Montageanleitung

Mounting Instructions

Instructions de montage

Istruzioni di montaggio

Instrucciones de montaje

Dialock Türterminal DTSH, DTSH FH

Dialock Door Terminal DTSH, DTSH FH

Dialock Terminal de Porte DTSH, DTSH FH

Dialock Terminale Porta DTSH, DTSH FH

Dialock Terminal de Puerta DTSH, DTSH FH

EN

FR

IT

ES

DE

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

37

English

Installation Instructions

Contents

Scope of delivery ..................................................................................39

Accessories (not included in the scope of delivery) .............................40

DTSH Application areas .......................................................................42

DTSH FH application areas .................................................................42

Features ...............................................................................................42

Installation instructions .........................................................................43

Start-up .................................................................................................63

Short instructions .................................................................................65

Operation ..............................................................................................66

Battery change .....................................................................................66

Emergency opening .............................................................................68

FAQ.......................................................................................................69

Maintenance and cleaning instructions ................................................69

Technical data ......................................................................................69

38

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

39

English

Installation Instructions

Always follow the instructions in the "Start-up and maintenance"

guide when starting up (assigning keys)!

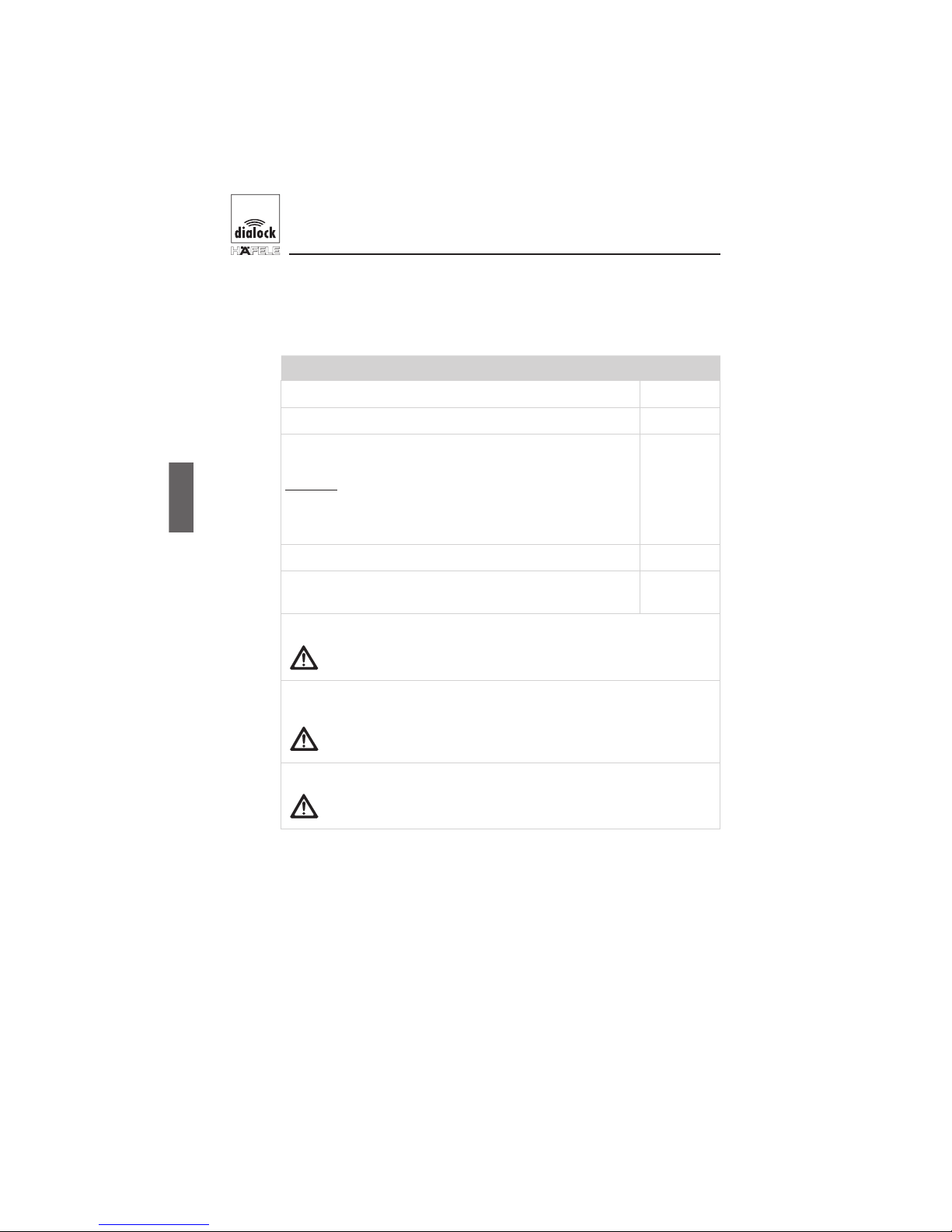

Scope of delivery

1 External module

1 Internal module

Small parts bag with

profile cylinder cover (break-open seal)

1 Promaseal strip (DTSH FH only)

Profile cylinder coverFig. 1

Profile cylinder

cover

Rotary knob

(fixed at hood)

