Page 1

THE

POWER

AMPLIFIER

INSTRUCTIONS

for OPERATION

and KIT ASSEMBLY

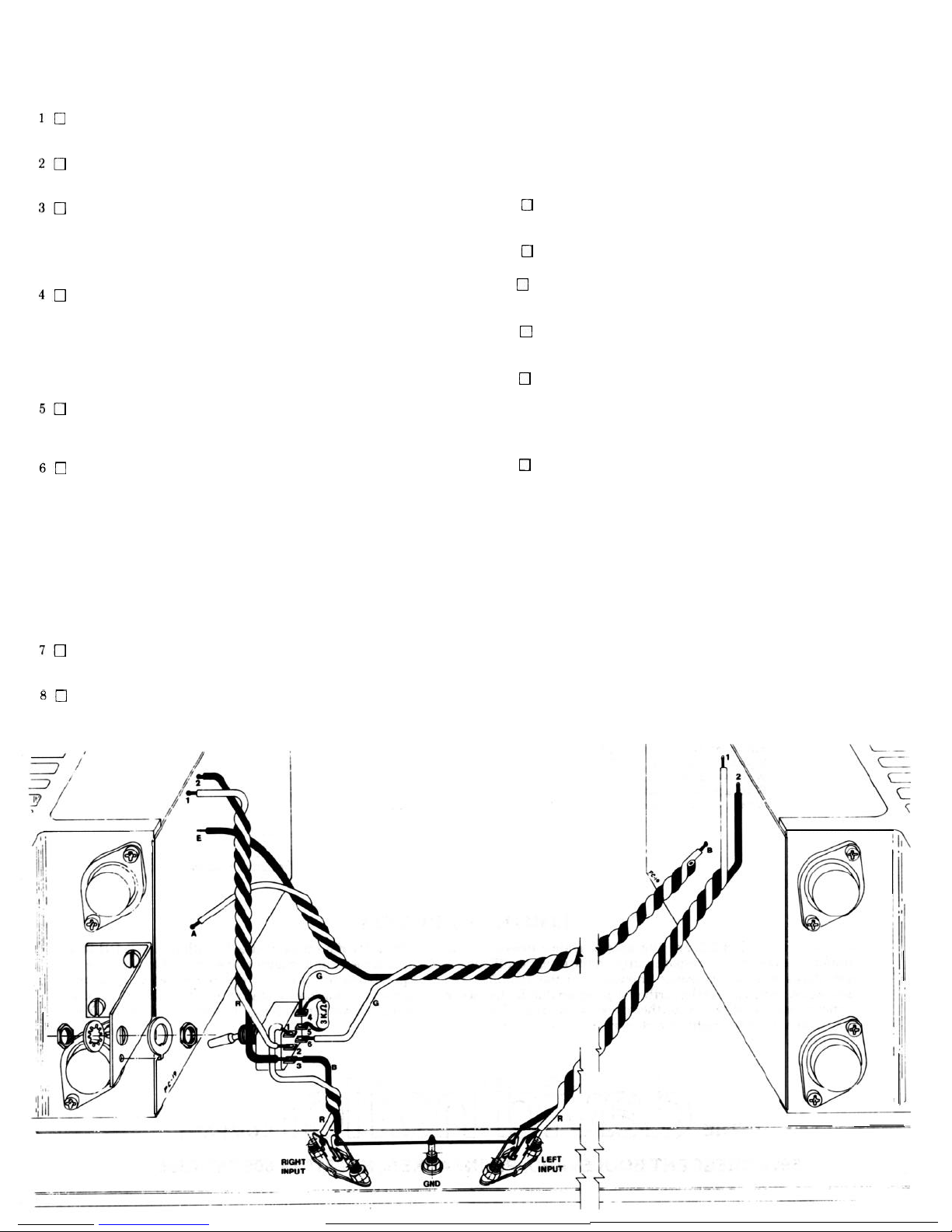

CAUTION:

IF THE SPEAKER FUSES BLOW,

SOME DISTORTED SOUND CAN BE

HEARD. THEREFORE

IF AMPLIFIER

MALFUNCTIONS, ALWAYS CHECK

FOR BLOWN FUSES FIRST.

serial

number in all

communications

THE DAVID HAFLER COMPANY

5910 Crescent Boulevard, Pennsauken, New Jersey 08109

Page 2

INTRODUCTION

The Hafler DH-220 is a two channel audio power amplifier

designed to the very highest performance standards. It is

available either as a kit, or fully assembled. Its 115 watt per

channel power rating is sufficient for driving all loudspeakers in

home applications, and its design assures extremely low distortion of all types. A combination of high performance, dependability, reliability, and moderate price is in the Hafler tradition of

using the very latest technology to provide outstanding value.

The DH-220 circuit is a refinement of the DH-200 design, a

Hafler landmark which has achieved worldwide recognition,

and has elicited glowing reviews since its 1979 introduction. As

in the DH-110 preamplifier, particular attention has been paid to

component quality, using polypropylene or film capacitors

wherever feasible, for example, for superior sound.

Combining the latest power MOSFET technology with uniquely simple and effective circuit topology reduces distortion of

all types, and at all power levels, over the full audio frequency

spectrum, to the vanishing point. In addition to its pace-setting

performance achievements, the conservative mode of operation accomplishes a new high in long term reliability and

exceptional resistance to abusive operating conditions. This is one of

the direct benefits of MOSFET utilization in overcoming a

serious limitation of conventional transistors

-

their tendency

to self-destruct under other than normal operating conditions.

So rugged is the DH-220 that it can deliver more than ten

amperes into a short circuit!

The speed

-

measured as the slew rate - of this design

delivers unmatched transient linearity, revealing the most

delicate shadings, textures and nuances of the music, surpassing

the capabilities of the most revealing loudspeakers and cartridges by a wide margin. Coupled with its unconditional stability, and ability to deliver adequate power into any loudspeaker

load, the result is absolute freedom from listening fatigue. The

longer you listen to this phenomenal amplifier, the more certain

you will be that you could not have made a better choice.

The oversized power transformer and bridge rectifier; the

massive heat sinks; the conservative operating levels of the

MOSFET output devices

-

all are evidence of the design efforts

to achieve exceptional reliability simultaneously with state of

the art sonics and specifications. And this circuit is convertible to

a high power monophonic amplifier with comparable stability

and specifications.

The fully complementary, symmetrical push-pull circuit,

which is direct coupled throughout (except at the input), incorporates all silicon devices in a format which is directly related to

the highly acclaimed DH-110 preamplifier. Its unique

selfprotecting output stage prevents the thermal runaway which is

a common threat to solid state amplifiers. The ruggedness and

conservative operation of the output stage allows the DH-220 to

avoid the need for special protective circuits which could compromise audio performance. Basic protective systems provide

maximum security against malfunction damage to the amplifier

or the speaker: the AC line fuse, B + fuses, thermal breakers,

and loudspeaker fuses. Nothing hinders the essential purity of

the audio signal.

Those who use these instructions to assemble the DH-220 kit

will find that the left and right audio modules (printed circuit and

heat sink assemblies) are preassembled and pretested. This

greatly simplifies the kit assembly so that it can be done in only a

few hours without special skills or know-how. Because of

the

modular arrangement, it is possible to operate on one channel if

the other requires service, and avoids the need to return the entire amplifier in cases where only one channel is at fault.

Accessories for special applications include provision for

monophonic use; a panel for standard 19” rack mounting; and

an alternative power transformer for international AC line

voltages.

Through advanced engineering geared to the audio perfectionist, and an efficient no-frills approach, Hafler is making high

technology high fidelity affordable.

CONTENTS

Operation........................

Page 3

Assembly Instructions

..................

4

Wiring the Kit

......................

6

If Problems Arise.

.....................

10

Service and Warranty

..................

11

AC Line Connections for Overseas Use.

...

12

Kit Parts List

.........................

13

Schematic Diagram

...................

14

Component Value Listing.

..............

15

Pictorial Diagram.

..................

Insert

Copyright 1984, All rights reserved.

Page 3

INSTALLATION

The

DH-220

is most likely to be installed out of sight in most

applications, since its power may be controlled by the AC

switching of most audio preamplifiers, like the Hafler DH-110. If

your control unit does not provide switching capacity sufficient

for the amplifier’s 7 amp needs (plus other equipment it is also

switching), you should use the amplifier’s own power switch. In

that case, turn on the preamplifier first; then turn the amplifier

on a few seconds

after

the preamp has been turned on, to avoid

any unnecessary turn-on transients from some preamplifiers.

Likewise, switch the power amplifier off first.

If the amplifier is to be installed close to a record player, you

should first check its position for freedom from hum pickup by

the cartridge from the field radiated by the power transformer

of the DH-220. Although the design of the transformer

minimizes such radiation, certain cartridges are more sensitive

than others, and require separation from the amplifier. Check at

a comparatively high volume setting, and while swinging the

tone arm throughout its arc. Often a few inches additional spacing will eliminate the problem.

Be sure to provide sufficient

ventilation

for the amplifier.

Unobstructed

air circulation

around the finned heat sinks and

above

the amplifier is important for long, trouble-free life. Never

put anything on top of the cover perforations. It is normal for the

top and the heat sinks to become warm in use.

It is expected that the amplifier will always be resting on its

feet, which should be on a hard enough surface that air flow

underneath is not obstructed. If it is mounted in a rack, or

through a panel, the feet may be removed so long as adequate

ventilation is provided through the bottom openings.

OPERATION

The red pilot lamp which is integral with the power switch

glows whenever the amplifier is turned on. A blown AC line fuse

is the most likely cause if it is not illuminated when the amplifier

is switched on.

