Haier AV22NMVERA, AV24NMVERA, AV26NMVERA, AV28NMVERA, AV30NMVERA Installation Manual

...

./0 --

Ftf <::B

Nmrs`kk`shnm R`mt`k

W>;:F MJFY UZRU ?:M_

X^OX7::>7:BWJ[8:

F[:BSR[JWF

F[;:SR[JWF

F[;<SR[JWF

F[;>SR[JWF

F[;@SR[JWF

F[;BSR[JWF

F[<:SR[JWF

F[<<SR[JWF

F[<>SR[JWF

F[<@SR[JWF

F[<BSR[JWF

F[<BSR[JWF

F[=:SR[JWF

F[=<SR[JWF

F[=>SR[JWF

F[=@SR[JWF

F[=BSR[JWF

F[>:SR[JWF

F[><SR[JWF

F[>>SR[JWF

F[>@SR[JWF

F[>BSR[JWF

HSRXJRXW

[arning on refrigerant leakage

Wafety caution

Rew environmentally friendly refrigerant V;87F

85 WJPJHX NRWXFPPFXNSR TPFHJ

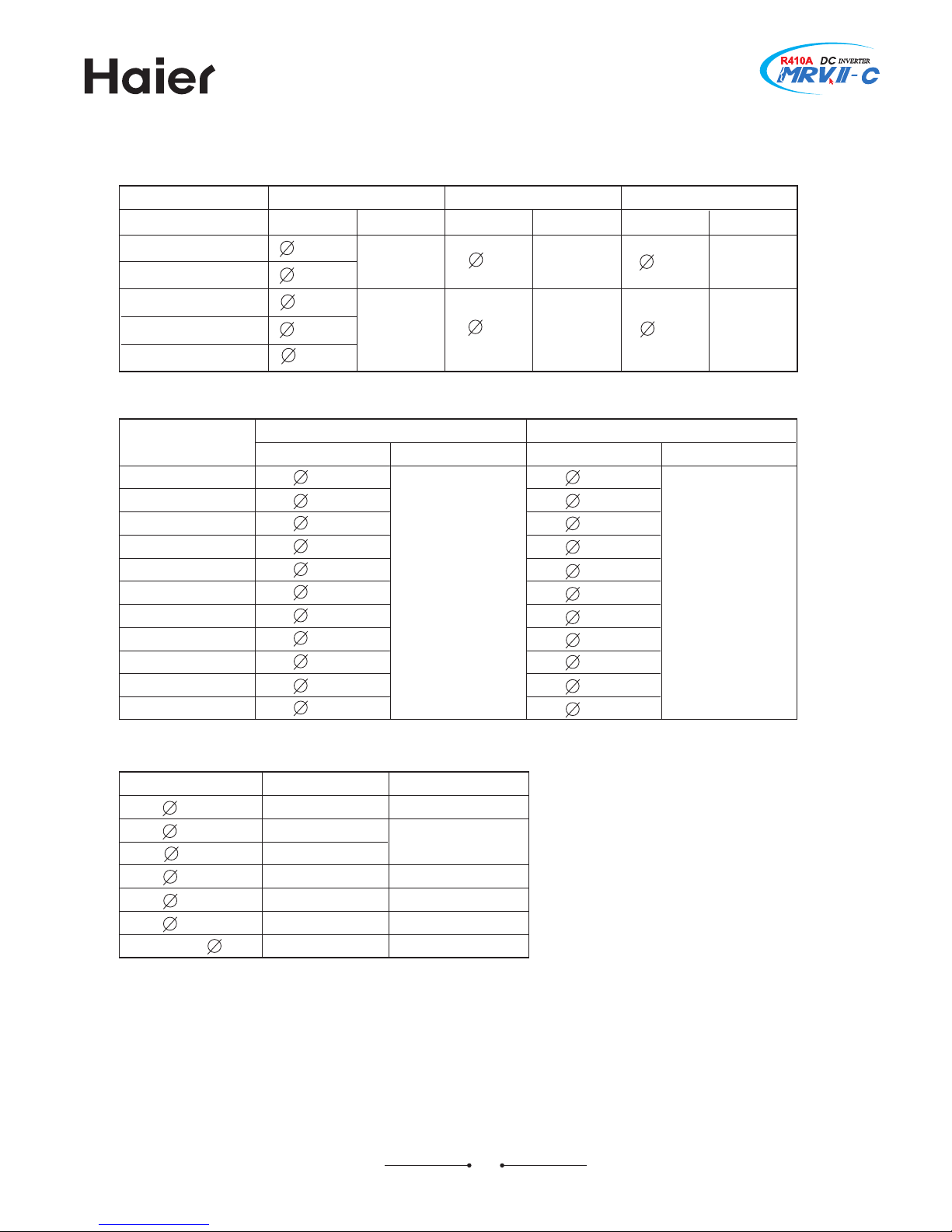

Hombination of outdoor units

Jquipment series

95 WFKJX] RSXJW

:5 HMJHO TSNRXW

;5 OJ] TSNRXW KSV NRWXFPPFXNSR

<5 VJKVNLJVFRX TNTJ NRWXFPPFXNSR

<58 [ork procedure

<59 Xhree principles of refrigerant pipes

<5: Honfirm refrigerant pipe

<5; Jquipment pipe length of bend pipe and branch pipe

<5< Granch pipe

<5= Lather pipe

<5> Tipe specifications and connection methods

<5? Tipe installation

<5@ Peakage testing

<587 Jvacuation

<588 Vefrigerant charging and additional charging

<589 Hheck valve operation

<58: Vequestment of copper pipe specs and thickness

<58; Xrial running

=5 NRISSV YRNX NRWXFPPFXNSR

=58 Gefore installation

=59 Wtandard accessories

=5: ;4way cassette unit installation

=5; Heiling concealed unit installation

=5< Qed static pressure duct unit installation

=5= Migh static pressure duct unit installation

=5> Honvertible unit installation

=5? [all mounted unit installation

=5@ Honsole unit installation

>5 SYXISSV YRNX NRWXFPPFXNSR

?5 JPJHXVNH [NVNRL

85 Tower wiring figure

95 Hommunication wiring figure

:5 Wpecs for power cable and communication wire

;5 Kield wiring

<5 [iring connection among units

=5 [iring of indoor and outdoor

>5 Jlectric characteristic

?5 Nnstallation instruction of central controller

@5 Honnecting method of central controller and connecting board

/iLY7;0

875 Iip switch setting when out of factory

@5 XVNFP STJVFXNSR

7:

7<

7>

7?

7@

87

8;

8<

8=

8>

8>

8>

8?

8@

8@

9?

9@

:8

:9

::

:;

:;

:<

:<

:=

:=

:=

;7

;@

<:

=8

=?

?=

@:

@?

87<

87=

87=

87>

87@

889

88:

88;

88<

88=

89:

89;

7:

[arnings on refrigerant leakage

Wdeqhfdq`ms cdmrhsx khlhs

Xhe room where the air conditioner is to be installed should be designed or chosen to meet the

standard in case of the refrigerant leakage3 which will ensure the refrigerant will not exceed the limit5

Xhe refrigerant V;87F in the air conditioner product is relatively safe without the poison and the

combustibility5 V;87F is environmentally friendly and is not restricted by the current or pending laws

regarding the protection of the ozone layer5

Visk of suffocation by the leakage of V;87F is minimal5 Mowever3 with the recent increase in the

number of high density buildings and use of multi air conditioner system to ensure effective use of

floor space3 energy conservation and individual control3 installers should ensure it is not possible

to exceed density limits in the event of a refrigerant leak5 Nn particular3 where a single unit of the

multi conditioner system is to be installed into a small room3 select a suitable model and installation

procedure so that if refrigerant leaks out3 density limits are adjacent rooms3 or install mechanical

ventilation combined with a gas leak detection device5

Xhe density can be calculated as shown belowA

Xotal amount of refrigerant /kg0

Qin5 volume of the room where indoor installed

density limit /kg6m

:

0

Xhe density calculation must be in accordance with GW JR :>?5

[hen installing the unit3 please take the above into consideration according to the local laws3 regulation5

Rote 8A Nf there are 9 or more refrigerant

systems in a single area3 the refrigerant amount

should be considered as the individual outdoor5

Kor exampleA

Kor the possible leaking refrigerant in room F3

G and H is 87kg5

Kor the possible leaking refrigerant in room I3

J and K is 89kg5

Rote 9A Xhe standards for minimum room

volume are as followsA

/80 Ro partition /shaded portion0

/90 [hen there is an effective opening with

the adjacent room for ventilation of leaking

refrigerant gas /opening without a door3 or an

opening 758<- or larger than the respective

floor spaces at the top or bottom of the door05

Voom F

Voom G Voom H Voom I Voom J Voom K

indoor unit

outdoor unit

e5g5 charged amount /89kg0

e5g5 charged amount /87kg0

indoor unit

indoor unit

outdoor unit

refrigerant pipe

7;

/:0 Nf an indoor unit is installed in each

partitioned room and the refrigerant piping is

interconnected3 attention must be paid to

ensure safeguards are in place to avoid density

limits being exceeded in each partitioned area5

[hen leak detection is interlocked with

mechanical ventilation equipment is installed

in the smallest room where the density limit

is exceeded3 the volume of the next smallest

room becomes the object5

Rote :A Xhe minimum indoor floor area

compared with the amount of refrigerant is

roughly as follows/when the ceiling height is

95>m05

small

room

large room

indoor unit

outdoor unit

refrigerant pipe

medium

room

smallest

room

gas leakage detector

total refrigerant amount

min5 indoor floor area /m

9

0

7

<

87 8< 97 9< :7 :<

;7

87 97 :7 kg

7<

[FVRNRL

Ne `mx `amnql`k ogdmnldm` `qd entmc 4d8f8

rldkk ne ehqhmf56okd`rd bts nee sgd onvdq rtookx

hlldch`sdkx6 `mc bnms`bs sgd cd`kdq sn ehmc nts{

sgd g`mckhmf ldsgnc8

\gdm mddc l`hmsdm`mbd `mc

qdo`hq6b`kk cd`kdq sn g`mckd hs8

Inm{s ots ehftqdr nq `mx nsgdq

sghmfr hmsn sgd hmkds9ntskds `mc

rvhmf kntudq vghkd sgd bnmchsh7

nmdq hr hm nodq`shnm

H`kk sgd cd`kdq sn s`jd ld`rtqdr sn oqdudms sgd

qdeqhfdq`ms eqnl kd`jhmf8

Wwitch

off

Nn such case3to continue using

the air conditioner will damage

the conditioner3and may cause

electrical shock or fire hazard5

Nncorrect maintenance and

repair may cause water leak3

electrical shock and fire hazard5

Gecause the high4speed fan

is very dangerous and may

cause injures5

Xhe leaked refrigerant over certain density may

cause oxygen deficient5Nf the air conditioner is

installed in a small room be sure to take measure

in order to prevent suffocation accident even in

case of refrigerant leakage

\gdm `hq bnmchshnmdq hr qdlnudc `mc qdhmrs`kkdc

cd`kdq rgntkc ad qdronmrhakd enq sgdl8

Nncorrect installation may cause water leaking3

electrical shock and fire hazard5

Inm{s chrl`mskd sgd ntskds ne sgd ntscnnq tmhs8

Xhe exposure of fan is very

dangerous witch may harm

human beings5

Fesdq ` knmf shld trd ne `hq bnmchshnmdq sgd a`rd

rgntkc ad bgdbjdc enq `mx c`l`fdr8

Nf the damaged base is not

repaired3 the unit may fall

down and cause accidents5

WFKJX] HFYXNSR

Nmportant safety information is displayed in this manual5 Tlease pay attention to these points and

keep them in the future carefully5

Jwok`m`shnm ne sgd hmchb`shnmr

Nncorrect operations may result in severe consequences of death or serious injures5

[FVRNRLA

Nncorrect operations may result in injures or machine damagesB in some cases may

cause serious consequences5

HFYXNSR A

A Nt must be strictly prohibited where marked with } Trohibited ~3 otherwise may result in

machine damages or endanger the users| personal safety5

Xhis information can ensure the correct operation of the machine5

NRWXVYHXNSRA

Ge sure to conform with the following important Wafety Hautions5

Xhe Wafety Hautions should be at hand so that they can be checked at any time when needed5

Nf the air conditoner is transferred to the new user3 this manual should be as well transferred to the new user5

7=

[FVRNRL

Sn fnncr nq mnancx hr odqlhssdc

sn ad ok`bdc nm nq rs`mc nm

ntscnnq tmhs8

Inm{s bkd`m `hq bnmchshnmdq

vhsg v`sdq8

Xhe falling of goods and

people may cause accidents5

Inm3s nodq`sd sgd `hq bnmchshnmdq vhsg

c`lo g`mcr8

Stherwise will be shocked5

Tmkx trd bnqqdbs sxod etrd8

Qay not use wire or any other

materials replacing fuse3othe4

rwise may cause faults or fire

accidents5

Inm{s ok`bd `mx atqmhmf

tmhs hm sgd `hqeknv ne `hq

bnmchshnmdq6vghbg l`x

b`trd hmbnlokdsd

bnlatrshnm

Sn hmek`ll`akd roq`x ekthc

rgntkc ad odqlhssdc sn ad

ok`bdc nq trdc md`q sn `hq

bnmchshnmdq6nsgdqvhrd l`x

b`trd ehqd `bbhcdms8

Fhq bnmchshnmdq rgntkc ad

bkd`mdc nmkx `esdq onvdq

rtookx hr bts nee sn jddo

eqnl rgnbj nq gtqs8

Stherwise may cause shock5

Hnmmdbs d`qsghmf vhqd8

Jarthing wire should not be

connected to the gas pipe3

water pipe3lightning rod or

phone line3incorrect earthing

may cause shock5

Zrd chrbg`qfd ohod bnqqdbskx sn

dmrtqd deehbhdms chrbg`qfd8

Nn correct pipe usage may cause water

leaking5

Fhq bnmchshnmdq b`m{s ad ad hmrs`kkdc hm

sgd dmuhqnmldms vhsg hmek`ll`akd f`rdr8

Xhe inflammable gases near to air conditioner

may cause fire hazard5

Nmrs`kkdc dkdbsqhb`k7kd`jhmf bhqbths aqd`jdq8

\gdm trd sgd etlhf`shmf hmrdbshbhcd

cnm{s nodq`sd `hq bnmchshnmdq8

Stherwise the poisonous chemicals

may settle in air conditioner3

which harm the health of

chemical4allergic people5

Nt easily causes electrical shock without

circuit breaker5

Rot permitted

when running

7>

Sdv dmuhqnmldms`kkx eqhdmckx qdeqhfdq`ms W>;:F

Nmportant safety information is displayed in this manual5 Tlease pay attention to these points and

keep them in the future carefully5

85 Wafety caution concerned with new refrigerant

Xhe pressure of refrigerant V;87F is 85= times than that of refrigerant V995 Xhe refrigerant oil has

also been changed5 Xherefore be sure that the former refrigerant oil and other contaminants are

not mixed into the refrigerating cycle of the air conditioner with the new refrigerant during installation

or service work5 Nf incorrect work is performed3 there is a possibility of serious accident5 Yse tools

and materials exclusive to V;87F5

95 Hautions on installation6service

C Ion.t mix other refrigerants or other refrigerant oil with V;87F5

C Xhe types of tools and joins3 including the service port differ from those of the former refrigerant

in order to prevent mixtakes5

C Xhe operation pressure of V;87F is high3 always use pipes with the correct wall thickness and

which are specified for V;87F5

C Iuring installation3 ensure pipes are clean and ensure contaminants do not enter the pipes because

the system will be affected by the impuries such as the water3 the dirt3 oil3 and so on5

C Jnsure brazing is completed using the nitrogen5

C Yse a vacuum pump for air purge5

C V;87F refrigerant is an azeotropic mixture type refrigerant5 Xherefore use liquid state to charge

the refrigerant5 Nf gas state refrigerant is used3 the composition of refrigerant will change which affects

the performance characteristics of the air conditioner5

:5 Qaterials

C Kor the refrigerant pipes3 use copper pipes and keep the number of joints to a minimum5

C [hen using long copper pipe for V;87F3 it is recommended to use the seamless copper material

which includes bonded oil3 of amount ;7mg687ml or less5

C Io not use crushed3 deformed or discoloured pipes5

C Yse material in which the amount of contaminates inside the pipes or joint are kept to an absolute

minimum5

C Xhe use of flared joint for joining refrigeration pipes should not be used3 except where fitted to

the indoor6outdoor units by the factory5

7?

