Page 1

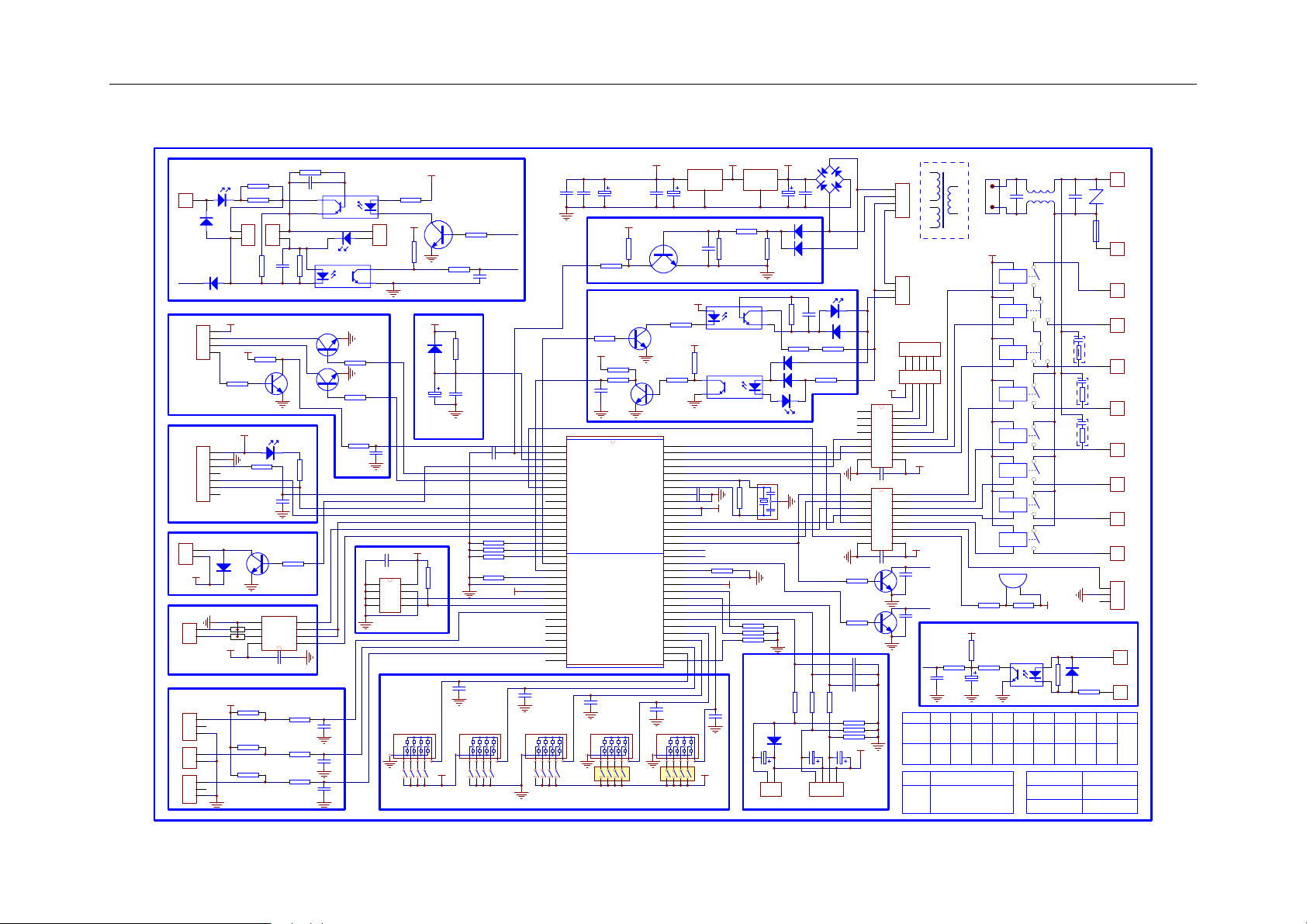

0010451167 PCB information – circuit diagram

XT1

INOUT

2200uF

LED5

2

E1

8.00M

1N4148

1

VDD

R8 10

D17

D1-D4

C34

104

D12

4148

D13

4148

103

C24

R63

LED4

27K

D15

4148

D14

4148

1K

4.7uF

R141KR15

E6

R7 10

R25

4

R13

1K

D16

4148

2.4K

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

4.7K

R27

4.7K

R26

C14 103

C15 103

C16 103

R61 20K

R62 20K

R60 20K

4.7uF

E7

+5

1

CN6

CN20

CN19

VDD

IC1

2003

104

C32

IC2

2003

104

C31

N5

9013

N4

9013

1

4

CN4

1

CN5

A

B

C

12345

12345

16

15

14

13

12

11

10

9

+12

16

15

14

13

12

11

10

9

+12

C35

104

C36

104

T1

TRAN1-2

C20

103

0.1UF/275V

LB1

CN1

C2

+12

RL6

JQ1AP-A

JQ1P-A

JQ1P-A

RL5

JQ1AP-A

RL4

JQ1AP-A

RL3

JQ1AP-A

RL2

JQ1AP-A

RL1

JQ1AP-1

BUZ1

100

R67

+5

R65

200K

R20

1K

2.2uF

4.7K

R35

220

IC8

R9

E8

TLP521-1

J1 J2 J3 J4 J5 J6 J7 J8 J9 J10

0.1UF/275V

RL8

RL7

+12

680

R6

1N4007

D11

C1

FUSE1

100K/1W

187

T3.15A/250V

187

187

187

RC3

0.033uF+120

187

RC1

0.033uF+120

187

RC2

0.033uF+120

187

187

187

187

187

R1

187

1 P2-P6

RV1

1 P1

1 P14

1 P13

1 P12

1 P11

1 P10

1 P9

1 P8

1 P7

CN7

1

1

P16

1

P17

P15

187

D10

1N4007

+5V

GND

CN17

CN16

CN12

CN11

CN15

R43

10K

R39 10K

R22 1K

AB32

+5

CGMXFC

VDDAREF

C33

104

N1 9013

OSC1

OSC2

VSSA

VDDA

VREFH

NOP

AVss

NOP

SW1

+5

470uF/16V

N3

9013

N2

9013

C12

103

E3

R11

R32

4.7K

R33

1K

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

103

R5 33K

R2

10K/0.5W

LED3

10K/0.5W

R3

1

CN23

1

2

2.2K

D9

CN14

+12

4

+5

1

R53 10K

+5

CN13

1

7

2

1

D19

4148

+12

DL1

2

DL2

1

+5

+5

1

2

1

1

R4

R54

N8

9013

R19

9013

N10

5

6

7

8

R44

R45

R46

CN22

2

1

C3

1K

103

10K

LED1

R12

560

1K

C6

102

R57

IC4 MAX487

DI4GND

DE

A

/RE

