Page 1

SERVICE MANUAL

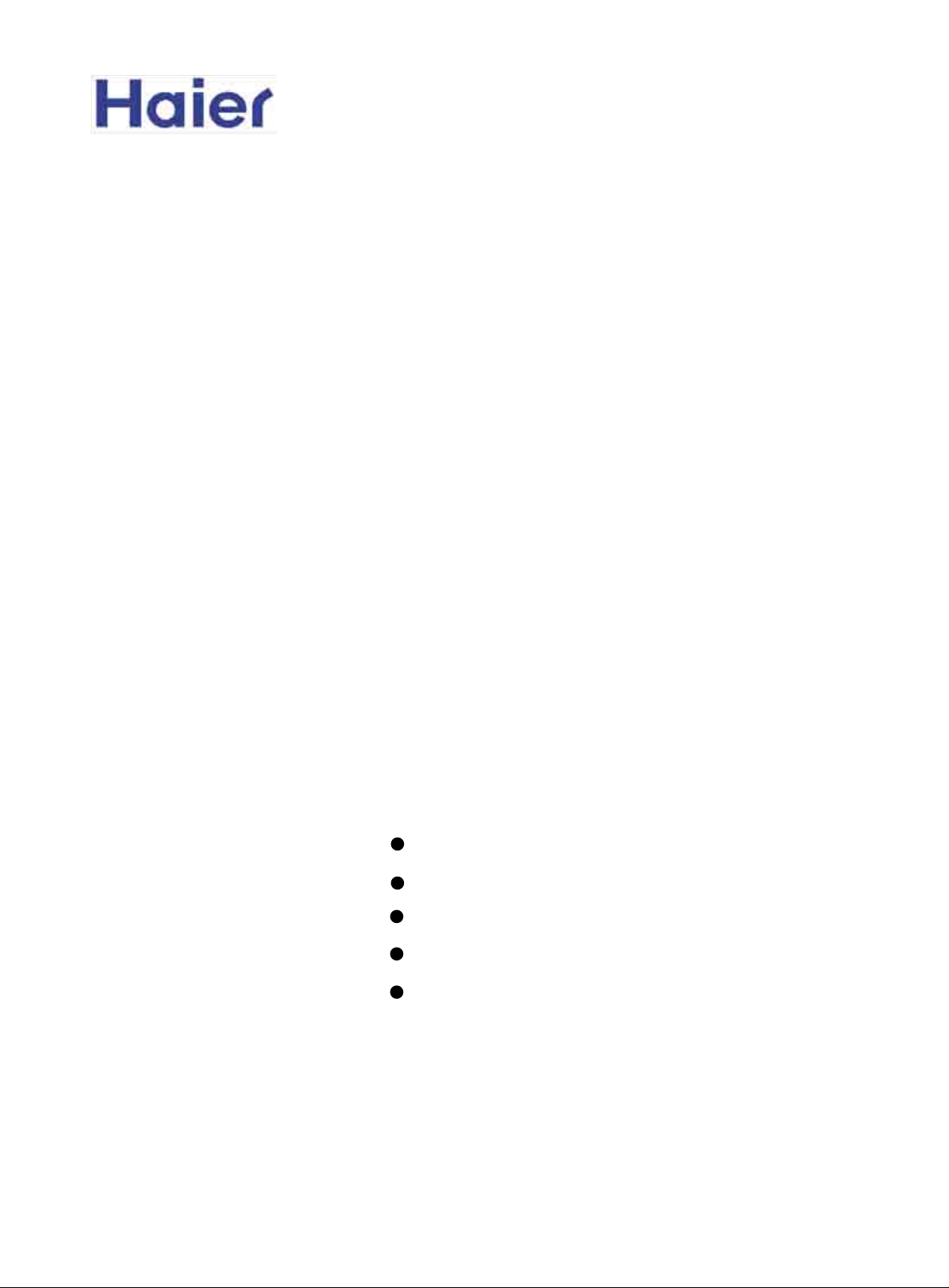

E-Multi

4-WAY CASSETTE INDOOR UNIT

D U C T I N D O O N I T

CONSOLE INDOOR UNIT

WALL MOUNTED INDOOR UNIT

T DOO R U NI T ( 2 8 /420 0 0 BT U /h )

OU

Haier Commercial Air Conditioner

Version: 200808

series

R U

SYJS-018-07REV.1

Page 2

Chff^j\bZe Abj Chg]blbhg^j

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

CONTENT

1.General information -----------------------------------------------------------------------------------------------1

1.1 Free Multi series line up --------------------------------------------------------------------------------------

1.2 Operation temperature range ------------------------------------------------------------------------------

2.Description of products & features ---------------------------------------------------------------------------

2.1 Product code explanation-------------------------------------------------------------------------------------

2.2 Product character ----------------------------------------------------------------------------------------------

3. Specification ------------------------------------------------------------------------------------------------------ 3

3.1 Outdoor unit ----------------------------------------------------------------------------------------------------

3.2 Cassette unit ---------------------------------------------------------------------------------------------------

3.3 Duct type --------------------------------------------------------------------------------------------------------

3.4 Console type ---------------------------------------------------------------------------------------------------

3.5 Wall mounted type --------------------------------------------------------------------------------------------

4. Net dimension of indoor and outdoor------------------------------------------------------------------------

4.1 AU282XHEAA -------------------------------------------------------------------------------------------------- 7

4.2 AU422XIEAA ---------------------------------------------------------------------------------------------------

4.3 Cassette type (AB07-14) ------------------------------------------------------------------------------------

4.4 Wall mounted type --------------------------------------------------------------------------------------------

4.5 Cassette type (AB21) -----------------------------------------------------------------------------------------

4.6 Duct type --------------------------------------------------------------------------------------------------------

4.7 Console type ----------------------------------------------------------------------------------------------------

5. Part name ---------------------------------------------------------------------------------------------------------

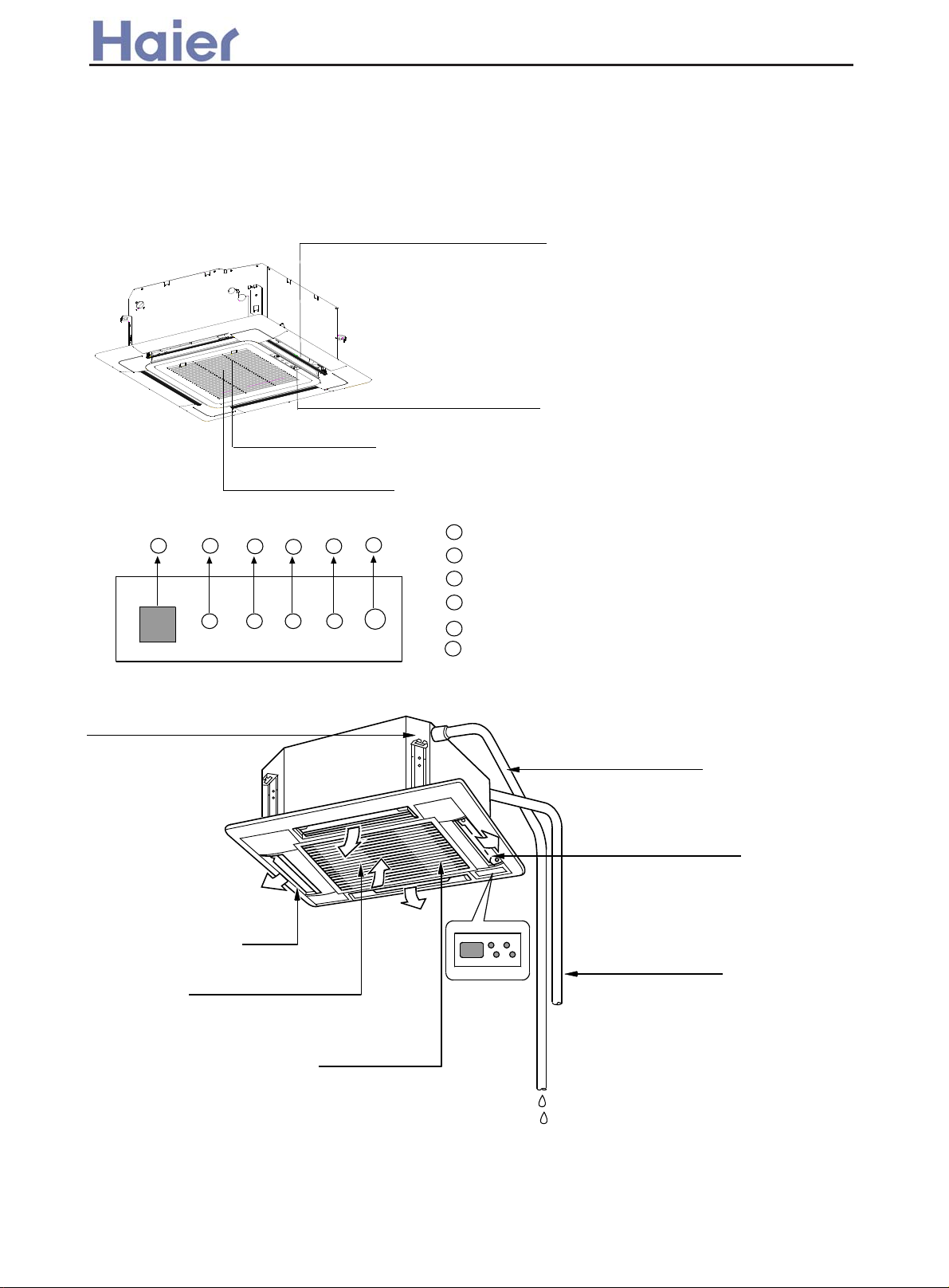

5.1 Cassette type AB07-14----------------------------------------------------------------------------------------

5.2 Cassette type AB21 -------------------------------------------------------------------------------------------

5.3 Duct type --------------------------------------------------------------------------------------------------------

5.4 Console type ---------------------------------------------------------------------------------------------------

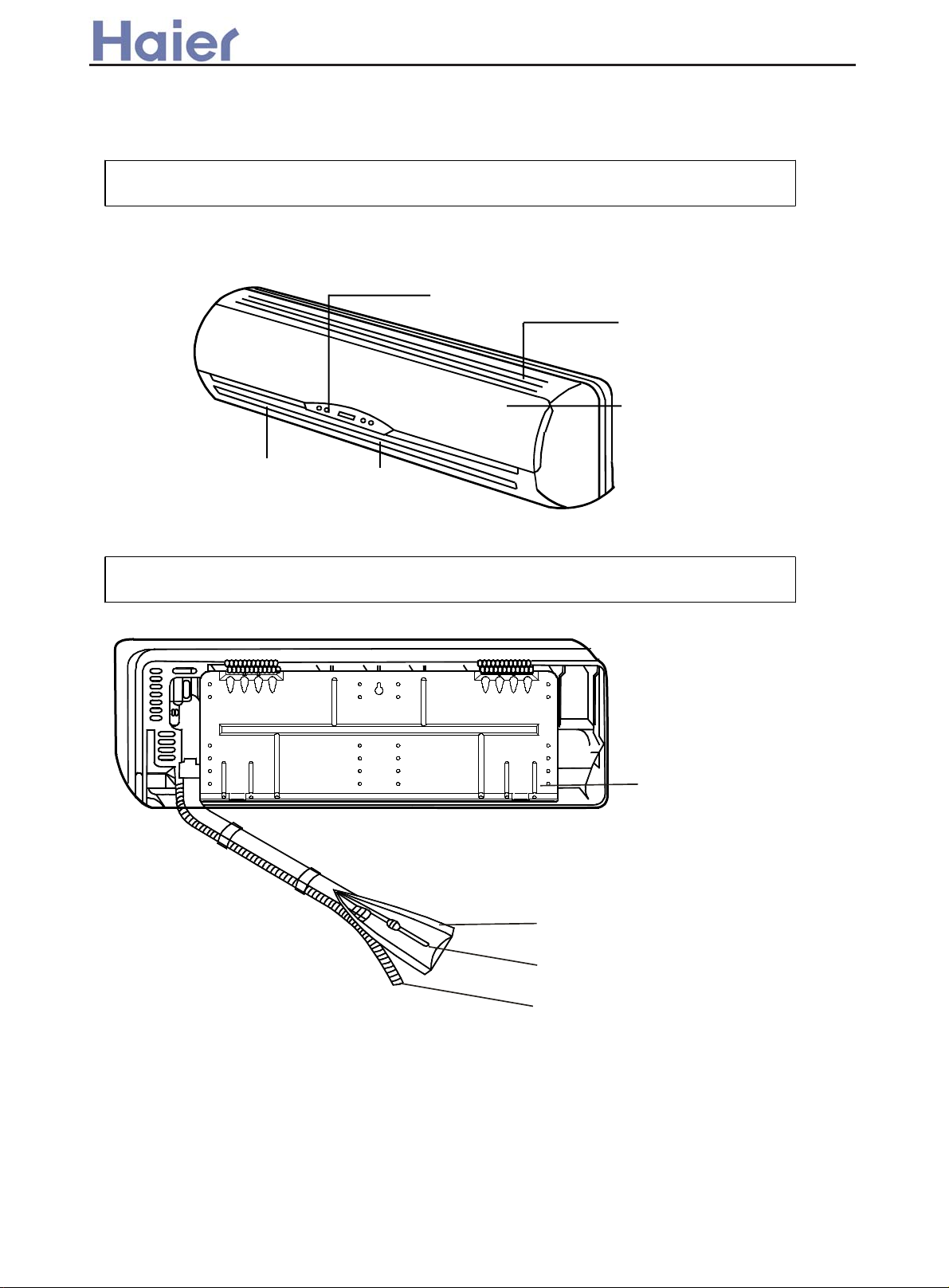

5.5 Wall mounted type --------------------------------------------------------------------------------------------

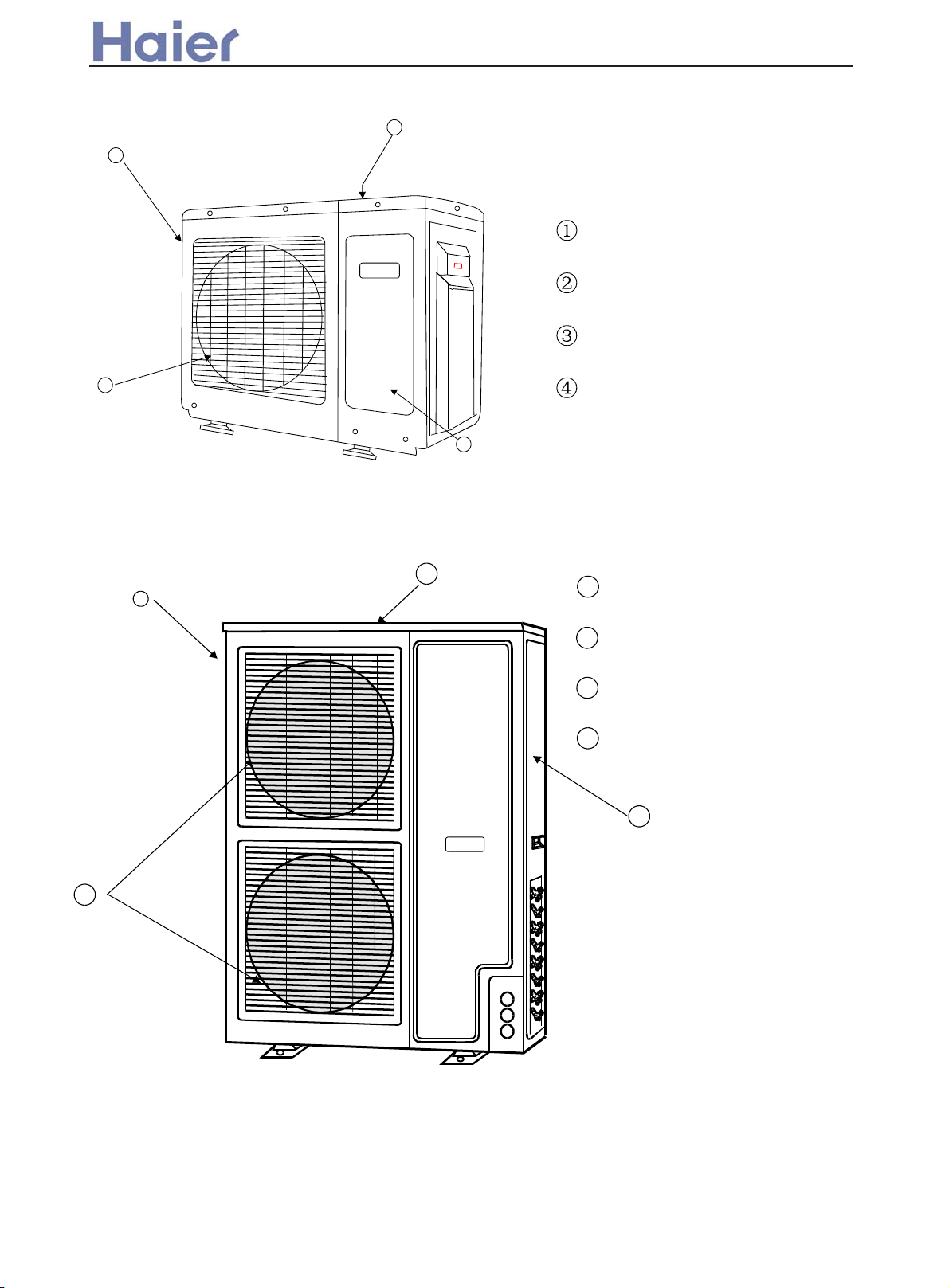

5.6 AU282XHEAA --------------------------------------------------------------------------------------------------

5.7 AU422XIEAA ---------------------------------------------------------------------------------------------------

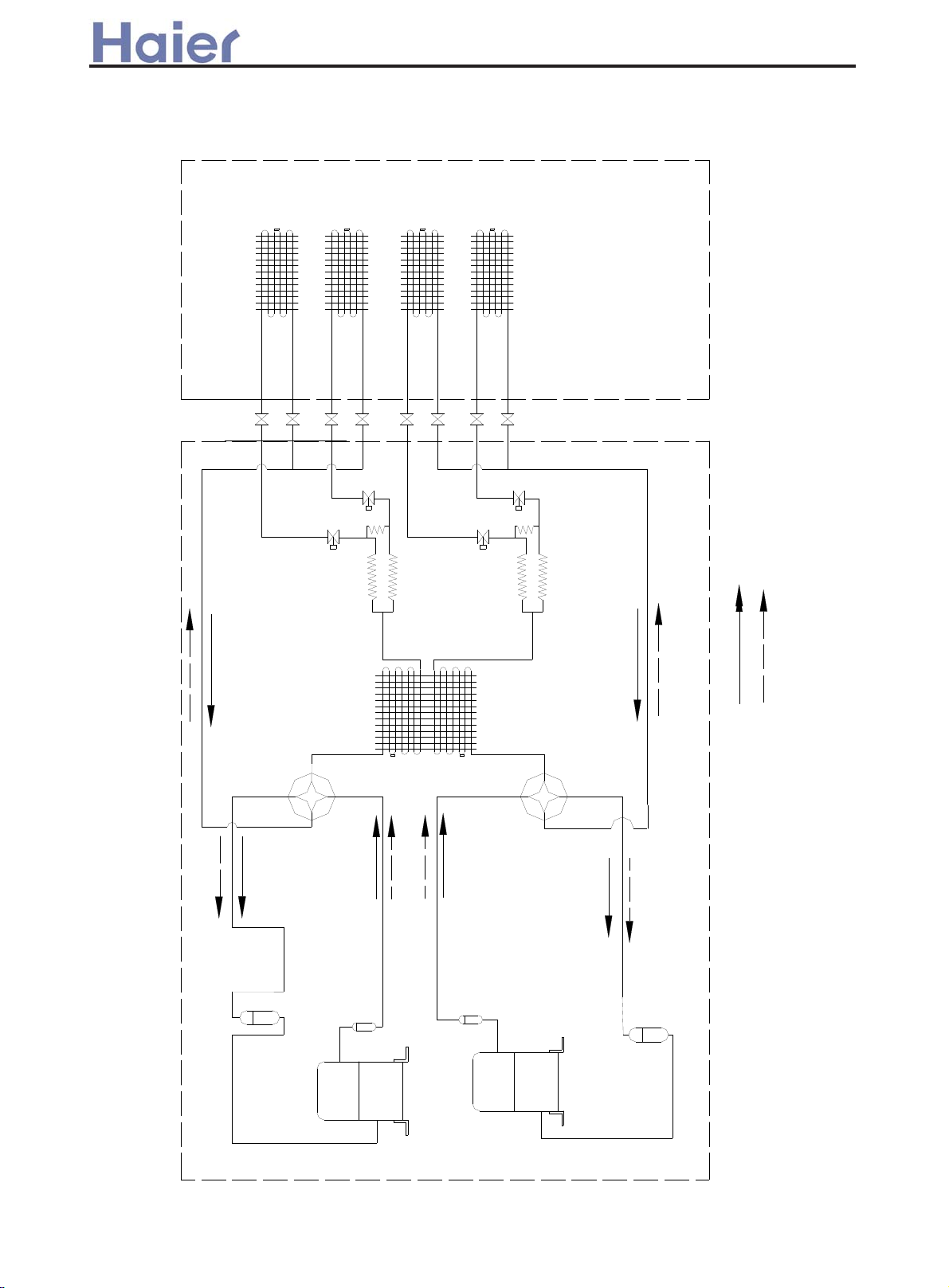

6. Refrigerant diagram --------------------------------------------------------------------------------------------

6.1 AU282XHEAA -------------------------------------------------------------------------------------------------- 16

6.2 AU422XIEAA ---------------------------------------------------------------------------------------------------

7. The unit capacity and performance mode ----------------------------------------------------------------

7.1 AU2 2XHEAA -------------------------------------------------------------------------------------------------- 18

7.2 AU422XIEAA ---------------------------------------------------------------------------------------------------

8. Installation procedure ------------------------------------------------------------------------------------------

8.1 Cassette type AB07-142XCEAA ---------------------------------------------------------------------------

8.2 Cassette type AB212XCEAA ------------------------------------------------------------------------------- 28

8.3 Duct type AE***XLEAA --------------------------------------------------------------------------------------

8.4 Console type AF***XCEAA ---------------------------------------------------------------------------------

8.5 Wall mounted type AS***XCEAA -------------------------------------------------------------------------- 50

9. Wiring diagram, PCB photo and function information --------------------------------------------------

9.1 AB07-142XCEAA ---------------------------------------------------------------------------------------------

9.2 AB212XCEAA --------------------------------------------------------------------------------------------------- 58

9.3 AF07-142XCEAA ----------------------------------------------------------------------------------------------

9.4 AS***XCEAA ----------------------------------------------------------------------------------------------------

9.5 Outdoor unit AU282XHEAA, AU422XIEAA--------------------------------------------------------------

10. Trouble shooting -----------------------------------------------------------------------------------------------

11. Outdoor performance curves -------------------------------------------------------------------------------- 77

12. indoor air velocity and temperature distribution curves ----------------------------------------------- 79

