Page 1

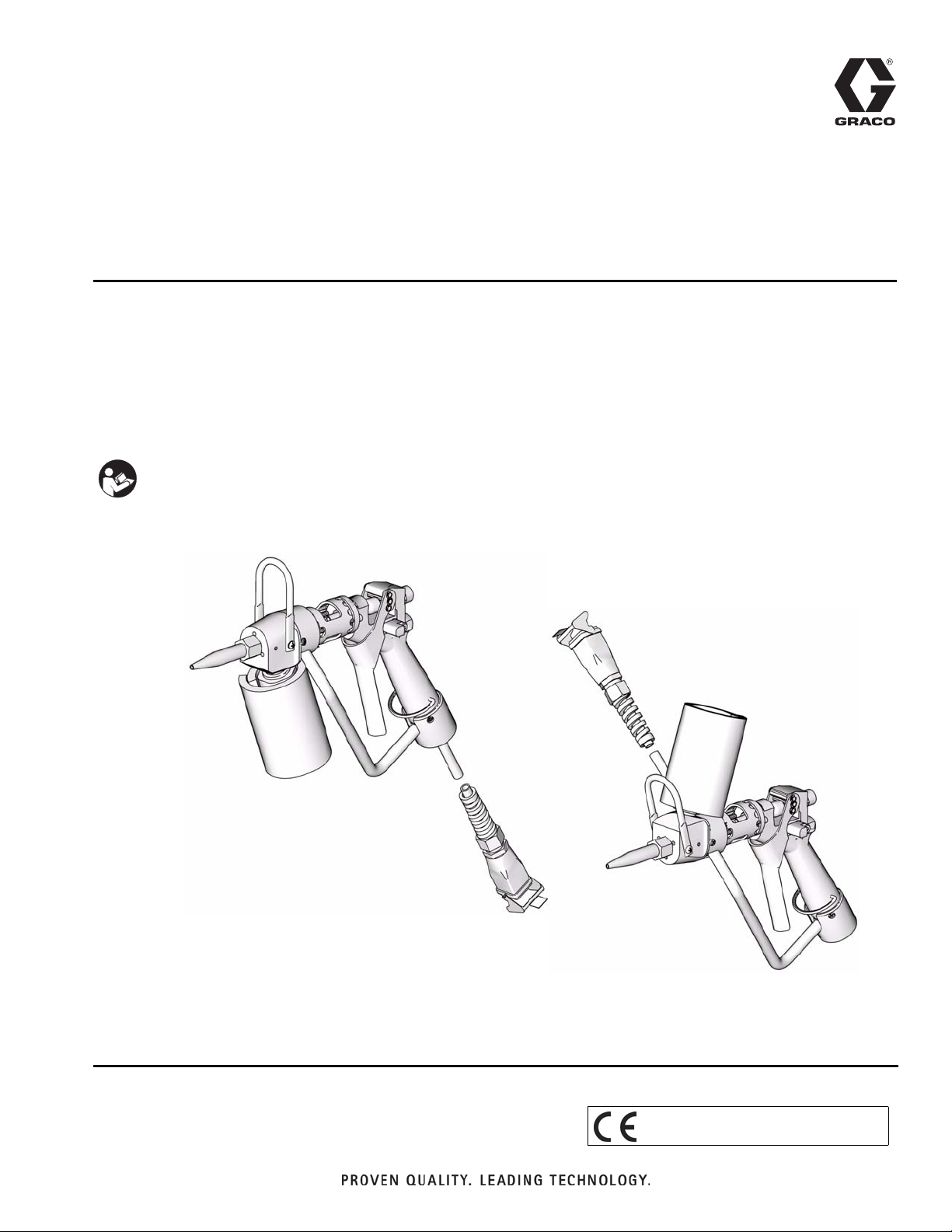

Instructions - Parts

Hot Melt

Dispense Guns

For dispensing non-flammable hot melt thermoplastic sealants and adhesives.

3500 psi (24.1 MPa, 241 bar) Maximum Working Pressure

See page 2 for model information.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

311209J

Bottom feed model

TI7700b

Top feed model

TI7702b

Page 2

Models

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connect Heated Hose . . . . . . . . . . . . . . . . . . . . . 5

Connect Electrical Cable . . . . . . . . . . . . . . . . . . . 5

Ground the System . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 7

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Heatup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Models

Model 249514 Bottom Feed

Model 249512 Bottom Feed with Trigger Switch

Model 249515 Top Feed

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Install New Heater Cartridge(s), RTD Sensor, or

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Inspection Frequency . . . . . . . . . . . . . . . . . . . . 12

Adjust Needle Assembly . . . . . . . . . . . . . . . . . . 12

Service Valve Stem and Seal . . . . . . . . . . . . . . 12

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 22

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 22

Model 249513 Top Feed with Trigger Switch

Model 297273 Top Feed with Swirl

Model 297274 Bottom Feed with Swirl

2 311209J

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

311209J 3

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

4 311209J

Page 5

Installation

Installation

Install gun as follows:

• connect material hose

• connect the electrical cable

• make sure the gun is grounded

Connect Heated Hose

1. Screw adapter onto gun swivel (A) and tighten

securely.

