures of a hydrogen containing

refrigerant and air above atmospheric pressure for pressure

testing as they may become flammable and could result in

an explosion. Refrigerant used as a trace gas should only be

mixed with dry nitrogen for pressurizing units. Failure to

follow these recommendations could result in death or

serious injury or equipment or property damage.

Step 2.3

Step 3.1 Step 3.2

3.1

Step - 3.1

Using a tank of nitrogen with attached regulator, charge the

system with 150 PSIG of dry nitrogen. Use adapter AD-87

(field supplied) to connect to the service valve. Check for

leaks at the flare fittings using soap bubbles or other

detection methods. If a leak is detected, repair and recheck.

If no leaks are detected, proceed to evacuate the system.

System Evacuation

3.2

Step - 3.2

Attach a manifold gauge, micron gauge, and vacuum pump

to the suction line port using adapter AD-87 (eld supplied).

(Illustration 5)

Evacuate the system to 350 microns.

Close the vacuum pump valve and check the micron

gauge. If the gauge rises above 500 microns in 60 seconds,

evacuation is incomplete or there is a leak in the system. If

the gauge does not rise above 500 microns in 60 seconds,

evacuation is complete.

Illustration 5

PAGE 8

INSTALLATION

3.3

Step - 3.3

Remove the adapter and hose connection from the

suction line port, and replace the cap. Hoses should not be

removed and service valves should not be opened until any

additional refrigerant needed for a refrigerant line longer

than 25 ft. has first been added.

3.4

Step - 3.4A & 3.4B

Remove the cap from the liquid line valve. Using the hex

wrench, open the valve, then replace and tighten the cap.

3.5

Step - 3.5A & 3.5B

Remove the cap from the suction line valve. Using the hex

wrench, open the valve, then replace and tighten the cap.

3.6

Step - 3.6

Wrap the lineset, drain line, and wiring starting at the bottom

of the bundle with an overlap type wrap, concluding at the

piping hole. Use a sealant to seal the piping hole opening

to prevent weather elements from entering the building.

(Illustration 6)

Step 3.3 Step 3.4A

Step 3.4B

Step 3.5A

ENGLISH SECTION A

Verify the condensate drain line has a constant pitch

downward for proper water ow. There should be no kinks

or rises in the tubing which may cause a trapping eect

resulting in the failure of the condensate to exit the piping.

Step 3.5B

It becomes

high midway.

Theendis immersed in water.

It waves.

Thegap with the

ground is too small

Illustration 6

Step 3.6

Lessthan

5cm

Thereisthe bad

smellfrom a sewer

INSTALLATION

PAGE 9

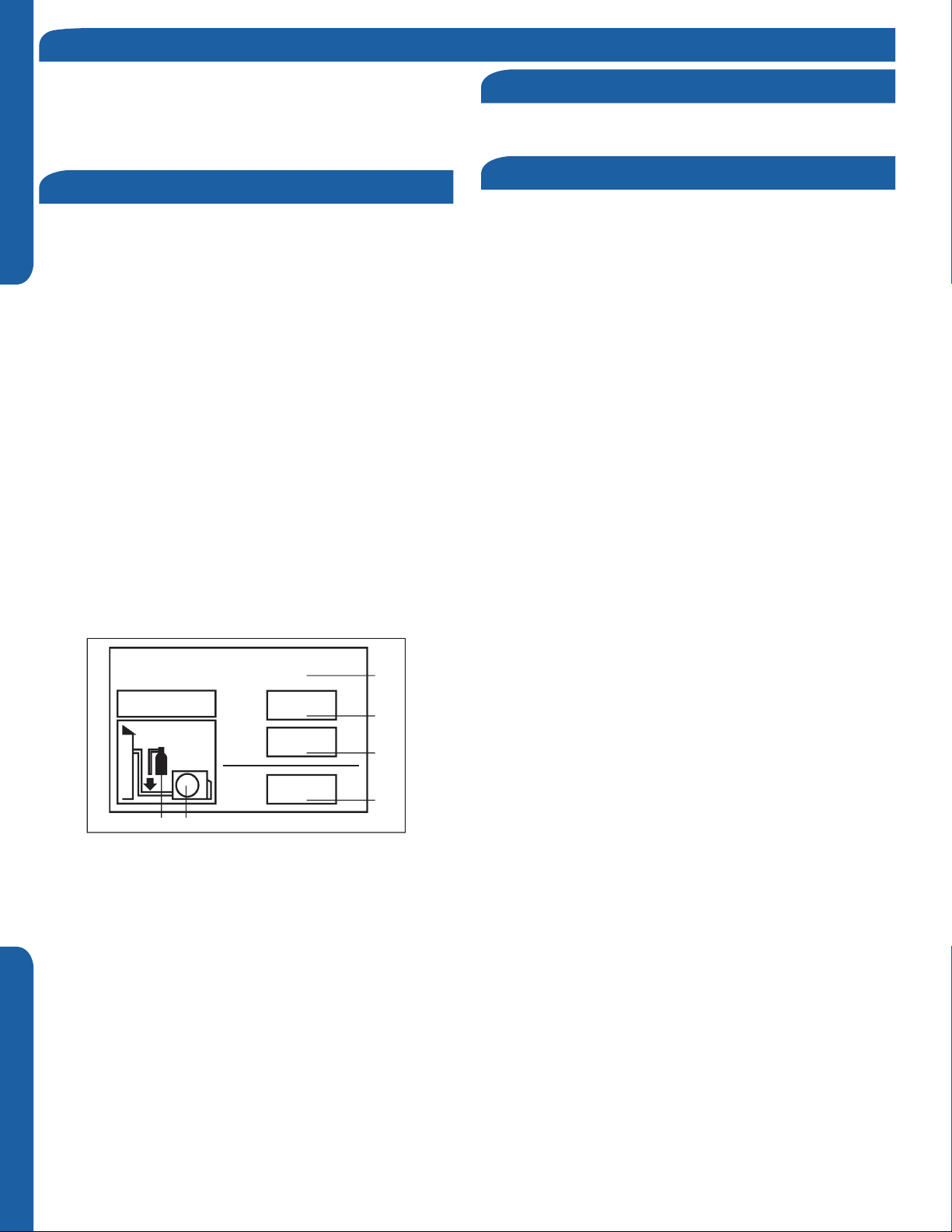

Step 4 - Charging

See Steps 5.2 - 5.5 for evacuating the system prior to

charging. The standard lineset length is 25ft. If the

installation length is different, adjust the refrigerant charge

by .5 oz / ft. for the 24K, 36K and 48K model. (Step 4 Illustration 4)

ENGLISHSECTION A

This product contains uorinated greenhouse gases covered

by the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type: R410A

GWP* value: 1975

GWP = global warming potential

Please ll in with indelible ink,

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged in the eld and

• 1+2 the total refrigerant charge on the refrigerant charge

label supplied with the product.

The lled out label must be adhered in the proximity of the

product charging port (e.g. onto the inside of the stop valve

cover).

A - contains uorinated greenhouse gases covered by the

Kyoto Protocol

B - factory refrigerant charge of the product: see unit name

plate

C - additional refrigerant amount charged in the eld

D - total refrigerant charge

E - outdoor unit

F - refrigerant cylinder and manifold for charging

Refrigerant Charge Label

System Test

Using the instruction manual, show the customer how to

properly use and care for the equipment.

Check Items for Test Run

Put check mark √ in boxes

No refrigerant leaks from line sets or other connections?

Are the linesets insulated properly?

Are the connecting wirings of indoor and outdoor firmly

inserted to the terminal block?

Is the connecting wiring of indoor and outdoor rmly

connected?

Is condensate draining correctly?

Is the indoor unit securely attached?

Is power source voltage correct according to local code?

Is there any noise?

Is the lamp normally lighting?

Are cooling and heating (when in heat pump) performing

normally?

Is the operation of room temperature sensor normal?

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

R410A

2

1=

2=

oz

oz

1

1+2=

FE

oz

A

B

C

D

PAGE 10

INSTALLATION

Section 5 - Explaining Operation to the End User

Protecti on wa lls

• Using the OPERATING INSTRUCTIONS, explain to the user how to use the air conditioner (the remote controller, removing

the air lters, placing or removing the remote controller from the remote controller holder, cleaning methods, precautions for

operation, etc.)

• Recommend that the user read the OPERATING INSTRUCTIONS carefully.

Section 6 - Seacoast Application

• The outdoor unit should be installed at least ½ mile away from the salt water, including seacoasts and inland waterways. If

the unit installed from ½ mile to 5 miles away from the salt water, including seacoasts and inland waterways, please follow the

installation instruction below.

• Install the outdoor unit in a place (such as near buildings etc.) where it can be protected from sea breeze which can damage

the outdoor unit.

ODU

ENGLISH SECTION A

Sea breeze

Sea

ODU

Sea breeze

ODU

Sea

• If you cannot avoid installing the outdoor unit by the seashore, construct a protection wall around it to block the sea breeze.

• A protection wall should be constructed with a solid material such as

concrete to block the sea breeze and the height and the width of the wall

ODU

should be 1.5 times larger than the size of the outdoor unit. Also, secure

over 28 in (700mm) between the protection wall and the outdoor unit for

Sea

Sea breeze

ODU

exhausted air to ventilate.

