Haier 1U09MACFRA, 1U12MACFRA, 1U18RACFRA, 1U26MACFRA, 1U35MACFRA Installation Manual

...

ROOM AIR CONDITIONER

INSTALLATION MANUAL

1U09MACFRA

1U12MACFRA

1U18RACFRA

1U24RACFRA

1U26MACFRA

1U35MACFRA

1U53RACFRA

1U71RACFRA

Please read this manual carefully before installation.

This appliance is filled with R32.

Keep this operation manual for future reference.

0011511008

条形码绘制区

Contents

Warning .................................................................................................................................1

Loading and Unloading/Transporting Management/Storage Requirements.............................3

Installation Instructions.............................................................................................................3

Relocation Procedures.............................................................................................................7

Maintenance Instructions..........................................................................................................7

Scrapping and Recovery..........................................................................................................10

Indoor/Outdoor Unit Installion Drawings............... ................................................................... 12

Safety Precautions .............................................................................................. .....................13

Read Before Installation ....................................... ............................................... .....................17

Installation Procedure........................................... ............................................... .....................20

Outdoor Unit Troubleshooting...................................................................................................25

Read the precautions in this manual

carefully before operating the unit.

This appliance is filled with R32.

Keep this manual where the user can easily find it.

WARNING:

Ask your dealer or qualified personnel to carry out installation work.Do not attempt to install

the air conditioner yourself. Improper Installation may result in water leakage, electric shocks,

fire or explosion.

Install the air conditioner in accordance with the instructions in this installation manual

Be sure to use only the specified accessories and parts for installation work.

Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

Electrical work must be performed in accordance with relevant local and national regulations

and with instructions in this installation manual,Be sure to use a dedicated power supply circuit

.

only. The wiring method should be in line with the local wiring standard.The type of connecting

wire is H07RN-F.

Use a cable of suitable length,Do not use tapped wires or an extension lead as this may cause

overheating, electric shocks, fire or explosion.

All the cables shall have got the local authentication certificate. During installation, when the

connecting cables break off, it must be assured that the grouding wire is the last one to be broken off.

If refrigerant gas leaks during installation, ventilate the area immediately.oxic gas may be produced

if the refrigerant comes into contact with fire,and explosion may be happen.

After completing installation, check for refrigerant gas leakage

When installing or relocating the air conditioner, be sure to bleed the refrigerant circuit to ensure

it is free of air, and use only the specified refrigerant (R32).

Make sure ground connection is correct and reliable.Do not earth the unit to a utility pipe, lightning

conductor or telephone earth lead. Imperfect earthing may result in electric shocks.

Be sure to install an earth leakage circuit explosion-proof breaker.

The breaker of the air conditioner should be all-pole switch and explosion-proof. The distance

between its two contacts should not be no less than 3mm. Such means for disconnection must be

incorporated in the wiring.

Do not use means to accelerate the defrosting process or to clean, other than those recommended by

the manufacturer.

The appliance must be stored in a room without continuously operating ignition sources, the radius of

the storage area should be no less than 2.5 m (for example:open flames, an operating gas appliance

or an operating electric heater).

Do not pierce or burn.

Be aware that refrigerants may not contain an odour.

The appliance must be installed, operated and stored in a room with a floor area larger than 3m

The room should be well ventilated.

Comply with national gas regulations.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

Cleaning and user maintenance shall not be made by children.

The air conditioner can not be discarded or scrapped randomly. If neccessary, please contact customer

service.

Connectors can not be reused in a confined space.

1

CAUTION:

Model

Factory charge(kg

CO2 Equivalent(t)

Do not install the air conditioner at any place where there is danger of flammable gas leakage.

In the event of a gas leakage, build-up of gas near the air conditioner may cause a fire to break out.

Tighten the flare nut according to the specified method such as with a torque wrench.If the flare nut

is too tight, it may crack after prolonged use, causing refrigerant leakage.

Take adequate steps to prevent the outdoor unit being used as a shelter by small animals.Small animals

making contact with electrical parts can cause malfunctions, smoke or fire.

