Hafei HFJ6371, HFJ6371B, HFJ6371C, HFJ6371E, HFJ1012 Service manual

...

1 GENERAL

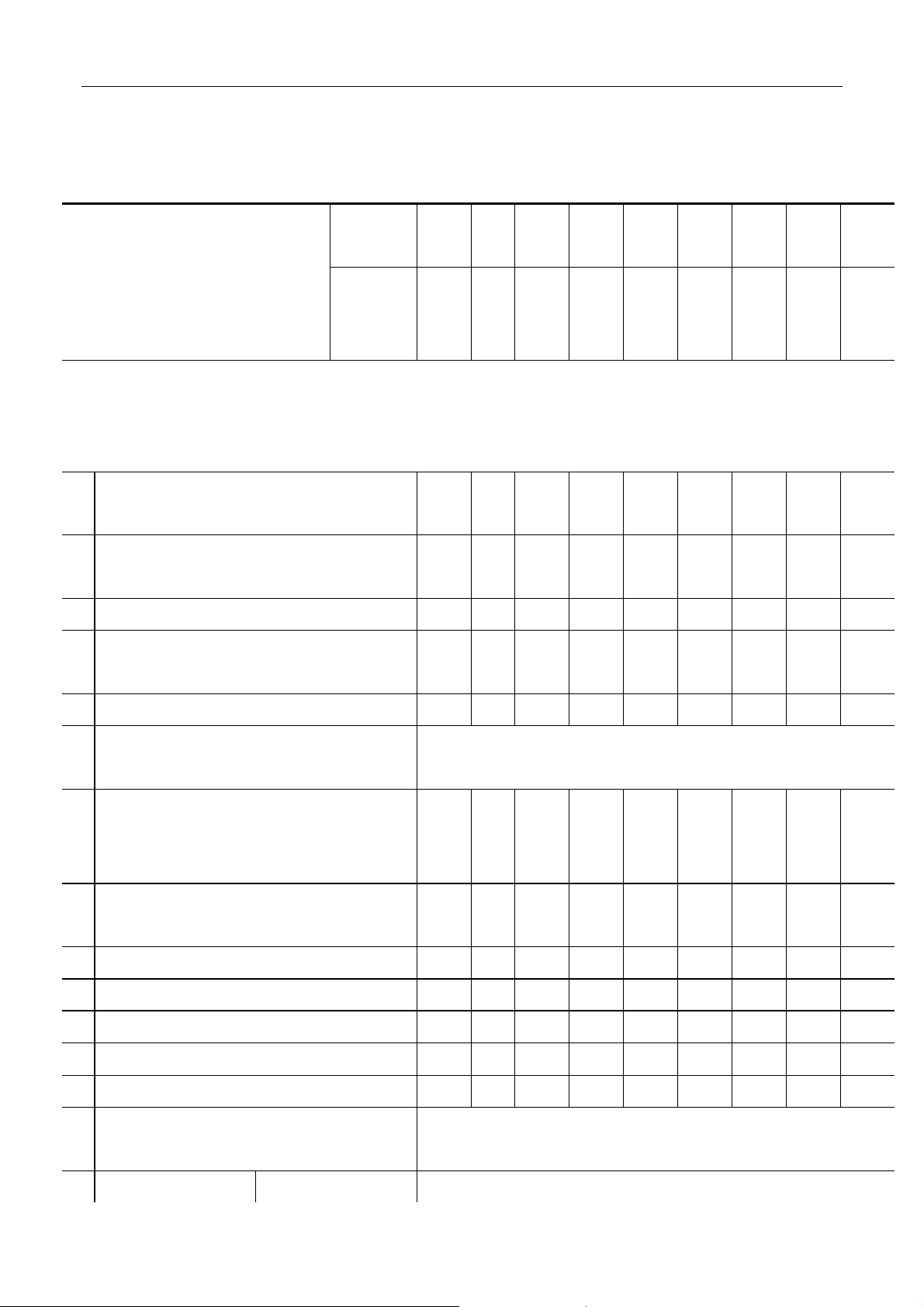

1.1 Performance Data

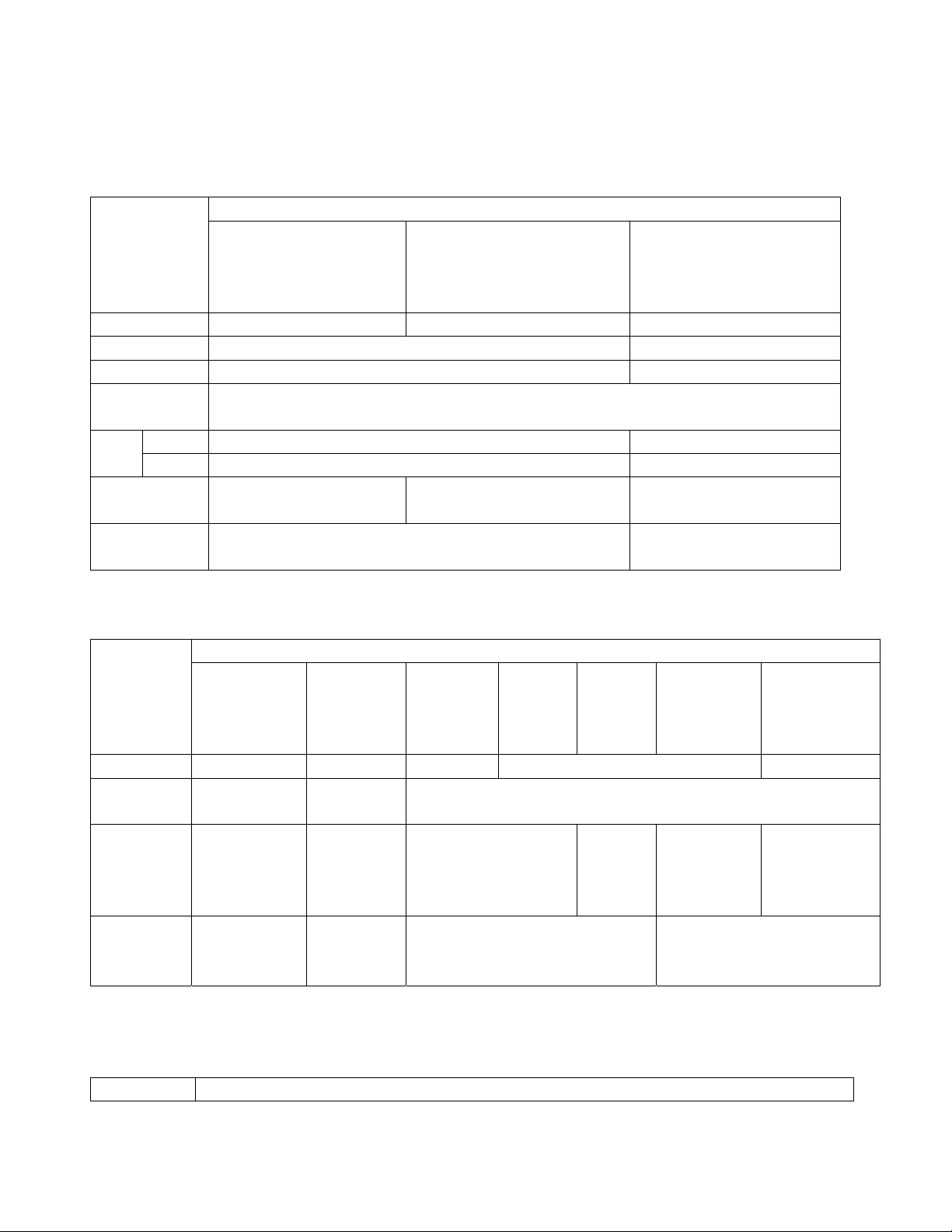

1.Main dimension (Table 1-1)

T able 1-1

Data

HFJ6371、HFJ6371B、

Item

HFJ6371C、HFJ6371E、

HFJ1012、HFJ1012B、

HFJ1012C 、HFJ1012E

Length(mm) 3721 3745 3562

Width(mm) 1480 1480

Height(mm) 1918 1918

Wheel

base(mm)

(mm)

Front

Rear 1220 (1200) 1220

Front

942 966 783

1235 (1215)

overhang(mm)

Rear

overhang(mm)

2.Mass data (Table 1-2)

Item

HFJ6350C

HFJ6351C、

HFJ6351CA

Cu r b w e i g ht 940kg 970kg 980kg 960kg 940kg

Max. total

1460kg 1460kg 1530kg

weight

The rated

load

660kg/800kg

6~8

670kg/790kg

6~8

(passenger

numbers)

