Page 1

CALL US ON OUR TOLL-FREE NUMBER:

LIGNE TÉLÉPHONIQUE SANS FRAIS :

CANADA: 1-800-554-2436

U.S.A.: 1-800-724-2436

www.hagen.com

(08/2002)

Page 2

Instructions

Read Thoroughly prior to installation and operation

IMPORTANT SAFEGUARDS

To guard against injur y, basic safety precautions should be observed when handling

the Fluval Canister Filter, including the following:

1. For the complete enjoyment, use and understanding of this product,

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

and all important notices on the appliance before using. Failure to do so may

result in damage to the unit.

2.

DANGER – To avoid possible electrical shock, special care should be taken since

water is employed in the use of this equipment. For each of the following

situations, do not attempt repairs yourself; return the appliance to an authorized

service facility for ser vice or discard the appliance.

A. If the Fluval Motor Unit falls into the water, DON’T reach for it! First unplug it

and then retrieve it. If the electrical components of the appliance get wet,

unplug the appliance immediately.

B. Carefully examine the appliance after installation. It should not be plugged in

if there is water on parts not intended to be wet.

C. Do not operate any appliance if it has a damaged cord or plug, or if it is

malfunctioning or if it is dropped or damaged in any manner.

The power

cord of this appliance cannot be replaced; if the cord is

damaged, the appliance should be discarded. Never cut

the cord.

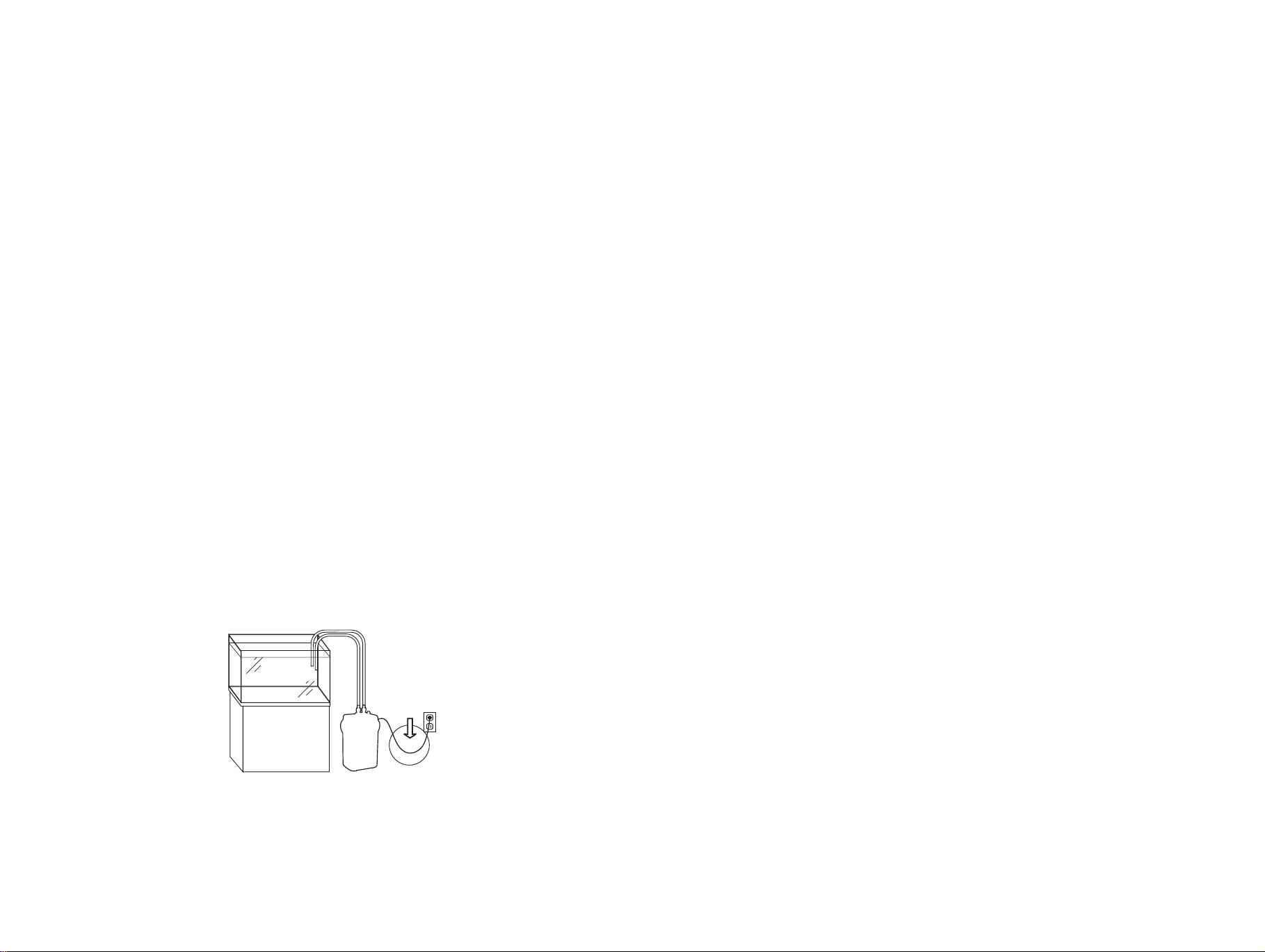

D.To avoid the possibility of the appliance plug or receptacle getting wet,

position the unit to one side of a wall mounted receptacle to prevent water

from dripping onto the receptacle or plug. A “drip loop”(see illustration)

should be arranged to the receptacle. The “drip loop” is that part of the cord

below the level of the receptacle or the connector if an extension cord is used,

to prevent water traveling along the cord and coming into contact with the

receptacle.

If the plug or receptacle does get wet, DON’T unplug the cord. Disconnect the

fuse or circuit breaker that supplies power to the appliance. Then unplug

and examine for presence of water in the receptacle.

Page 3

Instructions Cont’d

Introduction

3. Close supervision is necessar y when any appliance is used by or near children.

4.

To avoid injury, do not contact moving parts or hot parts

such as heaters, reflectors, lamp bulbs, etc.

5. Always unplug an appliance from an outlet when not in

use, before putting on or taking off parts, and before

cleaning. Never yank cord to pull plug from outlet. Grasp

the plug and pull to disconnect.

6. Do not use an appliance for other than intended use (i.e. don’t use on swimming

pools, garden ponds, bathrooms, etc.). The use of attachments not recommended

or sold by the appliance manufacturer may cause an unsafe condition.

7. Do not install or store the appliance where it will be exposed to the weather or to

temperatures below freezing.

8. Make sure an appliance is securely installed before operating it.

9. Read and observe all the impor tant notices on the appliance.

10. If an extension cord is necessary, a cord with a proper rating should be used.

A cord rated for less amperes or watts than the appliance rating may overheat.

Care should be taken to arrange the cord so that it will not be tripped over

or pulled.

11.The pump must not run dr y.

12.

SAVE THESE INSTRUCTIONS

For the complete use and understanding of this power filter it is recommended

that this manual is thoroughly read and understood. Failure to do so may result

in damage to this pump.

For the complete enjoyment, use and understanding of this Canister Power Filter, it is

recommended that this manual be thoroughly followed. Failur e to do so may r esult in loss of

fish life and/or damage to this filter. Save this manual for futur e reference.

This Fluval Canister Filter system incorporates the most advanced pump and media handling

technology presently available. It has numerous user features that permit greater control of

both the filter’s interaction with the aquatic environment and the aquarist’s desire to control

water characteristics. Now, more than ever, Fluval Canister filters provide a greater amount

of filter media and media configurations than any other comparable filter. A minimum of 4

and up to a maximum of 8 media types may be used in separate compartments, depending

on the filter chosen.

The space may be used according to the needs of each individual situation. Fluval

filters allow great flexibility to satisfy the many requirements of novice and advanced

enthusiasts alike.

Fluval Canister filters improve the way filter media is employed while at the same time

dramatically increasing filtration area. Water must pass through all media before it returns

to the aquarium. Instead of travelling in a direct path through the media, the water current

in the 4

the time that water is in contact with Fluval's many filtration media modules. The squared

design of the 4

round containers while improving the water flow characteristics.

Fluval filters support a greater mass of filter material. This increases the life and efficiency

of the filter system. Maintenance requirements are reduced. General water purity

remains constant.

th

generation Fluval system is actually directed in a complex flow path. This increases

th

generation Fluvals provides 35% to 55% increased volume over traditional

Conventional filters clog more rapidly and do not function as efficiently as Fluval. Fluval's

multi-leveled media design forces water into many channels and pathways which increases

contact time and thoroughly purifies water. Other filters cannot achieve the same level of

water purity. They cannot successfully increase the flow rate to the levels required to

compensate for the lack of filter media volume and contact time.

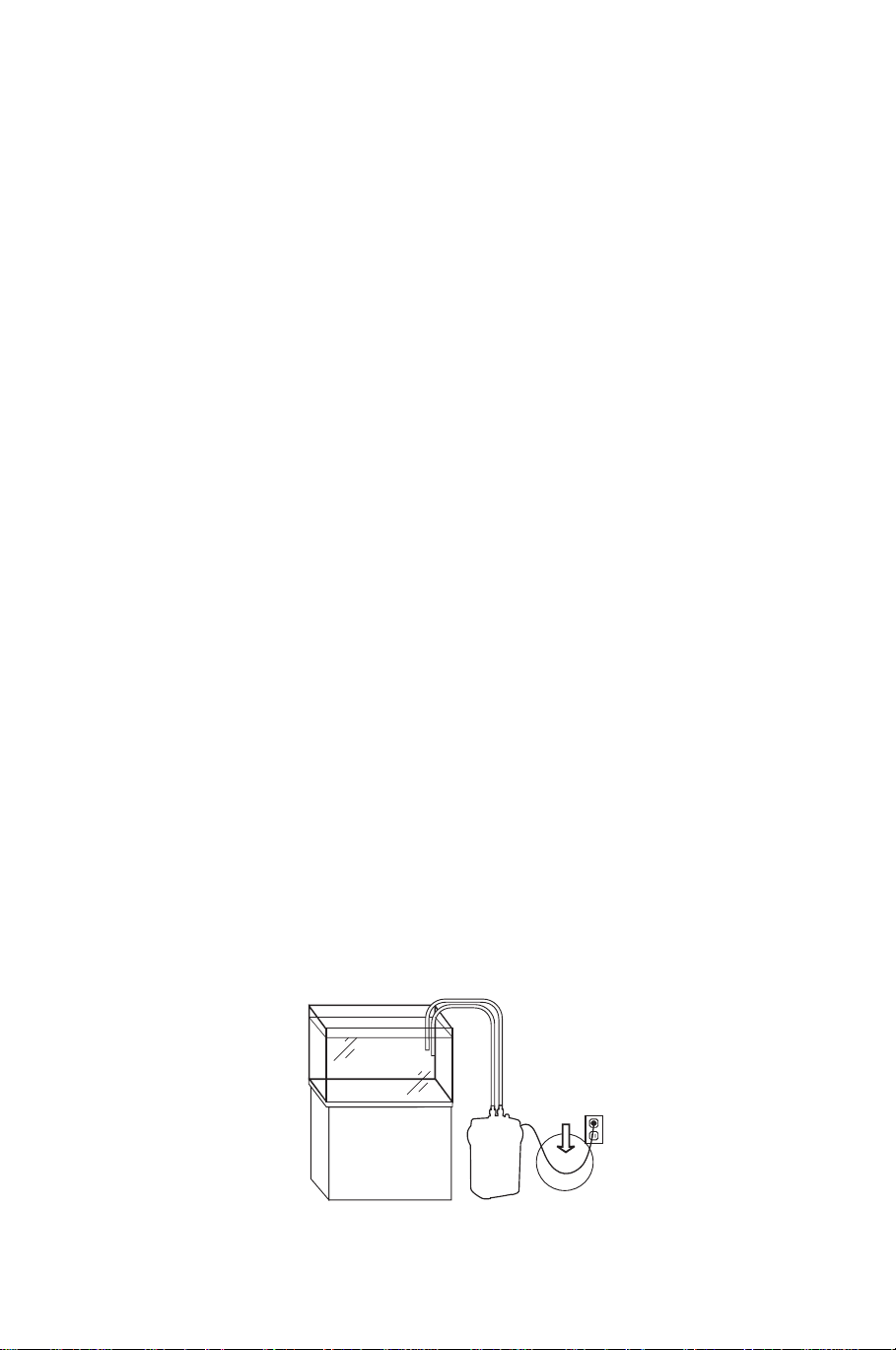

Canister filters are placed below the aquarium, to the side or back of the installation. They

do not detract from the beauty of the fish and their surroundings. Fluval filters are ideal for

custom situations where remote access to the filtration unit is required.

