Page 1

ZD0651ZD0651

GB

JKA Boards

Instructions/Data Sheet

This DBO and Hager devices conform with the following standards:

BS EN 61439-3 including Annex ZB.

Switch-disconnectors: BS EN 60947-3.

Residual Current Circuit Breaker (RCCB): BS EN 61008-1

Residual current operated circuit breaker with integral overload (RCBO): BS EN 61009-1

Miniature Circuit Breaker (MCB): BS EN 60898-1

Installation Instructions:

All product(s) must be installed by a suitably competent electrician

Giving consideration to their intended use and in accordance with the

current edition of BS 7671 (IET Wiring Regulations).

The Electricity at Work regulations and the Health and Safety at Work Act

shall be complied with.

Only equipment and arrangements specied in Hager’s technical

documentation / catalogue shall be used.

Install in the horizontal plane only.

Important notice:

To prevent potential overheating from loose connections the installer

shall check connections are tight to the torque levels stated in these

instructions prior to energizing this board. This check should include

factory made connections which may have loosened in transit.

Cable entry facilities:

Tightening torque values to be applied (Nm)

Switch-disconnector’s: 40A & 63A: 2.8 Nm

Switch-disconnector’s: 100A: 3.3 Nm

RCCB’s 40A & 63A: 2.8 Nm

RCCB’s 80A & 100A: 3.3 Nm

MCBs: 2.8 Nm

RCBO’s: 2.8 Nm

Earth & Neutral terminal bar connections: 2.0 Nm

Single conductors below 1.5mm² need to be doubled back in the

terminal bar

Front metal cover xing screws: 2.0 Nm

Good workmanship and proper materials must be applied by the installer.

The cable entry method shall, as far as reasonably practical, maintain the

non-combustable arrangement of the enclosure. Account shall be taken of

these instructions.