• Install the outdoor unit in a place where water can drain smoothly.

• If you cannot nd a place satisfying above conditions, please contact manufacturer. Make sure to clean the sea water and the

dust on the outdoor coil.

INSTALLATION

PAGE 11

[This page intentionally left blank.]

Section B - Indoor Unit Installation - Wall Mount

Required Tools for Installation

• Drill

• Wire Snipper

• Hole Saw 2 3/4”

• Vacuum pump

• Soap-and-water solution or gas leakage

detector

• Torque wrench

• 17mm, 22mm, 26mm

• Tubing cutter

• Flaring tool

• Razor knife

• Measuring tape

• Level

• Micron gauge

• Nitrogen

• Mini-Split AD-87 Adapter (1/4” to 5/16”)

• A - Non-adhesive Tape

• B - Adhesive Tape

• C - Saddle (L.S.) with screws

• D - Electrical wiring

• E - Drain hose (Included)

• F - Insulation

• G - Piping hole cover (Included)

Step 1 - Preparation

Procedure for Selecting the Location

• Choose a place solid enough to bear the

weight and vibration of the unit and where

the operation noise will not be amplied.

• Choose a location where the hot air

discharged from the unit or the operation

noise and will not cause a nuisance to the

user.

• There must be sucient space for

carrying the unit into and out of the site.

• There must be sucient space for air

passage and no obstructions around the

air inlet and air outlet.

• The site must be free from the possibility

of ammable gas leakage in a nearby

place.

• Install units, power cords and inter-unit

cables at least 10ft away from television

and radio sets. This is to prevent

interference to images and sounds.

(Noise may be heard even if they are more

than 10ft away depending on radio wave

conditions.)

ENGLISH SECTION B

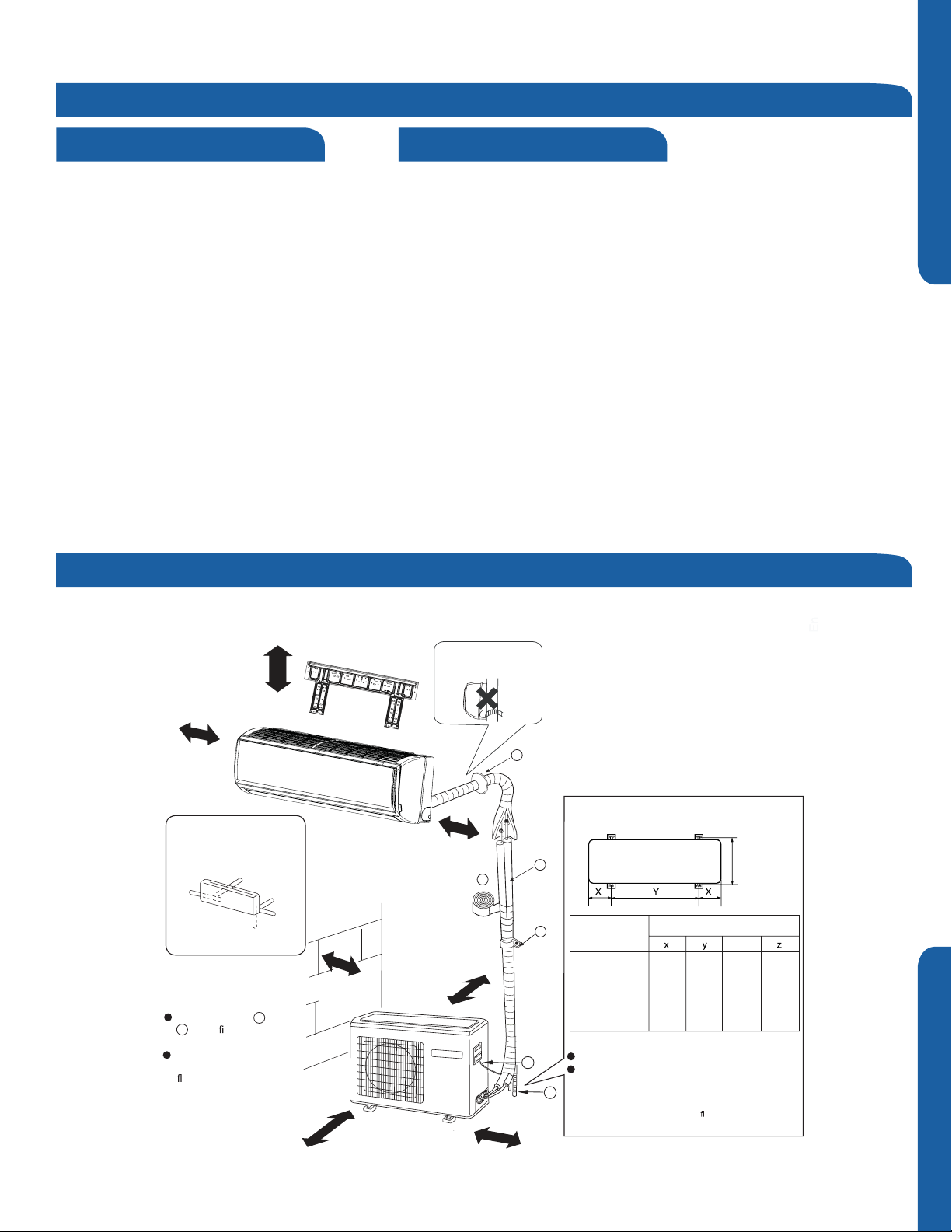

Clearances of Indoor and Outdoor Units

This picture is for reference only. Your product may look dierent. Read this manual before installation. Explain the operation of the unit to the user according to

this manual.

The models adopt HFC free refrigerant R410A

Attention must be paid to

more than 4in.

more than

4in.

Arrangement of piping

directions

Rear left

Left

Below

The marks from to

G

in the

name of the parts.

The distance between

the indoor unit and the

than 6 feet.

gure are the

oor should be more

Rear

right

Right

A

more than 4in.

the pitch of drain hose

more than 4in.

more than 4in.

G

Floor fixing dimensions of the outdoor unit

(Unit: inch)

eet t

23 5/8”

he l

Z

6 7/8”

ocal code.

16”

A

F

C

Fixing of outdoor unit

D

E

1 2

Model

1U24/36/42/48

LP2VHA

Anchor the outdoor unit to the pad.

When ins

he i

wall, t

Dimensions(inches)

1 x2

6 7/8”

talling the outdoor unit on a roof or a outside

hould m

nstallation s

more than 24in.

more than 6in.

INSTALLATION

PAGE 13

Step 2 - Installation of Wall Mount Type Indoor Unit

Attaching the Mounting Plate to the Wall

2.1

Step 2.1

ENGLISHSECTION B

Using a stud sensor, locate and mark the stud positions in the

wall where the indoor unit is to be mounted.

2.2

Step 2.2

Place the mounting plate on the wall in the desired location

taking into account the minimum clearances necessary for

proper operation.

Using a level, verify the mounting plate is horizontal and mark

the screw locations.

2.3

Step 2.3

Screw the mounting plate to the wall.

