Page 1

Order NO.WH070625S001V0

21FA18-T

(TB8873)

@ (2007)(Haier Electronic Company Limited)

All rights reserved. Unauthorized copying and distribution is a

violation of law.

1

Page 2

WARNING

This service information is designed for experienced repair technicians only and is not designed for use

by the general public. It does not contain warnings or cautions to advise non-technical individuals of

potential dangers in attempting to service a product. Products powered b electricity should be serviced

or repaired only by experienced professional technicians. Any attempt to service or repair the product

deal with in this service information by anyone else could result in serious injury or death.

CONTENT

1. SPECIFICATIONS………………………………………………………………………….. 3

2. WARNING…………………………………………………………………………………….. 4

3. FEATURES AND TECHINICAL DESCRIPTION………………………………………... 11

4. ADJUSTMENT………………………………………………………………………..………1 1

5. CIRCUIT DIAGRAM…………………………………………………………………………18

6. WIRING CONNECTION DIAGRAM……………………………………………………….18

7. CIRCUIT EXPLANATION.…………………………..…………………..………………….19

8. MAINTENANCE SERVICE AND TROUBLE SHOOTING………………………………22

2

Page 3

1. Specification

N

N

N

N

N

N

N

MODEL

ITEM

NO.

PICTURE

1

2

3

4

5

6

7

AUDIO

8

9

10

11

12

13

14

15

16

17

JACK

18

19

20

21

22

23

FUNCTION

Main IC 8873

CRT

Color system

Audio system

O.of channels

OSD language

Multi-picture modes

AV stereo

Super woofer

Surrounding sound

Treble/bass boost

Left/right balancer

ICAM

Multi-audio modes

Tone adjuster

MTS/SAP

Auto-volume leveling

AV input

AV output

DVD terminal

S-video jack

Headphone socket

SCART socket

21FA18-T

PURE FLAT 25

ENGLISH 29

back 1,side1 41

NO.

24

PAL 26

BG 27

218 28

5 30

√

×

×

×

√

×

√

×

×

×

back 1 42

back 1 43

back 1 44

×

×

31

32

33

34

35

36

37

38

39

40

45

46

47

48

ITEM

SOFTWARE

PARAMETER

FUNCTION

Digital curtain

Slow fading on & off

Semitransparent menu

on-flshing channel

changing

ZOOM

16:9 mode

Games

Calendar

Child-lock

Multi-functional lock

o-picture listening

Background light

Auto-timer on

FM RADIO

V-CH IP

O. of built-in speakers

Audio output power(W)

Total power input(W)

Voltage range(V)

Power frequency(Hz)

Time of sleep timer(MINS)

et weight(KG)

Gross weight(KG)

et dimension(MM)

Packaged dimension(MM)

21FA18-T

615/482/452

651/576/526

MODEL

√

√

√

√

√

√

1

√

√

√

√

×

√

×

×

2

5×2

70

160~250

50/60

120

23

26

3

Page 4

2. Warning

Safety Precautions

IMPORTANT SAFETY NOTICE

Many electrical identify these parts and mechanical parts in this chassis have special

safety-related characteristics! In the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same

components as recommended in this manual to prevent X-RADIATION, Shock, Fire, or

other Hazards.

Do not modify the original design without permission of the manufacturer.

General Guidance

An Isolation Transformer should always be used during the servicing of a receiver whose

chassis is not isolated from the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents that might result in personal injury caused by

electrical shocks.

It will also protect the receiver and it’s components from being damaged by accidental

shorts of the circuitry that might be inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown, replace it with a specified one.

When replacing a high wattage resistor (Oxide Metal Film Resistor, over 1W), keep the

resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to the high vacuum and large surface area of the picture tube, extreme care should be

taken in handling the Picture Tube. Do not lift the Picture Tube by its Neck.

X-RAY Radiation

Warning:

The source of X-RAY RADIATION in this TV receiver is the High Voltage Section and the

Picture Tube.

For continued X-RAY RADIATION protection, the replacement tube must be of the same

type as specified in the Replacement Parts List.

Before returning the receiver to the customer,

Always perform an AC leakage current check on the exposed metallic parts of the cabinet,

such as antennas, terminals, etc., to make sure that the set is safe to operate without any

danger of electrical shock.

4

Page 5

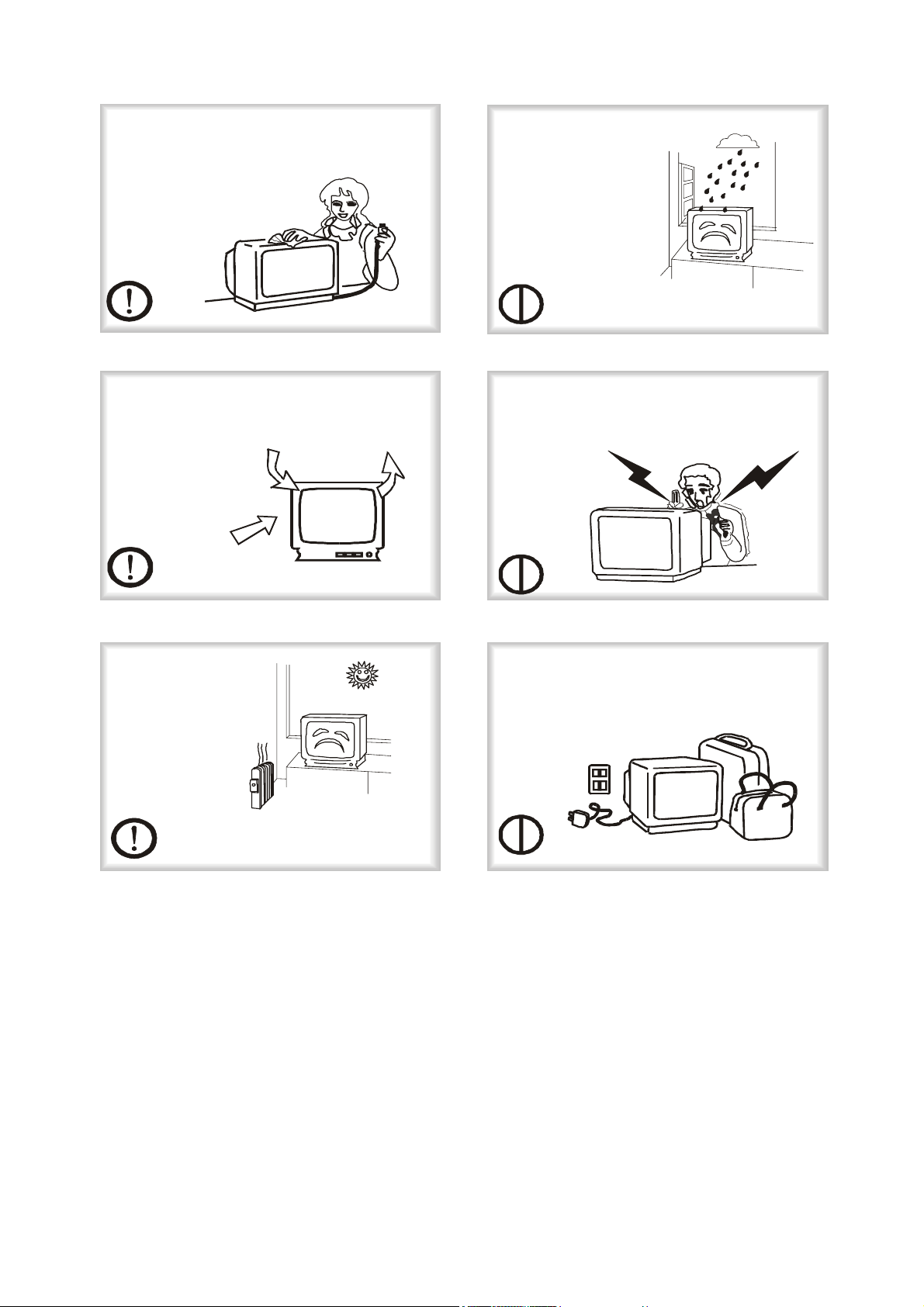

Warning and Cautions

1. When you clean the TV set, please pull

out the power plug from AC outlet. Don't

clean the cabinet and the screen with

benzen e, petrol a nd other chemical s.

