Haier AU482FIERA, AU282FHERA, AU48NFIERAG, AU60NFIERA, AU60NFIERAG Installation & Maintenance Instructions Manual

...

SYJS-11-2015REV.D Edition: 11-2015

R410A HEAT PUMP

MRVIII-S (G)

Design, Installation &

Maintenance instruction

AU282FHERA

AU482FIERA (G)

AU48NFIERA (G)

AU60NFIERA (G)

CONTENTS

1. General Information .................................................................................................................. 1

2. Specication ............................................................................................................................. 2

3. Indoor Model List ...................................................................................................................... 6

4. Refrigerant Circuit..................................................................................................................... 7

5. Dimension............................................................................................................................... 10

6. Wiring Diagram ....................................................................................................................... 12

7. Performance Curves............................................................................................................... 15

8. Outdoor Installation ................................................................................................................ 18

9. Electric Installation.................................................................................................................. 29

10. Trial Operation and The Performance .................................................................................. 34

11. Failure Code ......................................................................................................................... 43

12. Troubleshooting .................................................................................................................... 45

APPENDIX............................................................................................................................58

1

1. General Information

MRVllI-S adopts refrigerant R410a, which is the new generation of H-MRV. It is with DC inverter technology, high

efciency and energy saving, intelligent control, etc. All indoor units are with EEV to adjust the refrigerant ow,

collect the data by the precise temp. sensor. lndoors adopt the indoors of MRVllI-C below 48000BTU/h, add the

central control, room card function on the basis of original H-MRV. The system can realize max. 1 to 9.

Features:

1. High efciency and energy saving

1.1 Precise control, optimum operation

a. Simulate pressure control, to realize every indoor unit energy-saving and optimum operation.

b. Adopt inverter technology, adjust outdoor total load according to the actual request.

1.2 Indoor individual control, economic running

1.3 Advanced technology, high efciency, and energy saving

1.4 High efcient rotary compressor

a. Precise control EEV

b. Excellent piping system design

c. Long distance of refrigerant piping

1.5 Inverter operation, temperature sensor technology, reduce power consumption

2. Beautiful and comfortable

a. Compact outdoor appearance design

b. Perfect cooling and heating, more comfortable

c. Super slim design, t for the decor

3. Healthy and environment friendly

a. Adopt environment friendly refrigerant R410a, protect ozone layer against the earth being warmed up

b. Intelligent healthy module for removing formaldehyde, easily resolve the decoration pollution

c. Strong ultraviolet radiation to kill the bacteria, make indoor air more healthy

4. More convenient

a. Flexible control indoors

One outdoor can control multiple indoors at the same time

b. Multiple indoor control types

Infrared control, wired control, infrared control + wired control, central control

