Page 1

6LE003168Ad

HIC4xxA

Automatic Transfer Switching

z

Equipment 20 A - 160 A (4P)

Preliminary operations

Check the following upon delivery and after removal of

the packaging:

• Packaging and contents are in good condition.

• The product reference corresponds to the order.

• Contents should include:

- 1 HIC4xxA

- 1 Emergency handle extension rod

- 1 Set of terminals

- Quick Start instruction sheet

Accessories

• Bridging bars

• Voltage sensing and power supply tap.

• Terminal shrouds.

• Auxilliary contact block.

• Sealable cover.

This Quick Start is intended for personnel trained in the

installation and commissioning of this product. For

further details refer to the product instruction manual

available on www.hager.com.

This product must always be installed and

commissioned by quali ed and approved personnel.

Maintenance and servicing operations should be

Installation and Commissioning

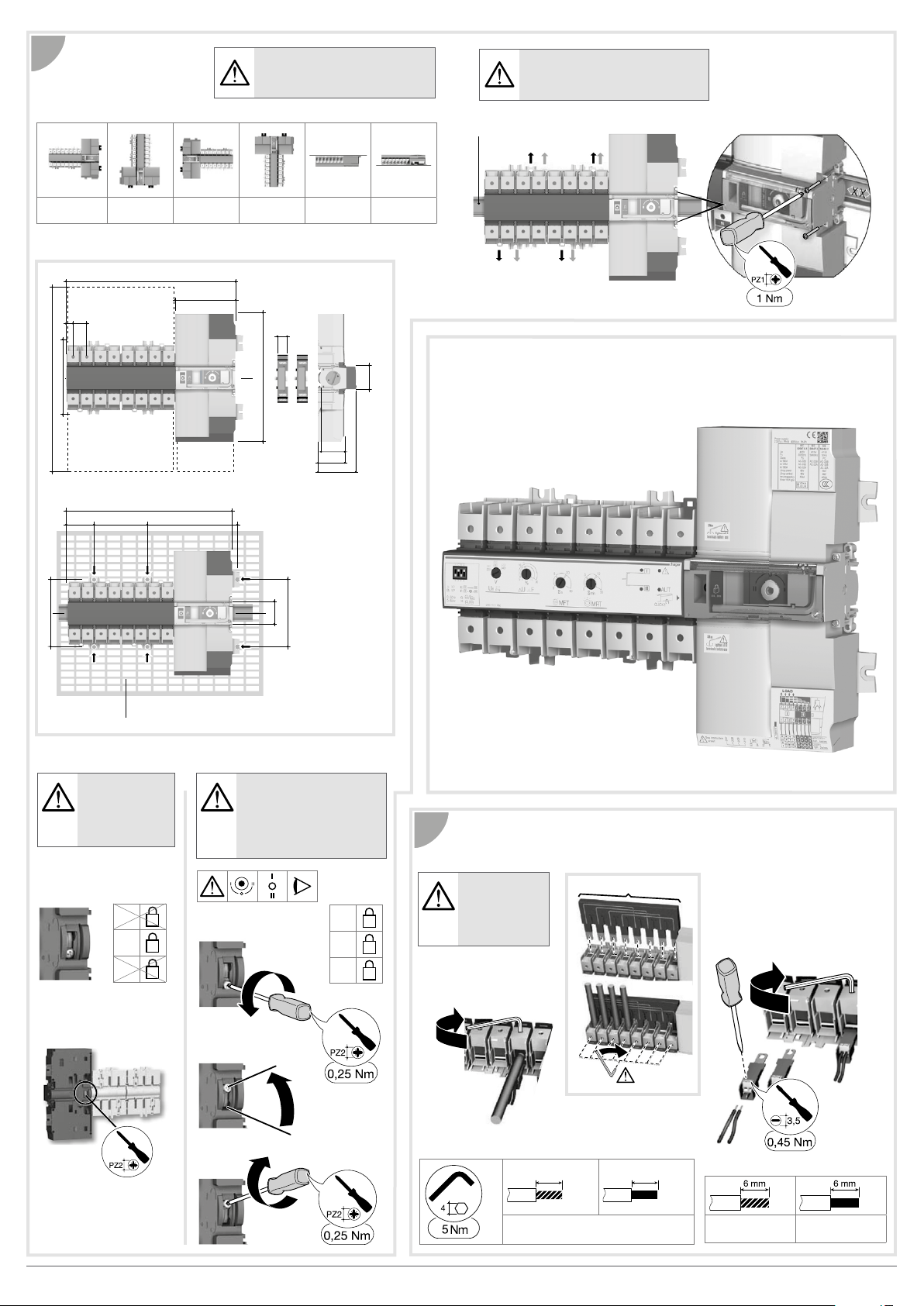

Step 1

Cabinet / Back

Plate Installation

Step 2

Connecting the

power section

performed by trained and authorised personnel.

