Haier AV08NMSETA Service Manual

SYJS-11-2016 REV.A Edition: 2016-11

Service Manual

MRV S

II

CONTENTS

1. General Information ................................................................................................................. 1

1.1 Indoor units ........................................................................................................................ 1

1.2 Features ............................................................................................................................2

2. Specication ...........................................................................................................................6

3. Refrigerant Circuit..................................................................................................................12

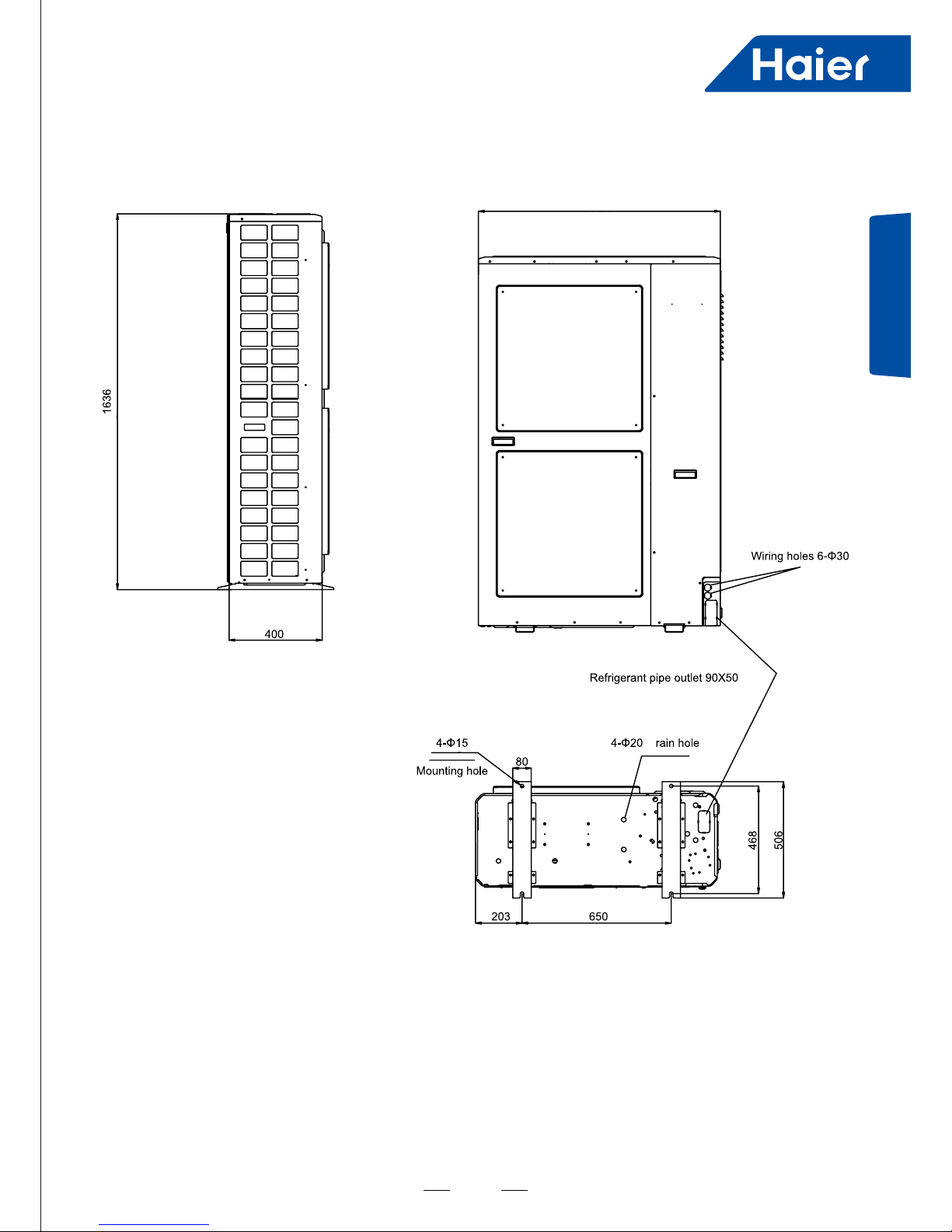

4. Dimension .............................................................................................................................13

5. Wiring Diagram ...................................................................................................................... 14

6. Performance Curves..............................................................................................................15

7. Noise Level ............................................................................................................................ 17

8. Outdoor Installation ...............................................................................................................18

9. Electric Installation.................................................................................................................37

10. Trial Operation .....................................................................................................................40

11. Dip Switch Setting ............................................................................................................... 50

12. Digital Tube Display .............................................................................................................53

13. Failure Code ........................................................................................................................ 54

14. Troubleshooting ...................................................................................................................58

APPENDIX ................................................................................................................................76

11

1. General Information

1.1 Indoor units

4-WAY CASSETTE TYPE/PB-700lB

AB092MCERA

AB122MCERA

AB162MCERA

HIGH WALL EEV INSIDE

AS072MGERA AS162MGERA

AS092MGERA AS182MGERA

AS122MGERA AS242MGERA

4-WAY CASSETTE TYPE/PB-950JB

AB182MCERA

AB242MCERA

AB282MCERA

AB302MCERA

AB382MCERA

AB482MCERA

MED ESP DUCT TYPE (80/120Pa)

AD182MZERA

AD242MZERA

AD282MZERA

AD302MNERA

AD382MNERA

AD482MNERA

LOW ESP DUCT TYPE

AD072MLERA

AD092MLERA

AD122MLERA

AD162MLERA

AD182MLERA

AD242MLERA

MED ESP DUCT TYPE (50/96Pa)

AD182MMERA

AD242MMERA

AD282MMERA

AD302MMERA

AD382MMERA

AD482MMERA

HlGH ESP DUCT TYPE

AD182MHERA

AD242MHERA

AD282MHERA

AD302MHERA

AD382MHERA

AD482MHERA

AD722MHERA

AD962MHERA

CONVERTlBLE TYPE

AC092MCERA

AC122MCERA

AC162MCERA

AC182MCERA

AC242MCERA

AC282MFERA

AC302MFERA

AC382MFERA

AC482MFERA

SLIM LOW ESP DUCT

AD072MSERA

AD092MSERA

AD122MSERA

AD162MSERA

AD182MSERA

AD242MSERA

BUILIT-IN FLOOR STANDING

AE072MLERA

AE092MLERA

AE122MLERA

AE162MLERA

AE182MLERA

AE242MLERA

2-WAY CASSETTE/1055IB

AB072MBERA

AB092MBERA

AB122MBERA

AB162MBERA

AB182MBERA

CONSOLE TYPE

AF072MAERA

AF092MAERA

AF122MAERA

AF182MAERA

ROUND-WAY SMART AIR FLOW CASSETTE/ PB-950KC

AB072MRERA

AB092MRERA

AB122MRERA

AB162MRERA

AB182MRERA

AB242MRERA

AB282MRERA

AB302MRERA

AB382MRERA

AB482MRERA

AB602MRERA

DC SLIM LOW ESP DUCT

AD072MSERA(D)

AD092MSERA(D)

AD122MSERA(D)

AD162MSERA(D)

AD182MSERA(D)

AD242MSERA(D)

22

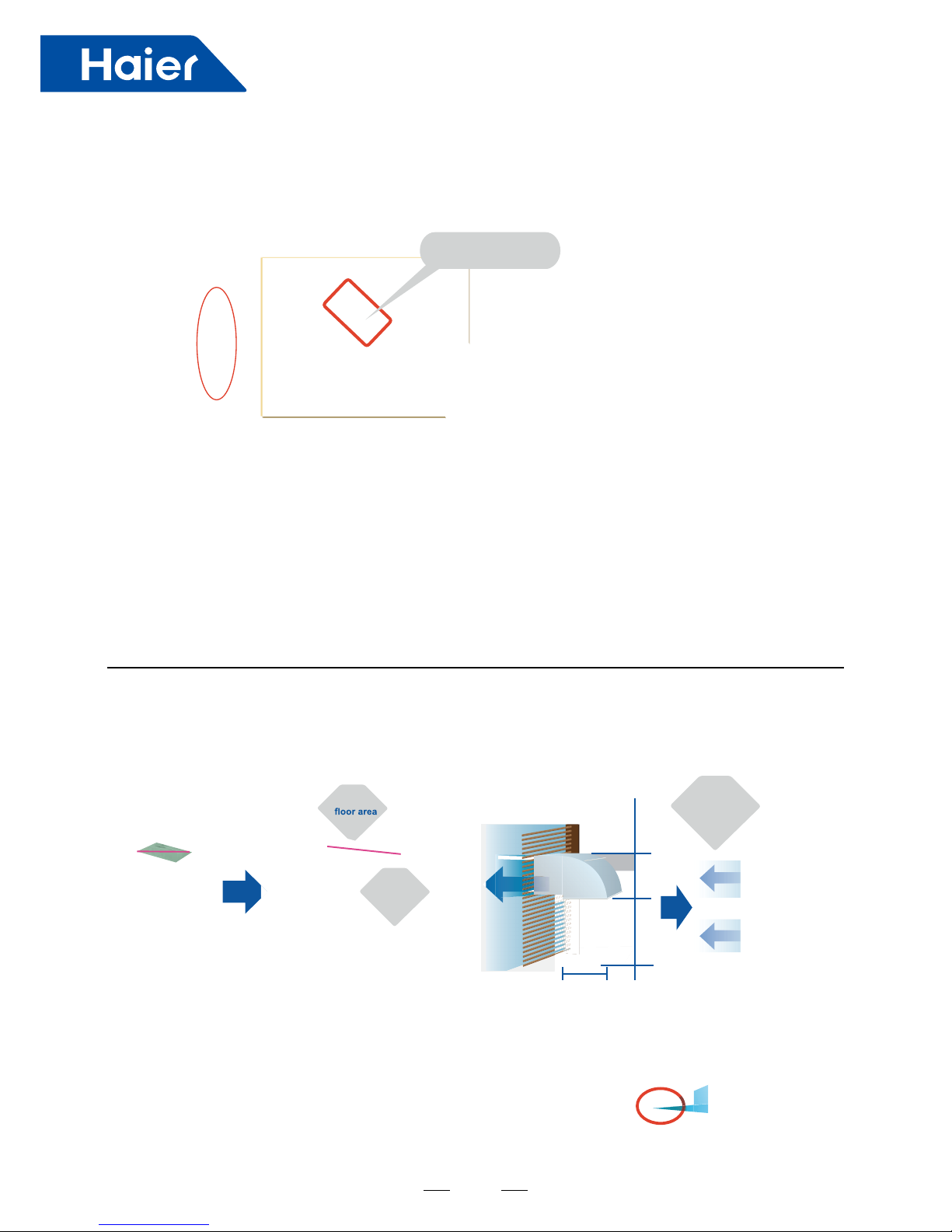

Outdoor structure

(8/10/12HP SIDE DISCHARGE)

More Bigger Outdoor Capacity, More Flexible Application

High efciency DC fan motor Vector inverter control

Large diameter fan

Double pressure sensor

High efciency condenser

Twin rotary DC Inverter compressor

•

DC fan motor with stepless inverer

•

180 degrees sine wave vector control,

•

High precision control, to achieve high

•

570mm big diameter axial ow fan

•

Zigzag design, reduce airow disturbance,

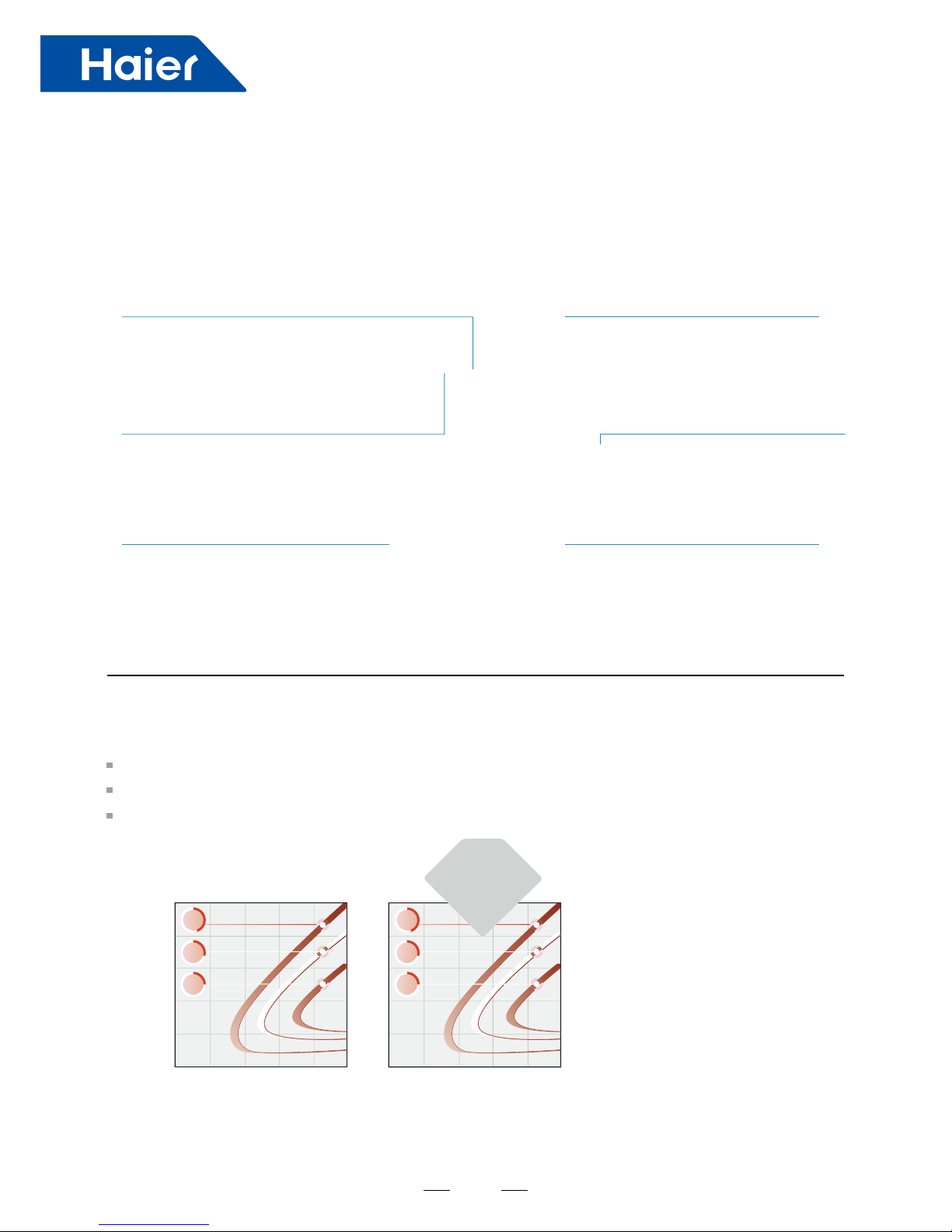

DC fan and fan motor

DC inverter fan motor more higher efciency in part load running

■ 16-stage speed control; high efciency running especially in low speed

■ Efciency increase 45% comparing with AC motor and power input largely decrease big diameter fan