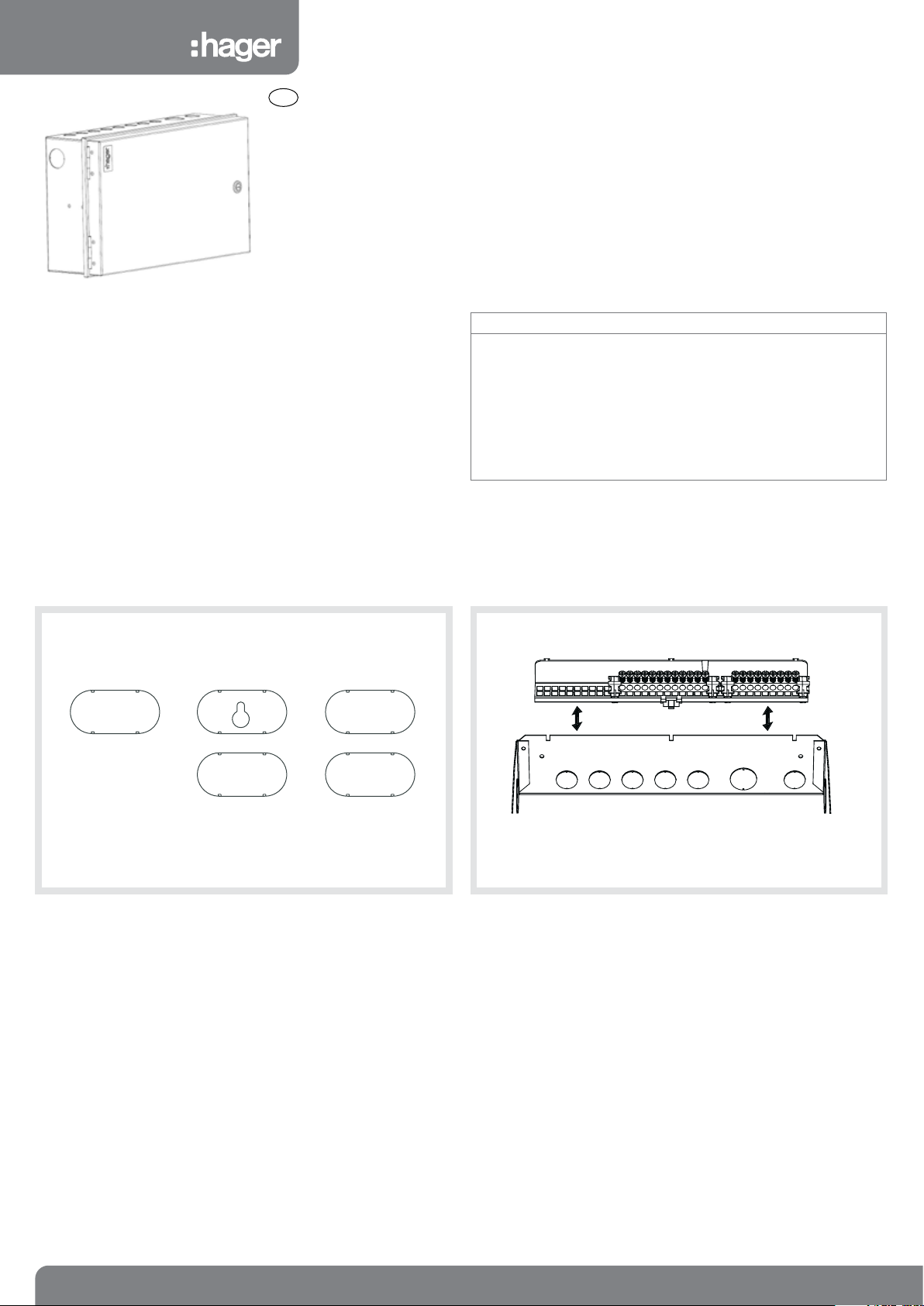

Metal Unit - Removing and replacing the terminal rail for cabling:

Metalclad units are provided with knockouts for standard 20, 25, and

32mm conduit and large rear knockouts.

Note: Only BASEC approved cable should be used

2

to 16mm2 for outgoing cables

1.0mm

up to 35.0mm2 for incoming live cables

Single conductors below 1.5mm² need to be doubled back in the terminal bar.

1

Pull and lift the terminal bar support away from the unit resting the rail

supported by the earth strap. After xing conduit/ cable glands, locate

the rail support and press down.

ZD0651 - Issue 3 03-15

Page 2

Guidance Notes:

The total load must not exceed the rating of the incoming device or the assigned assembly rating (InA) whichever is the lower. Each neutral and earth

connection must correspond numerically to its outgoing way. Additional blanks (ref. JK01B) are available to cover spare ways.

A pack is provided to label this DBO, please consult us for spares or replacements.

Operating Instruction leaet is provided overleaf. This leaet should be left for the end user.

Single conductors below 1.5mm² need to be doubled back in the terminal bar.

DBOs incorporating RCDs in TT systems should incorporate an S type (time Delayed) RCCB, e.g. 100 mA s-type RCCB . Alternatively a main switch with

RCBO protection on all outgoing circuits should be used.

Precautions need to be taken to prevent faults to earth on the supply side of the RCD (as per BS7671 regulation 531.4.1)

IP Ratings:

Cable access into the DBO must maintain the integrity so far as reasonably practicable. In essence, for surfaces accessible after installation, this means

maintaining the requirement for the horizontal top surface of the enclosure to provide a degree of protection of at least IP4X and elsewhere, IP30. For

rear cable access, the minimum number of knockout(s) shall be removed.

IP Code Description

IP2XC Protection against access

IP30 Protection against access with

IP4X A probe of 1mm diameter

with a tool (2.5mm diameter,

100mm long) making contact

with live hazardous parts

a tool (2.5mm diameter, shall

not penetrate)