Do not handle any control or power cables connected

to the product when voltage may be, or may become

present on the product, directly through the mains or

indirectly through external circuits.

Always use an appropriate voltage detection device to

con rm the absence of voltage.

Ensure that no metal objects are allowed to fall in the

cabinet (risk of electrical arcing).

Failure to observe good enginering practises as well as to

follow these safety instructions may expose the user and

others to serious injury or death.

Step 3

Control / Aux

Power terminal

connections

Step 4

Check

Risk of electrocution, burns or injury to

persons and / or damage to equipment.

Risk of damaging the device In case the

product is dropped or damaged in any way

it is recommended to replace the complete

product.

Step 5

PROGRAMMING

Step 6A

Automatic

Operation

Step 6B

Emergency Manual

Operation

Step 6C

Padlocking

6LE003168Ad1

Page 2

Installation

324

x2

X8

1

Ensure that the product is installed

on a fl at rigid surface

Recommended orientation

Recommended Ok Ok Ok Ok Ok

116

26

13

18

Tighten to avoid movement on the

DIN rail

DIN RAIL IEC 60715

.

Ok

143

350

52 104 176

131,5

326

6 mounting brackets 6x M6 screw - 2,5 Nm

Padlocking con guration

The HIC4xxA is

delivered with

padlocking

con gured to the

O position.

46

53

45

73,5

245

MAX : 2

47

131,5

To allow padlocking in all

positions (I - O - II), con gure

the HIC4xxA as follows

before installation. (Screw

is located at the back of the

product).

