Under Counter Water Filter

Installation Instructions

MODELS HF-2STAGE and HF-3STAGE

Chrome Brushed Nickel

The faucet may be mounted on the sink using an existing hole for a sprayer nozzle or

soap dispenser, or by drilling a hole at least 1/2" in diameter. Be sure the location of the

faucet allows the spout to extend slightly past the edge of the sink. Note: we recommend

enlisting the services of an approved or certied professional if drilling is required.

Preparing for Installation

Please read entire installation guide before installing the lter system.

Installation must comply with state and local laws.

The HF-2STAGE and HF-3STAGE are available in two

designer nishes, Polished Chrome and Brushed Nickel.

The HF-1STAGE is only available with the Chrome nish.

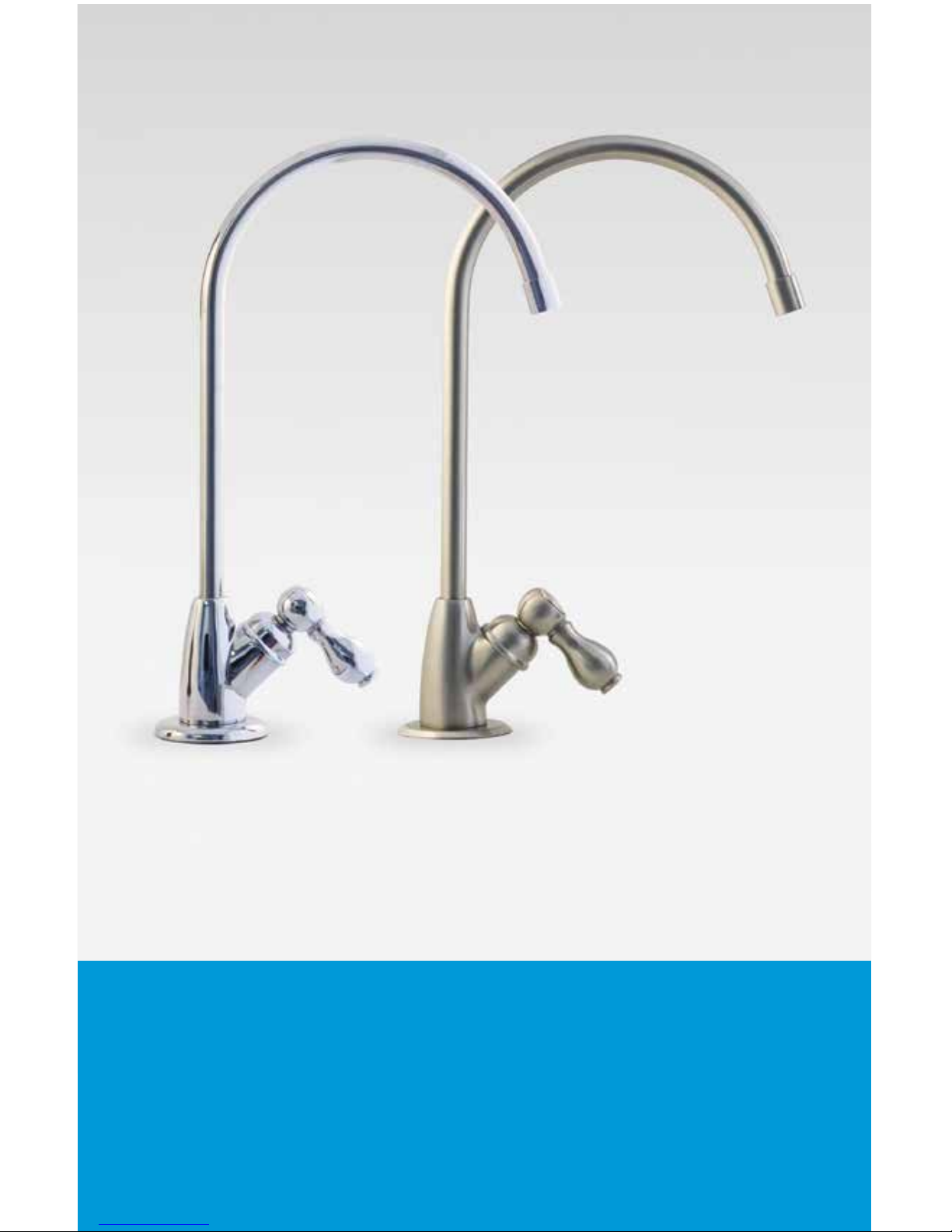

HF-3STAGE

HF-2STAGE

HF-1STAGE

A

HF-3STAGE lter unit

B

Faucet (1)