Step 2.1

Step 2.2

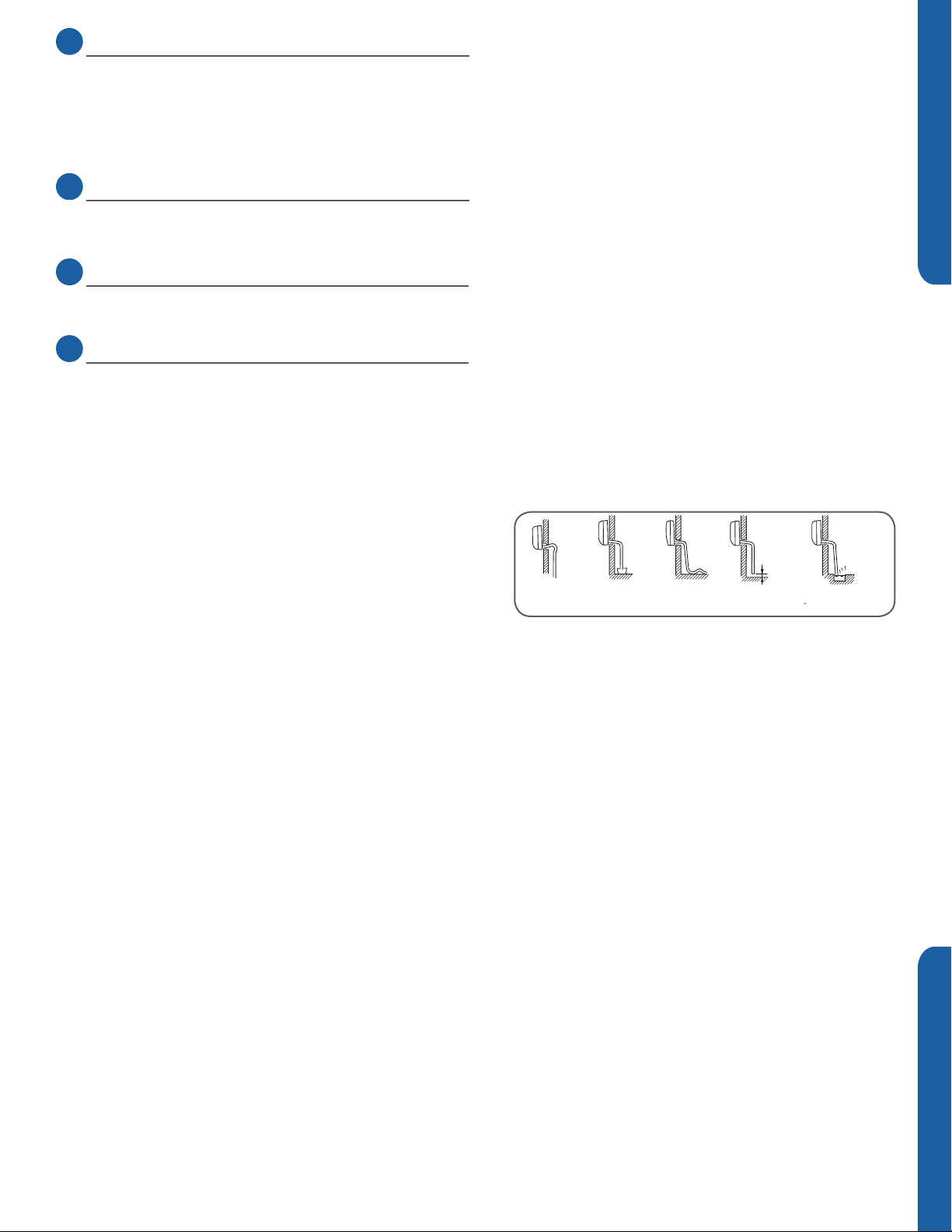

The piping for the indoor unit may be routed to the unit from

one of several directions. Left, Left Rear, Right, Right Rear, or

Below (Illustration 1).

2.4

Step 2.4

Knockouts are provided on the case for Left, Right, and Right

Below.

Drilling the hole through the wall for left rear or right rear

installation

2.5

Step 2.5A & 2.5B

Measure and mark the location where the piping hole is to be

drilled.

2.6

Step 2.6

Drill the piping hole using a hole saw of the correct diameter.

Angle the drill with a downward pitch to the outside wall so

that the outside hole will be ¼” lower than the inside hole,

giving the hole the proper angle for condensate drainage.

2.7

Step 2.7

Install the piping hole cover ange at the hole opening on the

inside wall.

NOTE: The cover ange may require modication to t

properly behind the wall unit housing.

2.8

Step 2.8A & 2.8B

Bundle the refrigerant piping, drain piping and wiring with

tape and pass the bundle through the piping hole.

NOTE: When bundling the power cable, leave sucient length

available in the indoor unit to make the connections to the

terminal block.

Step 2.3

Step 2.5A

Step 2.6

Step 2.8A

Piping Exit Options

Left

Step 2.4

Step 2.5B

Step 2.7

Step 2.8B

Rear left

Rear

right

PAGE 14

Right

Below

Illustration 1

INSTALLATION

Outdoor unit

Mounting the Indoor Unit Onto the Wall Plate

2.9

Step 2.9

With the top of the indoor unit closer to the wall, hang the

indoor unit on the upper hooks of the mounting plate. Slide

the unit slightly side to side to verify proper placement of the

indoor unit on the mounting plate. Rotate the lower portion

of the indoor unit to the mounting plate, and lower the unit

onto the lower hooks of the mounting plate. (Illustration 2)

Verify the unit is secure.

2.10

Step - 2.10

Slightly raise the entire unit vertically, pull the lower portion

of the unit o the lower hooks of the mounting plate and

away from the wall, then lift the upper portion of the unit o

the upper hooks of the wall plate.

Electrical Connections for the Indoor Unit

2.11

Step - 2.11A & 2.11B

To make the electrical connections for the indoor unit, two

cover plates must be removed. Raise the front cover to

access the screws to remove these covers.

2.13

Step - 2.13

Access the four conductor cable through the cover plate

opening and make the wiring connections noting the wire

color used on each terminal. The color of each wire must

match the same positions on the terminal block of the

outdoor unit. (Illustration 3)

Step 2.9

mounting plate

Illustration 2

Step 2.11A

ENGLISH SECTION B

Step 2.10

Step 2.11B

Failure to wire the system correctly may lead to improper

operation or component damage.

2.14

Step - 2.14A & 2.14B

After the terminal block wiring is completed, replace both

cover plates.

Note: Wall mount unit ships with HG remote controller. See

Section F for more information.

Step 2.12

Indoor unit

Step 2.13A

3wire 14AWG

Control Wiring

Power

Wiring

Step 2.13B

Illustration 3

Indoor Wall Unit Installation Complete

1

(

N

)

2

(L

)

3

(

C

)

1

(

N

)

2

(

L

)

3

(

C

)

INSTALLATION

PAGE 15

[This page intentionally left blank.]

Section C - Indoor Unit Installation - Cassette

Introduction - Overview

Cassette Product Information

The Cassette Indoor Air Handler ships consisting of a

cassette assembly and operational louver. The Cassette

Indoor Unit is operated via a factory supplied remote

control. Wired controller is optional.

The Cassette unit will install between standard dropped

brackets that are located at all four corners of the cassette

assembly.

The Cassette unit receives 230 volt line voltage from a

connection at the outdoor condensing unit. T

requirement for independent line voltage connections.

The cassette unit has a built in condensate pump and

Cassette unit. This hose connects the cassette

condensate drain outlet to the building's condensate drain

system.

The motorized louver is controlled via the remote control.

The louver has indicator lights that communicate function

and diagnostic information to the user and service technician.

here is no

Wired Controller is

Optional

Built-in Condensate

Pump and Float Switch

ENGLISH

Factory Supplied Remote

See Section F for more information

Outside Air

Mounting Hangers

Optional fresh air can be piped into the cassette assembly.

The knockout is located on the side of the cassette assembly.

entering the cassette. A 4” galvanized pipe should be used to

pipe in the fresh air.

Included with the cassette unit is factory provided insulating

tape. This tape should be placed over the refrigerant piping

connections at the indoor unit to prevent sweating.

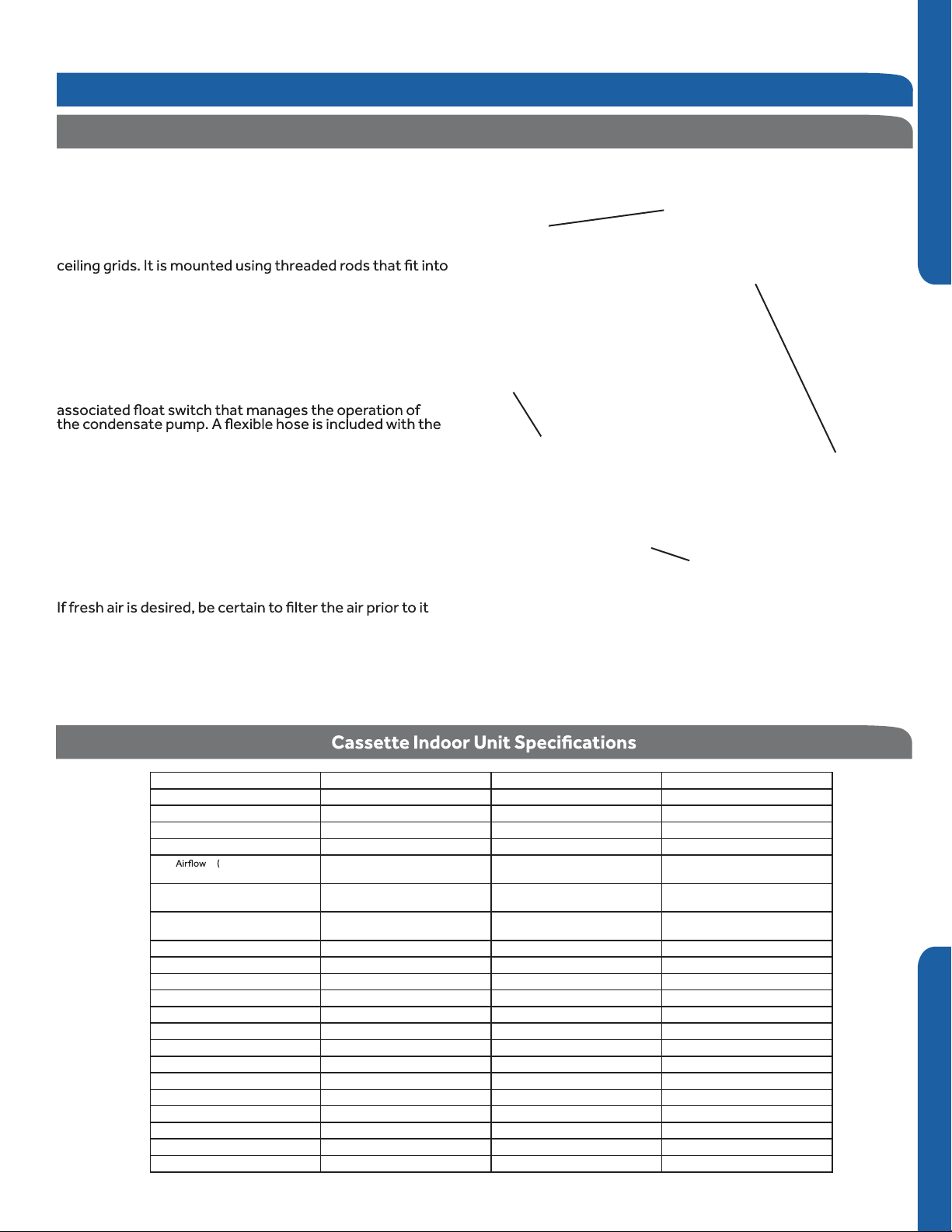

Indoor AL24LP2VHA AL36LP2VHA AL48LP2VHA

Rated Cooling Capacity Btu/hr 24,000 35,000 45,000

Rated Heating Capacity Btu/hr 27,300 36,500 49,000

Voltage, Cycle, Phase V/Hz/-

Fan Speed Stages 4+Auto 4+Auto 4+Auto

Turbo/High/Med/Low/

Quiet) CFM

Motor Speed ( Turbo/High/Med/

Indoor Sound Level dB (Turbo/High/

Chassis Dimension: Height in (mm)