B

RO

VCC

C25 104

10K

R18

10K

R17

10K

R16

C4 103

1

23

R58

N6

N7

4.7K

3

2

1

1K

1K

1K

IC6

TLP371

6

5

1

2

LED2

IC7TLP521

4

9013

4.7K

R28

9013

4.7K

R29

1K

R23

C23

103

C26 104

IC5

1

2

3

4

C17

103

C18

103

C19

103

1

24

CN10

R36

10K

24C01A

EEPROM

RB1

330

R10

+5

+5

4.7K

R30

N9

1K

C8

R21

102

+5

R55

D18

1N4148

10K

E9

C27

104

1uF

C5 102

10K

R51

10K

+5

8

7

6

5

J10

R59

10K

R56

R52

10K

+5v

J7J8J9

10K

R50

+5

C9

103

J5

J6

1/60

CHECK

104E4100uF

C22

C29

R24

1K

4.7K

R31

+5

C7

102

IC3

1

2

IRQ/50Hz

3

RESET

4

NOP

5

6

7

BEEP

8

IR

9

10

11

12

487

13

NET-O

14

NET-I

15

P/G

16

P/G

17

NOP

18

19

20

NOP

21

Vss

22

Vdd

23

SCL

24

SDA

25

26

A

27

B

28

C

29

D

30

31

32

C10

103

RB3RB2 RB5

J4

C11

103

RB4

SW2

J1J2J3

C21

103

+5

330

+5

C28 104

W2

INOUT

7805

TLP741/541

R49

C13

103

+5v

+12

R41

R64

56K

IC10

IC9

TLP521

+5

W1

7812

10K

R34

4.7K

R66

1M

10K

+5

R48 10K

R47 10K

R40 10K

E5

4.7uF

CN8

Page 2

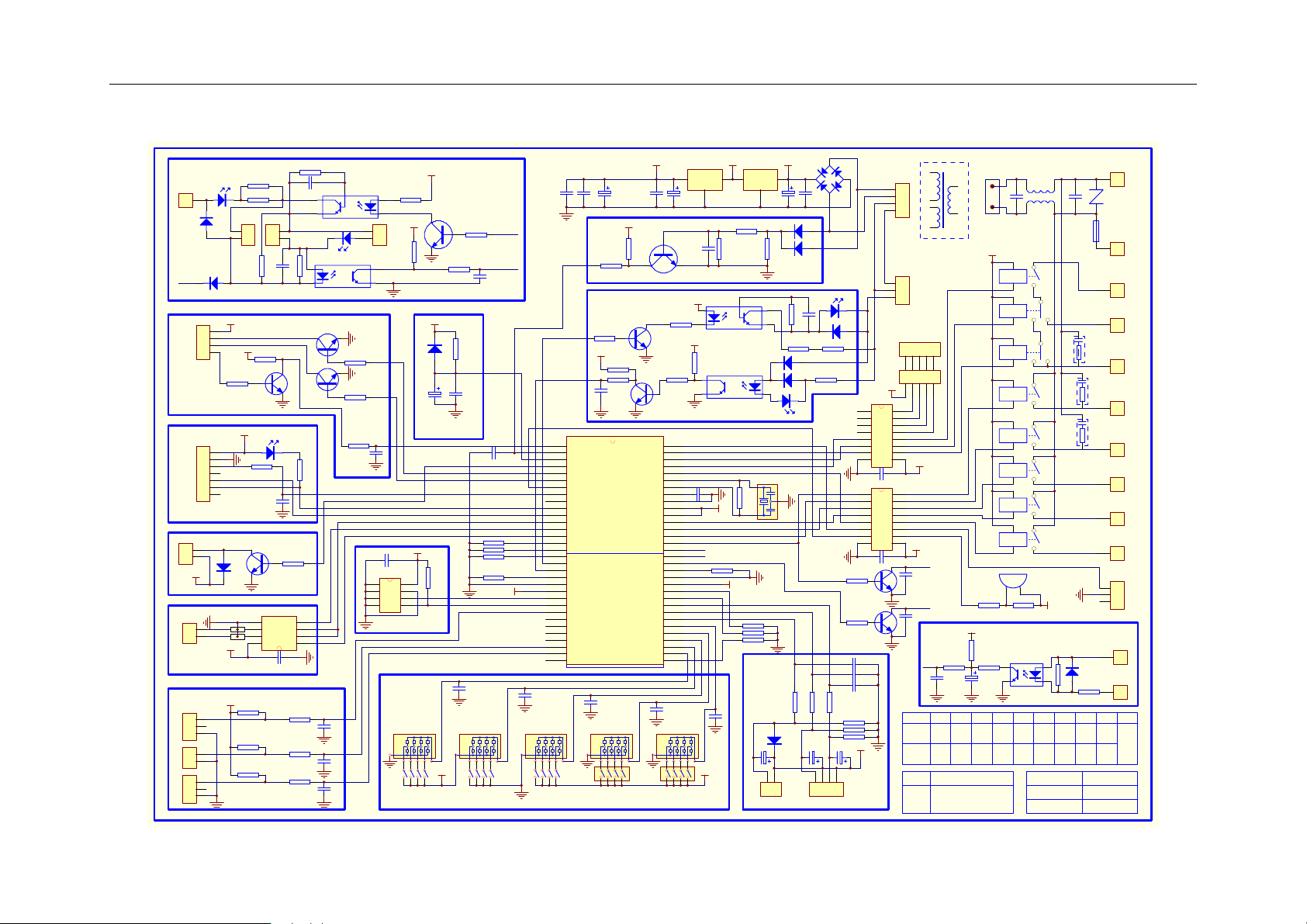

0010451167 PCB information – circuit diagram

通讯线

P15

1

187

D10

1N4007

零线

升降控制

+5V

GND

遥控接收

压机灯

定时灯

电源灯

水泵灯

2

1

CN17

CN16

远程控制

CN12

外部报警门开关浮子开关

CN11

CN15

2

1

1

2

1

1

LED3

R3

D9

CN14

+12

4

1

R53 10K

CN13

1

7

to遥控接收板

D19

4148

+12

DL1

DL2

+5

+5

R2

10K/0.5W

10K/0.5W

CN23

1

2

2.2K

R4

+5

R54

N8

9013

+5

R19

9013

N10

IC4 MAX487

5

6

7

8

10K

R44

10K

R45

10K

R46

R5 33K

C4 103

5

CN22

2

1

C3

1K

1

103

23

R58

9013

N6

10K

9013

N7

LED1

R12

560

1K

C6

102

4.7K

R57

R23

故障输出

DI4GND

3

DE

A

2

/RE

B

1

RO

VCC

C25 104

1K

R18

C17

103

1K

R17

C18

103

1K

R16

C19

103

TLP371

6

LED2

IC7TLP521

IC6

4.7K

R28

4.7K

R29

1K

C23

103

IC5

1

2

3

4

1

24

CN10

1

2

R36