2.

In order to prolong the using life of the

TV set, please place it on a ventilated

place.

4. To prevent the TV set from firing and

electric sh ock, don't

make the TV set rain

or moistu re.

5. Don't ope n the back cover , otherwise it is

possib le to dama ge the c ompon ents in the

TV set and ha rm you.

3.

Don' t place the

TV set in the

sunshine or near

heat source .

6. When the TV set i s n't going t o be used

for long time or it is in thunder and

lightening, please pull out the plug from AC

outlet a nd the ante nna plug from th e cover

of the TV set.

Explanation on the display tube

Generally, it is not needed to clean the tube surface. However, if necessary,its surface can be

cleane d w it h a dry cotton cloth after cutting off the power.D on't use any cleanser. If using ha r d

clot h, the tube surf ace will be dam a ged.

CAUTION: Before servicing receivers covered by this service manual and its supplements

and addenda, read and follow the SAFETY PRECAUTIONS.

NOTE: If unforeseen circumstances create conflict between the following servicing

precautions and any of the safety precautions, always follow the safety precautions.

Remember: Safety First.

5

Page 6

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power source before:

a. Removing or reinstalling any component, circuit board module or any other

assembly of the receiver.

b. Disconnecting or reconnecting any receiver electrical plug or other electrical

connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the receiver.

CAUTION: A wrong substitution part or incorrect installation polarity of electrolytic

capacitors may result in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other

voltage-measuring device (DVM, FETVOM, etc.) equipped with a suitable high voltage

probe. Do not test high voltage by “drawing an arc”.

3. Discharge the picture tube anode only by (a) first connecting one end of an insulated

clip lead to the degaussing or kine aquadag grounding system shield at the point where

the picture tube socket ground lead is connected, and then (b) touch the other end of

the insulated clip lead to the picture tube anode button, using an insulating handle to

avoid personal contact with high voltage.

4. Do not spray chemicals on or near this receiver or any of its assemblies.

5. Unless specified otherwise in this service manual, clean electrical contacts only by

applying the following mixture to the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator; 10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of contacts is not

required.

6. Do not defeat any plug / socket B+ voltage interlocks with which receivers covered by

this service manual might be equipped.

7. Do not apply AC power to this instrument and/or any of its electrical assemblies unless

all solid-state device heat sinks are correctly installed.

8. Always connect the test receiver ground lead to the receiver chassis ground before

connecting the test receiver positive lead.

Always remove the test receiver ground lead last.

9. Use with this receiver only the test fixtures specified in this service manual.

CAUTION: Do not connect the test fixture ground strap to any heat sink in this receiver.

Electrostatic ally Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components are usually called Electrostatic ally Sensitive (ES) Devices. Examples of

6

Page 7

typical ES devices are integrated circuits and some field effect transistors and

semiconductor “chip” components. The following techniques should be used to help

reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-

equipped assembly, drain off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to prevent potential shock

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly

on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup

or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static type folder removal device. Some solder removal devices not

classified as “anti-static” can generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges

sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately

before you are ready to install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement

ES device, touch the protective material to the chassis or circuit assembly into which

the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other

safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices.

(Otherwise even some normally harmless motions such as mutual brushing of your

clothes’ fabric or lifting of your foot from a carpeted floor might generate st atic electricity

sufficient to damage an ES device.)

General Soldering Guidelines

Use a grounded-tip, low-wattage soldering iron and appropriate tip size and shape that

will maintain tip temperature within the range of 500 oF to 600 oF.

Use an appropriate gauge of RMA resin-core solder composed of 60 parts tin/40 parts

lead.

Keep the soldering iron tip clean and well tinned.

Thoroughly clean the surfaces to be soldered. Use a mall wire bristle (0.5 inch, or 1.25cm)

brush with a metal handle. Do not use freon-propelled spay-on cleaners.

Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature. (500 o F to 600o F)

7

Page 8

b. Heating the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-type solder removal

device with solder braid.

CAUTION: Work quickly to avoid overheating the circuit board printed foil.

Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature. (500 o F to 600o F)

b. First, hold the soldering iron tip and solder the strand against the component lead

until the solder melts.

c. Quickly move the soldering iron tip to the junction of the component lead and the

printed circuit foil, and hold it there only until the solder flows onto and around both

the component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit board printed foil.

d. Closely inspect the solder area and remove any excess or splashed solder with a

small wire-bristle brush.

Remove /Replacement

Some chassis circuit boards have slotted holes (oblong) through which the IC leads are

inserted and then bent flat against the circuit foil. When holes are of slotted type, the

following technique should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique as outlined.

Removal

Desolder and straighten each IC lead in one operation by gently prying up on the lead with

the soldering iron tip as the solder melts.

Draw away the melted solder with an anti-static suction-type solder removal device (or

with solder braid) before removing the IC.

Replacement

Carefully insert the replacement IC in the circuit board.

Carefully bend each IC lead against the circuit foil pad and solder it.

Clean the soldered areas with a small wire-bristle brush. (It is not necessary to reapply

acrylic coating to the areas).

“Small-Signal” Discrete Transistor

Removal/Replacement

Remove the defective transistor by clipping its leads as close as possible to the

component body.

Bend into a “U” shape the end of each of three leads remaining on the circuit board.

Bend into a “U” shape the replacement transistor leads.

Connect the replacement transistor leads to the corresponding leads extending from the

8

Page 9

circuit board and crimp the “U” with long nose pliers to insure metal to metal contact then

solder each connection.

Power Output, Transistor Device

Removal/Replacement

Heat and remove all solder from around the transistor leads.

Remove the heat sink mounting screw (if so equipped).

Carefully remove the transistor from the heat sink of the circuit board.

Insert new transistor in the circuit board.

Solder each transistor lead, and clip off excess lead.

Replace heat sink.

Diode Removal/Replacement

Remove defective diode by clipping its leads as close as possible to diode body.

Bend the two remaining leads perpendicularly to the circuit board.

Observing diode polarity, wrap each lead of the new diode round the corresponding lead

on the circuit board.

Securely crimp each connection and solder it.

Inspect (on the circuit board copper side) the solder joints of the two “original” leads. If they

are not shiny, reheat them and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow stake.

