Haier AU182ABNAC, AC242ACNAC, AU242ABNAC, AC28NACNAC, AU28NABNAC Service Manual

...

HCFU-14CL03/R1 (AC142ACNAC+AU142ABNAC)

HCFU-18CL03/R1 (AC182ACNAC+AU182ABNAC)

HCFU-24CL03/R1 (AC242ACNAC+AU242ABNAC)

HCFU-28CM03/R1 (AC28NACNAC+AU28NABNAC)

HCFU-36CM03/R1 (AC36NACNAC+AU36NABNAC)

HCFU-42CM03/R1 (AC42NACNAC+AU42NABNAC)

MANUAL CODE: SYJS-006 EDITION:2002.12.31.

Haier Group

Super low outdoor ambient cooling at -15

Auto-restart function

Group control(with a group controller)

Auto-changeover

Compact design of indoor unit

Weekly timing(with a weekly timer)

With new environment friendly refrigerant R407C

Features

Service Manual

Commercial Air Conditioning

Convertible Type Low Ambient Cooling Series

CONTENTS

1. Description of Products & Features…………………...…….1

2. Specifications…………………………. ………………...……3

3. Safety precaution…………………………..………………….9

4. Net dimensions of indoor and outdoor unit………………...11

5. Installation instructions ……………………. ………………..17

6. Parts and functions …………………………..…… ..……….28

7. Remote controller functions………………………….………31

8. Refrigerant diagram…………………………..……………....43

9. Electrical control functions……………………………………44

10. Diagnostic information(trouble shooting)…………….……51

11. Electrical data.........................................…………….……56

12. Exploded views and parts lists...............……………. ……67

13. Perdormance curves……………............................... ……87

14. Noise level charts.....……………............................... ……93

15. Air velocity distribution …………............................... ……94

CONTENTS

Contents……..............................................…...………...…….1

- 1 -

1 DESCRIPTION OF PRODUCTS & FEATURES

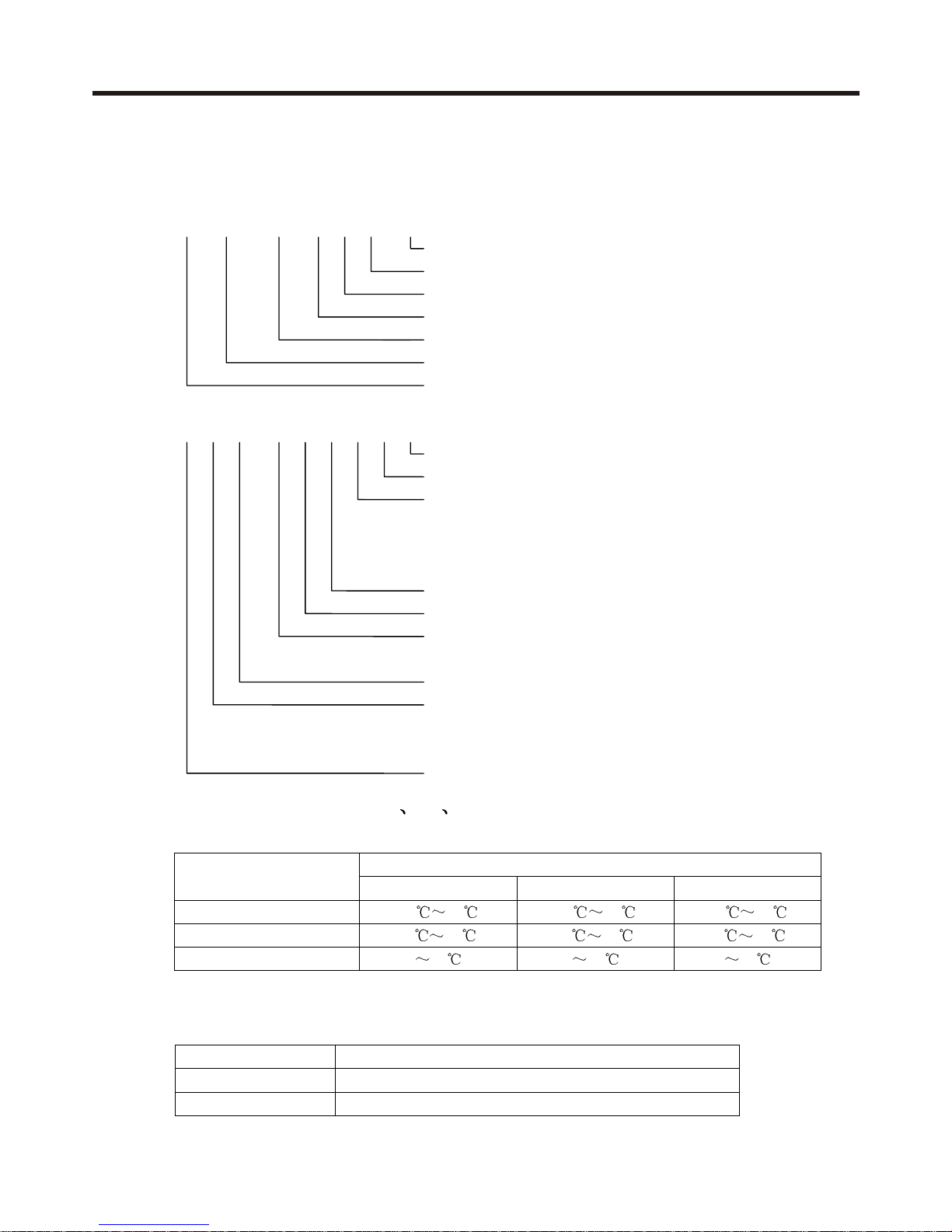

1.1 Products coding direction

Old code

H CFU – 42 C M 03 / R1

Refers to HFC refrigerant

Power: 03(230V/50Hz).04(240V/50Hz).12(115V/60Hz).13(230v/60Hz)

Low ambient cooling

“H” refer to cooling and heating, ”C” refer to cooling only

Nominal cooling capacity (BTU/h), 42=42000BTU/h

Indoor and outdoor unit code: "CF" Convertible type; "U" Outdoor unit

“H” means “Haier”

New code

A C 42 N A C N A C

Climate type: T1 (see table 1), and -15 degree cooling

Design number (A stands for fix speed type)

Product type: A stands for heat pump type, refrigerant is R22

B stands for heat pump type, refrigerant is R407

M stands for cool only type, refrigerant is R22

N stands for cool only type, refrigerant is R407

Appearance character

Product series: one by one type

Applicable voltage: 2 stands for 220-240V/50Hz,4 stands for 220v/60Hz

N stand for 380V/50Hz

Cooling / Heating capacity,42=42000BTU/h

Product type : “B” stands for cassette type, “C” stands for convertible

type, ”D” stands for duct, “S” stands for split type, ”Q” stands for chiller

system, "E" stands for ceiling concealed type, “U” stands for outdoor unit

Air conditioner

1.2 Brief Introduction to T1 T2 T3 working condition

Table 1

Climate type

Type of Air Conditioner

T1 T2 T3

Cool only

18

43 10 35 21 52

Heat pump

-7

43 -7 35 -7 52

Electricity heating

43 35 52

1.3 Operating Range of air conditioners

Low ambient cooling

Operation Operation Range Outside / Inside

Cooling

-15

0

C – 43oC

Dehumidifying

-15

0

C – 43oC

DESCRIPTION OF PRODUCTS & FEATURES

- 2 -

1.4 Products characteristic

(2).HFC refrigerant technology

To protect the environment, we have adopted the HFC refrigerant. The HFC R407C is of zero ODP

for the purpose of environmental protection.

(3).Ceiling/console convertible,flexible installation,convenient maintenance,saving

the users' expenditures

(4).Adopting single-phase or three-phase power supply,applicable for household

and commercial usage

(5).Dual air outlet design,floor air blowing,accelerating the indoor air circulation,

quick temperature adjustment

(6).Long-distance air blowing,large power,large cooling/heating ratio

(7).Intelligent remote control,convenient and flexible control

(8).Super-slim indoor unit design,luxury and nice-looking,saving space,harmonious

and unitive with the indoor environment

(9).Adopting screw-fastening for the air inlet grill,firmly fixed;adopting slipway

insert-lock fastening method for the filter screen,convenient cleaning or replacing

the filter screen without opening the air inlet grill.

.

The system can run the cooling operation at the low ambient temperature -15

(1).Low ambient temperature cooling technology

(10).Group control,units up to 128 sets can be controlled

DESCRIPTION OF PRODUCTS & FEATURES

- 3 -

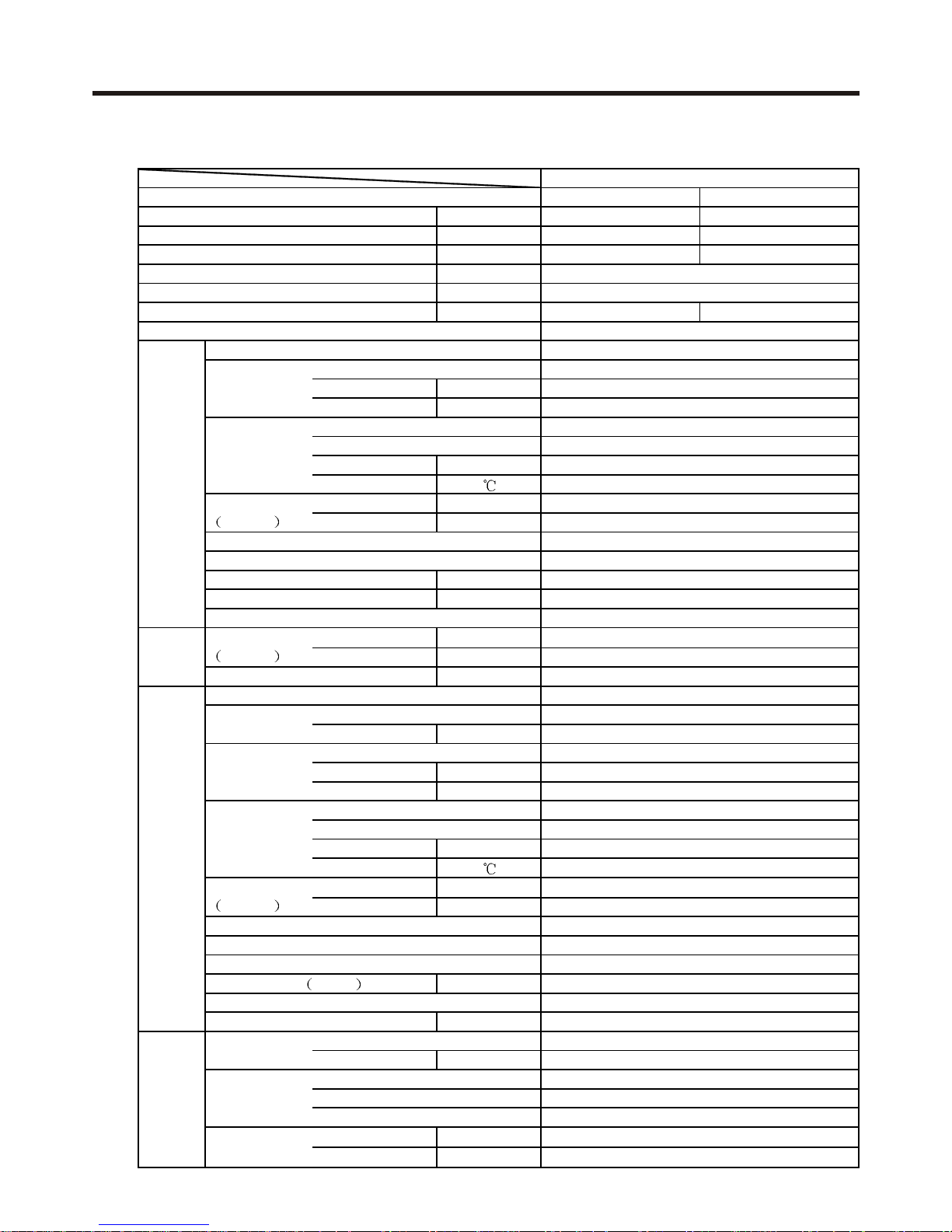

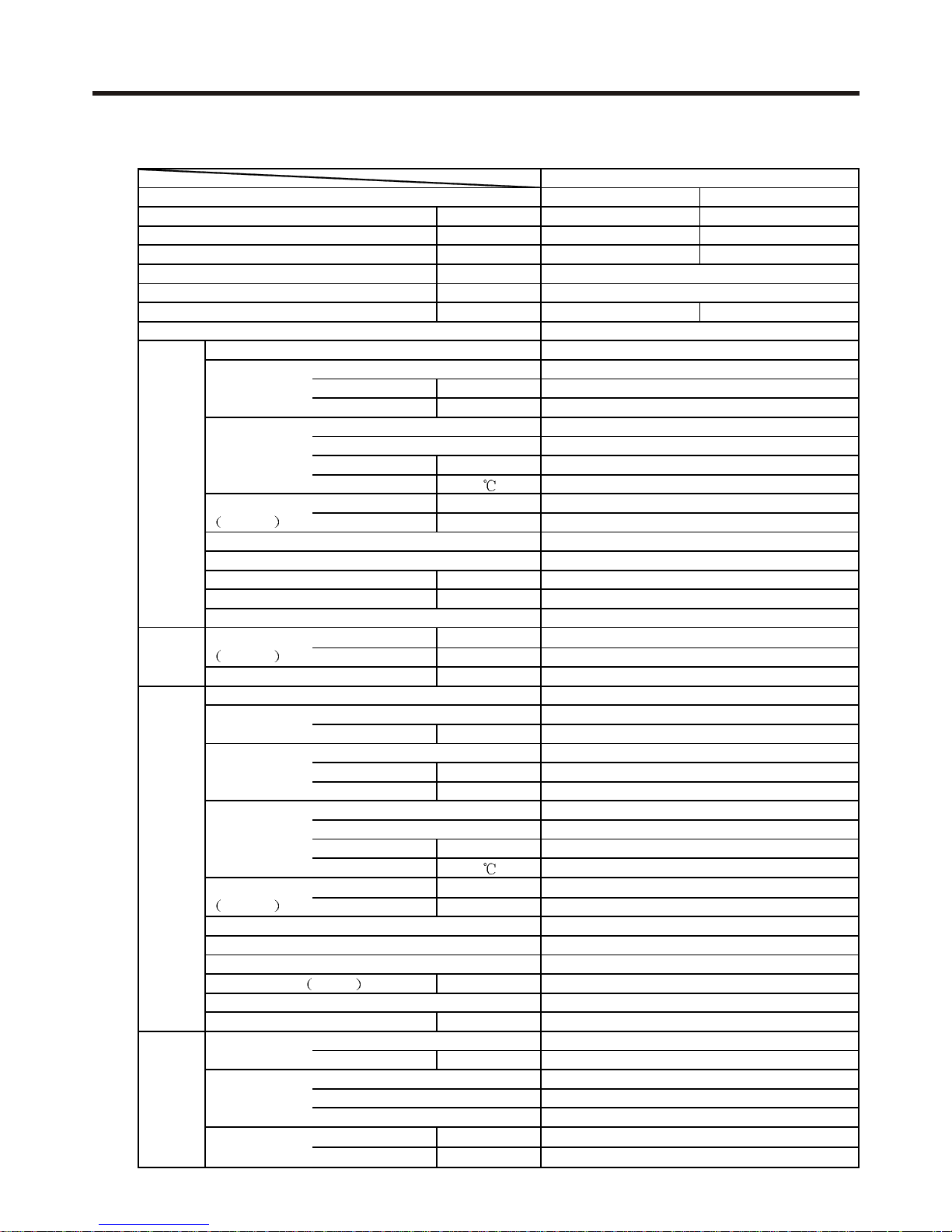

Function

Cooling Heating

Capacity BTU/h

14000 /

W

2000 /

EER or COP BTU/W

7.00 /

Dehumidifying capacity

10‐³×m³/h

Power source PH-V-Hz

Running current/Starting current

A

Power cable

Unit model (color)

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Control type (wireless/wired)

Fresh air hole dimension mm

Noise level (H-M-L) dB(A)

kg

External mm×mm×mm

Package mm×mm×mm

kg

Unit model (color)

Compressor Model / Manufacture

Type

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Refrigerant control method

Noise level

H-M-L

dB(A)

kg

Refrigerant Type

Charge kg

Pipe Liquid mm

Gas mm

Connect method

Drop

m

Piping length

m

Item Model

HCFU-14CL03/R1

1

1PH, 220V-230V, 50HZ

/

Indoor unit

AC142ACNAC / WHITE

CENTRIFUGAL×2

1070/1000/940

900

TP2M/9.52

2/2

0.199

2-7

Dimension

L×W×H

900×655×199

1150×750×300

PVC 18/20

wired

/

48/44/38

Weight (net / gross)

30/39

Panel

Dimension

L×W×H

/

/

Weight (net / gross)

/

Outdoor unit

AU142ABNAC / WHITE

ZR34K3E-TFJ-522 / COPELAND

scroll

Axial-flow×1

820

700/-/-

TP2M/9.52

2/2

0.225

43-60

Dimension

L×W×H

810×288×680

960×406×760

PVC,18/20

Capillary

Defrosting

Auto

15.88

FLARED

52/-/

Four way valve

/

Between

I.U. & O.U.