Empty

480kg/460kg 495kg/475kg --- --axle-load

(front/rear)

3.Performance data(Table 1-3)

Table 1-3

Item Data

HFJ6376、HFJ6376E

HFJ1016 、HFJ1016E

HFJ6350C、HFJ6351C、

HFJ6351CA

1960

1235 Tread

819 819

Data

HFJ6371、

HFJ6371E

HFJ6376、

HFJ6376E

5~8

(5~7)

HFJ6371B

、HFJ6371E

HFJ6376、

HFJ6376E

HFJ6371C

5~8

HFJ1012

HFJ1016

HFJ1016E、

、

HFJ1012E

2+440kg

or 5+245kg

Table 1-2

HFJ1012E、

HFJ1012B

HFJ1016

HFJ1012C

2+460kg

or 5+265kg

HFJ6371、HFJ6376

HFJ1012、HFJ1016、

HFJ6371B、HFJ6376

HFJ1012B、HFJ1016

HFJ6371C

HFJ1012C

HFJ6350C HFJ6351CA

HFJ6351C

Engine mode DA465Q-1A DA465Q DA462-1A DA462-1A DA465Q

Max. speed

Max. slope of

≥105km/h ≥100km/h ≥95km/h ≥100km/h ≥110km/h

≥20%

climb

Fuel

≤5.8L(40km/h) ≤5.5L(40km/h)

consumption

of 100km at

constant

speed

T ank capacity 36L

Min. turning

9.0m

diameter

Min. ground

≥150mm ≥165mm ≥150mm

clearance

4. Engine data( T able 1-4)

Table 1-4

Data

HFJ6371C

HFJ1012C、HFJ6350C

Item

HFJ6371、HFJ6376

HFJ1012、HFJ1016

、HFJ6371E、HFJ6376E

HFJ1012E、HFJ1016E、

HFJ6351C

HFJ6371B、HFJ6376

HFJ1012B、HFJ1016、HFJ6371E、

HFJ6376E

HFJ1012E、HFJ1016E、

HFJ6351CA

Mode DA465Q-1A DA465Q DA462-1A

Type

Cylinder

Four cylinder, four stroke, tandem, water cool, overhead camshaft,electronic fuel injection (EFI)

65.5mm 65.5mm 62mm

diameter

Stroke 78mm 72mm 72mm

Displacement 1051ml 970ml 870ml

Rated power 38.5kW/5200r/min 35.5kW/5000r/min 27kW/5200r/min

Rated torque

Compression

83N.m/3000~3500r/min 74N.m/3000~3500r/min 60N.m/3000~3500r/min

9.0:1

8.8:1 8.7:1

ratio

Ignition

6°~7°

advance angle

Min. fuel

275g/(kW·h) 275g/(kW·h) 300g/(kW·h)

consumption

rate

5.Transmission system (Table 1-5)

Table 1-5

Item 4MT 5MT

Clutch type

Gear box type

Main gear reduction ratio

Gear ratio 1

Reverse gear

2

3

4

5

st

gear

nd

rd

th

gear

th

gear

Single disc, dry and with diaphragm spring

Synchromesh type

5.125

3.505

gear

2.043

gear

1.383

1.000

3.536

Single disc, dry and with diaphragm

spring

Synchromesh type

5.125/4.444

3.652

1.948

1.424

1.000

0.795

3.466

5.125/4.444

3.505

2.043

1.383

1.000

0.806

3.536

6. Wheel and suspension (Table 1-6)

Table 1-6

Item

HFJ6350C、HFJ6351C、HFJ6371series HFJ6376 系列

Tire type 165/70 R 13 155R12C 165/70 R 13

Air pressure empty load(front/rear)

Full load(front/rear)

210kPa/250kPa 200kPa/220kPa

250kPa/250kPa

300kPa/350 kPa 220kPa/250 kPa

180kPa/220 kPa

Front suspension type MC, pherson type independent suspension

Rear suspension type Parallel leaf spring type rigid axle suspension

7.Steering system(Table 1-7)

Item

Steering gear type

Kingpin inclination

Caster

Camber

Toe-in

HFJ6350C、HFJ6351C、HFJ6376series、HFJ6371series

Rack and pinion type

12°±30'

6°±30'

0°±30'

0~5mm

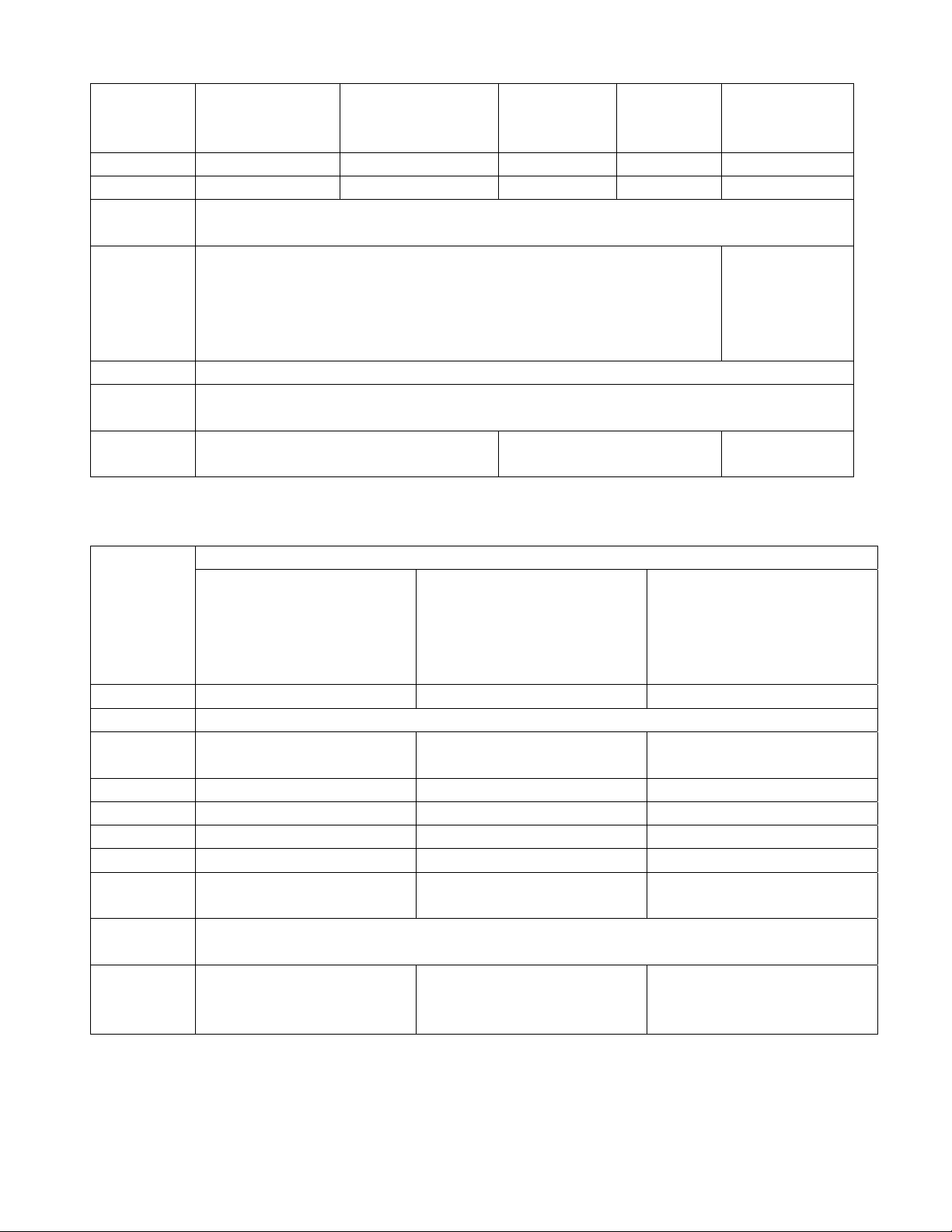

8.Brakes(Table 1-8)

Item HFJ6350C

HFJ6351Cseries 、 HFJ6376series 、

HFJ6371series

Brake type

Front wheel brake

Rear wheel brake

Parking brake

Dual hydraulic lines braking

Balanced double leading shoes and

drum type brake

Unbalanced leading/trailing shoes and

drum type brake

Mechanical cable type(acting on rear

wheels)

Dual hydraulic lines braking(with

vacuum power)

Full sliding caliper disc brake/ Balanced

double leading shoes and drum type

brake

Unbalanced leading/trailing shoes and

drum type brake

Mechanical cable type(acting on rear

wheels)