13. Air flow and static pressure chart --------------------------------------------------------------------------

8

1

1

2

2

2

3

4

5

6

7

7

8

9

9

10

11

11

12

12

12

13

13

14

15

15

16

17

18

20

23

23

37

44

54

54

62

66

68

76

86

Page 3

1. General information

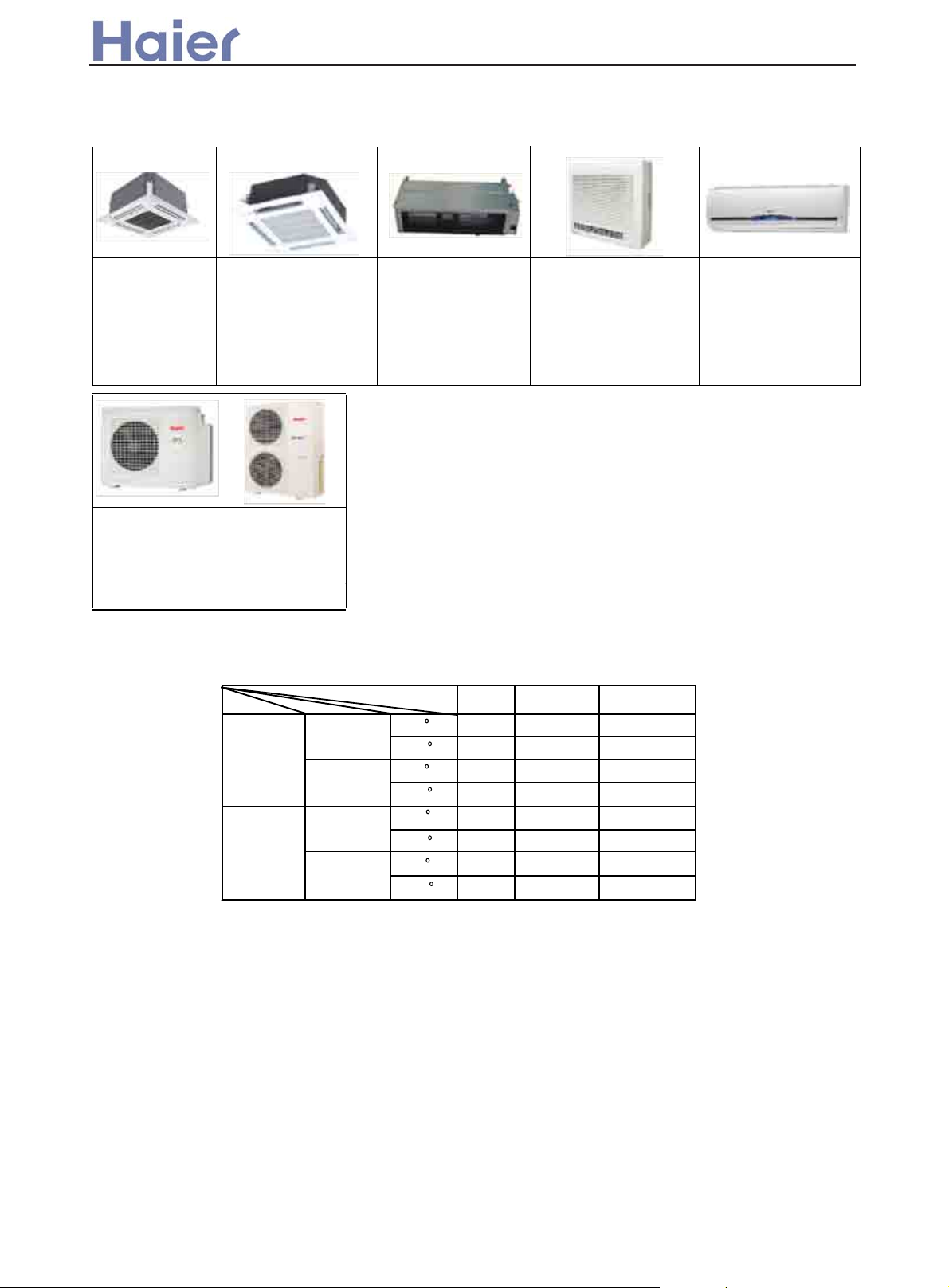

1.1 E-Multi (R410a) series line up

Chff^j\bZe Abj Chg]blbhg^j

AB072XCEAA

AB092XCEAA

AB212XCEAA

AB122XCEAA

AB142XCEAA

AU282XHEAA

AU422XIEAA

1.2 Operati on temperature range

Fixed frequency single unit,multi split unit

Indoor

Cooling

Outdoor

Heating

Indoor

Outdoor

AD072XLEAA

AD092XLEAA

AD122XLEAA

AD142XLEAA

AD212XLEAA

Rated Maximum Minimum

DB C

WB C

DB C

WB C

DB C

WB C

DB C

WB C

27 32 18

19 23 14

35 43 10

24 26 6

20 27 15

14.5 -- --

7 24 -7

6 18 --

AF072XCEAA

AF092XCEAA

AF122XCEAA

AF142XCEAA

AS072XCEAA

AS092XCEAA

AS122XCEAA

AS142XCEAA

z 1 z

Page 4

Chff^j\bZe Abj Chg]blbhg^j

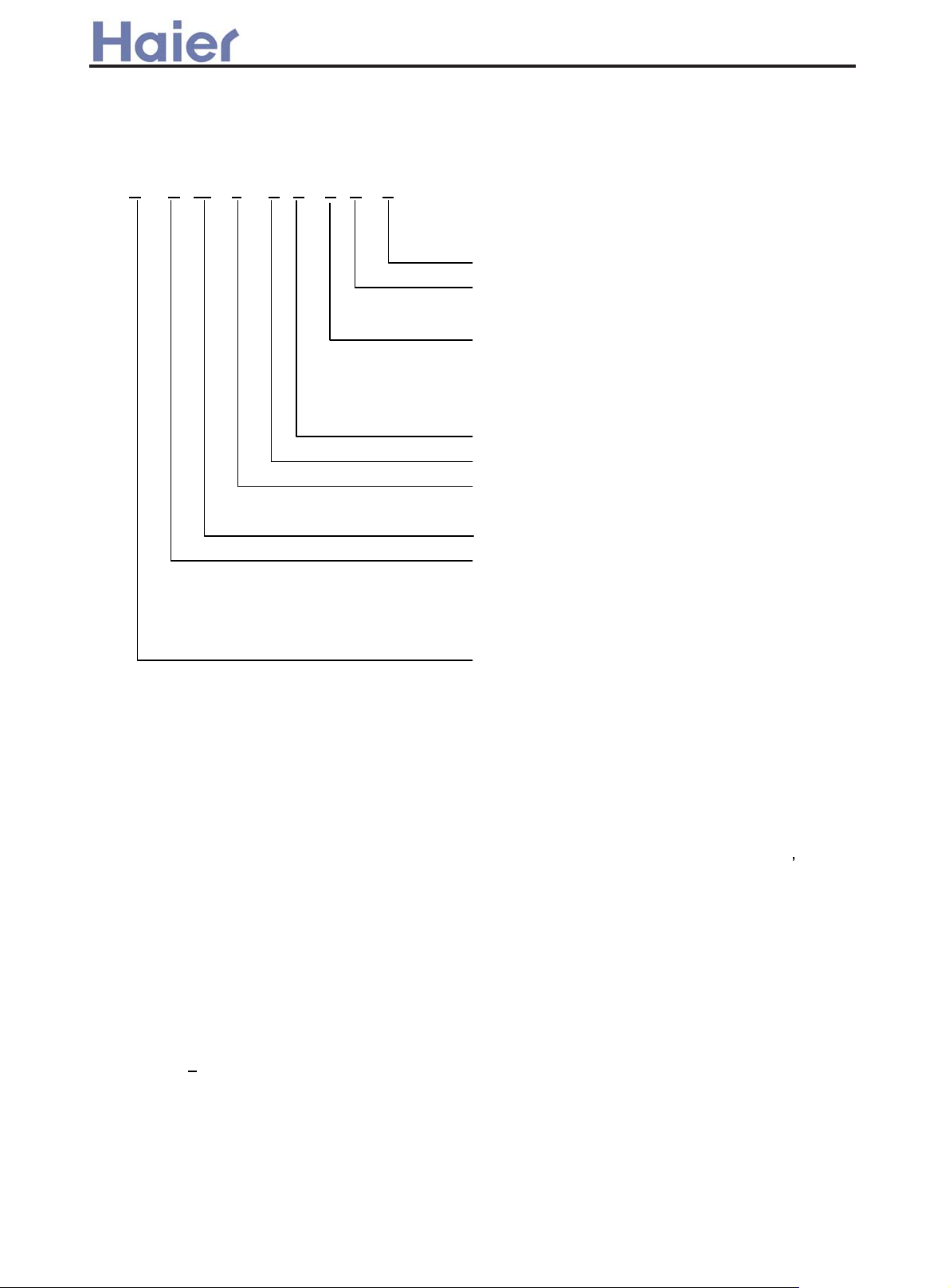

2.DESCRIPTION OF PRODUCTS & FEATURES

2.1. Products code explanation

A D 14 2 X L E A A

Climate type: T1 standard test condition

Design number (A stands for design sequence, Fixed

frequency type)

Product type: A stands for heat pump type, refrigerant is R22

B stands for heat pump type, refrigerant is R407C

E stands for heat pump type, refrigerant is R410

Q stands for cool only type, refrigerant is R410A

Design number,L means low pressure type

Product series: X stands for multi split units

Applicable voltage: 2 stands for 220~230V/50Hz,

4 stands for 220V/60Hz,N stand for 380~400VAC/50Hz

Cooling / Heating capacity,14=14000BTU/h

Product type : “B” stands for cassette type, “C” stands for

convertible type, ”D” stands for duct, “S” stands for wall

mounted type, ”Q” stands for chiller system, "E" stands for

ceiling concealed type, “U” stands for outdoor unit

Air Conditioner

A

2.2 Product character

2.2.1 Phylogeny

E-Multi(R410A) series is multi split ON/OFF type series, developed based on Free Multi (R407C).

2.2.2 Operating individually and operating simultaneously

The unit can realize individual operation which can control one unit running, stop, and adjusting running mode.

Also the unit can operate simultaneously which control multi indoor units at same time.

2.2.3 Variable quantity of indoor unit

If you want to add or reduce the quantity of indoor units (of course the match must correspond with the design),

it can meet your need at any time. More convenient, more random.

2.2.4 Universal outdoor unit, multiform indoor unit

We realize universal outdoor unit, and 6 kinds of indoor unit, choose freely according to customer

indoor decoration, more stylish and more beautiful

2.2.5 The total capacity of indoor unit can be more than that of outdoor unit.

When all the indoor units are running at the same time, the actual capacity of every indoor unit is proportional

according to outdoor capacity.

2.2.6 Long distribution pipe and high drop

The distance of outdoor and indoor can be max. 15m, and the drop between indoor and outdoor can be max.

up to 5m, consequently, the installation can be more free, and can meet various need of the customer.

2.2.7 Duct type unit be equipped with high efficiency filter, and its high static pressure can be up to

30Pa, running more silent, making room air more comfortable and more clean.

2.2.8 Auto-check function

The unit can display the malfunction codes on the control board by using advanced auto-check technology

,convenient for user find and dwell with the abnormal running.

2.2.9 Auto

restart function (optional )

All indoor units have auto-restart function. When the power supply cut off suddenly, the unit will automatically

recover the previous running mode once the power supply is on

s favor and

z 2 z

Page 5

Chff^j\bZe Abj Chg]blbhg^j

2.2.10 Variable Control modes

Wired remote control,Remote control,Group control,Weekly timer,Group control(For wired type)

2.2.11 universal PCB

Except AB072-142XCEAA types, the other units' PCBs are completely same with Free Multi

R407C types, so it's easy to get spare parts ,install Multi R410a and solve problems.

E-

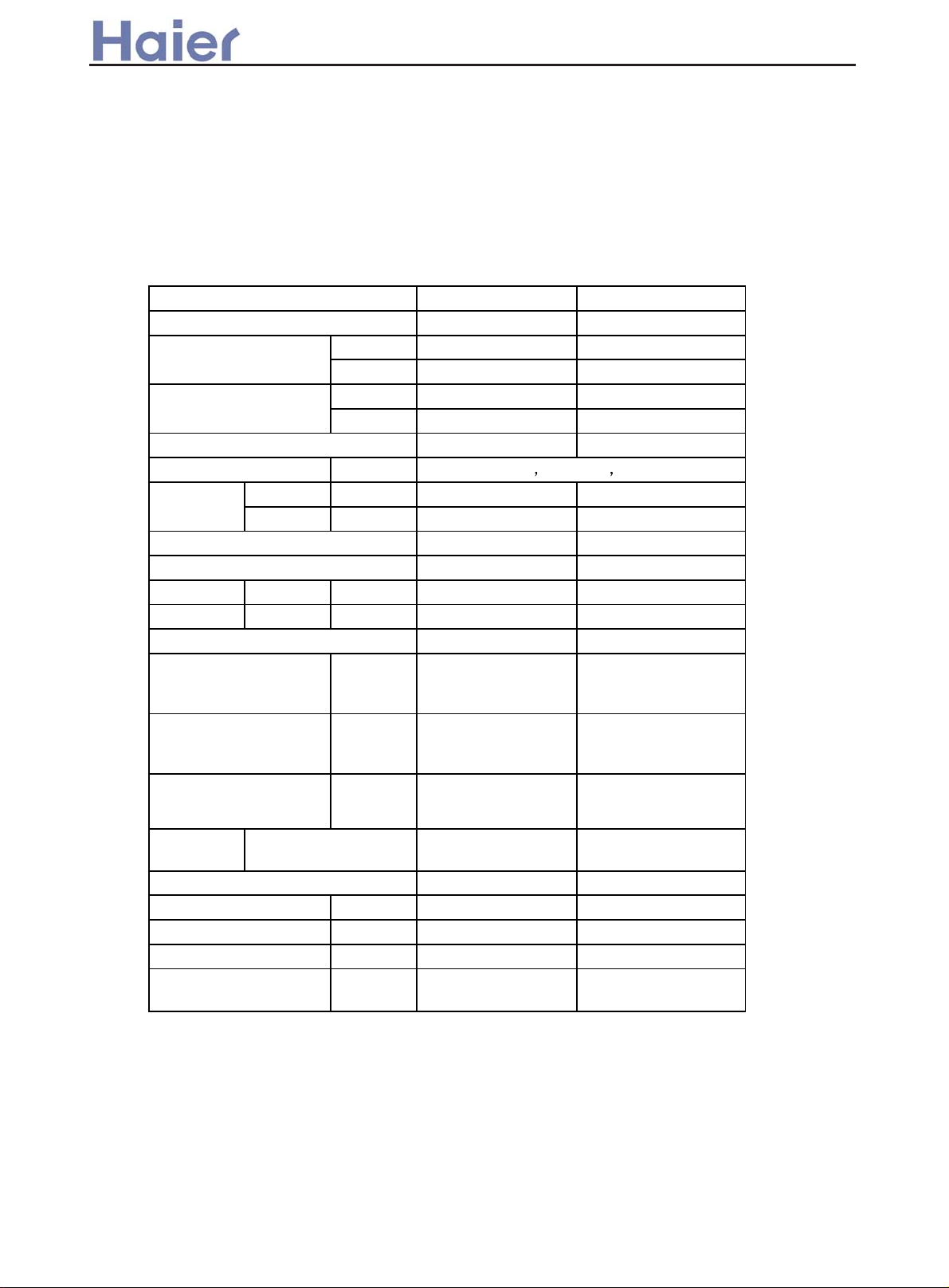

3. Speci

fication

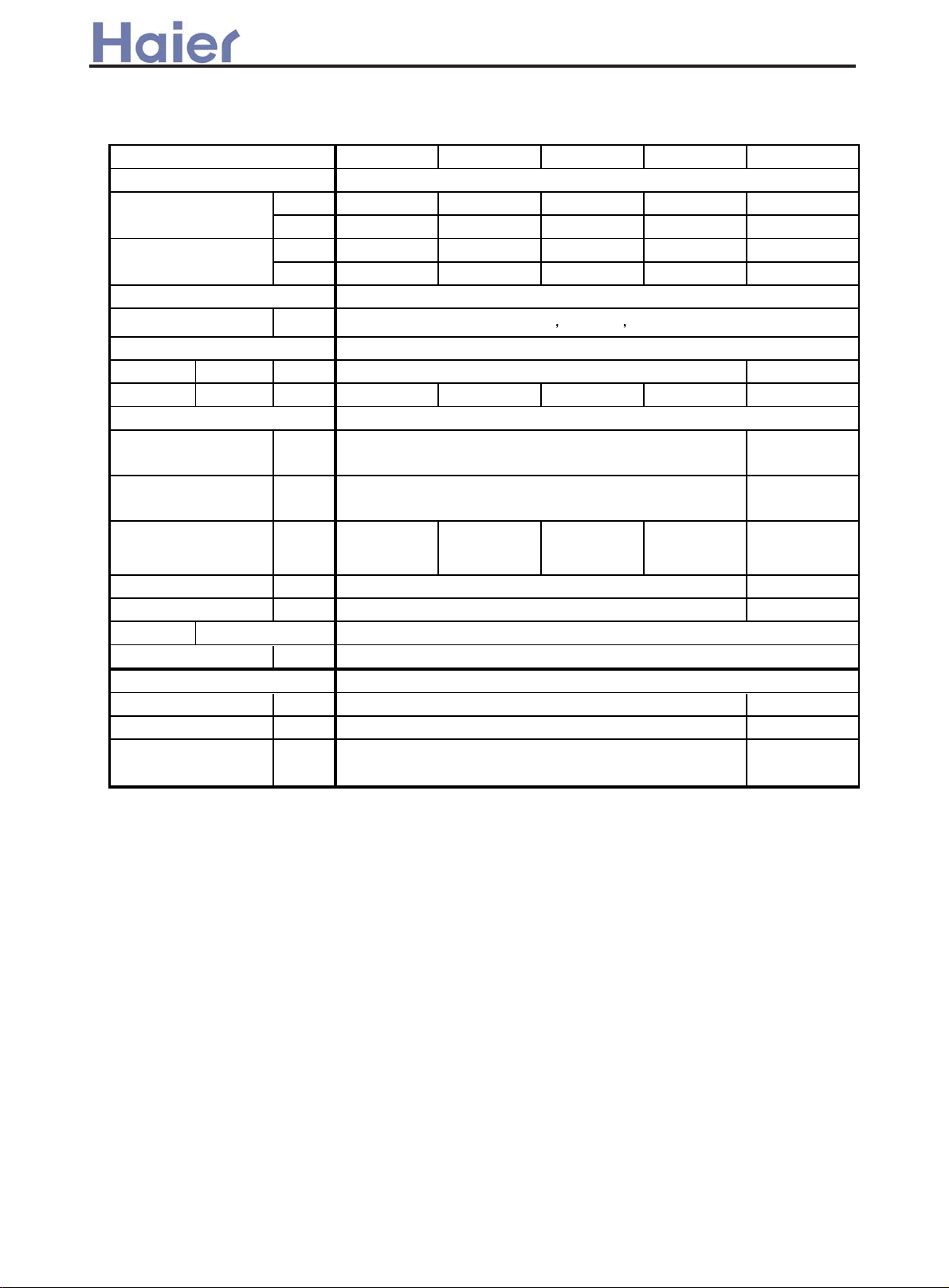

3.1.Outdoor Units

Model

Capacity

Cooling

Heating

Electrical parameters

Power supply

Power input

EER/COP

Performance

Air flow

Noise Level

Installation

External

dimensions(WxHxD)