Part No. Adapter Hose Size

120264 -8 JIC x -10 JIC -8

-- Not required -10

120265 -10 JIC x -12 JIC -12

2. Securely connect hose to gun swivel (A).

Connect Electrical Cable

1. Wrap hose cable around hose one time. Connect

electrical cable from hose to gun cable; engage

metal clip on top of connector.

FIG. 3: Connect Electrical Cable, Step 1

2. Place flat side of cable connection against hose,

making sure metal clip faces away from hose. This

will prevent damage to hose from clip rubbing

against it.

A

TI8057b

F

IG. 1: Hose Gun Swivel

3. Wrap connection with insulating cuff (B) (119889).

B

TI8056b

IG. 2: Insulating Cuff

F

IG. 4: Connect Electrical Cable, Step 2

F

3. Fasten Velcro insulation wrap (198422) snugly

around hose. Secure wrap with two Velcro straps

(198442) on ends of wrap.

IG. 5: Connect Electrical Cable, Step 3

F

311209J 5

Page 6

Installation

Ground the System

The following grounding instructions are minimum

requirements for a basic dispensing system. Your system may include other equipment or objects that must

be grounded. Check your local electrical code for

detailed grounding instructions for your area and type of

equipment. Your system must be connected to a true

earth ground.

• Fluid hoses: use only grounded fluid hoses with a

maximum of 25 feet (7.5 m) combined hose length

to ensure grounding continuity. Check electrical

resistance of your fluid hoses at least once a week.

If your hose does not have a tag on it that specifies

the maximum electrical resistance, contact the hose

supplier or manufacturer for the maximum resistance limits. If the hose resistance exceeds the recommended limits, replace it immediately.

• Gun: the gun is grounded by connecting it to the

properly grounded fluid hose and by a ground wire

in the cable. Check ground continuity between the

gun body and the heat control ground lug.

• Fluid supply container: ground according to the

local code.

• Flammable liquids in the dispense area: must be

kept in approved, grounded containers. Do not store

more than the quantity needed for one shift.

• All solvent pails used when flushing: ground

according to local code. Use only metal pails, which

are conductive. Do not place the pail on a non-conductive surface, such as paper or cardboard, which

interrupts the grounding continuity.

To maintain grounding continuity when flushing or relieving pressure: hold a metal part of the gun firmly to the

side of a grounded metal pail, then trigger the gun. To

reduce the risk of static sparking, ground the pump,

object being dispensed to, and all other spraying/dispensing equipment used or located in the spraying/dispensing area. Check your local electrical code for

detailed grounding instructions for your area and type of

equipment.