■ 570mm big diameter fan, more big air ow and more higher efciency

AC motor efciency DC motor efciency

100

80

60

40

20

0

100

80

60

40

20

0

0 200 400 600 800 1000 0 200 400 600 800 1000

45

%

85

%

95

%

87.5

%

35

%

25

%

efciency

45%

enhanced

Ø570mm fan

DC motor

control,efciency increase 45% comparing with

AC motor and power input largely decrease

64-bit operation

efciency and lower noise

air volume is bigger, the noise is lower

·

Equipped with high and low voltage

Pressure double sensors

·

Accurate Pressure control, the system run

more smoothly, more energy efciency

·

New type high efciency Ø8 inner

grooved tube

·

New hydrophilic corrugated ssure n,

high efciency

·

High chamber DC INVERTER twin rotary

conmpressor

·

Small vibration, low noise, high energy

effciency

1.2 Features

33

New DC inverter twin rotary compressor

■ Small torque change, good dynamic balance, the system runs stably,

little vibration, low noise, high efciency

■ More higher efciency in part load running

DC FAN

MOTOR

Strong

magnetic

rotor, small

vortex of

refrigerant

Low noise level

Night quiet operation function

Noise can be reduced to 45dB (A)

Low noise operation

■ DC INVERTER compressor, smooth operation, no need frequent start the compressor, effectively reduce the

noise outdoor

■ Vector inverter control, more precise control

■ DC fan motor, motor bracket used the non-resonance structure, ensure smooth running of the motor, reduce

operating noise

■ Big diameter fan, design according to aviation quieter principle

DC motor

High reliability

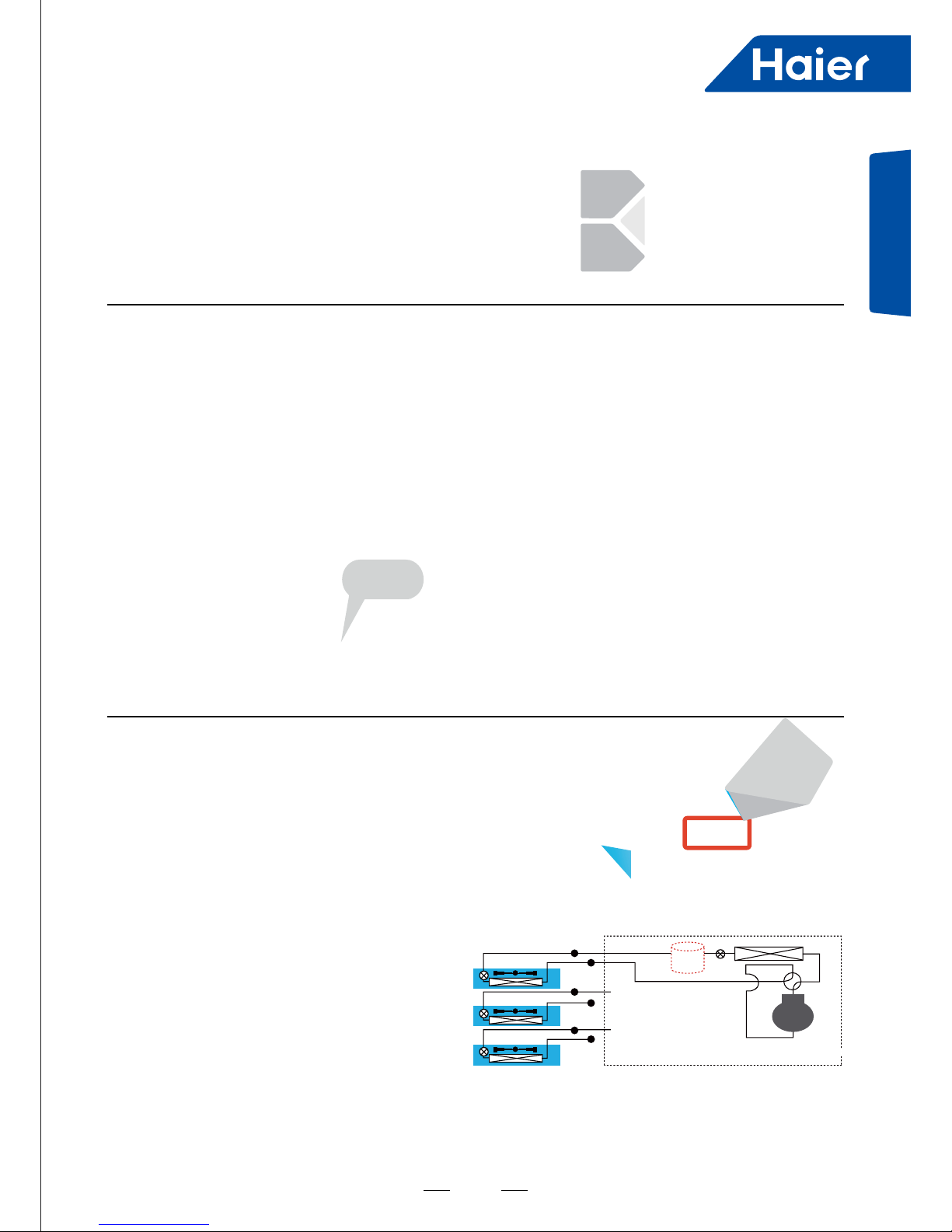

Refrigerant automatically reclaim technology

Set refrigerant automatically reclaim through dip switch,

the refrigerant in indoor and pipe can be automatically

return to outdoor, convenient in maintenance and

reducing waste of refrigerant, reduce customer

maintenance cost, improve the efciency of after-sales

maintenance

Refrigerant control technology

Refrigerant control technology without high pressure

accumulator, reducing the refrigerant volume and

enhancing the running efciency

Outdoor

Indoor

Indoor

Indoor

Without accumulator

Compressor

Press these 2

buttons

5 seconds

General Information

44

High reliability

Air inlet grill design on right side panel

Air inlet grill design, reducing the module temperature and avoid air dust into air conditioner

High and Low Double Pressure Sensor

Double pressure sensor with PID control technology

Together with high speed communication to realize the quick start of compressor and more precise control, the

temperature can be control ±0.5°C

Reducing the module

temperature

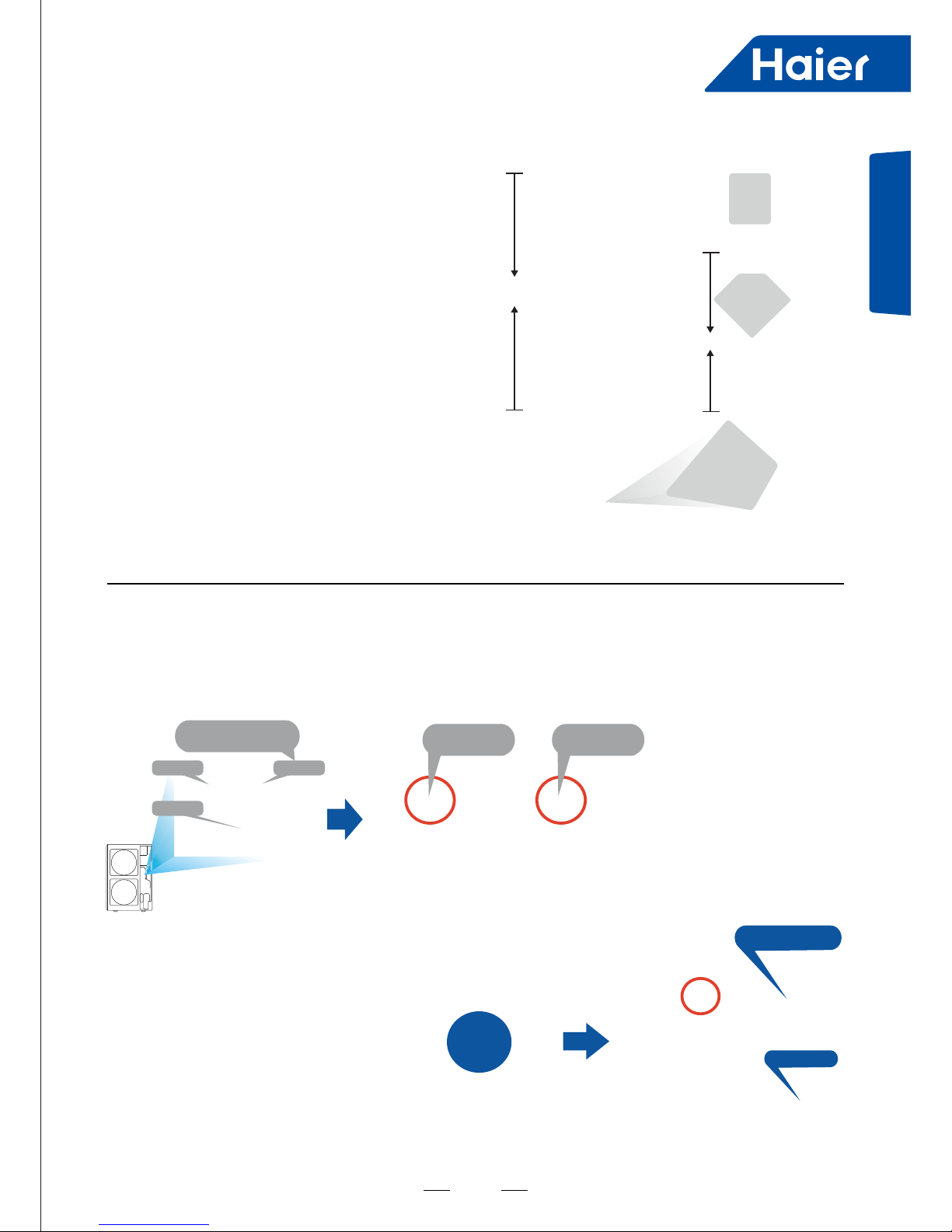

Easy installation

Compact side discharge design,

Big capacity, small oor area

Small oor area, only 0.42m², 43% oor area

can be reduced

Compact side discharge design

No need additional ventilation hood comparing with top

discharge unit

0.745m

2

0.42m

2

43%

reduced

188mm

height

reduced

0.8m

1.8m

0.77m

Good solution

for

narrow space

4 Way pipe connection

Front, rear, right, down 4 way pipe connection, exible installation

55

General Information

Long pipe length, high height drop

■ Total pipe length: 300m

■ Single pipe length: Max. 175m

■ From outdoor to the rst branch pipe: 135m

■

■ Height drop between indoor units: 15m

■ Separate Refrigerant Charging Valve

■ Easy for refrigerant charging

Separate

refrigerant

charging

valve

15m

50m

Single

pipe

length

175 m

length

300

m

Total pipe

Easy service

Parameter display panel

■ The rst original parameter display panel on the side

■ The parameter can be observed directly by opening the protective cover in case of maintenance, to

avoid removing the repair board

Easy maintenance for control

■ The control box is in front, reserving space

Parameter

display

Cover

AC FAN

Control PCB

Main PCB

Traditional products need to

open the front panel or top

control box cover for

maintenance

DC FAN

Control PCB

Maintenance

from the top

Hinge design

Difficult to

maintenance

from the front

From the rst branch to the farthest indoor

door unit: 40m Height drop: 50m (outdoor

above)/40m (outdoor below)

