SYJS-05-2018Rev.D Edition: 2018-05

Smart Power

Smart Power

CONTENTS

Part 1 General Information .......................................................................................................................................1

1. Nomenclature ......................................................................................................................................................2

2. Line up .................................................................................................................................................................3

3. Feature ................................................................................................................................................................5

Part 2 Indoor Units--4-Way Cassette Type ..............................................................................................................7

1. Feature ................................................................................................................................................................8

2. Specication ........................................................................................................................................................9

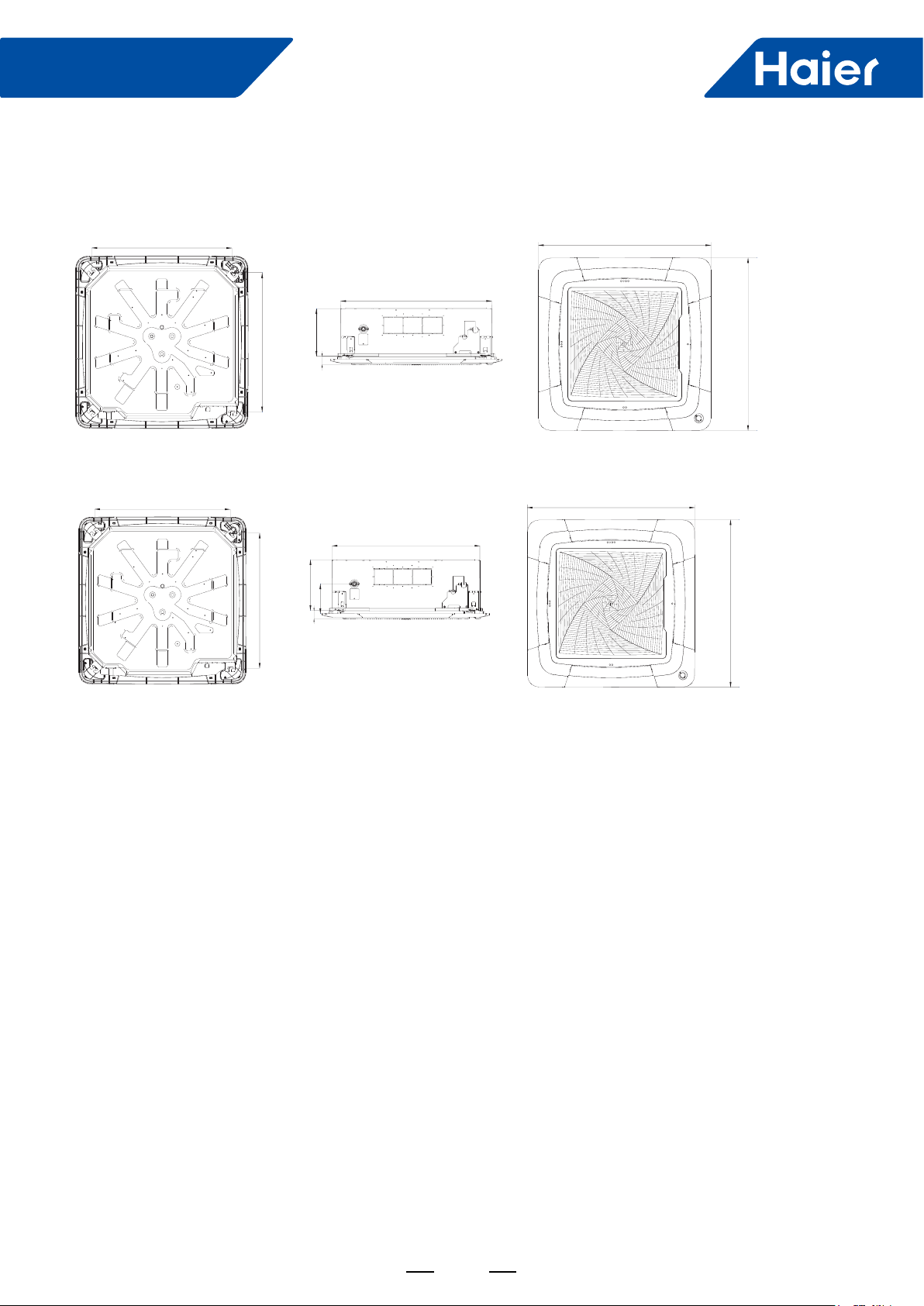

3. Dimension .........................................................................................................................................................15

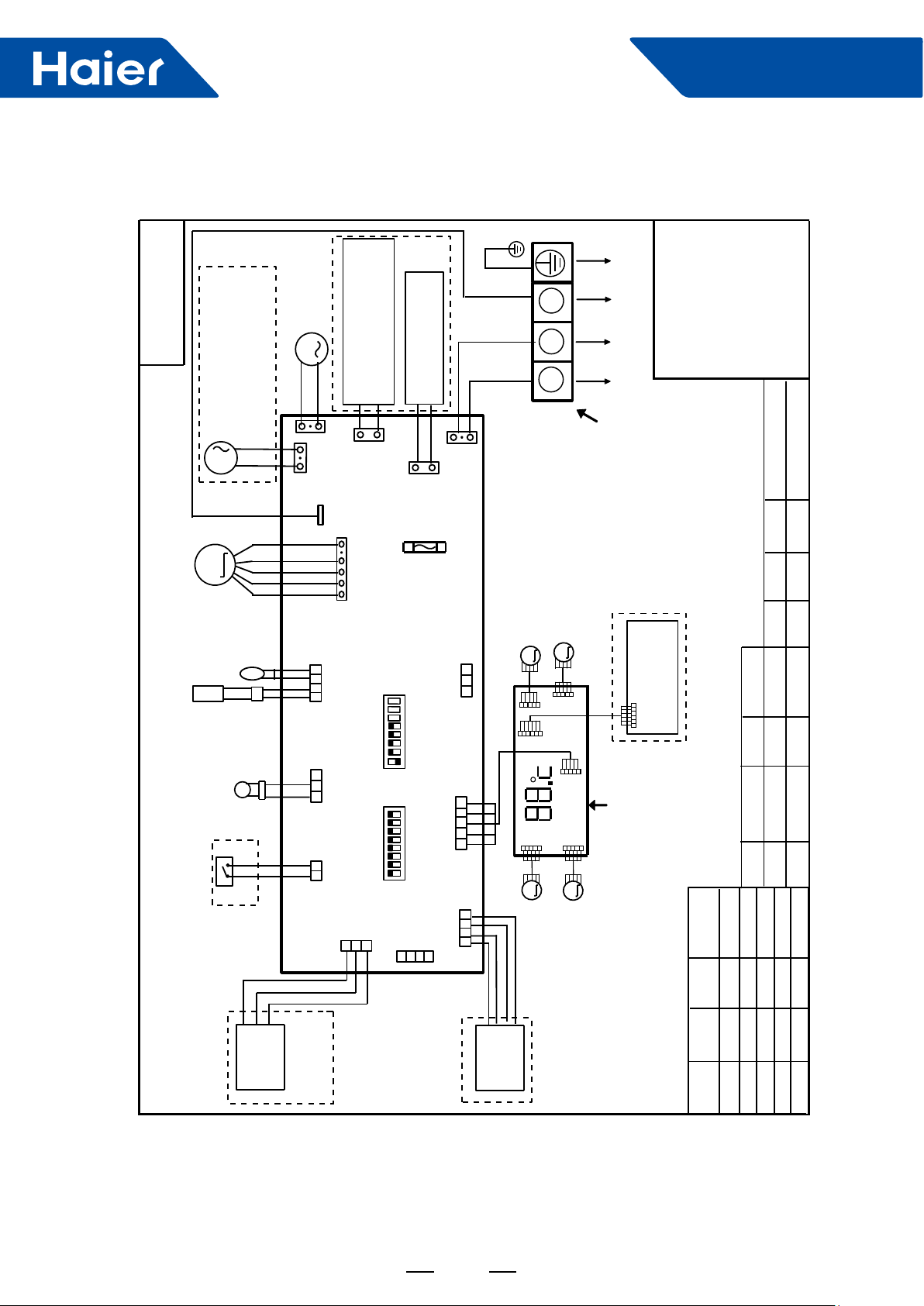

4. Wiring Diagram ..................................................................................................................................................16

5. Air Velocity and Temperature Distribution ..........................................................................................................17

6. Sound Pressure Level .......................................................................................................................................21

7. Installation .........................................................................................................................................................24

8. Test run ..............................................................................................................................................................30

Part 3 Indoor Units-Medium ESP Duct Type .........................................................................................................31

1. Feature ..............................................................................................................................................................32

2. Specication ......................................................................................................................................................34

3. Dimension .........................................................................................................................................................41

4. Wiring Diagram ..................................................................................................................................................43

5. Airow and Static Pressure Chart ......................................................................................................................46

6. Instalaltion .........................................................................................................................................................49

7. Sound Pressure Level .......................................................................................................................................58

Part 4 Indoor Unit-High ESP Duct Type ................................................................................................................59

1. Feature ..............................................................................................................................................................60

2. Specication ......................................................................................................................................................62

3. Dimension .........................................................................................................................................................68

4. Wiring Diagram ..................................................................................................................................................70

5. Airow and Static Pressure Chart ......................................................................................................................72

6. Installation .........................................................................................................................................................75

7. Sound Pressure Level .......................................................................................................................................87

Part 5 Outdoor Units ...............................................................................................................................................93

1. Specication ......................................................................................................................................................94

2. Dimension .......................................................................................................................................................103

3. Piping Diagram ................................................................................................................................................106

4. Wiring Diagram ................................................................................................................................................108

5. Noise Level ......................................................................................................................................................113

6. Outdoor Performace Curves ...........................................................................................................................121

7. Installation .......................................................................................................................................................130

Part 6 Electric Control and Toublleshooting ....................................................................................................... 152

1. Indoor Unit ......................................................................................................................................................153

2. Indoor Unit Dip Switch Setting .........................................................................................................................159

3. Outdoor Unit PCB Photo .................................................................................................................................165

4. Failure Code ....................................................................................................................................................172

5. Instructions of Parameters & Error Code Checking ........................................................................................195

6. Function ...........................................................................................................................................................204

7. Controller ......................................................................................................................................................216

Appendix Sensor Characteristic ..........................................................................................................................232

Smart Power

Part 1 General Information

1. Nomenclature ..........................................................................................................................................................2

2. Line up .....................................................................................................................................................................3

3. Feature ....................................................................................................................................................................5

1

1. Nomenclature

Smart Power

071 R GH EU 11 N

Climate & power supply

A: T1 & 220-240V, 1Ph, 50Hz

G: T1 & 220-240V, 1Ph, 50/60Hz

K: T1 & 380-400V, 3PH, 50/60Hz

Inverter/xed-speed

A: Fixed-speed

R: Inverter

Category

E: R410A

Version

1: Version 1

Appearance character

Cooling capacity

071 means 7.1kW;

Series

H: Smart portocol, power inverter

Type

B: Cassette

D: Duct

U: Outdoor unit

Indoor/outdoor unit

A: Indoor unit

1: 1:1 Outdoor unit

2: 1:2 Outdoor unit

2

Smart Power

2. Line up

Outdoor unit

Model Apperance

1UH071N1ERG

1UH090N1ERG

1UH105N1ERG

1UH125P1ERG

1UH125P1ERK

1UH140P1ERK

1UH160P1ERG

Indoor unit

1UH200W1ERK 1UH250W1ERK

Model Apperance

ABH071H1ERG

ABH090H1ERG

4-Way Cassette

Medium Esp Duct

High ESP Duct

ABH105H1ERG

ABH125K1ERG

ABH140K1ERG

ADH071M1ERG

ADH071M3ERG

ADH090M1ERG

ADH105M1ERG

ADH125M1ERG

ADH140M1ERG

ADH105H1ERG

ADH125H1ERG

ADH140H1ERG

ADH160H1ERG

ADH200H1ERG

ADH250H1ERG

3

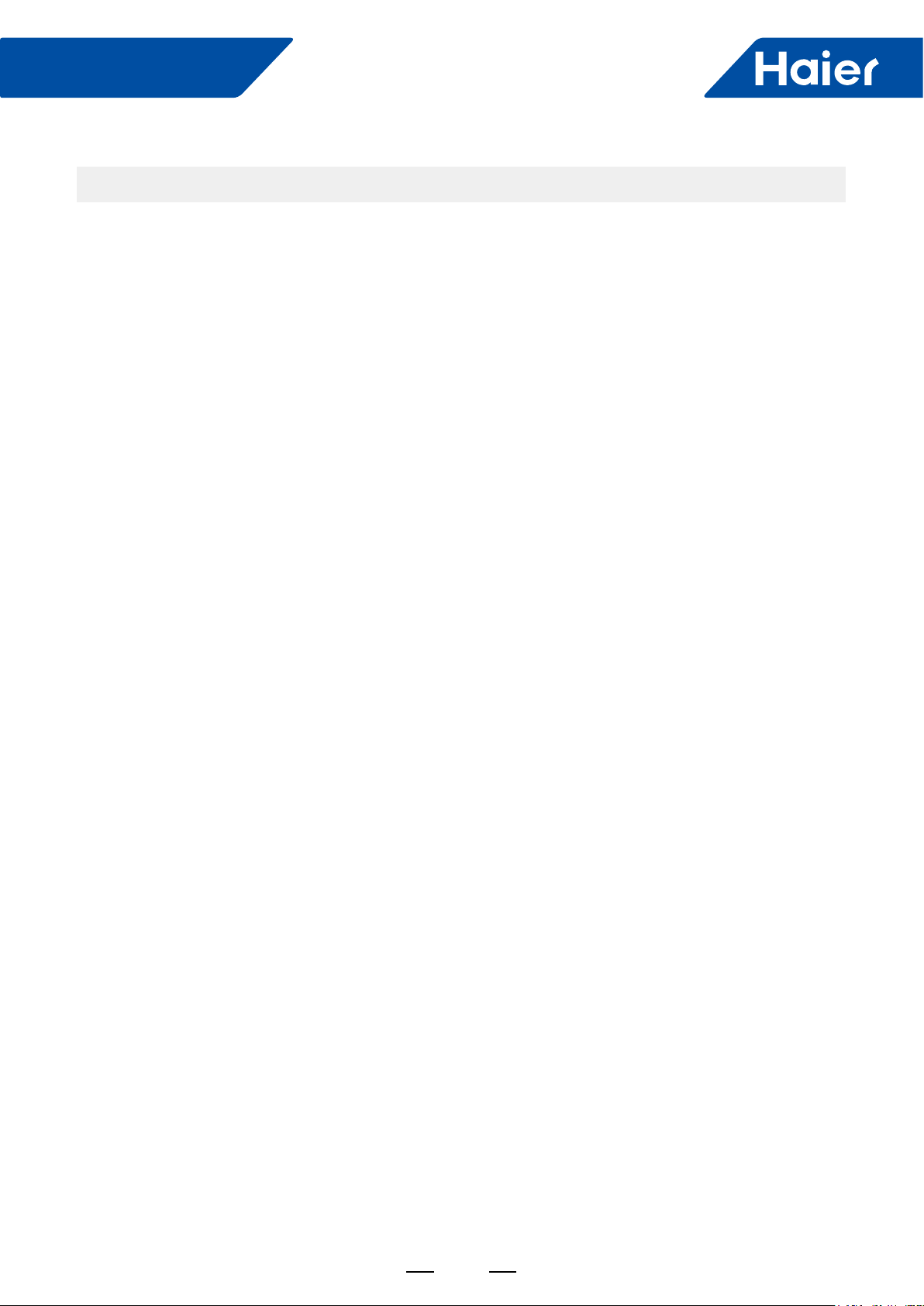

Panel 4-Way Cassette

Smart Power

Model Apperance

PB-950KB

PB-950MB

4

Smart Power

3. Feature

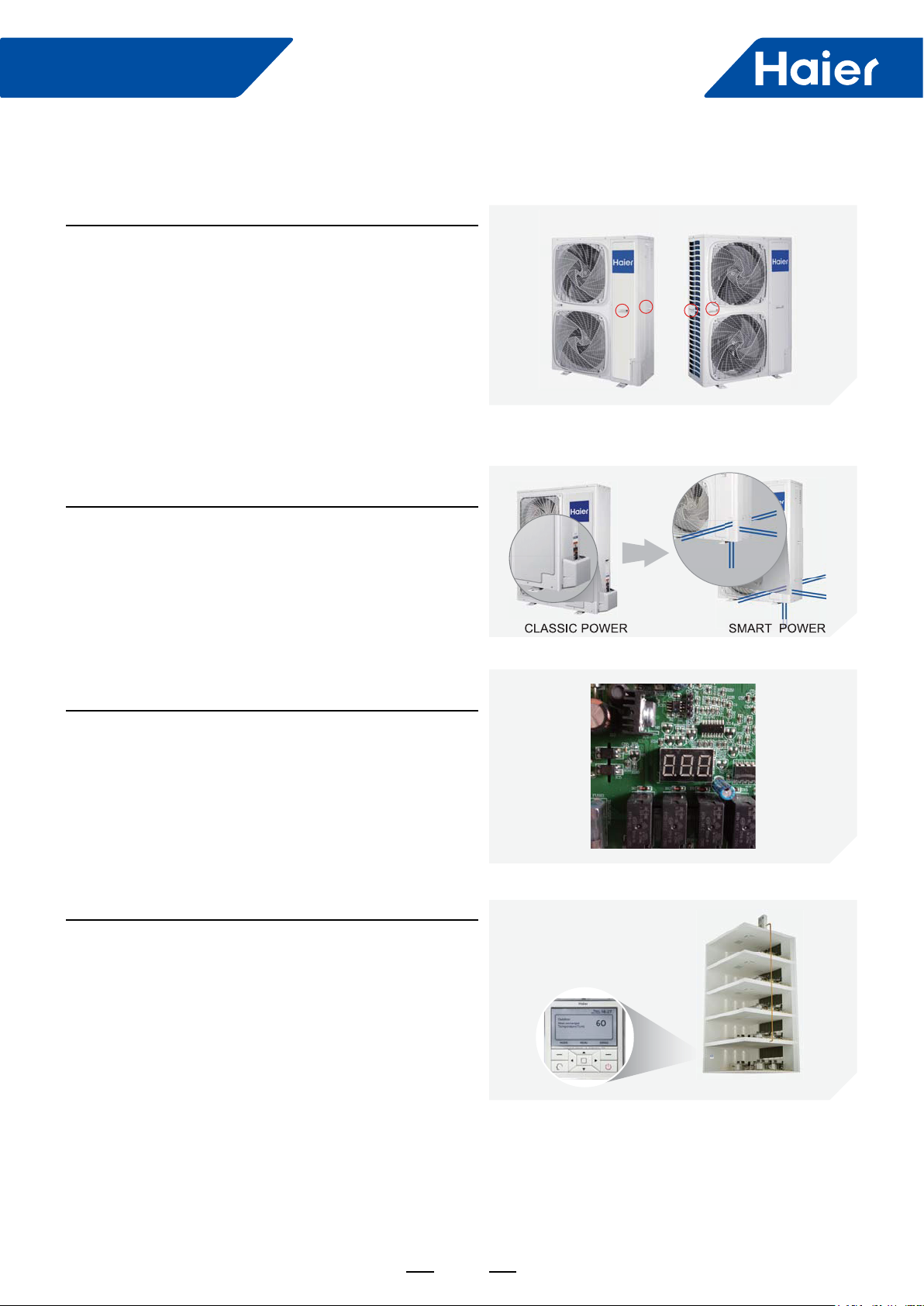

Double side 4 handles

Because of double side 4 handles design, it is very easy for

2 peoples carry it.

