Page 1

2958 Operational Description (NFPA-101)

The 2958 operation complies with the following building and fire codes: NFPA 101; NFPA 1-UFC; UBC; IBC; IFC;

SBC; California Building Code. Listings: UL Listed: Special Locking Arrangements and Auxiliary Locks; California

State Fire Marshal (CSFM) Listed.

The door is normally closed & secured and/or latched. The model 2958 secures the door in the locked condition,

and the display shows the preset delay time.

Activation of the 2958 is made by releasing the door latch and applying up to 15 lbs. of pressure to the door,

giving a pre-activation warning tone. (A 1 or 2 second nuisance delay will prevent false activation of the alarm).

When the nuisance delay time has been exceeded, the 2958 begins the irreversible door release cycle. At this

time the display continues to count down, the verbal warning continues and an alarm output is provided to alert

personnel of an unauthorized exit.

The integral digital countdown display and voice commands inform the person intending to exit of the seconds

remaining to unlock. The 2958 will release the door after the 15 or 30 second delay cycle has expired, allowing

free egress. A steady warning tone with the voice command “Exit Now” will sound until the MagLock is reset by

authorized personnel.

2958 Operational Description (BOCA/Chicago)

The 2958 operation complies with BOCA National Building Code and the Chicago Building Code: UL Listed,

Special Locking Arrangements and Auxiliary Locks.

The releasing operation of the 2958 is the same as described above, with the exception that the door relocks

automatically 30 seconds after closure. Each time the door is open before 30 seconds has elapsed the relock

timer resets and relocks the door in 30 seconds.

INSTALLATION INSTRUCTIONS

DELAYED EGRESS MAGLOCK

2958 / 2958T

PUSH UNTIL ALARM

SOUNDS. DOOR CAN BE

OPENED IN 15 SECONDS.

Application

When unauthorized egress is initiated, the 2958 delays egress through the door for 15 or 30 seconds.

Meanwhile, the person exiting must wait while personnel or security respond. An integral digital countdown

display and voice commands inform the person intending to exit of the seconds remaining to unlock. The door

unlocks after 15 or 30 seconds have elapsed, permitting egress. A signal from the fire/life safety system will

release the lock for uninhibited egress in an emergency.

Applications include:

· Restricting the egress of patients for their own safety.

· Restricting the egress of commercial center patrons for security application needs.

· Controlling pedestrian traffic in transportation facilities, including airport jetways and tarmacs

California Building

Code Compliant

KEEP PUSHING. THIS DOOR

WILL OPEN IN 15 SECONDS.

ALARM WILL SOUND.

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

1

Page 2

Included in Package

MAGLOCK

HOUSING ASSY. &

MOUNTING PLATE

TRIGGER &

ARMATURE BASE

ARMATURE

ARMATURE

SCREW PACK

MAGLOCK

SCREW PACK

TEMPLATE

1/2” DIA FOR WIRE

First install mounting plate at two slot locations only and make proper

adjustments before marking remaining five mounting hole locations.

FOLD ON DOTED LINE

Mark location five places:

#10 self dril/tap screws provided for up to 1/8” thick metal applications.

Note: Machine screws provided for applications with heavier

gauge material – Drill (#21) and tap for #10-32 screw.

PLACE AGAINST LOCK JAMB FOR L.H. DOORS

1/4” DIA GUIDE PIN HOLE 9/16” DEEP

PLACE AGAINST LOCK

JAMB FOR R.H.

DOORS

PLACE AGAINST DOOR

Center punch on mark

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

2

Page 3

Door and Frame Reference

Door and Frame Preparation Instructions

HINGE SIDE OF FRAME

(OPPOSITE FROM LOCK)

PAPER TEMPLATE

STEP 1. Locate the paper template and fold

along the dotted line. Place the folded edge of

the template against the door stop and door at

the header while against the vertical stop,

opposite the hinge side of the door. Tape in

place at this position.

STEP 2. As indicated on the paper template,

punch the designated hole locations on the

frame and armature mounting holes on the

door.

(NOTE: PRIOR TO DRILLING,

INSPECT TO SEE IF ANY OF THE HOLES

CANNOT BE DRILLED DUE TO THE FRAME

OR DOOR CONFIGURATION. A FILLER

PLATE OR ANGLE BRACKET MAY BE

REQUIRED. SEE PAGE 4.)