2. Securely crimp the leads of replacement component around notch at stake top.

3. Solder the connections

CAUTION: Maintain original spacing between the replaced component and adjacent

components and the circuit board to prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit board will weaken the

adhesive that bonds foil to the circuit board causing the foil to separate from or “lift-off” the

board. The following guidelines and procedures should be followed whenever this

condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the following procedure to

install a jumper wire on the copper pattern side of the circuit board. (Use this technique

only on IC connections).

1. Carefully remove the damaged copper pattern with a sharp knife. (Remove only as

much copper as absolutely necessary).

9

Page 10

2. Carefully scratch away the solder resist and acrylic coating (if used) from the end of

the remaining copper pattern.

3. Bend a small “U” in one end of a small gauge jumper wire and carefully crimp it around

the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper pattern and let it overlap

the previously scraped end of the good copper pattern. Solder the overlapped area

and clip off any excess jumper wire.

At other connections

Use the following technique to repair the defective copper pattern at connections other

than IC Pins. This technique involves the installation of a jumper wire on the component

side of the circuit board.

Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to insure that a hazardous condition will not exist if

the jumper wire opens.

Trace along the copper pattern from both sides of the pattern break and locate the

nearest component that is directly connected to the affected copper pattern.

Connect insulated 20-gauge jumper wire from the lead of the nearest component on one

side of the pattern break to the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so that it does not touch

components or sharp edges.

WARNING

RISKELECTRIC SHOCK

DONOT OPEN

WARNING:To reduce the risk of electric shick don’t remove cover or back.

No user-serviceable parts inside refer service to qualified service personnel.

Safety of operators has been taken into consideration at the design and manufacture phase, but

inappropriate operation may cause electric shock or fire. To prevent the product from being damaged,

the following rules should be observed for the installation, use and maintenance of the product. Read

the following safety instruction before starting the operation.

The User Manual uses the following symbols to ensure a safe operation and preventany damage to

operators or properties:

10

Page 11

3.FEATURES AND TECHINICAL DESCRIPTION

FUNCTIONS :

2

1.ALL-BAND CATV (470MHz) 2.I

3.Auto and manual tuning 4.Audio/video input/output interfaces

5.Multiple picture modes selection 6.Screen saver when no signal

7 PAL DK 8.218 programs Preset

9.volume setting stored 10.Program scan

11.Child LOCK 12.Slide curtain power on/off display,improve d eye

protection

C bus control

4. Adjustment

A..Factory adjustment information

Operation method: after the appliance is switched on, make the volume value to zero.

Then press “ V- ” key on the TV set and press the DISP button on remote controller at

the same time to enter the S state. Press DISP button one times and “S” will disappear,

Repeat the first step, you will enter the D mode. Now one “D” is displayed on the TV

screen.

Press PRO- and PRO+ buttons to select items for adjustment.

Press VOL- and VOL+ buttons to adjust selected items.

Press the POWER button to switch off the appliance and go back to the normal state.

B.Maintenance menu (Table 8)