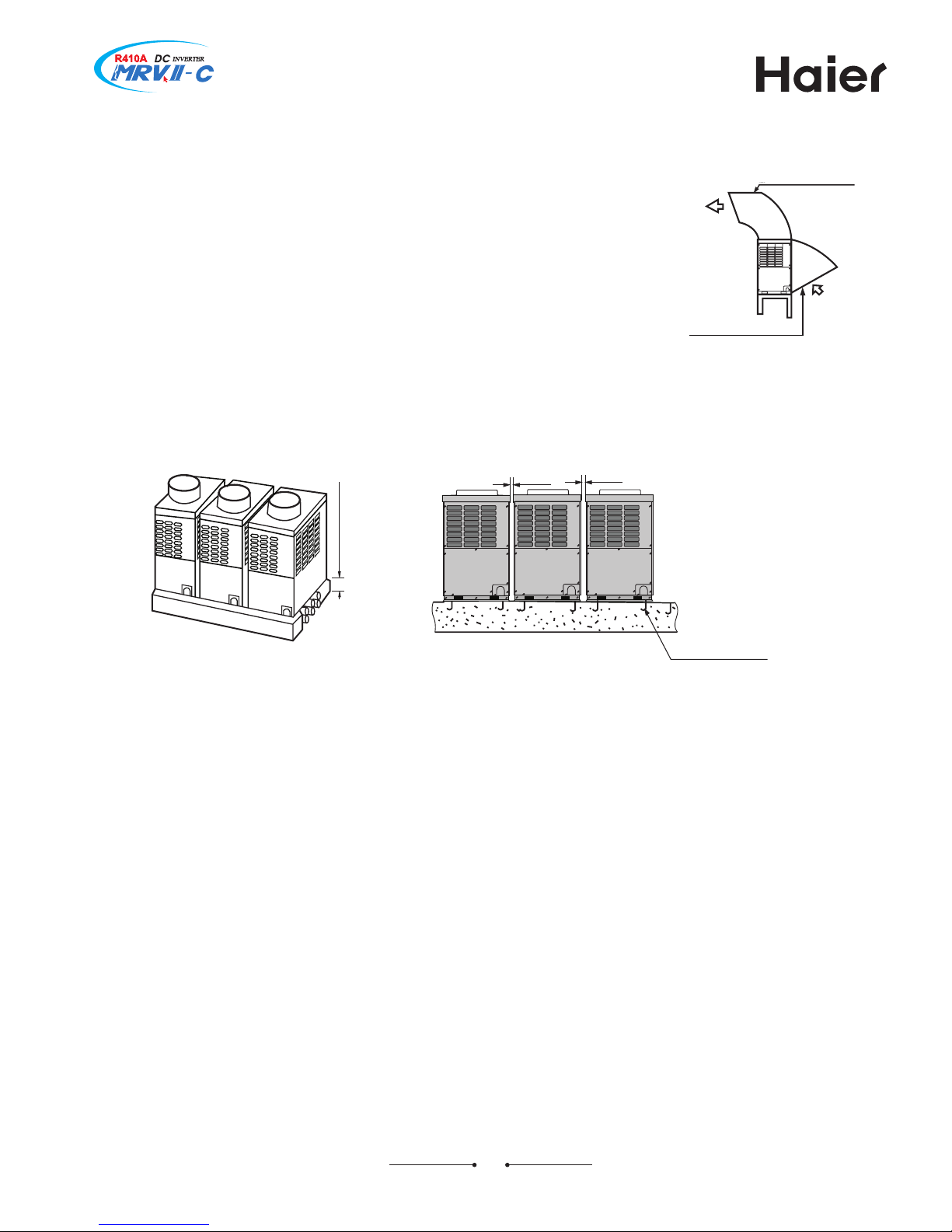

85 WJPJHX NRWXFPPFXNSR TPFHJ

over 977mm

over 977mm

air outlet snow

4proof cover

air inlet snow

4proof cover

over <77mm

refrigerant pipe

Q89 foundation screw

87MTA ; pieces

8=MTA = pieces

85 Nnstall adapter to change wind direction at the gas short circuit place5

95 [hen installing multiple units3 there should be enough air inlet place against

air in short circuit5

:5 Nn snowy area3 install the unit under the bracket or the snow4proof cover

against the accumulative snow on the unit5

;5 Io not install the unit at the place where the flammable gas will leak5

<5 Nnstall the unit at the strong enough place5

=5 Nnstall the unit at the flat place5

>5 [hen the refrigerant pipe is leaded out from the bottom of the uni3 the below

section should be a bracket with over <77mm height3 see below figure5

?5 [hen being installed at the place with strong wind3 set the air outlet of the

unit and the wind direction vertical5 Flso fix the unit with the screw5

@5 [hen opening the electric box cover for maintenance3 please fix the cover

with screw firmly5

7@

Hombination of outdoor units

FZ7?

UX] of Sutdoor unit

Hapacity/877[0

99=

9?7

::<

;77

;<7

<7=

<=7

=8<

=?7

>:7

?77

?<7

@77

@=7

8787

87?7

88:7

88?7

89:<

8:77

8:<7

MT

7?

87

89

8;

8=

8?

97

99

9;

9=

9?

:7

:9

:;

:=

:?

;7

;9

;;

;=

;?

87777

78777

77877

77787

77778

88777

79777

78877

78787

78778

77797

77788

77779

79787

79778

78797

78788

78779

77879

77789

7777:

Xotal UX]

FZ8=

FZ87 FZ89 FZ8;

8

8

8

8

8

9

9

9

9

9

9

9

9

:

:

:

:

:

:

:

:

87

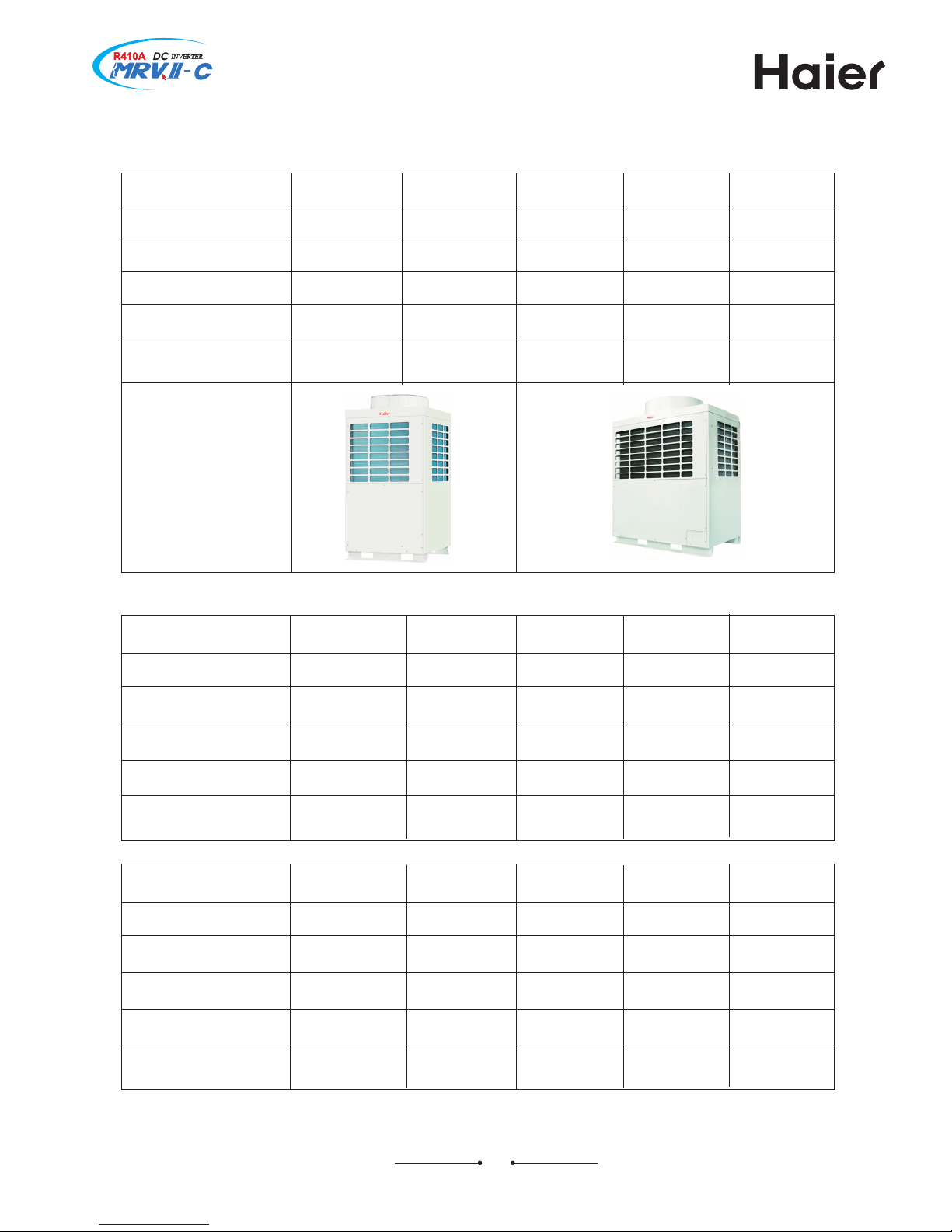

Jquipment series

85 Sutdoor units

95 Sutdoor units /combination of outdoor units0

corresponding MT

8?MT 97MT 99MT 9;MT 9=MT

model

FZ8?RQZJVF FZ97RQZJVF FZ99RQZJVF FZ9;RQZJVF FZ9=RQZJVF

cooling capacity

heating capacity

<75=

<=5<

<=57

=:57

=85<

=@

=?57

>=5<

>:57

?85<

max5 indoor quantity

total indoor capacity

/1877[0

9@

9<:{=<?

::

9?7{>9?

:=

:7?{?77

:@

:;7{??;

;:

:=<{@;@

corresponding MT

9?MT :7MT :9MT :;MT :=MT

model

FZ9?RQZJVF FZ:7RQZJVF FZ:9RQZJVF FZ:;RQZJVF FZ:=RQZJVF

cooling capacity

heating capacity

?757

@757

?<57

@<57

@757

87757

@=57

87?57

87857

88:57

max5 indoor quantity

total indoor capacity

/1877[0

;=

;77{87;7

<7

;9<{887<

<:

;<7{88>7

<=

;?7{89;?

<@

<7<{8:8:

corresponding MT

?MT 87MT 89MT 8;MT 8=MT

model

FZ7?RQZJVF FZ87RQZJVF FZ89RQZJVF FZ8;RQZJVF FZ8=RQZJVF

cooling capacity

heating capacity

995=

9<57

9?57

:85<

::5<

:>5<

;757

;<57

;<57

<757

appearance

max5 indoor quantity

total indoor capacity

/1877[0

8:

88:{9@;

8=

8;7{:=;

8@

8=?{;:=

9:

977{<97

9=

99={<??

88

corresponding MT

:?MT ;7MT ;9MT ;;MT ;=MT

model

FZ:?RQZJVF FZ;7RQZJVF FZ;9RQZJVF FZ;;RQZJVF FZ;=RQZJVF

cooling capacity

heating capacity

87?57

8985<

88:57

89=5<

88?57

8:85<

89:5<

8:>5<

8:757

8;<57

max5 indoor quantity

total indoor capacity

/1877[0

=:

<;7{8;7;

=;

<=<{8;=@

=;

<@7{8<:;

=;

=8?{8=7=

=;

=<7{8=@7

;?MT

FZ;?RQZJVF

8:<57

8<757

=;