STEP 3. Drill and tap the two mounting holes

as indicated on the paper template.

(NOTE:

READ NOTE ON TEMPLATE WITH REGARD

TO SELECTING THE PROPER HOLE SIZE

FOR ARMATURE MOUNTING BOLT.)

2-1/

2"

2-5/

8"

11"

2-3/

4”

NOTES:

- #10 self drill/tap screws provided for up to 1/8" thick metal applications

- For applications with heavier gauge material, drill (#21) and tap for #10-32 machine screws.

IMPORTANT! – IT IS HIGHLY RECOMMENDED THAT YOU FIRST INSTALL THE MOUNTING PLATE AT

TWO SLOT LOCATIONS ONLY. THIS WILL ALLOW YOU TO MAKE PROPER ADJUSTMENTS OF THE

LOCK’S POSITION PRIOR TO MARKING, DRILLING AND TAPPING THE FOUR PERMANENT MOUNTING

PLATE HOLES.

1/2” DIA FOR

WIRE

First install mounting plate at two slot locations only and make

proper adjustments before marking remaining five mounting

hole locations.

FOLD ON DOTED LINE

Mark location five places:

#10 self dril/tap screws provided for up to 1/8” thick metal

applications.

Note: Machine screws provided for applications with heavier

gauge material – Drill (#21) and tap for #10-32 screw.

PLACE AGAINST LOCK JAMB FOR L.H.

DOORS

1/4” DIA GUIDE PIN HOLE 9/16” DEEP

PLACE AGAINST

LOCK JAMB FOR

R.H. DOORS

PLACE AGAINST

DOOR

Center punch on

mark

PLACE AGAINST HEADER

1/2” DIA FOR WIRE

First install mounting plate at two slot locations only and make proper

adjustments before marking remaining five mounting hole locations.

FOLD ON DOTED LINE

Mark location five places:

#10 self dril/tap screws provided for up to 1/8” thick metal applications.

Note: Machine screws provided for applications with heavier

gauge material – Drill (#21) and tap for #10-32 screw.

PLACE AGAINST LOCK JAMB FOR L.H.

DOORS

1/4” DIA GUIDE PIN HOLE 9/16” DEEP

PLACE AGAINST

LOCK JAMB FOR

R.H. DOORS

PLACE AGAINST DOOR

Center punch on mark

TEMP-1511

SLOT

LOCATIONS

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

3

Page 4

STEP 1. Mount armature to door.

(See

figures 2A, 2B & 2C.)

STEP 2. Install the mounting plate

(filler

plate and/or angle bracket if needed – see

figures 1A, 1B & 1C)

to header with only the

two screws at the slotted hole locations at this

time. Snug the screws down lightly (do not

torque) so the mounting plate & lock can be

repositioned later.

STEP 3. Temporarily install the lock to the

mounting plate with the 1/4-20 socket head

screws encased in the lock.

STEP 4. With the lock mounted, close the

door so the armature holder just comes into

contact with the face of the lock. If the door

is not completely closed when the lock &

armature touch, open the door and reposition

the lock away from the door as described in

step 2.

(THIS IS TO PREVENT THE DOOR FROM

USING THE LOCK AS THE DOOR STOP.)

STEP 5. Remove the lock from the

mounting plate, mark & punch all remaining

screw and wiring holes. Drill & tap holes as

indicated on the paper template and install all

screws.

STEP 6. Reinstall the lock to the mounting

plate. At this point, if there is no need to

remove the lock for painting or any other

reason, install the anti-tamper plugs over the

socket head mounting screws, using a soft

hammer to avoid damage to the lock case.

ARMATURE MOUNTING INSTRUCTIONS

Figure 2B – HOLLOW METAL DOOR

From sexnut side of door, drill exactly 1/2" hole through

one metal thickness only. From armature side of door,

drill 5/8" hole to insert reinforcement tube. Press in

sexnut & reinforcement tube all the way and mount

armature to door using hardware provided per Figure 2B.

