Page 1

SPLIT SYSTEM AIR CONDITIONER

INSTALLATION MANUAL

Contents

1UH071N1ERG

1UH090N1ERG

1UH105N1ERG

1UH125P1ERG

1UH140P1ERG

1UH125P1ERK

1UH140P1ERK

Definitions

Safety considerations

Before installation

Selecting installation site

Precautions on installation

Refrigerant pipe size and allowable

pipe length

Refrigerant piping

Leak test andvacuum drying

Charging refrigerant

Pump down operation

Electrical wiring work

Test operation

11

13

14

15

15

17

1

2

3

6

7

8

English

No. 0150518634

This product must only be installed or serviced by qualified personnel.

Please read this manual carefully before installation.

Keep this operation manual for future reference.

Original instructions

Page 2

Haier Industrial Park,Qianwangang Road,Eco-Tech Development Zone,Qingdao 266555,Shandong,P.R.C.

DISPOSAL REQUIREMENTS:

Your air conditioning product is marked with this

symbol.This means that electrical and electronic

products shall not be mixed with unsorted

household waste.Do not try to dismantle the

system yourself:the dismantling of the air

conditioning system,treatment of the refrigerant,of oil and of

other part must be done by a qualified installer in accordance

with relevant local and national legislation.Air conditioners

must be treated at a specialized treatment facility for reuse,

recycling and recovery.By ensuring this product is disposed

of correctly,you will help to prevent potential negative consequences for the environment and human health.Please

contact the installer or local authority for more information.

Battery must be removed from the remote controller and disposed of separately in accordance with relevant local and

national legislation.

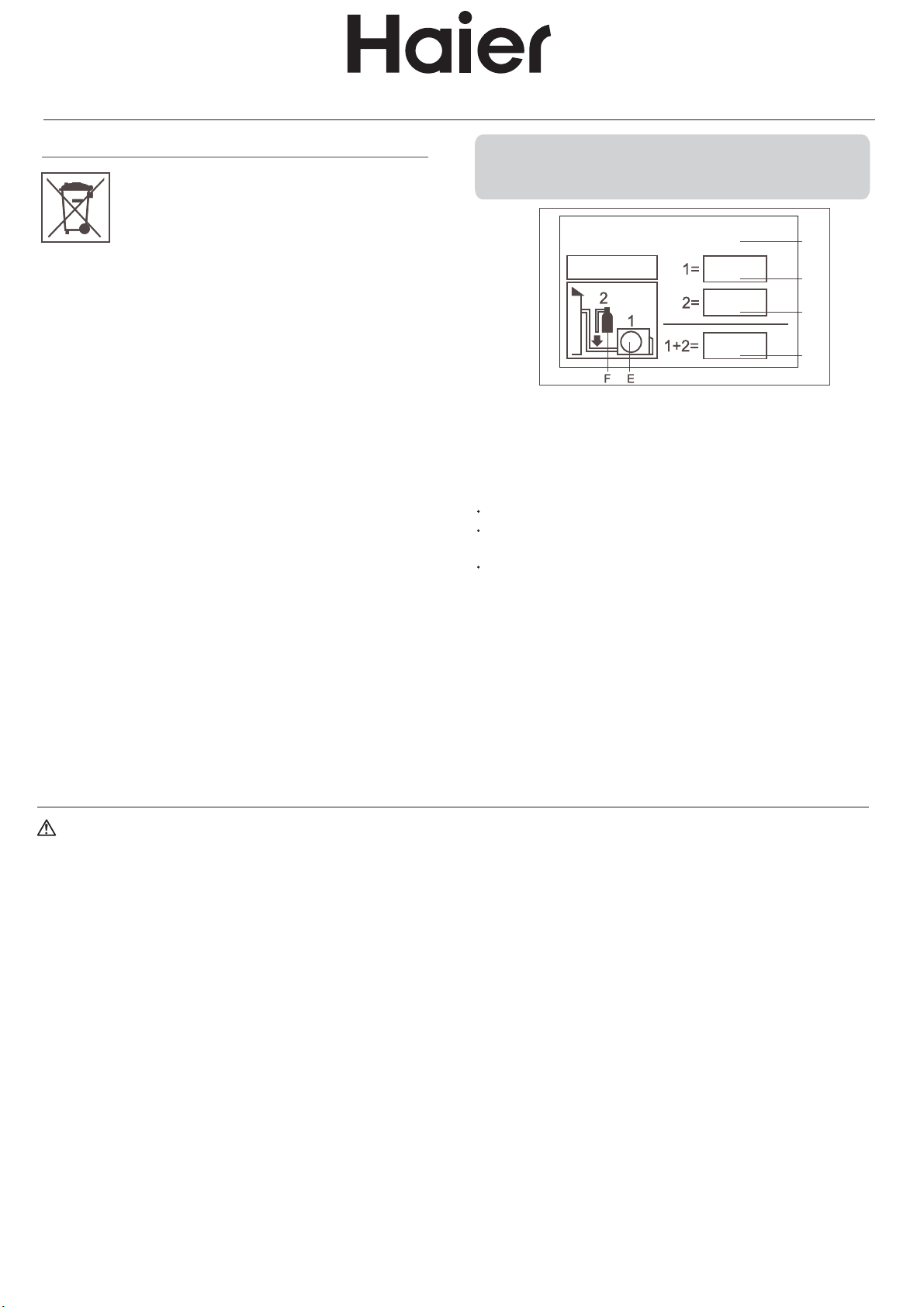

IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

R410A

This product contains fluorinated greenhouse gases covered

by the Kyoto Protocol.Do not vent into the atmosphere.

Refrigerant type:R410A

GWP*value:1975

GWP=global warming potential

Please fill in with indelible ink,

1 the factory refrigerant charge of the product

2 the additional refrigerant amount charged in the field

and

1+2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the

product charging port(e.g.onto the inside of the stop value

cover).

A contains fluorinated greenhouse gases covered by the

Kyoto Protocol

B factory refrigerant charge of the product:see unit name

plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

kg

kg

kg

A

B

C

D

WARNING

f the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in

I

order to avoid a hazard.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning use

of the appliance in a safe way and understand the hazards involved. Children shall not play with the appliance. Cleaning

and user maintenance shall not be made by children without supervision.

The appliances are not intended to be operated by means of an external timer or separate remote-control system.

Keep the appliance and its cord out of reach of children less than 8 years.

The A-weighted sound pressure level is below 70 dB.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for commercial

use by lay persons

The power cable should be H05RN-F 3G 4.0mm

2

.

Air conditioner working temperature: cooling 10~46 degree, heating -15~24 degree.

Page 3

1. Definitions

1.1. Meaning of warnings and symbols

Warnings in this manual are classified according to their

severity and probability of occurrence.

DANGER

Service company:

Qualified company which can perform or coordinate the

required serice to the unit.

Applicable legislation:

All international, European, national and local directives,

laws, regulations and/or codes which are relevant and

applicable for a certain product or domain.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

NOTICE

Indicates situations that may result in equipment or

property-damage accidents only.

INFORMATION

This symbol identifies useful tiops or additional information.

Some types of danger are represented by special symbols:

Accessories:

Equipment which is delivered with the unit and which needs

to be installed according to instructions in the documentation.

Optional equipment:

Equipment which can ooptionally be combined to the products

as per the subject of this manual.

Field supply:

Equipment which needs to be installed according to

instructions in this manual, but which are not supplied by

Haier.

2. Safety considerations

The precautions here, all cover very impertant topics, so be

sure to follow them catefully.

All activities described in this manual shall be carried out by

an installer.

Electric current.

Danger of burning and scalding.

1.2. Meaning of used terms

Installation manual:

Instruction manual specified for a certain product or application,

explaining how to install, configure and maintain it.

Operation manual:

Instruction manual specified for a certain product or application,

explaining how to operate it .

Maintenance instructions:

Instruction manual specified for a certain product or application,

which explains ( if relevant ) how to install, configute, operate

and/or maintain the product or application.

Dealer:

Sales distributor for products as per the subject of this manual.

Installer

Technical skilled person who is qualified to install products

as per the subject of this manual.

User:

Person who is owner of the product and/or operates the

product.

Be sure to wear adequate personal protection equipment (

Protection gloves, safety glasses......) when performing

installation, maintenance or service to the unit.

If not sure of installation procedures or operation of the unit,

always contact your local dealer for advice and information.

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit, leaks,

fire or other damage to the equipment. Be sure only to use

accessories, optional equipment and spare parts made by

which are specially designed for use with the products as

of subject in this manual and have them installed by an

installer.

DANGER: ELECTRICAL SHOCK

Switch off all power supply before removing the switch

box service panel or before making any connections

or touching electrical parts.

avoid electric shock, be sure to disconnect the power

To

supply 2 minute or more before servicing the electrical

parts. Even after 2 minute, always measure the voltage

at the terminals of main circuit capacitors or electrical

parts. Even after 2 minute, always measure the votage

at the terminals of main circuit capacitors or electrical

parts, and before touching, be sure that those voltages

are 50V DC or less.

3

Page 4

When service panels are removed, live parts can easily

be touched by accident, Never leave the unit unattended

during installation or servicing when the service panel is

removed.

DANGER: DO NOT TOUCH PIPING AND INTERNAL

PARTS

Do not touch the refrigerant piping, water piping or internal

parts during and immediately after operation. The piping

and internal parts may be hot or cold depending on the

working condition of the unit.