Chassis Dimension: Width in (mm)

Chassis Dimension: Depth in (mm)

Grill Dimension: Height in (mm)

Grill Dimension: Width in (mm)

Grill Dimension: Depth in (mm)

Weight (Ship/Net)- lbs (kg)

Drainpipe Size O.D. in 1 1/4 1 1/4 1 1/4

Internal Condensate Pump Standard Standard Standard

Max. Drain-Lift height in(mm)

Low/Quiet) RPM

Med/Low/Quiet)

Grill Model

Connections Flare Flare Flare

Liquid O.D. in 3/8 3/8 3/8

Suction O.D. in 5/8 5/8 5/8

208/230/60/1 208/230/60/1 208/230/60/1

740/630/480/400 990/900/776/700 1147/941/847/705

500/400/300/250

36/33/29/26

PB-950KB

9 5/8 (246)

33 1/8(840) 33 1/8(840) 33 1/8(840)

33 1/8(840)

2 (50)

37 3/8 (950)

37 3/8 (950)

79.4/68.3 (36/31)

39 3/8 (1000) 39 3/8 (1000) 39 3/8 (1000)

650/550/450/400 750/650/500/400

45/42/38/34

PB-950KB PB-950KB

9 5/8 (246)

33 1/8(840)

2 (50)

37 3/8 (950)

37 3/8 (950)

79.4/68.3 (36/31)

41/36/33/31

11 3/8 (288)

33 1/8(840)

2 (50)

37 3/8 (950)

37 3/8 (950)

83.8/70.5 (38/32)

SECTION C

INSTALLATION

PAGE 17

Introduction - Overview

Fresh Air Intake Option

The cassette has a marked area to cut out if outside air is

desired. The piping connection should be made with a 4 inch

ENGLISHSECTION C

entry into the cassette.

Fresh air

knock out

Condensate Handling

The Cassette unit has a built in condensate pump and water

level safety switch. There is no option for gravity drain. The

condensate pump is rated to lift water up to 24” from the

point of discharge on the cassette assembly.

Electrical Power

Follow all local codes and regulations when installing electrical

wiring.

Route required electrical power to area where cassette is to

be located. Maintain at least a 10 foot separation between TV

and Radio wiring and the power to the indoor unit.

14 Gauge AWG stranded wire should be used to make the

electrical connection between indoor and outdoor units.

This wiring will serve to power the indoor unit and establish a

communication link between indoor and outdoor units.

The wiring is connected at the indoor unit electrical terminal

blocks screws 1, 2, 3 and ground. There should be no

splices in the wires connected to terminals 1 or 3 as these

serve as communication signal wires and electrical power

power to the indoor unit, break wire 2 only.

The cassette unit comes with a grey connection hose with

clamp. This hose is connected to the cassette assembly

discharge hose port. The other end of the hose is sized to

accept 3/4 “ PVC piping.

here:

12 in. below

3-5 ft.

11 in. under

8.6 in.

8.6 in.

19.6 in. below

Air Delivery Clearances

Be certain to maintain proper clearances around the

Standard clearances for cassette air handlers require 5

feet of clearance in each direction. There should be 8 feet

of clearance from the face of the cassette louver to the

temperature control problems.

Service and Maintenance Clearances

Make sure there are adequate clearances for future

maintenance and service. Allow enough room to access the

condensate pump assembly and the electrical control box.

1 ft.

5 ft.

8 ft. Over

5 ft.

PAGE 18

INSTALLATION

Step 1 - Preparation

• Drill

• Wire Snipper

• Hole Saw 2 3/4”

• Vacuum pump

• Soap-and-water solution or gas leakage

detector

• Torque wrench

• 17mm, 22mm, 26mm

• Tubing cutter

• Flaring tool

• Razor knife

• Measuring tape

• Level

• Micron gauge

• Nitrogen

• Mini-Split AD-87 Adapter (1/4” to 5/16”)

• A - Non-adhesive Tape

• B - Adhesive Tape

• C - Saddle (L.S.) with screws

• D - Electrical wiring

• E - Drain hose (Included)

• F - Insulation

• G - Piping hole cover (Included)

Procedure for Selecting the LocationRequired Tools for Installation

• Place above the ceiling where you have

enough space to position the unit.

• Place where the drainage pipe can be

properly positioned.

• Place where the inlet and outlet air of the

indoor unit will not be blocked.

• Do not install the unit in a place with

heavy oil or moisture (e.g. - kitchens and

workshops)

• Do not install in a location with destructive

gas (such as sulfuric acid gas) or pungent

gas (thinner and gasoline) are used or

stored.

• Choose a place solid enough to bear the

weight and vibration of the unit and where

the operation noise will not be amplied.

• Install where there are no expensive items

like a television or piano below the indoor

unit.

• Leave enough space for maintenance.

• Install at least 3 ft. away from televisions

and radios to avoid interference.

ENGLISH SECTION C

Note:

1) R-410A refrigerant is a safe, nontoxic and

nonammable refrigerant. However, if

there is a concern about a dangerous level

of refrigerant concentration in the case of

refrigerant leakage, add extra ventilation.

Threaded Rod Mounting Information

The Cassette unit should be mounted to the building

structure using threaded rods. The threaded rods should

have washers and nuts to allow the height and level of the

cassette to be adjusted.

The threaded rods and attachment brackets are eld supplied

items. The materials required for mounting to the brackets

on the cassette assembly include:

4- 3/8” Threaded Rods

4- Mounting Brackets

8- Washers

8- Nuts (Double nut the assembly as shown)

INSTALLATION

PAGE 19

Step 2 - Installation of the Cassette Unit

Step By Step Guide To Cassette Installation

2.1

Step 2.1

Use cardboard template to locate center point of cassette for

mounting. Use a plumb bob and string to position cassette

ENGLISHSECTION C

by referencing center hole of template. Mark the mounting

positions of the threaded rods using the guides on the

cardboard template.

2.2

Step 2.2

Install threaded rods to structure using appropriate

fasteners.

2.3

Step 2.3

Lift the cassette and position the threaded rods into the 4

mounting clips on each corner of the cassette unit.

2.4

Step 2.4

Using a level, adjust the nuts on the threaded rods to obtain a

level reading across the bottom of the cassette unit.

2.5

Step 2.5A & 2.5B

Prior to routing the refrigerant lines to the unit, install the

supplied are nuts onto the refrigerant lines. Using a aring

tool, flare the refrigerant lines. Remove the caps attached

to the ends of the refrigerant line connections at the

cassette. Holding charge will be released.

Step 2.1

Step 2.2

Using a torque wrench, torque the ttings to the proper

specications. (See Outdoor Unit Section for are torque

settings.)

2.6

Step 2.6

Connect the grey exible drain hose supplied with the

cassette unit to the condensate pump discharge pipe of

the cassette. Tighten the clamp securely. Using 3/4 “ PVC,

connect the exible hose to the building’s condensate drain

system.

2.7

Step 2.7

Remove the electrical box cover. Remove the rubber

grommet and insert a 1/2 inch electrical connector and

reducing washer. Route electrical wiring into cassette unit.

Connect to wire terminas as indicated in schematic drawing.

(USE 14 AWG Stranded wire only.)

2.8

Step 2.8A & 2.8B ,C, D

Connect Louver assembly to cassette assembly. Connect

wires from louver to the harness on the cassette assembly.

There are two wire connections. (See photo for connections.)

Secure louver with four screws.

Step 2.3

Step 2.4

Reinstall electrical box cover.

Install return air grille into louver assembly.

Installation is now complete.

PAGE 20

INSTALLATION

Step 2 - Installation of the Cassette Unit

Step 2.5A

Step 2.5B

Step 2.8A

Step 2.8B

ENGLISH SECTION C

Step 2.6

Step 2.7

Step 2.8C

Step 2.8D

INSTALLATION

PAGE 21

Step 3 - Elec

Electrical Connections Indoor and Outdoor Units

trical Connections

14 AWG S

tranded Wire Only. (Central Controller Not Used)

Maintain 10 feet of separation between TV and any Radio wiring.

ENGLISHSECTION C

Indoor uni

Note: Cassette unit ships with remote controller. See Section F for more information.