=><{8><<

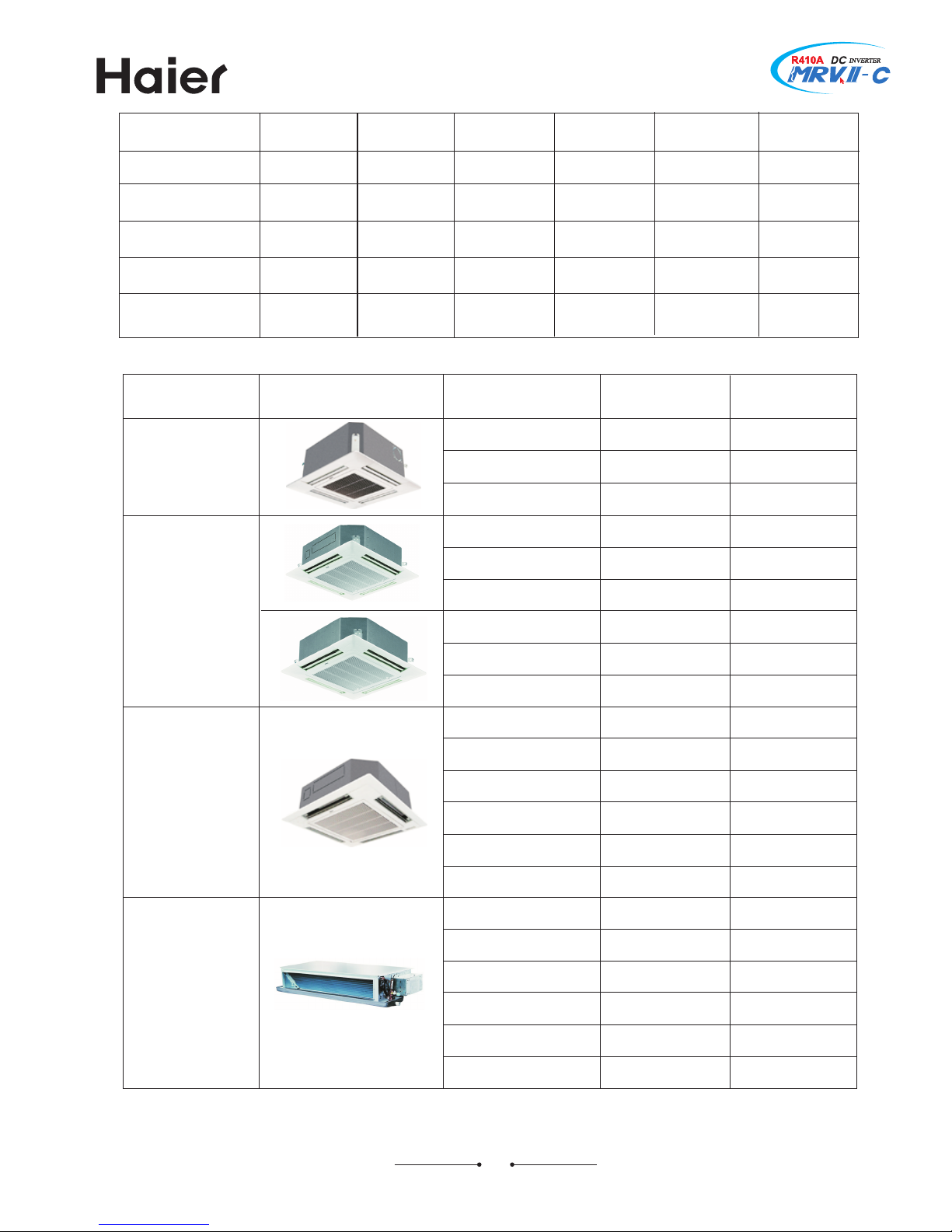

:5 Nndoor units

type appearance

model

cooling capacity

/O[0

heating capacity

/O[0

;4way cassette

type

;4way cassette

type

;4way cassette

type

low JWT duct type

FG7@9QHJVF

FG899QHJVF

FG8=9QHJVF

FG8?9QHJVF

FG9;9QHJVF

FG9?9QHJVF

FG:79QHJVF

FG:?9QHJVF

FG;?9QHJVF

FG8?9QJJVF

FG9;9QJJVF

FG9?9QJJVF

FG:79QJJVF

FG:?9QJJVF

FG;?9QJJVF

FI7>9QPJVF

FI7@9QPJVF

FI899QPJVF

FI8=9QPJVF

FI8?9QPJVF

FI9;9QPJVF

95?

:5=

;5<

<5=

>58

?57

@57

8859

8;57

<5=

>58

?57

@57

8859

8;57

959

95?

:5=

;5<

<5=

>58

:59

;57

<57

=5:

?57

@57

8757

895<

8=57

=5:

?57

@57

8757

895<

8=57

95<

:59

;57

<57

=5:

?57

89

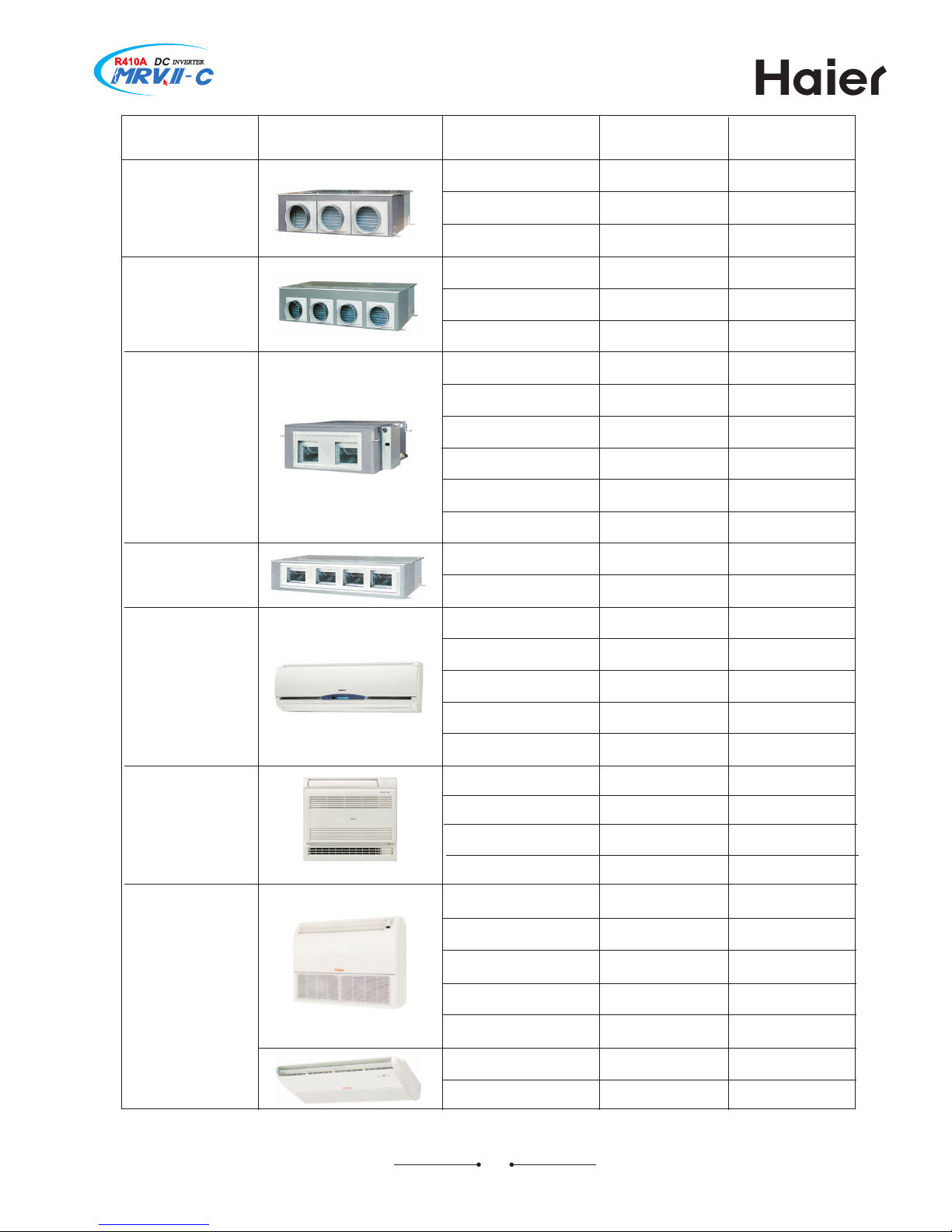

type appearance

model

cooling capacity

/O[0

heating capacity

/O[0

med JWT duct

type

med JWT duct

type

high JWT duct

type

high JWT duct

type

wall mounted

type

console type

convertible type

FI8?9QQJVF

FI9;9QQJVF

FI9?9QQJVF

FI:79QQJVF

FI:?9QQJVF

FI;?9QQJVF

FI8?9QMJVF

FI9;9QMJVF

FI9?9QMJVF

FI:79QMJVF

FI:?9QMJVF

FI;?9QMJVF

FI>99QMJVF

FI@=9QMJVF

FK7>9QFJVF

FK7@9QFJVF

FK899QFJVF

FK8?9QFJVF

FW7>9QHJVF

FW7@9QHJVF

FW899QHJVF

FW8=9QHJVF

FW8?9QHJVF

FH7@9QHJVF

FH899QHJVF

FH8=9QHJVF

FH8?9QHJVF

FH9;9QHJVF

FH:?9QKJVF

FH;?9QKJVF

<5=

>58

?57

@57

8859

8;57

=5:

?57

@57

8757

895<

8=57

<5=

>58

?57

@57

8859

8;57

995=

9?57

=5:

?57

@57

8757

895<

8=57

9<57

:857

959

95?

:5=

;5<

<5=

95<

:59

;57

<57

=5:

959

95?

:5=

<5=

95<

:59

;57

=5:

95?

:5=

;5<

<5=

>58

8859

8;

:59

;57

<57

=5:

?57

895<

8=

8:

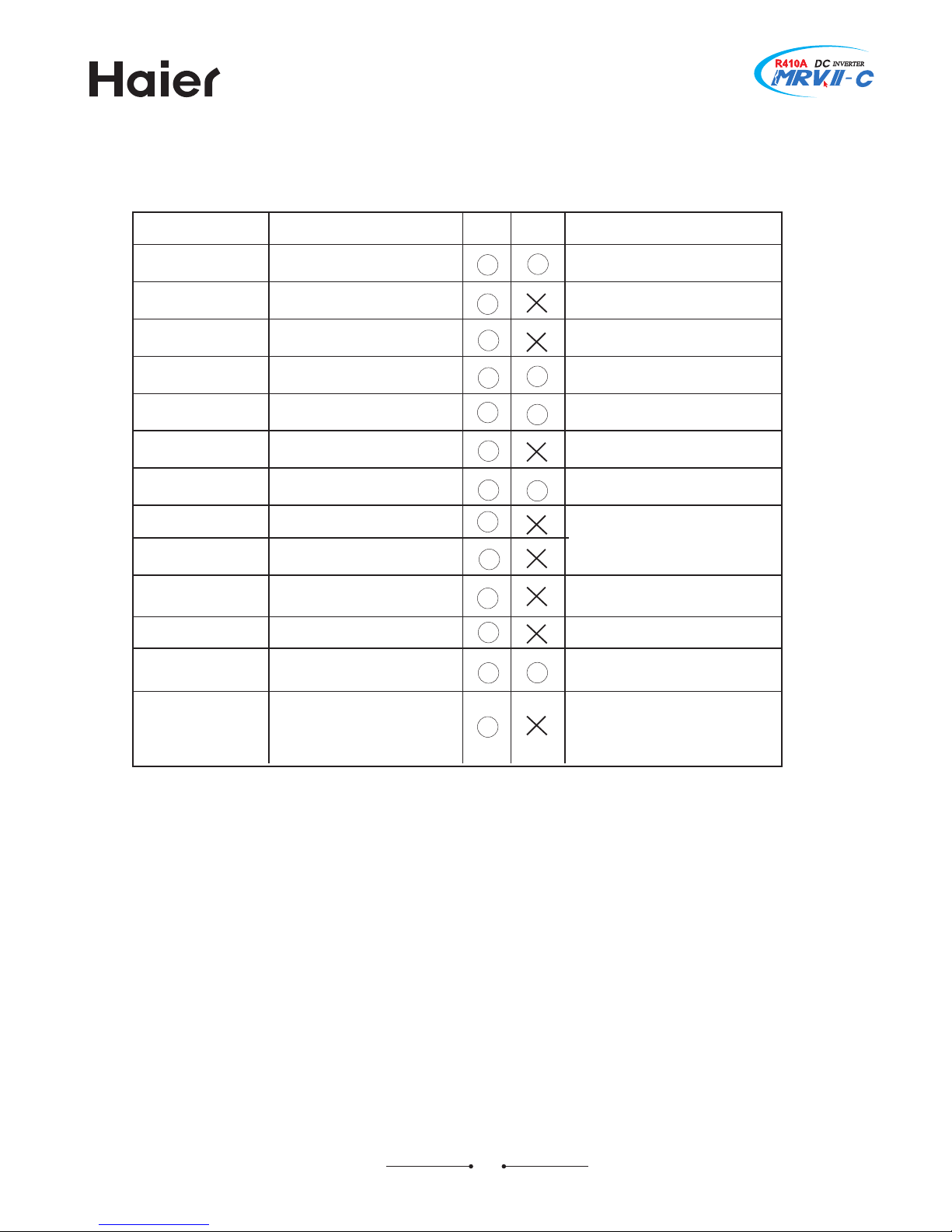

;5 Xools

RoteA Xhe pipes of V;87F connection with the same diameter can not be welded with the flared

joints5 ]ou must expand the diameter of pipe joint3 then weld the connecting pipe5

XSSP

knife

expander

spanner

flare tool

pipe bender

pressure gauge

welding torch

gauge manifold

charging hose

charging cylinder

leakage detector

TYVTSWJ

V99

V;87F

VJFWSR

electronic charging

scale

cut the pipe

enlarge the pipe

fasten the flare nut

flare the pipe

bend the pipe

used in leakage test

brazing the pipe

evacuation device

charging refrigerant

evacuation device

charging refrigerant

charging refrigerant

leakage detecting

for V;87F3 must enlarge the

projecting pipe

standard torque of 8693 <6?

pipe is larger

leakage test pressure is

higher

different pressure from V99A

max5A MT<5:Qpa min5A:5<Qpa

must ensure oil in vacuum

pump can not flow into the unit

when pump stops

vacuum pump with

one4way stop valve

V;87F can not be charged

as gas state

can not use freon detector

/HKHs or MHKHs03 V;87F

excludes Hl5 Yse the hydrogen

detector /or V8:;a detector0

Leneral tools/conventional tools can be used0

Gesides the above tools3 the following devices which service for V99 is necessary as the general tools5

85 torque wrench

95 pipe cutter

:5 reamer

;5 pipe bender

<5 level vial

=5 screwdriver

>5 hole core drill

?5 tape measure

@5 metal saw

Flso prepare the following equipment for the other installation procedureA

85 thermometer

95 ohmmeter

:5 voltmeter

Yse the exclusive tools for V;87F5

Qixing the different types of oil will cause the system working badly or clogged5

Xhe below table will compare the tools for V99 and V;87F5

8;

95 WFKJX] RSXJW

\FWSNSL

C Jnsure that all local3 national and international regulations are satisfied5

C Ffter the installation work has been completed3 perform a trial operation to check for possible

problem5 Kollow the owner.s manual to explain how to use and maintain the unit to the customer5

C Xurn off the main power supply switch /or breaker0 before any unit maintenance5

C Jnsure the customer keeps both the installation and owners manual together5

C Jnsure that all local3 national and international regulations are satisfied5

C Fsk the authorized dealer or qualified installation professional to install or maintain the air conditioner5

C Xurn off the main power switch or breaker before performing any electric work5

C Honnect all the electric wiries correctly5

C Iuring the transportation and installation of the air conditioner unit3 ensure that gaseous matter other

than the specified refrigerant does not enter into the refrigerant system5

C Io not modify the unit by removing any of the safety guards or by4passing any of the safety switches5

C Tlace the unit in the water or the moisture before installation may cause a short4circuit of electric

parts5

C Ffter unpacking the unit3 examine if there is possible damage5

C Io not install the unit at the place which will cause vibration5

C Xo avoid personal injury /with sharp edges03 be careful when handling parts5

C Terform installation work properly according to the installation manual5

C Nf the refrigerant gas has leaked in the transportation3 please ventilate the room immediately5

C Ffter installation3 please confirm the refrigerant system does not leak5

C Jlectric work must be performed by a qualified electrician according to the installation manual5 Qake

sure the air conditioner uses a special power supply5

C [hen connecting the installation wires3 be sure that all terminals are fixed5

C Honform to the regulation of the local electric company when wiring the power supply5

C Io not install the air conditioner in a location subject to a risk of exposure to a combustible gases5

8<

:5 HMJHO TSNRXW

Uqnsdbshnm cduhbd 4rtbg `r ghfg oqdrrtqd rvhsbg5

C Migh pressure switch is the device which can stop the unit automatically when the unit runs abnormally5