Page 4

Fluval 4th Generation: Advanced

Filter Design

Fluval Power Filters are designed to provide optimum aquarium filtration using a versatile combination of

mechanical, biological and chemical capabilities. This results in healthier fish and thriving aquatic plants.

Fluval filters are equipped with basic filter media. Additional filter chambers are available for many different

filter materials of your own choice. (See section on “Fluval Media Selection” for a complete listing of Fluval

Filter Media).

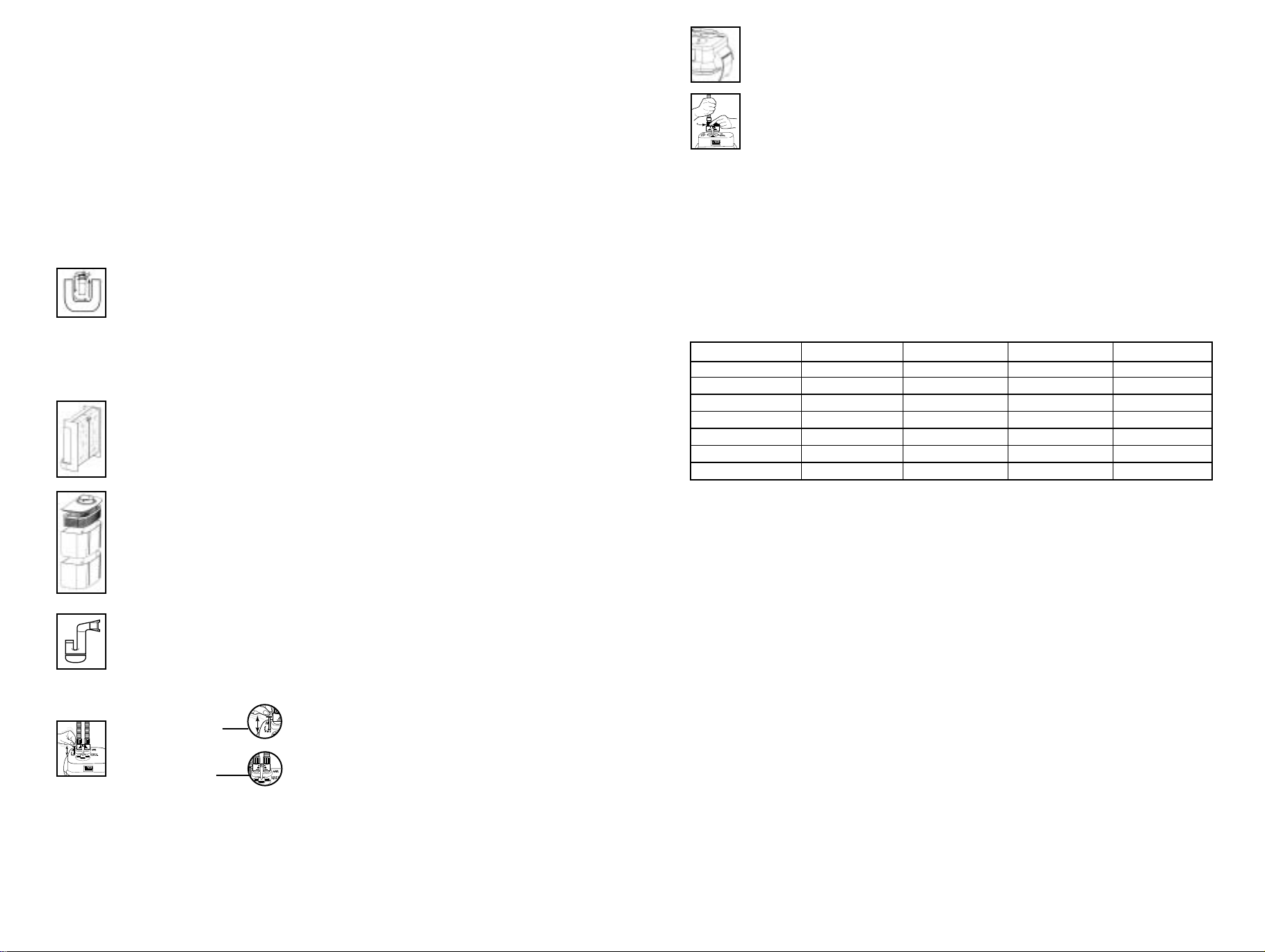

Lift-Lock Clamps

Two prominent clamps expedite the removal of the motor housing from the filter unit. By simply

lifting the clamps, the motor unit is separated from the filter's suction grip.

Hose Lock Nuts

Safety connectors ensure a tight, leak-proof seal for all hose connections.

Motor Unit

Fluval’s motor is hermetically sealed with epoxy to ensure that it will continue to operate without difficulty in

adverse conditions. It does not require liquid or air coolant and can be placed in a closed cabinet with

restricted air flow without affecting the life or performance of the filter. Fluval filters are the leaders in energy

efficiency, moving more water per watt of consumption than other comparable filters. Fluval canister filters

require no motor maintenance. The motor has no moving parts except for the impeller.

Impeller and Ceramic Impeller Shaft Insert

Fluval increases efficiency and long-term durability by providing a removable Ceramic Impeller

Shaft Insert. It provides quiet operation and increases motor life and efficiency.

Self-Cleaning Impeller Well

The Magnetic Impeller Shaft Insert incorporates a self-flushing channel to keep the unit clean and debris-free

during operation. It backwashes fine silt and debris from the impeller well, reducing maintenance to a simple

flush during filter media changes.

Mechanical Filtration Area - Foam Screen Frame

The foam is contained in a convenient, accessible frame. The screen captures large particulate

waste to prevent it from clogging the Biological Filtration Area. The foam's placement ensures

efficient mechanical removal of waste. The massive foam surface captures and lodges large

waste. As water flows through the unit, the waste is broken down into smaller particles.

Biological/Chemical Filtration Area - Stackable

Filter Media Baskets

The media baskets permit full access to all media. This allows for partial or full filter media

changes, based on the user's requirements. Filter media expires at various times. In the case of

biological media, it is recommended to make only partial media changes, so as not to disturb the

biological balance of the aquarium. Fluval's Filter Media Baskets provide a convenient way to

access the various media types to perform full or partial media changes.

Criteria for Filter Selection

Flow Rates

Fluval Filters are available in four models to handle all aquarium requirements, from the smallest to large

commercial aquariums. Flow rates start at

(Pump Output) depending on the model. Important factors in the choice of any filter are the filtration volume

and flow rate. The combination provides the essence of good filtration.

Water circulation is required to maintain oxygenation of the aquarium to sustain bacteria and biological

filtration. The more water filtered per hour, the cleaner the aquarium will remain.

Fluval's combination of contact time and flow provide the ideal filter function.

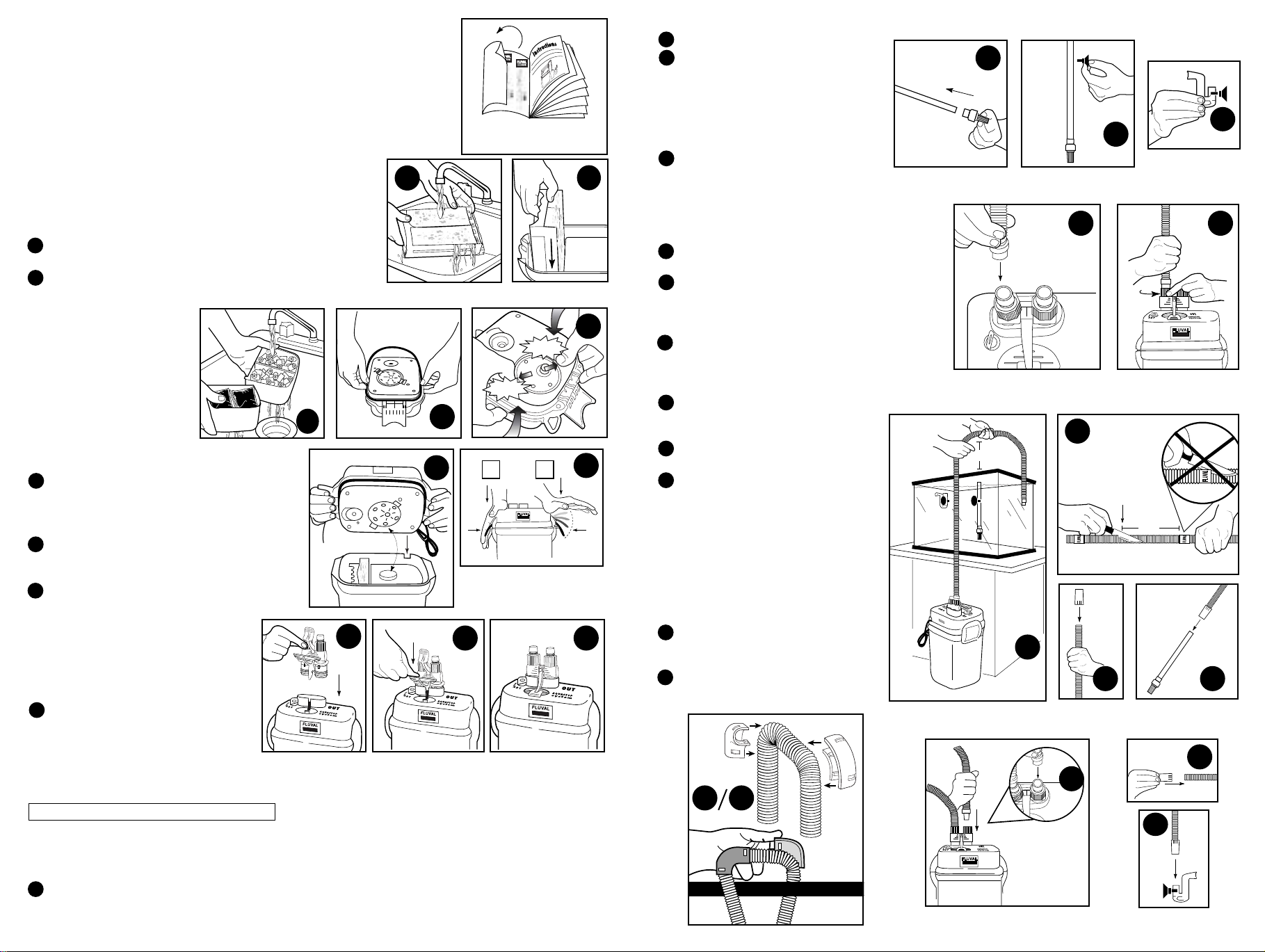

FLUVAL 104 204 304 404

Aquarium Capacity

Pump Output 480

Mechanical Area 36,800 mm

Biological Volume 1,37

Filtration Volume 3,2

Filter Circulation* 330

Water Column Height (max.) 1,35 m 1,35 m 1,60 m 2,05 m

*NOTE: Flow rates were measured with Intake and Output hoses that were the same length.

100 l/25 U.S. Gal. 200 l/40 U.S. Gal. 300 l/70 U.S. Gal. 400 l/100 U.S. Gal

l

/h-125 U.S. g/h 680 l/h-180 U.S. g/h 1000 l/h-260 U.S. g/h 1300 l/h-340 U.S. g/h

l

/h-85 U.S. g/h 420 l/h-110 U.S. g/h 710 l/h-185 U.S. g/h 850 l/h-225 U.S. g/h

Filter Area

The Fluval 4 series maximizes canister volume in all four models to provide more places for specific media

as well as increase the actual contact path through the canister. The filter chamber has been redesigned to

provide greater volume in its modern, aesthetic design. The more filter media volume, the greater the

mechanical efficiency and biological activity for the filtering process. Fluval meets this criteria.

l

l

480 liters

2

per hour up to

56,000 mm

2,0

l

4,6

l

2

1300 liters

56,000 mm

3,1

6,6

of hourly turnover

2

l

l

76,300 mm

4,2

8,5

2

l

l

.

Output Nozzle

The Fluval 4thgeneration Output Nozzle has been designed to provide strong currents within the

aquarium, rotating horizontal flow direction and the ability to be installed above, at level, or

below the water surface, depending on the aquarist’s choice. An important characteristic of any

filter is the way it promotes oxygen replacement in the aquarium. The Fluval Output Nozzle provides excellent

surface agitation for this purpose.

Self-Primer

A simple pumping motion of the Self-Primer initiates water flow.

Aqua-Stop

The Aqua-Stop makes maintenance easy by stopping the water flow, permitting you to separate the hose

assembly from the filter in one convenient step. It can be safely used to regulate water flow, without harming

the motor or its components.