Table 1-7

Table1-8

第 1 页 共 5页

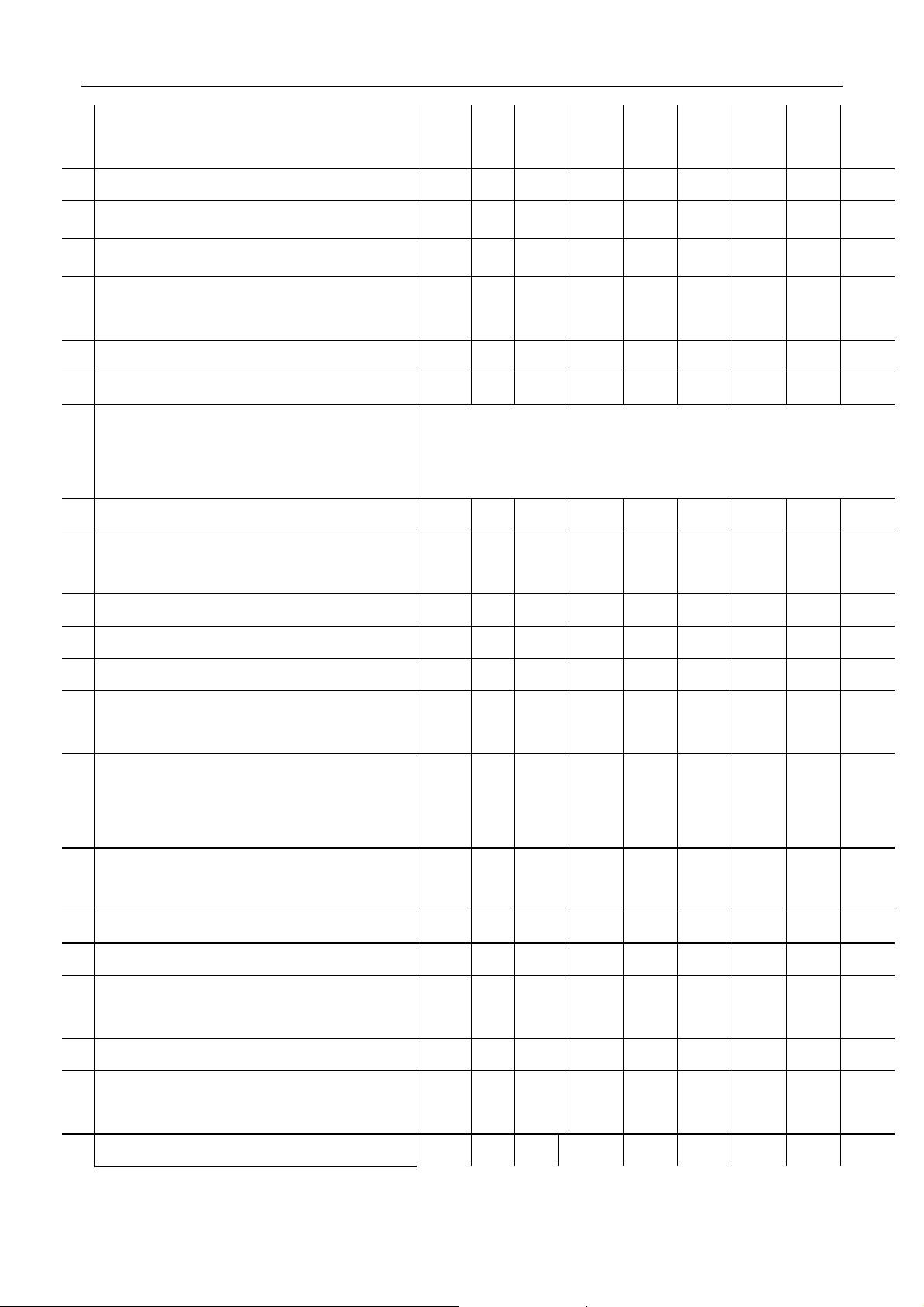

2 INSPECTION DATA AND MAINTENANCE PERIOD

2.1 TORQUE

The tightening performance of connecting bolt and nut is performed by screw thread. Each

fastener should be tightened to the torque specified in each section with moment wrench during

maintenance.

Table 2-1

System

Tighten position

Specified torque(N·m)

N·m kgf·m

Engine Cylinder head setscrew

Spark plug

Intake and exhaust manifold nut

Driven synchronous gear screw

Valve adjust nut

Initiative synchronous gear

screw

Connecting rod bearing cap nut

Crankshaft main bearing cap bolt

Flywheel screw

Oil plate screw

Oil drain plug

Rocker arm cap screw

Synchronous chain cover setscrew

Setscrew of oil pump

Oil pressure sensor

Oil filter stand

Setscrew of oil filter nib

Rear engine bracket-Body

fastening bolt

Oil pump safety valve spring seat

Left and right engine hangers

fastening bolt

Bracket mounting bolt

Tension pulley bracket bolt and

nut

Ignition shock sensor screw

sensor

O

2

Coolant temperature sensor

55~60

19.6~29.4

17.7~22.6

49.0~58.8

14.7~19.6

49.0~58.8

27.5~31.4

42.2~47.1

39.2~44.1

3.92~4.90

19.6~24.6

3.92~4.90

2.94~3.92

7.85~9.81

11.8~14.7

9.81~14.7

19.6~24.5

10.8~13.7

14.7~19.6

17.7~22.6

24.5~29.4

14.7~22.6

15~25

40~60

Max.20

5.5~6.0

2.0~3.0

1.8~2.3

5~6

1.5~2

5~6

2.8~3.2

4.3~4.8

4.0~4.5

0.4~0.5

2.0~2.5

0.4~0.5

0.3~0.4

0.8~1.0

1.2~1.5

1.0~1.5

2.0~2.5

1.1~1.4

1.5~2.0

1.8~2.3

2.5~3.0

1.5~2.3

1.5~2.6

4~6

Max.2

1

第 2 页 共 5页

Transmission

Cluth Cluth pressure plate bolt 17.7~27.5 1.8~2.8

Transmission case screw

Drain plug and oil filler

Extention case bolt

Rear bracket mounting bolt

Gear shift shaft case screw(M8)

Gear shift shaft case screw(M6)

Gear shift crossing shaft lock

screw

Connecting bolt of transmission

and cylinder

2.2 INSPECTION DATAS

14.7~19.6

29.4~49.0

14.7~19.6

14.7~19.6

8.83~11.8

5.88~9.81

14.7~19.6

19.6~24.5

1.5~2.0

3.0~5.0

1.5~2.0

1.5~2.0

0.9~1.2

0.6~1.0

1.5~2.0

2.0~2.5

The content of engine refers to 《HFJ6351B service manual》。

2

第 3 页 共 5页

2.3 MAINTENANCE SCHEDULE

Interval:

km×

2.5 10 20 30 40 50 60 70 80

This interval should be

1000

judged by odometer reading

or months, whichever comes

months 2 6 12 18 24 30 36 42 48

first.

ENGINE

Water pump(fan) drive belt(tension,

1

damage)

synchronizing toothed belt

2

(wear and damage)

3 IN and EH valve clearance A — A — A — A — A

Engine bolts (All cylinder head and

4

manifold fixings)

A — I — R — I — R

I — I — I — I — I

T — T — T — T — T

5 Engine oil filter R R R R R R R R R

Replace every 5000km. More frequent replacement if

6 Engine oil

under dusty driving conditions

Fuel hoses and connections ( hoses

7

aging , connections crack, damage or

loosening)

Cooling system hoses and connections

8

(leakage, damage)

I I I I I I I I I

—— I — — I — — I

9 High tension cords(aging and damage) —— I — — I — — I

Crankcase hose and nib

10

Spark plugs

11

Ignition timing

12

- -I - - I - - I

— R R R R R R R R

A A A A A A A A

I

13 Ignition shock sensor tightening torque A A A A A A A A A

Clean every 1000km on asphalt road and clean every

14 Air filter

2500km on dusty road

z Dust road Check referring to hard driving

3

第 4 页 共 5页

Acceleration cable and throttle valve

15

spindle

—

I.

I.L I.L I.L I.L I.L I.L I.L

L

16 Fuel filter ——— — R — — — R

17 PCV valve — — I — I — I — I

18 Clutch gap

Gear oil of transmission(check leakage

19

at normal level)

R I I I R I I I R

20 Damage and fastness of harness I I I I I I I I I

21 Coolant ——— — R — — — R

Replace every 50000km. More frequent check if under

22 Charcoal canister

dusty driving condition. Replace in time if clogging

or liquid fuel found.