YR-HBS01

t

3wire 14AWG

Control Wiring

Power

Wiring

Outdoor unit

1

(

N

)

2

(L

)

3

(

C

)

1

(

N

)

2

(

L

)

3

(

C

)

Step 4 - Louver Installation

To mount the louver cover onto the cassette assembly. Install 2 screws at the keyhole slot positions shown in the

rst photo. Place louver onto the 2 screws and press louver onto cassette housing. Swing hang clip into position.

(White circle.) Install remaining 2 screws and tighten the 4 screws. Connect electrical plugs to socket shown below.

Install the electrical cover box and then snap the return air grille into position.

Step 5 - Pull Vacuum on System

See Step 3.2 of the outdoor unit installation section for how to pull a vacuum.

Indoor Casset

PAGE 22

INSTALLATION

te Unit Installation Complete

Section D - Indoor Unit Installation - High ESP Duct

Introduction - Overview

High ESP Duct Product Information

The High ESP Duct Indoor Air Handler ships consisting of a

single assembly. The High ESP Duct indoor unit is operated

via a factory supplied wired remote control.

High ESP

that are located at all four corners of the High ESP Duct

The High ESP Duct unit receives 230 volt line voltage

from a connection at the outdoor condensing unit.

There is no requirement for independent line voltage

connections.

The High ESP Duct unit has a built-in condensate pump and

Duct unit. This hose connects the High ESP Duct

condensate drain outlet to the building’s condensate

drain system.

Included with the High ESP Duct unit is factory provided

insulating tape. This tape should be placed over the

refrigerant piping connections at the indoor unit to prevent

sweating.

g

assembly.

High ESP

ENGLISH

YR-E17 Wired Controller

See Section E for more information

Built-in

Condensate

Pump and

Float Switch

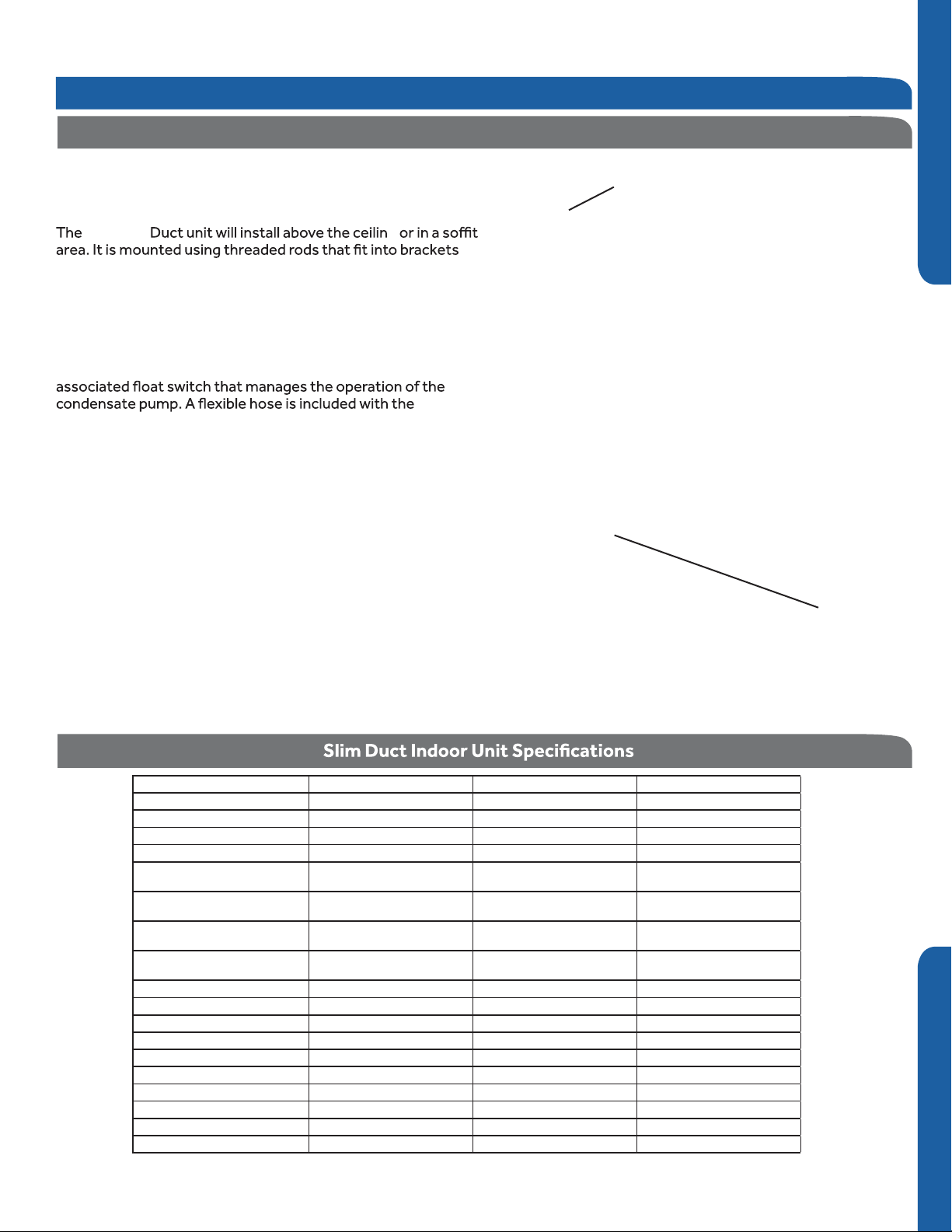

Indoor AM24LP2VHA AM36LP2VHA AM48LP2VHA

Rated Cooling Capacity Btu/hr 24,000 35,000 47,000

Rated Heating Capacity Btu/hr 26,500 37,500 52,000

Voltage, Cycle, Phase V/Hz/-

Fan Speed Stages 4+Auto 4+Auto 4+Auto

Airflow (Turbo/High/

Med/Low/Quiet) CFM

Motor Speed (Turbo/High/

Med/Low/Quiet) RPM

Max. External Static Pressure in.W.G

Indoor Sound Level dB (Turbo/High/

Dimension: Height in (mm)

Dimension: Width in (mm)

Dimension: Depth in (mm)

Weight (Ship/Net)- lbs (kg)

Internal Condensate Pump Standard Standard Standard

Max. Drain-Lift height in(mm)

(Pa)

Med/Low)

Connections Flare Flare Flare

Liquid O.D. in 3/8 3/8 3/8

Suction O.D. in 5/8 5/8 5/8

Drainpipe Size O.D. in 1 1/4 1 1/4 1 1/4

208/230/60/1 208/230/60/1 208/230/60/1

845/670/530/470 1100/950/735/675

950/860/760/700

0.6(150) 0.6(150) 0.6(150)

38/35/32/29 32/28/25/23

9 7/8 (250) 9 7/8 (250) 9 7/8 (250)

37 5/8 (957) 59 (1500) 59 (1500)

25 3/4 (655) 28 3/8 (720) 28 3/8 (720)

81.1/68.8(36.8/31.2) 130.1/121.3 (59/55) 132.3/114.6 (60/52)

27 9/16(700) 27 9/16(700) 27 9/16 (700)

1000/920/860/810 1180/1080/1010/960

1350/1150/930/765

41/36/33/31

INSTALLATION

SECTION D

PAGE 23

Introduction - Ov

r

erview

Condensate Handling

The High ESP Duct unit has a built-in condensate pump and

water level safety switch. There are also two optional ports

for gravity drainage. The condensate pump is rated to lift

water up to 24” from the point of discharge on the High ESP

ENGLISHSECTION D

Duct unit.

The High ESP Duct unit comes with a grey connection hose

with clamp. This hose is connected to the High ESP Duct unit

condensate discharge hose port. The other end of the hose

is sized to accept 3/4 inch PVC piping.

Electrical Power

Follow all local codes and regulations when installing electrical

wiring.

Route required electrical power to area where the High ESP

Duct unit is to be located. Maintain at least a 10 foot

separation between TV and Radio wiring and the power to

the indoor unit.

14 Gauge AWG stranded wire should be used t

electrical connection between indoor and outdoor units.

This wiring will serve to power the indoor unit and establish a

communication link between indoor and outdoor units.

The wiring is connected at the indoor unit electrical terminal

blocks screws 1, 2, 3 and ground. There should be no

splices in the wires connected to terminals 1 or 3 as these

serve as communication signal wires and electrical power

connections. If a safety switch needs to be in place to shut o

power to the indoor unit, break wire 2 only.

o make the

Recommended condensate piping c

here:

12 in. below

3-5 ft.

8.6 in.

ongurations are shown

11 in. unde

8.6 in.

19.6 in. below

Air Delivery Clear

Make certain to maintain proper clearances around the

High ESP Duct unit.

Inadequate clearances can cause sy

temperature control problems.