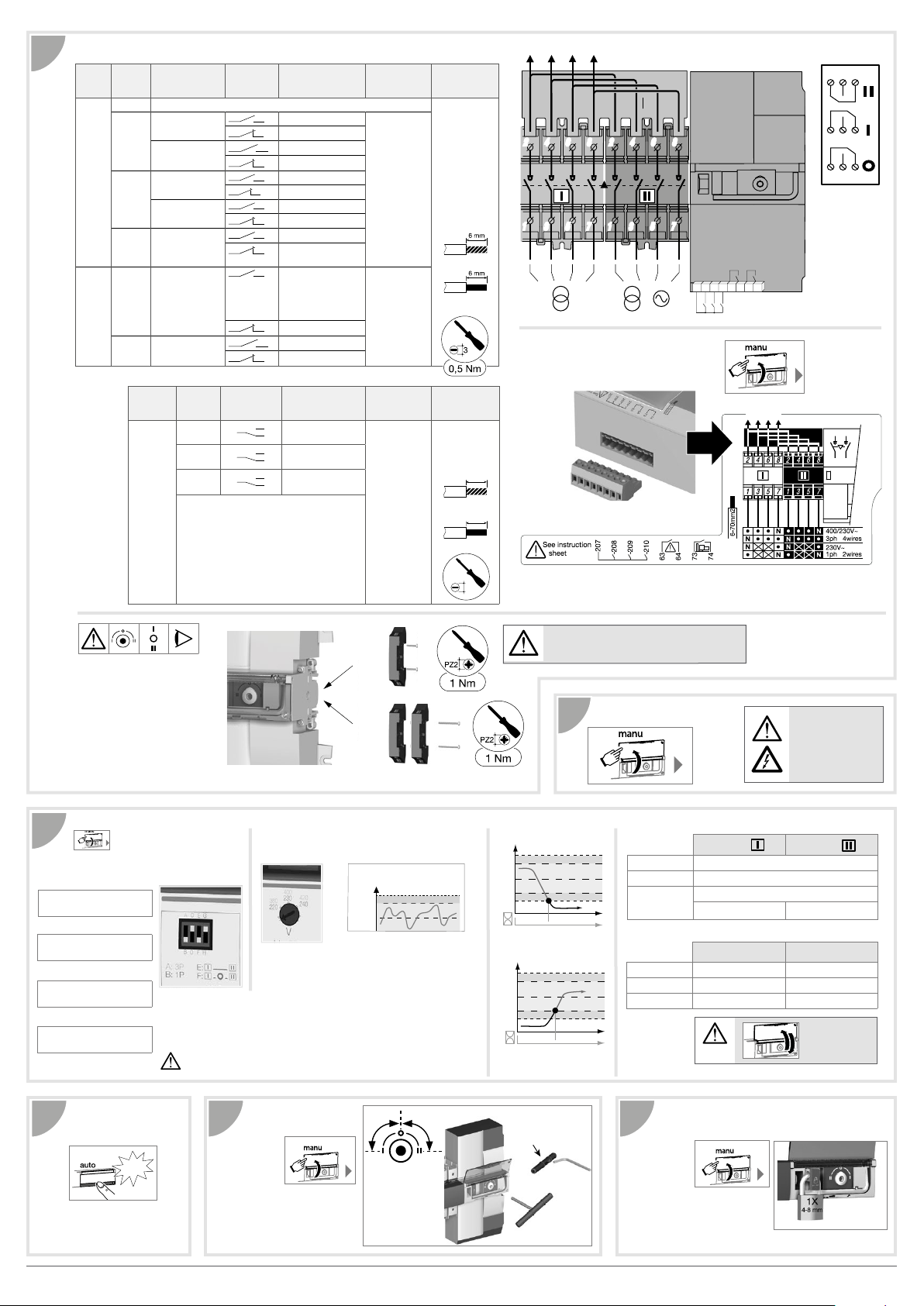

Power Terminal Connections

2

2

O

It is essential

to tighten

I

Step 1

I

all terminals

including those

not being used.

Voltage taps provide 2x ≤ 1.5 mm

connections.

They can be tted in any terminals on the

source supply side.

Do not use on the load side when

equipped with a bridging bar.

O

II

II

Step 2

Step 3

x2

Source supply side

Load side bridging bar

125A: HZI400

160A: HZI401

15 mm

10 mm2 to 70 mm

15 mm

2

0,5 mm2 to 1,5 mm20,5 mm2 to 2,5 mm

6LE003168Ad2

2

Page 3

Control / Aux power terminals and wiring

HYST

+∆U/

+∆F

Un

3

Type Terminal

Inputs 207 Common

Outputs 63 / 64 O1Network/Network or

Application Status of the

no.

208I1Network/Network

Network/Genset

209I2Network/Network

Network/Genset

210I3Network/Network or

Network/Generating

set

Network/Generating

set

73 / 74 O2Network/Genset.

contact

Description Output

With priority

Without priority

Automatic retransfer

Manual Retransfer

Source priority 1

Source priority 2

Stop the test on load

Test on load

AUTO mode

Automatic mode

inhibition

Product not available :

- Manual mode

- Command default

- Electronic default

- No source

Product available

No start command genset

Generating set starting

characteristics

Dry potential free

contact

Resistive load

2A 30 Vdc

0.5A 230Vac

Pmax :

60W or 125VA

Umax :

30Vdc or 230Vac

Recommended

connection

cross-section

stranded :

0,5 to 1,5 mm²

rigid :

0,5 to 2,5 mm²

0,5 mm2 to 1,5 mm

0,5 mm2 to 2,5 mm2

LOAD

2 4 6

246 8

1

1357

2

Ensure that the product is in Manual Mode

(front cover open).

8

2 4 6

246 8

5 7

3

1

3

1357

5 7

/

8

207208209210

I1 I2 I3

O1 O2

63 64 73 74

5 A AC1 / DC1

250 Vac / 30Vdc

22 24 21

11 14 12

01 04 02

Auxiliary contacts:

Fitting of auxiliary contacts:

6HZI300.

To t an AC, the switch must rst

be put in position O. An auxiliary

contact module comprises: one

NO / NC changeover contact for

each position (I-O-II).

To install use the long screws

supplied with the module.

PROGRAMMING

5

(

Manual operation)

Deep switch settings

&

Type of network: A-B

A: 3P

B: 1P

Frequency: C-D

C: 50Hz

D: 60Hz

Stop in 0 position: E-F

E: No stop in 0 position

F: 2s stop in 0 position

Type of application: G-H

G: Network - Genset

H: Network - Network

Type Terminal

Auxiliary

contact

block

HZI300

no.