23 Catalytic converter - - - - - - - - I

Wiring hardness connections and

— — I — I — I - I

24

headlights

25 Clutch pedal play I I I I I I I I I

26 Brake fluid(lever、leakage) I I I I R I I I I

27 Brake pedal play I I I I I I I I I

Parking brake lever and cable

28

I I I I I I I I I

(stroke and damage)

Brake discs and pads (wear, damage)

29

Brake drums and shoes (wear,

- I I I I I I I I

damage)

Brake hoses and pipes (leakage,

30

- I I I I I I I I

damage, clamp)

31 Tires (abnormal wear and pressure) - I I I I I I I I

32 Wheel, wheel nut(damage、torque) I I I I I I I I I

Shock absorber(oil leakage 、

33

I I I I I I I I I

damage)

34 Propeller shaft (damage) - - I - I - I - I

Transmission and Differential oil

35

R I I I R I I I R

(leakage, lever)

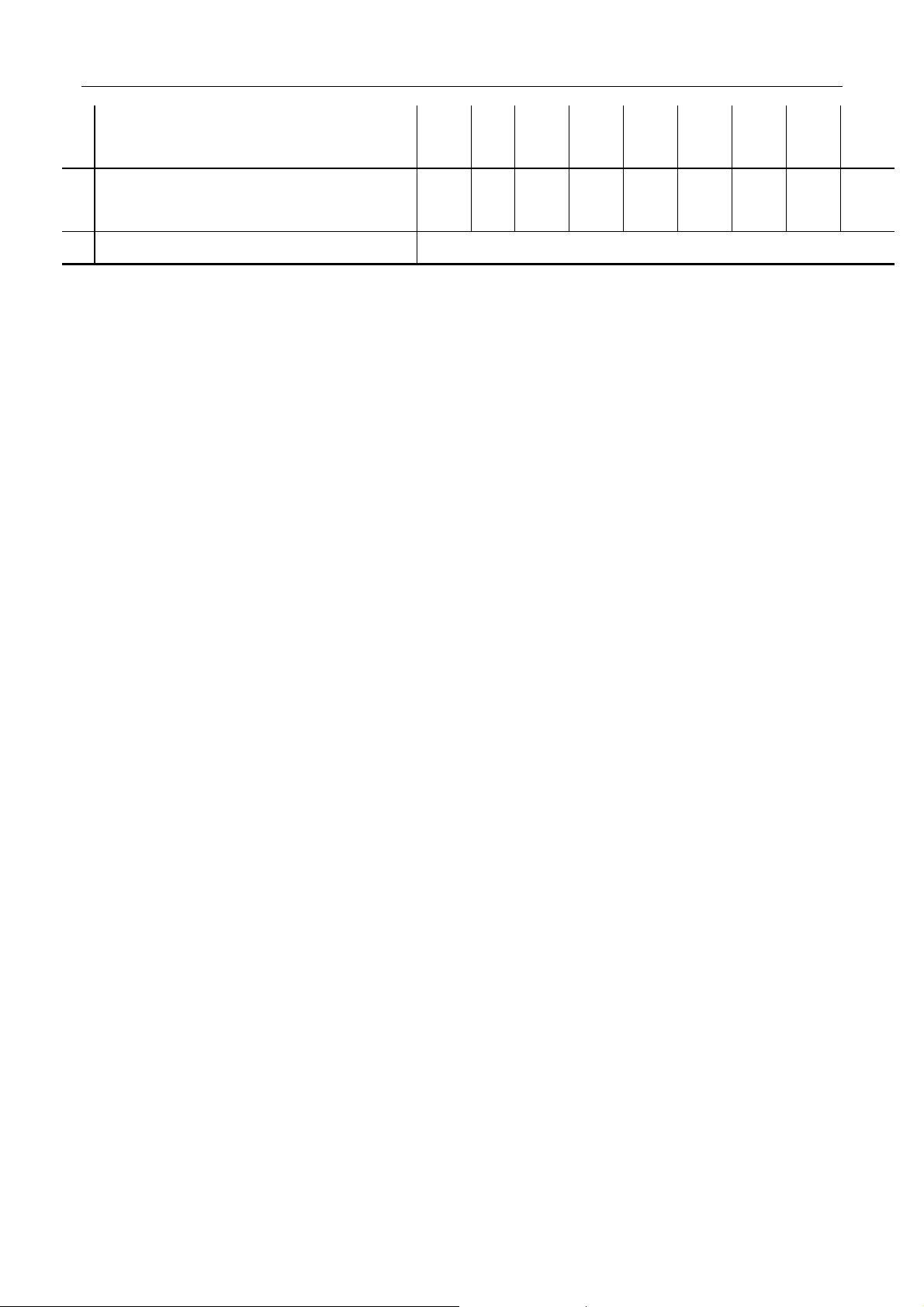

36 Main bolt and nut (tightness) T - T - T - T - T

4

第 5 页 共 5页

Steering (tightness, damage,

37

I I I I I I I I I

rattle, breakage)

Middle arm bush assy(lubrication

38

and tightness)

39 Test drive Test drive on completion of each service

Notice :

“A”-Inspection and connect ;“R”-Replace or repair;“T” -Tighten to the specified

torque;“L” -Lubricate “I” -Inspection and correct or replace if necessary;