Shipping

dimensions(WxHxD)

Cooling

Heating

H

H/M/L

Btu/h

kw

Btu/h

kw

Ph/V/Hz

kw

kw

m3/h

dB(A)

mm

mm

AU282XHEAA

28000 42000

8.2

31000 45000

9.0

230VAC

1PH

2720

2630

3.01/3.42 3.01/3.42

3800 6000

56 60

1068x340x840

1100x410x990 1095x410x1400

AU422XIEAA

12.3

13.0

50Hz

4.08

3.8

948x340x1250

Net weight/Shipping

weight

Compressor

type

Refrigerant type

Refrigerant liquid pipe

Refrigerant gas pipe

Max pipe length

Max drop between

I.N.&O.U

Scroll/Rotary

kg

mm

mm

m

m 5 5

88/94

Rotary Rotary

4x6.35 4x6.35

4x9.52 4x9.52

15 15

105/115

z 3 z

Page 6

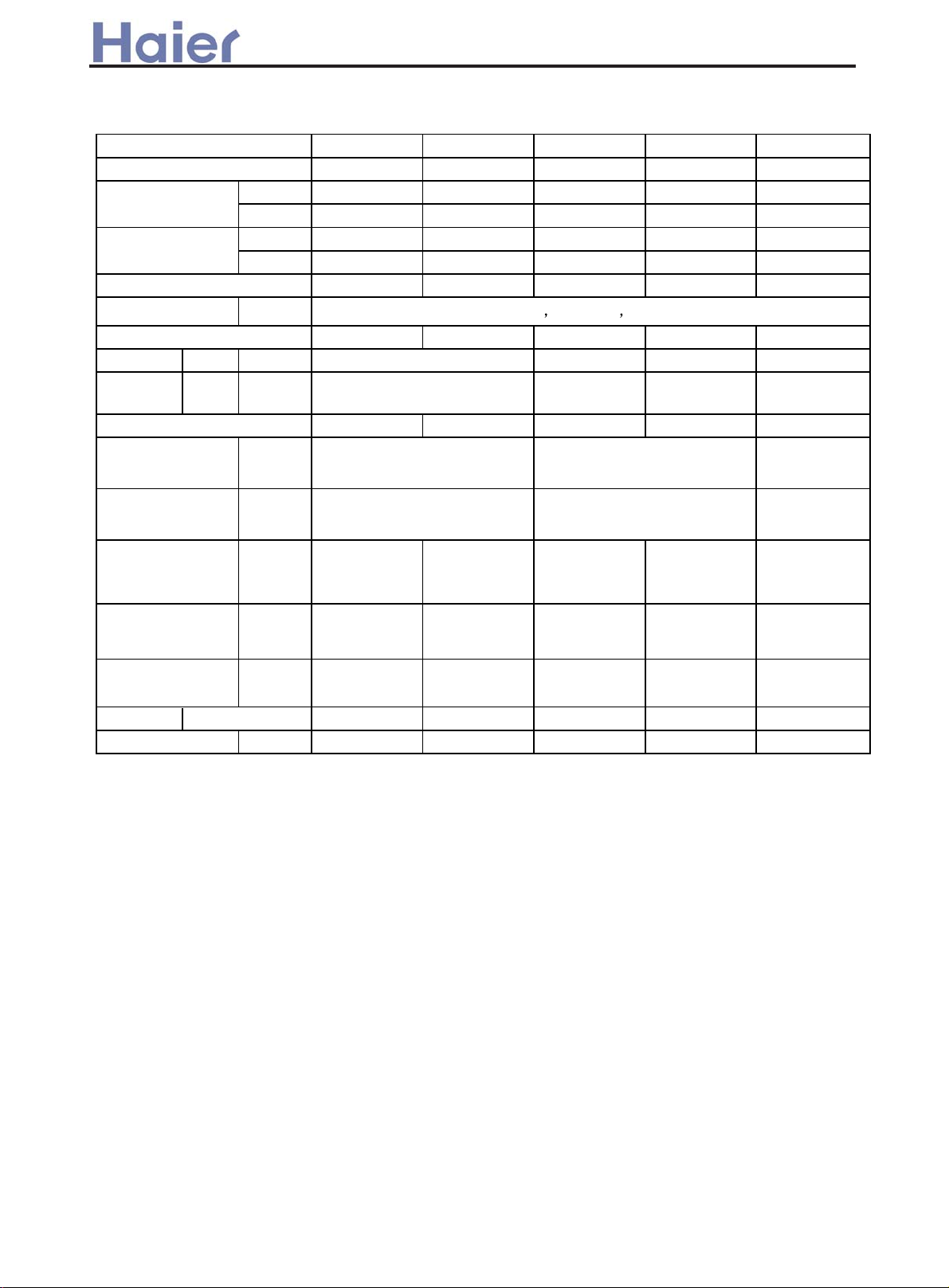

3.2. Cassette Type

Chff^j\bZe Abj Chg]blbhg^j

Model

Capacity

Cooling

Heating

Electrical parameters

Power supply

Performance

Air flow

Noise Level

H/M/L

H/M/L

Installation

External

dimensions(WxHxD)

Shipping

dimensions(WxHxD)

Net weight/Shipping

weight

Refrigerant liquid pipe

Refrigerant gas pipe

Control

Wired /Infrared

Static pressure

Panel

External dimensions

Shipping dimensions

Net weight/Shipping

weight

AB072XCEAA AB092XCEAA AB122XCEAA AB142XCEAA AB212XCEAA

Btu/h

kw

Btu/h

kw

Ph/V/Hz

7000 9000 12000 14000 20000

2.05

8000 10000 13000 15500

2.35

m3/h

dB(A)

37/34/32 37/34/32 41/38/33 41/38/33 46/43/40

mm

mm

kg

17/20 17/20 17/20

mm

mm

Pa

mm

mm

kg

2.6 3.5 4.1 5.8

2.2

2.9 3.8 4.5 6.4

1PH

230VAC

600/480/350

570/570/260

718/680/380

6.35

9.52

50Hz

19/23.5

1200/1000/800

840/840/240

930/930/330

27/33

9.52

12.7

Infrared(YR-H71)

0

700/700/60

740/750/115

2.8/4.8

950/950/80

980/980/100

6.0/9.0

AB072-142XCEAA Panel : PB-700IA

AB212XCEAA Panel : PB-950IA

z 4 z

Page 7

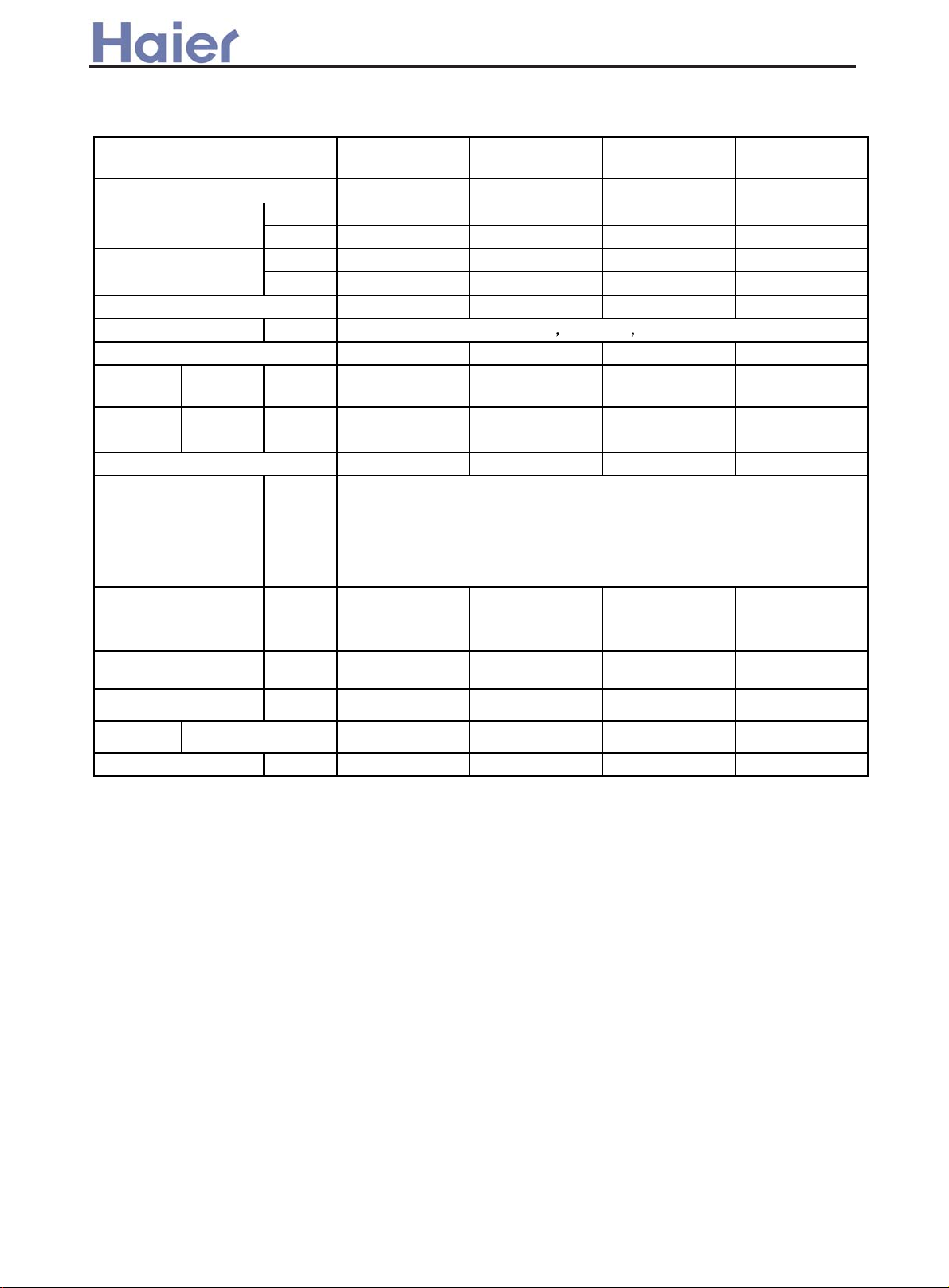

3.3. Duct type

Chff^j\bZe Abj Chg]blbhg^j

Model

Capacity

Cooling

Heating

Electrical parameters

Power supply

Performance

Air flow

Noise

Level

Installation

External

dimensions(WxHxD)

Shipping

dimensions(WxHxD)

Net weight

/Shipping weight

H/M/L

H/M/L

Btu/h

kw

Btu/h

kw

Ph/V/Hz

m3/h

dB(A)

mm

mm

kg

AD072XLEAA AD092XLEAA AD122XLEAA AD142XLEAA AD212XLEAA

7000 9000 12000 14000 21000

2.05

8000 10000 14000 15500 22000

2.35

560/450/360/300

38/34/31/29

674/450/225 828/225/450

18/20 18/20 20/22 20/22 28/32

2.6 3.5 4.1 6.1

2.9 4.1 4.5 6.4

1PH

230VAC

820/700/600/500 900/780/600/500 1200/950/700/550

44/42/37/33 44/40/35/29 46/44/40/33

50Hz

1124/450/225

976/288/526816/288/526

1272/288/526

Refrigerant liquid

pipe

Refrigerant gas

pipe

Control

Static pressure

Wired /Infrared

mm

mm

Pa

6.35 6.35 6.35 6.35

9.52 9.52 9.52 9.52 12.7

Wired Wired Wired Wired Wired

30 30 30 30 30

9.52

z 5 z

Page 8

3.4. Console Type

Chff^j\bZe Abj Chg]blbhg^j

Model

Capacity

Cooling

Heating

Electrical parameters

Power supply

Performance

Air flow

Noise

Level

Installation

External

dimensions(WxHxD)

Shipping

dimensions(WxHxD)

Net weight/Shipping

weight

H/M/L

H/M/L

Btu/h

kw

Btu/h

kw

Ph/V/Hz

m3/h

dB(A)

mm

mm

kg

AF072XCEAA AF092XCEAA AF122XCEAA AF142XCEAA

7000 9000 12000 14000

2.05

8000 10000 14000 15500

2.35

500/400/320 500/400/320 700/650/600 700/650/600

40/36/34 40/36/34 45/40/37 45/40/37

15.5/19 15.5/19 17/20.7 17/20.7

2.6 3.5 4.0

2.9 4.1 4.5

1PH

230VAC

720/205/630

780/280/690

50Hz

Refrigerant liquid pipe

Refrigerant gas pipe

Control

Static pressure

Wired /Infrared

mm

mm

Pa

6.35 6.35 6.35 6.35

9.52 9.52 9.52 9.52

Infrared Infrared Infrared Infrared

0 0 0 0

Console type units can be controlled by remote controller(YR-H71), centrol controller YCZA001 and weekly timer YCS-A001, but in central controller installation, it need detector YCJA001, console type c

ouldn't be connected with controller YR-E12

z 6 z

Page 9

3.5. Wall mounted type

Capacity

Cooling

Heating

Electrical parameters

Power supply

Performance

Air flow

Noise Level

l

Installation

External

dimensions(WxHxD)

Shipping

dimensions(WxHxD)

Net weight/Shipping

weight

Refrigerant liquid pipe

Refrigerant gas pipe

Control

Static pressure

- Multi R410a wall mounted indoor units use same PCB with R407C, they only can be controlled

E

by remote controller, in central control or weekly timer installation, it need detector to set address.

Model

Ph/V/Hz

H/M/L

H/M/L

Wired /Infrared

Btu/h

kw

Btu/h

kw

m3/h

dB(A)

mm

mm

kg

mm

mm

Pa

AS072XCEAA AS092XCEAA AS122XCEAA AS142XCEAA

7000 9000 12000 13000

2.05

7350 9500 13000 14500

2.15

350/300/240

40/35/31

795x197x265

Chff^j\bZe Abj Chg]blbhg^j

2.6 3.5 3.8

2.8 3.8

1PH

230VAC

880 315 3

/ / 30

7.6/10.6

6.35

9.52

Infrared(YR-H71)

0

50Hz

500/400/350

44/40/35

795x197x265

4.25

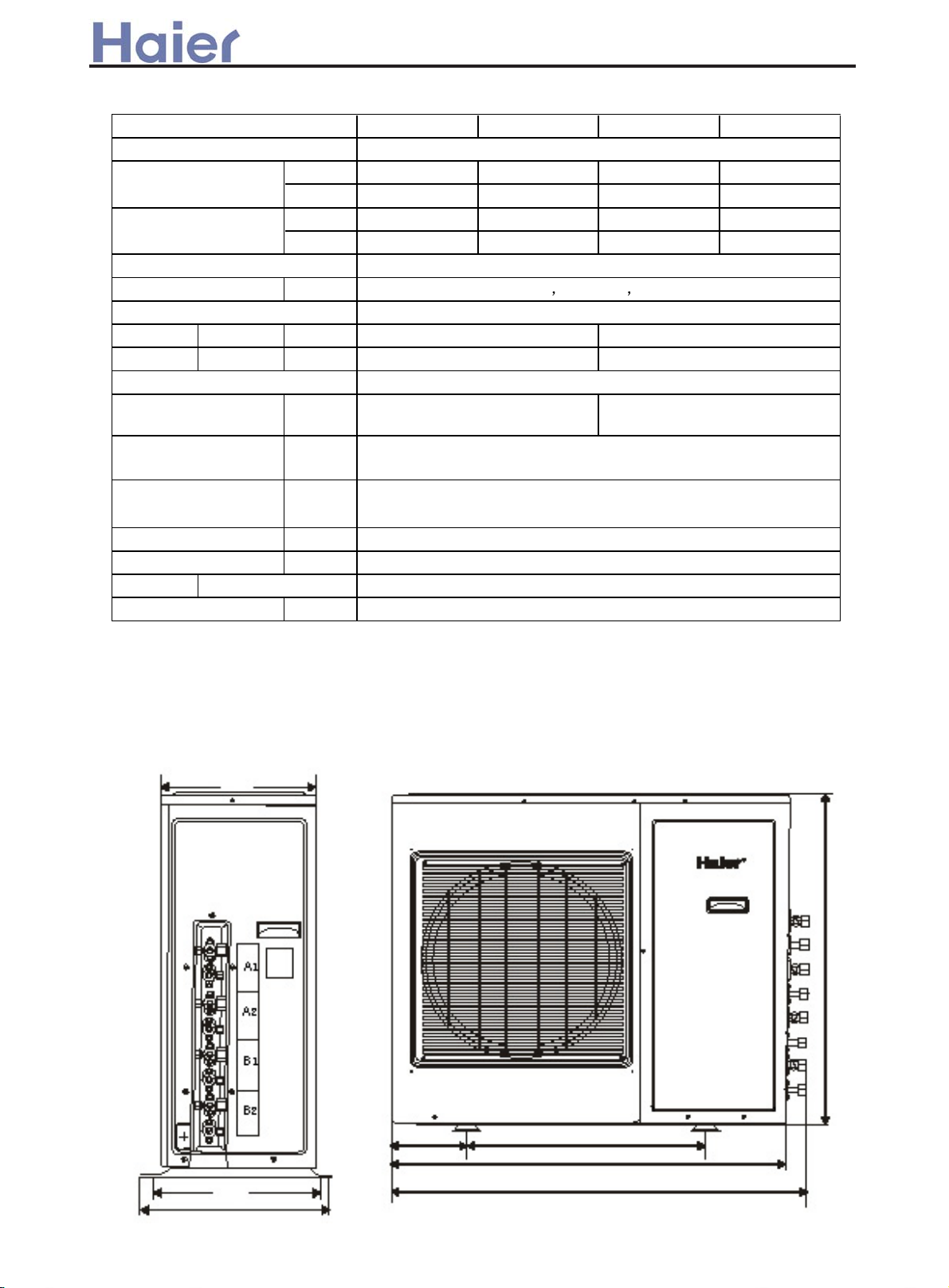

4. Net dimensions of indoor and outdoor

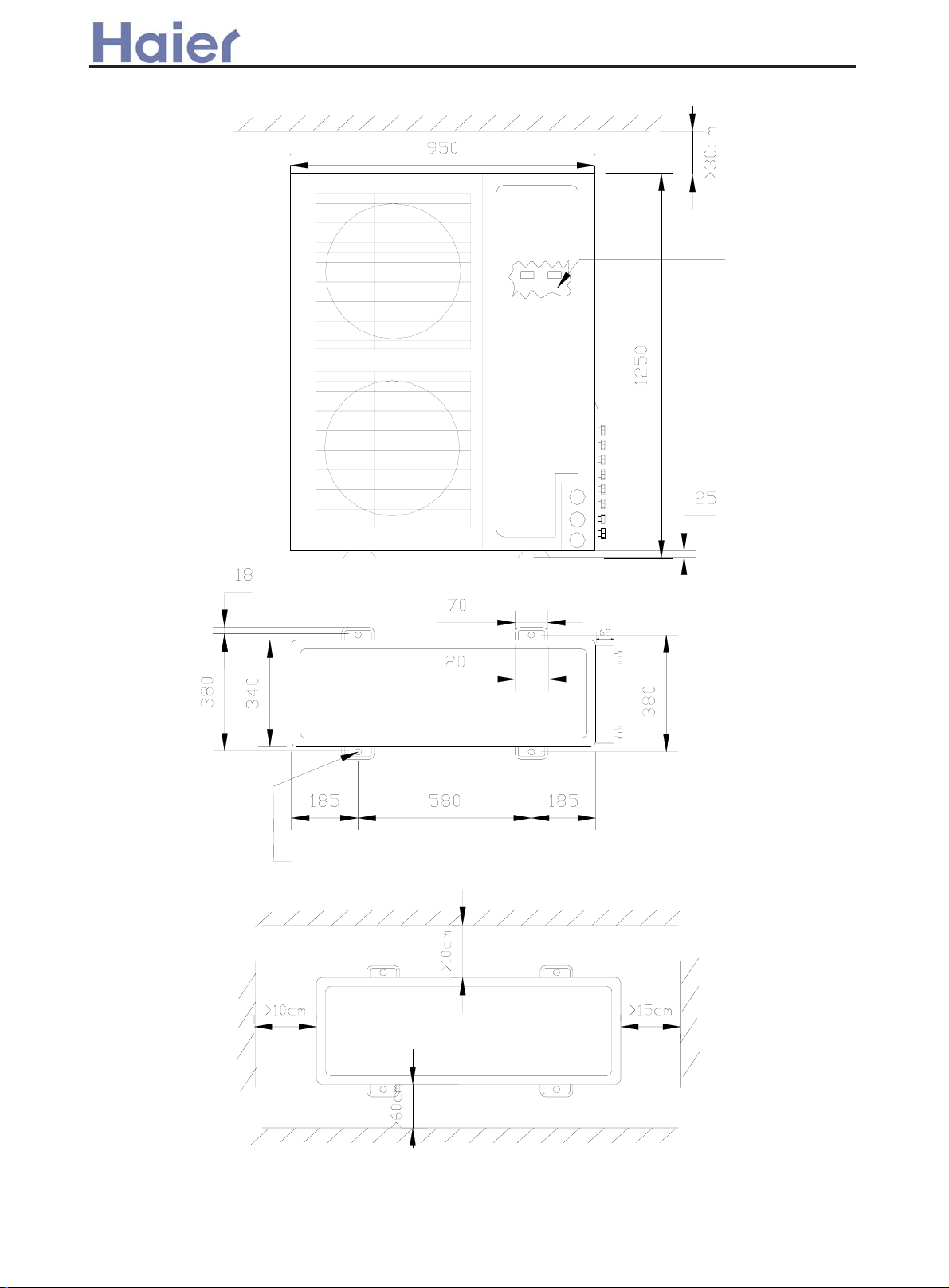

4.1.AU282XHEAA

340

380

416

185

830

580

950

1068

z 7 z

Page 10

4.2. Outdoor unit: AU422XIEAA

screw hole (M10)