10K

4

C26 104

24C01A

EEPROM电路

RB1

330

R10

+5

+5

8

7

6

5

J10

+5

室内外通讯电路

N9

1K

R21

+5

R55

D18

1N4148

10K

E9

C27

104

1uF

复位电路

R52

10K

+5v

J7J8J9

4.7K

R30

室内外通讯发送

室内外通讯接收

C8

102

C5 102

R51

R59

R56

R50

C9

103

J5

J6

1/60

CHECK

103

104E4100uF

C22

C29

+5

R43

10K

R24

1K

to线控器

4.7K

R31

+5

R39 10K

R22 1K

C7

102

IC3

1

升降门开关

2

IRQ/50Hz

3

RESET

4

NOP

5

升降方向

6

升降电源

7

BEEP

8

IR

9

空

10

电源灯/内故障灯

11

定时灯

12

487使能

13

NET-O

14

10K

10K

10K

10K

+5

步进电机A

步进电机B

步进电机C

步进电机D

无源触点开关

RB3RB2 RB5

NET-I

15

P/G反馈

16

P/G输出

17

NOP

18

线控器输入

19

线控器输出

20

NOP

21

Vss

22

Vdd

23

SCL

24

SDA

25

外部报警输入

26

A

27

B

28

C

29

D

30

高压滤网开关

31

浮子开关

32

无源触点

C10

103

RB4

SW2

J1J2J3

J4

换新风

电加热

CGMXFC

VREFH

水泵/水泵灯

四通/室外通讯输入

外风/室外通讯输出

压机/压机灯

VDDAREF

高压开关

低压开关

内盘管/液管

AB32

C11

103

VDDA

地址1

地址1

选择3

选择2

选择1

+5

470uF/16V

C33

104

N1 9013

N3

9013

N2

9013

低风

中风

高风

OSC1

OSC2

VSSA

健康

加湿

摆风

NOP

AVss

室温

气管

NOP

SW1

+12

IC10

IC9

R64

56K

R41

W1

7812

10K

R34

4.7K

W2

INOUT

7805

E3

C21

103

+5

330

R11

TLP741/541

+5

R32

4.7K

R33

1K

TLP521

64

63

62

61

60

59

58

C28 104

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

+5

室内外通讯发送

室内外通讯接收

R49

R66

1M

10K

+5

R48 10K

R47 10K

R40 10K

传感器

C12

103

C13

103

+5v

E5

4.7uF

CN8

盘管(气)

XT1

INOUT

2200uF

LED5

2

E1

8.00M

1N4148

1

VDD

R8 10

D17

D1-D4

C34

104

D12

4148

D13

4148

103

C24

R63

LED4

27K

D15

4148

D14

4148

1K

4.7uF

R141KR15

E6

R7 10

R25

步进电机D

步进电机C

步进电机B

步进电机A

R13

1K

4

D16

4148

2.4K

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

4.7K

R27

4.7K

R26

C14 103

C15 103

C16 103

R61 20K

R62 20K

R60 20K

4.7uF

+5

E7

1

CN6

CN20

CN19

VDD

IC1

2003

104

C32

IC2

2003

104

C31

N5

9013

N4

9013

室温盘管(液)