Fluval Operating Characteristics

The intake stem can be placed anywhere in the aquarium; ideally in a location that can be easily disguised

by decoration. The most usual placement is on the back wall of the aquarium. The intake stem draws water

and suspended debris near the aquarium’s bottom into the filter unit by siphoning.

Water flows through the input assembly and into the unit. It passes through the Foam Screen Frame which

strips most particulate matter from the passing flow and holds it. It then must flow down under the first media

basket and start its journey up through the grid into the rest of the media. The pump draws the water

upward through the media baskets where it must come into contact with each stage of filtration. Tremendous

versatility of media choice is allowed by this arrangement of media baskets. The traditional ease of access to

all media baskets without disturbing the rest of the media is maintained and enhanced by this new

configuration. Filter media removes particles and liquid impurities and can also be used to actively change

the chemical characteristics of the water, depending on the aquarist’s needs. As the water flows, it brings

oxygen into the filter, feeding the needs of the beneficial bacteria breaking down nitrogenous wastes.

After passing through each discrete chamber, purified water enters the impeller well to be pumped back

to the aquarium.

Page 5

Installation Instructions

AQUASTOP

system

OUT

*NOTE* READ ALL INSTRUCTIONS BEFORE ATTEMPTING TO INSTALL FILTER

There are no tools required to install, maintain or operate the Fluval system.

DO NOT PLUG IN FILTER UNTIL UNIT IS FILLED WITH WATER (see step 30).

Recommendation: Top up water in aquarium before commencing.

Assembly

(*All letter references apply to front cover drawings)

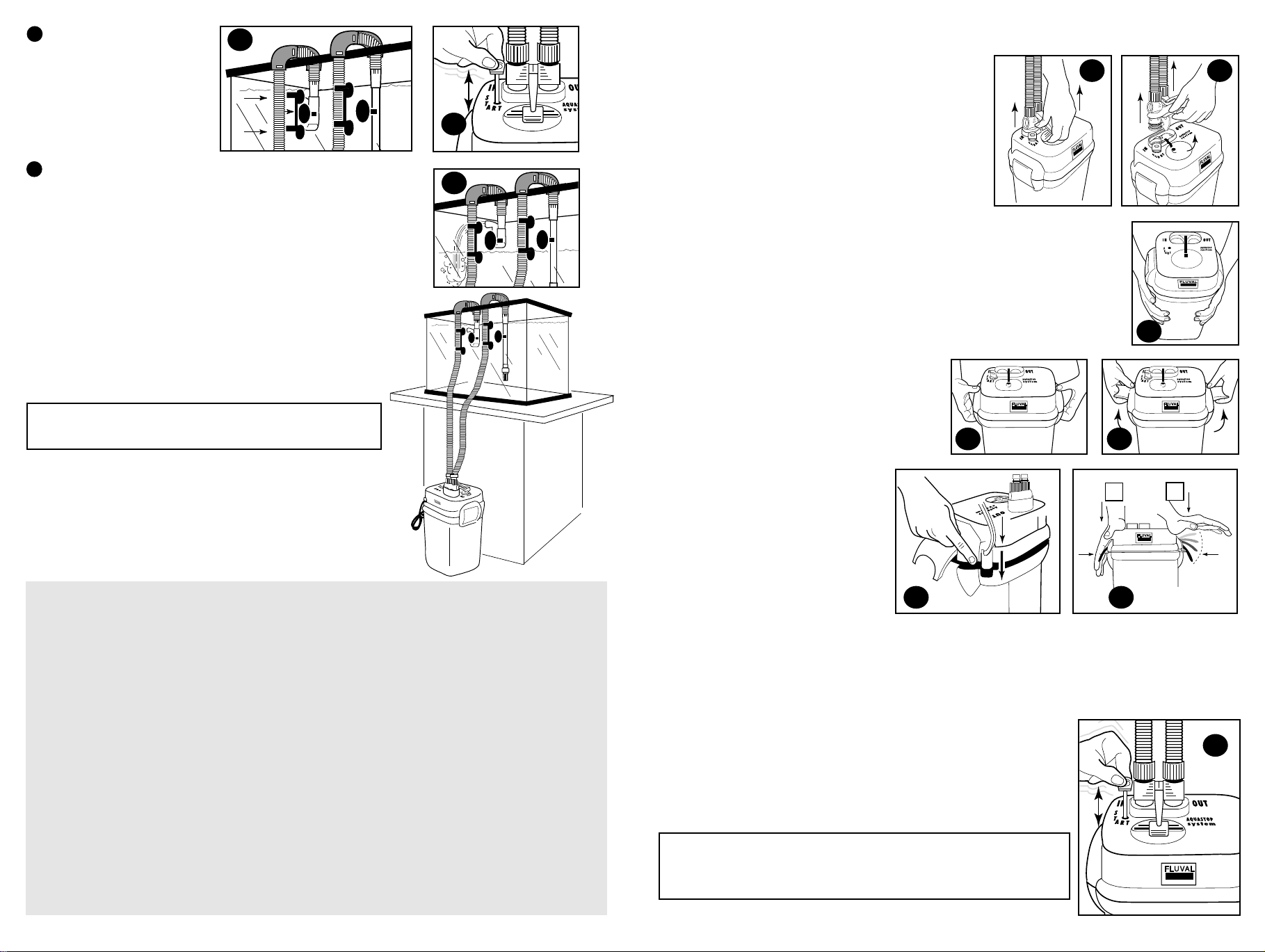

1) Verify that all components are present. (Refer to front cover).

2) Install feet. – Press one foot (A) into each of the four corners at

the bottom of the filter case.

PREPARING THE FILTER

3) Remove Motor Housing (B) from filter case.

4) Remove Foam Screen Frame (C) and Media Baskets (D) from filter case.

5 Rinse both sides of the Foam Screen Frame (C) under tap water

to remove any possible contaminants before initial use.

6 Replace Foam Screen Frame (C) in filter case. Refer to drawing for

proper placement.

7) Fill provided media in

appropriate media baskets.

(See inside front cover for

recommended placement). Remove

plastic bags from filter media

before placing them (do not

remove carbon from porous bags).

NOTE: The media placement

indicated on the front cover of the

booklet is only a recommendation.

For optimum media efficiency,

read “Filter Media” section.

8 Rinse all media under tap water to remove any dust

or debris before initial use.

9) Replace Media Baskets (D) in filter case and replace

media basket cover (F).

10 Remove Seal Ring (G) from plastic bag. To ensure

proper closure of unit, make sure Seal Ring is wet before

placing it in channel around base of Motor Housing (B).

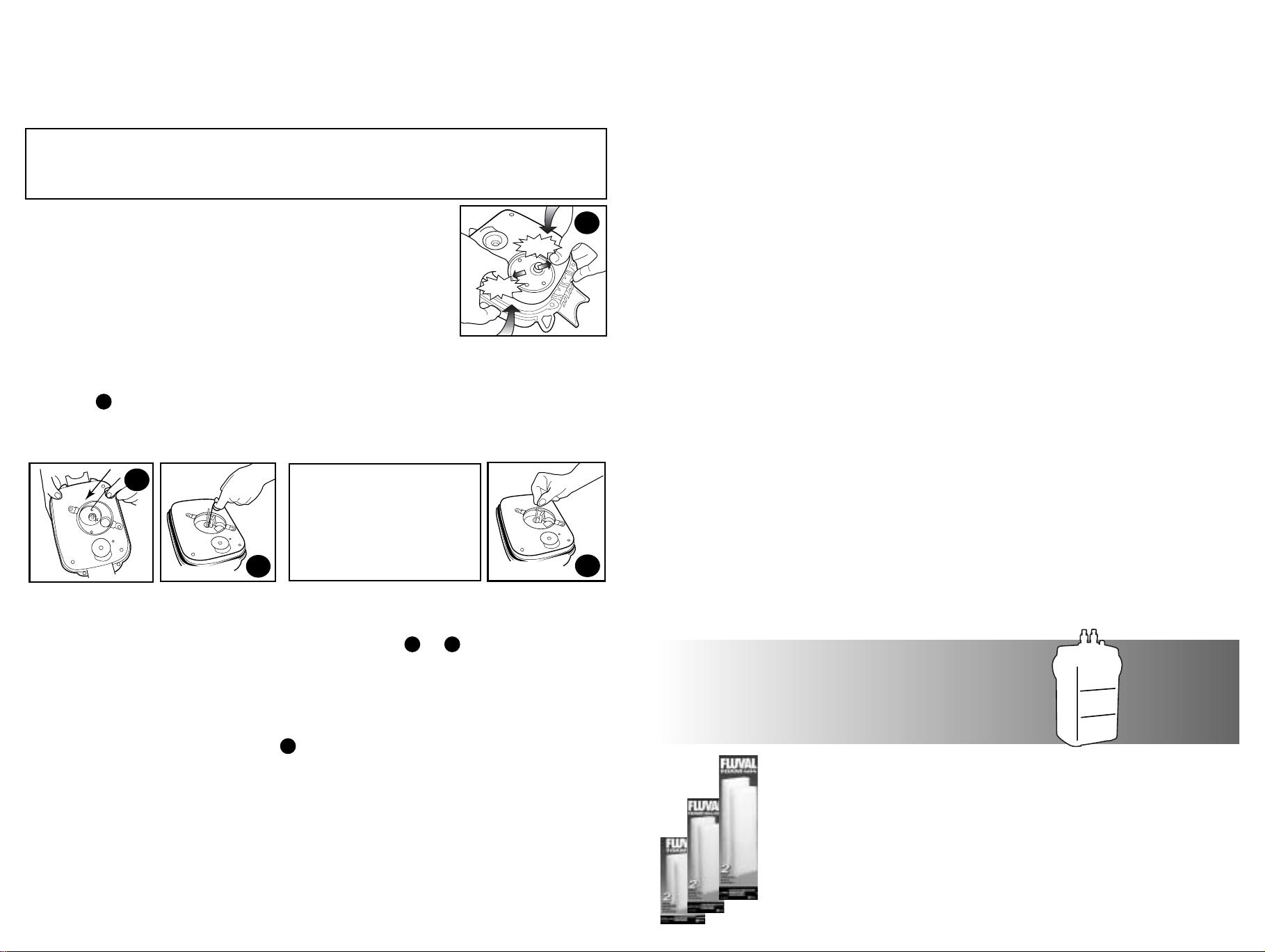

11 Install Impeller Cover (X) on underside of Motor

Housing (B) on top of Impeller. Squeeze tabs (see

drawing) to lock in place with a slight “click”.

NOTE: Do not fill the canister with water prior

to replacing the motor housing onto the filter

case. The motor housing incorporates a

self-priming feature that will allow water to

be siphoned into the canister. (See #30).

12 Replace Motor Housing (B) onto Filter Case

(U). Align Motor Housing with filter case and

push down to assure a tight, secure fit. Make

sure the power cord is properly aligned with

the indentation of the filter case. Then lock in place, one side at a time, with Lift Lock Clamps (H) (see

12b). If the unit does not close properly, verify that all inside components were placed correctly.

INSTALLING THE FILTER

FILTER MUST NEVER BE INSTALLED ABOVE WATER LEVEL.

13) Location – Place the unit in its final position before attaching hosing. The filter is best located beneath

the aquarium. Since the filter uses gravity-feed, ensure the filter is stationed below the water level of the aquarium.

NOTE: The distance between the bottom of the filter and the maximum water level must not exceed

4.5 ft (1.40 meters).

14 Insert the Aqua Stop (I) into Motor Housing (B) and push down the blue lever to lock the Aqua Stop in place. Open the

valves by pushing down the grey lever in order to let water flow to and from the canister. Be sure that the valves are fully

open before operating the unit.

8

14a

FLUVAL

5

12a

IMPORTANT: Refer to front cover

for component identification.

click!

click!

10

1 2

14b 14c

6

11

12b

15 Place Intake Strainer (J) on Intake Stem (K).

16 Attach Suction Cup Clip (L) on Intake Stem

(K) and affix to inside of aquarium in desired

location. To prevent blockage, the Intake

Strainer (J) should be placed at least of the

way down, but not touching the gravel. If it is

too long, cut straight across the Intake Tube with

a sharp knife.

17 Attach Suction Cup Clip (L) on Output

Nozzle (O).

18) Position Output Nozzle (O) in aquarium. It is

recommended to place it at or slightly below the water

surface. It can be rotated horizontally to ensure the output is

pointed where current is required.

19 Insert one end of Ribbed Hosing (P) on Intake Side of

Aqua Stop (I).

20 To secure hose, turn Hose Lock Nut (Q) upwards until it

tightens on the hose’s permanent Rubber Adapter. Ensure

that hose is securely locked on unit before proceeding to

next step.