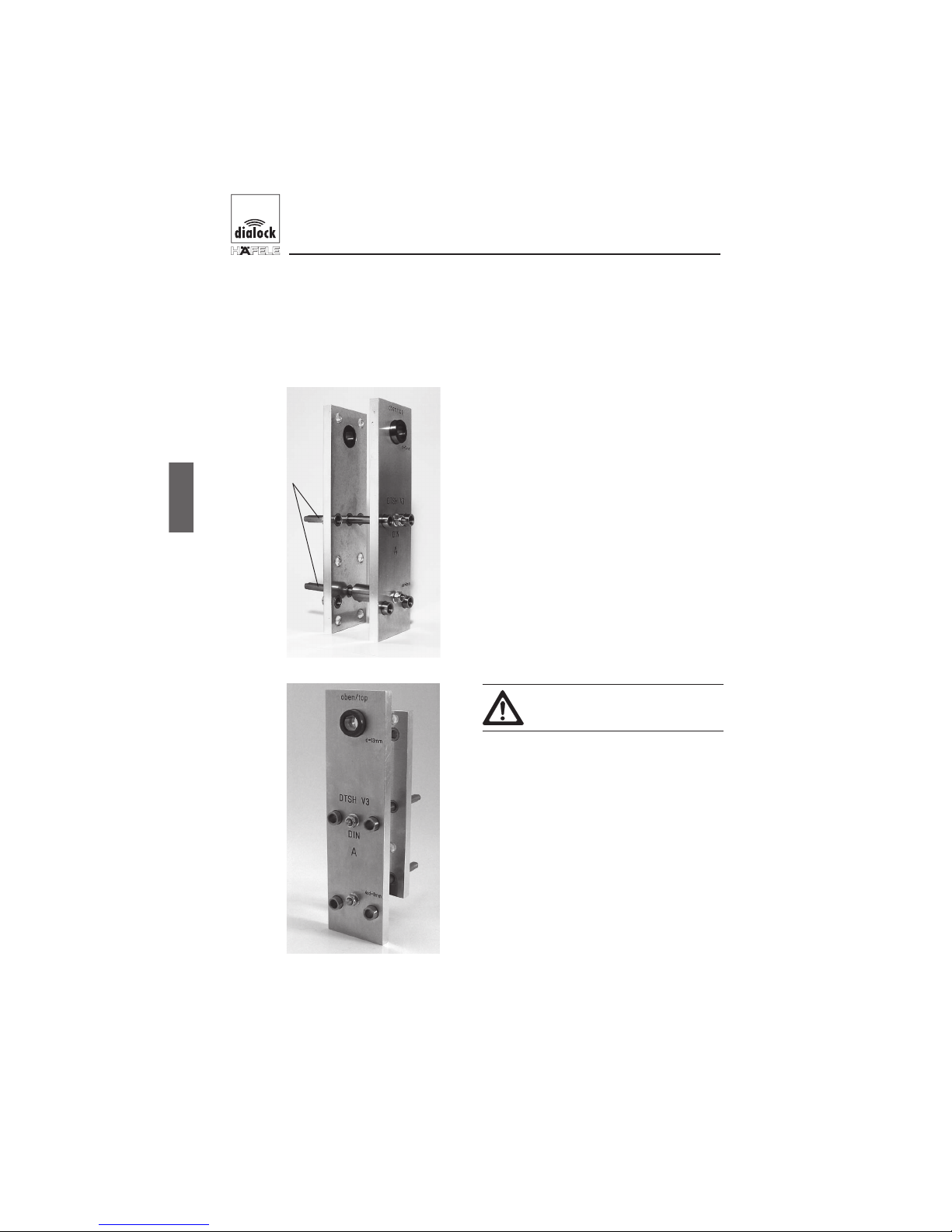

Internal module External moduleFig. 3

Promaseal stripFig. 2

40

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

Accessories (not included in the scope of delivery)

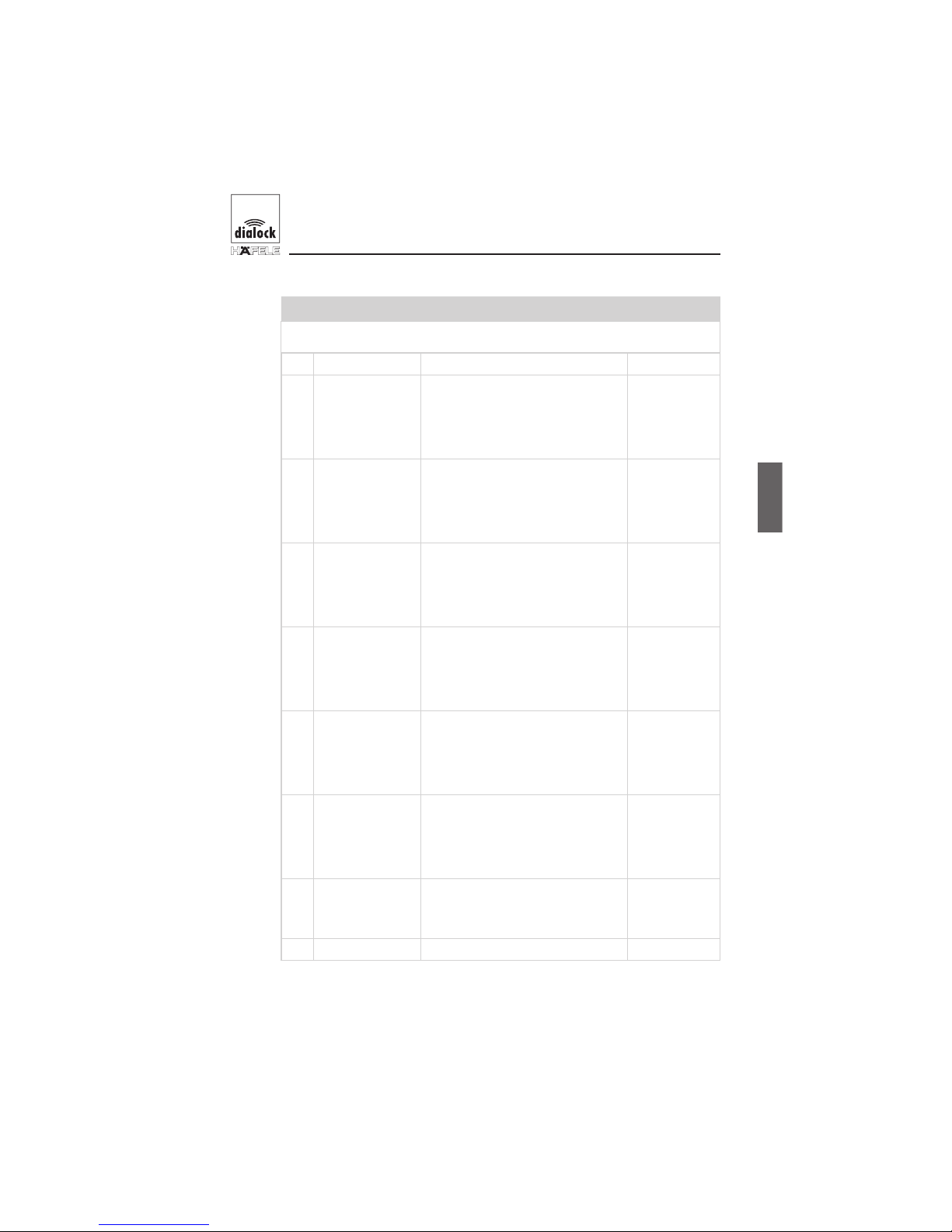

Accessories (not incl. in the scope of delivery) Cat. No.

