Page 1

VRM10S

VRM

10S CE

VRM12S

VRM

12S CE

VRM15S

VRM

15S CE

SUBWOOFER

SYSTEMS

®

Page 2

Declaration of Conformity

Application of Council Directive: 73/23/EEC (Low Voltage Directive)

89/336/EEC (EMC Directive)

Standard(s) to which Conformity is Declared: EN55103-1

EN55103-2

EN60065

Manufacturer’s Name: Hafler

Manufacturer’s Address: 546 South Rockford Drive, Tempe, Arizona 85281

Importer’s Name:

Importer’s Address:

Type of Equipment:

Amplified Subwoofer

Model No:

VRM10sCE VRM12sCE VRM15sCE

Year of Manufacturing: 1999 2000 2001 2002 2003

Serial Number:

I, the undersigned, hereby declare that the equipment specified above conforms

to the above Directive(s) and Standard(s)

Place: Hafler

Date: 12/01/98 James C. Strickland, VP Engineering

Page 3

– i –

25Hz-100Hz, ±2dB

>115dB (w/music @ 2m)

<3%, 25Hz (90dB @ 2m)

12” (305mm) Cellulose Fibre Cone

Santoprene Rubber Surround

2.5” (63.5mm) 4-Layer Voice Coil

102 oz. Magnet

1.8ft3(50.4Liter) Bass Reflex Down Firing

16.75”(H) x 18.50”(W) x 19.50”(D)

(46.35cm x 49.53cm x 49.21cm)

Black Ebony Ash Vinyl

74 lbs. (33.6kg)

Free Field Frequency Response

Peak Acoustic Output

Total Harmonic Distortion (THD)

Low Frequency Driver

Dimensions

Cabinet Finish

Net Weight

27Hz-100Hz, ±2dB

>112dB (w/music @ 2m)

<3%, 30Hz (90dB @ 2m)

10”(254mm) Cellulose Fibre Cone

Santoprene Rubber Surround

2” (51mm) 4-Layer Voice Coil

30 oz. Magnet

1.0ft3(28 Liter) Bass Reflex Down Firing

14.75”(H) x 16.0”(W) x 17.50”(D)

(37.46cm x 40.64cm x 40.64cm)

Black Ebony Ash Vinyl

51 lbs. (23.2kg)

SUBWOOFER MODEL

VRM10S

VRM12S

22Hz-100Hz, ±2dB

>118dB (w/music @ 2m)

<3%, 22Hz (90dB @ 2m)

15” (381mm) Cellulose Fibre Cone

Santoprene Rubber Surround

2.5” (63.5mm) 4-Layer Voice Coil

153 oz. Magnet

2.5ft3(70 Liter) Bass Reflex Down Firing

18.75”(H) x 20.0”(W) x 21.0”(D)

(46.35cm x 49.53cm x 49.21cm)

Black Ebony Ash Vinyl

88 lbs. (40kg)

VRM15S

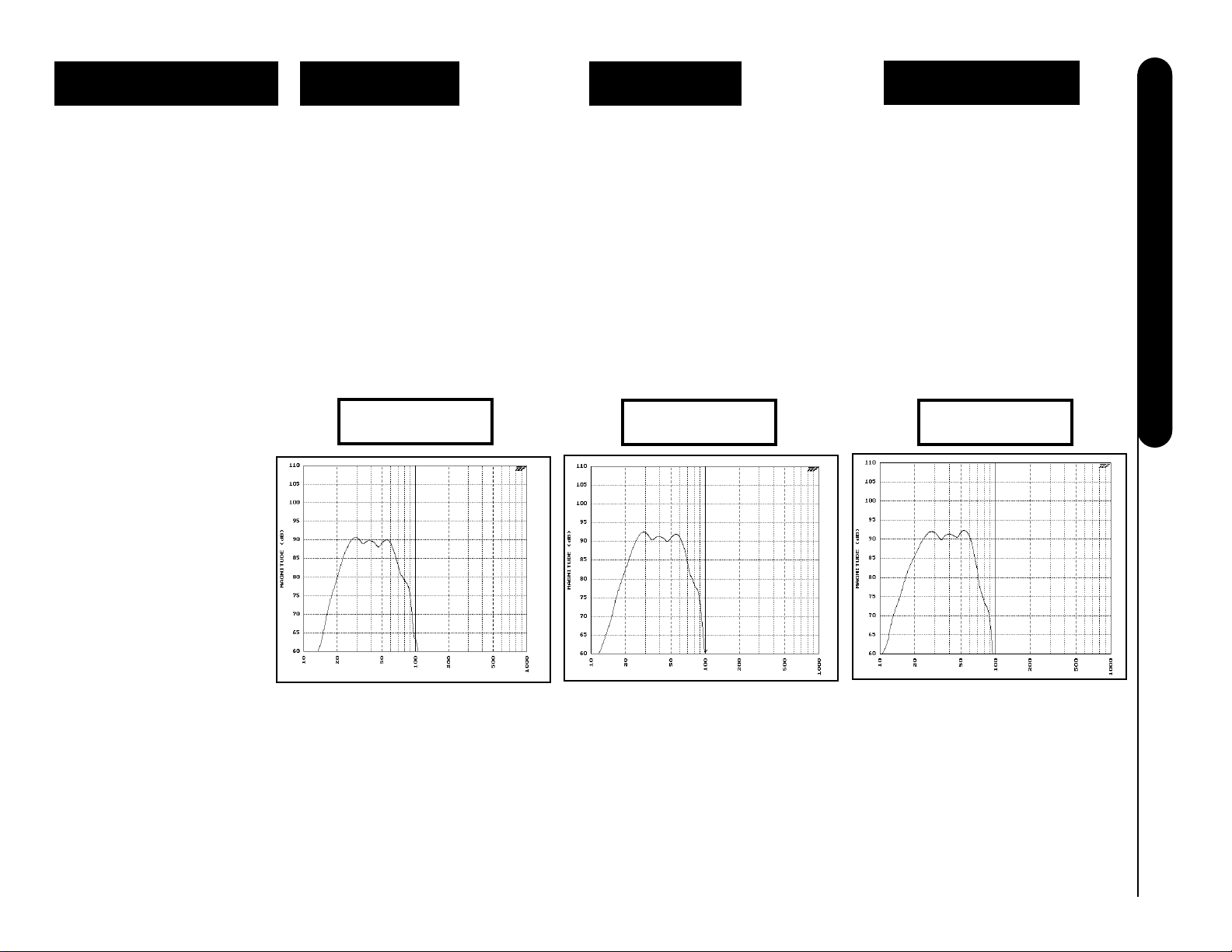

Frequency Response @ 2m*

Frequency Response @ 2m*

VRM10s

Frequency Response

Specifications are subject to change without notice.

Performance Specifications

VRM12s

Frequency Response

VRM15s

Frequency Response

Frequency Response @ 2m*

Page 4

– ii –

Power Rating

Signal-to-Noise

CMRR

Input Impedance

Input Sensitivity Range

Maximum Input

Gain

Crossover Frequency Variable from 40Hz~140Hz

Crossover Slope 24dB/octave (4th order) Linkwitz-Riley

Subsonic Filter 12dB/octave (-3dB @ 18Hz)

Specifications are subject to change without notice.