Function Function bewrite

OSDH-POS OSD Hortzontal position 14

OPT function OPTION B4

RCUT R CUT OFF 22

GCUT G CUT OFF 33

BCUT B CUT OFF 2D

GDRV G DRIVE 40

BDRV B DRIVE 40

CNTX SUB CONTRAST MAX 7F

BRTC SUB BRIGHT CENTER 52

COLC SUB COLOR CENTER FOR NTSC 40

TNTC SUB TINT CENTER 40

COLP SUB COLOR CENTER FOR PAL 02

COLD DVD COLOR CENTER (DIF) 05

SCNT Y-SUB CONTRAST 0A

CNTC SUB CONTRASRT CENTER 4B

CNTN SUB CONTRASRT MINIMUM 07

CNTD DVD CONTRAST MAX 7F

referen

ce

initializati

on

11

Page 12

BRTX SUB BRIGHT MAX 20

BRTN SUB BRIGHT MINIMUM 20

COLX SUB COLOR MAX 25

COLN SUB COLOR MINIMUM 0D

TNTX SUB TINT MAX 28

TNTN SUB TINT MINIMUM 28

ST3 SUB SHARP CENTER NTSC3.58 IN TV 19

SV3 SUB SHARP CENTER NTSC3.58 IN VIDEO 1D

ST4 SUB SHARP CENTER OTHER COLOR SYSTEM IN TV 25

SV4 SUB SHARP CENTER OTHER COLOR SYSTEM IN VIDEO 1D

SVD SUB SHARP CENTER IN DVD 1B

ASSH ASYMMETRY – SHARPNESS 05

SHPX SUB SHARPNESS MAX POINTS FROM CENTER VALUE 1A

SHPN SUB SHARPNESS MIN POINTS FROM CENTER VALUE 19

TXCX RGB CONTRAST DATA AT MAX DATA OF USER CONTRAST

OSD

RGCN RGB CONTRAST DATA AT MIN DATA OF USER CONTRAST

OSD

ABCL ABCL, 17

DCBS DCBS, 95

CLTB The data when TV mode & SOUND SYS = M 89

CLTD The data when TV mode & SOUND SYS = M 89

CLTM The data when TV mode & SOUND SYS = M AC

CLVO The data when YVU mode & SOUND SYS != M AD

CLVD The data when YVU mode & SOUND SYS = M 88

OSDA excursus 01

HPOS 50HZ HORIZONTAL PHASE 50HZ *

VP50 50 HZ VERTICAL PHASE 50HZ *

HIT 50HZ VERTICAL AMPLITUDE *

HPS SHIFT DAT OF 50/60HZ HORIZONTAL PHASE *

VP60 60HZ VERTICAL PHASE *

HITS SHIFT DATA OF 50/60 HZ HORIZONTAL PHASE *

VLIN V-LINEARITY *

VSC V-S CORRECTION *

VLIS V-LINEARITY *

VSS V-S CORRECTION *

UVBLACK

HBOW

high 4 digit is ublack low 4 digit is &vblack

VCD_1BH high 3 digit and VCD_24H

88

88

HPARA

BRTS SUB BRIGHT 00

RAGC RF AGC ADJUSTMENT 20

HAFC 1/2 AFC DATA ADJUSTMENT 86

NOIS Signal strength setting 0F

NDTC NOISE DET count (Weak -> Normal) 1F

VL1 VOLUME OUTPUT DATA AT 25% 09

VL25 VOLUME OUTPUT DATA AT 50% 3D

12

Page 13

VL50 VOLUME 100 57

VLX ??? 7F

MUTT Y-MUTE FOR SOFT START 00

STAT CONTRAST UP FOR SOFT START 00

FLG0 Flag0 44

FLG1 Flag1 70

SVM PIC1 SVM 50

VBLK V BLANKING START AND STOP POINT 00

VCEN V CENTERING 2E

UCOM 00:GND;01:R OUTPUT;10:B OUTPUT;11:MONITOR RF AGC

00

VIA ADC

PYNX Normal H.SYNC max 33

PYNN Normal H.SYNC min 11

PYXS Search H.SYNC max 22

PYNS Search H.SYNC min 1E

RCUTS RCUTS 00

GCUTS GCUTS 00

BCUTS GDRVS 00

GDRVS GDRVS 00

BDRVS BDRVS 00

AV_OPT Av option 04

OPT2 Option 2 1C

WAIT TIME Timing between power on and picture appearing 2F

CUR_CEN Curtain beginning position BB

CUR_STEP Curtain moving speed 02

AUSTP 04

MODE0 Multiple setting A9

MODE1 Multiple setting 0F

OSDF OSD frequency 68

STBG S TRAP f0 for BG 06

STI S TRAP f0 for I 08

STDK S TRAP f0 for DK 08

STM S TRAP f0 for M 08

08

SSBG 08

SSI 08

SSDK 08

SSM

SYNC 04

S TRAP HP/LP for BG S TRAP Q for BG S TRAP GD for BG

S TRAP HP/LP for I S TRAP Q for I S TRAP GD for I

S TRAP HP/LP for DK S TRAP Q for DK S TRAP GD for DK

S TRAP HP/LP for M S TRAP Q for M S TRAP GD for M

D5 D4 D3 D2 D1 D0

option

09

SYBBN 00

SYBBF 00

SYSR

02

BBCT Blue back hysteresis counter (BUS H sync detection 04

13

Page 14

VCD0 ???? 08

VCD1 D1D0:00 38M;01:38.9M?????? 01

BL25 % of ATT for Balance 25 1E

BL49 % of ATT for Balance 49 50

OV50 OSD vertical position for 50Hz 0C

OV60 OSD vertical position for 60Hz 02

HIT1 16.:9 adjust 11

HIT2 Zoom adjust 06

COLX2 3A optiomize adjust 05

PCON Run press key 0 image resume contrast 32

PBRI Run press key 0 image resume bright 32

PCOL Run press key 0 image resume color 32

PTIN Run press key 0 image resume tint 32

PSHA Run press key 0 image resume definition 32

PVOL 32

BR_BRI bright numerical value adjust 50

CO_BRI bright numerical value adjust 32

DK_BRI bright numerical value adjust 32

BK_BRI bright numerical value adjust 1E

BR_CONT Contrast numerical value adjust 64

CO_CON Contrast numerical value adjust 64

DK_CONT Contrast numerical value adjust 32

BK_CON Contrast numerical value adjust 32

V_NOISE Sound quarrel ‘snumerical value 28

V_MID 1E

V_QUIET 0F

PWR

BUS

MEM

Q501

QT01

OPT:

BIT FUNCTION

0 Hotel mode 1:welcome logo 0:haier logo

1 No use

2 V_Mute ON/OFF when CH changes(=1:ON)

3 AUDIO GAIN SW of tb1240

4 Not VT Down of AFT when No Signal(=1)

5 TINT 0:use 1:unused

6 Select TV sync(0) or MONITOR sync(1)

7 Mute of av switch key 1.use 0.no use

ABL:

BIT FUNCTION

0

ABL-Gain 00:-0.2;01:-0.4;10:-0.6;11:-0.8v

1

2 ABL Start Point 00:-0.0;01:-0.15;10:-0.3;11:-0.45v

14

Page 15

3

4

ACL ST ????????

5

6 WPS 0:Y peak limiter off 1:Y peak limiter on,105IRE

7 No use

DCBS

BIT FUNCTION

0

1

2

3

BLACK STRETCH black strecth

00:Off;01:Black stretch point,26IRE; 10 : 33 IRE; 11 : 43 IRE ???

Y GAMMA

00:Off;01:Y γ point 90 IRE,Gain –3dB; 10 : 82 IRE ; 11 : 75 IRE

4 VCD BS SW

5 VCD CORING

6 VCD BLACK

7 C TRAP Q

CLTO\CLTM\CLVO\CLVD

BIT FUNCTION

0

1

2

3

4

Y Delay Time

000:-40 nsec;001:0;010:40 nsec;011:80 nsec;100:120 nsec;101:160 nsec;110:200 nsec;

111:240 nsec

N Phase

00:USA(105 degree);01:Japan(93 degree);10:11:DVD

5 Color Y 0:Color gamma off ;1:On;

6 PN-ID Sens 0:PAL/NTSC killer sensitivity,1mVpp; 1:10mVpp

7 FID 0:Normal;1:Alwas killer off,i.e. always color on..

SYNC:

BIT FUNCTION

0 Select sync slice level for weak signal

1 Select sync separation level

2 Select H sync judgement : 0:BUS, 1:TC3

3 UNUSE

4 UNUSE

5 UNUSE

6 UNUSE

7 UNUSE

SYBBN:

BIT FUNCTION

0 UNUSE

1 UNUSE

2 Select window pulse for H lock detection

3 Select H lock detection mode

4 Select SY-DET-1 for sync dtection

5 Select SY-DET-2 for sync dtection

6 Select LPF mode for sync dtection

7 UNUSE

SYBBF

15

Page 16

BIT FUNCTION

0 UNUSE

1 UNUSE

2 Select window pulse for H lock detection

3 Select H lock detection mode

4 Select SY-DET-1 for sync dtection

5 Select SY-DET-2 for sync dtection

6 Select LPF mode for sync dtection

7 UNUSE

SYSR:

BIT FUNCTION

0 UNUSE

1 UNUSE

2 Select window pulse for H lock detection

3 Select H lock detection mode

4 Select SY-DET-1 for sync dtection

5 Select SY-DET-2 for sync dtection

6 Select LPF mode for sync dtection

7 UNUSE

FLG0:

BIT FUNCTION

0 0:NORMAL;1:PIF over modulation switch on

1 0:BPF;1:TOF

2 0:Nyquist Buzz cancel,on;2:off

3 0:Off, 1:If BB=1, RGB out is 110 IRE

4 TB1254N band pass filter switch

5 SIF FIX Select 0:fix to normal, 1:control with sound system

6 SIF 5.74 Select In D mode, aplly this bit to SIF 574

7 vco readjust when position select 0:disable;1:enable;

FLG1:

BIT FUNCTION

0 CW SW

1 V ramp bias

2 Sync. Sepa. level

3 Horizontal side blanking

4 UNSED

5 UNSED

6 1:count time clear to 20H;0:count time clear to 0H

7 1:user press key SLEEP clear time;0:no

SVM:

BIT FUNCTION

0

1

2

3

SVM gain

00:-6dB;01:0dB;10:+6dB;11:+12dB

SVM DL(svm delay)

00:off;01:-100ns;10:-60ns;11:-40ns

4 Mon、svm ??????

16

Page 17

5

6 1: SOFT CHANGE CHANNEL 0:no

7 UNUSE

VBLK

BIT FUNCTION

0

1

2

3

00:23H;01:33H;10:37H;11:41H (50Hz)

00:22H;01:30H;10:34H;11:38H (60Hz)

00:310H;01:299H;10:295H;11:291H (50Hz)

00:263H;01:254H;10:250H;11:246H (60Hz)

4

5

MODE0:

BIT FUNCTION

0 1:218 channels;0:100 channels

1 1:5060 (M system);0:tow way AV

2 0: SECAM;1:no

3 1:RGB Out-Cut Off DC;0:Y- MU T E

4 1:ALWAYS DISPLAY SOME MENU;0:SOMETIMES DISPLAY SOME MENU

5 0:ALPS 1:panasionc

6

7

SHOP OUT

00:DK;01:I;10:BG

MODE1:

BIT FUNCTION

0 0:no BG;1:yes

1 0:noI;1:yes

2 0:noDK;1:yes

3 0:no M;1:yes

4 0:when asm & search,set up VCO adjust req. ,1:only power on

0:PIF VCO adjust trigger 1: normal (12 :bit 7)