Black plastic spacer plate 917.90.492

Stainless steel spacer plate for DTSH FH 917.90.216

Profile cylinder cover (break-open seal),

plastic, black

Optional:

Stainless steel matt

Stainless steel polished

Brass polished

25 pieces 917.90.483

917.90.480

917.90.481

917.90.488

User key: Different models

4 x 1.5 V batteries, size AA Mignon type E91

Energizer

®

Ultra+

910.54.980

Lever handle aperture part: Different models.

DTSH FH: Only supplied models may be used

(see catalogue).

Single profile cylinder:

Length depends on door leaf thickness.

Single profile cylinder must be fitted with DTSH FH!

Mortise lock: Different models

DTSH: Locks in accordance with DIN 18251.

DTSH FH: Locks in accordance with DIN 18273.

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

41

English

Installation Instructions

Accessories (not incl. in the scope of delivery) Cat. No.

Mounting sets for DTSH

No. Door thickness Consisting of

1 37 – 47 mm 1 inner square spindle L=100mm 917.90.242

4 countersunk head screws

DIN 965 M4x30

für DTSH FH 917.90.121

2 47 – 57 mm 1 inner square spindle L=110mm 917.90.244

4 countersunk head screws

DIN 965 M4x40

for DTSH FH 917.90.122

3 57 – 67 mm 1 inner square spindle L=120mm 917.90.246

4 countersunk head screws

DIN 965 M4x50

for DTSH FH 917.90.124

4 67 – 77 mm 1 inner square spindle L=130mm 917.90.248

4 countersunk head screws

DIN 965 M4x60

for DTSH FH 917.90.126

5 77 – 87 mm 1 inner square spindle L=130mm 917.90.250

4 countersunk head screws

DIN 965 M4x70

for DTSH FH 917.90.128

6 87 – 97 mm 1 inner square spindle L=160mm 917.90.251

4 countersunk head screws

DIN 965 M4x80

for DTSH FH 917.90.130

7 97 – 107 mm 1 inner square spindle L=160mm on request

4 countersunk head screws

DIN 965 M4x90

for DTSH FH on request

42

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

DTSH Application areas

The Dialock DTSH door terminal is an electronic door fitting for use in

hotels. It is mounted to internal doors with mortise locks in accordance

with DIN 18 251* and can also be easily retrofitted to the door leaf. The

use of a single profile cylinder is recommended for emergency openings.

* Mortice lock bolt-through fixing holes must be present (fig. 4, page 43)

Using the Dialock DTSH door terminal on fire resistant and smoke

control doors invalidates the Fire Certificate of the doors!

Please contact your Häfele sales office if you intend to use the door terminal on fire resistant and smoke control doors.

DTSH FH application areas

Permission from the door manufacturer is required to install the DTSH FH.

If the DTSH FH door terminal is installed without permission, the Fire Certificate for the fire resistant and smoke control door will be invalidated. The

fitting must always be installed by trained personnel.

Features

Robust metal housing

Convenient and easy to use

Automatic activation using the latest RF technology

"Do not disturb" function using lock handle

Battery operation using normal commercial batteries, size AA (Mignon)

Infrared interface for easy configuration

Easy to install

Optional: Mechanical emergency opening is logged

(appropriate mortise lock required)

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

43

English

Installation Instructions

Installation instructions

DTSH:

Do not mount to fire resistant and smoke control doors!

Please contact your Häfele sales office.