11/12/14

21/22/24

01/02/04

Status of

thecontact

11

21

01

Description Output

Changeover switch

14

in position I

12

Changeover switch

24

in position II

22

Changeover switch

04

in position 0

02

characteristics

250Vac 5A AC1

30 Vdc 5A DC1

10

20

Source voltage supply conguration

é "

230/400 Vac version

Un (P-P):

380-420 Vac

Un (P-N):

220-240 Vac

The LED signalling and operation is only active when the product supply is

available. To set the dip switches, it is necessary to open the Auto/Manual

cover. Commissioning must always result in having at least 1 LED source

available on. (Therefore, the voltage and frequency must be within the dened

thresholds).

Any action on the potentiometers will change the settings, even when

the cover is closed.

HYST: 20% of ∆U/F settings

ΔU 5%/ ΔU20%

ΔF 3%/ ΔF 10%

Recommended

connection

cross-section

stranded :

0,5 to 1,5 mm²

rigid :

0,5 to 2,5 mm²

10 mm

0,5 mm2 to 1,5 mm

10 mm

0,5 mm2 to 2,5 mm2

2,5

2

Timer settings

Loss of priority

source timer

U/F

MFT: 0-30 sec

Return of priority

source timer

U/F

MRT: 0-30 min.

Use 20 mm screws for 1 module

Use 35 mm screws for 2 modules

4

Check

LED info

'

LED ON available

LED OFF missing or out of range

LED blinking

LED ON Fault Auto mode

LED OFF Product OK Manual mode

LED blinking Wait Manual retransfer

- a timer is counting down

- Test mode

MFT

[HYST]

[HYST]

MRT

LOAD

Whilst in manual

mode, check the

wiring and if ok

power up the

product.

Source availability LED's

Source

Fault and state of the product LED's

q

Source

AUT

Fault Reset

Automatic

6A 6B

operation

Click!

Close the front cover as shown

to put the product into automatic

mode.

Manual

operation

Open the front

cover as shown

to put into

manual mode.

Use the handle situated in the

front panel under the cover to

operate the transfer switch.

Check the changeover switch

position on the indicator before

operating.

90°

To simplify

operation use

the handle

with the

extension

provided.

90°

Extension

(Max 8 Mm)

Padlocking mode

6C

In order to

padlock put

the product in

manual mode.

Pull the locking

mechanism and insert a padlock

as shown.

As standard padlocking in the O

position. Congurable to I - O - II

(see step 1).

6LE003168Ad3

Page 4

535443D

Troubleshooting guide

w

7

Symptoms Action to be carried out Expected results

Adjusment

1

potentiometers of

the rated voltage

and frequency

and voltage

thresholds

The "Priority

2

SOURCE

Availability" LED

does not come on

The "Emergency

3

SOURCE

Availability" LED

does not come on

The product

4

remains switched

off after the

Priority SOURCE

is lost

The product does

5

not switch over

after the Priority

SOURCE is lost

The product does

6

not switch over

when the Priority

SOURCE is

restored

Return to

7

Priority SOURCE

has been

executed, but

the Emergency

Source (for

a Generator)

continues to

operate

Check for a voltage of 176 to 288 Vac on the supply terminals:

• 230 / 400 Vac model :

- Terminals 1-7 correspond to SOURCE 1

- Terminals 1-7 correspond to SOURCE 2

Check the following parameters:

• the type of network => 3P (DIP Switch 1 on position A)

• frequency => 50 Hz (DIP Switch 2 on position C)

• the nominal voltage => with a multimeter, measure the voltage accross the terminals and report the value on the

Check the thresholds and hysteresis of rated voltages (m U) and frequencies (m F) and report them on the

corresponding potentiometer

If using an Auto transformer - proceed as follows upon 1st switching on

• Step 1: HIC4xxA must be connected to a three-phase + neutral network (4NBL) for setting the neutral position.

Neutral position is detected upon rst switching on

• Step 2: Connect the autotransformers. Warning: Neutral must be connected on the same side as in step 1

How to reset the neutral position:

• Step 1: Open the cover

• Step 2 : Set DIP Switch 1 from 3P to 1P

• Step 3 : Set DIP Switch 1 from 1P to 3P

• Step 4 : Close the cover

Check the following parameters:

• the type of network => 3P (DIP Switch 1 on position A)

• frequency => 50 Hz (DIP Switch 2 on position C)

• the nominal voltage => with a multimeter, measure the voltage accross the terminals and report the value on the

CAUTION: a Generator operating off load can generate a Fr and a U lower than the nominal values:

Check the thresholds and hysteresis of rated voltages (m U) and frequencies (m F) and report them on the

corresponding potentiometer.