Chff^j\bZe Abj Chg]blbhg^j

Terminal block

z 8 z

Page 11

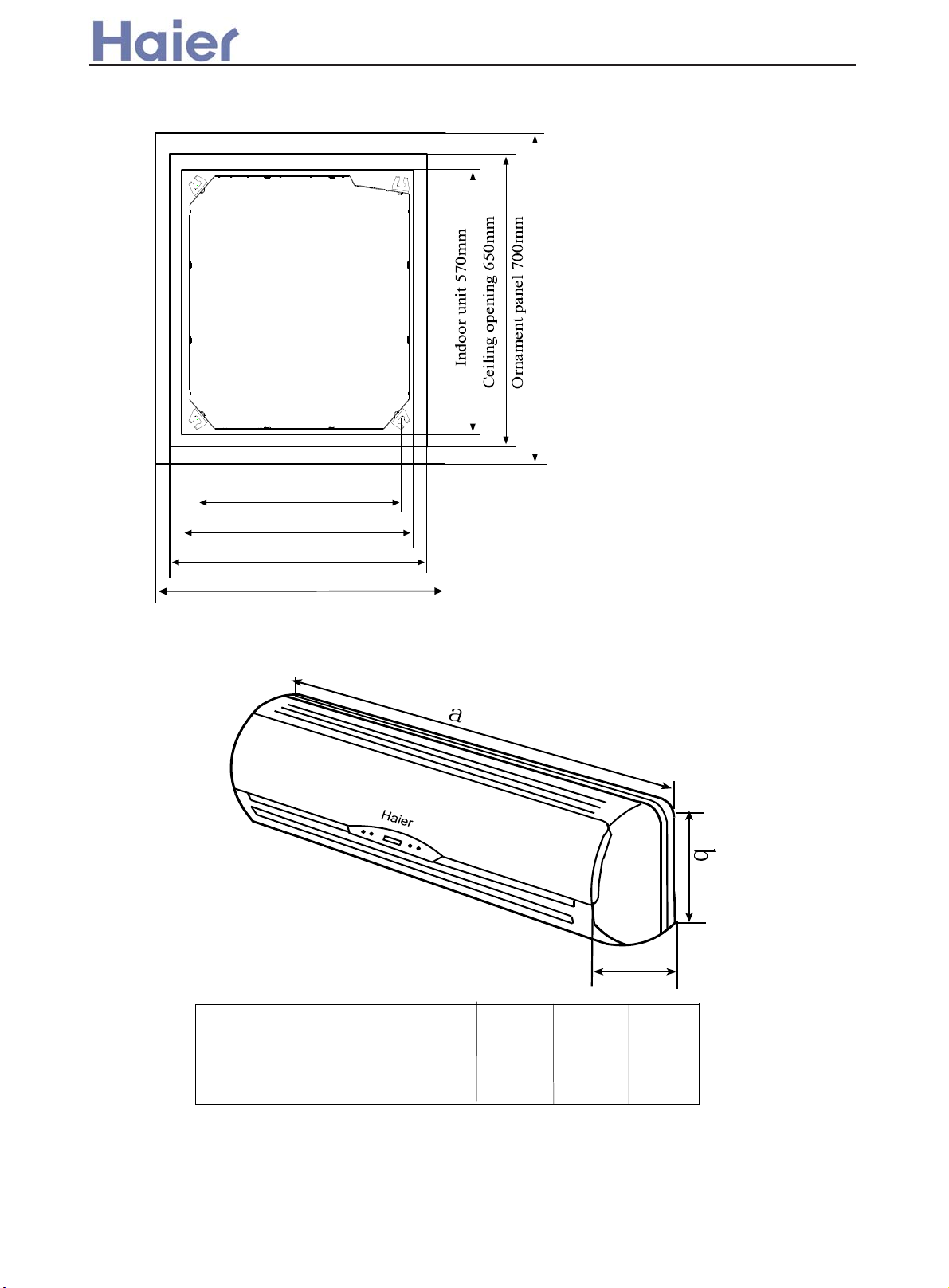

4.3. Cassette Type AB07-142XCEAA

Distance between

suspending bolts 535mm

Chff^j\bZe Abj Chg]blbhg^j

Indoor unit 570mm

Ceiling opening 650mm

Ornament panel 700mm

4.4. Wall Mounted Type AS07-142XCEAA

c

model

A S 0 7 2 X C E A A A S 0 9 2 X C EA

A

S 1 2 2 X CEEEEA

A A S 1 4 2 X C E A A

E

A

z 9 z

a

7

9 5

b c

2 6 5

1 8 2

Page 12

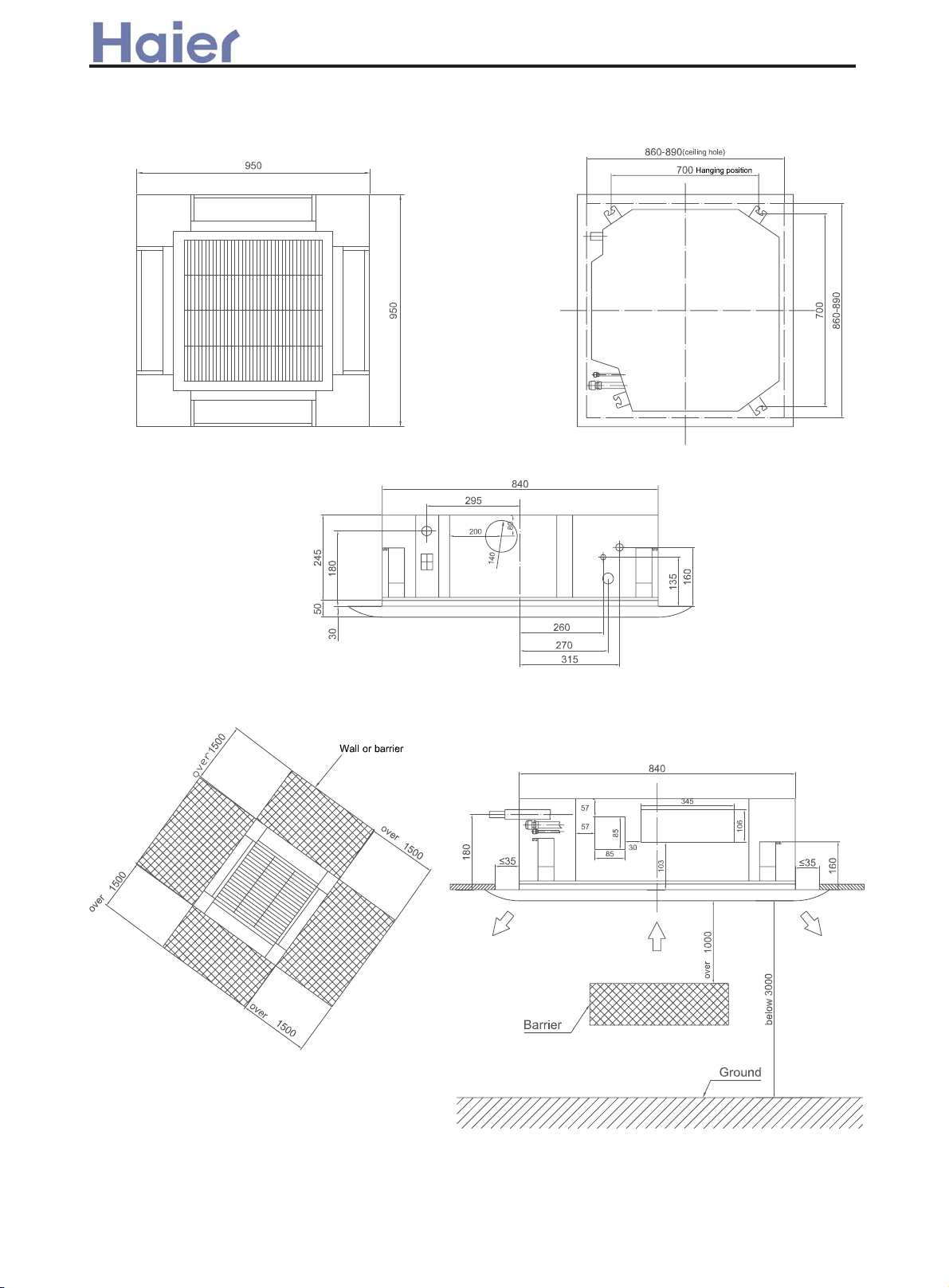

4.5. Model: AB212XCEAA

Chff^j\bZe Abj Chg]blbhg^j

z 10 z

Page 13

4.6. D u c t Ty p e A D * * * X L E A A

Figure showing installation dimensions: (unit:mm)

Chff^j\bZe Abj Chg]blbhg^j

Model

Series 07-09

Series 12-14

Series 18-21

a

b c

615

648 125

770

804 125

1060

1120 125

450

450

450

d

220

220

220

e

80

80

80

g

225

225

225

i

100

100

100

f

i

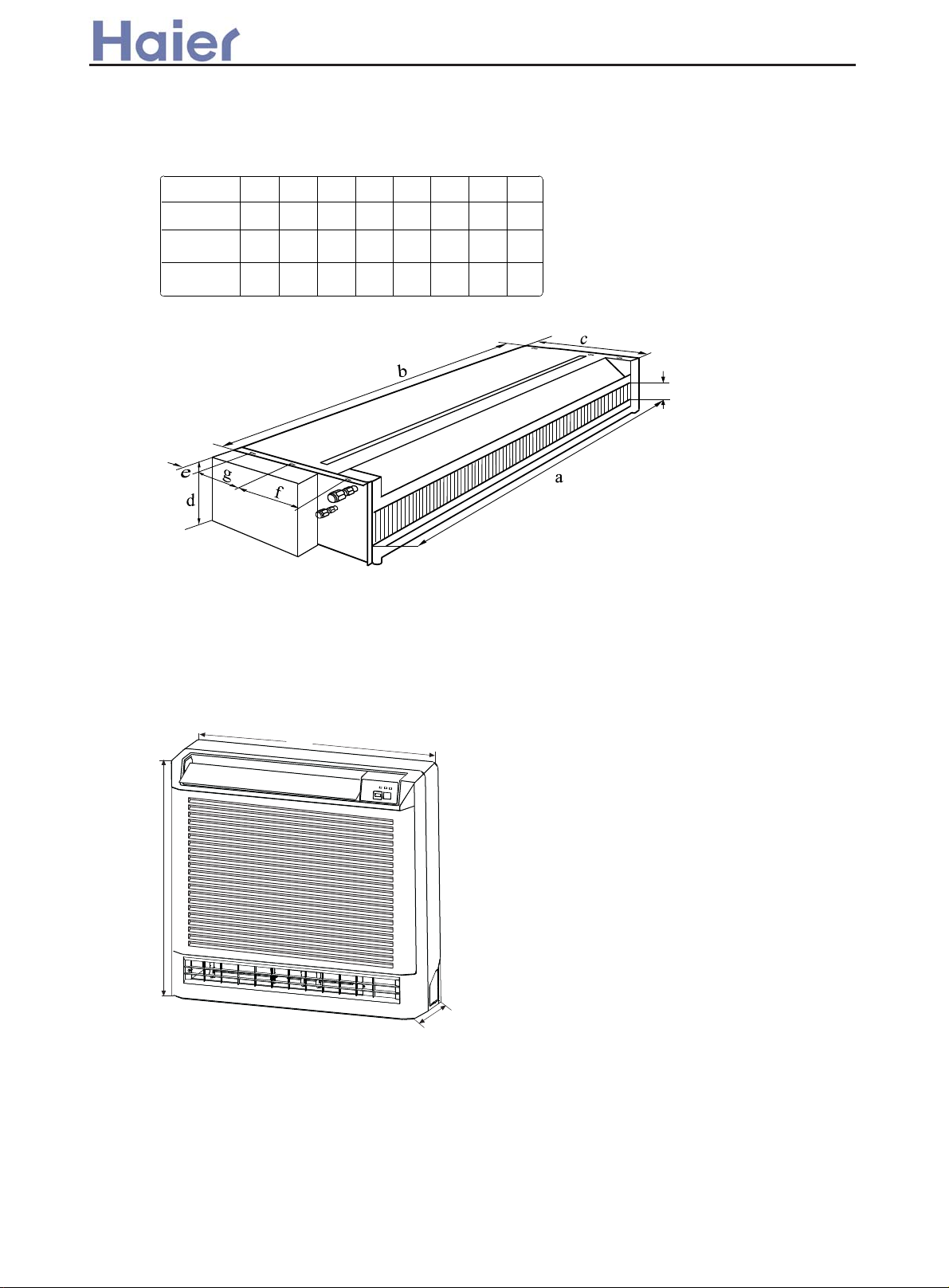

4.7. Console Ty p e A F* * * XCEA A

720

630

205

z 11 z

Page 14

5.Part Name

5.1 Cassette Type AB07-142XCEAA

Swing louver

(Air flow direction can be adjusted by using

the SWING button on the remote controller)

Operating Control Panel

Air Inlet Grille

Air Filter

(Inside of the Inlet Grille)

Chff^j\bZe Abj Chg]blbhg^j

Operating Control Panel

2

1

COMP TIMER OPER POWER

3

4

6

5

5.2. Cassette Type AB212XCEAA

Discharge unit (built in)

In cooling operation,

to discharge the

water from inside the

room.

Outlet

Air filter

(located in the suction grill)

1

Remote receiver

2

Compressor Lamp

3

TIMER Lamp

4

OPERATION Lamp

Power Lamp

5

6

Emergency switch

Drain Hose

Swing fender

(located in the outlet)

Refrigerant pipe

Cable line

Earthing line

Suction grill

z 12 z

Page 15

Chff^j\bZe Abj Chg]blbhg^j

5.3 Duct type AD***XLEAA

NOTE

When the unit have the Return air box (see the following picture)

when shipping from the factory and they are of back-side return air

type. During the installation, the unit also can be changed to a Downside Return air according to the user's need.

Electrical control box

5.4 Console Type AF***XCEAA

1

2

3

4

5

1.OUTLET

2.CONTROL PANEL

3.INLET

4.FILTER ( inside )

5.OUTLET

z 13 z

Page 16

5.5 Wall Mounted Type AS***XCEAA

INDOOR UNIT FRONT VIEW

Singal receiver window

Chff^j\bZe Abj Chg]blbhg^j

Air inlet grille

Air filter (inside)