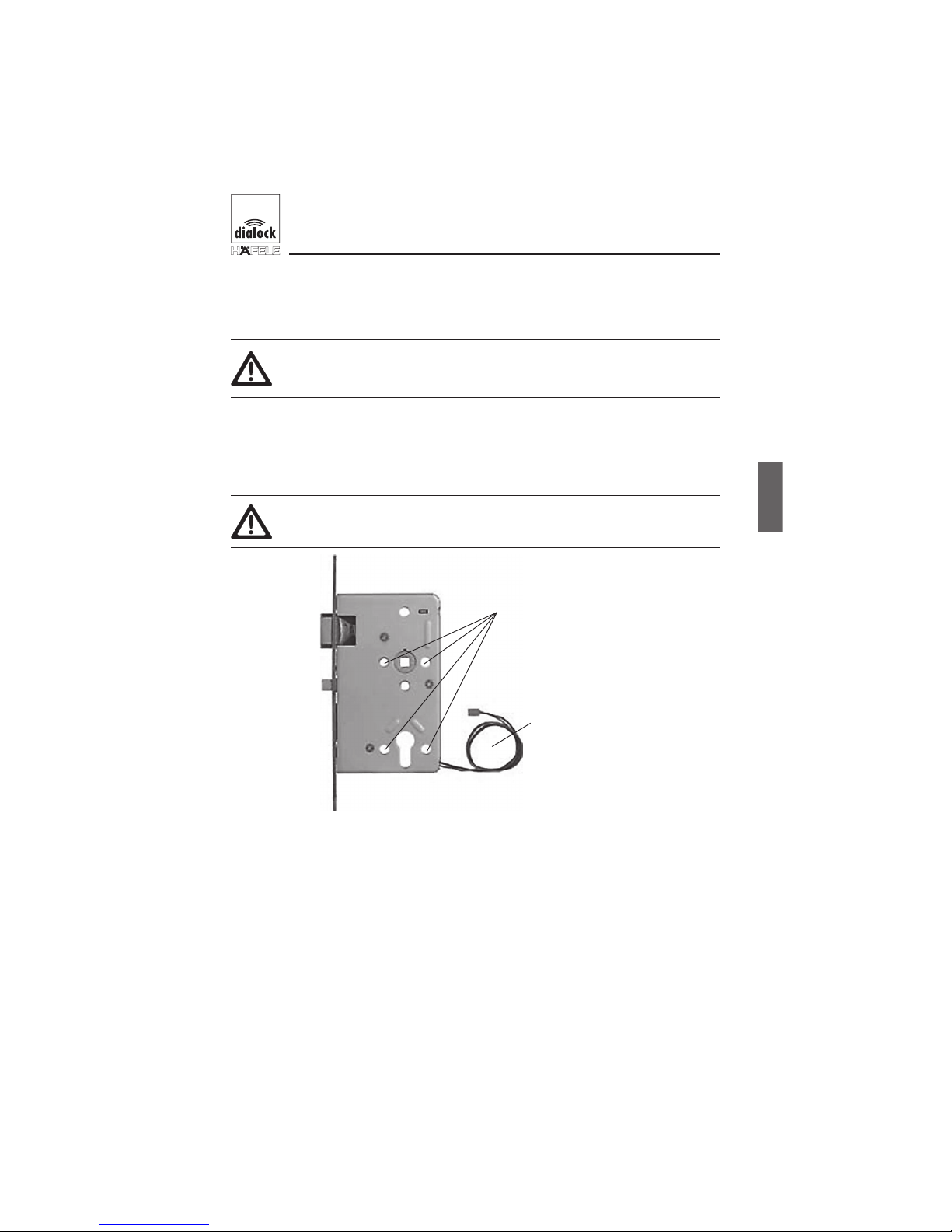

Installation requirement

The doors must be prepared for the use of DIN 18 251 locks (lock pocket

and mortise lock).

The mortise lock must have the depicted Mortice lock bolt-through

fixing holes for the fitting.

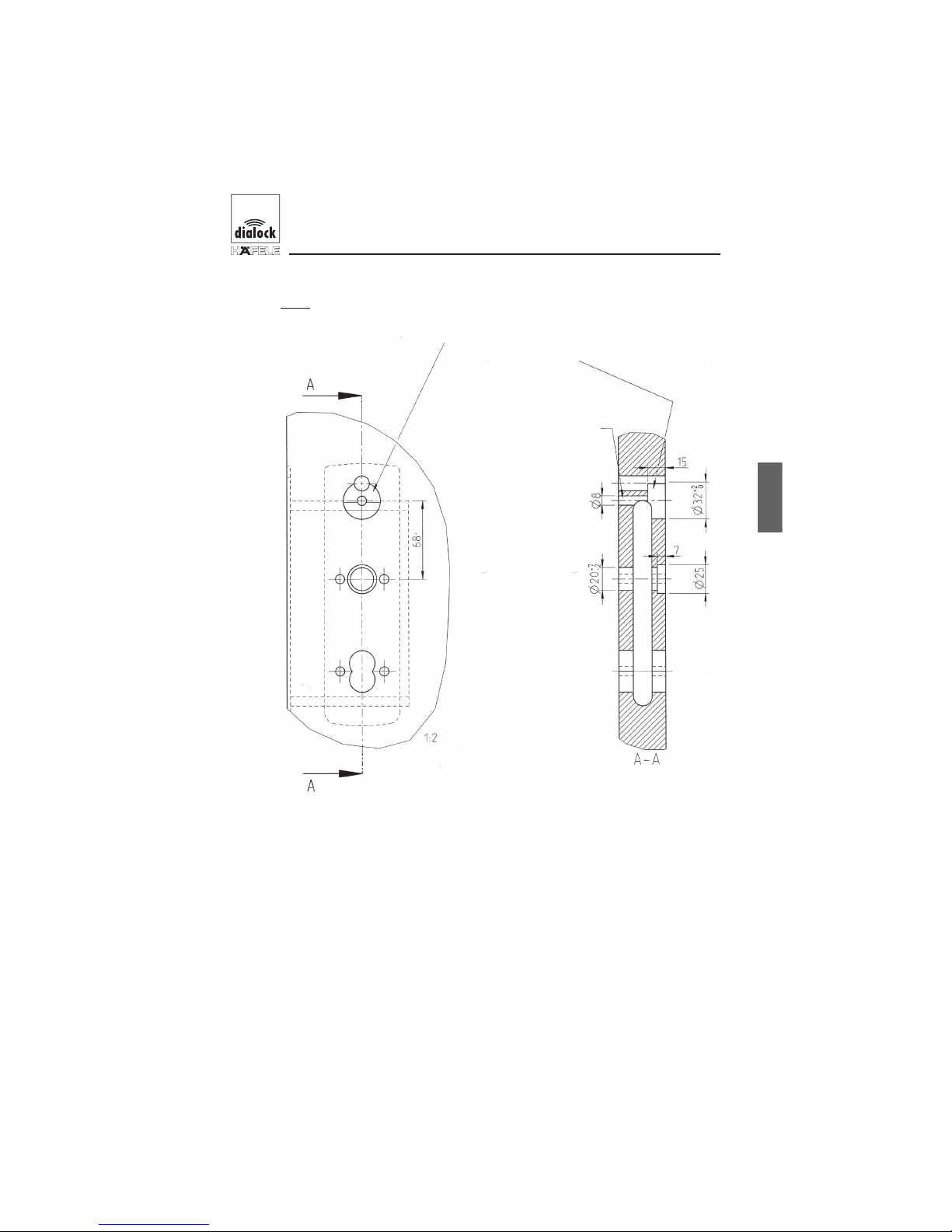

Fig. 4

The length of the following Dialock DTSH door terminal components

depends on the thickness of the door leaf. They must therefore be selected

accordingly.

Mounting set consisting of: Fixing screws and inner square spindle (for

scope of delivery see page 39).

Single profile cylinder (not included in the scope of delivery).

Cable only required for mortise

locks with emergency opening

log.

Mortice lock bolt-through fixing holes

44

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

The black plastic profile cylinder cover is also a break-open seal and

must not be fitted until start-up has taken place.

Do not bring media (keys) into the reading area during installation if

the batteries have been inserted!

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

45

English

Installation Instructions

Tools

Tools Cat. No.

Locking ring pliers (for fitting locking

ring to inner square spindle)

917.90.900

SW3 T-handle for

grub screws of lever handle aperture part

and removing the inner hood

006.32.013

DTSH DIN drilling jig 917.90.005

Router cutter for breakthrough to lock

nut

Ø 25 mm 910.54.995

Router cutter

with centring pin

only needed for

mortise lock with

mergency opening logging)

Fig. 5

Ø 32 mm 910.54.997

Stop for router cutter

(only needed for mortise lock with emergency opening log)

Fig. 6

32 mm 001.28.129

Drill bits

(cable leadthrough)

Fig. 7

13 mm 001.41.351

Drill

(Fastening spots)

8 mm 001.41.248

Drill

Cross slot screwdriver size 2 006.28.382

46

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

Installation

Condensation that forms on cold components can damage the

Dialock DTSH door terminal.