Idle Power: 11W / 150mA @ 120 VAC

Idle Power: 11W / 90mA @ 230 VAC

Normal Operation: 66W / 380mA @ 230VAC

Full Power: 330W / 3.3A @ 120VAC

Full Power: 315W / 1.7mA @ 230VAC

Unbalanced RCA Inputs

Gain Control (30dB range)

Low Pass Crossover (variable 40Hz~140Hz)

Phase DIP Switches (0°, -90°, -180°, -270°)

200W RMS @ 4 ohms

>100dB

>70dB typical @ 60Hz

47kΩ per phase balanced, 47kΩ unbalanced

RCA Input: 160mV to 5V RMS

Speaker Input: 50mV to 45W (receivers that

drive nominal 8Ω speaker loads)

RCA Input: 10V RMS

Speaker Input: 180W (receivers that drive

nominal 8Ω speaker loads)

+45dB max. to +15dB min.

Performance Specifications - Amplifier Section

Power Consumption

Rear Panel

Low -Pass Crossover Section

Page 5

– iii –

PERFORMANCE SPECIFICATIONS

Frequency Response Graphs i

INTRODUCTION 1

TECHNICAL DESIGN FEATURES 1

DESIGN FEATURES 4

INSTALLATION

Location 5

Typical Studio Installations 5

Home Theater Installations 5

Input Switch 6

XLR Wiring Configurations 7

OPERATION

Auto Turn-On/Sleep Mode 8

Input Sensitivity 8

Low-Pass Crossover 8

Phase Control 9

Set-up Procedure 9

AC Line 10

LED Indicator 10

Break-In and Warm Up 10

Cleaning and Maintenance 10

SERVICE POLICY &LIMITED WARRANTY 11

SAFETY PRECAUTIONS 12

Table of Contents

Page 6

– 1 –

The VRM10s/VRM12s/VRM15s monitors utilize a specially designed amplifier featuring our innovative Trans•ana circuitry. This topology, with its unique input-to-output configuration (derived from

our patented Trans•nova circuit), employs power gain in the MOSFET output stage that result in

superior sound quality.

The amplifier features an auto turn-on/off circuit that eliminates the need for a conventional power

switch. Input signals can be fed into the amplifier via Un-Balanced RCA jacks or Speaker level input

jacks. Each pair of inputs is combined into a mono-summed signal before being fed into a 4th order

Linkwitz-Riley low-pass crossover, adjustable from 40Hz~140Hz. If selected, the signal is then fed

into the Phase Control that allows the phase of the signal to be adjusted at 90˚, 180˚, or 270˚ increments.

The VRM10s is a 10” (254mm) low frequency transducer that features a 2” (51mm) voice coil and is

driven by a 30 oz. magnet. The VRM12s is a 12” (305mm) low frequency transducer that features a

2.5” (63.5mm) voice coil and is driven by a 102 oz. magnet. The VRM15s is a 15” (381mm) low frequency transducer that features a 2.5” (63.5mm) voice coil and is driven by a 153 oz. magnet. All

VRM transducers feature Cellulose Fiber cones for accurate sound reproduction and Santoprene

Rubber Surrounds that are immune to temperature fluctuations. This specialized rubber surround

controls woofer damping and reduces 2nd harmonic distortions for a very wide and flat frequency

response. The VRM series voice coils are 4-layers of copper wound on aluminum formers.

Aluminum voice coil formers provide excellent heat dissipation that provides higher power handling

versus plastic or Kapton type formers used by other manufacturers.

Introduction

Technical Design Features

Thank you and congratulations on your purchase of the HAFLER series of Subwoofer, the world's

finest brand in professional audio equipment.

The VRM series is comprised of three modules; the VRM10s, VRM12s, and VRM15s. The VRM10s

is an amplified 10" subwoofer. The VRM12s is an amplified 12" subwoofer and the VRM15s is an

amplified 15" subwoofer. All VRM series are designed and engineered for Home Theater Systems.

For ease of use, this manual is organized into two main sections: Installation and Operation.

"Installation" covers the set-up of your new HAFLER equipment in the system. "Operation" covers

the controls and how to use them for optimum performance.