6 311209J

Page 7

Pressure Relief Procedure

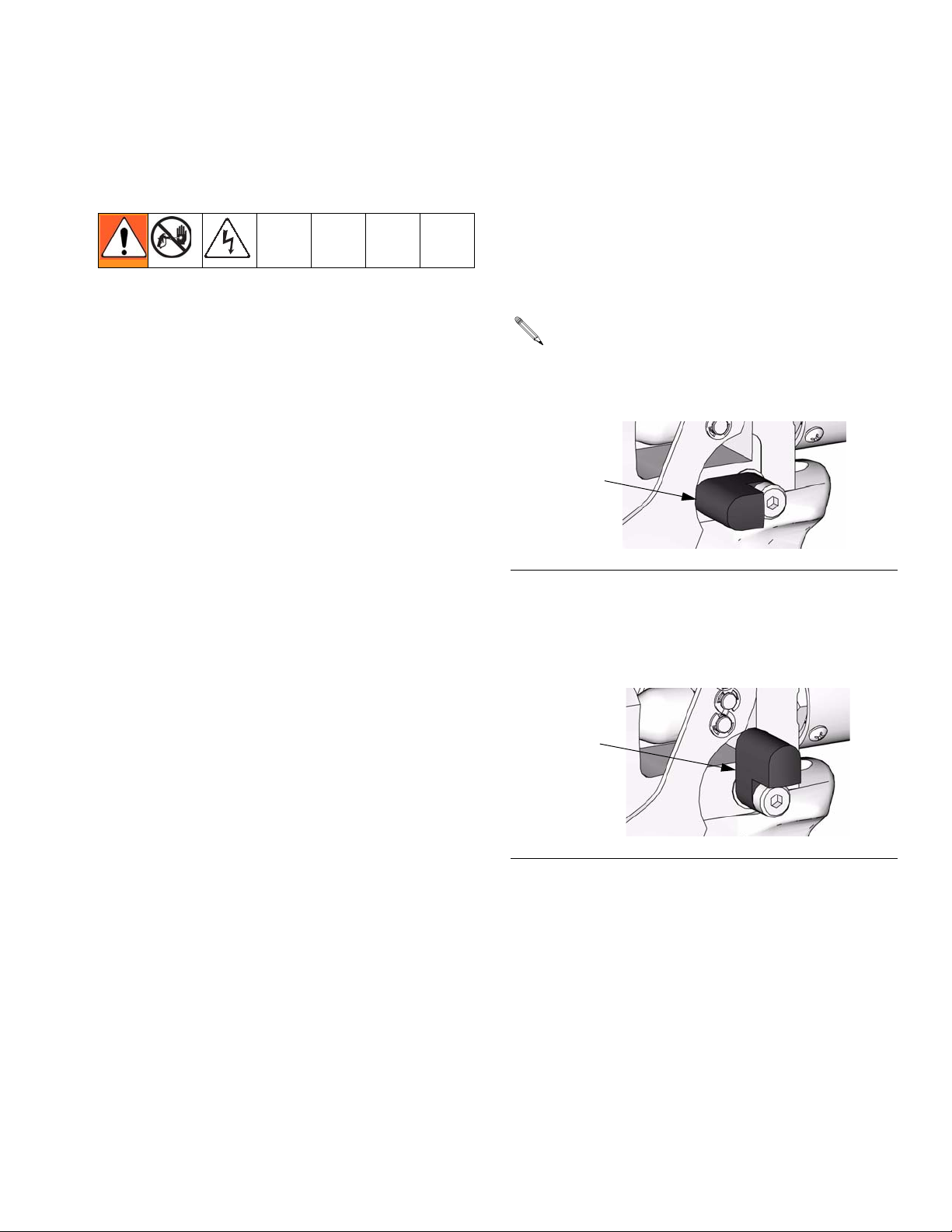

Pressure Relief

Procedure

1. Fully release gun trigger and engage gun trigger

lock. See F

2. Shut off fluid supply pump.

3. Hold a metal part of gun firmly to side of a grounded

metal waste container. Disengage gun trigger lock.

See F

4. Fully release gun trigger and engage gun trigger

lock. See F

IG. 6.

IG. 7. Trigger gun to relieve fluid pressure.

IG. 6.

Trigger Lock

Always engage trigger lock when you stop spraying to

prevent gun from being triggered accidentally by hand or

if dropped or bumped.

To engage trigger lock, release trigger and rotate lock

downward. See F

Do not try to force trigger valve open with trigger

lock engaged. This could result in component failure.

Trigger Lock

Engaged

F

IG. 6: Trigger Lock Engaged

IG. 6.

TI8049

5. Open pump drain valve to help relieve fluid pressure

in pump, hose, and gun. Triggering gun to relieve

pressure may not be sufficient. Have a container

ready to catch drainage.

6. Leave drain valve open until you are ready to dispense again.

7. If you think the gun nozzle or fluid hose is completely

clogged or that pressure has not been fully relieved

after following the previous steps, very slowly loosen

hose end coupling and relieve pressure gradually,

then loosen coupling completely. Clear nozzle or

hose obstruction

To disengage trigger lock, rotate it upward. See F

Trigger Lock

Disengaged

FIG. 7: Trigger Lock Disengaged

IG. 7.

TI8050

311209J 7

Page 8

Operation

Operation

Heatup

Heated fluid expands, causing a pressure rise in a

closed system.

• Relieve pressure (page 7) before heating up

equipment.

• Engage trigger retainer to hold gun open, to prevent excessive pressure buildup.

1. Turn ON electrical controls and main air to unit.

2. Lock dispense valve trigger open by pulling and

securing trigger using trigger retainer (Z).

Z

3. Activate heat controls.

4. After pump, hose, and gun are up to temperature,

release gun trigger retainer (Z) to close valve.

Engage gun trigger lock to prevent accidental dispense of high pressure heated fluid.

Z

TI8052b

Trigger Lock

Engaged

F

IG. 8: Trigger Retainer Locked

TI8049

TI8051b

FIG. 9: Trigger Retainer Unlocked and Trigger Lock

Engaged

8 311209J

Page 9

Operation

Dispensing

1. Start pump. Fluid flow rate is controlled at pump.

Adjust pump pressure to obtain desired flow rate.

Use lowest pressure necessary to dispense fluid.