C

Filter Cartridges (3)

D

Screws with anchors (2)

E

Faucet Rubber Washer (1)

F

Faucet Spacer (1)

G

Faucet Washer (1)

H

Faucet Nut (1)

I

3’x¼” Poly tubing (1)

J

Chrome nut (1)

K

Plastic collar (2)

L

Plastic tube insert (1)

M

3’x3/8” Poly tubing (1)

N

Brass nut (1)

O

Brass tube insert (1)

P

3/8” Brass Tee (1)

A

HF-2STAGE lter unit

B

Faucet (1)

C

Filter Cartridges (2)

D

Screws with anchors (2)

E

Faucet Rubber Washer (1)

F

Faucet Spacer (1)

G

Faucet Washer (1)

H

Faucet Nut (1)

I

3’x¼” Poly tubing (1)

J

Chrome nut (1)

K

Plastic collar (2)

L

Plastic tube insert (1)

M

3’x¼” Poly tubing (1)

N

Brass nut (1)

O

Brass tube insert (1)

P

¼” Brass Tee (1)

A

HF-1STAGE lter unit

B

Faucet (1)

C

Filter Cartridge (1)

D

Screws with anchors (2)

E

Faucet Rubber Washer (1)

F

Faucet Spacer (1)

G

Faucet Washer (1)

H

Faucet Nut (1)

I

3’x¼” Poly tubing (1)

J

Chrome nut (1)

K

Plastic collar (2)

L

Plastic tube insert (1)

M

3’x¼” Poly tubing (1)

N

Brass nut (1)

O

Brass tube insert (1)

P

¼” Brass Tee (1)

D

A

B

C

E

H

L

F

I M

G

J N

K

O

P

D

D

A

A

B

B

C

C

E

E

H

H

L

L

F

F

I

I

M

M

G

G

J

J

N

N

K

K

O

O

P

P

Recommended Installation Tools

• Variable speed drill w/ 7/32" bit

• Adjustable wrench

• Measuring tape

• Bucket

• Phillips head screwdriver

• Hammer

Before beginning installation, please ensure

all parts listed are present. If any part is

missing or damaged, do not attempt to install

the lter. Please contact Customer Service for

replacement parts at (888) 245-3114.

Estimated Installation Time: 45 minutes

Installation Instructions

3

Attach white tube to the brass tee: Slide the compression nut

onto the white tubing (with threads of the nut facing the end of

the white tube). Next, slide the plastic sleeve onto the white tube.

Place brass insert into the opening of white tube. Push the tip of

the white tubing into the opening of the brass tee. While holding the

white tube in place inside the brass tee, tighten the compression

nut to compress the plastic sleeve and create a seal. NOTE: Use a

wrench to ensure complete seal. Avoid over tightening.

4

Faucet Installation: Install as shown.

Tighten nut to secure faucet to sink.

5

Faucet Connection: Connect the

outlet hose to the base of the faucet by

sliding the chrome nut onto the tube

followed by the white collar. Place the

white insert into the end of the tube.

Press the tube against the faucet base

and slide the nut and collar up to the

threads. Use wrench to ensure seal is

sufciently tight.

Note:

Avoid over-tightening.

1

Unpack and unwrap contents.

Turn off and disconnect the cold

water supply.

2

Attach threaded ends of supplied

brass tee to the cold water supply line

and shut-off valve; tighten using an

adjustable wrench.

P

E

H

F

G

L

J

K

123

0.95”

0.80”

6

Unit Installation: Select a space

under your sink for the lter

unit that is at least 12 inches

from the bottom of your cabinet

and allows for easy access to

your cold water supply and for

lter replacements. Use the

mounting holes located at the

back of the unit to mark the wall

screw placements with a pencil.

6

Center to hole differences:

HF-1STAGE: 41mm

HF-2STAGE: 65mm

HF-3STAGE: 98mm

10

Turn the cold water on. Check

for leaks and proper installation:

place a towel under the lter unit

and check for leaks. Allow water to

run for 10 minutes to ush carbon

nes. Note: Never use oils to

lubricate the O-rings; O-rings come

pre-lubricated.