Page 7

– 2 –

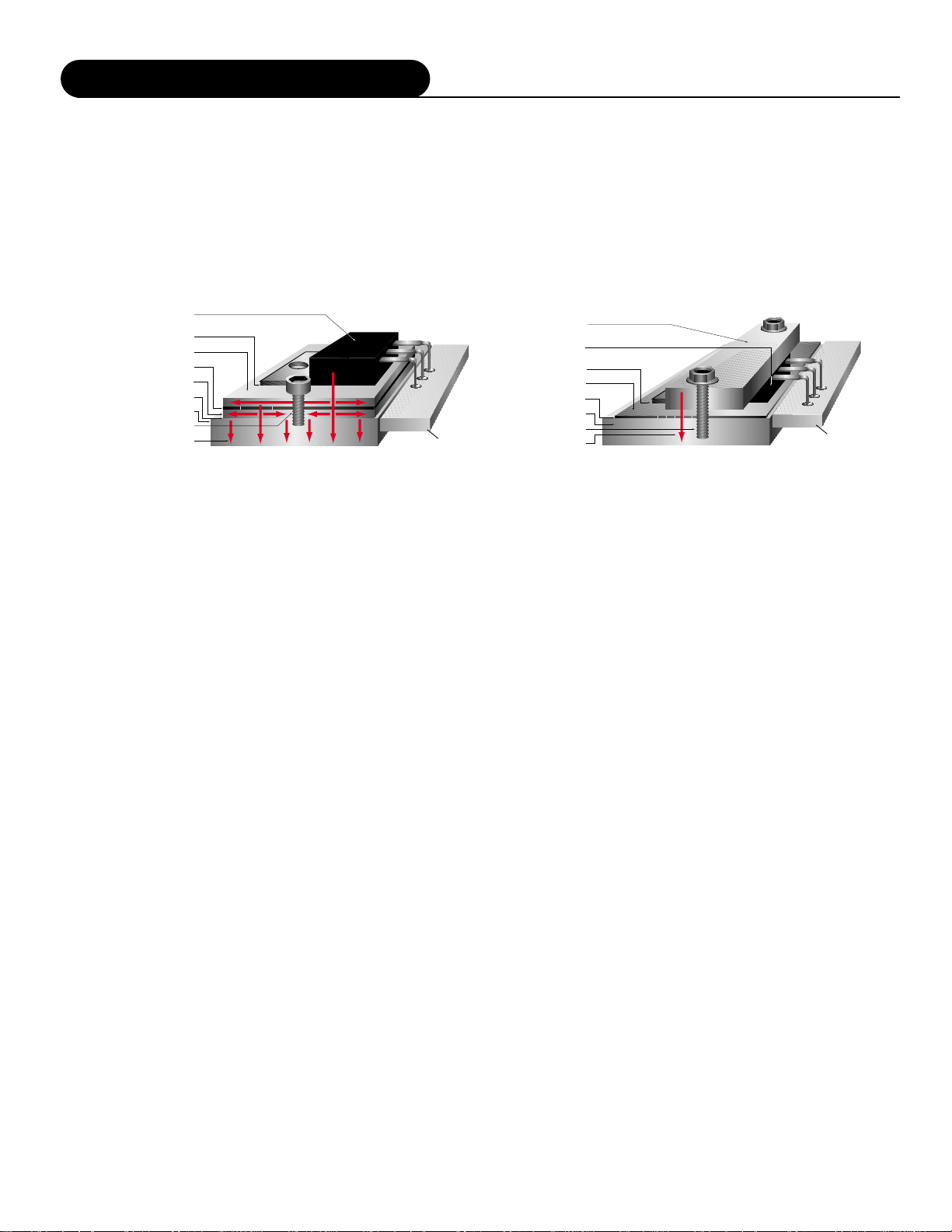

MEHSA

(Maximum Efficiency HeatSink Application) MEHSA is a proprietary process that yields up to 5 times

better heat transfer than traditional FET mounting techniques using the exact same components. A

multi-layer insulated metal substrate operating with minimal thermal resistance spreads heat both

downward and outward to quickly dissipate heat from each device across the heatsink. This process

combined with our DSM technology and MOSFET devices allows us to squeeze more watts per cubic

inch from every output device as well as provide consistent thermal stability.

The Result: Better reliability through faster heat dissipation.

Trans•ana

Trans•ana (TRANSconductance Active Nodal Amplifier) is a circuit that allows the audio signal to pass

through the amplifier at low voltage. The signal is directly level-shifted to the fixed high voltage rails

via a pair of driver transistors. Signal linearity is assured by an active node formed by the driver transistors at ultrasonic frequencies. This allows amplifier performance similar to Trans•nova which is highly

stable and linear while utilizing the advantages of a non-floating power supply.

The Result: An extended frequency band width accurately supplied to the output stages of the

amplifier.

MOSFET Devices

HAFLER is one of the few manufacturers in the sound community to utilize MOSFET devices in the

amplifier output stage. MOSFET (Metal Oxide Semiconductor Field Effect Transistor) devices offer several important inherent advantages over older bi-polar designs. These advantages include: thermal stability, fast switching speed, ultra low output impedance and wide bandwidth linearity. In addition,

MOSFETs operate very similarly to vacuum tubes in that they are more linear than bipolar transistors.

However, MOSFETs can deliver the midrange clarity without the limitations of transient response and

high frequency phase shifting normally associated with tube

operation.

The Result: Thermal stability, fast switching speed, ultra low output impedance and wide bandwidth

linearity.

The MEHSA Way The Old Way

Technical Design Features

Heat Monster:

High output MOSFET device

Solder

Copper heat spreader

Dielectric layer

Base Layer - aluminum

Thermal grease

Heat sink

Screw, no pressure on component!

Multiple heat paths

PC Board

Heat generating component

(typically a power MOSFET or

Clamp Bar

bipolar semiconductor)

Thermal grease

Mica

Thermal grease

Heat sink

Screw

Heat path

PC Board

Page 8

– 3 –

Subsonic Filter

The VRM series uses a Subsonic Filter to prevent the woofer from reproducing inaudible frequencies.

Subsonic frequencies (known as infrasonic frequencies) are signals below the normal human hearing

range.The subsonic filter reduces the energy of these frequencies and restrains the woofer from operating outside its optimum linear excursion. This type of electronic control eliminates the mechanical distortion caused by a woofer traveling beyond its XMAX, improves power handling, increases reliability

and improves sonic performance.

The Result: Improved power handling, increased reliability and improved sonic performance.

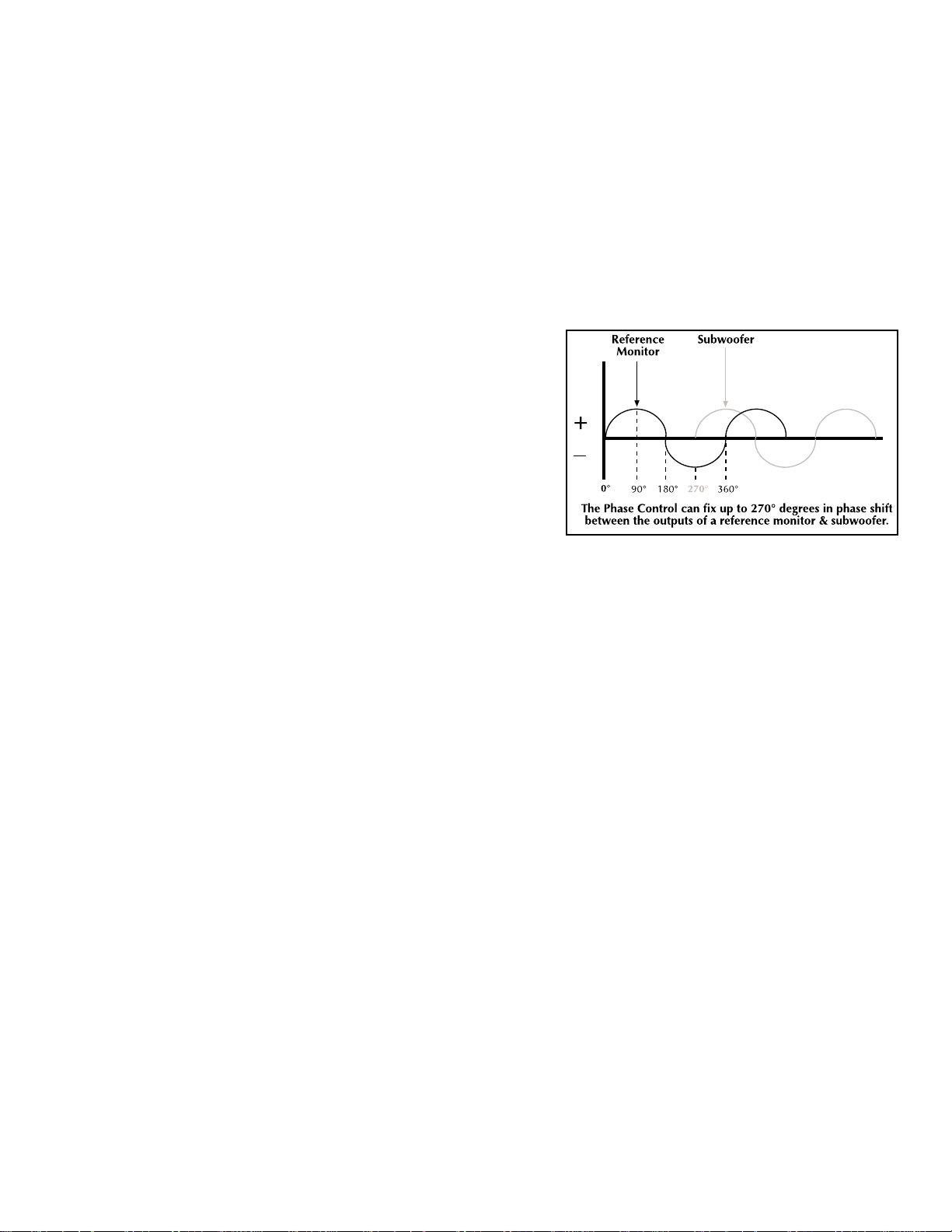

Phase Control

The Phase Control is used to align the arrival time of the subwoofer’s output information with satellite monitors. Aligning

both signals will insure that both Subwoofer and reference

monitor information arrive at the listening position at the same

time. This eliminates the possibility of acoustical cancellation

and improves the reproduction of transients in the crossover

region.

