Page 1

CASSETTE TYPE AIR CONDITIONER

Indoor Unit Operation & Installation

Manual

AB094FAAHA

AB124FAAHA

AB184FCAHA

AB244FCAHA

AB424FCAHA

AB484FCAHA

No.0010576722A

Please read this operation manual before using the air conditioner.

Please keep this manual carefully and safely.

Page 2

Contents

Cautions

Part name of the unit

Maintenance

Trouble Shooting

When Trouble Happens

Customer Need-to-know

Installation Procedure

Electrical Wiring..............................................................................

Technical Specification

...........................................................................................

........................................................................

......................................................................................

..........................................................................

..................................................................

.....................................................................

....................................................................

....................................................................

10-11

1-5

6

7-9

12-13

14

15-25

26-28

29

Page 3

Cautions

Disposal of the old air conditioner

Before disposing an old air conditioner

that goes out of use, please make sure it's

inoperative and safe. Unplug the air

conditioner in order to avoid the risk of

child entrapment.

It must be noticed that air conditioner

system contains refrigerants, which require

specialized waste disposal. The valuable

materials contained in a air conditioner can

be recycled. Contact your local waste

disposal center for proper disposal of an

old air conditioner and contact your local

authority or your dealer if you have any

question. Please ensure that the pipework

of your air conditioner does not get

damaged prior to being picked up by the

relevant waste disposal center, and

contribute to environmental awareness by

insisting on an appropriate, anti-pollution

method of disposal.

Disposal of the packaging of your new

air conditioner

All the packaging materials employed in

the package of your new air conditioner

may be disposed without any danger to the

environment.

The cardboard box may be broken or cut

into smaller pieces and given to a waste

paper disposal service. The wrapping bag

made of polyethylene and the polyethylene

foam pads contain no fluorochloric

hydrocarbon.

Consult your local authorities for the name and

address of the waste materials collecting

centers and waste paper disposal services

nearest to your house.

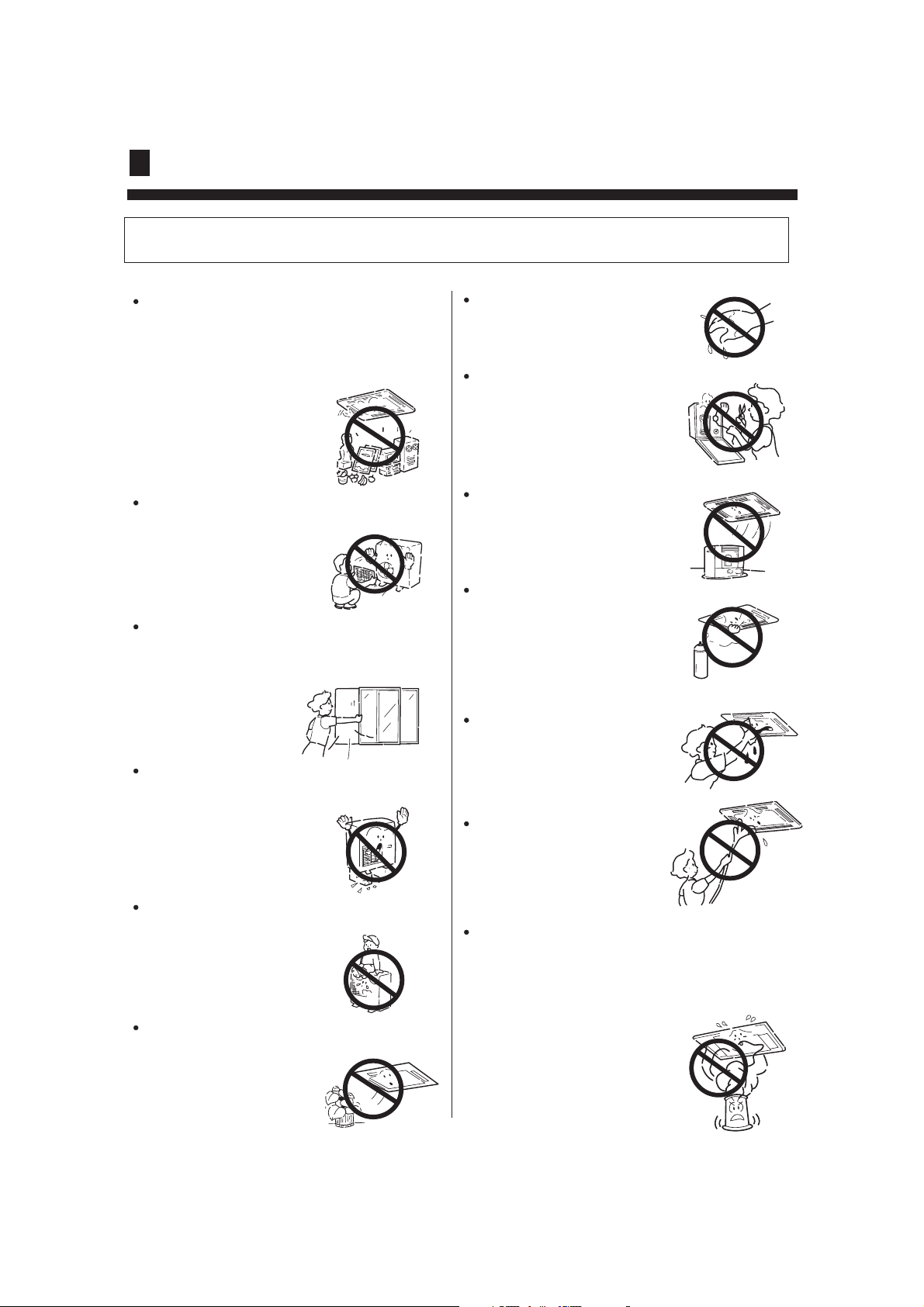

Safety Instructions and Warnings

Before starting the air conditioner, read the

information given in the User's Guide

carefully. The User's Guide contains very

important observations relating to the

assembly, operation and maintenance of the

air conditioner.

The manufacturer does not accept

responsibility for any damages that may

arise due to non-observation of the following

instruction.

Damaged air conditioners are not to be

put into operation. In case of doubt, consult

your supplier.

Use of the air conditioner is to be carried

out in strict compliance with the relative

instructions set forth in the User's Guide.

Installation shall be done by professional

people, don't install unit by yourself.

For the purpose of safety, the air

conditioner must be properly grounded in

accordance with specifications.

Always remember to unplug the air

conditioner before opening inlet grill. Never

unplug your air conditioner by pulling on the

power cord. Always grip plug firmly and

pull straight out from the outlet.

All these valuable materials may be taken to a

waste collecting center and used again after

adequate recycling.

1

Page 4

Cautions

All electrical repairs must be carried out

by qualified electricians. Inadequate repairs

may result in a major source of danger for

the user of the air conditoiner.

Do not damage any parts of the air

conditioner that carry refrigerant by

piercing or perforating the air conditioner's

tubes with sharp or pointed items, crushing

or twisting any tubes, or scraping the

coatings off the surfaces. If the refrigerant

spurts out and gets into eyes, it may result

in serious eye injuries.

Do not obstruct or cover the ventilation

grille of the air conditioner. Do not put

fingers or any other things into the

inlet/outlet and swing louver.

Do not allow children to play with the air

conditioner. In no case should children be

allowed to sit on the outdoor unit.

4. The wiring method should be in line with the

local wiring standard.

5. The power cable and connecting cable are

self-provided. The requirement of the power

cable:

H05RN-F 3G 1.5mm

2

The requirement of the connecting cable:

H05RN-F 2¡`(1.0~1.5)mm

2

All the cables shall have got the European

authentication certificate.

6. The breaker of the air conditioner should be

all-pole switch; and the distance between its two

contacts should be no less 3mm. Such means for

disconnection must be incorporation in the fixed

wiring.

7. The waste battery shall be disposed properly.

8. The indoor unit installation height is at least

2.5m.