108mm between control box and toppanel,

easy maintenance from the top Control box is

with hinge design, easy to open for maintenance

66

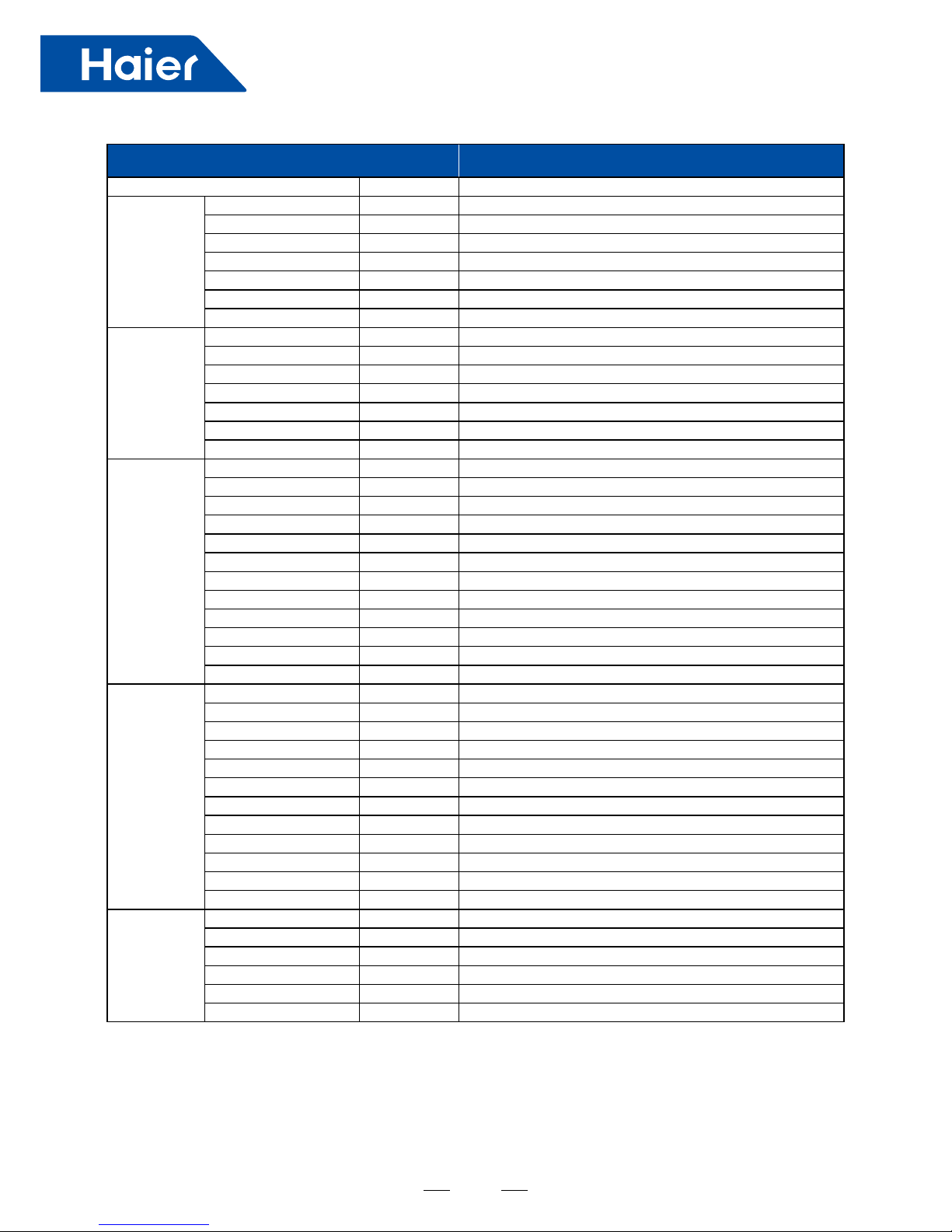

2. Specication

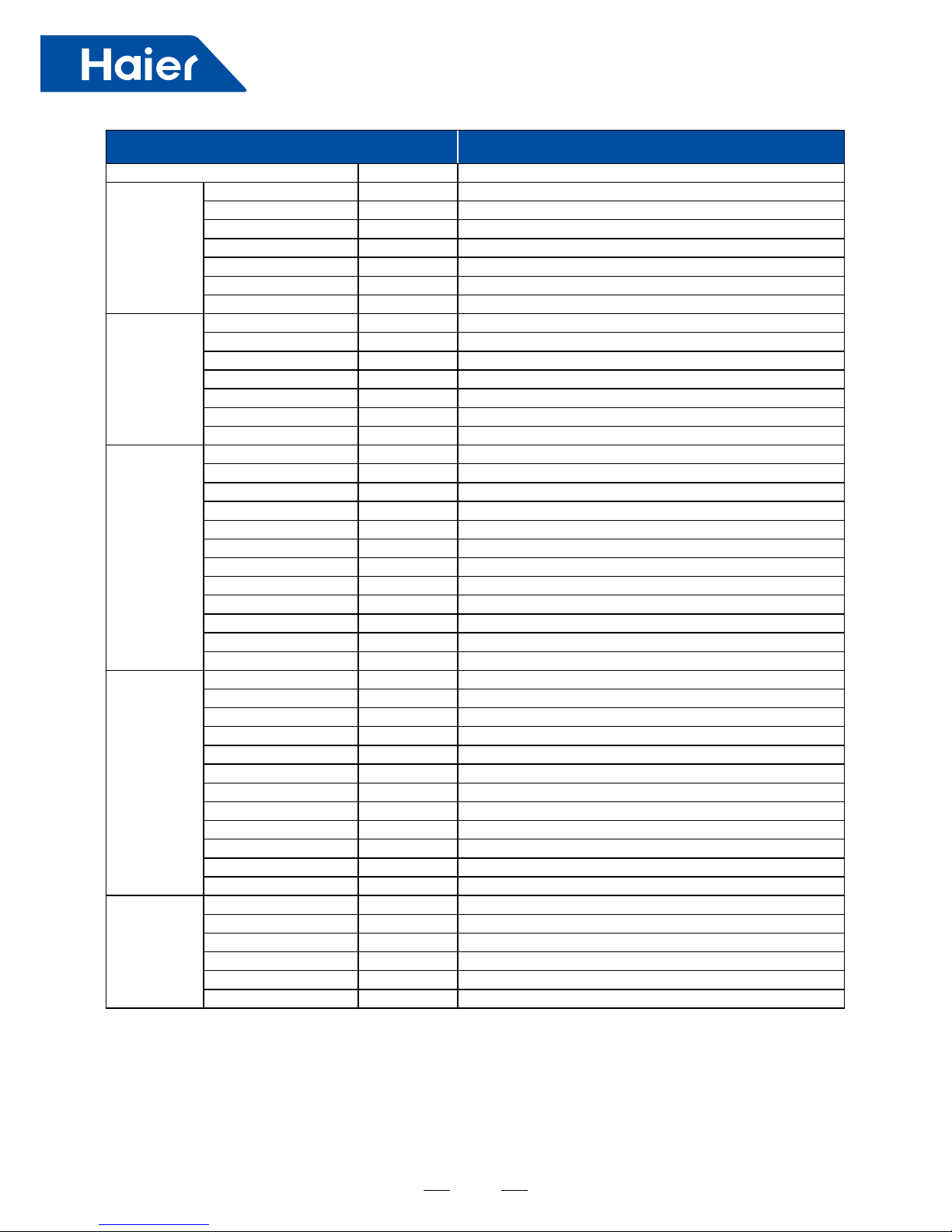

Model AV08NMSETA

Power supply Ph/V/Hz 3/380~400/50/60

Cooling

Rated capacity kW 22.6

Rated capacity kBtu/h 77.1

Rated power input kW 5.79

Max. power input kW 10.42

EER 3.90

Rated current A 9.6

Max. current A 17.2

Heating

Rated capacity kW 25

Rated capacity kBtu/h 85.3

Rated power input kW 5.43

Max. power input kW 9.78

COP 4.60

Rated current A 9

Max. current A 16.2

Compressor

Brand MITSUBISHI ELECTRIC

Model LNB53FCAMC

Type Rotary

Compressor quantity 1 INV

Capacity W 16860

Power Input W 5200

Rated current (RLA) A 15.4

Speed rps 60.0

Crankcase Heater W 60.0

Refrigerant oil brand IDEMITSUKOSAN CO.,LTD

Refrigerant oil type FV50S

Refrigerant oil charge ml 1700.0

Outdoor fan

motor

Brand NIDEC TECHNO

Model SIC-81FW-F1145-1

Voltage 310.0

IP Class IP42

Type DC

Insulation class E

Safe class I

Power Input W 145.0

Output W 200.0

Rated current A 0.6

Capacitor μF /

Speed rpm 147-770

Outdoor fan

Brand SHUNWEI

Model /

Material Plastic

Type Axial

Diameter mm 570

Height mm 202

77

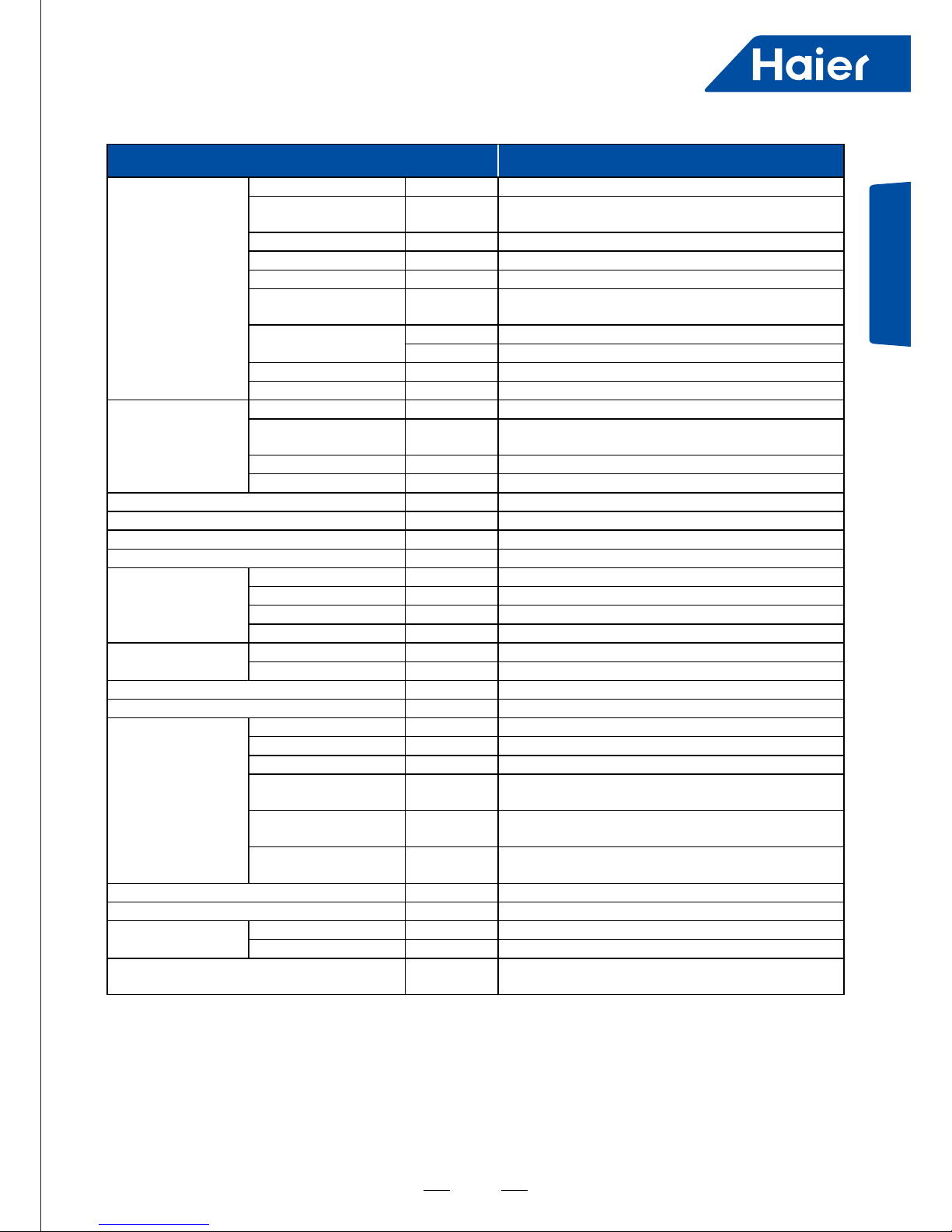

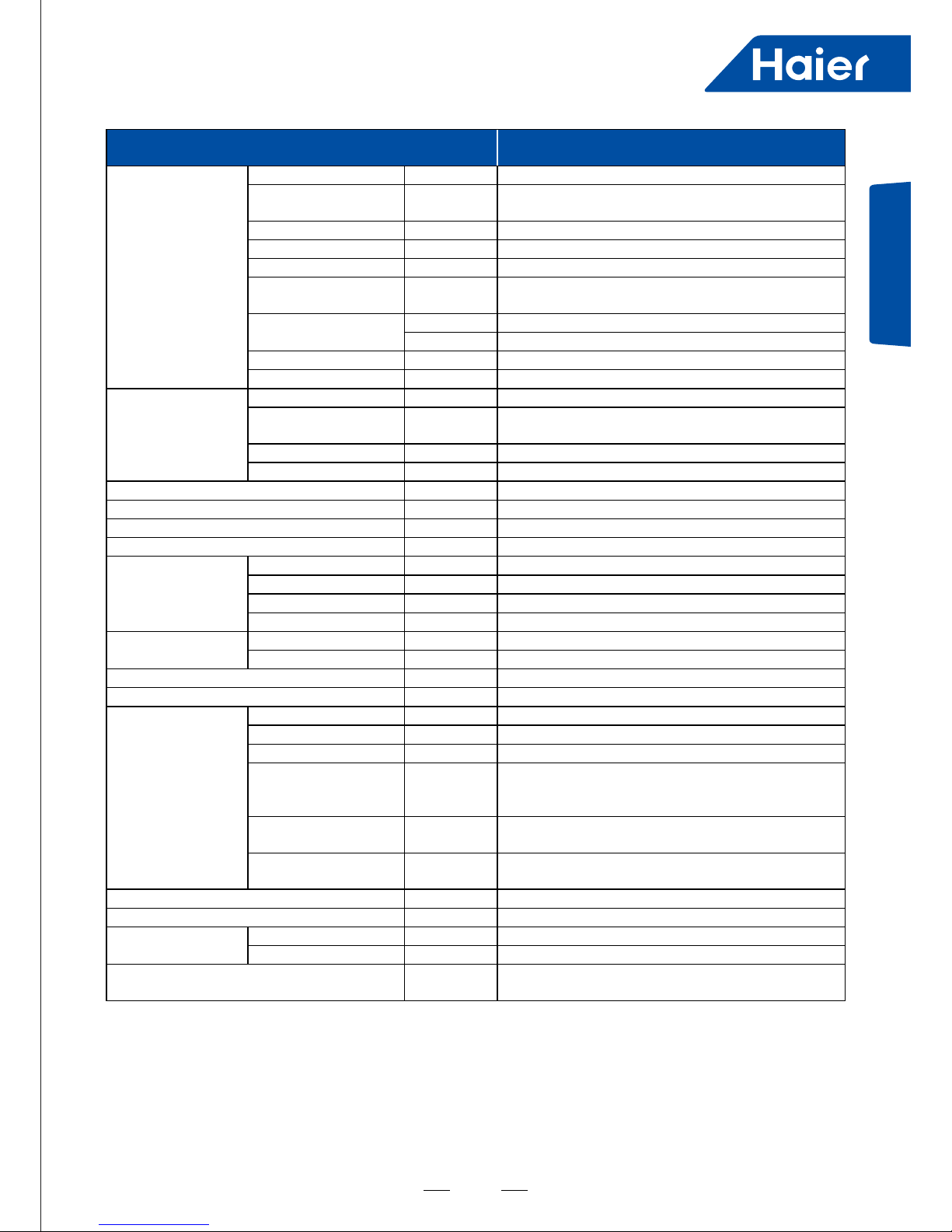

Specication

Model AV08NMSETA

Outdoor coil

Number of rows 2

Tube pitch (a)×row

pitch (b)

mm 19.05×22

Fin spacing mm 1.4

Fin type (code) HYDROPHILIC ALUMINIUM

Fin coating type Optional Clear lacquer

Salt spray test

duration

Hour 168

Tube outside dia.and

type

INNERGROOVE TUBE

mm Ф8

Coil length × height mm 1122×1584

Number of circuits 14

Cabinet coating

Coating type Powder coating

Salt spray test

duration

Hour 72

Sheet metal material Hot zinc plate

Sheet metal thickness mm 1.0

Control panel enclosure IP class Standard IP24

Outdoor air ow m

3

/h 10000

Outdoor sound level (sound pressure level ) dB (A) 55

Outdoor sound level (sound power level ) dB (A) 66

Outdoor unit

Dimension (W*H*D) mm 1050×400×1636

Packing (W*H*D) mm 1150×510×1790

Net weight kg 168

Gross weight kg 183

Refrigerant

Type R410A

Charged volume kg 7.4

Throttle type EXV

Design pressure MPa 4.15

Refrigerant piping

Liquid pipe mm 9.52

Gas pipe mm 19.05

Total pipe lenth m 300

Max. pipe length

(Equivalent/ Actual)

m 175/150

Max.Diff. indoor/

outdoor unit

m

50 (Outdoor higher than indoor)

40 (Indoor higher than outdoor)

Max.Diff. indoor/indoor

unit

m 15

Connectable indoor unit ratio % 50%~130%

Maximum indoor units Piece 13

Connection wiring

Power wiring mm

2

6.0

Signal wiring mm

2

Shield wire: (0.75-2)*2

Operation Range °C

Cooling: -15~43

Heating: -15~21

■ Norminal condition: indoor temperature (cooling): 27DB (°C)/19WB (°C), indoor temperature (heating): 20DB

(°C)

/14.5 WB(°C) Outdoor temperature (cooling): 35DB (°C)/24WB ( °C ), outdoor temperature (heating): 7DB

(°C)

/6WB (°C

)

The noise level will be measured in the third octave band limited values in the semi-anechoic chamber, using a

Real Time Analyser calibrated sound intensity meter. It is a sound pressure noise level.