MAX :5

MAX :15

Total power input

Weight (net / gross)

59/66

Piping

R407C

1.8

6.35

2 SPECIFICATIONS

9.4/40.7

/

SPECIFICATIONS

- 4 -

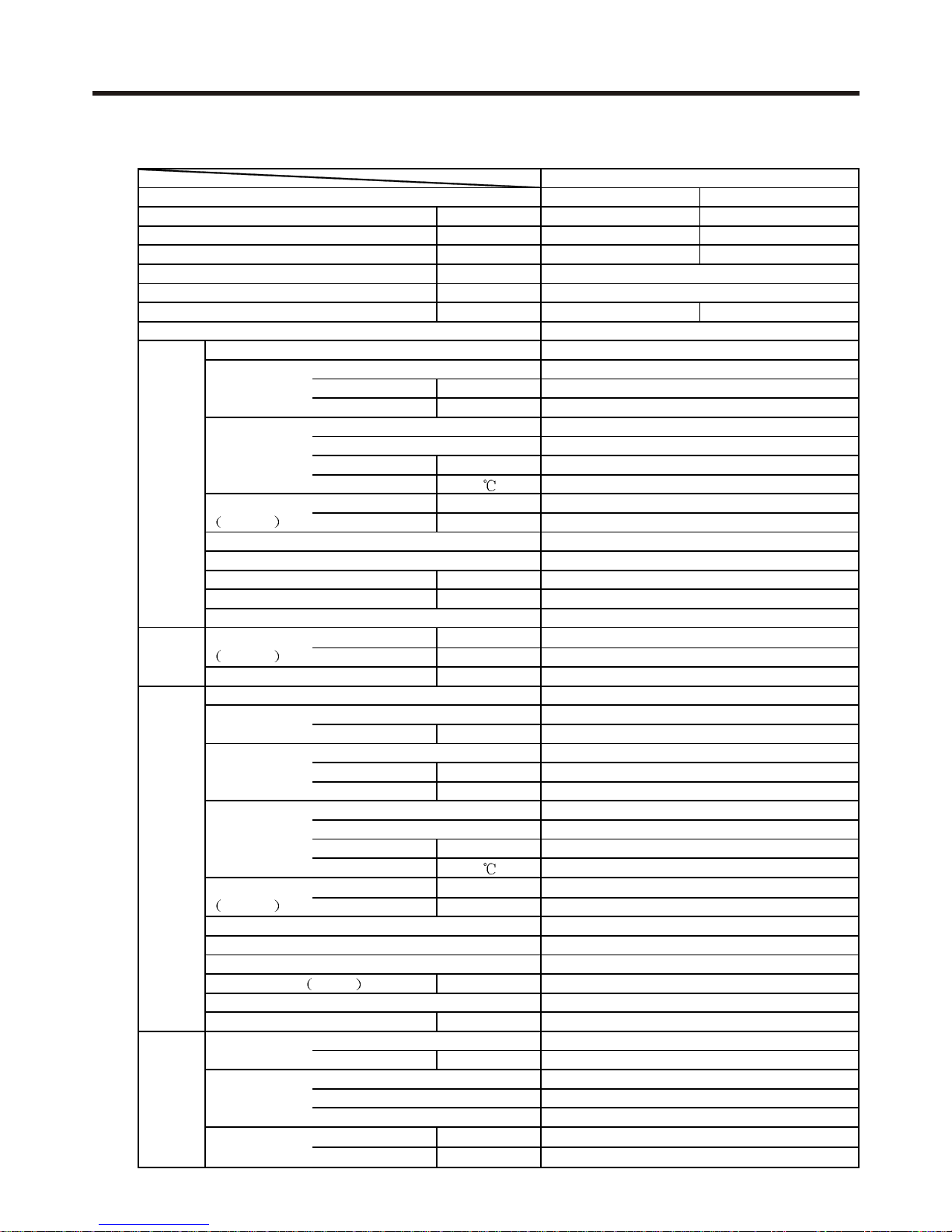

Function

Cooling Heating

Capacity BTU/h

18000 /

W

2000

/

EER or COP BTU/W

9

.00 /

Dehumidifying capacity

10‐³×m³/h

Power source PH-V-Hz

Running current/Starting current A

Power cable

Unit model (color)

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Control type (wireless/wired)

Fresh air hole dimension mm

Noise level (H-M-L) dB(A)

kg

External mm×mm×mm

Package mm×mm×mm

kg

Unit model (color)

Compressor Model / Manufacture

Type

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Refrigerant control method

Noise level

H-M-L

dB(A)

kg

Refrigerant Type

Charge kg

Pipe Liquid mm

Gas mm

Connect method

Drop

m

Piping length

m

Item Model

HCFU-18CL03/R1

1

1PH, 220V-230V, 50HZ

/

Indoor unit

AC182ABNAC / WHITE

CENTRIFUGAL×2

500/450/380

1050

TP2M/9.52

2/2

0.

199

2-7

Dimension

L×W×H

990×655×199

1160×760×310

PVC 18/20

wired

/

43/42/40

Weight (net / gross)

29/39

Panel

Dimension

L×W×H

/

/

Weight (net / gross)

/

Outdoor unit

AU182ABNAC / WHITE

ZR34K3E-TFJ-522 / COPELAND

scroll

Axial-flow×1

820

700/-/-

TP2M/9.52

2/2

0.225

43-60

Dimension

L×W×H

810×288×680

960×406×760

PVC,18/20

Capillary

Defrosting

Auto

15.88

FLARED

52/-/46

Four way valve

/

Between

I.U. & O.U.

MAX :

5

MAX :

15

Total power input

Weight (net / gross)

58/66

Piping

R407C

1.80

6.35

/

9.3/46.0

SPECIFICATIONS

- 6 -

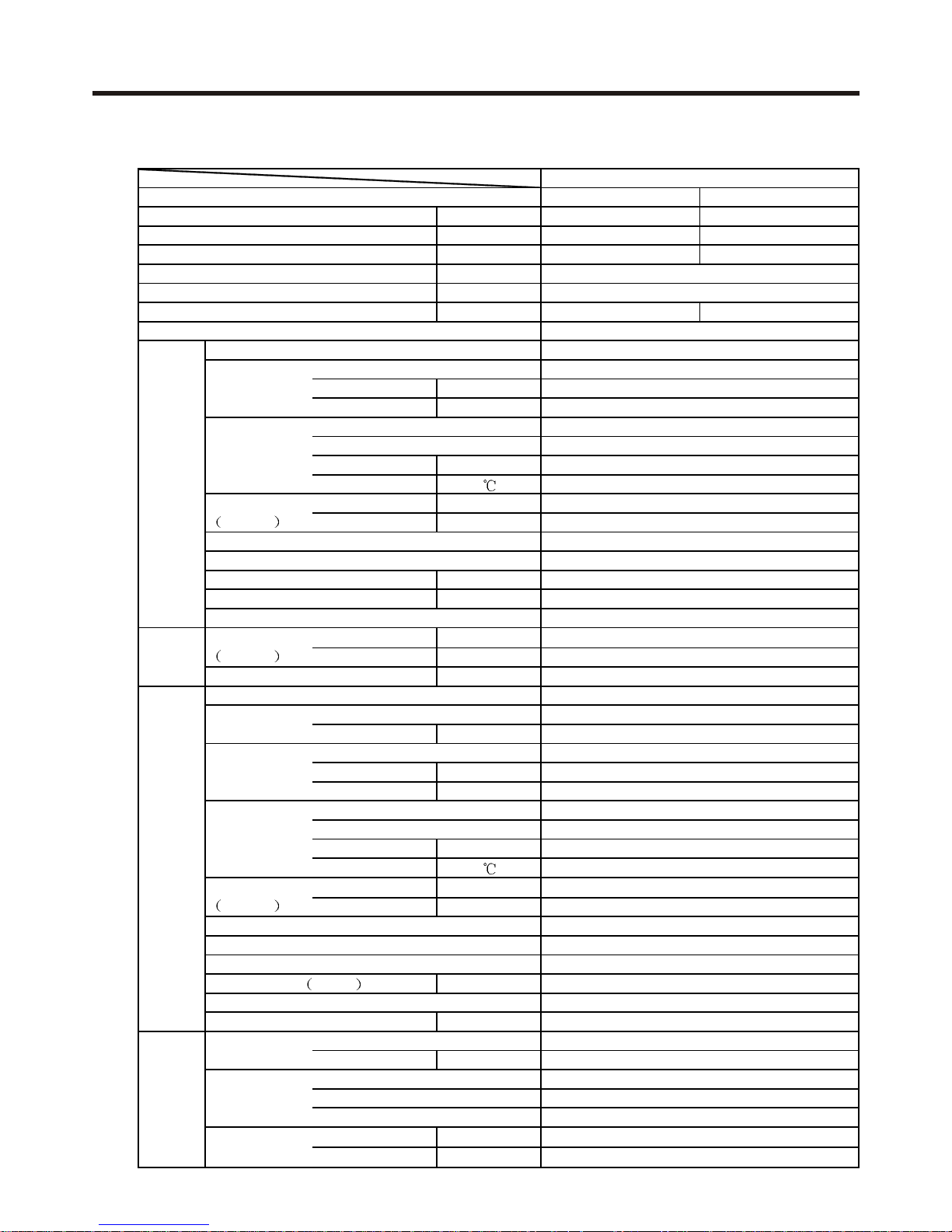

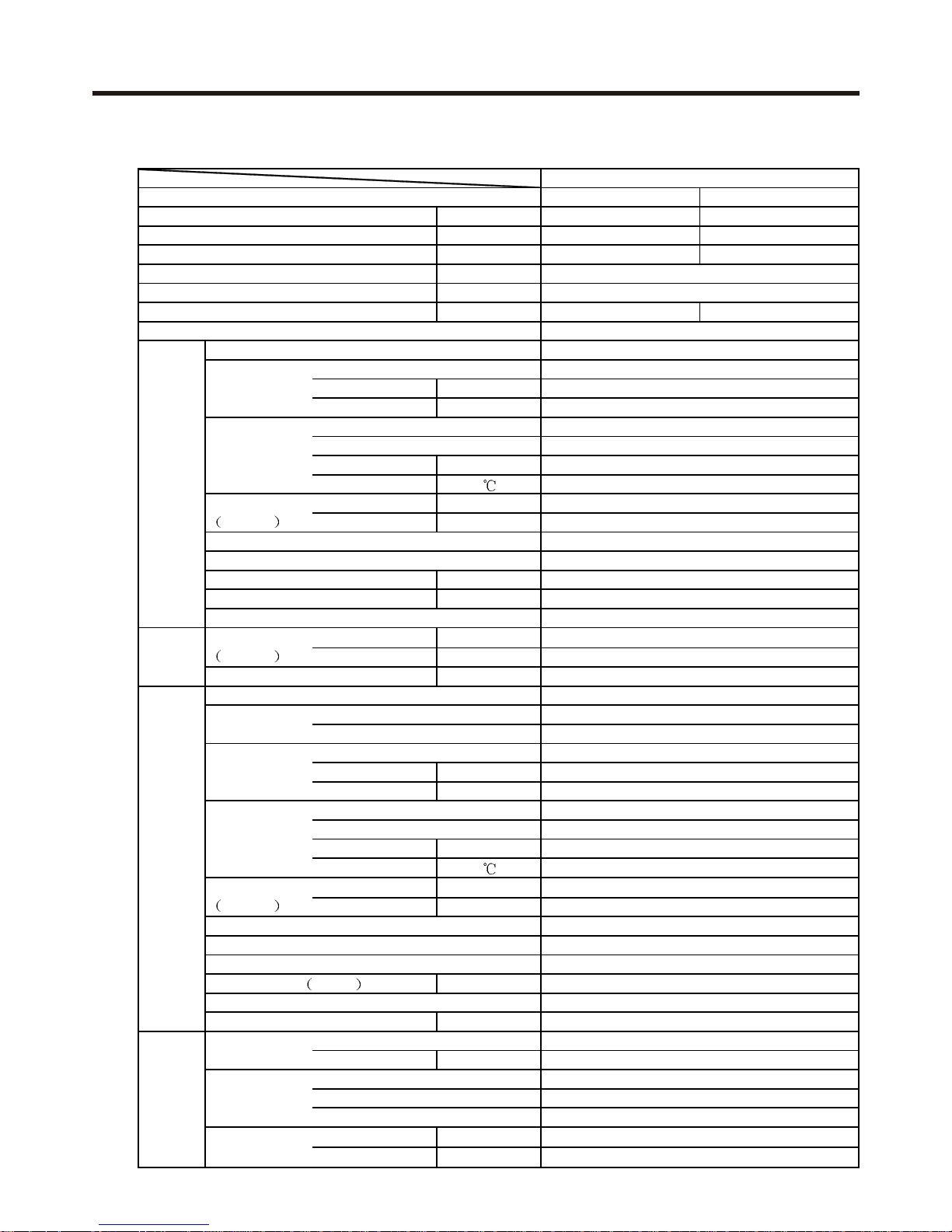

Function

Cooling Heating

Capacity BTU/h

24000 /

W

2800 /

EER or COP BTU/W

8.57 /

Dehumidifying capacity

10‐³×m³/h

Power source PH-V-Hz

Running current/Starting current A

Power cable

Unit model (color)

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Control type (wireless/wired)

Fresh air hole dimension mm

Noise level (H-M-L) dB(A)

kg

External mm×mm×mm

Package mm×mm×mm

kg

Unit model (color)

Compressor Model / Manufacture

Type

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Refrigerant control method

Noise level

H-M-L

dB(A)

kg

Refrigerant Type

Charge kg

Pipe Liquid mm

Gas mm

Connect method

Drop

m

Piping length

m

Item Model

HCFU-24CL03/R1

3

1PH,220V~230V,50Hz

/

Indoor unit

AC242ACNAC / WHITE

CENTRIFUGAL×2

1300/1200/1000

1300

TP2M/9.52

2/2

0.221

2-7

Dimension

L×W×H

1320×715×235

1380×770×300

PVC 18/20

wired

/

35/32/29

Weight (net / gross)

40/57

Panel

Dimension

L×W×H

/

/

Weight (net / gross)

/

Outdoor unit

AU242ABNAC / WHITE

ZR34K3E-TFJ-522 / Copeland

scroll

Axial-flow×1

840/-/-

3240

TP2M/9.52

3/3

0.62

43-60

Dimension

L×W×H

948×830×340

1050×979×440

PVC,18/20

Capillary

Defrosting

Auto

15.88

FLARED

58/-/50

Four way valve

/

Between

I.U. & O.U.

MAX :15

MAX : 30

Total power input

Weight (net / gross)

70/85

Piping

R407C

1.85

9.52

12.5/60.1 /

SPECIFICATIONS

Function

Cooling Heating

Capacity BTU/h

28000 /

W

28

00 /

EER or COP BTU/W

10.0 /

Dehumidifying capacity

10‐³×m³/h

Power source PH-V-Hz

Running current/Starting current A

Power cable

Unit model (color)

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Control type (wireless/wired)

Fresh air hole dimension mm

Noise level (H-M-L) dB(A)

kg

External mm×mm×mm

Package mm×mm×mm

kg

Unit model (color)

Compressor Model / Manufacture

Type

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Refrigerant control method

Noise level

H-M-L

dB(A)

kg

Refrigerant Type

Charge kg

Pipe Liquid mm

Gas mm

Connect method

Drop

m

Piping length

m

Item Model

HCFU-28CM03/R1

3

3N,380V~400V,50Hz

/

Indoor unit

AC28NACNAC / WHITE

CENTRIFUGAL×2

1300/1200/1000

1300

TP2M/9.52

2/2

0.221

2-7

Dimension

L×W×H

1320×715×235

1380×770×300

PVC 18/20

wired

/

35/32/29

Weight (net / gross)

40/57

Panel

Dimension

L×W×H

/

/

Weight (net / gross)

/

Outdoor unit

AU28NABNAC / WHITE

ZR34K3E-TFJ-522 / Copeland

scroll

Axial-flow×1

840/-/-

3240

TP2M/9.52

3/3

0.62

43-60

Dimension

L×W×H

948×830×340

1050×979×440

PVC,18/20

Capillary

Defrosting

Auto

15.88

FLARED

58/-/50

Four way valve

/

Between

I.U. & O.U.