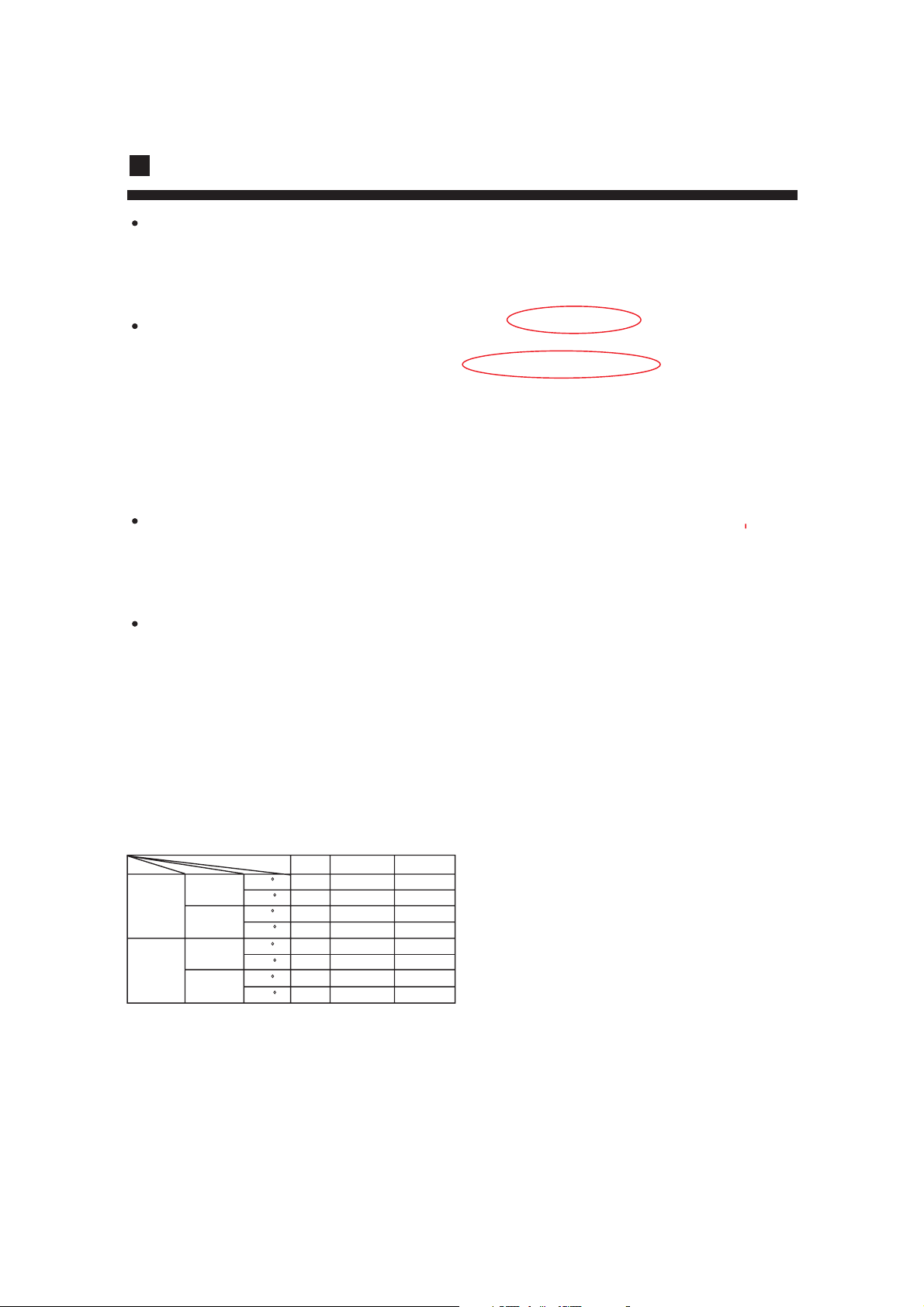

Specifications

The refrigerating circuit is leak-proof.

The machine is adaptive in following

situation

1. Applicable ambient temperature range:

Rated Maximum Minimum

27 32 21

DB C

19.5 23 15

WB C

DB C

35 43 21

WB C

24 26 15

20 27 20

DB C

15 15 15

WB C

7 21 -10

DB C

6 15 --

WB C

Cooling

Heating

Indoor

outdoor

Indoor

outdoor

2. If the supply cord is damaged, it must be

replaced by the manufacturer or its service

agentor a similar qualified person.

3. If the fuse on PC board is broken please

change it with the type of T 3.15A /250VAC.

2

Page 5

Cautions

Safety cautions

Carefully read the following information in order to operate the airconditioner correctly.

Below are listed three kinds of Safety Cautions and Suggestions.

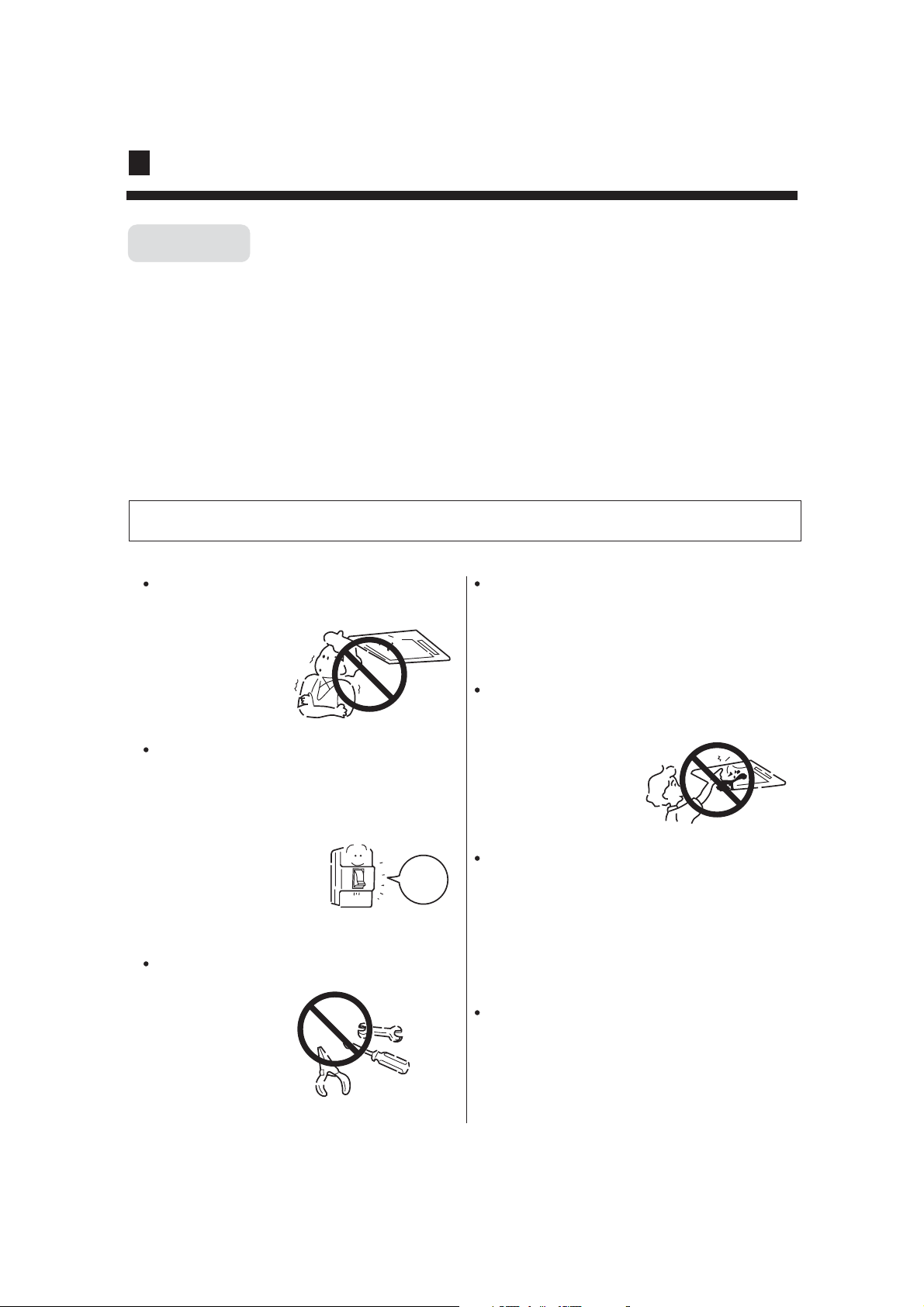

WARNING!

CAUTION!

INSTRUCTIONS: These information can ensure the correct operation of the machine.

Be sure to conform with the following important Safety Cautions.

The Safety Cautions should be at hand so that they can be checked at any time when needed.

If the conditioner is transferred to the new user, this manual should be as well transferred to the new user.

Incorrect operations may result in severe consequences of death or serious injuries.

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

WARNING!

Don't blow the human body with the cooling

air too long, and don't let the room tempera-

ture decrease too low

either.

Otherwise the one

will feel unpleasant

or harm ones' health.

If any abnormal phenomena is found (e. g.

smell of firing), please cut off the power

supply immediately, and contact the dealer

to find out the handling method.

In such case, to continue

using the conditioner will

damage the conditioner,

and may cause electrical

shock or fire hazard.

When need maintenance and repairment,

call dealer to handle it.

Incorrect mainten-

ance and repairment

may cause water

leak, electrical shock

and fire hazard.

switch

off

Please let the dealer be responsible for installing

the conditioner.

Incorrect installation may cause water leak, elec-

trical shock and fire hazard.

Don't put fingers or any other things into the

inlet/outlet and swing louver while the condi-

tioner is in operation.

Because the highspeed

fan is very dangerous

and may cause injuries.

Call the dealer to take measures to prevent the

refrigerant from leaking.

If conditioner is installed in a small room be sure

to take every measure in order to prevent suffoca-

tion accident even in case of refrigerant leakage.

When conditioner is deinstalled or reinstalled

dealer should be responsible for them.

Incorrect installation may cause water leaking,

electrical shock and fire hazard.

3

Page 6

Cautions

CAUTIONS!

Conditioner should not be used for any other

purpose other than airconditioning.

Don't use air-conditioner for any other special

purposes, e.g. the preservation and protection

of food, animals, plants,

pecision apparatus as well

as work of art, otherwise

the qualities of these

stuffs may be damaged.

Don't dismantle the outlet of the outdoor unit.

The exposure of fan is

very dangerous which

may harm human beings.

When air-conditioner is co-used with other

heat-radiator the frequent replacement of

room atmosphere should be required.

Inefficient ventilation may cause

suffocation.

After a long time use of air-conditioner the

base should be checked for any damages.

If the damaged base is

not repaired, the unit

may fall down and

cause accidents.

No goods or nobody is permitted to placed on

or stand on outdoor unit.

The falling of goods and

people may cause accidents.

Pets and plants should not be blowed directly

in the air flow.

Otherwise will suffer

damage.

Don't operate the air-conditioner with damp hands.

Otherwise will be shocked.

Only use correctly-typed fuse.

May not use wire or any other

materials replacing fuse, otherwise may cause faults or fire

accidents.