Air outlet grille

INDOOR UNIT BACK VIEW

Louver

Mounting plate

Heat preservation pipe

z 14 z

Connecting pipes

Drainage pipes

Page 17

5.6. Outdoor Unit A U 2 8 2 X H E A A

3

1

Chff^j\bZe Abj Chg]blbhg^j

Air inlet

Air outlet

Air inlet

2

5.7. AU422XIEAA

1

Service panel

4

3

1

Air inlet

Air outlet

2

Air inlet

3

Service panel

4

4

2

z 15 z

Page 18

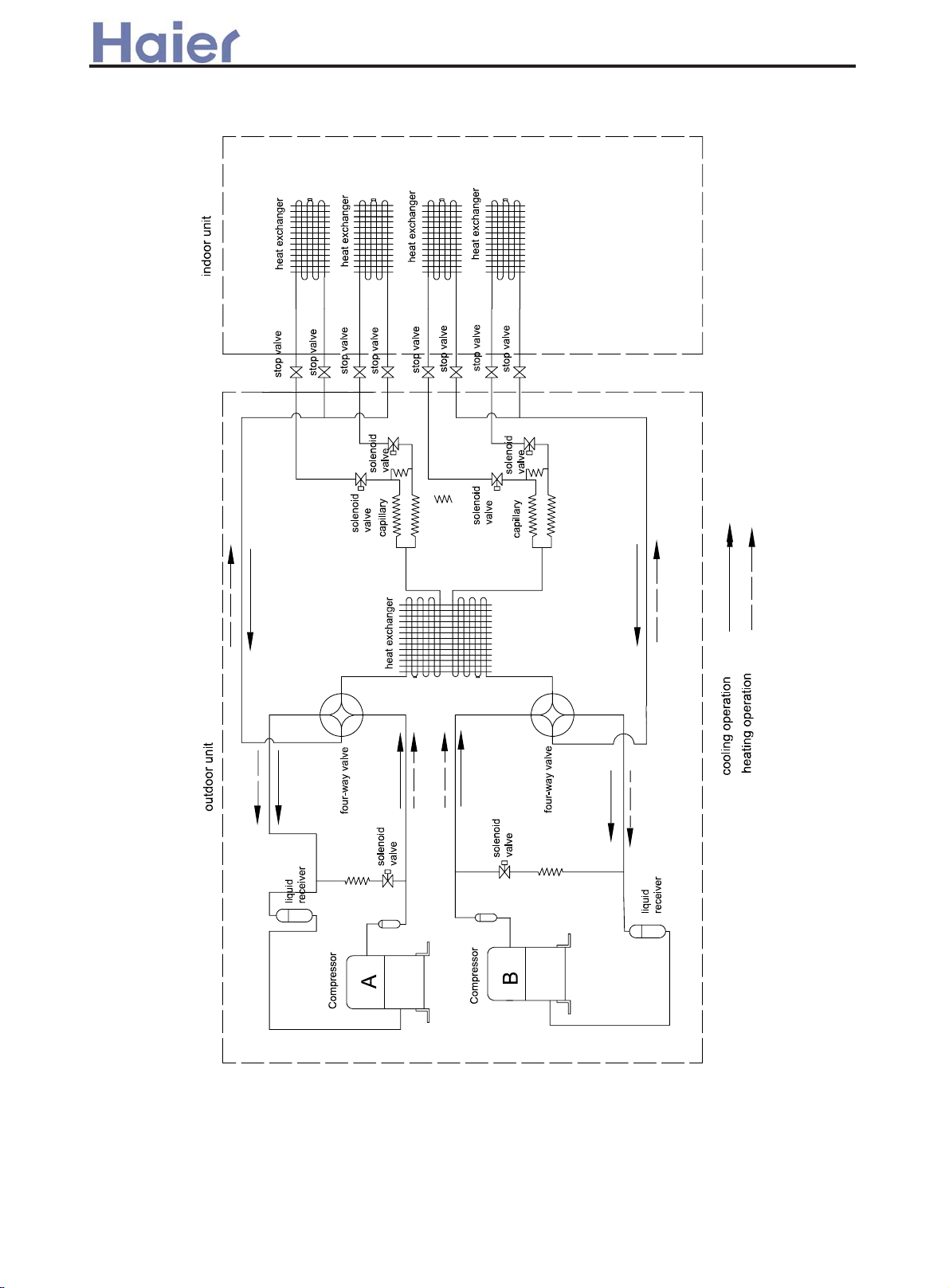

6. Refrigerant Diagram

6.1. Refrigeration diagram for AU282XHEAA

Chff^j\bZe Abj Chg]blbhg^j

indoor unit

heat exchanger

stop valve

heat exchanger

stop valve

stop valve

valve

solenoid

heat exchanger

stop valve

stop valve

valve

solenoid

capillary

heat exchanger

heat exchanger

stop valve

stop valve

stop valve

valve

solenoid

valve

solenoid

capillary

heating operation

cooling operation

outdoor unit

liquid

four-way valve

receiver

A

Compressor

Compressor

B

four-way valve

liquid

receiver

z 16 z

Page 19

6.2. Refrigerant diagram for AU422XIEAA

Chff^j\bZe Abj Chg]blbhg^j

z 17 z

Page 20

Chff^j\bZe Abj Chg]blbhg^j

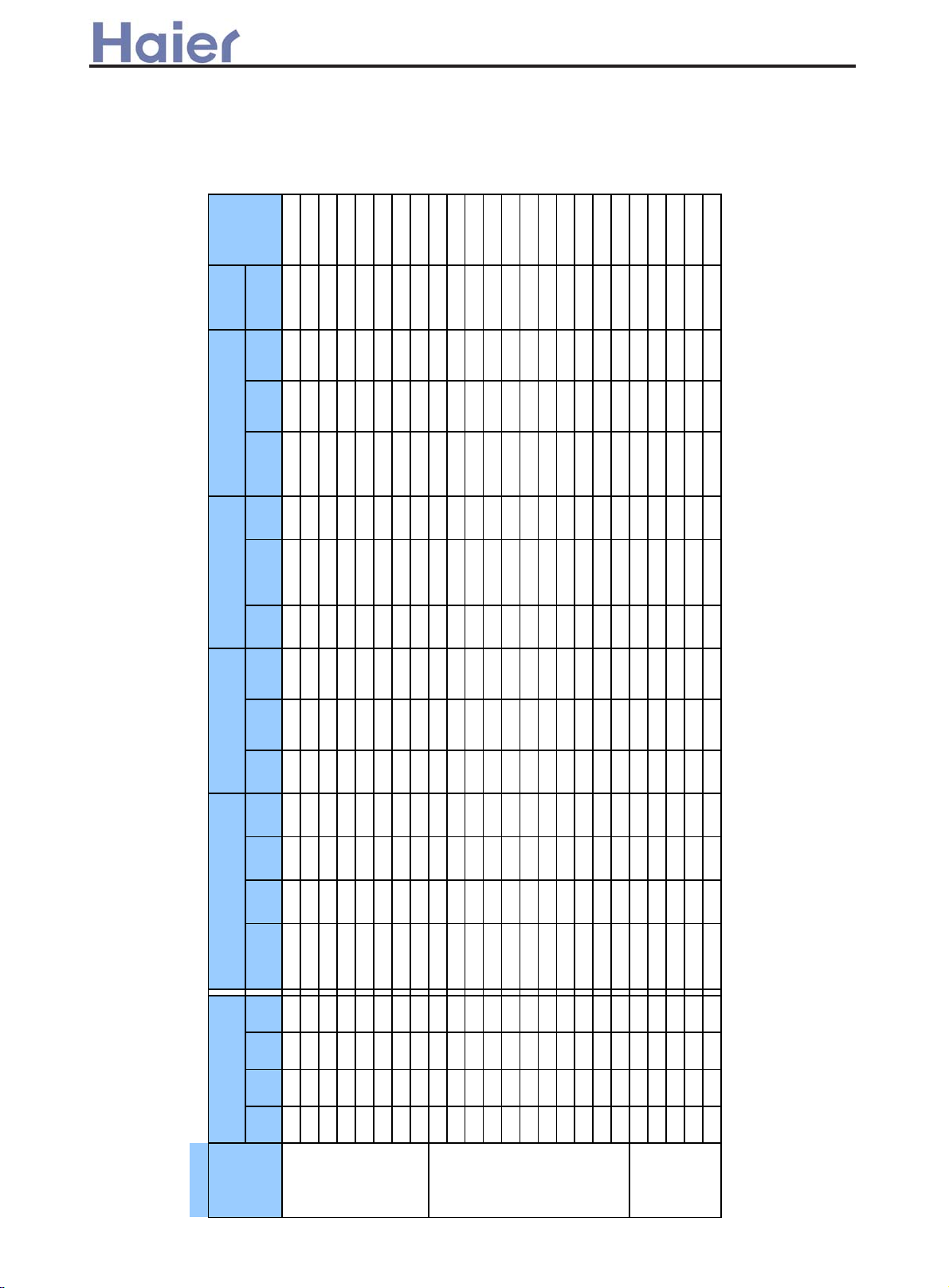

7. The unit capacity and performance mode:

7.1. AU282XHEAA

(A stands for A system, B stands for B system).

LABEL

ENERGY

EER

rated

(W/W)

capacity

Data

max.

data

rated

(A)@230V

total current

min.

data

Data

max.

data

(kW)

rated

total power input

min.

data

data

max.

data

rated

total cooling

capacity(kW)

min.

data

B2

Unit

B1

Unit

A2

Unit

(Nom. cooling)

A1

Unit

Rated capacity Output/kW

B2

Unit

B1

Unit

A2

Unit

Combinations

A1

072 — 072 — 3.20 — 3.20 — 3.20 6.40 6.40 1.40 2.55 2.55 6.21 11.31 11.31 2.51 E

092 — 092 — 3.50 — 3.50 — 3.50 7.00 7.00 1.40 2.65 2.65 6.21 11.76 11.76 2.64 D

072 — 092 — 3.20 — 3.50 — 3.20 6.70 6.70 1.40 2.65 2.65 6.21 11.76 11.76 2.53 E

072 072 — — 2.05 2.05 — — 3.20 4.10 4.10 1.40 1.45 1.45 6.21 6.43 6.43 2.83 C

092 092 — — 2.05 2.05 — — 3.50 4.10 4.10 1.40 1.45 1.45 6.21 6.43 6.43 2.83 C

072 092 — — 2.05 2.05 — — 3.20 4.10 4.10 1.40 1.45 1.45 6.21 6.43 6.43 2.83 C

122 — 122 — 3.80 — 3.80 — 3.50 7.00 7.00 1.45 2.72 2.72 6.43 12.07 12.07 3.01 B

142 — 142 — 4.10 — 4.10 — 4.10 8.20 8.20 1.45 2.72 2.72 6.43 12.07 12.07 3.01 B

072 072 142 — 2.05 2.05 4.10 — 3.20 8.20 8.20 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

092 092 142 — 2.05 2.05 4.10 — 3.20 8.20 8.20 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

072 092 142 — 2.05 2.05 4.10 — 3.20 8.20 8.20 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

072 072 122 — 2.05 2.05 3.50 — 3.20 7.60 7.60 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

092 092 122 — 2.05 2.05 3.50 — 3.20 7.60 7.60 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

072 092 122 — 2.05 2.05 3.50 — 3.20 7.60 7.60 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

072 072 072 — 2.05 2.05 3.20 — 3.20 7.30 7.30 1.40 2.60 2.60 6.21 11.54 11.54 2.81 C

072 072 092 — 2.05 2.05 3.50 — 3.20 7.60 7.60 1.40 2.60 2.60 6.21 11.54 11.54 2.92 C

072 092 092 — 2.05 2.05 3.50 — 3.20 7.60 7.60 1.40 2.60 2.60 6.21 11.54 11.54 2.92 C

072 092 072 — 2.05 2.05 3.20 — 3.20 7.30 7.30 1.40 2.60 2.60 6.21 11.54 11.54 2.81 C

092 092 092 — 2.05 2.05 3.50 — 3.50 7.60 7.60 1.40 2.70 2.70 6.21 11.98 11.98 2.81 C

072 072 072 072 2.05 2.05 2.05 2.05 3.20 8.20 8.20 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

072 072 072 092 2.05 2.05 2.05 2.05 3.20 8.20 8.20 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

072 072 092 092 2.05 2.05 2.05 2.05 3.20 8.20 8.20 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

072 092 092 092 2.05 2.05 2.05 2.05 3.20 8.20 8.20 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

1to4

092 092 092 092 2.05 2.05 2.05 2.05 3.50 8.20 8.20 1.40 2.72 2.72 6.21 12.07 12.07 3.01 B

Unit

Comb.

COOLING

1to2

z 18 z

1to3

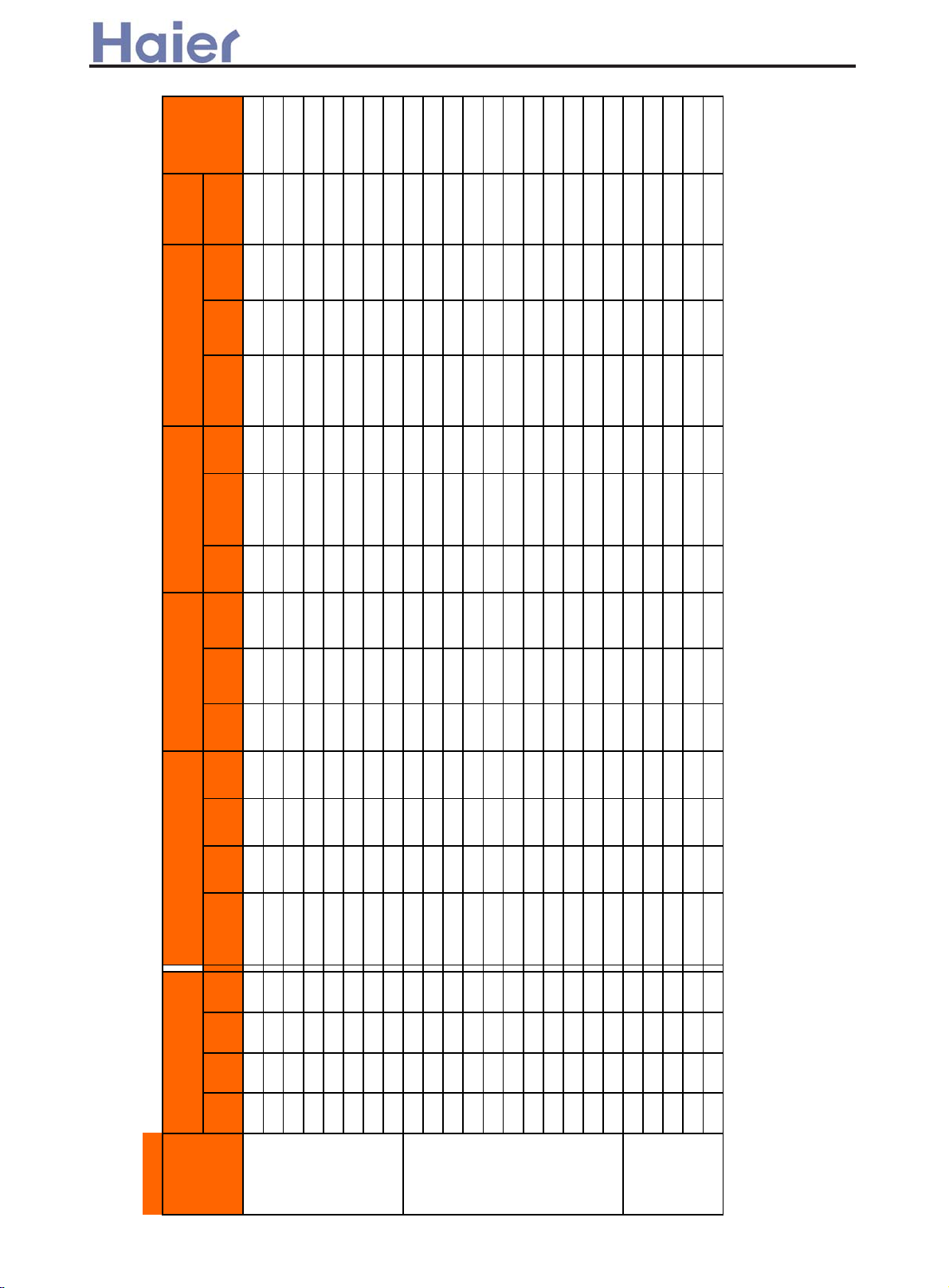

Page 21

LABEL

ENERGY

EER

rated

(W/W)

capacity

Data

max.

data

rated

(A)@230V

total current

min.

data

Data

max.

(W)

data

rated

Chff^j\bZe Abj Chg]blbhg^j

total power input

min.

data

data

max.

data

rated

total heating

capacity(KW)

min.

data

B2

Unit

B1

Unit

A2

Unit

(Nom. heating)

A1

Unit

Rated capacity Output/kW

B2

Unit

Combinations

Comb.

HEATING

Unit

Unit

Unit

B1

A2

A1

072 — 072 — 3.50 — 3.50 — 3.50 7.00 7.00 1.65 2.70 2.70 7.40 11.98 11.98 2.59 F

092 — 092 — 3.80 — 3.80 — 3.80 7.60 7.60 1.65 2.60 2.60 7.40 11.54 11.54 2.92 D

072 — 092 — 3.50 — 3.80 — 3.50 7.30 7.30 1.65 2.60 2.60 7.40 11.54 11.54 2.81 D

072 072 — — 2.35 2.35 — — 3.50 4.70 4.70 1.65 1.55 1.55 7.40 6.88 6.88 3.03 C

092 092 — — 2.35 2.35 — — 3.80 4.70 4.70 1.65 1.55 1.55 7.40 6.88 6.88 3.03 C

072 092 — — 2.35 2.35 — — 3.50 4.70 4.70 1.65 1.55 1.55 7.40 6.88 6.88 3.03 C

122 — 122 — 4.00 — 4.00 3.80 7.60 8.20 1.80 2.80 2.80 8.07 12.42 12.42 2.71 E

142 — 142 — 4.50 — 4.50 — 4.50 9.00 9.00 1.55 2.63 2.63 6.88 11.67 11.67 3.42 B

072 072 142 — 2.35 2.35 4.50 — 3.50 9.20 9.20 1.65 2.63 2.63 7.40 11.67 11.67 3.50 B

092 092 142 — 2.35 2.35 4.50 — 3.80 9.20 9.20 1.65 2.63 2.63 7.40 11.67 11.67 3.50 B

072 092 142 — 2.35 2.35 4.50 — 3.50 9.20 9.20 1.65 2.63 2.63 7.40 11.67 11.67 3.50 B

072 072 122 — 2.35 2.35 3.80 — 3.50 8.50 8.80 1.65 2.63 2.63 7.40 11.67 11.67 3.23 C

092 092 122 — 2.35 2.35 3.80 — 3.80 8.50 8.80 1.65 2.63 2.63 7.40 11.67 11.67 3.23 C

072 092 122 — 2.35 2.35 3.80 — 3.50 8.50 8.80 1.65 2.63 2.63 7.40 11.67 11.67 3.23 C

072 072 072 — 2.35 2.35 3.50 — 3.50 8.20 8.20 1.65 2.65 2.65 7.40 11.76 11.76 3.09 C

072 072 092 — 2.35 2.35 3.80 — 3.50 8.50 8.50 1.65 2.65 2.65 7.40 11.76 11.76 3.21 C

072 092 092 — 2.35 2.35 3.80 — 3.50 8.50 8.50 1.65 2.65 2.65 7.40 11.76 11.76 3.21 C

072 092 072 — 2.35 2.35 3.50 — 3.50 8.20 8.20 1.65 2.65 2.65 7.40 11.76 11.76 3.09 C

092 092 092 — 2.35 2.35 3.80 — 3.80 8.50 8.50 1.65 2.65 2.65 7.40 11.76 11.76 3.21 C

072 072 072 072 2.35 2.35 2.35 2.35 3.50 9.40 9.40 1.65 2.63 2.63 7.40 11.67 11.67 3.57 B

072 072 072 092 2.35 2.35 2.35 2.35 3.50 9.40 9.40 1.65 2.63 2.63 7.40 11.67 11.67 3.57 B

072 072 092 092 2.35 2.35 2.35 2.35 3.50 9.40 9.40 1.65 2.63 2.63 7.40 11.67 11.67 3.57 B

072 092 092 092 2.35 2.35 2.35 2.35 3.50 9.40 9.40 1.65 2.63 2.63 7.40 11.67 11.67 3.57 B

092 092 092 092 2.35 2.35 2.35 2.35 3.80 9.40 9.40 1.65 2.63 2.63 7.40 11.67 11.67 3.57 B

1to2

1to3

1to4

Note: For wall mounted unit, please refer to the data on its nameplate.

z 19 z

Page 22

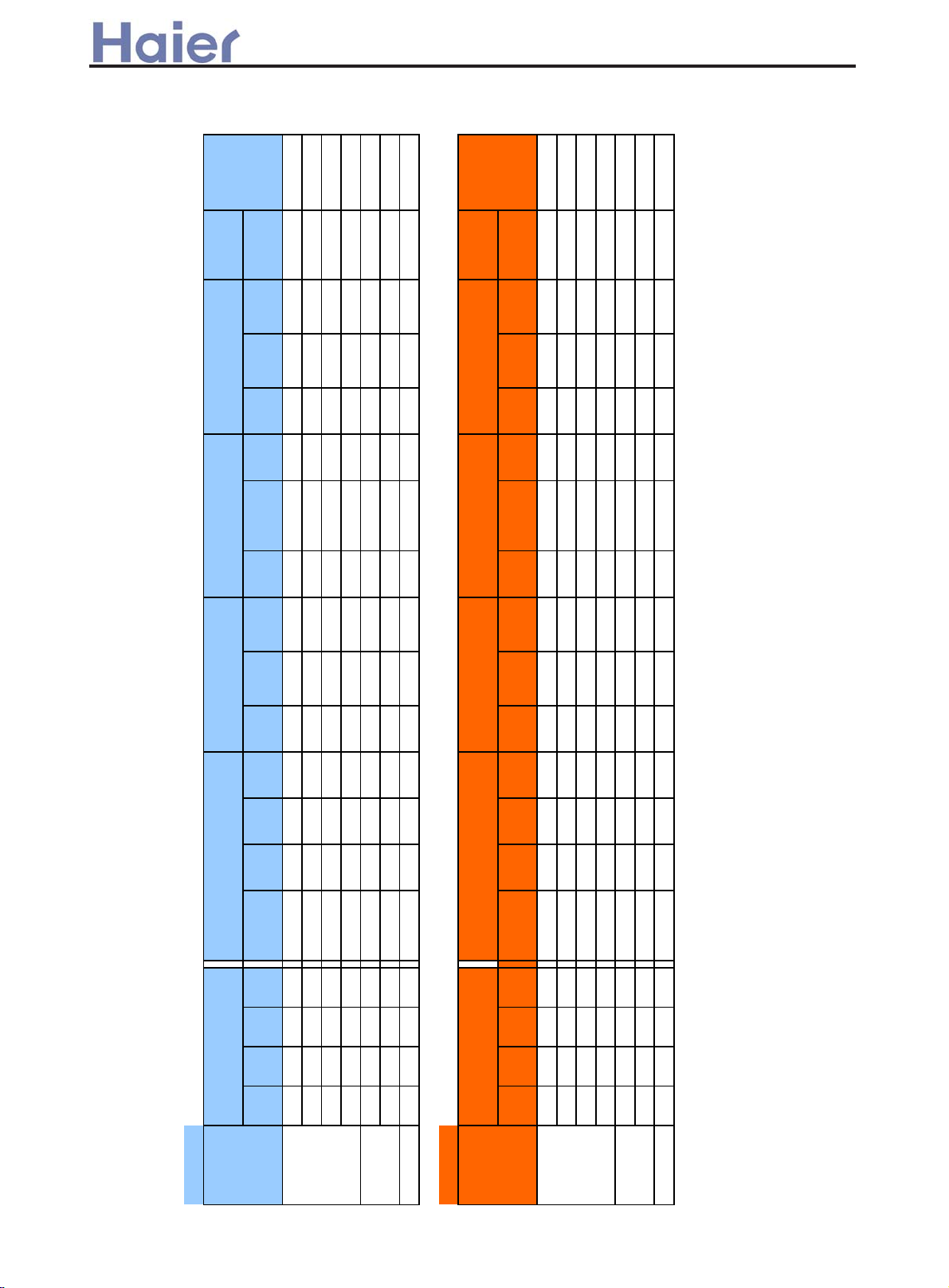

Chff^j\bZe Abj Chg]blbhg^j

7.2. The unit capacity and performance mode for AU422XIEAA:

LABEL

ENERGY

EER

rated

(W/W)

capacity

Data

max.

data

rated

(A)@230V

total current

min.

data

Data

max.

data

(kW)

rated

total power input

min.

data

data

max.

LABEL

ENERGY

EER

rated

(W/W)

capacity

Data

max.

data

rated

(A)@230V

total current

min.

data

Data

max.

(W)

data

rated

total power input

min.

data

data

max.

data

rated

total cooling

capacity(kW)

min.

data

B2

Unit

B1

Unit

A2

Unit

(Nom. cooling)

A1

Unit

Rated capacity Output/kW

B2

Unit

B1

Unit

A2

Unit

Combinations

A1

122 — 122 — 4.00 — 4.00 — 4.00 8.00 8.00 1.90 3.60 3.60 8.43 15.97 15.97 2.22 F

122 122 — — 3.08 3.08 — — 4.00 6.15 6.15 1.90 2.10 2.10 8.43 9.32 9.32 2.93 C

122 — 212 — 4.00 — 6.15 — 4.00 10.15 10.15 1.90 3.70 3.70 8.43 16.42 16.42 2.74 D

212 — 212 — 6.15 — 6.15 — 6.15 12.30 12.30 1.90 4.08 4.08 8.43 18.10 18.10 3.01 B

Unit

122 122 212 — 3.08 3.08 6.15 — 4.00 12.30 12.30 1.90 4.08 4.08 8.43 18.10 18.10 3.01 B

data

rated

total heating

capacity(KW)

min.

data

B2

Unit

B1

Unit

A2

Unit

(Nom. heating)

A1

Unit

Rated capacity Output/kW

B2

Unit

B1

Unit

A2

Unit

Combinations

A1

122 — 122 — 4.40 — 4.40 — 4.40 8.80 8.80 1.95 3.65 3.65 8.65 16.19 16.19 2.41 F

122 122 — — 3.30 3.30 — — 4.40 6.60 6.60 1.95 2.10 2.10 8.65 9.32 9.32 3.14 C

122 — 212 — 4.40 — 6.50 — 4.40 10.90 10.90 1.95 3.50 3.50 8.65 15.53 15.53 3.11 C

212 — 212 — 6.50 — 6.50 — 6.50 13.00 13.00 1.95 3.80 3.80 8.65 16.86 16.86 3.42 B

122 122 212 — 3.30 3.30 6.50 — 4.40 13.10 13.10 1.95 3.80 3.80 8.65 16.86 16.86 3.45 B

122 122 122 — 3.08 3.08 4.00 — 4.00 10.15 10.15 1.90 3.70 3.70 8.43 16.42 16.42 2.74 D

Unit

122 122 122 — 3.30 3.30 4.40 — 4.40 11.00 11.00 1.95 3.50 3.50 8.65 15.53 15.53 3.14 C

COOLING

Comb.