The Result: Eliminates phase cancellation and improves transient response.

Speaker Level Inputs

Does your receiver have only speaker level outputs? No problem! Hafler’s Speaker Level Input circuitry

converts the speaker line outputs (high level) from your receiver into pre-amp line inputs (low level) for

your VRM amplifier. This allows compatibility with a variety of receivers as well as the ability to retrofit

your new Hafler subwoofer into existing systems without the need for external adapters.

Santoprene Rubber Surround

Santoprene is a very durable and temperature tolerant material which provides a consistent support

necessary for the linear motion of the speaker cone. In addition, the damping capabilities eliminate

the transmission of sonic disturbances between the cone and the frame of the speaker. This greatly

improves the accuracy of the woofer’s low frequency response.

The Result: Improves woofer’s low frequency response.

Aluminum Voice Coil Former

The transducers voice coil former is black anodized aluminum for highly efficient thermal transfer.

Another method of producing voice coils is with Kapton® formers. Although this material is very resistant to heat, any heat generated by the transducer is “trapped” on the copper voice coil windings.

HAFLER uses aluminum voice coil formers because aluminum acts like a “heat sink” and helps dissipate heat away from the voice coil. This allows winding high temperature copper wire in multiple layers for improved efficiency.

The Result: Improves power handling by efficiently dissipating heat.

Page 9

– 4 –

1. RCA Input/Speaker Level Input Switch

2. Gain Control

3. RCA Input

4. RCA Output (full range)

5. Speaker Line Input

6. Speaker Line Output (Full range)

7. Low-Pass Crossover

8. Phase Switches

9. Enclosure Vent

10. AC Line Input

11. AC Line Fuse

Design Features

9

2

4

3

7

1

10

11

6

1

5

8

Page 10

Home Theater Installations

Home Theater installations are typically medium sized living rooms or game rooms that

have large flat, uncovered walls. Acoustics in

this type of installation can have a big effect

on the SPL (Sound Pressure Level) and f3 (low

frequency cut-off) of the subwoofer because

the walls are very reflective. The only elements in these installations that acoustically

“absorb” sounds are furniture and carpet.

Dramatic “Boundary Loading” can be

achieved by locating the subwoofer under a

table, next to a wall or in a corner (FIG. 4),

thus increasing SPL and lowering the f3 of the

subwoofer system. Locating the subwoofer in

the middle of the room or in a large open area

where there are few reflective surfaces will

cause a decrease in SPL and an increase in f3.

Experiment with different locations in the

room to determine which type of bass response works best in your home theater.

– 5 –

Location

The size of the room used for your Home Theater can have a significant effect on the bass response of

your system. Since many movies exaggerate explosions, earthquakes, and other low frequency effects,

a high performance subwoofer system is required. Your Hafler subwoofer is specially designed for

these high levels of excursion and linearity. In order to get the most out of your subwoofer, Hafler has

documented the differences between typical Studio and Home Theater installations.

Typical Studio Installations

In typical studio installations, damping material is usually used on the walls and ceilings make the

room “acoustically dead." In this type of anechoic environment, the subwoofer will tend to experience

minimal “Boundary Loading” effects. Firing the subwoofer downward (FIG. 1) or directly facing forward (FIG. 2) and keeping the cabinet at least 5” (12.7 cm) away from any wall will provide best

results.

FIG. 1

Downward Firing

FIG. 2

Forward Firing

Keep subwoofer enclosure 5”

(12.7 cm) from any wall

Installation

Left

Front

Center

Front

Left

Rear

Listening Area

Right

Front

Subwoofer

Right

Rear

Page 11

– 6 –

Speaker Level Outputs

VRM Subwoofer

VRM Satellite Speaker

VRM Satellite Speaker

Receiver

Installation

+ -

+ -

Page 12

– 7 –

Installation using RCA (low level) Inputs

Receiver

VRM Subwoofer

Signal Level Output

Signal Level Loop (SLL)

Shown here passing low-level signal to an optional

component such as signal processor or an additional

Hafler VRM Subwoofer.

Page 13

– 8 –

*This graph was generated by setting the variable crossover to 40Hz

50Hz, 60Hz, 70Hz, 80Hz, 90Hz, 100Hz, 120Hz & 140Hz.

Auto Turn-on / Sleep Mode

The VRM subwoofers automatically turn on when they sense an input signal. When the signal being

fed to the VRM is turned off, the subwoofer’s amplifier will turn off and go into “sleep mode.” This

feature eliminates the inconvenience of operating a mechanical power switch.

Input Sensitivity

The Input Sensitivity is used to match the VRM series with signal levels from a variety of signal

sources. The Input Sensitivity uses a potentiometer to match input levels over a 30dB range and is

variable from 0dB to -30dB. The numbers listed on the back panel indicate attenuation from maximum gain, calibrated in dB.

Low-Pass Crossover

The Low-Pass Crossover is used to set the electrical cutoff point of the subwoofer enclosure. The

Crossover uses a variable potentiometer to set the cutoff point anywhere between 40Hz and 140Hz.

When the control is set to its full CLOCKWISE position the cutoff frequency is set to 140Hz Low-Pass.

When the control is set to its full COUNTER CLOCKWISE position the cutoff frequency is set to 40Hz

Low-Pass.

It is important to match the Low-Pass crossover point

of the subwoofer with the High-Pass crossover point

of the high frequency reference monitors.

Mismatching the crossover points can cause dips or

peaks in the acoustical response. Overlapping the

crossover points (i.e., subwoofer at 60Hz Low-Pass &

high frequency monitors at 50Hz High-Pass) can

cause a peak between 50Hz and 60Hz.

Underlapping the crossover points (i.e., subwoofer at

40Hz Low-Pass & high frequency monitors at 70Hz

High-Pass) will cause a dip between 40Hz and 70Hz.

We recommend using a crossover setting whenever

possible to minimize “localization” of the subwoofer,

usually between 50Hz and 60Hz. These low frequencies make it nearly impossible to detect where the

subwoofer is in the listening room.

Operation

Electrical Crossover Response*

50

70

80

60

40HZ

Low Pass

90

140

100

120

50

60

70

80

40HZ

Low Pass

90

140

100

120

Page 14

– 9 –

Phase Control

The Phase Control switches allow the VRM subwoofer to be acoustically aligned with other speakers in

your system. 0˚, -90˚, -180˚, or -270˚ degrees of phase shift at 80Hz can be selected using DIP switches 2, 3, and 4. For 0˚ degrees of phase shift, leave all three switches in the OFF (up) position. –270˚

degrees of phase shift occurs when switch 2 is selected in the ON (down) position. –180˚ degrees can

be achieved by selecting both switches 2 and 3 in the ON (down) position. Finally, selecting all

switches 2, 3, and 4 in the ON (down) position produces –90˚ degrees of phase shift.