If using an Auto transformer - proceed as follows upon 1st switching on

• Step 1: HIC4xxA must be connected to a three-phase + neutral network (4NBL) for setting the neutral position.

Neutral position is detected upon rst switching on.

• Step 2: Connect the autotransformers. Warning: Neutral must be connected on the side dened in Step 1

How to reset the neutral position:

• Step 1: Open the cover

• Step 2 : Set DIP Switch 1 from 3P to 1P

• Step 3 : Set DIP Switch 1 from 1P to 3P

• Step 4 : Close the cover

Check if voltage is between 176 to 288 VAC across the power supply terminals of emergency SOURCE :

• 230 / 400 Vac model: - Terminals 1-7 corresponding to the Emergency Source

In case of transformer/ Genset, check that FT timer (Main Failure Timer) has nished counting down.

• Use a stopwatch.

• Start the stopwatch when the product has lost its Priority SOURCE.

- Contact 73 - 74 must be closed after 60s max (M-G application )

- GENSET run command = Contact 73-74 Closed

- GENSET stop command = Contact 73-74 Opened

Check that the product is not in manual mode:

• Automatic mode = Cover closed

• Manual mode = Cover open

Check that automatic operation has not been inhibited by an external order (terminals 207-210)

Check the status of led « Emergency SOURCE availability ».If it is off, refer to the symptom concerned (higher in the

list)

In case of Transformer/ Transformer, check the setting of FT timer (Main Failure Timer). The duration of this time

delay is between 0 and 60s. If necessary, use a stopwatch to check switching to SOURCE after FT countdown

Check that the product is not in manual mode:

- Automatic mode = Cover closed

- Manual mode = Cover open

Check that automatic operation has not been inhibited by an external order (terminals 207-210).

Check the state of the "Priority Source Availability" LED. If it is off, refer to the symptom concerned (higher in the list) The "AUT" and "Emergency

Check the setting of RT timer (Main Return Timer). The duration of this delay is between 0 and 30 min. Use a

stopwatch to check the switch to Priority SOURCE after the RT timer

Check that the "manual retransfer" function is not active*

• Retransfer mode activated = Contact 207-208 closed

• Retransfer mode desactivated = Contact 207-208 open

* if this function is not required

Check CDT timer (Cool Down Timer) has nished counting down - Fixed time delay:4 min

• Use a stopwatch.

- Start the stopwatch when the product has switched over to the Priority SOURCE.

- Contact 73-74 must be open after time delay CDT has nished counting down

Check that the product is not in Automatic mode:

- Automatic mode = Cover close

- Manual mode = Cover open

Check that automatic operation has not been inhibited by external control commands (terminals 207-210)

1P (DIP Switch 1 on position B)

60 Hz (DIP Switch 2 on position D)

potentiometer

1P (DIP Switch 1 on position B)

60 Hz (DIP Switch 2 on position D)

potentiometer

The AUT LED is lit (if the cover is

closed)

The "Priority SOURCE Availability"

LED is lit

The "Emergency SOURCE

Availability" LED is lit

The "AUT" LED is lit

The Genset works and the LED

"Emergency Source Disponibility"

is lit

The "AUT" LED is lit

The "AUT" and "Emergency

SOURCE Availability" LEDs are lit

At the end of the time delay, the

product switches to mechanical

position 0, and to emergency

SOURCE

The "AUT" LED is lit

SOURCE Availability" LEDs are lit

At the end of the time delay, the

product switches to mechanical

position 0, and to priority SOURCE

Contact 207-208 must be open to

enable switching to priority SOURCE

The GenSet switches off and led "

Emergency SOURCE availability"

is OFF”

The "AUT" LED is lit

Hager Electro S.A.S., Boulevard d'Europe, B.P. 3, 67215 OBERNAI CEDEX, France - www.hager.com OCOM 129068Hager 01.19 6LE003168Ad4

535443D / Printing size: A3 / Recto-verso / Black / 90g/m² / Final size A4

Loading...

Loading...