MAX :

15

MAX :

30

Total power input

Weight (net / gross)

74/89

Piping

R407C

1.85

9.52

12.5/60.1 /

SPECIFICATIONS

Function

Cooling Heating

Capacity BTU/h

36000 /

W

3600 /

EER or COP BTU/W

10.0 /

Dehumidifying capacity

10‐³×m³/h

Power source PH-V-Hz

Running current/Starting current A

Power cable

Unit model (color)

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Control type (wireless/wired)

Fresh air hole dimension mm

Noise level (H-M-L) dB(A)

kg

External mm×mm×mm

Package mm×mm×mm

kg

Unit model (color)

Compressor Model / Manufacture

Type

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Refrigerant control method

Noise level

H-M-L

dB(A)

kg

Refrigerant Type

Charge kg

Pipe Liquid mm

Gas mm

Connect method

Drop

m

Piping length

m

Item Model

HCFU-36CM03/R1

5

3N, 380V-400V, 50HZ

/

Indoor unit

AC36NACNAC / WHITE

CENTRIFUGAL×3

1300/1200/1000

1600

TP2M/9.52

3/3

0.338

2-7

Dimension

L×W×H

1920×715×235

1980×761×295

PVC 18/20

wired

/

56/54/52

Weight (net / gross)

46/52

Panel

Dimension

L×W×H

/

/

Weight (net / gross)

/

Outdoor unit

AU36NABNAC / WHITE

ZR34K3E-TFJ-522 / COPELAND

scroll

Axial-flow×2

840/-/-

6000

TP2M/9.52

5/5

0.92

43-60

Dimension

L×W×H

948×1225×340

1050×1375×440

PVC,18/20

Capillary

Defrosting

Auto

19.05

FLARED

52/-/46

Four way valve

/

Between

I.U. & O.U.

MAX :30

MAX : 50

Total power input

Weight (net / gross)

85/111

Piping

R407C

3.1

9.52

6.4/32

/

SPECIFICATIONS

Function

Cooling Heating

Capacity BTU/h

42000 /

W

4600 /

EER or COP BTU/W

9.1

Dehumidifying capacity

10‐³×m³/h

Power source PH-V-Hz

Running current/Starting current A

Power cable

Unit model (color)

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Control type (wireless/wired)

Fresh air hole dimension mm

Noise level (H-M-L) dB(A)

kg

External mm×mm×mm

Package mm×mm×mm

kg

Unit model (color)

Compressor Model / Manufacture

Type

Fan Type × Number

Speed r/min

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter

Flow

Total area m²

Temp. scope

External mm×mm×mm

Package mm×mm×mm

Drainage pipe (material , I.D./O.D.)

Refrigerant control method

Noise level

H-M-L

dB(A)

kg

Refrigerant Type

Charge kg

Pipe Liquid mm

Gas mm

Connect method

Drop

m

Piping length

m

Item Model

HCFU-42CM03/R1

5

3N, 380V-400V, 50HZ

/

Indoor unit

AB42NACNAC / WHITE

CENTRIFUGAL×3

980/880/820

2040

TP2M/9.52

3/3

0.199

2-7

Dimension

L×W×H

1920×715×235

1980×761×295

PVC 18/20

wireless

/

43/41/39

Weight (net / gross)

46/53

Panel

Dimension

L×W×H

/

/

Weight (net / gross)

/

Outdoor unit

AU42NAANAC / WHITE

ZR34K3E-TFJ-522 / COPELAND

scroll

Axial-flow×2

840/-/-

6000

TP2M/9.52

5/5

0.92

43-60

Dimension

L×W×H

948×1225×340

1050×1375×440

PVC,18/20

Capillary

Defrosting

Auto

19.05

FLARED

64/-/-

Four way valve

/

Between

I.U. & O.U.

MAX :30

MAX : 50

Total power input

Weight (net / gross)

85/111

Piping

R407C

3.2

9.52

/

/

9.3/32

SPECIFICATIONS

WARNING

CAUTION

WARNING

CAUTION

This system should be applied to places of office, restaurant, residence and the like. Appliaction to inferior

environment such as engineering shop could cause equipment malfunction.

Please entrust installation to either the company which sold you the equipment or to a professional contractor.

Defects from improper installations can be the cause of water leakage, electric shocks and fires.

Execute the installation accurately, based on following the installation manual. Again, improper installations can

result in water leakage, electric shocks and fires.

When a large air-conditioning system is installed to a small room, it is necessary to have a prior planned

countermeasure for the rare case of a refrigerant leakage, to prevent the exceeding of threshold concentration.

In regards to preparing this countermeasure, consult with the company from which you purchased the equipment,

and make the installation accordingly. In the rare event that a refrigerant leakage and exceeding of threshold

concentration does occur,there is the danger of a resultant oxygen deficiency accident.

For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insufficient,

injury can result from a falling of the unit.

Execute the prescribed installation construction to prepare for earthquakes and the strong winds of typhoons and

hurricanes, etc. Improper installations can result in accidents due to a violent falling over of the unit.

For electrical work, please see that a licensed electrician executes the work while following the safety standards

related to electrical equipment, and local regulations as well as the installation instructions, and that only exclusive

use circuits are used.

Insufficient power source circuit capacity and defective installment execution can be the cause of electric shocks and

fires.

Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted to

the terminal connection part, through properly securing it. Improper connection or securing can result in heat

generation or fire.

Take care that wiring does not rise upward, and accurately install the lid/service panel. Its improper installation can

also result in heat generation or fire.

WARNING

In either case, important safety related information is indicated, so by all means, properly observe all that is mentioned.

After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please

explain operating methods as well as maintenance methods to the user (customer) of this equipment, based on the owner's

manual.

Moreover, ask the customer to keep this sheet together with the owner's manual.

Please read these "Safety Precautions" first then accurately execute the installation work.

Though the precautionary points indicated herein are divided under two headings, and

those points which are related to the strong possibility of an installation done in error

resulting in death or serious injury are listed in the section. However, there is also a

possibility of serious consequences in relationship to the points listed in the section as well.

- 10 -

SAFETY PRECAUTIONS

3 SAFETY PRECAUTIONS

When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the designated

refrigerant (please see nameplate) within the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this

company can result in water leakage, electric shock, fire and refigerant leakage.

The position of indoor unit must be above the floor 2.5m.

WARNING

Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightening rod or a telephone

ground wire.

Improper placement of ground wires can result in electric shock.

The installation of an earth leakage breaker is necessary depending on the established location of the unit. Not

installing an earth leakage breaker may result in electric shock.

Do not install the unit where there is a concern about leakage of combustible gas.

The rare event of leaked gas collecting around the unit could result in an outbreak of fire.