The pilot lamp also provides a high temperature indication. In

the unlikely event that the amplifier ceases to function, and the

amp blinks on and off steadily, it indicates that one of the thermal breakers has shut down the amplifier because of excessive

temperature rise in a heat sink. When the heat has dissipated in

a few minutes, the amplifier should return to normal operation.

If the lamp again blinks, check for insufficient ventilation, or an

excessive input signal, or an input which may have dangerous

signal content (such as oscillation). Failing evidence of this, the

amplifier may have malfunctioned. Because of the very large

heat sinks, it is highly unlikely that any normal signal will cause

the amplifier to overheat.

Loudspeaker Fuse Selection

The DH-220 power amplifier is supplied with 2 amp fuses in

the speaker lines. Experience has shown that since an overload

must exist for a few seconds for a fuse to blow, a 2 amp fuse will

protect most speaker systems, and only blow when overload occurs. Smaller fuses tend to blow too easily, and larger fuses do

not adequately protect most speaker systems.

A pair of 5 amp fuses are also supplied as alternatives for the

speaker fuse holders. These should be substituted if the power

output of the amplifier is to be tested, and these or intermediate

values may be used if the amplifier is to be operated at very high

power levels into 4 ohm loads.

If the manufacturer of your speakers recommends a specific

value of fuse for their protection, we suggest that you obtain

AC

fuses of that value and install them in the back panel.

Loudspeaker Power Ratings

There are no U.S. standards for rating the power handling of

loudspeakers. As a result, the manufacturers’ usual “music

power”ratings, or suggested amplifier limits, are of only

minimal help in determining safe operating levels with

amplifiers which can deliver substantial amounts of power. You

must take into consideration the type of music, and the levels

you like, to provide long term trouble-free operation of your

speaker choice, when you have a sizeable amplifier like the

DH-220.

Connections

AC

The AC power cord should be plugged into 120 volts, 60 Hz,

on the switched outlet of a preamplifier which can provide at

least 7 amps, or 840 watts. Then the amplifier power switch may

be left on, and it will be controlled by the rest of the system. Or. it

may be plugged into a 120 volt wall outlet, and switched on and

off independently.

If your line (mains) voltage is different, be sure you have the

alternate power transformer which can accommodate several

line voltages, and be sure it is wired for your mains voltage as

described later in this manual

before you pIug in the amplifier.

Input

Conventional shielded cables, such as those supplied with

your preamplifier, provide the input signal to the sockets on the

back panel of the DH-220. Be sure that the outer shield connection is secure, to avoid hum. The length of these cables (so as to

permit remote location of the amplifier, if desired) is limited only

by the output impedance of the preamplifier. If it is 600 ohms or

less, as with the DH-101 and DH-110 Hafler preamps, for instance, cable lengths up to 50 feet are premissible without loss of

Page 4

performance. Special low capacitance cables enable even

greater distance between preamp and amplifier. It is desirable

to keep the left and right input cables close together throughout

their length to minimize the likelihood of hum pickup. Also, you

should avoid running them parallel to AC cords

-

these should

be crossed at right angles.

Output

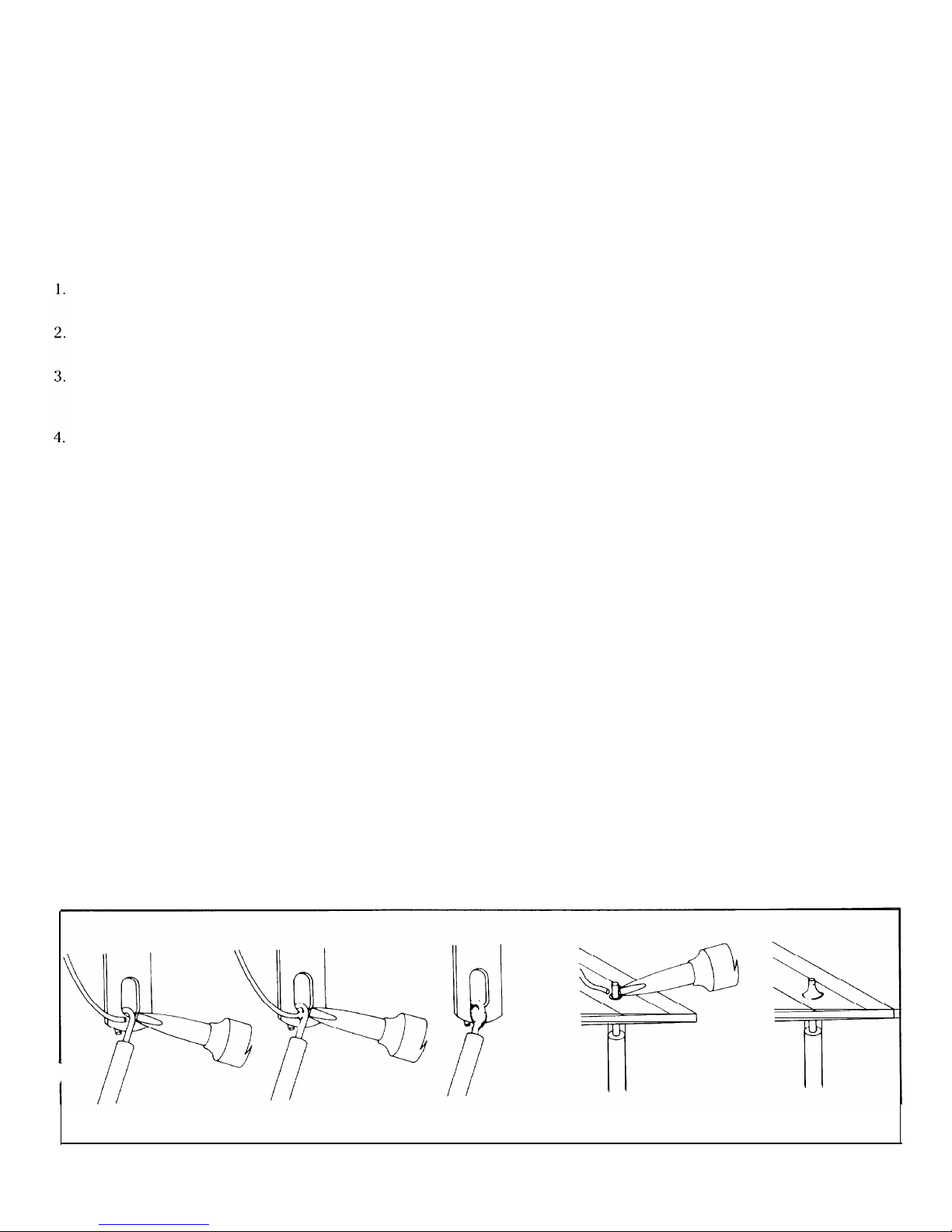

The loudspeakers (or headphones) connect to the red and

black terminals on the back panel. These binding posts provide

several convenient alternative connecting methods. The screw

cap may clamp the bared wire end, or a “spade lug” attached to

it, but a better connection will be made by locating the hole drilled through the shaft of the terminal when the cap is unscrewed.

Insert the twisted end of the bared wire so that the cap will

clamp it in place. Always be sure that no strands of wire are

unsecured, and that the bared end is not too long to risk contacting other elements. A soldered end or fitting is the safest solution.

These terminals also accept standard plug-in “banana pin con-

nectors,” including the double ones with standard

3/4”

spacing,

available from electronic supply houses. These are the most

convenient, especially if you may wish to interchange speakers

occasionally.

It is important to maintain correct phasing of the speakers

when making their connections. Some speaker terminals are

coded red and black, or + and

-,

etc. It is important that the

“sense” of one speaker’s connections match the others. If one is

reversed, you will find that the sonic image has a “hole in the

middle,” and that it is deficient in bass. Speaker wire always

identifies one conductor to make this easy. There may be a

molded ridge in one lead, or the color of the insulation on one

wire is different, or the wire itself may be color coded. If pin

plugs are used, be suretheyare color coded, or that you follow

the indexing mark ononeside of the double connectors.

Select speaker wire of sufficient size to preserve the high

damping factor (and excellent speaker control) of your

amplifier. Standard 18 gauge lamp cord (“zipcord”) is satisfactory for distances up to 30 feet for an

8

ohm speaker. As the

distance increases, larger wire sizes are recommended. The

next larger wire size is

#16,

and it is often preferred by perfectionists. If you have 4 ohm speakers, the maximum cable length

for best results is halved.

The black output terminals are electrically connected to the

chassis internally. Be certain that when the amplifier is operated

in its normal stereo mode that the red output terminals are never

connected together. In the special case when the amplifier has

been internally modified for monophonic bridged operation,

the output is taken from the two red terminals

only.

Then, the

black terminals are left unconnected.

Headphones are normally operated from the loudspeaker

outputs, but are usually connected through a junction box

which provides switching from phones to speakers. Such a box

usually provides some added resistance to reduce the sensitivity

of the phones, and thus minimize the likelihood of hearing component noise, because of the low setting required at the volume

control. Some headphone boxes utilize a “common ground”

system which makes it particularly important that you carefully

observe the proper connections. While the black ground terminals can be connected together, the red ones must not be.

Some headphones, such as electrostatic types, are less sensitive and may need little or no resistance in series for normal

operation. These could be easily interchanged with the

speakers through the use of double banana plugs.

KIT ASSEMBLY INSTRUCTIONS

There are three basic rules for success in electronic kit

building:

1. Read the instructions carefully, and follow them in order.

2. Make secure solder connections which are bright and

smooth.