Stylish Design

Built-in valve design

The new built-in valve design, it can realize 4 way pipe

connection (front, rear, right, down) , it is more beautiful and

easy installation.

Easy Installation

"888" digital test panel

All running parameters & error code can be checked from

"888" digital display, installer can make easy work.

Wired controller data check

Running parameters can be checked by controller, if

installer is not easy to go to the outdoor unit site, just stay

indoor to check, installer can make easy work.

5

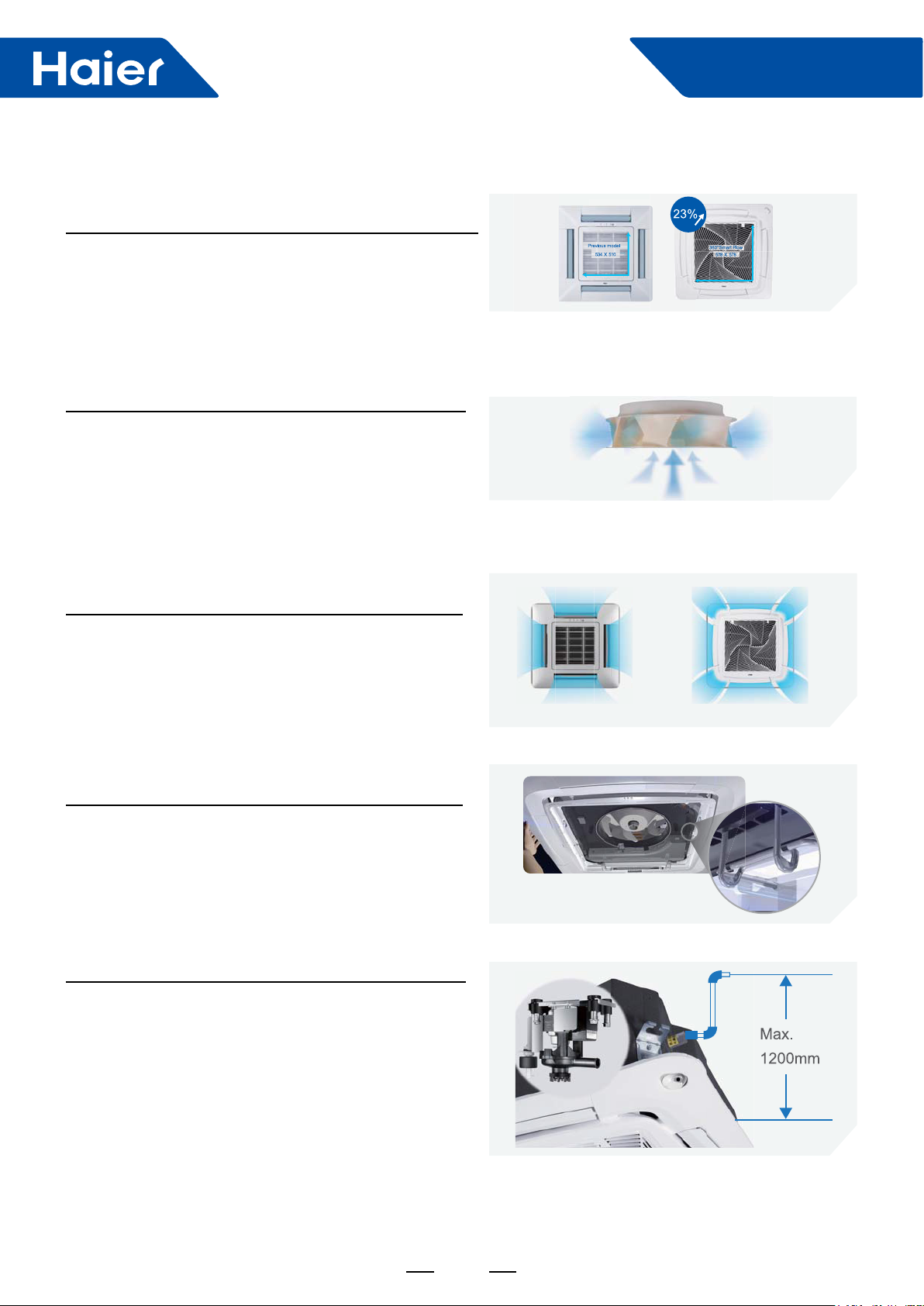

Low Sound Level

Super big inlet grille

Compared to conventional air inlet grill, we enlarge the air

inlet area by 23%, lower air speed & lower the sound level.

New designed fan

The diameter of new fan is enlarged based on acrodynamic

theory, so that there is the least resistance against airow.

Reduce 3dB (A) for sound level.

Smart Power

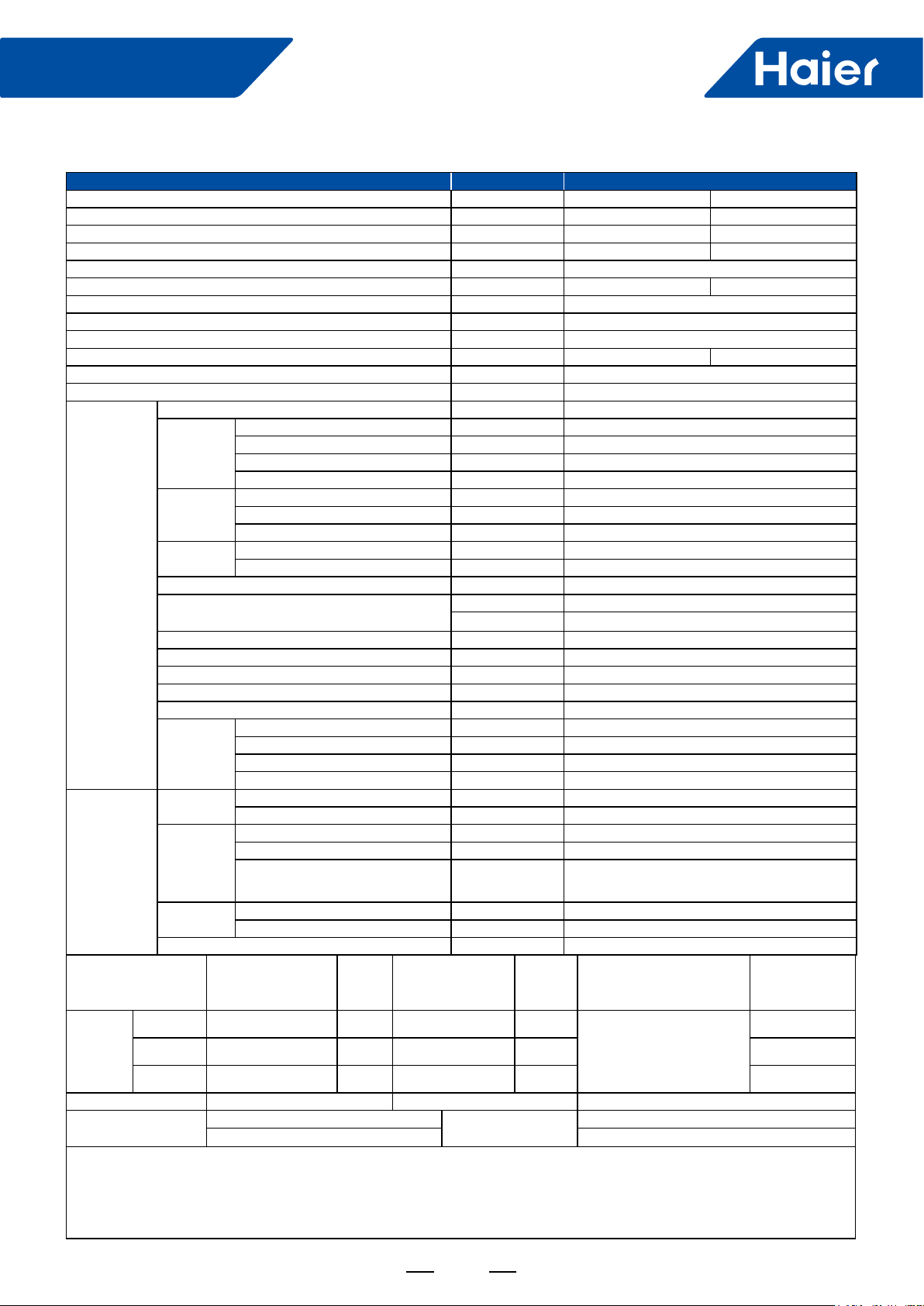

Comfort Airflow

360° air supply

360° air supply without blind spot.

Easy Installation

Convenient clip

There is clip to lock the panel. Just one installer can

nish the screwing for panel. Save manpower and easy

installation.

High lift-up drain pump

It can lifts condensed water up to 1200mm, which is more

exible to install the duct according to the layout.

4 way air ow

Unique 360° air ow design

6

Smart Power

Part 2 Indoor Units--4-Way Cassette Type

1. Feature ....................................................................................................................................................................8

2. Specication ............................................................................................................................................................9

3. Dimension..............................................................................................................................................................15

4. Wiring Diagram ......................................................................................................................................................16

5. Air Velocity and Temperature Distribution ..............................................................................................................17

6. Sound Pressure Level ...........................................................................................................................................21

7. Installation .............................................................................................................................................................24

8. Test run ..................................................................................................................................................................30

7

1. Feature

Stylish Design

"Spiral" panel

"Spiral" concept, "Haier" image.

Flap is closed when air conditioner off

There is no crack from the ap and the panel when the air

conditioner off. More elegance.

Smart Power

ABS material panel

ABS material makes the panel "piano white", different from

"dark white" PS material color. The panel and ap are

the same material. After 10 years, the panel color won't

change to yellow color because the ABS material prevents

discoloration against light raying.

New designed fan

The diameter of new fan is enlarged based on acrodynamic

theory, so that there is the least resistance against airow.

Reduce 3dB (A) for sound level.

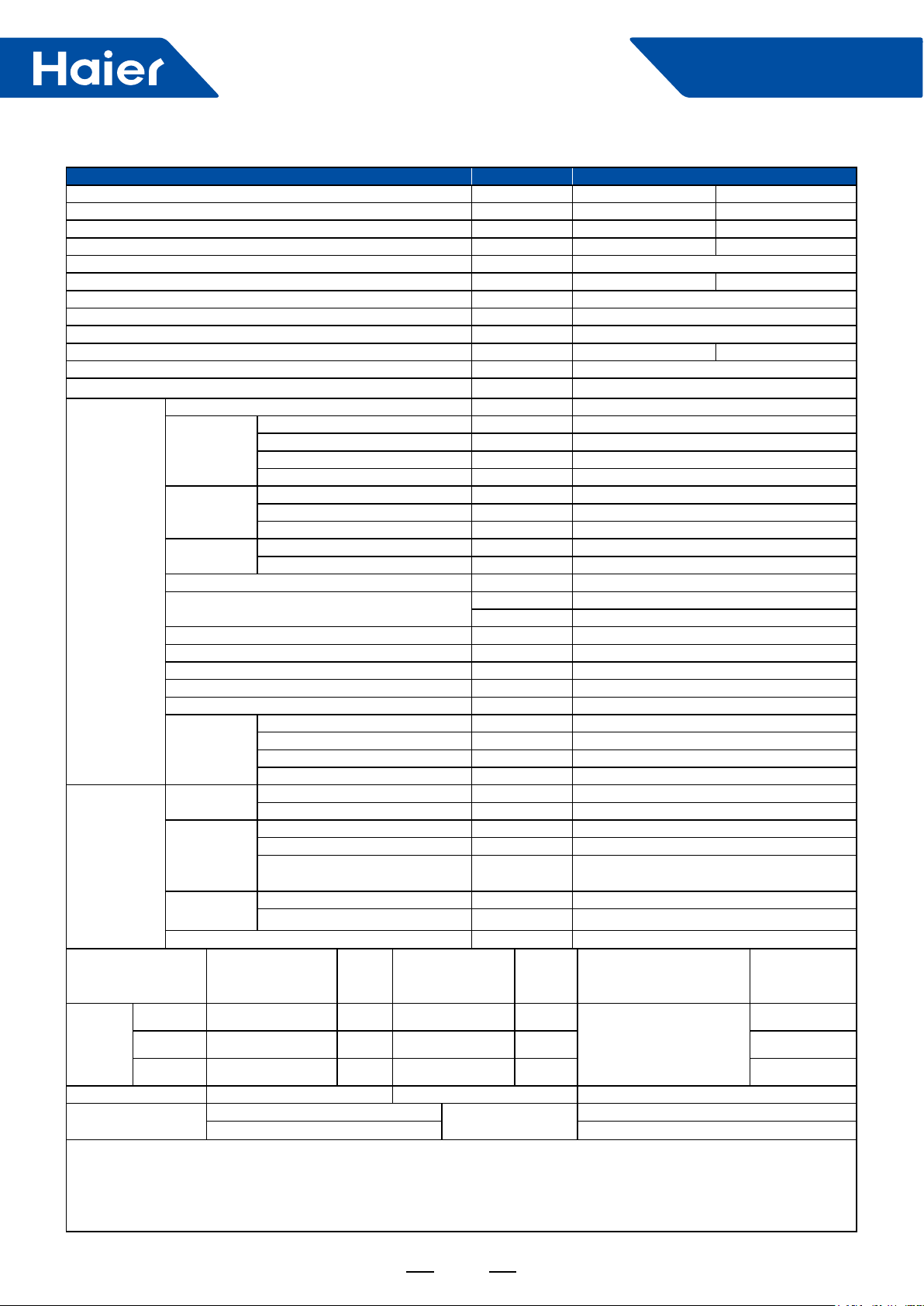

Individual flap control

The four aps can be controlled individually according

to end users by controller, providing maximum comfort

throughout the room, it is a good solution to avoid "air

conditioning disease".

Adiustable

Comrner installation solution

8

Comfort solution

Smart Power

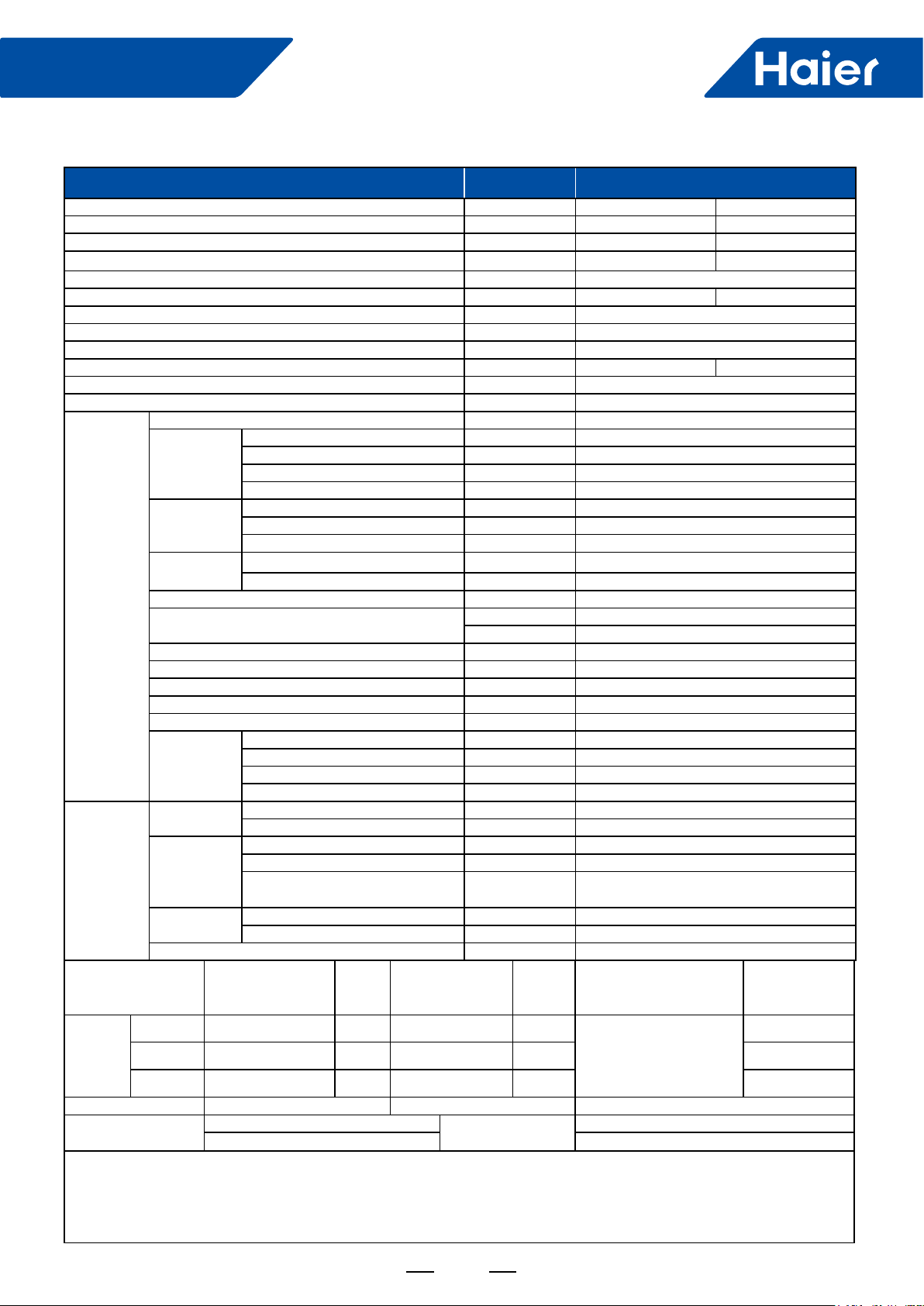

2. Specication

Item Model ABH071H1ERG/1UH071N1ERG

Function Cooling Heating

Capacity kW 7.1 (2.0~8.0) 7.8 (2.0~9.0)

Sensible heat ratio 0.72 /

Total power input kW 1.89 (0.4~3.2) 2.0 (0.4~3.2)

Max. power input W 4000

AEER or ACOP W/W 3.65 3.8

Dehumidifying capacity 10

Power cable 4.0mm

Power source N, V, Hz 1PH, 220-240V~, 50/60Hz

Running/Max. Running current A/A 8.7 (2.0-17.5)/17.5 9.1 (2.0-17.5)/17.5

Start current A 3

Circuit breaker A 30

Unit model (color) ABH071H1ERG

Type×Number CENTRIFUGALX1

Fan

Heat

exchanger

Dimension

Indoor unit

Piping

Cooling Pdesignc (kW) : 7.1kW SEER/CLASS 6.3/A++

Heating

Tdesignh: -10°C Tbivalent: -8°C TOL: -20°C Elbu: 0

Max. cooling condition

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter.