88

Model AV10NMSETA

Power supply Ph/V/Hz 3/380~400/50/60

Cooling

Rated capacity kW 28

Rated capacity kBtu/h 95.5

Rated power input kW 8

Max. power input kW 14.4

EER 3.50

Rated current A 13.2

Max. current A 23.8

Heating

Rated capacity kW 31.5

Rated capacity kBtu/h 107.5

Rated power input kW 7.5

Max. power input kW 12.4

COP 4.20

Rated current A 12.4

Max. current A 22.3

Compressor

Brand MITSUBISHI ELECTRIC

Model LNB53FCAMC

Type Rotary

Compressor quantity 1 INV

Capacity W 16860

Power Input W 5200

Rated current (RLA) A 15.4

Speed rps 60.0

Crankcase Heater W 60.0

Refrigerant oil brand IDEMITSUKOSAN CO.,LTD

Refrigerant oil type FV50S

Refrigerant oil charge ml 1700.0

Outdoor fan

motor

Brand NIDEC TECHNO

Model SIC-81FW-F1145-1

Voltage 310.0

IP Class IP42

Type DC

Insulation class E

Safe class I

Power Input W 145.0

Output W 200.0

Rated current A 0.6

Capacitor μF /

Speed rpm 147-770

Outdoor fan

Brand SHUNWEI

Model /

Material Plastic

Type Axial

Diameter mm 570

Height mm 202

99

Specication

■ Norminal condition: indoor temperature (cooling): 27DB (°C)/19WB (°C), indoor temperature (heating): 20DB

(°C)

/14.5 WB(°C) Outdoor temperature (cooling): 35DB (°C)/24WB ( °C ), outdoor temperature (heating): 7DB

(°C)

/6WB (°C

)

The noise level will be measured in the third octave band limited values in the semi-anechoic chamber, using a

Real Time Analyser calibrated sound intensity meter. It is a sound pressure noise level.

Model AV10NMSETA

Outdoor coil

Number of rows 2

Tube pitch (a)× row

pitch (b)

mm 19.05×22

Fin spacing mm 1.4

Fin type (code) HYDROPHILIC ALUMINIUM

Fin coating type Optional Clear lacquer

Salt spray test

duration

Hour 168

Tube outside dia.and

type

INNERGROOVE TUBE

mm Ф8

Coil length × height mm 1122×1584

Number of circuits 14

Cabinet coating

Coating type Powder coating

Salt spray test

duration

Hour 72

Sheet metal material Hot zinc plate

Sheet metal thickness mm 1.0

Control panel enclosure IP class Standard IP24

Outdoor air ow m

3

/h 10000

Outdoor sound level (sound pressure level ) dB (A) 58

Outdoor sound level (sound power level ) dB (A) 69

Outdoor unit

Dimension (W*H*D) mm 1050×400×1636

Packing (W*H*D) mm 1150×510×1790

Net weight kg 168

Gross weight kg 183

Refrigerant

Type R410A

Charged volume kg 7.4

Throttle type EXV

Design pressure MPa 4.15

Refrigerant piping

Liquid pipe mm 9.52

Gas pipe mm 22.22

Total pipe lenth m 300

Max. pipe length

(Equivalent/ Actual)

m 175/150

Max.Diff. indoor/

outdoor unit

m

50 (Outdoor higher than indoor)

40 (Indoor higher than outdoor)

Max.Diff. indoor/indoor

unit

m 15

Connectable indoor unit ratio % 50%~130%

Maximum indoor units Piece 16

Connection wiring

Power wiring mm

2

10.0

Signal wiring mm

2

Shield wire:(0.75-2)*2

Operation Range °C

Cooling: -15~43

Heating: -15~21

1010

Model AV12NMSETA

Power supply Ph/V/Hz 3/380~400/50/60

Cooling

Rated capacity kW 33.5

Rated capacity kBtu/h 114.3

Rated power input kW 9.75

Max. power input kW 15.4

EER 3.44

Rated current A 16.4

Max. current A 26

Heating

Rated capacity kW 37.5

Rated capacity kBtu/h 128

Rated power input kW 9.62

Max. power input kW 15

COP 3.90

Rated current A 16.2

Max. current A 25.3

Compressor

Brand MITSUBISHI ELECTRIC

Model LNB53FCAMC

Type Rotary

Compressor quantity 1 INV

Capacity W 16860

Power input W 5200

Rated current (RLA) A 15.4

Speed rps 60.0

Crankcase heater W 60.0

Refrigerant oil brand IDEMITSUKOSAN CO.,LTD

Refrigerant oil type FV50S

Refrigerant oil charge ml 1700.0

Outdoor fan

motor

Brand NIDEC TECHNO

Model SIC-81FW-F1145-1

Voltage 310.0

IP class IP42

Type DC

Insulation class E

Safe class I

Power input W 145.0

Output W 200.0

Rated current A 0.6

Capacitor μF /

Speed rpm 147-770

Outdoor fan

Brand SHUNWEI

Model /

Material Plastic

Type Axial

Diameter mm 570

Height mm 202

1111

Specication

Model AV12NMSETA

Outdoor coil

Number of rows 2

Tube pitch (a)× row

pitch (b)

mm 19.05×22

Fin spacing mm 1.4

Fin type (code) HYDROPHILIC ALUMINIUM

Fin coating type Optional Clear lacquer

Salt spray test duration Hour 168

Tube outside dia.and

type

INNERGROOVE TUBE

mm Ф8

Coil length × height mm 1122×1584

Number of circuits 14

Cabinet coating

Coating type Powder coating

Salt spray test duration Hour 72

Sheet metal material Hot zinc plate

Sheet metal thickness mm 1.0

Outdoor air ow m

3

/h 10000

Outdoor sound level (sound pressure level ) dB (A) 60

Outdoor sound level (sound power level ) dB (A) 71

Outdoor unit

Dimension (W*H*D) mm 1050×400×1636

Packing (W*H*D) mm 1150×510×1790

Net weight kg 168

Gross weight kg 183

Refrigerant

Type R410A

Charged volume kg 7.4

Throttle type EXV

Design pressure MPa 4.15

Refrigerant piping

Liquid pipe mm 12.7

Gas pipe mm 25.4

Total pipe lenth m 300

Max. pipe length

(Equivalent/ Actual)

m 175/150

Max.Diff. indoor/outdoor

unit

m

50 (Outdoor higher than indoor)

40 (Indoor higher than outdoor)

Max.Diff. indoor/indoor

unit

m 15

Connectable indoor unit ratio % 50%~130%

Maximum indoor units Piece 16

Connection wiring

Power wiring mm

2

16.0

Signal wiring mm

2

Shield wire:(0.75-2)*2

Operation range °C

Cooling: -15~43

Heating: -15~21

■ Norminal condition: indoor temperature (cooling): 27DB (°C)/19WB (°C), indoor temperature (heating): 20DB

(°C)

/14.5 WB(°C) Outdoor temperature (cooling): 35DB (°C)/24WB ( °C ), outdoor temperature (heating): 7DB

(°C)

/6WB (°C

)

The noise level will be measured in the third octave band limited values in the semi-anechoic chamber, using a

Real Time Analyser calibrated sound intensity meter. It is a sound pressure noise level.