1

4

CN4

1

CN5

A

B

C

12345

12345

16

15

14

13

12

11

10

9

+12

16

15

14

13

12

11

10

9

+12

C35

104

T1

TRAN1-2

水泵指示灯

0.1UF/275V

CN1

+12

JQ1AP-A

JQ1P-A

JQ1P-A

JQ1AP-A

JQ1AP-A

JQ1AP-A

JQ1AP-A

JQ1AP-1

LB1

C2

RL6

RL5

RL4

RL3

RL2

RL1

BUZ1

压机指示灯

100

R35

无源触点开关

220

IC8

R9

E8

TLP521-1

有装饰

冷暖

面板

无装饰

单冷

面板

4.7K

负离子

加氧

电脑板型号

C36

104

连接

断开

一拖一

一拖多

无源触点开关

C20

103

R67

+5

R65

200K

R20

1K

2.2uF

J1 J2 J3 J4 J5 J6 J7 J8 J9 J10

有温度

有室

遥控

补偿

室外

无温度

无室

线控

补偿

室外

去掉R58,短接CN22

去掉R4,R5,C3,C4,D9,D10

短接CN23

0.1UF/275V

C1

FUSE1

RL8

RC3

0.033uF+120

RL7

0.033uF+120

+12

1N4007

680

D11

R6

R1

100K/1W

其它机型内机地

一拖一

2P吊落

一拖多

KFR-120Q

专用号

0010451167

版本号 5

零线

187

RV1

T3.15A/250V

187

火线

高风

187

中风

187

低风

187

RC1

0.033uF+120

水泵

187

RC2

摆风

187

加湿

187

健康

187

电加热

187

CN7

换新风

无源火线

187

无源零线

187

址选择

不选择

1 P2-P6

1 P1

1 P14

1 P13

1 P12

1 P11

1 P10

1 P9

1 P8

1 P7

1

1

P16

1

P17

备用

Page 3

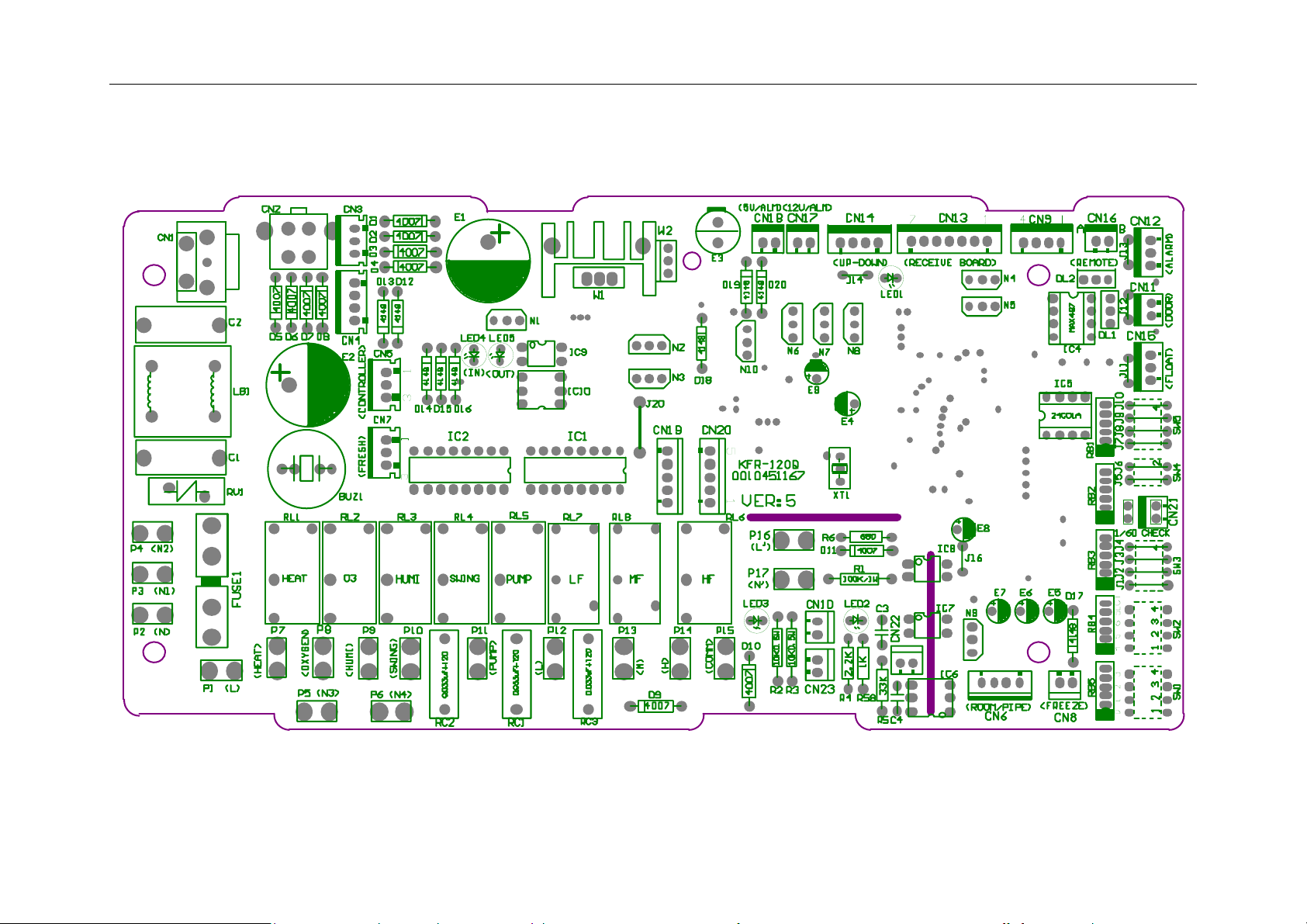

0010451167 PCB information – characters on board(horizontal)

Page 4

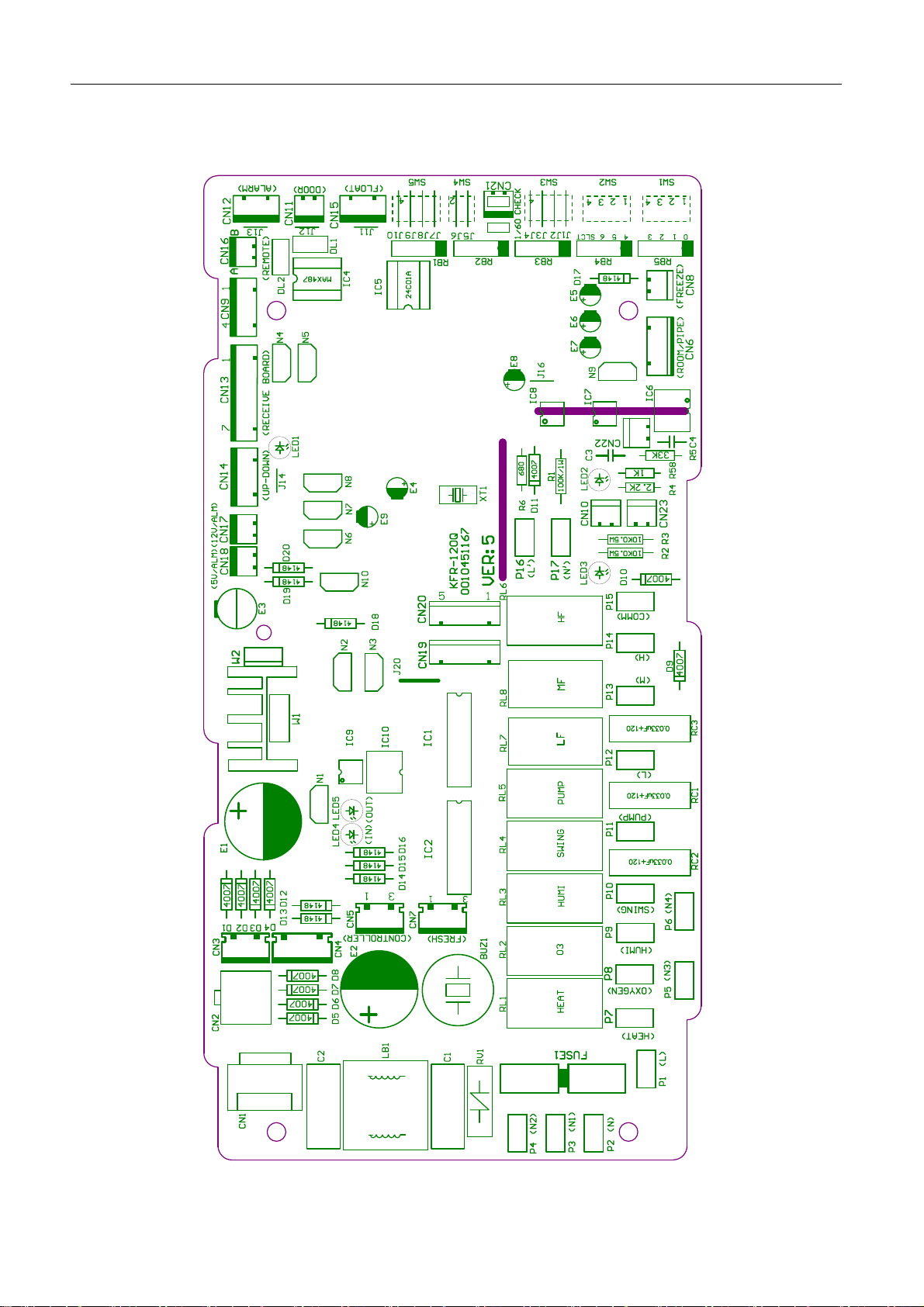

0010451167 characters on board(vertical)

Page 5

Condition for the PCB data:

1.Working ambient temperature:-10℃~70℃, relative humidity:30%~95%

2.Preserved ambient temperature:-20℃~80℃,relative humidity:30%~95%