[hen the high pressure switch acts3 the cooling6heating mode will stop but the running PJI on wired

controller will be light still5 Xhe wired controller will display failure code5

[hen the following cases occur3 the protection device will actA

Nn cooling mode3 air outlet and air inlet of outdoor are clogged5

Nn heating mode3 indoor filter is sticked with ductB indoor air outlet is clogged5

[hen protection device acts3 please cut off the power source and re4start up after eliminating the

trouble5

\gdm onvdq hr e`hktqd

C [hen power is failure in running3 all the operations will stop5

Ffter being electrified again3 if with re4satrt up function3 the unit can resume to the state before power

off automaticallyB if without re4satrt up function3 the unti needs to be switched on again5

[hen abnormal occurs in running because of the thunder3 the lightning3 the interference of car or

radio3 etc3 please cut off the power source3 after eliminating the failure3 press +SR6SKK+ button to

start up the unit5

C Xhe heating mode adopts the heat pump type that absorbs outdoor heat energy and releases into

indoor5 Wo if outdoor temperature goes down3 the heating capacity will decrease5

Ideqnrshmf hm gd`shmf lncd

C Nn heating mode3 outdoor defrosting will affect the heating efficiency5 Xhe unit will defrost for about

9{87 minutes automatically3 at this time3 the condensate will flow from outdoor3 also in defrosting3

the vapour will appear at outdoor3 which is normal5 Nndoor motor will run at low speed or stop3 and

outdoor motor will stop5

Ygd tmhs nodq`shnm bnmchshnm

C Xo use the unit properly3 please operate the unit under the allowed condition range5

Nf operating beyond the range3 the protection device will act5

Xhe relative humidity should be lower than ?7-5 Nf the unit runs at the humidity over ?7- for a long

period3 the dew on the unit will drop down and the vapour will be blowed from air outlet5

Hgdbj adenqd nodq`shnm

C Xurn on the main power supply 89 hours or more before starting the operation5

C Hheck and ensure earth wiring is connnected5

C Hheck and ensure air filter is fitted to indoor unit5

Md`shmf b`o`bhsx

Hnloqdrrnq oqnsdbshnm

C Xhe outdoor unit will not operation within : minutes after the air conditioner restarts immediately after

stop or the power supply has been turned on5 Xhus the compressor will be protected5

8=

;5 OJ] TSNRXW KSV NRWXFPPFXNSR

Nn order to prevent problems before they arise3 carefully read the installation manual provided together

with the equipment before installation5

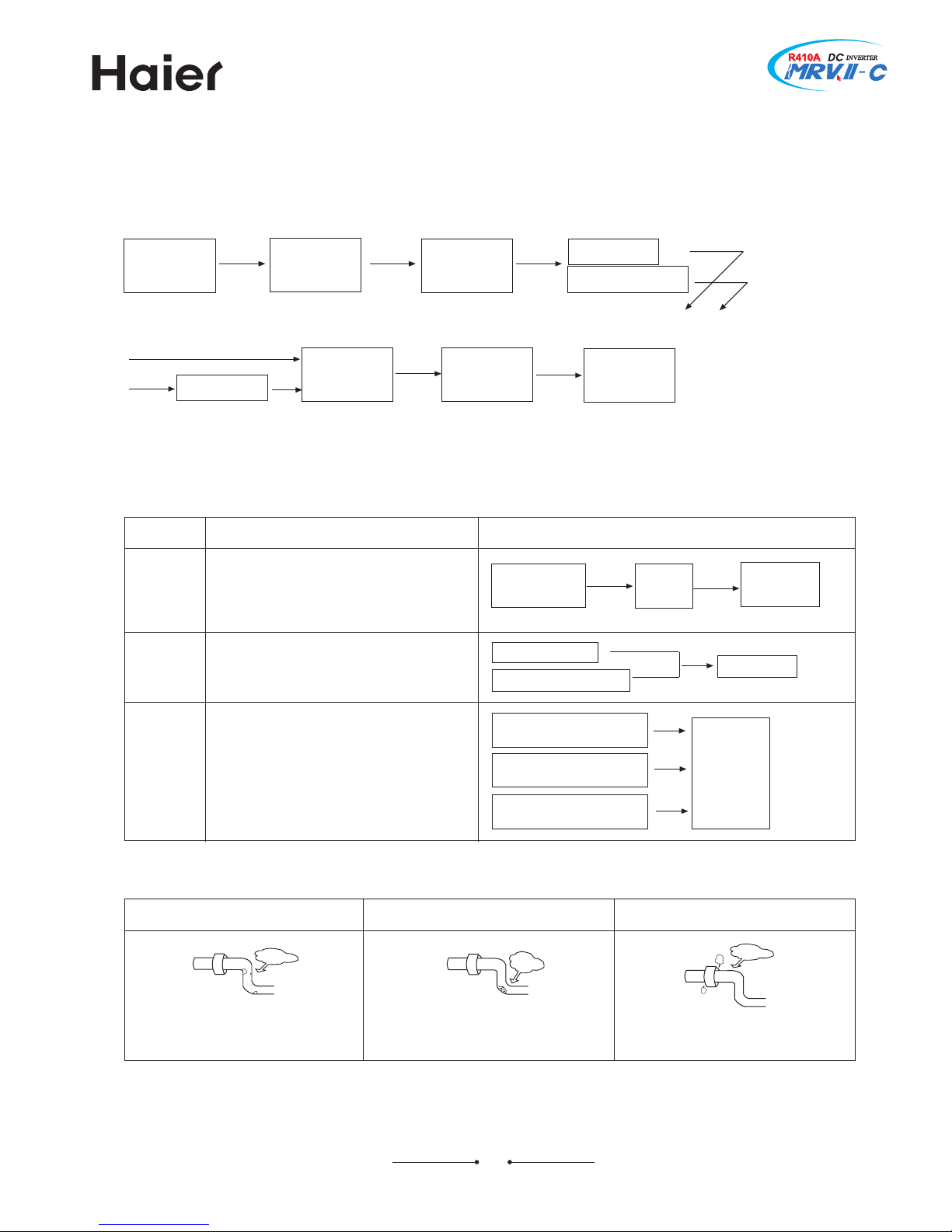

>8; Nmrs`kk`shnm oqnbdctqd 4enq xntq hmenql`shnm5

prepare work schedule

indoor unit installation

refrigerant piping installation

drain piping installation

duct work

insulation work

electric wiring work

outdoor unit foundation work

outdoor unit installation

refrigerant piping connection

leakage test

evacuation and drying

additional refrigerant charging

maintenance panel installation

trial running and adjustment

hand over

procedure

key points

list the installation work content

drafting of diagram

C control wiring system diagram

C refrigerant piping system diagram

C power wiring system diagram

sleeve installation

pay careful attention to the downward slope of the drain pipe

be sure to check the indoor model in order to avoid any

installation mistakes5 Nf the model has an installation pattern3

attach the pattern to the ceiling to mark the ceiling opening

position and to keep dust away5

make sure that the pipe system is dry3 clean and airtight5 [hen

brazing pipes3 blow out the system with nitrogen5

pipes should have downward slope of at least 868775

make sure that the pipe system is dry3 clean and airtight5 [hen

brazing pipes3 blow out the system with nitrogen5

be especially careful to close off all gaps where connections

are made to the indoor unit and at joints in the branching kit5

Io not forget the drain pipe5

use the 94core shielded wires for the control wires and use

individual power supply for the indoor and outdoor units5

set the switches correctly as indicated in the wiring diagram5

switch settings

make sure the unit is horizontal5

confirm that there should be enough service space and

adequate air flow around the outdoor5 Nndicate the unit model

clearly5

connect the pipes from the building to the outdoor3 and the

pipes between outdoors5

charge the system by nitrogen and keep for 9;hours3 the

system pressure should be ;7kf6cm

9

and without decrease5

Jvacuation the system through the checking joints on liquid

pipe stop valve and on the gas pipe stop valve with V;87F

specially vacuum pump5

record the additional amount added to the system5

confirm the maintenance panel in correct dimension and

position5 Peaving no gaps between the panel and the ceiling5

operate the indoor units one by one3 confirm the wires and the

pipes are correct5

8>

<5 VJKVNLJVFRX TNTJ NRWXFPPFXNSR

?8; \nqj oqnbdctqd

indoor unit

installation

sizing the

pipe

preliminary

installation

flaring

nitrogen gas blow

flushing

leakage

testing

evacuation

brazing

?8< Ygqdd oqhmbhokdr ne qdeqhfdq`ms ohodr

Vemember the below principlesA

results

dry

clean

airtight

C Qoisture /in the form of rainwater or water used

during installation0 getting inside of the pipes5

C Qoisture from condensation forming or seeping

into the pipes5

C Sxidation inside pipes during brazing

C Iirt3 dust3 or foreign matter getting inside pipes

C Toor brazing

C Toor flaring

how to prevent

careful handling

of pipes

charging

nitrogen

evacuation

nitrogen gas blow

careful handling of pipes

flushing

use of suitable material

/copper pipes3 solder3 etc0

perform basic work of

brazing carefully

perform basic work of flaring

carefully

leakage test

Xhe refrigerant pipes exampleA

keep dry

keep clean keep airtight

moisture

GFI

dirt

GFI

leakage

GFI

8?

?8= Hnmehql qdeqhfdq`ms ohod

85 Tlease select the refrigerant pipe of the below material5

QaterialA the phosphoric oxidize seamless copper pipe3 modelA H8997X4869M /diameter is over

8@57<0B H8997X47/diameter is below 8<5??05

95 Xhickness and specsA

Honfirm the pipe thickness and specs according to the pipe selection method/the unit is with V;87a3

if the pipe over 8@57< is 74type3 the pressure preservation will be bad3 thus it must be 869M type and

over the min5 thickness5

:5 Xhe branch pipe and the gather pipe must be from Maier5

;5 [hen installing the stop valve3 refer to the relative operation instruction5

<5 Xhe pipe installation should be in the allowable range5

=5 Xhe installation of branch pipe and gather pipe should be performed according to the relative manual5

Y`akd ;

capacity code

indoor

capacity

rank

equivalent

to MT

equivalent to

cooling capacity

75?

857

859<

85>

957

95<

:57

:59

;57

<57

?57

8757

959

95?

:5=

;5<

<5=

>58

?57

@57

8859

8;57

995=

9?57

Y`akd <

7> type

7@ type

89 type

8= type

8? type

9; type

9? type

:7 type

:? type

;? type

>9 type

@= type

capacity code

outdoor

model

equivalent

to MT

equivalent to

capacity

indoor

unit

quantity

FZ7?

FZ87

FZ89

FZ8;

FZ8=

FZ8?

FZ97

FZ99

FZ9;

FZ9=

FZ9?

FZ:7

FZ:9

FZ:;

FZ:=

FZ:?

FZ;7

FZ;9

FZ;;

FZ;=

FZ;?

?

87

89

8;

8=

8?

97

99

9;

9=

9?

:7

:9

:;

:=

:?

;7

;9

;;

;=

;?

995=

9?57

::5<

;757

;<57

<75=

<=57

=85<

=?57

>:57

?757

?<57

@757

@=57

87857

87?57

88:57

88?57

89:5<

8:757

8:<57

8:

8=

8@

9:

9=

9@

::

:=

:@

;:

;=

<7

<:

<=

<@

=:

=;

=;

=;

=;

=;