c. Free combination

Due to the different space, select indoor type freely

d. Multiple air sending, air return types

5. Easy installation

Super long piping system, free installation

2

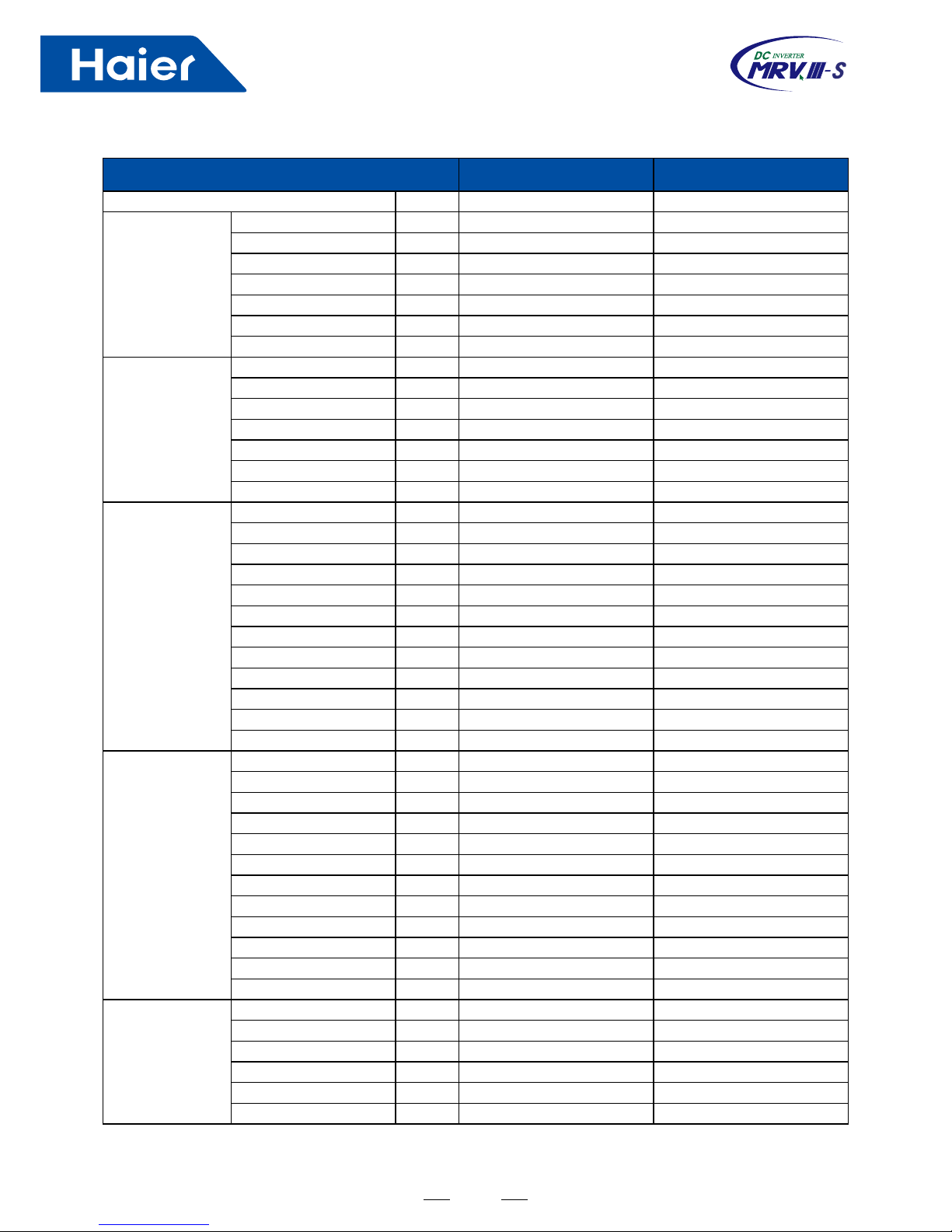

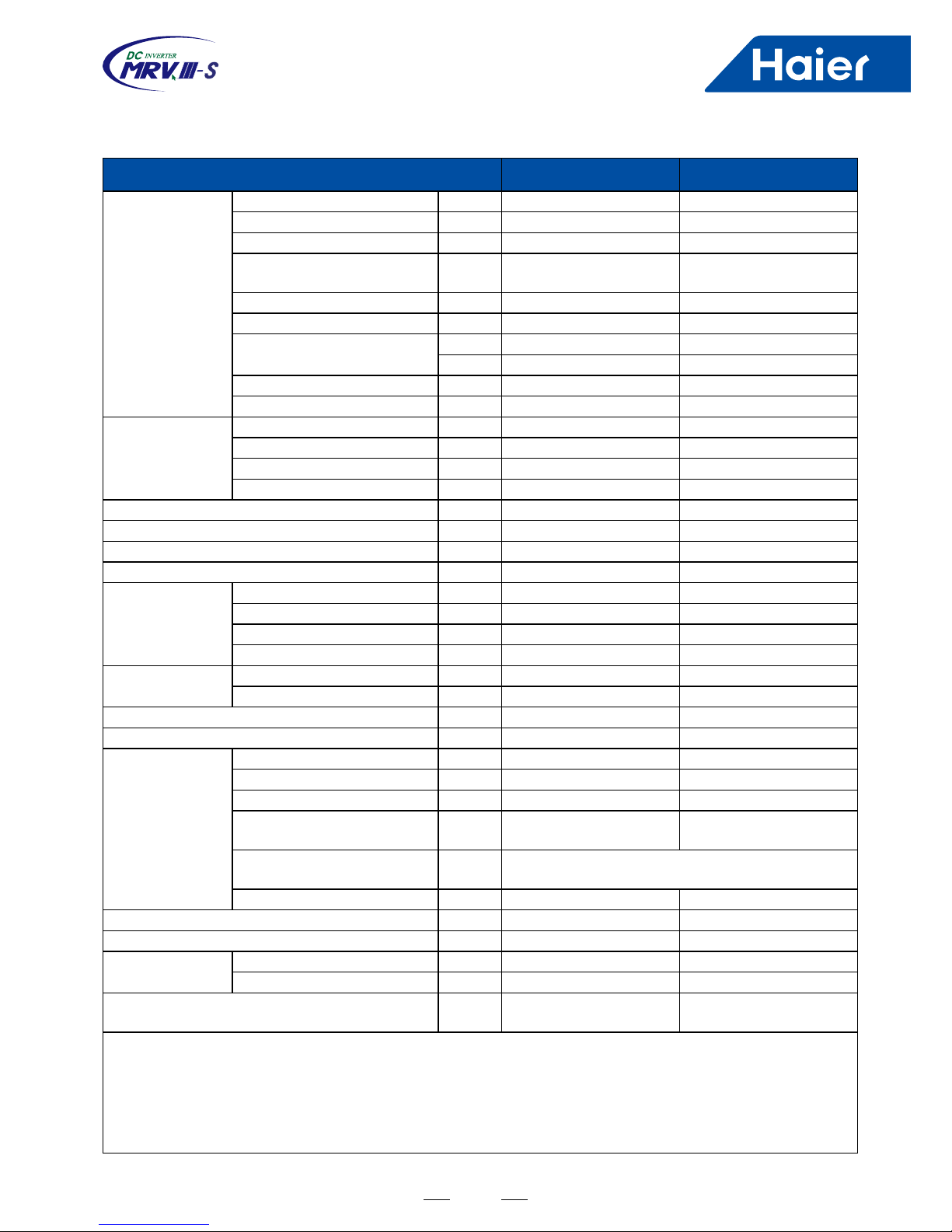

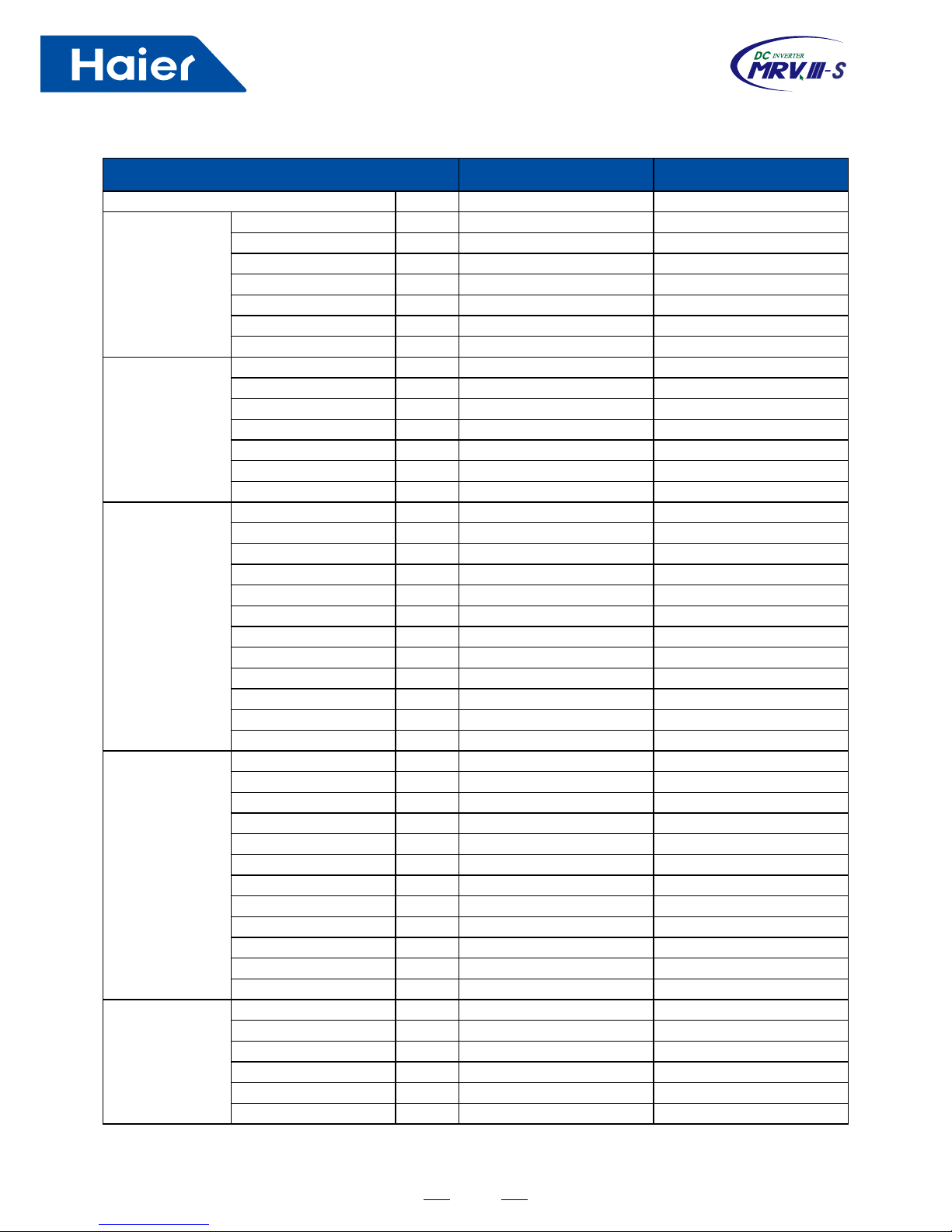

2. Specication

Model AU282FHERA AU482FIERA (G)

Power supply Ph/V/Hz 1/220~230/50 1/220~230/50/60

Cooling

Rated capacity kW 8 15

Rated capacity kBtu/h 27.3 51.2

Rated power input kW 2.2 4.2

Max. power input kW 4.1 6.2

EER 3.64 3.57

Rated current A 10.5 21.2

Max. current A 20.7 31.3

Heating

Rated capacity kW 9.5 17

Rated capacity kBtu/h 32.4 58

Rated power input kW 2.15 4

Max. power input kW 3.9 5.8

COP 4.42 4.25

Rated current A 10.3/19.8 20.2

Max. current A 19.8 29.3

Compressor

Brand MITSUBISHI ELECTRIC MITSUBISHI ELECTRIC

Model TNB220FLHMC LNB42F

Type Rotary Rotary

Compressor quantity 1 INV 1 INV

Capacity W 7130 13980W

Power input W 2200 4240W

Rated current (RLA) A 9.7 16.1

Speed rps 60 60

Crankcase heater W 27 28

Refrigerant oil brand IDEMITSUKOSAN CO.,LTD IDEMITSUKOSAN CO.,LTD

Refrigerant oil type FV50S FV50S

Refrigerant oil charge ml 870 1400

Outdoor fan motor

Brand BROAD OCEAN PANASONIC

Model Y6S443C81 EHDS80BAS

Voltage 208-230 208-230

IP class IP44 IP23

Type AC DC

Insulation class F E

Safe class I I

Power input W 260 124

Output W 110 100*2

Rated current A 1.2 0.4

Capacitor μF 5 /

Speed rpm 1000 960

Outdoor fan

Brand HONG MING SHUNWEI

Model / /

Material Plastic Plastic

Type Axial Axial

Diameter mm 450 450

Height mm 148 148

3

Model AU282FHERA AU482FIERA (G)

Outdoor coil

Number of rows 2 2

Tube pitch (a)×row pitch (b) mm 19.05×22 19.05×22

Fin spacing mm 1.70 1.5

Fin type (code)

HYDROPHILIC

ALUMINIUM

HYDROPHILIC

ALUMINIUM

Fin coating type Optional Clear lacquer Clear lacquer

Salt spray test duration Hour 168 168

Tube outside dia. and type

INNERGROOVE TUBE INNERGROOVE TUBE

mm Ф8 Ф8

Coil length×height mm 955×792 970×1200

Number of circuits 4 6

Cabinet coating

Coating type Powder coating Powder coating

Salt spray test duration Hour 72 72

Sheet metal material Hot zinc plate Hot zinc plate

Sheet metal thickness mm 0.8 0.8

Control panel enclosure IP class Standard IP24 IP24

Outdoor air ow m

3

/h 3500 6500

Outdoor sound level (sound pressure level ) dB (A) 55 59

Outdoor sound level (sound power level ) dB (A) 66 70

Outdoor unit

Dimension (W*H*D) mm 960×380×830 960×380×1250

Packing (W*H*D) mm 1095×410×985 1095×410×1400

Net weight kg 74 105

Gross weight kg 89 113

Refrigerant

Type R410A R410A

Charged volume kg 2.6 3.6

Throttle type EXV EXV

Design pressure MPa 4.15 4.15

Refrigerant piping

Liquid pipe mm 9.52 9.52

Gas pipe mm 15.88 19.05

Total pipe length m 50 100

Max. pipe length

(Equivalent/ Actual)

m 35 70

Max. Diff. indoor/outdoor unit m

30 (Outdoor higher than indoor)

20 (Indoor higher than outdoor)

Max. Diff. indoor/indoor unit m 10 10

Connectable indoor unit ratio % 50%~130% 50%~130%

Maximum indoor units Piece 4 8

Connection wiring

Power wiring mm

2

6 10

Signal wiring mm

2

Shield wire: (0.75-2)*2 Shield wire: (0.75-2)*2

Operation range °C

Cooling: 10~43

Heating: -15~21

Cooling: -15~43

Heating: -15~21

Nominal condition:

Indoor temperature (cooling): 27 DB(°C)/19 WB(°C), indoor temperature (heating): 20 DB(°C)/14.5 WB(°C).