ð Please ensure that all components are at ambient temperature!

The way in which the fitting is mounted to wooden doors is described in

the following.

Please adhere to the following procedure when installing the Dialock

DTSH door terminal:

Insert mortise lockA. Page 47

Drill holes for fixing screws and connecting cableB. Page 48

Remove mortise lock, clean and re-insertC. Page 53

Insert single profile cylinderD. Page 54

Adjust external module for right-pointed/left-pointed door E.

handle

Page 56

Secure inner square spindleF. Page 57

Mount external module of Dialock DTSH door terminalG. Page 58

Mount internal moduleH. Page 60

Fig. 8

With emergency opening

log, protect connecting cable

during the drilling procedure

as shown in the illustration.

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

47

English

Installation Instructions

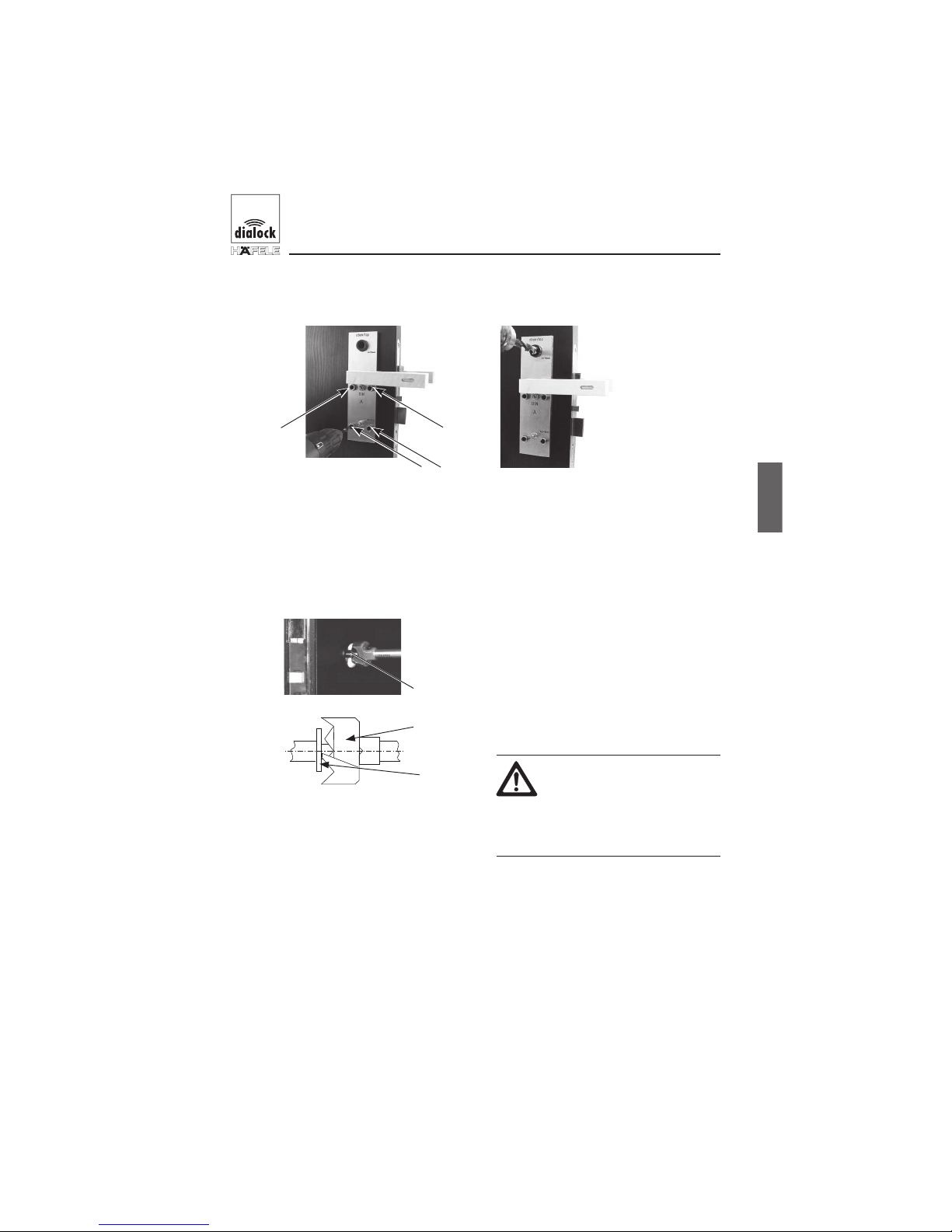

Insert mortise lockA.

Risk of the cable being crushed by mortise lock with emergency

opening log!

Insert mortise lock.1.

Fig. 9

cable

Fig. 10

cable

Fig. 11

Hooded

screw

Fig. 12

Screw in the mortise lock. 2.

With mortise lock with emergency opening log, the mortise lock connecting cable must be fixed in position as shown in fig. 11.

Check position of mortise lock using a locking cylinder. The locking cyl-3.

inder must be easy to insert. If necessary, increase size of lock pocket

or clear the locking cylinder access route.

incorrect

correct

48

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

B. Drill holes for fixing screws and connecting cable

In order to obtain a neat drill hole, the through holes should first be

part drilled from one side of the door to the middle of the door leaf

and then drilled through from the other side of the door.

Preparing for drilling

Without emergency opening log

Drilling pattern without emergency opening logFig. 13

Cable drill hole

Ø 13 mm, continuous

for connecting cable for external /

internal module

Depth cutting

Ø 25 mm:

external only: 7 mm deep

4 x fixing holes

Ø 8 mm, continuous

Outer contour

DTSH

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

49

English

Installation Instructions

Depth cutting only needed for Fig. 14

emergency opening log

Depth cutting to lock pocket Ø 32 mm

Centring hole for

router cutter with

centring pin

Space for

coupling

Inside of

door

Outside of

door

Section:

Drilling pattern with Fig. 15

emergency opening

logging

Only for emergency opening log

50

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

Drilling jig parts A-BFig. 16

Select drilling jig with part A-B and 1.

A-C for the individual drill holes:

Insert centring pins for drilling jig 2.