1212

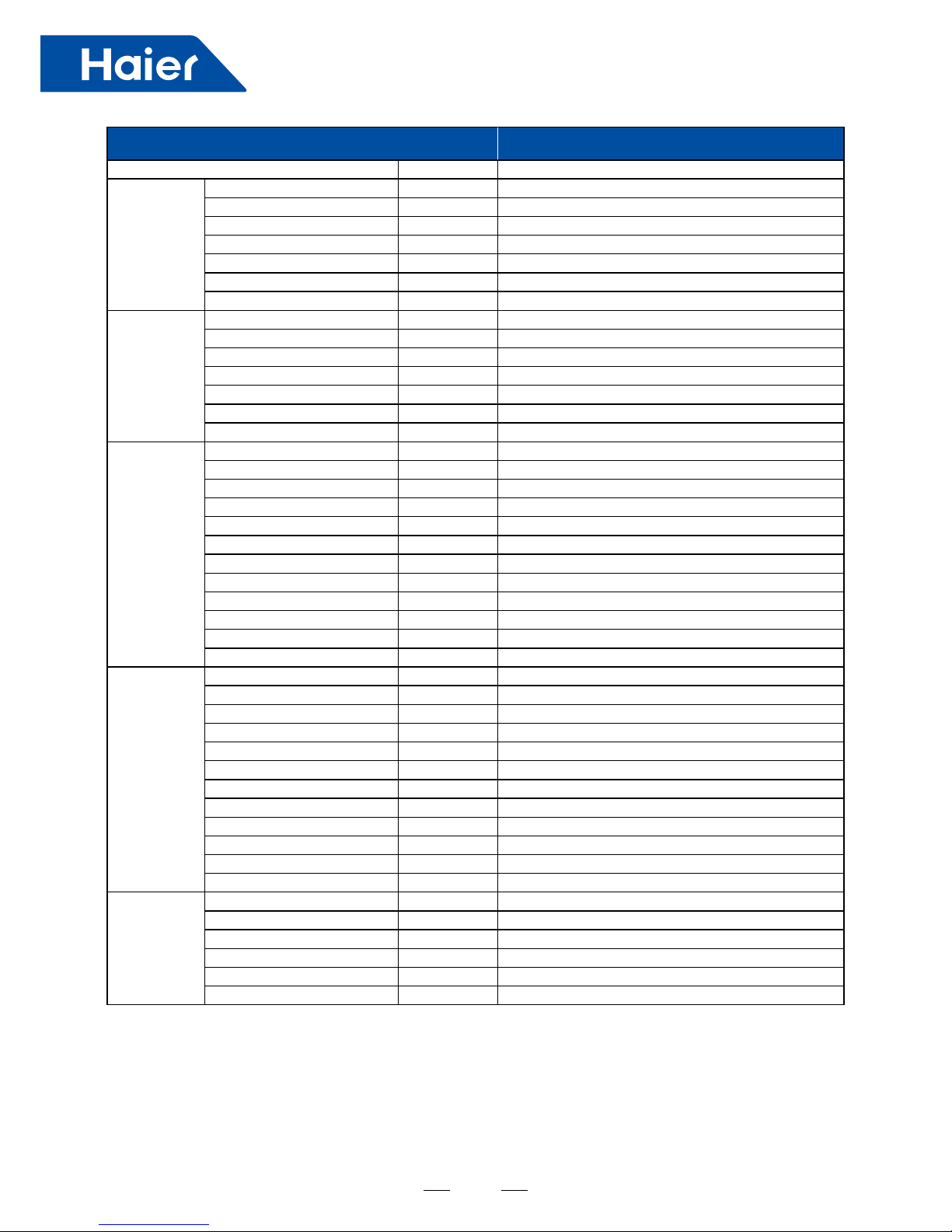

3. Refrigerant Circuit

Ambient temp. sensor Ta

Electronic expansion valve PMV

Spray valve SV2

Suction temperature sensor Ts

Unload valve SV1

Discharging temperature sensor Td

Gas pipe valve

Oil temperature sensor Toil

Ambient temp. sensor Ta

Gas pipe valve

1313

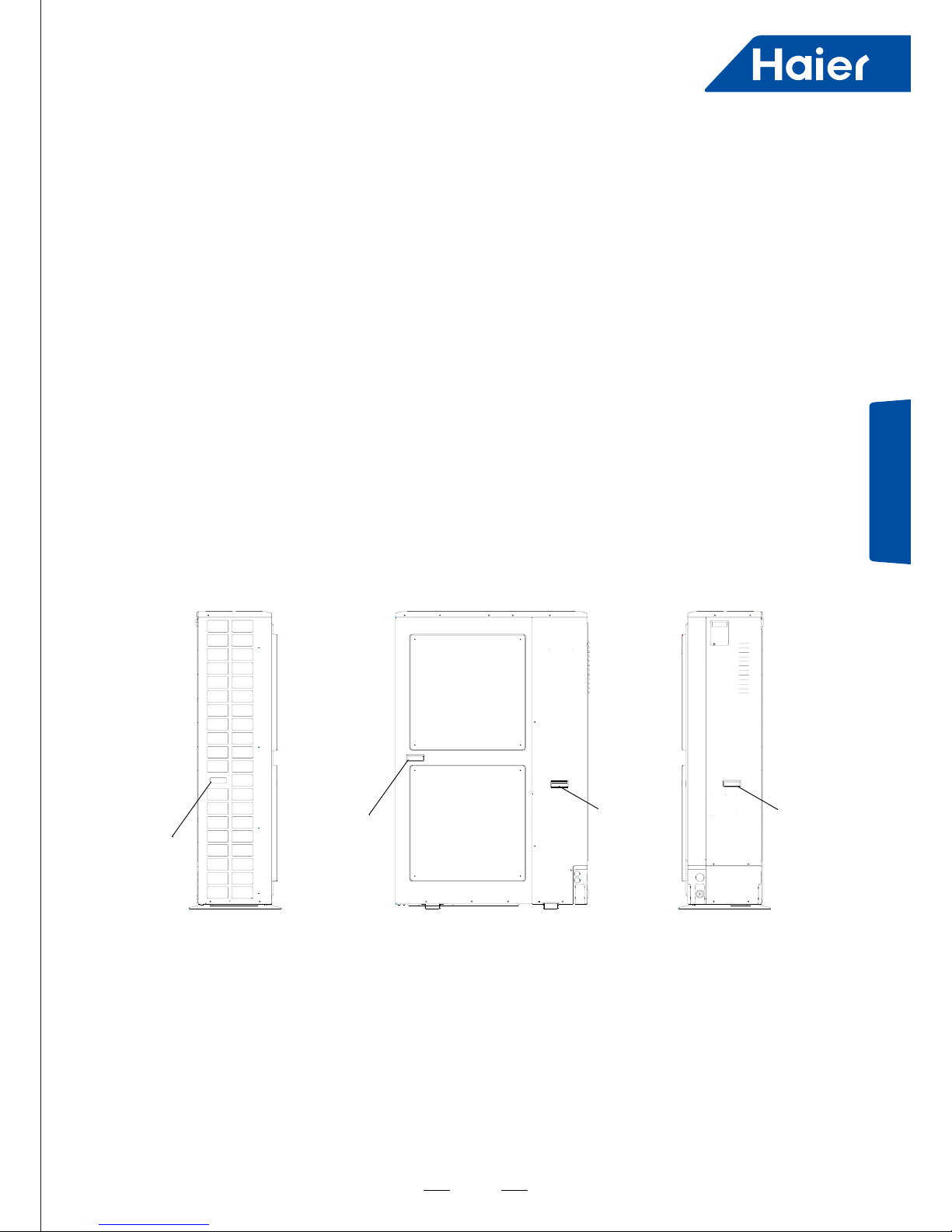

Dimension

4. Dimension

1050

D

1414

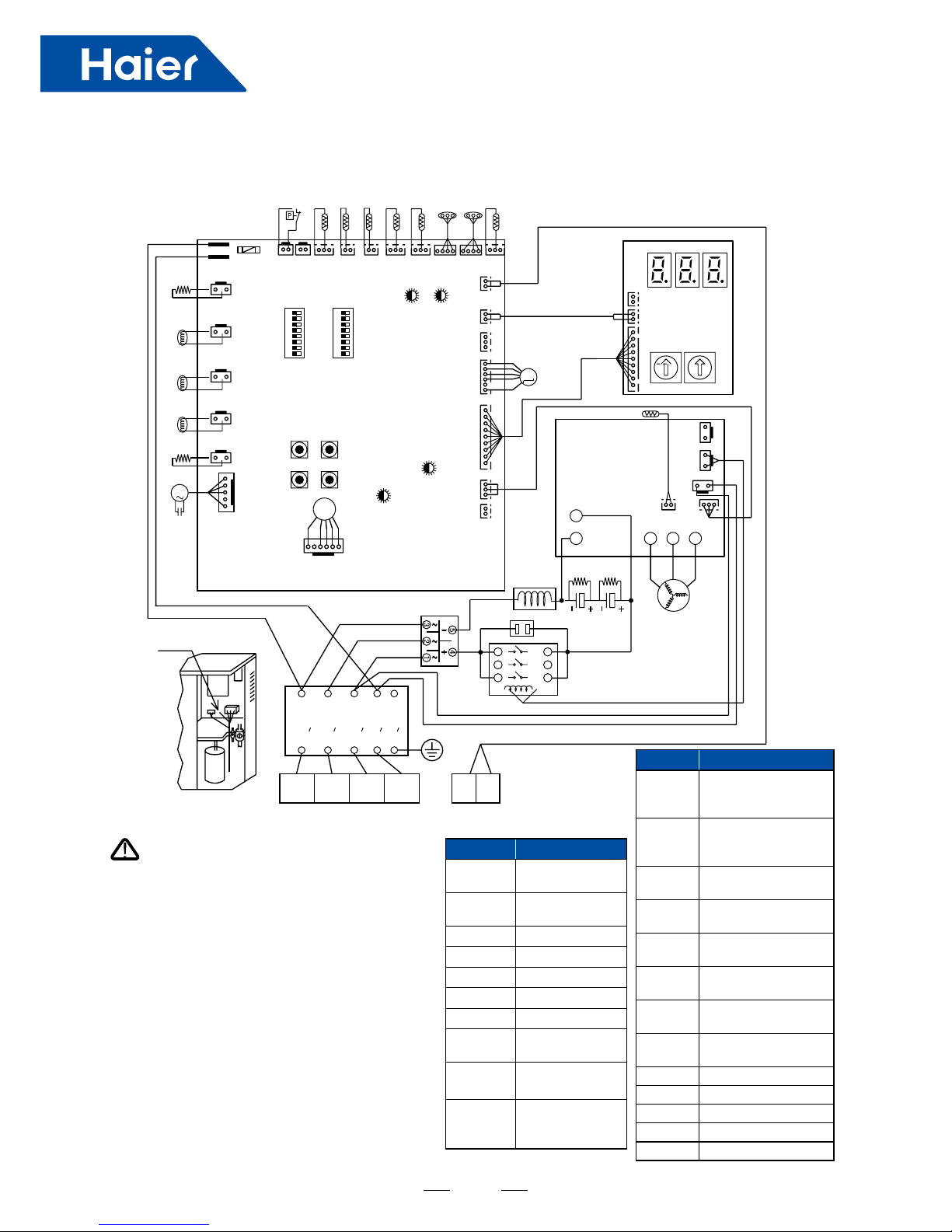

SYMBOL

Notes

Please power off rstly for about 10 minutes

before checking control box, and make sure the

voltage between P and N below 20V.

• Please check the power rstly before test, and

make sure the crankcase heater powering on for

12 hours at least to protecting compressor.The

switch BM1-1 is used for locking the indoor units

number, the initial situation is "OFF". After power on,

the display board will display【U**】,"**"indicates

the number of indoor units that the outdoor unit

can communicate with. If it can match the actual

number of indoor units, please change "OFF" to

"ON", or else x the communication problem rstly.

Forbid connecting the power wire to the "P" and "Q",

otherwise the control board will be damaged.Please

make sure the earth wire connecting the grounding

hole on the electric box rmly.