Outdoor temperature (cooling): 35 DB(°C)/24 WB(°C), outdoor temperature (heating): 7 DB(°C)/6 WB(°C).

The data is measured with 7.5m equivalent pipe and 0m height difference.

The noise level will be measured in the third octave band limited values in the semi-anechoic chamber, using a real

time analyser calibrated sound intensity meter. It is a sound pressure noise level.

4

Model AU48NFIERA (G) AU60NFIERA (G)

Power supply Ph/V/Hz 3/380~400/50/60 3/380~400/50/60

Cooling

Rated capacity kW 15 18

Rated capacity kBtu/h 51.2 61.4

Rated power input kW 4.2 5.5

Max. power input kW 6.2 7.3

EER 3.57 3.27

Rated current A 6.7 9.8

Max. current A 10 13

Heating

Rated capacity kW 17 20

Rated capacity kBtu/h 58 68.2

Rated power input kW 4 5.25

Max. power input kW 5.8 6.7

COP 4.25 3.81

Rated current A 6.4 9.4

Max. current A 9.6 12

Compressor

Brand MITSUBISHI ELECTRIC MITSUBISHI ELECTRIC

Model LNB42F LNB42F

Type Rotary Rotary

Compressor quantity 1 INV 1 INV

Capacity W 13980W 13980W

Power input W 4270W 4270W

Rated current (RLA) A 12 12

Speed rps 60 60

Crankcase heater W 28 28

Refrigerant oil brand IDEMITSUKOSAN CO.,LTD IDEMITSUKOSAN CO.,LTD

Refrigerant oil type FV50S FV50S

Refrigerant oil charge ml 1400 1400

Outdoor fan motor

Brand PANASONIC PANASONIC

Model EHDS80BAS EHDS80BAS

Voltage 208-230 208-230

IP class IP23 IP23

Type DC DC

Insulation class E E

Safe class I I

Power input W 124 124

Output W 100*2 100*2

Rated current A 0.4 0.4

Capacitor μF / /

Speed rpm 960 960

Outdoor fan

Brand SHUNWEI SHUNWEI

Model / /

Material Plastic Plastic

Type Axial Axial

Diameter mm 450 450

Height mm 148 148

5

Model AU48NFIERA (G) AU60NFIERA (G)

Outdoor coil

Number of rows 2 2

Tube pitch (a)×row pitch (b) mm 19.05×22 19.05×22

Fin spacing mm 1.5 1.5

Fin type (code)

HYDROPHILIC

ALUMINIUM

HYDROPHILIC

ALUMINIUM

Fin coating type Optional Clear lacquer Clear lacquer

Salt spray test duration Hour 168 168

Tube outside dia. and type

INNERGROOVE TUBE INNERGROOVE TUBE

mm Ф8 Ф8

Coil length×height mm 970×1200 970×1200

Number of circuits 6 6

Cabinet coating

Coating type Powder coating Powder coating

Salt spray test duration Hour 72 72

Sheet metal material Hot zinc plate Hot zinc plate

Sheet metal thickness mm 0.8 0.8

Control panel enclosure IP class Standard IP24 IP24

Outdoor air ow m

3

/h 6500 6500

Outdoor sound level (sound pressure level ) dB (A) 59 60

Outdoor sound level (sound power level ) dB (A) 70 71

Outdoor unit

Dimension (W*H*D) mm 960×380×1250 960×380×1250

Packing (W*H*D) mm 1095×410×1400 1095×410×1400

Net weight kg 105 105

Gross weight kg 11 3 113

Refrigerant

Type R410A R410A

Charged volume kg 4 4

Throttle type EXV EXV

Design pressure MPa 4.15 4.15

Refrigerant piping

Liquid pipe mm 9.52 9.52

Gas pipe mm 19.05 19.05

Total pipe length m 100 100

Max. pipe length

(Equivalent/ Actual)

m 70 70

Max. Diff. indoor/outdoor unit m

30 (Outdoor higher than indoor)

20 (Indoor higher than outdoor)

Max. Diff. indoor/indoor unit m 10 10

Connectable indoor unit ratio % 50%~130% 50%~130%

Maximum indoor units Piece 8 9

Connection wiring

Power wiring mm

2

4 4

Signal wiring mm

2

Shield wire: (0.75-2)*2 Shield wire: (0.75-2)*2

Operation range °C

Cooling: -15~43

Heating: -15~21

Cooling: -15~43

Heating: -15~21

Nominal condition:

Indoor temperature (cooling): 27 DB(°C)/19 WB(°C), indoor temperature (heating): 20 DB(°C)/14.5 WB(°C).