Set-up Procedure

1) Place all your speakers and any acoustically significant components in their working location in the

listening environment.

2) Insert a sine wave signal into the audio path.

Be careful to turn down the level before turning on

the amplifiers.

3) Choose a frequency that corresponds to the crossover frequency between the VRM subwoofer and

the reference monitors.

4) From the listening position, alternate between the VRM subwoofer and the full range speakers and

adjust the levels until they have the same acoustic output. Use an SPL meter, a microphone on a VU

meter, or your ears to accomplish this.

5) With all speakers on, try the 0˚, -270˚, -180˚, and –90˚ degree phase settings. The setting with the

highest SPL reading from your listening position will produce the most effective acoustic alignment.

6) Set the VRM10s/VRM12s/VRM15s gain control according to your preference. This will not affect the

acoustic alignment of your system.

Here is a list of some items that

can affect acoustic alignment: Relocating speakers, changing the VRM

subwoofer Low Pass frequency, changing the acoustic environment (i.e., traps, diffusers, etc.), changing

the listening position.

Although this procedure produces the maximum achievable acoustic gain for your system, listening

tests may still lead you to prefer another setup.

Example of how phase misalignment between high frequency speakers and a subwoofer can cause

cancellation

Operation

Page 15

– 10 –

AC Line

The VRM10s/VRM12s/VRM15s operate from a 115 VAC/60Hz power line.

The VRM10sCE/VRM12sCE/VRM15sCE operate from a 230 VAC 50/60Hz power line. Connection is

made by a 16 gauge, IEC Type 320, grounded line cord. For safety considerations only a properly

grounded (earthed) receptacle should be used. If a grounded circuit is not available, do not break off

the ground pin; use the proper adapter plug for a two wire receptacle with the grounding plug suitably

connected to earth ground.

Important: The power line fuse is mounted on the rear panel. If this fuse blows, replace it only with

the same type and rating as indicated in the parts list.

LED Indicator

Amplifier operation is monitored internally and has a

status LED. This indicator can be used for system

troubleshooting. The LED will illuminate GREEN if

signal is present at the subwoofer’s input. The LED will

turn off and the amplifier will go into sleep mode if

signal is not present.

Break-in and Warm-up

We recommend initially breaking in the subwoofer for approximately 8 hours with musical information

to establish the subwoofer’s natural bass response.

Cleaning & Maintenance

There is no requirement for regular maintenance on the electronic components of the subwoofer. If the

cabinet or woofer becomes soiled, it can be cleaned using a damp, soft cloth. If the subwoofer is located in a particularly dusty environment, cleaning the inside with compressed air or vacuuming every 18

to 24 months is sufficient.

COLOR

STATUS

GREEN

Power on

NO LED

Sleep Mode

Page 16

– 11 –

Rockford Corporation (Hafler Division) offers a limited warranty on Hafler products on the following

terms:

•

Length of Warranty

1 year on Subwoofer Monitors

•

What is Covered

This warranty applies only to products sold to the original owner and is non-transferable. This

warranty only applies to units sold in the continental United States. You are required to have a

copy of the receipt stating the customer’s name, dealer name, product purchased and date of

purchase.

•

Products found to be defective during the warranty period will be repaired or replaced (with

product deemed to be equivalent) at Hafler’s discretion.

•

What is NOT Covered

1. Damage caused by accident, abuse, improper operations, water, theft

2. Service performed by anyone other than Hafler or an Authorized Hafler service center

3. Any product purchased outside the United States (please contact your local dealer)

4. Shipping charges to get the unit to Hafler

5. Any product which has had the serial number defaced, altered, or removed

•

Limit on Implied Warranties

Any implied warranties including warranties of fitness for use and merchantability are limited in

duration to the period of the express warranty set forth above. Some states do not allow

limitations on the length of an implied warranty, so this limitation may not apply. No person is

authorized to assume for Hafler any other liability in connection with the sale of the product.

•

How to obtain service or technical support

Please call 1-800-669-9899 for Rockford/Hafler support. You must obtain an RA # (return

authorization number) to return any products to Hafler. You are responsible for shipment of

product to Hafler.

Rockford Corporation

Hafler Division

2055 E. 5th Street

Tempe, Arizona 85281

Service Policy and Limited Warranty

Page 17

– 12 –

The lightning flash with arrowhead symbol within an equilateral triangle is

intended to alert the user to the presence of uninsulated “dangerous voltage” within the product’s enclosure, that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the

user of the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the appliance.

1.Read Instructions

All the safety and operating instructions of your Hafler equip

ment should be read before power is applied to the equipment.

2.Retain Owner’s Manual

These safety and operating instructions should be retained for

future reference.

3.HEED WARNINGS

All warnings on the equipment and in the operating instructions

are important and should be followed.

4.FOLLOW INSTRUCTIONS

All operating and use instructions are important and should be followed.

5.HEAT

The equipment should be kept away from areas of high temperature, i.e., heater vents, radiators, stoves/ovens, fireplaces, etc.

6.VENTILATION

The equipment should be used in an area suitable for proper ventilation. Care should be taken not to impede airflow in and

around the cabinet.

7.WATER AND MOISTURE

The equipment should not be used in or around water, such as a

bathtub, sink, or swimming area. Also, the equipment should not

be used in areas prone to flooding, such as a basement.

8.POWER SOURCES

The equipment should be connected only to a power source of

the same voltage and frequency as that listed on the rear panel

above the power cord entry point.

9.POWER CORD PROTECTION

Power cords should be arranged so they do not interfere with the

movement of objects in the room: people, fan blades, utility carts,

etc. Also, care should be taken that the cord is not pinched or

cut, and placed so it is not in danger of being pinched or cut, as

in under a rug, around a tight corner, etc.

10.POWER CORD GROUNDING

The power supply cord is of a three wire grounded type, designed

to reduce the risk of electric shock sustained from a live cabinet.

It is assumed to be of suitable length for most uses of the equipment. The use of extension cords and power strips is discouraged

unless they are of suitable rating to deliver the required total current for safe operation of all connected equipment. Furthermore,

extension cords or power strips must provide the same three wire

grounded connection. It is important that the blades of the equipment’s plug be able to fully insert into the mating receptacle.

Never remove the round grounding pin on the plug in an attempt

to mate to a two wire ungrounded receptacle: use a grounding

adapter with the grounding tab or wire suitably connected to earth

ground.

11.NON-USE PERIODS

During periods of extended non-use, the power cord should be

unplugged from the power source.

12..CLEANING

The equipment should be cleaned only as detailed in the operating instructions.

13..OBJECT AND LIQUID ENTRY

Care should be taken so that objects and/or liquids, such as cleaning fluids or beverages, are not spilled into the enclosure of the

equipment.