Figure 2A – SOLID DOOR

Drill exactly 3/8" diameter through the door. From sexnut side of

door, drill ½” diameter hole 1-3/8" deep. Mount armature to door

with hardware provided per Figure 2A.

Figure 2C – REINFORCED ALUMINUM OR

HOLLOW METAL DOOR

Use letter “F” drill and tap for 5/16-18 machine screw. Mount

armature to door with hardware provided per Figure 2C.

ARMATURE

HOLDER

ARMATURE

5/16 – 18 ARMATURE

MOUNTING SCREW

DOOR

REINFORCEMENT

BY OTHERS

LETTER “F”

DRILL & TAP 5/

16-18

REGULAR, FILLER PLATE & ANGLE BRACKET DETAILS

Figure 1A

REGULAR

Figure 1B

WITH FILLER PLATE

FILLER

PLATE

Figure 1C

WITH ANGLE BRACKET

ANGLE

BRACKET

ARMATURE

HOLDER

5/16 – 18 ARMATURE

MOUNTING SCREW

ARMATURE

1/2”

SEX

NUT

DOOR

1–3/

8"

5/8" DRILL

5/16 – 18 ARMATURE

MOUNTING SCREW

ARMATURE

HOLDER

ARMATURE

1/2" DRILL

REINFORCEMENT

TUBE

1 – ¾”