The pressure adjustment depends on hose length,

fluid viscosity, and nozzle size.

2. Disengage gun trigger lock.

Trigger Lock

Disengaged

TI8050

F

IG. 10: Trigger Lock Disengaged

3. Squeeze trigger in all the way. Fluid flow begins with

the slightest pressure on trigger and stops when

trigger is released.

Shutdown

1. Turn off all heat at controller.

2. Shut off fluid supply pump.

3. Trigger gun to relieve pressure while system is still

hot.

4. With gun over a waste container, hold trigger open

by securing with trigger retainer (Z).

Z

TI8051b

FIG. 11: Trigger Retainer Locked

TI8051

311209J 9

Page 10

Troubleshooting

Troubleshooting

Some solutions require disassembling gun. Always

relieve system pressure and disconnect electrical cable

before performing these procedures.

Problem Cause(s) Solution(s)

Material leaks from front of gun body Seat or packing is worn

.

Replace seat (6) or packing (47).

Obstruction inside gun

Worn needle

Material leaks from back of gun body Needle seal or packing is worn Replace seals (4c) or packing (4d).

Gun does not shut off Needle or seat is worn

Spring is broken or not installed correctly

Obstruction inside gun

Gun does not heat material Loose heater wires

Loose sensor wires

Heater cartridge failed

Sensor failed

Temperature controller failed

No power to heating circuitry

Remove seat (6). Check and replace

if necessary.

Check and replace needle (4a) if necessary.

Replace needle (4a) or seat (6).

Check and replace spring (14) if necessary.

Remove seat (6). Check and replace

if necessary.

Check and reconnect wire connections.

Check and reconnect wire connections.

Replace failed heater.

Replace failed sensor.

Refer to Therm-O-Flow

311208 as appropriate.

®

200 manual

10 311209J

Page 11

Service

Service

Install New Heater Cartridge(s), RTD Sensor, or Switch

After adjusting or servicing gun, ensure that fluid will

not trigger on when trigger lock is engaged. If fluid

does flow, gun is not assembled correctly or trigger

lock is damaged. Reassemble gun or return it to

your nearest Graco distributor. Do not use gun until

the problem is corrected.

1. If fluid continues to flow after trigger is released:

• gun valve may need adjustment,

• gun valve may be obstructed or damaged,

• or needle assembly (4) or seat (6) may be worn

or damaged.

Replace needle assembly (4) or seat (6) as

instructed on page 12.

2. Use Repair Kit 253553 for Manual Hot-Melt Guns

249512, 249513, 249514, 249515, 297273, and

297274.

1. Remove covers (9 and 16).

2. Pull terminal block (36) out of handle and disconnect lead wires of failed components.

3. Gently slide new heater(s) or sensor into appropriate hole.

4. Feed new wires through conduit to terminal block

(36) and connect after cutting to length and stripping.

5. Use an ohm meter to check:

a. Heater pins 1 to 2, 445 +/- 35 .

b. RTD sensor pin 3 to 4, 108 +/-1 at 70°F

(21°C).

c. Continuity to gun body from pin 8.

d. No continuity from pins 1-7 to gun body or con-

nector shell, or ground pin 8.

ΩΩ

ΩΩ

Viewed from wire end of connector

All models except

249514 and

249515

All

Models

{

{

FIG. 12: 8 Pin, 240 Volt Shown

311209J 11

Page 12

Service

Inspection Frequency

Dispense Valve

Inspect dispense valve at every use for leakage or other

visible damage.

Heater

Every two weeks, check heater for proper resistance.

Resistance should be approximately 890 ohms, +/- 70

ohms for the 240V valves. Replace heater if necessary.

Also inspect heater when performing regular maintenance procedures.

Sensor

Every two weeks, check sensor resistance. Resistance

should be 108 ohms at 70° F (21° C). Replace sensor if

necessary.

Also inspect sensor when performing regular maintenance procedures.

4. Trigger gun and use a 1/8 in. open-end wrench on

flats of needle to turn needle (4a) clockwise one turn

as viewed from handle end of gun.

5. Release trigger; a slight free play of the trigger handle should occur.

6. Repeat Step 4 until free play occurs.

7. Tighten hex nut (4g) to lock the adjustment.

Service Valve Stem and Seal

If fluid leaks past seal (4c), the seal or needle (4a) may

be worn or damaged. To replace seal or valve stem, use

the following procedure.

1. Relieve pressure in system.

2. Disconnect gun from hose.

Adjust Needle Assembly

The trigger travel and corresponding valve opening are

factory set. To adjust this setting, use the following procedure.

1. Relieve pressure in system.

2. Disconnect gun from hose.

3. Use 11/32 in. wrench to loosen hex nut (4g).

3. Remove cover (16), and then slide heater cartridge

and sensor cartridge out of body (2).