3.Power supply:220VAC、50/60Hz,voltage range:160V~250V

4.Precise of temperature control:±1℃

0010451167 PCB information – port and definition

P1——connect to external power supply, live line: L (220VAC)

P2——connect to external power supply, neutral line: N (0VAC)

P3、4、5、6——control external load, neutral line: N1、N2、N3、N4(0VAC)

P7——control external load, electrical heat: HEAT (control output 220VAC)

P8——control external load, health function: OXYGEN (control output 220VAC)

P9——control external load, humidification: HUMI (control output 220VAC)

P10——control external load, SWING(control output 220VAC)

P11——control external load, WATER PUMP(control output 220VAC)

P12——control external load, indoor fan motor low speed: L(control output 220VAC)

P13——control external load, indoor fan motor mid speed: M(control output 220VAC)

P14——control external load, indoor fan motor high speed: H(control output 220VAC)

P15——communication with fixed frequency single outdoor unit: COMM(0~220VAC)

P16——input control, signal live line: L’(220VAC)

P17——input control, signal neutral line: N’(0VAC)

CN1——input port of transformer (220VAC)

CN2——input port 1 of transformer (no use)

CN3——input port 2 of transformer (no use)

CN4——input port 3 of transformer (1-2、14VAC,3-4、12VAC)

CN5——input control, connecting port to wired controller: CONTROLLER(three bits: 1. power supply:

12VAC, 2. power supply: 0VAC, 3. communication: COMM.).

