Hafele America 104 User Manual

Mounting instructions

Wall Terminal

Technical information

All wall terminals are supplied in the basic method of operation.

With this method of operation, electronic keys are given access

authorisations directly at the wall terminal with a special programming

key stick (green). Up to 100 electronic keys can be allocated per wall

terminal. With a clearing key stick (red), the access authorisations of an

authorised electronic key can be withdrawn directly at the wall terminal.

If a different method of operation needs to be chosen, please contact

your Dialock sales office.

Technical data

Voltage supply 10 - 12 VDC, 8 - 10 VAC

Continuous current intake <200 mA

Peak current intake 250 - 400 mA, depending on

Number of relays 1 - 3

Contact load relay

Voltage on contact max. 60 VDC, max. 125 VAC

Current on contact max. 2 A, (short term)

Contact rating max. 30 W, max. 60 VA

Continuous current max. 1 A

Data retention in case of power cut 10 years

Mounting instructions

number of relays

for external

sector

Protection level

Reader module IP 68 IP 54

Control electronics module IP 66 IP 66

Temperature-operating range

Reader module -20 - 80 °C 0 - 60 °C

Control electronics module 0 - 60 °C 0 - 60 °C

relative air humidity (non

condensating)

engl. 15

0 - 95 % 0 - 95 %

for internal

sector

Range of application

Wall terminals control electric door openers and motor locks for:

l

external or internal doors

or:

l

automatic roller shutters

l

barriers

appliances and installations, such as goods dispensers or sun beds

can also be monitored via wall terminals.

Important characteristics:

l

suitable for surface- and flush fitted installation

l

can be used as cash terminal

l

can be connected to a central unit (PC) via online adapter

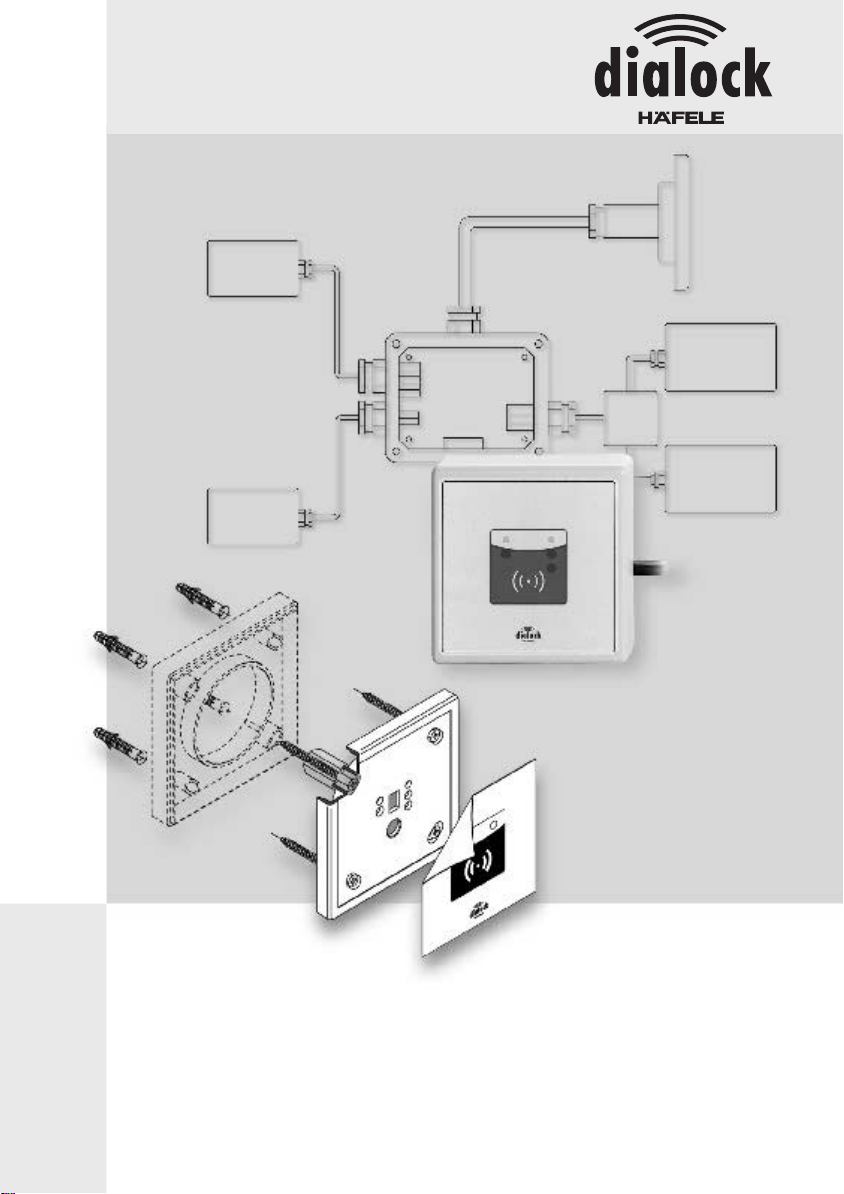

Supply schedule

The configuration supplied, consists of:

l

reader module with approx. 2.5m long, round, flat band cable and

plug for connection to the control electronics module

l

front foil to apply onto the reader module

l

spacer plate for the surface installation of the reader module

l

control electronics module with one relay (optionally up to 3)

l

screw fixings for the casing of the control electronics module

l

PG-9-screw fixing for connecting the flat band cable to the control

electronics module

l

feeder implement to connect cables to the control electronics module

l

spare plug for the flat band cable

Mounting instructions

16 engl.

Installation

Mounting instructions

The following steps are necessary for the installation:

l

install the reader module

l

install the control electronics module

l

electrical installation

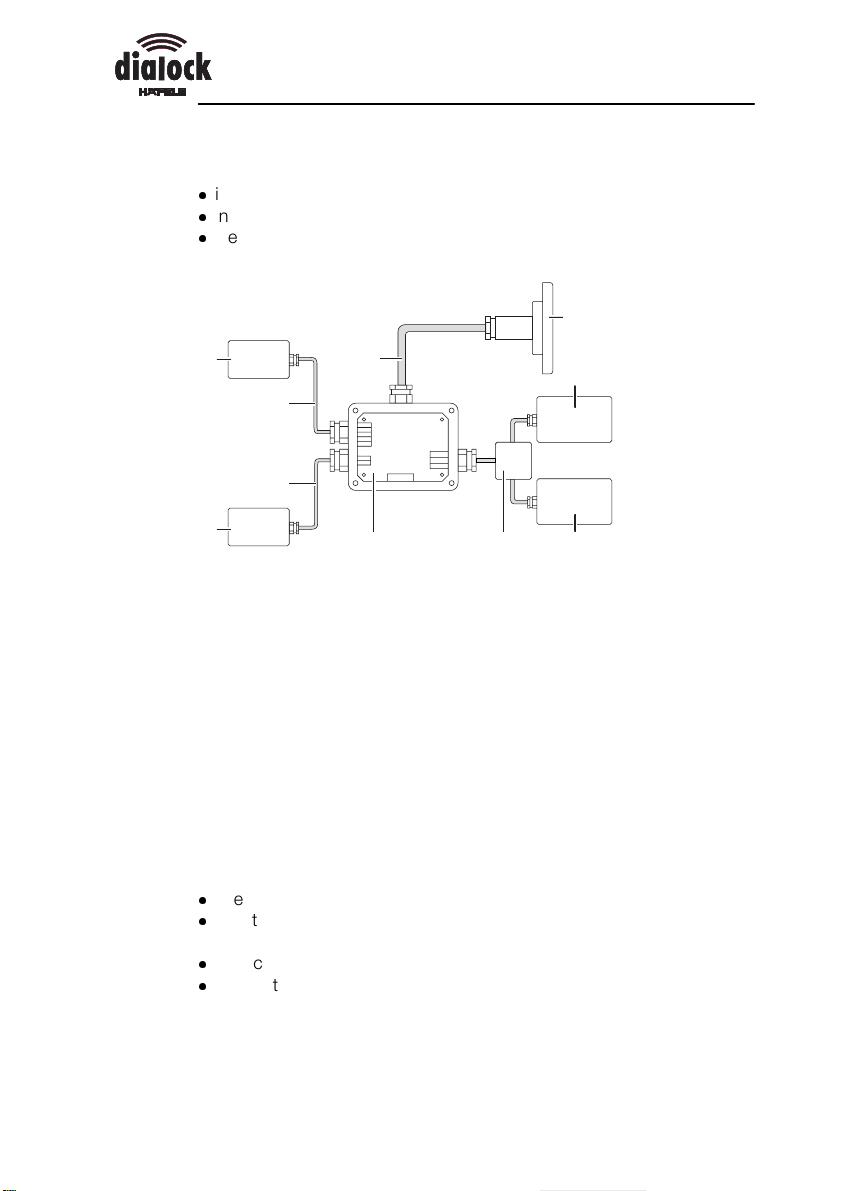

2

10

9

8

7

1

3

6 5 4

1 flat band cable (round, shielded)

2 reader module

3 element to be switched (appliance)

4 power supply for element to be switched (appliance)

5 distributor

6 control electronics module

7 power supply for control electronics module

8 conductor

9 interface cable (optional)

10 online-adapter (optional)