5 The algorithm of ASM. 0:ASM doesn't judge IFLOCK with case 4. 1:ASM judge IF

LOCK with case 4

6 The algorithm of ASM. 0:ASM doesn't judge Fhsync with case 4. 1:ASM judge Fhsync

with case 4

7 TINT polarity ,input to V/C/D. 0:normal 1:invert

AV _ O P T :

Byte FUNCTION

Video1 Video2 Video3

0 VIDEO DVD

1 VIDEO S-VIDEO DVD

2 VIDEO DVD VIDEO

3 VIDEO S-VIDEO DVD

4 VIDEO/S-VIDEO DVD

5 VIDEO/S-VIDEO VIDEO DVD

6 VIDEO DVD VIDEO

7 VIDEO VIDEO DVD

OPT2:

17

Page 18

BIT FUNCTION

0 lunar calendar 1:have lunar calendar ; 0:no lunar calendar

1 No use

2 1:english 0:chinese

3 AV WITH MUTE;1:yes;0:no

4 No use

5 1:super incept 0:no

6 No use

7 0:boot-strap welcome 1:no

MOD:

BIT FUNCTION

0

1

2

3 MOD.3:0 CUTOFF range:-0.65~+0.65;1:-0.65~+0.85

4

5

6

7

OSDA

BIT FUNCTION

0

1

2

3 OSD ABL: RGB ABCL 0:ABCL active for OSD 0:inactive

4

5

6

7

akb

CUTOFF

SENSITI

VITY

000:NO;001:45.75;011:38.9;100:38.0

OSD CONTRAST

00:80 IRE 01:70;02:60;03:50;

00:*9.75;01:*10.00;10:*10.25;11:*10.50

You can change the DATA with “*” mark when necessary.

5. CIRCUIT DIAGRAM

6. WIRING CONNECTION DIAGRAM

18

Page 19

21"-TSB-2IN1 Ref. Chassis(CQ0765)

XP201

1234567

SPOT

B

G

R

+9V

N301 AN7522N

12

BL301

R-10W8

XS301

2

1

BL302

R-10W8

XS302

2

1

N206

HS0038A2

VD207

S701

CH +

S702

CH S703

VOL +

S704

VOL S705

TV/VIDEO

S706

MENU

L909

!

QHXC-54F(AL)

XS601

!

C305

C306

4.7u

4.7u

C314

2.2U

V303

2SC2878A

22K

R309

2SC2878A

V301

VD301

A1015Y

1SS133

C313

47u

4.7K

R313

B6

+9V

GND

1

5V

2

IR

3

R239

270

R761

5.6K

R762

11K

R763

15K

R764

30K

R765

110K

+13V

RT601

!

XS602

PDC7RQPP6B744

1

1

(EMC)C602

!

0.1u/250V

(EMC)L602

LCL -04

!

(EMC)C601

0.22u/250VAC

!

SW601

B5

+5V CPU

R200

0

C200

47u

R235

1K

C201

0.01u

R581

10K

V555

R557

D400

0.5W12

R559

1.8K

R558

470

VD570

MTZ10A

B4

(EMC)VD603~VD606

RM11C

C606

C605

1KV 1000p

1KV 1000p

23

(EMC)L603

C603

1

LCL -04

1KV 1000p

C604

R698

1KV 1000p

7

0.5W220K

R602

7W 1R8

(EMC)N601

DRAIN1GND2VCC3FB/OCP4SYNC

RZ601

R601

0.5W220K

!

C696

F601

10u/50V

2.5A/250V

GND

VCC1OUT12GND3OUT14STANDBY5IN16GND7IN28VOL9OUT210GND11OUT2

B3

+12V

C309

R320

C310

1/2W-4.7K

0.01u

470u/25V

+5V-2

R305

C307

R308

68K

47u

270K

2.2u

C301

R301 5.6K

R303

C304

0.01

2.2K

V302

64

63

POWER

RMT-IN

U/V1L/H2KEY3GND4RESET5X-TAL6X-TAL7TEST8+5V9GND10GND11SCP-OUT12H-OUT13H.AFC14V-SAW15V-OUT16H-VCC17GND18Cb19Y-IN20Cr21EXT-AUDIO122C-IN23EXT-IN24ALC FILTER25TV-IN(1Vp-p)26ABCL-IN27AUDIO-OUT128AUDIO-OUT229TV-OUT(2Vp-p)30SIF-OUT31EXT-AUDIO2

R582

10K

ON

OFF

C1815Y

B6

+9V

VD571

1SS133

C570

4.7u

N602A

TLP421

C607

150u/450V

VD608

EU2A

L605TEM2011

CQ0765RT

C697

1000p/1KV

R681

2W-1K

10u/50V

5

R695

0.25W470

VD682

MTZ18C

L

C3022.2u

R302 5.6K

R

C303

R304

2.2K

R314

0.01

C312

R312

47K

0.1UF

22K

C311

VD306

2.2U

1SS133

N202

3

2

1

R207

V556

!

2

3

C681

VD302

VD305

1SS133

1SS133

NM24C08EN

R228 10K

5

VSS4SDA

6

A2

SCL

R22910K

7

C250

R230

A1

TEST

47

10u

8

A0

VCC

C249

0.01u

R234

22K

R233

22K

C247

100P

60

59

61

62

VT

AV SW

SYSTEM

TV SYNC

C202

0.01u

1K

C203

CH20p

R205

R209

33K

1K

V203

A1015Y

R210

4.7K

R570 1W 27

N205

1

3

7808

C520

C521

0.01u

2

470u/16V

1

R697

4

3W 56K

22n/630V

47n

C694

VD699

TRG1C

VD696

OPEN

C698

220p/1KV

C695

OPEN

R693

1W 5.1R

VD698

EU2A

VD697

EU2A

R694

1W 1.5K

VD695

C693

1SS133

3900P

57

58

SCL1

SDA1

(EMC)

C205

G201

10u

8M

C204

CH20p

R237

1.5K

R236

8.2K

VD201

HZ3.6V

H.VCC

+8V

C522

0.01u

R645

0.25W 1K

T601

BCK-05I-5

!

1 14

C699

3

5

7

!

R531

12M

!

C615 AC400V2200p

VD251

HZ10

L207

PL-10uH

C245

C244

10u

0.01u

55

54

52

53

56

5V

GND

MUTE

D GND

R446

C207

C206

10K

8200P

0.01u

L201

10u

VD420

RD9.1CB

R699

0.25W 1K

C622

VD621

!

RU4YX

2200u/25V

R6212W 1

C621

470p/2KV

9

W608

VD625

EU2A

0.5W10

11

470p/1KV

C629

VD622

!

R631

RU4YX

0.5W 0.22

13

C624

2200u/25V

C623

470p/1KV

C627

470p/2KV

10

12

VD624S2L60U

C600

100P

C625

8

VD623

RU4YX

!

!