Service and Maintenance Clearances

Make sure there are adequate clearances for future

maintenance and service. Allow enough room to access the

condensate pump assembly and the electrical control box.

ances

stem freezing and

PAGE 24

INSTALLATION

Step 1 - Preparation

• Drill

• Wire Snipper

• Hole Saw 2 3/4”

• Vacuum pump

• Soap-and-water solution or gas leakage

detector

• Torque wrench

• 17mm, 22mm, 26mm

• Tubing cutter

• Flaring tool

• Razor knife

• Measuring tape

• Level

• Micron gauge

• Nitrogen

• Mini-Split AD-87 Adapter (1/4” to 5/16”)

• A - Non-adhesive Tape

• B - Adhesive Tape

• C - Saddle (L.S.) with screws

• D - Electrical wiring

• E - Drain hose (Included)

• F - Insulation

• G - Piping hole cover (Included)

Procedure for Selecting the LocationRequired Tools for Installation

• Place above the ceiling or in sot area

where you have enough space to position

the unit.

• Place where the drainage pipe can be

properly positioned.

• Place where the inlet and outlet air of the

indoor unit will not be blocked.

• Do not install the unit in a place with

heavy oil or moisture (e.g. - kitchens and

workshops)

• Do not install in a location with

destructive gas (such as sulfuric acid gas)

or pungent gas (thinner and gasoline) are

used or stored.

• Choose a place solid enough to bear the

weight and vibration of the unit and where

the operation noise will not be amplied.

• Install where there are no expensive

items like a television or piano below the

indoor unit.

• Leave enough space for maintenance.

• Install at least 3 ft. away from televisions

and radios to avoid interference.

Threaded Rod Mounting Information

ENGLISH SECTION D

Note:

1) R-410A refrigerant is a safe, nontoxic

and nonammable refrigerant. However,

if there is a concern about a dangerous

level of refrigerant concentration in the

case of refrigerant leakage, add extra

ventilation.

The High ESP Duct unit should be mounted to the

building structure using threaded rods. The threaded

rods should have washers and nuts to allow the height

and level of the High ESP Duct unit to be adjusted.

The threaded rods and attachment brackets are eld supplied

items. The materials required for mounting to the brackets

on the High ESP Duct unit include:

4- 3/8” Threaded Rods

4- Mounting Brackets

Washers

Nuts (Double nut the assembly as shown in step 2.3)

INSTALLATION

PAGE 25

Step 2 - Installation of the High ESP Duct Unit

Step By Step Guide To High ESP Duct Unit Installation

2.1

Step 2.1

ENGLISHSECTION D

Determine and mark the position of where the High ESP

Duct unit is to be installed. Install the hardware necessary

to mount the threaded rods. Always select a location

strong enough to support the indoor High ESP Duct unit.

2.2

Step 2.2

Install the threaded rods to the hardware attached to the

structure.

2.3

Step 2.3

Lift the High ESP Duct unit and position the threaded rods into

the 4 mounting clips, one located on each corner of the unit.

2.4

Step 2.4

Using a level, adjust the nuts on the threaded rods to obtain

level readings both side to side and front to back on the

High ESP Duct unit.

2.5

Step 2.5 - 2.5A

Prior to routing the refrigerant lines to the unit, install the

supplied are nuts onto the refrigerant lines. Using a aring

tool, flare the refrigerant lines. Remove the caps attached

to the ends of the refrigerant line connections at the High

ESP Duct unit. Holding charge should leak out. Attach the

refrigerant lines to the air handler.

Using a torque wrench, torque the ttings to the proper

specications. (See Outdoor Unit Section for are torque

settings.)

Step 2.1

Step 2.2

Step 2.3

2.6

Step 2.6

Connect the grey flexible drain hose supplied with the High

ESP Duct unit to the condensate pump discharge pipe of

the High ESP Duct unit. Tighten the clamp securely. Using

3/4 “ PVC, connect the flexible hose to the building’s

condensate drain system.

2.7

Steps 2.7 - 2.7A - 2.7B

Route the 14AWG stranded 4 conductor power/

communication cable and the wired remote cable to the air

handler. Use reducing washers and appropriate connector

to attach the power/communication cable to the unit. The

wired remote cable will enter the unit through a rubber

grommet. The 4 conductor cable connects to the terminal

block at terminals 1, 2, 3, and ground. The wired remote

cable connects to the air handler main board at connector

CN1. Re-install electrical box cover.

2.8

Step 2.8

The unit is now ready for connection to the ductwork.

The return air duct can be congured as either a rear side

inlet or bottom side inlet.

Step 2.4

PAGE 26

INSTALLATION

Rear side air inlet

Step 2 - Installation of the High ESP Duct Unit

Step 2.5

Step 2.5A

Step 2.7A

Step 2.7B

Re-install electrical box cover

ENGLISH SECTION D

Step 2.6

Step 2.8

Diffuser

Return Duct

Bottom side air inlet

Step 2.7

Diffuser

Return Duct

INSTALLATION

INSTALLATION IS NOW COMPLETE

PAGE 27

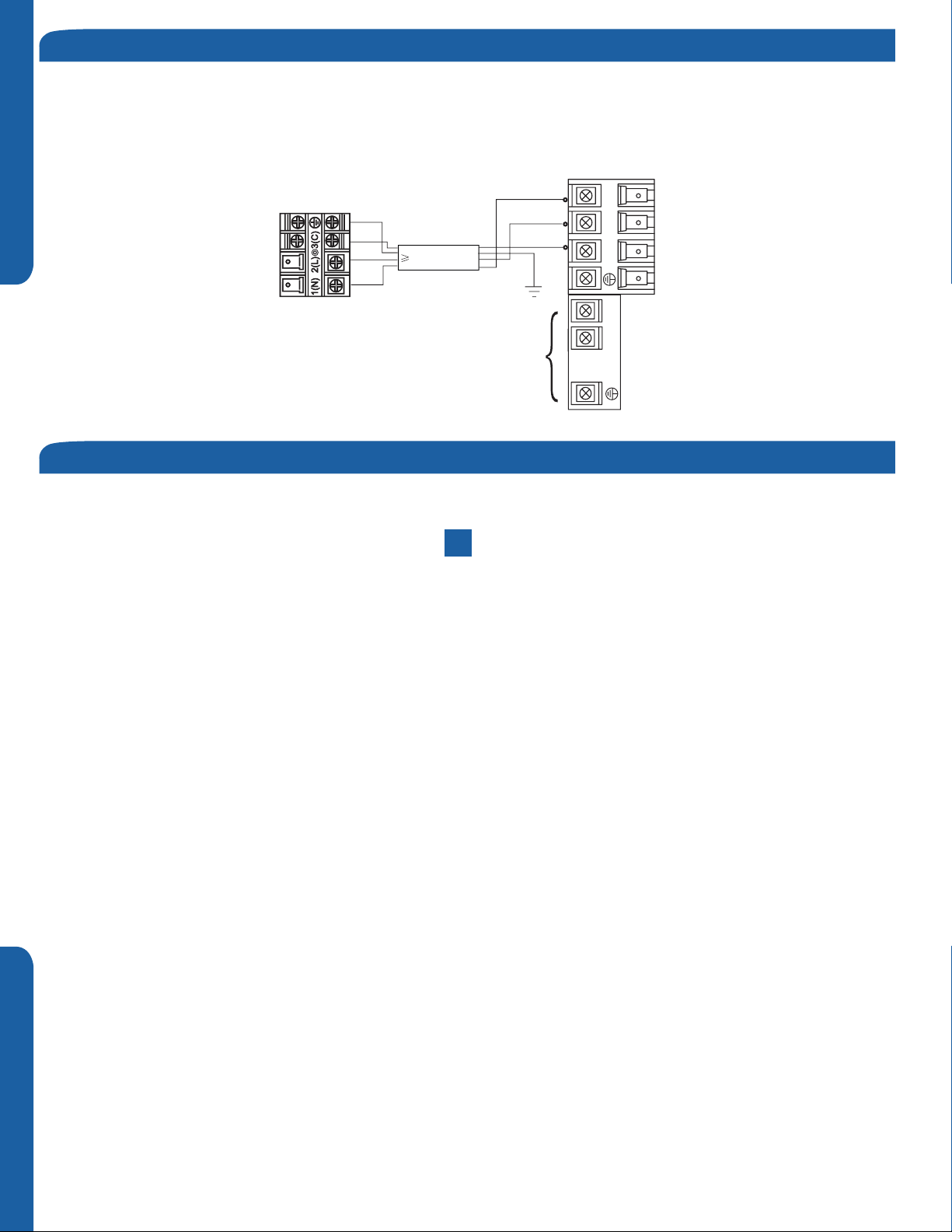

Step 3 - Electrical Connections

Outdoor unit

Electrical Connections Indoor and Outdoor Units

14 AWG Stranded Wire Only. (Central Controller Not Used)

Maintain 10 feet of separation between TV and any Radio wiring.

ENGLISHSECTION D

Indoor unit

3wire 14AWG

Control Wiring

Power

Wiring

1

(

N

)

2

(L

)

3

(

C

)

1

(

N

)

2

(

L

)

3

(

C

)

Note: High ESP Duct unit ships with YR-E17 wired controller. See Section E for more information.

Step 4 - Pull Vacuum on System

See Step 3.2 of the outdoor unit installation section for how to pull a vacuum.

Indoor High ESP Duct Unit Installation Complete

PAGE 28

INSTALLATION

Section E - Wired Controller YR-E17

WIRED CONTROL PANEL FUNCTIONS

Features and Interface

Clock; Parameter setting/Inquiry; Malfunction

display

Timer ON/OFF; Sleep function; Parameter

setting/Inquiry; Malfunction display

ROOM/SET temp. and humidity display, each

step is 0.5°C (1°F). For example, if the temp is

25°C (77°F), it will display 25.°C (77°F). Humidity

display function is reserved.