Please instruct the customer to keep the area around the unit clean

The temperature of refrigerant circuit will be high, please keep the inter-unit wire away from copper pipes

that not thermally insulated.

Only qualified personnel can handle, fill, purge and dispose of the refrigerant.

HOW TO USE DRED APPLIANCE

Please consult your reseller and/or installer to determine if you have a DRED

appliance.

Connect output from your home's electricity power meter (where

available) to the RJ45 connector on the outdoor unit, as shown.

(This function is unavailable on some models.)

IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

R32

2

1=

2=

1

1+2=

F E

This product contains fluorinated greenhouse gases covered

by the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type: R32

GWP=global warming potential

3 GWP* value=675

tCO2=(1+2) x 3 /1000

1U26MACFRA 0.65

1U35MACFRA

1U53RACFRA

1U71RACFRA

0.79

1

1.3 0.88

)

kg

kg

kg

A

B

C

D

0.44

0.54

0.69

The filled out label must be adhered in the proximity of the

product

charging port (e.g. onto the inside of the stop value

cover).

A contains fluorinated greenhouse gases covered by the

Protocol

Kyoto

B factory refrigerant charge of the product: see unit name

plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

2

Loading and Unloading/Transporting Management/Storage Requirements

Diameter of the liquid

connecting pipe (mm)

Extra gas amount per meter

after standard length (g)

Notes: The most gas amount should be: initial gas amount + extra gas amount <

1) The products shall be carefully handled during loading and unloading.

2) Do not give impact to the indoor and outdoor units, or otherwise product damage may result.

3) Be sure to read the safety cautions before conducting any work.

4) Dry powder extinguishers or other suitable fire extinguishing apparatus .aera gnidaol eht ta deppiuqe eb dluohs

5) Untrained personnel cannot be engaged in loading and unloading of air conditioners with flammable refrigerants.

6)

Smoking and open fire are not allowed around the air conditioner.

Transporting Management Requirements

1) The maximum transporting volume of finished products shall be determined as per local regulations.

2) The vehicles used for transporting shall be operated as per local laws and regulations.

3) Dedicated after-sales vehicles shall be used for maintenance transportation, and exposed transporting of

refrigerant cylinders and the products to be maintained is not allowed.

4) A rain cover or similar shield material of the transporting vehicles should have certain flame retardancy.

5) Leakage warning device of flammable refrigerant shall be installed inside the closed-type compartment.

6) Anti-static device shall be equipped inside the compartment of transporting vehicles.

7) Dry powder extinguishers or other suitable fire extinguishing apparatus shall be equipped inside the driver's cab.

8)

The transporting vehicles shall run at a constant speed, and heavy acceleration/deceleration shall be avoided.

High-temperature area shall be avoided during transporting, and necessary radiating measures shall be taken

9)

in case the temperature inside the compartment is too high.

Storage Requirements

1) The storage package of equipment used shall be such that no leakage of refrigerant will be caused due to

mechanical damage of the equipment inside.

2) The maximum quantity of the equipment allowed to be stored together shall be determined as per local

regulations.

Installation Instructions

WARNING!

The area of the room in which R32 refrigerant air conditioner is installed cannot be less than the minimum

area specified in the table below, to avoid potential safety problems due to out-of-limit of refrigerant

concentration inside the room caused by leakage of refrigerant from refrigeration system of the indoor unit.

Once the horn mouth of connecting lines is fastened, it may not be used again (the air tightness may be

affected).

A whole connector wire shall be used for indoor/outdoor unit as required in the operation specification of

installation process and operation instructions.

It should be stated in the manual that an entire connection pile should be used.

It should be stated in the manual that it is recommended to place the joint of the connection pipes at the outdoor side,

if can’t be at the outdoor side, the side that cannot be reused (not detachable) must be installed at the indoor side.

When the connection pipe is reused, the horn mouth needs to be reinstalled.

R32 Air Conditioner Adding Extra Gas With Longer Pipe Calculator

∅6/∅6.35 20g

∅9/∅9.52 50g

permitted gas by safety standard.