Your hand may suffer burns or frostbite if you touch the

piping or internal parts. To avoid injury, give the piping

and internal parts time to return to normal temperature

or, if you must touch them, be sure to wear protective

gloves.

Warning:

Ask your dealer or qualified personnel to carry out

installation work. Do not install the machine by yourself.

Improper installation may result in water leakage, electric

shocks or fire.

Perform installation work in accordance with this installation

manual.

Improper installation may lead to water leakage, electric

shocks or fire.

The equipment is not intended for use in a potentially

explosive atmosphere.

For 1UH series units only.

For year

conditions, such as Electronic Data Processing rooms,

contacet yout dealer or see the engineering databook or

the service manual.

Consult your local dealer regarding what to do in case

of refrigerant leakage. When the unit is to be installed in

a small room, it is necessary to take proper measures so

that the amount of any leaked refrigerant does not exceed

the concentration limit in the event of a leakage. Otherwise,

this may lead to an accident due to oxygen depletion.

Be sure to use only the specified accessories and parts

for installation work.

Failure to use the specified parts may result in water

leakage, electric shocks, fire, or the unit falling.

Install the unit on a foundation that can withstand its

weight.

Insufficient strength may result in the fall of equipment

and causing injury.

Carry out the specified installation work in consideration

of strong winds, typhoons, or earthquakes.

Improper installation work may result in accidents due to

fall of equipment.

Make sure that all electrical work is carried out by qualified

personnel according to the applicable legislation and this

installation manual, using a separate circuit.

Insufficient capacity of the power supply circuit or improper

electrical capacity of the power supply circuit or improper

electrical construction may lead to electric shocks or fire.

round cooling applications with low indoor humidity

Make sure that all wiring is secure, using the specified

wires and ensuring that external forces do not act on the

terminal connections or wires.

Incomplete connection or fixing may cause a fire.

When wiring between the indoor and outdoor units, and

wiring the power supply, form the wires so that the

fronstside panel can be securely fastened.

If the frontside panel is not in place, overheating of the

terminals, electric shocks or a fire may be caused.

If refrigerant gas leaks during installation work, ventilate

the area immediately.

Toxic gas may be produced if refrigerant gas comes into

contactwith fire.

After completing the installation work, check to make

sure that there is no leakage of refrigerant gas.

Toxic gas may be produced if refrigerant gas leaks into

the room and comes into contact with a source of fire,

such as a fan heater, stove or cooker.

When planning to relocate former installed units, you

must first recover the refrigerant after the pump down

operation.

Never directly touch any accidental leaking refrigerant.

This could result in severe wounds caused by frostbite.

Be sure to install an earth leakage circuit breaker in

accordance with applicable legislation. Failure to do so

may cause electrical shock and fire.

Caution:

Earth the unit.

Earthing resistance should be according to applicable

legislation.

Do not connect the earth wire to gas or water pipes,

lightning conductor or telephone earth wire.

Incomplete earthing may cause electric shocks.

Gas pipe.

Lgnition or explosion may occur if the gas leaks.

Water pipe.

Hard vinyl tubes are not effective earths.

Lightning conductor or telephone earth wire.

Electric potential may rise abnormally if struck by a

lightning bolt.

Install drain piping according to this installation manual

to ensure good drainage, and insulate the pipe to prevent

condensation.

Improper drain piping may cause water leakage, and

make the fumitures get wet.

Install the indoor and outdoor units, power wire and

connecting wire at least 1 meter away from televisions

or radios to prevent image interference or noise.

(Depending on the radio waves, a distance of 1 meter

may not be sufficient to eliminate the noise.)

Do not rinse the outdoor unit, This may cause electric

shocks or fire.

Do not install the unit in places such as the following:

Where there is mist of mineral oil, oil spray or vapour

for example a kitchen.

Plastic parts may deteriorate, and cause them to fall

out or water to leak.

Where corrosive gas, such as sulphurous acid gas,

is produced.

Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

4

Page 5

Where there is machinery which emits electromagnetic

waves.

Electromagnetic

andcause malfunction of the equipment.

Where flammable gases may leak, where carbon fiber

or ignitable dust is suspended in the air or where volatile

flammables, such as thinner or gasoline, are handled.

SUch gases may cause a fire.

Where the air contains high levels of salt such as that

near the ocean.

Where voltage fluctuates a lot, such as in factories.

In vehicles or vessels.

Where acidic or alkaline vapour is present.

Do not allow a child to mount on the outdoor unit or

avoid placing any object on the unit. Falling or tumbling

may result in injury.

The unit may stop for several minutes during normal

operation for "defrosting the unit", or when in "thermostat

stop" operation.

This appliance is intended to be used by expert or trained

users in shops, in light industry and on farms, or for

commercial use by lay persons.

Provide a logbook

In accordance with the relevant national and international

codes, it may be necessary to provide a logbook with the

equipment containing at least

- info on maintenance.

- repair work,

- results of tests,

- stand-by periods,

- etc...

In Europe, EN378 provides the necessary guidance for this

logbook.

waves

may disturb the control system,

3. Before installation

3.1. Scope of this manual

This manual describes the procedures for handling, installing

and connecting 1UH071~140 units.

Check the following if the ground-fault circuit interrupter is

triggered:

Make sure that the interrupter is compatible with high

frequencies.

This unit has an inverter, so an interrupter capable of

handling high frequencies is needed to prevent

malfunction of the interrupter itself.

3.3. Precautions for R410A

The refrigerant requires strict cautions for keeping the

system clean, dry and tight.

- Clean and dry

Foreign materials (including mineral oils or moisture)

should be prevented from getting mixed into the system.

- Tight

Read "9. Precautions on refrigerant piping" on page 10

carefully and follow these procedures correctly.

Since

R410A is a mixed refrigerant, the required additional

refrigerant must be charged in its liquid state.(If the

refrigerant is in state of gas, its composition changes

and the system will not work properly).

The connected

exclusively for R410A.

indoor units must be indoor units designed

3.4. Installation

For installation of the indoor unit(s), refer to the indoor

unit installation manual.

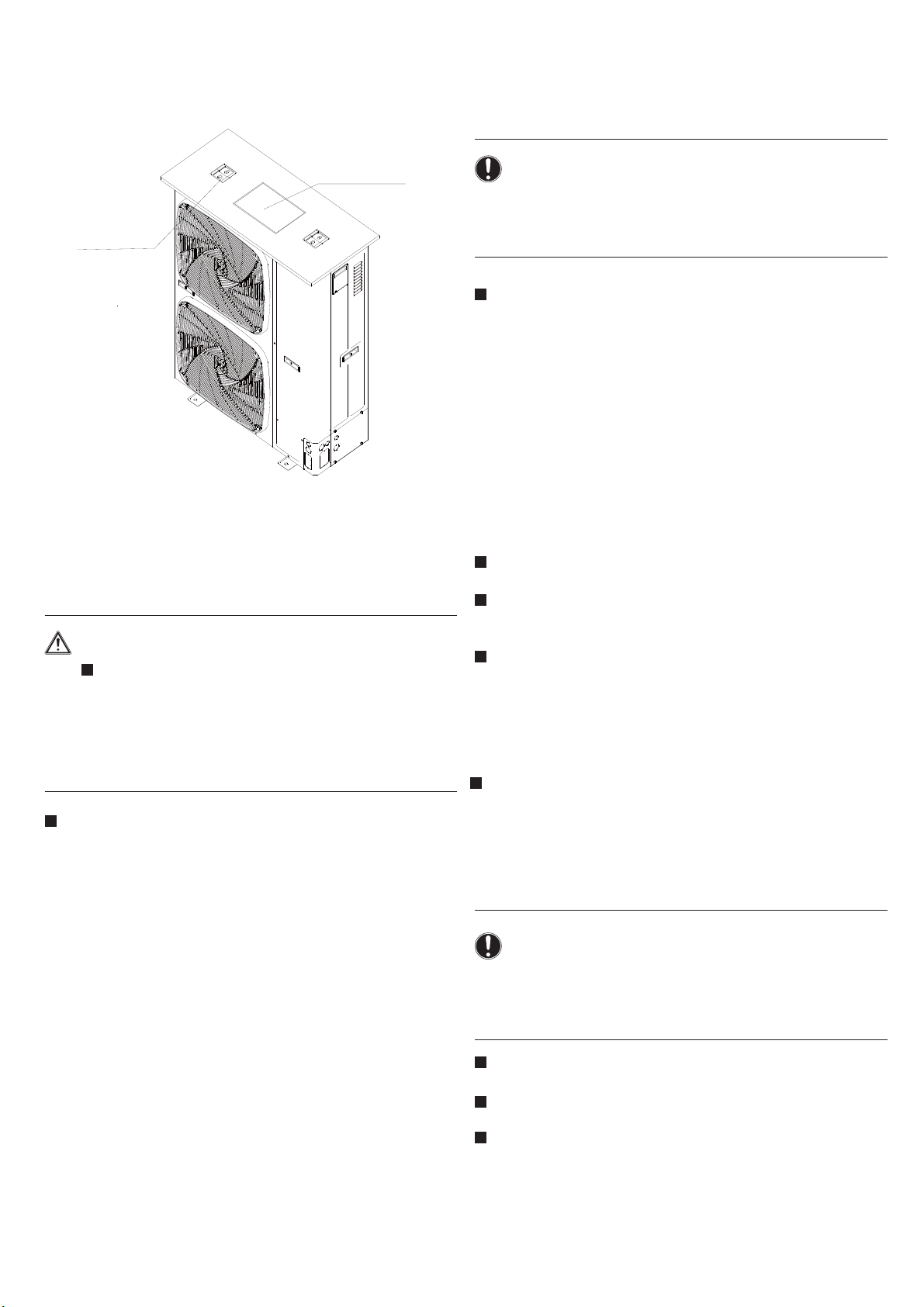

Illustrations show 1UH140P1ERK outdoor unit type.