(part A) through the square spindle

and cylinder apertures of the mortise lock. (Fig. 16)

Place drilling jig part B onto the 3.

centring pins from the other side

of the door. Clamp drilling jig into

position using a screw-clamp.

Drilling jig parts A-CFig. 17

Do not damage surface of

door.

Use drilling jig

The drilling jig consists of parts A, B and C. The drilling template must be

prepared in combinations A-B and A-C depending on the drill hole.

Centring

pins

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

51

English

Installation Instructions

Drill holes on inside of door

Fig. 18 Fig. 19

Drill the fixing holes at both sides

as far as the middle of the door leaf

using the 8 mm drill bit.

Drill 13 mm hole at both sides for

cable connection.

Fig. 20

Fig. 21

Cut out the coupling area.

Note:

Cutting only required on the outside.

Do not damage mortise

lock with router cutter.

Slide the spacer onto the

journal of the router cutter to prevent damage.

(Fig. 20, 21)

Spacer

25 mm router

cutter

25 mm router

cutter

Spacer

52

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

Only required with emergency opening log!

Drilling jig parts A-CFig. 22

Drill through to the middle of the door

leaf from both sides using the 8 mm

drill bit to connect the emergency

opening log. (Centring hole for 32 mm

router cutter)

This procedure can

destroy the connecting

cable for emergency

opening log. The connecting cable must not

be routed in the lock

pocket at location A,

fig. 22!

Fig. 23

Remove mortise lock

from lock pocket!

Depth cutting as far as lock pocket.

Page 49, fig. 15, section A-A.

A

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

53

English

Installation Instructions

C. Remove mortise lock, clean and re-insert

Fig. 24

Remove mortise lock.

Outside of door is already drilled and cut.

Before continuing, remove debris

and clean lock pocket.

With emergency

opening log, lead connecting cable into the

inside of the lock pocket and out via the hole

that has been cut.

Fig. 25

Pay attention to cable routing when inserting the connecting cable!

Do not crush cable! (Fig. 25)

Insert mortise lock as described in "A. Insert mortise lock" on page 47.

Connection cable

Depth cutting

Door leaf

Connector

Mortise lock

Lock pocket

54

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

D. Insert single profile cylinder

Failure to follow these instructions will destroy the single profile

cylinder and the lock.

Do not use force.

Only use one single profile cylinder with the correct length!

(See fig. 26)

A

a1

a2

External fitting

Door leaf

Single profile cylinder

Forend screw

Important when ordering:

A = a

1

+ a

2

a1 = inner fitting height:

Recess in fitting for single profile cylinder

at least 19 mm to a maximum of 24 mm.

a

2

= Distance between middle of forend screw and door leaf surface.

Fig. 26

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

55

English

Installation Instructions

The follower must be in the correct position!

Otherwise the switching mechanism will be damaged.

The follower only needs to be adjusted with a mortise lock with emergency opening log.

Adjust follower of single profile cylinder as shown

in the illustration on the right. The follower should

always point in the direction of the door hinge.

The position of the single profile cylinder should be checked carefully before screwing in the forend screw (page 47, fig. 12).

The forend screw supplied with the single profile cylinder must be

used with emergency opening log. The length of the forend screw

should not exceed the backset + max. 10 mm, otherwise the emergency opening log sensor may be destroyed..

Slide single profile cylinder into door lock until forend 1.

screw can be screwed in from the edge of the door.

Check whether the follower (locking lug) rotates

smoothly when the key is turned. Otherwise correct the

position of the single profile cylinder.

Tighten single profile cylinder with forend screw. 2.

Re-check whether the follower (locking lug) rotates

smoothly when the key is turned. Otherwise correct the

position of the single profile cylinder.

The single profile cylinder is only used for emergency opening, not for

locking.

Attempting to lock the door using force may damage the mortise lock!

45

o

Fig. 28

Fig. 27

Fig. 29

56

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

E. Adjust external module for right-pointed/left-pointed door handle

The Dialock DTSH FH door terminal is supplied already set up and

must not be modified.

Place lever handle aperture part onto outer square spindle of external

module so that the direction of movement matches the application.

Fig. 30

Right-pointed door handle,

zero position

Fig. 31

Left-pointed door handle leftside

zero position

Rotate outer square spindle with lever handle aperture part to upper 1.

stop position (zero position) and hold.

Gently knock pin (3 x 24) mm into the hole marked "R" or "L" with a 2.

hammer. Set stop limit by inserting pin into "R45" or "L45" hole.

Secure pins with stickers so that they do not fall out.3.

The spring of the lever handle aperture part is pre-tensioned.

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

57

English

Installation Instructions

F. Secure inner square spindle

Rotate marking (lug) (1) of coupling 1.

part in direction V (2).

Before inserting the inner square spindle into the cou-2.

pling part, align it so that the groove of inner square

spindle and the grub screw of the lever handle aperture

part are pointing in the same direction.

Insert inner square spindle in inner coupling part so that 3.

the pins are sitting in the recesses in the coupling part.

Insert locking ring into groove in the 4.

inner coupling part with locking ring

pliers. Ensure that the opening of the

locking ring is not above any of the

abovementioned inner square spindle

pins. (Fig. 36)

The inner square spindle is now installed.

After the inner square spindle has been installed in the external module, the marking (lug) of the coupling part must always be pointing in

direction V. The inner square spindle must not be twisted when it is

inserted in the door lock.

Fig. 32

Inner square spindle Fig. 33

with groove

Fig. 34

Fig. 35 Fig. 36

1 "Lug"

2 Arrow marking

58

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

G. Mount external module of Dialock DTSH door terminal

Fig. 37

The following prerequisites must be complied

with:

Holes drilled as per drilling plan

Door lock and locking cylinder inserted

If the distance between the surface of the door

leaf (outer) and the lock case is less than 6 mm a

spacer plate must be used, otherwise the external

module will be touching the lock cover.

Always use a stainless steel spacer

plate with DTSH FH - plastic is not

allowed!

Fig. 38

Fig. 39

Before putting on the external module, check 1.

whether the lug of the coupling part is pointing

in direction V (see fig. 36, page 57).

Insert inner square spindle into lever follower 2.

(fig. 38) and lead connecting cable through top

hole (13 mm). It is imperative to pay attention

to the cable routing!