For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it to

prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

CAUTION

- 11 -

SAFETY PRECAUTIONS

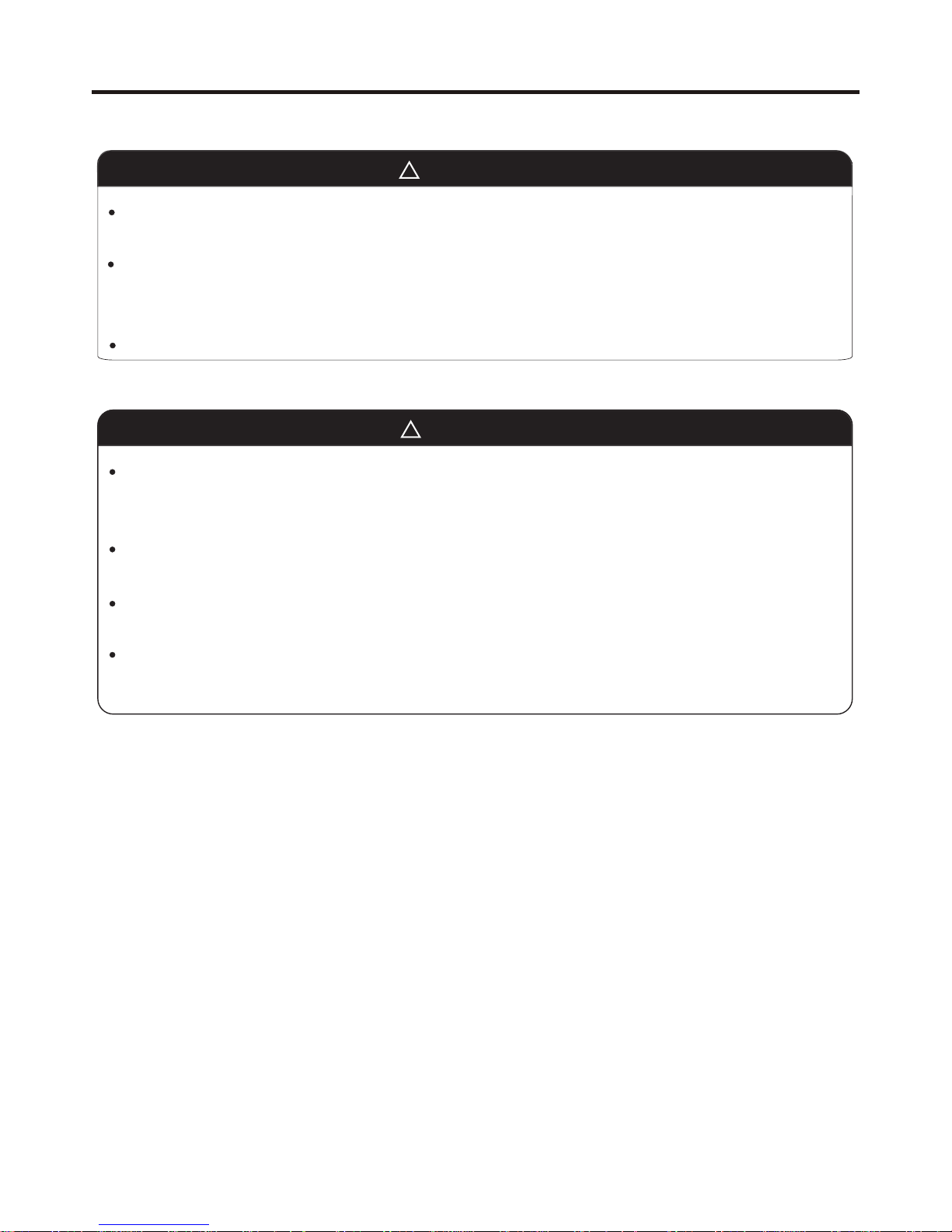

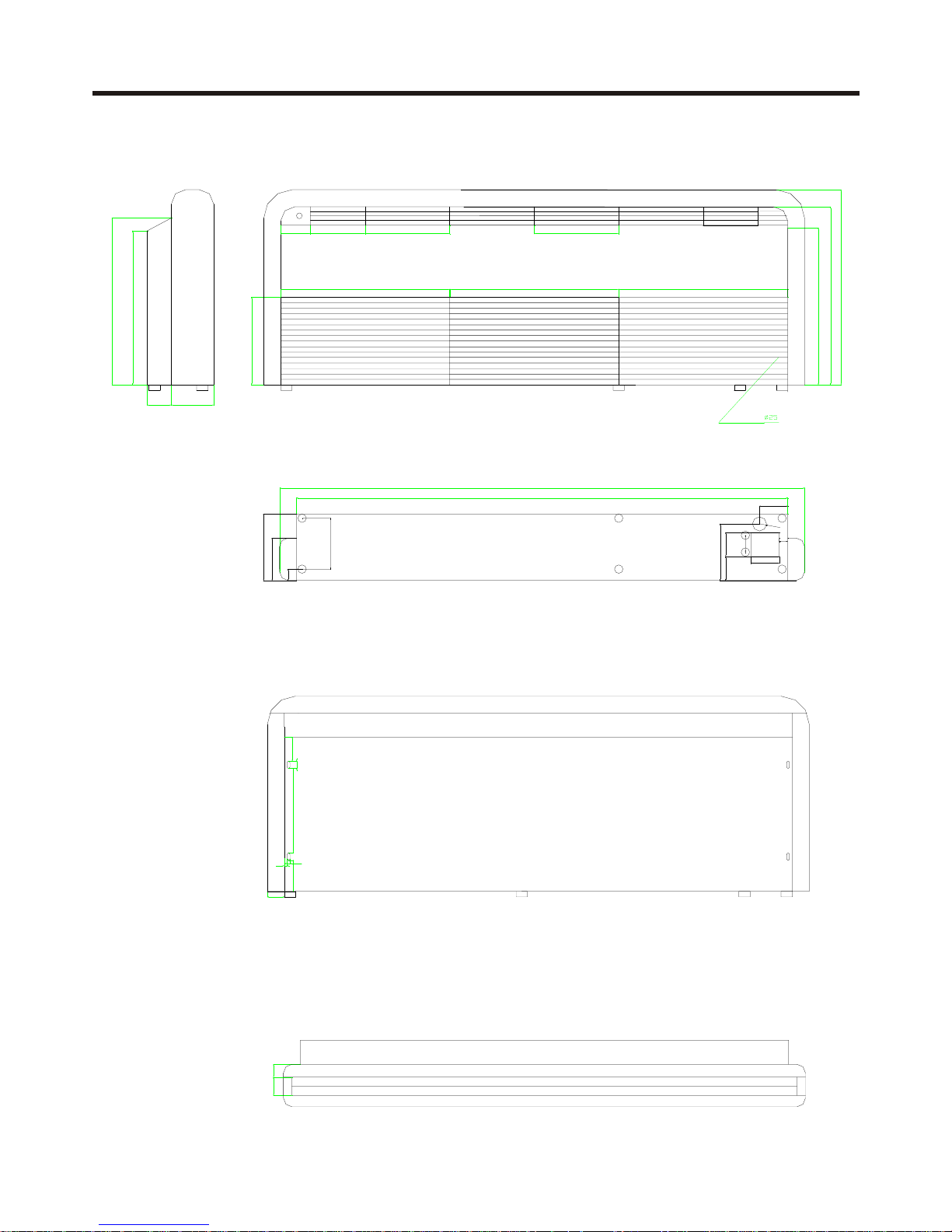

Model: HCFU-14CL03/R1 HCFU-18CL03/R1 Indoor unit

Model: HCFU-14CL03/R1 HCFU-18CL03/R1 Outdoor unit

6

5

5

240

2

0

0

9

480

30

265

220

200

580

288

810

680

75

65

150

100 100

110

190

170

400

4 NET DIMENSIONS OF INDOOR AND OUTDOOR UNIT

NET DIMENSIONS OF INDOOR AND OUTDOOR UNIT

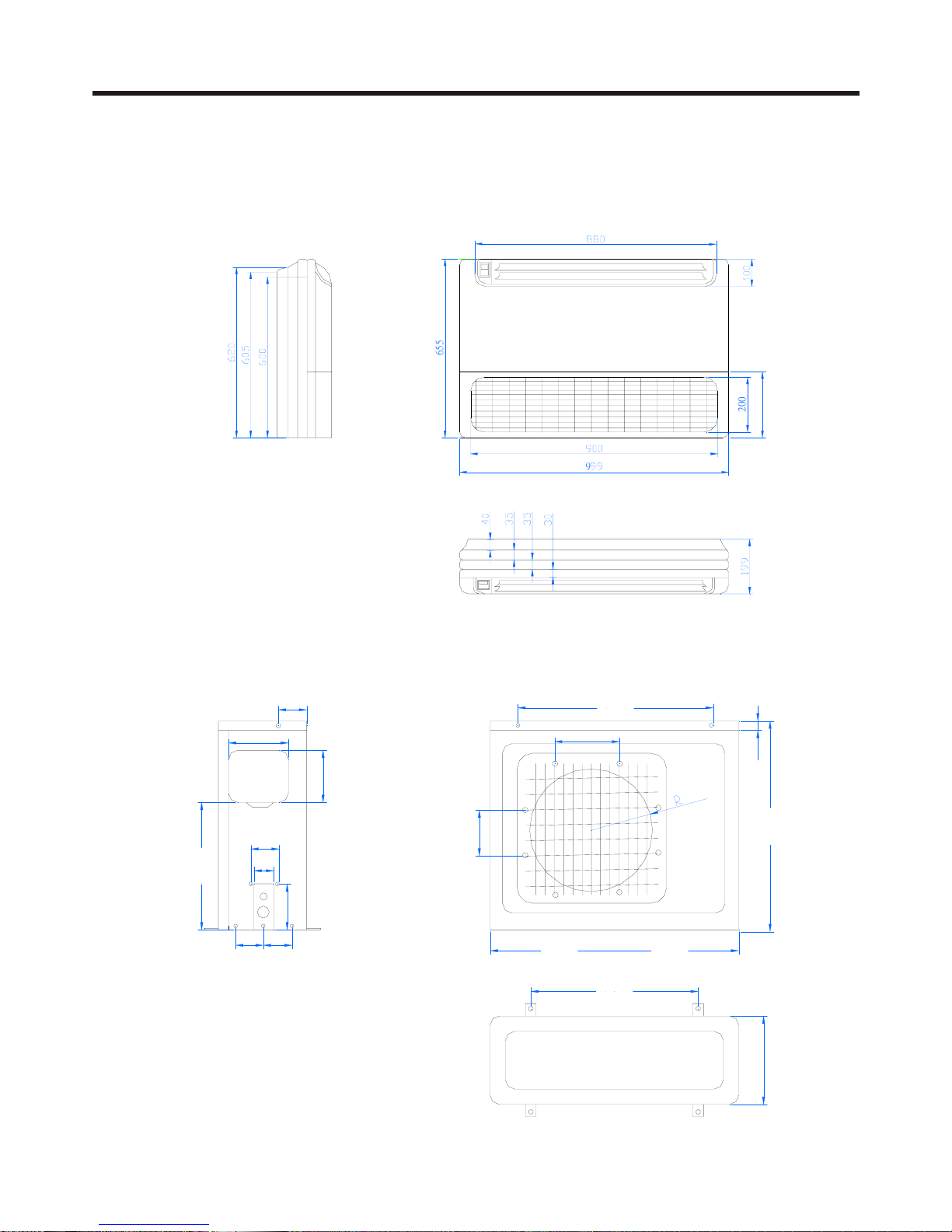

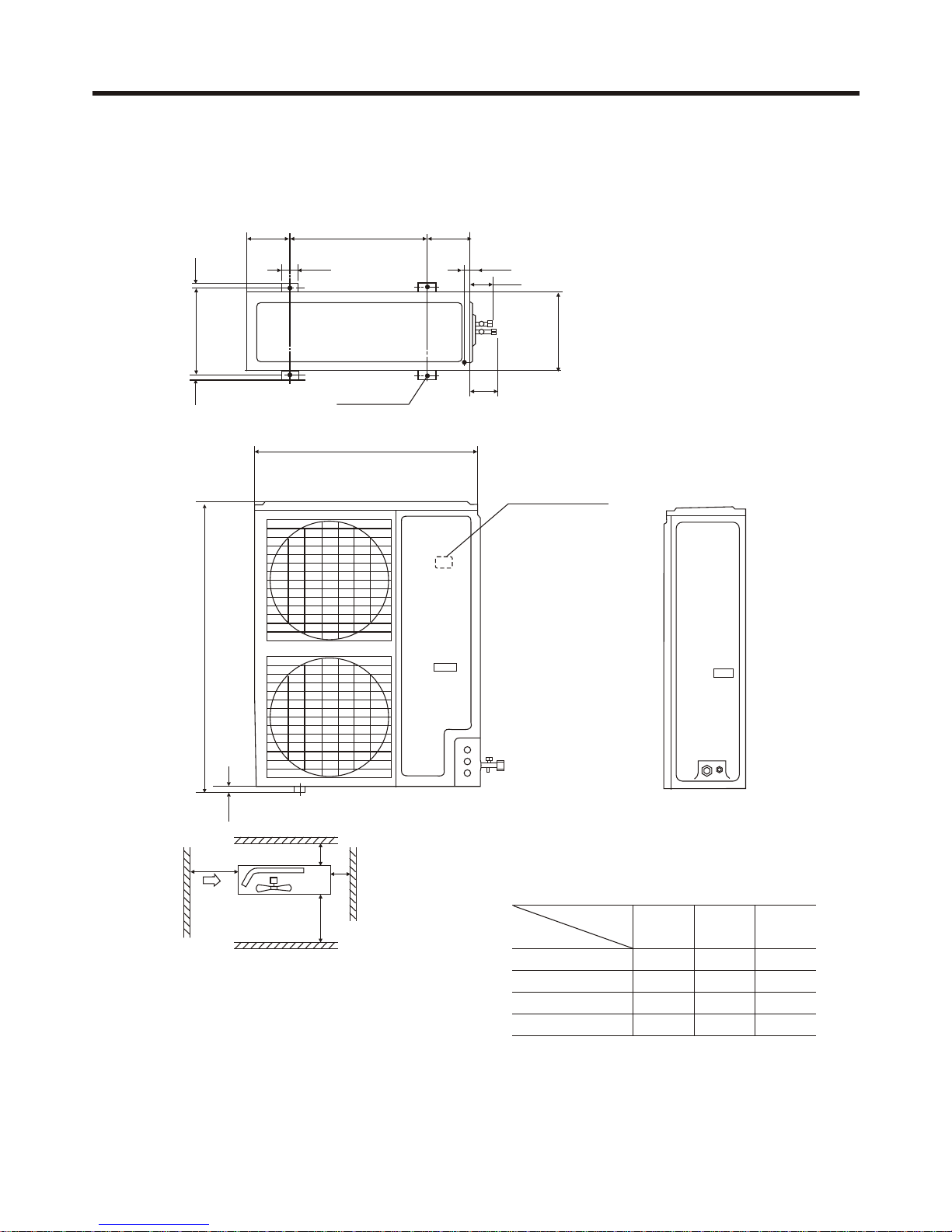

Model: HCFU-24CL03/R1 HCFU-28CM03/R1 Indoor unit

110

180

60

85

100

30

555

630

690

105 195

300

600 600

310.63

85

25

300

10 10

545

590

85 150

60

1200

150

235

1320

40

195

100

85

45

65

R15

drainage pipe

NET DIMENSIONS OF INDOOR AND OUTDOOR UNIT

Note (1) Fix the parts with screws

(2)Don't intake the strong wind directly

to the outlet air-flow hole.

(3)A one meter distance should be

kept from the unit top

(4)Don't block the surroudings of the unit with sundries.

Installation Servicing Space(at Least)

Unit:mm

Installation

I

300

100

0

0

150

0

500

100

0

II III

Dimension

L1

Leave space Leave space

Leave space

L2

L3

L4

185 185

55

70

70

Screw Hole

(M10)

580

Power Wiring Terminal

Power Wiring

Distribution Hole

L1

L2

L3

L4

Back Air-flow Hole

Back Airflow Hole

Outlet Air-flow Hole

Repairing Space

70

1024

1818

340

380

840

25

Model: HCFU-24CL03/R1 HCFU-28CM03/R1 Outdoor unit

NET DIMENSIONS OF INDOOR AND OUTDOOR UNIT

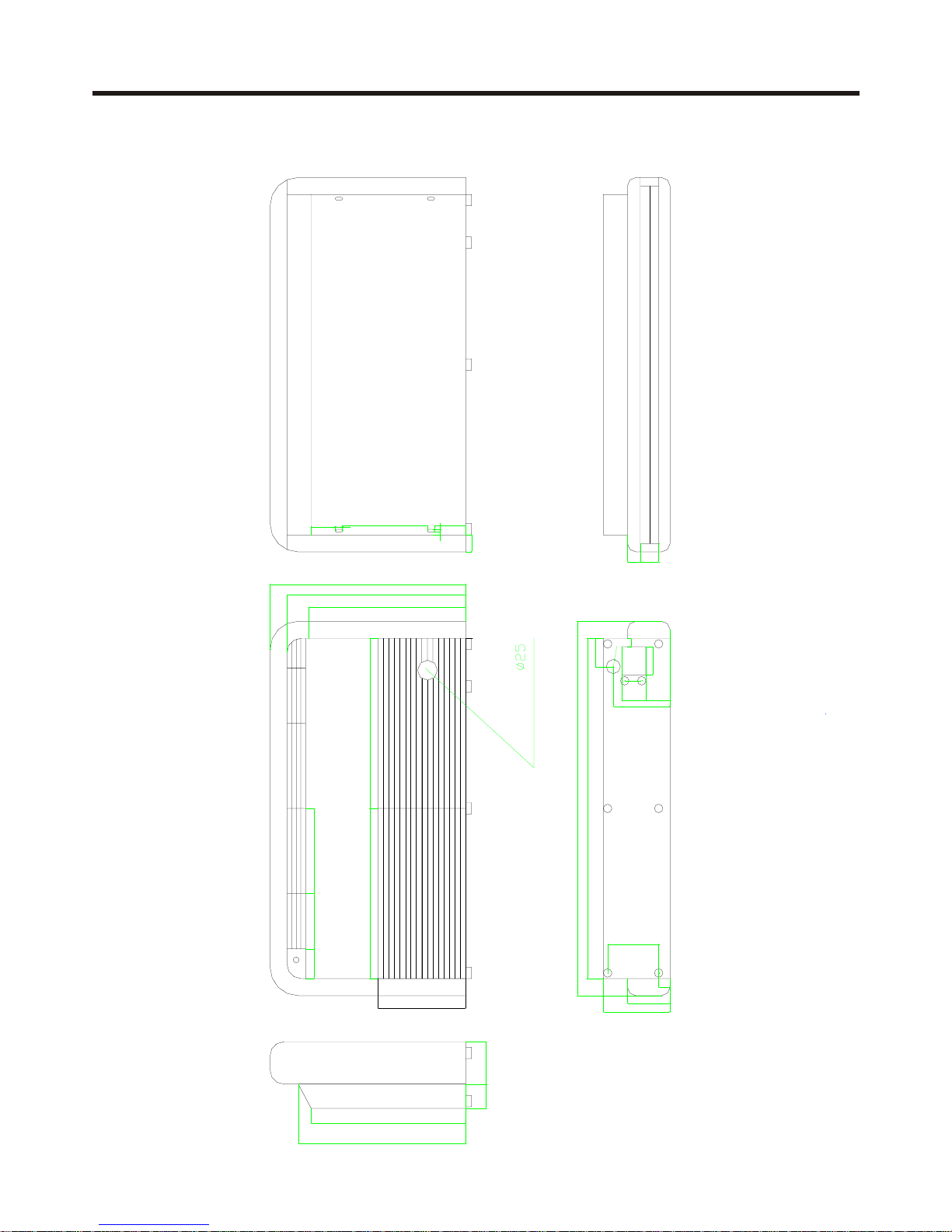

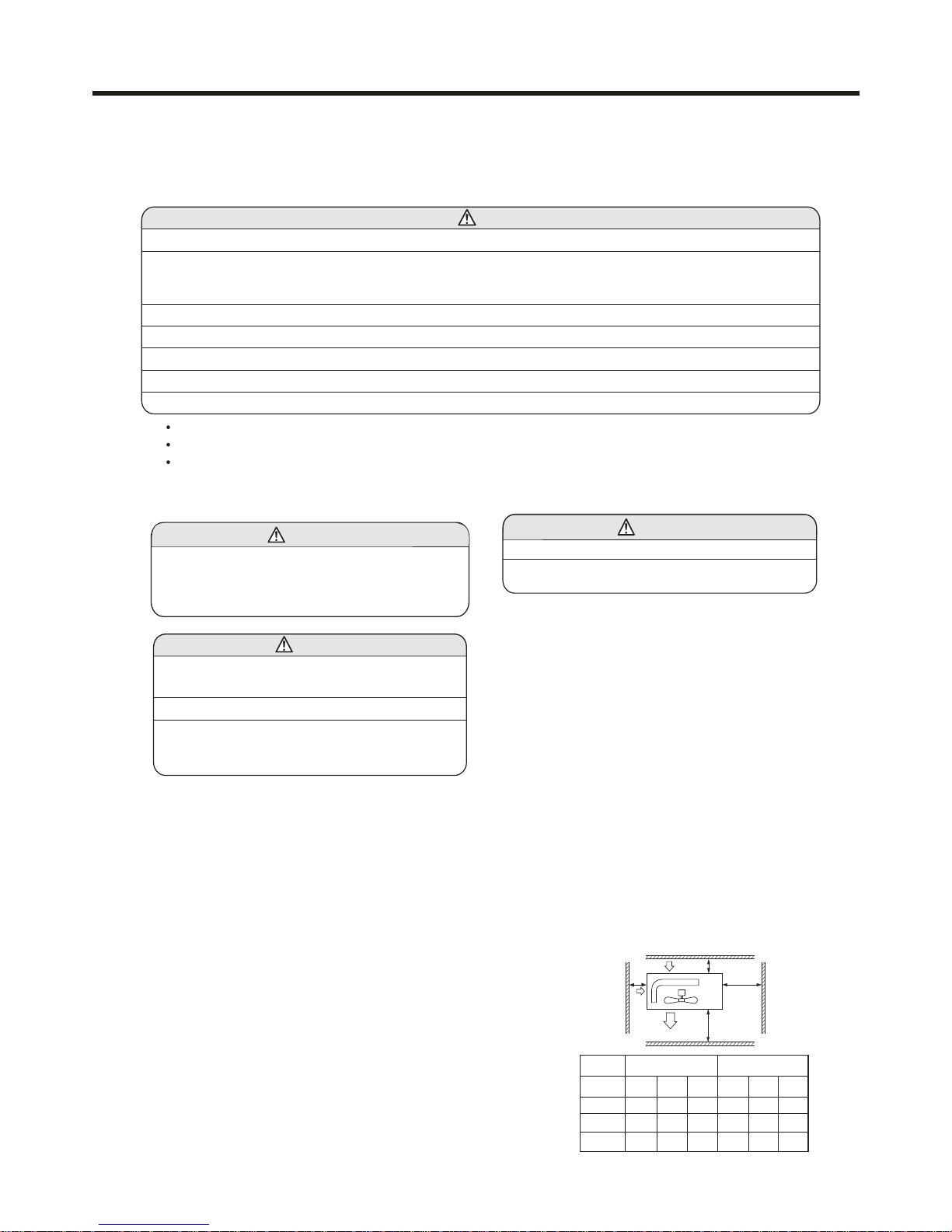

Model: HCFU-36CM03/R1 HCFU-42CM03/R1 Indoor unit

R15

85

100

195

1920

1800

600

690

630

100

85

310

590

545

40

235

150

180

85 150

60

195

600

105

600

300300

555

30

110

60

85

300

10

10

25

65

45

drainage pipe

NET DIMENSIONS OF INDOOR AND OUTDOOR UNIT

185 185

30

52

88

Screw Hole

(M10)

580

950

Power wiring Terminal

70

1818

340

380

1250

25

Note : (1). Fix the parts with screws

(2).Don't intake the strong wind directly

to the outlet air-flow hole.