14..DAMAGE REQUIRING SERVICE

Hafler equipment should be serviced by qualified service personnel when:

A.The power supply cord or plug has been damaged, or

B.Objects have fallen onto, or liquid has been spilled into the

equipment, or

C.The equipment has been exposed to rain, or

D.The equipment does not appear to operate normally or

exhibits a marked change in performance, or

E.The equipment has been dropped, or the enclosure has

been damaged.

15.SERVICING

The user should not attempt to service the equipment beyond that

which is described in the operating instructions. All other service

should be referred to qualified service personnel.

16.CARTS AND STANDS

The equipment should be used with carts or stands only of sufficient strength and stability for the use intended.

An equipment and cart combination should be moved

with care. Quick stops and starts, excessive force, and uneven surfaces may cause the equipment and cart combination to topple.

NOTICE - IMPORTANT SAFETY INFORMATION

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

WARNING:

DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

TO PREVENT FIRE OR SHOCK HAZARD

!

Page 18

– 13 –

1.LEA LAS INSTRUCCIONES

Todas las instrucciones de seguidad y operación de su equipo

Hafler, deben ser leídas antes de que el equipo sea conectado

dléctricamente.

2.CONSERVE EL MANUAL DEL PROPIETARIO

Estas instrucciones de seguridad y operación, deben ser conservadas para futuras referencias.

3.CUADROS DE ADVERTENCIAS

Todas las advertencias en el equipo y en las instrucciones de

operación, son importantes y deben ser seguidas.

4.SIGA LAS INSTRUCCIONES

Todas las instrucciones de uso y operación son importantes y

deben ser seguidas.

5.CALOR

El equipo debe ser mantenido lejos de areas de alta temperatura,

como por ejemplo: ventilaciones de calentadores, radiadores, estufas/hornos, hogueras, etc.

6.VENTILACION

El equip debe ser usado en áreas con ventilación adecuada.

Deben er tornadas las precauciones necesarias para no impedir el

flujo de aire dentro y alrededor del aparato.

7.AGUA Y HUMEDAD

El equipo no debe ser usado en el agua ó alrededor de ésta, tales

como en una bañera, tanque o áreas de nado. También, el equipo

no debe ser usado en áreas propensas a inundaciones, tales como

en un sótano.

8.FUENTES DE PODER

El equipo debe ser conectado a una fuente de poder del mismo

voltaje y frecuencia que el indicado en el panel trasero sobre el

punto de entrada del cable de corriente.

9.PROTECCION DEL CABLE DE CORRIENTE

Los cables de corriente deben ser dispuestos de forma tal que no

interfieran con el movimiento de objetos en la sala: personas,

aspas de ventilación, carretillas, etc. También, es necesario tener

cuidado de que el cable no esté punzado o cortado, y debe estar

ubicado de forma tal que esto no ocurra, como podría suceder

debajo de una alfombra o al pasar el cable por una esquina

aguda, etc.

10.ATERRAMIENTO DEL CABLE DE CORRIENTE

El cable de corriente es del tipo aterrado de tres hilos, diseñado

para reducir el riesgo de una descarga eléctrica procendent de un

chasis energizado. Se asume que su longitud es suficiente para la

mayoría de usos del equipo. El uso de extensiones y multienchufes no es recomendado, a menos que tengan el amperaje

adecuado para poder suministrar la corrioente requerida pra la

operación segura de todo el equipo conectado. Aun más, las

extensiones deben proveer de la misma conección aterrada de tres

hiles. Es importante que el enchufe se pueda introducir completamente en el receptáculo. Nunca remeva el pin de aterramiento en

un intento por conectar el cable en un receptáculo de dos hilos

no aterrado: use un adaptador de aterramiento que esté adecuadamente conectado a un punto de tierra.

11.PERIODOS SIN USO

Durante períodos prolongados sin uso del equipo, el cable de corriente debe ser desconectado de la fuente de electrixidad.

12..LIMPIEZA

El equip debe ser limpiado solo en la forma que se detalla en las

instrucciones de operación.

13..INTRODUCCIÓN DE OBJETOS Y LIQUIDO

Deben ser tornadas precauciones con el fin de que objetos y/ó

líquidos, tales como fluidos de limpieza y gaseosas, no sean derramados dentro del chassis del aparato.

14.DAÑOS QUE REQUIEREN DE SERVICIO

Los equipos Hafler deben ser llevados a servicio por personal calificado cuando:

A.El cable de corriente ó el enchufe haya sido

dañado, ó

B.Objetos ó líquido hayan sido introducidos ó der

ramado en el equipo, ó

C.El equipo haya sido expuesto a lluvia, ó

D.El equipo aparenta no operar normalmente ó exhibe

un marcado cambio en su desempeño, ó

E.El equipo se ha caído, o el chassis ha sido golpeado.

15.SERVICIO

El usuario no deberá intentar darle servicio al equipo más allá de

lo que está descrito en el instructivo de operación. Todo lo demás,

deberá ser referido a servicio por personal calificado.

16.CARRETILLAS Y SOPORTES

El equipo podrá ser usado con carretillas y soportes que tengan la

fortaleza y estabilidad suficiente para el uso previsto.

La combinación equipo/carretilla deberá ser movida con cuidado.

Rápidas paradas y arranques, excesiva fuerza y superficies imparejas, pueden causar el volcamiento del conjunto de

carretilla/equipo.

El símbolo de flecha relámpago dentro de un triángulo equilátero, es

para alertar al usario de la presencia de “voltajes peligrosos” no aislados en el interior del aparato, los cuales pueden ser de suficiente

magnitud para constituir un riesgo de choque eléctrico a las personas.

El símbolo de exclamación dentro de un triángulo equilátero, es

para alertar al usuario de la presencia de instrucciones importantes

de operación y mantenimiento (servicio) en la documentación que

acompaña al equipo.

ADVERTENCIA – INFORMACION DE SEGURIDAD IMPORTANTE

PELIGRO

RIESGO DE DESCARGA

´

ELECTRICA NO ABRIR.

´

!

PRECAUCIONS:

Para Prevenir el incendio o la descarga electrica, no

exponer este equipo a la lluvia o a la humedad

´

Page 19

– 14 –

1.LIRE LES INSTRUCTIONS

Le mode d’emploi et les mesures de sécurité de votre équipement

Hafler devraient être consultés avant sa mise en marche.

2.CONSERVER LE GUIDE DE L’UTILISATEUR

Le mode e’emploi et les mesures de sécurité devraient être conservés

pour des références futures.

3.CONSIDÉRATIONS DE MISE EN GARDE

Le mode d’emploi et les mises en garde concernant cet équipement

sont de grande importance et devraient être suivis.

4.SUIVRE LE MODE E’EMPLOI

Le mode d’emploi et les conseils d’utilisation sont importants et

devraient être suivis.

5.CHALEUR

Le matériel devrait être préservé loin de toute source de chaleur:

radiateurs, cuisinière/fours, cheminées,…etc.

6.VENTILATION

Le matériel devrait être utilisé dans un endroit à bonne ventilation. Il

reste nécessaire de respecter la circulation de flux d’air à l’intérier et

autour du meuble.