If a mortise lock with emergency opening log is 3.

being used, attach connecting cable to connector in external module and roll up connecting

cable in the 32 mm recess.

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

59

English

Installation Instructions

Fig. 40

Do not trap cable!

Vertically align external module so that the 4.

guide pins of the external module engage in the

holes.

Slide external module towards door leaf until it 5.

is lying flat against it. (Fig. 40)

If the external module does not lie flat against the

door:

ð Check drill holes and remove wood debris if

necessary.

The external module is now installed.

60

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

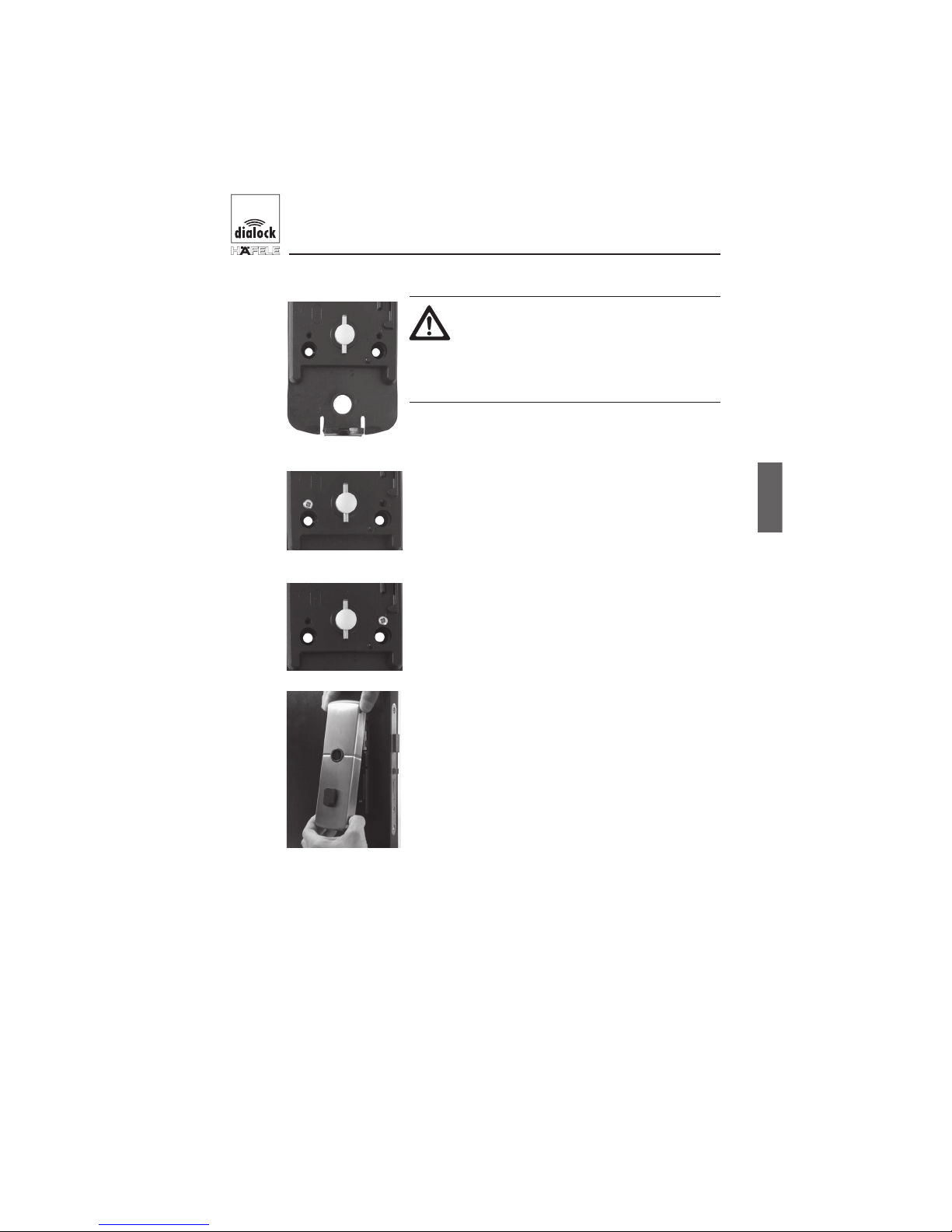

H. Mount internal module

Fig. 41

Fig. 42

Fig. 43

Risk of crushing!

Pay attention to cable routing!

Line 13 mm DTSH FH cable hole with Proma-1.

seal strips, shorten to door leaf thickness and

glue in parallel to cable.

Lead connector of connecting cable through 2.

opening in internal module fixing plate, fig. 42.

Place internal module fixing plate on inside of 3.

door leaf.

Loosely secure fixing plate using the four fixing 4.

screws.

Check vertical alignment at internal and exter-5.

nal module and then tighten fixing screws.

Plug connector of connecting cable into socket 6.

above battery holder and roll up connecting

cable as shown in fig. 43.

Insert battery into battery holder. 7.

Pay attention to correct polarity!

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

61

English

Installation Instructions

Fig. 44

Fig. 45

Fig. 46

Fig. 47

Pay attention to position of

"Do not disturb" rotary knob!

The rotary knob must be vertical during

installation and the grooved side of the

square spindle at the internal module

must point in the direction of the forend.

The direction of rotation of the "DND" lever can 8.

be set to right or left if required.

Fig. 44: Direction of rotation right/left

without screw

Fig. 45: Direction of rotation left

with screw position A

Fig. 46: Pivot direction right

with screw position B

Remove hood of internal module. With long 9.

door handle pins, slide the hood onto the

square spindle first.

A

B

62

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

Fig. 48

And tighten screw.10.

Always use the original grub screws in

the provided small parts bag.

ð Remove other grub screws from lever

handle aperture part if necessary.

Always use the provided lever handle with

the DTSH FH.

The small parts bag for the FH version

does not contain any grub screws. The

screws of the lever handle are used in

this case.

Mount inner and outer lever handle to the rel-11.

evant square spindle and tighten grub screws

using Allen key (3 mm).

Fig. 49

The internal and external modules are now installed

A mechanical check must be performed when assembly is complete.

Push the lever handle on the inside of the door to operate the mortise lock:

ð Pull back the latchbolt (escape function), or the latchbolt and deadbolt,

depending on the type of mortise lock.