Other types also follow this installation manual.

This outdoor

when used as the outdoor unit for the simultaneous

operation system. Refer to catalogues for details.

Never operate the unit with a damaged or disconnected

discharge thermistor and suction thermistor, burning of

the compressor may occur.

Be sure to confirm the model name and the serial no.

of the outer(front) plates when attaching/detaching the

plates to avoid mistakes.

When closing the service panels, take care that the

tigntening torque does not exceed 4.1 N.M.

unit requires the pipe branching kit(optional)

3.2. Precautions

CAUTION

Since maximum working pressure is 4.15 MPa or 41.5

pipes of larger wall thickness may be required. Refer

bar,

to paragraph "6.2. Selection of piping material" on page

10.

NOTICE: Insulation resistance of the compressor

If, after installation, refrigerant accumulates in the

compressor, the insulation resistance can drop, but if it

is at least 1

Turn the power on and leave it on for six hours. Then,

check if the insulation resistance of the comressor has

risen or not.

The compressor will heat up and evaporate any refrigerant

in the compressor.

, then the machine will not break down.

5

Page 6

3.5. Accessories

Check if the following accessories are included with the unit:

See the figure below for the location of the accessories.

- Do not climb, sit or stand on top of the unit.

- Be sure that sufficient precautions are taken, in

accordance with applicable legislation, in case of

refrigerant leakage.

installation

manual

rubber base

foot

4. Selecting installation site

4.1. General

WARNING

Be sure to provide for adequate measures in order

to prevent that the outdoor unit be used as a shelter

bye small animals.

Small animals making contact with electrical parts

can cause malfunctions, smoke or fire. Please instruct

the customer to keep the area around the unit clean.

NOTICE

This is a class A product. In a domestic environment

this product may cause radio interference in which case

the user may be required to take adequate measures.

When installing the unit in a place exposed to strong

wind, pay special attention to the following.

Strong winds of 5 m/sec or more blowing against the

outdoor unit's air outlet causes short circuit (suction of

discharge air), and this may have the following

consequences:

- Deterioration of the operational capacity.

- Frequent frost acceleration in heating operation.

- Disruption of operation due to rise of high pressure.

- When a strong wind blows continuously on the face

of the unit, the fan can start rotating very fast until it

breaks.

Refer to the figures for installation of this unit in a place

where the wind direction can be foreseen.

Repare a water drainage channel around the foundation,

to drain waste water from around the unit.

If the water drainage of the unit is not easy, please build

up the unit on a foundation of concrete blocks, etc.(the

height of the foundation should be maximum 150mm).

If you install the unit on a frame, please install a waterproof

plate(field supplu) within 150mm of the underside of the

unit in order to prevent the invasion of water from the

lower direction.

When installing the unitin a place frequently exposed to

snow, pay special attention to elevate the foundation as

high as possible.

Make sure that the unit is installed level.

Select an installation site where the following conditions

are satisfied and that meets with your customer's approval.

- Places which are well-ventilated.

- Pllaces where the unit does not bother next-door

neighbours.

- Safe places which can withstand the unit's weight and

vibration and where the unit can be installed level.

- Places where there is no possibility of flammable gas

or product leak.

- The equipment is not intended for use in a potentially

explosive atmosphere.

- Places where servicing space can be well ensured.

- Places where the indoor and outdoor units's piping and

wiring lengths come within the allowable ranges.

- Places where water leaking from the unit cannot cause

damage to the location (e.g. in case of a blocked drain

pipe)

- Places where the rain can be avoided as much as

possible.

- Do not install the unit in places often used as work place.

In case of construction works (d.g.grinding works ) where

a lot of dust is created, the unit must be covered.

- Do not place any objects or equipment on top of the

unit( top plate).

4.2. General

NOTICE

When operating the outdoor unit in a low outdoor

amnient temperature, be sure to follow the instructions

described below.

To prevent exposure to wind, install the outdoor unit with

its suction side facing the wall.

Never install the outdoor unit at a site where the suction

side may be exposed directly to wind.

To prevent exposure to wind, install a baffle plate on the

air discharge side of the outdoor unit.

In heavy snowfall areas it is very important to select an

installation site where the snow will not affect the unit

and set the outlet side at a right angle to the direction

of the wind.

6

Page 7

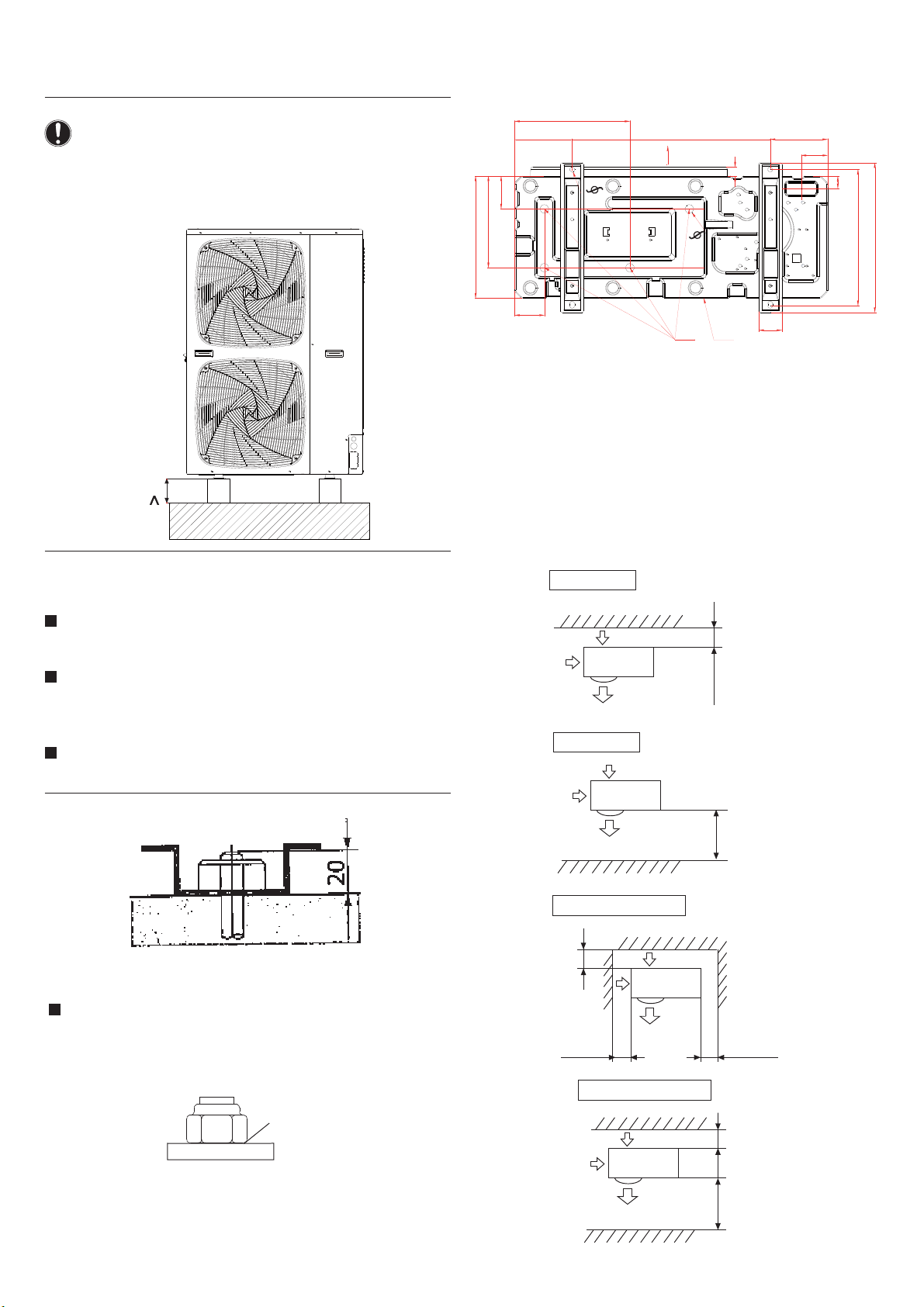

5. Precautions on installation

NOTICE

If drain holes of the outdoor unit are covered by a

mounting base or by floor surface, raise the unit in order

to provide a free space of more than 130mm under the

outdoor unit.

130mm

If the coating on the fastening area is stripped off, the

nuts rust easily.

Dimensions (bottom view)(unit of measurement:mm)

349

174 A 600 174

80

F

99

2-

15

C

27

4-

367

276

26

90

D

70

E

A leg pitch1

B leg pitch2

C Front grill (air outlet side)

D Drain hole

E Bottom frame

F Knock-out hole (for piping line)

37

450

B (405~410)

5.1. Foundation work

Check the strength and level of the installation ground

so that the unit will not cause any operating vibration or

noise after installation.

In accordance with the foundation drawing in the figure,

fix the unit securely by means of the foundation bolts.

(Prepare four sets of M12 foundation bolts, nuts and

washers each which are available on the market.)