Symbol Signication

HEATER,

2

Crankcase

heater

SV1

Unloading

valve

SV2 Spray valve

4WV 4-way valve

CA Capacitor

ACFAN2 AC fan motor

DCFAN1 DC fan motor

HPS

High pressure

switch

Td

Discharging

temp. sensor

Te1, 2

Defrost

temperature

sensor

Symbol

Signication

Ts

Suction

temperature

sensor

Ta

Ambient

temperature

sensor

Pd

High pressure

sensor

Ps

Low pressure

sensor

Toil

Oil temperature

sensor

EEV

Electronic

expansion valve

Tn

IPM temperature

sensor

CB1, 2

Electrolytic

capacitor

R Red

W White

BL Blue

B Black

Y Yellow

5. Wiring Diagram

L1 L2 L3 N E

L1 L2 L3 N E

~

~

~

T1

T2

T3

L1

L2

L3

L1 L2 L3 N

PQ

M

M

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

M

HPS Td Te1 Te2 Ts Ta Ps Pd Toil

6.3A 250VAC

FUSE1

CN1 CN2 CN3 CN4 CN5 CN6 CN7 CN29 CN28 CN30

CN26

CN18

CN17

CN16

CN25

ACFAN2

HEATER2

SV2

SV1

4WV

HEATER

CA

CONTROL BOARD

SW1

LED1

DCFAN1

LED3

LED4 LED2

SW2

SW3

SW4

BM1 BM2

ON

ON

CN21

CN9

CN20

CN8

CN24

CN10

CN11

0150513195

LD1 LD2 LD3

CN32

CN31

CN30

LED

DISPLAY

SW01 SW02

INV Board

Tn

CN7 CN8

CN2

CN3

CN1

U V W

P

N

EEV

R W B

B

BB

B

B

W

W

W

W

W

PTC

CB1 CB2

Y

Y

R1 R2

REACTOR

R

COMP

AC Contactor

Earth Wire

Noise Filter

R W BL B

WARNING

1515

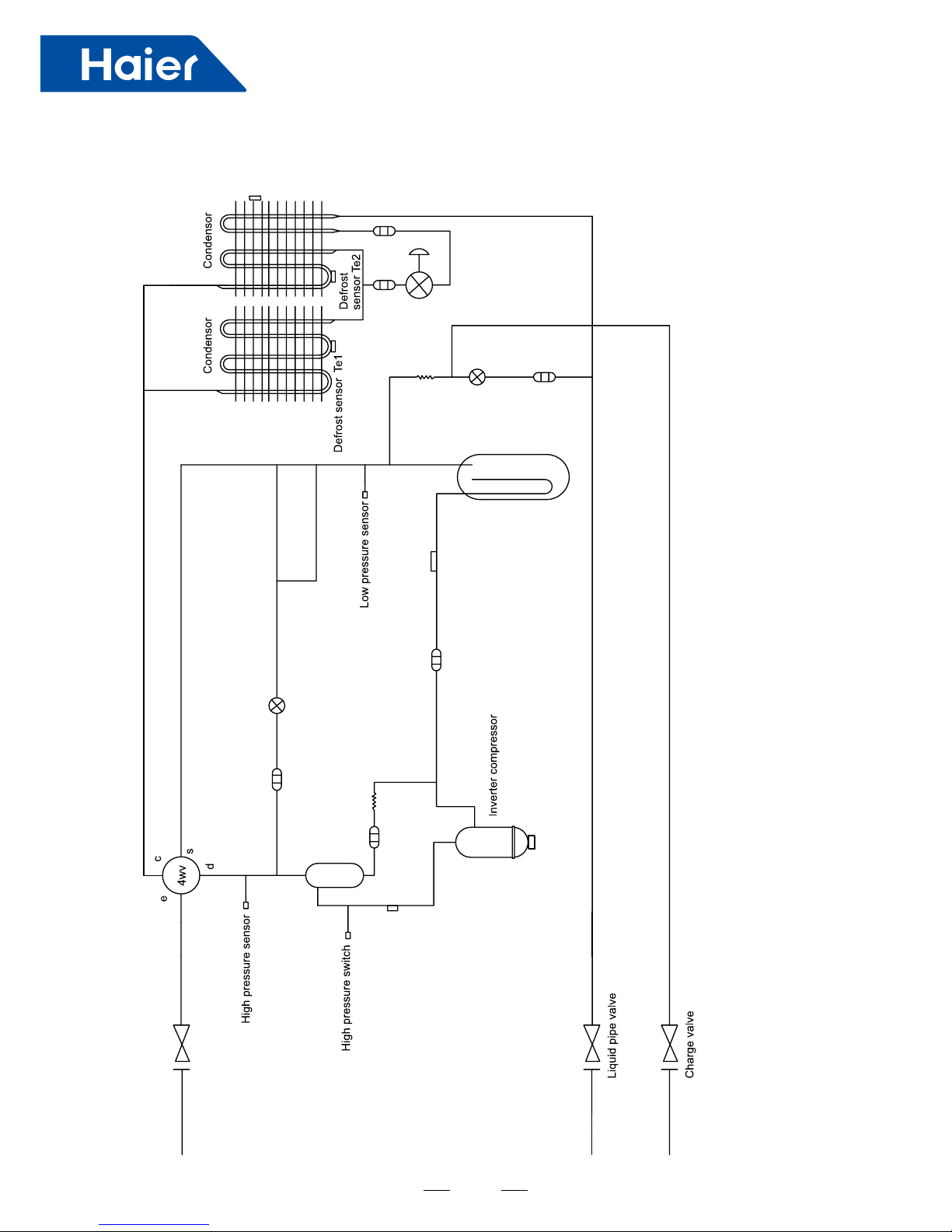

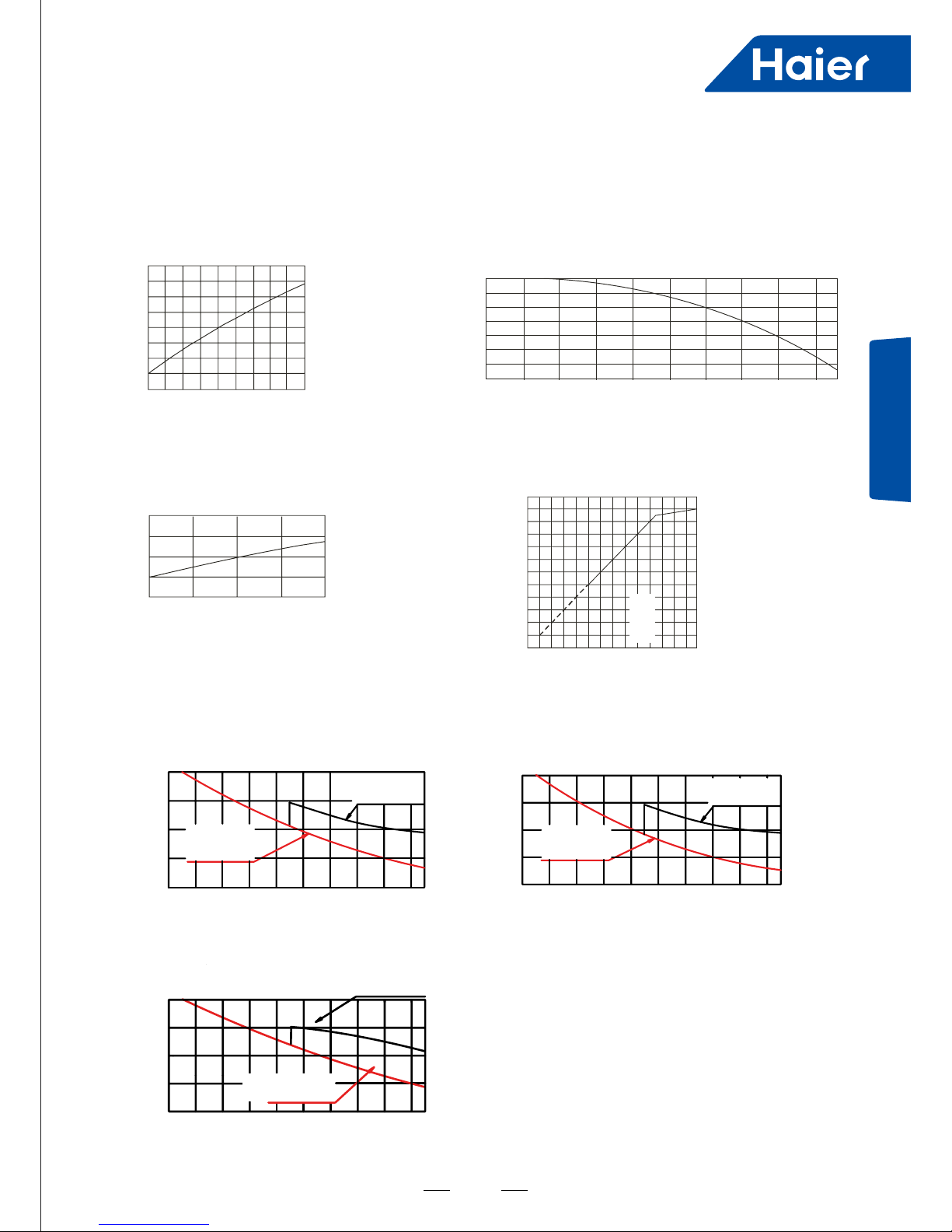

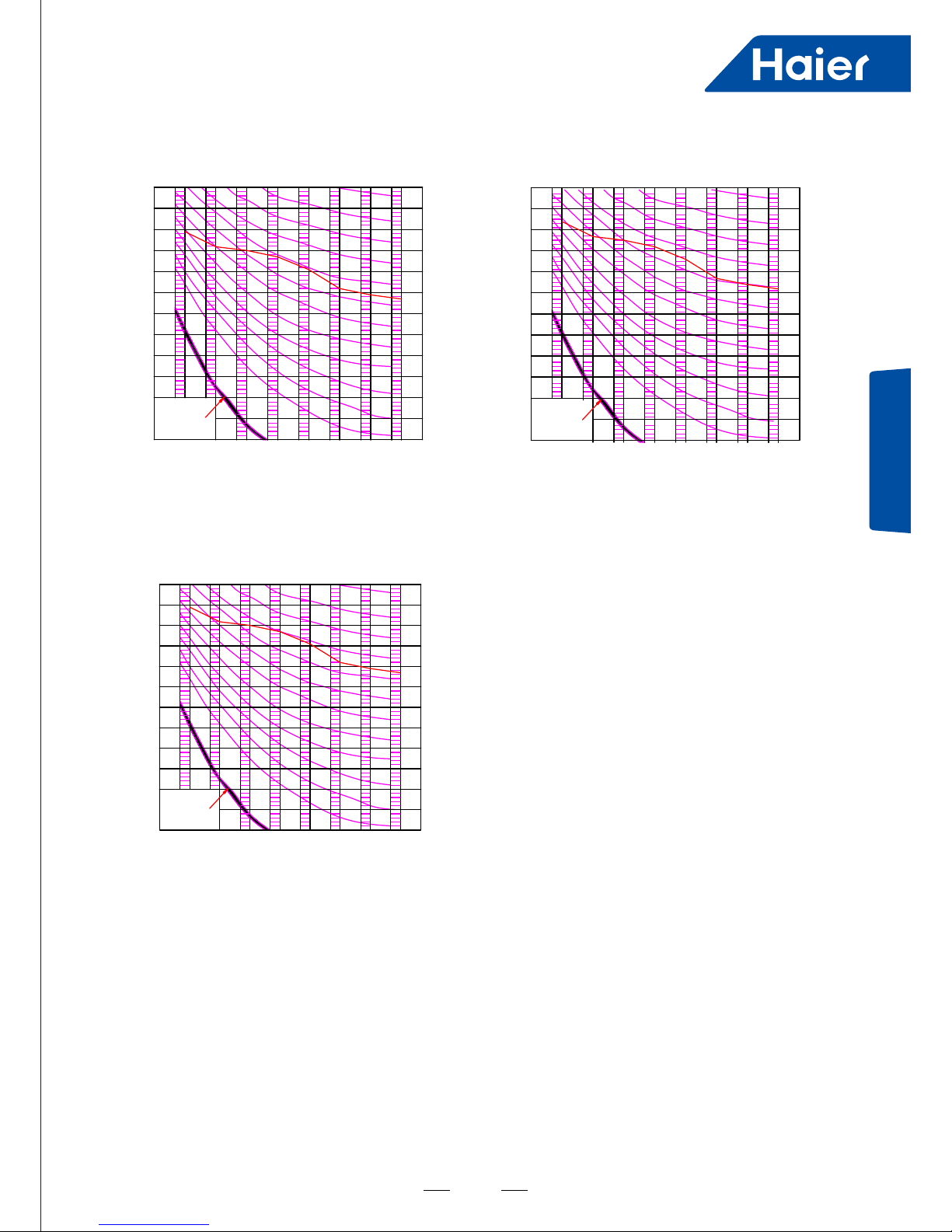

Performance Curves

(1) Calculation methed of refrigerating capacity----refrigerating capacity to be known=refrigerating

capacity*(A*B*C*D*E)W

E. Fall of refrigerant pipe of indoor and outdoor unit, capacity compensation value of pipe length

C. Capacity modication value under airow variation

rate of indoor unit group (only fro duct unit)

A. Capacity compensation value of indoor

air wet-bulb temperature condition

B. Capacity compensation value of outdoor

air dry-bulb temperature condition

D. Capacity compensation suitable for

total capability of indoor unit group

6. Performance Curves

1.2

1.1

1.0

0.9

0.8

15 20 24

Indoor air dry-bulb temperature (°C )

Capacity modication value

1.2

1.1

1.0

0.9

Outdoor air wet-bulb temperature (°C )

Capacity modication value

-5 200 255 3010 3515 40 43

1.1

1.0

0.9

80 90 100 110 120

Airow variation rate (%)

Capacity modication value

120

100

100 120 130

80

60

40

20

20

40 60 80

0

Total capacity of indoor unit group (%)

Standard

capacity

liquid pipe

: φ12.7

gasp ipe

:φ31.8

Single-way pipe length m

)

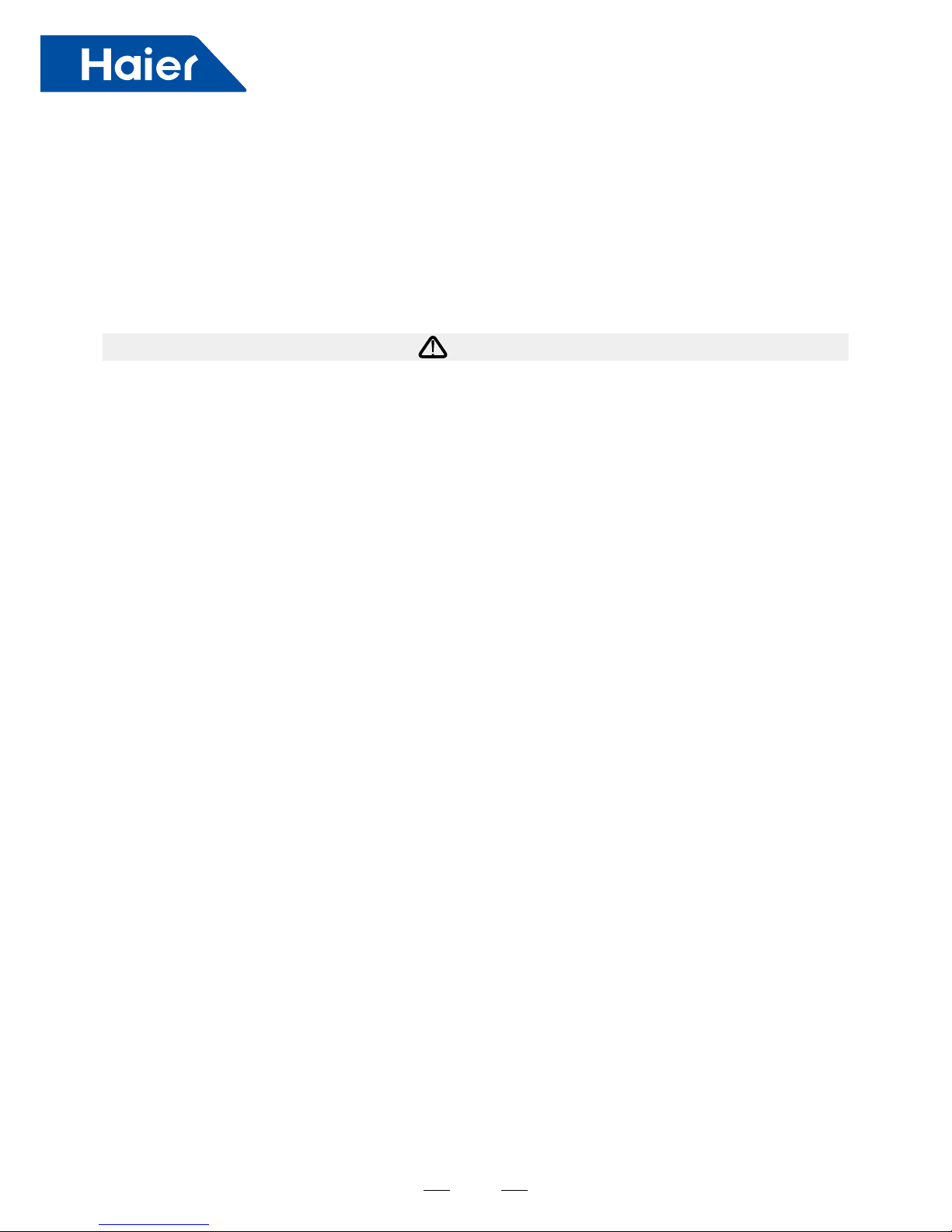

AV12NMSETA

)

Capacity modication value

1.00

0.95

0.90

0.85

0.80

100

120

140

160

180

20

40 60 80

0

Liquid pipe: φ12.7

Gas pipe : φ25.4

Liquid pipe: φ15.88

Gas pipe : φ28.58

Single-way pipe length (m)

AV12NMSETA

Capacity modication value

1.00

0.95

0.90

0.85

0.80

100

120

140

160

180

20

40 60 80

0

Liquid pipe: φ12.7

Gas pipe : φ22.22

Liquid pipe: φ9.52

Gas pipe : φ19.05

Single-way pipe length (m)

AV08NMSETA

Liquid pipe: φ12.7

Gas pipe : φ25.4

Liquid pipe: φ9.52

Gas pipe : φ22.22

Capacity modication value

1.00

0.95

0.90

0.85

0.80

100

120

140

160

180

20

40 60 80

0

Single-way pipe length (m)

AV10NMSETA

1616

Notes:

• The refrigerant pipe should be thickened when the single way length is over 90m.

• When in cooling mode, outdoor is lower than indoor; or when in heating mode, outdoor is higher than indoor, the

compensation factor should be decreased the below value from the above gure.

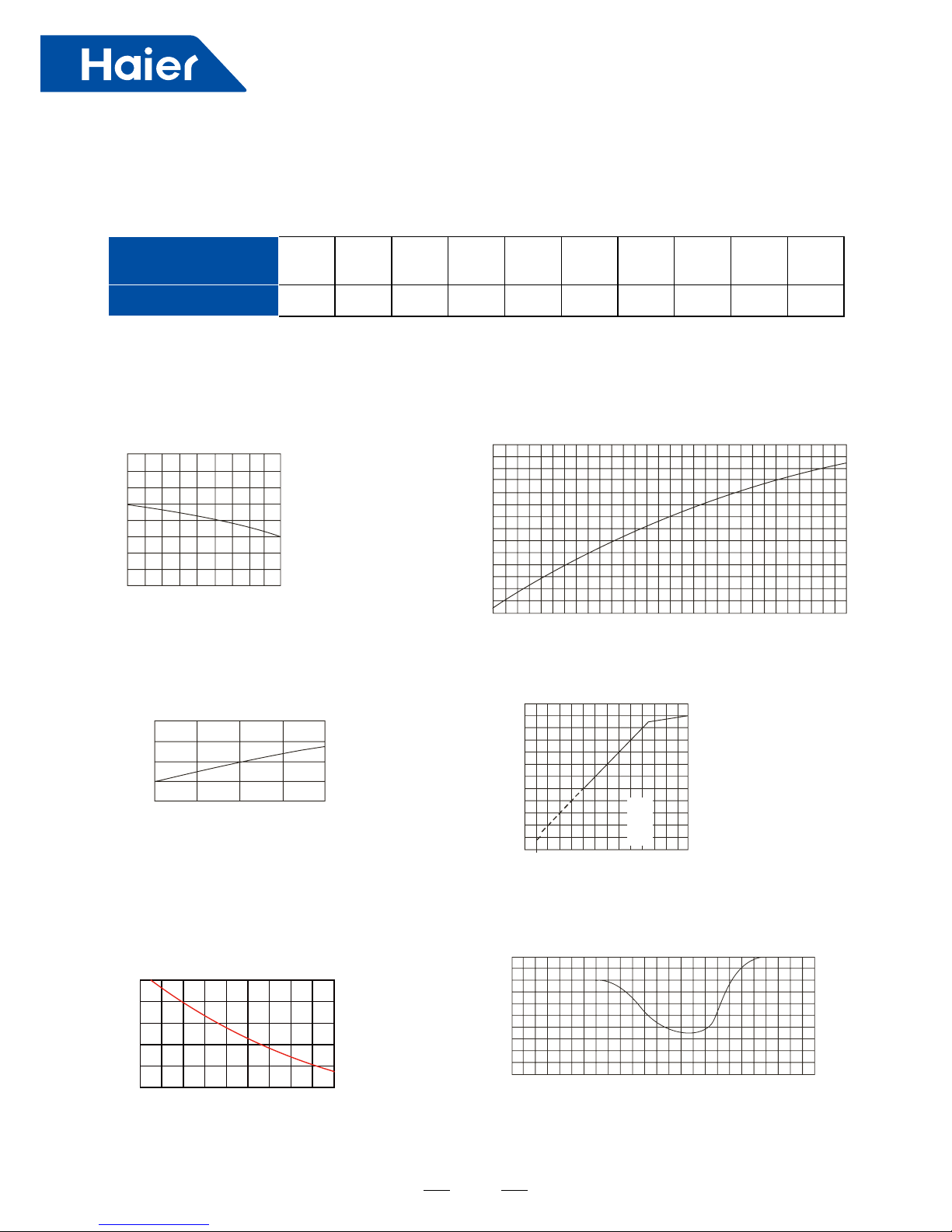

(2) Calculation method of refrigerating capacity----heating capacity to be known=refrigerating

capacity*(A*B*C*D*E*F)W

Vertical height drop

between indoor and

outdoor

5m 10m 15m 20m 25m 30m 35m 40m 45m 50m

Adjustment factor 0.003 0.006 0.009 0.012 0.015 0.018 0.021 0.024 0.027 0.030

A. Capacity compensation value of indoor

air dry-bulb temperature condition

C. Capacity modication value under airow variation

rate of indoor unit group (only fro duct unit)