9

Connect supply lines: insert tubing

from the tee tting into the inlet side

and insert tubing from the faucet into

the outlet side. Use diagram on the

right to mark tubing depth to ensure

they get inserted completely.

9

It is VERY IMPORTANT to insert tubing

completely so leaking does not occur.

7

Use a 7/32” drill bit to

drill holes for the plastic

anchors provided. Carefully

tap the anchors into the

drilled hole with a hammer.

Mount unit to the wall

with the screws. For the

HF-3STAGE — Pull the

protective plastic strip from

the battery compartment.

The red LED should ash

and beep ve (5) times to

indicate that the battery is

installed correctly.

Depth to insert 2

and 3-stage tubing

Depth to insert single stage tubing

(Diagram is actual size)

2

1

8

Attach each

sump to

the bottom

of the unit

housing. Align

connection

points, push

the sump

up and turn

to the right.

Ensure that

the sump is

locked in.

Enjoy clean, healthy water and the

peace of mind that comes from

award-winning lter technology.

Care and Maintenance

To clean your lter unit, wipe down the exterior with a damp cloth.

For the HF-3STAGE only: Once lters are at 95% capacity (about every

6 months), the battery alarm will sound and ash red when water is

owing and will continue for 15 seconds once water is turned off. Change

the battery every time you replace your lters. The battery is included

with the lter replacement cartridges.

Pure Satisfaction

All HAHN Filtration products offer a 90-day 100% satisfaction guarantee.

(A 1-year warranty is included, which covers defects in materials and

workmanship.) If for any reason you are not satised with your purchase,

simply call us or the dealer you purchased from. A Return Authorization

Code and a full refund will be promptly issued upon return. Thank you for

choosing HAHN Filtration!

This lter system is designed and tested for use with genuine HAHN

Filtration parts, including replacement lters and all hardware except for

the actual faucet. Use of parts from other manufacturers may result in loss

of contaminant reduction performance, system damage or failure. Use

of parts from other manufacturers (besides the faucet) will also void your

warranty. Please visit www.hahnltration.com for all replacement parts.

HF-123STAGE_OM_201403

HF-1STAGE

Replacement cartridge:

HF-1-R

Rated service ow:

0.5 gpm / 1.89 lpm

Max capacity:

200 gal / 757 L

Min working pressure:

20 psi (1.40 kg/cm

2

)

Max working pressure:

80 psi (5.62 kg/cm

2

)

Min operating temperature:

40° F (4.44° C)

Max operating temperature:

90° F (32.22° C)

HF-2STAGE

Replacement cartridge:

HF-2-R

Rated service ow:

0.5 gpm / 1.89 lpm

Max capacity:

450 gal / 1703.44 L

Min working pressure:

20 psi (1.40 kg/cm

2

)

Max working pressure:

80 psi (5.62 kg/cm

2

)

Min operating temperature:

40° F (4.44° C)

Max operating temperature:

90° F (32.22° C)

HF-3STAGE

Replacement cartridge:

HF-3-R

Rated service ow:

0.5 gpm / 1.89 lpm

Max capacity:

600 gal / 2271.25 L

Min working pressure:

20 psi (1.40 kg/cm

2

)

Max working pressure:

80 psi (5.62 kg/cm

2

)

Min operating temperature:

40° F (4.44° C)

Max operating temperature:

90° F (32.22° C)

The HF-2STAGE and HF-3STAGE systems are Tested and Certied

by NSF International against NSF/ANSI Standards 42, 53 and

401 for the reduction of the claims specied on the Performance

Data Sheet and substantiated by test data at www.nsf.org

Precautions:

• Filter is only to be used with cold water.

• If you experience a leak at the hose connection, disconnect and re-seat the hose.

• HAHN Filtration is not liable for consequential or incidental damages due to

improper installation.

Do not use with water that is microbiologically unsafe or of unknown water quality

without adequate disinfection before or after the system. Systems certied for cyst

reduction may be used on disinfected waters that may contain lterable cysts.

Manufactured by Sink Warehouse, LP

4601 Spicewood Springs Rd, Suite 1-100, Austin, Texas 78759

(888) 245-3114

•

www.hahnltration.com

Loading...

Loading...