3. Check your work carefully after each step.

The DH-220 amplifier is a versatile component with

sophisticated circuitry which has been made remarkably easy

to build by individuals with many years of experience in the

design and engineering of the finest performing audio kits, and

in the preparation of their manuals.

Kit building should be fun, and we are certain you will find this

to be so. Assembly will be faster, easier, and more enjoyable if

you have someone help you by reading the steps aloud, selecting the required parts, and preparing the necessary wire

lengths in advance as you proceed. Fatigue increases the risk of

error, so take a break rather than push to early completion.

There are relatively few separate components in this design, to

make it easy to pack everything away, if need be.

Your work area should have good lighting, the proper tools,

and a place where the large pictorial diagram can be positioned

within easy reach for checking. The tools should include:

1,

2.

3.

4.

5.

6.

7.

8.

9.

A 40 to 100 watt soldering iron with a

1/4"

or smaller tip which

reaches at least

600°F.

60/40 (60% tin) ROSIN CORE solder,

1/16"

diameter or

smaller. (Smaller diameters are easier to work with.)

A damp sponge or cloth to wipe the hot top of the iron.

A wire stripping tool for removing insulation. This can be a

single-edge razor blade, but inexpensive stripping tools are

safer, faster and easier.

A medium-blade screwdriver (about

1/4"

wide).

Needle-nose pliers (a long, narrow tip).

Diagonal or side-cutting small pliers.

Large “gas” or “slip-joint” pliers.

A

1/4" “Spin-tite”

nut driver may be helpful, but is not

necessary.

Page 5

A soldering “gun” is

not

recommended. The unfamiliar user is

more likely to damage the etched circuit boards with its higher

heat potential and unbalanced weight. Also, because he may

not wait long enough for it to reach operating temperature each

time it is switched on, poor solder connections are more likely.

Pencil irons are much lighter and easier to use, and there is no

waiting time when solder connections follow in sequence, as in

kit building. Make sure you have a holder for it, though, and

always unplug it when you take a break.

Proper Soldering

There are four steps to making a good solder connection:

Make a good mechanical connection to hold the wire in position while heat and solder is applied.

Heat

thejunction

of the wire and lug, or hole, with the bright,

shiny top of the iron.

After heating for a couple seconds, apply solder to the junc-

tion. It should melt immediately and flow smoothly around

both surfaces.

Allow the connection to cool undisturbed.

Remember that the connection is made by the solder, not by

mechanically attaching the wire to the terminal. Usually the

wire is looped through the lug and crimped in place, but some

prefer to just place it through the hole and rely on the stiffness of

the wire to hold it while soldering. Connections to numbered

holes on the circuit board are handled this way.

Good solder connections are

essential

for trouble-free

noise-

free operation. A good solder joint does not require much solder

around the conductors. Never “butter” partially melted solder

on the joint, as it is useless. A good connection looks smooth and

bright because the solder flows into every crevice when the

parts are hot enough. The iron must have a bright, shiny tip to

transfer heat easily to the junction. That’s why the damp sponge

should be used frequently to wipe the tip, and occasionally you

must add a small amount of solder to the tip, too. If a connection

is difficult to heat, “wet” the tip with a small blob of solder to provide a bigger contact surface to the joint. Once the solder flows

around the conductors, any movement must be avoided for a

few seconds to allow a good bond. When cool, check the connection by wiggling the wire. If in doubt, or if the connection is

not shiny, re-heat the joint. Excess solder may be removed from

a connection by heating it and allowing the solder to flow onto

the iron, which is then wiped on the sponge.

ALL SOLDER USED MUST BE ROSIN CORE.

Never use acid core solder or any separate flux in electronic

work. Silver solder is also not suitable. If in doubt about unmarked solder, always obtain a fresh supply of rosin core solder. We

recommend 60/40 for easiest use. Do not confuse it with 40/60,

which is harder to melt.

The general procedure is to use a hot iron for a short time to

heat a connection, then add solder with the iron still in contact.

Remove the solder once it flows, and then remove the iron. A

cooler iron applied for a longer time is more likely to damage

components, or lift the copper circuit pattern from the boards. A

break in the etched circuit can be mended by simply soldering a

small piece of wire across it. Do not allow much build-up of

solder on the tip of the iron, or it may fall into adjacent circuitry.

When soldering to a numbered hole on the board, insert the

wire from the components side, and apply the iron, leaving

some bare wire exposed so that you can see that the hole is then

filled with solder for a secure bond. A round wooden toothpick

is suggested so that you can heat and clear the hole of solder if it

hinders your inserting the wire. Some builders prefer to clear

every hole first with a touch of the iron and toothpick. If the wire

has first been “tinned,” no additional solder may be necessary if

solder fills the hole, but it is good practice to push the wire

through, and then back it up a bit, to be sure solder fills the hole

from both sides. Make certain a bright, shiny flow is evident

from the wire, across the hole, onto the circuit pattern on the

board.

“Tinning” refers to the process of applying a light coating of

solder to the bared wire end. This keeps all the strands secured,

and also makes a good connection easier. Simply touch the wire

with the iron for a couple of seconds, and apply solder. Allow the

excess to flow away onto the iron. When properly done, the

wire is uniformly bright, and no larger than before. The hookup

wire supplied with this kit does not normally need tinning, for it

is pre-tinned.

5

Page 6

Wiring the Kit

If any components are unfamiliar to you, checking the pictorial diagram should quickly identify them. Or, the quantities,

and the process of elimination as you check the parts list, will

help. The pictorial diagram is necessarily distorted to some extent for clarity, so that you can trace every wire in a single

overall view for verification as you work. You may wish to

check off on the diagram as you solder each location.

To “prepare” a wire means to cut the designated length from

the coil of that color, and strip about

1/4"

of insulation from each

end. The wire supplied in the kit is

#18,

so you can set adjustable

wire-strippers accordingly. The transformer leads are

#16

or

#18

and the line cord is

#16.

Be careful that you do not nick the

wire when you strip it (that can happen more easily if you do not

use wire strippers) for that weakens it. The wire supplied in this

kit is “bonded stranded,” which provides exceptional flexibility

with resistance to breakage for easier use, and it is pre-tinned.

Whenever a connection is to be soldered, the instructions will

so state, or indicate by the symbol (S). If more than one wire is to

be soldered to

the

same terminal,

they

will be indicated by (S-2),

(S3),

etc. If soldering is not called for, other connections have

yet to be made to that terminal. They would be more difficult if

the connection was already soldered. Every connection in the

kit will be soldered when it is complete. After soldering a connection, it is best to clip off any excess lead length to minimize

the possibility of a short circuit (as on switch lugs, where terminals are very close together), and for a neat appearance.

Be sure that uninsulated wires cannot touch adjacent ter-

minals or the chassis metalwork.

The symbol

(#)

indicates a connection is to be made to that

point. When a lug number is specified without (#) it is simply a

locating reference.

When the instructions call for twisting two or three wires

together, the length of wire indicated anticipates a fairly tight,

uniform twist by hand, of three full turns every two inches. If

you find the wires too short, loosening the twist will gain some

needed length.

Handle the circuit boards carefully. They represent a major

part of the kit cost. Stand-up components, such as transistors,

should be checked when you install the module, to be sure all

leads are separated.

All of the active circuitry is contained on the PC-19 board,

which has been carefully tested to assure that it meets every

specification. Only the interconnection of power supply

elements is left to the builder. Take the time to be accurate and

neat, and you can be sure that your completed amplifier will

meet the performance of a factory assembled unit, and can continue to perform properly for years to come. Check your work,

and make sure the entire step has been completed before placing a check mark in the space provided, and continuing on to

the next step.

KEP nuts have been supplied as a convenience. These have

lockwashers attached, and the lockwasher always goes onto the

screw first. If the sheet metal screws have hex heads, you may

find it easier to first start them with a regular screwdriver, to set

the thread, and then use the more convenient nut driver, if one

is available.

Mechanical Assembly

1 r When you unpack your kit, you will find that the

transformer, large capacitors, and the output assemblies

have been temporarily fastened to the chassis for safe

shipment. Disengage these, and include this hardware

with the rest when you check off the components

against the parts list in the back of the manual. We

recommend this check-off to be sure you have

everything, and to enable you to identify any unfamiliar

items by comparing them with the pictorial diagram. An

egg carton is ideal for keeping hardware items

separated.

A “set” of hardware includes one screw and one KEP nut (with

its attached lockwasher). Always install the lockwasher side of

the nut first. If the size of the hardware is not specified, use the

#6

size. The smallest size is

#4

and

#lO

the largest. Always insert

the screw from the outside of the chassis.

It will simplify matters if you first separate the

#4

nuts from the

#6

nuts, which have the same outside dimensions. A #4 screw

will pass through a

#6

nut, aiding identification.

2

L

Select the four rubber feet, four sets of #6 hardware, and

the chassis. Insert each screw through a foot so that the

head is recessed, and install the feet on the outside at

each corner hole.