It is best to screw in the foundation bolts until their length

are 20mm from the foundation surface.

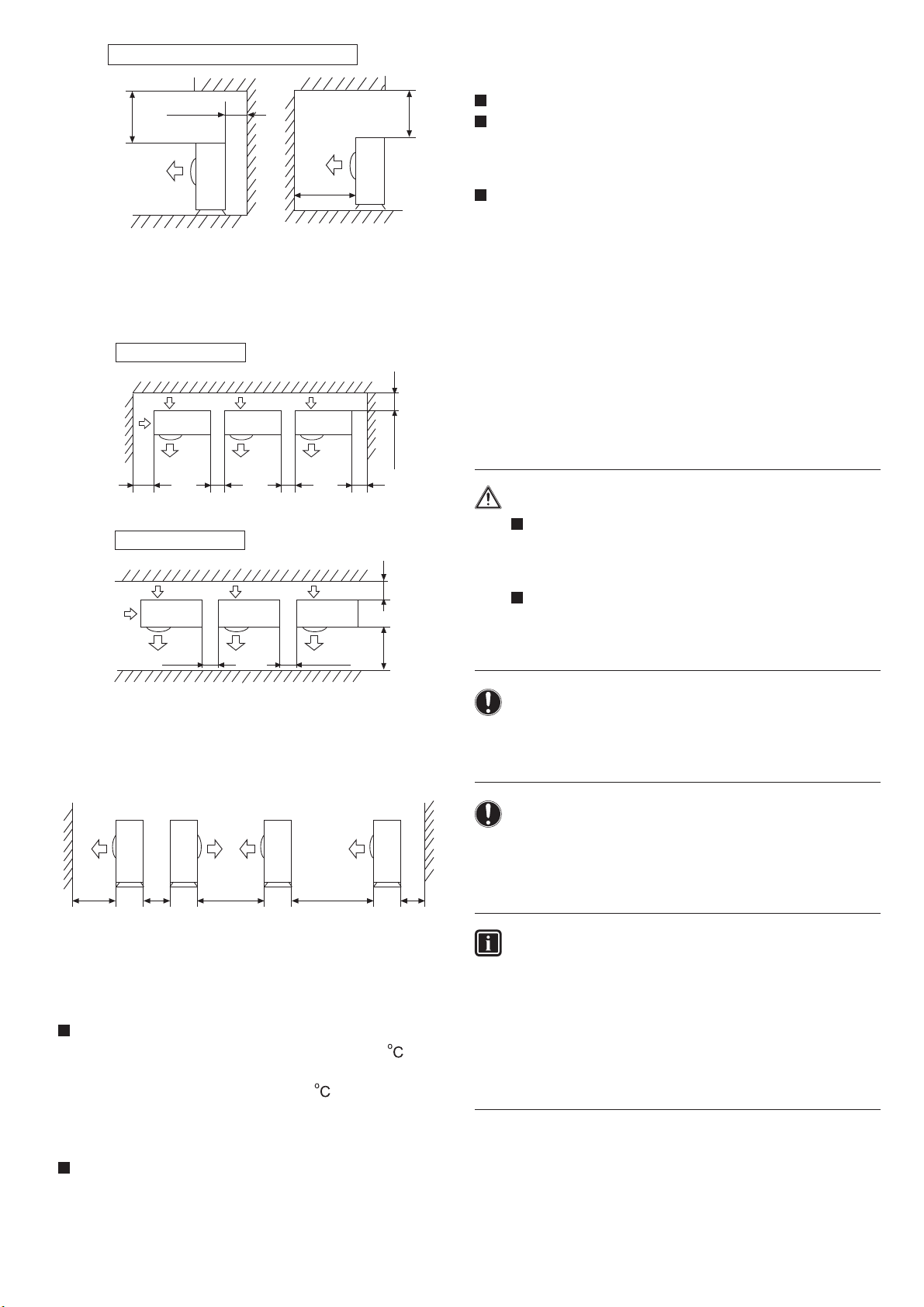

5.2.Selection of installation location of outdoor

(1)Single-unit installation (unit: mm)

Back

Above 150

Front

Above 500

Back and side

Height of barriers is

below that of outdoor unit

Fix the outdoor unit to the foundation bolts using nuts

with resin washers(1) as shown in the figure.

1

Above 200

Above 150 Above 300

Front and back

Above 150

Above 1000

7

Page 8

When barriers exist above the unit

5.3. Drain pipe disposal

Above 150

Above 500

Above

1000

The top and two side surfaces must be exposed to open

space, and barriers on at least one side of the front and back

shall be lower than the outdoor unit.

(2) Multi-unit installation (unit: mm)

Back and side

Above 200

Above 150

Above 300

Above 300

Above 300

Front and back

Make sure the drain works properly.

where buildups of snow can be expected, the

Above 1000

In regions

accumulation and freezing of snow in the space between

the heat exchanger and external plate may lower operating

efficiency.

After punching the knock-out hole, the application of

repair-type paint on the surface around the edge sections

is recommended to prevent rust.

6. Refrigerant pipe size and

allowable pipe length

DANGER

Piping an other pressure containing parts shall

comply with the applicable legislation and shall be

suitable for refrigerant. Use phosphoric acide

deoxidised seamless copper for refrigerant.

Installation shall be done by an installer, the choice

of materials and installation shall comply with

applicable legislation. In Europe the EN378 is the

application standard that shall be used.

Above 300 Above 300

Above 1000 Above 200

Height of barriers is below that of outdoor unit

(3) Multi-unit installation in front and back (unit: mm)

Standard

Above 1000

Above 300

Above 1500

Above 2000

Above 200

The top and two side surfaces must be exposed to open

space, and barriers on at least one side of the front and back

shall be lower than the outdoor unit.

The installation service spaces shown in the illustrations

are based

on an air intake temperature of 35

(DB) for

COOL operation. In regions where the air intake

temperature regularly exceeds 35

(DB), or if the heat

load of outdoor units is expected to regularly exceed

the maximum operating capacity, reserve a larger space

than that indicated at the air intake side of units.

Regarding the required air outlet space, position the

units with consideration to the space required for the

onsite refrigerant piping work as well. Consult your dealer

if the work conditions do not match those in the drawings.

INFORMATION

It is forbidden to discharge refrigerant into the atmosphere.

Collect the refrigerant in accordance with the freon

collection and destruction law.

NOTICE

To persons in charge of piping work:

Be sure to open the stop valve after piping installing

and vacuuming is complete. (Running the system with

the valve closed may break the compressor.)

NOTICE

Do not use flux when brazing the refrigerant piping.

For brazing, use phosphor copper brazing filler metal

(BCuP) which does not require a flux.

(If a chlorine flux is used, the piping will corrode, and

if the flux contains fluoride, if will cause the coolant oil

to deteriorate, adversely affecting the coolant piping

system.)

8

Page 9

6.1. Necessary Tools and Materials

Prepare the following tools and materials necessary for installing and servicing the unit.

Necessary tools for use with R410A(Adaptability of tools that are for use with R22 and R407C).

1. To be used exclusively with R410A ( Not to be used if used with R22 or R407C )

Tools/Materials Use Notes

Gauge Manifold Evacuating,refrigerant charging 5.09MPa on the High-pressure side.

Charging Hose Evacuating, refrigerant charging Hose diameter larger than the concentional ones.

Refrigerant Recovery Equipment Refrigerant recovery

Refrigerant Cylinder Refrigerant charging Write down the refrigerant type. Pink in color at the top of the cylinder.

Refrigerant Cylinder Charging Port Refrigerant charging Hose diameter larger than the conventional ones.

Flare Nut Connecting the unit to piping Use Type-2 Flare nuts.

2. Tools and materials that may be used with R410 with some restrictions

Tools/Materials Use Notes

Gas leak detector Detection of gas leaks The ones for HFC type refrigerant may be used.

Vacuum Pump Vacuum drying May be used if a reverse flow check adaptor is attached.

Flare Tool Flare machining of piping Chages have been made in the flare machining dimension.Refer to the next page.

Refrigerant Recovery Equipment Recovery of refrigerant May be used if designed for use with R410A.

3. Tools and materials that are used with R22 or R407C that can also be used with R410A

Tools/Materials Use Notes

Vacuum Pump with a Check Valve Vacuum drying

Bender Bending pipes

Torque Wrench Tightening flare nuts Only 12.70 (1/2'') and 15.88(5/8'') have a larger flare machining dimension.

Pipe Cutter Cutting pipes

Welder and Nitrogen Cylinder Welding pipes

Refrigerant Charging Meter Refrigerant charging

Vacuum Gauze Checking vacuum degree

4. Tool and materials that must not used with R410A

Tools/Materials Use Notes

Charging Cylinder Refrigerant Charging Must not be used with R410-type units.

Tools for R410A must be handled with special care, and keep moisture and dust from entering the cycle.

9

Page 10

6.2. Piping Materials

Types of Copper Pipes (Reference)

Maximum Operation Pressure Applicable Refrigerants

3.4MPa R22, R407C

4.15MPa R410A

Use pipes that meet the local standards.

Piping Materials/Radial Thickness

Use pipes made of phosphorus deoxidized copper.

Since the operation pressure of the units that use R410A is higher than that of the units for use with R22, use pipes with

at least the radial thickness specified in the chart below. (Pipes with a radial thickness of 0.7mm or less may not be used.)