21 Pull Ribbed Hosing (P) up to aquarium rim (leave some

slack), where the Intake Stem (K) is positioned, and cut

approximately 5" above the rim with a sharp knife.

IMPORTANT: Ribbed Hosing (P) should not be cut within 1.5" (4 cm) of Fluval wording (cut ribbed area only).

22 Push Rubber Adapter (R) on the cut end

of Ribbed Hosing (P) and attach to Intake

Stem (K).

23 Affix two Hose Elbows (S) on Ribbed

Hosing (P) to ensure a lock-fit on aquarium rim.

24 Attach the permanent Rubber Adapter from

the remaining piece of Ribbed Hosing (P) to the

Output Side of the Aqua Stop (I).

25) Hand-tighten Hose Lock Nuts (Q).

26) Pull Ribbed Hosing (P) up to aquarium rim,

where the Output Nozzle (O) is positioned, and

cut approximately 5" above the rim with a

sharp knife. IMPORTANT: Ribbed Hosing (P)

should not be cut within 1.5" (4 cm) of Fluval

wording (cut ribbed area ONLY).

27 Push Rubber Adapter (R) on the cut end

of Ribbed Hosing (P) and attach to Output

Nozzle (O).

28 Affix two Hose Elbows (S) on Ribbed

Hosing (P) to ensure a lock-fit on aquarium rim.

3

/

4

15

IN

S

T

5"

16

19 20

OUT

AQUASTOP

TA

R

system

21b

4 cm

21a

22a 22b

24

23 28

27b

17

27a

Page 6

29 Attach Suction Cup Bracket (M) to

Ribbed Hosing (P) on outside of tank

to affix hosing neatly in place.

STARTING THE FILTER

NOTE: An empty bucket or container

should be handy in case it is needed

for inadver tent leaks while working

with the filter.

30 In order to start the water flow, ensure that the Output Nozzle (O) is above

the water surface. Make sure that the valves are open - the grey lever on

the Aqua Stop should be in the ‘down’ position.

Pump the Self-Primer (T) several times vigorously (use a fully extended ‘UP’

and ‘DOWN’ motion). Keep pumping the Self-Primer until you hear the

water being drawn into the unit and filling it. By pumping the Self-Primer,

water is pulled into the unit through the Intake Stem. As the unit fills with

water, the pressure forces the air out of the unit through the output hosing.

Return the Self-Primer to the ‘DOWN’ position. Once the unit has filled,

you can plug it into a power source. Water should then flow in a steady

stream from the Output Nozzle. If it doesn’t, check that there are no kinks

or loops in the hosing. Then continue to pump the primer until unit starts to

run on its own. Once the unit is operating normally, the grey lever on the

Aqua Stop can be used to regulate water flow, without harming the motor.

CAUTION: Do not operate the filter with the grey lever on the Aqua Stop

closed more than half way.

Never plug in unit until it is completely full. The Fluval unit

should never be allowed to run dry. Premature operation

may result in damage to the motor.

NOTE: Some air will inevitably be trapped within the unit as it fills, also,

new media may release trapped air into the Filter Case. This may result in

some noise as the unit starts working. The configuration of the filter will

eventually expel all air pockets in the filter over time. If the Filter Case

continues to trap and expel air over an extended time, carefully examine

the Input/Output Sides for air leaks. Ensure there is no air source (such as

an airstone or aeration device) entering the Intake Side of the filter.

A Note About Media

Efficiency is directly affected by the filter materials used. In any canister unit it is critical that proper procedures be

carefully followed. Otherwise, the mechanical or biological efficacy may be impaired. In many cases the location of

the media in the baskets will determine its main purpose. For instance, depending on media basket positions,

carbon can act as a primary dir t screen or a major area of bacterial population. To ensure the maximum utility of

the filter, there are a few basic rules of thumb that should be followed.

Properly prepare all filter materials before use.

Porous material, such as carbon, has a tremendous open area within the matrix and requires a bit of time to expel

atmospheric gasses. It should be soaked for several minutes before being added to the media basket. There are other

materials that require more extensive rinsing. Ammonia Remover and peat fibers may require a thorough rinsing to

ensure they do not add extra particles that may prematurely clog other modules or discharge into the aquarium.

Mechanical filtration should be used during the first stages of filtration.

Create a coarse to fine screen with the media chosen. The Foam Screen is an effective mechanical sieve that will

remove coarse and medium debris. A finer screen can be placed in the lowest Media Basket to ensure the purest

stream possible before it enters the biological [and possibly chemical] filtration that relies on debris-free water for

maximum efficiency.

Incorporate Biological areas after mechanical filtration. Protect from debris as much as possible.

There are a number of media that become highly biological in nature as they mature. This is due to the fact that

these substrates provide clean, hard attachment points for the beneficial bacteria to colonize. For nitrifying bacteria

to be most effective, they must receive a constant stream of waste-free water that carries ammonia, nitrite and

oxygen in the solution.

29

30a

30b

Maintenance Procedures

NOTE: It is recommended to periodically lubricate all rubber parts

(ex. motor head seal ring, primer stem and Aqua Stop seal ring)

with Fluval Silicone Lubricant (A-325).

Media Maintenance

Filter materials must be periodically replaced or cleaned. The various

Fluval media have instructions for use on the individual packaging.

Actual lifespan of any type of media varies according to usage and

the individual characteristics of an aquarium.

Close the valves by fully lifting the grey lever. Unplug the filter. Then

f.2

gently lift the large blue center handle to release the Aqua-Stop

transported in an upright position to eliminate the possibility of water splash.

***NOTE: Grip the filter canister body ●, not the Lift-Lock Handles when transporting the unit

from installation to maintenance area. The Lift-Lock Handles are designed to release the motor

housing from the filter case only. They should not be used as grasping points to transport an intact

filter. If used as carrying handles, there is the possibility of the unit separating and water spilling.

It is not necessary to remove the hose system from the aquarium unless the hoses or the Aqua-Stop

require cleaning. Periodic cleaning is recommended to

ensure an optimal flow rate. In order to clean the

Aqua-Stop or hosing, rinse under water and, if necessary,

use an appropriate Fluval Cleaning Brush or tool.

Once the filter is in a waterproof place such as a sink, raise

the Lift-Lock Clamps to free the motor housing from the filter

f.4 f.5

case

●●

Filter” for detailed instruction on Media Baskets.

IMPORTANT: Empty water from filter case before

proceeding. Tilt the unit over a sink while

holding the media baskets in place in order to

empty water from the filter.

Rinse or replace media as required. The filter

case should be rinsed whenever the media is

cleaned or changed. NEVER use soap or

detergents when cleaning. Any remaining

traces may result in damage to sensitive fish tissues.

Replace Media Baskets in the filter case and slide in the Foam Screen Frame. To perform any required Impeller

care, see "Impeller Maintenance"section. Set the Motor Housing back in place. There is only one way in which the

unit can be properly assembled. Make sure the power cord is properly aligned with the indentation on the filter

case ●. Press Motor Housing down to assure a tight, secure fit. Then lock in place, one side at a time, with the

Lift-Lock Clamps (H) ●. Return the filter to its original position. Insert the Aqua-Stop

(I) into the Motor Housing (B) and push down the blue lever to lock the Aqua-Stop in

place. Open the valves by pushing down the grey lever in order to let water flow to

and from the canister. IMPORTANT: In order to restart the filter after maintenance,

ensure that the Output Nozzle is above the water surface when attaching the

Aqua-Stop to the Motor Housing. Water should start flowing immediately, otherwise,

pump the Self Primer to start ●.

See the section “Preparing the

f.6

f.7

f.8

f.3

f.6

Allow the filter case to completely fill before plugging the unit into power.

The Fluval unit should never be allowed to run dr y. Plugging the unit in

before the filter case is full may prevent the self-priming feature from

working properly.

f.1

. The filter should be

●●

f.4

f.1 f.2

f.3

f.5

1

2

f.7

f.8

Page 7

Alternate new media introduction

Filter media should be changed at the regular recommended intervals. However, not all media should be replaced at one

time. Stagger filter media changes so there is always old filter media in the filter. This enhances replacement of important

bacterial colonies lost with discarded media. It promotes rapid seeding for continued bacterial action within the filter.

To further heighten the bacterial filter, use Nutrafin Cycle Biological Aquarium Supplement once a week to institute,

supplement and promote the correct beneficial bacteria and to encourage them to become the dominant strains within

the bacterial filter.

WARNING

The power supply cord of this appliance cannot be replaced; if the cord is damaged, the appliance

should be discarded. Disconnect the plug from all appliances inside the aquarium before putting hands

in the water. The pump must never be allowed to run dry.

Impeller Maintenance

Important: these motor units contain an Impeller Fan with Ceramic Shaft. This kind of

shaft is more resistant to wear and tear but it is fragile. Special care is recommended

during maintenance.

The impeller well has an effective self-cleaning feature. Regular monitoring for dirt

build-up can help lengthen the life of the impeller and motor unit.

To access the impeller, remove the impeller cover by squeezing the two tabs ●.

The Magnetic Impeller should be cleaned when necessary. To remove it, gently grasp the

impeller fan and withdraw it from the well and rinse off under clean water. Check that the Impeller Well is clean.

If necessary, use a Fluval Cleaning Brush to clean it out. Then reinsert Impeller.

When maintenance is complete, place the Impeller Cover (X) into its seat again and lock it in place by pressing the tabs

until a "click" is heard (make sure that the Impeller Shaft is properly reinserted into the shaft support ring of the

Impeller Cover).

NOTE: It is not recommended to remove the Ceramic Shaft Assembly unless it breaks.

Specific notes concerning Fluval 104 and 204

The Fluval 104 and 204 models come with a ceramic shaft, which is attached to its yellow plastic support (Ceramic Shaft

Assembly). It is not recommended to remove the Ceramic Shaft Assembly unless it breaks. To remove the yellow Ceramic

Shaft Assembly from the Impeller Well use the provided Ceramic Shaft tool (Z) and .

To reinsert the Ceramic Shaft Assembly: place the Magnetic Impeller (W) on the Ceramic Shaft Assembly and reinsert

them into the Impeller Well by pushing gently on the Impeller Fan to lock them in place.

Specific notes concerning Fluval 304 and 404

The Fluval 304 and 404 models come with a Ceramic Shaft fixed on the bottom of the Impeller Well by a Rubber

Support. The Ceramic Shaft can be easily extracted and reinserted by hand, paying close attention to the Rubber

Support to ensure that it has not come out of its seat . Note: Be sure to reinsert the impeller cover to ensure

proper alignment.

The Impeller will wear over a longer period of time. Replacement parts may be ordered from your local pet dealer

(see ”Fluval Spare Parts” list).

f.9

(Models 104 and 204 only)

f.10

f.11

Warning: These motor units

incorporate a ceramic impeller

shaft. This shaft is permanently

attached to its plastic holder for

safe handling. The shaft is brittle

to lateral pressure. Take extreme

care when handling.

Do not try to bend the shaft.

f.12

f.9

f.10 f.11

click!

click!

(Models 304

and 404 only)

f.9

f.12

Fluval Media Selection

Types of Filtration

Mechanical – Removal of waste particles and solid debris through mechanical strainers.

Biological – Breakdown and elimination of organic toxins - ammonia and nitrite - through bacterial action.

Chemical – Active change of water characteristics through the use of chemical compounds.

Fluval Filtration Area

Section 1 – The Foam Screen Frame

Fluval offers a wide variety of filter materials, some capable of performing more than one job. Fluval 4thgeneration filters

provide automatic mechanical particle removal with the Foam Screen Frame. It is extremely important to remove wastes

before they enter the more delicate media in the Media Baskets.

Section 2 – The Stack of Media Baskets

The true power of the Fluval System resides in the versatility of the media choices available for the Stack of Media Baskets.

This section is meant as more of a guide than a definitive manual. Versatility and aquarist choice of media should be the

main criteria. However, it is best to follow some or all of the following guidelines. The choice of media should follow a

number of criteria.

Bottom Media Basket

Media that continues the mechanical capture of waste should be in the lowest media basket, purifying and removing

particles before they can clog delicate pores of biological or chemical substrates. Fluval Media such as “Pre-Filter”,

“Carbon” and “Zeo-Carb” can be used to further screen small particles from the water. Pre-Filter is inert, acting solely to

create a screen. Carbon removes dyes, medications and solubilized wastes that a simple screen cannot. “Zeo-Carb”

removes ammonia from the water. This is often used in beginning set-ups to keep initial spikes lower than would

occur naturally.