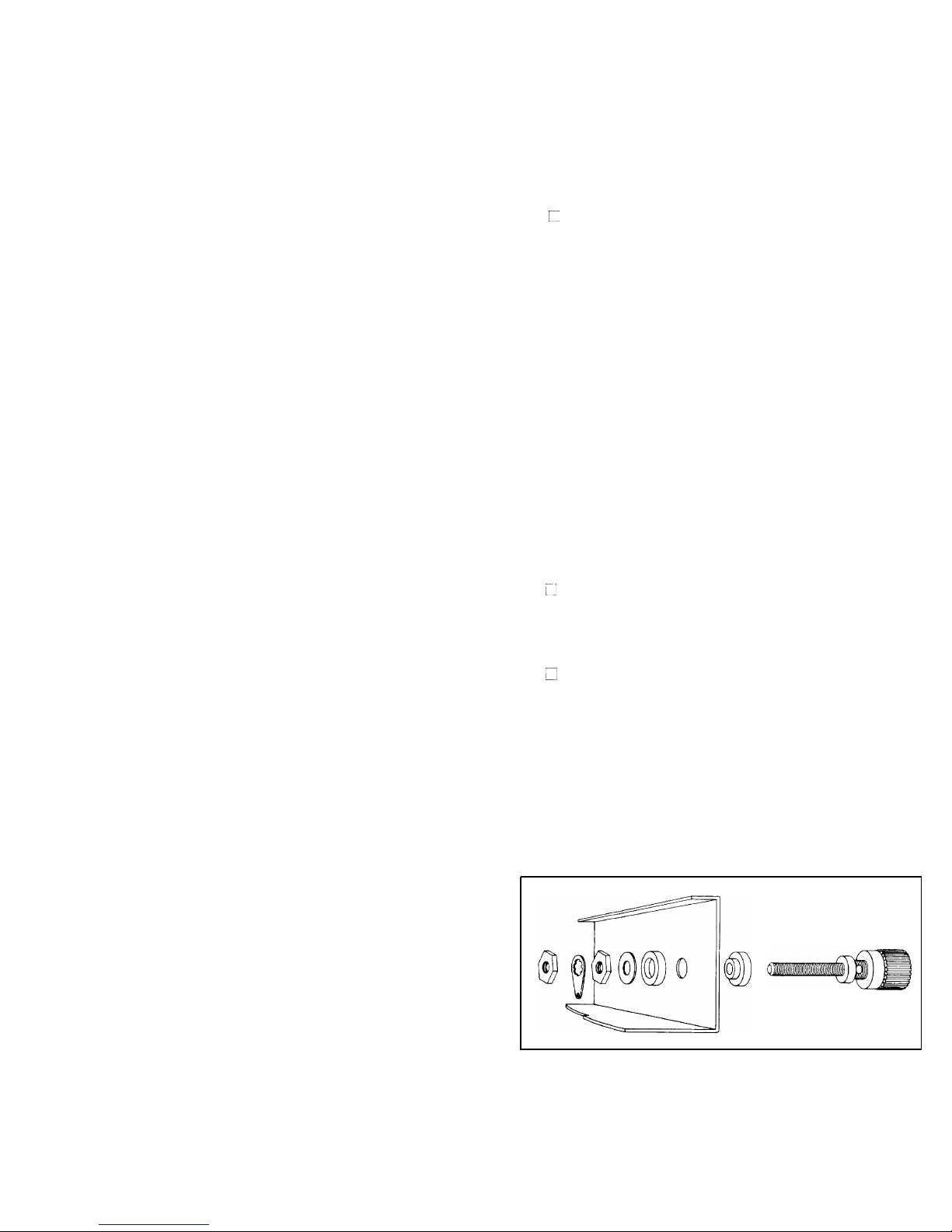

3

1

Select th

e wo red output terminals. Install them in the

t

sequence shown below, in the two center holes LR and

RR marked

'

+’

at the rear of the chassis. Before you fully

tighten the first nut, unscrew the cap to expose the hole

drilled through the threaded shaft. Connection of loudspeaker wires will be easier if these holes are positioned

vertically. A nail through the hole will keep it positioned

while the hardware is tightened. Each connecting lug

should point downward before the last nut is secured. Be

sure both nuts on each terminal are

tight,

as they are dif-

ficult to reach when the amplifier is completed.

4 Select the two black output terminals and install them or

either side of the red ones, at LB and RR. Be sure the

shaft holes are vertical, the lugs point downward. and

each nut is tight.

6

Page 7

5 n Select the two round fuse holders, and two each

1/2”

rubber washers, lockwashers and nuts. First install the rubber washer on the holder, so it will be outside the chassis,

and then fasten the fuse holders at LF and RF, with the

tip lugs pointing towards each other, toward the center

of the chassis.

6

U Select the two input sockets and 4 sets of #4 hardware.

Install the sockets

inside

the chassis at LS and RS so that

the short lug of each socket is near the hole between the

two sockets.

7

0

Select the single ground lug (with lockwasher teeth) and

one set of #4 hardware. Install it between the input

sockets, pointing toward the bottom. Bend it out for access, and twist it

90°

for easier insertion of a wire later.

Be sure this lug is

tight,

as the locking teeth must cut

through the chassis paint for a good ground connection.

8

ri

Select the four-lug diode block DB, the long #6 screw,

and a nut. Install the rectifier in the center hole near the

rear of the chassis, with the plus

(+)

terminal located

over the tiny indexing hole at position four. Correct

orientation of this rectifier is

essential

for proper wir-

ing.

9 n Select the single fuse clip, and one set of #4 hardware. In-

stall the clip in the right front chassis hole FC, closest to

the foot.

10

0

Select the two dual fuse clips and four sets of #4 hard-

ware. Install these in the pairs of holes FL and FR on

either side of the center of the chassis.

11 0

Select the

5-lug

terminal strip and two sets of #4 hardware. Install it in the front holes TS, next to the single

fuse clip. Note the position of the mounting lugs (to the

right) in the pictorial diagram.

NOTE: Kits provided with the multiple voltage power transformer

for use in locations outside the United States having a line (mains)

voltage other than 120 VAC are also supplied with an additional twolug terminal strip which is to be installed using an additional set of

#4

hardware on the other side of the chassis, below the dual fuse clip FL.

12 0 Select the power switch. Install it with the red window to

your right as viewed from the front. The switch snaps

into chassis hole PS from the outside.

13

q

Select the AC line cord and the plastic strain relief.

Separate the two conductors for 2”. Cut 1” off one of the

two leads, and strip

1/4"

of insulation from each lead.

Twist the strands tightly, and tin each end. Make a sharp

'V'

in the cord

8 1/2"

from the longest cut end by bending it

back on itself. Install the relief with the small end nearest

the cut end of the cord. Crimp the two halves of the relief

around the wire at the

'V'

with heavy pliers, to partially

form it before insertion into back panel hole AC. Then

grip the larger diameter with the plier tips, squeeze it

tightly, and insert the cord and the relief from the outside. A flat side of the relief mates with the hole shape,

and it snaps into position when fully inserted.

14

15

16

170

18

0

Connect the shorter lead to FC lug

#l.

(S). Connect the

longer lead to the

lower

hole of TS lug

#2.

(S). Note that

lug 2 is the second protruding lug on the terminal strip. It

is

not

the mounting bracket for the terminal strip.

Soldering this lead to the lower hole now will make later

connections to the top portion of the lug easier. Be sure

no stray strands of either line cord conductor are left

unsoldered.

Prepare a

6 1/2"

green wire. Connect one end to dual fuse

clip FL lug

#l.

Connect the other end to the other dual

clip FR lug

#l.

(S).

Prepare a

6 1/2"

white wire, Connect one end to FR lug

#3.

Connect the other end to FL lug

#3.

(S).

Prepare two 7” white wires. Start with one wire projecting

3/4"

beyond the other, and twist them uniformly

together throughout their length. Connect the project-

ing end to RF lug

#l.

(S). Connect the corresponding end

of the other wire to

RFlug #2.

(S). Place this pair over the

right edge of the chassis.

Prepare two more 7” white wires. Start as before with

one wire

3/4"

longer, and twist them together. Connect

the longer end to LF lug #2 (S). Connect the other wire to

LF lug

#l.

(S). Place these wires off to the left.

Prepare an 8” green wire and a 10” white wire. Start

with the white wire

3/4”

longer than the green wire, and

twist them uniformly together. Connect one end of the

green wire to the lug on black output terminal LB. Connect the corresponding end of the white wire to red

terminal LR. (S). Place these wires off to the left.

Page 8

19 c3 Prepare a 7” green wire. Connect one end to terminal

LB. (S-2). Place this wire towards the center of the

chassis.

20 Ll Prepare a 10” white wire and a

10”

green wire. Starting

with the white wire

3/4"

longer, twist them together. Connect the projecting white wire to red terminal RR. (S).

Connect the green wire to terminal RB. Place these

wires off to the right.

2 1

C

Prepare a 5 1/2" green wire. Connect one end to terminal

RB. (S-2). Place this wire towards the center of the

chassis.

22 0 Prepare a 16” green wire, but strip

1 1/4"

of insulation

from one end. Prepare a 15” white wire. Start with the

normally stripped

(l/4”)

ends even, and twist these wires

uniformly together. Thread the longer bared end of the

green wire through LS short lug

#2

from the top left,

then through GLlug

#3,

and connect it to RSshort lug

#4.

Solder only LS lug

#2.

Connect the corresponding end of

the white wire to LS lug

#l.

(S). Place this wire up under

the chassis rear lip, above the output terminals, and off

to the left.

23

L!

Prepare a

6 1/2"

green wire. Connect one end to CL lug

#3.

(S2). Place this wire over the rear of the chassis.

24

C

Prepare a 10” green wire and a 10” white wire. Twist

these together with the ends even. Connect the green

wire from the right to RS short lug

#4.

(S-2). Connect the

white wire to RS lug

#5.

(S). Place these wires off to the

right.

25 0 Prepare two 22” white wires, and twist them together

throughout their length. 8” in from one end of the pair,

cut

one

of the wires, and unwind it about 1 1/2" in each

direction from the cut. Strip

1/4"

of insulation from each

of these cut ends. Place the longer portion of the wire

along the lower front edge of the chassis, with the break

at the terminal strip TS. Connect the cut end from the left

to TS lug

#2.