HOLLOW

METAL DOOR

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

4

Page 5

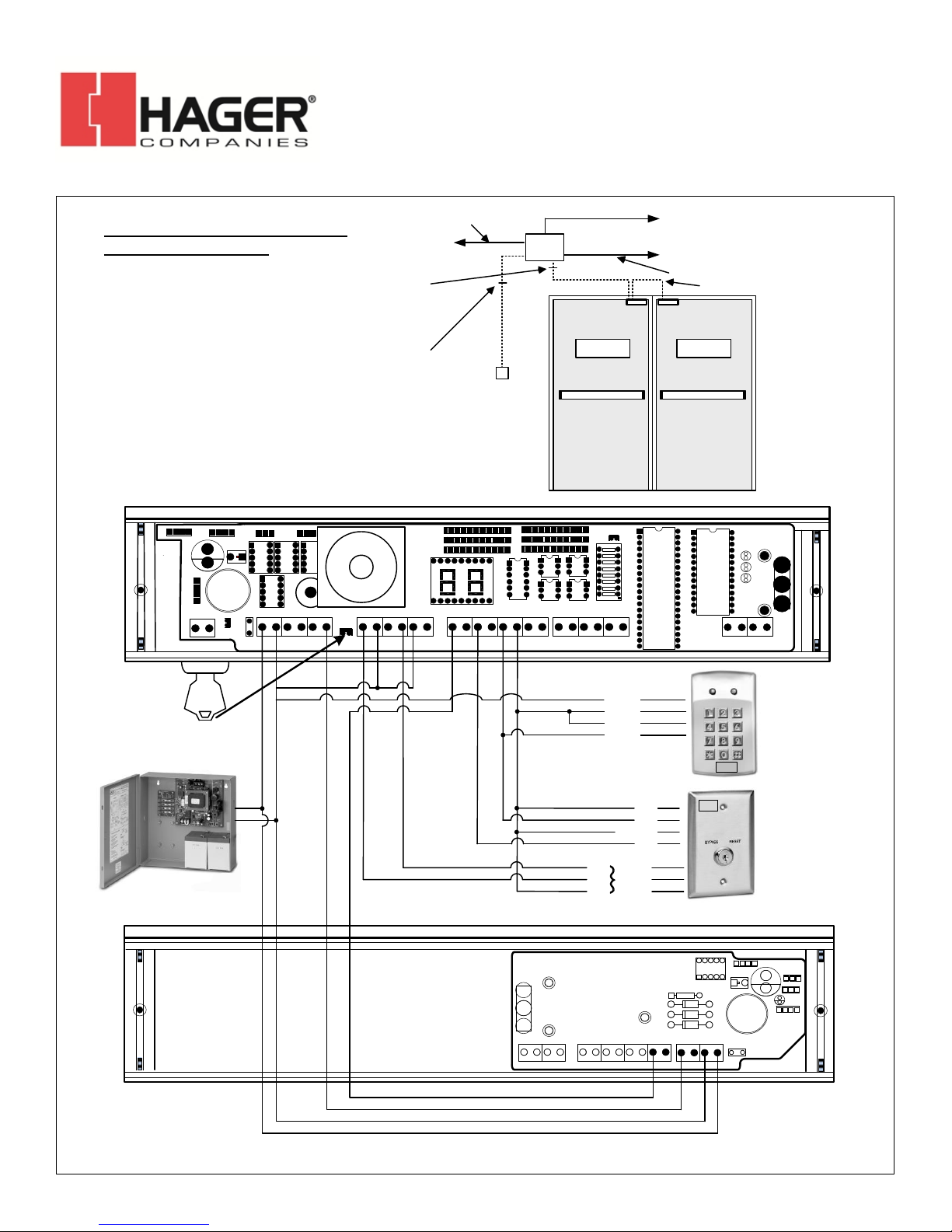

Typical System Wiring – Single

Door (Model 2958)

+

-

C

NO

(OPTIONAL)

+

-

+

-

(OPTIONAL)

RED

GRN

BLK

WHT

BLK

BLU

RED

L3

OPTIO

N

C NC

- + - +

NC NONO C

C NC

NO CNO C

NO C NO C

NO C

NC NO

C NC

[ BAS ]

[ DPS ]

[RESET][RM TRIG]

[REX]

[RED RLY][GRN RLY]

[ LOCK ]

[ FP ]

[ PWR ]

J6

J7

J2

[IBO]

[EXT SPKR]

REMOVE J6 ONLY IF A

FIRE PANEL OR SMOKE

DETECTION SYSTEM IS

CONNECTED TO [FP]

INPUT (Pg. 8)

3 or 5

conductors

8 or 10

conductors

Power

Supply

To Fire Panel

AC Mains

2

conductors

PUSH UNTIL ALARM SOUNDS.

DOOR CAN BE OPENED IN 15

SECONDS.

Key Switch or

Access Control

(Optional)

To Smoke

Detection

System

2 conductors

Digital Keypad

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

2900 Series

Power

Supply

Key Switch

Reset Station

Remote

Speaker

(OPTIONAL)

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

5

Page 6

3 or 5

conductors

8 or 10

conductors

Power

Supply

To Fire Panel

AC Mains

2 conductors

4 conductors (2958T only)

PUSH UNTIL ALARM

SOUNDS. DOOR CAN

BE OPENED IN 15

SECONDS.

PUSH UNTIL ALARM

SOUNDS. DOOR CAN

BE OPENED IN 15

SECONDS.

+

-

2900 Series

Power Supply

RED

GRN

BLK

WHT

BLU

BLK

BLK

L3

OPTI

ON

Digital Keypad

(OPTIONAL)

+

-

C

NO

Key Switch or

Access Control

(Optional)

Typical System Wiring – Pair of

Doors (Model 2958T)

REMOVE J6 ONLY IF A FIRE

PANEL OR SMOKE DETECTION

SYSTEM IS CONNECTED TO [FP]

INPUT (Pg. 8)

SLAVE

To Smoke

Detection

System

2 conductors

TB2

TB1

[ LOCK ]

IN

[ PWR ]

TB5

TB6

TB4

TB3

[ DPS ]

[ BAS ]

TB7

NO C NC

NO C NC

NO C NC

NO C

+ -+ -

Z4

D1

Z1

D2

R7

RLY1

J1

R9

C4

BAS

DPS

C1

J4

TB8

[ ATS ]

[TRIG

OUT ]

C NC

- + - +

NC NONO C

C NC

NO CNO C

NO C NO C

NO C

NC NO

C NC

[ BAS ]

[ DPS ]

[RESET][RM TRIG]

[REX]

[RED RLY][GRN RLY]

[ LOCK ]

[ FP ]

[ PWR ]

J6

J7

J2

[IBO]

[EXT SPKR]

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

Key Switch

Reset Station

(OPTIONAL)

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

6

Page 7

+

-

C

NO

(OPTIONAL)

3 or 5

conductors

8 or 10

conductors

Power

Supply

To Fire Panel

AC Mains

2 conductors

PUSH UNTIL ALARM SOUNDS.