B. Capacity compensation value of outdoor air

wet-bulb temperature condition

D. Capacity compensation suitable for

total capability of indoor unit group

E. Capacity compensation value of pipe

length between outdoors

F. Capacity compensation value for defrost

capability of outdoor heat exchanger

1.2

1.2

1.1

1.0

0.9

0.8

15 20 24

Indoor air dry-bulb temperature (℃)

1.1

1.0

0.7

0.9

0.6

0.8

0.5

-15 -10 -5 0

Outdoor air wet-bulb temperature (℃)

5

10 15

1.1

1.0

0.9

80 90 100 110 120

Airow variation rate (%)

Capacity modication value

120

100

100 120 140

80

60

40

20

20

40 60 80

0

Total capacity of indoor unit group (%)

Standard

capacity

Capacity modication value

Capacity compensation value

All the modules in the same

Single-way pipe length (m)

1.00

0.98

0.96

0.94

0.92

0.90

0

20 40 60 80 100 120

140

160

180

Capacity compensation value

Outdoor air wet-bulb temperature (℃)

1.0

0.9

0.8

-15 -10 -5 0 5 10

1717

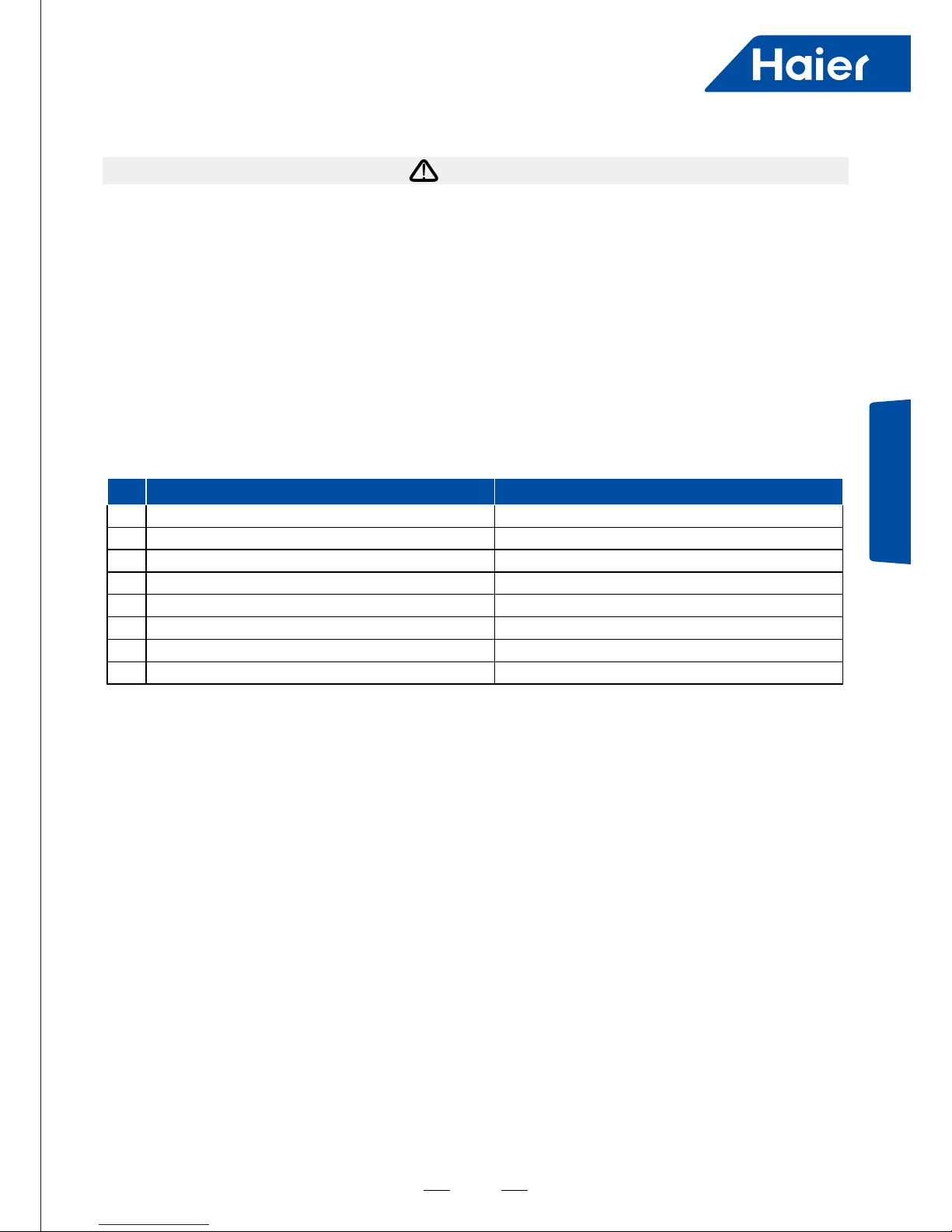

Noise Level

7. Noise Level

AV08NMSETA

H

Octave band sound pressure level dB (A

)

Limit of

audible

continuous

noise

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-20

NC-30

NC-40

NC-50

NC-60

Octave band center frequency Hz

AV10NMSETA

Octave band sound pressure level dB (A

)

Limit of

audible

continuous

noise

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-20

NC-30

NC-40

NC-50

NC-60

Octave band center frequency Hz

H

AV12NMSETA

Octave band sound pressure level dB (A

)

Limit of

audible

continuous

noise

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-20

NC-30

NC-40

NC-50

NC-60

Octave band center frequency Hz

H

1818

8. Outdoor Installation

■ This manual should always be accessible and close to this air condition equipment.

■ There are two types of indications, "WARNING" and "CAUTION". The indication preventing from death

or heavy injury is listed as "WARNING". Even the indication listed as "CAUTION " may also cause serious

accident. Both of them are related to safety, and should be strictly followed.

■ After installation and start-up commissioning, please handover the manual to the user. The manual should be

well kept in safe place and close to the unit.

■ The installation or the maintenance should be performed by an authorized agency. The wrong operation of this air

condition equipment may cause water leakage, electric shock or re.

■ Please install the unit on the top of a solid foundation or structure which is strong enough to support the unit.

■ The installation of this air condition equipment should follow local construction codes.

■ Use the right cable size, secure the terminal rmly, organize the cables well and make sure no tension is added

on cables. Cable insulation should not be damaged. The incorrect installation may lead to overheat or re.

■ When installing or moving the unit, the refrigerant system should be vacuumed and recharged with R410A

refrigerant. If any other gas enters the system, it may lead to abnormal high pressure which may cause damage

or injury.

■

Please use the proper manifolds or branches during the system installation. The wrong parts may cause

refrigerant leakage.

■ Keep the drain pipe away from toxic gas vents to prevent possible pollution of indoor environment.

■ During or after the installation, please check whether there is refrigerant leakage. If any leakage, please take

any measures for ventilation. The refrigerant may be toxic at some concentration levels.

■ The unit is not explosion-proof. Please keep it away from ammable gases.

■ The drain pipe should be installed per this manual to ensure proper drainage. The pipe should be well insulated

to avoid condensation. Wrong installation may lead to water leakage.

Both liquid pipe and the gas pipe should be also well insulated. Not enough insulation may lead to system

performance deterioration or humidity formation.

■ This air condition equipment is not intended to be operated by persons with lack of experience and training,

unless they have supervision or instruction concerning use of this air condition equipment.

■ Please keep children away from this air condition equipment.

WARNING

1919

Outdoor Installation

■ Grounding wire should be connected with the grounding bar. The grounding wire can not be connected to the gas

pipe, water pipe, lightening rod or the telephone grounding wire. Improper grounding may cause

electric shock.

■ Units installed on roof should have appropriate access and handrail.

■ Use the wrench to fasten the nut and are at proper torque. Excessive torque may cause ared section to broke

leading to refrigerant leakage.

■ After refrigerant pipe installation, please take nitrogen leakage test to avoid refrigerant leakage.

■ R410A is the only permitted refrigerant.

■ To avoid mischarging wrong refrigerant, the check valve diameter is changed for R410A. To strengthen the pipe,

the ared pipe dimension is also changed. Please use R410A specied tools as shown below.

R410A specied tools Remarks

1

Gauge manifold Range: HP >4.5MPa, LP >2MPa

2

Charge hose Pressure: HP:5.3MPa, LP:3.5MPa

3

Electronic weight for charging R410A No other means permitted

4

Torque wrench

5

Flare tool

6

Copper pipe gauge for adjusting projecting margin

7

Vacuum pump tting Vacuum pump must be equipped with check valve

8

Leakage detector Only Helium detector permitted

When charging refrigerant, the refrigerant must be in liquid state from the tank.

■ To prevent EMC interference on other appliances, please keep indoor unit, outdoor unit, power cable and

connecting wire at least 1m away from those appliances .

■ Fluorescent lamp (reverse phase or rapid start type) may interfere the remote controller's signal. Please install

indoor unit away from uorescent lamp. The farther the better.

For installation, please review the items below:

■ Is the connected units quantity and the total capacity in the allowable range?

■ Is the refrigerant pipe length in the limited range?

■ Is the pipe size proper? And if the pipe installed horizontally?

■ Is the branch pipe installed horizontally or vertically?

■ Is the additional refrigerant counted correctly and weighed by the standard balance?

■ Is there refrigerant leakage?

■ Is all the indoor power supplies can be on/off simultaneously?

■ Is the power voltage in compliance with the data marked on the rating label?

■ Is the address of indoors has been set?

CAUTION

2020

(1) Before installation

1) Before installation, check if the model, power supply, pipe, wires and parts purchased respectively are correct.

2) Check if the indoors and outdoors can be combined as the following.

Outdoor Indoor

Capacity (X 100W) Indoor Qty Total indoor capacity (X 100W)

AV08NMSETA 13 113~293

AV10NMSETA 16 140~364

AV12NMSETA 16 167~436

Air-conditioner can't be installed in the place with inammable gas. Or it will cause re

hazard.

The unit should be installed at the place where the cold/hot air or noise will not interfere

the neighbours.

The unit should be installed at the place with good ventilation. No obstacle at the air

inlet/outlet. And no strong wind blows the unit.

The installation space refers to the latter info.

The unit should be installed at the strong enough place. Or it will cause vibration and

noise.

The place where the water can ow uently.

The place where no other heat source will affect the unit.

Pay attention to the snow against clogging the outdoor.

In installation, install the anti-vibration rubber between the unit and the bracket.

The unit is better not be installed at the below places, or it will cause damage.

The place where there is corrosive gas (spa area etc).

The place blowing salty air (seaside etc).

Exists the strong coal smoke.

The place with high humidity.

The place where there is device emitting Hertzian waves.

The place where voltage changes greatly.

(2) Installation place selection

2121

Outdoor Installation

(3) Transportation and hoisting

Hoisting

■ Please remove the outdoor unit to the installation location as far as possible near place befor open the packaging.

■ Forbid on the equipments to place anything, need to use 2 ropes while promoting outdoor.

■ Please according to following way hoisting outdoor:

■ Ensure that the outdoor unit when hosting the level to rise slowly.

■ Do not remove the packaging.

■ When hoisting do not have to tie up the elevator to the unit hits on the packaging and the outside wrapping.

■ When hoisting exterior must use the suitable protection.

Handling

Before the installation, outdoor do not deposit any material, otherwise likely has the re or the accident.

When handling unit, please operate as shown in the following gure and note the following points