1to2

1to3

1to4 122 122 122 122 3.08 3.08 3.08 3.08 4.00 12.30 12.30 1.90 4.08 4.08 8.43 18.10 18.10 3.01 B

HEATING

z 20 z

Comb.

1to2

1to3

1to4 122 122 122 122 3.30 3.30 3.30 3.30 4.40 13.20 13.20 1.95 3.80 3.80 8.65 16.86 16.86 3.47 B

Note: For wall mounted unit, please refer to the data on its nameplate.

Page 23

Chff^j\bZeAbjChg]blbhg^j

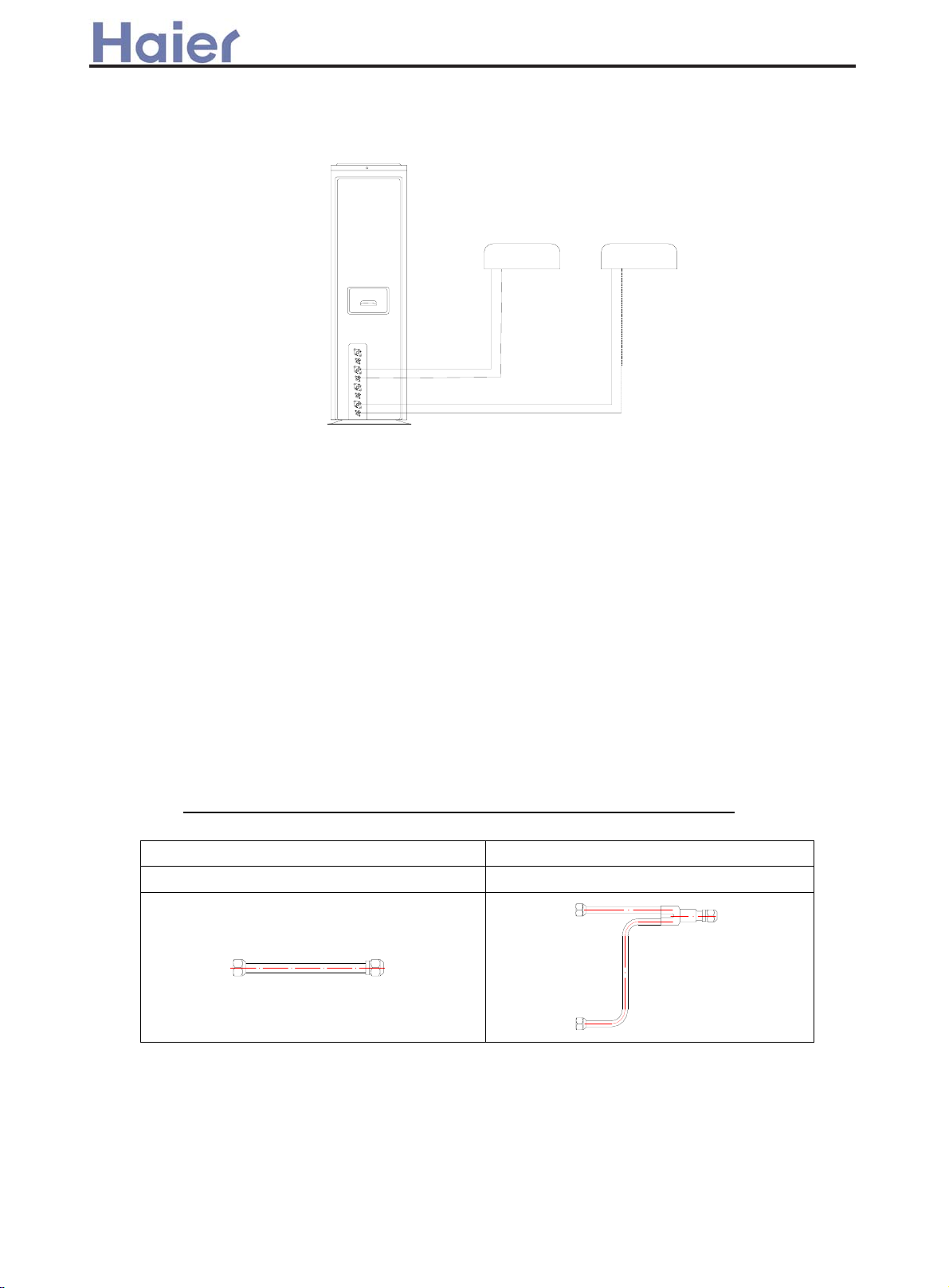

1 TO 2(except for 21000BTU/h units)

Outdoor unit

Indoor units

A2 B2

A1

A2

B1

B2

Communication Wire connection:

1. The indoor unit whose liquid pipe is connected to A1 in A system is called unit A1, its communication

wire of A1(3)、 A1(4) should be connected to A1(P)、A1(Q) respectively.

2. The indoor unit whose liquid pipe is connected to A2 in A system is called unit A2, its communication

wire of A2(3) 、A2(4) should be connected to A2(P)、A2(Q) respectively.

3. The indoor unit whose liquid pipe is connected to B1 in B system is called unit B1, its communication

wire of B1(3) 、B1(4) should be connected to B1(P)、B1(Q) respectively.

4. The indoor unit whose liquid pipe is connected to B2 in B system is called unit B2, its communication

wire of B2(3) 、B2(4) should be connected to B2(P)、B2(Q) respectively.

Note: Because the customers themselves matcTh the communication wire, and the P and Q

are nonpolar, the customers must use shielded communication wires.

Special Installation Guide to 21000BTU indoor units on Free Multi system

Only for outdoor unit AU422XIEAA working with 21000BTU indoor units

1. Special accessory pipes for 21000BTU indoor units:

A B

Changing pipe (3/8-1/2) Collecting pipe (1/4-3/8)

φ9.52 φ12.7

z 21 z

φ6.35

φ6.35

φ9.52

Page 24

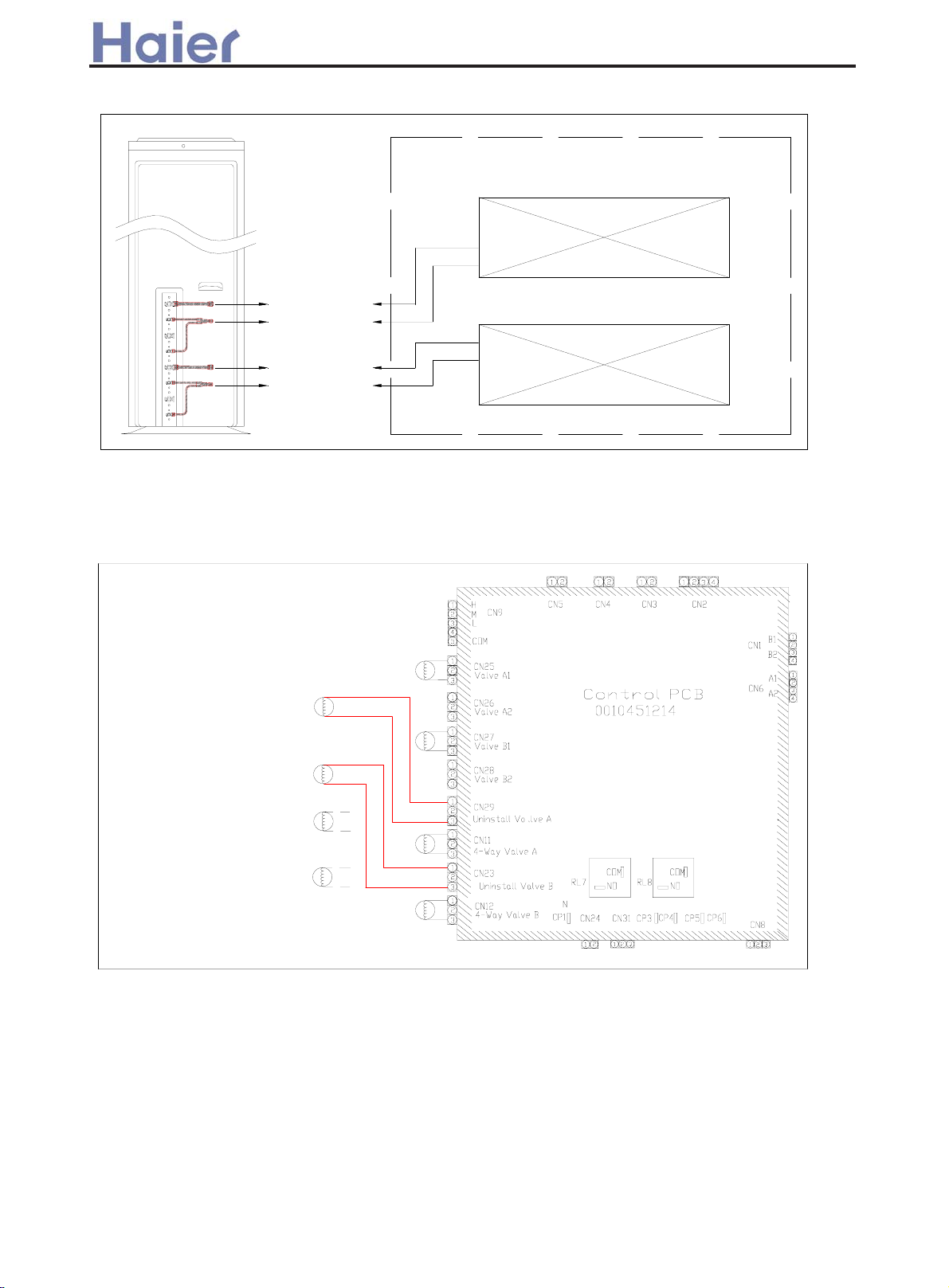

2. Pipe installations:

Chff^j\bZe Abj Chg]blbhg^j

21000BTU indoor unit

A1

A2

B1

B2

Gas pipe φ12.7

Liquid pipe

Gas pipe

Liquid pipe

φ9.52

φ12.7

φ9.52

21000BTU indoor unit

Note: Though AU422XIEAA can match with the R407C free multi indoor unit, we do not

recommend so. Because that will not only lower the capacity,also the changing pipe

0010759292 will be required for all R407C free multi indoor unit when installation.

3. Outdoor wiring diagram should be changed as the following:

Coil of solenoid vavle A2

should be changed to

connected with CN29.

Coil of solenoid vavle B2

should be changed to

connected with CN23.

By-pass vavle on both

system A and system B

should be pulled out and

not connected.

z 22 z

Page 25

Chff^j\bZe Abj Chg]blbhg^j

8. Installation Procedure

8.1.1. Selection of Installation Place (For AB072-142XCEAA)

(1) Place above the ceiling where it is enough space to arrange the unit.

(2) Place where the drainage pipe can be arranged well.

(3) Place where inlet and outlet air of indoor and outdoor unit will not be blocked.

(4) Do not expose the unit to the place with heavy oil or moisture (e.g.kitchen and workshop).

(5) Do not set the unit in the place where destructive gas (such as sulfuric acid gas) or pungent

gas (thinner and gasoline) concentrates and retains.

(6) Place strong enough to support the unit .

(7) No expensive articles such as television and piano below indoor unit.

(8) Enough space for maintenance.

(9) Place more than 1m away from television and radio to avoid disturbing television and radio.

(10) Easy for maintenance.

1.5m

Air outlet

2.5m Over

Air inlet

Air outlet

1.5m

( 1) Position of ceiling openin g between unit and suspending bolt (front view of unit).

( 11) D imension of co nnectin g pip e

AB072XCEAA

AB092XCEAA

AB122XCEAA

AB142XCEAA

Gas pipe

Liquid pipe

9.52mm

6.35mm

8.1.2. Electrical Wiring

Ca uti ons: U se c oppe r w ire onl y. Pa ram et

GFIC 7 ;15></9 4:+201T205,HH3-;15></9 3Q+1065T205,HH

Power supply :1PH,220-230V~,50Hz.

Power supply wire parameters: H05RN-f 3G(0.75~1.5)mm

Signal wire parameters: H05RN-F 2x0.75mm

The signal wire must be shielded wire.

2

3

2

Wiring methods:

1.Wiring method of ring terminal

For connecting line which end is a ring,its wiring method

as shown in the right figure: remove wiring screw and pass

it through the end ring of connecting line,then connect it to

the terminal block and tighten screw.

2. Wiring method of straight terminal

For connecting line which end is not a ring, its wiring method

as follows: loosen wiring screw ans insert the end of connecting

line totally into the terminal block,then tighten the screw and pull

the connecting line slightly to confirm that it is clamped firmly.

Wiring method of ring terminal

Correct crimp

connection of wire

Terminal block

Crimp connection

clamp

Incorrect crimp

connection of wire

z 23 z

Page 26

(3) Install a suspending bolt

To support the unit weight ,anchor bolt should be used in the case of

the existing ceiling. For new ceiling, use flush-in type bolt, built-in

type bolt or parts pretared in the field.

Before going on installing, adjust the distance to ceiling.

Ceiling

Note: All the above mentioned parts shall be prepared in feild,

the diameter of suspending bolt is M10

Chff^j\bZe Abj Chg]blbhg^j

Roof

Anchor bolt

Long nut or thread

Suspending bilt M10

8.1.3 . Installation of indoor unit

<Installation Example>

In case of no ceiling

Install unit temporarily

Put suspending bracket on the suspending bolt to hang the unit up. Be sure to use nut and

washer at both end of the breaket to secure firmly.

After installation on the ceiling

(1) Adjust unit to its right position (Refer to preparation for installation-(1))

(2)Check that unit is horizontal.

Water pump and floating switch is installed inside indoor unit,check four corners of the unit for

its lever using horizontal comparator or PVC tube with water.(If unit is tilting against the direction

of water drainage,problem may occur on floating water leakage.)

Nut (Prepare in feild)

Washer (Prepared in feild)

In the case of existing ceiling

(1)Install unit temporarily

Put suspending bracket on the suspending bolt to hang the

unit up.Be sure to use nut and washer at both end of the

bracket to secure it firmly.

(2)Adjust the height and position of the unit.

(3)Proceed with procedure (4) of " In the case of no ceiling "

Fasten (double nuts)

Suspending bolts

leveler

Polythene pipe

Insert

Washer fixing pad

(prepared in feild)

[ secure the washer firmly]

z 24 z

Page 27

Chff^j\bZe Abj Chg]blbhg^j

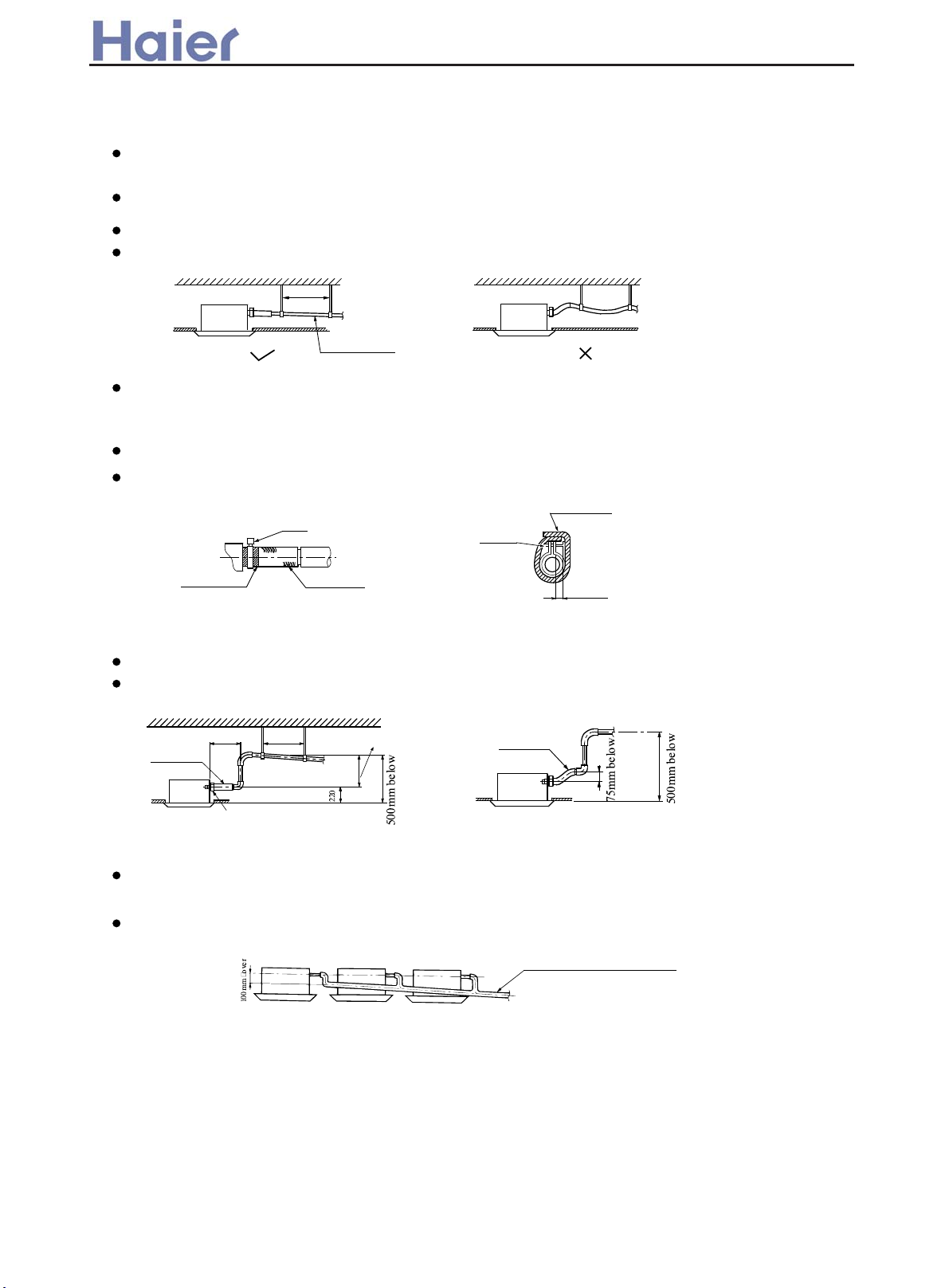

8.1.4. In s t al la t io n o f w at e r d ra i na ge pi p e

(1) Install water drainage pipe

Pipe diameter shall be equal or larger than that of connecting pipe (Pipe of polythene; size:

25mm; O.D.: 32mm )

Drainpipe should be short, with a downward slope at least 1/100 to prevent air bag from forming.

If downward slope of drainpipe cannot be made,lifting pipe shall be installed.

Keep a distance of 1-1.5m between suspending bolts, to make water hose straight.

1-1.5m

slope over 1/100

Use the drainage hose and clip provided with unit.

Insert water pipe into water plug until it reaches the white tape.

Tighten the clip until head of the screw is less than 4mm from hose.

Wind the drainage hose to the clip using seal pad for heat insulation.

Insulate drainage hose in the room.

Large size seal pad

Clip

Clip

(accessory)

Tape(white)

Draingage hose

4mm below

8.1.6. C au t io n s f o r t he w a te r d r ai n ag e li f t in g p ip e

Installation height of water drainage lifting pipe shall be less than 280mm

There should be a right angle with unit ,300mm from unit.

300mm below

Drainage hose

Clip

Water drainage

lifting pipe

< Note >

The slope of water drainage hose shall be within 75mm , make the drainage plug not to bear

excessive force.

If several water hoses join together, of as per following procedures.

Suspending bracket

1-1.5m

220mm

280mm unter

Slope below 1/100

Drainage hose

Connection drainage hose with a T-joint

Specifications of the selected drainage hoses shall meet the requirements for the unit running

z 25 z

Page 28

Chff^j\bZe Abj Chg]blbhg^j

8.1.6. In s t al la t io n o f O r na m e nt Pa n el

Install ornament panel on indoor unit

(1) Check whether indoor unit is horizontal with leveler or polythene pipe filled with water , and

check that the dimension of the ceiling opening is correct. Take off the lever gauge before

installing the ornament panel.

(2) Fasten the screws to make the height difference between the two sides of indoor unit less than

5mm.

(3) Firstly fix it with screws temporarily.

(4) Fasten the two temporarily fixing screws and other two, and tighten the four screws.

(5) Connect the wires of synchro-motor.

(6) Connect the wire of signal.

(7) If no response of remote controller,check whether the wiring is correct,restart remote controller

10 seconds after shut off power supply.

Electric control box

Panel limitation board installation

(1)Install the panel board in the direction shown in

the figure.

(2)The incorrect direction will result in water leakage,

meanwhile swing and signal receiving are displayed

that cannot be connected.