Minimum Room Area

Type

LFL

kg/m3

hv

m

Total Mass Charged/kg

Minimum Room Area/m

2

4 7 10 15 20 30 50

R32 0.306

0.6

1.0

1.8

2.2

0.68

1.14

2.05

2.50

0.90

1.51

2.71

1.08 1.32

1.80

3.24

2.20

3.97

3.31 3.96 4.85 5.60

1.53

2.54

4.58

1.87

2.41

3.12 4.02

5.61 7.24

6.86 8.85

The maximum refrigerant charge amount (M)

Indoor unit Outdoor unit M kg

AS26TACHRA 1U26MACFRA 0.85

AS35TBCHRA 1U35MACFRA 0.99

AS53TCCHRA 1U53RACFRA 1.4

3

AS71TECHRA 1U71RACFRA 1.7

1. Procedures: operation shall be made as per controlled procedures to minimize the probability of risks.

2. Area: area shall be divided and isolated appropriately, and operation in an enclosed space shall be avoided.

Before the refrigeration system is started or before hot working, ventilation or opening of the area shall be

guaranteed.

3. Site inspection: the refrigerant shall be checked.

4. Fire control: the fire extinguisher shall be placed nearby, and fire source or high temperature is not allowed;

the sign of “No smoking” shall be arranged.

1. Indoor unit: nitrogen is sealed during the delivery of indoor units (inside the evaporator), and the red sign at

the top of the green plastic seal cap on the evaporator air pipes of the indoor unit shall be checked first after

unpacking. In case the sign is raised, the nitrogen sealed still exists. Afterwards, the black plastic seal cap at the

joint of evaporator liquid pipes of the indoor unit shall be pressed, to check whether nitrogen still exists. In case

no nitrogen is sprayed out, the indoor unit is subject to leakage, and installation is not allowed.

2. Outdoor unit: the leak detection equipment shall be extended into the packing box of the outdoor unit, to

check whether the refrigerant is leaking. If the refrigerant leakage is identified, installation is not allowed, and the

outdoor unit shall be delivered to the maintenance department.

1. The room area checked cannot be less than the area specified on the warning sign of the indoor unit.

2. Inspection on the surrounding environment of place of installation: the outdoor unit of flammable

refrigerants air conditioner cannot be installed inside an enclosed room reserved.

3. Power supply, switches or other high-temperature articles such as the fire source and oil heater shall be

avoided below the indoor unit.

4. The power supply shall be provided with earthing wire and be reliably earthed.

5. While punching the wall with an electric drill, whether embedded water/electricity/gas pipelines are

designed at the hole preset by the user shall be verified in advance. It is recommended that the through-wall holes

reserved shall be used as much as possible.

1. Favorable ventilation shall be maintained at the place of installation (doors and windows are opened).

2. Open fire or high-temperature heat source (including welding, smoking and oven) higher than 548

is not

allowed within the scope of flammable refrigerant.

3. Anti-static measures shall be taken, such as the wearing of cotton clothes and cotton gloves.

4. The place of installation shall be convenient for installation or maintenance, and cannot be adjacent to heat

source and flammable and combustible environment.

5. In case of refrigerant leakage of the indoor unit during installation, the valve of the outdoor unit shall be

closed immediately, and windows shall be opened, and all the personnel shall be evacuated. After the leakage of

refrigerant is handled, the indoor environment shall be subject to concentration detection. Further handling is not

allowed until the safety level is reached.

6. In case the product is damaged, it must be delivered to the maintenance point. Welding of refrigerant

pipelines at the user’s site is not allowed.

7. The installation position of air conditioner shall be convenient for installation or maintenance. Barriers shall

be avoided around the air inlet/outlet of the indoor/outdoor unit, and the electrical appliance, power switches,

sockets, valuables and high-temperature products within the scope of both sidelines of the indoor unit shall be

avoided.