Middle Media Basket

The middle media basket is useful for chemical modifications of the water. “Peat Fibre” and “Peat Granular” are an

example of this. An important consideration for media placement is the type. Peat Fibre consists of strands which can rise

up and wrap around an impeller. For this reason, any media that is string-like in nature should be kept below other filter

media. The middle chamber can begin the biological reduction process as well. Many media types will serve as both

mechanical and biological, offering an excellent place for beneficial bacteria to populate. Even many chemical compounds

will support colonies of bacteria. With the main mechanical purification of the water stream occurring in the Foam Screen

Frame and below the second media basket, it is normal to load additional biological media into the middle media basket.

“BioMax”, extra “Carbon” or “Ammonia Remover” are quite commonly used in the mid-media basket. This is also the

area where more exotic media chosen for a specific application can occur.

Top Media Basket

The highest basket receives the purest water stream, making this the proper place for dedicated biological media.

“BioMax” provides optimal biological power in a very compact ring. With the multitude of pores perforating the surface

and internal matrix, “BioMax” is an ideal substrate for the top media basket. It also provides a trap to capture any loose

strands that might affect the operation of the impeller.

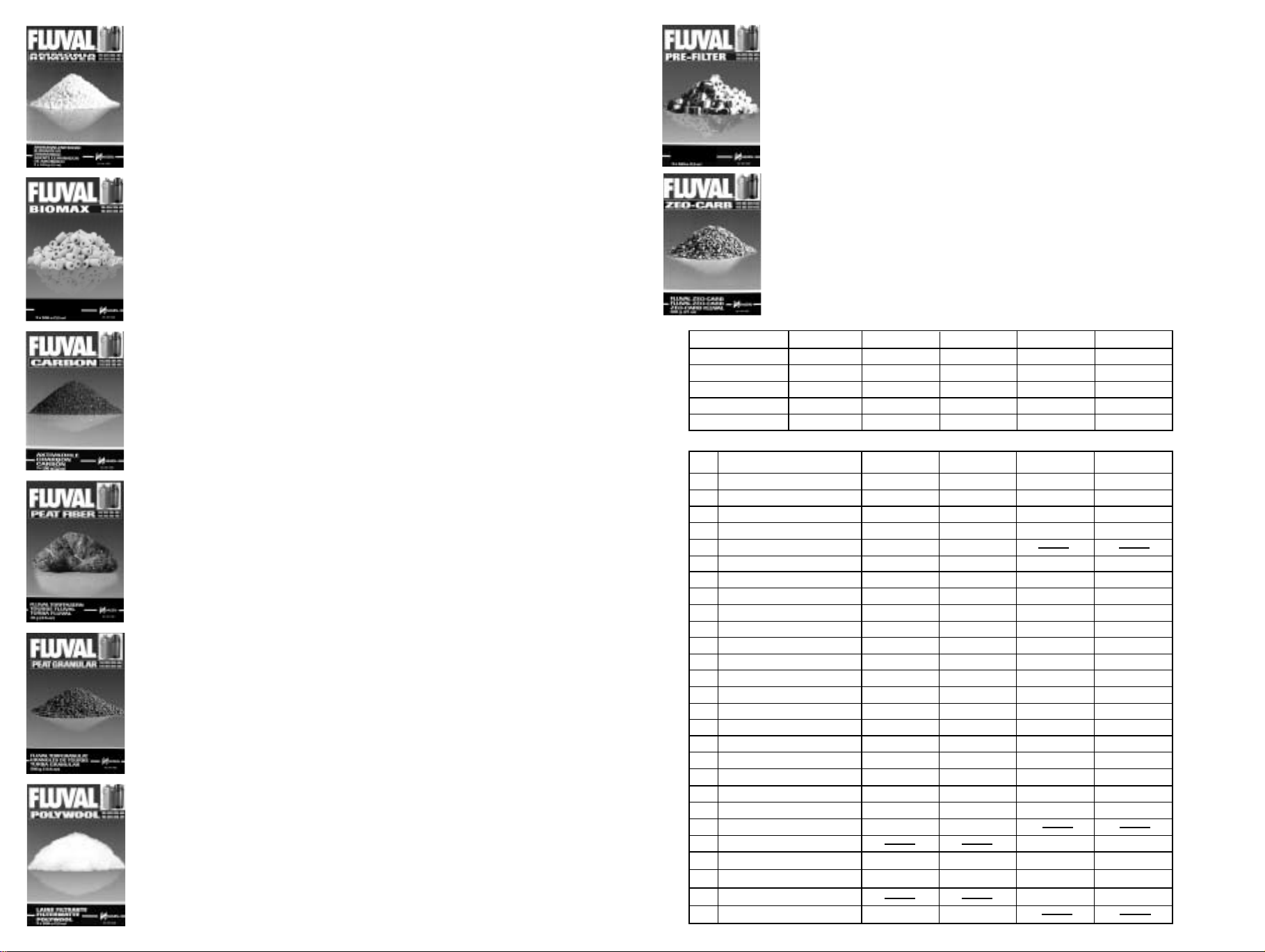

FLUVAL

Foam

- FS

Fluval Foam Screen Insert – 2 Pack

The construction of the Foam inserts allows large waste capture in the Foam Screen Frame, to eliminate

most solid wastes before they can clog biological and fine mechanical media. The numerous pathways

that the water is forced to travel through as it flows through the foam also increase the filtering efficiency.

Although not permanent, the foam inserts can be rinsed and reused a number of times before

replacement.

FILTER

MEDIA

A-220, A-222, A-226

FS

H

M

L

Page 8

Ammonia Remover

Ammonia Remover removes ammonia before it can harm fish. An effective addition to normal filter media, it

reduces unacceptable levels of ammonia. In chloramine treated water, it helps remove excess ammonia

created when the chloramine bond is broken to release free ammonia. Ammonia Remover should be used

exclusively in freshwater as its ionic functions release captured ammonia in brackish and saltwater. Ammonia

Remover does not show any physical change as it loses its activity, which is determined by the amounts of

ammonia it contacts. Ammonia Remover should not be left in the filter longer than a month.

– M, H

A-1480 (3x180 g), A-1485 (700 g)

Pre-Filter

Fluval Pre-Filter consists of inert, solid ceramic rings used to trap large and medium solid particles before they

clog the finer sieves of the media baskets above. The media forces water into many complex paths as it

moves through this layer. This further increases its mechanical and biological activity and expands the actual

contacted filter area. An additional benefit, it supports large populations of bacteria for proper biological

action on ammonia and nitrite.

This reduces the need for frequent changes of the active filter media. Pre-Filter is permanent, and requires

only occasional rinsing. This media can be used in fresh and marine environments without difficulty.

– L

A-1470 (750 g)

BioMax

Fluval BioMax is suitable for both fresh and marine aquariums. When used in a center or top media basket,

Fluval BioMax is the ideal host material for large populations of beneficial bacteria. The ring size and shape

provide an excellent strainer for medium and large particulate wastes when used in the middle media basket.

The biological activity is still noticeable when used in lower levels, but the rings will clog much more rapidly

than when they are used higher in the filter. Bacterial activity and growth will gradually clog the internal pores

that make it such a fantastic biological substrate. BioMax should be replaced every six months, but only half

should be replenished at one time to allow proper seeding from older media to new.

Carbon

Fluval Activated Carbon provides many benefits in both fresh and marine water. The high quality carbon

provides a large porous area to trap minute particles. Besides providing a small sieve for mechanical trapping

of organic wastes, carbon also removes liquid wastes from water. These include urine, dyes or impurities in

solution. This action provides sparkling clear water in the aquarium. The large internal surface area also

provides numerous points for important bacterial colonies to form and thrive. Carbon should always be

removed during medication. It has also been recently noted that carbon will adsorb a large percentage of

many of the nutrients in plant fertilizer products. As such, it should be used carefully when keeping live plants.

Carbon loses its activity without outward sign. In general, carbon should be replaced on a monthly basis to

ensure that active adsorption is maintained.

Fluval Peat Fiber A-1460 (70 g)

Fluval Peat Fiber is a select fibrous peat ideal for use in freshwater aquariums. This safe, natural filter media

provides optimal water conditions for many species of fish originating from specific tropical environments. Many

species of fish can benefit from the compounds found in Fluval Peat Fiber. Examples include species of South

American Cichlids (Angelfish, Discus, Apistogramma etc.), Corydoras Catfish, Tetras, Gouramis and Barbs.

Fluval Peat Fiber will gradually release beneficial elements and will contribute to vibrant colors, enhance

breeding success, and give superior conditions for a variety of fish species that thrive in soft acidic water.

It is recommended to verify the desired pH and KH levels by testing with Nutrafin pH and KH test kits on a

regular basis. Fluval Peat Fiber will gradually reduce pH and KH levels. The recommended KH range is 50 to

120 mg/L (approx. 3 to 7 dKH to support safe, stable pH levels) for proper maintenance of certain species of

fish. Use Nutrafin pH Stabilizer for superior results in maintaining an optimal KH value. The replacement of

Fluval Peat Fiber media is determined by testing and the diminishing effect it has on pH and KH levels.

Fluval Peat Fiber should be placed in the middle media basket of canister filter systems to avoid strands from

entering the impeller chamber.

Fluval Peat Granular A-1465 (500 g)

Fluval Peat Granular is a select granular peat ideal for use in freshwater aquariums. This concentrated, safe,

natural filter media provides optimal water conditions for many species of fish originating from specific tropical

environments. Many species of fish can benefit from the compounds found in Fluval Peat Granular. Examples

include species of South American Cichlids (Angelfish, Discus, Apistogramma etc.), Corydoras Catfish, Tetras,

Gouramis and Barbs.

Fluval Peat Granular releases beneficial elements and will contribute to vibrant colors, enhanced breeding

success, and superior conditions for a variety of fish species that thrive in soft acidic water.

It is recommended to verify the desired pH and KH levels by testing with Nutrafin pH and KH test kits on a

regular basis. Fluval Peat Granular is a concentrated filter media and will initially reduce pH and KH levels at

a quicker rate than fibrous peat. The recommended KH range is 50 to 120 mg/L (approx. 3 to 7 dKH to

support safe, stable pH levels) for proper maintenance of certain species of fish. Use Nutrafin pH Stabilizer for

superior results in maintaining an optimal KH value. The replacement of Fluval Peat Granular media is

determined by testing and the diminishing effect it has on pH and KH levels.

PolyWool

“PolyWool” is a common filter material that can be used to provide an inexpensive mechanical screen in the

lower media baskets. This will remove fine particles and keep biological materials from being clogged

prematurely. It will polish aquarium water to a crystal clear finish.

– M, H

– L, M

– L, M

A-1455

A-1440 (3x100 g), A-1445 (375 g)

Zeo-Carb

Zeo-Carb combines UltraGrade Carbon with Ammonia Remover to protect the aquarium from build-ups of

both ammonia and liquified wastes, dyes and medications. The ammonia remover will also help remove the

ammonia released when the chloramine bond in some municipal water supplies must be broken. The purity

of the carbon prolongs active life and releases no phosphates into the water. Zeo-Carb should be replaced

at least every month, more often if the aquarium is heavily loaded to ensure that the medias remain active

and useful.