It is a sound pressure noise level.

Drainage pipe (material, I.D./O.D.) mm PVC 26/32

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 75

Electricity heater kW /

Sound power noise level (H) dB (A) 52

Sound pressure noise level (H-M-L-SL) dB (A) 36/33/29/26

Weight (Net/Shipping) kg/kg 31/36

Panel

Refrigerant

Pipe

Between

I.D &O.D

Connection method Flared

Average Pdesignh (-10°C) 6.0kW SCOP/CLASS 4.2/A+

Warmer Pdesignh (2°C) 6.5kW SCOP/CLASS 4.8/A++ 1615

Colder Pdesignh (-22°C) / SCOP/CLASS / /

Speed (H-M-L-SL) r/min 500/400/300/250

Fan motor output/input power W 72/112

Air-ow (H-M-L-SL) m

Type/Diameter mm Inner grooved pipe/φ7.0

Row 2

Total area m

External (L×W×H) mm×mm×mm 840/840/246

Package (L×W×H) mm×mm×mm 990/990/310

Model PB-950KB/PB-950MB

External dimensions (W/D/H) mm 950/950/50

Shipping dimensions (W/D/H) mm 1000/1000/110

Net weight/Shipping weight kg 6.5/9

Type/Charge g R410A/2500

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max pipe length

(without charge refrigerant)

MAX. Drop m 30

MAX. Piping length m 50

Indoor temperature: 32°C/23°C Max. heating

Outdoor temperature: 46°C/-°C Outdoor temperature: 24°C/18°C

-3×m3

/h 2.4

3

/h 1260/1070/820/680

2

Wired YR-E16A(O)/YR-E17(O)

Infrared YR-HBS01(S)

m 20

QCE (Annual electricity

consumption for cooling)

kWh:

QHE (Annual electricity

consumption for heating)

kWh:

Indoor temperature: 27°C/-°C

condition

2

/

377

1899

9

Smart Power

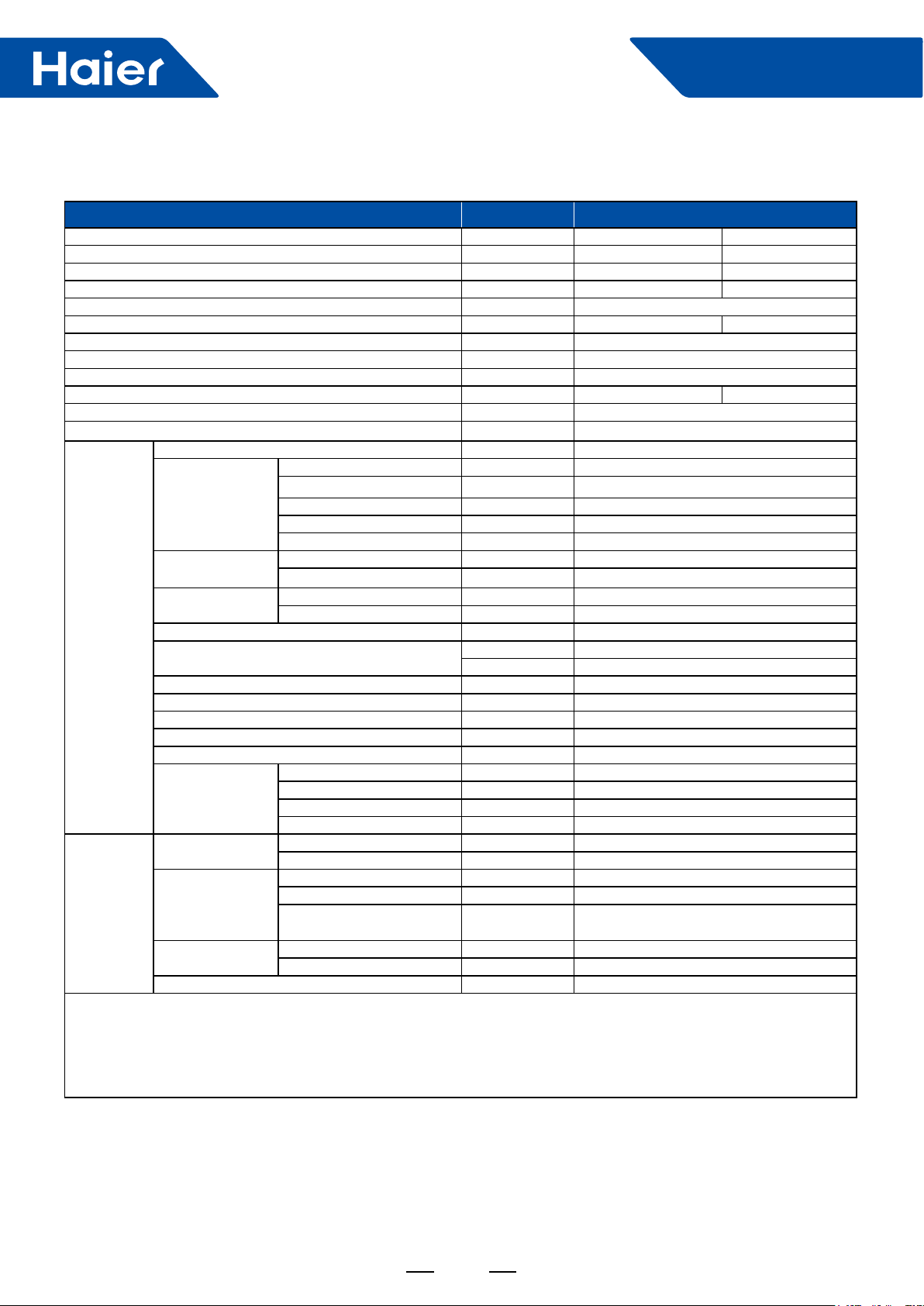

Item Model ABH090H1ERG/1UH090N1ERG

Function Cooling Heating

Capacity kW 9 (2.5~10) 10.1 (2.5~11)

Sensible heat ratio 0.72 /

Total power input kW 2.56 (0.5~3.5) 2.69 (0.5~3.5)

Max. power input W 4400

AEER or ACOP W/W 3.44 3.87

Dehumidifying capacity 10

Power cable 4.0mm

Power source N, V, Hz 1PH, 220-240V~, 50/60Hz

Running/Max. Running current A/A 11.6 (2.3-19.2)/19.2 11.9 (2.3-19.2)/19.2

Start current A 3

Circuit breaker A 30

Unit model (color) ABH090H1ERG

Type×Number CENTRIFUGALX1

Fan

Speed (H-M-L-SL) r/min 600/500/400/350

Fan motor output/input power W 77/125

Air-ow (H-M-L-SL) m

Type/Diameter mm Inner grooved pipe/φ7.0

Row 2

Total area m

External (L×W×H) mm×mm×mm 840/840/246

Package (L×W×H) mm×mm×mm 990/990/310

Indoor unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 26/32

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 75

Electricity heater kW /

Sound power noise level (H) dB (A) 57

Sound pressure noise level (H-M-L-SL) dB (A) 41/36/33/29

Weight (Net/Shipping) kg/kg 31/36

Model PB-950KB/PB-950MB

Panel

External dimensions (W/D/H) mm 950/950/50

Shipping dimensions (W/D/H) mm 1000/1000/110

Net weight/Shipping weight kg 6.5/9

Refrigerant

Type/Charge g R410A/2500

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max pipe length

Piping

Pipe

(without charge refrigerant)

Between

I.D &O.D

MAX. Drop m 30

MAX. Piping length m 50

Connection method Flared

Cooling Pdesignc (kW) : 9kW SEER/CLASS 6.3/A++

Average Pdesignh (-10°C) 8.1kW SCOP/CLASS 4.1/A+

Heating

Warmer Pdesignh (2°C) 8.8kW SCOP/CLASS 4.8/A++ 2416

Colder Pdesignh (-22°C) / SCOP/CLASS / /

Tdesignh: -10°C Tbivalent: -8°C TOL: -20°C Elbu: 0

Max. cooling condition

Indoor temperature: 32°C/23°C Max. heating

Outdoor temperature: 46°C/-°C Outdoor temperature: 24°C/18°C

condition

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter.

It is a sound pressure noise level.

-3×m3

/h 2.5

3

/h 1470/1260/1050/940

2

2

/

Wired YR-E16A(O)/YR-E17(O)

Infrared YR-HBS01(S)

m 20

QCE (Annual electricity

consumption for cooling)

kWh:

QHE (Annual electricity

consumption for heating)

kWh:

Indoor temperature: 27°C/-°C

516

2798

10

Smart Power

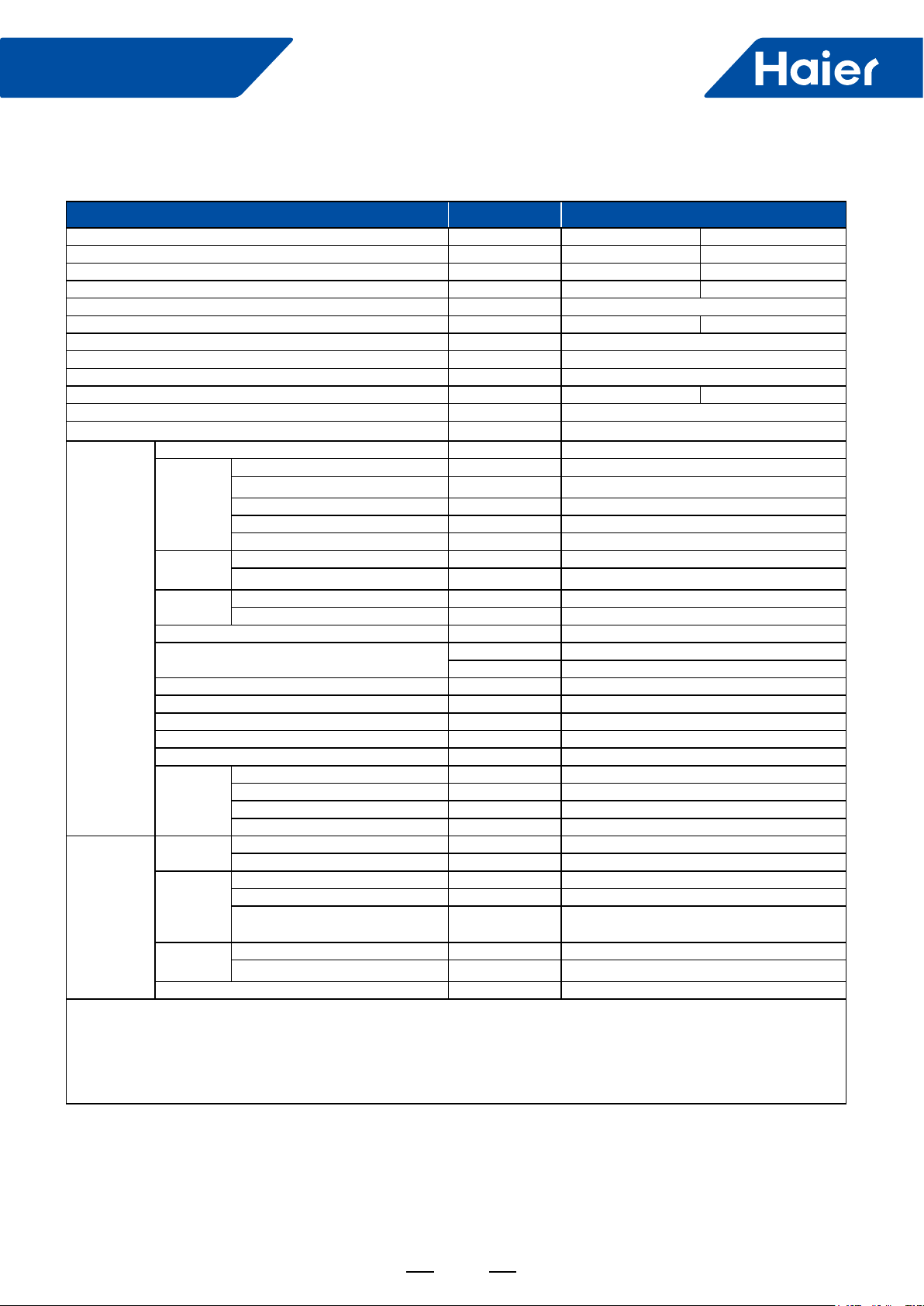

Item Model ABH105H1ERG/1UH105N1ERG

Function Cooling Heating

Capacity kW 10 (2.5~11) 10.6 (2.5~11.3)

Sensible heat ratio 0.72 /

Total power input kW 2.99 (0.5~4.0) 2.86 (0.5~4.0)

Max. power input W 4900

AEER or ACOP W/W 3.29 3.64

Dehumidifying capacity 10

Power cable 4.0mm

Power source N, V, Hz 1PH, 220-240V~, 50/60Hz

Running/Max. Running current A/A 13.6 (2.3-20)/20 12.7 (2.3-20)/20

Start current A 3

Circuit breaker A 30

Unit model (color) ABH105H1ERG

Type×Number CENTRIFUGALX1

Fan

Speed (H-M-L-SL) r/min 650/550/450/400

Fan motor output/input power W 82/134

Air-ow (H-M-L-SL) m

Type/Diameter mm Inner grooved pipe/φ7.0

Row 2

Total area m

External (L×W×H) mm×mm×mm 840/840/246

Package(L×W×H) mm×mm×mm 990/990/310

Indoor unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 26/32

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 75

Electricity heater kW /

Sound power noise level (H) dB (A) 62

Sound pressure noise level (H-M-L) dB (A) 45/42/38/34

Weight (Net/Shipping) kg/kg 31/36

Model PB-950KB/PB-950MB

Panel

External dimensions (W/D/H) mm 950/950/50

Shipping dimensions (W/D/H) mm 1000/1000/110

Net weight/Shipping weight kg 6.5/9

Refrigerant

Type/Charge g R410A/2500

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max pipe length

Piping

Pipe

(without charge refrigerant)

Between

I.D &O.D

MAX. Drop m 30

MAX. Piping length m 50

Connection method Flared

Cooling Pdesignc (kW) : 10kW SEER/CLASS 6.8/A++

Average Pdesignh (-10°C) 8.2kW SCOP/CLASS 4.1/A+

Heating

Warmer Pdesignh (2°C) 8.8kW SCOP/CLASS 4.8/A++ 2566

Colder Pdesignh (-22°C) / SCOP/CLASS / /

Tdesignh: -10°C Tbivalent: -8°C TOL: -20°C Elbu: 0

Max. cooling condition

Indoor temperature: 32°C/23°C Max. heating

Outdoor temperature: 46°C/-°C Outdoor temperature: 24°C/18°C

condition

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter.

It is a sound pressure noise level.