4. Loosen needle nut.

5. Remove screws (33).

6. Unscrew needle with body from yoke.

7. Remove seal-cartridge assembly from body and

replace seals and/or needle. Repack grease area of

packing nut prior to reassembly.

8. Reassemble in reverse order and follow Adjust

Needle Assembly, page 12.

12 311209J

Page 13

Notes

Notes

311209J 13

Page 14

Parts

Parts

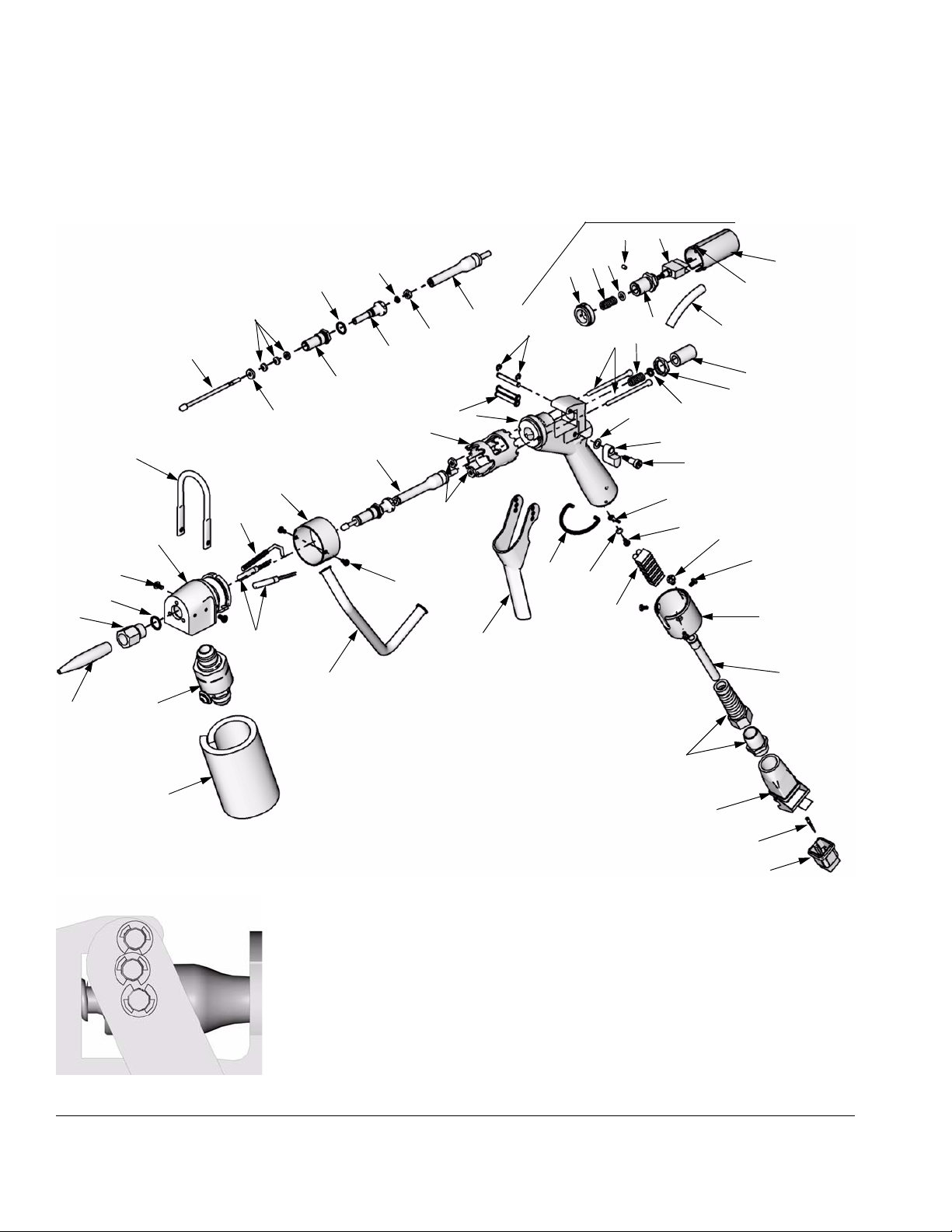

Models 249514 and 249512, Hot Melt Guns

Model 249512 Only

27

19

52

14

33

46

36

4j

4d

4c

4a

4e

4b

26

16

21

2

31

47

6

22

18

7

8

4f

3

4

32

4g

24

41

4h

25

1

17

54

14

35

51

5

23

30

27

34

37

50

55

53

5

11

48

32

9

10

12

20

13

29

15

Detail A

TI8059

Orient snap rings as shown. For

ease of assembly, install pins

and snap rings from top to bottom. Middle snap ring must be

installed facing up, then rotated

to position shown. Snap rings

must be flush with each other

without overlapping.