2200u/35V

N204

7805

H.VCC

1

3

+8V

VD253

VD252

HZ10

HZ10

R226

R225

270

270

R211

8.2K

C208

0.47U

B3

+12V

0.47u(M)

C610

B7

+180V

C630

22u/250V

V5992SB892

R598

10K

1KV 470p

R628

0.5W 2.2

C626

+5V-2

2

L209

Sin1SW2G3SO4SO

PL-12uH

VD261

MTZ5.6C

C252

R217

0.5W 270

C239

C240

10u

0.01u

R227

270

49

R-OUT50G-OUT51B-OUT

D Vcc3.3V

N201

TMPA8873

C209

470u

0.22u(M)

C210

VD681

MTZ5.1B

1

B4

+13V

C640

R462

220u/160V

18K

R599

1K

R596

10K

R5973K9

C251

0.01u

100u

C235

C234

100u

0.01u

C237

0.22u

C236

2200P

1u

L205

220K

C238

R223

R224 30K

42

43

46

47

48

44

45

YC 5V

RF AGC

APC FIL

SYNC-OUT

BLACK DET

MONITOR-OUT

C212

C214

R213

C211

0.01u

L212

47u

R595

0.25W-1K

N705

TA7805

2

C568

470u/16V

R639

0.5W 150k

RP601

20K

C643

R640

3.6K

V598

2SB892

R215

0.1u(M)

100

100

0.1u(M)

VD204

R212

OPEN

100

C213

R214

1u

100

R813

1K

VD264

H.VCC

MTZ5.6C

+8V

C223

2.2u 50V

VD614

1N4148

VD641

1N4148

3

B5

+5V CPU

C569

0.01u

B1

+115V

R643

39K

K

0.15u

R

A

N604

KA431LZ

VD599

1N4148

R115

15k

DK/I/BG

Z101

N6283

5

L204 PL-12uH

R222

40

IF IN41IF IN

IF GND

R216

100

C216

0.47u

C215

10u

R201

1M

Input1Vcc2Pump Up3GND4Output5Out Vcc6Reference

R401

16K

C401

2700p

C409

220u/35V

B2

+27V

+115V

R110

10K

VD101

1SS133

V102

C1815Y

M

C229

C230

470u

0.01u

C231

C233

C232

4.7u

2.2u

OPEN

39

37

38

S-REG

IF AGC

AUDIO MON

VD202

C219

1SS133

0.1u(M)

10u

C220

C248

R218

0.47u

100K

C221

0.1u(M)

L

N401

C402

NC

C403

0.22u

R402

0.5W 1

C407

VD401

R405

62K

R407

10k

W401

OPEN

B6

R1282W12K

+33V

N121

C126

C125

uPC574J

AGC 1VT 2SCL 4SDA 5MB 6IF

1000P

10u 50V

R100

220

R111

6.8K

R107

L103

OPEN

C104

1uH

0.01u

R112

R106

2.2K

R109

390

0

C105

C103

0.01u

V101

2SC2216

C106

R108

OPEN

VD263

R231

1.5M

MTZ5.6C

R232

OPEN

R221

750

NP 10u

C227

C226

0.47u

C2281000P

35

34

36

SIF-IN33DC NF

PIF PLL

IF-VCC(5V)

C255

47u

32

VD205

R250

OPEN

100

R811

1K

R241

A1015Y

C224

3.3K

2.2u 50V

R

B6

+9V

STV9302A

R404

12K

7

R403

C404

5.6K

10u/16V

VD402

1N4761A

L401

TEM2011

100u/35V

EU2A

R406 47K

C405

25V/0.47u

C406

1000u/25V

R409

1.2k

R412

0.68

W402

OPEN

ADS3+33V

W109

SHORT

R103

OPEN

R130

1K

C102

0.01u

R105

0

R102

R113

1.5K

3.9K

15K

C130

R114

C109

MTZ5.1B

100k

4.7u

C108

C107

220u

0.01u

33

C225

0.01u

R220

4.7K

C257

R242

330

V204

0.01u

R246

150

R247

150

X203

A1015Y

L10.7M

R219

100

R263

3.3K

V214

R408

150

C408

100V 0.047u

V431

2SC2383

R434

R432

1K

330

R433

330

C431

500V3900p

+9V

C-IN

C

U101

9

11

L104

68uH

R245

1K

V205

C1815Y

R244

330

R243

2.2K

C412

0.39u630V

V432

!

2SD2499

C416

C415

2KV 680p

2KV 6800p

T402

BCT-02

C432

1000p

C433

L405

47u/35V

ZZ0008

R435

2W 270

R439

0.5W 20K

R810

R800

560

0.5W 100

C807

V805

22u 16V

C800

2SC1815Y

100u 16V

R801

100

R803

R804

100

R802

220

75

C802

R806

10u

1K

V802

R805

2SC1815Y

2.2K

C440

100V4700p

R436

B1

+115V

0

R808

100K

C803

0.01u

LX37

L407

RU2A

VD413

R451

1W4.7K

+200V

6

5

3

4

1

2

10

(EMC)T401

!

JF0501-19910

C400

10u 160V

XS801

Y

C801

470u 10V

VD266

MTZJ3.6A

R817

75

HV

KFC

KSC

7

XS802

V-OUT

L-OUT

AV-OUT

R-OUT

R807

75

VIDEO1 IN

R809

75

AUDIO1 IN(L)

R814

OPEN

AUDIO1 IN(R)

R812

OPEN

Y

R818

75

Cb

R819

75

Cr

L410

LHDY

XS401

5

4

4

3

3

2

R413

1

0.5W4.7K

1

C411

1uF/160V

XP402

4

3

HEAT

2

1

R460

0.5W 220K

C423

100V 0.1u

R442

10K

R901100

560

R902

R911 100

R912

560

R921

R922

560

B

R

G

SPOT

XS901

R904

15K 2W

VD901

1N4148

V901

2SC2482

R903

C901

1K

330P

VD911

1N4148

V911

2SC2482

R913

C911

1K

330P

VD921

1N4148

100

V921

2SC2482

R923

C921

330P

1K

R931

1.2K

VD950

MTZ10A

R932

2K7

+

C931

L901

10u/16V

PL-12uH

GND

1234567

9V

GND

AV (Pin 61)

OSD Pin 61(N201)

TV

AV1

AV2

DVD

R905

0.5W1.2K

R915

R925

R914

15K 2W

VE1A CRT SOCKET

R924

15K 2W

R927

R935

10K

V933

2SC1815

C933

R936

0.01u

47K

VD931

VD932

SHORT

SHORT

R933

330

SYS(Pin 59)

SYS Pin 59(N201)

0V

M

0V

D/K

5V

I

0V

B/G

0.5W1.2K

RF10-1W-4.7

XS903

XP903

2

2

1

1

VE1 CRT

0.5W1.2K

C902

2KV 1000P

XS902

200V

4

3

HEAT

2

1

GND

R940

33

C932

47u/16V

V931

R934

A1015

1K

0V

5V

5V

5V

Page 20

Page 21

7. Circuit Explanation

1、Microprocessor and Small signal processing: super monolithic integrated circuits :

Haier8873

Haier8873CSN is super large integrated circuit decoder, containing intermediate image

amplifying, intermediate sound amplifying, horizontal and vertical scan, small signal

processing, color decoding, hi-pressure tracing and over-load protection, I2C bus control.

Information introducing functions and testing data for maintenance is listed in Table 1.