-3×m3

/h 3

3

/h 1680/1530/1320/1190

2

2

/

Wired YR-E16A(O)/YR-E17(O)

Infrared YR-HBS01(S)

m 20

QCE (Annual electricity

consumption for cooling)

kWh:

QHE (Annual electricity

consumption for heating)

kWh:

Indoor temperature: 27°C/-°C

538

2900

11

Smart Power

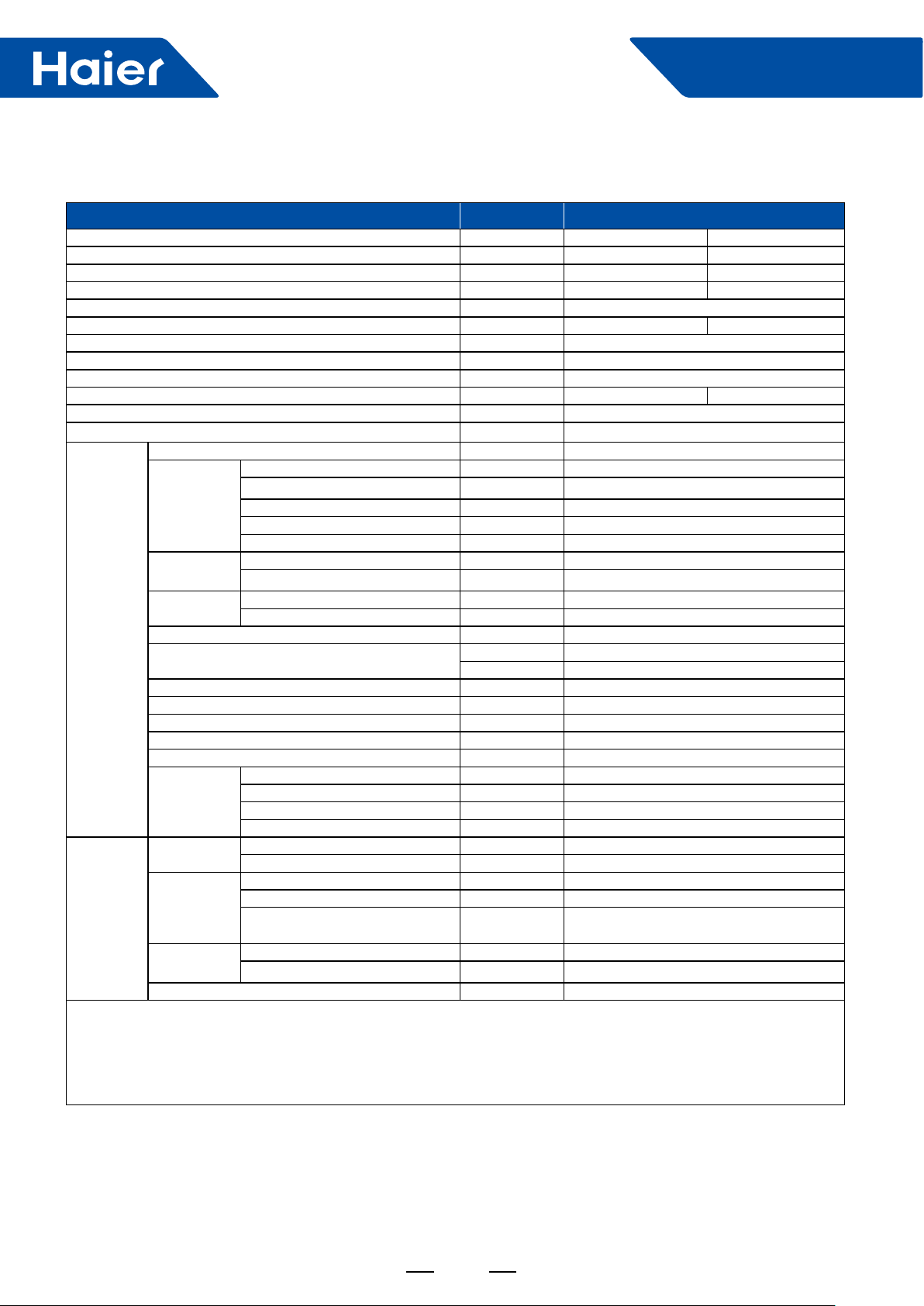

Item Model ABH125K1ERG/1UH125P1ERK

Function Cooling Heating

Capacity kW 12.5 (3.5~14.5) 13.1 (4~17)

Sensible heat ratio 0.74

Total power input kW 3.67 (1.0-6.0) 3.71 (1.0-6.0)

Max. power input W 7000

AEER or ACOP W/W 3.38 3.50

Dehumidifying capacity 10

Connection cable (indoor to outdoor)

Power source N, V, Hz 3PH~, 380~415, 50/60Hz

Running/Max. Running current A/A 6.1/10.8 6.3/10.8

Start current A 3

Circuit breaker

Unit model (color) ABH125K1ERG

Type×Number CENTRIFUGALX1

Speed (H-M-L)

Fan

Fan motor input power kW 0.12

Fan motor output power kW 0.09

Air-ow (H-M-L) m

Type/Diameter mm Inner grooved pipe/φ7.0

Total area

External (L×W×H) mm×mm×mm 840/840/288

Package (L×W×H) mm×mm×mm 990*990*380

Indoor unit

Heat exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 21/25

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 75

Electricity heater kW /

Sound power noise level (H) dB (A) 64

Sound pressure noise level (H-M-L) dB (A) 48/45/52

Weight (Net/Shipping) kg/kg 40/45

Model PB-950KB/PB-950MB

Panel

External dimensions (W/D/H) mm 950/950/50

Shipping dimensions (W/D/H) mm 1000/1000/110

Net weight/Shipping weight kg 6.5/9.0

Refrigerant

Type/Charge g R410A/3700

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max pipe length

Piping

Pipe

(without charge refrigerant)

Between I.D &O.D

MAX. Drop m 30

MAX. Piping length m 75

Connection method Flared

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter.

It is a sound pressure noise level.

-3×m3

/h 4.9

A

r/min

3

/h 1950/1600/1440

2

m

3Ph, 40A(from outdoor)

750/650/500

4.0mm

/

2

Wired YR-E17(O)/ YR-E16A(O)

Infrared YR-HBS01(S)

m 30

12

Smart Power

Item Model ABH125K1ERG/1UH125P1ERG

Function Cooling Heating

Capacity kW 12.5 (3.5~14.5) 13.1 (4~17)

Sensible heat ratio 0.74

Total power input kW 3.67 (1.0-6.0) 3.71 (1.0-6.0)

Max. power input W 6500

AEER or ACOP W/W 3.38 3.51

Dehumidifying capacity 10

Power cable 6.0mm

Power source N, V, Hz 1, 220~240, 50/60

Running/Max. Running current A/A 17.0 (8.7-30.0)/30A 17.2 (8.7-30.0)/30A

Start current A 3

Circuit breaker

Unit model (color) ABH125K1ERG

Type×Number CENTRIFUGALX1

Speed (H-M-L)

Fan

Fan motor input power kW 0.12

Fan motor output power kW 0.09

Air-ow (H-M-L) m

Indoor unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 21/25

Type/Diameter mm Inner grooved pipe/φ7.0

Total area

External (L×W×H) mm×mm×mm 840/840/288

Package (L×W×H) mm×mm×mm 990*990*380

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 75

Electricity heater kW /

Sound power noise level (H) dB (A) 64

Sound pressure noise level (H-M-L) dB (A) 48/45/42

Weight (Net/Shipping) kg/kg 40/45

Model PB-950KB/PB-950MB

Panel

External dimensions (W/D/H) mm 950/950/50

Shipping dimensions (W/D/H) mm 1000/1000/110

Net weight/Shipping weight kg 6.5/9.0

Refrigerant

Type/Charge g R410A/3700

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max pipe length

Piping

Pipe

(without charge refrigerant)

Between

I.D &O.D

MAX. Drop m 30

MAX. Piping length

Connection method Flared

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

-3×m3

/h 4.9

A

r/min

3

/h 1950/1600/1440

2

m

750/650/500

2

40

/

Wired YR-E17(O) or YR-E16A(O)

Infrared YR-HBS01 (S)

m 30

m

75

13

Smart Power

Item Model ABH140K1ERG/1UH140P1ERK

Function Cooling Heating

Capacity kW 13.4 (3.5~15.0) 14.5 (4.0~18.0)

Sensible heat ratio 0.74

Total power input kW 4.05 4.11

Max. power input W 7200

AEER or ACOP W/W 3.27 3.48

Dehumidifying capacity 10

Connection cable(

from outdoor to indoor)

Power source N, V, Hz

Running/Max. Running current A/A 6.8/11.0 7.0/11.0

Start current A 3

Circuit breaker

Unit model (color)

Type×Number

Speed (H-M-L)

Fan

Fan motor input power kW 0.12

Fan motor output power kW 0.09

Air-ow (H-M-L) m

Indoor unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 21/25

Type/Diameter mm Inner grooved pipe/φ7.0

Total area

External (L×W×H) mm×mm×mm 840/840/288

Package (L×W×H) mm×mm×mm 990*990*380

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 75

Electricity heater kW /

Sound power noise level (H-M-L) dB (A) 64

Sound pressure noise level (H-M-L) dB (A) 48/45/42

Weight (Net/Shipping) kg/kg 32/38

Model PB-950KB/PB-950KB

Panel

External dimensions (W/D/H) mm 950/950/50

Shipping dimensions (W/D/H) mm 1000/1000/110

Net weight/Shipping weight kg 6.5/9.0

Refrigerant

Type/Charge g R410A/3700

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max pipe length

Piping

Pipe

(without charge refrigerant)

Between I.D

&O.D

MAX. Drop m 30

MAX. Piping length

Connection method Flared

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

-3×m3

/h

H05RN-F 4G 2.5mm2

4.9

3PH~, 380~415, 50/60Hz

A

3Ph,40A (

from outdoor)

ABH140K1ERG

CENTRIFUGALX1

r/min

3

/h 1950/1600/1440

2

m

750/650/550

/

Wired YR-E17(O) OR YR-E16A(O)

Infrared YR-HBS01 (S)

m 30

m

75

14

Smart Power

3. Dimension

ABH071H1ERG/ABH090H1ERG/ABH105H1ERG

765

765

ABH125K1ERG/ABH140K1ERG

246

47

950

840

59

950

765

765

288

47

168

950

840

59

950

15

4. Wiring Diagram

0150516956

DC FAN MOTOR

PIPING

ROOM CARD

DRAIN

PUMP

M

ELECTRIC HEATING TERMINAL

FRESH AIR MOTOR /

EXTERNAL ALARM OUTPUT

(FUNCTION IN FUTURE )

( Contact rating_230VAC,3A)

M

CN10

CN9

CH1

M

.

ROOM

TEMP.

SENSOR

.

TEMP

SENSOR

FLOAT

SWITCH

CN6

CN3

CN19

CN1

CN11

BA

RATING_230VAC,3A

CN8

C

ELECTRIC HEATING

CONNECT TO THIRD PARTY RELAY

CN15

INDOOR UNIT

MAIN CONTROL

BOARD

SW1(BM1)

87654321

ON

OFF

SW3(BM3)

87654321

ON

OFF

CN26

B

A

THERMOSTAT / FUSE

L

FUSE

T5A 250VAC

CN13

CN14

CN4

RD

BLK

N

CN16

Y/G

WHT

LOUVER STEP

M

M

LOUVER

MOTOR2

CN2

.

3

2

1

LOUVER STEP

M

CN6

CN4

STEP MOTOR4

INDOOR UNIT

MOTOR1

CN1

CN7

CN3

M

LOUVER

STEP MOTOR3

Smart Power

Y/G:YELLOW/GREEN

RD:RED WHT:WHITE

BLK:BLACK

******************

TO OUT DOOR UNIT

TERMINAL BLOCK

INTELLIGENT

MOVE EYE DEVICE

I.R .RECEIVER

(WITH DIGITAL

DISPLAY)

CAPACITY

I.R .RECEIVER :

7.1

(KW)

9.0

INFRARED REMOTE

RECEIVER .

TEMP.:TEMPERATURE

(SLIM)

TYPE DEFINE

Cassette

ON

SW1-8

OFF

SW1-7

OFF

SW1-6

COOL HEAT

COOL ONLY

HEAT PUMP

SW1-5

Room card

SW1-4

OFF

ON

unavailable

available

ON

OFF

14.0

10.5

12.5

ON

OFF OFF ON

OFF ON

ON

ON

ON

ON

OFF

ON

OFF

SW1-3

C

B

A

WIRED

CONTROLLER

WiFi

MODULE

NOTE:

1.DASHED PARTS ARE OPTIONAL.

2.USER SHOULD NOT CHANGE THE

DIP SWITCH SW1 SW3 WITHOUT GUIDENCE

3.SW3-5->SW3-8 ARE USED FOR WIRED CONTROLLER

ADRESS SELECT. SW3-1->SW3-4 ARE RESERVED.

ON

SW1-2

ON

SW1-1

16

Smart Power

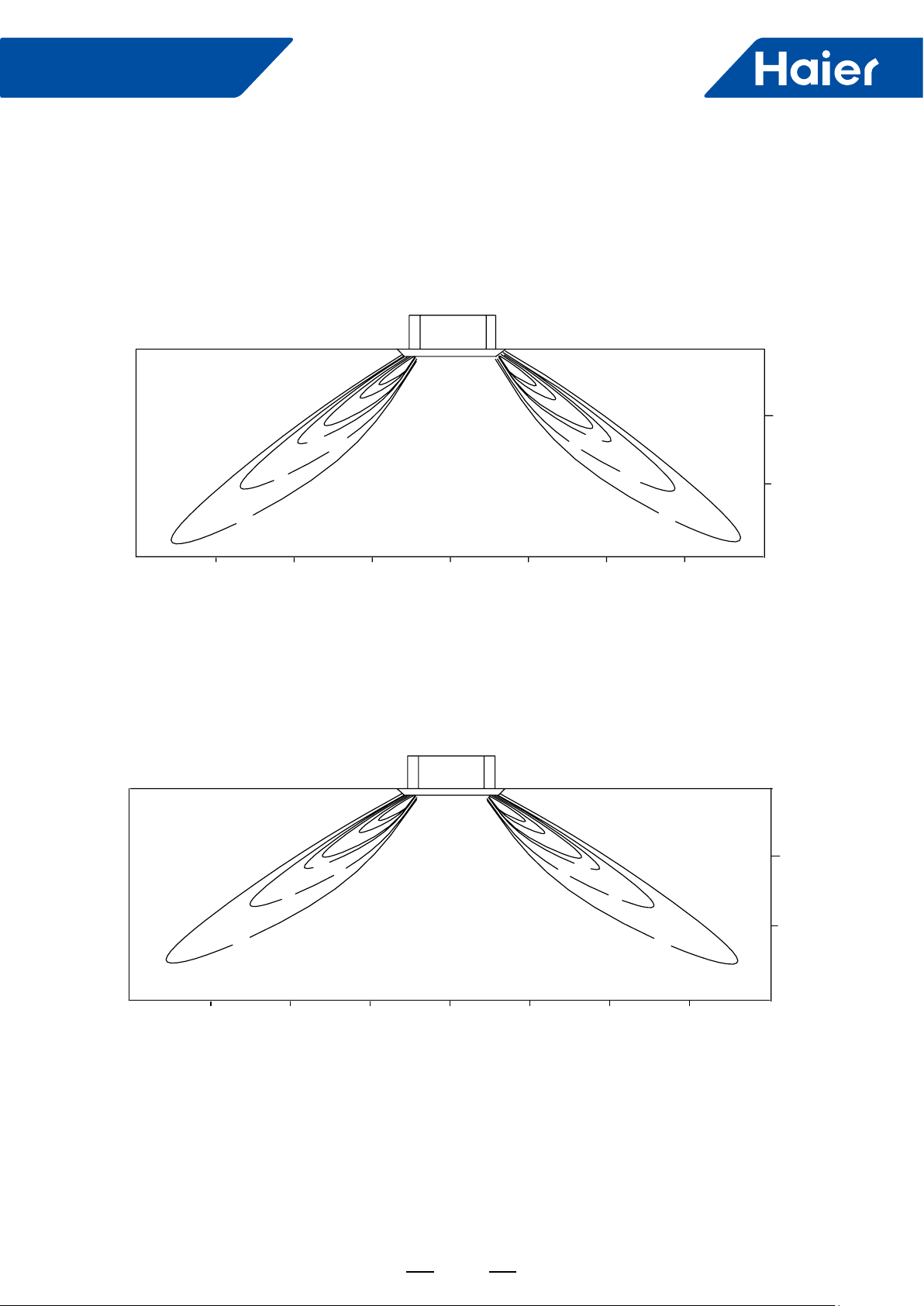

5. Air Velocity and Temperature Distribution

ABH071/090/105H1ERG:

a. Cooling/Air velocity distribution

Cooling

Blowy angle: 33

Air velocity distribution

2.5m/s

2.7m

2m

2.5m/s

1.5m/s

0.5m/s

4m

3m

b. Cooling/Temperature distribution

Cooling

Blowy angle: 33

Temperature distribution

17°C

20°C

1m

0m

1m

17°C

1.5m/s

2m2m

20°C

0.5m/s

3m

1m

0m

4m

2.7m

2m

1m

4m

22°C

3m

2m

1m

0m

17

1m

22°C

2m 3m

0m

4m

c. Heating/Air velocity distribution

Heating

Blowy angle: 60

Air velocity distribution

Smart Power

2.7m

2m

1.0m/s

4m

3m

d. Heating/Temperature distribution

Heating

Blowy angle: 60

Temperature distribution

2.0m/s

3.0m/s

1m

0m

3.0m/s

1m

2.0m/s

1.0m/s

2m2m

3m

4m

1m

0m

2.7m

4m

3m

26°C

29°C

32°C

1m

0m

18

32°C

1m

29°C

26°C

2m2m

3m

4m

2m

1m

0m

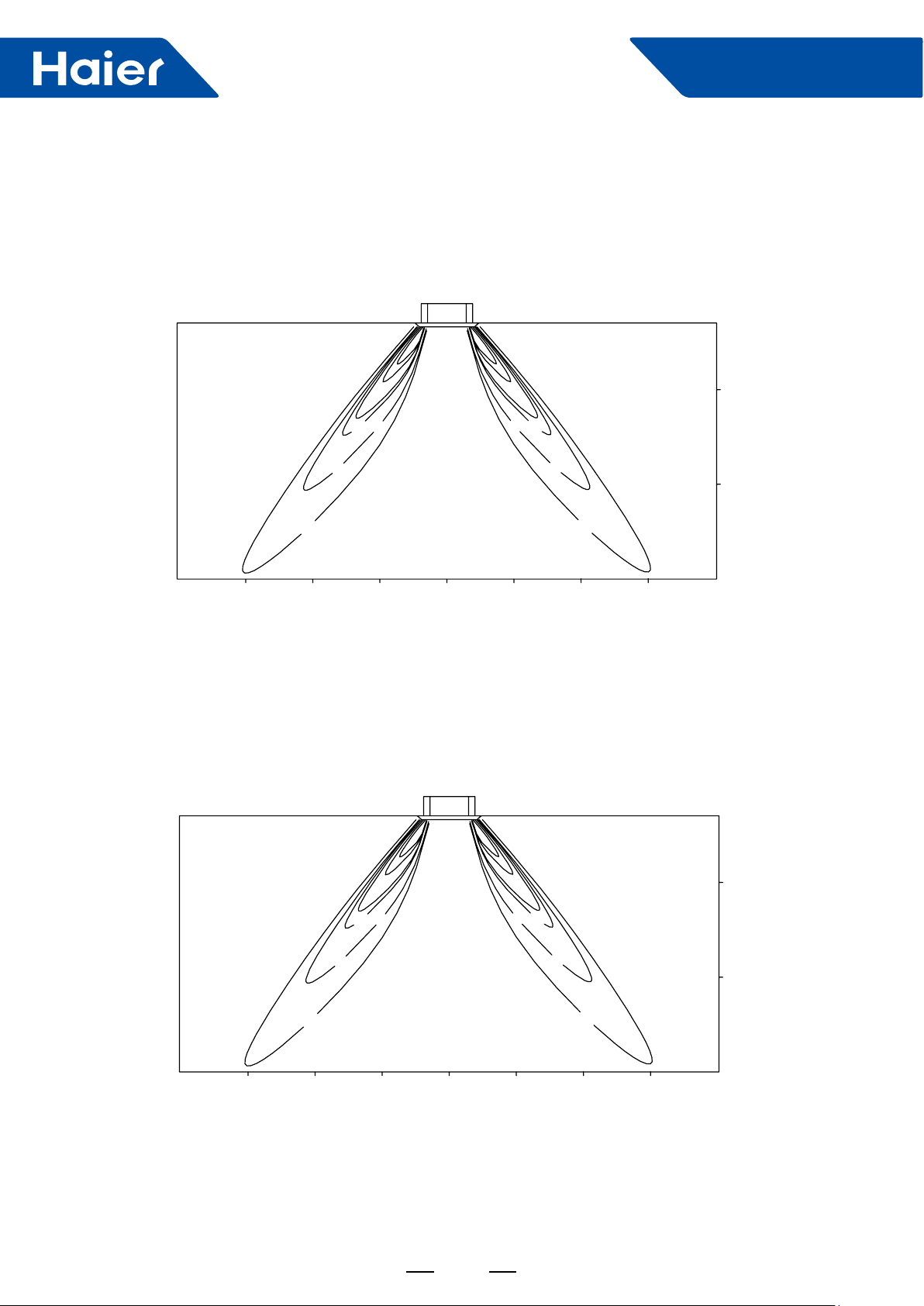

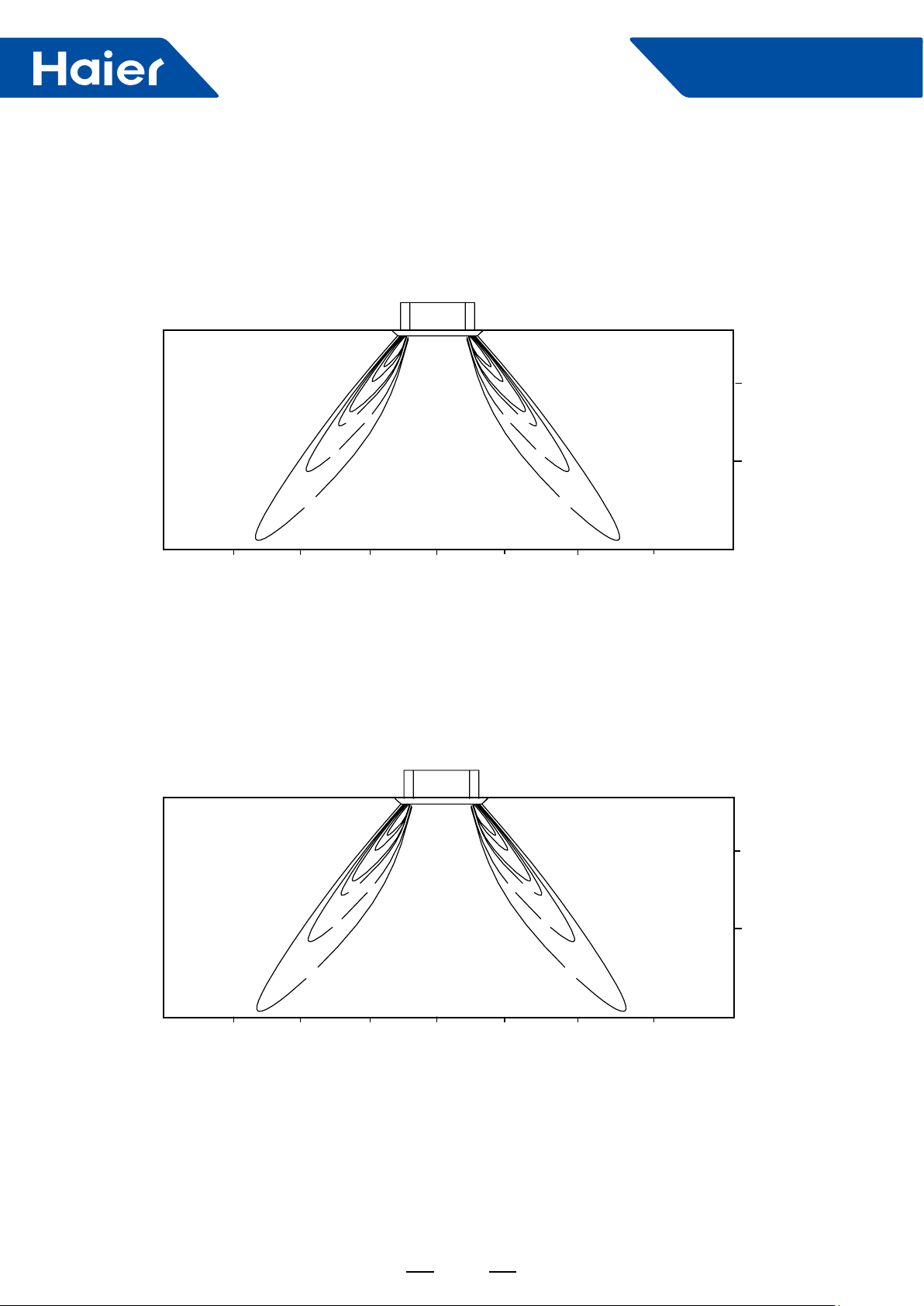

Smart Power

AB125-140

a. Cooling/Air velocity distribution

Cooling

Blowy angle: 33

Air velocity distribution

2.5m/s

2.7m

2m

3.0m/s

1.5m/s

0.5m/s

4m

3m

b. Cooling/Temperature distribution

Cooling

Blowy angle: 33

Temperature distribution

21°C

23°C

18°C

1m

0m

1m

18°C

2m2m

21°C

2.0m/s

1.0m/s

23°C

3m

1m

0m

4m

2.7m

2m

1m

4m

3m

1m

0m

19

1m

2m2m

3m

0m

4m

c. Heating/Air velocity distribution

Heating

Blowy angle: 60

Air velocity distribution

Smart Power

2.7m

2m

1.5m/s

3m

d. Heating/Temperature distribution

Heating

Blowy angle: 60

Temperature distribution

3.5m/s

2.5m/s

1m

0m

3.5m/s

1m

2.5m/s

1.5m/s

2m2m

1m

0m

3

m

4m4m

2.7m

2m

3m

27°C

33°C

30°C

1m 3 m

0m

1m

33°C

30°C

27°C

2m2m

20

1m

0m

4m4m

Smart Power

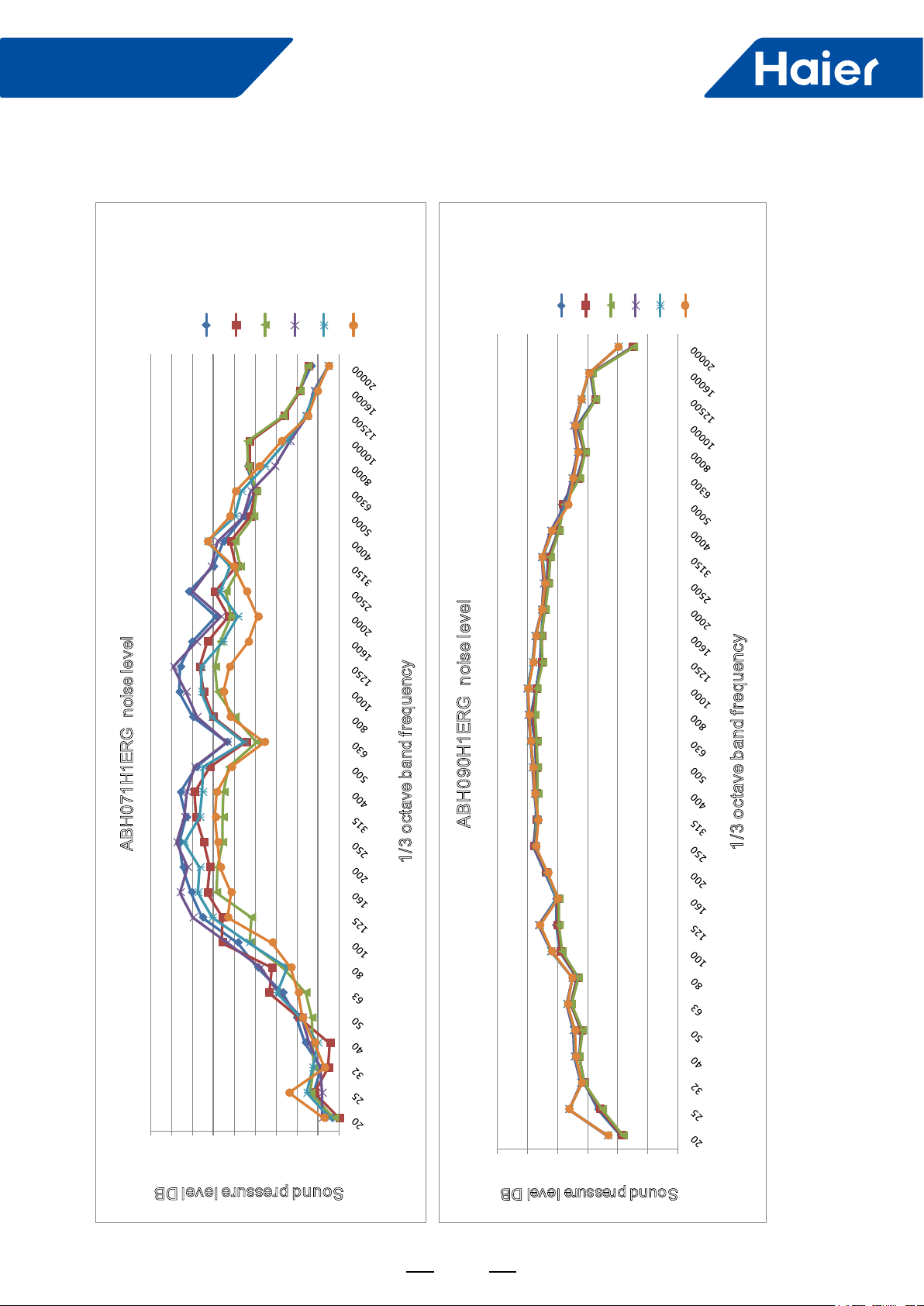

0.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

45.00

Sound pressure level DB

1/ 3 octave band frequency

ABH071H1ERG noise level

Cooling-high

Cooling-med

Cooling-low

Heating-high

Heating-med

Heating-low

0

10

20

30

40

50

60

Sound pressure level DB

1/3 octave band frequency

ABH090H1ERG noise level

Cooling-high

Cooling-med

Cooling-low

Heating-

high

Heating-med

Heating-low

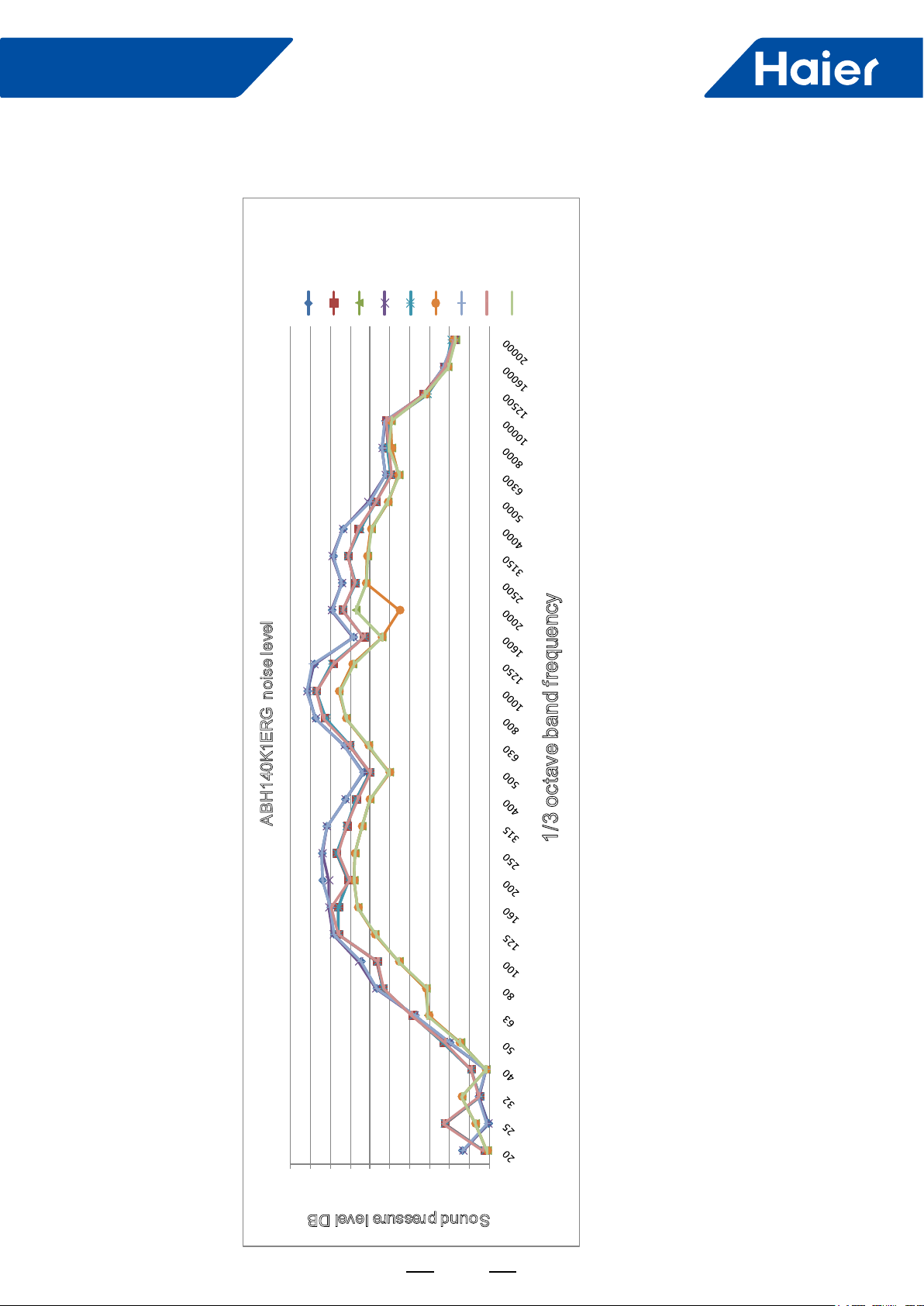

6. Sound Pressure Level

21

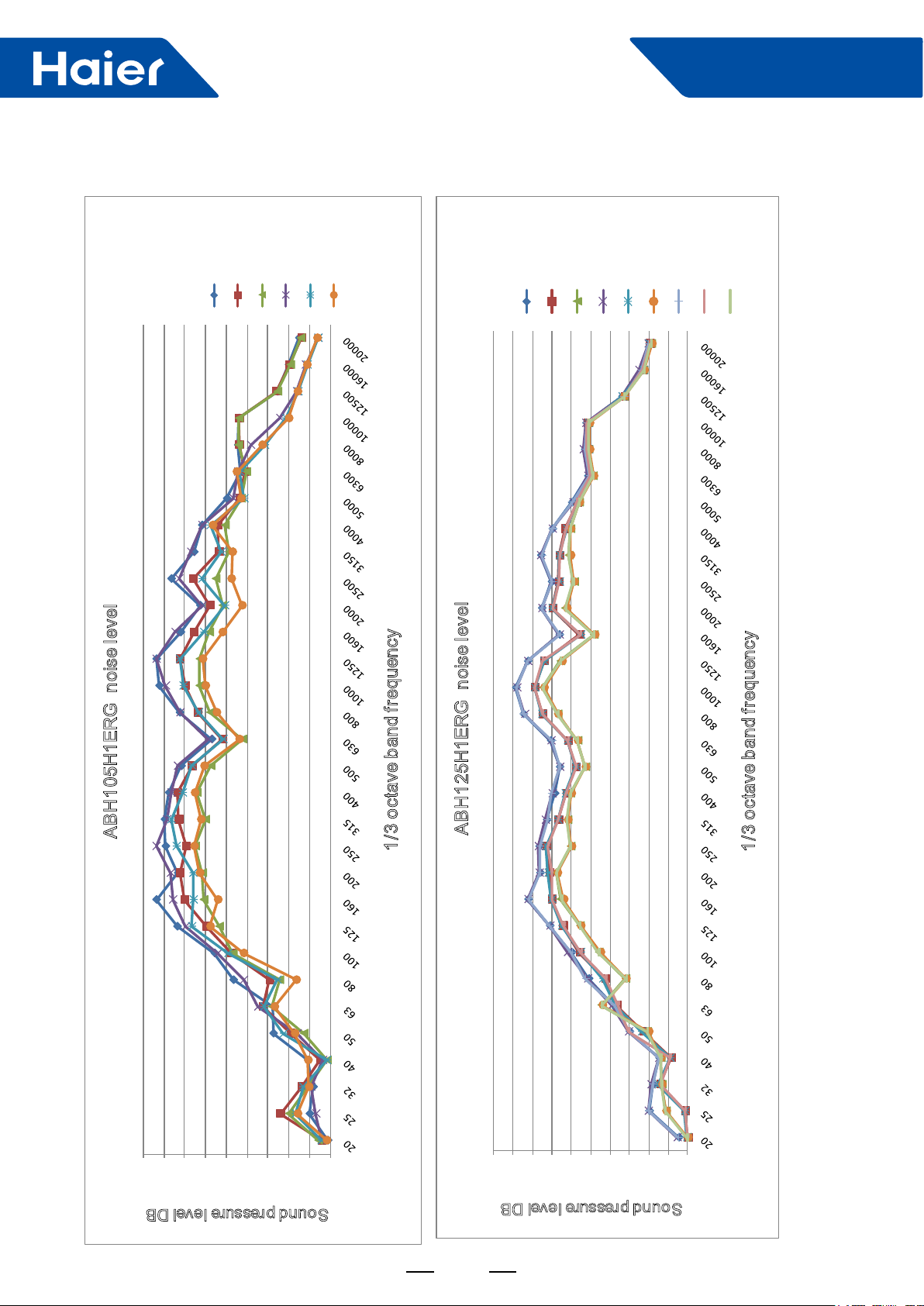

Smart Power

0.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

45.00

Sound pressure level DB

1/3 octave band frequency

ABH105H1ERG noise level

Cooling-high

Cooling-med

Cooling-low

Heating-high

Heating-med

Heating-low

0.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

45.00

50.00

Sound pressure level DB

1/3 octave band frequency

ABH125H1ERG noise level

Cooling-high

Cooling-med

Cooling-low

Heating-high

Heating-med

Heating

-low

Fan-high

Fan-med

Fan-low

22

Smart Power

0.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

45.00

50.00

Sound pressure level DB

1/3 octave band frequency

ABH140K1ERG noise level

Cooling

-high

Cooling

-med

Cooling-low

Heating-high

Heating-med

Heating

-low

Fan-high

Fan-med

Fan-low

23

Smart Power

7. Installation

7.1 Before installation <Don’t discard any accessories until comp>

• Determine the way to carry unit to installation place.