FIG. 13: Models 249514 and 249512, Hot Melt Guns

14 311209J

TI8058b

Page 15

Parts

Model 249514

Manual Hot Melt Gun, Bottom Feed, Extrude,

No Switch

Model 249512

Manual Hot Melt Gun, Bottom Feed, Extrude, with

Switch

Ref.

No. Part No. Description Qty

1 15G017 HANDLE 1

2 15F983 BODY, gun 1

3 15G006 SPACER, thermal, isolator 1

4◆ 287734 NEEDLE, assy, includes 4a-4j 1

4a 15G531 NEEDLE 1

4b C27053 SUPPORT, packing 1

4c* C27060 SEAL, needle 3

4d* 103338 PACKING, o-ring 1

4e 15F993 NUT, packing 1

4f 15F991 SCREW, adjustment 1

4g C19284 NUT, hex 1

4h 15F997 YOKE, gun 1

4j* 106560 PACKING, o-ring 1

5 RETAINER, spring

C27037 Model 249514 1

15G004 Model 249512 1

6◆ 15G001 ADAPTER, seat 1

7 C32003 NOZZLE 1

8 287736 SWIVEL, assy (inline with stop) 1

9 15G018 COVER, gun handle 1

10 119876 CONDUIT, flex 1

11† C27036 NUT, lock 1

12 116673 BUSHING, strain relief 1

13 116637 CONNECTOR, cable coupler hood 1

14 C00020 SPRING 1

15 115860 INSERT, male 1

16 15F989 COVER, gun wires 1

17 C27051 TRIGGER, gun 1

18 15G022 TUBE 1

19 C32368 RING 1

20 119889 COVER, swivel 1

21 C32255 SENSOR, temperature 1

22 119885 CARTRIDGE, heater 2

23 C34009 TRIGGER, lock 1

24 C27035 PIN, trigger 3

25 C20442 RING, snap, external 6

26 15G020 HANGER 1

27 15G121 WASHER, gun 1

28❄ 15K546 WIRE, 18AWG, 600V 1

29 115862 CONNECTOR, male, crimp

Model 249514 5

Model 249512 7

Ref.

No. Part No. Description Qty

30 C78160 TERMINAL 1

31 100035 SCREW, 8-32 x .31 2

32 103854 SCREW, 6-32 x .25 5

33 120103 SCREW, socket-hd., 8-32 x 2.50 2

34 108483 SCREW, shoulder 1

35 C20565 WASHER, spring washer 1

36 15G060 BLOCK, terminal 1

37 102975 SCREW, 6-32 x .25 1

39‡❄ C07535 TUBE, heat shrink 1

40❄ C34137 INSULATOR, fiberglass 1

41 C19286 NUT, 8-32 2

42❄ 15K547 WIRE, 22AWG, 600V 1

43❄ C33049 TAPE, adhesive, fiberglass 1

44❄ 198422 COVER, protective 1

45❄ 198442 STRAP, retaining mix manifold 2

46 100272 WASHER, #6, internal lock 1

47*◆ 103610 PACKING, o-ring 1

48 116807 SCREW, 10-24 x .25 1

49* 617836 SLEEVE, fiberglass braid, #10 blk 2

50‡ 15G003 COVER, switch 1

51‡ C32370 SWITCH 1

52‡ 15G019 SPACER, cover mounting 1

53‡ 112699 TUBE 1

54‡ 102273 SCREW, set, 6-32 x .19 1

55‡ SCREW, 4-40 x .25 3

* Parts included in Seal Kit 253553

(purchase separately).

◆ Parts included in Repair Kit 289901

(purchase separately).

† Model 249514 only.

‡ Model 249512 only.

❄ Not shown.

311209J 15

Page 16

Parts

Models 249515 and 249513, Hot Melt Guns

6

26

2

31

47

7

Detail A

15

13

29

12

Model 249513 Only

52

14

54

51

50

55

5

535

20

25

33

14

10

27

24

41

8

32

4

22

1

35

23

30

3

11

27

34

37

16

32

46

4j

21

19

36

4h

4c

4g

17

4f

4a

4e

4d

18

9

4b

TI8060b

TI8059

Orient snap rings as shown. For

ease of assembly, install pins

and snap rings from top to bottom. Middle snap ring must be

installed facing up, then rotated

to position shown. Snap rings

must be flush with each other

without overlapping.

FIG. 14: Models 249515 and 249513, Hot Melt Guns

16 311209J

Page 17

Parts

Model 249515

Manual Hot Melt Gun, Top Feed, Extrude, No Switch

Model 249513

Manual Hot Melt Gun, Top Feed, Extrude,

with Switch

Ref.