(3).A one meter distance should be

kept from the unit top

(4).Don't block the surroundings of the unit with sundries

Installation Servicing Space(at Least)

Unit:mm

Installation

I

300

100

0

0

150

0

500

100

0

II III

Dimension

L1

Leave space Leave space

Leave space

L2

L3

L4

L1

L2

L3

L4

Back Air-flow Hole

Back Airflow Hole

Outlet Air-flow Hole

Repairing Space

Model: HCFU-36CM03/R1 HCFU-42CM03/R1 Outdoor unit

NET DIMENSIONS OF INDOOR AND OUTDOOR UNIT

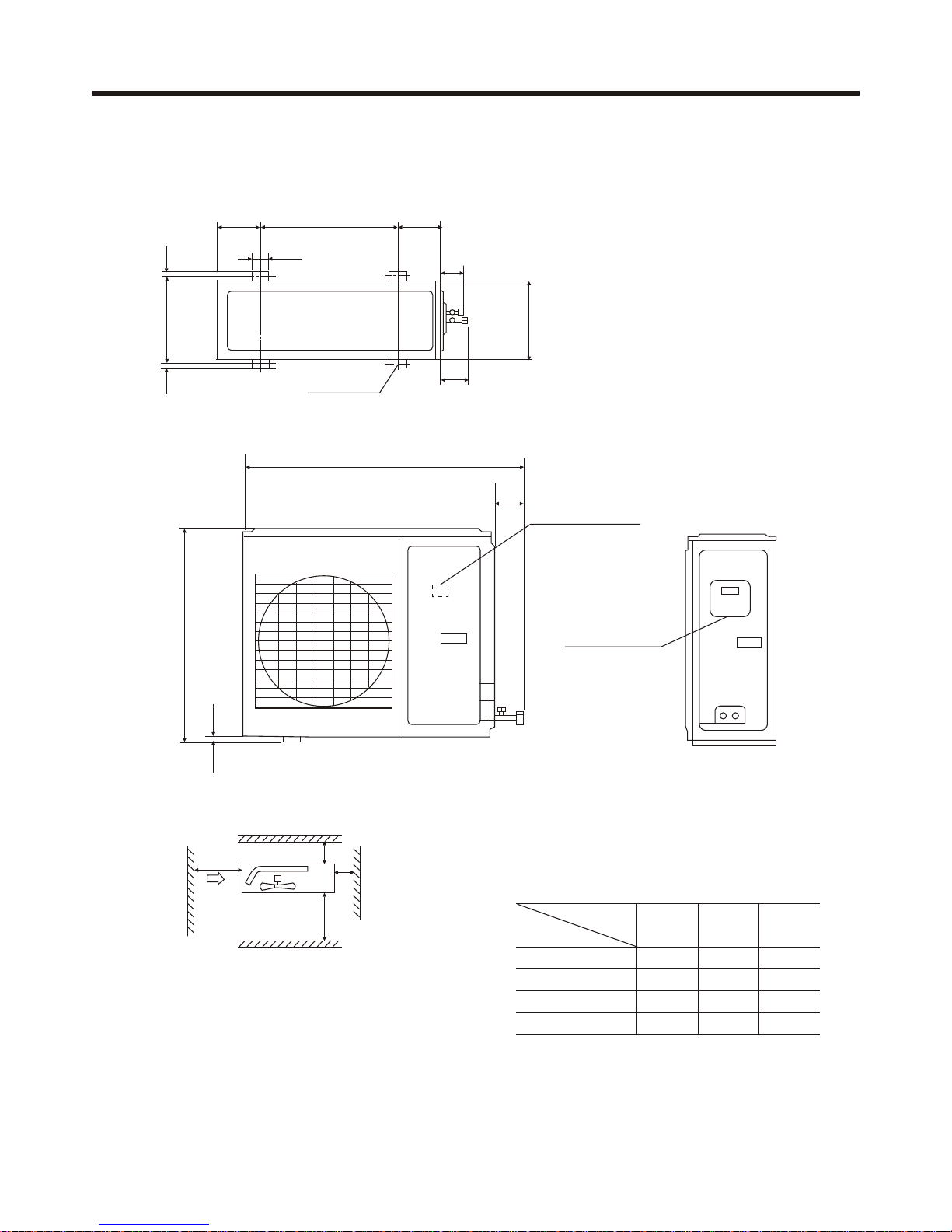

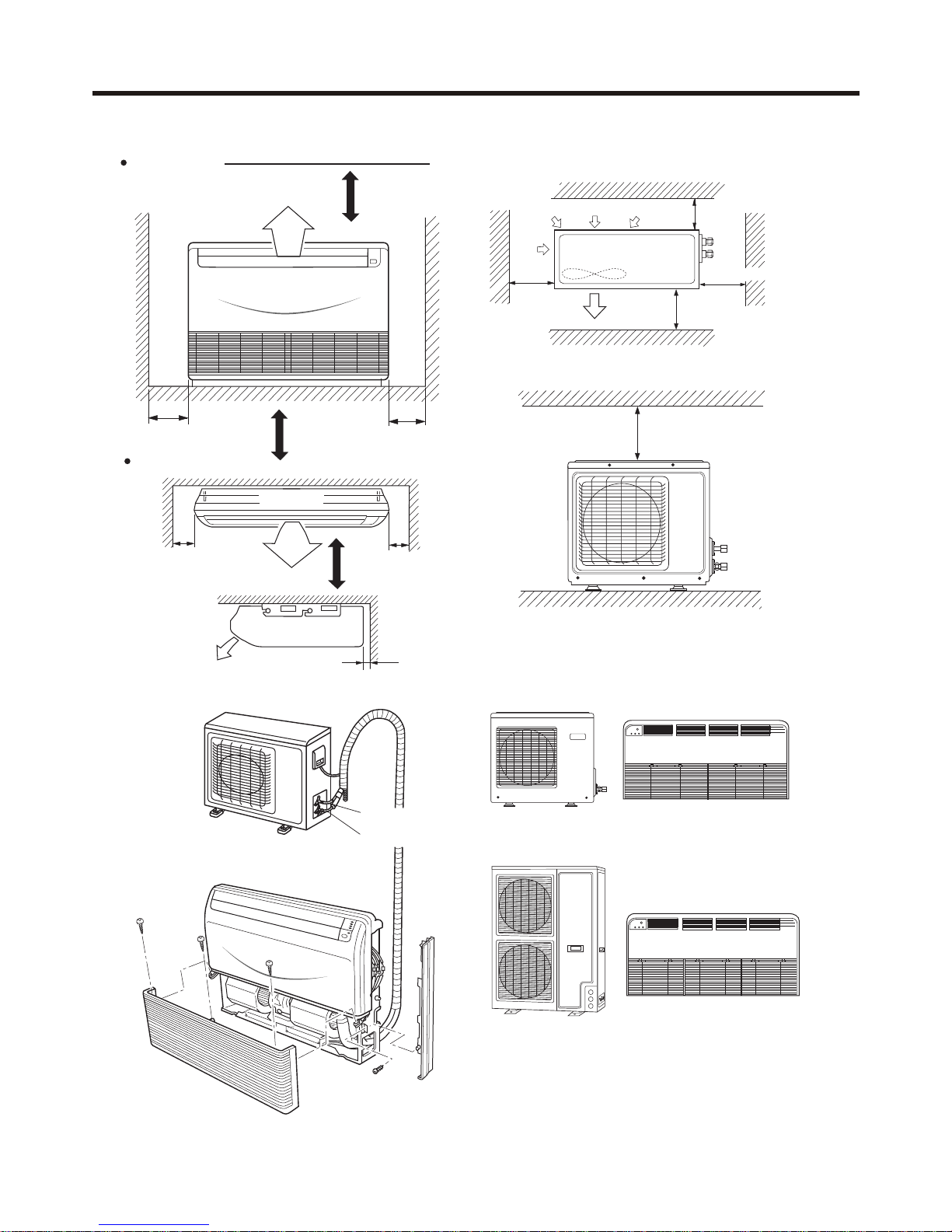

(1) If possible, do not install the unit where it will be

exposed to direct sunlight.(If necessary, install a

blind that does not interfere with the air flow.)

(2) Install the outdoor unit in a place where it will be

free from being dirty or getting wet by rain as much

as possible.

(3) Install the unit where connection to the indoor unit

is easy.

(4) During heating operation, drain water flows from

the outdoor unit. Therefore, install the outdoor unit

in a place where the drain water flow will not be

obstructed.(Reverse cycle model only)

(5) Do not place animals and plants in the path of the

warm air.

(6) Take the weight of the air conditioner into account

and select a place where noise and vibration are

small.

(7) Select a place where the warm air and noise from

the air conditioner do not disturb neighbors.

(8) Provide the space shown in Fig.2 so that the air

flow is not blocked. Also for efficient operation, leave

open three of the four directions front, rear, and both

sides.

For authorized service personnel only

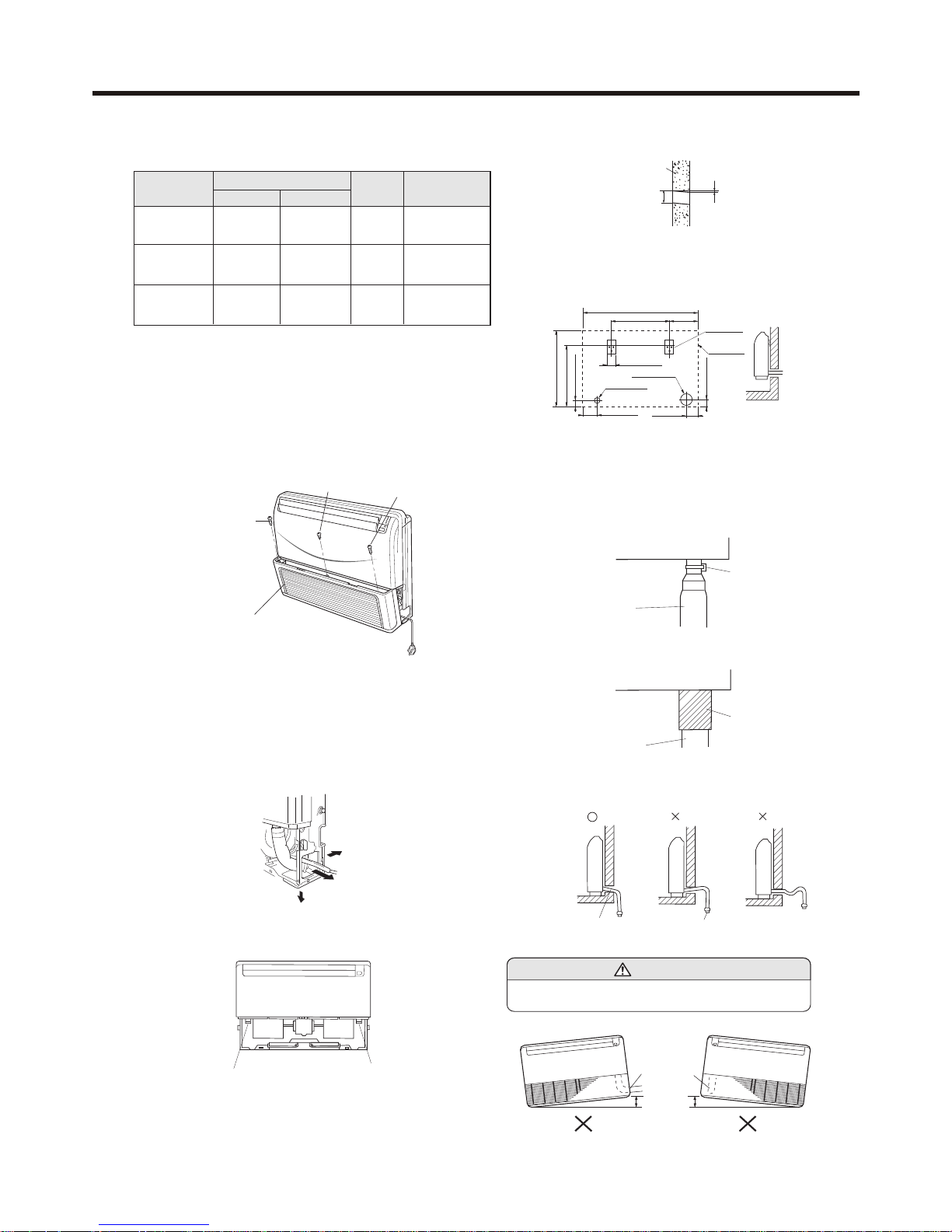

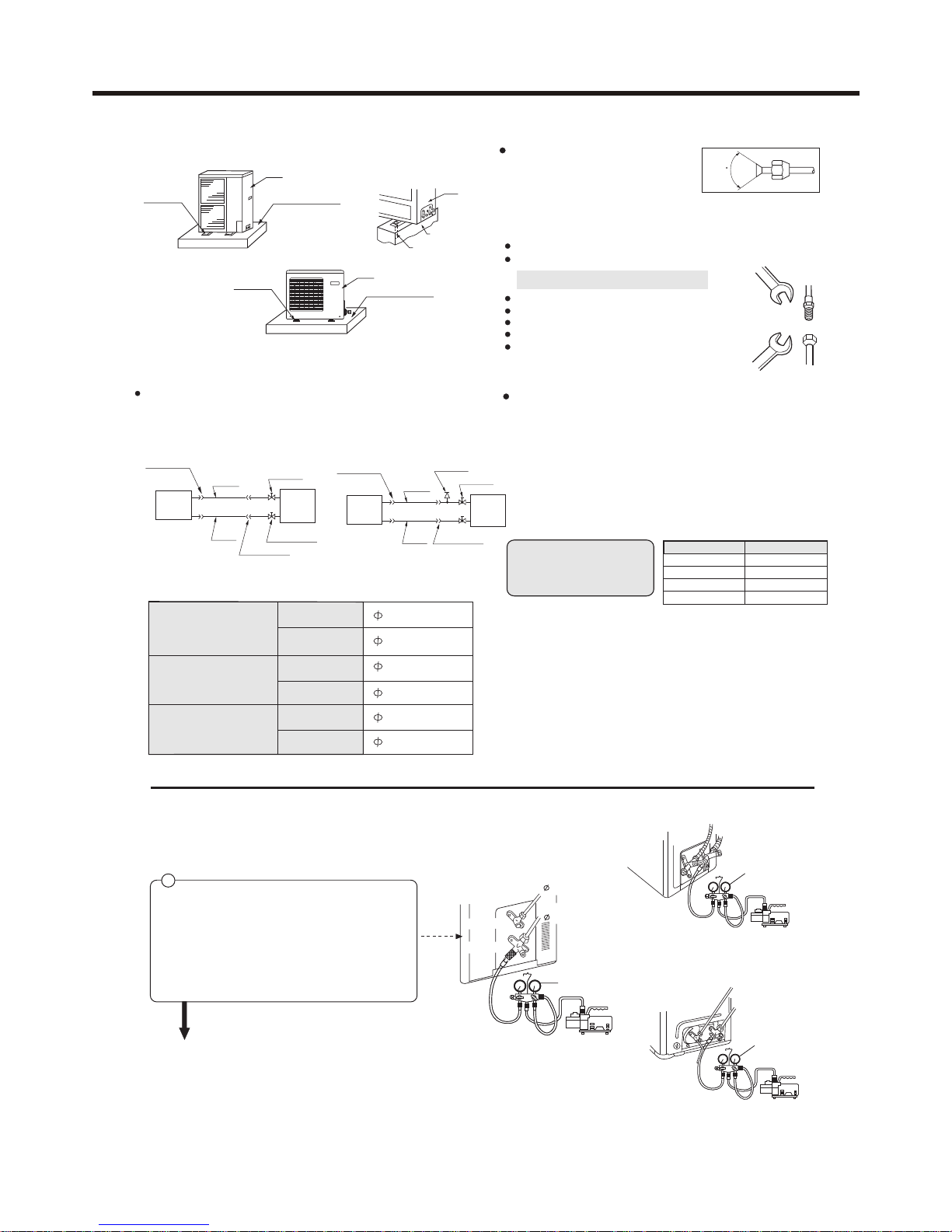

SELECTING THE MOUNTING POSITION

2. OUTDOOR UNIT

Decide the mounting position with the customer

as follows:

1. INDOOR UNIT

(1) Install the indoor unit level on a strong wall, floor, ceiling

which is not subject to vibration.

(2) The inlet and outlet ports should not be obstructed: the

air should be able to blow all over the room.

(3) Install the unit near an electric outlet or special branch

circuit.

(4) Do not install the unit where it will be exposed to direct

sunlight.

(5) Install the unit where connection to the outdoor unit is

easy.

(6) Install the unit where the drain pipe can be easily installed.

(7) Take servicing, etc. into consideration and leave the

spaces shown in Fig.1. Also install the unit where the filter

can be removed.

NOTE: The appearance may be different from models.

(1) Install the unit where it will not be tilted by more than 5•

(2) When installing the outdoor unit where it may be

exposed to the strong wind, fasten it securely.

Install at a place that can withstand the weight of the

indoor and outdoor units and install positively so that

the units will not topple or fall.

CAUTION

(1)Do not install where there is the danger of com bustible gas leakage.

(2) Do not install near heat sources.

(3) If children under 10 years old may approach the

unit, take preventive measures so that they can not reach the unit.

L2

L3

L1

500

(Servicing

space)

Air outlet

Air inlet

Air

inlet

Series

24,28 36,42

Case

Distance

L1

L2

L3

open open

open open

500

500

300 300

open open

0 0

100 150 100 150 150300

I II III I II III

Be careful not to scratch the room air conditioner when handing it.

After installation, explain correct operation to the customer, according to the operating manual.

Let the customer keep this installation manual because it will be used when the room air conditioner is serviced

or moved.