CN6——input control, ambient temp.-coil temp. sensor connecting port: ROOM/PIPE(1-2、ROOM,

3-4、PIPE。)

Indoor ambient temp. sensor: R25=23KΩ+-2.5%,B25/50=4200K+-3%,range:(-40,80)

Indoor coil temp. sensor: R25=10KΩ+-3%,B25/50=3700K+-3%,range:(-20,90)

CN7——control external load, fresh air control: FRESH(1. blank, 2. power supply 0VDC, 3. control

output: 12VDC.)

CN8——input signal: FREEZE(no use)

CN9——input control(no use)

CN10——communication with fixed frequency single outdoor unit: (0~12VDC)

CN11——input signal, door switch: DOOR(1-2 short circuit is normal, cut off P8 output)

CN12——input signal, external alarm input: ALARM(1-3 short circuit is normal, if cut off, air

conditioner stops work.)

Note: For convertible type, cassette type, duct type units, CN11 and CN12 must be in short

circuit, or PCB will display failure information.

CN13——input signal, wiring port of remote receiver board: RECEIVE BOARD(1. power supply 5VDC,

2. power supply 0VDC, 3. remote signal, 4. signal output of running lamp 0VDC, 5. signal output of timer

Page 6

lamp 0VDC,6. signal output of power lamp 0VDC, 7. signal output of water pump running lamp 0VDC)

CN14——control external load, auto elevating function (1. signal of door switch close, 2. output of

elevating direction control 0VDC, 3. output of elevating power control 0VDC, 4. power supply 12VDC)

CN15——input signal, detecting water level of float switch (1-3 short circuit is normal, cut off shows

that level exceeds the limitation).If float switch cuts off or occurs other failure, LED1 will flash 10 times.

CN16——input control, wiring port of central controller: REMOTE(1、RS485-B,2、RS485-A。)

CN17——output signal, output signal of failure alarm, control external load, 12V/ALM(1. control output

0VDC, 2. power supply 12VDC)

CN18——output signal (no use)

CN19——control external load, swing 1(1、16VDC,2、0VDC,3、0VDC,4、0VDC,5、0VDC.)

CN20——control external load, swing 2(1、16VDC,2、0VDC,3、0VDC,4、0VDC,5、0VDC.)

CN21——input signal, spring switch, CHECK(1、input signal of earthing, 2. power supply 0VDC)

CN22——short circuit means selecting single split communication type.

CN23——short circuit means selecting multi split communication type.

Page 7

0010451167 PCB information – function selection(ON is 1, OFF is 0)

The standard condition for PCB in factory

SW1:4 bits are OFF

SW2:4 bits are OFF

SW3:4 bits are ON

SW4:2 bits are ON

SW5:4 bits are ON

SW1-SW2: used for indoor unit to set unit address from 1 to 16’

SW3-SW5: used for indoor unit to select different functions.(every dip switches are corresponding to

J1-J10.

SW2-4——logistic relationship of control function(door card control and remote/ wired control)0

means logistic relationship is “and”, 1 means the later coming is preferential.

J1,SW3-1——function selection-control type: 1 means remote control, 0 means wired control.

J2,SW3-2——function selection-temperature compensation in heating mode: 1means “yes”, 0means

“no”.

J3,SW3-3——function selection-outdoor communication: 1means “yes”, 0means “no”. This PCB

must be 1.

J4,SW3-4——function selection-heat pump unit: 1means “heat pump”, 0means “cooling only”.

1/60——test in short circuit, but in operation short circuit mustn’t be permitted.

CHECK——short spring switch control, it also can be used as switch of convertible type except for

testing.

J5,SW4-1——function selection-elevating function: 1means “yes”, 0means “no”.

J6,SW4-2——function selection –health function: 1means common (indoor fan motor running); 0

means special (indoor, outdoor running).

J7,SW5-1——function selection –swing mode: 1 means common(simultaneous motor), 0 means

special (swing motor).

J8,SW5-2——function selection – system combination: 1means fixed frequency single unit, 0 means

fixed frequency multi split.

J9,SW5-3——function selection –group control: 1 stands for the master unit (its address in wired

controller is 0), 0 stands for the slave units (the address should be set by the dip switch, their addresses

only can be in the range: 1~15)

J10,SW5-4——function selection –preset: 1 no meaning, 0 no meaning

Page 8

0010451167 PCB information- control type

Control type selection between remote and wired: select by dip switch J1, SW3-1(1 means remote control;

0means wired control).

For remote control type, please use remote controller YR-H71, and a remote receiver is equipped with

indoor unit. For wired control type, wired controller YR-E12 will be used, 3-core shied wire is equipped with

indoor unit.

Door card control: controls ON/OFF, the start up setting will comply with last time request memorized

according to condition memorize function. Its difference with emergency switch of convertible type unit lies:

the emergency switch control will perform in the condition: 24degrees, auto fan speed in auto mode.

The function combination between door card and remote/wired control type: select by dip switch: SW2-4(0

means “and”, 1 means later coming is preferential.)

Dip switch position in wired control type: Only one indoor unit of all indoor units connected with wired

controller is the master unit, whose address is 0, function selection switch(J9,SW5-3)is 1. The others are

slave units, and the quantity can be 0~15, whose addresses are(SW1:1~4)from 1 ~15, and cannot

repeat.

Wiring request in wired control type: the wired controller ports A-B-C are connected with indoor port CN5

(1-2-3) through 3-core shield wire. Requirements:

1. Port A only connects with either of indoor port CN5(1)

2. Port B connects with port CN5 (2) of all indoor units.

3. Port C connects with port CN5 (3) of all indoor units.

Dip switch position in central control type: the addresses (SW1:1~4;SW2:1~4)of indoor units connected

with central controller can not repeat. In principle, they should be in the order from small to big.