No. Part No. Description Qty.

1 15G017 HANDLE 1

2 15F983 BODY, gun 1

3 15G006 SPACER, thermal, isolator 1

4◆ 287734 NEEDLE, assy, includes 4a-4j 1

4a 15G531 NEEDLE 1

4b C27053 SUPPORT, packing 1

4c* C27060 SEAL, needle 3

4d* 103338 PACKING, o-ring 1

4e 15F993 NUT, packing 1

4f 15F991 SCREW, adjustment 1

4g C19284 NUT, hex 1

4h 15F997 YOKE, gun 1

4j* 106560 PACKING, o-ring 1

5 RETAINER, spring 1

C27037 Model 249514

15G004 Model 249512

6◆ 15G001 ADAPTER, seat 1

7 C32003 NOZZLE 1

8 287736 SWIVEL, assy (inline with stop) 1

9 15G018 COVER, gun handle 1

10 119876 CONDUIT, flex 1

11† C27036 NUT, lock 1

12 116673 BUSHING, strain relief 1

13 116637 CONNECTOR, cable coupler

hood

14 C00020 SPRING 1

15 115860 INSERT, male 1

16 15F989 COVER, gun wires 1

17 C27051 TRIGGER, gun 1

18 15G022 TUBE 1

19 C32368 RING 1

20 119889 COVER, swivel 1

21 C32255 SENSOR, temperature 1

22 119885 CARTRIDGE, heater 2

23 C34009 TRIGGER, lock 1

24 C27035 PIN, trigger 3

25 C20442 RING, snap, external 6

26 15G020 HANGER 1

27 15G121 WASHER, gun 1

28❄ 15K546 WIRE, 18AWG, 600V 1

29 115862 CONNECTOR, male, crimp

Model 249515 5

Model 249513 7

Ref.

No. Part No. Description Qty.

30 C78160 TERMINAL 1

31 100035 SCREW, 8-32 x .31 2

32 103854 SCREW, 6-32 x .25 5

33 120103 SCREW, socket-hd., 8-32 x 2.50 2

34 108483 SCREW, shoulder 1

35 C20565 WASHER, spring washer 1

36 15G060 BLOCK, terminal 1

37 102975 SCREW, 6-32 x .25 1

39‡❄ C07535 TUBE, heat shrink 1

40❄ C34137 INSULATOR, fiberglass 1

41 C19286 NUT, 8-32 2

42❄ 15K547 WIRE, 22AWG, 600V 1

43❄ C33049 TAPE, adhesive, fiberglass 1

44❄ 198422 COVER, protective 1

45❄ 198442 STRAP, retaining mix manifold 2

46 100272 WASHER, #6 internal lock 1

47*◆ 103610 PACKING, o-ring 1

48 116807 SCREW, 10-24 x .25 1

49* 617836 SLEEVE, fiberglass braid,

#10 blk

50‡ 15G003 COVER, switch 1

51‡ C32370 SWITCH 1

52‡ 15G019 SPACER, cover mounting 1

53‡ 112699 TUBE 1

54‡ 102273 SCREW, 6-32 x .19 1

55‡ SCREW, 4-40 x .25 3

* Parts included in Seal Kit 253553

(purchase separately).

1

◆ Parts included in Repair Kit 289901

(purchase separately).

† Model 249515 only.

‡ Model 249513 only.

❄ Not shown.

2

311209J 17

Page 18

Parts

4

Models 297274 and 297273, Hot Melt Guns

Top feed

Model 297273

only

26

2

47

6

8

15

29

21

13

22

12

10

4a

18

16

4c

4b

4

32

4d

3

24

41

4e

50

4j

54

51

27

4f

4h

4g

25

33

52

55

5

14

1

35

53

23

34

30

37

48

46

17

19

36

32

9

Bottom feed

Model 29727

only

10

12

7, 56

20

Detail A

TI8059

Orient snap rings as shown. For

ease of assembly, install pins

and snap rings from top to bottom. Middle snap ring must be

installed facing up, then rotated

to position shown. Snap rings

must be flush with each other

without overlapping.

FIG. 15: Models 297274 and 297273, Hot Melt Guns

13

29

15

TI8061b

18 311209J

Page 19

Parts

Model 297274

Manual Hot Melt Gun, Bottom Feed, Swirl,

with Switch

Model 297273

Manual Hot Melt Gun, Top Feed, Swirl, with Switch

Ref.

No. Part No. Description Qty.