1. Forbids to demolish the wooden foundation.

2. Prevent the outdoor to incline.

3. Should be handling more than two.

Handle 2

Handle 1

Handle 3

Handle 4

2222

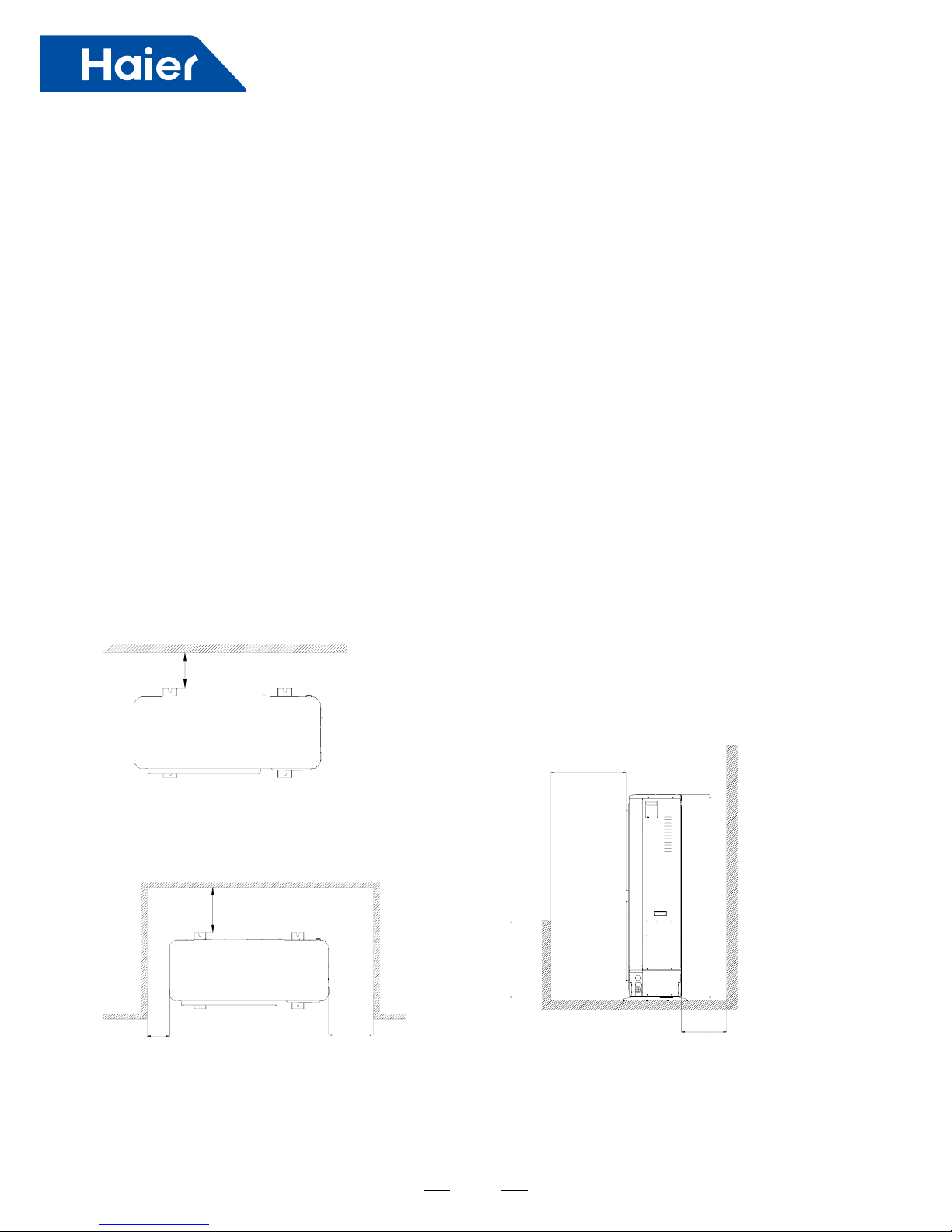

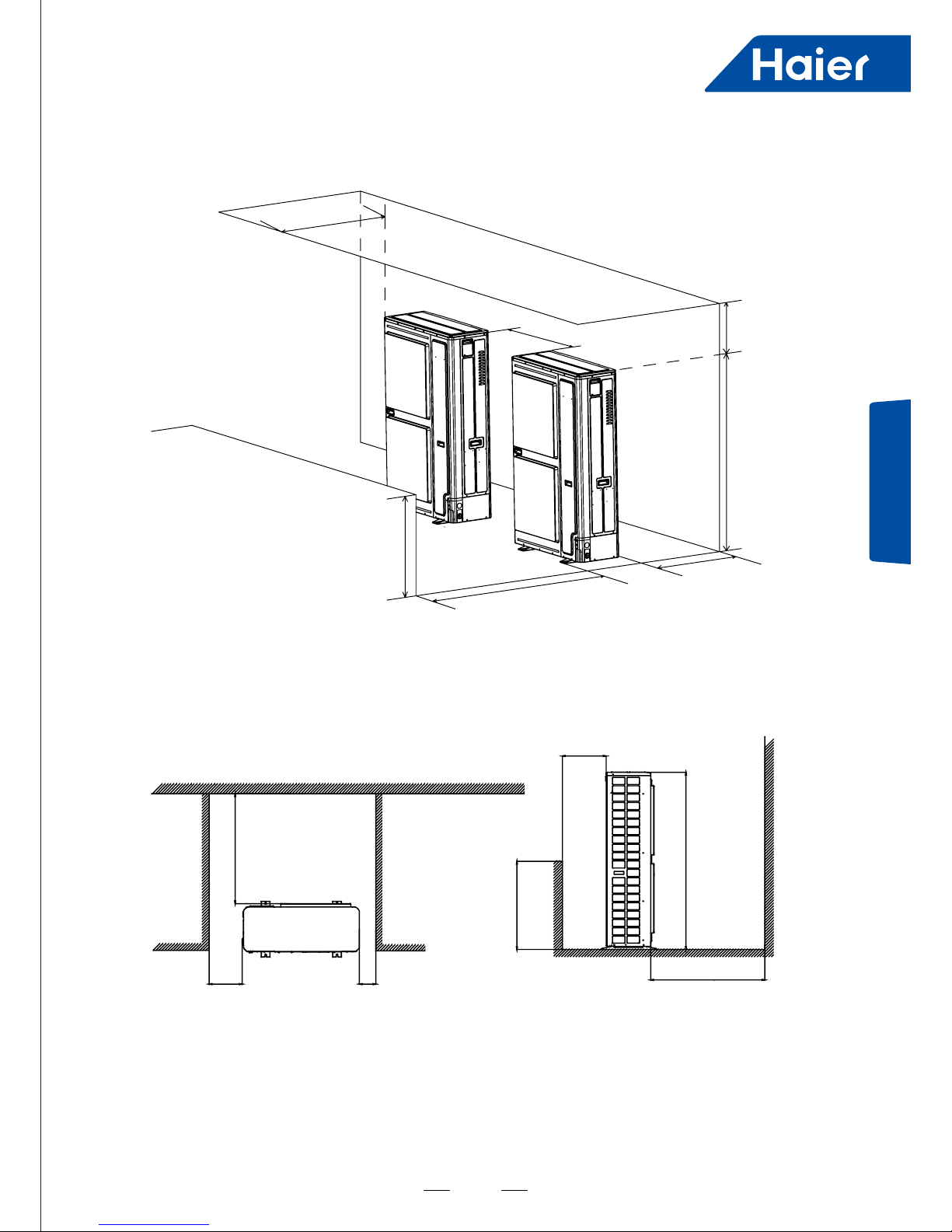

Single installation around the opening

Inlet

Outlet

Min200mm

Single installation around the closed

Inlet

Outlet

Min300mm

Min300mmMin150mm

Min360mm

Outdoor installation

Installation location

■ Outdoor unit should be placed in well ventilated and dry place.

■ Outdoor noise and exhaust should not affect neighbors and around the ventilation.

■ Ensure the ground steadily reliable.

■ Do not install the outdoor unit on high oil, salt spray or harmful gases.

■ Don't being installed to electromagnetic wave can directly radiate an electricity box and keep off electromagnetic

wave radiation possibly, at least more than 3 meters.

■ When ice snow overlay area installs outdoor unit, please add to defend snow cover.

■ Outdoor unit installed in the shade, avoiding direct sunlight or high temperature heat sources of radiation.

■ Do not install in dusty or polluted place to prevent outdoor unit heat exchanger jam.

■ The outdoor unit should install in the public unapproachable place.

Installation and maintenance space

As shown below, install the outdoor unit should allow sufcient space for handing and maintenance.

Case 1: Stumbling block on the inlet , also upside opens.

H

A

h

Single installation around the opening

Single installation around the closed

2323

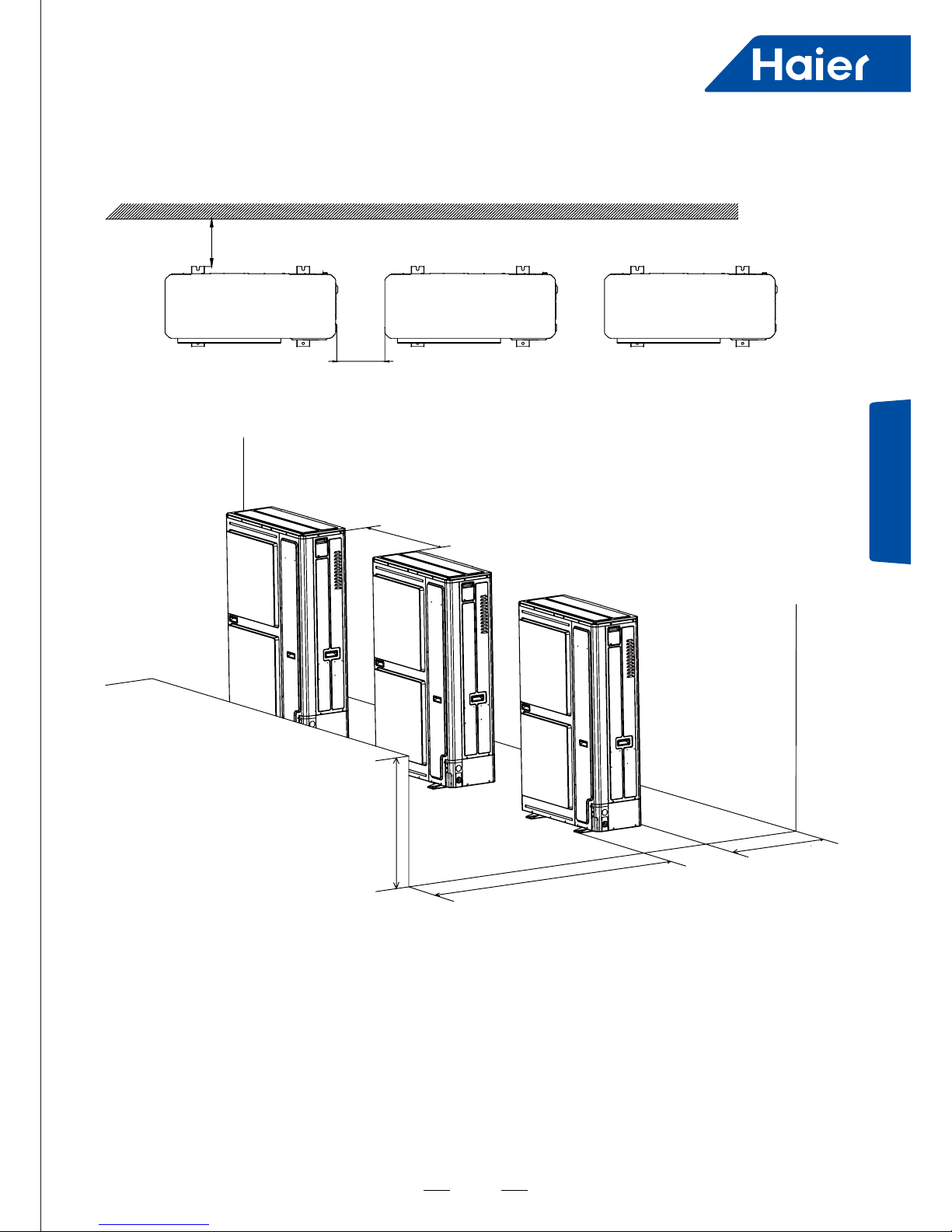

Outdoor Installation

Multi Outdoor

Min300mm

Min300mm

Min360mm

Min300mm

Inlet

Outlet

h

A

2424

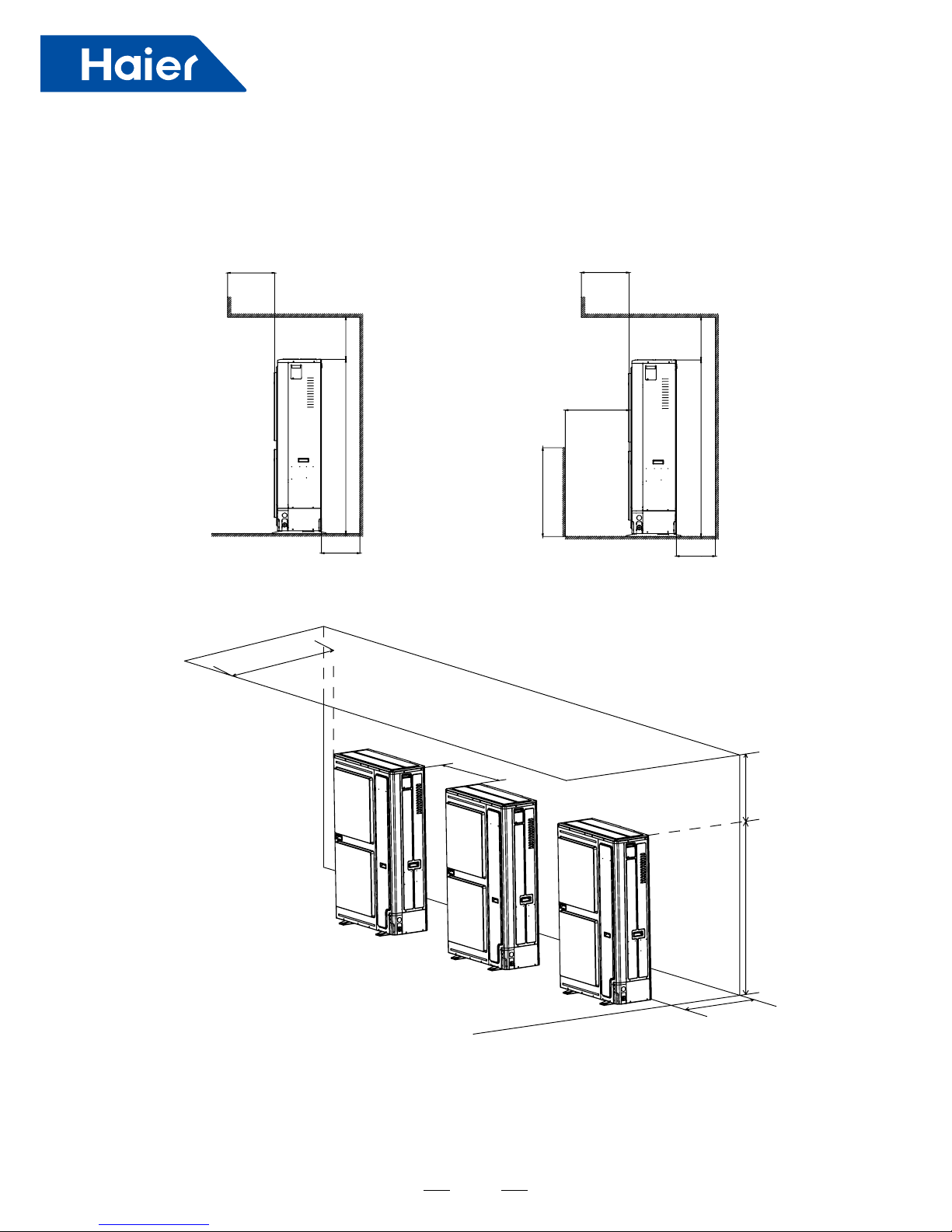

Case 2: Stumbling block on the inlet and top side

Single Outdoor

Multi Outdoor

Max300mm

Min360mm

Min300mm

Min500mm

H

Max300mm Max300mm

Min

500

mm

Min360mm Min360mm

L

H

H

A

Min

500

mm

2525

Outdoor Installation

Case 3:Stumbling block on the outlet, both right and left side

Single Outdoor

Max300mm

Min300mm

Min150mm

Min300mm

Min1000mm

Min1000mm

Min360mm

Min360mm

Min500mm

H

H

A

L

h

Not more than two sets

Loading...

Loading...