Don't place any burning unit

in the air flow of air-conditioner,

which may cause incomplete

combustion.

No inflammable spray fluid

should be permitted to be

placed or used near to airconditioner otherwise may

cause fire accidents.

Air-conditioner should be

cleaned only after power

supply is cut off to keep

from shock or hurt.

Don't clean air-conditioner

with water.

Otherwise may cause

shock.

When use the fumigating insecticide don't

open air-conditioner.

Otherwise the poisonous chemicals may settle

in air-conditioner which harm the health of

chemical-allergic people.

4

Page 7

Cautions

Installation

Please ask the dealer or specialist to install, never try by the users themselves. After the installation please

be sure of the following conditions.

WARNING !

Please call dealer to install the air-conditioner.

Incorrect installation may cause water leaking, shock and fire hazard.

CAUTION !

Air-conditioner can't be installed in the environment with inflammable gases because the

inflammable gases near to air-conditioner may

cause fire hazard.

Installed electrical-leaking circuit breaker.

It easily cause electrical shock without circuit

breaker.

[Location]

Air-conditioner should be located in well-vented

and easily-accessible place.

Air-conditioner should not be located in the

following places:

(a) Places with machine oils or other oil vapours.

(b) Seaside with high salt content in the air.

(c) Near to hot spring with high content of sulfide

gases.

(d) Area with frequent fluctuation of voltage e.g.

factory, etc.

(e) In vehicles or ships.

(f) Kitchen with heavy oil vapour or humidity.

(g) Near to the machine emitting electric-magnetic

waves.

(h) Places with acid, alkali vapuor.

TV, radio, acoustic appliances etc are at least 1 m

far away to the indoor unit, outdoor unit, power

supply wire, connecting wire, pipes, otherwise

images may be disturbed or noises be created.

Connect earthing wire.

Earthing wire should not be connected to the gas pipe, water pipe,

lightning rod or phone line, incorrect earthing may cause shock.

Use discharge pipe correctly to ensure efficient

discharge.

Incorrect pipe use may cause water leaking.

As required, take measures against heavy snow.

Earthing

[Wiring]

Air-conditioner should be equipped with special

power supply wire.

[Operating noise]

Choose the following locations:

(a) Capable of supporting air-conditioner weight,

don't increase operating noise and vibration.

(b) Hot vapour from outdoor unit outlet and ope rating noise don't disturb neighbour.

No obstacles around the outdoor unit outlet.

5

Page 8

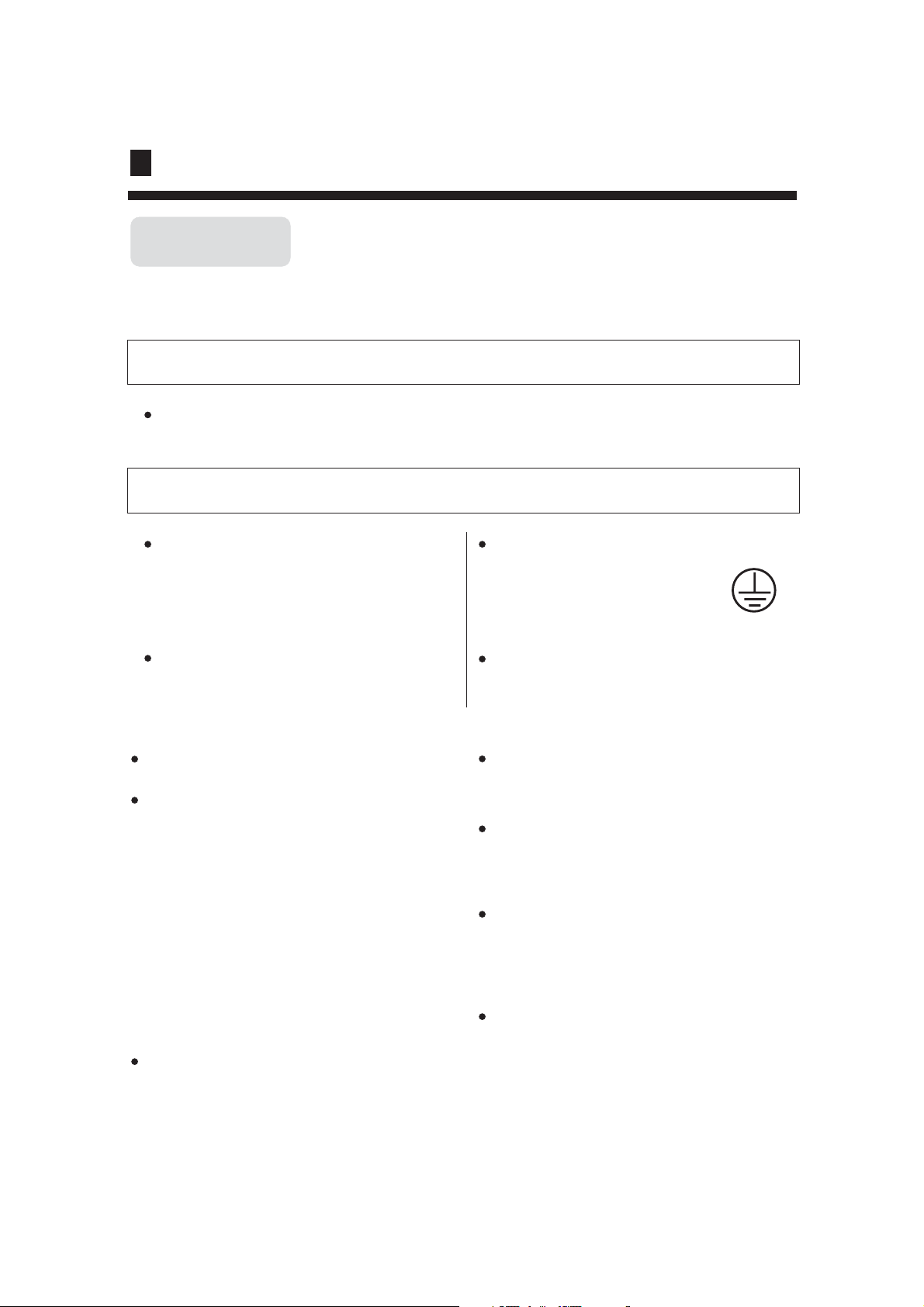

Introduction to Spare Parts

Discharge unit (built in)

In cooling operation,

to discharge the

water from inside the

room.

Drain Hose

Swing fender

(located in the outlet)

Outlet

Air filter

(located in the suction grill)

Suction grill

Refrigerant pipe

Cable line

Earthing line

Anti-bacteria filter

Air intakeAir Outlet

6

Page 9

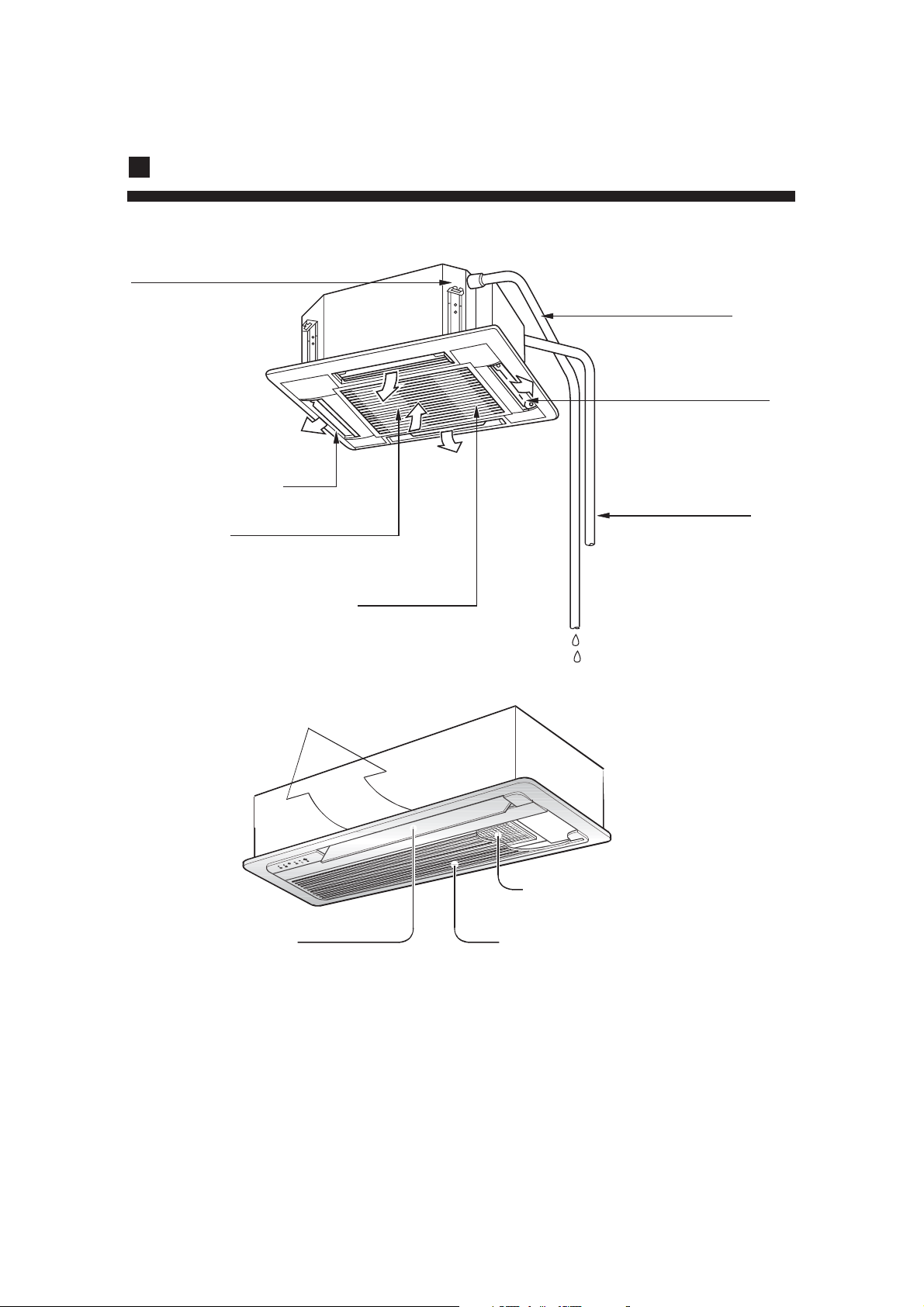

Maintenance

[Clean air filter]

NOTE

1. Open inlet grill

Press the elliptical "PUSH" knob, the inlet

grill will automatically drop. (the inlet grill

is catched with two pothooks)

When having to clean, don't dismantle

air-filter,otherwise may cause faults.