• Don’t remove packing until unit reaches installation place.

• If unpacking is unavoidable, protect unit properly.

7.2 Selection of installation place

(1) Installation place shall meet the following and agreed by customers:

• Place where proper air ow can be ensured.

• No block to air ow.

• Water drainage is smpoth.

• Place strong enough to support unit weight.

• Place where inclination is not evident on ceiling.

• Enough space for mainenance.

• Indoor and outdoor unit piping length is within limit. (Refer to Installation Manual for outdoor unit.)

• Indoor and outdoor unit, power cable, inter unit cable are at least 1 m away fromT.V. radio. This is helpful to avoid

picture disturbance and noise. (Even if 1 m is kept, noise can still appear if radio wave is strong)

(2) Ceiling height

Indoor unit can be installed on ceiling of 2.5-3m in height. (Refer to Foeld setting and Installation Manual of

ornament panel.)

(3) Install suspending bolt.

Check if the installation place is strong enough to hold weight. Take necessary measures in case it is not safe.

(Distance between holes are marked on paper pattern. Refer to paper pattern for place need be reinforced)

(4) Selection of installation location of outdoor

With consent from the user, installation location shall:

• Be sufcient to bear weight of the units, with air circulation.

• Avoid direct radiation from heat sources or other heat sources.

• Facilitate the drainage of condensate. Holes in wall shall also facilitate drainage.

• Be such that noise and heat air will not disturb neighbors.

• Be free of heavy snow in winter.

• Allow air inlets and outlets to be free of barriers.

• Not allow air outlet to directly face strong airow.

• Facilitate installation at four corners, with 1m space above the unit.

• Be convenient for maintenance and repair.

• For installation of multiple units, sufcient space shall be ensured to avoid short circuit.

• The air conditioner shall not be mounted on a non-dedicated metal frame (e.g. burglar mesh) .

• When the outdoor unit is installed on a street side, its height shall not be less than 2.5m.

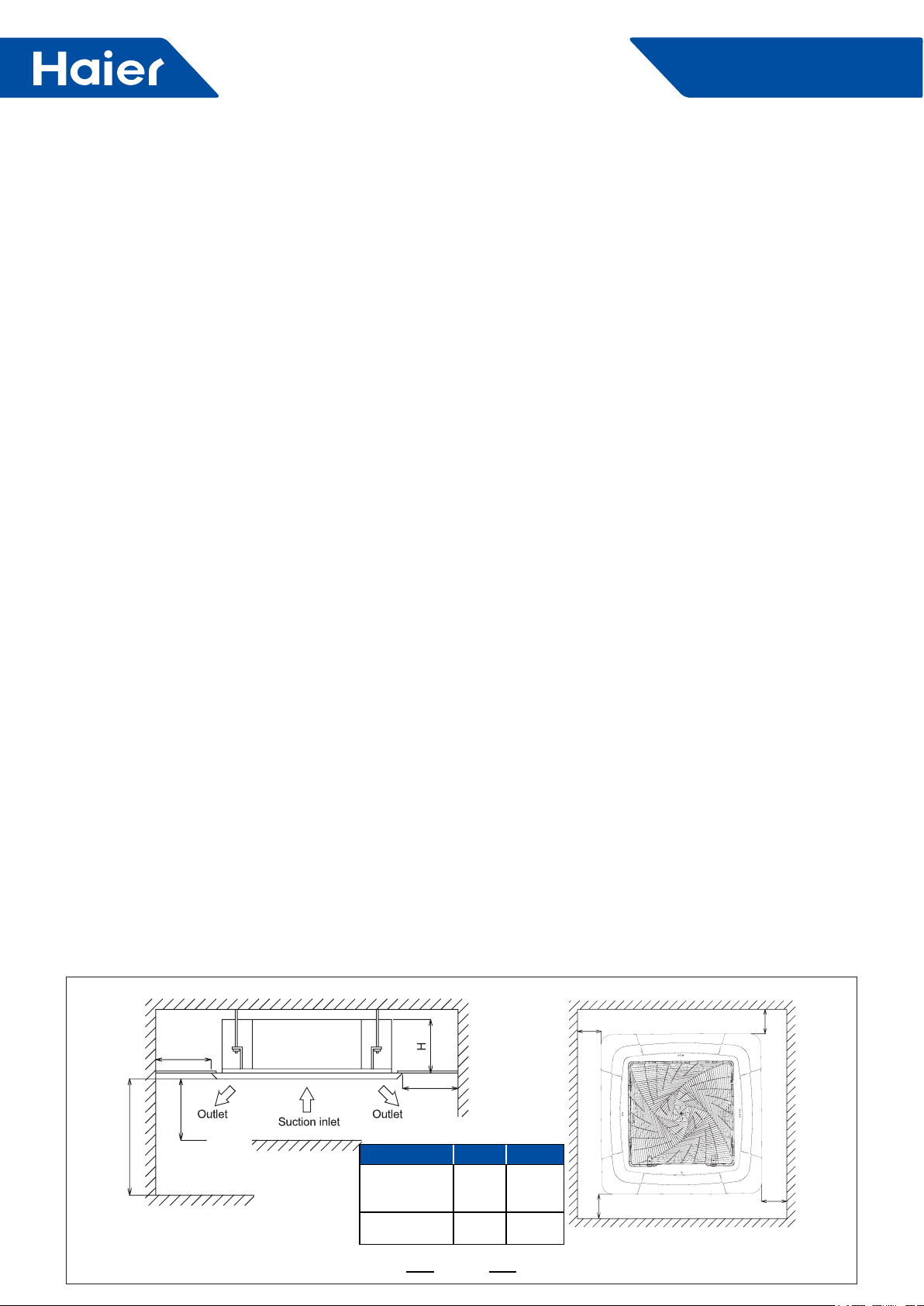

≥1500

I

≥1500

Space required for installation (unit: mm)

≥1500

Model H(mm) I(m)

ABH071H1ERG

ABH090H1ERG

ABH105H1ERG

ABH125K1ERG

ABH140K1ERG

246 2.5≤I≤3.5

288 2.5≤I≤4.2

24

≥1500

≥1500

≥1500

≥1500

Smart Power

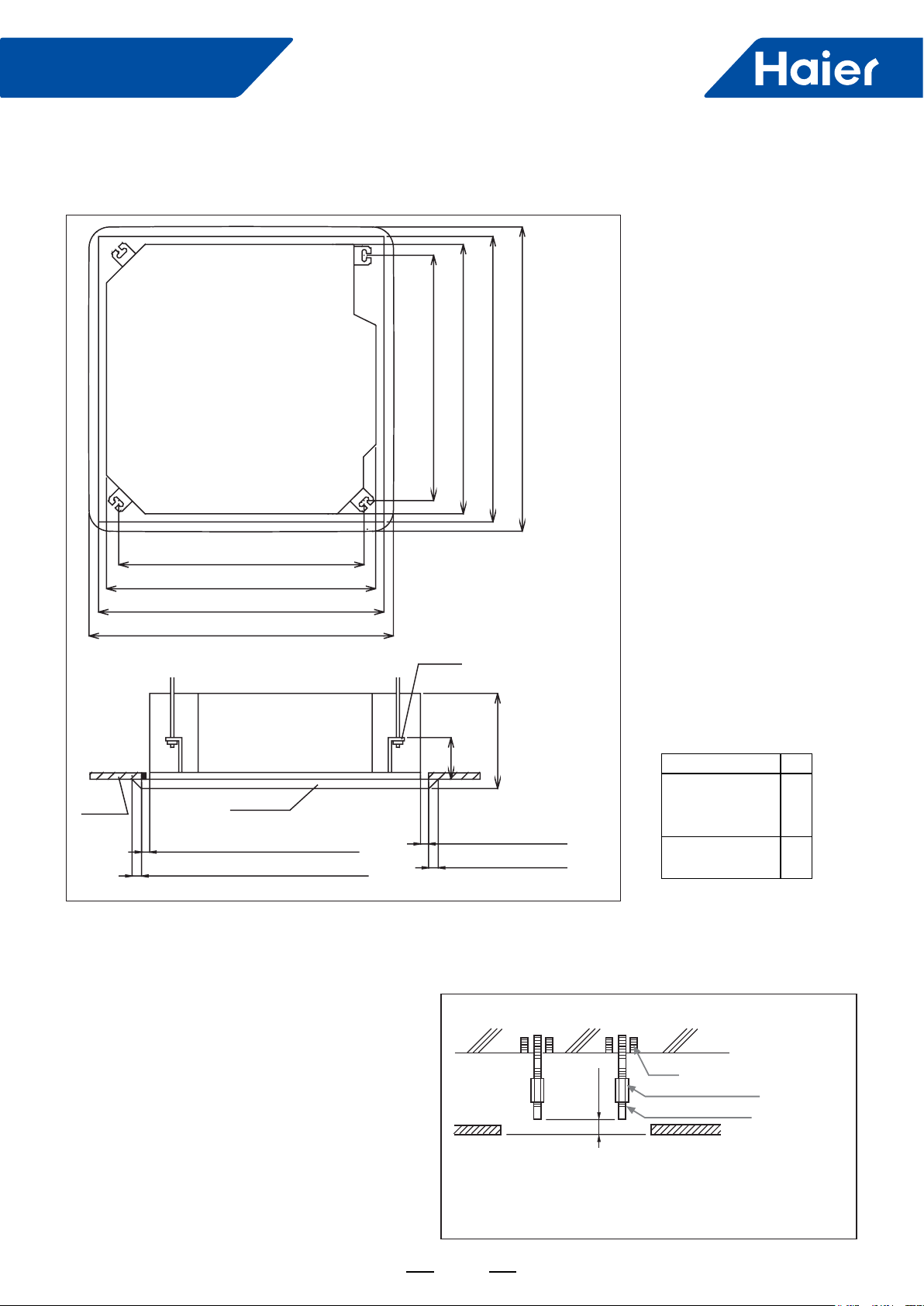

7.3 Preparation before installation

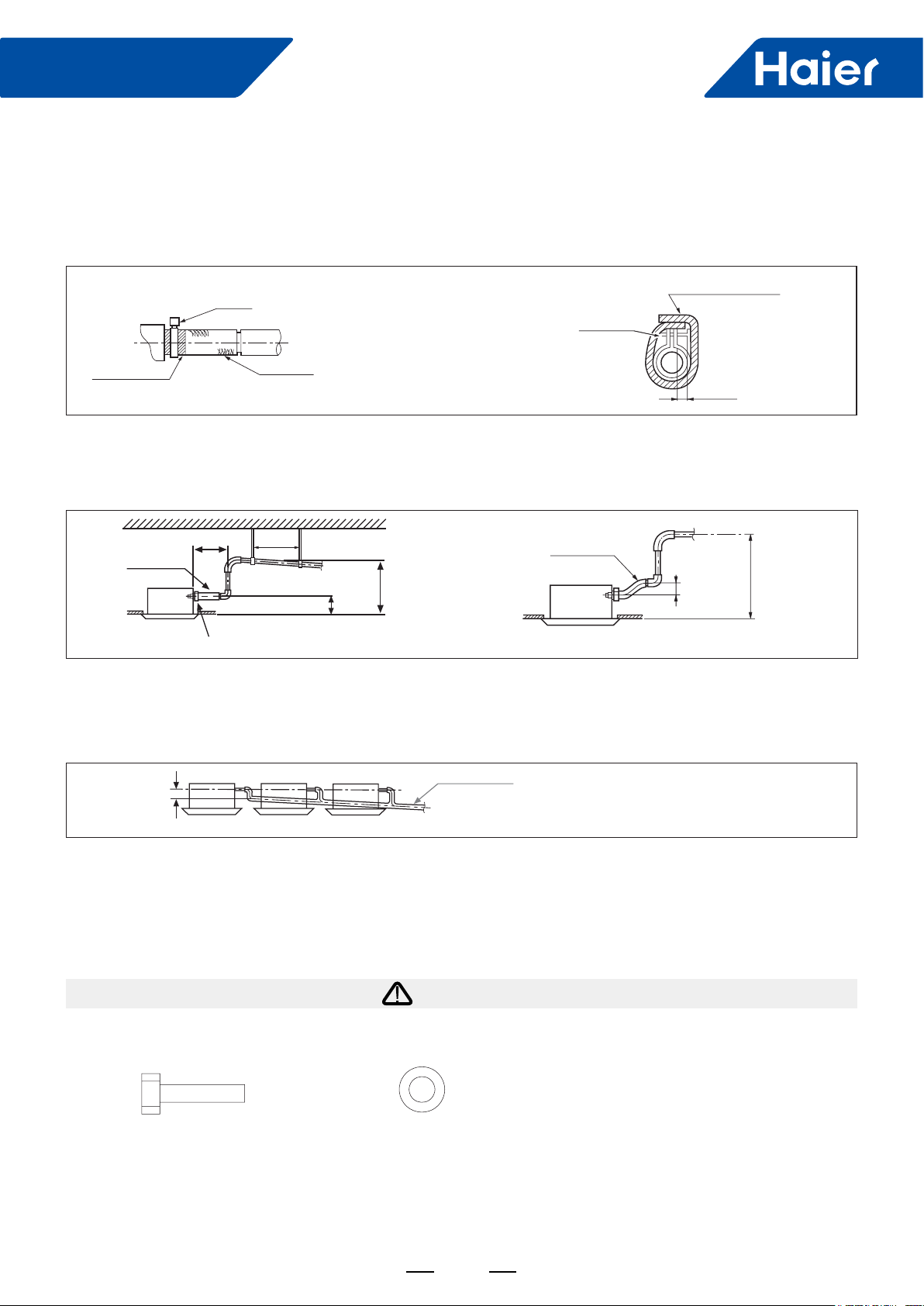

(1) Location relationships between ceiling opening and hanging screw

Ceiling

765 (Spacing of hanging screw)

850 (Indoor unit)

890 (Ceiling opening)

950 (Trim panel)

Trim panel

Distance between indoor unit and

ceiling≤20

Overlap between ceiling and trim

panel≥30

850 (Indoor unit)

765 (Spacing of hanging screw)

Hanger bracket

130

Distance between indoor

unit and ceiling≤20

Overlap between ceiling

and trim panel≥30

950 (Trim panel)

890 (Ceiling opening)

H

Model H

ABH071H1ERG

ABH090H1ERG

ABH105H1ERG

ABH125K1ERG

ABH140K1ERG

299

341

Note:

Overlap between the ceiling and decorative panel shall be 30mm or more. The distance between indoor unit and

ceiling shall be 20mm or less. If it’s more than 20mm, add ceiling materials at or repair the ceiling.

(2) Complete all pipes (for refrigerants and drainage)

and wires (for connection of indoor and outdoor

units) to be connected to indoor unit before

installation so that they can be connected to indoor

unit immediately after installation.

(3) Install hanging screws

• To bearing the unit weight, use foundation bolts on

existing ceilings, or embedded bolts, buried bolts or

other parts that is provided on site on new ceilings.

Before installation is continued, adjust the distance

from ceiling.

Note:

All the above parts are to be provided on installation sites.

Diameter of hanging screws is M10.

25

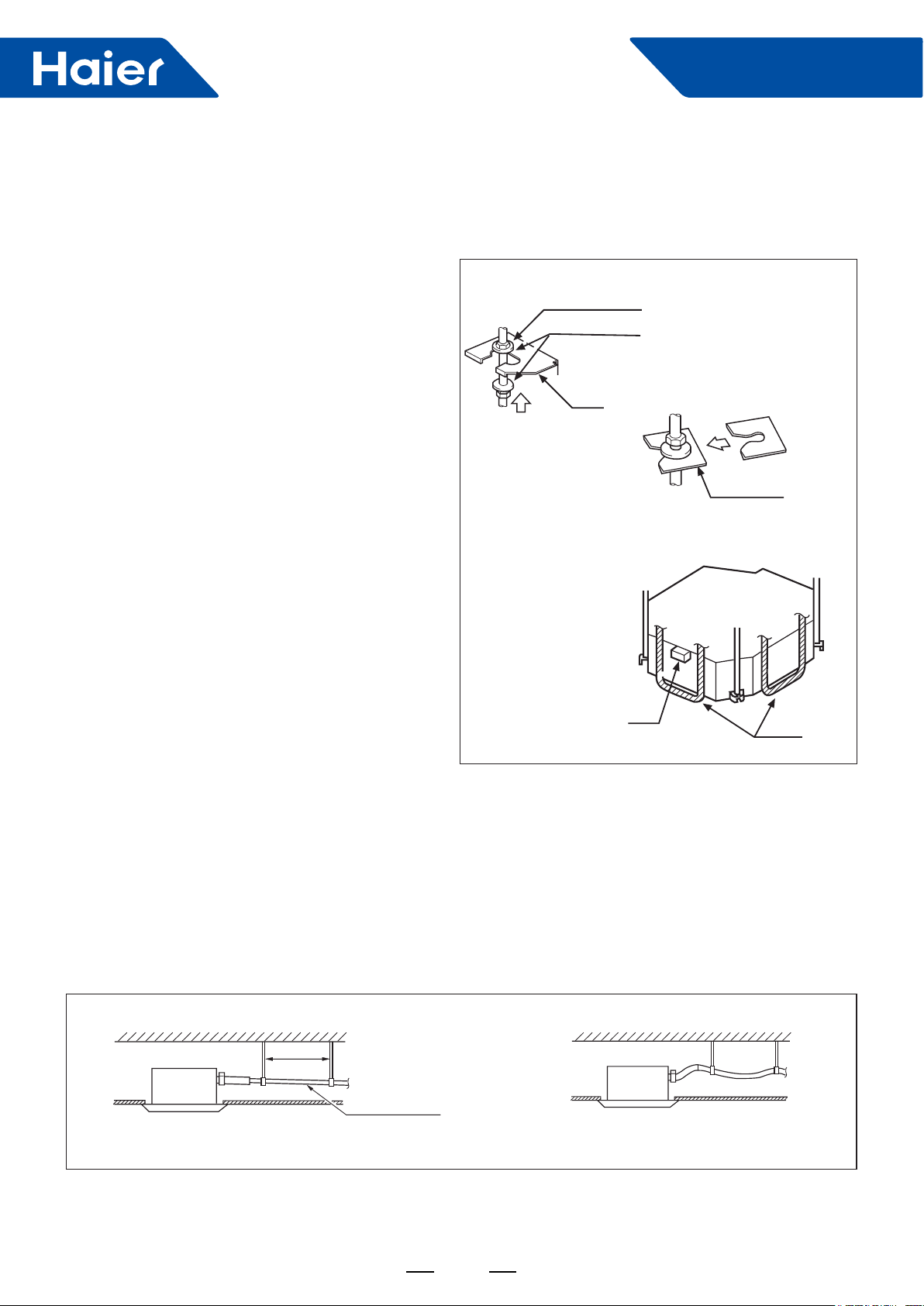

<Installation example>

Bolt

Long nut or threaded coupling

50-80mm

Hanging screw (M10)

Ceiling

Roof slab

7.4 Installation of indoor unit

Installation sequence on new ceiling: (1) → (3) → (4) → (5)

(1) Temporary installation of indoor unit

• Attach hangers to hanging screws, and make sure to

use nuts and washers on both upper and lower ends of

hangers so as to x them rmly. A washer xing plate

(to be provided on site) can prevent the washer from

dropping off.