Outdoor temperature (cooling): 35 DB(°C)/24 WB(°C), outdoor temperature (heating): 7 DB(°C)/6 WB(°C).

The data is measured with 7.5m equivalent pipe and 0m height difference.

The noise level will be measured in the third octave band limited values in the semi-anechoic chamber, using a

real time analyser calibrated sound intensity meter. It is a sound pressure noise level.

6

3. Indoor Model List

4-WAY CASSETTE TYPE/PB-700lB

AB092MCERA

AB122MCERA

AB162MCERA

HIGH WALL EEV INSIDE

AS072MGERA AS162MGERA

AS092MGERA AS182MGERA

AS122MGERA AS242MGERA

4-WAY CASSETTE TYPE/PB-950JB

AB182MCERA

AB242MCERA

AB282MCERA

AB302MCERA

AB382MCERA

AB482MCERA

MED ESP DUCT TYPE (80/120Pa)

AD182MZERA

AD242MZERA

AD282MZERA

AD302MNERA

AD382MNERA

AD482MNERA

LOW ESP DUCT TYPE

AD072MLERA

AD092MLERA

AD122MLERA

AD162MLERA

AD182MLERA

AD242MLERA

MED ESP DUCT TYPE (50/96Pa)

AD182MMERA

AD242MMERA

AD282MMERA

AD302MMERA

AD382MMERA

AD482MMERA

HlGH ESP DUCT TYPE

AD182MHERA

AD242MHERA

AD282MHERA

AD302MHERA

AD382MHERA

AD482MHERA

AD722MHERA

AD962MHERA

CONVERTlBLE TYPE

AC092MCERA

AC122MCERA

AC162MCERA

AC182MCERA

AC242MCERA

AC282MFERA

AC302MFERA

AC382MFERA

AC482MFERA

SLIM LOW ESP DUCT

AD072MSERA

AD092MSERA

AD122MSERA

AD162MSERA

AD182MSERA

AD242MSERA

BUILIT-IN FLOOR STANDING

AE072MLERA

AE092MLERA

AE122MLERA

AE162MLERA

AE182MLERA

AE242MLERA

2-WAY CASSETTE/1055IB

AB072MBERA

AB092MBERA

AB122MBERA

AB162MBERA

AB182MBERA

CONSOLE TYPE

AF072MAERA

AF092MAERA

AF122MAERA

AF182MAERA

FRESH AIR DUCT TYPE

AD482MPERA

AD722MPERA

AD962MPERA

7

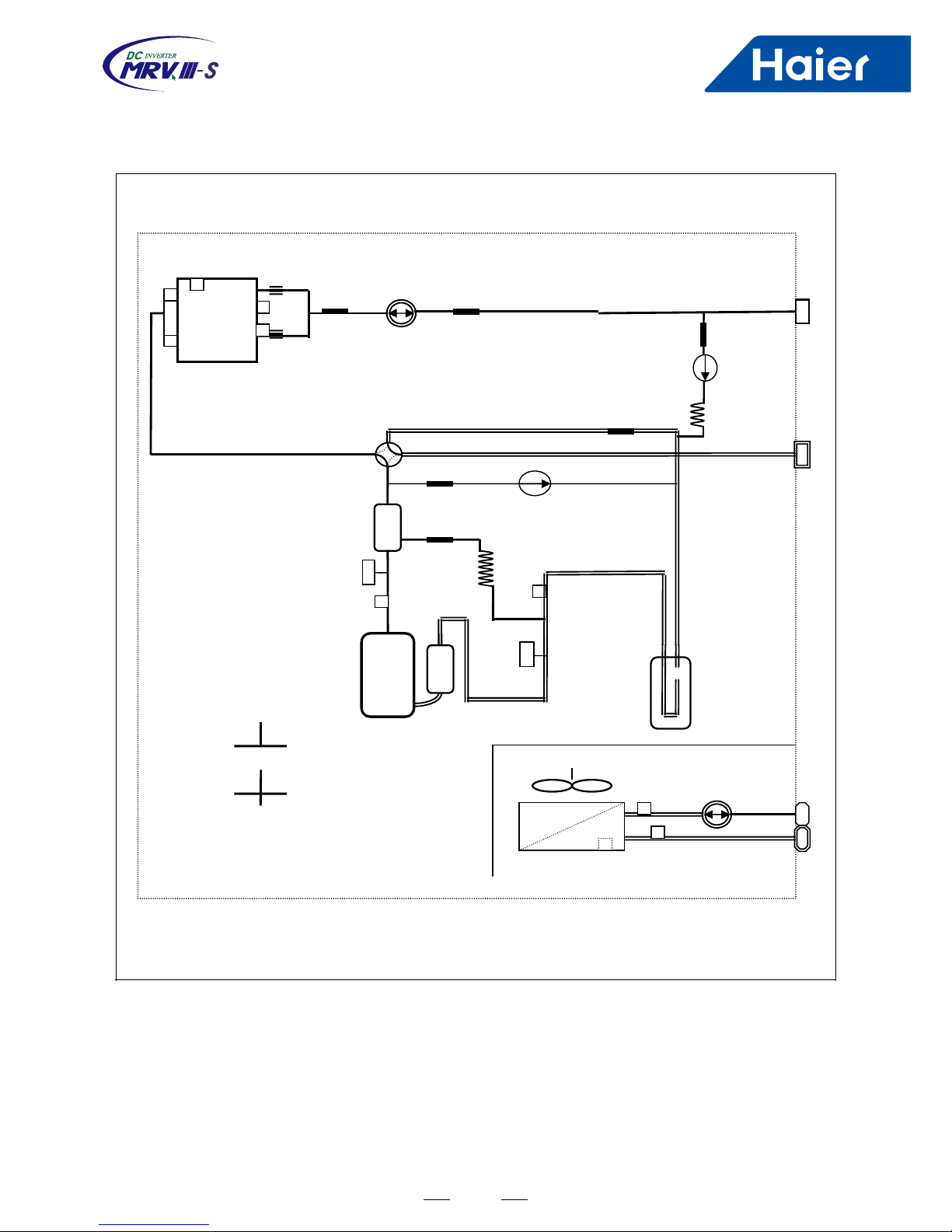

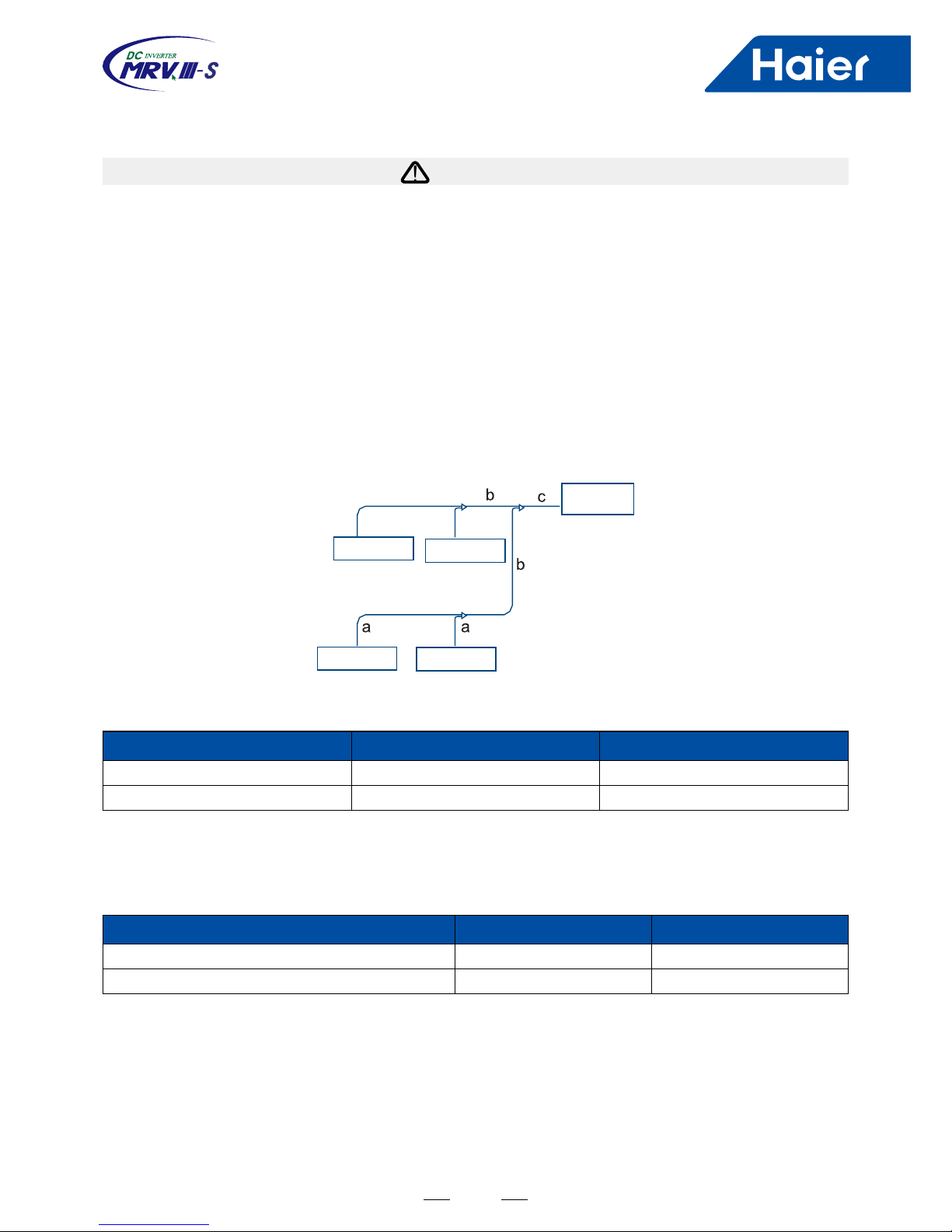

4. Refrigerant Circuit

Ta

Liquid pipe

Tc

Strainer P MV Strainer

Strainer

Te S

4-way valve

Gas pipe

Oil segregator

SV1

OP

Oil return capillary

Ts

Td

Compressor

LP

Gas-liquid

Segregator

Legend

Connected

Disconnected

2cT PMV

Outdoor unit

Ta

Indoor unit

Tc1

Strainer

Strainer

Strainer

AU282FHERA

SV2

8

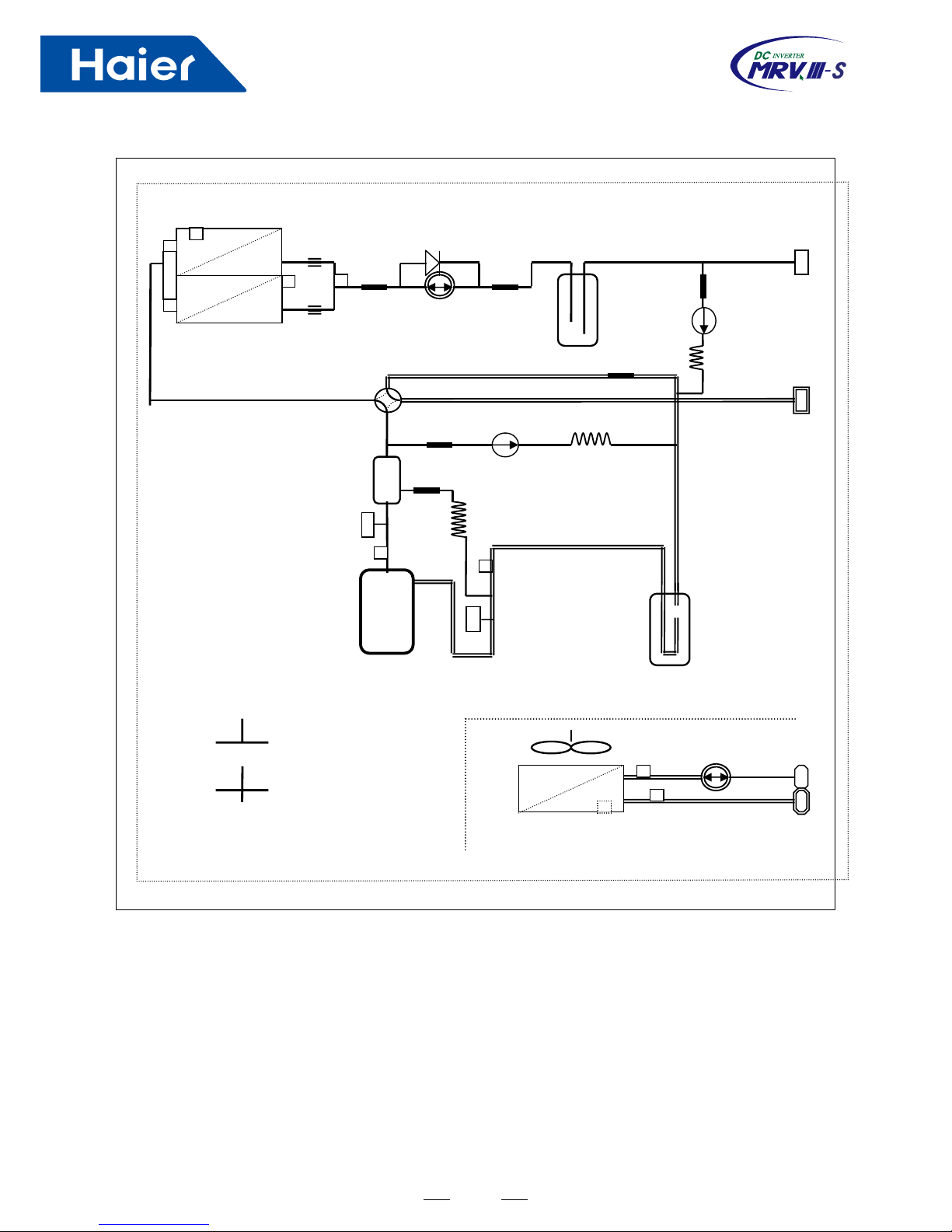

Ta

One-way valve Liquid pipe

室外 HEX T e

Tc Strainer

Strainer PMV Strainer S

Accumulator

4-way valve Gas pipe

Strainer SV1

Strainer

Oil segregator Strainer

OP Oil return capillary

Td Ts

LP

Gas-liquid

Segregator

Legend

Connected PMV

Tc2

Disconnected Ta Tc1

Outdoor

Indoor

Compressor

T

AU482FIERA (G), AU48NFIERA (G), AU60NFIERA (G)