DOOR CAN BE OPENED IN 15

SECONDS.

Key Switch or

Access Control

(Optional)

REMOVE J6 ONLY IF A FIRE

PANEL OR SMOKE

DETECTION SYSTEM IS

CONNECTED TO [FP] INPUT

(Pg. 8)

To Smoke Detection

System

2 conductors

+

-

+

-

Keep

Closed

To

Unlock

Close

To

Override

Unlock

Patient

Protection

System

To

Patient Protection

System

3 conductors

Wiring to

Infant & Patient

Protection Systems

1. Close and hold REX input. The

2958 will be in the Bypass mode

and will be unlocked.

2. Whenever the IBO input is closed

and held, the 2958 will instantly

relock and rearm. Egress is possible

as the normal 15/30 sec delayed

unlock.

3. Releasing the IBO input will

return the 2958 to the Bypass mode.

4. Releasing the REX input will

rearm the system.

5. Upon power-up, you must

manually reset

the lock to activate the IBO input.

System Operation

(OPTIONAL)

RED

GRN

BLK

WHT

BLK

BLU

RED

L3

OPTI

ON

C NC

- + - +

NC NONO C

C NC

NO CNO C

NO C NO C

NO C

NC NO

C NC

[ BAS ]

[ DPS ]

[RESET][RM TRIG]

[REX]

[RED RLY][GRN RLY]

[ LOCK ]

[ FP ]

[ PWR ]

J6

J7

J2

[IBO]

[EXT SPKR]

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

2900 Series

Power

Supply

Digital Keypad

Key Switch

Reset Station

REMOTE

SPEAKER

(OPTIONAL)

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

7

Page 8

Wiring Details & Functions (ALL OPTIONS SHOWN)

REQUEST TO EXIT

KEY SWITCH OR

ACCESS

CONTROL

SYSTEM

(OPTIONAL)

REMOTE RESET

SWITCH

(OPTIONAL)

REMOTE

STATUS PANEL

(OPTIONAL)

FIRE

ALARM

INPUT

(OPTIONAL)

POWER

SUPPLY

12VDC

OR 24VDC

Dry,

N/C

BLK

RMB X L3

RED

EXTERNAL

TRIGGER

SWITCH

OR

SDC REX PUSH BAR

(OPTIONAL)

DOOR POSITION

SWITCH

(DPS)

BOND ALERT (BAS)

[DPS]

N/O

COM

N/C

[ATS]

ANTI-TAMPER SWITCH

(ATS)

MONITORING OPTIONS

N/O

COM

N/C

N/O

COM

N/C

GR

N

SMOKE DETECTION

SYSTEM INPUT

(OPTIONAL)

Dry,

N/C

INSTANT

BYPASS

OVERRIDE

(OPTIONAL)

[PWR]

[FP]

[LOCK]

[GRN

RLY]

[RED

RLY]

[RM TRIG]

[RESET]

[REX]

12 VDC OR 24 VDC

TO CLOSED FIRE/SMOKE

DETECTOR CONTACT

SLAVE/TANDEM LOCK

POWER TERMINALS

LOCK SECURE

OUTPUT

ALARM OUTPUT

EXTERNAL TRIGGER

SWITCH INPUT

EXTERNAL RESET SWITCH

INPUT

REQUEST TO EXIT

INPUT

[IBO]

INSTANT BYPASS OVERRIDE

INPUT

N/O

COM

JUMPER

J6

(SEE PG

9)

C NC

- +

-

+

NC NONO

C

C

NC

NO

C

NO

C

NO

C

NO C

NO

C

NC NO

C NC

[ BAS

]

[ DPS

]

[RESET

]

[RM

TRIG]

[REX]

[RED

RLY]

[GRN RLY]

[ LOCK

]

[ FP ]

[ PWR

]

J

6

J

7

J

2

[IBO]

[EXT

SPKR]

REMOTE

SPEAKER

(OPTIONAL)

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

TERMINAL BOARD CONNECTIONS

POWER IN POWER IN +

COM

N/C

AUX LOCK AUX LOCK +

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/O

COM

N/O

COM

[MBS]

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

8

Page 9

DIP SWITCH SETTINGS

REQUEST TO EXIT PERIOD – The Request to Exit (REX) time is selectable for 1, 15, 20, or 30 seconds. The REX time is

the period of time the lock will remain “bypassed”, after a remote normally open contact switch is momentarily activated.