Connect the other end to the

lower

hole of

TS lug

#5.

(S). Place this pair along the front edge of the

chassis, under the power switch, with the ends projecting from the front corners of the chassis.

26

il

Select a 1 megohm resistor (brown-black-green) and

trim the leads to

1/2”.

Connect one lead to TS lug

#2.

(S3).

One of these 3 leads has already been soldered to the

lower lug hole. Connect the other lead to TS lug

#3.

27 n Select the diode and trim its leads to

1/2”.

Note that one

end of the diode is marked with a stripe (or an arrow

head will point to that end). Connect the marked end to

TS lug

#4.

Connect the other lead to TS lug

#3.

(S2).

28

0

Prepare a 4” green wire. Connect one end to TS lug

#4.

Select a spade connecting lug, and solder it to the other

end. Place this wire down against the chassis, and connect it to the PS lug on the right, near the edge of the

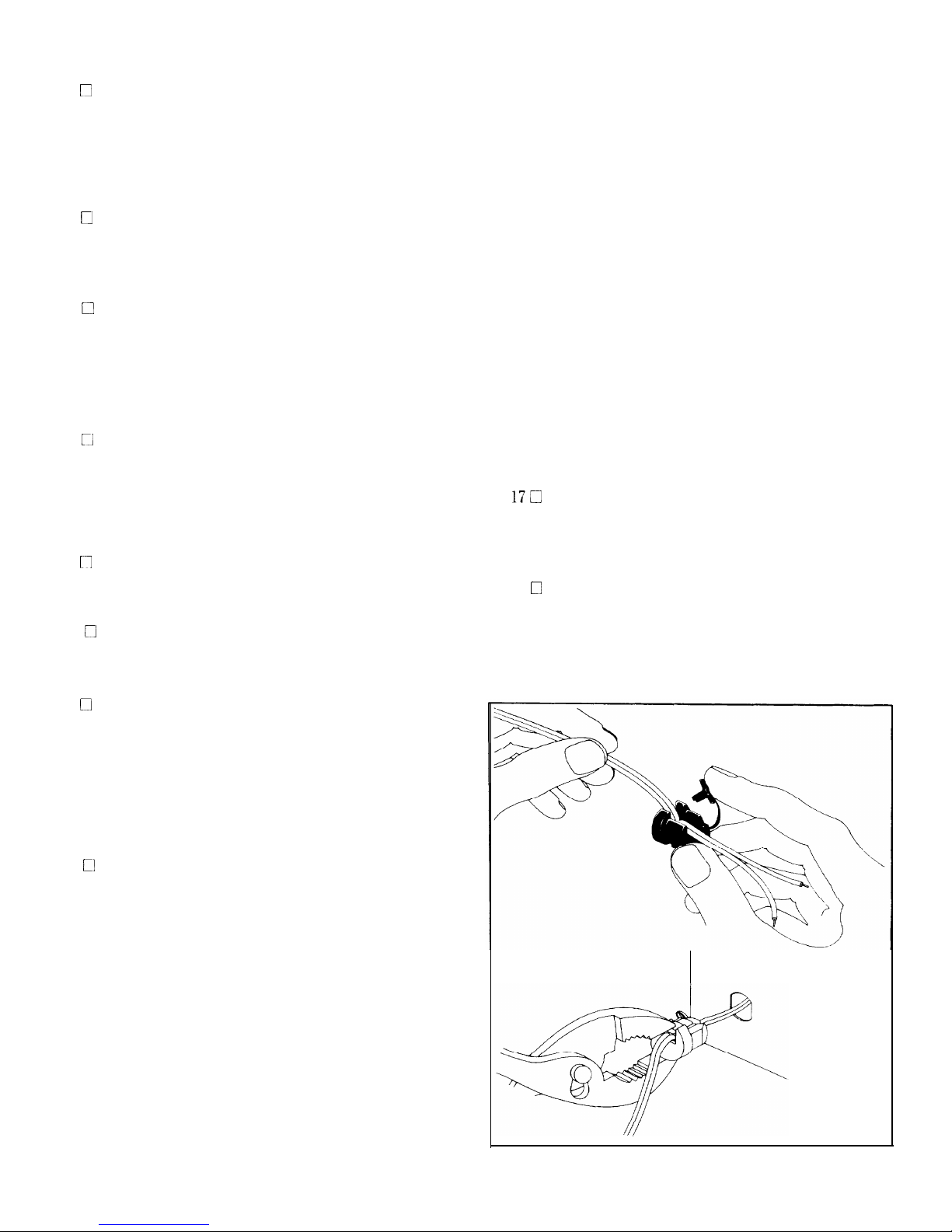

chassis.

The proper way to attach a spade lug to a wire is to first

cut the bared wire end to the right length (no more than

1/4"

so that the insulation will be securely gripped by the

longer, outer tabs, while the wire does not protrude into

the spade clamp area. Tin the bare wire end. Bend the

shorter, middle set of tabs tightly around the bare wire,

and then bend the longer tabs around the insulation.

Then flow solder into the joint around the bare wire,

keeping the solder away from the spade section.

29

Prepare a 2” white wire. Connect one end to FC lug

#2.

(S). Select another spade lug, and solder it to the other

end. Connect it to the PS middle lug.

30

0

Select the 0.39 mfd

(.39K)

capacitor and trim its leads to

1/2"

Connect one lead to TS lug

#4.

(S3). Connect the

other lead to TS lug

#5.

31 0 Select the two large round capacitor brackets, the two

large capacitors, and 6 sets of #6 hardware. Place a

bracket around the bottom of each capacitor, and fasten

it snugly with one set of hardware through the clamp.

Note the direction of insertion of the screw for easy servicing access in the future. The clamps need not be

tightened now

-

just made snug. Place each assembly

on the chassis, at CL and CR, noting the position of the

clamp, and fasten them securely. Be sure no wires are

trapped by the bracket. Then loosen the clamps, and

position the capacitors so that each + terminal is positioned as in the pictorial diagram. The + terminal will

usually be so marked, but if not, it may be identified by a

red dot. Note that the + terminal of CL is nearest the

terminal of CR. Make sure the capacitors are seated

against the chassis and tighten both clamps.

32

0

Select the 4 plain solder lugs and then 4 short

#lO

SEMS

screws (with lockwasher attached). Install these in the

capacitors, with the lugs pointing as in the diagram.

33

C

Prepare a 6” green wire. Connect one end to DB lug

#l.

(S). Connect the other end to CL lug

#l.

34 E Prepare a 4%” green wire. Connect one end to FL lug

#l .

(S-2). Connect the other end to CL lug

#l.

(S2).

35

G Prepare a 6” white wire. Connect one end to DB lug

#4.

(S). Be sure this is the + terminal of the rectifier. Connect

the other end to CR lug

#2.

36 q Prepare a

4 3/4"

white wire. Connect one end to

FRlug #3.

(S-2). Connect the other end to CR lug

#2.

(S2).

37 •1 Remove all insulation from a 3” white wire. Connect one

end to CL lug

#2.

(S). Connect the other end to CR lug

#l.

(S).

38 [7 Select the power transformer, the 4 flat washers, and the

4 sets of

#10

hardware. Position the transformer with

the red leads to the center rear of the chassis, and the

black and black/white leads towards the power switch.

If the transformer is the special multiple voltage version,

the additional leads should be placed as shown elsewhere in this manual for the desired line (mains) voltage.

The red/yellow lead will likely be the correct length. If

you wish to shorten the red leads for neatness in connecting them to the rectifier terminals, it is easier to strip

them before the transformer is mounted.

8

Place the white pair of wires under the front chassis lip.

Install a flat washer on top of each transformer foot after

the screw is inserted from below, and then add the nut.

Be sure no wires are trapped.

Page 9

The transformer leads may be trimmed as desired for a neat job,

but be sure you do not cut any of them too short (particularly if

yours is the multi-voltage version, and any change to a different

supply voltage is likely). Cutting the leads too short for re-use

may void its warranty, if it is thought to be defective. Consult the

multi-voltage diagrams elsewhere in this manual fcr connections to the terminal strips which may differ from the

stepby-

step instructions here.

Be sure all strands of each transformer lead are tinned and

soldered together before connection to a lug, so that there is no

possibility of a stray strand touching anything but the lug.

39

0

40

u

41

42

G

43

ci

44

0

45

17

46

0

47

q

48

0

Select the remaining spade lug, and solder it to the black

transformer lead. Connect it to the PS left lug.

Select the

.005

(502M) disc capacitor, and trim its leads to

l/2”

or less. Wrap one lead around the shaft of the spade

lug which is connected to the PS left (inside) lug. Wrap

the other lead around the shaft of the spade lug connected to the middle lug. Solder both leads. Be sure

there is adequate clearance between these connections,

and that the spade lugs are fully engaged.

Connect the black/white transformer lead to TS lug

#5.

(S3). One of these wires was previously soldered to the

lower hole of this lug.

Twist together the two red transformer leads for

neatness, and connect one iead to DB lug

#2.

Connect

the other to DB lug

#3.

Select the

.Ol

mfd (103M) disc capacitor, and trim its

leads to

3/4"

Strip two

1/2”

pieces of insulation from the

green wire, and slide one piece over each of the

capacitor leads. Connect one lead to DB lug

#2. (S-2)

Connect the other lead to DB lug

#3. (S-2)

Make sure

both leads are securely soldered to each lug. Here you

could overlook a poor connection.

Connect the red/yellow transformer lead to the center

of the bare wire between the capacitor lugs. (S). Lowest

hum in the unit will be attained when all of the wires

which connect here are as close to the center of this wire

as possible.