Push the lever handle on the outside:

The coupling is disconnected, i.e. the lever handle has no effect, but it

must be automatically returned to the horizontal idle position via the return

spring. If this is not the case, check the individual assembly steps

DTSH FH:

Have confirmation of installation signed by fitter as documentation

for the customers's construction file.

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

63

English

Installation Instructions

Start-up

The Dialock DTSH door terminal is supplied in so-called "simple mode"

for standalone operation (SA). This is the only operating mode that is

described in these instructions. Details about the use of the DTSH in conjunction with software applications (Dialock HOTEL, PERSONNEL, hotel

management systems etc.) can be found in the relevant documentation.

Prevent use of user keys by unauthorised persons.

Keep the programming and clearing keys in a safe place, since locking authorisations can be allocated to and withdrawn from a user key

with these two keys.

The programming and clearing keys must be assigned as follows during

initial start-up:

This step is only possible after switching on for the first time.

Perform the initial start-up quickly and without interruptions!

Have green programming key and red clearing key ready.1.

Present the green programming key to the control panel until the blue 2.

LED is permanently on. An acoustic signal will be heard.

Remove programming key: Red LED flashes.3.

Present red clearing key to the control panel whilst red LED is flashing.4.

64

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

If no red clearing key is presented to the control panel within 5 seconds, the procedure will be automatically interrupted.

The red clearing key must be presented to the control panel again to

complete the initial start-up.

When the key has been trained successfully, the LED will be perma-5.

nently blue and an acoustic signal will be heard. The Dialock DTSH

door terminal then goes into normal operating mode.

If persistent errors occur:

ð Notify the service location.

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

65

English

Installation Instructions

Short instructions

Allocate locking authorisations to user key

Present green programming key to the control panel. 1.

ð Blue LED flashes.

Present user key that has to be trained to the control panel for 5 sec-2.

onds. The locking authorisations for the user key have been allocated

when the blue LED flashes briefly.

Remove trained user key.3.

Present the next user key to be trained to the control panel within 4.

5 seconds.

Withdraw locking authorisations from user key

Present red clearing key to the control panel. 1.

ð Red LED flashes.

Present user key that has to be cleared to the control panel. When 2.

the red LED flashes briefly, the locking authorisations have been withdrawn. The Dialock DTSH door terminal then goes into normal operating mode.

If no more keys are presented to the control panel the DTSH goes

into the normal operating mode.

Withdraw locking authorisations from all user keys

If a user key has been lost and you wish to cancel its locking authorisations, all user keys must first be deleted at the Dialock DTSH door terminal. Access rights must then be re-allocated to all user keys with locking

authorisations.

Present red clearing key to the control panel. 1.

ð Red LED flashes.

Present green programming key to the control panel. 2.

ð Red LED flashes briefly.

Re-allocate access rights to all user keys that are still to have locking 3.

authorisations.

66

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

Operation

Present user key to the control panel - red LED flashes briefly. An 1.

acoustic signal will be heard. If the user key does not have locking

authorisation the signal will be heard twice.

The blue LED flashes and the red LED goes off.2.

The Dialock DTSH door terminal is ready for opening for approx. 3 sec-3.

onds. The door can be opened by pushing the lever handle.

If the LEDs do not change from red to blue: 4.

ð Present user key closer to control panel.

If the LEDs still do not change from red to blue: 5.

ð User key is not authorised

Battery change

If the battery charge is low, the red and blue LED flash alternately three

times when the electronics are switched on.

ð A battery change is recommended.

The date and time are saved when the battery is removed, and reloaded

again after new batteries have been inserted. The clock stops for the duration of the battery change.

ð Replace batteries quickly!

If the time needs to be accurate to the minute, the date and time can be

corrected with the Dialock MDU (only of interest for operation with the personnel and hotel software!).

However, the user keys always retain their authorisation.

Smooth operation of the Dialock DTSH door terminal is only guaranteed, if weak batteries are replaced immediately. Always use highquality batteries.

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

67

English

Installation Instructions

Do not throw batteries in the household waste!

ð Dispose of batteries in an environmentally friendly way, e.g. using a

municipal collection point.

The following steps are required to change the batteries:

The batteries are located in the internal module of the Dialock DTSH door

terminal.

Loosen the grub screw of lever handle aperture part at the inside of the 1.

door using an Allen key.

Pull lever handle aperture part from inner square spindle.2.

Loosen screw from underside of internal module.3.

Remove hood of internal module.4.

Remove old batteries.5.

Insert new batteries into battery holder as quickly as possible. 6.

Ensure that the polarity is correct (see figure 43, page 60)!

Re-attach hood of internal module and tighten screw on underside of 7.

internal module.

Mount lever handle aperture part to inner square spindle and tighten 8.

grub screw using Allen key.

68

English

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

Installation Instructions

Emergency opening

Push in break-open seal (profile cylinder cover) with a small screw-1.

driver and remove.

Open Dialock DTSH door terminal using an emergency opening key.2.

Insert new break-open seal.3.

The single profile cylinder is only used for opening, not for locking.

Attempting to lock the door using force may destroy the emergency

opening log facility!

Fig. 50

Dialock Door Terminals DTSH, DTSH FH - Status: 07.2008 - 732.29.134

69

English

Installation Instructions

FAQ

I've lost a user key and want to block it.

What should I do?

If a user key has been lost and you wish to cancel its locking authorisations, all user keys must first be deleted at the Dialock DTSH door terminal. Access rights must then be re-allocated to all user keys with locking

authorisation.

See under: "Withdraw locking authorisations from all user keys".

Maintenance and cleaning instructions

The DTSH is maintenance-free apart from having to change the batteries.

No lubricants must be introduced into the DTSH. These could destroy sensitive components and cause the DTSH to fail.

Do not use scouring agents to clean the surface of the DTSH. If necessary, use a dry, soft cotton cloth or a soft cloth moistened with a mixture of

water and washing up liquid or neutral cleaner. Do not use cleaning agents

containing alcohol or other organic solvents or thinner under any circumstances.

Technical data

Dimensions (26 x 65 x 227) mm ((L x W x H)

Power supply 4 x 1.5 V batteries, size AA Mignon

type E91 Energizer

®

(Cat. No.: 910.54.980)

Temperature range 0 – 65°C

Humidity 0 – 90%, not condensed

Right reserved to make technical changes.

Loading...

Loading...