Piping Connection

Flare connection

Indoor

Unit

Gas pipe

Liquid

pipe

Flare connection

3-way valve

Outdoor

unit

2-way valve

z 26 z

Page 29

Chff^j\bZe Abj Chg]blbhg^j

8.2.1. Installation procedure (For AB212XCEAA)

(1) Installation place shall meet the following and agreed by customers:

Place where proper air flow can be ensured.

No block to air flow.

Water drainage is smpoth.

Place strong enough to support unit weight.

Place where inclination is not evident on ceiling.

Enough space for mainenance.

Indoor and outdoor unit piping length is within limit. (Refer to Installation Manual for outdoor unit.)

Indoor and outdoor unit, power cable, inter unit cable are at least 1 m away fromT.V. radop. This is helpful

to avoid picture disturbance and noise. (Even if 1 m iskept, noise can still appear if radio wave is strong)

(2) Ceiling height

Indoor unit can be installed on ceiling of 2.5-3m in height. (Refer to Foeld setting and Installation Manual of

ornament panel.)

(3) Install suspending bolt. Check if the installation place is strong enough to hold weight. Take necessary

measures in case it is not safe. (Distance between holes are marked on paper pattern. Refer to paper pattern

for place need be reinforced)

Air outlet

1500mm Over

Air inlet

Air outlet

1500mm Over

(2) Cut an opening in ceiling for installation if necessary. (when ceiling already exists.)

Refer to paper pattern for dimension of ceiling hole.

Connect all pipings (refrigerant, water drainage), wirings (inter unit cable) to indoor unit, before installation.

Cut a hole in ceiling, may be a frame should be used to ensure a smooth surface and to prevent vibration.

Contact your real estate dealer

(3) Install a suspending bolt.

(Use a M10 bolt)

To support the unit weight, anchor bolt shall be used in the case of already exists ceiling. For new

ceiling, use built-in type bolt or parts prepared in the field.

Before going on installing adjust space between ceiling.

<Installation example>

Roof

Anchor bolt

Long nut

Suspending bolt

Ceiling

Note: All the above mentioned parts shall be prepared in field.

z 27 z

Page 30

Chff^j\bZe Abj Chg]blbhg^j

4

4. INSTALLATION OF INDOOR UNIT

In the case of new ceiling

(1) Install unit temporally

Put suspending bracket on the suspending bolt. Be sure to use nut and washer at both ends of the bracket.

(2) As for the dimensions of ceiling hole, see paper pattern. Ask your real estate dealer for details.

Center of the hole is marked on the paper pattern.

Center of the unit is marked on the card in the unit and on the paper pattern.

Mount paper pattern onto unit using 3 screws . Fix the corner of the drain pan at piping outlet.

< After installation on the ceiling >

(3) Adjust unit to its right position. (Refer to preparation for the installation-(1))

(4) Check unit's horizontal level.

Watert pump and flating switch is installed inside indoor unit, check four corners of the unit for its level

using horizontal compartor or PVC tube with water. (If unit is tilting against the direction of water drainage,

problem may occur on floating switch, causing water leakage.)

(5) Remove the washer mounlting , and tighten the nut above.

(6) Remove the paper pattern.

In the case of ceiling already exists

(1) Install unit temporally

Put suspending bracket on the suspending bolt.

Be sure to use nut and washer at both ends

of the bracket. Fix the bracket firmly.

(2) Adjust the height and position of the unit.

(Refer to preparation for the installation (1) ).

(3) Proceed with and of "In the case of new ceiling".

5

2

4

3

6

Nut (Prepare in feild)

Washer (Prepared in feild)

Suspending bolts

Fasten (double nuts)

Level

Center of ceiling hole Paper pattern

Screw (accessory)

[Fix the paper pattern]

Insert

Washer fixing pad

(prepared in feild)

[ secure the washer firmly]

Polythene pipe

Screws at the piping outlet is fixed at the corner

of drain pan.

Paper pattern

5

Screw (accessory)

z 28 z

Page 31

Chff^j\bZe Abj Chg]blbhg^j

5

5. REFRIGERANT PIPING

(As for outdoor piping, please refer to installation Manual of outdoor unit.)

Outdoor is precharged with refrigerant.

Be sure to see the Fig.1, when connecting and removing piping from unit.

For the size of the flare nut, please refer to Table 1.

Apply refrigerant oil at both inside and outsid of lflare nut. Tighten it band tight 3-4 turns then tighten it.

Use torque specified in Table 1. (Too much force may damage flare nut, causing gas leakage).

Check piping joints for gas leakage. Insulate piping as shown in Fig. below.

Cover joint of gas piping and insulator with seal.

Apple refrigerant oil

Torque spanner

Piping joing

Flare nut

6

6. INSTALLATION OF WATER DRAINAGE PIPE

Medium size seal pad 11 (accessory)

(Cover the piping joint

with seal pad.)

Clamp 3

spanner

Gas pipe

Liquid pipe

7

Insulator (accessory)

(For liquid pipe)

Insulator (accessory)

(For gas pipe)

Table 1

8

7

Pipe

size

1420~1720N.cm

6.35

(144~176kgf.cm)

3270~3990N.cm

9.52

(333~407kgf.cm)

12.7

(504~616kgf.cm)

15.88

(630~770kgf.cm)

19.05

Tighten

torque

4950~6030N.cm

6180~7540N.cm

9720~11860N.cm

(990~1210kgf.cm)

A(mm)

8.3~8.7

12.0~12.4

15.4~15.8

18.6~19.0

22.9~23.3

Flare shape

(1) Install water drainage pipe

Pipe dia, shall be equal or larger than that of unit piping.(pipe of polyethylent; size: 25mm; O.D:32mm)

Drain pipe should be short, with a downward slope at least 1/100 to prevent air bag from happening.

If downward slope can't be made, take other measures to lift it up.

Keep a distance of 1-1.5m between suspending brackets, to make water hose straight.

1-1.5m

R0.4 ~ 0.8

Slope over 1/100

Use the self-provided stiff pipe and clamp with unit. Insert water pipe into water plug until it reaches the

1

white tape. Tighten the clip until head of the screw is less than 4mm from hose.

Wind the drain hose to the clip using seal pad 9 .

Insulate drain hose in the room.

Tape (White)

Clamp

Self-provided stiff pipe

<Cautions for the drain water lifting pipe

Clamp

(accessory)

Large size seal pad

(accessory)

4mm below

10

Installation height shall be less than 280mm.

There should be a right angle with unit, 300mm from unit.

Suspending bracket

1~1.5m

drain water lifting pipe

Clamp

(accessory)

Self-provided stiff pipe

(accessory)

(Note)

Drain hose

(accessory)

300mm below

The slope of water drain hose (1) shall be within 75mm, don't apply too much force on it.

If several water hoses join together, do as per following proceedures.

Connect water hoses with a T joint.

Specifieations of the water hoses shall meet the requirements for the unit running.

z 29 z

Page 32

(2) Check if water drainage is smooth after installation.

Charge, through air outlet or inspecting hole, 1200ccd water to see water drainage.

After wiring

Check water drainage in cooling operation.

When wiring is not complete

Remove cover of control box, short connect "CHECK" terminal of the indoor unit, which is on the uper

part of indoor unit PCB. Connect 1PH power to terminal 1 and 2 on terminal block.

Note, in this operation, fan will be running.

Upon confirmation of a smooth water drainage, be sure to cut off power supply

and remove short connection of "CHECK" terminal.

Chff^j\bZe Abj Chg]blbhg^j

Maintenance

Inspecting hole

Method of water charging

Self-provided stiff pipe

Water drainage port for

maintenance

(Drain water from

this hole)

100mm

Watering can of plastic

pipe should be about

100 mm long

PCB on

indoor unit

Terminal block

Charge water from

inspecting hole

Charge water from

air outlet

z 30 z

Cover of controll box

Page 33

Chff^j\bZe Abj Chg]blbhg^j

7

7. WIRING

All supplied parts. materials and wiring operation must in appliance with

local code and regulations.

Use copper wire only.

When make wiring, please refer to wiring diagram also.

All wiring work must be done by qualified electricians.

A circuit breaker must be installed, which can cut power supply to all system.

See Installation Manual of outdoor unit for specifications of wires, circuit breaker, switches and wiring etc.

Connecting of unit

Remove cover of switch box (1) , drag wires into rubber tube A, then, after proper wiring with other wires,

tighten clamp A. Connect wires of correct pole to the terminal block inside.

12

Wind seal

Upon connecting, replace control box cover (1) and (2).

Obscrve the following when connecting power supply

terminal block:

Don't connect wires of different specifications to the same

terminal block.

(Loose wire may cause overheating of circuit)

Connect wires of same specifications as shown in right Fig.

around wires. (Be sure to do that, or, dew may occur).

Terminal block

Grounding lead

Cover of control box(1)

<<WARNING>>

Rubber tube A

Connect wires of the

same specifications

at two sides.

*

Rubber tube

Attach seal pad

Cover of control box(2)

Don't fail to seal it, or water may come in.

Note: Have it sealed, leaving no space.

Seal pad (small size )

Out

Field wiring

(Wind around wire)

Don't connect wires

of the different

specifications.

In

Don't connect wires of

the same specifications

at one side.

12

8

8. WIRING EXAMPLE

As for outdoor unit circuit, please see Installation Manual of outdoor unit.

Note: All electric wires have their own poles, poles must match that on terminal block.

9

9. INSTALLATION OF ORNAMENT PANEL

Cautions for the installation

Be sure to show customers Operation Manual and guide them how to operate unit

correctly. Before installation. read also the Installation Manual of indoor unit.

With this ornament , 2 or 3 air flow direction is not available.

Suitable height is 3 m.

1. Prepare ornament panel Handling of ornament panel

Ornament panel shall not be placed face down or against wall, neither

on an uneven object.

Don' t bend carelessly the swing flap, or, problem may occur.

Remove air inlet grill from ornament panel *

(1)

1

Push in the bar on inlet grill and lift it up. (Refer to Fig. 1)

Lift it up for about 45 degree and remove it from ornament. Tear off adhesive

2

tape fixing air filter on the back of the air inlet grill. (Refer to Fig. 2)

(2)

Remove cover plate at corner

Tear off the adhesive tape, and slide it off. (Refer to Fig. 3)

Bar

Fig. 1

h

45

Slide

Ad esive tape

Fig. 2

Fig. 3

z 31 z

Page 34

Chff^j\bZe Abj Chg]blbhg^j

2. Mounting on high ceiling

(1) Ornament panel can be mounted on ceiling as high as 3 m.

(2) Please install pad as accessary.

Cut open the pad along cutting ling. Use part a only and discard part b . (Refer to Fig. 4)

1

Install part a of the pad on the place shown in Fig. 5. Refer to Fig. 6.

2

Cutting line

Place it on the frame.

Leave no space.

a

50

Fig. 4

Part a of the pad

Swing flap motor

100

b

(3)Wiring on ornament panel

Connecting of wiring of the swing

flap motor on ornament panel. (2 places)

(Refer to Fit . 10)

If connecting is not made, error code

(A7) appears on remote controller. So,

make proper connecting.

3. Install ornament panel on indoor unit.

For indoor unit installation, please

refer to Installation Manual.

(1)

As shown in Fig . 7, match the position of swing

flap motor with that of the indoor unit piping hole ,

so that ormament panel can be placed on to indoor

unit.

(2)

Installation of ornament panel

1

Place the holding ring on swing flao motor side

teporarily on hooks of the indoor unit. (2 pcs)

2

Put the other two holding rings on the hooks at

side of the indoor unit. (Care should be taken not to

push wiring of swing flap motor into seals).

3

Screw in all 4 screws under holding ring for about

15mm. (Pancl will rise).

4

Adjust the ornament panel as per Fig. 7 to cover

opening on the ceiling.

5

Tighten screws to redrce the thickness of seals

between ornament and indoor unit to 5-8mm.

Caution

If screws are not tighten tight,

problems in Fig, 8 might occur.

Tighten screws properly.

If there are still space

after tightening of screws,

please readjust the height

Gas leakage.

Gas leakage

from roof.

of indoor unit.

(Refer to Fig. 9)

Fig. 5

Side of indoor unit

both

Part a of the pad

2

Swing flap motor

3

Indoor unit

Ceiling material

Fig. 6

Side of ornament panel

Fig. 10

Wiring diagram

Holding ring

Piping hole position

4

Fig. 7

If indoor unit is at horizontal level and water

drainage is smooth, then, indoor unit height

can be adjusted throrgh holes at corners of

ornament panel.

1

Seal

5 _ 8mm

Ornament panel

Hook

2

Contamination

Mist exists and drop down.

Fig. 8

Leave no space.

Fig. 9

z 32 z

Page 35

Chff^j\bZe Abj Chg]blbhg^j

4. Installation of inlet grill and cover plate

(1)

Installation of inlet grill

Install in reversed order of "Prepare ornament pandl".

Inlet grill can be adjusted into four directions by turning inlet grill. Inlet grill position can be adjusted as

per customers request.

When installing inlet grill, take care not to twist wiring of swing flap motor.

(2)

Install cover plate on the corner

1

As shown in Fig. 11 tie the

cover plate onto the bolt on

ornament plate.

2

Install cover plate onto

ornament plate.

(Refer to Fig. 12)

Fig. 11

Pay special care to the following and check after installation

Slide all five hold rings

to let them drop in holes

on ornament plate,

Fig. 12

Item to the checked

Is indoor unit firmly installed?

Is gas leakage check performed?

Is unit properly insulated?

Is water drainage smooth?

Is power voltage meet that stipulated on the nameplate?

Is wiring and piping correctly arranged?

Is unit safely grounded?

Is wire size correct?

Are there any obstacles on air inlet and outlet grill of

indoor and outdoor unit?

Is record made for piping length and refrigerant

charging amount?

Unproper installation may cause

Unit might fall down, make vibration or noise.

This may lead to gas shortage.

Dew or water drop may occur.

Dew or water drop may occur.

Problem may occur or parts got burned.

Problem may occur or parts got burned.

There might be a danger of electric shock.

Problem may occur or parts got burned.

This may cause poor cooling.

It is hard to control refrigerant charging

amount.

Check

- 33 z

Page 36

Chff^j\bZe Abj Chg]blbhg^j

! Warning

The electric wiring work shall be conducted by qualified electricians according to the installation

instructions. A separate power circuit shall be used. Insufficient power cord amperage or improper

wiring will cause danger of electric shock or fire.

During wiring connection, the power cord shall be of the specified cable and reliably fastened so

that external forces applied to the cable wouldnt transfer to the terminals. Improper connection or

fastening will cause danger of heating, fire etc.The power cord must be fitted with a grounding wire.

Grounding shall be made as specified. Unreliable grounding will cause electric shock. The grounding

wire shall not be connected to the gas pipeline, water pipeline, thunder arrestor and telephone wire

! Caution

A current leakage breaker shall be installed, otherwise it electric shock would happen easily.

The connection method of power cord is "Y" type.

If the power cord is damaged, it must be replaced by the manufacturer or its service center or

similar personnel to avoid risks. The power supply to the indoor unit shall be laid in complying

with the operational instruction manual.

The electric wiring shall avoid contacting with the high temperature part of the piping so as to

prevent the cable insulation melts and cause dangers.

After connected on the terminal block, the wires shall be bent to U form and then fastened with

wire clip.

The control wiring and refrigerant piping may be laid and fastened together.

Before completion of vacuum pumping of the refrigerant pipe system, do not electrify the indoor

unit.

The power cord of the indoor unit and connection wiring between indoor and outdoor units

shall be laid out according to the operational instruction manual of the indoor unit.

The connection of the power cord shall comply with the local regulations.

The power supply wiring connection should meet the local regulation.

After electric installation,power on them to do electric leakage test.

!

!

Wiring connection method : (the wiring diagram is attached inside the machine)

1) Ring terminal connection method

If there is a ring at the end of the connection wire,

the wire connection method is as shown in the right

figure. Remove the terminal screw and insert it

through the ring at the connection wire end, then

connect to the terminal board and fasten the screw.

2) Straight terminal connection method

If there isnt a ring at the end of the connection wire,

the connection method shall be: loosen the terminal

screw, insert the connection wire end completely into the terminal board and fasten the screw.

Pull the connection wire outwards slightly to confirm it is clamped tightly.

3) Clamping method of the connection wire

After wire connection is finished, the connection wire must be pressed tightly with wire clips,

which shall apply to the outer sheath of the connection wire.

Connection method

for ring terminal

z 34 z

Page 37

Chff^j\bZe Abj Chg]blbhg^j

Wire connection for built-in indoor unit

Insert from outside the connection wire and signal transmission wire through the wall hole

with pipeline already arranged.

Pull out the front ends of connection wire and signal wire and make a circle on the signal wire.

Connect the connection wire according to the connection method and indoor and outdoor wiring

diagram.

Pull the connecting conductor outwards slightly to confirm it is clamped tightly.

Connect the plug for connecting the signal wire with the plug of the signal wire connected

from the indoor unit.

After wire connection is finished, install wire clips using the same method for connection wire

clamping.

Note: When connecting the indoor unit and the outdoor unit, please do connect the wires

with the same color terminals.

Notes:

Before connecting the conductors between indoor unit and outdoor unit, check for the

number on the indoor and outdoor units connecting terminals. Connect the terminals with

the same color and number with a wire.

Wrong connection would damage the controller of the air conditioner or the machine

couldnt operate.

Do not connect the connection wire and signal wire with the same cable. They shall be

connected respectively to ensure system normal operation.

For some models, connection wire shall be provided by the user.

If the fuse on PC board is broken please change it with the type of T 3.15A /250VAC.

The power cable and connecting cable are self-provided.

power cable

H05RN-F 3G (1.0~1.5)mm

Signal cable

2

H05RN-F 2 (0.75~1.5)mm

X

2

All the cables shall have got the European authentication certificate.

The breaker of the air conditioner should be all-pole switch; and the distance between

its two contacts should be no less 3mm. Such means for disconnection must be

incorporation in the fixed wiring.

The signal wire must be shielded wire.

Note: The terminal block will be the below two types due to different models.

When wiring, please select the proper wiring type due to the actual terminal block.

INDOOR UNIT

TERMINAL BLOCK

OUTDOOR UNIT

TERMINAL BLOCK

P Q

L N

POWER SUPPLY:

1PH,220-230V~,50Hz

A 1 A 2 B 1 B2

P Q P Q P Q P Q

Y/G

P Q L N

POWER SUPPLY:

1PH,220-230V~,50Hz

Y/G

P Q

POWER

1PH,220-230V~,50Hz

P Q

L N

POWER

1PH,220-230V~,50Hz

L N

SUPPLY:

SUPPLY:

Y/G

INDOOR UNIT

TERMINAL BLOCK

Y/G

OUTDOOR UNIT

TERMINAL BLOCK

P Q L N

POWER SUPPLY:

1PH,220-230V~,50Hz

A1 A2 B 1 B2

P Q P Q P Q P Q

POWER SUPPLY:

1PH,220-230V~,50Hz

Y/G

Y/G

P Q L N

P Q L N

P Q L N

POWER SUPPLY:

1PH,220-230V~,50Hz

POWER SUPPLY:

1PH,220-230V~,50Hz

Y/G

Y/G

z 35 z

Page 38

Chff^j\bZe Abj Chg]blbhg^j

8.3. Duct Type (For AE***XLEAA)

8.3.1. Installation Procedure

Indoor unit

1. Select suitable places the outlet air can be sent to the

entire room, and convenient to lay out the connection

pipe, connection wire and the drainage pipe to outdoor.

2. The ceiling structure must be strong enough to support

the unit weight.

3. The connecting pipe, drain pipe and connection wire

shall be able to go though the building wall to connect

between the indoor and outdoor units.

4. The connecting pipe between the indoor and outdoor

units as well as the drain pipe shall be as short as possible. (See Figure 1)

5. If its necessary to adjust the filling amount of the refrigerant, please refer to the installation

manual attached with the outdoor unit.

6. The connecting flange should be provided by the user himself.

7. The indoor unit have 2 drainage outlet, one outlet be jamedwith rubber cap, during installation

only use another outlet (In/Out liquid pipe side). When necessary, use the two together.

8. Do not place the TV, equipment, facility, piano etc, expensive goods below the AC. This is to

prevent the water dropping down from the AC and lead to damage to the goods.

Fig 1

After selecting the unit installation location, proceed the following steps:

1. Drill a hole in the wall and insert the connecting pipe and wire through a PVC wall-through tube

purchased locally. The wall hole shall be with a outward down slope of at least 1/100. (See

Figure 2)

2. Before drilling check that there is no pipe or reinforcing bar just behind the drilling position.

Drilling shall avoid at positions with electric wire or pipe.

3. Mount the unit on a strong and horizontal building roof. If the base is not firm, it will cause

noise, vibration or pipe broken and refrigerant leakage (see Figure 6).

4. Support the unit firmly.

5. Change the form of the connection pipe, connection wire and drain pipe so that they can go

through the wall hole easily.