5

第 1 页 共 3页

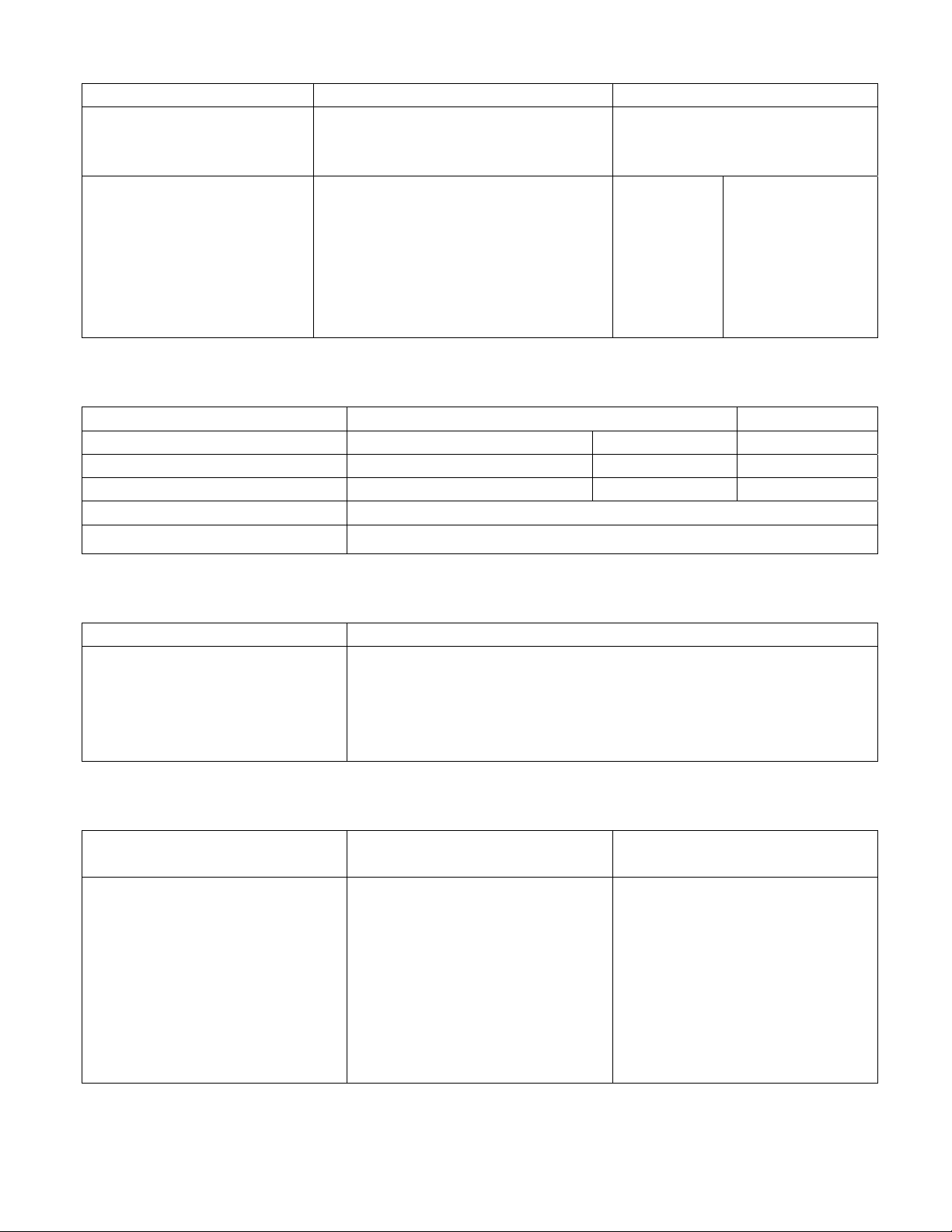

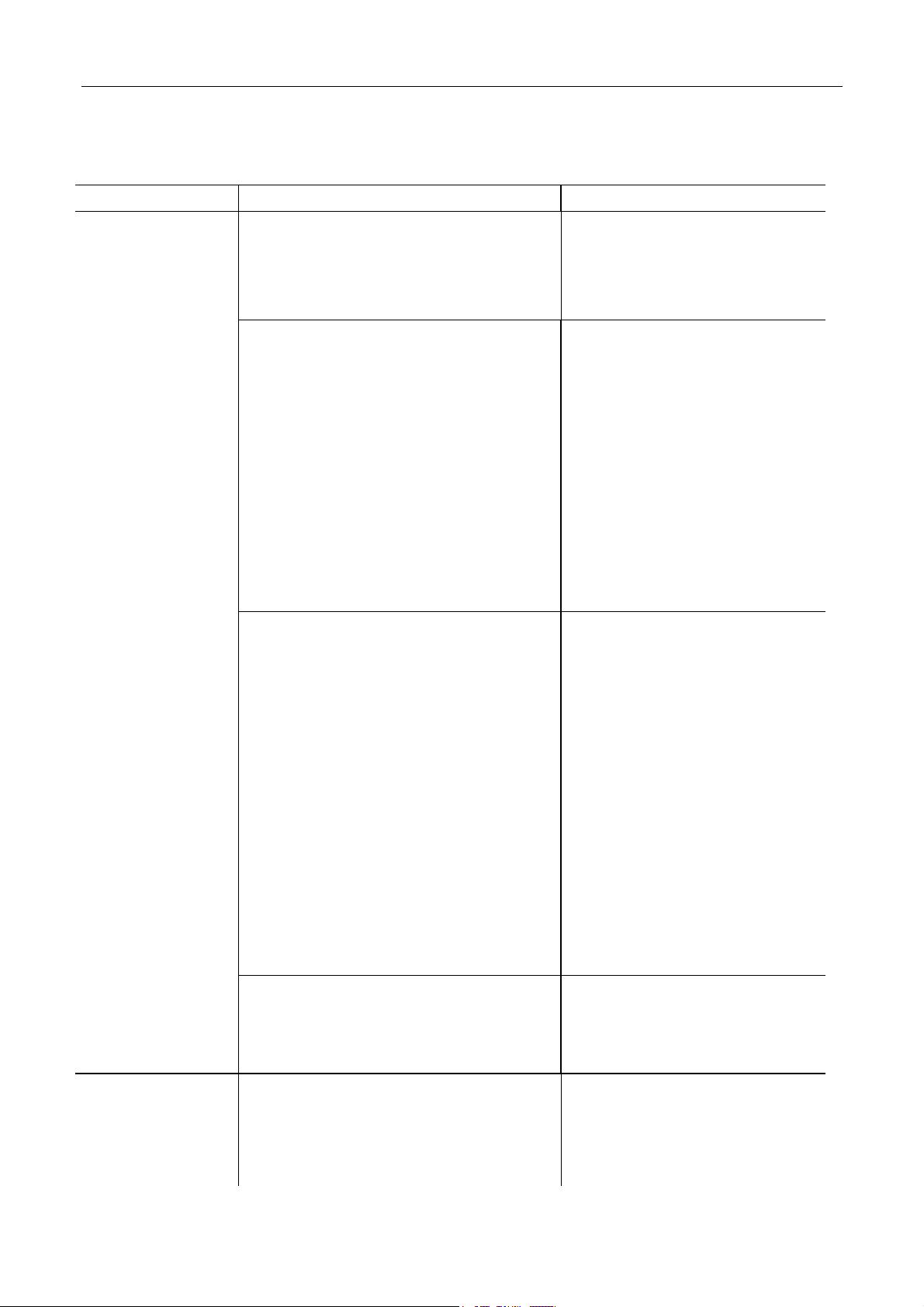

3 TROUBLE SHOOTING

3.1 ENGINE

TABLE 3-1

Condition Possible cause Correction

Hard starting

High idling

a、Starter will not run

1. Loose battery terminal connection

2 Brack-circuited in cord connection

3 Defective of starter

b、No sparking

1 Improper ignition timing

2 Poor grounded

3 Cracked rotor or cap in distributer

Defective ignition coil

4

5 Improper clearance or burnted in

spark

6 Brack-circuited or short-circuited

in cord connection

7 Connector loose or damaged

8 Damage of main breaker contact

9 Defective ECU

c、Malfunction of the fuel system

1. Electronic fuel pump feed fuel

pressure

Lack

2. Fuel injectors damaged or clogged

3 Fuel hose fold and fuel filter clogged

4 Vacuum hose or fuel pressure adjuster

broken off or damaged

5 Connector loose or damaged

6 Damage of main breaker contact or oil

pump breaker contact

7 short-circuited or open-circuited

8 Defective ECU

d、Inadequate compression

1 Damaged cylinder gasket

2 Improper valve clearance

3 Wornpistons,rings or cylinder

1. ECU doesn’t self-study after break

2. Throttle can’t restore completely

3. Intake system leakage

4. Idle adjuster (stepper motor) damaged

Clean and retighten

Check or repair

Repair or replace

Adjust

Repair

Replace

Replace

Adjust or replace

Check or repair

Adjust or replace

Replace

Repair or replace

Repair or replace

Replace or Clean

Replace

Installation or replace

Replace or adjust

Replace

Check and repair

Replace

replace

Adjust、repair or replace

repair or replace

Flameout, then self-study

check and adjust

check and repair

replace

1

第 2 页 共 3页

Not enough power

Enging noise

Overheating

Excessive engine

oil consumption

Hard shifting

1Accelerator control and throttle cable

improperly adjusted

2 Cylinder compression pressure reduce

3Improper ignition timin

4Fuel pressure adjuster damaged and make

fuel feeding reduce

5Insufficient intake

6Clogged exhaust

7Defective spark plug or improper spark

clearance

8 Firing a gun when engine racing

9 Fuel injectors clogged or damaged

10 Clogged fuel filter

11 Damaged throttle position sensor

12 Defective fuel pump or insufficient

pressure

1 Worn bearing, crank and arm.

2 Worn crankshaft,connecting-rod bearing and

piston

3 Worn piston ring

4 Improper valve clearance

5 Valve clearance too large

1 Improper ignition timing

2 Inexactitude clearance of spark plug

or accumulated carbon.

3 Loose of air intake manifold or jam

of exhaust manifold.

4 .Loose of water wheel belt

5 Lack of coolant or jam of hose.

6 Inexactitude clearance or damage of

water pump

7 Lack of oil

8 Damage of oil pump or jam of

lubricating way.

9 Damage of cyclinder gasket

10 Slipping cluth

11 Jam of radiator

1 Defective valve guide bushes oil seals

2 Sticky piston ring

3 Worn piston ring groove and ring

4 Improper location of piston ring gap

5 Badly worn valves or valve guide bushes

6 Exhaust of oil through breeze hole by

high pressure which caused by overheat.

1 Wron synchronizer hub

2 Wron synchronizer gear

3 Broken locating balls

4 Distorted or unevenly worn shift fork shaft

Adjust

1 check valve、 spark plug、

cylinder gasket leakage;

2 Valve rubbing

Adjust

Adjust or replace

Check inlet system

Check exhaust system or clear

away carbon deposit

Adjust or replace

Check high voltage wire

Clean or replace

Replace

Replace

Repair or replace

Replace

Replace or repair

Replace

Adjust

Adjust

Adjust

Clean or adjust

Retighten or clean

Adjust

Refill or clean

Repair or replace

Refill

Clean or replace

Replace

Repair or replace

Clean or replace

Replace

Replace

Adjust

Replace

Replace

Check relative position

Replace

Replace

Replace

Repair or replace

2

第 3 页 共 3页

Noisy clutch

Bright of trouble

pilot lamp in panel

Poor emission

1. Worn or broken release bearing

2. Input shaft front bearing worn down

3 Excessive rattle of clutch disc hug

4 Cracked clutch disc

5 Pressure plate and diaphragm spring

rattling

6 Clutch facings soaked with oil

7 Weakened torsion spring

1 Trouble of EFI system

2 Trouble of wire

1 Damage of TWC and O

sensor, which

2

caused by use of lead fuel.