Size(mm) Radial Thickness(mm)Size(inch)

6.35

9.52

12.7

15.88

19.05 3/4'' 1.0t

1/4''

3/8''

1/2''

5/8''

0.8t

0.8t

0.8t

1.0t

Although it was possible to use type-O for pipes with a size of up to

1/2H pipes for units that use R410A.(Type-O pipes may be used if the pipe size is

Type

Type-O pipes

Type-1/2H or Hpipes

19.05(3/4") with conventional refrigerants, use type-

19.05 and the radial thickness is 1.2t.)

The table shows the standards in Japan. Using this table as a reference, choose pipes that meet the local standards.

Flare Machining (type-O and OL only)

The flare machining dimensions for units that use R410A is larger than those for units that use R22 in order to increase

air tightness.

Flare Machining Dimension(mm)

External dimension of pipes

6.35

9.52

12.7

15.88

19.05

Size

1/4"

3/8"

1/2"

5/8"

3/4"

Dimension A

R410A R22

9.1

13.2

16.6

19.7

24.0

9.0

13.0

16.2

19.4

23.3

Dimension A

If a clutch type flare tool is used to machine flares on units that use R410A, make the protruding part of the pipe between

1.0 and 1.5mm. Copper pipe gauge for adjusting the length of pipe protrusion is useful.

Flare Nut

Type-2 flare nuts instead of type-1 nuts are used to increase the strength. The size of some of the flare nuts have also

been changed.

Flare nut dimension(mm)

17.0

22.0

26.0

29.0

36.0

Dimension B

17.0

22.0

24.0

27.0

36.0

Dimension B

External dimension of pipes Size

6.35

9.52

12.7

15.88

19.05

1/4"

3/8"

1/2"

5/8"

3/4"

R410A(Type2) R22(Type1)

Using this table as a reference, choose pipes that meet the local standards.

10

Page 11

NOTICE

For new installations, use the standard pipe sizes.

When using existiong pipes, size-up is allowed as

mentioned in the table above.

Additional restrictions towards allowable pipe lengths,

as mentioned in the table 7.3 on page 11, must be

taken into account.

Not using the standard lpipe size may result in

capacity decrease. The installer must acknowledge

this and judge this very carefully in function of the

complete installation.

Existing or pre-installed piping can be used

Cautions on handling the service port

Always use a charge hose equipped with a valve

depressor pin, since the service port is a Schrader type

valve.

After handling the service port, make sure to tighten the

service port cap securely. For the tightening torque, refer

to the table below.

Check for refrigerant leaks after tightening the service

port cap.

7. Refrigerant piping

1. Piping must comply with the criteria below.

Piping diameter must comply with the limitations as

indicated in paragraph "7.2. Refrigerant pipe size " on

page 11.

Piping length must be withinlimits of the allowable piping

length as in paragraph "7.3. Allowable pipe length and

height difference" on page 11.

Piping must be designed for R410A. See paragraph

"6.2. Selection of piping material" on page 10.

2. Piping can be reused without cleaning when:

Total 1-way piping length:

No compressor breakdown has occurred in the history

50m.

of the unit to be replaced.

A correct pump down operation can be executed:

- Operate the unit continuously for 30minutes in cooling

mode.

- Execute a pump down operation.

- Remove the air conditioning units to be replaced.

Check the contamination inside the existing piping.

If you cannot meet all these requirements, the existing

pipes must be cleaned or replaced after removing the air

conditioning units to be replaced.

7.1. Piping diagram for single split

Flare connection

Indoor

unit

Gas pipe

Liquid

pipe

7.2. Piping size for single split

ABH071H1ERG

ABH090H1ERG

ABH105H1ERG

ABH125K1ERG

ABH140K1ERG

PipeModel

Liquid pipe

Gas pipe

Diameter of pipe

9.52mm

15.88mm

Install the removed flare nuts

90+0.5

to the pipes to be connected,

then flare the pipes.

3-way stop valve

Outdoor

unit

3-way stop valve

3. Prepare the flare connections for higher pressure. See

paragraph 6.2

Cautions on handling the stem cap

The stem cap is sealed where indicated by the arrow.

ake care not to damage it.

T

After handling the stop valve, make sure tighten the stem

cap securely

. For the tightening torque, refer to the table

below.

Check for refrigerant leaks after tightening the stem cap.

7.3. Limitations for one way piping length and vertical

height difference for single split

Model

One way piping

length

ABH071H1ERG

ABH090H1ERG

ABH105H1ERG

less than 50 m

ABH125K1ERG

ABH140K1ERG

less than 75 m

Vertical height

difference

(between indoor

less than 30 m

less than 30 m

and outdoor)

11

Page 12

Precautions for refrigerant piping

Do not twist or crush piping.

Be sure that no dust is mixed in piping.

Bend piping with as wide angle as possible.

Keep insulating both gas and liquid piping.

Check flare-connected area for gas leakage.

7.4. Piping connection method

Apply refrigerant oil to the joint and the flange.

To bend a pipe, give the roundness as possible not to

crush the pipe.

When connecting pipe, hold the pipe centre to centre and

then screw nut on by hand, refer to Fig.

Be careful not to let foreign matters, such as sands enter

the pipe.

Spanner

Joint

Spanner

Nut

Pipe diameter Fastening torque (N.m)

Liquid pipe 6.35mm

Liquid pipe 9.52mm

Gas pipe 12.7mm

Gas pipe 15.88mm

Gas pipe 19.05mm

14.2-17.2

32.7-39.9

49.5-60.3

61.8-75.4

97.2-118.6

Cutting out the two slits makes it possible to install as

shown in the figure "Field pipes in 4 directions".

(Use a metal saw to cut out the slits.)

To install the connecting pipe to the unit in a downward

direction, make a knock-out hole by penetrating the

centre area around the knock-out hole using a

6mm

drill (4x).

After knocking out the knock-out hole, it is recommended

to apply repair paint to the edge and the surrounding

end surfaces to prevent rusting.

When passing electrical wiring through the knock-out

holes, remove any burrs from the know-out holes and

wrap the wiring with protective tape to prevent damage.

7.5. Preventing foreign objects from entering

Plug the pipe through-holes with putty or insulating

material (procured locally) to stop up all gaps, as shown

in the figure.

Field pipes can be installed in four directions (A, B, C,

D, E).

E

C

A

B

D

A: Forward

B: Backward

C: Sideways

D: Downward

E: Power supply cable,outdoor and indoor connection cable

1 Putty or insulating material (produced locally)

If there is any possibility that small animals enter the system

through the knock-out holes, plug the holes with packing

materials (field supplied).

Insects or samall animals entering the outdoor unit may cause

a short circuit in teh electrical box.

Seal knock-out holes to avoid snow and humidity entering.

7.6. Preventing foreign objects from entering

Be careful not to let the indoor and outdoor piping come

into contact with the compressor terminal cover.

If the liquid-side piping insulation might come into contact

with it, adjust the height as shown in the figure below.

Also, make sure the field piping does not touch the bolts

or outer panels of the compressor.

When the outdoor unit is installed above the indoor unit

the following can occur:

The condensed water on the stop valve can move to the

indoor unit. To avoid this, please cover the stop valve with

sealing material.

12

Page 13

If the temperature is higher than 30

higher than RH 80

should be at least 20mm in ouder to avoid condensation

on the surface of the sealing.

Be sure to insulate the liquid and gas-side field piping.

NOTICE

Any exposed piping may cause condensation.

, then thickness of the sealing materials

and the humidity is

NOTICE

Do not purge the air with refrigerants. Use a vacuum

pump to evacuate the installation. No additional

refrigerant is provided for air purging.

Make sure that the gas stop valve and liquid stop

valve are firmly closed before performing the leak

test or vacuum drying.

8.2. Leak test

(The highest temperature that the gas-side piping can

reach is around 120

material which is very resistant.)

DANGER

No not touch piping and internal parts.

7.7. Cautions for necessity of a trap

To avoid the the risk of oil held inside the riser piping flowing

back into the compressor when stopped and causing liquid

compression phenomenon, or cases of deterioration of oil

return, it will be necessary to provide a trap at each difference

in height of 10m in the riser gas piping.

A trap is not necessary when the outdoor unit is installed

at higher position than the indoor unit.

, so be sure to use insulating

8. Leak test and vacuum

drying

When all piping work is complete and the outdoor unit is

connected to the indoor unit, it is necessary to :

The leak test must satisfy specification EN378-2.

1 Vacuum leak test

1.1 Evacuate the system from the liquid and gas piping

to -100.7 kPa(5 Torr).

1.2 Once reached, turn off the vacuum pump and check

that the pressure does not rise for at least 1 minute.

1.3 Should the pressure rise, the system may either

contain moisture (refer to the paragraph " Vacuum

drying ") or have leaks.

2 Pressure leak test

2.1 Break the vacuum by pressurizing with nitrogen gas

to a minimum gauge pressure of 0.2 MPa (2 bar).

Never set the gauge pressure higher than the

maximum operation pressure of the unit, i.e. 4.0MPa

(40bar).

2.2 Test for leaks by applying a bubble test solution to

all piping connections.

NOTICE

Make sure to use a recommended bubble test solution

from your wholesaler.

Do not use soap water, which may cause cracking of

falre nuts (soap water may contain salt, which absorbs

moisture that will freeze when the piping gets cold).

and/or lead to corrosion of flared joints (soap water may

contain ammonia which causes a corrosive effect between

the brass flare nut and the copper flare).

check for any leakages in the refrigerant piping

to perform vacuum drying to remove all moisture in the

refrigerant piping.