<Work at ceilings>

(2) Adjust units to appropriate installation locations.

Refer to "7.3 Preparation before installation."

Tighten (double nuts)

[secure hanger]

Smart Power

Nut (to be provided on site)

Washer (to be provided on site)

Hanger

Insert

(3) Correct levelness of air conditioner units.

• The indoor unit is equipped with a built-in drainage

pump and a oat switch. Correct levelness with a level

or water-lled polyethylene pipe.

Washer xing plate

(to be provided on site)

[secure the washer]

Note:

If the unit inclines towards reverse direction of

condensate ow, the oat switch can not work normally

and water leakage will be resulted.

(4) Pull out the original xing plate that prevents the

washer from dropping off, and tighten nuts.

(5) Remove the installation cardboard.

7.5 Installation of drain pipe

(1) Install drain pipe

• Diameter of the drain pipe shall be greater than or equal to that of the connecting pipe.

(PE pipe: size: I.D.: 25mm; O.D.: 32mm)

• The drain pipe shall be short and have a downward slope of at least 1/100 to prevent pockets.

• If it is impossible to provide sufcient slope to the drain pipe, a drain lift pipe shall be installed.

• To avoid bending of the drain pipe, hangers shall be kept 1-1.5m away from each other.

Level

Polythene pipe

Correct

1-1.5m

Slope over 1/100

Wrong

26

Smart Power

Use a drain hose and clamp.

Insert the drain hose into the drainage outlet until it reaches the white tape. Then tighten the clamp.

For heat insulation, wind the drain hose with sealing gaskets. Provide heat insulation to indoor drain hose.

Clamp

Clamp (accessory)

Tape (White)

<Precautions for drain lift pipe>

The drain lift pipe shall be installed as low as possible.

The drain lift pipe shall be perpendicular to the unit and not more than 300mm away from the unit.

In 300mm 1-1.5m

Drain hose

Clamp

Drain hose

Hanger

202mm

Large-size sealing gasket (accessory)

Below 4mm

Drain hose

75 below

500 below

Note:

• The slope of accessory drain pipe shall be within 75mm so that the drainage outlet does not necessarily bear

excessive external force.

• If multiple drain pipes join together, install them as follows.

T-joint conuent drain pipe

Above

100mm

The size of conuent drain pipe selected shall be suitable for operating capacity of the units.

(2) Check drainage is smooth after installation.

• Check drainage by lling in 1200cc water slowly from air outlet or inspection hole.

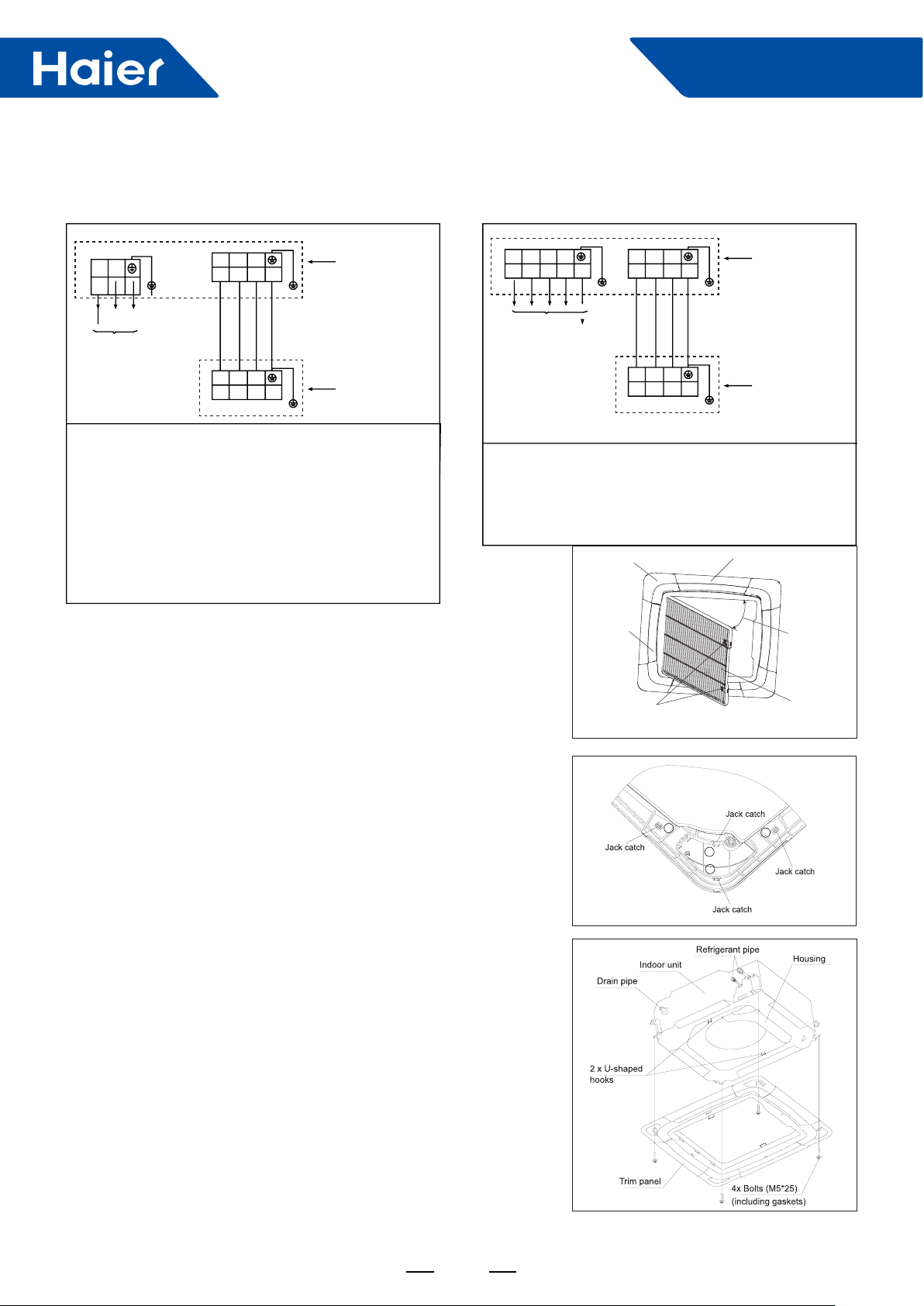

7.6 Installation instruction for embedded air-conditioning panel

1. Before installation

WARNING

The trim panel shall be put on buffer materials when unpacked to prevent being scratched by hard objects.

Please conrm the following accessories delivered with the product:

Bolt (M5*25) Qty: 4 Gasket Qty: 4

27

Connect and x the power supply cable, indoor-outdoor connection cable as following:

Smart Power

L N

Power supply:

1PH, 220-240V~,

50/60Hz

3

2

1

3

2

1

Outdoor unit

terminal blocks

Indoor unit

R S T N

Power supply:

380-415V, 3N~,

50/60Hz

terminal blocks

Power supply cable:

1UH071N1ERG, 1UH090N1ERG, 1UH105N1ERG:

H05RN-F 3G 4.0mm

1UH125P1ERG, 1UH140P1ERG:

H05RN-F 3G 6.0mm

Indoor and outdoor connection cable: H05RN-F 4G

2.5mm

2

2

2

For three phase power supply models:

1UH125P1ERK, 1UH140P1ERK

Power supply cable: H05RN-F 5G 4.0mm

Indoor and outdoor connection cable: H05RN-F 4G

2.5mm

2

2. Installation

(1) Conrming the position of unit hanger

Please conrm the installation position of the hanger for indoor unit

is about 130mm above the ceiling. For details, please refer to the

Instructions for Installation and Maintenance of indoor unit.

(2) Removing the air-inlet grille

Open the air-inlet grille to make it at an angle of 45° to the trim

panel. As shown in the following gure, please remove the air-inlet

grille as per the operation requirements.

(3) Installing the panel

1) Please remove the four (4) angle trim panels. Removal method: Flip

the jack catches of the angle trim panel in the order of

①②③④

, as

shown in the following gure. The ipping direction is indicated by the

arrows. Then the angle trim panel can be removed.

2) Pull out the two (2) U-shaped hooks on the indoor unit from below.

3) Adjust the panel direction to make the angle side engraved with "Pipe

side" consistent with the refrigerant pipe of the indoor unit, and make

the angle side engraved with "Drain side" consistent with the drain

side of the indoor unit. Then hang the 2 hooks in the inner side of the

panel on the 2 U-shaped hooks of the indoor unit.

4) Finally x the panel on the indoor unit with the bolts (M5*25) and

gaskets delivered with the unit.

Caution: Gaskets must be used for xing, or else the panel would be

easy to fall off.

5) When tightening the four (4) bolts, please make sure there is no

clearance between the panel xing seat on the side of the indoor

unit and the panel xing seat on the side of the panel. That is to say:

the bolts shall be fully tightened (see * in the gure) . If there is a

clearance, air leakage or water leakage is likely to occur.

3

2

1

3

2

1

Outdoor unit

terminal blocks

Indoor unit

terminal blocks

2

1

3

4

2

28

Smart Power

CAUTION

• Improper tightening of bolts would lead to the faults shown in

the following gure.

• After tightening the bolts, if there is a clearance between the

ceiling and the trim panel, please readjust the height of the

indoor unit.

If the elevation level of the indoor unit and drain pipe are not

affected, you can adjust the height of the indoor unit through the

corner pore on the trim panel. Please keep the unit horizontal

in the process of adjustment, or else water leakage is easy to

occur.

• Please do not swing the louver blade by hand, or else the

blade mechanism would be damaged.

6) Connection of trim panel. Connect the black lead-out terminal

of the panel to the black lead-out terminal of the indoor unit

housing.

7) When the installation of panel is complete, please x the four

(4) angle trim panels.

• Hang and tighten the strap of the angle trim panel on the

shackle of the trim panel, as shown in the gure.

• Fix the angle trim panel on the trim panel.

29

8) Installing the air-inlet grille.

Install the air-inlet grille with the steps opposite to that

for removing.

For reference

The method for removing angle trim panels when the

installation of trim panel is complete:

1) Insert a straight screwdriver in the notch① . Gently

turn the screwdriver downward, and slowly insert it in,

and then move it up and down to make the angle fall

off.

2) Make the angle②and③fall off in the same way.

3) Take off the angle trim panel by hand.

8. Test run

8.1 Check items

1. Indoor unit

• Is operation of each button on the remote control unit normal?

• Does each lamp light normally?

• Do not air ow direction louvers operate normally?

• Is the drain normal?

Smart Power

¢

¢

¢

2. Outdoor unit

• Is there any abnormal noise and vibration during operation?

• Will noise, wind, or drain water from the unit disturb the neighbors?

• Is there any gas leakage?

Customer guidance

Explain the following to the customer in accordance with the operation manual:

(1) Starting and stopping method, operation switching, temperature adjustment, timer, air ow switching, and other

remote control unit operations.

(2) Air lter removal and cleaning, and how to use air louvers.

(3) Give the operation and installation manuals to the customer.

8.2 Test run

This unit will be started instantly without "ON" operation when electric power is supplied. Be sure to execute "OFF"

operation before electric power is disconnected for servicing.

• This unit has a function of automatic restart system after recovering power stoppage

1. Before starting test run (for Heat pump models)

Conrm whether the power source breaker (main switch) of the unit has been turned on for over

12 hrs to energize the crankcase heater in advance of operation.

2. Test run

• Run the unit continuously for about 30 minutes, and check the following. Suction pressure at check joint of service

valve for gas pipe.

• Discharge pressure at check joint on the compressor discharge pipe.

• Temperature difference between return air and supply air for indoor unit.

30

Smart Power

Part 3 Indoor Units-Medium ESP Duct Type

1. Feature ..................................................................................................................................................................32

2. Specication ..........................................................................................................................................................34

3. Dimension..............................................................................................................................................................41

4. Wiring Diagram ......................................................................................................................................................43

5. Airow and Static Pressure Chart ..........................................................................................................................46

6. Instalaltion .............................................................................................................................................................49

7. Sound Pressure Level ...........................................................................................................................................58

31

1. Feature

250

250

mm

High Effciency

DC fan motor

Haier duct adopts DC fan motor, compared to conventional

AC fan motor, DC fan motor is more effciency.

Torque(kgfcm)

100

80

60

40

25%

35%

40%

Smart Power

Torque(kgfcm)

100

80

60

40

85%

87.5%

90%

Comfortable

Consistent airflow

The indoor units contain up to 3 fans which can provide

consistent airow in different ESP enhancing the comfort.

Flexible Design

Super slim

250mm of thickness for better installation application fexibility.

20

0

200 400 600 800 1000

Rev(r/min)

20

0

200 400 600 800 1000

AC motor efficiency DC motor efficiency

120Pa

100Pa

70Pa

50Pa

Air Flow

2500

m/h³

2500

100%

2000

1500

50po 70po 100po 120po

Common

Air Flow

2500

2500

m/h³

100%

2000

1500

50po 70po 100po 120po

m/h³

2500

2500

100%

100%

2250

m/h³

90%

1900

250

Rev(r/min)

m/h³

2500

m/h³

76%

1700

mm

100% airflow when the ESP

m/h³

100%

reach 120pa for Haier duct

ESP

Oniy 68% airflow when the ESP

reach 120pa for traditional duct

m/h³

68%

ESP

Return air choices

Friendly design: Rear air return or bottom air return

is available.

Rear air return

Bottom air return

32

Smart Power

High lift-up drain pump

It can lift condensed water up to 750mm, which make

installation more exible according to the layout.

Adjustable E.S.P control

Because of the DC fan motor, the duct unit can adjust

E.S.P :10/30/50/70Pa(7.1kW,8.2kW), 30~120Pa

(10,12.5,14kW) by the wired controller, it can optimise air

duct work installation, maintain airow and sound levels

as required.

H

Air volume

M

L

Max.

750mm

H

M

L

External Statlc Pressure(E.S.P)

E.S.P setting(Pa) 30 40 50 60 70 80 90 100 110 120

33

Smart Power

2. Specication

Item Model ADH071M1ERG/1UH071N1ERG

Function Cooling Heating

Capacity

Sensible heat ratio

Total power input

Max. power input

AEER or ACOP Dehumidifying capacity

Connection cable( from outdoor to indoor)

Power source

Running/Max.

Running current Start current

Circuit breaker

Unit model (color) ADH071M1ERG

Type×Number CENTRIFUGALX2

Speed (H-M-L)

Fan

Fan motor output/ input power

Air-ow (H-M-L)

External static pressure

Type / Diameter

Row 3

Total area

External (L×W×H)

Package (L×W×H)

Indoor

unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.)