Connect the

single

green wire from output terminal LB

to the center of the bare wire next to the transformer

lead. (S).

Connect the

single

green wire from RB to the center of

the bare wire on the other side of the transformer lead.

(S).

Connect the green wire from CL lug #3 between the two

input sockets to the center of the bare wire also. (S).

Select the output assembly modules (the two major

items in the kit). You will note that the only difference,

which identifies the left or the right module, is the position of the thermal breaker, which is located between

one pair of output transistors on the heat sink rib. Before

connecting wires to these modules it is best that you take

the time to inspect the underside of the bottom row of

holes to make certain that connections already made to

some of these are well soldered. You will be making con-

nections from the top side to holes

3,5,6,7,8

and 10.

Make sure the proper connection point is clear at each of

these. If it is filled with solder, running the iron along the

underside will uncover the hole, and it may be cleared

with a wooden toothpick.

Now position the right module (with the breaker at the

front when the long bottom row of eyelets is next to the

chassis) with the circuit board

up,

against the side of the

chassis.

Wires will be connected to the holes from the top of the board,

and you must be sure they are soldered securely to the bright

circuit ‘pads’. Each hole is ‘plated through’ - it makes a connection to the other side of the board - and a good solder connection which heats the wire and the circuit pad properly will allow

solder to flow through the hole for a secure connection.

Even though the connecting wires are just long enough to make

the connections now, they will be rather long when the

amplifier is completed. That is why working room is limited.

Any wire which is to be connected to a hole on the board should

have a tight, tinned end. The wire supplied in the kit is already

tinned, so it would not normally require additional tinning

unless the tip is frayed. Melt a small amount of solder on the tip

of the iron so that it will make a good contact with both the

bared wire end, and the circuit pad as the wire is inserted into

the hole. Then add additional solder so that there is a smooth,

bright transition from the wire to the board as it cools undisturbed. If you must use a great deal of heat on a connection, make

sure that you have not loosened any adjacent connections in the

process

-

especially wires from the back side of the board.

The holes

#lo

and #3 are very close to capacitors on the board.

Be sure heat does not damage these capacitors.

49

II

Prepare a 5 1/2" green wire. Connect one end to hole

#lO

on the circuit board. (S). Make sure it

cannot

contact the

transistor mounting screw near the underside. Connect

the other end to FR lug

#2

(S).

50

0

Prepare a 6” white wire. Connect one end to hole

#3.

(S).

Connect the other end to FR lug

#4.

(s).

51

C

Select the green and white twisted pair from the output

terminals RR and RB. Connect the white wire to hole

#5.

(S). Connect the green wire to hole #7 (S).

52

q

Select the pair of white wires from RF. Connect the

shorter wire to hole

#6.

(S). Connect the other wire to

hole #8 (S).

53 Select 4 of the long sheet metal screws. Take care to see

that no wires are trapped in the process, while you tilt up

the module and fasten it to the end of the chassis. The

screws are inserted between the heat sink fins, and then

engage the

chassis.

54 0 Select the green and white pair of wires from input

socket RS. Connect the white wire from the left to the

top (rear) hole

#l.

(S). Connect the green wire to hole

#2.

(S). These wires should be soldered to the circuitry on the

underside of the board, although they are connected

from the top side of the board, assuring a good connec-

tion. These wires will be specifically positioned later,

9

though they now seem long.

Page 10

55

I

56

[

57

:

58

:

59

I

60

:

61

1

62

!

63

I

64

:

Select the white pair of wires at the front of the chassis.

Tuck the excess-wire into the corner and connect one

wire to each of the lugs on the thermal breaker. Solder

each.

Select the left output module, check it as before to see

that underside connections near the holes are secure,

and that the holes are visible. Place it against the left side

of the chassis with the breaker at the front, board up.

Prepare a 6” green wire. Connect one end to hole

#lo.

(S). Be sure it cannot touch the transistor mounting

screw! Connect the other end to FL lug

#2.

(S).

Select the green and white pair from output terminals

LB and LR. Connect the green wire to hole

#7.

(S). Con-

nect the white wire to hole

#5.

(S).

Select the white pair from LF. Connect the shorter wire

to hole

#8

(S). connect the other wire to hole #6 (S).

Prepare a

5 1/2

white wire. Connect one end to hole

3.

(S). Connect the other end to FL lug

#4.

(S).

Select 4 sheet metal screws and fasten the module to the

chassis, making sure no wires are trapped.

Select the green and white pair from input socket LS.

Connect the green wire to the top rear hole

#2.

(S). Con-

nect the white wire to hole

#l.

(S). Solder these on the

back of the board.

!

Tuck the excess of the remaining white pair of wires into

the front corner, and connect one wire to each lug of the

thermal breaker. Solder each.

:

Select the 7 ampere

slo-bid

fuse (a slo-bid fuse has distinctive internal construction) and install it in the single fuse

clip FC.

65 C Select four 5 amp regular fuses, and install them in the

dual fuse clips FL and FR.

66

0

Select the two 2 amp fuses, and install them in the twist

type fuse holders on the back panel. These fuses will provide reasonable protection for most speakers. See the

Operation section of this manual for more detailed information. The remaining 5 amp fuses are alternates for

the back panel holders for high power test purposes.

67

0

For lowest distortion performance and lowest noise, cor-

rect placement of some wires is important. The wires

from the output terminals and the back panel fuse

holders should be kept against the chassis. The input

socket pairs should be about an inch above the chassis,

(the left pair can be tucked under the rear chassis lip),

and should turn upwards at the bottom center of the circuit board, about

1/2"

to 1” off the board, in the plane

defined by the edges of the finned heat sinks. The wires

to the dual fuse clips should be kept away from the board

and against the chassis, bringing the excess length forward of the fuses. The leads to the power supply

capacitors should be kept away from the boards. The

green ground leads from the black output terminals and

the ground lug should be brought together through most

of their length.

68 Check all your soldered connections

-

especially those

on the fuse clip lugs, which are sometines difficult to

solder to. Clip off any excess bare wire which could short

to adjacent lugs or the chassis. Pay particular attention

to the stranded wires from the transformer and line

cord, and check the power switch connections. Now

turn the amplifier upside down and shake out any bits of

wire or solder.

69 q Slide the cover in place, and install it with the eight sheet

metal screws.

70

0

Remove the backing from the serial number label, and

apply it to the bottom at the center rear. (This may have

already been done at the factory.)

IF PROBLEMS ARISE

Each circuit module, which comprises all the “active”

amplifier circuitry, has been incircuit tested to standards identical to factory built amplifiers, prior to being packed in a kit.

Thus, with careful assembly, the likelihood of a circuit fault is

near zero. If you are certain the problem lies in the power

amplifier, check the pilot lamp. If it is blinking, excessive

temperature has shut down the amplifier. After a few minutes to

cool, it will turn on automatically. If it soon shuts down again,

and the amplifier has sufficient ventilation, the malfunction

is

either internal, or the result of an excessive (and very likely

inaudible) input signal. In that case, the source must be

investigated.

If

the pilot lamp is not lighted, the main fuse in the single fuse

clip near the power switch is probably open.

If

a replacement 7

ampere Slo-Blo fuse (do not use a larger value) also blows, the

amplifier has a power supply problem, and requires profes-

sional service.

If

there is a problem in only one channel of the amplifier, that

channel may be isolated by removing the power supply fuses in

the adjacent dual fuse clip, and the other channel may be used

monophonically. We do not encourage local service of this

amplifier because some components may not be available locally, and substitutions are not recommended at all. You may

return a defective module for factory service. This reduces shipping weight and the likelihood of damage. To remove the

module (leave the heat sink attached to the circuit board) tag

each wire with the circuit board hole number as you unsolder it

from the board, and

insulate

each bare wire end. It is safer to

also remove the power supply fuses from that channel. The

wires to the thermal breaker must be temporarily

soldered

together,

and insulated.

Adjustments for Bias and DC Offset

These two potentiometers on each circuit board have been

set at the factory and should not normally require adjustment

for the life of the amplifier. In the event of repairs such as transistor replacement, the following is the procedure, after removing all input and output connections to the amplifier.

10

Page 11

Bias

Remove

the B +

fuse F2. This

fuse

is in the line from the ’ +’

capacitor

terminal to hole#3 on the board. Connect

an

ammeter’s

' +

'

!ead to the fuse clip nearest the large filter

capacitors. Connect the’

-’

lead to the other side of the fuse clip.

Avoid intermittent connections, and do not short the leads

together. Turn the amplifier on, and if possible adjust the line

voltage to 120 volts. Adjust P2, near the middle of the board, to

275

mA.

Turn the amplifier off, and when the current drops to

zero, then remove the ammeter and replace the fuse.

Offset

A DC voltmeter capable of resolving 10 mV variations is

needed. Connect it to the output terminals of the selected channel, and adjust

Pl,

near the top of the board, to zero volts, + 10

mV.

A small correction of the control will produce a large initial

change, which will settle

down

in a second. Repeat these small

changes to achieve zero volts.

SERVICE POLICY AND LIMITED WARRANTY

The DH-220 Power Amplifier has been carefully engineered

to provide many years of use without requiring any maintenance or servicing.

Factory assembled units are subjected to several physical and

electrical tests before shipment. The output circuit board

assemblies of kit units are similarly tested prior to shipment.

In

spite of all this testing,shipping damage does occur, kits are not

assembled properly or someone “goofs” and service and/or

maintenance will be required. The David Hafler Co. provides

complete service facilities at the factory to make any

necessary

repairs.