If there is a possibility of moisture being present in the

refrigerant piping (for example, rainwater may have entered

the piping), first carry out the vacuum drying procedure

below until all moisture has been removed.

8.1. General guidelines

All piping inside the unit has been factory tested for leaks.

Use a 2-stage vacuum pump with a non-return valve

which can evacuate to a gauge pressure of-100.7kPa(5

Torr absolute,-755mm Hg).

Connect the vacuum pump to both the service port of

the gas stop valve and the liquid stop valve to increase

efficiency.

8.3. Vacuum drying

To remove all mositure from the system, proceed as follows:

1 Evacuate the system for at least 2 hours to a target

vacuum of -100.7 kPa(=-1.007 bar).

2 Check that, with the vacuum pump turned off, the target

vacuum is maintained for at least 1 hour.

3 Should you fail to reach the target vacuum within 2 hours

or maintain the vacuum for 1 hour, the system may contain

too much moisture.

4 In that case, break the vacuum by pressurizing with

nigrogen gas to a gauge pressure of 0.05 MPa (0.5bar)

and repeat steps 1 to 3 unit all moisture has been removed.

5 The stop valves can now be opened, and/or additional

refrigerant can be charged .

13

Page 14

INFORMATION

After opening the stop valve, it is possible that the

pressure in the refrigerant piping does not rise. This

migeh be caused by e.g. the closed state of the

expansion valve in the outdoor unit circuit, but does not

present any problem for correct operation of the unit.

This unit requires additional charging of refrigerant

according to the length of refrigerant piping connected

at the site.

Make sure to charge the refrigerant in liquid state to the

liquid pipe. Since R410A is a mixed refrigerant, its

composition changes if charged in its gaseous state and

normal system operation would then no longer be assured.

Before charging, check whether the refrigerant cylinder

has a suphon attached or not and position the cylinder

accordingly.

9. Charging refrigerant

9.1. Important information regarding the

refrigerant used

This product contains fluorinated greenhouse gases covered

by the Kyoto Protocol. Do not vent gases into the

atmopsphere.

9.2. Precautions and general guidelines

When servicing the unit requires the refrigerant system

to be opened, treatment and evacuation of refrigerant

must be done in accordance with applicable legislation.

Refrigerant can not be charged until field wiring has been

completed.

Refrigerant may only be charged after performing the

leak test and vacuum drying.

CAUTION

Fill using a cylinder

with a siphon

attached Charge the

liquid refrigerant with

the cylinder in upright

position.

On this model it is not necessary to charge additionally if

the piping length

20m.

Fill using a cylinder

siphon attached

with a

Charge the liquid

refrigerant with the

cylinder in up-sidedown position.

9.3. Complete recharging

NOTICE

Berore recharging, make sure to execute vacuum

drying of the intermal piping of the unit as well. To do

so, use the internal service port of the unit. Do not use

the service ports located on the stop valve, since

vacuum drying can not be performed properly from

these ports.

Outdoor units have 1 port on the piping. It is between

the heat exchanger and the 4-way valve.

When charging a system, care shall be taken that

its maximum permissible charge is never exceeded,

in view of the danger of liquid hammer.

WARNING

Refrigerant cylinders shall be opened shlowly.

Always use protective gloves and protect your eyes

when charging refrigerant.

DANGER

When the power is on, please close the front panel

when leaving the unit unattended.

Charging with an unsuitable substance may cause

explosions and accidents, so always ensuren that

the appropriate refrigerant (R410A) is charged.

In case complete recharging is required (after a leak, etc.),

refer to teh information below to determine the necessary

amount of refrigerant.

WARNING

Some sections of the refrigerant circuit may be

isolated from other sections caused by components

with specific functions (e.g. valves). The refrigerant

circuit therefore features additional service ports for

vacuuming, pressure relief or pressurizing the circuit.

In case it is required to perform brazing on the unit,

ensure that there is no ressure remaining inside the

unit. Internal pressures need to be released with ALL

the service ports indicated on the figures below

opened. The location is depending on mode type.

14

Page 15

-

-

-

-

1 Make sure that stop valves

both on liquid and on gas side

are open.

_

9.4. Total charging weight of the refrigerant

(after a leak, etc.)

The total charging amounts relate to the refrigerant piping

length as in "Maximum total one-way piping length" of the

table in paragraph "8.4. Allowable pipe length and height

difference" on page 8.(E.g. twin: L1+L2)/

2 Push the BS4 pumping-down

operation button on the PC

board of the outdoor unit (8

seconds).

Compressor and outdoor

fan will start operation

automatically.

The indoor unit fan may

automatically start running.

Please pay attention to

this.

3 Close the stop valve on the

liquid side securely about 2

minutes after the compressor

started ooperation.

Never leave the outdoor

unit unattended with

oopened front panel when

power supply is on.

In case the stop valve on

the liquid side is not

securely closed during

4 Once compressor operation

stops after 2 to 5 minutes (a),

close the stop valve on the

gas side securely.

compressor operation,

during compressor

operation, pumping-down

operation cannot be

executed.

5 Turn off the power supply.

(a) If after finishing pumping-down operation the outdoor

unit does not operate, not even when the remote controller

switch is turned on, the remote controller may or may

not indicate "

". But this is not a malfunction.

Refrigerant piping length (liquid side)

Model

(a)

1UH071N1ERG

1UH090N1ERG

1UH105NS1ERG

1UH125P1ERG

1UH125P1ERK

1UH140P1ERG

1UH140P1ERK

5-10m

10-20m

2.5 2.5 2.5

2.5 2.5 2.5

30-40m

20-30m

2.95

2.95

3.4

3.4 3.85

3.7 3.7 3.7 4.15 4.6

40-50m

5.05 5.5 5.95

50-60m

---

-

60-70m

670-80m

-

-

10. Pump down operation

This unit is equipped with an automatic pump down operation

which will collect all refrigerant from the field piping and indoor

unit in the outdoor unit. To protect the environment, make sure

to perform the following pump down operation when relocating

or disposing of the unit.

INFORMATION

For more details, refer to the applicable service manual.

When in need of operation, turn off the main power supply

and turn it on again. Make sure that stop valves both on

liquid and gas side are open and be sure to ooperate the

unit in cooling operation during test run.

WARNING

Make sure to re-open both stop valves before restarting

operation of the unit.

11. Electrical wiring work

WARNING

All wiring must be performed by an authorized

electrician.

All components procured on the side and all elecrtic

construction shall comply with the applicable

legislation.

DANGER: HIGH VOLTAGE

To avoid electrical shock, make sure to disconnect the

power supply 1 minute or more before servicing the

electrical parts. Even after 1 minute, always measure

the voltage at the terminals of main circuit capacitors

or electrical parts and, before touching , make sure that

those voltages are 50VDC or less.

15

Page 16

NOTICE

To persons in charge of electrical wiring work:

Do not oerate the unit until the refrigerant piping is

complete. (Running it before the piping is ready will

break the compressor.)