Energy Saving function. This icon will be displayed only when energy saving function is set.

Filter Cleaning

Child Lock

Lock/Central

Motion Sensing (Reserved)

Left/Right Swing. This icon is displayed only

when in swing function

ENGLISH SECTION E

Up/Down Swing. This icon is displayed only when

in swing function

Sleep function. This icon is displayed when setting the

sleep function. Remaining sleeping time is displayed in

the top right corner.

Heat Reclaim Ventilation. This icon is displayed when

setting the heat reclaim ventilation.

Electrical Heating. This icon is displayed when electrical

heating is set on DC wired control.

Intelligent Mode--automatic cycling.

Cooling Mode

Heating Mode

Fan Mode

Dry Mode

User Friendly: Back light; Room temperature display

Functions:

Ventilation; ECO; Filter Cleaning; Error Code display; Child

Lock; Parameter Inquiry; Unit NO. Setting; Static Pressure

Grade Inquiry; Temp. Compensation setting; Forced

Cooling/Heating

Clock; Timer; Sleep Function; Heat Reclaim

INSTALLATION

PAGE 29

A TYPE 1, FOR AL24/36/42/48LP2VHA, AM24LP2VHA

Indoor 1

Wire controller

port

Indoor 2

Wire controller

port

Indoor N

Wire controller

port

Indoor 15

Wire controller

port

control wiring of

Wire controller

TYPE 2, FOR AM36/42/48LP2VHA

Indoor 1

Wire controller

port

Indoor 2

Wire controller

port

Indoor N

Wire controller

port

Indoor 15

Wire controller

port

Indoor16

Wire controller

port

Wire controller

Indoor16

Wire controller

port

(master unit)

(master unit)

The communication wiring is 189ft (4.8 meter) long; if the

actual length is more than it, please distribute wiring

according to below table:

B

Indoor 1

Wire controller

port wire

Wire controller

C

Indoor 1

Wire controller

port wire

Wire controller

Polar wire

Wire controller

control wiring of

Wire controller

Wire controller

There are three methods to connection wire controller and

the indoor units:

A: One wired controller can control max.up to 16 sets of

indoor units, for Flexifit Pro series indoor units, there are two

connection method:

Type 1: for model AL24/36/42/48LP2VHA,AM24LP2VHA,the

wiring connection between wired controller - the master unit

(directly connected to the wired controller), master unit slave unit, slave unit-slave unit should be one to one match of

all three lines.

Type 2: for model AM36/42/48LP2VHA,The wiring connection

between wired controller-the master unit (directly connected

to the wired controller) should be three polar wire, and the

wiring between master unit - slave unit, slave unit-slave unit

should be one to one match of two polar lines.

Note: PCB DIP switches are used for setting slave units, please refer

to indoor unit wiring diagram.

B. One wire controller controls one indoor unit, and the indoor

unit connects with the wire controller through 3 pieces of

polar wire.

C. Two wired controllers control one indoor unit. The wire

controller connected with indoor unit is called master one, the

other is called slave one. Master wire controller and indoor

unit; master and slave wire controllers are all connected

through 3 pieces of polar wire.

Note: There are PCB DIP switches for slave or master units

selection, please refer to the indoor unit wiring diagram to get

details.

*One side of the shielded sheet of communication wire

must be earthed.

Indoor PCB port.

For location

number ,refer

to indoor unit wiring

diagram.

About the wire:

The wire controller is equipped with special communication

wiring in the accessories. 3-core terminal (1-white 2-yellow 3red) is connected with the terminal A, B, C of wire controller

respectively.

WIRED CONTROLLER INSTALLATION

Wired Controller Wiring Instructions

Dimensions

Unit: inch (mm)

ENGLISH

Dip Switch

Dip Switch ON/OFF Function Default Setting

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

SW1-7

SW1-8

ON Set as the slave controller

OFF Set as the master controller

ON Ambient temp. display available

OFF Ambient temp. display unavailable

ON Display ambient temp. from PCB of indoor

OFF Display ambient Temp. from wired controller

ON Auto-restart invalid

OFF Auto-restart valid

ON Fahrenheit

OFF Celsius

ON Swing angle adjustment available

OFF Swing angle adjustment unavailable

ON Up/Down and Left/Right swing

OFF Up/Down swing

ON Fresh Air unit

OFF General unit

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

REMOTE CONTROLS

PAGE 31

WIRED CONTROLLER OPERATION

Settings & Functions

Initialization

The wired controller will

ENGLISHSECTION E

1

2

3

This cycle keeps repeating until initialization is complete.

The green ON/OFF LED will also ash continuously until

initialization is complete.

If the wired controller is unable to communicate with the

indoor unit PCB after powering on, initialization will terminate

in 4 minutes. The communication malfunction can be checked

using the malfunction inquiry function. (See Malfunction

Display)

momentarily display

all display icons upon

powering up or when

resetting the system.

During the initialization

process, the controller

will display, in a

repeating order:

88:88 (upper left

corner), 88:88 (upper

right corner) 88.8

(main temperature).

Mode Setting

NOTE: This function requires the ON/OFF key LED to be

turned OFF and the screen backlight to be illuminated.

Press and hold the MODE key for 5 seconds, the number of

the mode currently being used will display in the upper left

corner of the screen. (Default is 0) Press the pq keys to

change to one the dierent modes available: 0, 1, 2, or 3.

Press SET to conrm the setting.

NOTE: Corresponding modes

0 – [Intelligent] [Cooling] [Heating] [Fan] [Dry]

1 – [Cooling] [Heating] [Fan] [Dry]

2 – [Cooling] [Fan] [Dry]

3 – [Cooling] [Heating] [Fan] [Dry] (same as 1)

Error Code Display

Note: This function requires the ON/OFF key LED to be

turned OFF and the screen backlight to be illuminated.

Press and hold the TIME key for 10 seconds. The unit number

will display in the upper left corner of the screen. The error

code/historical error code will display in the upper right corner

of the screen. Press pq keys to select the unit number to

view its error codes. Under Error Code display screen, press

and hold the TIME key for 5 seconds to clear the fault codes of

all the units.

Switching between Fahrenheit & Celsius

To switch from Celsius to Fahrenheit, select the mode you

wish to operate (COOL, HEAT, DRY, INTELLIGENT/AUTO).

Press and hold the p key to reach 30 °C then continue holding

the p key for 15 seconds until the display reads 86 °F. Use the

pq keys to adjust to desired temperature.

To switch from Fahrenheit to Celsius, select the mode you

wish to operate (COOL, HEAT, DRY, INTELLIGENT/AUTO).

Press and hold the q key to reach 60 °F then continue holding

the q key for 15 seconds until the display reads 16 °C. Use the

pq keys to adjust to desired temperature.

Clock Function

1. The clock is displayed in 24 Hour time

A. It cannot be set for AM/PM.

B. The clock function cannot be set when SLEEP

function or a timer function is currently set.

When the system is rst powered up, after initialization, the

clock will default to 12:00. Within 10 seconds of the clock being displayed, the time can be set. The clock icon and minutes

portion of the time display will be ashing. Press the pq keys

to adjust the minutes. (Pressing and holding the pq keys will

accelerate the time adjustment.) With the minutes set, press

the TIME key. The clock icon and hours portion of the time

display will now begin ashing. Press the pq keys to adjust

the hours. Press the SET key to conrm the setting.

To set the clock after initial power up or reset time has expired, press and hold the TIME key for 5 seconds. The clock

icon and minutes portion of the time display will begin ashing. Press the pq keys to adjust the minutes. With the min-

utes set, press the TIME key. The clock icon and hours portion

of the time display will now begin ashing. Press the pq keys

to adjust the hours. Press the SET key to conrm the setting.

If neither pq key is pressed within 10 seconds, or if the

MODE, FAN, or ON/OFF keys are pressed prior to pressing the

SET key, the setting function is canceled and the time reverts

back to the previous setting.

Screen Saving

With the system turned o, tap the TIME key to activate the

screen backlight (if not already lit).

1. Press and hold the TIME and q keys for 5 seconds to set the

backlight “on” time. The set time will be displayed in the upper

right corner of the screen.

2. Press the pq keys to adjust the time. Set times available

are: 0 seconds (backlight always on), 15 seconds, 30 seconds,

and 60 seconds. Initial default time is 15 seconds.

3. With time selection made, press the SET key to conrm the

setting.

Press the MODE, FAN, TIME, SET, or ON/OFF key to exit the

function. If no key is pressed in 10 seconds, the function

will also exit. If there are no current errors or historical error

codes, “--” will be displayed.

PAGE 32

INSTALLATION

If neither pq key is pressed within 10 seconds, or if the

MODE, FAN, or ON/OFF keys are pressed prior to pressing the

SET key, the setting function is canceled and reverts back to

the previous setting.

WIRED CONTROLLER OPERATION

Settings & Functions

ECO Energy Saving Function

NOTE: This function requires the ON/OFF key LED to be

turned ON and the screen backlight to be illuminated.