– L, M, H

A-1490 (3x150 g), A-1495 (600 g)

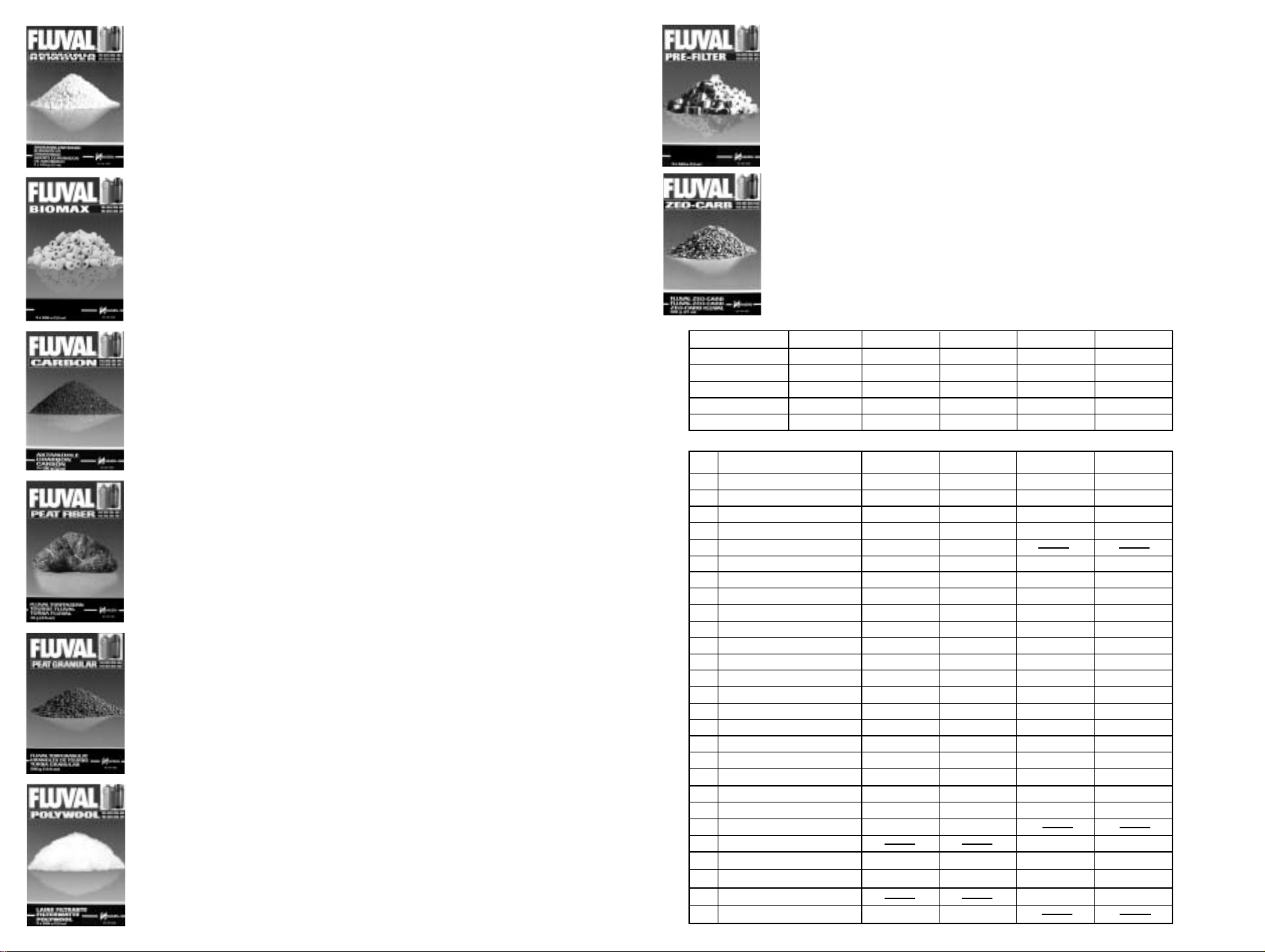

Technical Specifications

Type Fluval 104 Fluval 204 Fluval 304 Fluval 404

Item Number

Filter Volume Liters 3.2

A-200 A-205 A-210 A-215

l

4.6

l

6.6

l

8.5

l

Filter Baskets Number 2 3 3 4

Pump Output

l

/h 480 680 1000 1300

Pump Output US g/h 125 180 260 340

Spare Parts

Parts Fluval 104 Fluval 204 Fluval 304 Fluval 404

A Rubber Feet A-20121 A-20121 A-20121 A-20121

B Motor Housing A-20100 A-20120 A-20140 A-20160

C Foam Screen Frame A-20117 A-20137 A-20137 A-20177

D Media Basket A-20045 A-20045 A-20070 A-20070

E Media Basket Tray A-20047 A-20047

F Media Basket Cover A-20042 A-20042 A-20067 A-20067

G Motor Seal Ring A-20038 A-20038 A-20063 A-20063

H Lift-Lock Clamps A-20022 A-20022 A-20022 A-20022

I Aqua-Stop A-20060 A-20060 A-20060 A-20060

J Intake Strainer with check ball A-20007 A-20007 A-20007 A-20007

K Intake Stem A-20005 A-20005 A-20005 A-20005

L Suction Cup (40 mm) with clip A-15520 A-15520 A-15520 A-15520

M Suction Cup (30 mm) Bracket A-1216 A-1216 A-1217 A-1217

N 30 mm Suction Cup A-15041 A-15041 A-15041 A-15041

O Output Nozzle A-20001 A-20001 A-20001 A-20001

P Ribbed Hosing A-20014 A-20014 A-20015 A-20015

Q Hose-Lock Nuts A-20058 A-20058 A-20058 A-20058

R Rubber Adapter A-20016 A-20016 A-20017 A-20017

S Hose Elbow A-20018 A-20018 A-20019 A-20019

T Self-Primer Assembly A-20020 A-20020 A-20020 A-20020

U Filter Case A-20118 A-20138 A-20158 A-20178

V1 Ceramic Shaft Assembly A-20041 A-20041

Ceramic Shaft + Rubber Support

V2

W Magnetic Impeller A-20111 A-20111 A-20152 A-20172

X Impeller Cover A-20116 A-20136 A-20156 A-20156

Y

Impeller Well Insert A-20174 A-20174

Z Ceramic Shaft Tool A-17015 A-17015

A-20066 A-20066

Page 9

Ammonia Remover

Ammonia Remover removes ammonia before it can harm fish. An effective addition to normal filter media, it

reduces unacceptable levels of ammonia. In chloramine treated water, it helps remove excess ammonia

created when the chloramine bond is broken to release free ammonia. Ammonia Remover should be used

exclusively in freshwater as its ionic functions release captured ammonia in brackish and saltwater. Ammonia

Remover does not show any physical change as it loses its activity, which is determined by the amounts of

ammonia it contacts. Ammonia Remover should not be left in the filter longer than a month.

– M, H

A-1480 (3x180 g), A-1485 (700 g)

Pre-Filter

Fluval Pre-Filter consists of inert, solid ceramic rings used to trap large and medium solid particles before they

clog the finer sieves of the media baskets above. The media forces water into many complex paths as it

moves through this layer. This further increases its mechanical and biological activity and expands the actual

contacted filter area. An additional benefit, it supports large populations of bacteria for proper biological

action on ammonia and nitrite.

This reduces the need for frequent changes of the active filter media. Pre-Filter is permanent, and requires

only occasional rinsing. This media can be used in fresh and marine environments without difficulty.

– L

A-1470 (750 g)

BioMax

Fluval BioMax is suitable for both fresh and marine aquariums. When used in a center or top media basket,

Fluval BioMax is the ideal host material for large populations of beneficial bacteria. The ring size and shape

provide an excellent strainer for medium and large particulate wastes when used in the middle media basket.

The biological activity is still noticeable when used in lower levels, but the rings will clog much more rapidly

than when they are used higher in the filter. Bacterial activity and growth will gradually clog the internal pores

that make it such a fantastic biological substrate. BioMax should be replaced every six months, but only half

should be replenished at one time to allow proper seeding from older media to new.

Carbon

Fluval Activated Carbon provides many benefits in both fresh and marine water. The high quality carbon

provides a large porous area to trap minute particles. Besides providing a small sieve for mechanical trapping

of organic wastes, carbon also removes liquid wastes from water. These include urine, dyes or impurities in

solution. This action provides sparkling clear water in the aquarium. The large internal surface area also

provides numerous points for important bacterial colonies to form and thrive. Carbon should always be

removed during medication. It has also been recently noted that carbon will adsorb a large percentage of

many of the nutrients in plant fertilizer products. As such, it should be used carefully when keeping live plants.

Carbon loses its activity without outward sign. In general, carbon should be replaced on a monthly basis to

ensure that active adsorption is maintained.

Fluval Peat Fiber A-1460 (70 g)

Fluval Peat Fiber is a select fibrous peat ideal for use in freshwater aquariums. This safe, natural filter media

provides optimal water conditions for many species of fish originating from specific tropical environments. Many

species of fish can benefit from the compounds found in Fluval Peat Fiber. Examples include species of South

American Cichlids (Angelfish, Discus, Apistogramma etc.), Corydoras Catfish, Tetras, Gouramis and Barbs.

Fluval Peat Fiber will gradually release beneficial elements and will contribute to vibrant colors, enhance

breeding success, and give superior conditions for a variety of fish species that thrive in soft acidic water.

It is recommended to verify the desired pH and KH levels by testing with Nutrafin pH and KH test kits on a

regular basis. Fluval Peat Fiber will gradually reduce pH and KH levels. The recommended KH range is 50 to

120 mg/L (approx. 3 to 7 dKH to support safe, stable pH levels) for proper maintenance of certain species of

fish. Use Nutrafin pH Stabilizer for superior results in maintaining an optimal KH value. The replacement of

Fluval Peat Fiber media is determined by testing and the diminishing effect it has on pH and KH levels.

Fluval Peat Fiber should be placed in the middle media basket of canister filter systems to avoid strands from

entering the impeller chamber.

Fluval Peat Granular A-1465 (500 g)

Fluval Peat Granular is a select granular peat ideal for use in freshwater aquariums. This concentrated, safe,

natural filter media provides optimal water conditions for many species of fish originating from specific tropical

environments. Many species of fish can benefit from the compounds found in Fluval Peat Granular. Examples

include species of South American Cichlids (Angelfish, Discus, Apistogramma etc.), Corydoras Catfish, Tetras,

Gouramis and Barbs.

Fluval Peat Granular releases beneficial elements and will contribute to vibrant colors, enhanced breeding

success, and superior conditions for a variety of fish species that thrive in soft acidic water.

It is recommended to verify the desired pH and KH levels by testing with Nutrafin pH and KH test kits on a

regular basis. Fluval Peat Granular is a concentrated filter media and will initially reduce pH and KH levels at

a quicker rate than fibrous peat. The recommended KH range is 50 to 120 mg/L (approx. 3 to 7 dKH to

support safe, stable pH levels) for proper maintenance of certain species of fish. Use Nutrafin pH Stabilizer for

superior results in maintaining an optimal KH value. The replacement of Fluval Peat Granular media is

determined by testing and the diminishing effect it has on pH and KH levels.

PolyWool

“PolyWool” is a common filter material that can be used to provide an inexpensive mechanical screen in the

lower media baskets. This will remove fine particles and keep biological materials from being clogged

prematurely. It will polish aquarium water to a crystal clear finish.

– M, H

– L, M

– L, M

A-1455

A-1440 (3x100 g), A-1445 (375 g)

Zeo-Carb

Zeo-Carb combines UltraGrade Carbon with Ammonia Remover to protect the aquarium from build-ups of

both ammonia and liquified wastes, dyes and medications. The ammonia remover will also help remove the

ammonia released when the chloramine bond in some municipal water supplies must be broken. The purity

of the carbon prolongs active life and releases no phosphates into the water. Zeo-Carb should be replaced

at least every month, more often if the aquarium is heavily loaded to ensure that the medias remain active

and useful.

– L, M, H

A-1490 (3x150 g), A-1495 (600 g)

Technical Specifications

Type Fluval 104 Fluval 204 Fluval 304 Fluval 404

Item Number

Filter Volume Liters 3.2

A-200 A-205 A-210 A-215

l

4.6

l

6.6

l

8.5

l

Filter Baskets Number 2 3 3 4

Pump Output

l

/h 480 680 1000 1300

Pump Output US g/h 125 180 260 340

Spare Parts

Parts Fluval 104 Fluval 204 Fluval 304 Fluval 404

A Rubber Feet A-20121 A-20121 A-20121 A-20121

B Motor Housing A-20100 A-20120 A-20140 A-20160

C Foam Screen Frame A-20117 A-20137 A-20137 A-20177

D Media Basket A-20045 A-20045 A-20070 A-20070

E Media Basket Tray A-20047 A-20047

F Media Basket Cover A-20042 A-20042 A-20067 A-20067

G Motor Seal Ring A-20038 A-20038 A-20063 A-20063

H Lift-Lock Clamps A-20022 A-20022 A-20022 A-20022

I Aqua-Stop A-20060 A-20060 A-20060 A-20060

J Intake Strainer with check ball A-20007 A-20007 A-20007 A-20007

K Intake Stem A-20005 A-20005 A-20005 A-20005

L Suction Cup (40 mm) with clip A-15520 A-15520 A-15520 A-15520

M Suction Cup (30 mm) Bracket A-1216 A-1216 A-1217 A-1217

N 30 mm Suction Cup A-15041 A-15041 A-15041 A-15041

O Output Nozzle A-20001 A-20001 A-20001 A-20001

P Ribbed Hosing A-20014 A-20014 A-20015 A-20015

Q Hose-Lock Nuts A-20058 A-20058 A-20058 A-20058

R Rubber Adapter A-20016 A-20016 A-20017 A-20017

S Hose Elbow A-20018 A-20018 A-20019 A-20019

T Self-Primer Assembly A-20020 A-20020 A-20020 A-20020

U Filter Case A-20118 A-20138 A-20158 A-20178

V1 Ceramic Shaft Assembly A-20041 A-20041

Ceramic Shaft + Rubber Support

V2

W Magnetic Impeller A-20111 A-20111 A-20152 A-20172

X Impeller Cover A-20116 A-20136 A-20156 A-20156

Y

Impeller Well Insert A-20174 A-20174

Z Ceramic Shaft Tool A-17015 A-17015

A-20066 A-20066

Page 10

Notice d’utilisation

Avant d’installer ou de faire fonctionner cet appareil, lire attentivement cette notice.