WARNING

(1) For the room air conditioner to operate satisfactorily, install it as outlined in this installation manual.

(2) Connect the indoor unit and outdoor unit with the room air conditioner piping and cords available from our

standard parts. This installation manual describes for the correct connections so that the installation set

available from our standard parts should be used.

(3) Installation work must be performed in accordance with national wiring standards by authorized personnel only.

(4) Never cut the power cord, lengthen or shorten the cord, or change the plug.

(5) Also, do not use an extension cord.

(6) Plug in the power cord plug firmly. If the receptacle is loose, repair it before using the room air conditioner.

(7) Do not turn on the power until all installation work is done.

WARNING

WARNING

5 INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Floor console

Fig. 1

15.88mm dia.

2 cm

or more

Ceiling

Indoor unit

30 cm

or more

30 cm

or more

Left

Right

30 cm

or more

30 cm

or more

1.5m

1.5m

1.5m

Left

Right

may be different

For series24, 28

For series 36,42

Note: For series 36, 42 no floor console type, the function

below about floor console is invalid to the series.

30 cm

or more

60 cm

or more

40 cm or more

30 cm

or more

Fig. 2

For series 14,18

60 cm

or more

Under ceiling

6.35mm dia

Outdoor unit

Indoor unit

For series 14,18

INSTALLATION INSTRUCTIONS

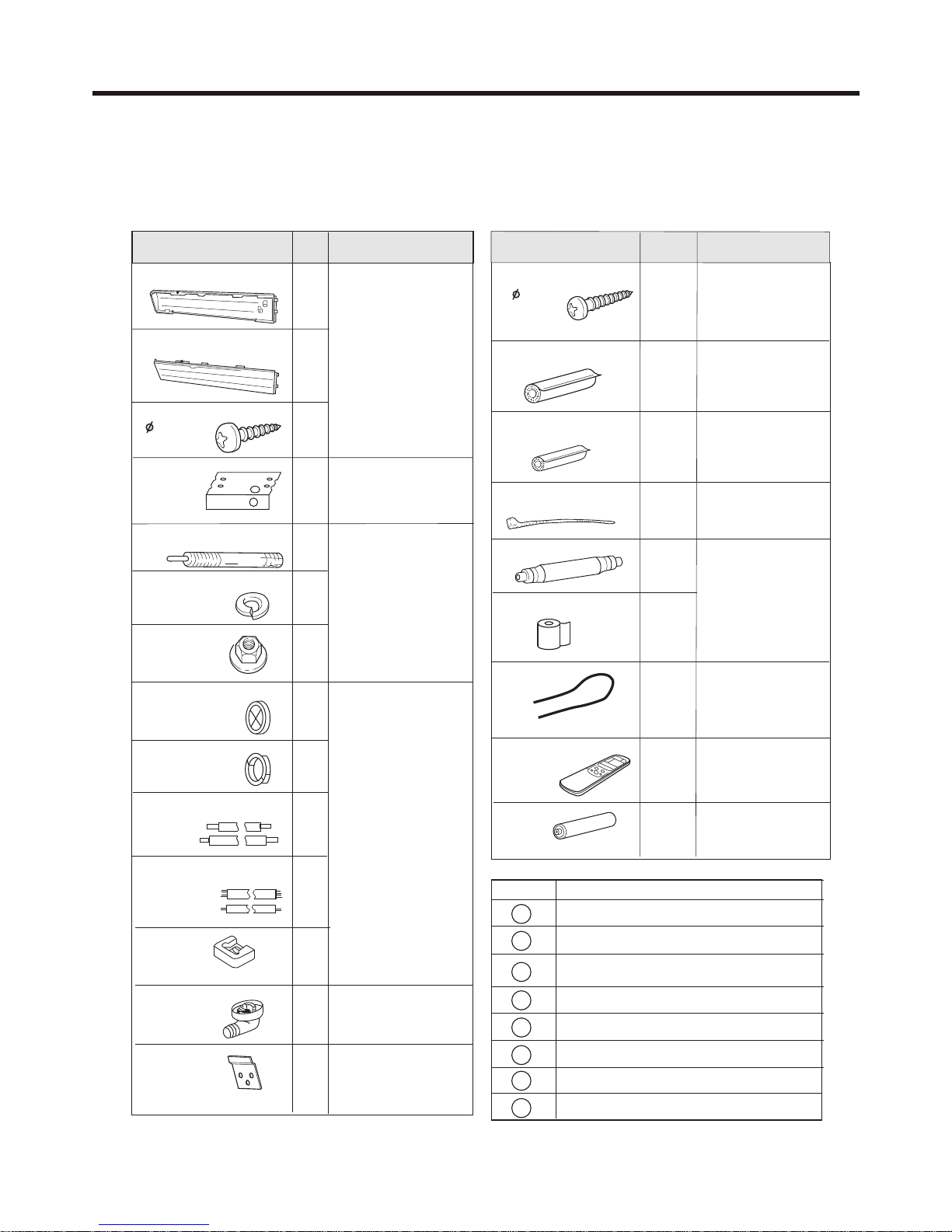

Mark Parts name

Adhesive tape

Saddle (L.S) with screws

Connecting electric cable

for indoor and outdoor

Drain hose

Heat insulation material

Piping hole cover

Putty

Plastic clamp

Optional parts

A

B

C

D

E

F

G

H

STANDARD PARTS

The following installation parts are furnished.

Use them as required.

ACCESSORIES

Name and shape

Q'ty

Application

6

For fixing the wall

bracket.

For series 24,28,36,42

no this part.

Tapping screw

( 4x20)

Coupler heat insulator(large)

1

For indoor side pipe

joint (Large pipe)

Coupler heat insulator(small)

1

For indoor side pipe

joint (Small pipe)

Nylon fastener

1

For fixing the drain

hose

Drain hose

Non-adhesive tape

1

1

VT wire

1

For fixing the drain

hose L 280mm

For series 24,28,36,42

VT wire is not available

Remote

controller

Battery

1

2

Use for air conditioner

operation

For remote controller

unit

Name and shape

Q'ty

Application

1

For series 24,28, 36,42

the two cover plate are

not available

Cover plate (left)

Cover plate (right)

Installation

template

Anchor bolt

Spring washer

Special nut

Pipe hole cover

Wall hole cover

Main pipes

Connecting cables

1

2

1

4

4

4

1

1

1

1

For positioning the

indoor unit

For under ceiling type.

For suspending the

indoor unit from ceiling

4

Tapping screw

( 4x10)

Cushion

Drain-elbow

1

Only for the heat pump

type

Wall bracket

2

For suspending the indoor

unit on the wall.For series

24,28,36,42 no this part.

INSTALLATION INSTRUCTIONS

INSTALLATION PROCEDURE

PREPARING INDOOR UNIT

INSTALLATION

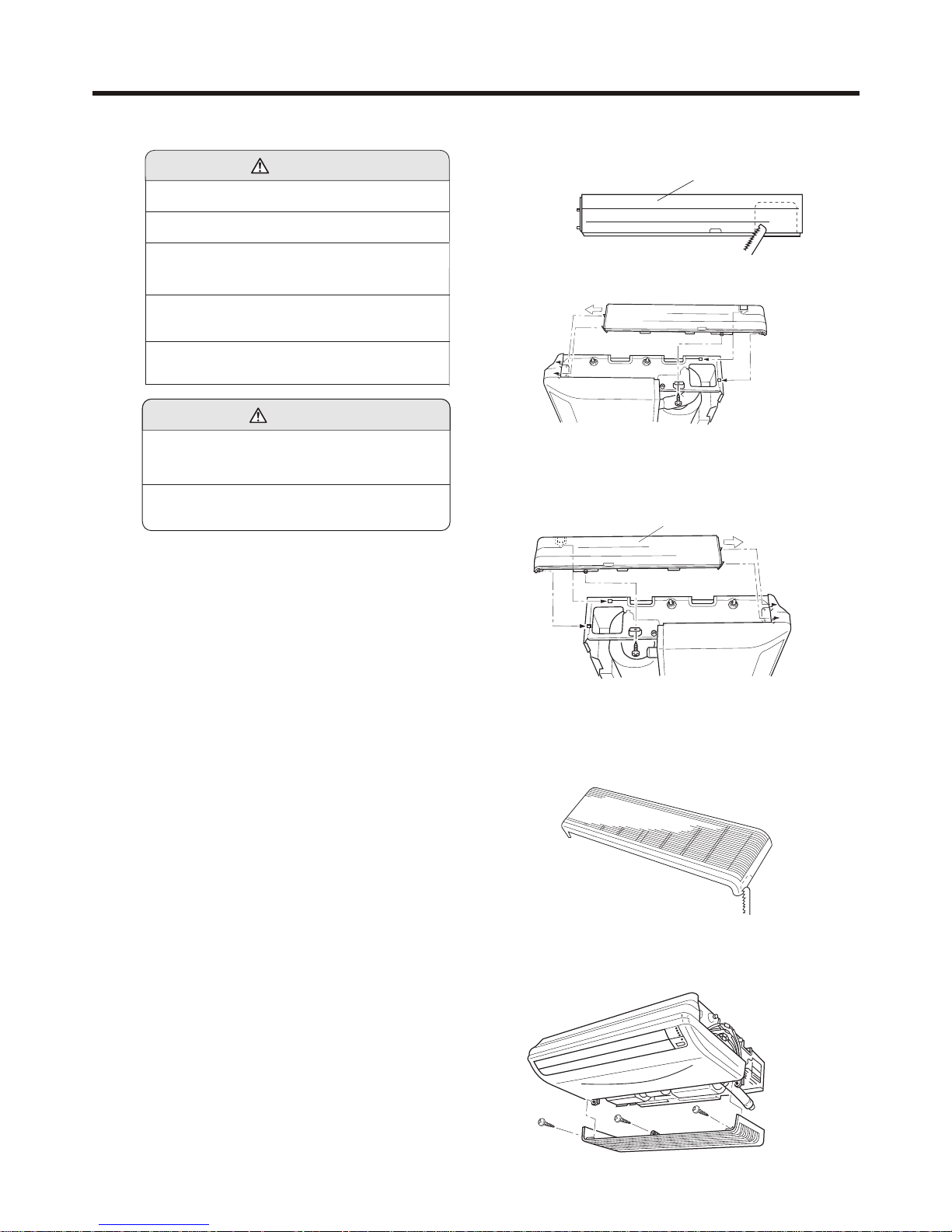

1. REMOVE THE INTAKE GRILL

Install the room air conditioner as follows:

Open the intake grill and remove the three or four or six screws.

(Fig. 3)

When the directions are selected, drill a 7 cm dia. hole on the wall so

that the hole is tilted downward toward the outdoor for smooth water

flow. When the pipe is led out from the rear, make a hole in Fig.6, at

the position shown.

(Fig. 5)

Drain hose (Left side) Drain hose (Right side)

CONNECTION PIPE REQUIREMENT

Table 1

Series

Diameter

Liquid side Gas side

Maximum

length

Maximum height

(between indoor

and outdoor)

14,18

6.35 mm

9.52 mm

15.88 mm

19.05mm

15 m

50 m

5 m

15 m

9.52 mm 15.88 mm

30 m

15 m

24,28

36,42

Remark: The main unit can be wired before the indoor unit is

installed. Select the most appropriate installation order.

For series 24,28,36,42 not the power plug, but 3-core connecting cable.

A. FLOOR CONSOLE TYPE (For series 36,42 no this type )

1. DRILLING FOR PIPING

Select piping and drain directions.(Fig.4) (For series 14,18)

The piping and drain can be made in three directions as shown

below.For series 24,28,36,42 can be made rear and down two

directions.

The drain hose can be connected to either the left or right side.(Fig.5)

For series 24,28,36,42 only right side.

(Fig. 4)

rear

right

down

Select whether the drain hose will be connected to the

left or right side.(for series 24,28,36,42 only the right side).(Fig.5)

Insert the drain hose into the drain pan, then secure the

drain hose with a nylon fastener. (Fig.8)

Wall

7cm

6mm

Indoor unit outdoor unit

2. INSTALLING DRAIN HOSE

(Fig. 6)

For series 14,18 when installing set to wall, install the

accessory wall bracket at the position shown in Fig.7,

and mount the set to it.

(Fig. 7)

INSTALL THE DRAIN HOSE

Wrap the insulation (drain hose) around the drain hose

connection.(Fig.9)

Drain pan

Drain hose

Nylon fastener

(Fig. 8)

(Fig. 9)

Drain pan

Drain hose

Insulation

(Drain hose)

Wall bracket

Side of set

Arrange the drain hose

lower than this portion.

Fig. 10

Be sure to arrange the drain hose correctly so that it is

leveled lower than the drain hose connecting port of the

indoor unit.

OK NO NO

Drain hose

A A

CAUTION

Do not install the unit drain hose side is too high. Height A

should be less than 5 mm.(Fig.11)

Fig. 11

Drain hose

Fig. 3

Machine screw

Tapping screw

Tapping screw

Intake grill

65.5cm

99cm

50cm

24.5cm

6.5cm

12.5cm 10cm

6.5cm

53cm

4.5cm

7cm hole

3.5cm hole

INSTALLATION INSTRUCTIONS

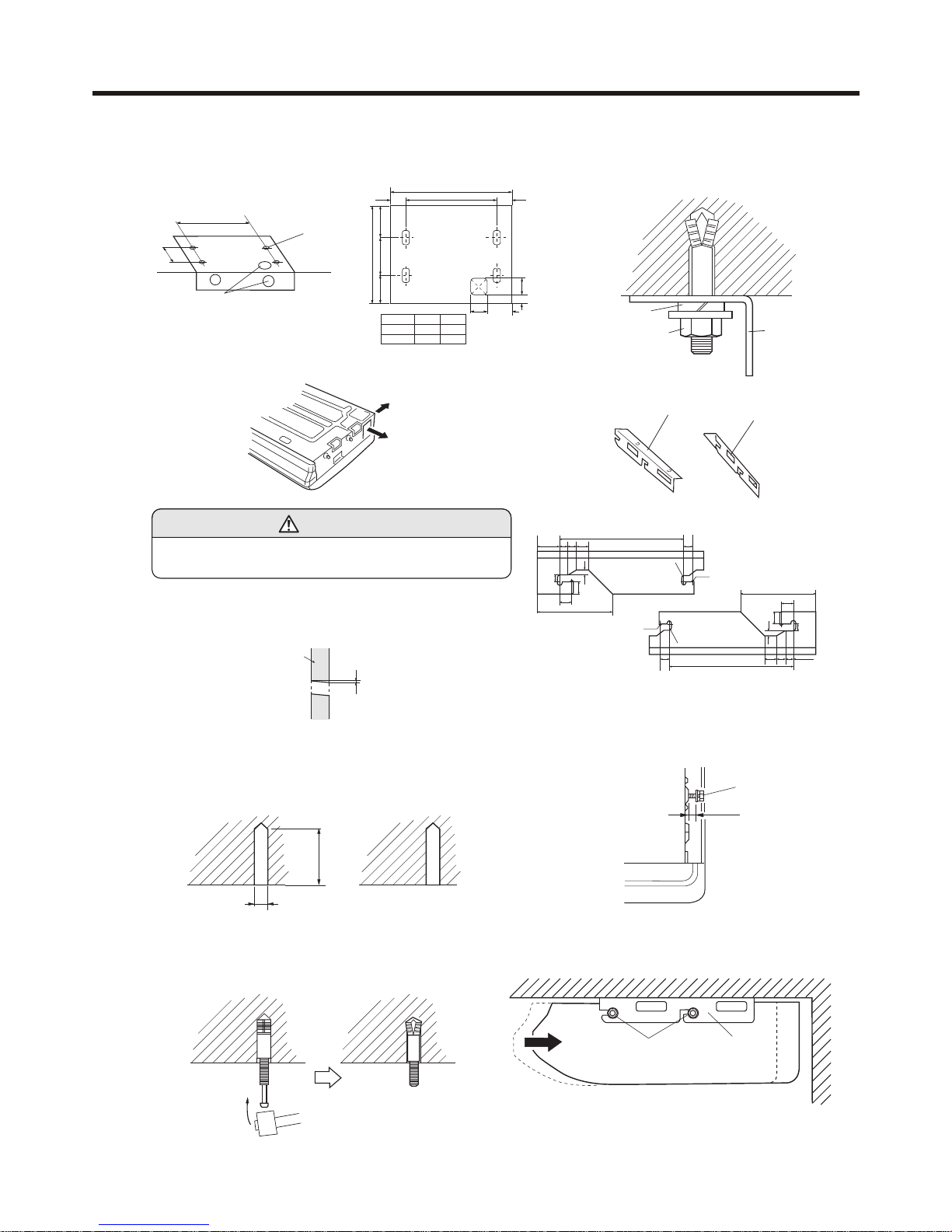

Installation

template

Wall

Ceilling

Drilling position

for piping

Drilling position

for anchor bolt

200mm

900mm

Select piping and drain directions. For series 24,28,36,42 only rear side(Fig.13)

B. UNDER CEILING TYPE

Using the installation template, drill holes for piping and anchor bolts(for

holes).(Fig.12)

Fig. 12

For series 14,18

1. DRILLING FOR PIPING

Fig. 13

CAUTION

60 to 70mm

12.7mm

Fig. 16

Insert the anchor bolts into the drilled holes, and drive the pins

completely into the anchor bolts with a hammer. (Fig. 16)

2. DRILLING HOLES FOR ANCHOR BOLTS AND

INSTALLING THE ANCHOR BOLTS

Install the drain hose at the rear; it should not be installed

on the top or right side.