Table 1

Step Function

U/V

1

L/H

2

KEY INPUT

3

DIGITAL GND

4

CPU RESET

5

X.TAL

6

X.TAL

7

TEST

8

+5 VCC

9

GND

10

SIGNAL GND

11

HORIZONTAL SYNC SIGNAL INPUT

12

HORIZONTAL RETURN PULSE

13

SIGNAL INPUT CHARACTER

HORIZONTAL LOCATION

HORIZONT AL AFC

14

VERTICAL SIGNAL PRODUCE

15

LOCATION

VERTICAL RETURN PULSE SIGNAL

16

INPUT CHARACTER VERTICAL

LOCATION

17 HORIZONTAL VCC

18 GND

19 Cb SIGNAL INPUT

20 Y SIGNAL INPUT

21 Cr SIGNAL INPUT

22 EXT AUDIO

23 COLOR SIGNAL INPUT

24

EXTERIOR VEDIO SIGNAL INPUT2

Working

Voltage

(V)

0 600 5000

1.8 600 5000

5 600 15000

0 0 0

5 600 10000

2.3 600 1000

2.0 600 15000

0 0 0

5 400 4500

0 0 0

0 0 0

1 750 150

1.7 500 550

6.3 750 1400

4.3 750 1500

5.3 750 1300

8.7 100 100

0 700 900

2.4 750 5000

2.4 750 5000

2.4 700 4500

0 0 0

0 0 0

2.4 700 4500

Ground Resistance (R)

Positive

(Ω)

Negative

(Ω)

25

ALL FILTER 3.4 320 300

VEDIO SIGNAL INPUT

26

ABCL-IN

27

AUDIO OUTPUT 1

28

2.6 750 5000

4.5 750 5000

3.5 750 1400

19

Page 22

AUDIO OUTPUT 2

29

TV OUTPUT

30

SIF SIGNAL OUTPUT

31

EXTERIOR AUDIO 2

32

SIF SIGNAL INPUT AND LEVEL REVIS

33

DC FEEDBACK

34

PIF PLL

35

+5 IF VCC

36

S-REG

37

AUDIO MON

38

IF AGC

39

IF GND

40

IF INPUT

41

IF INPUT

42

RF AGC

43

BLACK DET

44

MONITOR OUTPUT

45

APC FIL

46

YV 5V

47

48

SYNC OUT

8.8 100 100

3.6 700 950

1.8 700 2100

4.3 750 1400

2.9 750 5000

2.2 750 1400

2.4 500 1500

5 750 1100

2.1 750 4000

4.4 700 1400

1.7 0 5000

0 650 0

0 650 4500

0 750 4500

3.5 500 1400

5 600 1100

1.9 650 2200

1.8 750 5000

5 0 5000

100 0

1.8

VCC

49

RED SIGNAL OUTPUT

50

GREEN SIGNAL OUTPUT

51

BLUE SIGNAL OUTPUT

52

TV SIMULATE GND

53

GND

54

+5V VCC

55

MUTE

56

I2C SERIAL BUS DATA LINE 0

57

I2C SERIAL BUS COLOCK LINE 0

58

SYSTEM

59

TUNE VOLTAGE

60

AV CHOICE CONTROL

61

HORIZONTAL SYNCHRONIZATION

62

SIGNAL

REMOTE CONTROL INPUT

63

POWER

64

3.3 750 100

2.9 750 1100

2.9 750 1100

3.1 0 1100

0 0 0

0 400 0

5.1 600 4500

0 600 7500

0 600 12500

0 600 12500

0.1 600 12500

4.4 600 10000

0.2 600 10000

4.5 600 12500

5 600 12500

3.6 600 8000

1.Analysis of common path circuits

High frequency television signals, received via an antenna (or transmitted through a cable

TV system) to the input terminal of the high frequency tuner A101, are processed for

tuning and high frequency amplifying and mixing, then a 38.9MHz image intermediate

frequency and 34.4MHZ and intermediate frequency signal will be released at the IF

terminal of Z101 to b of the transistor V101, where signals are amplified to compensate for

the insertion losses of the sound surface wave filter. Single or dual-ended input is used for

20

Page 23

the sound surface wave filters Z101 of this appliance according to system properties.

Intermediate frequency signals will be transmitted to (41) and (42) of N201(HAIER8873).

The mixed signals of picture video signals and secondary sound intermediate frequency

signals output from (31) of N201, After sound carrier frequency is trapped by the trap filter,

intermediate frequency signals are amplified and PLL image decoded, The AGC time

constant is dependent on C233 (2.2u) connected to (39) of N201 (HAIER8873),.

2.Analysis of sound power amplifying circuits

Sound power amplifying circuits are composed of integrated circuits AN7522N and

peripheral components. AN7522N is an integrated electrical circuit . Information

introducing functions and testing data for AN7522N maintenance is listed in Table 4. T if a

cylindrical color card is installed then a fluke III digital multimeter is used.

Grounding Resistance (R)

Positive

(Ω)

Negative (Ω)

No. Function

Working

Voltage (V)

1 VCC 12.56

2 OUT1+ 6.52

3 GND 0

4 OUT1- 6.52

5 STANDBY 3.75

6 IN1 1.43

7 GND 0

8 IN2 1.43

9 VOLUME 1.99

7 GND 0

8 IN2 1.43

9 VOLUME 1.99

3.Analysis of vertical sync and vertical scan output circuits

The field sync signals segregated from compound sync signals are used to activate the

vertical frequency segregation system which commences when a set amount of vertical

sync pulse signals are tested. Of the sync pulse frequencies obtained from segregation,

some are transmitted to the vertical tooth wave generator. The vertical frequency tooth

wave, after geometric processing, is transmitted from (16) of N204 (HAIER8873) to (5) of

vertical scan output IC N401 (STV9302A). The external resistor R443 (5.6KΩ) of N201 (16)

provides a reference current to the vertical tooth wave generator. The external capacitor

C244 (0.1uF) of pin (2) forms the vertical ramp wave. The vertical ramp wave is sending

the pin (4) of the vertical scan output integrated circuit N401 that is a complete bridge

current drive output circuit. After shaped and amplified the vertical ramp wave is output

from pin (2) of N401.

Information introducing functions and testing data for STV9302A maintenance is listed in

Table 4. if a cylindrical color card is installed then a fluke III digital multimeter is used.

Table 5

Grounding Resistance (R)

Positive

(Ω)

Negative

(Ω)

No. Function

Working

Voltage

(V)

21

Page 24

1 input 2.61 0 0

2 VCC 26.56 0.45 1.9

3 PUMP UP 2.21 0.5 ∞

4 GND 0 0.9 1.25

5 output 16.31 0.68 1.75

6 OUT VCC 26.87 0.5 2.95

7 reference 2.62 0.65 1.3

4.Analysis of horizontal sync and horizontal scan output circuits

As the horizontal oscillation circuit is installed inside N201 (HAIER8873), Some brightness

signals including compound sync signals are transmitted to the internal sync segregation

circuits, where horizontal sync and vertical sync pulses are segregated. R321 (10K), R462

(12K) 、C452 (3900pF) 、VD436 and T401 are connected to N201 (13) are phase-lock

loop filters. Horizontal pumping signals are transmitted from (13) of N201 to horizontal

promotion transistor V431 (2SC2383), and then drive the H-DRIVE transformer. After

being amplified through it switches power transistor V432 (2SC5885) to control the

horizontal scan of the electronic-beam.C412 is a horizontal S correction capacitor and

L407 is for horizontal linear inductor. T401 is a horizontal output transformer. The

horizontal return pulse output from (7) of T402 is transmitted to pin (27) of N201 who

controls ABL circuits. ABL avoid high-voltage over rated value that will cause X-ray and

affect your health.