MESURES DE SÉCURITÉ

Pour éviter tout accident, il est important de suivre les précautions suivantes:

1. Pour bien comprendre le fonctionnement de l’appareil et en obtenir un rendement

optimal, il est important de

SÉCURITÉ

2.

DANGER – Du fait de l’utilisation de l’eau et d’un appareil électrique, une

grande prudence est de rigueur. Dans chacune des situations suivantes, ne pas

essayer de réparer l’appareil soi-même ; l’envoyer pour réparation à un service

autorisé ou le jeter.

A.Si le bloc-moteur du filtre Fluval tombe à l’eau, NE PAS le ramasser !

LE DÉBRANCHER D’ABORD, et ensuite le sortir de l’eau. Si par mégarde les

composants électriques sont mouillés, débrancher immédiatement l’appareil.

B. Vérifier l’appareil après son installation.

C. Ne pas faire fonctionner un filtre défectueux, tombé ou endommagé. Idem si

la fiche ou le cordon sont endommagés. Le cordon d’alimentation de cet

appareil ne peut être remplacé. S’il est endommagé, l’appareil

doit être jeté. Ne jamais couper le cordon.

D. Afin d’éviter que l’appareil ou la prise de courant soient mouillés, installer

l’appareil d’un côté ou l’autre du bac et faire un col de cygne. Le col de cygne

est la partie du fil qui se trouve entre la prise de courant et le corps de l’appareil

(voir illustration) ou sous la prise de courant et le connecteur si une rallonge est

utilisée. L’eau ne coule pas ainsi le long du fil et n’entre pas en contact avec la

prise de courant.

ainsi que toutes les instructions notées sur l’appareil

LIRE ET SUIVRE TOUTES LES MESURES DE

:

Notice d’utilisation (suite)

3. Il est recommandé de surveiller étroitement les enfants qui utilisent cet appareil ou

qui s’en trouvent à proximité.

4.

Pour éviter les accidents, ne pas toucher aux pièces mobiles

ou chaudes comme les chauffe-eau, les réflecteurs, les

ampoules, etc.

5. Toujours débrancher l’appareil quand il n’est pas utilisé,

quand des pièces sont enlevées ou remplacées et avant

l’entretien. Ne jamais tirer sur le fil pour débrancher

l’appareil; prendre la fiche et débrancher l’appareil.

6. Ne pas utiliser cet appareil pour un autre emploi que celui pour lequel il a été

fabriqué (ne pas l’utiliser dans une piscine, un bassin de jardin, une baignoire,

etc.). Les pièces non vendues ou non recommandées par le fabricant pourraient

compromettre la sécurité de l’appareil.

7. Ne pas exposer cet appareil aux intempéries ou à une température en-dessous

de 0°C.

8. Vous assurer que l’appareil est bien installé avant de le faire fonctionner.

9. Lire et suivre toutes les instructions concernant cet appareil.

10. Si une rallonge électrique est nécessaire, vous assurer qu’elle est d’un calibre

suffisant. Un cordon de calibre inférieur ou de moins d’ampères ou de watts que

l’appareil peut surchauffer. Le cordon doit être placé de façon à éviter que

quelqu’un ne trébuche.

11.Ce filtre ne doit pas fonctionner à sec.

12.

CONSERVER CES INSTRUCTIONS. Pour une compréhension

complète de ce filtre à moteur, il est recommandé de lire soigneusement ce

manuel. Manquer à cette recommandation peut entraîner des dommages

à l’appareil.

Si la fiche ou la prise de courant sont mouillées, NE PAS débrancher le

cordon. Débrancher dans un premier temps le fusible ou disjoncteur qui fournit

l’électricité à l’appareil, et ensuite débrancher l’appareil en vérifiant qu’il n’y ait

pas d’eau dans la prise.

Page 11

Introduction

Pour une compréhension complète du fonctionnement de ce filtre extérieur, et pour en profiter

pleinement, il est recommandé de lire soigneusement ce manuel. Manquer à cette

recommandation peut entraîner des dommages au filtre. Conserver ces instructions.

Le filtre extérieur Fluval combine pompe d’avant-garde et grande variété de masses filtrantes.

Il est simple à utiliser et permet de plus facilement prévoir son action sur l’environnement

aqueux et sur les caractéristiques de l’eau. Plus que jamais, le filtre Fluval peut contenir une

plus grande quantité de masses filtrantes qui peuvent être utilisées dans un nombre de

combinaisons impensable dans un autre filtre. Selon le modèle, un minimum de 4 masses et

un maximum de 8 masses peuvent être utilisées et placées dans des compartiments séparés.

L’espace de filtration peut être utilisé selon les besoins propres à chaque situation. Les filtres

Fluval permettent une plus grande flexibilité d’emploi et ils répondent aux besoins autant des

aquariophiles débutants que chevronnés.

Dans le filtre extérieur Fluval, le rendement et la surface des masses filtrantes sont supérieurs.

L’eau doit passer à travers toutes les masses filtrantes avant de retourner dans l’aquarium. Au

lieu de suivre un parcours direct à travers les masses, le courant d’eau dans le système Fluval

e

– 4

génération doit emprunter un chemin constamment détourné. Ceci accroît le temps qu’il

faut à l’eau pour traverser tous les modules de filtration. La forme carrée du filtre Fluval - 4

génération accroît de 35 à 55 % le volume de filtration comparativement à ce que l’on peut

s’attendre des contenants cylindriques habituels, et elle permet une meilleure circulation de l’eau.

Le filtre Fluval peut contenir un plus grand volume de masses filtrantes. Ceci augmente la

durée et l’efficacité du système de filtration, en réduit l’entretien et favorise une eau d’une

pureté générale constante.

Les filtres ordinaires s’obstruent plus rapidement et ils ne sont pas aussi efficaces que les filtres

Fluval. Le design à multiples niveaux de la chambre de filtration du filtre Fluval force l’eau à

emprunter un chemin constamment détourné, ce qui augmente le temps de contact eau-masse

et purifie complètement l’eau. Les autres filtres sont incapables d’atteindre un même niveau de

purification. En effet, il est impossible dans ces filtres d’augmenter le courant d’eau au niveau

nécessaire pour compenser le manque de volume de filtration et de temps de contact eaumasse filtrante.

Les filtres extérieurs sont placés sous l’aquarium, sur le côté ou à l’arrière. Ils n’altèrent en rien

la beauté des poissons et du milieu. Le filtre Fluval est idéal dans des situations où il doit être

installé à distance de l’aquarium.

e

Fluval – 4egénération :

Conception d’avant-garde

Le filtre à moteur Fluval a été fabriqué pour accomplir une filtration optimale de l’eau d’un aquarium grâce

aux multiples combinaisons de masses mécaniques, biologiques et chimiques qu’on peut y faire.

Le filtre Fluval est pourvu des masses essentielles. Des chambres supplémentaires de filtration sont disponibles

pour de nombreuses masses filtrantes différentes à votre choix. (Voir la section «Masses filtrantes Fluval» pour

une liste complète des masses Fluval).

Bloc-moteur

Le moteur du filtre Fluval est hermétiquement scellé pour assurer son fonctionnement même dans des

conditions défavorables. Il ne nécessite pas de refroidisseur liquide ou d’aération et peut être placé dans un

endroit clos où l’aération est réduite. De plus, il consomme très peu d’énergie. Le moteur du filtre extérieur

Fluval est sans entretien. Il ne comporte qu’une seule pièce mobile : la couronne.

Couronne et arbre d’entraînement en

céramique

Le filtre Fluval possède un arbre d’entraînement facile à remplacer, ce qui accroît l’efficacité et

la durabilité de l’appareil qui fonctionne silencieusement, et augmente la durée et le rendement

du moteur.

Puits auto-nettoyant de la couronne

L’arbre d’entraînement de la couronne comprend un canal d’auto-nettoyage qui garde l’unité propre et sans

débris quand l’appareil fonctionne. Il permet de repousser les débris et le limon hors du puits et de réduire

l’entretien à un simple rinçage au moment des changements de masses.

Filtration mécanique –

Cadre de l’épurateur-mousse

La structure qui maintient la mousse en place est pratique et facile d’accès. L’épurateur-mousse

capture les grosses particules de déchets pour empêcher qu’elles n’obstruent le filtre biologique.

La surface massive de la mousse retient les gros déchets. Comme l’eau circule dans l’appareil,

les déchets se décomposent en petites particules.

Filtration biologique/chimique – Paniers

empilables de filtration

Grâce aux paniers de filtration, il est facile d’avoir accès à toutes les masses filtrantes. Ce système

permet le remplacement partiel ou total des masses filtrantes, selon les besoins de l’utilisateur. La

durée d’efficacité des masses varie. Dans le cas d’une masse biologique, il est recommandé de

n’en changer qu’une partie pour ne pas fragiliser l’équilibre biologique de l’aquarium.

L’assemblage de paniers du filtre Fluval permet d’avoir facilement accès à toutes les masses

filtrantes pour faire un changement total ou partiel de celles-ci.

Sortie d’eau

La 4egénération des filtres Fluval possède une sortie d’eau conçue pour produire des courants

d’eau puissants dans l’aquarium. Cette sortie d’eau est orientable et peut être installée sous

l’eau, à la surface ou au-dessus de l’eau, selon les besoins. La capacité d’un filtre à permettre le

remplacement de l’oxygène dans la masse d’eau est un facteur important dans le choix d’un appareil. Dans

ce but, la sortie d’eau Fluval produit une excellente agitation de l’eau de surface.

Page 12

Amorçage automatique

Un simple pompage de la clé d’amorçage déclenche le débit d’eau.

Aqua-Stop

L’Aqua-Stop simplifie l’entretien du filtre en arrêtant le débit d’eau pour vous permettre de séparer le montage

de tuyaux du filtre, en un seul mouvement. Ce mécanisme peut être utilisé sans danger pour régler le débit

d’eau, sans endommager le moteur ou ses pièces.

Manettes de blocage/ déblocage instantanés

Deux grosses manettes permettent de séparer rapidement le bloc-moteur de la cuve de filtration.

En soulevant simplement les manettes, le bloc-moteur se sépare de la ventouse du filtre.

Écrous de blocage

Des raccords sûrs assurent une étanchéité à toutes les connexions de tuyaux.

Critères pour le choix du modèle de filtre

Débit

Le filtre Fluval est disponible en quatre modèles pour répondre à toutes les exigences, du plus petit

aquarium au grand aquarium commercial. L’appareil offre un débit de

par heure selon le modèle. (NOTE: Les débits ont été mesurés avec des tubes d’entrée et de sortie d’eau de

la même longueur.) Un bon volume de filtration et un débit suffisant sont deux facteurs de base pour une

bonne filtration.

La circulation de l’eau est nécessaire au maintien de l’oxygénation de l’aquarium pour soutenir les

bactéries qui réalisent la filtration biologique. Plus grand est le volume d’eau filtrée par heure, plus

l’aquarium reste pur.

Le temps de contact eau-masse filtrante et le débit offert par le filtre Fluval sont idéaux.

Volume de l’aquarium

Débit / Pompe 480

Surface mécanique 36,800 mm

Volume-masse biologique

Volume-chambre de filtration

Débit / Filtre * 330

Hauteur de la colonne (max.) 1,35 m 1,35 m 1,60 m 2,05 m

*NOTE: Les débits ont été mesurés avec des tubes d’entrée et de sortie d’eau de la même longueur.

f.1

FLUVAL 104 204 304 404

100 l/25 U.S. Gal. 200 l/40 U.S. Gal. 300 l/70 U.S. Gal. 400 l/100 U.S. Gal

l

/h-125 U.S. 680 l/h-180 U.S. 1000 l/h-260 U.S. 1300 l/h-340 U.S.

2

56,000 mm

1,37

l

3,2

l

l

/h-85U.S.g/h 420l/h-110U.S.g/h 710 l/h-185U.S.g/h 850l/h-225U.S.g/h

f.4

2,0

4,6

l

l

Chambre de filtration

La 4e génération du filtre Fluval maximise l’espace de filtration dans les quatre modèles, les caractéristiques de

débit ont été redéfinies pour offrir plus de place à chaque masse filtrante et allonger le trajet que doit

emprunter l’eau pour traverser toutes les masses filtrantes. La chambre de filtration a été redessinée pour offrir

plus de volume dans un design moderne et esthétique. Plus le volume de filtration est grand, plus l’efficacité

de l’activité biologique et mécanique est grande. Le filtre Fluval a été fabriqué en fonction de ce qui précède.