It is the owner’s responsibility

to return or ship the unit freight

prepaid to the factory service department. Units shipped freight

collect will not be accepted. For units to be repaired under

war-

ranty a copy of the dated bill of sale must accompany the unit.

Shipment should be via UNITED PARCEL SERVICE. Parcel

Post is not a safe way to ship electronic equipment. The factory

will not be responsible for damage caused by parcel post shipment and repairs will be made at the owner’s expense. When

shipping your DH-220 be sure to insure it for the full value of an

assembled amplifier.

Use the original carton and packing material to ship your

amplifier. Enclose with the unit the following information:

1.

2.

3.

4.

5.

Complete shipping address (Post Office Box numbers are

often

not

acceptable.)

The serial number.

Copy of dated bill of sale if repairs are to be made under war-

ranty.

Description of the malfunction. If intermittent, please note.

We also suggest further identifying the unit as yours by put-

ting a label on the bottom or tieing a label with your name

and address on the line cord.

All service work is guaranteed for 90 days.

Warranties apply to the original purchaser only. Warranties

are void if: a) the amplifier has been either physically or electrically abused or used for some purpose for which it was not

designed, or b) the amplifier has been modified without factory

authorization.

The transformer warranty is void if the leads have been cut

too short for reuse. If you think a transformer is defective the

leads must be unsoldered, not cut, for its return.

Technical assistance to help you locate the source of a problem may be obtained by calling the Technical Services Department at 609-662-6084, 8 a.m.-4:30 p.m. E.T. It is helpful to

know the serial number of the unit and the results of any tests

you have performed.

SERVICING AN AMPLIFIER MODULE

If you are certain that the problem is confined to one of the

amplifier modules (comprising the circuit board, heat sink, and

output transistors), you may remove and return only the

module for service. Be sure that the components on the circuit

board are well protected

-

as by a surrounding sleeve of corrugated cardboard which rests against the heat sink, and projects beyond the components. Properly packed and insured for

$150, this assembly can be sent by parcel post, as well as UPS, if

necessary. A service fee of $20 must be sent with every module,

since the fault may have been caused by a wiring error

elsewhere. For this reason, too, and because we have no control

over its proper reinstallation, the service warranty on a separate

module is limited to assurance of its proper functioning when it

leaves the service facility. All modules are tested before being

returned to you. If you believe the fault is the factory’s warranty

responsibility, include the serial number and the

bill of sale.

If in

our judgement the fault is entirely a manufacturing defect, a

portion of the service fee will be refunded. Only a complete

amplifier can be fully checked and given a service warranty.

WARRANTY FOR KIT-BUILT UNITS

The parts in a DH-220 kit are warranted for a full year from

the purchase date. If a defective component is found on a circuit

board or in a kit, simply return the

individual

part to the factory

prepaid together with the serial number and the date of purchase, and it will be replaced at no charge.

If you cannot locate what is wrong with your DH-220, return it

to the factory with a copy of the dated bill of sale, and a check for

$40. If the sole cause of the problem is a defective part, the unit

will be repaired and returned to you transportation prepaid, and

your $40

less a charge for repackaging and shipping

will be

returned to you. If the problem is found to be an error in your

assembly of the amplifier, the amplifier will be put in proper

working order, tested to be sure it is meeting specifications, and

returned to you (freight prepaid within the continental U.S.). Excess shipping charges for expedited service, or overseas

delivery are your responsibility. At the sole discretion of the factory service department, if the time required for diagnosis,

repair and testing, and the nature of the malfunction warrants it,

a portion of the submitted repair fee may be rebated.

This warranty is void if the kit has not been completely

assembled or if other than rosin core solder has been used. Units

assembled with acid core solder or paste flux will be returned

unserviced.

WARRANTY FOR FACTORY ASSEMBLED UNITS

The DH-220 is warranted for three years from the purchase

date including parts and labor and normal shipping costs from

the factory to the owner within the continental U.S. The owner

is responsible for returning the unit to the factory and must submit a copy of the dated bill of sale.

This warranty gives you specific legal rights. You

have other rights which vary from state to state.

may also

11

Page 12

The power transformer supplied in

DH-220

amplifiers sold in

the

lJSA

is intended for 120 volt, 60 Hz operation only. For use

in other countries, a multi-voltage transformer is available at

higher cost. It has dual tapped primary windings which can be

arranged in various series-parallel combinations for 100,

110,

120,

200,

220 and 240 volt 50 or 60 cycle AC mains. The

schematic diagram details the wiring combinations which are

represented

pictorially here.

Note that a separate 2-lug terminal strip is required when the

multi-voltage

transformer is used. This is supplied in kits which

include the special transformer. If the amplifier is operated with

200

to 240 volt tines, the 7 amp line fuse which is supplied should

be replaced with a 4 amp

Slo-Blo

type fuse.

n

VOLTAGE CHART

measured

with 120 volt line, no signal. with respect to the ground buss between the two capacitors in the power supply.

E

B

c

E

B

c

s

G

D

Ql

62.6

62.1)

0.88

Q8

63.0 62.0

1.54 Q401

0

1.0

65.4

Q2

-62.6 -62.0 -0.37

Q9

-1.27 -0.6

1.54

Q402

0 1.0

65.4

Q3

-0.32

0.22

61.8

QlO

-63.0 -62.0

0

Q403

0

-0.8 -65.4

Q4

-0.32

0.22 61.8

Q11

-63.0 -62.0 -1.35 Q404

0

-0.8 -65.4

Q5

0.8 0.22

-62.0

Ql2

1.0

1.54

65.0

Q6

0.8 0.22

-62.0

Q13

-0.8 -1.35 -65.0

Q7

63.0

62.0 0

12

Page 13

KIT

PARTS

LIST

Minor variations may sometimes be encountered in value

or appearance. These will not affect performance.

Part No.

Fuse Envelope

6

Fuse, 5 ampere

2

Fuse, 2 ampere

1 Fuse, 7 ampere, Slo-Blo

1 Additional fuse, 4 ampere, Slo-Blo

(International use only)

1

1

2

2

1

4

2

1

2

2

1

2

2

2

1

1

1

1

1

1

1

1

1

Chassis

Cover

Capacitor.

10,000

mfd,

75V

Bracket, round, for capacitor

Diode rectifier block

Feet, rubber

Fuse holder, round

Fuse clip, single

Fuse clip, dual

Input socket

Line cord, with plug

Output module assembly

(1 each, left

&

right)

Output terminal, black, with hardware

Output terminal, red, with hardware

Power switch

Strain relief, plastic

Terminal strip, 5 lug

Additional 2 lug terminal strip

(International use only)

Power transformer

Alternate transformer

MS149

MS152

CL121

HZ125

QDll1

HR149

XA013

XA012

XA014

XPO14

WA016

AH326

XKOll

XK012

SLlll

HR144

XK018

XK016

TA123

Hardware Envelope

1 Lug, solder type, internal tooth,

#6

4 Lug, solder type,

#lO

3 Lug, spade,

l/4”

12 Nut,

#4-40

KEP

11 Nut,

#6-32

KEP

4 Nut,

#l0-32

KEP

2 Nut,

l/2”,

for fuse holder

12 Screw, machine,

#4

x 5/ 16”

10 Screw, machine,

#6

x

l/2”

4 Screw, machine,

#l0

x

l/2”

4 Screw,

#l0

x

l/4”,

SEMS

16 Screw, sheet metal,

#6

x

l/2”

1 Screw, machine, #6 x 3/4”

4 Washer, flat,

7/8”

2 Washer, locking, internal tooth,

l/2”

for fuse holder

2 Washer, rubber,

l/2”,

for fuse holder

Small Parts Envelope

1 Capacitor,

.0l

mfd, disc (103M)

1 Capacitor,

.005

mfd, disc (502M)

1 Capacitor,

.39

mfd(International use only)

Wire, white,

#18

Wire, green,

#18

Registration card

TA124

WS024

1 Diode

wso22

1 Label, serial number

LM016

1 Resistor, 1 megohm

--o,*

-R4-

+d2-

_R

-D3+t

2-

-Rg-

+C

-C2-

__cs-

R3-

Part No.

SF012

SF01 1

SF02 1

SF026

Part No.

HZ1 15

HZ1 16

xzo14

HKlll

HK112

HK113

HK118

HA1 13

HA1 16

HA1 19

HA1 18

HP1 18

HA1 15

HW114

HW116

HRll7

Part No.

CZ112

CZ113

CEl l7

QD115

LR015

RDl13

VIEWED FROM

COMPONENT

SIDE

Page 14

Page 15

COMPONENT VALUES

All resistors are

l/4

w carbon film unless specified otherwise

Rl 470,000 ohms

R2

1,800 ohms

R3

47,000 ohms

R4

47,000 ohms

R5

1,000 ohms

R6

1,000 ohms

R7

47,000 ohms

R8

560 ohms

R9

560 ohms

RIO

1,800 ohms

Rll

1,800 ohms

R12

270 ohms

R13

47 ohms

R14

47 ohms

R15

47 ohms

R16

47 ohms

R17

1,800 ohms

R18

1,800 ohms

R19

270 ohms

R20

1,800 ohms

R21

82 ohms

R22

560 ohms

R23

470 ohms

R24

10 ohms

R25

33,000 ohms

R26

3,300 ohms, lW, metal film

R27

1,000 ohms, 1/4W, metal film

R28

150 ohms, 1/4W, metal film

R29

1,800 ohms

R30

82 ohms

R31

47 ohms,

1/4W,

carbon comp.

R32

47 ohms,

1/4W,

carbon camp.