When activated with an access control system, the REX time cycle begins immediately after the access control open time

expires. The 2958 will automatically relock if the door is opened, and then closed during the REX time cycle.

TRIGGER TYPE – The trigger type is selectable for “REMOTE” or “INTERNAL”. Selecting INTERNAL mode uses the internal

trigger sensor to activate the Exit Delay cycle. Selecting REMOTE mode disables the internal trigger. Activation of the Exit

Delay cycle is triggered by an external exit device equipped with a normally open contact switch.

POWER-UP OPTION* – The power-up option, indicating the state of the 2958 upon restoration of system power, is

selectable to “UNLOCKED” or “LOCKED”. In the LOCKED mode, the 2958 will attempt to reset to secure mode. In the

UNLOCKED mode, the 2958 will remain unlocked and the digital display will indicate two horizontal bars “--“. Turning the

reset switch momentarily to the reset position will relock and rearm the door. This feature enables the 2958 to comply with

code requirements in jurisdictions that require manual reset/relock upon loss and restoration of system power.

ALARM TYPE – The alarm type is selectable to “TONE ONLY” or “VOICE”. When secure, the 2958 digital display will

indicate a 15 second delay time. Upon activation of the irreversible Exit Delay cycle, the digital display begins counting

down to zero. In VOICE mode, the countdown will be accompanied by a warning beeping tone and verbal exit instructions.

When the digital display indicates zero, the 2958 releases. The speaker output changes to a continuous warning tone and

the verbal instruction announces “Exit Now”. In TONE ONLY mode, the countdown will be accompanied by a warning

beeping tone only, which changes to a continuous tone once the Exit Delay cycle expires.

MESSAGE TYPE – The message type is selectable to “MSG1” or “MSG2”.

MSG1: (Female Voice) “Exit in 12 seconds, facility staff has been notified...Exit in 5 seconds...exit now...”

MSG2: (Male Voice) “Exit in 12 seconds, security has been alerted...Exit in 5 seconds...exit now…”

Both messages repeat “Exit now” until the lock is reset.

WARNING!

CONTACT AUTHORITY HAVING

JURISDICTION FOR APPROVAL

PRIOR TO SELECTING DELAY TIME

OR PWR-UP SETTINGS

*

OFF

MESSAGE TYPE

VOICE / TONE

PWR-UP

OPTION*

REQUEST TO EXIT

RELOCK DELAY

(SEC)

NUISANCE

DELAY*

201

5

3

0

1

UNLOCKED

TONE

ONLY

MSG

#2

21

76

543

8

ON

TRIGGER TYPE

INTERNAL

O N

NUISANCE DELAY* – The Nuisance delay time feature, intended to avoid accidental triggering, is selectable for 1 or 2 seconds.

Releasing the door latch and pushing on the door will activate the internal trigger sensor. Activating the trigger beyond the

nuisance delay time will start the irreversible Exit Delay cycle time. The Nuisance Delay time period is included in the lock release

cycle and it will not increase or decrease the “total time to unlock” once the 2958 is activated. Releasing the door before the end

of the Nuisance delay time will turn off the warning alarm and reset the 2958 to secure mode.

RELEASE TIME* – The Release time is selectable for 15 or

30 seconds. The Nuisance Delay time period is included in

the door release cycle and it will not increase or decrease the

“total time to unlock” once the MagLock is activated.

1 SEC. 2 SEC.

RELEASE

TIME*

15 SEC. 30 SEC.

JUMPER SETTINGS

JUMPER J6 (Fire Alarm Input) – Factory Installed.

Remove J6 only if a dry, normally closed contact from a

fire alarm OR smoke detector system is connected to the

Fire Panel [FP] terminals.

INSTALLED: The 2958 will enter the alarm mode if the

door is held open past the request to exit period.

REMOVED: The 2958 will remain unlocked if the door is

held open past the request to exit period. No alarm will

sound. The 2958 will relock and rearm upon closure of the

door.