No fire source around the

place of installation

Cotton clothes Anti-static gloves

BEWARE

ELECTROSTATICS

Goggles

Read operator’ manual

Read technical manual

Operator’ manual;operating instructions

4

• Electrical Safety Requirements

Note:

1. The surrounding conditions (ambient temperature, direct sunlight and rainwater) shall be noticed during

electrical wiring, with effective protective measures being taken.

2. Copper wire cable in line with local standards shall be used as the power line and connector wire.

3. Both the indoor unit and outdoor unit shall be reliably earthed.

4. Wiring for the outdoor unit shall be made first and then the indoor unit. The air conditioner can only be

powered on after wiring and pipe connection.

5. The dedicated branch circuit must be used, and leakage protector with sufficient capacity must be installed.

• Qualification Requirements of Installer

Relevant qualification certificate must be obtained as per national laws and regulations.

• Indoor Unit I

nstallation

1. Fixation of wall panel and piping layout

In case of left/right water pipe connection for the indoor unit, or in case the evaporator interface of the indoor

unit and the horn mouth of the connecting piping cannot be extended to the outdoor side for installation, the

connector pipes shall be connected to the evaporator piping interface of the indoor unit in the process of horn

mouth.

2. Piping layout

During layout of connecting pipes, drain hose and connector wires, the drain hose and connecting wire shall

be placed at the bottom and top respectively. The power line cannot be twined with the connector wire. The drain

pipes (especially inside the room and mac

hine) must be ventilated with thermal insulation materials.

3. Nitrogen charging for pressure maintaining and leak detection

After the evaporator of the indoor unit is connected to the connector pipe (after welding), nitrogen more than

4.0MPa shall be charged inside the evaporator and the piping connected to evaporator with a nitrogen cylinder

(adjusted by a reducing valve). Afterwards, the valve of the nitrogen cylinder shall be closed, for leak detection

with soapy water or leak detecting solution. The pressure shall be maintained for more than 5 minutes, and then

whether the system pressure is reduced or not shall be observed. In case the pressure is reduced, leakage can be

identif

ied. After the leak point is handled, the steps above shall be repeated.

After the evaporator of the indoor unit is connected to connecting piping, nitrogen shall be charged for

pressure maintaining and leak detection. Afterwards, the evaporator shall be connected to the two-way stop valve

and three-way stop valve of the outdoor unit. After the copper cap of the connecting piping is fastened, nitrogen

more than 4.0MPa shall be charged at the access hole of the three-way stop valve with a charging hose. The valve

of the nitrogen cylinder shall be closed, for leak detection with soapy water or leak detecting solution. The

ssure shall be maintained for more than 5 minutes, and then whether the system pressure is reduced or not shall

pre

be observed. In case the pressure is reduced, leakage can be identified. After the leak point is handled, the steps

above shall be repeated.

The operation above can also be completed after the indoor unit is connected to the connecting pipelines and

the two-way stop valve and three-way stop valve of the outdoor unit, after the access hole of the outdoor unit is

connected to the nitrogen cylinder and pressure gauge and after more than 4.0MPa nitrogen is charged. No leak

points are identified in the leak detection at the joint/welding junction of the indoor unit and at the joi

nt of

connecting pipelines of the two-way stop valve and three-way stop valve of the outdoor unit. It must be

guaranteed that each joint is available for leak detection during installation.

The next step (vacuumizing with a vacuum pump) can only be continued after the installation steps (nitrogen

charging for pressure maintaining and leak detection normal) are completed.

• Outdoor Unit Installation

1. Fixation and connection

Note:

a) Fire source shall be avoided within 3m around the place of installation.

b) The leak detection equipment of refrigerant shall be placed at a low position in the

outdoor, and shall be opened.

5

1) Fixation

The support of the outdoor unit shall be fixed onto the wall surface, and then the outdoor unit shall be fixed onto

the support horizontally. In case the outdoor unit is wall-mounted or roof-mounted, the support shall be firmly

fixed, to avoid the damage of strong wind.

2) Installation of connecting pipes

The cone of the connecting pipes shall be aligned with the conical surface of corresponding valve connector.

The nut of connecting pipes shall be installed at a proper position and then be tightened with a spanner. Excessive

tightening torque shall be avoided, or otherwise the nut may be damaged.