When the directions are selected, drill 80mm and 50mm or 150mm

dia. hole on the wall so that the hole is tilted downward toward the

outdoor for smooth water flow.

3. INSTALLING BRACKETS

Fig. 17

Install the brackets with nuts, washers and spring

washers.(Fig. 17)

Spring washer

Special nut

Bracket

4. INSTALLING INDOOR UNIT

68

16 21 28

381

232

26.5

26.5

2-R2.5

10

18

7.5

4-R5

For series 24,28,36,42

Bracket (Right)

Bracket (Left)

For series 14,18

68

16

21

28

381

232

26.5

26.5

2-R2.5

10

18

7.5

4-R5

Reset the hex bolts as shown in Fig.18.

Hex bolt

8 to 13mm

Indoor unit

Fig. 18

Apply the indoor unit to the brackets.(Fig.19)

Now, securely tighten the hex bolts in both sides.

Fig. 19

Bolt

Bracket

Indoor unit

A

B

40 40

100mm

720mm

87.5mm

147mm

326mm

247mm

85

53

series A B

24,28

36,42 1920 1840

12401320

Rear (Install the drain hose

in the direction.)

Right

Wall

6mm

Fig. 15

With a concrete drill, drill four 12.7 mm dia. Holes.(Fig.15)

INSTALLATION INSTRUCTIONS

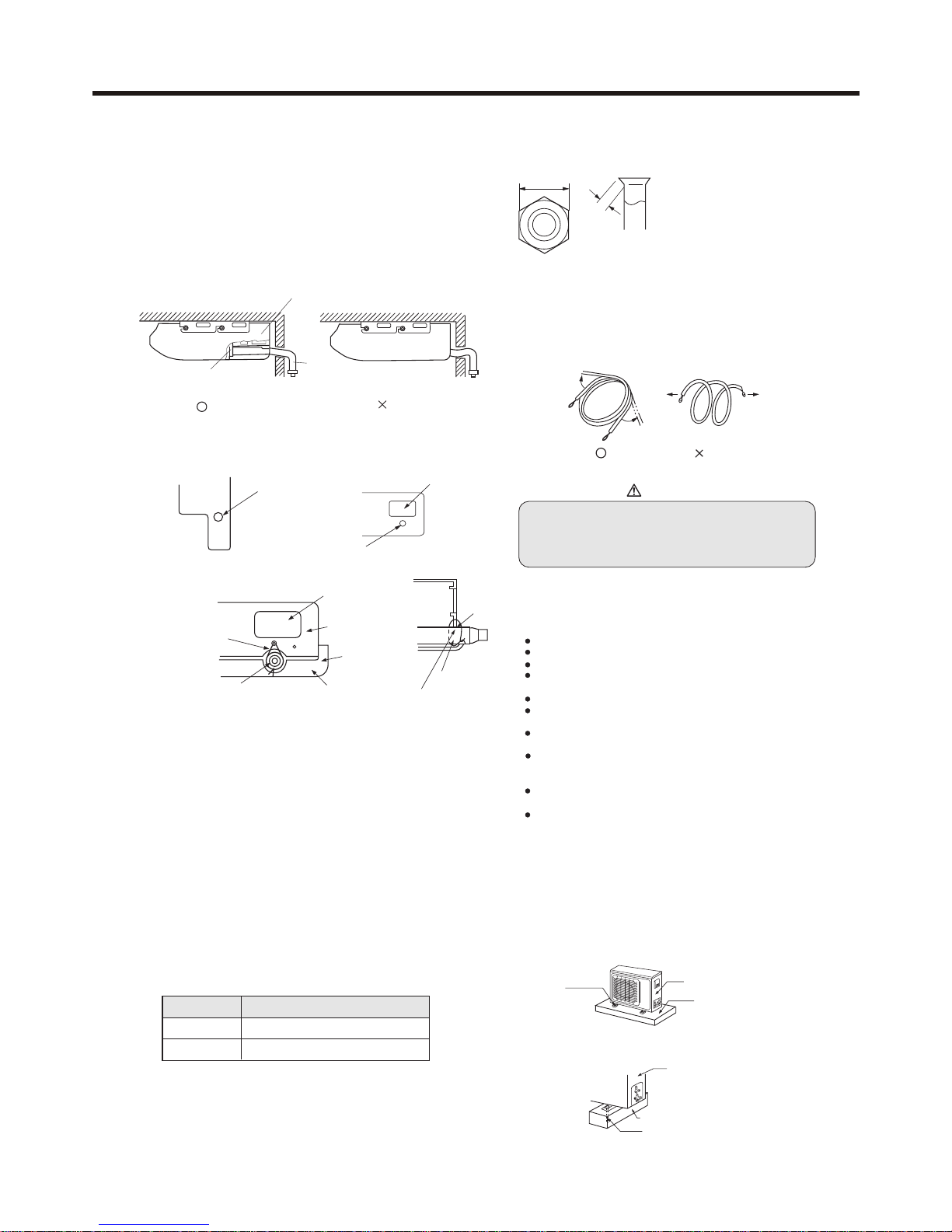

1. FLARE PROCESSING

(1) Cut the connection pipe with pipe cutters so that the pipe is

not deformed.

(2) Holding the pipe downward so that cuttings cannot enter the

pipe, remove the burrs.

(3) Remove the flare nut from the indoor unit pipe and outdoor

unit and assemble as shown in(Table1) and insert the flare

nut onto the pipe, and flare with a flaring tool.

(4) Check if the flared part "L" (Fig.22)is spread uniformly and

that there are no cracks.

For series 24,28,36,42

Fig. 21

When drain hose is arranged backward.Secure the drain hose with

the VT wire. (Fig. 21)

5. INSTALL THE DRAIN HOSE

Select whether the drain hose will be connected to the left or right

side.(Fig.5)

Insert the drain hose into the drain pan, then secure the drain hose

with a nylon fastener.(Fig.8)

Wrap the insulation (drain hose)around the drain hose connection.

(Fig.9)

Be sure to arrange the drain hose correctly so that it is leveled lower

than the drain hose connecting port of the indoor unit.(Fig.20)

CONNECTING THE PIPING

OUTDOOR UNIT INSTALLATION

Fig. 22

2. BENDING PIPES

Fig. 23

The pipes are shaped by your hands. Be careful not to

collapse them.

L

Width across flats

L dimension

Liquid pipe

1.6 to 1.8mm(6.35mm dia)

Gas pipe

2.2 to 2.4mm(15.88mm dia)

Gas pipe

3.4 to 2.6mm(19.05mm)

Liquid pipe

1.8 to 2.0mm(9.52mm)

Table 1

Pipe Flare nut

Small pipe

Large pipe

Small (width across flats 22mm)

Large (width across flats 24mm)

WARNING

BE SURE TO READ THESE INSTRUCTIONS. CAREFULLY BEFORE

BEGINNING INSTALLATION. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD CAUSE SERIOUS INJURY OR DEATH,

EQUIPMENT MALFUNCTION AND /OR PROPERTY DAMAGE. BE

SURE TO READ INSTALLATION MANUAL FOR INDOOR UNIT WITH

THIS MANUAL.

1. Selection of the place of installation

Select the place of installation satisfying the following

conditions and, at the same time, obtain consent from the

client or user.

Place where air circulates.

Place free from heat radiation from other heat sources.

Place where drain water may be discharged.

Place where noise and hot air may not disturb the

neighbors.

Place where there is not heavy snowfall in winter.

Place where obstacles do not exist near the inlet air

port and outlet air port.

Place where the outlet port may not be exposed to a

strong wind.

Place surrounded at four sides are not suitable for

installation.

A 1m or more of overhead space is needed for the unit.

Mount guide-louvers to place where short-circuit is a

possibllity.

When installing several units, secure sufficient suction

space to avoid short circuiting.

Fig. 20

Remove the hole cover.

OK

Arrange the drain hose

lower than this portion

Drain hose

NO

VT wire hole

Drain hose

Piping hole

VT wire

Drain hose

For series 24,28,36,42

no this part

Piping hole

Base (Bottom)

Intake grill

VT wire hole

Pass the drain hose through here

Cut the grill

OK

NO

Extend the pipe by unwinding it

Fix the unit in a proper way according to the condition of

a place where it is installed by referring to the following.

(1) Installation

2. Installation of outdoor unit

For series 14,18

Fig. 25

(a) Concrete foundation(Fig. 25)

For series 14,18

Anchor bolt

(b) Foundation anchor

Unit

Concrete foundation

Anchor bolt

Concrete foundation

Unit

INSTALLATION INSTRUCTIONS

Note (1)

Place the concrete

foundation

deep enough.

Connecting method

Apply refrigerant oil at half union as large and flare nut.

To bend a pipe, give the roundness as possible not to

crush the pipe.

When connecting pipe, hold the pipe centre to centre

then screw nut on by hand, refer to Fig.

Be careful not to let foreign matters, such as sands

enter the pipe.

(4) Piping connection (Fig.26)

Note (1)

Give enough room for the concrete

foundation to fix anchor bolts.

For series 24,28

To fix by bolts

Concrete foundation

(a) Concrete foundation

For series 36,42

Fig. 25

(b) Foundation anchor

Outdoor

unit

For series 14,18

For series 24,28,36, 42

(1) Outline of piping

3. Refrigerant piping

Service

Flare connection

Check joint

Gas pipe

Liquid

pipe

Flare connection

Indoor

unit

Outdoor

unit

3-way valve

Flare connection

Gas pipe

Liquid

pipe

Flare connection

Indoor

unit

2-way valve

(2) Piping size

Install the removed flare nuts

to the pipes to be connected,

then flare the pipes.

90 •0.5

One way piping length: Less than 15 mm

Vertical height difference: Less than 5 m

(3) Limitations for one way piping length and vertical

height difference.

Precautions for refrigerant piping

(Fig. 26)

Do not twist or crush piping.

Be sure that no dust is mixed in piping.

Bend piping with as wide angle as possible.

Keep insulating both gas and liquid piping.

Check flare-connected area for gas leakage.

Forced fastening without

centering may damage the

threads and cause a gas

leakage.

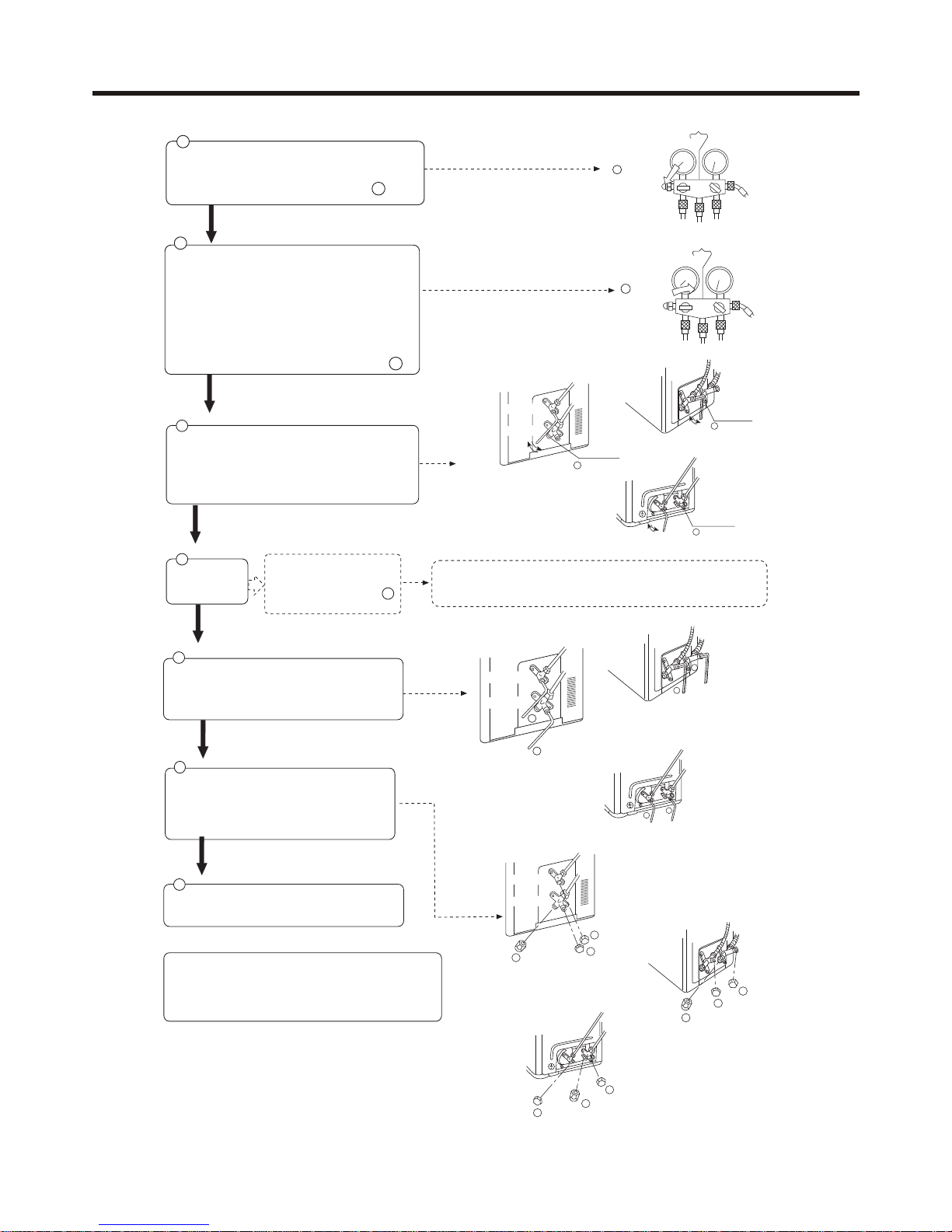

(5) Purging mehtod ( the refrigerant is R407C )

Install the unit so that the angle of inclination must be less than

3 degrees.

Series 24,28

Gas pipe

15.88x1.0mm

Liquid pipe

Gas pipe

9.52x0.8mm

15.88x1.0mm

Series 36,42

Liquid pipe

Gas pipe

9.52x0.8mm

19.05x1.0mm

Liquid pipe

6.35x0.8mm

Series 14,18

Pipe dia Fastening torque

Liquid pipe 6.35mm

Gas pipe 15.88mm

Liquid pipe 9.52mm

Gas pipe 19.05mm

18N.m

60N.m

40N.m

110N.m

For series 24,28

1

Detach the service port's cap of 3-way valve, the

valve rod's cap for 2-way valve and 3-way's, connect

the service port into the projection of charge hose

(low) for gaugemanifold. Then connect the projection

of charge hose (center) for gaugemanifold into

vacuum pump.

To use vacuum pump

Vacuum pump

Gaugemanifold

2-way valve

3-way valve

Liquid Side

6.35mm (1/4")

Gas Side

15.88mm (5/8")

For series 14,18

For series 36,42

Gaugemanifold

Vacuum pump

2-way valve

3-way valve

Vacuum pump

3-way valve

2-way valve

Gaugemanifold

Anchor bolt

Unit

Unit

Concrete

foundation

Anchor bolt

Unit

Anchor bolt

Concrete foundation

INSTALLATION INSTRUCTIONS

Detach the charge hose from the service port, open

2-way valve and 3-way. Turn the valve rod

anticlockwise until hitting lightly.

6

If it does not stop gas leakage, discharge whole refrigerants from the serice port.

After flaring work again and vacuumize, fill up prescribed refrigerant from the gas

cylinder.