2 Damage of TWC and O

sensor, which

2

caused by misfire of ignition system.

3 Leakage of exhaust system, ECU can’t

get the right signal of O

sensor,

2

causing air/fuel ratio rich

Replace

Replace

Repair

Replace

Repair or replace

Clean or replace

Replace

Diagnose with Hi-Scan

Check ( if connect firmly 、

break-circuit or short-circuit)

Replace

Replace

Repair

3

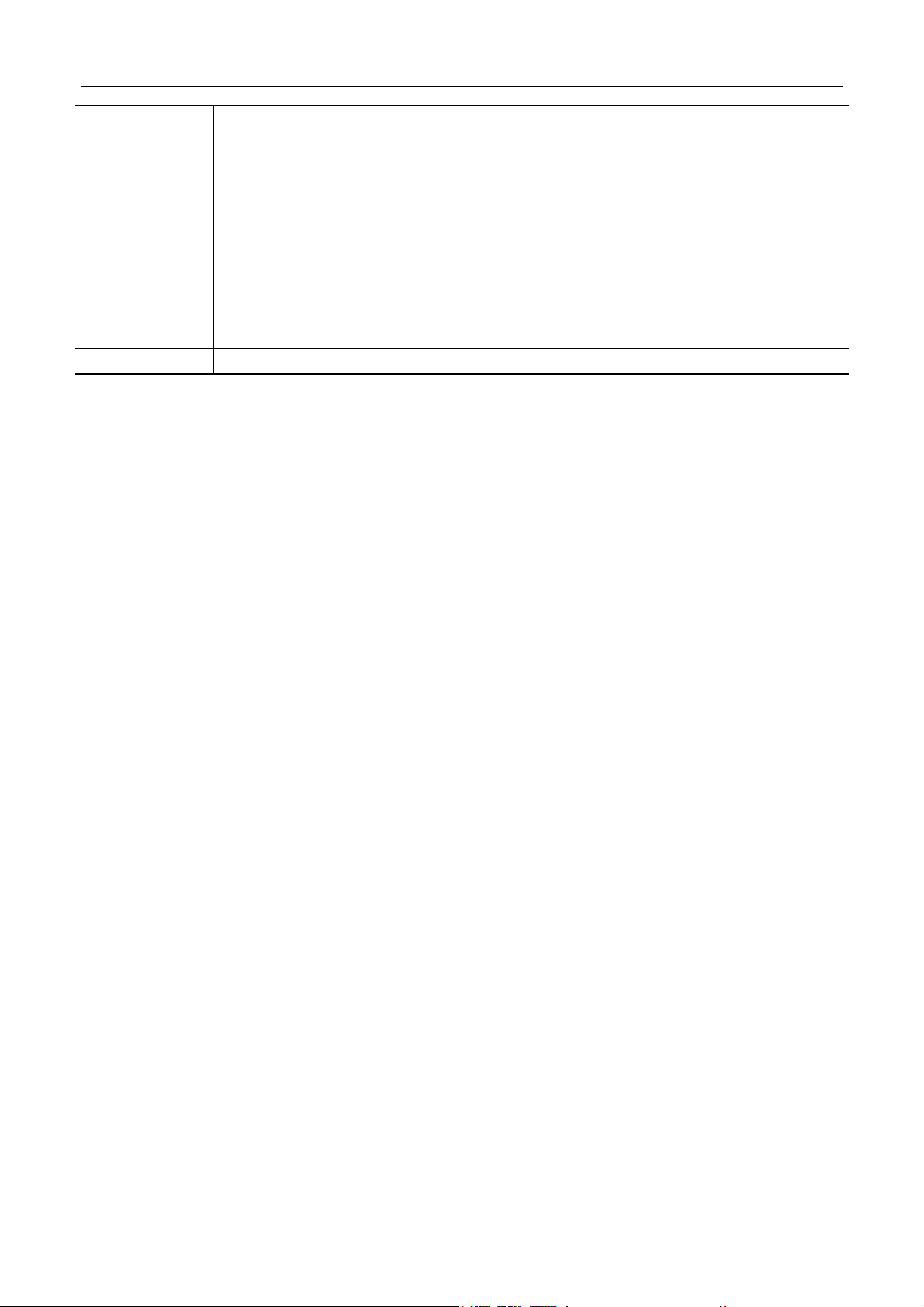

4 ENGINE

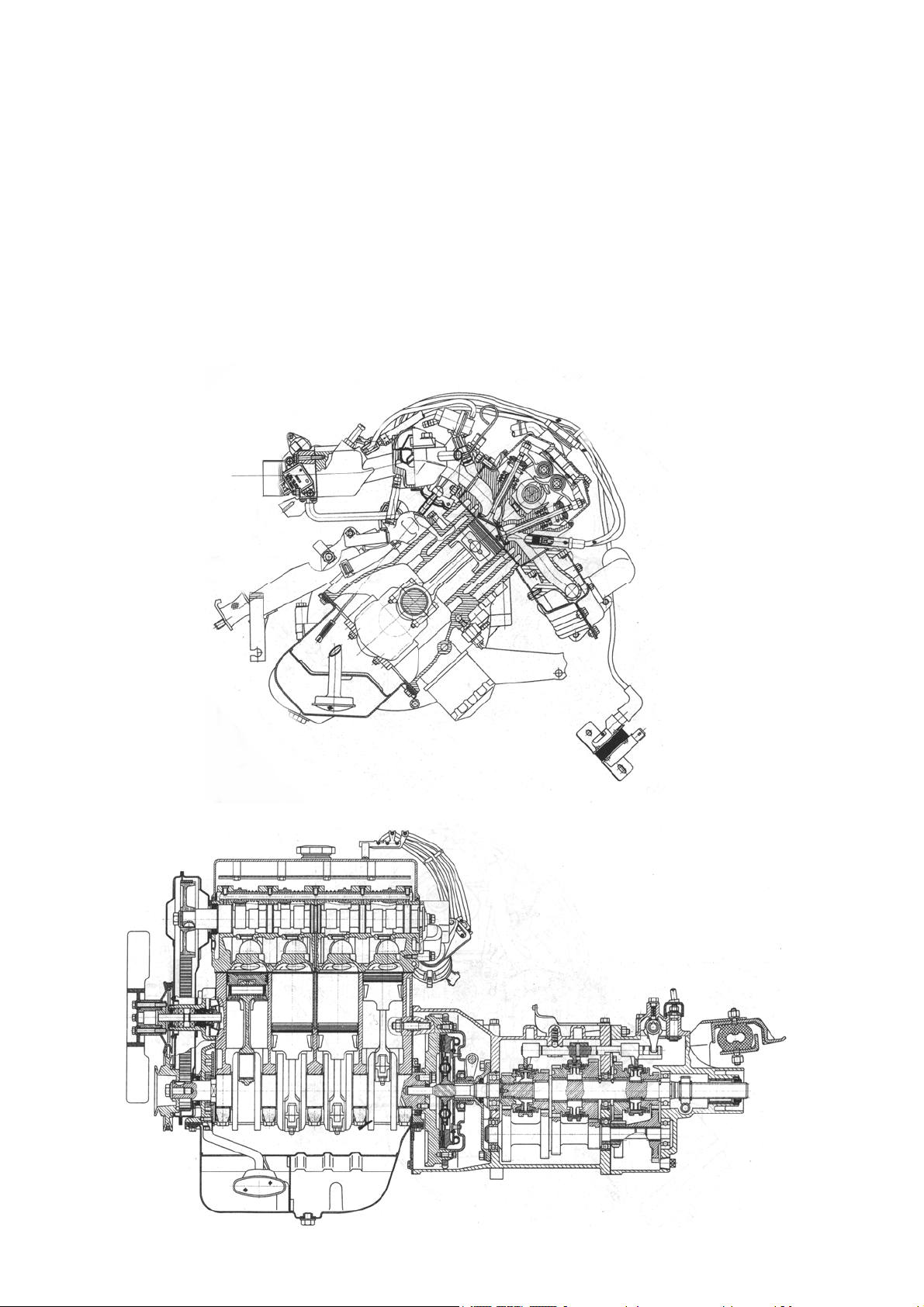

4.1 General

The engine is in-line 4-cylinders, water-cooled, 4-stroke cycle MPI gasoline unit

with valve mechanism arranged for “V”-type valve configuration and overhead camshaft,

which is installed in cylinder head and driven by crankshaft with timing chain. With

compare to general model, no valve lifter is available in the model, so that valves is driven

in more directive method and open or close more promptly (See Fig.4-1).