Press the SET key. The swing louver function icon will

ECO

be ashing) Press the SET key to conrm the setting. The ECO

icon will remain on.

To cancel ECO function, repeat the above steps.

NOTE: The energy saving default parameters are listed below:

74°F Lowest temperature limit of Cooling and Dry mode.

78°F Highest temperature limit of Heating mode.

74°F – 86°F Temperature adjustment range in Cooling and Dry

mode.

60°F – 78°F Temperature adjustment range in Heating mode.

be displayed. Press the pq keys to advance through

the functions to select ECO function. (The icon will

ECO Parameter Setting

NOTE: This function requires the ON/OFF key LED to be

turned ON and the screen backlight to be illuminated.

For Cooling

Under Cooling mode, set the temperature to 86°F. Press and

hold the FAN key for 5 seconds. The Cooling ECO param-

eter (ashing) will be displayed in the upper left corner of the

screen. Default temperature is 74°F. Press the pq keys to

adjust the lowest target cooling temperature. Press the SET

key to conrm the setting and exit setup.

For Heating

Under Heating mode, set the temperature to 60°F. Press and

hold the FAN key for 5 seconds. The Heating ECO parameter

(ashing) will be displayed in the upper right corner of the

screen. Default temperature is 78°F. Press the pq keys to

adjust the highest target heating temperature. Press the SET

key to conrm the setting and exit setup.

ENGLISH SECTION E

Timer Function Setting

NOTE: The display backlight must be illuminated before proceeding. To turn the backlight on, press any key (MODE, FAN, pq,

TIME, or SET) located at the bottom of the

display, or press the ON/OFF key located at

the top of the display.

Timer ON

Press the TIMER key once, the ON timer icon will appear in the

upper right corner of the screen. The ON icon and hour position are ashing. Press the pq keys to set the hour. Press

the TIMER key again, the ON icon and minutes position are

now ashing. Press the pq keys to set the minutes. Press the

SET key to conrm the setting.

Timer OFF

Press the TIMER key 3 times, the OFF timer icon will appear in

the upper right corner of the screen. The OFF icon and hour

position are ashing. Press the pq keys to set the hour.

Press the TIMER key again, the OFF icon and minutes position

are now ashing. Press the pq keys to set the minutes. Press

the SET key to conrm the setting.

Timer ON/OFF

Press the TIMER key 5 times, the ON/OFF timer icon will appear in the upper right corner of the screen. The ON icon and

hour position are ashing. Press the pq keys to set the hour.

Press the TIMER key again, the ON icon and minutes position

are now ashing. Press the pq keys to set the minutes. Press

the TIMER key again, the OFF icon and hour position are now

ashing. Press the pq keys to set the hour. Press the TIMER

key again, the OFF icon and minutes position are now ashing.

Press the pq keys to set the minutes. Press the SET key to

conrm the setting. Based on the times set, the indoor unit

will determine which event happens rst (ON-OFF or OFFON) and adjusts the arrow direction accordingly.

Static Pressure Grade Inquiry & Adjustment

NOTE: This function requires the ON/OFF key LED to be

turned ON and the screen backlight to be illuminated.

Press and hold the SET and FAN keys for 5 seconds. The current static pressure will be displayed in the upper right corner

of the screen and the “Static Pressure” icon will begin to ash.

Press the TIME key to shift the unit no. displayed in the upper

left corner of the screen. The unit numbers are from 00-15.

Press the pq keys to change the static pressure grade,

shown in the upper right corner of the screen.

Number range is 01-04. Press the SET key to conrm the

setting. Press the MODE, FAN, or ON/OFF key to exit the

function. If no key is pressed in 10 seconds, the function will

also exit.

INSTALLATION

If neither pq key is pressed within 10 seconds, or if the

MODE, FAN, or ON/OFF keys are pressed prior to pressing the

SET key, the setting function is canceled and reverts back to

the previous setting.

Timer Cancel

Press the TIME key up to 9 times to cycle through the timer

settings. When the timer icon disappears, the timer function is

canceled.

Note: An active timer function will remain displayed on screen

until the set time has been reached and command completed.

PAGE 33

WIRED CONTROLLER OPERATION

Settings & Functions

Left/Right/Up/Down Swing

The swing function deter-

ENGLISHSECTION E

mines air circulation.

1. Press SET key to access

Swing function circulation.

2. Use pqkeys to select

desired swing function.

If SW7 is on, air will circulate

UP/DOWN/LEFT/RIGHT.

3. Press SET key to conrm

swing function selection.

Parameter Inquiry

NOTE: This function requires the screen backlight to be illuminated. The ON/OFF key LED can be either On or O.

Press and hold the SET key for 5 seconds. The unit number

will be displayed in the upper left corner of the screen. The

data type and current data will be displayed in the upper right

corner of the screen.

Press the pq keys to scroll through the data types. (See

chart for data type/current data)

Press the MODE, FAN, SET, or ON/OFF key to exit the function. If no key is pressed in 10 seconds, the function will also

exit.

Forced Cooling/Heating

Note: This function requires the ON/OFF key LED to be

turned OFF and the screen backlight to be illuminated.

Forced Cooling

When the system is turned o in cooling mode, press and hold

the ON/OFF key for 10 seconds. The system will enter forced

cooling. The temperature display will display a ashing “LL”.

Press the ON/OFF key to exit forced cooling mode.

Forced Heating

When the system is turned o in heating mode, press and hold

the ON/OFF key for 10 seconds. The system will enter forced

heating. The temperature display will display a ashing “HH”.

Press the ON/OFF key to exit forced heating mode.

NOTE: When in forced cooling or heating, all keys are disabled

except for the ON/OFF key.

Child Lock Function

NOTE: This function requires the screen backlight to be illuminated. The ON/OFF key LED can

be either On or O.

Child Lock can be used to prevent unintended

operation of the control unit.

1. Press SET and the q keys together for 5 seconds to

activate the Child Lock function. The child lock icon will be

displayed on the left side of the screen. All normal functions of

the keys will be disabled.

Unit Number Setting

NOTE: This function requires the screen backlight to be il-

luminated. The ON/OFF key LED can be either On or O.

Press and hold the SET key for 10 seconds. The wired controller address and communication address between the indoor

and outdoor unit are displayed in the upper left corner of the

screen. The central address is displayed in the upper right

corner of the screen.

Press the pq keys to select the indoor unit number: 0 - 3F.

Press the SET key to conrm the setting. Press the MODE,

FAN, or ON/OFF key to exit the function. If no key is pressed in

10 seconds, the function will also exit.

PAGE 34

INSTALLATION

2. To unlock the Child Lock function, press the SET key and

the q arrow together for 5 seconds. The child lock icon will

disappear from the screen. All normal functions of the keys

will be restored.

Temperature Compensation Setting

Note: This function requires the ON/OFF key LED to be

turned OFF and the screen backlight to be illuminated.

Press and hold the FAN keys for 5 seconds, the current

temperature compensation value is displayed in the upper

right corner of the screen. (The default value is 00). Press the

pq keys to change the temperature compensation value.

The adjustment range is -07°F to +07°F. Press the SET key to

conrm the setting. Press the MODE, FAN, TIME, or ON/OFF

key to exit the function. If no key is pressed in 10 seconds, the

function will also exit.

NOTE: The compensation value is used for ambient temperature and is valid only for the wired controller sensor.

WIRED CONTROLLER OPERATION

Settings & Functions

Sleep Function

NOTE: This function requires the ON/OFF key LED to be

turned ON and the screen backlight to be illuminated.

Press the SET key. The swing louver function icon

will be displayed. Press the pq keys to advance

through the functions to select the SLEEP func-

tion. The Sleep and Sleep “o” time icons will be

displayed. (The Sleep icon will be ashing) Press the TIME key,

the “o” icon will begin to ash. Press the pq keys to set the

“o” time. (Time range is 0.5h to 72h) Press the SET key to

conrm the setting. The Sleep function and “o ” time icons

will remain on.

If neither pq key is pressed within 10 seconds, or if the

MODE, FAN, or ON/OFF keys are pressed prior to pressing the

SET key, the setting function is canceled and reverts back to

the previous setting.

To cancel the Sleep function. Press the SET key. The swing

louver function icon will be displayed. Press the pq keys to

advance through the functions to select the SLEEP function.

The Sleep and Sleep “o” time icons will be displayed. (The

Sleep icon will be ashing) Press the SET key to cancel the

function.

Filter Cleaning

NOTE: This function requires the ON/OFF key LED to be

turned ON and the screen backlight to be illuminated.

ENGLISH SECTION E

Other Functions

Note: These functions require the ON/OFF key LED to be

turned OFF and the screen backlight to be illuminated.

Auto Restart

Setting DIP switch SW1-4 located on the PCB of the wired

control to the “on” position will disable the auto restart function. When the switch is in the “o” position, auto-restart is

enabled (default position). When the switch is in the “on” posi-

tion, auto-restart is disabled.

Information retained in auto-restart are: Mode, Fan Speed,

Temperature Setting, Swing State, and Heat Reclaim Ventilation function.

Communication Error of Wired Controller

If there is no communication between the wired controller and

indoor unit for 4 minutes, when checking error codes, “07” will

be displayed in the upper right corner of the display.