SV2

9

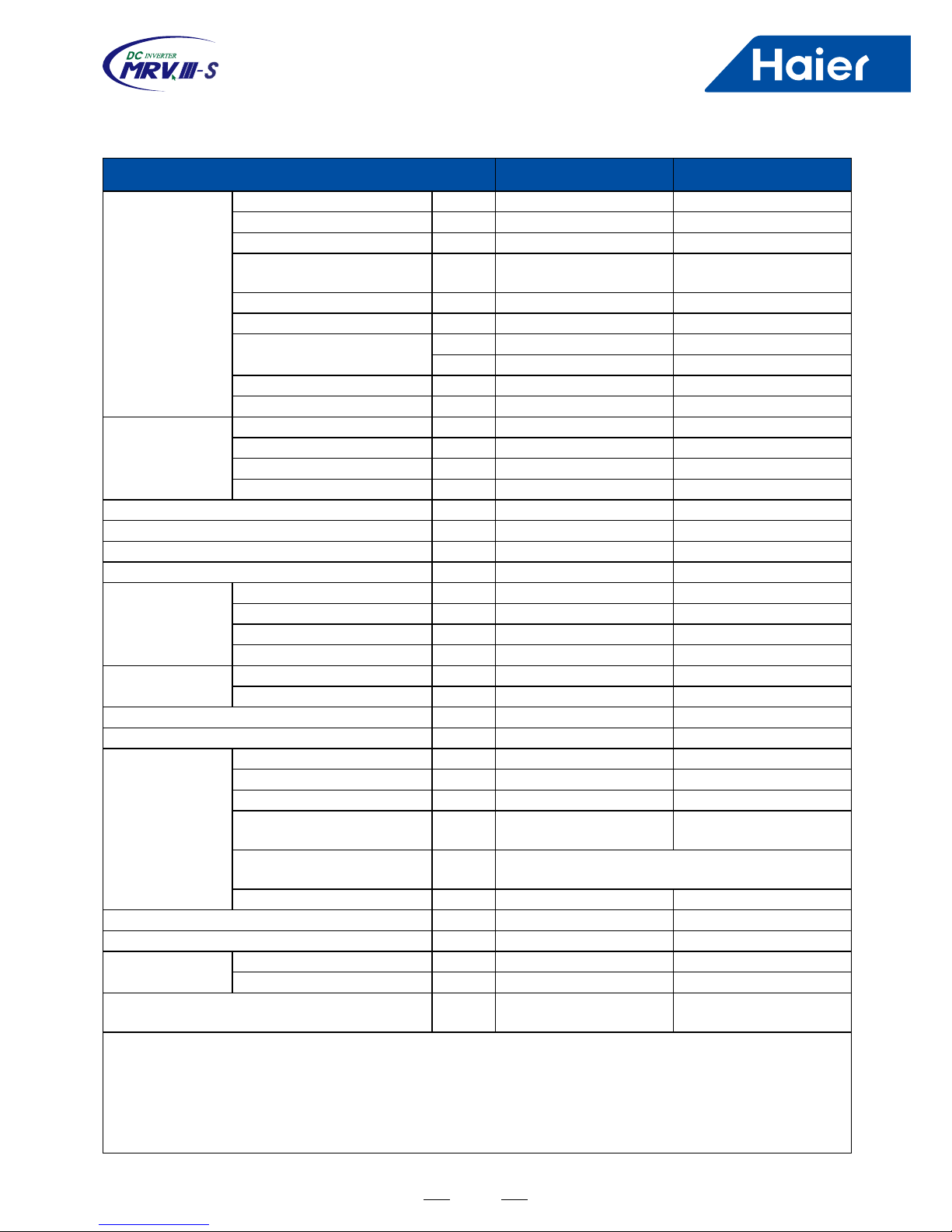

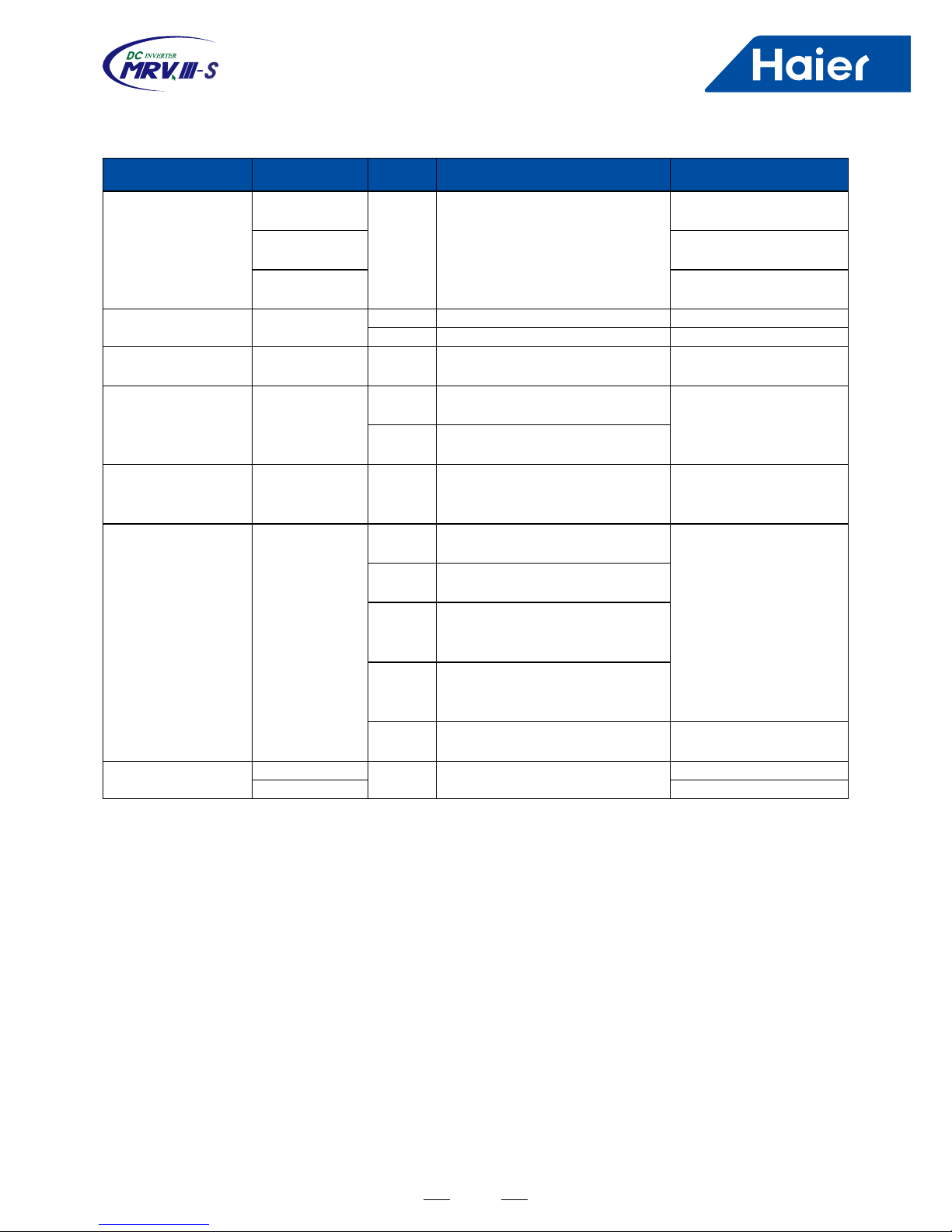

Part name Model Sign Function Date

Compressor

AU282

Capacity control, meet indoor load

request by adjusting the frequency

Motor resistance

(at 20°C): 0.88Ω

AU482

Motor resistance

(at 20°C): 0.29Ω

AU48/60N

Motor resistance

(at 20°C): 0.53Ω

Pressure switch ALL

HP High pressure protection 4.15Mpa, OFF

LP Low pressure protection 0.05Mpa, OFF

Electronic expansion

valve

ALL PMV In heating, refrigerant ow control

¢

2.4

Solenoid valve ALL

SV1

Keep balance of high/low pressure

when compressor starts up or stops

AC220V

SV2

Refrigerant jet protection when

discharging temp. is too high

4-way valve ALL 4WV

Change over between cooling and

heating

AC220V, electried in heat;

not electried in cooling or

defrosting

Temp. sensor ALL

Te

Check frost condition of outdoor

heat exchanger

R (25°C)=10K B

(25/50°C)=3700K

Ts

Detect the suction temp. of

compressor

Tc

Check the temp. of main pipe of

condenser gas pipe control PMV in

heating

Ta

Detect ambient temp. set primary

setting for fan speed target

pressure and PMV open angle

Td

Detect the discharging temp. of

compressor

R (80°C)=50K B

(25/80°C)=4450K

Heater

AU282

HEATER Used to heat oil in compressor

25W, 220V

AU482/48N/60N 28W, 220V

10

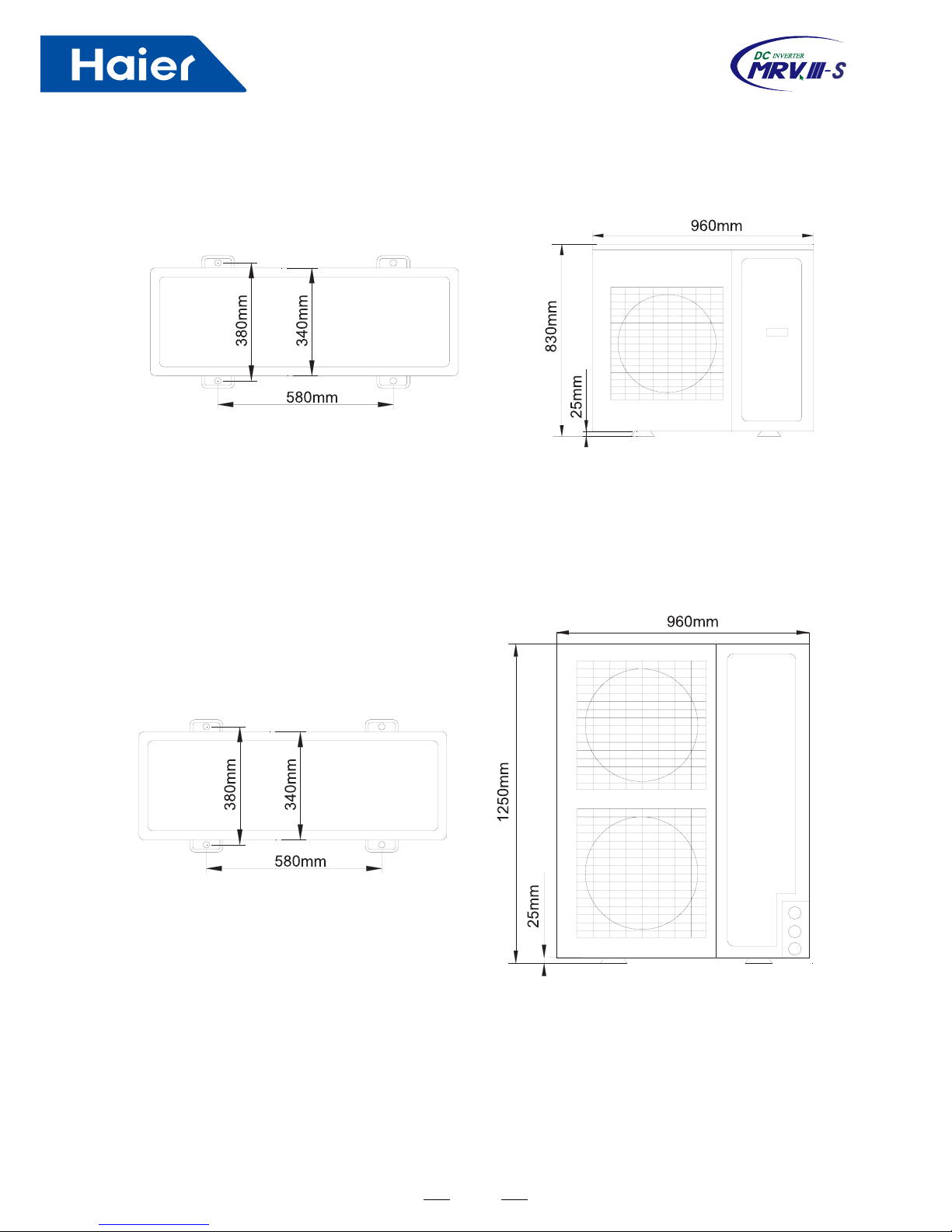

5. Dimension

AU282FHERA

AU482FIERA (G), AU48NFIERA (G), AU60NFIERA (G)

11

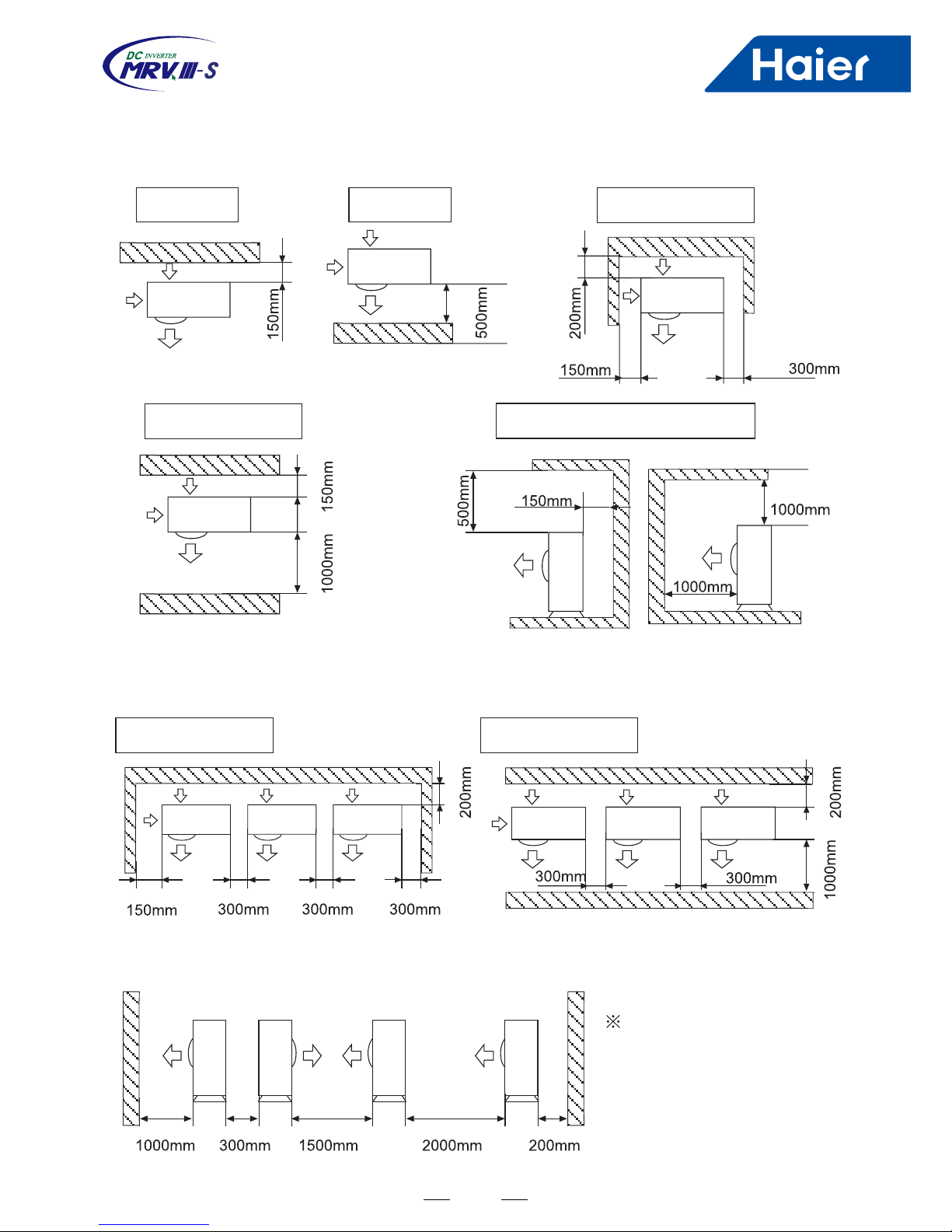

1. Single unit scenario

Over

Over

Over

OverOver

Over

Over

Over

Over

Over

Over

The top and two side surfaces must be exposed to open space, and obstacles on at least one side of the front

and back shall be lower than the outdoor unit.

※

2. Multiple units scenario:

Over

Over

Over

Over Over Over Over

Over Over

Obstacles shall be lower than the outdoor unit.

※

3. Front-and-back: Standard size

Over Over Over Over Over

.