1 15G017 HANDLE 1

2 15F983 BODY, gun 1

3 15G006 SPACER, thermal, isolator 1

4 287734 NEEDLE, assy, includes 4a-4j 1

4a 15G531 NEEDLE 1

4b C27053 SUPPORT, packing 1

4c* C27060 SEAL, needle 3

4d* 103338 PACKING, o-ring 1

4e 15F993 NUT, packing 1

4f 15F991 SCREW, adjustment 1

4g C19284 NUT, hex 1

4h 15F997 YOKE, gun 1

4j* 106560 PACKING, o-ring 1

5 15G004 RETAINER, spring 1

6 15G002 ADAPTER, swirl 1

7 118072 HEAD, applicator, swirl 1

8 287736 SWIVEL, assy (inline with stop) 1

9 15G018 COVER, gun handle 1

10 119876 CONDUIT, flex 1

12 116673 BUSHING, strain relief 1

13 116637 CONNECTOR, cable coupler

hood

14 C00020 SPRING 1

15 115860 INSERT, male 1

16 15F989 COVER, gun wires 1

17 C27051 TRIGGER, gun 1

18 15G022 TUBE 1

19 C32368 RING 1

20 119889 COVER, swivel 1

21 C32255 SENSOR, temperature 1

22 119885 CARTRIDGE, heater 2

23 C34009 TRIGGER, lock 1

24 C27035 PIN, trigger 3

25 C20442 RING, snap, external 6

26 15G020 HANGER 1

27 15G121 WASHER, gun 1

28❄ 15K546 WIRE, 18AWG, 600v 1

29 115862 CONNECTOR, male, crimp 7

30 C78160 TERMINAL 1

31 100035 SCREW, 8-32 x .31 2

32 103854 SCREW, 6-32 x .25 5

33 120103 SCREW, socket-hd., 8-32 x 2.50 2

34 108483 SCREW, shoulder 1

Ref.

No. Part No. Description Qty.

35 C20565 WASHER, spring washer 1

36 15G060 BLOCK, terminal 1

37 102975 SCREW, 6-32 x .25 1

39❄ C07535 TUBE, heat shrink 1

40❄ C34137 INSULATOR, fiberglass 1

41 C19286 NUT, 8-32 2

42❄ 15K547 WIRE, 22AWG, 600V 1

43❄ C33049 TAPE, adhesive, fiberglass 1

44❄ 198422 COVER, protective 1

45❄ 198442 STRAP, retaining mix manifold 2

46 100272 WASHER, lock 1

47* 103610 PACKING, o-ring 1

48† 116807 SCREW, mach, pan head, cross 1

49* 617836 SLEEVE, fiberglass braid,

#10 blk

50 15G003 COVER, switch 1

51 C32370 SWITCH 1

52 15G019 SPACER, cover mounting 1

53 112699 TUBE 1

54 102273 SCREW, set, socket 1

55 SCREW, mach, Phillips rnd hd 3

56 117950 NOZZLE, 0.030 1

* Parts included in Seal Kit 253553 (purchase separately).

† Model 297274 only.

1

❄ Not shown.

2

311209J 19

Page 20

Accessories

Accessories

Part No. Description

C34137 Fitting insulation, 1/8 in. thick x 2 in.

wide. Sold by the foot.

C33049 Adhesive tape, high temp for secur-

ing insulation (C34137),

1 in. x 108 ft.

198422 Wrap, velcro, 10 in. x 10 in. Covers

electrical connection on heated

hose.

198442 Strap, velcro. Use two around ends

of wrap (198422) for security.

20 311209J

Page 21

Technical Data

Technical Data

Maximum operating temperature 400°F (204°C)

Maximum fluid working pressure 3500 psi (24.1 MPa, 241 bar)

Outlet port size 5/8-18 UNF-2B

Inlet port size on gun housing 7/8-14 UNF- 2B

Inlet port size on fluid swivel 7/8-14 JIC(m)

Voltage 230/240 Vac

Wattage 120 W

Resistance temperature detector

(platinum RTD; 0.00385 ohm/ohm/°C) 108.2 ohms @ 70°F

Heater resistance individually: 890 ohms, +/- 70 ohms

wired in parallel: 445 ohms, +/- 35ohms

Weight without swivel: 2.7 lb (1.2 kg)

with swivel: 3.4 lb (1.5 kg)

Dimensions Height: 7.5 in. (191 mm)

Width: 3.0 in. (76 mm)

Length:

Models 249514 and 249515: 9.0 in. (229 mm)

Models 249512 and 249513: 10.5 in. (267 mm)

Models 297273 and 297274: 11.5 in. (292 mm)

Wetted parts Aluminum, fluorocarbon rubber, stainless steel, PTFE,

carbon steel, brass

311209J 21

Page 22

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 311209

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2006, Graco Inc. is registered to I.S. EN ISO 9001

www.graco.com

Revised 3/2008

Loading...

Loading...