JUMPER J7 (DOOR PROP)

LOCKED

VOICE

MSG

#1

REMOTE

J7

JUMPER J6

(SEE PG 9)

C NC

- +

-

+

NC

N

O

N

O

C

C

N

C

N

O

C

N

O

C

N

O

C

NO

C

N

O

C

NC

NO

C

NC

[

BAS

]

[

DPS

]

[RES

ET]

[RM

TRIG]

[REX

]

[RED

RLY]

[GRN RLY]

[ LOCK

]

[ FP

]

[ PWR ]

J6

J

7

J

2

[IBO

]

[EXT

SPKR]

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

9

Page 10

STEP 1. After the lock has been mounted to the door and frame per the provided template, feed the wiring through the

access hole and out to the controller board. Re-install the lock front cover onto the lock. Ensure that the trigger sensor is

aligned with the hole in the cover. The sensor is preset at the factory to slightly project through the cover. WARNING: DO

NOT ATTEMPT TO ADJUST THE TRIGGER SENSOR LENGTH. AS THIS WILL RESULT IN DAMAGE TO THE SENSOR

AND VOID THE WARRANTY.

STEP 2. Make all wiring connections to the lock. Observe the polarity of the input power terminals. The lock senses the

power supply voltage and automatically configures itself for 12vdc or 24vdc operation. Correct power supply voltage must be

used for proper lock operation. WARNING: INPUT TERMINALS FOR RESET, REX AND REMOTE TRIGGER MUST ONLY

BE CONNECTED TO A NORMALLY OPEN MOMENTARY DRY CONTACT SWITCH (I.E. 2915 DIGITAL KEYPAD).

CONNECTION TO A VOLTAGE OR A “WET” OUTPUT MAY DAMAGE THE LOCK AND VOID THE WARRANTY.

STEP 3. Slowly swing the door closed and visually observe the position of the armature trigger as it approaches the trigger

sensor on the lock. If the provided mounting template was used during the lock and armature installation, the trigger & sensor

should align with one another both horizontally and vertically. The LED on the back of the trigger sensor will light when the

armature trigger is detected. IMPORTANT: CORRECT OPERATION OF THIS LOCK DEPENDS ON THE TRIGGER

SENSOR BEING ABLE TO DETECT THE ARMATURE TRIGGER WHEN THE DOOR IS CLOSED. A PROXIMITY

ADJUSTMENT CAN BE MADE TO THE TRIGGER FOR FINE TUNING. THIS IS EXPLAINED IN STEP 4.

STEP 4. After alignment has been verified, close the door and apply power to the lock. The digital display will show a two bars

“- -“ indicating that the lock is in the Manual Power Up mode. Push on the door to verify that the door is unlocked. Reset the

lock at this time by turning the built in key switch clockwise or by triggering the remote reset input. The lock should now secure

the door and the LED display will show the delay time . You may change the mode to Auto Power Up by setting the #6

dipswitch to the ON position. Now when you first apply power, the door will be secure and the LED display will display the delay

time without having to reset the lock.

STEP 5. Activation of the 2958 can be made by door movement or an external trigger. When using the door movement

method, activation is achieved through the way the armature hardware is designed. When someone unlatches the door and

applies up to 15 lbs. pressure, the lock will hold onto the armature while simultaneously letting the door & trigger armature

move away from the lock & trigger sensor. Sensitivity in the detection of the trigger movement can be adjusted for optimum

sensitivity & performance. This adjustment can be made by using the 5mm hex wrench provided with the lock. The center of

the trigger or “target” is spring loaded and can be screwed in and out of the armature thus either decreasing or increasing the

space between itself and the sensor. The “spring” feature of the target is to prevent damage from direct contact with the

trigger sensor. Depending on the accuracy of the alignment, the trigger does not have to physically touch the sensor to operate

correctly.

TRIGGER SENSOR

TRIGGER

HORIZONTAL

ALIGNMENT

VERTICAL

ALIGNMENT

C

C

2958 LOCK BODY

2958 ARMATURE

1581S

ARMATURE

Lock Adjustment and Operation

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

10

Page 11

Standard Features

1650 lbs. Holding Force

15 or 30 Second Exit Delay when activated.