7.EAU ET HUMIDITE

Le matériel ne devrait pas être utilisé près d’une source d’eau, telle

qu’une baignoire, un évier, ou une aire de baignade. De plus, le

matériel ne devrait pas être utilisé dans des lieux sujets aux innondations, tels que les sous-sols.

8.SOURCES D’ÉNERGIE

Le matériel devrait seulement être relié à une source d’énergie de

même voltage et fréquence que celle indiquée sur le tableau arrière,

au dessus de la fiche d’entrée de la prise de courant.

9.PROTECTION DE LA PRISE DE COURANT

La prise de courant devrait être arrangée de façon à ne pas interférer

avec le déplacement d’objets (chariots, pales de ventillateurs…etc.)

ou de personnes à l’intérieur de la pièce. D’autre part, il faudrait faire

tres attention à ce que la prise ne soit pas percée ou coupée, ou disposée de façon à risquer de l’être, comme sous un tapis, autour d’un

angle pointu…etc.

10.PRISE DE COURANT ÀTROIS FICHES

La prise de courant est composée de trois fiches, désignées à réduire

le risque de décharge électrique de l’appareil.

Elle devrait être de longueur suffisante pour la plupart des utilisations

de ce matériel. L’utilisation de rallonge t d’adaptateur est déconsellée

à moins dêtre en mesure de fournir la charge électrique requise à un

fonctionement sans risque, de tout matériel relié.

11.PÉRIODES DE NON-UTILISATON

Durant les périodes de non-utilisation, la prise de courant ne

devrait pas être branchée à une source d’energie.

12.NETTOYAGE

Le matériel devrait être nettoyé en respectant les instructions

indiquées.

13.PENETRATION DES LIQUIDES

Un attention particulière est éxigée quant à la dispersion de liquides tels que les produits de nettoyage et boissons, de façcon à

éviter toute pénetration dans l’enceinte du matériel.

14.DÉGÂT NÉCESSITANT UNE RÉVISION

Le matériel Hafler devrait être révisé par des personnes qualifées

de service après-vente, lorsque:

A.Les fiches ou la prise de courant ont été endommagé, ou:

B.De objets sont tombés sur le matériel, ou des liquides s’y sont

dispersés, ou:

C.Le matériel a été exposé à la pluie, ou:

D.Le matériel ne semble pas fonctioner correctement, ou

affiche un changement de performance, ou:

E.Le matériel a été renversé à terre, ou l’enceinte a été

endommagée.

15.REVISION

L’utilisateur ne devrait pas essayer de réviser le matériel en allant

plus loin que ce qui a été décrit dans le mode d’emploi. Toute

autre réviion devrait être confiée à un personnel qualifié.

16.CHARRIOTS ET MEUBLES

Le matériel devriat être utilisé avec des charriots et meubles de

qualité et stabilité suffisante à son utilisation préconçue.

L’ensemble du matériel et du charriot devrait être déplacé avec

précaution. Des mises en marche et arrêts brusques, des collisions

excessives ainsi que des surfaces inégales peuvent renverser

l’ensemble du matériel et du charriot.

ATTENTION: INFORMATIONS IMPORTANTES DE SÉCURITÉ

La lumière clignotante du symbole de la flêche à l’intérieur d’un triangle

équilatéral, à pour objet d’alerter l’utilisateur de la présence “d’un voltage dangereux” non-isolé à l’intérieur du produit, qui pourrait être de magnitude suffisante au risque d’éléctrocution.

Le point d’exclamation, à l’intériur d’un triangle équilatéral, à pour objet de

prévenir l’utilisateur de l’importance des instructions de fonctionement et de

maintenance, jointes à l’appareil.

´

´

AVERTISSEMENT:

Afin de prevenir les risques de feu ou de choc, ne pas

exposer cet appareil a la pluie ou a l'humidité

´

´

ATTENTION

RISQUE DE CHOC

ELECTRIQUE NE PAS OUVRIR

!

Page 20

– 15 –

1.INSTRUKTIONEN LESEN

Alle Sicherheits- und Operationshinweise Ihres Hafler Equipments

sollten vor der Inbetriebnahme gelesen werden.

2.BETRIEBSANLEITUNG AUFBEWAHREN

Bewahren Sie die Bedienungsanleitung sorgfältig auf, damit Sie in

dieser auch in Zukunft nachschlagen können.

3.WARNUNGEN BEACHTEN

Alle Warnungen des Gerätes und der Bedienungsanleitung sind

extrem wichtig und müssen befolgt werden.

4.INSTRUKTIONEN BEACHTEN

Alle Operations- und Gebrauchshinweise sind extrem wichtig und

müssen beachtet werden.

5.HITZE

Das Equipment sollte fern von Hitze ausstrahlenden Geräten

aufgestellt werden, wie z.B. Heizungen, Öfen etc.

6.VENTILATION

Das Equipment sollte so aufgestellt werden, dab eine ausreichende

Ventialition gewährt wird.

7.WASSER UND FEUCHTIGKEIT

Das Equipment sollte nicht im oder in der Nähe von Wasser

benutzt werden, wie z.B. in Schwimmbädem, Saunen etc. Es sollte

ebenfalls nicht in Überschwämmungsgefährdeten Gebieten

aufgestellt werden, wie z.B. Kellerräumen.

8.STROMANSCHLUb

Das Equipment darf nur an eine Stromversorgung angeschlossen

werden, die die gleichen Parameter aufweist, welche auf der

Rückseite, über em Anschlubterminal des Gerätes, aufgelistet sind.

9.SCHUTZ DER ZULEITUNG

Die Zuletungen sollten so verlegt werden, dab diese nicht in den

Bewegungsbereich anderer Möbelstücke oder Personen hereinragen. Achten Sie darauf, das das Kabel nicht gequestscht oder

durchschnittren wird, wie z.B. unter Schränken oder an scharfen

Kanten etc.

10.MASSEANSCHLUb

Das dreiadrige Anschlubkabel ist mit einem Erdungsleiter ausgestattet, welcher die Risiken eines Elektroschocks verringert. Das

Kabel hat eine Länge, welche für die meisten Anwendungen völlig

ausreicht. Wenn Sie Verlängerungskabel benutzen, achten Sie

darauf, das dies die erforderlichen Ströme bertragen können.

Benutzen Sie immer dreiadrige Verlängerungskable.

11.ZEITRÄUME IN DENE DAS GERÄT NICHT GENUTZT WIRD

Wird das Gerät über einen längeren Zeitraum nicht genutzt (z.B.

Urlaub), ziehen Sie bitten den Netzstecker aus der Steckdose.

12.REINIGEN

Reinigen Sie das Gerät nur, wie in der Bedienungsanleitung detailliert beschrieben.

13.EINDRINGEN VON FREMDKÖRPERN

Achten Sie darauf, dab weder Fremdkörper, noch Flüssigkeiten in

das Gerät eindringen.