In the environment where there is too

much dust, air filter should be cleaned

for more times.

(about half a year one time)

PUSH

Open two

pothooks

Press the elliptical knob

the inlet grill will

automatically drop

Pothook

(B) Wash with water.

With too much dust, use soft brush and neutral

detergent.

Swing off the water, and then place in cool place.

5. Install air filter

(1) Put filter into protruding parts at the top of

the inlet grill.

(2) Connect the two pothooks with inlet grill

See 2

2. Open two othooks

3. Dismantle air filter

Drag the knob of

the grill back lift

Air filter

the filter and take

down.

4. Clean

CAUTION!

(A) Remove dust with vacuum filter.

Connect the two pothooks with inlet grill

6. Close inlet grill

See 1.

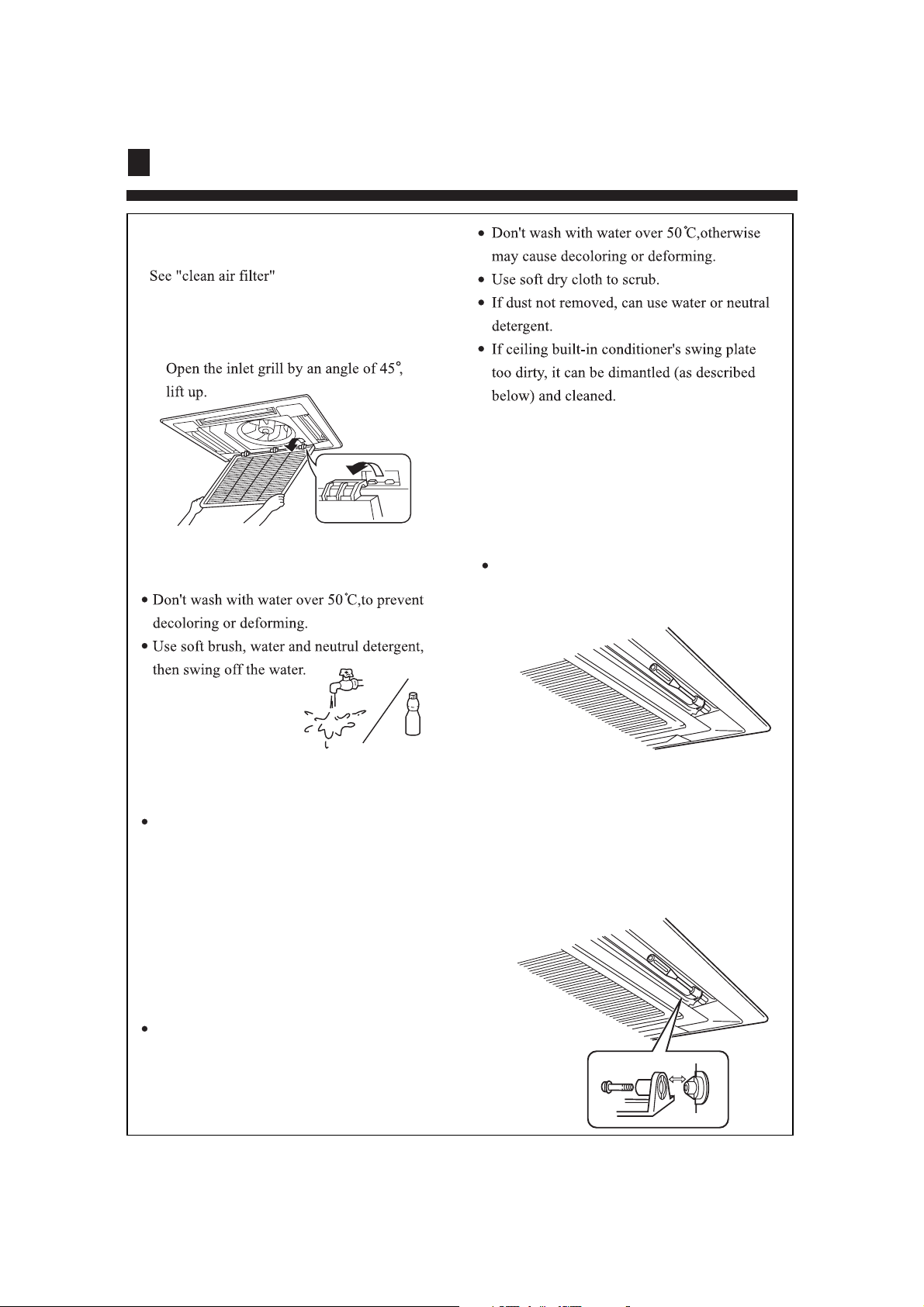

[Clean inlet grill]

1. Open inlet grill

Press the elliptical "PUSH" knob, the inlet

grill will automatically drop. (the inlet grill

is catched with two pothooks)

PUSH

Open two

pothooks

Press the elliptical knob

the inlet grill will

automatically drop

Pothook

7

Page 10

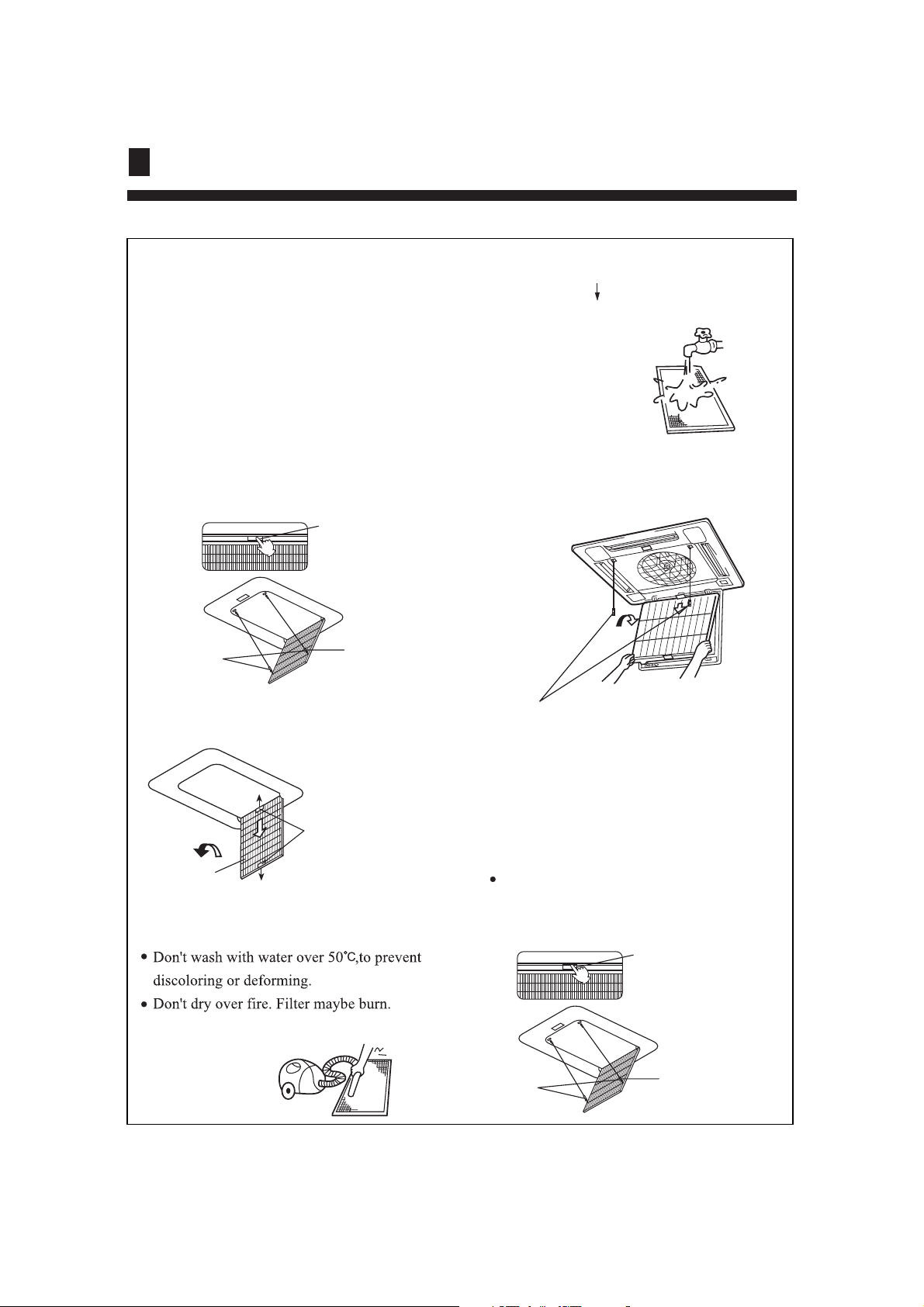

Maintenance

2. Take off airfilter

3. Take of inlet grill

[Dismantle and install swing

plate ]

1. Fix the swing plate at the bottom.

2. Dismantle the swing plate.

4. Clean

CAUTION!