R33

220 ohms, 1/2W

R34

2,200 ohms, 1/2W

R35

10 ohms

R36

1 ohm,

1OW

R37

10 ohms, 5W

R38

28,000 ohms,

1/4W,

metal film

R40

1

470 ohms,

1/2W

R402

470 ohms,

1/2W

R403

220 ohms,

1/2W

R404

220 ohms,

1/2W

R405 1 meg ohms,

1/2W

Cl

C2

C3

C4

C5

C6

C7

C8

C9

Cl0

Cl1

Cl2

Cl3

Cl4

Cl5

Cl6

Cl7

Cl8

Cl9

C20

2 mfd,

5OV,

Film

330

pF, 63OV,

Film

.Ol

mfd,

25OV,

Film

.OOl

mfd,

25OV,

Film

.OOl

mfd,

25OV,

Film

0.1 mfd,

lOOV,

Film

0.1 mfd,

lOOV,

Film

470 mfd, 1 OV, Non-polar Electrolytic

150

pF, 63OV,

Film

330

pF, 63OV,

Film

.Ol mfd,

25OV,

Film

100 mfd,

lOOV,

Electrolytic

.Ol

mfd,

25OV,

Film

100 mfd,

lOOV,

Electrolytic

.Ol

mfd,

25OV,

Film

.Ol

mfd,

25OV,

Film

150

pF, 63OV,

Film

.Ol

mfd,

25OV,

Film

.Ol

mfd,

25OV,

Film

0.1 mfd,

lOOV,

Film

Part No.

C21

RC044

RC023

RC043

RC043

RC015

RC015

RC043

RC045

RC045

RC023

RC023

RC029

RC039

RC039

RC039

RC039

RC023

RC023

RC029

RC023

RC053

RC045

RC04 1

RC013

RC036

RZo13

RMo21

RM013

RC023

RC053

RZOll

RZOll

RD114

RDl15

RC013

RW012

RW013

RM053

RDll7

RDI

17

RDll4

RDl14

RDI 13

CP115

CP134

CP135

CP136

CP136

CC125

CC125

CN113

CP133

CP134

CP135

CL122

CP135

CL122

CP135

CP135

CP133

CP135

CP135

CC125

C22

C23

C40

1

C402

C403

C404

C405

C406

C407

C408

Dl

D2

D3

D4

D5

D6

D7

D8

D9

DlO

Dll

D12

D13

D14

D15

D16

D40

1

0.1 mfd,

lOOV,

Film

0.1 mfd,

lOOV,

Film

.OOl

mfd,

25OV,

Film

680 pF,

5OOV,

Mica

0.1 mfd,

lOOV,

Film

10,000 mfd,

75V,

Electrolytic

10,000 mfd,

75V,

Electrolytic

.Ol

mfd,

lOOOV,

Disc

.39

mfd,

lOOV,

Polyester

.005

mfd,

lOOOV,

Disc

0.1 mfd,

IOOV,

Film

IN4

148 Diode

IN4 148 Diode

IN4

148 Diode

IN4 148 Diode

IN4 148 Diode

IN4 148 Diode

IN4

148 Diode

IN4 148 Diode

FDH-400 Diode

FDH-400 Diode

IN4 148 Diode

lN5240B

1OV

Zener Diode

IN5240B 1OV

Zener Diode

IN4 148 Diode

IN4003 Diode

IN4003 Diode

IN4003 Diode

DB40 1 Diode Bridge, 25A

Pl 1,000 ohms trimpot

P2

1,000 ohms trimpot

F4O1 7A,

Slo-Blo MDX

F402 5A,

3AG

F403

5A,

3AG

F404 2A, 3AG (size optional)

F405

4A,

Slo-Blo MDX

T40 1

Power Transformer, Domestic

T402 Power Transformer, International

Ql

2N5401

::

2N5550

2N5550

Q4

2N5550

Q5

2N5401

::

2N5415

NP2222

QlO

2N5550

Qll 2N3440

Q12

2N3440

Q13

2N5415

Q401 2SK134

Q402

2SK134

Q403

2SJ49

Q404

2SJ49

TB40 I Thermal Breaker

TB402

Thermal Breaker

Ll Output Inductor

15

CC125

CC125

CP136

CM121

CE115

CL121

CL121

CZI 12

CEl17

cz113

CEl15

QDll6

QD116

QD116

QD116

QDll6

QD116

QD116

QDl16

QD121

QDl21

QD116

QDlll

QDlll

QD116

QD115

QD115

QD115

QD117

RPOll

RPOll

SF02 1

SF012

SF012

SF01

1

SF026

TA123

TA124

QP122

QNl28

QN128

QN128

QP122

QP122

QP122

QP123

QN124

QNl28

QN125

QN125

QP123

QNl12

QNl12

QPl12

QP112

SF024

SF024

TA112

Page 16

SPECIFICATIONS

Power Rating:

Less than 0.02% total harmonic distortion at

any power level up to 115 watts continuous average power

per channel into 8 ohms at any frequency between 20 Hz

and 20

kHz

with both channels driven.

Input Impedance:

47,OOO

ohms.

Input Sensitivity:

1.55 volts rms for 1 15 watts into 8 ohms.

IM

Distortion

(SMPTE):

Less

than

O.OOS’%,

from1 wattto1

15

Damping

Factor:300

to 1kHzz

into8ohms

watts into8 ohms. 60 to 10

kHzzinto8ohms

Typical THD at 115 watts into 8 ohms:

I kHz -

0

00

25%

__

IO

kHz - 0.007%

20

kHz - 0.012’/‘

Frequency Response into 8 ohms:

-

3

dB.

2 Hz to 160

kHz

at 1 watt

+O,

-0.5

dB, 6

Hz to 60

kHz

at 1 15 watts

Rise Time:

10

kHz. 60

volts peak to peak square wave,

10%

to

90% 2.5 us.

Slew Rate:

10

kHz. 60

volts peak to peak square wave: 30

VI’,~

s.

Semiconductor Complement:

26

transistors. 8 power

Mosfets, 29

diodes, 4 zener diodes. 1 diode bridge.

Typical Channel Separation: 20

Hz:>

75 dB

1

kHz:>85 dB

20

kHz:

>6S

dB

Power Consumption:

1 15 watts into 8 ohms:

840

VA;

Quiescent: 125 VA.

Size:

5-1/8”

high. 16” wide, 10-l/2” deep.

Signal

to Noise Ratio, unweighted:

Better than 100 dB at 115

watts into 8 ohms.

Net Weight:

26

Ibs.

Shipping Weight: 30

Ibs.

All Specifications are subject to change without notice.

Printed in

USA

16

Page 17

Page 18

Page 19

Page 20

INSTRUCTIONS FOR

THE HAFLER DH-222 AMPLIFIER BRIDGING KIT

FOR THE DH-220

The DH-222 may be installed in a Hafler DH-220 power

amplifier to enable easy conversion to a high power

monophonic amplifier, bridging the two conventional channels to a single floating output which can deliver in excess of

400 watts into an 8 ohm load. Its rated power output is 350

watts across the audio band.

When switched to monophonic operation (UP), signal input

should be provided to the

LEFT

input jack only, and the output

should be connected only to the two center BED

( +)

terminals.

No connection of the load is to be made to the black output

terminals. Because of the floating output, neither side of the

load may be grounded. Thus it is unlikely that stereo speaker

switching boxes, or headphone adapters may be used, as these

often have a common ground between the left and right channels.

The speaker fuses may be replaced with higher values than

the 2-5 ampere range suggested for stereo operation, if desired, depending on the degree of protection for the speaker

which is intended. The graph shows the nominal sustained

power output limit of a 7 ampere standard fuse, which is the

maximum recommended value. Smaller values will provide

more protection for the speakers; larger ratings are at the

user’s risk.

fuse blows in mono operation, both should be replaced, for it is

likely that the second has been weakened. For equivalent load

impedance, each speaker fuse provides the same power output

protection as in stereo operation.

With the internal conversion switch DOWN, the amplifier

functions as a conventional stereo amplifier, with normal

input and output connections. The minimum recommended

load impedance, which is limited only by thermal factors (ability of the heat sinks to dissipate high energy levels), is 6 ohms

in mono; the usual 3 ohms in stereo. The amplifier circuit can

safely accommodate lower impedance loads, of course.

The conversion, which takes less than an hour, involves

only changes to the input wiring, and installation of the switch

with its mounting bracket and one resistor. These instructions

assume familiarity with the usual kit building descriptions,

and reminders. For more details in this regard, see the construction section

of your

DH-220 amplifier manual. You must

be certain you have made a good solder connection wherever

one is called for, not only to the wire you have attached, but to

any others already connected to that point. The notation

(

S)

indicates a soldered connection; (S-2) denotes that there are

two wires to be soldered. Use only 60/40 rosin core solder. Be

careful not to let the soldering iron touch adjacent components

on the circuit board: excessive heat could change their

opera-

Both speaker fuses should be the same value. If one speaker

tion, with the possibility of damage to the amplifier.

KIT PARTS LIST

Switch, DPDT

Mounting bracket

Indexing washer

Lockwasher

Nut, switch mounting

Nut, 6-32 KEP

Screw, machine, 6-32

Resistor, 3000 ohms

Wire, red, 22 gauge

Wire, green, 22 gauge

Wire, black, 22 gauge

sz114

MS183

HW123

HW122

HK125

HK112

HA116

FLzo17

I

1

I

I

I

6

12

16

RESISTIVE LOAD IMPEDANCE -

n

LIMITED WARRANTY

The

parts in the DH-222 are guaranteed against defects for one year from the date of purchase. Installation in a DH-220