shall not enter the enclosure

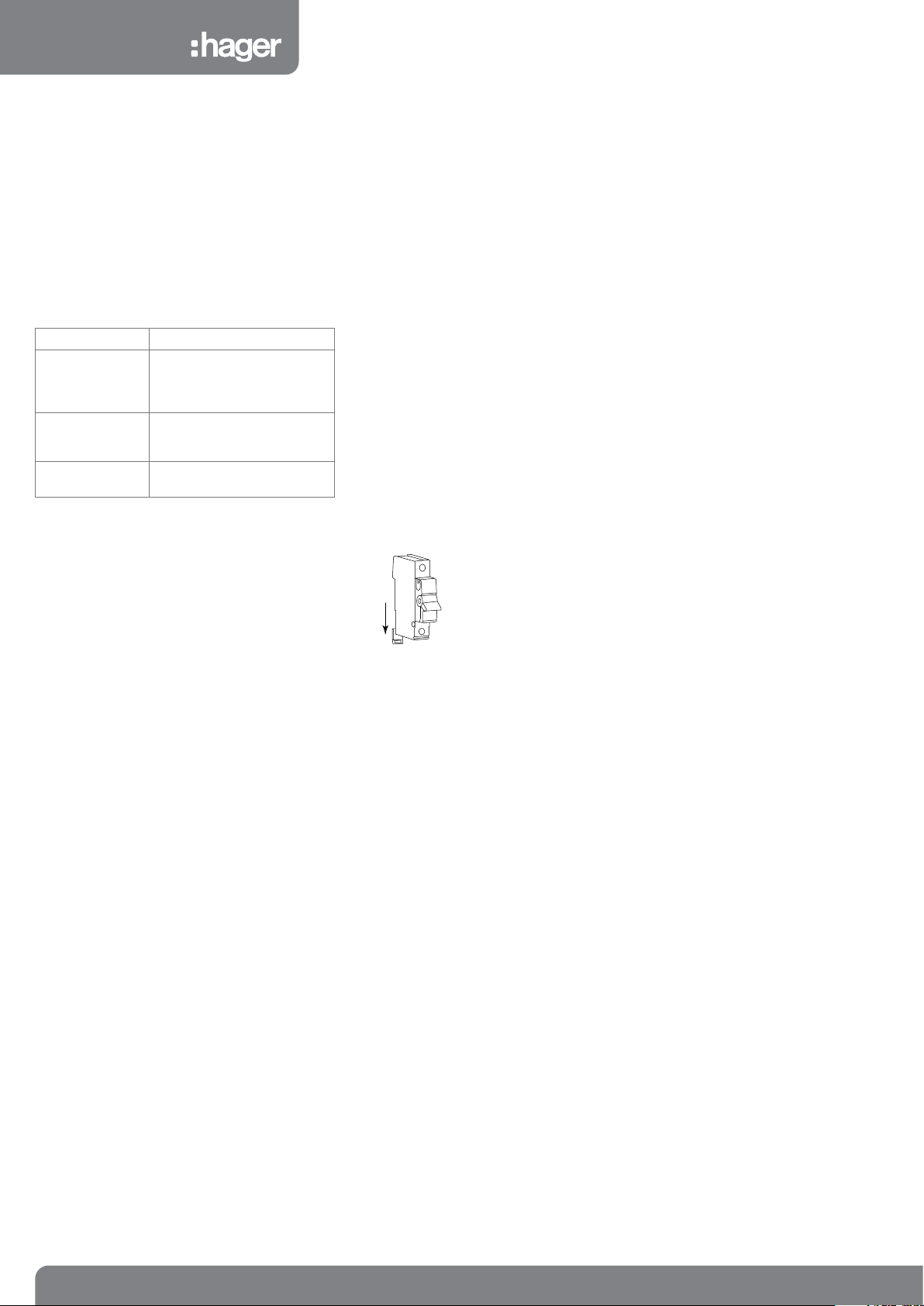

Fitting Hager MCBs and RCBOs:

Only equipment and arrangements specied in Hager’s technical

documentation / catalogue shall be used.

1. Isolate the electrical supply from the DBO.

2. Remove the front cover.

3. Fully slacken the lower terminal of the device.

4. Fully open the bottom device clip (g 1.)

g 1.

Warranty

This distribution board is offered with a 24 month warranty against defective material or manufacture. If a warranty claim is necessary, please call the

technical support number given at the bottom of the page and we will be pleased to help.

For dimensional information and weights please consult the Hager catalogue.

5. Locate the device onto the din rail, and busbar. Ensure that the

busbar tooth is within the device terminal cage.

6. Close the bottom device clip.

7. While holding the device rmly onto the busbar, fully tighten the lower

terminal screw.