14.ERFORDERLICHER REPARATURSERVICE

Hafler Equipment sollte nur von qualifizierten Service-Technikern

instand gesetzt werden, wenn:

A.Das Stromversorgungskabel beschädigt wurde

B.Eine Flüssigkeit in das Gerät eingedrimgem ist

C.Das Gerät Regen ausgesetzt wurde

D.Das Gerät nicht mehr ordnungsgemäb funktioniert, ggf. nicht

mehr die volle Leistung abgibt

E.Das Gerät runtergefallen ist oder das Gehäuse

beschädigt wurde

15.SERVICE

Der Benutzer sollte nur den Service ausführen, der in der

Bedienungsanleitung für den Benutzer freigegeben wird. Den weiterführenden Service sollte nur von qualifizierten Tevhnikern

durchgeführt werden.

16.AUFSTELLUNG

Das Equipment sollte so aufgestellt werden, dab der gewählte

Untergrund die erforderliche Stabilität aufweist, so dab eine

gefahrlose Bnutzong gewährleistet wird.

Das Equipment und der Untergrund sollte mit äuberster Vorsicht

bewegt werden. Bei schnellen Bewegungen oder starkem

Abbremsen, kann es zum Umkippen des Equipments kommen.

ACHTUNG – WICHTIGE SICHERHEITS – INFORMATIONEN

Der Blitz mit dem Pfeil, in einem gleihschenkligen Dreieck, soll den

benutzer vor unisolierter “gefährlicher Spannung” innerhalb des

Gerätes warnen.

Das Ausrufezeichen, in einem gleichschenkligen Dreieck, soll den

Benutzer darauf aufmerksam machen, dab dem Gerät wichtige

Operations - und Service - Informationen beigefügt sind.

ACHTUNG

GEFAHR EINES

ELEKTRISCHEN SCHLAGS

Um die gefahr eines elektroschocks oder feuer zu

vermeiden, setzen sie das gerat keinem regen oder

extremer feuchtigkeitaus.

¨

NICHT OFFNEN

WARNUNG:

!

¨

Page 21

– 16 –

1.LEGGETE LE ISTRUZIONI

Tutte le istruzioni riguardanti la sicurezza ed il funzionamento

devono essere lette prima di applicare tensione all’apparato.

2.CONSERVATE IL MANUALE

Queste istruzioni riguardanti la sicurezza ed il funzionamento

devono essere conservate come riferimento futuro.

3.AVVERTENZE

Tutte le avvertenze poste sull’apparato e sul libretto di istruzioni

sono importanti e devono essere seguite.

4.SEGUIRE LE ISTRUZIONI

Tuttle le istruzioni operative e di funzionamento devono essere

seguite.

5.TEMPERATURA

L’apparato deve essere mantenuto lontano da tuttle le zone ad alta

temperature, termosifoni, termoconvettori, stufe e forni, caminetti

ed altro.

6.VENTILAZIONE

L’apparato deve essere posizionato in aree convenienti per una

corretta ventilazione. Prestare attenzione che sia consentita circolazione d’aria attorno e dentro il cabinet.

7.ACQUA E POLVERE

L’apparato deve essere posizionato lontano da zone contenenti

acqua, come vasche a bagno, acquari e piscine. Inoltre non deve

essere impiegato in aree soggette ad allagamento, come le cantine.

8.REQUISITI DI ALIMENTAZIONE

L’apparato deve essere connesso solo ad un’alimentazione della

stessa tensione e frequenza di quanto scritto sulla parte posteriore

del telaio.

9.PROTEZIONE DEL CAVO DI ALIMENTAZIONE

Il cavo di alimentazione deve essere posizionato in modo di non

interferire con il movimento di oggetti nella stanza: persone, ventilatori, carrelli, ecc…prestate attenzione anche che il cavo non sia

tagliato o spellato e che non possa tagliarsi e spellarsi.

10.MESSA A TERRA

Il cavo di alimentazione è del tipo a tre fili con terra ed è progettato pr ridurre il rischio di shock elettrici. Si presume che sia della

lunghezza sufficiente per la maggior parte degli impieghi.

L’impiego di prolunghe e adattatori è sconsigliato se questi non

garantiscono la potenza sufficiente per i corretto fuinzionamento

degli apparati connessi. E altersì importante che vengano sempre

impiegate prolunghe con la configurazaione a tre fili con terra.

NOTARE – IMPORTANTI INFORMAZIONI SULLA SICUREZZA

11.PERIODI DI NON UTILIZZO

Durante lunghi periodi di non utilizzo, staccare il cavo di

alimentazione.

12.PULIZIA

L’apparato deve essere pulito solo come indicato dalle

istruzioni.

13.INGRESSO DI OGGETTI E LIQUIDI

Si deve prestar attenzione che oggetti e liquidi, come fluidi

detergenti e bibite, non vengano versati all’interno dell’ap

parato.

14.RIPARAZIONI

Gli apparati Hafler devono essere riparati da personale

qualificato quando:

A.Il cavo di alimentazione o la spina sono danneg

giati

B.Oggetti sono caduti all’interno del telaio o quando del

liquido è entrato

C.Quando l’apparato è stato esposto a pioggia

D.Quando l’apparato non sempra funzionare normalmente o

quando esibisce un cambiamento di prestazioni o

E.Quando è caduto o il telaio è stato danneggiato

15.ASSISTENZA

L’utente non deve tentare di prestare assistenza all’apparato, se non

per quanto esposto nelle istruzioni. Tutti gli altri interventi devono

essere effettuati da un tecnico specializzato.

16.CARRELLI E STAND

L’apparato deve essere impiegato su carrelli o stand solo se questi

sono sufficientemente solidi e stabili per la funzione a cui si vuole

dedicarli.

La combinazione di carrello ed apparato deve essere mossa con

cautela. Fermate e partenze improvvise, forze eccessiva e superfici

irregolari, possono ribaltare la cominzione carrello e apparato.

Il simbolo del fulmine in un triangolo equilatero vuole avvertire della presenza di tensioni elevate non isolate e di valore sufficiente per costituire

rischio di shock elettrico alle persone.

Il punto esclamativo contentuto in un triangolo equilatero vuole avvertire

l’utente della presenza di parti di servizio e di manutenzione che sono

dettagliate nel manuale di istruzioni.

ATTENZIONE:

Per prevenire incendio scariche elettriche, non esporre

questo apparato a pioggia o umiditá.

ATTENZIONE

ATTENZIONE:

RISCHIO DE SCARICHE

ELETTRICHE NON APRIRE

!

Page 22

– 17 –

Notes

Page 23

– 18 –

Notes

Page 24

5/2000 M.J.T.

LIT. 10653

MADE IN THE USA

This product is designed, developed and assembled in the USA by a dedicated group of

American workers. The majority of the components used in the construction of this product

are produced by American companies. However, due to the global nature of their

manufacturing facilities and the electronics parts industry in general, some parts may be

manufactured in other countries.

®

A DIVISION OF ROCKFORD CORPORATION

546 SOUTH ROCKFORD DRIVE

TEMPE, ARIZONA 85281 U.S.A.

1-888-HAFLER1 / 480-967-3565

WWW.HAFLER.COM

Loading...

Loading...