NOTE

When the filter too much dust

To spray the special detergent for vent fan or

utensils.

5. Install inlet grill

6. Install air filter

7. Close inlet grill

see 3

see "Clean air filter"

see 1

[Clean outlet and shell]

CAUTION!

Use water to clean the plate and don't heavily

scrub, otherwise the fine hair may fall off.

Unscrew the screw at both ends of the swing

plate.

[Dismantle and install swing

plate ]

3. Install swing plate

Lightly rotate swing plate to insert the ridge

at both ends of the outlet into the groove

and then screw up.

CAUTION!

Don't use gasoline, benzene, dilutant,

polishing powder, or liquid inseticide.

8

Page 11

Maintenance

Seasonal Reserve

Post-season Care

Operate the unit with FAN mode on a fair day for about half

a day to dry the inside of the unit well.

Stop operation and turn off the power supply switch .Electric

power is consumed even the air conditioner is in stop.

Clean the air filter, indoor unit and outdoor unit,and cover

the unit with dustcoat.

Pre-season Care

See that there is no obstacles blocking the air

inlet and air outlet of both indoor and outdoor

unit to avoid reduce the working efficiency.

Be sure to install the air filter, ensure that the air filter is not dirty. Otherwise may result in

machine damages or cause malfunciton due to dust inside the unit

To prevent compressor when start in HEAT mode,

please cut in the power supply switch 12 hours

before starting run,furthermore, always keep the

power supply switch on during the using senson.

NOTE

The inner part of indoor unit must be cleaned. Consult dealer, because clean must be done by

1.

technician.

In cooling operation, discharging system discharge water in room.

2.

9

Page 12

Trouble Shooting

The followings are not malfuncition

Water flowing sound is heard

Hua

Hua

Cracking sound is heard

It smells.

During operation, white fog comes out of

indoor unit.

When the air conditoner is started, when the

compressor starts or stops during operation

or when the air conditioner is stopped,it sometimes sounds Bi- Bi- or Godo-Godo. It is

the flowing sound of the refrigerant , not a

malfunction.

This is caused by heat expansion or contraction of plastics

Air blown out from the indoor unit sometimes

smells. The smell results from smells of

furniture, paint , tobacco absorbed by indoor

unit.

When in COOL or DRY mode, a thin water

fog can be seen blown out of unit ,this is the

condensed fog because the suddenly cooled

indoor air is blown out.

Automatically switch into FAN mode during

cooling.

The air conditioner cannot be restarted soon

after it stops.

Air conditioner does not start?

To prevent frost from being accumulated on the

indoor unit heat exchanger, it sometimes automatically switched into the FAN mode,but it will

soon back to the cooling mode.

This is because of the self-protection function

of the system, therefore,it cannot be restarted

for about three minutes after it stops.

Please wait for

three minutes

10

Page 13

Trouble Shooting

Air does not blow or the fan speed cannot be

changed during drying.

Water or vapor generated from the outdoor

unit during heating.

During heating,indoor fan is still running even

unit is stopped.

In DRY mode, when room temperature

becomes 2 C higher than temperature setting,

unit rill run intermittently at LO speed regardless

of FAN setting

This happens when the frost accumulated on

the outdoor unit is removed (during defrosting

operation).

Defrosting operation

To get ride of the excess heat, indoor fan will

continue running for a while after unit automatically stops.

Please check the following things about your air conditioner before making a

service call.

Is the power supply switch on ?

**?

Power supply switch is not in

ON position.

Unit fails to start.

Is city supply power normal ?

ON

OFF

11

Is the earth leakage breaker

in action ?

Be sure to turn off the power

supply switch immediately and

contact the sales dealer.

Page 14

When Trouble Happens

Insufficient cooling or heating

The operation controller

adjusted as required

Any obstacle exists at the air

inlet or outlet?

Any other heat sources in the

room?

Air filter too dirty ?

Door or window left opened ?

Insufficient cooling

Sunlight direct into the

room ?

Horizontal swing louver

upward ? (in HEAT mode)

Too crowed in the room ?

Cooled air blown out ( when heating)

When the air conditioner does not operate properly after

you have checked the above-mentioned items or when

following phenomenon is observed,stop the operation of

the air conditioner and contact your sales dealer.

1)The fuse or breaker often shuts down.

2)Water drops off during cooling or drying operation.

3)There is an irregularity in operation or abnormal sound that

is audible.

12

Page 15

When Trouble Happens

1. Error display

Indoor unit malfunction display code

Indoor unit malfunction Display code

Float switch or water motor abnormal E0

Outdoor unit abnormal E1

Liquid temperature sensor is abnormal

Gas temperature sensor is abnormal

Indoor unit adress abnormal

(Firstly you saw E5 in controller LCD,

and then the failure code is changed

from E5 to E9)

Indoor unit EEPROM data is abnormal

E3

E4

E5

E6

The communication with electronic

expansion box is abnormal

The communication between the

wire remote controller and indoor

unit control board is abnormal

The communication between indoor

and outdoor unit is abnormal

Water temp. sensor is abnormal (Only

used for the twin energy source function)

Remote controller Timer and Operation indicator malfunction code

When the unit running, Timer indicator flash stand for indoor unit malfunction

Timer indicator

Flashing times

Flashing once

Flashing twice

Flashing 3 times The environment temperature sensor is abnormal

Flashing 4 times The communication with outdoor unit is abnormal

Flashing 5 times

Flashing 10 times

Flashing 11 times

Flashing 12 times Indoor unit EEPROM data is abnormal

Flashing 15 times Water temp. sensor is abnormal

The liquid tube temperature sensor is abnormal

The gas tube temperature sensor is abnormal

The ommunication with the electronic expansion valve control board is abnormal

Indoor unit PG fan motor is abnormal

Indoor unit water overflow or float switch is abnormal

Indoor unit malfunction

£¤Only used for the twin energy source function£'

Display codeIndoor unit malfunction

E7

E8

E9

E0

Outdoor unit malfunction display code

When the wire remote controller display E1,Can check the outdoor unit control board LED1 or outdoor

unit malfunction display code to sure outdoor unit malfunction.

When the operation indicator flashing stand for outdoor unit malfunction,Operation indicator flashing

times can't determinant outdoor unit malfunction ,You must check the outdoor unit control board LED1

flashing times or outdoor unit malfunction display code to sure outdoor unit malfunction.

Others malfunction manual plese read the outdoor unit manual.

Please keep this manual carefully and safely.

13

Page 16

Customer Need-to-know

Customer Need-to-know

Please install the air conditioner according to the requirements specified in this manual to ensure

the air conditioner work well.

Be careful not to scratch the surface of the case during moving the air conditioner.

Please keep the installation manual for future reference when maintenance and changing installation place.

After installation ,please use the air conditioner according to the specification in the operation

manual.

Using Directions

Adjust suitable airflow direction

Keep the proper indoor temperature.

Too cool or hot is not good for your health.

Furthermore,it will result in excessive

consumption of electric power.

Optimal

temperature

Avoid direct sunlight and airflow

Effectively use timer.

Using TIMER mode, you can make the room

temperature reach a suitable temperature when

you wake up or go back home.

ATTENTION: after finishing installation,confirm no refrigerant leakage.

14

Page 17

Installation Procedure

Installation tools

The installation tools listed in the

following sheet can be used as required.

1. Screw driver

2. Hacksaw

3. Drill with a diameter of 60mm

4. Inner hexagon spanner,shifting

spanner

5. Spanner (14, 17, 19,24,27mm)

6. Pipe cutter

7. Pipe expander

8. Knife

9. Pincers

10. Leakage detector or soapy water

11. Band tape

12. Scraper

13. Refrigerant oil

Standard accessories

The following parts mentioned in this

manual are the installation accessories

we prepared.

Following in the list are the accessories

supplied with the unit,which can be used

as required

No.

1

2

3

4

5

6

7

Accessory parts

Remote controller

Battery

Wire clamp

Heat

insulation

sheathing

Accesories

Screw cap

Remote

controller

bracket

Qty.

1

2

4

1+1

1

1+1

1

Symbol Parts Name

A

B

C

D

E

F

Adhesive tape

Pipe clamp

Connecting hose

Drainage hose

Non-hydroscopic

heat insulating material

Gypsum powder

15

Page 18

Installation Procedure

CAUTIONS:

To ensure proper installation, read "Cautions" carefully before

installation, start the unit correctly and show

customers how to operate and

working. After

maintain the unit.

Meanings of Warning and Cautions:

Warning! Serious injury or even death might happen, if it is not observed.

Caution! Injury to people of damages to machine might happen, if it is not observed.

WARNING!

Installation shall be done by professional people, don't install unit by yourself. Incorrect installation will

cause water leakage, electric shock or fire.

Install unit as per the Manual. Incorrect installation will cause water leakage, electric shock or fire

accident.

Be sure to use specified accessaries and parts. Otherwise, water leakage, electric shock, fire accident or

unit falling down may happen.

Unit should be placed on a place strong enough to hold the unit. Or, unit will fall down causing injuries.