8. After tting all outgoing devices and connecting all outgoing cables,

please check the tightness of all cable connections. This should

include all factory made connections, which may have loosened

during installation or transit.

ZD0651 ZD0651

2

Hager Technical Help Line: 01952 675 689

Hager Technical Fax: 01952 675 557

Website: www.hager.co.uk

E-mail us: info@hager.co.uk

ZD0651 - Issue 3 03-15

Page 3

Interface characteristics

Rated & operational voltage (Un / Ue)

230V a.c. 50Hz

Rated insulation voltage (Ui)

320V a.c. 50Hz

Rated impulse withstand voltage (Uimp)

4kV

Rated current of the Assembly (InA)

100A, 63A

Note: Dependent upon rating of main incoming device

Rated current of an Outgoing circuit (Inc)

MCB 6A - 63A (marked rated current on device)

RCBO 6A - 50A (marked rated current on device)

Rated conditional short-circuit current of the ASSEMBLY (Icc)

Annex ZB: 16 kA rms at 250V, power factor 0.6 with equipment and arrangements specied in Hager’s technical documentation /

catalogue.

Protection against electric shock

Consumer unit shall be installed in an electrical system conforming to the current edition of IEC 60364 / BS 7671

Rated diversity factor (RDF) / Values of assumed loading

1way = 1.0

2way – 3way = 0.8

4way – 5way = 0.7

6way – 9way = 0.6

10way and above = 0.5

Rated frequency (fn)

50 Hz

Pollution degree

2

Types of system earthing for which the ASSEMBLY is designed

TNC-S, TN-S when installed in an electrical installation complying with BS 7671

Hager recommends for TT systems a 100A type S time delayed RCCB or a main switch with RCBO protection only on all outgoing circuits.

Indoor use only

Stationary ASSEMBLY

Degree of protection

IP2XC with door open and full compliment of outgoing devices and or blanks tted.

IP30 with door closed and full compliment of outgoing devices and or blanks tted.

Note: Where cables are installed through top wall of enclosure, gaps of IP4X to be maintained.

Intended use

Intended for use in domestic (residential) or similar premises.

Electromagnetic compatibility (EMC) classification

EMC Environment B

External design

JKA: Wall-mounted, surface type, enclosed assembly.

Mechanical impact protection

IK 05

The type of construction

Fixed parts

Type A DBO (Distribution board for use by ordinary persons)

Rated current of outgoing unit (Inc)

RCCB 40A -100A (marked rated current on device)

Note: RDF only applies to continuously and simultaneously loaded

circuits.

In principle, this means adjacent circuit-breakers having a load

‘on’ time exceeding 30 minutes or where a load not exceeding 30

minutes has an ‘off’ time less than the ‘on’ time, will need to have

the rated diversity factor applied as indicated.

3

ZD0651 - Issue 3 03-15

Page 4

START

T

B

T

ON

ON ON

T

Blank RCCB RCBO (two module) MCB RCBO Switch

(one module)

Use circuit as

normal

YES

NO

Does device

stay ON?

NO

Does device

supply socket

outlets

YES

Try & reset device once

MCB

or

RCBO

MCB

tripped

What device

is it?

RCCB

Try & reset device once

Use circuit as

Does device

all MCBs devices

Reset RCCB

normal

YES

stay ON?

NO

Turn OFF

Unplug all

appliances from

circuit and reset

device / replace fuse*

Unplug faulty

appliance until

repaired. Reset device.

Other appliances may

NO

Does device

stay ON?

Plug in & switch on

YES

appliances one at a time

until device trips / blows,

identifying faulty appliance

D

Insulated

Dimensions

(mm)

Enclosure Size

8 12 16 22 2x12 2x16 2x22 3x22

A 254 326 398 505 326 398 505 505

B 236 236 236 236 472 472 472 708

C N/A N/A N/A N/A N/A N/A N/A N/A

D 125 125 125 125 125 125 125 125

A

be used

NO

Does device

stay ON?

Turn ON MCBs

devices one at a time

until RCCB trips again,

identifying faulty circuit

YES

4

ZD0651 - Issue 3 03-15

Loading...

Loading...