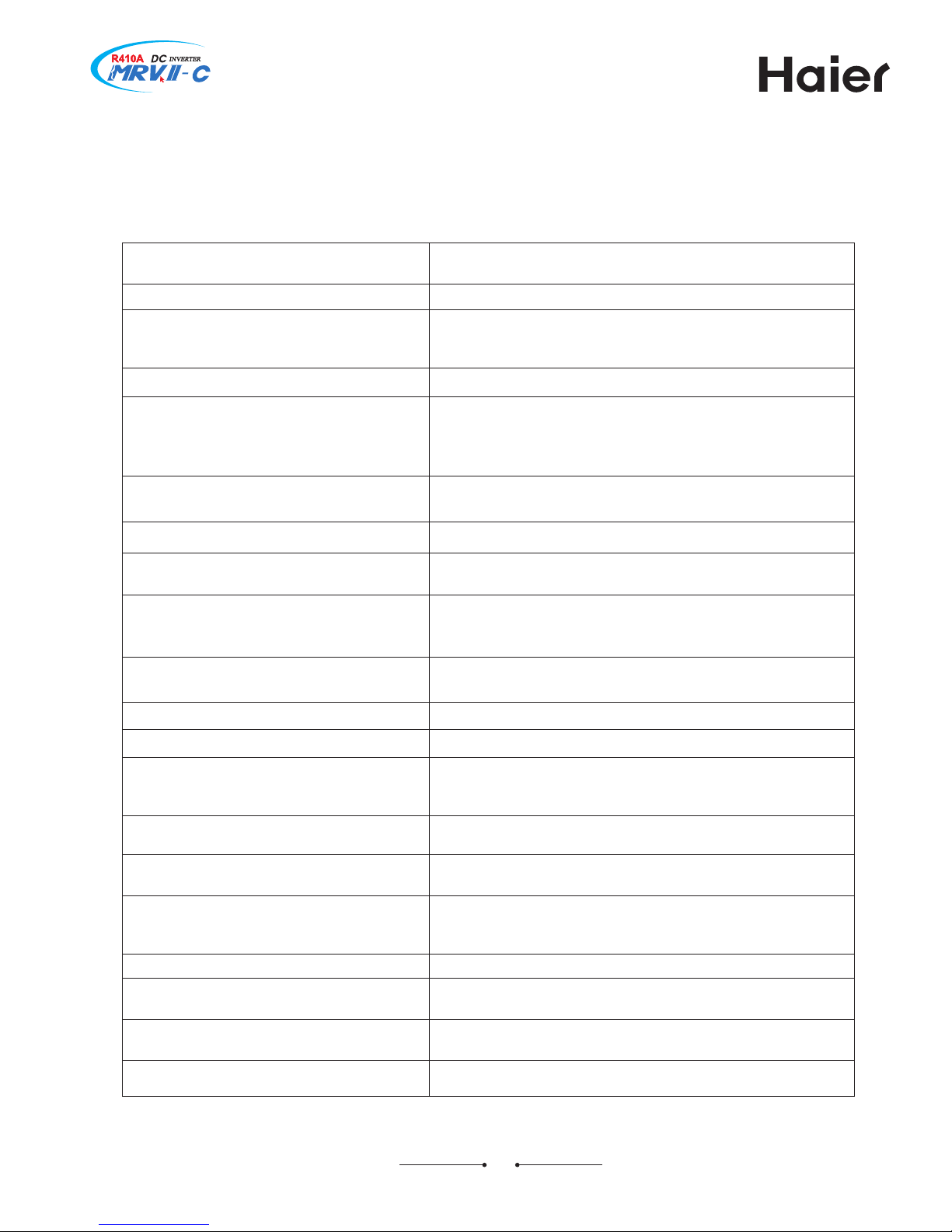

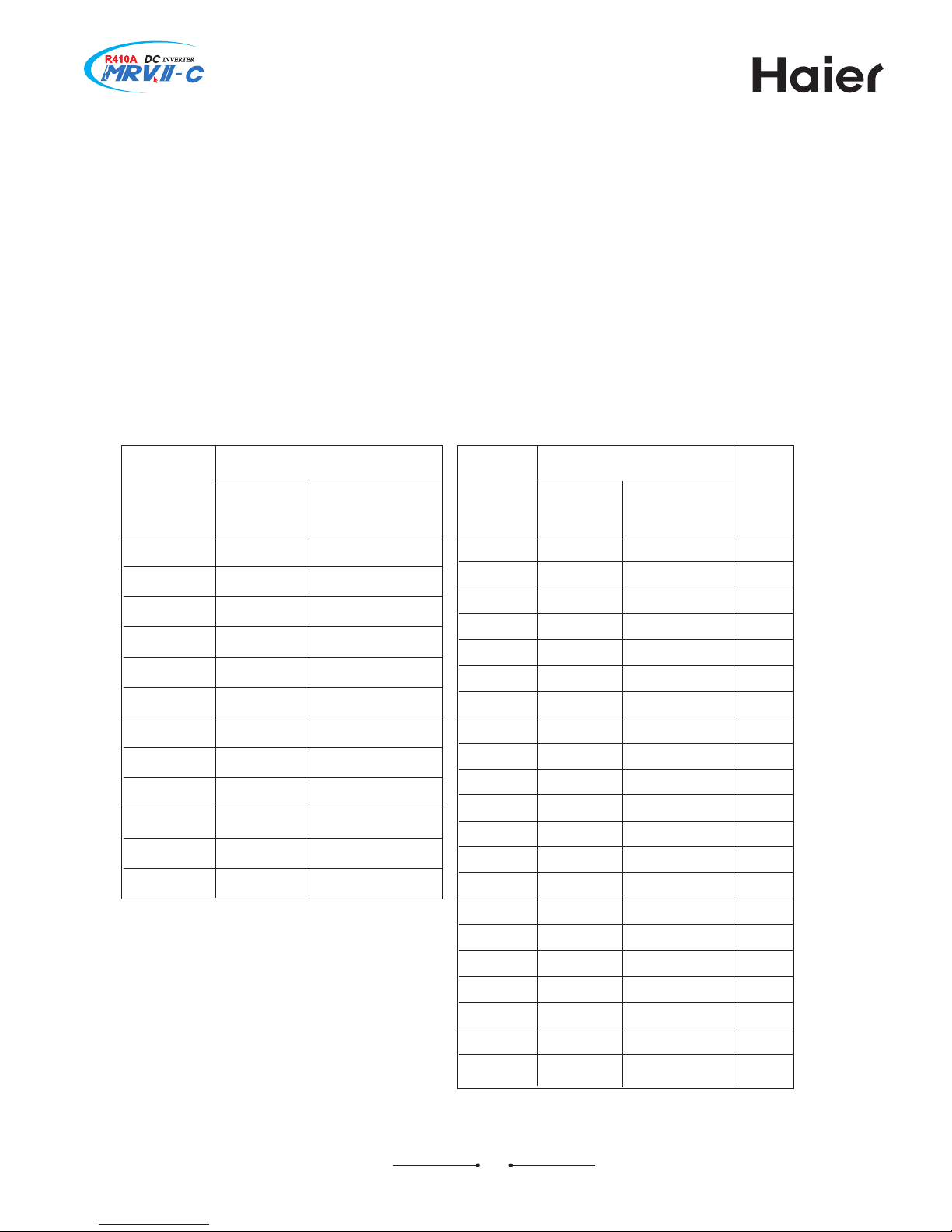

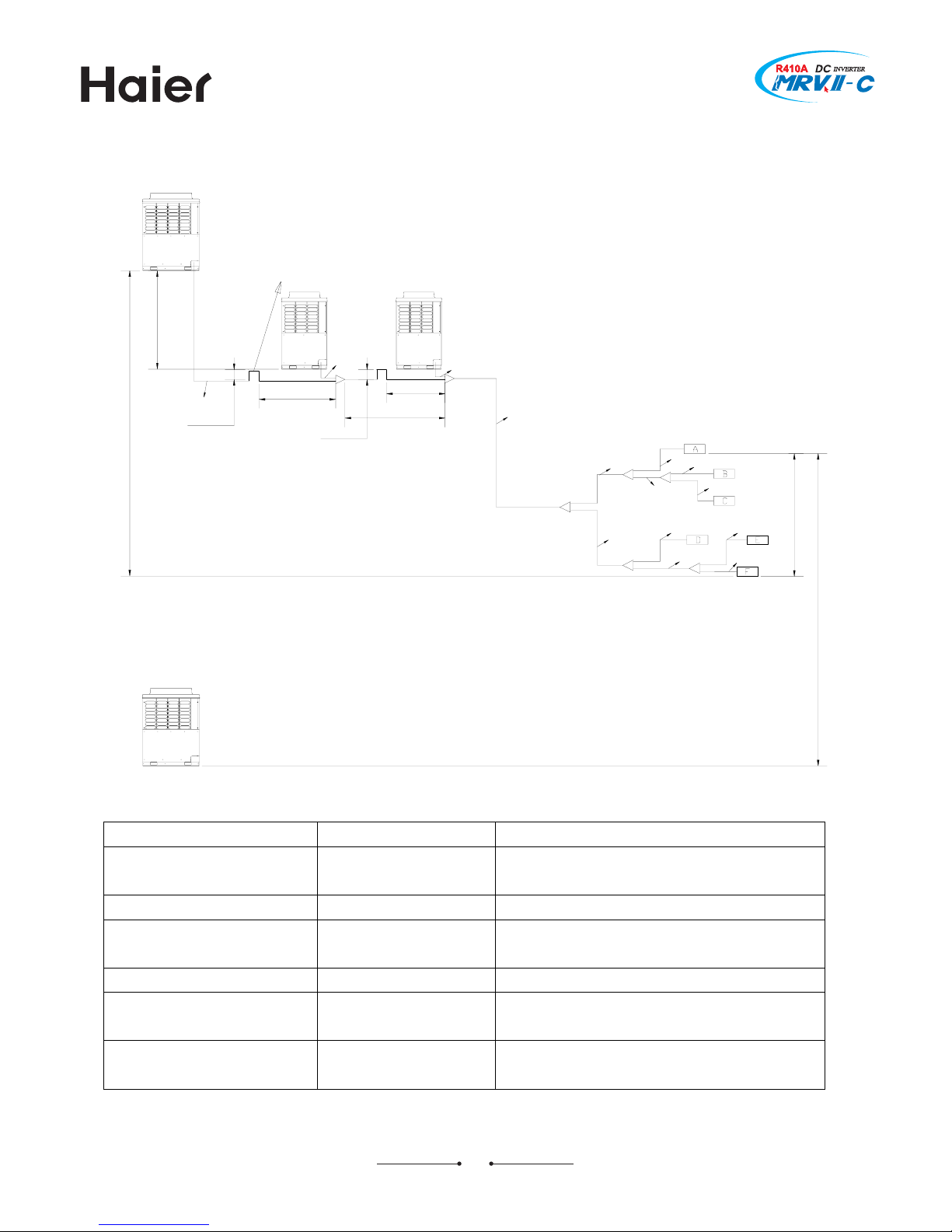

Allowable refrigerant piping length and height difference

a. Allowable pipe length and height difference

Single way total pipe length 300m

Single way max. pipe length Max. 150m

Main pipe between outdoor to 1st branch Max. 90m

Pipe length between outdoors Less than 10m to 1st branch pipe

Outdoor is upper Max. 50m Height difference between indoor and

outdoor

Outdoor is lower Max. 40m

Height difference between outdoors(in the same system) Within 5m (better be horizontal)

Max. pipe length from 1st branch pipe to indoor Max. 40m

Height difference between indoors Max. 15m

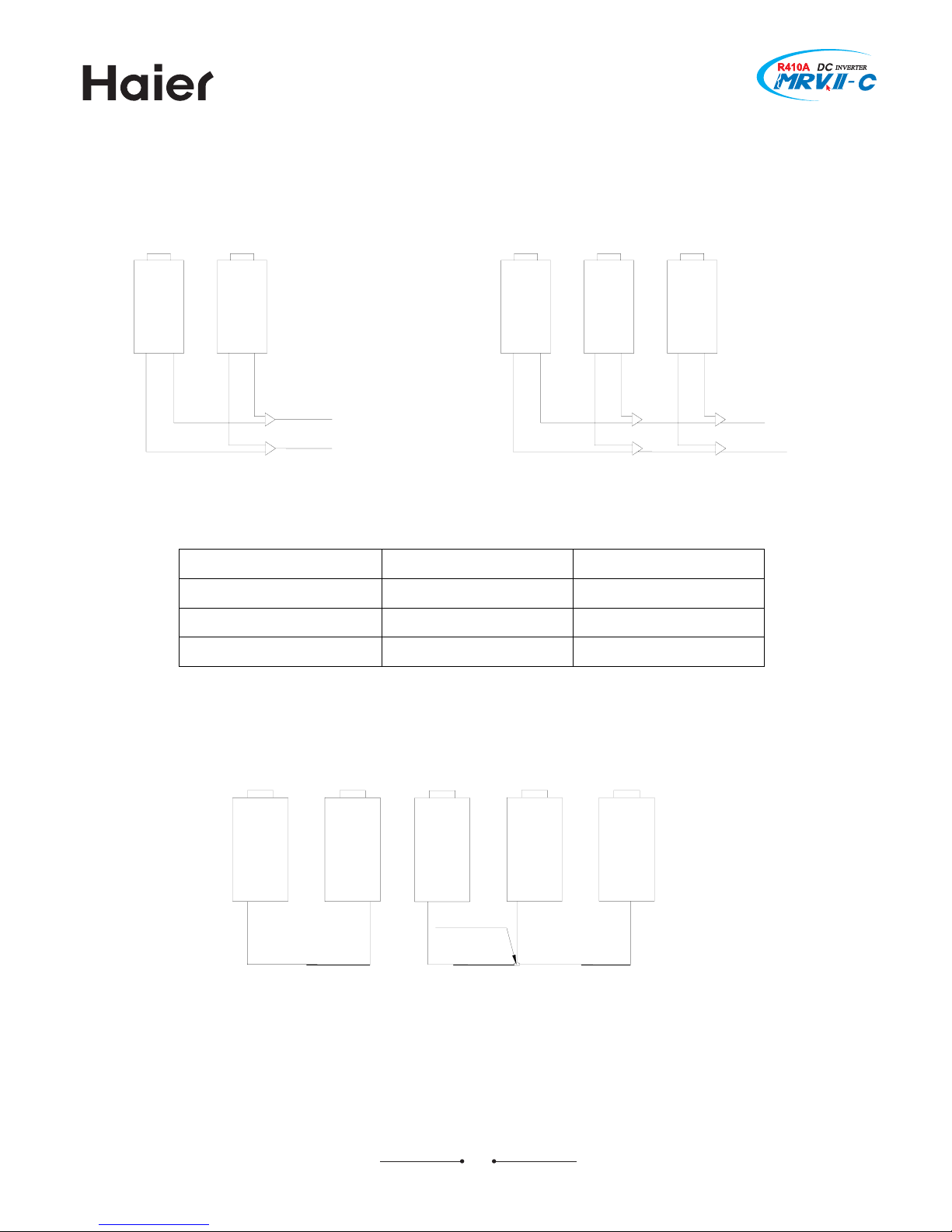

b. Pipe length between outdoors

3

outdoor1

outdoor2

outdoor

3

L1<10m,

L2+L3

<10m

Gas/liquid pipe:

1st gather pipe

2st gather pipe

Oil equalization pipe:

height difference between outdoors:

h

<5m

L5+L6

<10m

Note: a. HZG-30/A includes HZG-20/A;

b. The connection pipe among outdoors can not be higher than the stop valve position;

c. The connection pipe among outdoors should be horizontal or be in a certain angle as

the below figure (less than 15degree).