When install the unit, take in consideration of storms, typhoom, earthquake. Incorrect installation may

cause unit to fall down.

All electric work shall be done by experienced people as per eocal code, regulations and this Manual.

Use exclusive wire for the unit. Incorrect installation or undersized electric wire may cause electric

shock or fire accident.

All the wires and circuit shall be safe. Use exclusive wire firmly fixed. Be sure that external force

will not affect terminal bolck and electric wire. Poor contact and installation may cause fire accident.

Arrange wire correctly when connectin indoor and outdoor power supply. Fix terminal cover firmly to

avoid overheat, electric shock or even fire accident.

In case retrigerant leakage occurred during unit installation, keep a good ventilation in the room.

Poisonous gas will occur when meet with fire.

Check the unit upon installation. Be sure there is no leakage. Refrigerant will induce poisonous gas

when meet heat source as heater, oven, etc.

Cut power supply before touching terminal bolck.

CAUTION!

Unit shall be grounded. But grounding shall not be connected to gas pipe

water pipe, telephone line. Poor grounding will cause electric shock.

Be sure to install a leakage breaker to avoid electric shock.

Arrange water drainage according to this Manual. Cover pipe with insulation materials in case

dew may occur. Unproper installation of water drainage will cause water leakage and wet your furniture.

To maintain good picture or reduce noise, keep at least 1 m from T.V. radio, when install indoor and outdoor unit, connecting wire and power cable. (If the radio wave is relatively strong, 1 m is not enough

to reduce noise).

Don't install unit in following places:

(a) Oil mist or oil gas exists, such as kitchen, or, plastic parts may get aged, or water leakage.

(b) Where there is corrosive gas. Copper tube and welded part may be damaged due to corrosion,

causing leakage.

(c) Where there is strong radiation. This will affect unit's control system, causing malfunction of the unit

(d) Where flamable gas, dirt, and volatile matter (thinner, gasoline) exist, These matter

might cause fire accident.

Refer to paper pattern when installing unit.

Cautions for the installation personnel

Don't fail to show customers how to operate unit.

16

Earthing

Page 19

Installation Procedure

1

1. BEFORE INSTALLATION

Determine the way to carry unit to installation place.

Don't remove packing until unit reaches installation place.

If unpacking is unavoidable, protect unit properly.

2

2. SELECTION OF INSTALLATION PLACE

(1) Installation place shall meet the following and agreed by customers:

Place where proper air flow can be ensured.

No block to air flow.

Water drainage is smooth.

Place strong enough to support unit .

Place where inclination is not evident on ceiling.

Enough space for maintenance.

Indoor and outdoor unit piping length is within limit. (Refer to Installation Manual for outdoor unit.)

Indoor and outdoor unit, power cable, inter unit cable are at least 1 m away fromT.V. radio. This is helpful

to avoid picture disturbance and noise. (Even if 1 m is kept, noise can still appear if radio wave is strong)

(2) Ceiling height

Indoor unit can be installed on ceiling of 2.5-3m in height. (Refer to Field setting and Installation Manual of

ornament panel.)

(3) Install suspending bolt. Check if the installation place is strong enough to hold weight. Take necessary

measures in case it is not safe. (Distance between holes are marked on paper pattern. Refer to paper pattern

for place which need be reinforced)

<Don't discard any accessories until completed>

Air outlet

1500 Over

AB424FCAHA

Air outlet

Air inlet

2500 Over

AB484FCAHA

Installation space

310

1500 Over

Air outlet

1500 Over

AB184FCAHA

Air outlet

Air inlet

2500 Over

AB244FCAHA

260

1500 Over

AB094FAAHA AB124FAAHA

17

Page 20

Installation Procedure

3

3. PREPARATION FOR THE INSTALLATION

(1) Position of ceiling opening between unit and suspending bolt.

AB424FCAHA AB484FCAHA

860-890

780

(Ceiling opening)

(Distance between suspending bolts)

AB184FCAHA AB244FCAHA

Refrigerant pipe

680

840(Indoor unit)

950(Ornament panel)

£¤Ceiling opening)

(Distance between suspending bolts)

620

860-890

890(Ceiling opening)

*

(Distance between suspending bolts)

680

(Distance between suspending bolts)

840(Indoor unit)

890(Ceiling opening)

*

950(Ornament panel)

AB094FAAHA AB124FAAHA

807.6

761

700

A

Suspending bracket

Ceiling

A

460

500(GRILLE)

712.6

831

860(GRILLE)

350

438

Note:

Dimension of ceiling opening marked with * can be as

large as 910mm, but the matching part of ceiling with

ornament panel shall be over 20mm.

20 Over

(2) Cut an opening in ceiling for installation if necessary. (when ceiling already exists.)

Refer to paper pattern for dimension of ceiling hole.

Connect all pipings (refrigerant, water drainage), wirings (inter unit cable) to indoor unit, before installation.

Cut a hole in ceiling, may be a frame should be used to ensure a smooth surface and to prevent vibration.

Contact your real estate dealer

(3) Install a suspending bolt.

(Use a M10 bolt)

To support the unit weight, anchor bolt shall be used in the case of already exists ceiling. For new

ceiling, use built-in type bolt or parts prepared in the field.

Before going on installing adjust space between ceiling.

Suspending bolts

(160)

<Installation example>

Anchor bolt

Long nut

50~100

Suspending bolt

Ceiling

Roof

Note: All the above mentioned parts shall be prepared in field.

18

Page 21

Installation Procedure

4

4. INSTALLATION OF INDOOR UNIT

In the case of new ceiling

(1) Install unit temporarily

Put suspending bracket on the suspending bolt. Be sure to use nut and washer at both ends of the bracket.

(2) As for the dimensions of ceiling hole, see paper pattern. Ask your real estate dealer for details.

Center of the hole is marked on the paper pattern.

Center of the unit is marked on the card in the unit and on the paper pattern.

Mount paper pattern onto unit using 3 screws . Fix the corner of the drain pan at piping outlet.

< After installation on the ceiling >

(3) Adjust unit to its right position. (Refer to preparation for the installation-(1))

(4) Check unit's horizontal level.

Water pump and flating switch is installed inside indoor unit, check four corners of the unit for its level

using horizontal compartor or PVC tube with water. (If unit is tilting against the direction of water drainage,

problem may occur on floating switch, causing water leakage.)

(5) Remove the washer mounting , and tighten the nut above.

(6) Remove the paper pattern.

In the case of ceiling already exists

(1) Install unit temporarily

Put suspending bracket on the suspending bolt.

Be sure to use nut and washer at both ends

of the bracket. Fix the bracket firmly.

(2) Adjust the height and position of the unit.

(Refer to preparation for the installation (1) ).

(3) Proceed with and of "In the case of new ceiling".

5

2

4

3

6

Nut (Prepare in feild)

Washer (Prepared in feild)

Suspending bolts

Fasten (double nuts)

Level

Polythene pipe

Center of ceiling hole Paper pattern

Screw (accessory)

[Fix the paper pattern]

19

Insert

Washer fixing pad

(prepared in feild)

[ secure the washer firmly]

Screws at the piping outlet is fixed at the corner

of drain pan.

Paper pattern

5

Screw (accessory)

Page 22

Installation Procedure

5. REFRIGERANT PIPING

5

(As for outdoor piping, please refer to installation Manual of outdoor unit.)

Outdoor is precharged with refrigerant.

Be sure to see the Fig.1, when connecting and removing piping from unit.

For the size of the flare nut, please refer to Table 1.

Apply refrigerant oil at both inside and outside of lflare nut. Tighten it band tight 3-4 turns then tighten it.

Use torque specified in Table 1. (Too much force may damage flare nut, causing gas leakage).

Check piping joints for gas leakage. Insulate piping as shown in Fig. below.

Cover joint of gas piping and insulator with seal.

Apply refrigerant oil

Torque spanner

Piping joing

Flare nut

6

6. INSTALLATION OF WATER DRAINAGE PIPE

Medium size seal pad 11 (accessory)

(Cover the piping joint

with seal pad.)

Clamp 3

spanner

Gas pipe

Liquid pipe

7

Insulator (accessory)

(For liquid pipe)

Insulator (accessory)

(For gas pipe)

8

7

Table 1

Pipe

size

6.35

9.52

15.88

19.05

Tighten

torque

1420~1720N.cm

(144~176kgf.cm)

3270~3990N.cm

(333~407kgf.cm)

6180~7540N.cm

(630~770kgf.cm)

9720~11860N.cm

(990~1210kgf.cm)

A(mm)

8.3~8.7

12.0~12.4

18.6~19.0

22.9~23.3

Flare shape

2

45

0.5

90

(1) Install water drainage pipe

Pipe dia, shall be equal or larger than that of unit piping.(pipe of polyethene; size: 25mm; O.D:32mm)

Drain pipe should be short, with a downward slope at least 1/100 to prevent air bag from happening.

If downward slope can't be made, take other measures to lift it up.

Keep a distance of 1-1.5m between suspending brackets, to make water hose straight.

1-1.5m

R0.4 ~ 0.8

A

Slope over 1/100

Use the self-provided stiff pipe and clamp with unit. Insert water pipe into water plug until it reaches the

1

white tape. Tighten the clip until head of the screw is less than 4mm from hose.

Wind the drain hose to the clip using seal pad 9 .

Insulate drain hose in the room.

Clamp

Tape (White)

Self-provided stiff pipe

<Cautions for the drain water lifting pipe>

Clamp

(accessory)

Large size seal pad

(accessory)

4mm below

10

Installation height shall be less than 280mm.

There should be a right angle with unit, 300mm from unit.