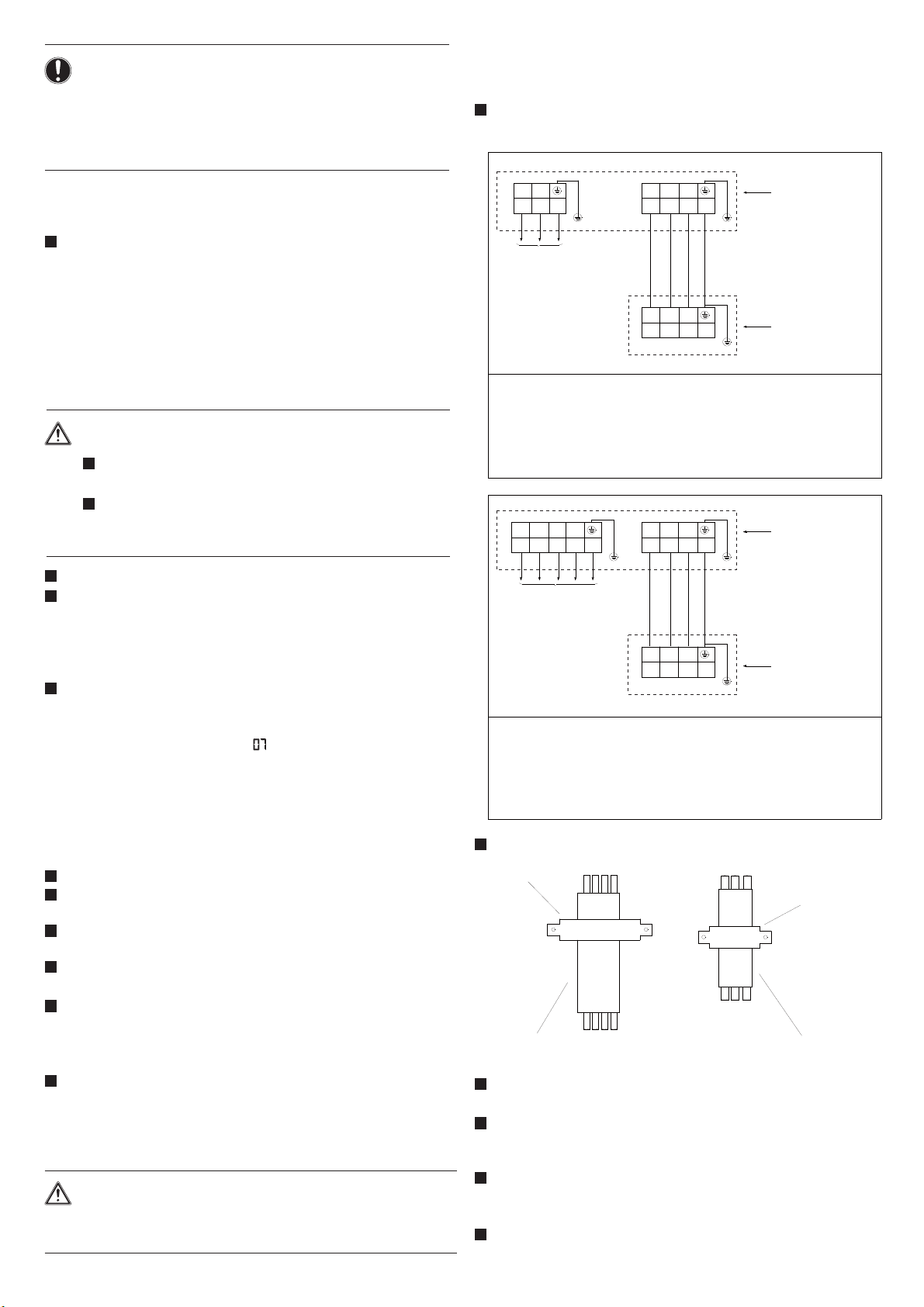

11.2. Connecting power supply and inter-unit

wiring

Connect and fix the power supply cable, indoor-outdoor

connection cable as following:

11.1. Precautions on electrical wiring work

When servicing the unit requires the refrigerant system

to be opened, treatment and evacuation of refrigerant

must be done in accordance with applicable legislation.

Refrigerant can not be charged until field wiring has been

completed.

Refrigerant may only be charged after performing the

leak test and vacuum drying.

DANGER

Before obtaining access to terminal devices, all

supply circuits must be interrupted.

Be sure to install an earth leakage circuit breaker

in accordance with aplicable legislation. Failure to

do so may cause electrical shock.

Use only copper wires.

A main switch or other means for disconnection, having

a contact separation in all poles, must be incorporated

in the fixed wiring in accordance with applicable legislation.

Do not turn on the main switch until all the wiring is

completed.

For Y1

Make sure to connect power supply cables in normal

phase. If

of the indoor unit indicates "

operate. Change any two of the three power supply

cables (L1,L2,L3) to correct phase.

If the contact in the magnetic switch should be forcibly

turned on while the equipment is inoperative, the

compressor will burn out. Never try to forcibly turn on

the contact.

Never squeeze bundled cables into a unit.

Fix cables so that cables do not make contact with the

pipes (especially on high pressure side).

Secure the electrical wiring with cable ties as shown in

the figure in 11.2 (for single split) or 12.3 (for maxi split).

Make sure no external pressure is applied to the terminal

connectors.

When installing the earth leakage circuit breaker make

sure that it is compatible with the inverter (resistant to

high frequency electrical noise ) to avoid unnecessary

opening of the earth leakage circuit breaker.

As

advancing capacitor not only will deteriorate power factor

improvement effect, but also may cause capacitor

abnormal heating accident due to high-frequency waves.

Therefore, never install a phase advancing capacitor.

CAUTION

Be sure to install the required fuses or circuit

breakers.

connected in reverse phase, the remote controller

" and the equipment cannot

this unit is equipped with an inverter, installing a phase

LN

123

Outdoor unit

terminal blocks

Power supply:

1PH,220-240V~,

50/60Hz

123

Indoor unit

terminal blocks

For single phase power supply models:

1UH071N1ERG,1UH090N1ERG,1UH105N1ERG,

1UH125P1ERG,1UH140P1ERG

Power supply cable: H05RN-F 3G 4.0mm

2

Indoor and outdoor connection cable: H05RN-F 4G 2.5mm

RST N

123

Outdoor unit

terminal blocks

Power supply:

380-415V,3N~,

50/60Hz

123

Indoor unit

terminal blocks

For three phase power supply models:

1UH125P1ERK,1UH140P1ERK

Power supply cable: H05RN-F 5G 2.5mm

Indoor and outdoor connection cable:

H05RN-F 4G 2.5mm

2

2

Fix the cable with the clip to prevent slide.

Clip

Outdoor-indoor unit

Power supply cable

connection cable

Secure the cable to the stop valve attachment plate so

that it does not slide.

When cables are routed from the unit, a protection sleeve

for the conduits (PG-insertions) can be inserted at the

knock-out hole.

When you do not use a wire conduit, be sure to protect

the wires with vinyl tubes to revent the edge of the knockout hole from cutting the wires.

Follow the electric wiring diagram for electrical wiring

works.

16

2

Clip

Page 17

Form the wires and fix the cover fimmly so that the cover

may be fit in properly.

When you do not use a wire conduit, be sure to protect

the wires with vinyl tubes to revent the edge of the knockout hole from cutting the wires.

Follow the electric wiring diagram for electrical wiring

works.

Form the wires and fix the cover fimmly so that the cover

may be fit in properly.

- Do not connect wires of different gauge to the same

power supply terminal. (Looseness in the connection may

cause overheating.)

Use the correct screwdriver to tighten the terminal screws.

Small screwdrivers can damage the screw head and

prevent appropriate tightening.

Over-tightening the terminal screws can damage the

screws.

11.3. Specifications of standard wiring

components

CAUTION

Select all cables and wire sizes in accordance with

applicable legislation.

After finishing the electrical work, confirm that each

electric part and terminal inside the electric part box

is connected securely.

The earth leakage breaker must be a high-speed

type breaker of 30 mA(

0.1 s).

12.1. Pre-run checks

Items to check

Electrical wiring

Inter-unit wiring

Ground wire

Refrigerant

piping

Extra refrigerant

Is the wiring as mentioned on the

wiring diagram?

Make sure no wiring has been

forgotten and that there are no missing

phases or reverse phases.

Is the unit properly grounded?

Is the wiring between units connected

in series correct?

Are any of the wiring attachment

screws loose?

Is the insulation resistance at leaset

1

- Use a 500V mege-tester when

measuring insulation.

- Do not use a mega-tester for low voltage circuits.

Is the size of the piping appropriate?

Is the insulation material for the piping

attached securely?

Are both the liquid and gas pipes

insulated?

Are the stop valves for both the liquid

side and the gas side open?

Did you write down the extra

refrigerant and the refrigerant piping

length?

?

12. Test operation

DANGER

Never leave the unit unattended during installation

or servicing. When the service panel is removed

live parts can be easily touched by accident.

INFORMATION

Note that during the first running period of the unit,

required power input may be higher than stated on the

nameplate of the unit. This phenomenon originates

from the compressor that needs elapse of a 50 hours

run in period before reaching smooth operation and

stable power consumption.

Be sure to perform a test run.

Be sure to fully open the liquid-side and gas-side stop

valves. If you operate the unit with stop valves closed, the

compressor will break down.

Be sure to execute the first test run of the installation in

cooling mode operation.

Never leave the unit unattended with an open front panel

during test run.

12.2. Precautions regarding test-runs

1

In order to detect stop valves failing to open, operation

of the unit is compulsorily performed in cooling for 2-3

minutes during the first test run, even if the remote

controller was set to heating operation. In this case, the

remote controller will have kept displaying the heating

symbol all the time and the unit will switch to heating

operation automatically after elapse of that time.

In case you cannot ooperate the unit in test run mode

2

for any unusual reason, refer to "12.6. Failure diagnosis

at the moment of first installation" on page 22.

In case of a wireless remote controller, execute the run

3

only after having installed the indoor unit decoration

panel with infrared receiver first.

In case the panels of indoor units are not yet installed

4

to the indoor units, make sure to shut off the power

supply after finishing the complete test run.

complete test run surely includes shutting off power

A

5

after having performed a normal operation stop on the

remote controller. Do not stop operation by turning circuit

breakers off.

17

Page 18

12.3. Refrigerant pipe size for maix split system

The MAXI SPLIT system is an ideal option for open spaces in medium sized premises such as shops and offices,where

two,three or four units are required.These can be Cassettes ( AB Series) or Ceiling supended (AC Series) models and

can be connected to a single outdoor unit using twin,triple,quadruple manifold.Please refer to the table below to choose

suitable manifold and wire controller according to combinations of indoor unit and outdoor unit.