19

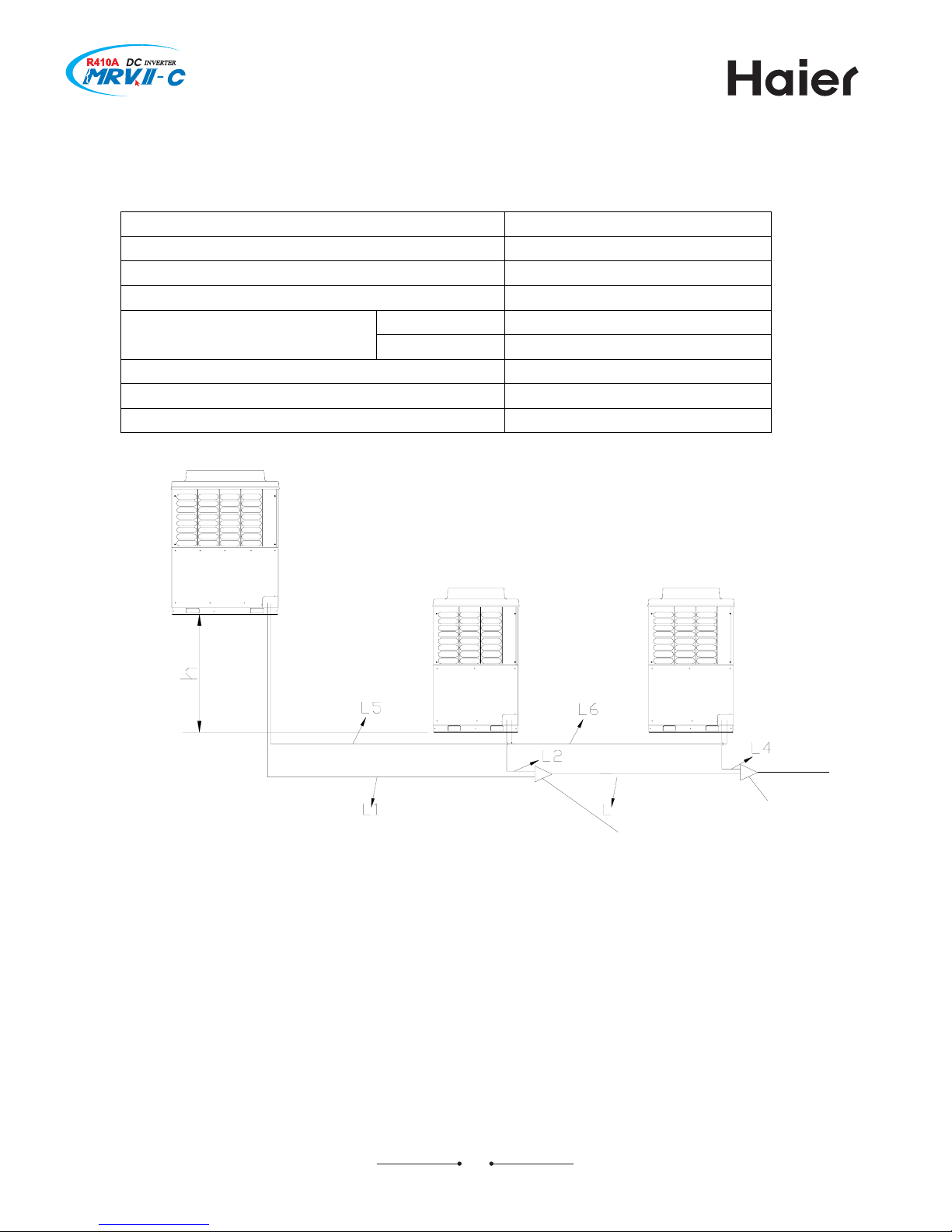

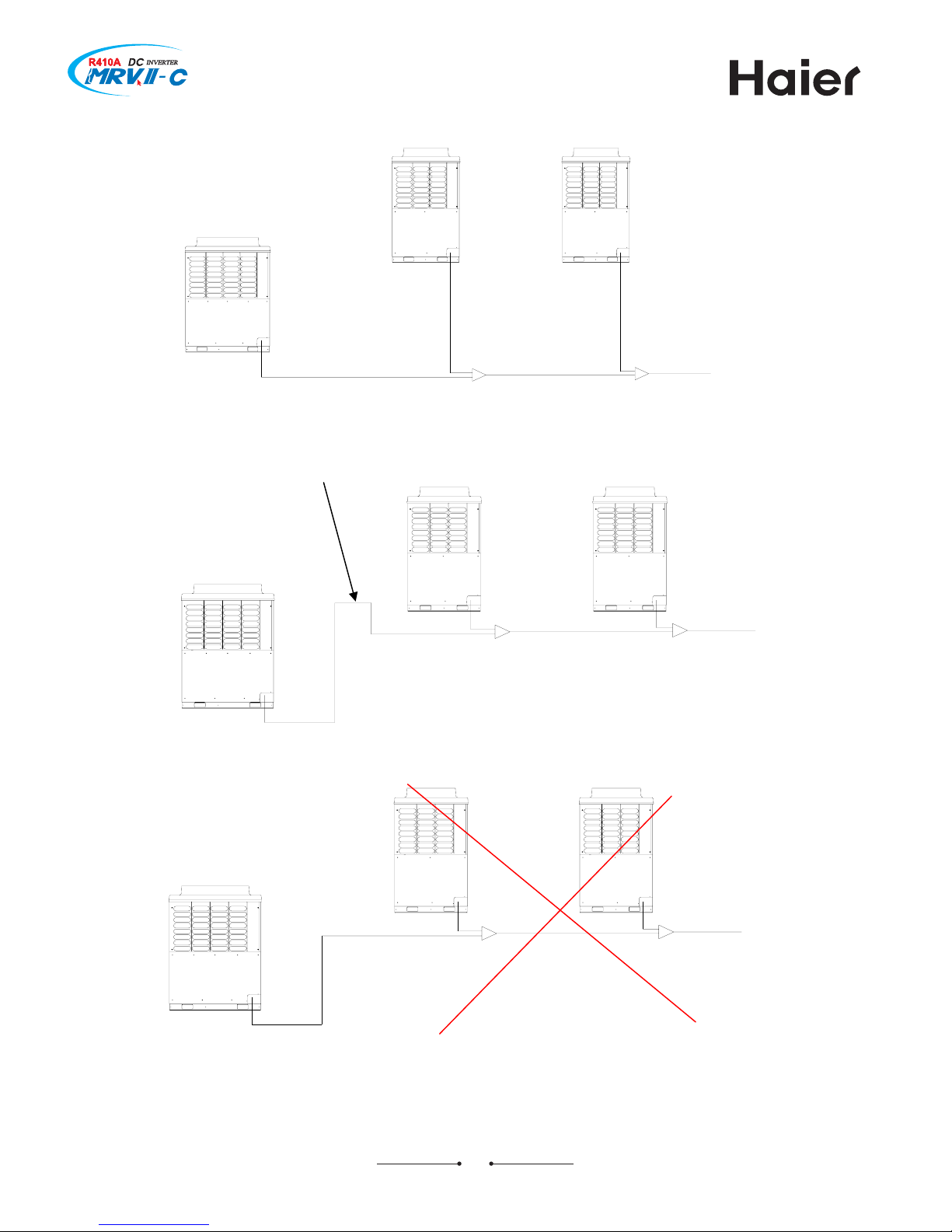

outdoor1

outdoor

2 outdoor3

outdoor1

outdoor2

outdoor3

Installation at high difference:

outdoor1

outdoor2 outdoor3

20

outdoor1

outdoor2

outdoor3

Oil trap (upright projecting pipe, 200mm high), as the figure:

outdoor1

outdoor2 outdoor3

Below is forbidden (compressor oil will flow into the lowest outdoor).

outdoor1

outdoor2

outdoor3

21

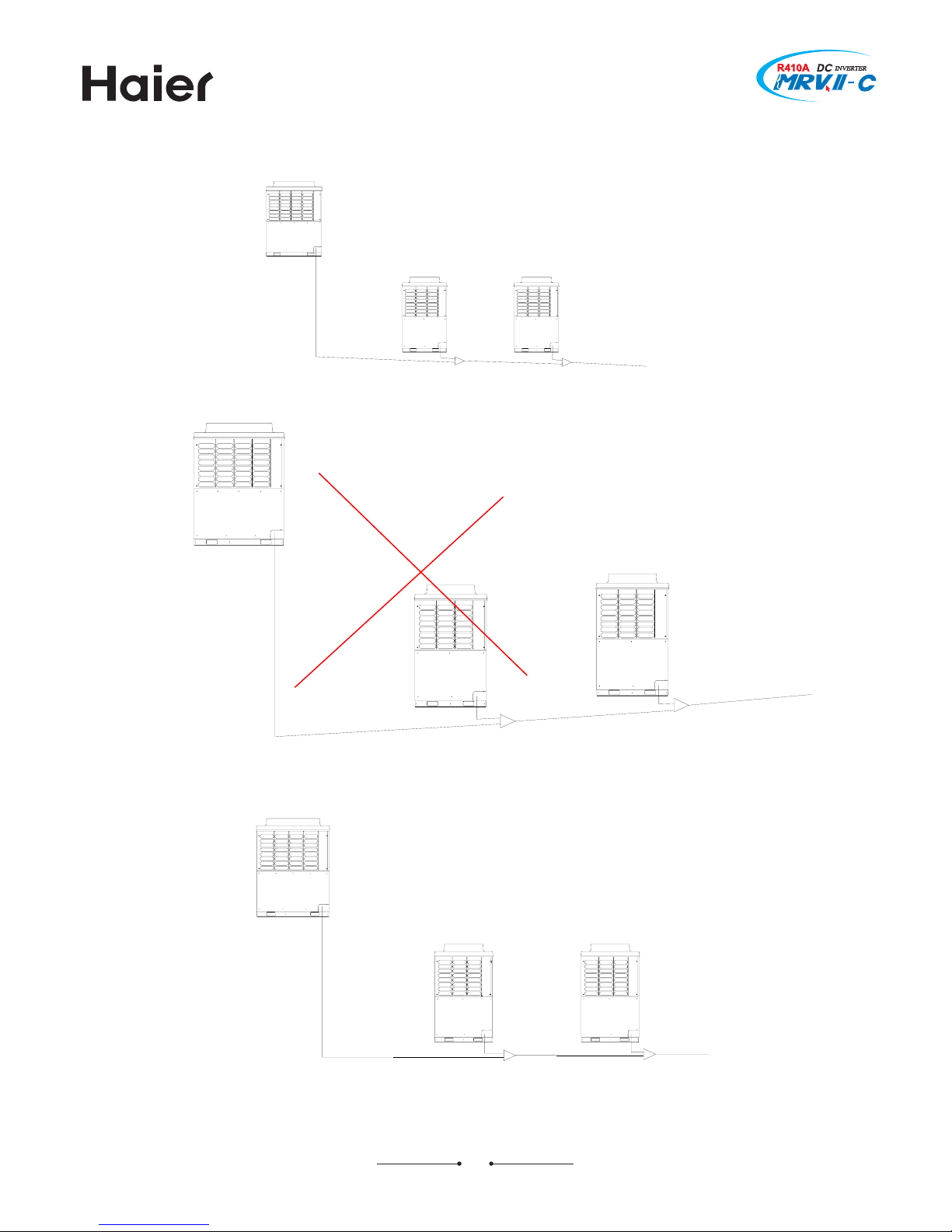

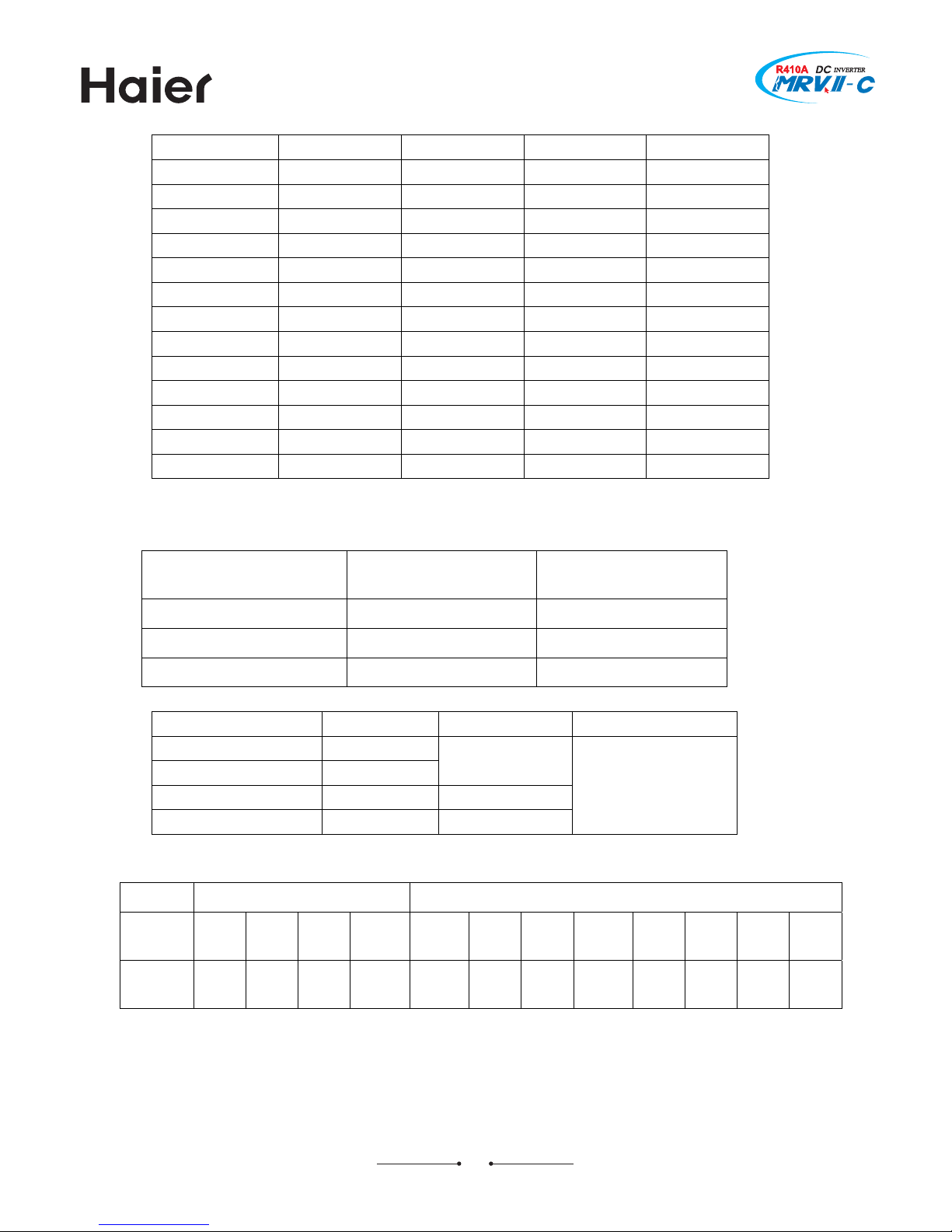

c. Allowable pipe length and height difference

Max. length Pipe in above figure

Single way total pipe length 300

L1+L2+ L3+ L4+ L5+ L6+ L7+L8+ L9+ L10+

L11+ L12+ L13+ L14+ L15

Single way max. pipe length 150 L1+L3+ L5+ L7+ L14+ L13

Max. pipe length after 1st

branch pipe

40 L7+L13+L14

Main pipe actual length 90 L5

Height difference between

indoors

15 ————

Height difference between

outdoors

5 ————

outdoor3

outdoor2

over 200mm

over 200mm

below 2m

below 2m

L7+L14+L13<40m

L1

L5

L14

L15

L13

L12

L11

L10

L9

L8

L7

L6

L2+L3

<10m

L4

L3

L2

L1

<10m

outdoor1

max. drop:5m

outdoor is lower, max. drop is 40m

max. drop:15m

outdoor is uppper,m ax. drop is 50m

when the distance between outdoors is over

2m, the oil trap must be set (upright projecting

pipe, 200mm high)

22

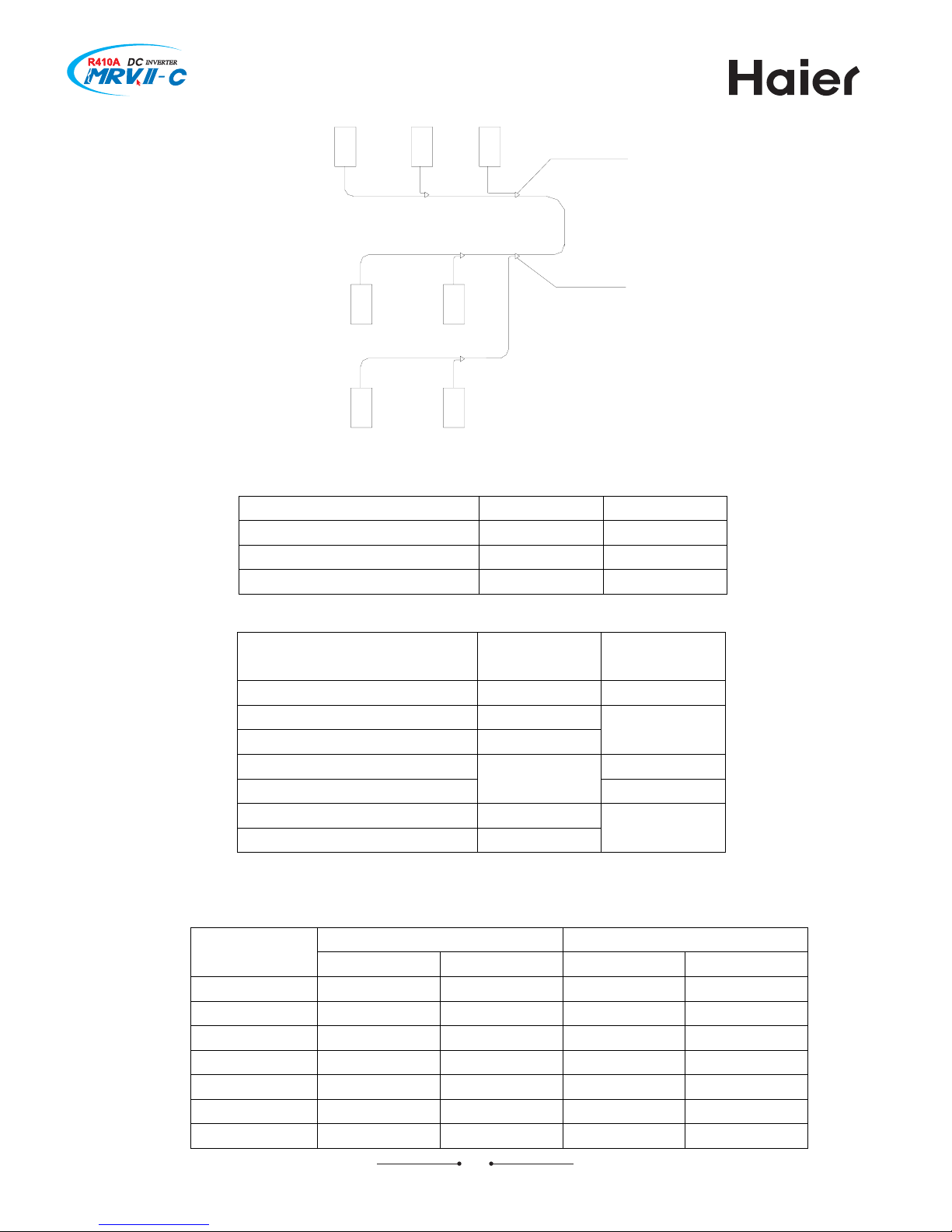

(2) Pipe specification:

aa

d

e

ee

c

b

aa

b

outdoor gather pipe

the first branch

a. Pipe “a” diameter (between indoor and branch pipe) (depends on indoor pipe, for wall

mounted unit, please refer to its specification)