Suspending bracket

1~1.5m

drain water lifting pipe

Clamp

(accessory)

280 below

220

500 below

Self-provided stiff pipe

(accessory)

75 below

500 below

(Note)

Drain hose

(accessory)

300mm below

The slope of water drain hose (1) shall be within 75mm, don't apply too much force on it.

If several water hoses join together, do as per following proceedures.

Connect water hoses with a T joint.

Over 100

Specifications of the water hoses shall meet the requirements for the unit running.

20

Page 23

Installation Procedures

7.

INSTALLING THE DECORATED BOARD ON THE BODY OF INDOOR UNIT

7

As shown in Fig. 1, make the wind deflector motor of the decorated board face to the orifice of the indoor

6

unit, and then mount the decorated board onto the body of the indoor unit.

swing ring

orifice location

2

deflector motor

3

1

2

4

Mounting the decorated board:

a. Hang temporarily the swing rings(2 pcs) opposite to the deflector motor of the decorated board on the ring

stators of the swing rings of the indoor unit;

b. Hang temporarily the other swing rings on the ring stators of the swing rings of the indoor unit (take care

not to get the lead wire of the deflector motor into the sealing);

c. Screw all 4 hex head screws under the rings about 15mm to lift the board;

d. Turn and adjust the decorated board in the direction of arrow as shown in Fig. 4 until it covers the hole of

the ceiling.

e. Fasten the screw to keep the thickness of the sealing between the decorated board and the unit body within

5-8mm, as shown in Fig. 2.

indoor unit

ceiling material

f. Mount the wiring of the decorated board according to the mounting drawing attached tothe inside of the

machine;

g. Check with the control if the mounting is correct and make sure if the machine work snormally;

h. Mount the air inlet grid and angle covers.

sealing

5-8mm

decorated board

Fig.1

Fig.2

21

Page 24

Installation Procedures

Attention

Inappropriate tightening of screws might cause the faults as

shown in Fig. 3.

Tighten the screws properly.

If there is still a gap between the decorated board and the ceiling

after tightening the screws, please readjust the height of the body

of the indoor unit. (Fig. 4)

If the indoor unit keeps the horizontal level and the drainpipe

cant be influenced, adjust the height of the body of the indoor

unit from the holes on the angles of the decorated board.

air leakage

leakage

from roof

pollution

Fig.3

vapour condensate drops

any gap is not allowed

Wiring of Decorated Board

a. Connect it to the connector of the wind deflector motor lead on the decorated board (Fig. 5);

b. Connect it to the receiving terminal of remote control on the decorated board.

side of decorated board

electrical cabinet

AB184~484FCAHA

<circuit diagram>

side of indoor unit

(different from the actual condition)

Fig.4

Fig.5

22

Page 25

Installation Procedures

Mounting Air Inlet Grid and Angle Covers

(1) Mounting the air inlet grid:

Take care not to wind the lead of the wind deflector motor during mounting the air inlet grid.

(2)For Model AB184-484FCAHA units, the angle covers should be mounted on the angles.

¢ Tie the thread of the angle cover onto the cleat on the decorated board as shown in Fig. 6.

¢ Mount the angle cover onto the decorated board (as shown in Fig. 7).

cleat

Slide the 5 locks to mount angle covers

to fit the holes on decorated board

Fig.6 Fig.7

Attention

£¡

For proper drainage, the drainpipes should be connected according to the installation manual. Heat

preservation should be performed as to prevent condensing. Improper connections may cause the water

leakage.

Requirements:

The drainpipe of the indoor unit should be heat-insulated.

Heat insulation should be treated for the connection with the indoor unit. Improper heat insulation may cause

condensing.

The drainpipe with the down gradient of over 1/100 cant be in the S shape, or abnormal sound can be caused.

The lateral length of the drainpipe should be kept with 20m. Under the condition of long pipes, supports can

be provided every 1.52m as to avoid unevenness.

The central piping should be connected according the following drawing.

Take care not to apply external force on the connection of the drainpipes.

heat

insulating

material

1.5m~2m

down gradient

over 1/100

support bracket

s-shape elbow

as big as possible (about 10 CM)

down gradient

over 1/100

VP30

23

Page 26

Installation Procedures

Piping Materials & Heat Insulating Materials

As to prevent condensation, heat insulating

treatment should be performed. The heat

insulating treatment for piping should be done

respectively.

Piping

Material

Heat Insulating

Material

Hard PVC tube VP31.5mm

(inner bore)

Vesicant polythene

thickness: over 7mm

Hose

The attached hoses can be used to adjust the eccentricity and angle of the hard PVC tube.

Stretch the hose directly to make connections as to avoid distortion. The soft end of the hose should be

positioned with a clamp.

The hose should be used in the lateral direction.

eccentricity adjustment (max.20mm)

o

45 bending (max.)

20

hose

o

45

indoor unit

hose clamp

hose

Heat Insulating Treatment:

Wrap the connection between the clamp and the root segment of the indoor unit without any gap with heat

insulating materials as shown in the drawing

hose hose clamp

Lifting Drainpipe

The drainpipe can be lifted 360mm.

When the down gradient of the drainpipe cant be ensured, after upright

lifting, the drainpipe is in the down slope.

attached heat

insulating material

heat insulating

material

horniness pvc pipe

Confirming Drainage

The drainage should be confirmed during the test run to make sure that there is

leakage at the connection.

The confirmation of drainage should be also performed during the installation in

the winter season.

Fill water from the outlet or the specified position and confirm the drainage.

Fill 600cc water with a hose from the outlet or the specified location on the machine.

Add the water slowly. Dont add water to the motor of the drainage pump.

After mounting the electrical system, do refrigerating operation and meanwhile

add water and check.

If the electrical installation hasnt been completed, pull out the terminal(2P)

of the floater switch on the electrical cabinet. After confirming the drainage,

connect the terminal of the floater switch and run the drainage pump for 5

minutes until it stops automatically.

Confirm the sound of the motor:

Confirm the sound of the motor of the drainage pump and meanwhile check

the drainage.

24

lifting

360mm below

100mm

below

indoor unit

under the ceiling

lifting 500mm below

joint of drainpipe

Page 27

Installation Procedure

Tubing Permissible Length & Height Difference

Please refer to the attached manual of outdoor units.

Tubing Materials & Specifications

Model

Tubing Size

(mm)

Tubing

Material

AB094~

124FAAHA

Gas pipe

Liquid pipe

Phosphor deoxybronze seamless pipe (TP2) for

air conditioner

12.70

6.35

AB184~

244FCAHA

15.88

9.52

AB424~

484FCAHA

19.05

9.52

Refrigerant Filling Amount

Add the refrigerant according to the installation instruction of outdoor unit. The addition of R22

refrigerant must be performed with a measure gage to ensure the specified amount while compressor

failure can be caused by filling too much or little refrigerant.

Connecting Procedures of Refrigerant Tubing

Proceed the flare tube connecting operation to connect all the refrigerant tubes.

Dual wrenches must be used in the connection

of indoor unit tubing.

Mounting torque refers to the right table

wrench

Outer

Diameter of

Tubing (mm)

6.35

9.52

12.70

15.88

19.05

Mounting

Torque (N-m)

11.8(1.2kgf-m)

24.5(2.5kgf-m)

49.0(5.0kgf-m)

78.4(8.0kgf-m)

98.0(10.0kgf-m)

13.7(1.4kgf-m)

29.4(3.0kgf-m)

53.9(5.5kgf-m)

98.0(10.0kgf-m)

117.7(12.0kgf-m)

Increase mounting

Torque (N-m)

Cutting and Enlarging

Cutting or enlarging pipes should be proceeded

by installation personnel according to the

operating criterion if the tube is too long or flare

opening is broken.

Vacuumizing

Vacuumize from the stop valve of outdoor units

with vacuum pump. Refrigerant sealed in indoor

machine is not allowed to use for vacuumization.

Open All Valves

Open all the valves of outdoor units. [NB: oil

balancing stop valve must be shut up completely

when connected one main unit.]

Checkup for Air Leakage

Check if there is any leakage at the connecting part

and bonnet with hydrophone or soapsuds.

Connecting

Connecting

circular terminals:

1. Connecting circular terminals:

The connecting method of circular terminal is

shown in the Fig. Take off the screw, connect it

to the terminal tier after heading it through the

ring at the end of the lead and then tighten it.

2.Connecting straight terminals:

The connection methods for the circular terminals

are shown as follows: loosen the screw before

putting the line terminal into the terminal tier,

tighten the screw and confirm it has been clamped

by pulling the line gently.

3.Pressing connecting line

After connecting line is completed, press the

connecting line with clips which should press on

the protective sleeve of the connecting line.

correct

pressing

terminal tier

pressing clip

25

wrong

pressing

Page 28

Electrical Wiring

Warning

Electrical construction should be made with specific mains circuit by the qualified personnel according

to the installation instruction. Electric shock and fire may be caused if the capacity of power supply

is not sufficient.

During arranging the wiring layout, specified cables should be used as the mains line, which accords

with the local regulations on wiring. Connecting and fastening should be performed reliably to avoid

the external force of cables from transmitting to the terminals. Improper connection or fastness may

lead to burning or fire accidents.

There must be the ground connection according to the criterion. Unreliable grounding may cause

electrical shocks. Do not connect the grounding line to the gas pipe, water pipe, lightening rod and

telephone line.

Attention

Only copper wire can be used. Breaker for electric leakage should be provided, or electric shock may

occur.