The top and two side

surfaces must be exposed

to open space, and

obstacles on at least one

side of the front and back

shall be lower than the

outdoor unit

Back

Front

Front and prole

Obstacles

shall be

lower than

the outdoor

unit

Front and back

Front and back

Back and prole

When there are obstacles above

12

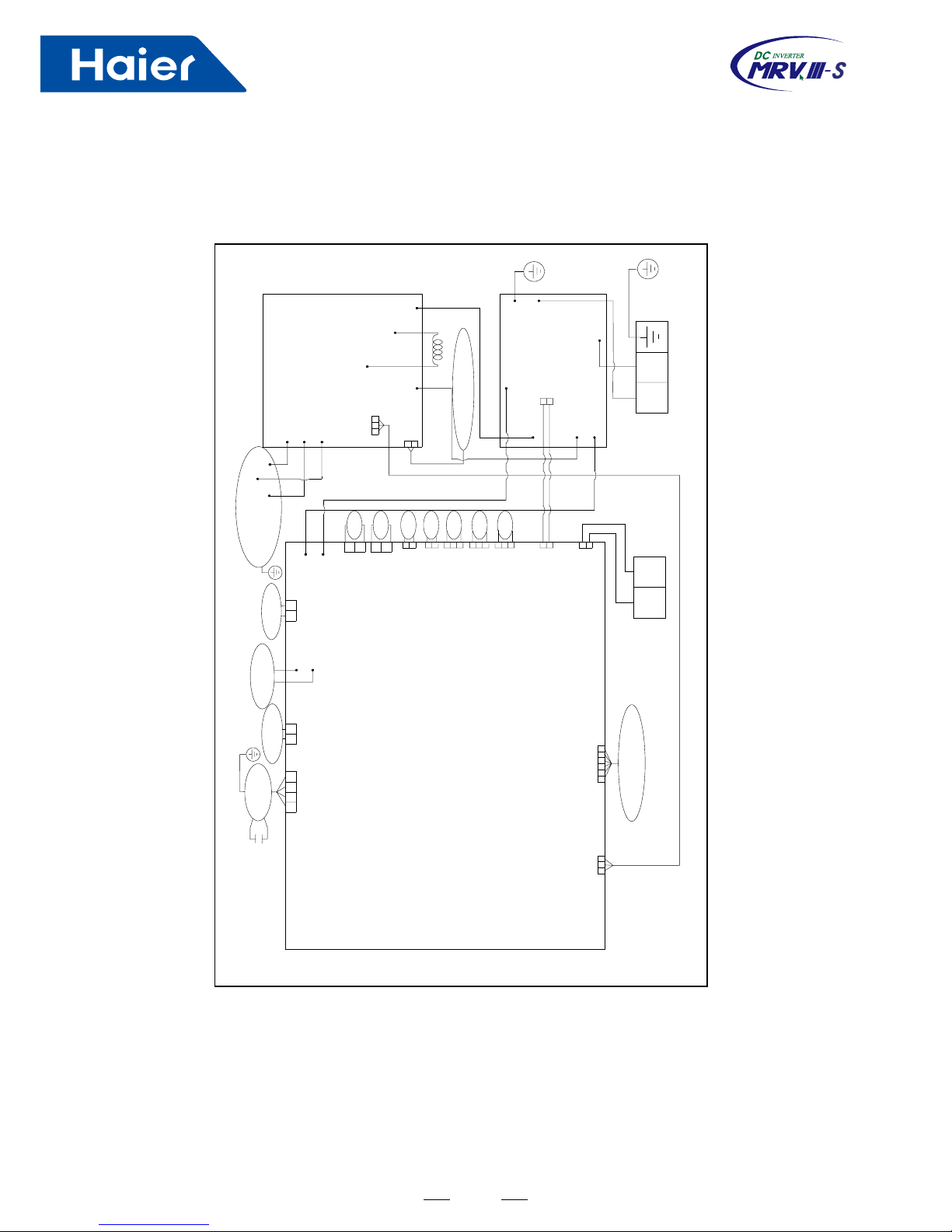

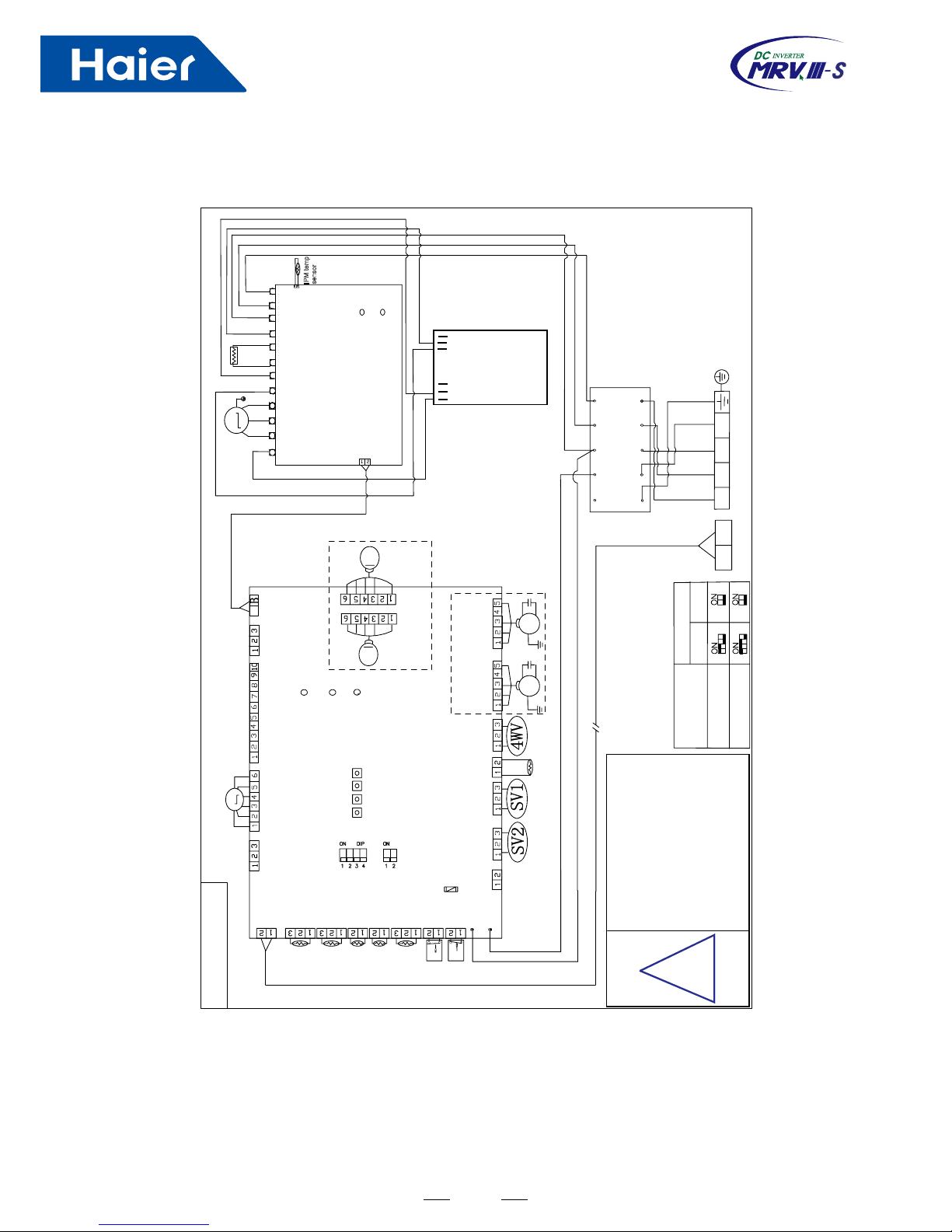

6. Wiring Diagram

Control board

I P M

NOISE FILTER

CN11

CN6

NO

COM

CN5

LN

CN1

CN2

CN3

CN4(PTC)

CON2

CON3

CN2

CN1

HP

LP

CN5

CN4

CN7

CN6

CN3

TCTETD

TS

TA

(OUT/IN_COM )CN21

P

Q

PMV

CN8

MODULE_COM

CN10

4-WAYS V2

HEATER

CN14

ACFAN1

FAN MOTOR

STARTUP CAPACITOR

CN9

CN2C N1

CN3

CN4

CN5(U)

CN6(V)

CN7(W)

P M V

U

W

V

COMP

HEATER

4-WAY VALVE

SPRAY VALVE

ISPM TEMPERATURE SENSOR

0150503461

Communication wire

with indoor unit

POWER SUPPLY

Y: yellow G: green

B: black BL: blue

W: white R: red

CN19

B

W

W

B

R

W

WB

B

Y/G

Y/G

WB

AU282FHERA

13

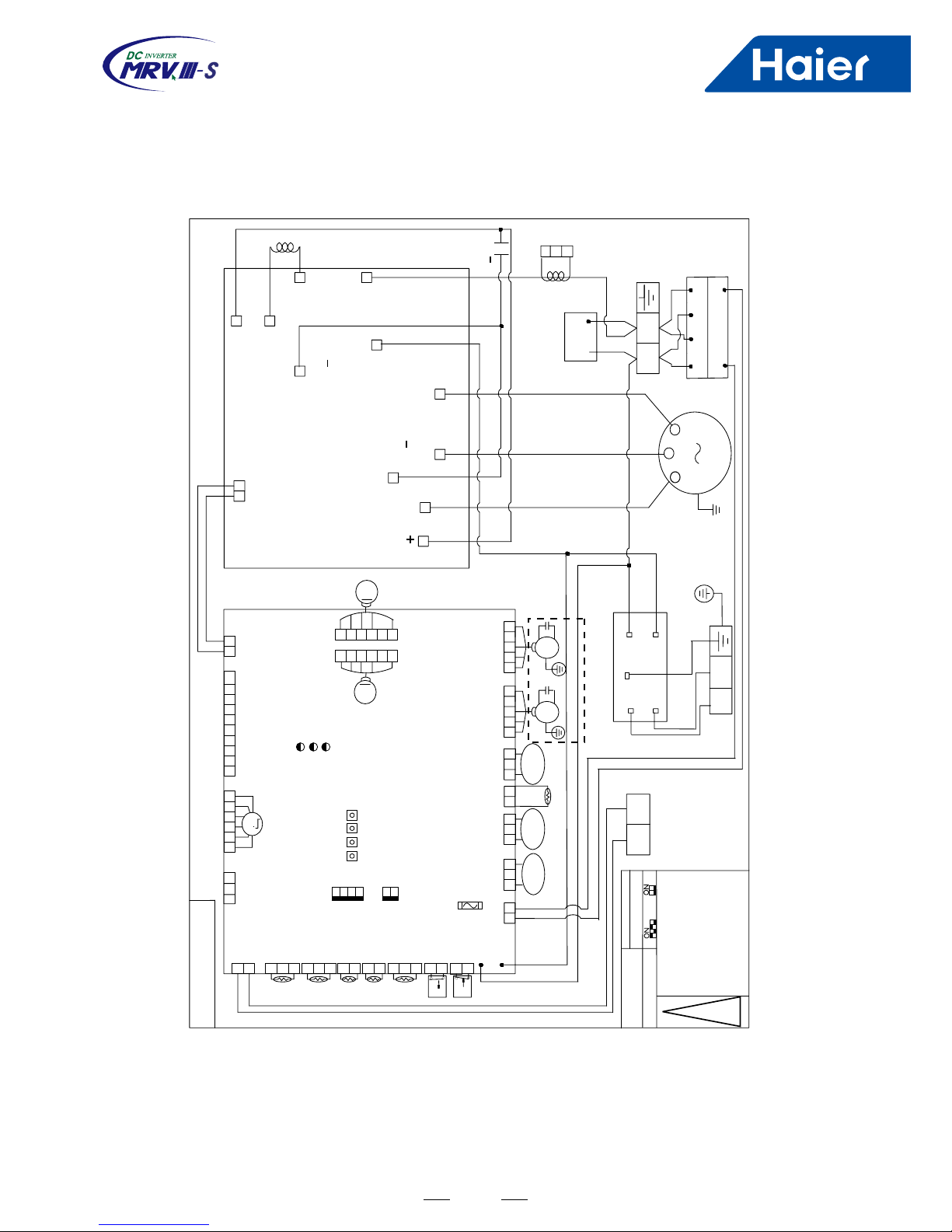

AU482FIERA (G)

P

SV2

P Q

SV1 4WV

HEATER

P

L

N

1

6

2 3 4

5

L

N

CN603 CN609

V

W

L

ACL

ACN

L

L

N

LINE

LOAD

L

N

+

U

Y

/

G

U

V

W

R W B

.