Caractéristiques de fonctionnement

Le tuyau d’entrée d’eau est directement fixé à l’adaptateur/raccord, qui peut être installé n’importe où sur le

cadre de l’aquarium. Il est préférable de le placer là où il peut facilement être dissimulé par des décorations.

Habituellement, on le place à l’arrière de l’aquarium. L’entrée d’eau attire par siphonnage l’eau et les débris

en suspension dans le fond de l’aquarium et ensuite dans le filtre.

L’eau pénètre dans le tube d’entrée d’eau et ensuite dans l’entrée d’eau. Elle traverse la double mousse qui

retient la plupart des particules en suspension. L’eau est ensuite acheminée dans le fond de la cuve sous

2

480 litres

56,000 mm

3,1

6,6

par heure à

2

l

l

1 300 litres

76,300 mm

4,2

l

8,5

l

2

la grille pour remonter dans les modules et traverser les différentes masses filtrantes. La pompe aspire l’eau à

travers la chambre de filtration où elle entre en contact avec chaque masse filtrante. Cet assemblage de modules

permet une multitude de combinaisons de masses filtrantes. L’accès facile à chaque masse filtrante, sans toucher

aux autres masses, est maintenu et même amélioré grâce à la nouvelle configuration de la cuve. Les masses

filtrantes éliminent les particules en suspension et les déchets liquides et certaines d’entre elles modifient les

caractéristiques chimiques de l’eau, selon les besoins de l’aquariophile. Alors que l’eau traverse les masses

filtrantes, elle fournit au filtre de l’oxygène pour alimenter les bonnes bactéries qui décomposent les déchets

azotés. Après avoir passé par tous les modules de filtration, l’eau purifiée entre dans le puits de la couronne pour

être rejetée dans l’aquarium.

INSTRUCTIONS POUR L’INSTALLATION

*NOTE* LIRE TOUTES LES INSTRUCTIONS AVANT D’INSTALLER LE FILTRE.

Aucun outil n’est nécessaire pour installer, entretenir ou faire fonctionner le filtre Fluval.

NE PAS BRANCHER LE FILTRE AVANT QUE L’AQUARIUM SOIT REMPLI D’EAU (voir étape 30).

Recommandation : remplir l’aquarium d’eau avant de commencer.

ASSEMBLAGE

(* Toutes les lettres de référence s’appliquent aux dessins de la page de couverture)

1) S’assurer que toutes les pièces sont incluses. (Se référer à la page de couverture).

2) Installer les pieds. Insérer un pied (A) dans chaque rainure sous la cuve.

PRÉPARATION DU FILTRE

3) Enlever le bloc-moteur (B) de la cuve du filtre.

4) Retirer le cadre de l’épurateur-mousse (C) et les paniers de filtration (D) de la

cuve du filtre.

5 Rincer les deux côtés du cadre de l’épurateur-mousse (C) sous l’eau du robinet afin d’enlever tous les

contaminants possibles avant l’utilisation initiale.

6 Replacer le cadre de l’épurateur-mousse (C) dans la cuve du filtre. Se référer au dessin pour la mise

en place appropriée.

7) Déposer les masses dans les paniers de filtration appropriés. (Voir l’intérieur de la page de couverture pour

la disposition recommandée). Retirer les masses filtrantes des sacs de plastique avant de les disposer (laisser le

.

charbon dans les sacs poreux). NOTE : La disposition des masses, illustrée sur la page de couverture du livret

d’instructions, n’est qu’une recommandation. Pour une efficacité optimale des masses, lire la section sur les

masses filtrantes.

8 Rincer toutes les masses sous l’eau du robinet pour en éliminer la poussière ou les déchets avant

l’utilisation initiale.

9) Replacer les paniers de filtration (D) dans la cuve du filtre

et replacer le couvercle des paniers de filtration (F).

10 Retirer le joint d’étanchéité (G) de son sac de plastique.

Afin de s’assurer que le bloc-moteur s’ajuste correctement à la

cuve du filtre, ne pas oublier de mouiller le joint d’étanchéité

avant de le placer dans la rainure autour de la base du

boîtier (B).

11 Installer le couvercle de la couronne (X) sur le dessous du bloc-moteur (B) et au-dessus de la couronne.

Presser les butées (voir dessin) pour serrer en place avec un léger déclic.

NOTE : Ne pas remplir le récipient avec de l’eau avant d’avoir replacé le bloc-moteur sur la cuve du filtre.

Le bloc-moteur

comprend un

mécanisme

d’auto-amorçage

permettant de

siphonner l’eau dans

la cuve du filtre

(voir n° 30).

8

5

10

IMPORTANT : se référer à

la page de couverture pour la

désignation des pièces.

6

11

click!

click!

Page 13

12 Replacer le bloc-moteur (B) sur la cuve du filtre (U)

m

AQUASTOP

system

OUT

en les alignant et pousser vers le bas afin d’assurer un

ajustement serré et solide. S’assurer que le cordon

d’alimentation est bien aligné avec l’échancrure de la

cuve du filtre. Serrer ensuite en place les

manettes de blocage/déblocage instantanés

(H), une à la fois (12b). Si l’appareil ne se ferme

pas correctement, s’assurer que toutes les pièces à

l’intérieur ont été bien placées.

INSTALLATION DU FILTRE

LE FILTRE NE DOIT JAMAIS ÊTRE INSTALLÉ

AU-DESSUS DU NIVEAU D’EAU DE L’AQUARIUM.

13) Emplacement – Placer le filtre dans sa position finale avant d’y fixer les tuyaux. Pour un rendement

optimal, placer le filtre sous le bac. Étant donné que le filtre s’alimente par gravité, vous assurer qu’il est placé sous le

niveau de l’eau d’aquarium. Note : La distance entre le bas du filtre et le niveau maximal d’eau

dans l’aquarium ne doit pas

dépasser 1,40 m.

14 Insérer l’Aqua-Stop (I) dans le bloc-

moteur (B) et pousser le levier bleu vers

le bas pour serrer l’Aqua-Stop en place.

Ouvrir les valves en poussant le levier

gris vers le bas pour laisser l’eau couler

à l’intérieur et à l’extérieur de la cuve du

filtre. S’assurer que les valves sont

complètement ouvertes avant de faire

fonctionner l’unité.

15 Insérer l’épurateur d’entrée d’eau (J) au tube

d’entrée d’eau (K).

16 Fixer la pince de la ventouse (L) sur le tube d’entrée

d’eau (K) et accoler à l’intérieur de l’aquarium à

l’endroit désiré. Afin d’empêcher l’obstruction,

l’épurateur d’entrée d’eau (J) doit être placé au moins

3

/

au vers le bas, mais sans toucher le gravier. Si c’est

4

trop long, couper le tube d’entrée d’eau avec un

couteau tranchant.

17 Fixer une pince de

ventouse (L) à la sortie

d’eau (O).

18) Placer la sortie d’eau

(O) dans l’aquarium. Il est

recommandé de la placer à

la surface de l’eau ou

légèrement sous sa surface.

Vous pouvez faire tourner la

sortie d’eau horizontalement

pour vous assurer qu’elle

est dirigée là où le courant

est requis.

19 Insérer une extrémité du

tuyau strié (P) du côté de l’entrée de l’Aqua-Stop (I).

20 Pour fixer le tuyau, tourner l’écrou de blocage (Q) vers le haut jusqu’à ce qu’il

serre l’adapteur de caoutchouc permanent du tuyau. S’assurer que le tuyau est

solidement en place avant de passer à l’étape suivante.

21 Tirer le tuyau strié (P) jusqu’au cadre de l’aquarium (garder un peu de jeu) par

rapport à l’endroit où est placé le tube d’entrée d’eau (K) et couper à environ 13 cm

au-dessus du cadre avec un couteau tranchant.

IN

S

T

AQUASTOP

TA

R

syste

14a

19

OUT

FLUVAL

15

12a

20

14b

16

1

2

12b

14c

17

5"

21a

IMPORTANT : le tuyau strié (P) ne devrait pas être coupé en dedans de 4 cm du

lettrage Fluval. (Couper seulement dans la section striée).

22 Pousser l’adapteur de caoutchouc (R) sur l’extrémité coupée du tuyau strié (P) et

le fixer au tube d’entrée d’eau (K).

23 Fixer deux coudes pour tuyau (S) au tuyau strié (P) pour s’assurer qu’ils tiennent

bien au cadre de l’aquarium.

24 Fixer l’adapteur de caoutchouc permanent de la pièce restante du tuyau strié (P)

du côté de la sortie de l’Aqua-Stop (I).

25) Serrer à la main l’écrou de blocage (Q).

26) Tirer le tuyau strié (P) jusqu’au cadre de l’aquarium où la sortie d’eau (O) est

placée et couper à environ 13 cm au-dessus du cadre avec un couteau tranchant.

IMPORTANT : le tuyau strié (P) ne devrait pas être coupé en dedans de 4 cm du

lettrage Fluval. (Couper seulement dans la section striée).

27 Pousser l’adapteur de caoutchouc (R) sur l’extrémité coupée du tuyau strié (P) et

le fixer à la sortie d’eau (O).

28 Fixer deux coudes pour tuyau (S) au tuyau strié (P) pour s’assurer qu’ils tiennent

bien au cadre de l’aquarium.

29 Fixer les supports à ventouses (M) aux tuyaux striés (P) à l’extérieur de

l’aquarium pour que les tuyaux restent bien en place.

21b

4 cm

22a 22b

24

23 28

DÉMARRAGE DU FILTRE

NOTE : un seau ou un contenant vide devrait être à port ée

de la main au cas où des fuites d’eau sur viendraient tout en

travaillant avec le filtre.

30

Afin de démarrer le débit d’eau, s’assurer que la sortie d’eau

(O) est au-dessus de la surface de l’eau. S’assurer que les valves

sont ouvertes; le levier gris de l’Aqua-Stop devrait être à la

position « EN BAS ».

Pomper plusieurs fois vigoureusement avec la clé d’amorçage (T)

(exécuter un mouvement complet « EN HAUT » et « EN BAS »).

Continuer à pomper avec la clé d’amorçage jusqu’à ce qu’on

entende l’eau entrer dans la cuve du filtre, et la remplir. En

pompant avec la clé d’amorçage, l’eau entre dans la cuve du

filtre grâce au tube d’entrée. Au fur et à mesure que la cuve se

remplit d’eau, la pression force l’air, sous forme de

bulles, en dehors de la cuve par le tuyau de sortie d’eau.

Rabaisser la clé d’amorçage en position « EN BAS ».

Une fois le filtre rempli, le brancher au bloc

d’alimentation. Le débit d’eau devrait alors être

régulier à partir de la sortie d’eau. Si tel n’est pas le cas,

vérifier que les tuyaux n’ont ni entortillement ni boucle.

Continuer ensuite à pomper avec la clé d’amorçage

jusqu’à ce que le filtre démarre. Dès qu’il fonctionne

normalement, on peut utiliser le levier gris de l’AquaStop pour régler le débit d’eau, sans endommager le moteur.

MISE EN GARDE : Le levier gris de l’Aqua-Stop ne doit pas être fermé plus qu’à la moitié lorsque le filtre fonctionne.

Ne jamais brancher le filtre à la prise électrique avant que la cuve soit complètement

remplie. Cet appareil ne devrait jamais fonctionner à sec. Une mise en opération

prématurée pourrait endommager le moteur.

29

30b

30a

27b

27a

Page 14

NOTE : de l’air sera inévitablement comprimé dans l’appareil pendant le

remplissage de la cuve; de nouvelles masses laisseront également

échapper de l’air emprisonné dans la cuve du filtre ce qui entraînera du

bruit quand le filtre commencera à fonctionner. La configuration du filtre

permet l’expulsion avec le temps de toutes les poches d’air enfermées. Si

la cuve retient et rejette de l’air après un certain temps, examiner

soigneusement le système d’entrée et de sortie d’eau pour vous assurer

qu’il ne fuit pas. Aucune source d’air (comme des pierres à air ou autres

aérateurs) ne doit pénétrer dans l’entrée d’eau du filtre.

À propos des masses filtrantes

L’efficacité du filtre est directement reliée aux masses filtrantes

utilisées. Dans tout système à cuve il est primordial de suivre les

instructions à la lettre. Sinon, l’efficacité mécanique et biologique

peut être diminuée. Dans bien des cas, l’ordre des masses dans les

paniers déterminera le rôle qu’elles joueront. Par exemple, selon la