Wiring request in central control type: port A-B is connected with indoor port CN16(A-B)through 2-core

shield wire. Requirements:

1. Port A connects with port CN16(A)of all indoor units.

2. Port B connects with port CN16(B)of all indoor units.

When only use remote control type, please select remote control unit, and install according to installation

manual, there is no other special request.

When only use wired control type, please select wired control unit, and install according to installation

manual. When control multi indoor units, take care the requirements of dip switch and wiring, there is no

other special request.

When only use central control type, please firstly install according to air conditioner requests and set the

dipswitch, there is no other special request.

When central control type(128×)and remote control type are used simultaneously, set the dip switch

according to central control type, there is no other special request.

When central control type(128×)and wired control type (16×)are used simultaneously, max. indoor

Page 9

units sets: 128×16 can be controller. Address setting of central controller can be met firstly, and then

modulate the address setting of slave unit wired controlled.

LED in indoor PCB:

1. LED1:is the state lamp for remote receiver as well as failure lamp. If indoor unit is normal, LED1 is on,

or if failure occurs, LED1 flashes regularly, and you can adjust failure type according to the flash times.

2. LED2:is used for multi split units as communication lamp. If communication between indoor and

outdoor is normal, LED2 will be on.

3. LED3:is used for single split units as communication lamp. If communication between indoor and

outdoor is normal, LED3 will be on.

4. LED4、LED5:is the lamp that shows the data receiving or sending between wired controller and PCB,

If LED4、LED5 be on in turn, communication between wired controller and PCB is normal.

Page 10

10. Diagnostic information

10.1 Failure code

remote control type unit:

failure description

indoor ambient temp. sensor failure

indoor coil temp.sensor failure

outdoor ambient temp. sensor failure

or 4-way valve broken down in heating mode

outdoor coil temp. sensor failure

over-current protection failure or phase sequence fault

refrigerant system pressure too high or low

communication between indoor PCB and receiver panel failure

communication between indoor PCB and outdoor PCB

drainage failure

Note: For convertible type unit, drainage failure is not available.

Wired control type unit failure code:for old wired controller

Failure description Failure code on wired

controller

Indoor ambient temp. sensor abnormal E1

Indoor coil temp. sensor abnormal E2

Outdoor ambient temp. sensor abnormal E3

Outdoor coil temp. sensor abnormal E4

Over current protection E5

Over high or low pressure protection E6

Communication between panel and indoor

E8

abnormal

Communication between indoor and outdoor

E9

abnormal

Water pump failure E0

indoor running

lamp flash times

1

2

3

4

5

6

8

9

10

Page 11

Failure code with wired controller YR-E12:

For

remote

type, flash

times

10 08 21 Drainage system failure Float switch broken down for more than

1 01 01 Indoor ambient temp. sensor

2 02 02 Indoor coil temp. sensor failure sensor broken down or short circuit for

3 4A 11 Outdoor ambient temp. sensor

4 49 12 Outdoor coil temp. sensor

5 48 10 Over-current protection CT check abnormal 3 times in 30m

6 53 14 High pressure abnormal High pressure switch acts 3 times in 30m

8 07 06 Communication between wired

9 06 05 Communication between

11 0B 30 Outside alarm signal input Outside signal broken down for more than

12 03 20 Gas pipe temp. sensor

13 0D 31 Solenoid valve abnormal Solenoid valve act incorrectly 3 times

15 05 17 EEPROM abnormal EEPROM data missing

Failure

code on

wired

controller

For central

control,

failure code

Failure description Reason

25m continuously

sensor broken down or short circuit for

failure

failure

failure (compressor

discharging temp. sensor)

controller and indoor abnormal

indoor and outdoor abnormal

abnormal

more than 2m continuously

more than 2m continuously

sensor broken down or short circuit for

more than 2m continuously

Sensor broken down or short circuit for

more than 2m continuously

Communication abnormal for more than

4m continuously

Communication abnormal for more than

4m continuously

10s

Sensor broken down or short circuit for

more than 2m continuously

continuously

Page 12

8.2 Trouble Shooting - Detailed for engineer

Plug the supply coil properly

Return to the controller manufacturer for

repair

The power supply coil isn’t plugged

well

Damaged fuse Replace with a good one

Damaged wave filtering component

Return to the controller manufacturer for

Plug the transformer well or replace with a

The transformer isn’t plugged well or

repair

good one

is damaged

Damaged component on power

supply unit of indoor board

Return to the controller manufacturer for

repair

Replace with a good connection cable

Damaged major chip

Damaged connection cable between

Connect the cable well

board and indoor board isn’t

connected well

Connection cable between display

display board and indoor board

Damaged reception adaptor Replace with a good one

Return to the controller manufacturer for

repair

Damaged remote circuit or major chip

Return to the controller manufacturer for

repair

Damaged major chip

Damaged dynatron Q1 Replace with a good one

Damaged buzzer Replace with a good one

Connect connection parts well

Replace with a good 2803

well with connection cable

CN8 on indoor board is not plugged

Damaged 2803

Damaged 2803 Replace with a good 2803

Damaged relay JK1 Replace with a good one

Damaged relay JK2 Replace with a good one

Unavailable voltage at input part of

circuit board

Unavailable voltage at one end of

the fuse

consequent pole of transformer

Unavailable output from the

Trouble Checkup result Possible reasons Corresponding solution

No response after

power being

connected

chip

Improper output of 7805

Normal power supply for major

Indicator lamps do not light

Display board does

not make normal

response

Remote control cannot be received

wo ends of the buzzer

Unavailable square wave signal at

t

The buzzer does

not beep while

making remote

No output from 2803 on indoor

Available square signal at two

control

board

ends of the buzzer

Normal output of relays K1, JK2,

JK3

Indoor blowing fan

does not run

No output at 16 pin of 2803 on

JK2 on indoor board

of relay

No output at relay JK1 on indoor

indoor board

Unavailable voltage on COM port

Indoor blowing fan

cannot not

board

generate low wind

Page 13

Replace with a good 2803

Replace with a good 2803

Press sleep button 10 times within 5

seconds (and the buzzer will beep 4 times),

the system is then set to power breakdown

memory mode.