CURRENT

B W

B W

ACL

ACN

PTC

UP

M

DCFAN

SW01

CN20

CN8

CN24 CN11

EEV

M

LED_DISPLAY MODULE_COM

CN21

CN7

CN6

CN5

CN4

CN3

CN2

OUT/IN

TS

TE

TD

LP

CN1

CN19 CN18 CN17 CN25 CN16 CN15 CN14

(DOWN)

T6.3A/250VAC

ACFAN2 ACFAN1

(UP)

HP

TC

TA

SW02

M

DOWN

CN13

CN12

B

M

M

B

B

W

W

W

NOISE FILTER

SW01

SW02

482

TYPE

SETTING

COMMUNICATION WIRE

WITH INDOOR UINIT

Note:

Parts in dashed line are

optional. Arrow on current

transducer aims at side of

compressor

B:Black W:White R:Red

Y:Yellow G:Green

0150510341

1 2 3

1 2 3 4 5 6

1 2 3 4 5 6 7 8 9

10 A B

CN19

1 2

CN615

CN614

CN616

CN612

CN610

CN608

CN602

CN20

PTC

CN613

CN611

DC+

DC

DC

DC

SW4 SW3 SW2 SW1

ON

1 21 2 3 4

ON

DIP

6 5 4 3 2 1

6 5 4 3 2 1

Y

/

G

1 2

1 2 3 1 2 3

1 2

1 2 3

1 2 3 4 5 1 2 3 4 5

1 2

1 2

1 2 3 1 2 1 2 1 2 3

1 2 3 1 2

Reactor

LED3

LED2

LED1

Capacitance

123

!

Control Board

Inverter Module

When first powered up,the LED2

flicker times by 1Hz frequency ind-

icate model 482 flicker 4 times).

The LED2 flicker times by 2Hz freq-

uency indicate the searched indoor

numbers. When make sure correct,

SW01_4 dip is set on,or the machi-

ne can't run.

DC FAN SW01-1 dip switch is set ON

AC FAN SW01-1 dip switch is set OFF

14

AU48NFIERA (G), AU60NFIERA (G)

SW02

T

S

R

DC+L2 L1 DC-T S R

CN604

LED601

LED602

IGBT

R

W B

BL

Y/G

E

N L3

L2

L1

NOISE FILTER

E

N

L3

L2

L1

P

Q

R

S T

N

W

B

G

R

W

W

W

SW01

SW02

!

U

R

V

W

W

B

COMP

P W V U N

CN607

+CD +CD

P

P

M

M

CN12

(DOWN)

(DOWN)

(UP)

(UP)

M

CN7

TA

CN6

TS

CN2

LP

CN1

HP

CN21

OUT/IN

CN20

CURRENT

EEV

CN24

LED_DISPLAY

ACL

ACN

CN19 CN18 CN17 CN25 CN16

PTC

CN15 CN14

CN13

DCFAN2

ACFAN1

M

SW01

SW4 SW3 SW2 SW1

DCFAN1

ACFAN2

A

T6.3A-250VAC

FUSE1

LED1 LED2 LED3

R

G

R

CN3

TD

CN4

TE

CN5

TC

CN10

CN11

MODULE_COM

HEATER

CN8

B

B

W

WW

AU48NFIERA(G)

Note:

Parts in dashed line are optional.

Arrow on current transducer aims at

side of compressor

TYPE

SETING

REACTOR

IPM temp

sensor

0150510342

The LED2 flicker times by 2Hz frequency indic-

ate the searched indoor numbers. When make

sure correct,SW01_4 dip is set on,or the machi-

ne can't run.

B:Black W:White R:Red Y:Yellow G:Green

DC FAN SW01-1 dip switch is set ON

AC FAN SW01-1 dip switch is set OFF

When first powered up, please make

sure SW01 dip switch is accord with

the right excel. The LED2 flicker times

by 1HZ frequency indicate model(48N

flicker 5 times, 60N flicker 6 times)

AU60NFIERA(G)

Control Board

15

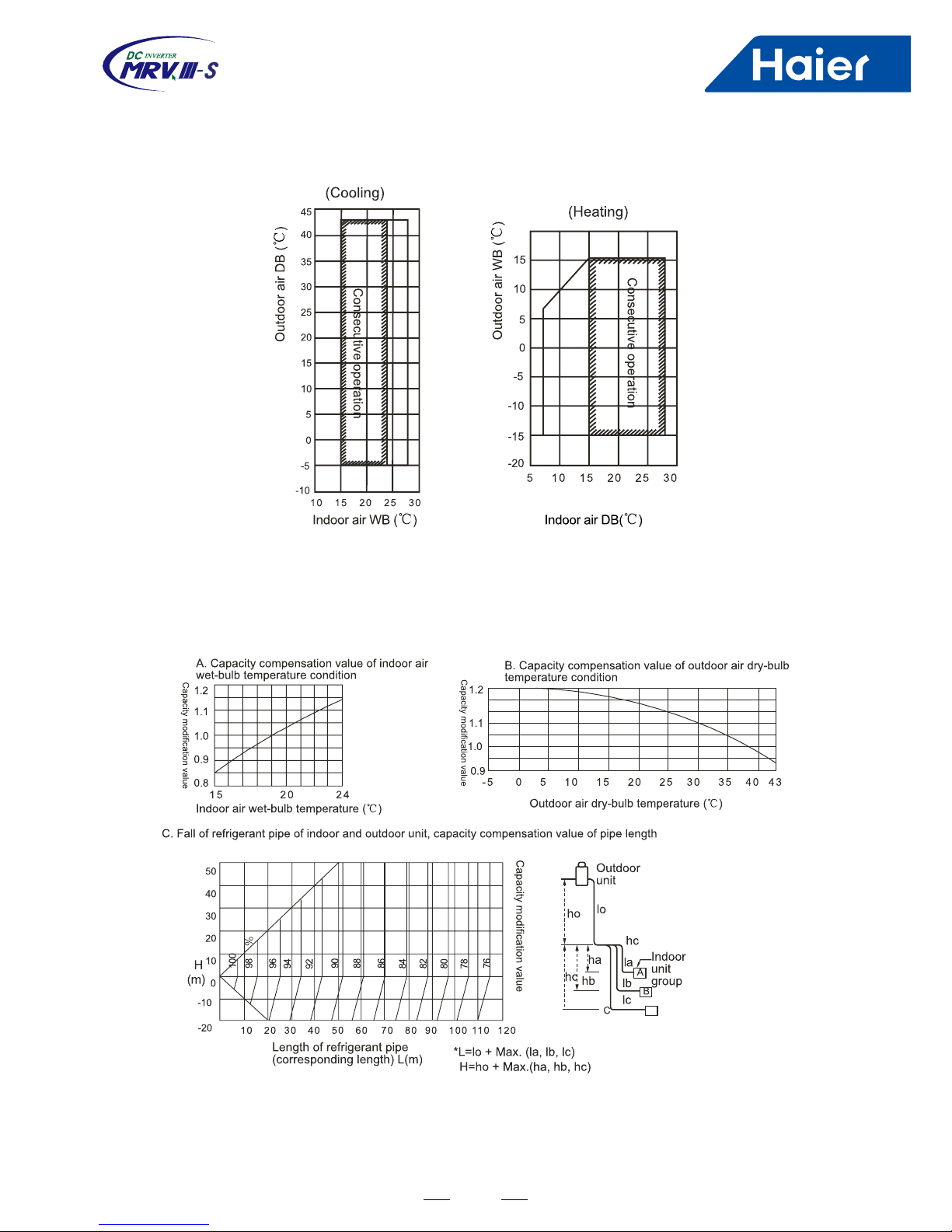

7. Performance Curves

7.1 Running range

Note

: AU282FHERA lowest cooling temperature is 10.