Controller (O-Optional, S-Standard)

Fresh air hole dimension

Electricity heater

Sound power noise level (H)

Sound pressure noise level (H-M-L)

Weight (Net/Shipping)

Refrigerant

Type / Charge g R410A/2500

Recharge quantity g/m 45

Liquid m 9.52

Gas mm 15.88

Max.pipe lengh without

Piping

Pipe

charge refrigerant

Between

I.D &O.D

MAX.Drop m 30

MAX.Piping length m 50

Connecting method Flared

Cooling Pdesignc (kW): 7.1kW SEER/CLASS 6.3/A++

Average Pdesignh (-10°C) 6.0kW SCOP/CLASS

Heating

Warmer Pdesignh (2°C) 6.0kW SCOP/CLASS

Colder Pdesignh (-22°C) / SCOP/CLASS

Tdesignh: -10°C Tbivalent: -10°C TOL: -15°C Elbu: 0

Max. cooling

condition

Indoor temperature: 32°C/23°C

Outdoor temperature: 46°C/-°C Outdoor temperature: 24C/18C

Max. heating condition

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

kW

7.1 (2.0~9.0) 8 (2.0~10.0)

0.72 /

10

kW

W

W/W

-3×m3

/h

2.03 (0.4~4.0) 2.0 (0.4~4.0)

4000 4000

3.41 3.89

N, V, Hz

A/A

8.8 (2.0-17.5) /17.5 9.2 (2.0-17.5) /17.5

A

A

1ph,30A (from outdoor)

r/min

W

3

m

/h

Pa

mm

m

2

Inner grooved pipe/φ7.0

mm×mm×mm

mm×mm×mm

mm

Wired

YR-E16A(O)/YR-E17(S)

Infrared

mm

kW

dB (A)

dB (A)

kg / kg

mm 20

QCE(Annual electricity

consumption for cooling)kWh:

4.2/A+

4.8/A++

QHE(Annual electricity

consumption for heating)kWh:

/

Indoor temperature: 27°C/-°C

H05RN-F 4G 2.5mm2

2

4.0mm

1, 220-240, 50/60

3

950/860/760

85/111

1050/840/630

10/30(default)/50/70

7.668

957/655/250

1170/860/340

PVC 25/29

YR-HBS01(O)

145

/

58

38/35/32

31.2/36.8

390

1982

1652

/

34

Smart Power

Item Model ADH071M3ERG/1UH071N1ERG

Function Cooling Heating

Capacity kW 7.1(2.0~9.0) 8(2.0~10.0)

Sensible heat ratio 0.72 /

Total power input kW 2.03(0.4~4.0) 2.0(0.4~4.0)

Max. power input W 4000 4000

AEER or ACOP W/W 3.41 3.89

Dehumidifying capacity 10

Power cable 4.0mm

Power source N, V, Hz 1, 220~240, 50/60

Running/Max. Running current A/A

Start current A 0.52

Circuit breaker A

Unit model (color)

Type×Number

Speed (H-M-L) r/min

Fan

Fan motor output/ input power kW

Air-ow (H-M-L) m

External static pressure Pa

Type/Diameter mm

Total area m

External (L×W×H) mm×mm×mm 957/655/250

Package (L×W×H) mm×mm×mm 1170/860/340

Indoor

unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 25/29

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 145

Electricity heater kW /

Sound power noise level (H) dB (A) 58

Sound pressure noise level (H) dB (A) 38/35/32

Weight (Net / Shipping) kg / kg 31.2/36.8

Refrigerant

Type / Charge g R410A/2500

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max.pipe lengh without

Piping

Pipe

charge refrigerant

Between

I.D&O.D

MAX.Drop m 30

MAX.Piping length m 50

Connecting method Flared

Cooling Pdesignc (kW): 7.1kW SEER/CLASS 6.3/A++

Average Pdesignh (-10°C) 6.0kW SCOP/CLASS

Heating

Warmer Pdesignh (2°C) 6.5kW SCOP/CLASS

Colder Pdesignh (-22°C) / SCOP/CLASS

Tdesignh: -10°C Tbivalent: -10°C TOL: -15°C Elbu: 0

Max. cooling

condition

Indoor temperature: 32°C/23°C

Outdoor temperature: 46°C/-°C Outdoor temperature: 24C/18C

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

-3×m3

/h 2.4

2

8.8(2.0-17.5)/17.5 9.2(2.0-17.5)/17.5

1Ph,30A(from outdoor)

ADH071M3ERG

CENTRIFUGALX2

1050/950/850/750

0.27/0.2

3

/h

1450/1200/950/700

25/37/50/70/90/100/110/120/130/150

Inner grooved pipe/φ7.0

2

7.668

Wired YR-E16A(O)/YR-E17(S)

Infrared YR-HBS01 (O)

20

QCE(Annual electricity

consumption for cooling)kWh:

4.2/A+

4.8/A++

Max. heating condition

QHE(Annual electricity

consumption for heating)kWh:

/

Indoor temperature: 27°C/-°C

390

1982

1652

/

35

Smart Power

Item Model ADH090M1ERG/1UH090N1ERG

Function Cooling Heating

Capacity kW 8.5 (2.5~10) 9.5 (2.5~11)

Sensible heat ratio 0.72 /

Total power input kW 2.50 (0.5~4.4) 2.50 (0.5~4.4)

Max. power input W 4400 4400

AEER or ACOP W/W 3.33 3.72

Dehumidifying capacity 10

Power cable 4.0mm

Power source N, V, Hz 1, 220-240, 50/60

Running/Max. Running current A/A

Start current A 3

Circuit breaker A

Unit model (color) ADH090M1ERG

Type×Number CENTRIFUGALX2

Speed (H-M-L) r/min 1020/920/820

Fan

Fan motor output/ input power W 112/147

Air-ow (H-M-L) m

External static pressure Pa 10/30(default)/50/70

Type/Diameter mm Inner grooved pipe/φ7.0

Row 3

Total area m

External (L×W×H) mm×mm×mm 957/655/250

Package (L×W×H) mm×mm×mm 1170/860/340

Indoor

unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 25/29

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 145

Electricity heater kW NONE

Sound power noise level (H) dB (A) 60

Sound pressure noise level (H-M-L) dB (A) 40/37/34

Refrigerant

Type / Charge g R410A/2500

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max.pipe lengh without

Piping

Pipe

charge refrigerant

Between

I.D &O.D

MAX.Drop m 30

MAX.Piping length m 50

Connecting method Flared

Cooling Pdesignc (kW): 8.5kW SEER/CLASS 6.1/A++

Average Pdesignh (-10°C) 7.0kW SCOP/CLASS

Heating

Warmer Pdesignh (2°C) 7.8kW SCOP/CLASS

Colder Pdesignh (-22°C) / SCOP/CLASS

Tdesignh: -10°C Tbivalent: -10°C TOL: -15°C Elbu: 0

Max. cooling

condition

Indoor temperature: 32°C/23°C

Outdoor temperature: 46°C/-°C Outdoor temperature: 24C/18C

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

-3×m3

/h 2.5

2

11.1 (2.3-19.2) /19.2 11.1 (2.3-19.2) /19.2

1Ph,30A(from outdoor)

3

/h 1300/900/700

2

/

Wired YR-E16A(O)/YR-E17(S)

Infrared YR-HBS01(O)

m 20

QCE(Annual electricity

consumption for cooling)kWh:

4.1/A+

4.8/A++

Max. heating condition

QHE(Annual electricity

consumption for heating)kWh:

/

Indoor temperature: 27°C/-°C

485

2256

1928

/

36

Smart Power

Item Model ADH105M1ERG/1UH105N1ERG

Function Cooling Heating

Capacity kW 10 (2.5~11) 10.4 (2.5~12)

Sensible heat ratio 0.72 /

Total power input kW 2.93(0.5~4.5) 2.97 (0.5~4.5)

Max. power input W 5000 5000

AEER or ACOP W/W 3.37 3.46

Dehumidifying capacity 10

Power cable 4.0mm

Power source N, V, Hz 1, 220~240, 50/60

Running/Max. Running current A/A

Start current A 3

Circuit breaker A

Unit model (color)

Type×Number

Speed (H-M-L) r/min

Fan

Fan motor output/ input power kW

Air-ow (H-M-L) m

External static pressure Pa

Type/Diameter mm

Total area m

External (L×W×H) mm×mm×mm 1500/700/250

Package (L×W×H) mm×mm×mm 1710/865/320

Indoor

unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 26/32

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 100

Electricity heater kW /

Sound power noise level (H) dB (A) 55

Sound pressure noise level (H) dB (A) 32/28/25/23

Weight (Net / Shipping) kg / kg 49/61

Refrigerant

Type / Charge g R410A/2500

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max.pipe lengh without

Piping

Pipe

charge refrigerant

Between

I.D&O.D

MAX.Drop m 30

MAX.Piping length m 50

Connecting method Flared

Cooling Pdesignc (kW): 10kW SEER/CLASS 6.7/A++

Average Pdesignh (-10°C) 9.7kW SCOP/CLASS

Heating

Warmer Pdesignh (2°C) 10.2kW SCOP/CLASS

Colder Pdesignh (-22°C) / SCOP/CLASS

Tdesignh: -10°C Tbivalent: -10°C TOL: -15°C Elbu: 0

Max. cooling

condition

Indoor temperature: 32°C/23°C

Outdoor temperature: 46°C/-°C Outdoor temperature: 24C/18C

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

-3×m3

/h 3.2

2

13.3 (2.3-19.0) /21.0 13.5 (2.3-19.0) /21.0

1Ph,

40A (from outdoor)

ADH105M1ERG

CENTRIFUGALX3

1050/950/850

0.16/0.2

3

/h

2000/1740/1380/1280

30-120

Inner grooved pipe/φ7.0

2

/

Wired YR-E16A(O)/YR-E17(S)

Infrared YR-HBS01 (O)

20

QCE(Annual electricity

consumption for cooling)kWh:

4.0/A+

4.8/A++

Max. heating condition

QHE(Annual electricity

consumption for heating)kWh:

/

Indoor temperature: 27°C/-°C

548

3624

2976

/

37

Smart Power

Item Model ADH125M1ERG/1UH125P1ERG

Function Cooling Heating

10

kW

kW

W

W/W

-3×m3

/h

12.5 (3.5~15.0) 13.7(4~18.0)

3.67 (1.0~6.5) 3.91 (1.0~6.5)

6500 6500

3.37 3.47

N, V, Hz

17.0 (8.7-30.0) /30A 17.5 (8.7-30.0) /30A

A

A

r/min

kW

3

m

/h

Pa

mm

2

m

mm×mm×mm

mm×mm×mm

mm

Wired

Infrared

mm

kW

dB (A)

dB (A)

kg / kg

g

g/m

m 30

4.9

2

1ph, 220~240, 50/60

3

40

1100/1000/950

0.32/0.4

2250/1960/1680

30-120

Inner grooved pipe/φ7.0

/

1500/700/250

1710/865/320

PVC 26/32

YR-E17 (S)/YR-E16A(O)

YR-HBS01 (O)

125

/

62

39/36/33/31

52/62

R410A/3700

45

Capacity

Sensible heat ratio 0.74 /

Total power input

Max. power input

AEER or ACOP

Dehumidifying capacity

Power cable 6.0mm

Power source

Running/Max. Running current A/A

Start current

Circuit breaker

Unit model (color) ADH125M1ERG

Type×Number CENTRIFUGALX3

Speed (H-M-L)

Fan

Fan motor output power/input power

Air-ow(H-M-L)

ESP

Type/Diameter

Total area

External (L×W×H)

Package (L×W×H)

Indoor

unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.)

Controller (O-Optional, S-Standard)

Fresh air hole dimension

Electricity heater

Sound power noise level (H)

Sound pressure noise level (H-M-L)

Weight (Net / Shipping)

Refrigerant

Type / Charge

Recharge quantity

Liquid mm 9.52

Gas mm 15.88

Max.pipe lengh without

Piping

Pipe

charge refrigerant

Between

I.D&O.D

MAX.Drop m 30

MAX.Piping length m 75

Connecting method Flared

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

38

Smart Power

Item Model ADH125M1ERG/1UH125P1ERK

Function Cooling Heating

Capacity kW 12.5 (3.5~15.0) 13.7(4~18.0)

Sensible heat ratio 0.74 /

Total power input kW 3.67 (1.0~6.5) 3.91 (1.0~6.5)

Max. power input W 7000 7000

AEER or ACOP W/W 3.37 3.47

Dehumidifying capacity 10

Power cable 4.0mm

Power source N, V, Hz 3, 380~415, 50/60

Running/Max. Running current A/A

Start current A 3

Circuit breaker A

Unit model (color) ADH125M1ERG

Type×Number CENTRIFUGALX3

Speed (H-M-L) r/min 1200/1050/900

Fan

Fan motor input power/output power kW 0.32/0.4

Air-ow (H-M-L) m

ESP Pa 30-120

Type/Diameter mm Inner grooved pipe/φ7.0

Total area m

External (L×W×H) mm×mm×mm 1500/700/250

Package (L×W×H) mm×mm×mm 1710/865/320

Indoor

unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 26/32

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 125

Electricity heater kW /

Sound power noise level (H) dB (A) 62

Sound pressure noise level (H-M-L) dB (A) 39/36/33/31

Weight (Net / Shipping) kg / kg 52/62

Refrigerant

Pipe

Piping

Type / Charge g R410A/3700

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max.pipe lengh without

charge refrigerant

Between

I.D&O.D

MAX.Drop m 30

MAX.Piping length m 75

Connecting method Flared

-3×m3

/h 4.9

2

6.1/10.8 6.5/10.8

3Ph,40A (from outdoor)

3

/h 2250/1960/1680/1500

2

/

Wired YR-E17(S)/YR-E16A(O)

Infrared YR-HBS01 (O)

m 30

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

39

Smart Power

Item Model ADH140M1ERG/1UH140P1ERK

Function Cooling Heating

Capacity kW 13.4 (3.5~16) 15.0 (4.0~19.0)

Sensible heat ratio 0.74 /

Total power input kW 4.05 (1.0~6.5) 4.29 (1.2~6.5)

Max. power input W 7200 7200

AEER or ACOP W/W 3.27 3.47

Dehumidifying capacity 10

Power cable 4.0mm

Power source N, V, Hz 3,380~415, 50/60

Running/Max. Running current A/A

Start current A 3

Circuit breaker A

Unit model (color) ADH140M1ERG

Type×Number CENTRIFUGALX3

Speed (H-M-L) r/min 1250/1120/900

Fan

Fan motor input power/output power kW 0.32/0.4

Air-ow (H-M-L) m

ESP Pa 30-120

Type/Diameter mm Inner grooved pipe/φ7.0

Total area m

External (L×W×H) mm×mm×mm 1500/700/250

Package (L×W×H) mm×mm×mm 1710/865/320

Indoor

unit

Heat

exchanger

Dimension

Drainage pipe (material, I.D./O.D.) mm PVC 26/32

Controller (O-Optional, S-Standard)

Fresh air hole dimension mm 125

Electricity heater kW /

Sound power noise level (H) dB (A) 64

Sound pressure noise level (H-M-L) dB (A) 41/36/33

Weight (Net / Shipping) kg / kg 52/63

Refrigerant

Type / Charge g R410A/3700

Recharge quantity g/m 45

Liquid mm 9.52

Gas mm 15.88

Max.pipe lengh without

Piping

Pipe

charge refrigerant

Between

I.D&O.D

MAX.Drop m 30

MAX.Piping length m 75

Connecting method Flared

Norminal condition:

Indoor temperature (cooling) : 27DB (°C)/19WB (°C) , Indoor temperature (heating) : 20DB (°C)

Outdoor temperature (cooling) : 35DB (°C)/24WB (°C) , Outdoor temperature (heating) : 7DB (°C)/6WB (°C)

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter. It is a sound pressure noise level.

-3×m3

/h 5.2

2

6.8(2.9-10.5)/11.0 7.0(2.9-10.5)/11.0

3Ph,40A (from outdoor)

3

/h 2500/2160/1780

2

/

Wired YR-E17(S)/YR-E16A (O)

Infrared YR-HBS01 (O)

m 30

40

Smart Power

3. Dimension

3.1 ADH071M1ERG ADH071M3ERG ADH090M1ERG

air inlet

air outlet

41

3.2 ADH105M1ERG AD1H125M1ERG ADH140M1ERG

Smart Power

return air

supply air

42

Smart Power

4. Wiring Diagram

ADH071M1ERG ADH090M1ERG

0150519911

REMOTE RECEIVER

CONNECT TO THIRD PARTY RELAY

RATING_12VDC

ELECTRIC HEATING TERMINAL

B:BLACK

R:RED

W:WHITE

Y/G:YELLOW/GREEN

ROOM

FLOAT

SWITCH

WIFI

ROOMCARD

SENSOR

TEMP.

CN29

CN5

CN19

87654321

CN18

4321

CN7

CN36

CN6

CN13

CN15

CN16

OFF

ON

SW1

SW2

ON

OFF

FUSE

CN22

CN8

T5A/250VAC

C

B A

CN23

CN1

CN14

CN9

CH2

M

PUMP

CN37

CH3

CN4

CH1

C

B

A

WIRED

Y/G

R

3

2

B

1

W

CONTROLLER

TO OUT DOOR

Static

pressure

1st level

OFF

SW1-5

OFF

SW1-4

Type define

Medium ESP DUCT

OFF

SW1-8

ON

SW1-7

Room card

available

unavailable

ON

OFF

SW1-6

4th level

3rd level

2nd level

ON

OFF

ON

ON

OFF

ON

PIPING TEMP.

SENSOR

R O T O M N A F C D

M

NOTE:

USER SHOULD NOT SET SW1

1.DASHED PARTS ARE

OPTIONAL.

2.

AND SW2 WITHOUT GUIDENCE.

3.THE BRIDGE (CN22 CN23) ON SLAVE

UNITS PCB SHOULD BE CUT OFF WHEN

43

7.1

9.0

CAPACITY

(KW)

ON OFF ON

OFF ON ON

/ / /

/

SW1-3

SW1-2

SW1-1

ONE WIRED CONTROLLER CONTROL MORE

THAN ONE UNIT.

4.REFER TO INSTALLATION MANULTO

GET MUCH MORE DETAILS ABOUT THE

STATIC PRESSURE LEVEL SELECTION.

ADH071M3ERG

Smart Power

ROTOM NAF CD

0150523302

M

CN6

CN21

PUMP

M

CN4

ON

OFF

SW03

12345678

CN41

M

CN5

ROOM

FRESH AIR MOTOR

(SW01-6 select OFF) /

EXTERNAL ALARM OUTPUT

(SW01-6 select ON)

( Contact rating_230VAC,3A)

CH1

CH2

Heater_N

3

2

CN1

1

N L S

FUSE

TO OUT DOOR

CH4

SENSOR

TEMP.

MODEL

FOR ALL DUCTED

MODEL

AD71S2SM1FA

Y/G:YELLOW/GREEN

SW01-8

SW03-8

SW03-7

Y/G

OFF

OFF

SW01-7

OFF

SW01-6

3

OFF

SW03-4 SW03-5 SW03-6

SW03-3

SW03-2

OFF OFF OFF OFF OFF OFF OFFON

SW03-1

SW01-5

SW01-4

OFF

SW01-3

ON

SW01-2

ON

SW01-1

OFF

2

1

AM24LP2VHA

OFF

OFF

OFF

OFF

OFF

ON

ON

AD50S2SM1FA

ADH071M3ERG

ON

ON

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

OFF

REMOTE RECEIVER

CN34

WIFI

MODULE

ROOMCARD

SW01

12345678

ON

OFF

CN16

FLOAT

SWITCH

PIPING

CN13

SENSOR

TEMP.

Heater_L

A

B

C

CN22

B A

C

CN22-1

B A

C

CONTROLLER

WIRED

NOTE:

1.DASHED PARTS ARE OPTIONAL.

2.SW03-4 IS AT ON POSITION,DO NOT CHANGE

THE SETTINGS OF SWITCHS WITHOUT GUIDANCE.

3.WHEN ONE WIRED CONTROLLER CONTROL MULTIPLE INDOOR UNIT,

IT CAN CONNECT ANOTHER INDOOR UNIT BY CN22 OR CN22-1.

WHEN TWO WIRD CONTROLLERS CONTROL ONE INDOOR UNIT,

THE WIRED CONTROLLER NEED CONNECT WITH CN22 AND CN22-1.

ADDRESS SETTING ON THE

->SW03-08 IS USED FOR

4.SW03-5

SITUATION OF ONE WIRED CONTROLLER CONTROL MORE THAN

ONE INDOOR UNIT.

5.REFER TO SERVICE MANUL TO GET MUCH MORE DETAILS

ABOUT THE STATIC PRESSURE LEVEL SELECTION.

44

Smart Power

WHT:white YL:yellow

ADH105&125&140M1ERG

0150517885