The wiring of the mains line is of Y type. The power plug L should be connected to the live wire and

plug N connected to null wire while should be connected to the ground wire. For the type with auxiliary

electrically heating function, the live wire and the null wire should not be misconnected, or the surface

of electrical heating body will be electrified. If the power line is damaged, replace it by the professional

personnel of the manufacturer or service center.

The power line of indoor units should be arranged according to the installation instruction of indoor units.

The electrical wiring should be out of contact with the high-temperature sections of tubing as to avoid

melting the insulating layer of cables, which may cause accidents.

After connected to the terminal tier, the tubing should be curved into be a U-type elbow and fastened

with the pressing clip.

Controller wiring and refrigerant tubing can be arranged and fixed together.

The machine cant be powered on before electrical operation. Maintenance should be done while the

power is shut down.

Seal the thread hole with heat insulating materials to avoid condensation.

Signal line and power line are separately independent, which cant share one line. [Note: the power line,

connecting line, signal line are provided by users. Parameters are shown as below: 3×(1.0-1.5) mm

parameters for signal line: 2×(0.75-1.25)mm

2

( shielded line)]

2

;

Supply Wiring Drawing

communication

C2

C1

C2

C1

R

R

communication

Note:

1:L(black)

2:N(white)

3:C(red)----It's no use for Builtin EEV Type on the indoor unit .

OUTDOOR UNIT TERMINAL BLOCK

U

W

V

CM

Compressor

INDOOR UNIT TERMINAL BLOCK

1 2 3

W B R

POWER SUPPLY:1PH,220-230V,50/60Hz

R

POWER SUPPLY:

Y/G

ST

26

AU52LFIAHA

N

Lm1

3N~,380-400V,50 /60Hz

AB094FAAHA

AB124FAAHA

AB184FAAHA

AB244FAAHA

AB424FAAHA

AB484FAAHA

Lm2

Page 29

Electrical Wiring

Field setting

Field setting the unit number

Indoor unit number setting

Indoor unit number setting switch and confirmation of the settings.

There is a 4-position dial switch for setting the indoor unit number and fan speed level on the computer board of the indoor unit.

Setting way is as follows:

Before connecting the power supply, please set the indoor unit number manually according to the following table

Matrix of the dial switch and indoor unit number

Position 1 Position 2 Position 3 Representing unit number

000 1

100 2

010 3

110 4

001 5

101 6

011

111

1

The first bit of SW02 and SW03 is used to choose

wired control or remote control type .

ONmeans that the unit with wired controller .And

OFFis remote controller.

2

The second bit of SW02 is used to choose built-in or

outside electronic expansion valve setting.

ON means built-in type.And "OFF"means outside type.

3

The second bit of SW03 is used to select the twin energy

source function.

"ON":The unit without TES function.

"OFF":The unit can be used as TES function.

When it is used for TES function ,the water tempeture

sensor is available .

7

8

SW02

Example:

SW03

Example:

ON

Pos.1

ON

Pos.1

Pos.

SW01

Example:

ON

: 0

010

ON

Pos.2Pos.3Pos.

Pos.1

Setting for No. 3 indoor unit

2

ON

"ON" means that in heating mode the

indoor unit fan speed can be choosed to

middle and low level. "OFF" means that

the indoor unit fan speed can be choosed

to high, middle and low level.After

Pos.

2

producing in plant , the position is "OFF".

OFF

: 1

1

4

Auto restart (

After the Auto restart is set, if power failure suddenly occurs while the air conditioner is working, it will resume the

previous working state when the power is supplied again.

*The setting method of auto restart function of wired remote control model or wired control+ remote control model:press

the [sleep] button of the wired control or remote control 10 times within 5 seconds and after the buzzer rings 4 times,the

air conditioner will enter the state of auto restart function.

The cancel method :press the [sleep] button of the wired control or remote control 10 times within 5 seconds and after the

buzzer rings 2 times, the Auto restart function will be cancelled.The setting method of wireless remote control:press the

[swing] button of the remote control 10 times within 5 seconds and after the buzzer rings 4 times,the air conditioner

will enter the state of auto restart function;

The cancel method :press the [swing] button of wireless remote controller 10 times within 5 seconds and after the buzzer

rings 2 times, the Auto restart function will be cancelled;

*The setting method of wireless remote control:press the [swing] button of the remote control 10 times within 5 seconds

and after the buzzer rings 4 times,the air conditioner will enter the state of auto restart function;

The cancel method :press the [swing] button of wireless remote controller 10 times within 5 seconds and after the buzzer

rings 2 times, the Auto restart function will be cancelled;

Notes: When a power failure suddenly occurs during the air conditioner is working after the Auto restart is set, if the air

conditioner will not be used for a long time, please cut off the power supply to prevent its operation from being resumed

after the power is supplied again, or press the "Switch On/Off" button after the power comes again.

to be applied for a necessary situation

)

:

27

Page 30

Electrical Wiring

The unit has temperature compensation function.

(

Only used for remote controller)

You can use [swing] button of the remote controller to set or cancel temperature compensation function.

(1) About temperature compensation function setting

* The setting method for heating mode:

press [ON/OFF] button of the remote controller to start the indoor unit, setting temperature: 24¡ , press [swing] button 7

times in 5 seconds, the buzzer will ring twice, and enter heating temp. compensation mode.

set compensation temp. , if the set temp.is 25¡ , the compensation temp. is +1¡ , you can set it in range of 0¡ to +6¡

*The setting method for cooling mode:

press [ON/OFF] button of the remote controller to start the indoor unit, setting temperature:24¡ : press [swing] button

7 times in 5 seconds, the buzzer will ring twice, and enter cooling temp. compensation mode.

(2) Temperature compensation function checking

*In cooling mode, setting temp.: 30 degree, High fan speed, press [swing] button 7 times in 5 seconds, The Running lamp

will flash, the times of flash is same with cooling compensation setting number

*In heating mode, setting temp. :16 degree, high fan speed, press [swing] 7 times in 5 seconds, the running lamp will flash,

the flashing times is same with heating compensation setting number

Concerning MRV Auto Restart function for H-MRV models

Haier Auto Restart function when the unit power drops down suddenly, the unit microprocessor will store the previous

working condition and when the power is on again, the unit will run as this memory.

Auto Restart function is designed basically on the MRV whole system, but it is suitable for each indoor unit individually.

If some of indoor units power cut down, but the outdoor unit and the other indoor units still work, maybe problems will

happen such as freezing at cooling mode and overload protection at heating mode on those indoor units without power.

Reason

When one or some indoor units power drops down and the other indoor units are still work, the indoor units without

the power, will keep the previous working condition before the power is off.

And expansion valve keeps open at a kind of opening rate condition as the previous requirement,so there is refrigerant

flowing in the exchanger, but the indoor fan stops working. If the units work at cooling mode, the indoor units without the

power will maybe make freezing. If the unit works at heating mode, maybe the outdoor unit compressor will stop because

of the pressure or temperature protection. This is our design basically on Auto Restart function currently.

Haier, Herewith, solemnly informs our customers, installers, distributors, etc. when making installation,

please make sure when the power is shut down whether artificially or accidentally, the whole system

including outdoor unit and all the indoor units must be off. If you do not make the installation as

our indication, Haier will not be responsible for any problem resulting from this.

Pay special care to the following and check after installation

Item to the checked

Is gas leakage check performed?

Is unit properly insulated?

Is water drainage smooth?

Is power voltage meet that stipulated on the nameplate?

Is wiring and piping correctly arranged?

Is unit safely grounded?

Is wire size correct?

Are there any obstacles on air inlet and outlet grill of

indoor and outdoor unit?

Is record made for piping length and refrigerant

charging amount?

Unproper installation may cause

Unit might fall down, make vibration or noise.

This may lead to gas shortage.

Dew or water drop may occur.

Dew or water drop may occur.

Problem may occur or parts got burned.

Problem may occur or parts got burned.

There might be a danger of electric shock.

Problem may occur or parts got burned.

This may cause poor cooling.

It is hard to control refrigerant charging

amount.

28

Check

Page 31

Technical Specifications

Model

Power Supply

Cooling Capacity

heating Capacity

Noise

(Indoor Units)

Net Weight

(Indoor Units)

Air Volume

(Indoor Units)

Net Dimensions(mm)

Panel Dimensions(mm)

Refrigerant liquid pipe/

Refregerant gas pipe

Model

Power Supply

Cooling Capacity

heating Capacity

Noise

(Indoor Units)

Net Weight

(Indoor Units)

Air Volume

(Indoor Units)

AB094FAAHA

1PH.220V~,60Hz

AB424FCAHA

1PH.220V~,60Hz

2800W

3200W

--

20kg

3

400m

/h

710*440*270

860*500*60

6.35/12.7

2800W

3200W

35kg

3

1580m

/h

AB124FAAHA

1PH.220V~,60Hz

3600W

3900W

--

20kg

450m3/h

710*440*270

860*500*60

6.35/12.7

AB484FCAHA

1PH.220V~,60Hz

3600W

3900W

42dB(A)37dB(A)

35kg

1920m3/h

A184FCAHA

1PH.220V~,60Hz

6000W

6300W

34dB(A)

28kg

3

900m

/h

840*840*240

950*950*80

9.52/15.88 9.52/15.88

AB244FCAHA

1PH.220V~,60Hz

7200W

8000W

35 dB(A)

28kg

1020m

840*840*240

950*950*80

3

/h

Net Dimensions(mm)

Panel Dimensions(mm)

Refrigerant liquid pipe/

Refregerant gas pipe

950*950*80

9.52/19.05 9.52/19.05

950*950*80

29

Loading...

Loading...