• Vacuumizing

A digital vacuum gauge shall be connected for vacuumizing. The duration of vacuumizing shall be at least 15

minutes, and the pressure

of the vacuum gauge shall be below 60Pa.Afterwards, the vacuumizing equipment shall

be closed, and whether the reading of the digital vacuum gauge is increased or not shall be observed after the

pressure is maintained for 5 minutes. In case no leakage is identified, the two-way stop valve and three-way stop

valve of the outdoor unit may be opened. Finally, the vacuumizing hose connected to the outdoor unit can be

disassembled.

• Leak Detection

The joint of connecting pipes for the outdoor unit shall be subject to leak detection with soap bubble or

dedicated leak detection equipment.

• Post-installation Inspection Items and Test Run

Post-installation Inspection Items

qesnoC dekcehC eB ot smetI uence of Improper Installation

Whether the installation is firm or not The unit may fall, vibrate or make a noise

Whether the inspection on air leakage is completed The refrigerating capacity (heating capacity) may be

insufficient

Whether the unit is fully insulated Condensation or drip may occur

Whether the drainage is smooth or not Condensation or drip may occur

Whether the power voltage is identical to that

Failure may occur or the parts may be burned

marked on the nameplate

Whether the circuit and pipeline are installed

Failure may occur or the parts may be burned

correctly

Whether the unit is safely earthed Electric leakage may occur

Whether the type of wire is in line with relevant

Failure may occur or the parts may be burned

regulations

Whether barriers are identified at the air inlet/outlet

of the indoor/outdoor unit

Whether the length of refrigerant pipes and the

The refrigerating capacity (heating capacity) may be

insufficient

The refrigerant amount charged cannot be confirmed

refrigerant amount charged are recorded

Test Run

1. Preparations

(1) Power on is not allowed before all the installation operations are completed and before the leak

detection is proven qualified.

(2) The control circuit shall be connected correctly and all the wires shall be firmly connected.

(3) The two-way stop valve and three-way stop valve shall be opened.

(4) All the scattered articles (especially the metal filing and thread residue) shall be removed from the unit

body.

2. Me

thods

(1)

Switch on the power supply and press the “ON/OFF” on the remote controller, after which the air

conditioner will start operating.

(2) Press “Mode” to select refrigeration, heating and sweeping wind, and observe whether the air

conditioner is under normal operation.