The matching table of MAXI SPLIT series

Manifold

Model

FQG-2Y100A 2

FQG-2Y200A 2

FQG-3Y100A 3

FQG-3Y200A 3

FQG-4Y200A 4

Gas side manifold Liquid side manifold

Outdoor

unit Model

1UH105 18000BTU

1UH125

1UH140

1UH105 12000BTU

1UH125

1UH140

1UH125

1UH140

Indoor Unit

Model

24000BTU

28000BTU

18000BTU

12000BTU

Number

of indoor

Units

Wire

controler

YR-E14 OR

YR-E16

YR-E14 OR

YR-E16

YR-E14 OR

YR-E16

YR-E14 OR

YR-E16

YR-E14 OR

YR-E16

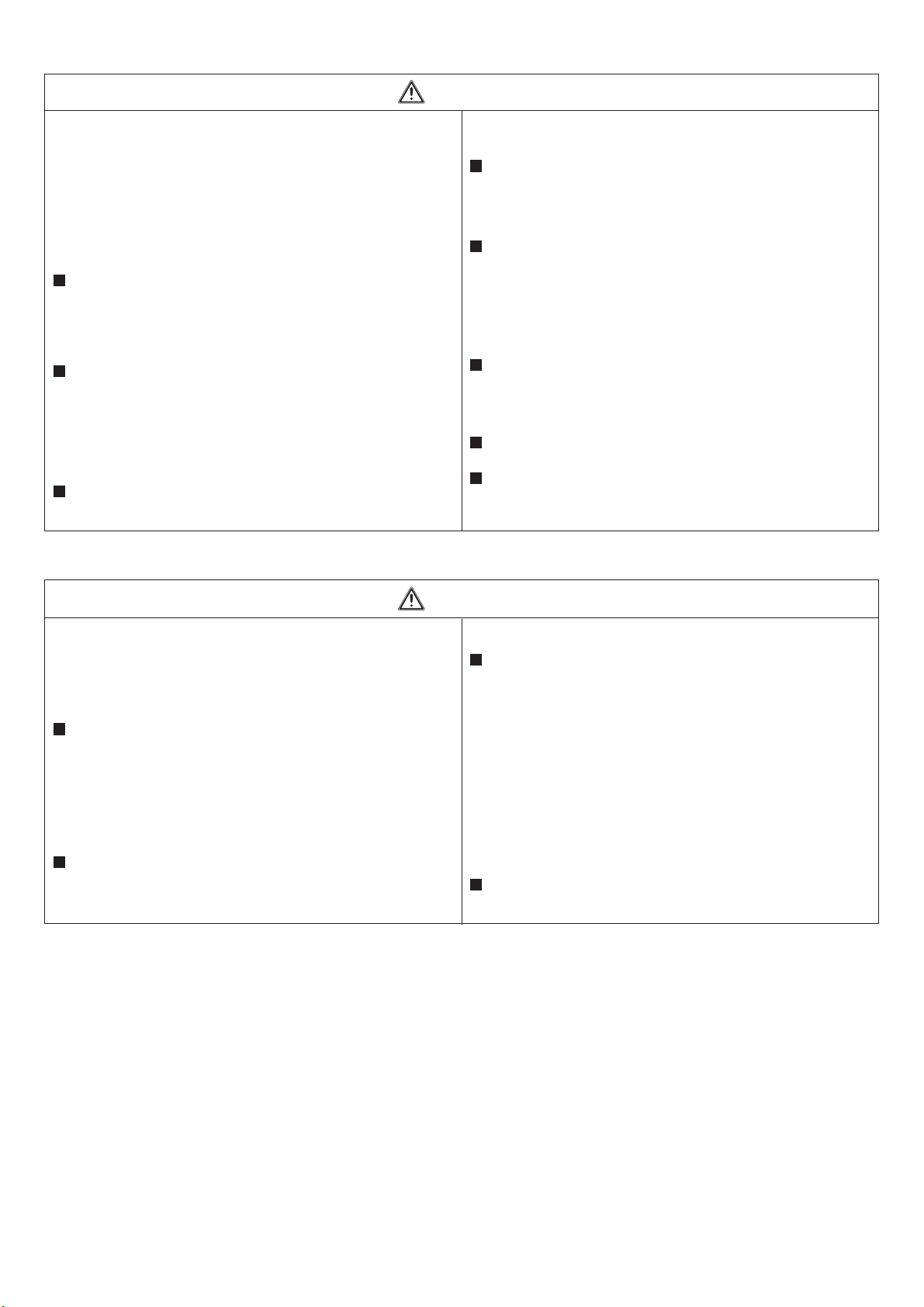

MAXI SPLIT SYSTEM UNITS WIRING DIGRAM

123

123

123

123

123

terminal block

Indoor unit 1

terminal block

Indoor unit 2

terminal block

Indoor unit 3

terminal block

Indoor unit 4

SRNTNL

3N~,50Hz,

380-400V

3PH TYPE

master

slave

slave

slave

1PH~,50Hz,

220-230V

1PH TYPE

Note:

1. The master is the indoor unit which connect to a wired

controller, others are slaves, please purchase wired

controller separately for MAXI system.

2. For one MAXI split system there is only one master.

3. For the MAXI system with 2 to 3 indoor units, the wiring

method is the same with the diagram on the left except for

the indor units quantity.

4. Make sure that the wire connection for all units in MAXI

system OK before running.

terminal block

Outdoor unit

18

Page 19

12.4. Specification of refrigerant charge for single split and maxi split.

1.It is not neccesary to charge additionally when the piping length L+P

20m.

2.Please charge refrigerant additionally according to the following table when the piping length L+P

complete recharge .

Single Split Twin Triple Quadruple

L1

L2

L

L3

(L-20)*45+P*30

(L-20)*45+P*30

(L-20)*45+P*30

L>20

L

20,L+P>20

__

(L+P-20)*30

(L+P-20)*30

P=L1+L2+L3+L4

Charge(g)

1UH105

1UH125

1UH140

P(m)

L

L>20

(L-20)*45

(L-20)*45

(L-20)*45

P=0

L

,L+

L 20

(L+P-20)*30

(L+P-20)*45

(L+P-20)*45

P>20

P=L1+L2 P=L1+L2+L3

L1

L2

L>20

(L-20)*45+P*30

(L+P-20)*45

(L+P-20)*45

L

20,L+P>20

( +P-20)*30L

(L+P-20)*30

(L+P-20)*30

Remark:

a.L is the main pipe length of liquid pipe;P is the sum length of branch liquid pipes.

b.The piping length L+P means the sum of the main pipe and branch pipes.

For MAXI system (Twin,Triple,Quadruple), piping length=L+P

L.

For single split system,L+P=L,because P=0.

Example 1:

Outdoor unit

1UH105

Note:

(1)L=15<20;L+P=L+L1+L2=15+10+5=30>20

(2)Refrigerant charging amount=(L+P-20)*30=300g

(3)TYPE 18K means capacity 18000Btu/h type

L=15( 9.52)

L1=10( 6.35)

L2=5( 6.35)

Indoor unit

TYPE 18K

TYPE 18K

Example 2:

Outdoor unit

1UH125

Note:

(1)L=30>20;P=L1+L2+L3+L4=10+10+5+5=30

(2)Refrigerant charging amount=(L-20)*45+P*30=1350g

(3)TYPE 12K means capacity 12000Btu/h type

L=30( 9.52)

L1=10( 6.35)

L1=10( 6.35)

L1=5( 6.35)

L1=5( 6.35)

20m or need to

L1

L2

L

L3

L4

L>20

__

(L-20)*45+P*30

(L-20)*45+P*30

Indoor unit

TYPE 12K

TYPE 12K

TYPE 12K

TYPE 12K

19

Page 20

When installing MAXI SPLIT Series(1UH105N1ERG/1UH125P1ERG/1UH125P1ERK/1UH140P1ERG/1UH140P1ERK),Please

refer to the table below concerning the pipe lengths , heights and sizes.

608080

608080

80 80

20

Page 21

12.5 Before Installing (Relocating) the Unit or Performing Electric Work

CAUTION

Ground the unit.

Do not connect the grounding on the unit to gas pipes,water

pipes, lightning rods, or the grounding terminals of

telephones. Improper grounding presents a risk of electric

shock, smoke, fire, or the noise caused by improper

grounding may cause the unit to malfunction.

Make sure the wires are not subject to tension.

If the wires are too taut, they may break or generate

heat and/or smoke and cause fire.

Install a breaker for current leakage at the power source

to avoid the risk of electric shock.

Without a breaker for current leakage, there is a risk

of electric shock, smoke or fire.

Use breakers and fuses (electrical current breaker, remote

switch<switch+Type-B fuse>,molded case circuit breaker)

with a proper current capacity.

The use of large-capacity fuses, steel wire, or copper

wire may damage the unit or cause smoke or fire.

Before the Test Run

Do not spray water on the air conditioners or immerse the

air conditioners in water.

Water on the unit presents a risk of electric shock.

Periodically check the platform on which is placed for damage

to prevent the unit from falling.

If the unit is left on a damaged plarform, it may topple

over, causing injury.

When installing draining pipes, follow the instructions in the

manual, and make sure that they properly drain water so as

to avoid dew condensation.

If not installed properly, they may cause water leaks

and damage the furnishings.

Properly dispose of the packing materials.

Things such as nails may be included in the package.

Dispose of them properly to prevent injury.

Plastic bags present a choking hazard to children.

Tear up the plastic bags before disposing of them to

prevent accidents.

CAUTION

Do not operate switches with wet hands to avoid electric.

Do not touch the refrigerant pipes with bare hands during

and immediately after operation.

Depending on the state of the refrigerant in the system,

certain parts of the unit such as the pipes and

compressor may become very cold or hot and may

subject the person to frost bites or burning.

Do not operated the unit without panels and safety guards

in their proper places.

They are there to keep the users from injury from

accidentally touching rotating, high-tempreture or

high-voltage parts.

Do not turn off the power immediately after stopping the unit.

Allow for at least five minutes before turning off the unit,

otherwise the unit may leak water or experience other

problems.

Do not operate the unit without air filters.

Dust particles in the air may clog the system and cause

malfunction.

21

Page 22

12.6. Failure diagnosis

22

Page 23

Page 24

Address:Haier Industrial Park,Qianwangang Road,Eco-Tech Development Zone,Qingdao 266555,Shandong,P.R.C.

Contacts: TEL +86-532-88936943; FAX +86-532-8893-6999

Website: www.haier.com

Loading...

Loading...