Indoor(×100W) Gas pipe Liquid pipe

22~28 φ9.52 φ6.35

36~56 φ12.7 φ6.35

71~140 φ15.88 φ9.52

c. Pipe “c” diameter (main pipe, between outdoor gather pipe and the first branch pipe)

Main pipe Enlarged main pipe Outdoor

capacity

Gas pipe Liquid pipe Gas pipe Liquid pipe

22.6KW φ19.05 φ9.52 φ22.2 φ12.7

28.0KW φ22.2 φ9.52 φ25.4 φ12.7

33.5KW φ25.4 φ12.7 φ28.58 φ12.7

40.0KW φ25.4 φ12.7 φ28.58 φ12.7

45.0KW φ28.58 φ12.7 φ31.8 φ12.7

50.6KW φ28.58 φ15.88 φ31.8 φ15.88

56.0KW φ28.58 φ15.88 φ31.8 φ15.88

23

b. Pipe “b” diameter (between branch pipes)

When the later indoor capacity is less than 14.0KW, the specification of pipe b should refer

to the data in table a.

Total indoor capacity after the

branch pipe

Gas pipe Liquid pipe

14.0KW《<16.8KW

Φ15.88 Φ9.52

16.8KW《X<22.4KW

Φ19.05

22.4KW《X<33.0KW

Φ22.22

Φ9.52

Φ9.52

33.0KW《X<47.0KW

Φ12.7

47.0KW《X<71.0KW

Φ28.58

Φ15.88

71.0KW《X<101.0KW

Φ31.88

》101.0KW

Φ38.1

Φ19.05

61.5KW φ28.58 φ15.88 φ31.8 φ15.88

68.0KW φ28.58 φ15.88 φ31.8 φ15.88

73.0KW φ31.8 φ19.05 φ38.1 φ19.05

80.0KW φ31.8 φ19.05 φ38.1 φ19.05

85.0 KW φ31.8 φ19.05 φ38.1 φ19.05

90.0 KW φ31.8 φ19.05 φ38.1 φ19.05

96.0 KW φ31.8 φ19.05 φ38.1 φ19.05

101.0KW φ38.1 φ19.05 φ38.1 φ22.22

106.5KW φ38.1 φ19.05 φ38.1 φ22.2

113.0KW φ38.1 φ19.05 φ38.1 φ22.2

118.0KW φ38.1 φ19.05 φ38.1 φ22.2

123.5KW φ38.1 φ19.05 φ38.1 φ22.2

130.0 KW φ38.1 φ19.05 φ38.1 φ22.2

135.0KW φ38.1 φ19.05 φ38.1 φ22.2

Note: When the distance from outdoor to the longest indoor is over 90m, the main pipe

diameter should be enlarged.

d. Pipe “d” diameter (between gather pipes)

Total outdoor capacity

before the gather pipe

Liquid pipe (a, c) Gas pipe (b, d)

~68.0KW φ15.88 φ28.58

69.0~96.0KW

φ19.05 Φ31.8

97.0KW~ φ19.05 Φ38.1

e. Pipe “e” diameter (between outdoor and the gather pipe)

outdoor capacity Gas pipe Liquid pipe Oil equalization pipe

8HP φ19.05

10HP φ22.2

φ9.52

12, 14 HP φ25.4 φ12.7

16HP φ28.58 φ12.7

φ9.52

Copper pipe selection:

hardness softness Half-hardness

Outer

diameter

φ6.35 φ9.52 φ12.7 φ15.88 φ19.05 φ22.2 φ25.4 φ28.58 φ31.8 φ34.9 φ38.1 φ41.3

Min.

thickness

0.8 0.8 1.0 1.0 1.0 1.1 1.2 1.4 1.4 1.4 1.4 1.43

Note: If the copper pipe with outer diameter φ19.05 is coil pipe, the thickness should be

over 1.1.

24

9<

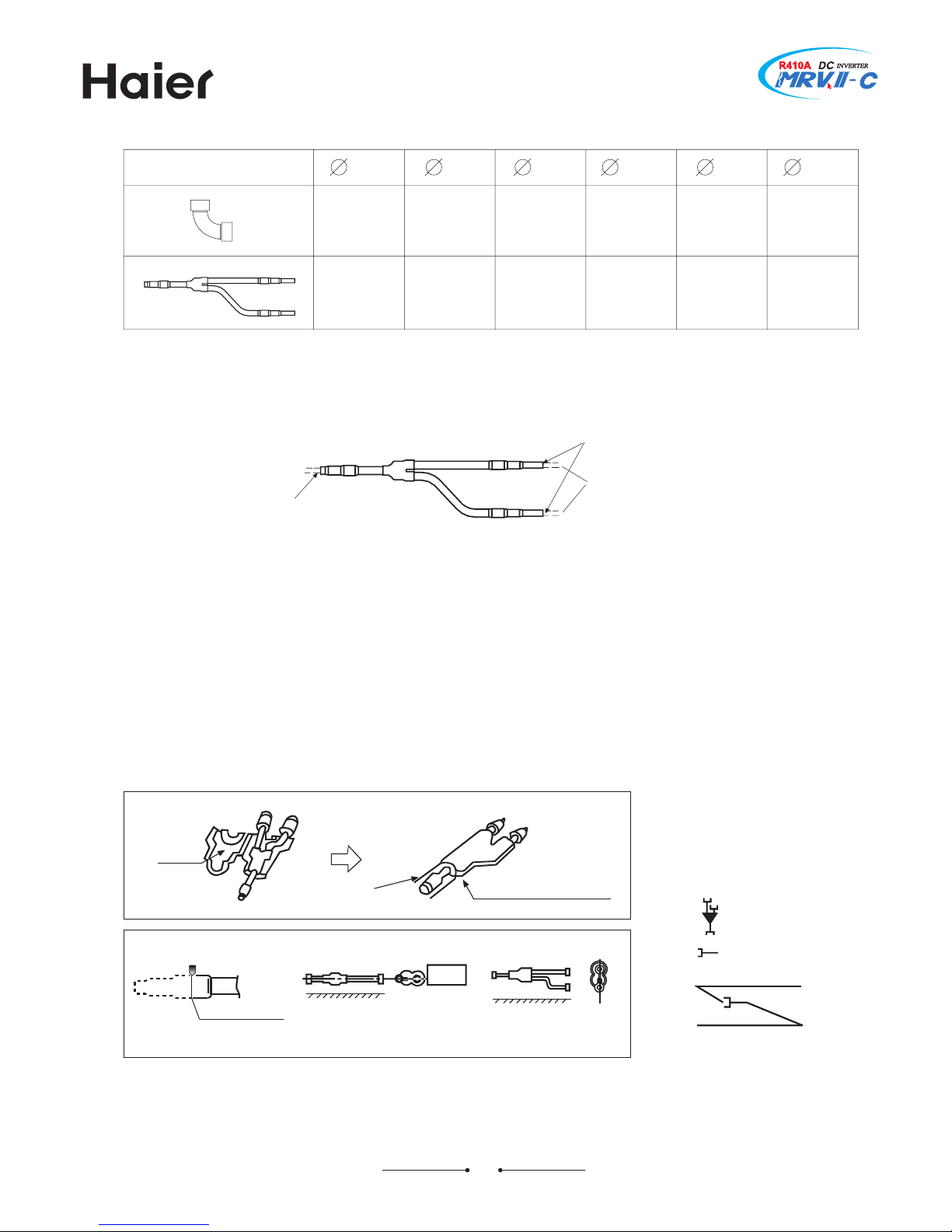

?8> Jpthu`kdms ohod kdmfsg ne admc ohod `mc aq`mbg ohod

Tipe size

bend pipe

branch pipe

=5:< @5<9 895> 8<5?? 8@58 :85?

758= 758? 7597 759< 75:< 75<<

75< 75< 75< 75< 75< 75<

?8? Gq`mbg ohod

Nmsqnctbshnm ne aq`mbg ohodD

to outdoor unit

to next branch or indoor unit

field piping

field piping

inlet

outlet

outlet

RoteA

85 [hen connecting the gather pipe or branch pipe and the outdoor3 please pay attention to the outdoor pipe

dimension5

95 [hen adjusting the diameter among gather pipes and among the units3 please must execute at the branch

pipe side5

:5 Tlease install the branch pipe/gas6liqiud side0 in horizontal or vertical direction5

;5 [hen welding with hard solder3 please must blow nitrogen5 Nf not3 a number of oxide will be produced and

cause heavy damage5Gesides3to prevent water and dust into the pipe3 please make the brim as outer roll5

<5 Nf the size of the selected field pipe is different from that of the branch pipe3 the connecting pipe should be cut

with the pipe cutter5

WignA

inner diameter treatment

connection

between branches

connection for pipes

with different diameter

outer diameter treatment

Kloor

Trepare on field

Weal the connection and wrap the

heat insulator with adhesive tape

Fdhesive side

[rong

Morizontal

Vight

Kloor

Hut off pipe with the cutter

Hut off at the middle

9=

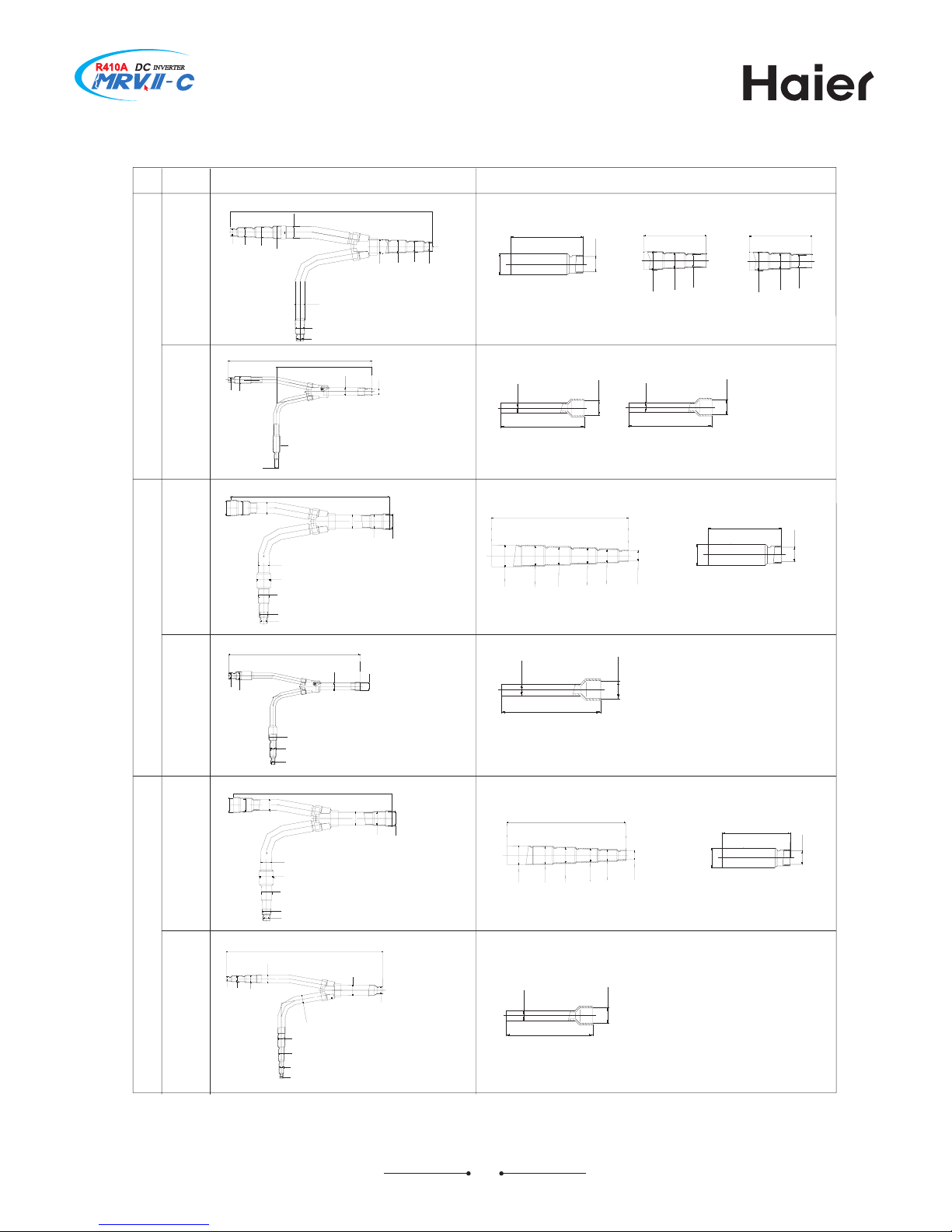

Granch pipe/unitA mm3 NIA inner diameterB SIA outer diameter0

Wide

Honnection of manifold pipe

Las

Tipe

Piquid

Tipe

Las

Tipe

Las

Tipe

Piquid

Tipe

Piquid

Tipe

KUL4G::<F

KUL4G<7=FKUL4G>:7F

:?;

NI8=58

NI8@5:

NI995;

NI9<5;

SI99599

SI9<5;

NI995;

NI8@5:

NI8=58

SI8@57<

NI8=58

NI895@

9:?

NI=5<

NI@5>

NI@5>

NI=5<

SI895>

NI@5>

<<

SI=5:<

NI@5>

<<

SI=5:<

NI@5>

87;

SI8<5??