6

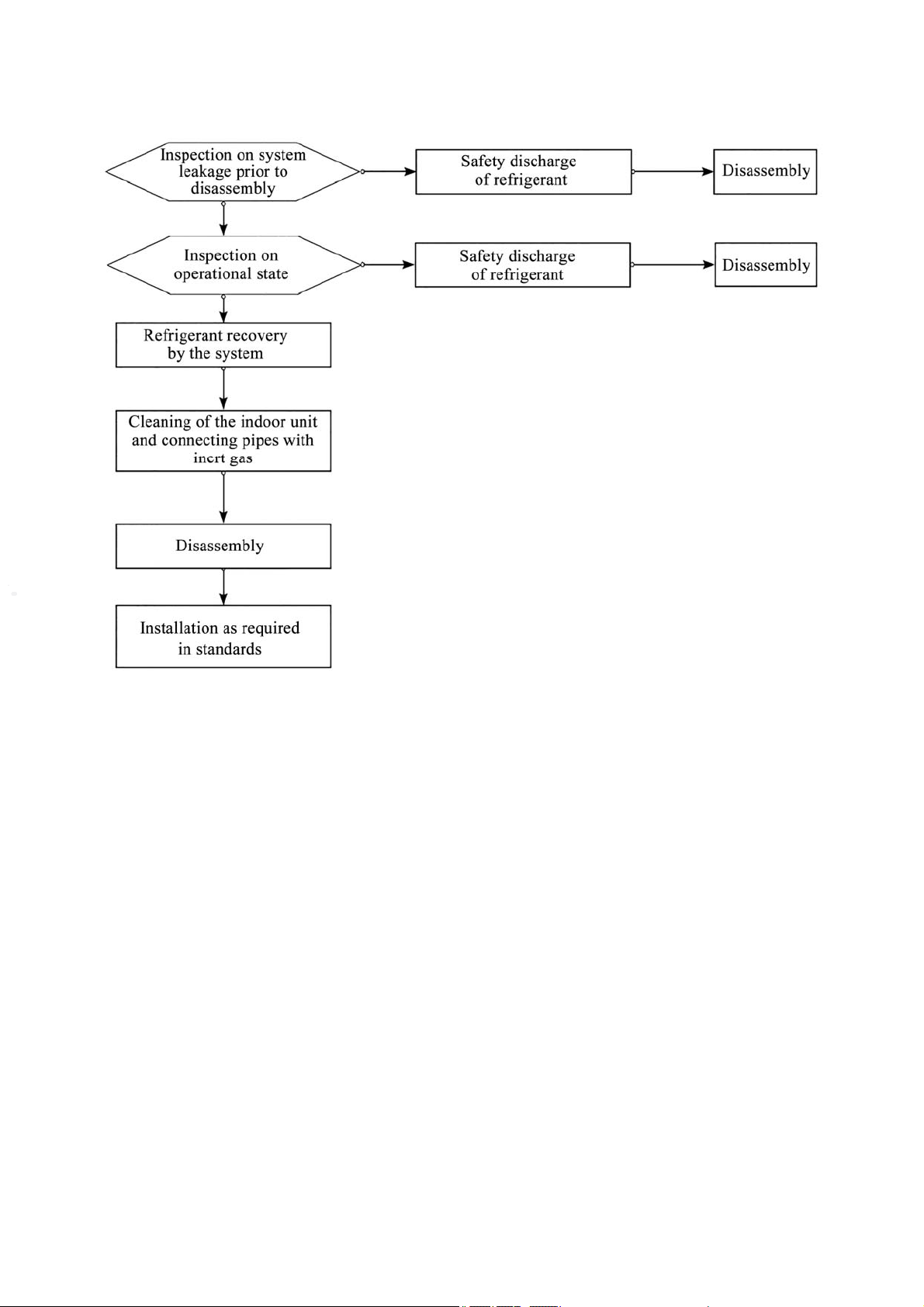

Relocation Procedures

Note: in case relocation is required, the joint of evaporator gas/liquid pipes of the indoor unit shall be cut off with

a cutting knife. Connection is only allowed after re-flaring (the same to the outdoor unit).

Maintenance Instructions

Maintenance Precautions

Precautions

• For all the faults requiring welding the refrigeration pipelines or components inside the refrigeration system

of R32 refrigerant air conditioners, maintenance at the user’s site is never allowed.

• For the faults requiring radical disassembly and bending operation of the heat exchanger, such as the

replacement of the outdoor unit chassis and integral disassembly of the condenser, inspection and maintenance at

the user’s site are never allowed.

• For the faults requiring replacement of the compressor or parts & components of refrigeration system,

maintenance at the user’s site is not allowed.

• For other faults not involved in the refrigerant container, internal refrigeration pipelines and refrigeration

elements, the maintenan

ce at the user’s site is allowed, including the cleaning and dredging of the refrigeration

system requiring no disassembly of refrigeration elements and no welding.

• In case replacement of gas/liquid pipes is required during maintenance, the joint of evaporator gas/liquid

pipes of the indoor unit shall be cut off with a cutting knife. Connection is only allowed after re-flaring (the same

to the outdoor unit).

Qualification Requirements of Maintenance Personnel

1. All the operators or the maintenance personnel involved in refrigerating circuits shall be provided with the

effective certificate issued by an industry-accepted assessment institute, to ensure that they are qualified for safety

disposal of refrigerant as required in the assessment regulations.

2. The equipment can only be maintained and repaired as per the method recommended by the manufacturer.

In case

the assistance from personnel of other disciplines is required, the assistance shall be supervised by the

personnel with qualification certificate involved in flammable refrigerant.

7

Loading...

Loading...