In case of gas leakage, tighten

parts of pipe connection. If

leakage stops, then proceed

steps.

6

No gas leakage?

5

4

Open the valve rod for the 2-way valve to and angle of

anticlockwise 90 degree.

After 6 seconds later, close the 2-way valve and male

the inspection of gas leakage.

CAUTION:

If the refrigerant of the air conditioner leaks, it is necessary to make

all the refrigerant out, then charge the liquid refrigerant into air

conditioner according to the amount marked on the name plate.

To prevent the gas leakage, turn the service port's

cap, the valve rod'd cap for 2-way valve and 3-way's

a lottle more than the point where the torque increases

suddenly.

7

8

After attaching the each caps, check the gas leakage

around the caps.

2

Open

2

Open the handle at low in gaugemanifold, operate

vacuum pump. If the scale-moves of gause (low)

reach vacuum condition in a moment, check 1 again.

3

Close

Vacuumize for over 15min. And check the level gauge

which should read -0.1 MPa (-76 cm Hg) at low

pressure side. After the completion of vacuumizing,

close the handle 'Lo' in gaugemanifold and stop the

operation of the vacuum pump.

Check the condition of the scale and hold it for 1-2min.

If the scale-moves back in spite of tightening, make

flaring work again, the return to the beginning of 3 .

For series 24,28

For series 36,42

3-way valve

2-way valve

Open

90•

Service port

90•

4

90• for 6 sec.

For series 14,18

2-way valve

3-way valve

Open

90•

90•

Service port

4

90• for 6 sec.

2-way valve

3-way valve

90•

Service port

90•

4

90• for 6 sec.

Open

3

For series 24,28

3-way valve

2-way valve

6

6

For series 36,42

Liquid pipe 9.52mm

Gas pipe 19.05mm

2-way valve

3-way valve

6

6

6

6

2-way valve

3-way valve

For series 14,18

Service port cap

7

3-way valve

2-way valve

7

Valve rod cap

Valve rod cap

7

For series 24,28

2-way valve

3-way valve

7

Valve rod cap

Valve rod cap

7

Service port cap

7

For series 14,18

3-way valve

2-way valve

7

Valve rod cap

Valve rod cap

7

Service port cap

7

For series 36,42

INSTALLATION INSTRUCTIONS

GAS LEAKAGE INSPECTION

After connecting the piping, check the joints for gas leakage with gas leakage detector.

CAUTION

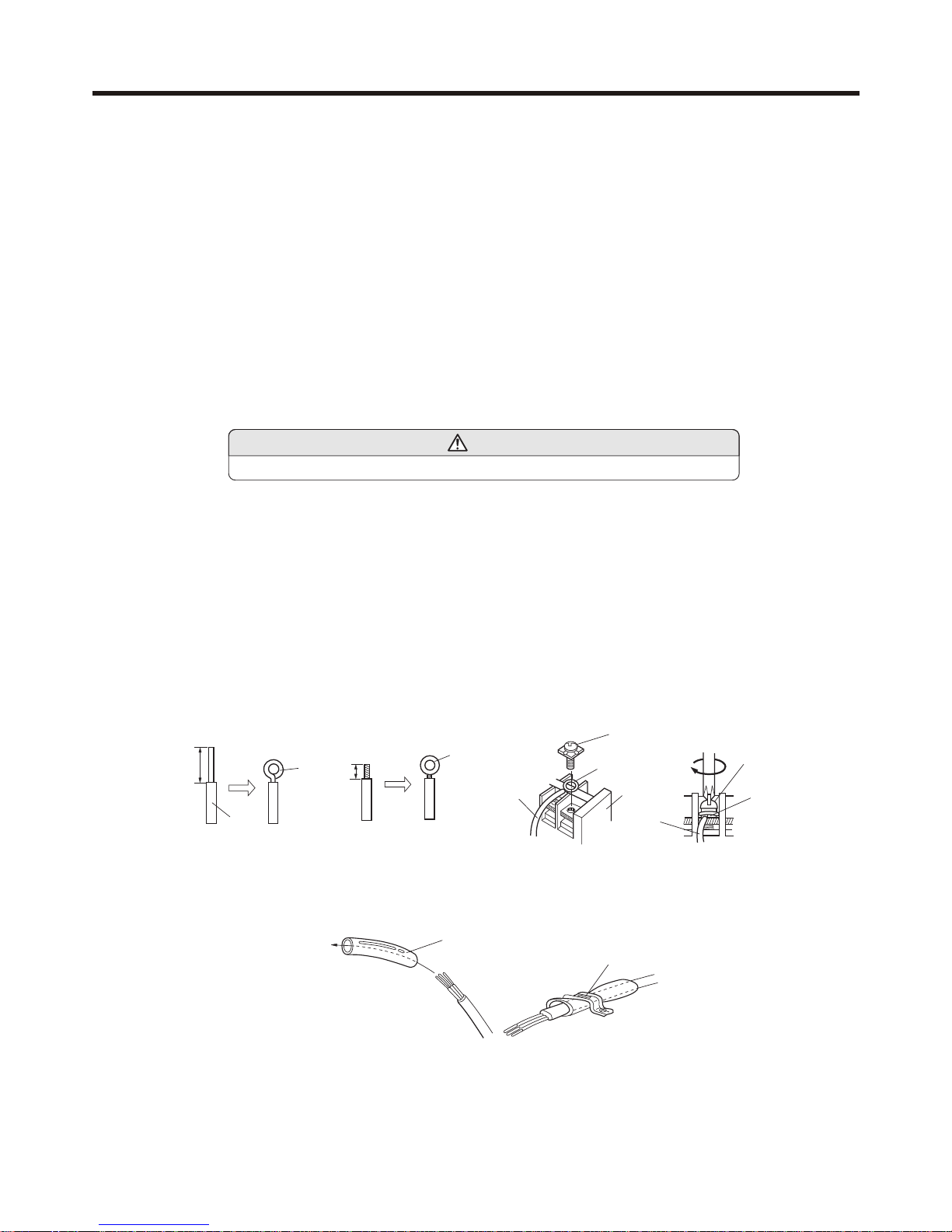

HOW TO CONNECT WIRING TO THE TERMINALS

A. For solid core wiring (or F-cable)(Fig.28A)

(1) Cut the wire with a wire cutter or wire-cutting pliers, then strip the insulation to about 25mm of the exposed solid wire.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal board.

(3) Using pliers, bend the solid wire to form a loop suitable for the terminal screw.

(4) Shape the loop wire properly, place it on the terminal board and tighten securely with the terminal screw using a screw driver.

B. For strand wiring(Fig.28B)

(1) Cut the wire with a wire cutter or wire-cutting pliers, then strip the insulation to about 10mm of the exposed strand wiring.

(2) Using a screwdriver, remove the terminal screw(s)on the terminal board.

(3) Using a round terminal fastener or pliers, securely clamp a round terminal to each stripped wire end.

(4) Position the round terminal wire, and replace and tighten the terminal screw using a screw driver.

Fig. 28

Screw with

special washer

Round

terminal

Wire

Terminal

board

Screw with

special washer

Round

terminal

Wire

A. Solid wire

Insulation

Strip 25mm

Loop

B. Strand wire

Strip 10mm

Round

terminal

After passing the connection cord and power cable through the insulation tube, fasten it with the cord clamp, as shown in Fig.29

HOW TO FIXED CONNECTION CORD AND POWER CABLE AT THE CORD CLAMP

Fig. 29

Cord clamp

Insulation tube

Use VW-1, 0.5 to 1.0 mm thick, PVC tube as the insulation tube.

If needing to remove the refrigerant gas when installation or repair , please refer to

the following procedures:

1. Cut off the power

2. (After confirming the power is cut off) pull the power cable plug terminals of the low-pressure

pressure-switch out.

3. (After confirming the power cable terminals of the low-pressure pressure-switch is cut off) After

powering on the unit again and switch to COOLING mode,perform refrigerant gas removing

according to the normal refrigerant gas removing procedure.

4. After finishing refrigerant gas removing , cut off the power , then insert the power cable terminals

of the low-pressure pressure-switch properly.

INSTALLATION INSTRUCTIONS

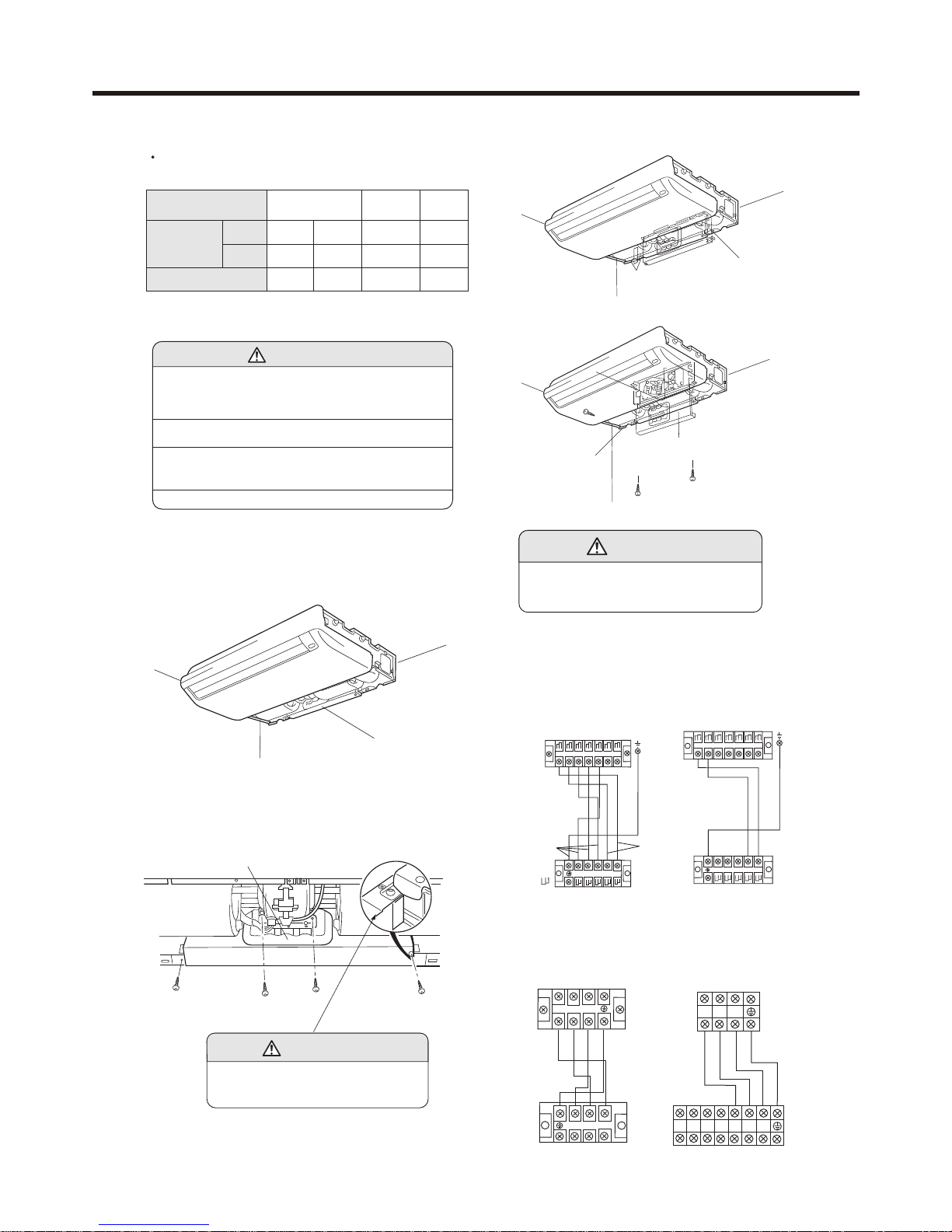

1. INDOOR UNIT SIDE

(1) Remove the electric component box.

INDOOR UNIT SIDE

(2) Pull out the electric component box.

Fig. 32

(3) Remove the electric component box cover.

Fig. 33

(1) Remove the cord clamp.

(2) Process the end of the connection cords to the

dimensions shown in Fig.34.

(3) Connect the end of the connection cord fully into the

terminal block.

(4) Wiring

Fig. 30

Electric component box

CAUTION

Be careful not to pinch the lead wires

between the electric component box

and base.

ELECTRICAL REQUIREMENT

Electric wire size and fuse capacity:

Table 5

ELECTRICAL WIRING

Series

Connection

cord

(mm2)

Fuse capacity(A)

MAX

MIN

14,18 24,28 36,42

3.5 3.5 3.5 3.5

2.5

2.5 2.5 2.0

20 30 30 30

CAUTION

(1) Match the terminal block numbers and connection

cord colors with those of the outdoor unit.

Erroneous wiring may cause burning of the electric

parts.

(2) Connect the connection cords firmly to the terminal

block. Imperfect installation may cause a fire.

(3) Always fasten the outside covering of the connection

cord with the cord clamp.(If the insulator is chafed,

electric leakage may occur.)

(4) Always connect the ground wire.

Fig. 31

Electric component box

Remove the four tapping

screws.

CAUTION

Do not remove the screws. If the screws

are removed, the electric component

box will fall.

(4) Fasten the connection cord with a cord clamp.

(5) Fasten the end of the connection cord with the screw.

(6) For series 24,28,36,42,the power cable and connecting

are self-provided.

Outdoor

unit

Indoor

unit

Outdoor

unit

1 2 3

1

2

3

For series 14,28

For series 36,42

Indoor

unit

Outdoor

unit

1 2 3

1 2 3

N

TSR

Base

Electric component box cover

Remove the three tapping screws.

Fig. 34

For series 14,18

Indoor unit

Outdoor unit

1 2 3 4 5 L N

1

2345

H05RN-F

4G0.75mm

2

H07RN-F

2 2.0mm

2

Electric component box

For series 14,18

Indoor unit

Outdoor unit

H07RN-F

3G 2.0mm

2

1 2 3 4 5

1

2345

L N

Heat model

Cool model

INSTALLATION INSTRUCTIONS

TEST RUNNING

CUSTOMER GUIDANCE

Explain the following to the customer in accordance with the

operating manual:

(1) Starting and stopping method, operation switching, temperature

adjustment, timer, air flow switching, and other remote control

unit operations.

(2) Air filter removal and cleaning, and how to use air louvers.

(3) Give the operating and installation manuals to the customer.

MOUNT THE COVER PLATE AND

THE INTAKE GRILL

Note: The following installing procedure only for series 14,18

1.Mount the cover plate. (Right)

(1) Cut a pipe exit hole in the right plate. This is only when the

pipe exits from the right side.(This operation is not required

when the protrusion is on the top or rear.)

(2) Join the cover plates (right) and mount with screws.

Cover plate (Left)

2. Mount the cover plate.(Left)

(1) Join the cover plate (left) and mount with screws.

Fig. 37

(1) The power source capacity must be the sum of the

room air conditioner current and the current of other

electrical appliances. When the current contracted

capacity is insufficient, change the contracted capacity.

(2) When the voltage is low and the air conditioner is dif ficult to start, contact the power company the voltage

raised.

CAUTION

1. CHECK ITEMS

(1) INDOOR UNIT

(1) Is operation of each button on the remote control unit normal?

(2) Does each lamp light normally?

(3) Do not air flow direction louvers operate normally?

(4) Is the drain normal?

(2) OUTDOOR UNIT

(1) Is there any abnormal noise and vibration during operation?

(2) Will noise, wind, or drain water from the unit disturb the neighbors?

(3) Is there any gas leakage?

(1) Cut the right side of the intake grill. This is only

when the pipe exits from the right side

3. Mount the intake grill.

Fig. 38

(2) Insert the hinges on the bottom of the intake grill into the

holes in the base assembly. Then mount the arms to the

three areas on the top of the intake grill.

Fig. 39

Fig. 35

Cover plate (Right)

Fig. 36

ELECTRICAL WIRING

(1) Always use a special branch circuit and install a special

receptacle to supply power to the room air conditioner.

(2) Use a circuit breaker and receptacle matched to the

capacity of the room air conditioner.

(3) The circuit breaker is installed in the permanent wiring.

Always use a circuit that can trip all the poles of the

wiring and has an isolation distance of at least 3mm

between the contacts of each pole.

WARNING

(4) Perform wiring work in accordance with standards so

that the room air conditioner can be operated safely

and positively.

(5) Install a leakage circuit breaker in accordance with the

related laws and regulations and electric company

standards.

INSTALLATION INSTRUCTIONS

Loading...

Loading...