Return to the controller manufacturer for

repair

Plug CN4 well with the connection cable

Plug CN6 and the connection cable well

Socket CN4 is not plugged well with

Damaged relay JK3 Replace with a good JK3e

No output at 15 pin of 2803 Damaged 2803

No voltage at COM of relay JK3 on

Damaged relay JK2 Replace with a good JK2

oor board

ind

No output at relay JK2 on indoor

board

Damaged relay JK3 Replace with a good JK3

No output at 14 pin of 2803 Damaged 2803

board

No output at relay JK3 on indoor

Damaged relay JK6 Replace with a good JK6

No output at 11 pin of 2803 Damaged 2803 Replace with a good 2803

board

No output at relay JK6 of indoor

Damaged relay JK7 Replace with a good JK7

Socket CN6 is not plugged well with

d

output of relay JK7 on indoor

No output at 18 pin of 2803 Damaged 2803 Replace with a good 2803

No

No setting has been made

Damaged chip IC6 of indoor board

boar

Available output of relay JK7 on

connection cable

indoor board

Damaged relay JK5 on indoor board Replace with a good JK5

No output of relay JK5 on indoor

board

No output at 12 pin of 2803 Damaged 2803 Replace with a good 2803

connection cable

Available output of relay JK5 on

indoor board

Trouble Checkup result Possible reasons Corresponding solution

No swing wind

No output of

four-way valve

during heating

Indoor blowing fan

cannot generate

medium wind

Indoor blowing fan

cannot generate

high wind

No output of swing

Unavailable power

breakdown memory

Unavailable power

breakdown memory

program

under swing mode

Page 14

It will restore automatically when

the temperature of indoor coil pipe

after three minutes

The compressor will work normal

rises to 7

Too low temperature of indoor coil pipe

causes overcooling protection

Damaged 2803 Replace with a good 2803

Plug the connection cable well

Connection cable between the compressor

Damaged relay JK6 on indoor board Replace with a good JK6

it

It will restore normally after 3

It will automatically restore when

the temperature of indoor coil pipe

falls to 57

and JK6 isn’t plugged well

Too high temperature of indoor coil pipe

causes overheat protection

Plug the connection cable well

Damaged 2803 Replace with a good 2803

Damaged relay JK6 on indoor board Replace with a good JK6

Connection cable between compressor

Damaged Q2 Replace with a good Q2

and JK6 isn’t plugged well

Plug the connection cable well

Socket CN6 is not plugged well with

Damaged relay JK8 on indoor board Replace with a good JK8

connection cable

or board

Three minutes’ protection for compressor

No output at 11 pin of 2803 on

indo

Trouble Checkup result Possible reasons Corresponding solution

During cooling program,

the compressor does not

start when the

temperature meets

No output of relay JK6 on indoor

board

board

3 minutes’ delay protection for compressor

During heating program,

No output of relay JK6 on indoor

proper conditions

No output at 11 pin of 2803 of

the compressor does not

start when the

indoor board

temperature meet proper

conditions

No output of relay JK6 on indoor

board

Available output of relay JK6 on

indoor board

During heating program,

the compressor does not

start when the

temperature meet proper

conditions

Available output of relays on

No output of relay JK8 on indoor

No output at collector of Q2 on

indoor board

board

During cooling program,

the compressor works

while outdoor blowing

indoor board

fan does not

Page 15

It will automatically restore when

the temperature of indoor coil

pipe falls to 57

Too high temperature of indoor coil pipe

causes overheat protection

Damaged Q2 Replace with a good Q2

Plug the connection cable well

Socket CN6 is not plugged well with

Damaged relay JK8 on indoor board Replace with a good JK8

Return to the controller

manufacturer for repair

connection cable

Damaged rectification diode D6-D7 etc.

Damaged transformer CT1 Replace with a good one

Return to the controller

manufacturer for repair

Replace with a good one

Damaged temperature sensor for indoor

coil pipe

Damaged 2803 Replace with a good 2803

Plug the connection cable well

Damaged relay JK4 on indoor board Replace with a good JK4

Socket CN5 is not plugged well with

Replace with a good one

Faulty connection cable to transmit float

feedback signal

connection cable

No output at collector of Q2 on

indoor board

Trouble Checkup result Possible reasons Corresponding solution

During heating program,

the compressor work while

outdoor blowing fan does

not

During heating program,

No output of relay JK8 on indoor

board

the compressor work while

Available output of relays on

indoor board

Current transformer outputs

normally

outdoor blowing fan does

not

ormally

Transformer CT1outputs

abn

Inaccurate protection current Adjust the adjustable potentiometer

Abnormal overcurrent

detection

Damaged major chip

Damaged indoor temperature sensor Replace with a good one

With timing indicator and

compressor indicator

extinguishing, the

With timing indicator and

operation indicator flashes

compressor indicator

every second

lighting, the operation

indicator flashes every

second

o output of relay JK6 on indoor

No output at 13 pin of 2803 on

oard

indoor board

N

b

Water pump indicator

flashes every second

indoor board

Available output of relay JK6 on

(trouble for water

discharging)

Loading...

Loading...