During the planning phase, the following installation measures need to

be considered:

l

internal or external installation of the modules

l

exact location for the modules to be installed, considering the

position of the elements to be switched (i.e. door lock, barrier)

l

surface- or flush fitted installation of the modules

l

connection of the wall terminals to a central unit (PC) via online-

adapter

engl. 17

Mounting instructions

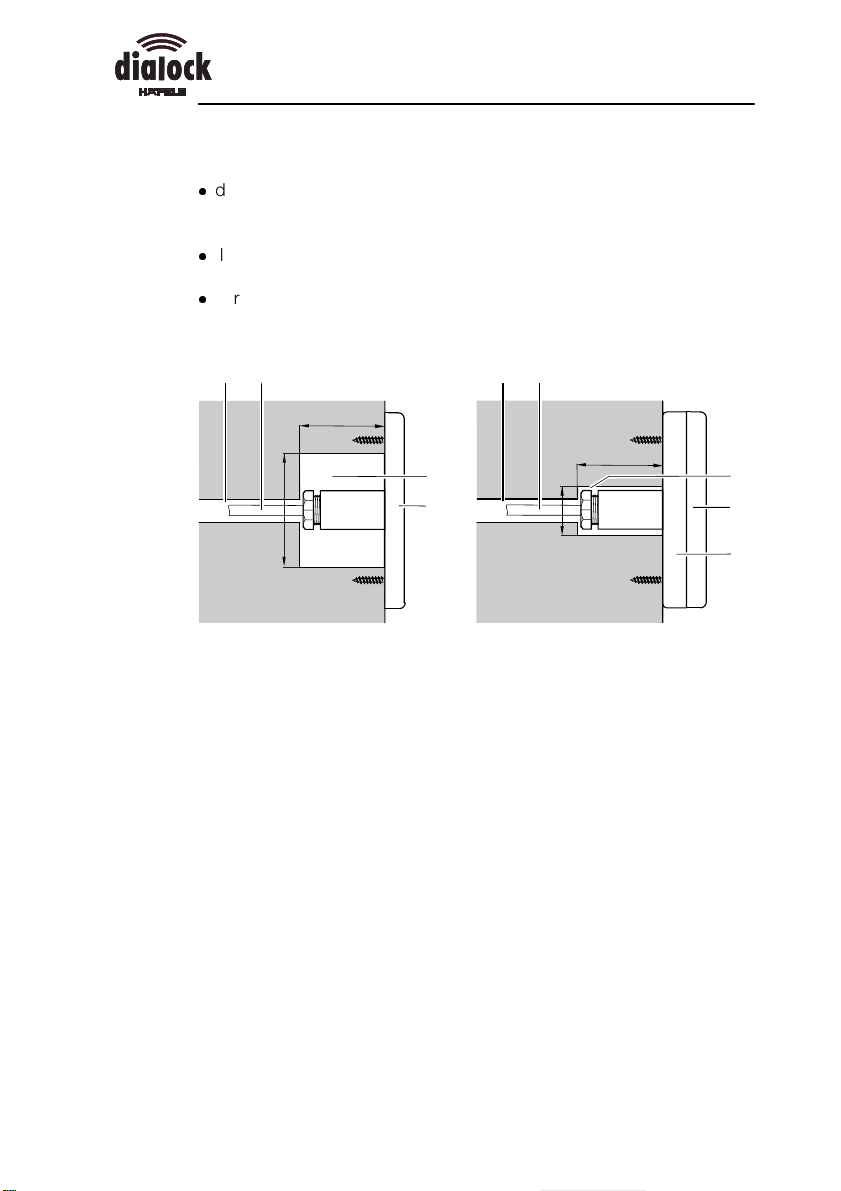

Install the reader module

Preparations:

l

drill a hole into the wall for the connecting cable between the reader

module and the control electronics module. Lay a protective pipe

with an internal diameter of at least 12 mm or a cable channel.

l

flush fitted installation: install a flush fitted container with a diameter of

70 mm and a minimum depth of 60 mm.

l

surface installation: drill a 25 mm diameter hole and minimum 48 mm

depth for the PG-9-screw fixing.

2

2

1

min. 60

1

70

3

4

min. 48

min. 25

3

4

5

Flush fitted installation (left) and surface installation (right) of the reader module

1 protective pipe (internal diameter min. 12 mm)

2 cable (diameter = 8 to 9 mm, length = 2,5 m)

3 flush fitted container, resp. drilling for PG-9-screw fixing

4 reader module

5 spacer plate

1. for flush fitted installation: drill a 12 mm diameter hole in the centre

of the flush fitted container.

2. for flush fitted installation: remove the spacer plate of the reader

module.

18 engl.

Loading...

Loading...