Fig 2

z 36 z

Page 39

Chff^j\bZe Abj Chg]blbhg^j

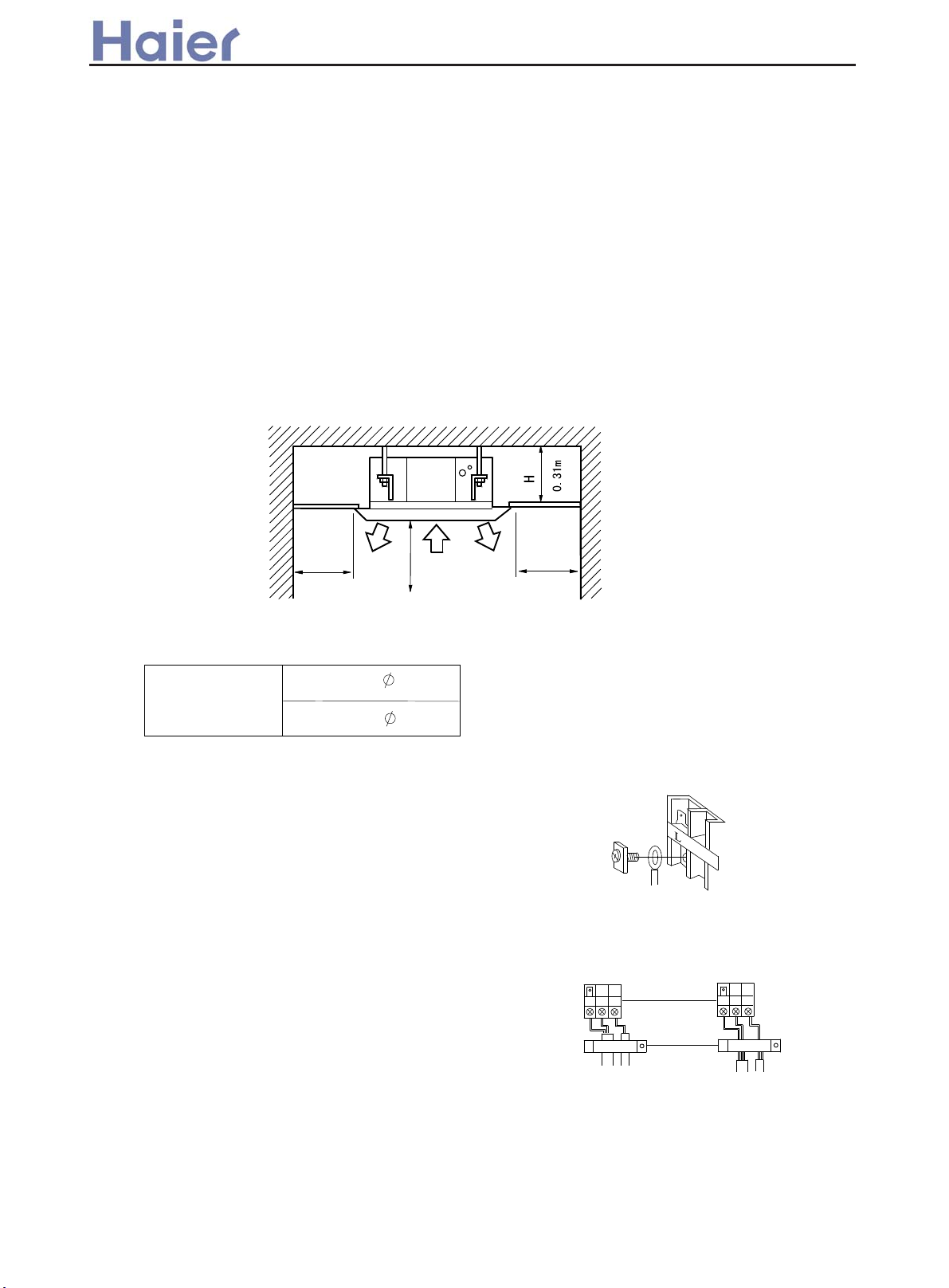

When installing the ceiling concealed type indoor unit, a specially designed return air

bellows shall be installed, as shown in Figure 3, Figure 4.

Figure 3

Figure 4

Ceiling

Air outlet grille

Installing building roof

5m( 50Pa)

0.5m(0Pa)or

Air supply

Air outlet duct

Unit

A

Return air bellows

Return air

Return air bellows

Air supply

No obstacles

within 1 m(0Pa)

Unit

Return air

Each air return and supply duct should fix to the floor precast slab by using an iron stand. Use glue to

seal the interface closely. Recommend the distance between the air return duct and the wall is more than

150mm.

The distance between air duct outlet and air conditioner outlet is according to the length of actually installed

air duct and in service behavior of the static pressure terminal: Installation sketch map for long and short

air duct is showed below, when connect to short air duct, using low static terminal (terminal color is white),

the distance between air duct outlet and air conditioner outlet is no more than 0.5m; when connect to long

air duct, using middle static terminal (terminal color is red), the distance between air duct outlet and air

conditioner outlet could be within 5m at this point.

Figure 5

sling dog

drain piping

air return duct

air return shutter

transition

air duct

air outlet

duct

air diffuser

joint of air diffuser

Drain piping of condensed water should keep a downhill grade of 1% or more. Use insulating pipe to cover

the drain piping of condensed water to keep warmth.

As figure shown, suspend and install the unit.

Figure 6

M8 broad foundation bolt

M8 suspension screw

Unit

M8 broad lock ring

M8 nut

Figure 6

z 37 z

Page 40

Chff^j\bZe Abj Chg]blbhg^j

Installation for air duct of indoor unit

1. Installation of air discharge duct

This type of unit uses circular air duct with its caliber of 180mm.

An additional transitive air duct is necessary for the circular air duct to connect to the air

supply inlet. It should be also connected to its respective air diffuser separately. See

Fig.1. Adjust the wind speed of each air diffuser outlet to keep in line on the whole, so

as to meet a demand of the air conditioner in the room.

Indoor unit

flexible joint

or static pressure box

Fig1: Duct connected

transitive air duct

circular air duct

joint of air diffuser

air diffuser

2. Installation of air return duct

Use rivets to connect the air return duct to the air return inlet of the indoor unit. The

other end connects to the air return shutter. as shown in Fig.2.

air return

shutter

air return

duct

Fig2: Duct return connected

indoor unit

rivet

3. Air duct insulation

Insulation layer is needed for air supply and return duct. First, paste a glue nail to the

air duct, and then attach the insulation cotton that has a tinfoil layer and use the glue

nail cover to fix. Finally, seal the air duct interface with tinfoil adhesive tape closely.

as shown in Fig3.

galvanized

board

glue nail

insulating

fabric

tinfoil

glue nail cover

adhesive tape

z 38 z

Page 41

Chff^j\bZe Abj Chg]blbhg^j

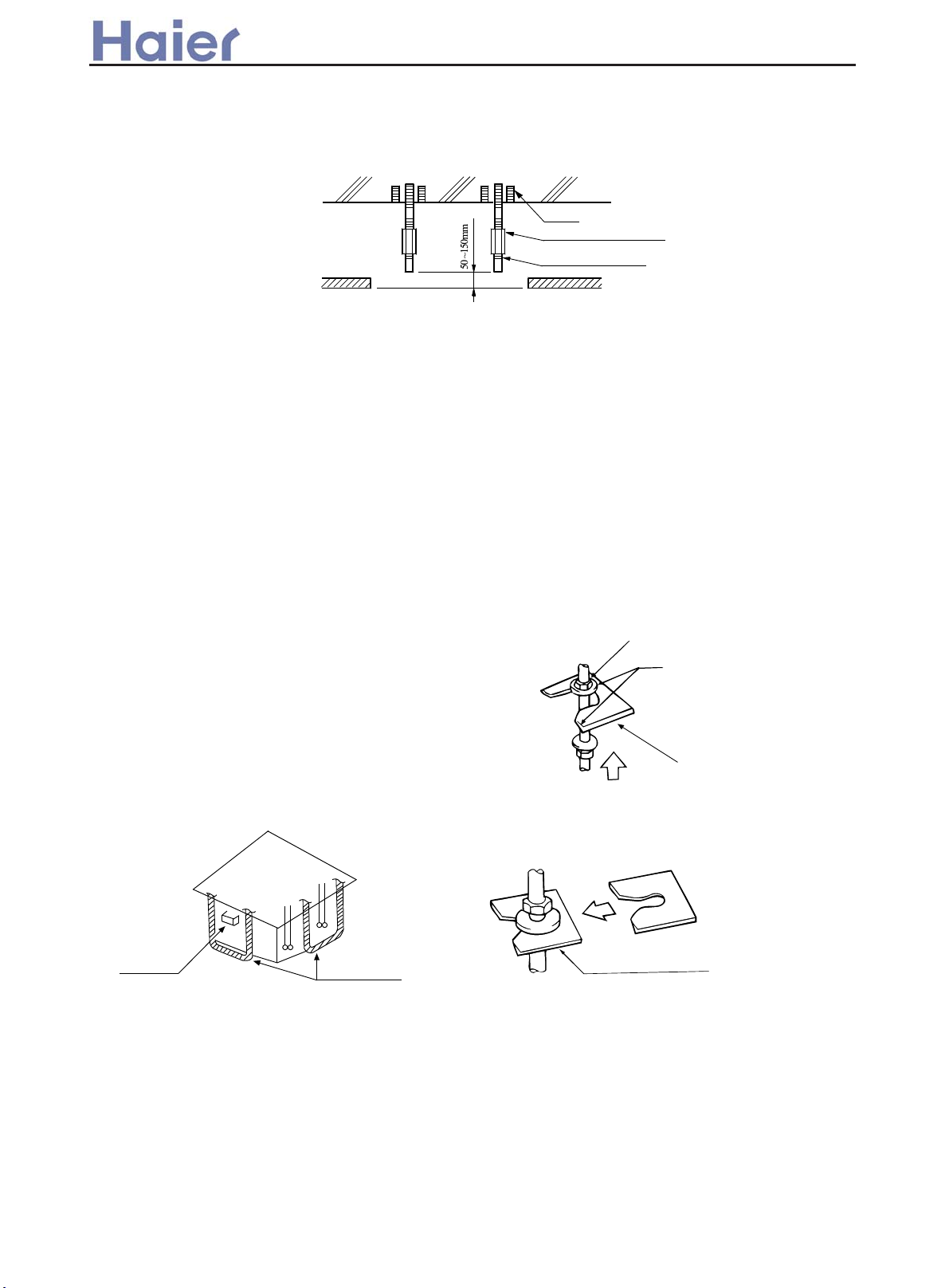

Installing the suspension screw:

Use M8 or M10 suspension screws (4, prepared in the field) (when the suspension screw

height exceeds 0.9 m, M10 size is the only choice). These screws shall be installed as

follows with space adapting to air conditioner overall dimensions according to the original

building structures.

Wooden structure

A square wood shall be supported by the beams and then set the suspension screws.

Square wood

Suspension

screw

New concrete slab

To set with embedded parts, foundation bolts etc.

Knife embedded part

Guide plate embedded part Pipe suspension foundation bolt

Original concrete slab

Use hole hinge, hole plunger or hole bolt.

Steel reinforcement structure

Use steel angle or new support steel angle directly.

Beam

Iron reinforcement

Foundation bolt

Hanging bolt

Suspension screw

Support steel angle

Hanging of the indoor unit

Fasten the nut on the suspension screw and then hang the suspension screw in the T

slot of the suspension part of the unit.

Aided with a level meter, adjust level of the unit within 5 mm.

z 39 z

Page 42

Chff^j\bZe Abj Chg]blbhg^j

! Caution

In order to drain water normally, the drain pipe shall be processed as specified in

the installation manual and shall be thermal insulated to avoid dew generation.

Improper hose connection may cause indoor water leakage.

Requirements

The indoor drain pipe shall be thermal insulated.

The connection part between the drain pipe and the indoor unit shall be insulated so as to

prevent dew generation.

The drain pipe shall be slant downwards (greater than 1/100). The middle part shall not be

of S type elbow, otherwise abnormal sound will be produced.

The horizontal length of the drain pipe shall be less than 20 m. In case of long pipe, supports shall be provided every 1.5

Central piping shall be laid out according to the following figure.

Take care not to apply external force onto the drain pipe connection part.

2m to prevent wavy form.

1.5m~2m

Insulation

(supplied by the user)

To the largest (app. 10cm)

Down slope above 1/100

Support

Down slope

above 1/100

VP30

S type elbow

Pipe and insulation material

Pipe

Insulation

Rigid PVC pipe VP31.5mm (internal diameter)

Foamed PE with thickness above 7mm

Hose

2

Drain pipe size: ? 19.05mm

(3/4") PVC pipe

The hose is used for adjusting the off-center and angle of the rigid PVC pipe.

Directly stretch the hose to install without making any deformation.

The soft end of the hose must be fastened with a hose clamp.

Please apply the hose on horizontal part

Hose Hose clamp

Insulation treatment:

Wrap the hose and its clamp until to the

indoor unit without any clearance with

insulating material, as shown in the figure.

Wall

Outside

Slant

Drain pipe (supplied

by the user)

Drain confirmation

Subsidiary insulation

Insulation

Rigid PVC pipe

During trial run, check that there is no leakage at the pipe connection part during water

draining even in winter.

z 40 z

Page 43

Chff^j\bZe Abj Chg]blbhg^j

Allowable pipe length and drop

These parameters differ according to the outdoor unit. See the instruction manual attached

with the outdoor unit for details.

Supplementary refrigerant

The refrigerant supplementation shall be as specified in the installation instructions

attached with the outdoor unit. The added refrigerant shall be R22.

The adding procedure shall be aided with a measuring meter

for a specified amount of supplemented refrigerant

Requirement

Overfilling or underfilling of refrigerant will cause compressor

fault. The amount of the added refrigerant shall be as specified

in the instructions.

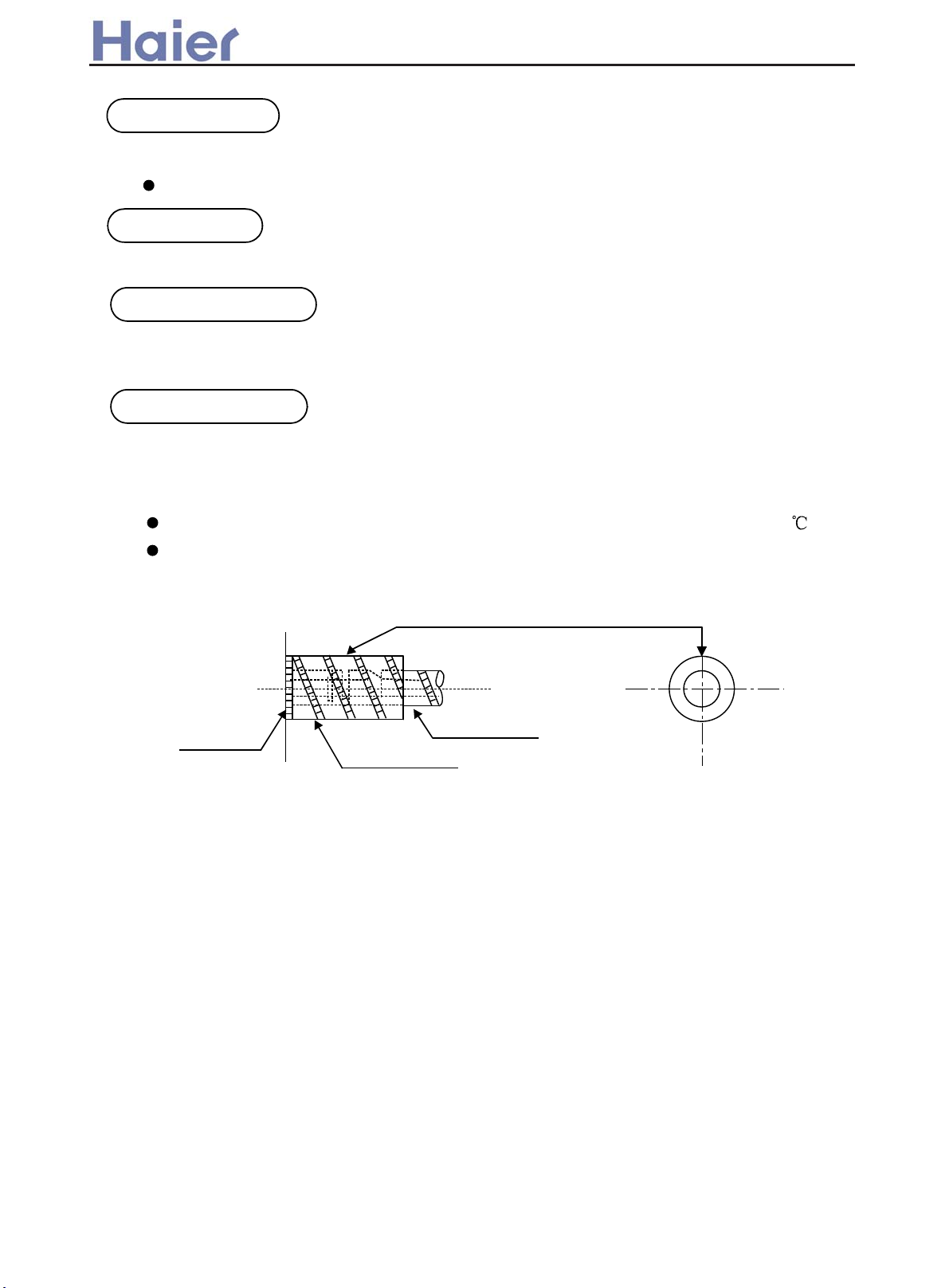

Connection of refrigerant pipe

Conduct flared connection work to connect all refrigerant pipes.

A

Pipe expander

Pipe cutting and expanding

If the pipe is too long or the flare is damaged, it needs to be cut or expanded.

1. Pipe cutting 2. Removing burrs 3.Insertion nut 4. Pipe expansion

Pipe expansion dimensions as follows:

Pipe diameter

6.35 mm (1/4") 0.8 ~ 1.5

9.52 mm (3/8

12.7 mm (1/2

15.88 mm (5/8

The connection of indoor unit pipes must use double spanners.

The installing torque shall be as given in the following table.

Connecting pipe

O.D.(mm)

? 6.35

? 9.52

? 12.70

? 15.88

*

Size A (mm)

"

) 1.0 ~ 1.8

"

) 1.2 ~ 2.0

"

) 1.4 ~ 2.2

Installing torque

(N-m)

11.8 (1.2kgf-m)

24.5 (2.5kgf-m)

49.0 (5.0 kgf-m)

78.4 (8.0 kgf-m)

Correct

Slope Damage Bur Partial Overlong

Increased installing

torque (N-m)

13.7 (1.4 kgf-m)

29.4 (3.0 kgf-m)

53.9 (5.5 kgf-m)

98.0 (10.0 kgf-m)

Incorrect

Double-spanner

operation

z 41 z

Page 44

Chff^j\bZe Abj Chg]blbhg^j

Vacuum pumping

With a vacuum pump, create vacuum from the stop valve of the outdoor unit.

Emptying with refrigerant sealed in the outdoor unit is absolutely forbidden.

Open all valves

Open all the valves on the outdoor unit.

Gas leakage detection

Check with a leakage detector or soap water that if there is gas leakage at the pipe

connections and bonnets.

Insulation treatment

Conduct insulation treatment on both the gas side and liquid side of pipes respectively.

During cooling operation, both the liquid and gas sides are cold and thus shall be insulated

so as to avoid dew generation.

The insulating material at gas side shall be resistant to a temperature above 120

The indoor unit pipe connection part shall be insulated.

The notch upward (Attached detail view)

Field piping side

Indoor unit

Subsidiary insulation tube

.

z 42 z

Page 45

8.4. Installation Precedure(For AF***XCEAA)

Selection of installation place

Place where it is easy to route drainage pipe

more than

more than

more than

more than

Fig1

330

617

Fig2

Fig3

Tool necessary

1. Screw driver

2. Hacksaw

3. 70mm dia.hole core drill

4. Spanner(dia. 17,27mm)

5. Spanner(14,17,27mm)

6. Pipe cutter

7. Flaring tool

8. Knife

9. Nipper

10. Gas leakage detector or soap water

11. Measuring tape

12. Reamer

13. Refrigerant oil

Standard accessories

Following parts shall be field supplied

Mark

A

B

C

D

E

F

Part name

Adhensive tape

Pipe clip

Connecting hose

Insulation material

Putty

Drain hose

and outdoor piping.

Place ,away from heat source and with less

direct sunlight.

Place where cool and warm air could be

delivered evently to every corner of the room.

Place near power supply socket.Leave enough

space around the unit.

Place ,robust not causing vibration,where the

body can be supported sufficiently.

To prevent interference, place it at least 1m

away from other electric machines, such as

TV set, radio.

Installing

According to the dimension of the figure 2 shown,

nail two cement steel nails on the wall,Keep 2~3

mm out.then hang the back of the unit on them.

There must be no gap between the indoor unit

and wall.

Remove the front panel,then use two expansible

screws to fix the unit on the floor.As figure 3

shown.

Once refrigerant piping and drain piping connections

are complete,fill the gap of the throght hole with putty.

Attach the front panel and front grille in their orginal

positions once all connections are complete.

Shape and description

No.

Note: There isn't connecting wire with this unit.

Chff^j\bZe Abj Chg]blbhg^j

QTY

Remote controller

Expansion

Self-tapping screw

Wall hole cover

Dry battery #7

Cement steel nail

bushing

6

Fixing the unit