Fig.4-1

The engine adopts BOSCH M1.5.4 EMS or DELPHI EFI system. Comparing with

carburetor engine, a great improvement has made in power, economic and low

temperature starting performances.

The engine that has functions of sequential ignition, sequential injection, knock

closed-loop control, idle closed-loop control, canister control, A/C control etc, with

distributor, is a closed-loop control engine manage system. Sensors available for the

system include TPS(throttle position sensor), MAT/MAP(manifold air temperature &

pressure sensor), knock sensor, coolant temperature sensor, oxygen sensor, rotation speed

sensor ( in distributor,also called Hall sensor). The actuators include fuel pump (inside

fuel tank), injectors, ignition coils, idle adjustor(also as stepper motor), purge valve.

·ENGINE CHARACTERISTICS

· Valves in the head is arrayed in V type with inlet pipe and exhaust pipe in

configuration of orthogonal flowing pattern, so that efficiency of charge and exhaust is

high.

·Combustion chamber shape is multi-sphere, with low burning consumption and high

power performance.

·The camshaft and the rocker arm shaft are installed in the head for more solid

construction, which reduce noise from inlet system and quantity of parts in induction

system. These make engine more compact.

·The timing chain driving camshaft has characteristics of light weight and small

operating noise.

·The engine block uses material of high quality iron-casting and has a construction of

gantry for high rigidity.

· The crankshaft are constructed of one-piece forged alloy steel , which supports with

five bearings and have an advantage of low vibration.

· The exhaust manifold and pipe adopt double pipe type, for no interference with each

other. One pipe is connected to 1st and 4th cylinders, the other to 2nd and 3rd cylinders.

·Electronic fuel injection system has a central unite of ECU(electronic control unit),

which control accurately quantity of injecting fuel, ignition advance, so that engine works

well under varies operation conditions.

·Use three-way catalytic converter to reduce CO, HC and NOx, emissions in exhaust, in

order to make the vehicle become GREEN MOTOR.

·Crankcase emission controls

Leakage pipeline is located in the block. The leakage flows to the head

through crankcase, and fuel is separated from the air with separation plate

in the head before it is taken out.

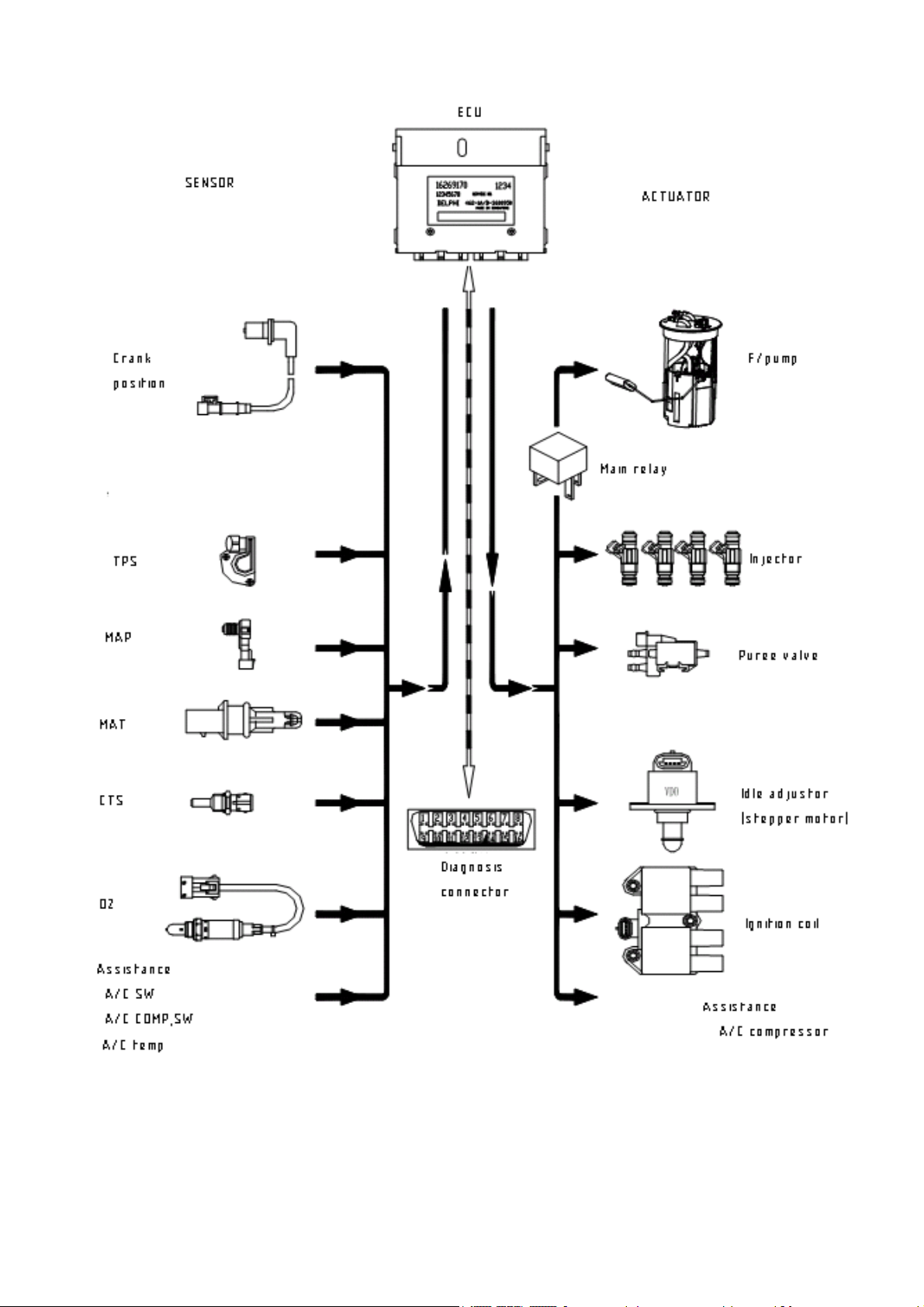

4.2 PRINCIPLE AND CONSTRUCTION OF EMS

1. Parts

As general electronic control system, there are three portions that

construct electronic control fuel injection system: sensors, control unit,

actuators.

(1)Sensors

Sensor is a device that responds to a physical stimulus (heat, light, sound,

pressure, motion, flow, and so on), and produces a corresponding electrical

signal, which can be used by ECU. General sensors in EFI include load sensor

which responds to air volume every cycle directly or indirectly, rotation

speed sensor which responds to engine speed, crankshaft position sensor which

responds 1st cylinder TDC; TPS, coolant temperature sensor, air charge

temperature, barometric pressure sensor, oxygen sensor which responds to

oxygen volume in exhaust and is used by closed control, manifold inlet

pressure sensor.

(2)Electronic Control Unit (ECU)

The device is applied to receive and handle signals from sensors, instruct

actuators to control engine.

(3)Actuators

Actuators are applied to do instructions of ECU and control fuel quantity.

Main parts include power fuel pump and magnetic injectors.

·Variables

Control variables are applied to decide instructions for actuators by

ECM, such as gasoline load, engine speed, coolant temperature, air

temperature, air pressure etc. features. In general, one sensor informs

one piece of information.

Tow more important variables in varies variables of engine (known as

main control variables) are engine speed and engine load.

For engine, the load can be informed with air volume each cycle. When

knowing engine speed, it is easy to know air volume every cycle according

air volume every time unit. So generally use air charge as load.

ECU decides basic injecting quality and basic ignition BTDC by main control

variables value and modify those values by other sub information such as

coolant temperature, air temperature, so that accept last values about

injecting quantity and ignition advance.

·INFORMATION FLOW OF EMS

Information flow of EMS is shown in Fig.4-2.

Opened-loop control

Load sensor

Rotation speed sensor

Other sensors

ECU

Closed-loop control for λ

Closed-loop control for knock

Closed-loop control for idle speed

Fuel-metering actuator

Ignition timing actuator

Other actuators

Engine

Oxygen sensors

Knock sensors

Rotation speed sensor

Fig.4-2

ECU receives various information about engine responded by sensors to

calculate and product instructions to actuators to make engine operate in

perfect condition, which the power fuel pump and the injectors carry out

fuel-metering injection, and the ignition coil and the distributor carry out

ignition control.

Results of control is unknown by the way of the foregoing statement.