NI@5>

NI895@

87;

SI8<5??

877

NI@5>

SI895>

:9:

NI9?5?

SI9959

NI9<5=

SI9<5;

NI9<5=

NI9?5?

SI99599185<

NI8=58

NI995;

NI8@5:

NI895@

<<

SI=5:<

NI@5>

8?7

SI9?5<?

NI9<5=

NI995;

NI8@5:

NI8=58

NI895@

877

NI@5>

SI895>

9:?

NI@5>

NI@5>

NI=5<

SI895>

NI895@

NI895@

NI895@

<<

SI=5:<

NI@5>

:??

NI@5>

NI@5>

NI=5<

SI9<5;

NI895@

NI895@

NI8=58

SI8@57<

NI8=58

SI8@57<

NI8=58

:9:

NI9?5?

SI9959

NI9<5=

SI9<5;

NI9<5=

NI9?5?

SI99599185<

NI8=58

NI995;

NI8@5:

NI895@

8?7

SI9?5<?

NI9<5=

NI995;

NI8@5:

NI8=58

NI895@

877

NI@5>

SI895>

NI@5>

NI895@

9>

Gq`mbg ohod rdkdbshnmD

Yns`k b`o`bhsx ne hmcnnq tmhsr4;::\5

Qdrr sg`m ==?

Sns kdrr sg`m ==? `mc kdrr sg`m ?:@

Sns kdrr sg`m ?:@ `mc kdrr sg`m A=:

Sns kdrr sg`m A=:

Gq`mbg ohod lncdk

KVL7G==?F

KVL7G?:@F

KVL7GA=:F

KVL7G;=?:F

PP

PP

PP

PP

PP

PP

PP

PP

KUL4G8:<7F

Honnection of manifold pipe

<<

SI=5:<

NI@5>

;7<

NI@5>

SI9<5;

SI8@57<

NI8=58

NI895@

NI8=58

NI8@5:

NI995;

NI995;

NI8@5:

NI895@

NI@5>

NI=5<

:==

NI:?5:

SI:85><

SI9?5=

NI:9

SI:85><

NI:9

NI:?5:

NI9?5?

877

NI@5>

SI895>

8?7

SI9?5<?

NI9<5=

NI995;

NI8@5:

NI8=58

NI895@

8;7

SI:85><

NI9?5?

NI9

<5=

NI995;

8:?

SI99599

NI8=58

NI895@

NI8@5:

9?

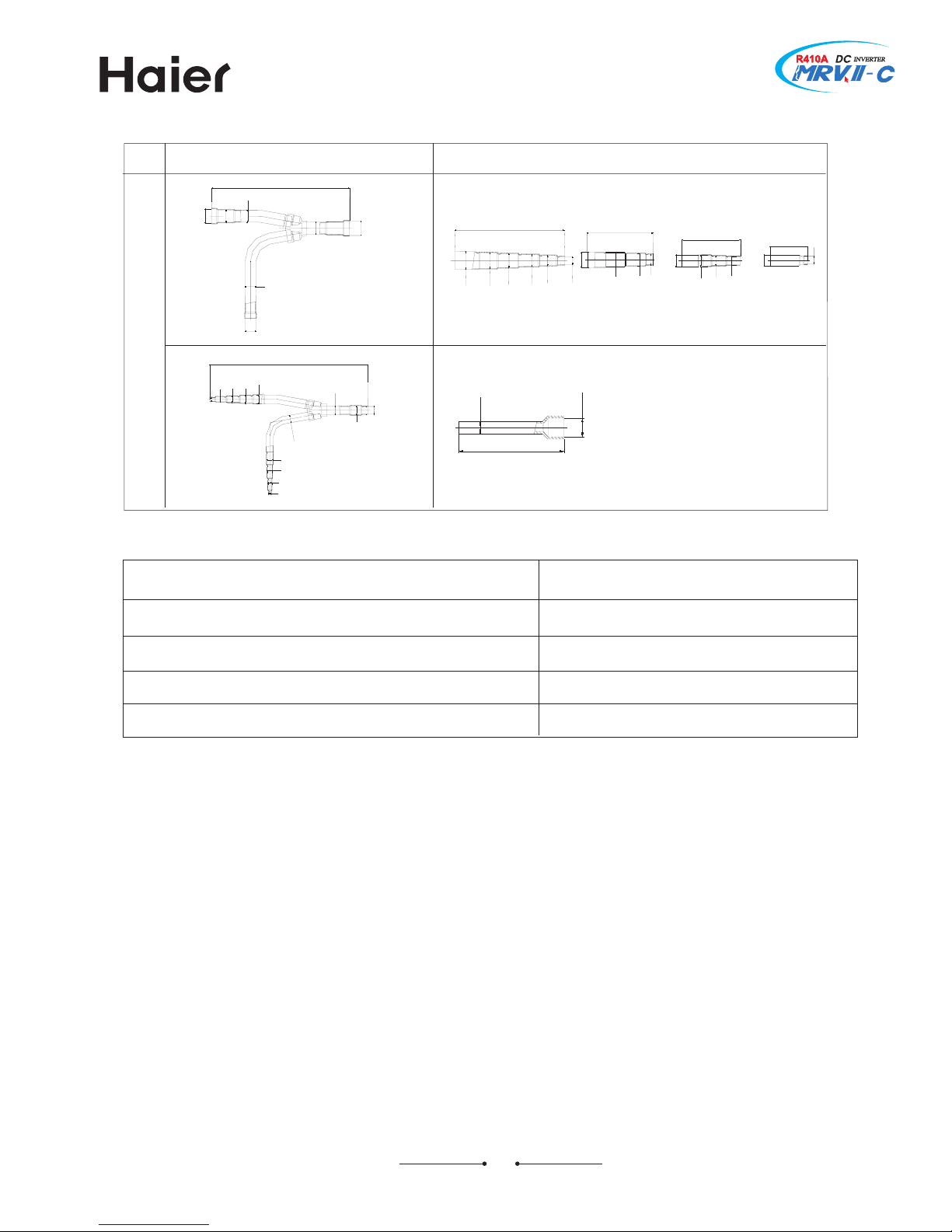

?8@ L`sgdq ohod

Lather pipe is used for combination of outdoor unit

M^L4976F/for 9 basic modules0B M^L4:76F/for : basic modules0

unitAmm3 NIA inner diameterB SIA outer diameter

RoteA Hut off the pipe from its middle when using

Qodel holm

Qark

Qanifold pipe

Nnsulation

material

holm

fieSXVU`

a

`

b

c

d

fieSYVU`

gcX[TZ

RVTX

RVTV[

gcXXTXX

RVTX

RVTV[

gcW_TW

RVTX

RVTV[

XVV

ZVZVWX

y

z

WV

gcW[T^^

RVTX[

RVTW

gcW_TV[

RVTX[

RVTW

ZV

gcW_TV[

RVTX[

RVTW

gcW[T^^

RVTX[

RVTW

RVTX[

RVTW

gc_T[X

RVTX[

RVTW

ZV ZV ZV

WV

ZXZ

_ZT[

RVTX[

RVTW

ZV

RVTX[

RVTW

ZV ZV

WV

RVTX[

RVTW

{

|

WV

gcW[T^^

RVTX[

RVTW

gcW_TV[

RVTX[

RVTW

ZV

RVTX[

RVTW

RVTX[

RVTW

RVTX[

RVTW

gc_T[X

RVTX[

RVTW

ZV ZV ZV

WV

ZXZ

_ZT[

RVTX[

RVTW

ZV

RVTX[

RVTW

ZV ZV

WV

RVTX[

RVTW

gcX[TZ

RVTX

RVTV[

gcXXTXX

RVTX

RVTV[

gcW_TW

RVTX

RVTV[

XVV

ZVZVWX

csxkpm

WXV

WZ

gcY[TW

RVTX

RVTV[

WXV

WZ

gcY^TW

RVTX

RVTV[

gcY^TW

RVTX

RVTV[

YV

gcY^TW

RVTX[

RVTW

[[V

\\]

WX

gcX^T\

RVTX

RVTV[

W[

W^_

gcWXT]

RVTX[

RVTW

gcWXT]

RVTX[

RVTW

csxkpm

gcX^T\

RVTX

RVTV[

gcX[TZ

RVTX

RVTV[

gcXXTXX

RVTX

RVTV[

gcW_TW

RVTX

RVTV[

Z\[

\ZV

W[

RVTX

RVTV[

WYX

gcX^T\

RVTX

RVTV[

gcY^TW

RVTX

RVTV[

gcYWT^

RVTX

RVTV[

gcX^T\

RVTX

RVTV[

gcX[TZ

RVTX

RVTV[

gcXXTXX

RVTX

RVTV[

gcW_TW

RVTX

RVTV[

Z\[

\ZV

W[

gcX^T\

RVTX

RVTV[

WYX

gcX^T\

RVTX

RVTV[

gcY^TW

RVTX

RVTV[

YWT^

RVTX

RVTV[

Qark

Honnection of manifold pipe

Las

side

Piquid

side

gcW_TV[

gcW[T^^

gcWXT]

gc_T[X

Las

side

Piquid

side

gcX^T\

Las

side

Piquid

side

Las

side

gcW[T^^

gcW[T^^

gcW_TV[

gcW_TV[

gcWXT]

gc_T[X

csxkpm

9@

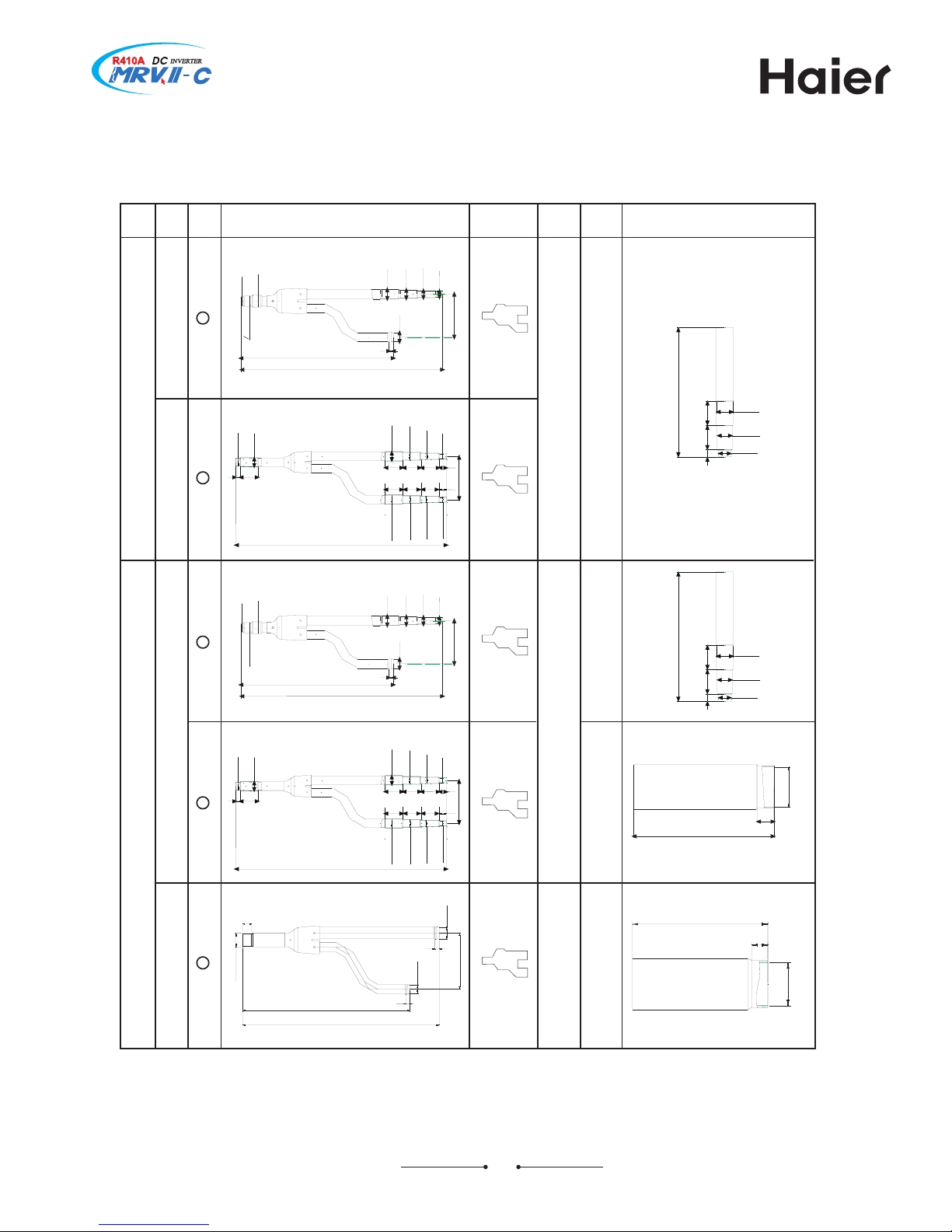

?8A Uhod rodbhehb`shnmr `mc bnmmdbshnm ldsgncr 4tmhsD ll5

H5 Tipe spec and the torque

diameter

Xhickness/mm0

75?

75?

857

857

857

859

Xorque/R5m0

8={97

;7{<7

@7{897

877{8;7

444

444

=5:<

@5<9

895>

8<5??

8@57<

9<5;

Rot less than 9?5<?

Qore than 85;

G5 Nndoor unit

Las pipe side

Qodel

Hapacity

7>

7@

89

8;

8=

8?

9;

9?

:9

:?

;?

@5<9

@5<9

895>

895>

895>

8<5??

8<5??

8<5??

Klared joint

Piquid pipe side

=5:<

=5:<

=5:<

=5:<

=5:<

@5<9

@5<9

@5<9

@5<9

@5<9

Iiameter

Honnecting

method

Iiameter

Honnecting

method

Klared joint

895>

8<5??

8<5??

F5 Sutdoor unit

Las pipe side Piquid pipe side Sil pipe side

FZ7?RQZJVF

FZ87RQZJVF

Iiameter

Honnecting

method

Grazing

Klared

joint

@5<9

Qodel

@5<9

FZ89RQZJVF

FZ8;RQZJVF

FZ8=RQZJVF

@5<9

895>

Iiameter

Honnecting

method

Iiameter

Honnecting

method

Grazing

Klared

joint

Klared

joint

Klared

joint

=5:<

8@57<

99599

9<5;

9<5;

9?5<?

(1) Outdoor pipe dimension

a

bb

ac

d

The pipe “a, b, c, d” should be confirmed as to the below table.

Former outdoor capacity Liquid pipe (a, c) Gas pipe (b, d)

~68.0KW φ15.88 φ28.58

69.0KW~96.0KW φ19.05 φ31.8

Over 97.0KW φ19.05 φ38.1

Note: When the single pipe length is over 90m, the above pipe should be enlarged as the

former information.

(2) Oil equalization pipe connection

oil equalization

pipe

φ9.52

T-shape

3-way pipe

oil equalization

pipe

φ9.52

18~32HP

34~48HP

18~32HP 34~48HP

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

30

Pipe dimension among outdoors

Loading...

Loading...