5.Analysis of video amplifying circuits

The video amplifying circuits are comprised of V901, V911, V921 and peripheral

components. R, G and B signals output from N201 (50), (51) and (52), 3 video power

transistor are available for amplifying the input R, G, B. White balance adjustment is

completed through N202 under control of an I2C serial bus control system.

8. Maintenance Service and Trouble shooting

A. Principle integrated circuits

A1. 21 INCH color TV set composed of the following sections

(1) Small signal processing: super monolithic integrated circuits N201(Haier8873).

and memory N202 (AT24C08).

(2) Sound power amplifying: integrated circuits N301 ( AN7522N).

(3) Horizontal and Vertical scan output circuits: Vertical output integrated circuits

N401 (STV9302A), Horizontal output transistor V432 (2SC5885), Horizontal

flying back transformer T401 (JF0501-19910).

(4) Switch power supply: switch transformer T601 (BCK-05I-5), power IC N601

(CQ0765).

22

Page 25

A2. Main integrated circuits:

p

(1) Haier8873 Microprocessor

Picture IF/sound IF/video processing/H and V

Scan/color decoding

(2) STV9302A Vertical output integrated circuits

(3) AN7522N Sound power amplifying integrated circuits

A3. Error Detection Process

1.

Normal

Normal

The failure of horizontal

The failure ofhorizontal unit

unit orN201

orN204

Check to see

if , 8v,

5v is normal

Normal

Check VD604~VD607,

C607, N601, N604 etc.

Check to see if the

collector voltage of V598

is 27V

Check the control

voltage of V599 or

CPU

Check N202 ,ect

No light and sound

Check to see if

Fuse is normal

Normal

Abnormal

ower pin

Abnormal

Normal

Check switch

Abnormal

Check to see 110V、180V

etc. voltage is normal

Abnormal

T est to see all terminal

Resistance of load

power unit

Normal

Check the

Loader

Check to see if

rectifying tube

is normal

Abnormal

Abnormal

Change

rectifying diode

23

Page 26

2

Normal

Check the voltage

of all pins of XS903

Normal

Video amplifying

board is abnorma

Normal

Test filament voltage Test the base voltage of V431

Whether G2 voltage is normal

Abnormal

Heater Resistor

open

Abnormal

Inspect the circuit

l

from pin50 、51、

52 of N201 to

video amplifying

Normal

Check to see if +8V

voltage is normal at

PIN 17 of N201

Check G201、N201 and

peripheral circuit of N201

No raster

Check to see if be

voltage of V432 is

NO

Check the voltage

of V432 collector is

Higher

T401,VD415 or

C415,C416 are

Change wrong component

or check peripheral circuit

Normal

Abnormal

Normal Abnormal

Check the circuit

from pin13 of N201 to

existed?

YES

InspectT401、R436

normal

Lower

V432 is not well

welded or open

Abnormal

Abnormal

Check +8V power supply

V431

etc

.

24

Page 27

f

p

y

0

3

Yes

Change N201 and

repair circuit

Normal

4.

Enter D-MODE or enter

S-MODE with customer

remote controller. Make

RAGC tuned to 25 or so.

Noise on picture just

Yes

Check to see if the voltage of

pin 15 and pin16 of N201 is

normal

Not exist

Check to see if RAGC is

Yes

disappears.

Horizontal bright line

Make R328 open. Multimeter is at range RΧ1K. Red

probe connects to ground. Touch No.5 of N401 with

black probe. Bright line flashes for a moment

Check to see if voltage of pin6 at

N401 is normal

No

Inspect N201

and peripheral

components of

N2

1

at 00 mode

Z101、N20and PIF

Check to see if the deflection

yorks are connected, C433 is

peripheral component of N401

No sound and picture

Snowy noise exist

No

Inspect V101、

part

Yes

open or weldless. Inspect

and N401 itsel

Check to see if voltage

output available at tuner

Yes

Antenna

or tuner is

abnormal

No

No

Inspect +27V

ower suppl

Exist

No

Inspect the

circuit from

CPU to tuner

25

Page 28

5

6.

Picture exists but no sound

Make C305/C306 open. Multimeter is at band RΧ1K. Red

probe connect to ground. Touch No.6 OR No.8 of N301 with

No noise

Power amplifier is abnormal.

Inspect N301 and peripheral

Inspect N201 and peripheral

Change V901 or

weld V901 again

components of N301

Inspect C301、C302

Yes

component of N201

Check to see if V901 is

open or not well welded

Yes

Make C301 OR C302 collector

open. Touch No.6 OR No.8 of V301

Yes

Lack of red

Inspect R902,R903,R904

with black probe to see if noise

Check to see if voltages of XS901

No

Inspect Inspect the circuit from

are normal

Have noise

No

Check to see if

+11V exists

No

Inspect +11V

power supply

No

Yes

No.50of N201 to No.3

of XS903

26

Page 29

Troubleshooting

Before calling service personnel, please check the following chart for a

possible cause to the trouble you are experiencing.

Symptom

TV is not

turned on

Good picture ,

no sound

Poor color / tint,

good sound

Spots appear

on the screen

Lines appear

on the screen

Double images

or ghosts

Snowy picture or

black screen

Check these things

Be sure t he power cord is plugg ed in .

The MUTE f unction may be used.

Adjust the volume of the TV set.

The cont rast, color and tint m ay be incorrectly ad ju st ed.

If you change t he direction of the TV while the TV is on, the picture

may suffer from color shading. If so, turn off the TV and allow about

30 minut es to cool, t hen turn on the T V again.

The broadcast signal may be jammed by other electrical sources such

as cars, motorcycles, electric trains, high tension lines, neon signs, hair

dryers.

The broadcast signal may be jammed by other TV receivers, personal

compu ters, and T V games, as well a s interferen ce from radio stati ons.

Interference may be due to broadcast waves reflected from m ountains

or buildings.

Check if the direction of the antenna is changed.

The anten na may be disconn ected or falling out.

Check if the di rection of the antenn a is changed.

The bat t er ies in the remote control may be exha uste d.

The batteries may be improperly installed.

Check if there are obstacles between the remote control and the

remote (infrared ray) receiver.

Check if there is strong light int er f erence around the rem ot e ( in frared)

receiver.

Check if the main power is ON.

The following conditions are not troubles

Clacking noise inside

the receiver

Uneven colour in a

certain portion of the

screen

It may result fr om the e xpans ion of the shell cau sed by a tempe rature

change . This wi ll not af fect t he pictur e and so und q uality .

If the picture is too bright, this may occur according to the nature of

the pictures. Reduce the contrast, it may resume to normal.

CAUTION

In case of problems , have your T V serviced by qualified personne l. Never

attem pt to service the set yourself since opening the cabinet may expose

you to dangerous v oltage or other hazards.

27

Page 30

Sincere Forever

Haier Group

Haier Industrial Park, No. 1, Haier Road

266101,Qingdao,China

http://www.haier.com

28

Loading...

Loading...