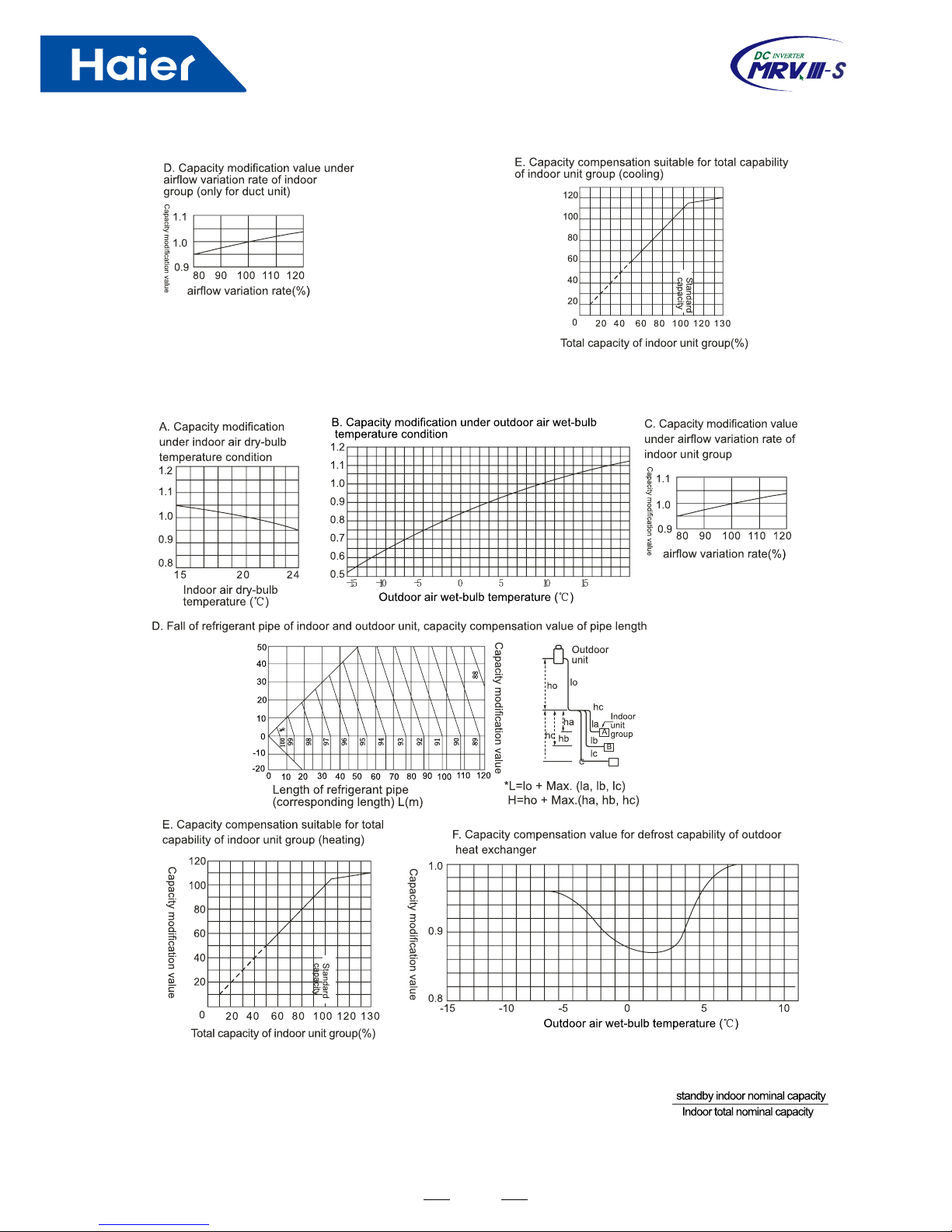

7.2 Calculation method

(1) Calculation method of refrigerating capacity---Refrigerating capacity to be known

=Refrigerating capacity×(A×B×C×D×E) W

16

(2) Calculation method of heating capacity---Heating capacity to be known

= Heating capacity×(A×B×C×D×E×F) W

Outdoor modied capacity with a single indoor running = outdoor modied capacity *

(3) Calculation method of refrigerating capacity---Only one indoor unit running

(Outdoor modied capacity: heating or cooling capacity after modify item 1 and 2)

unit

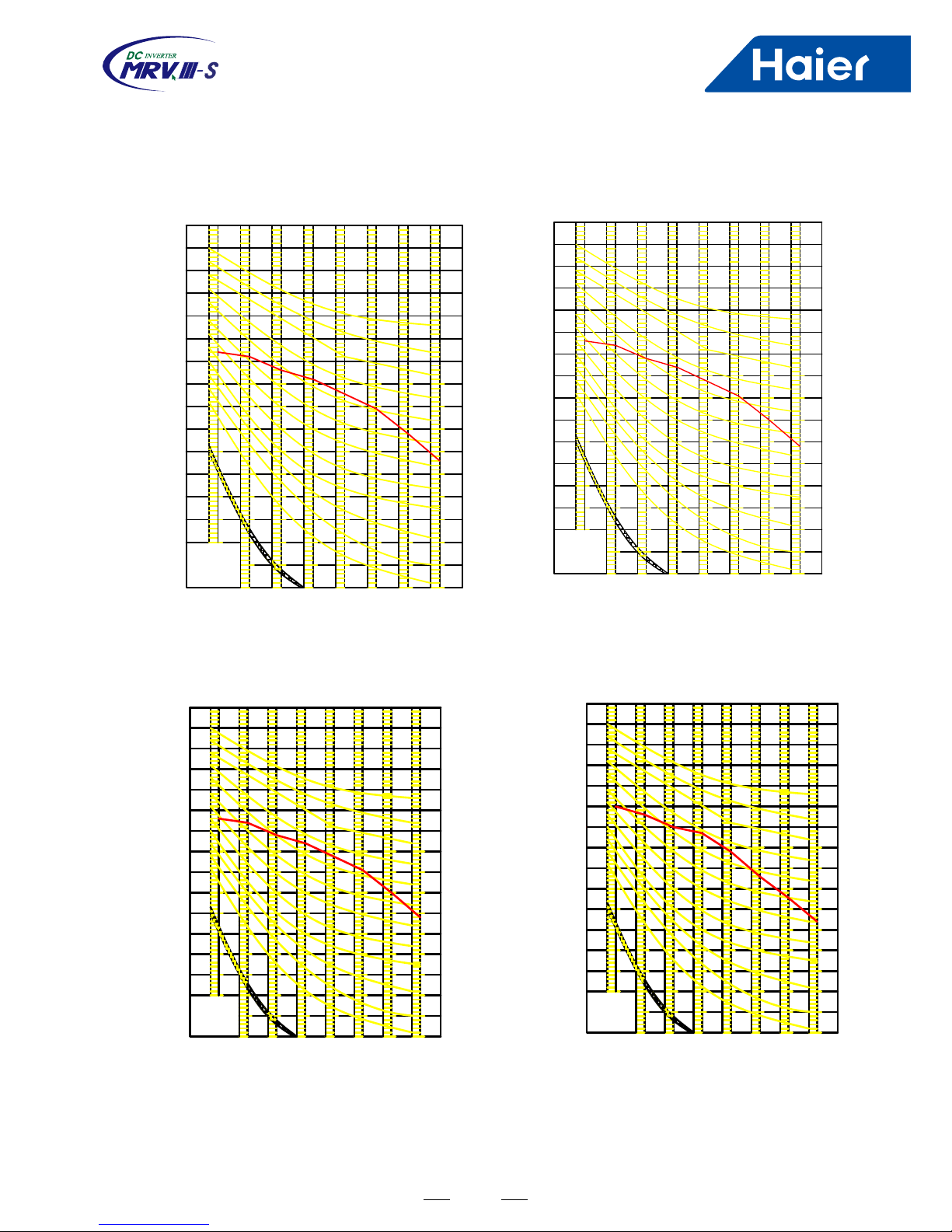

17

20

30

40

50

60

80

70

AU282FHERA

1252 50 500 1000 2000 4000 800063

NC-20

NC-30

NC-40

NC-50

NC-60

NC-70

Octave band center frequency

Octave band sound pressure level

dB

Limit of audible

continuous

noise

20

30

40

50

60

80

70

AU482FIERA(G)

63 1252 50 500 1000 2000 4000 8000

NC-20

NC-30

NC-40

NC-50

NC-60

NC-70

Octave band center frequency (Hz)

Octave band sound pressure level

dB

Limit of audible

continuous

noise

20

30

40

50

60

80

70

00010 0020 0040 008365 210 520 05

NC-20

NC-30

NC-40

NC-50

NC-60

NC-70

20

30

40

50

60

80

70

00010 0020 0040 008365 210 520 05

NC-20

NC-30

NC-40

NC-50

NC-60

NC-70

Octave band center frequency

Octave band center frequency

Octave band sound pressure level dB

Octave band sound pressure level

dB

Limit of audible

continuous

noise

Limit of audible

continuous

noise

AU48NFIERA(G)

AU60NFIERA(G)

(Hz)

(Hz)

(Hz)

7.3 Noise level

18

8. Outdoor Installation

8.1 Installation cautions

SAFETY PRECAUTIONS

■ Please read these "Safety Precautions" rstly then accurately execute the installation work.

■ Though the precautionary points indicated herein are divided under two headings, "WARNING" and "CAUTION",

those points which are related to the strong possibility of an installation done in error resulting in death or

serious injury are listed in the "WARNING" section. However, there is also a possibility of serious consequences

in relationship to the points listed in the "CAUTION" section as well. In either case, important safety related

information is indicated, so by all means, properly observe all that is mentioned.

■ After completing the installation, along with conrming that no abnormalities were seen from the operation tests,

please explain operating methods as well as maintenance methods to the user (customer) of this equipment,

based on the owner's manual.

■ Moreover, ask the customer to keep this sheet together with the owner's manual.

WARNING

■ This system should be applied to places of ofce, restaurant, residence and the like. Application to inferior

environment such as engineering shop could cause equipment malfunction.

■ Please entrust installation to either the company which sold you the equipment or to a professional contractor.

Defects from improper installations can be the cause of water leakage, electric shocks and res.

■ Execute the installation accurately, based on following the installation manual. Again, improper installations can

result in water leakage, electric shocks and res.

■ When a large air-conditioning system is installed to a small room, it is necessary to have a prior planned

countermeasure for the rare case of a refrigerant leakage, to prevent the exceeding of threshold concentration. In

regards to preparing this countermeasure, consult with the company from which you purchased the equipment,

and make the installation accordingly. In the rare event that a refrigerant leakage and exceeding of threshold

concentration does occur, there is the danger of a resultant oxygen deciency accident.

■ For installation, conrm that the installation site can sufciently support heavy weight. When strength is

insufcient, injury can result from a falling of the unit.

■ Execute the prescribed installation construction to prepare for earthquakes and the strong winds of typhoons and

hurricanes, etc. Improper installations can result in accidents due to a violent falling over of the unit.

■ For electrical work, please see that a licensed electrician executes the work while following the safety standards

related to electrical equipment, and local regulations as well as the installation instructions, and that only

exclusive use circuits are used. Insufcient power source circuit capacity and defective installment execution can

be the cause of electric shocks and res.

■ Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted

to the terminal connection part, through properly securing it. Improper connection or securing can result in heat

generation or re.

■ Take care that wiring does not rise upward, and accurately install the lid/service panel. Its improper installation

can also result in heat generation or re.

■ When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the

designated refrigerant (please see nameplate) within the refrigeration cycle.

■ Rupture and injury caused by abnormal high pressure can result from such mixing.

■ Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this

company can result in water leakage, electric shock, re and refrigerant leakage.

19

CATUION

■ Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightening rod or a

telephone ground wire.

■ Improper placement of ground wires can result in electric shock.

■ The installation of an earth leakage breaker is necessary depending on the established location of the unit.

■ Not installing an earth leakage breaker may result in electric shock.

■ Do not install the unit where there is a concern about leakage of combustible gas. The rare event of leaked gas

collecting around the unit could result in an outbreak of re.

■ For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it

to prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

8.2 Refrigerant piping

Outdoor

Indoor 1

Indoor 2

Indoor 3

Indoor 4

a. Pipe "a" diameter (between indoor and branch pipe) (depends on indoor pipe)

Indoor(×100W) 07~09 Gas pipe φ9.52 Liquid pipe φ6.35

12~18 φ12.7 φ6.35

24 φ15.88 φ9.52

b. Pipe "b" diameter (between branch pipe)

The branch pipe diameter depends on the total capacity of indoors connected with it. If indoor capacity is more than

outdoor capacity, it is conrmed by the outdoor capacity.

Total indoor capacity after the branch pipe (100W) Gas pipe Liquid pipe

<112 φ15.88 φ9.52

112<X<234 φ19.05 φ9.52

Loading...

Loading...