1 or 2 Second Nuisance Delay

75dB Alarm Tone with Digital Display & Selectable

Voice Instruction

Choice of Activation Trigger:

- Door Movement

- Exit Device w/ REX Switch

- Touch Sense Bar w/REX Switch

Vandal resistant Proximity Sensor Trigger

Auto Sensing 12/24VDC input power

Connection for Tandem Option (Pairs of Doors)

Optional Features

DPS Door Position Switch

MBS Bond Alert Sensor

ATS Anti Tamper Switch

Selectable Automatic & Manual Power-Up

Feature

Auto Power-Up – Occurs when power is restored

and/or the fire panel is restored.

Manual Power-Up –

This is a UBC & California

Building Code Compliant Feature –

Only after power

restoration and fire panel reset may the lock be reset

manually at the opening. Lock can be reset with the

built-in reset key switch or, a key switch or keypad

adjacent to the door.

Inputs & Outputs

REX Input

Fire Alarm/Smoke Detection System Release

Remote Reset Input

Remote Trigger Input

Tandem/Slave Lock Input

IBO – Instant Bypass Override

DPS – Door Position Status (Optional)

MBS – Magnetic Bond Status (Optional)

ATS – Anti-Tamper (Optional)

Alarm Output

Lock Status Relay Output

- Door Secure

- Door Unlocked

Specifications

Interior Applications Only

Input Voltage Requirements:

Dual Voltage (Auto Sensing) –

12/24 VDC (+/- 10%)

(Use with a UL 294 Standard Power Supply)

Power Consumption:

Standard Model (1650 lbs.) -

2958 – 820/500 mA@ 12/24 VDC

2958T – 1500/850 mA @ 12/24 VDC

Energy Saver (1200 lbs., “E” Option) –

2958 – 452/274 mA@ 12/24 VDC

2958T – 660/686 mA @ 12/24 VDC

Size: 11"L x 2-3/4"H x 2-5/8"D

Lock Status Relay Rating: 1 Amp @ 30V resistive

Alarm Output Rating: 1 Amp @ 30V resistive

DPS Rating: 250 mA @ 30V resistive

BAS Rating: 250 mA @ 30V resistive

ATS Rating: 1 Amp @ 30V resistive

Operating Condition: 0-49 deg C, 85% RH

(non-condensing)

Building & Fire Life Safety Code Compliant

2958ND

IBC International Building Code

IFC International Fire Code

NFPA 101 Life Safety Code

NFPA 1, UFC, Uniform Fire Code

UBC Uniform Building Code

CBC California Building Code

SBC Standard Building Code

2958BD

BOCA National Building Code compliant

Chicago Building Code compliant

GWXT, GWXT7 - Auxiliary Locks - UL,cUL Listed

FWAX - Special Locking Arrangements - UL Listed

Only the 2958 and the 2958T have

been UL listed as Special Locking

Arrangements to UL Standard 294,

and NFPA 101.

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

11

Page 12

Sense Bar Trigger Non-Latching

4801

Power

Wall Mount Reset Station (Optional)

Power

A pair of doors requires the 2958T

Power

Pushing either door triggers

the delayed release of both doors.

Latching Exit Device with

Built-in Switch Kit Trigger

Power

ETW

Hinge

Switch

Kit

PUSH UNTIL ALARM SOUNDS.

DOOR CAN BE OPENED IN 15

SECONDS.

PUSH UNTIL ALARM SOUNDS.

DOOR CAN BE OPENED IN 15

SECONDS.

PUSH UNTIL ALARM SOUNDS.

DOOR CAN BE OPENED IN 15

SECONDS.

PUSH UNTIL ALARM SOUNDS.

DOOR CAN BE OPENED IN 15

SECONDS.

PUSH UNTIL ALARM SOUNDS.

DOOR CAN BE OPENED IN 15

SECONDS.

Systems Applications Reference

Activation by a remote trigger for doors with or without latching hardware:

Activation by applying pressure to doors with latching hardware:

2958 Delayed Egress MagLock

Installation Instructions

S-EA00051

3/28/12

HAGER COMPANIES 139 Victor Street, St. Louis, MO 63104 ● (800) 325-9995

12

Loading...

Loading...