Sometimes it is necessary to keep a feature in a range, for example, to make

air/fuel close to theory air/fuel ratio 14.7 for satisfying emissions

requirements or keep idle speed near 850r/minn or prevent knock on high-load

condition. Closed-loop control is a way that forms close circuit in EMS. On

the other hand, opened-loop control system is a control system that doesn’t

form close circuit. The portion of short-line is closed-loop control, the

portion of solid-line is opened-loop control (Fig 4-2).

It is necessary to indicate that it is impossible for electronic control

system to change engine operating condition. Only external conditions, like

man or engine operating environment, can change engine operating condition

by changing engine main control variables. For example, engine operating

condition is changed because throttle open degree is changed, which air volume

charged is changed, or a vehicle is driven on upright from flat ground, engine

speed will reduces though other conditions aren’t changed.

2. Principle

Electronic fuel injection system is a system that the central part is

engine electronic control unit.

Sensors installed on positions of engine respond to various operating

features and inform ECU.

According these information, engine–ECU controls injecting quantity,

ignition advance accurately, based on preparing control program to make

engine operate perfectly in various conditions.

When ignition switch ON, ECU or ECM is powered. As soon as the first crank

rotation signal is checked, the fuel pump is powered and fuel press out with

the pump. The fuel flows to fuel distribution pipe on engine through fuel

filter and then the injectors installed on inlet manifold near intake ports,

which inject fuel into cylinders. The fuel pressure, which is controlled with

the pressure regulator on end of fuel rail, is 300kPa for both systems. Because

pressure difference is constant with pressure regulator and section area of

injector is constant too, so ECU can control injecting quantity every cycle

by means of controlling the injector on-time. When injector opens, fogging

fuel is injected into manifold which mixes with air and is inducted cylinder

on inlet stroke to fire.

Driver can control throttle open degree with acceleration pedal to control

air volume. ECU receives information such as air temperature, coolant

temperature, air pressure, engine speed etc. and calculate out air volume

and basic injecting period.

In a real run, after the basic injecting period is calculated, a modified

value is prepared by information of feedback signal of oxygen sensor on

exhaust system, instant load, battery voltage etc. ECU corrects the injecting

quantity to actual injecting quality. ECU decides accurate injecting phase

by preprogramming data, engine speed or crank position signals.

BOSCH M1.5.4 EMS adopts a pattern of sequential ignition with distributor.

DELPHI adopts a pattern of directive ignition without distributor. Drive

circuit in ECU open or close ignition coil primary circuit, and supply

ignition signals to 1-4 cylinders and 2-3 cylinders.

Both systems have self-diagnosis function. The service light in meter is

lighted when troubles occurs.

Vehicle will operate in hirple pattern while parts in the system have

trouble. There is a connector for tester.

BOSCH M1.5.4 is shown in Fig.4-3 a).

DELFHI system is shown in Fig 4-3 b).

Knock sensor

Fig.4-3a)

Fig 4-3b)

·SENSORS

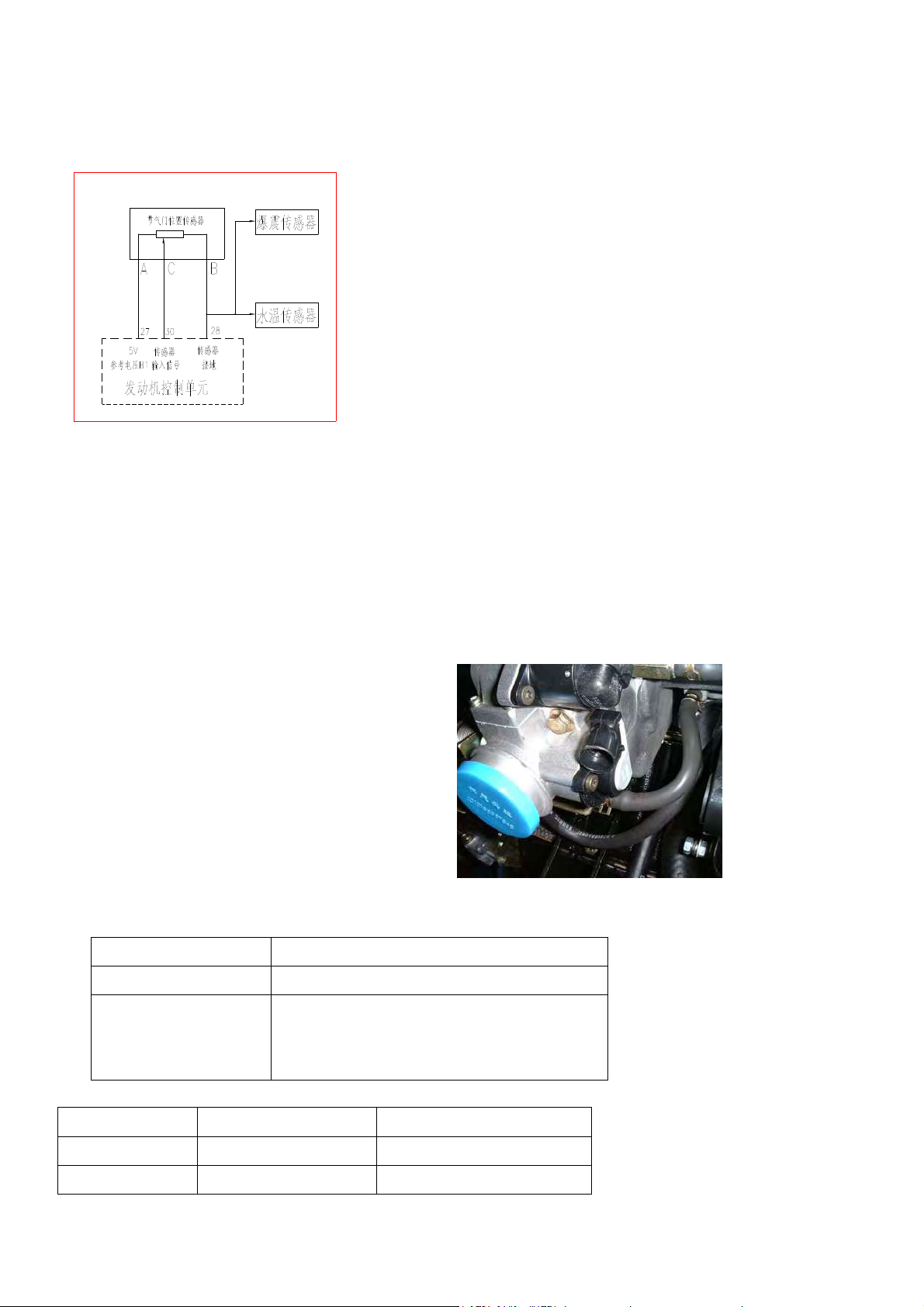

1) Throttle position sensor

A sensor which is installed on throttle assembly coaxially (throttle assembly install

on the front end of intake pipe),provide load, load range and acceleration information.

Throttle position sensor monitors open degree of the throttle. The sensor is resistance type, which

is powered with 5V by ECU and products voltage signal to ECU. The circuit diagram sees Fig. 4-4a).

a)(DELPHI)

节气门位置传感器-Throttle position sensor(TPS)

爆震传感器- Knock sensor

水温传感器-Coolant temperature sensor

参考电压-Ref. Voltage

传感器输入信号-Sensor input signal

传感器接地-Sensor earth

发动机控制单元-Engine-ECU

b)(BOSCH) c)(DELPHI)

FIG.4-4

Item BOSCH(Fig.4-4b)

Resistance(1-3) 1.95~2.10KΩ

Resistance(2-3)

1.10~2.80KΩ

Full close -full

open

Item BOSCH(Fig.4-4a) DELPHI(Fig.4-4c)

Full close 0.1V~0.9V 0~0.25V

Full open 3.0V~4.8V 0~5V

2) Intake temperature/pressure sensor(Fig4-5a),Fig.4-5b))

A sensor is installed on the intake manifold stable pressure chamber to

offer engine load and temperature information, which is used to decided

injecting quantity and ignition timing.

For BOSCH M1.5.4 , the voltage of 5V, which is supplied by ECU powers the sensor.

Voltage between terminal 4 and ground is in a range of 3.8 – 4.2V. Voltage responded to

pressure is 0.8 - 1.3V while idling,1.521 - 1.683V for 40kpa and 4.859~5.043V for

102kpa。Using ohmmeter to measure resistance between terminals 1,2, the value should be

2.2~2.7KΩ for 20℃ and 1.1~1.4KΩ for 30℃. If faulty, replace the sensor, see

fig.4-5) .

Fig.4-5a)

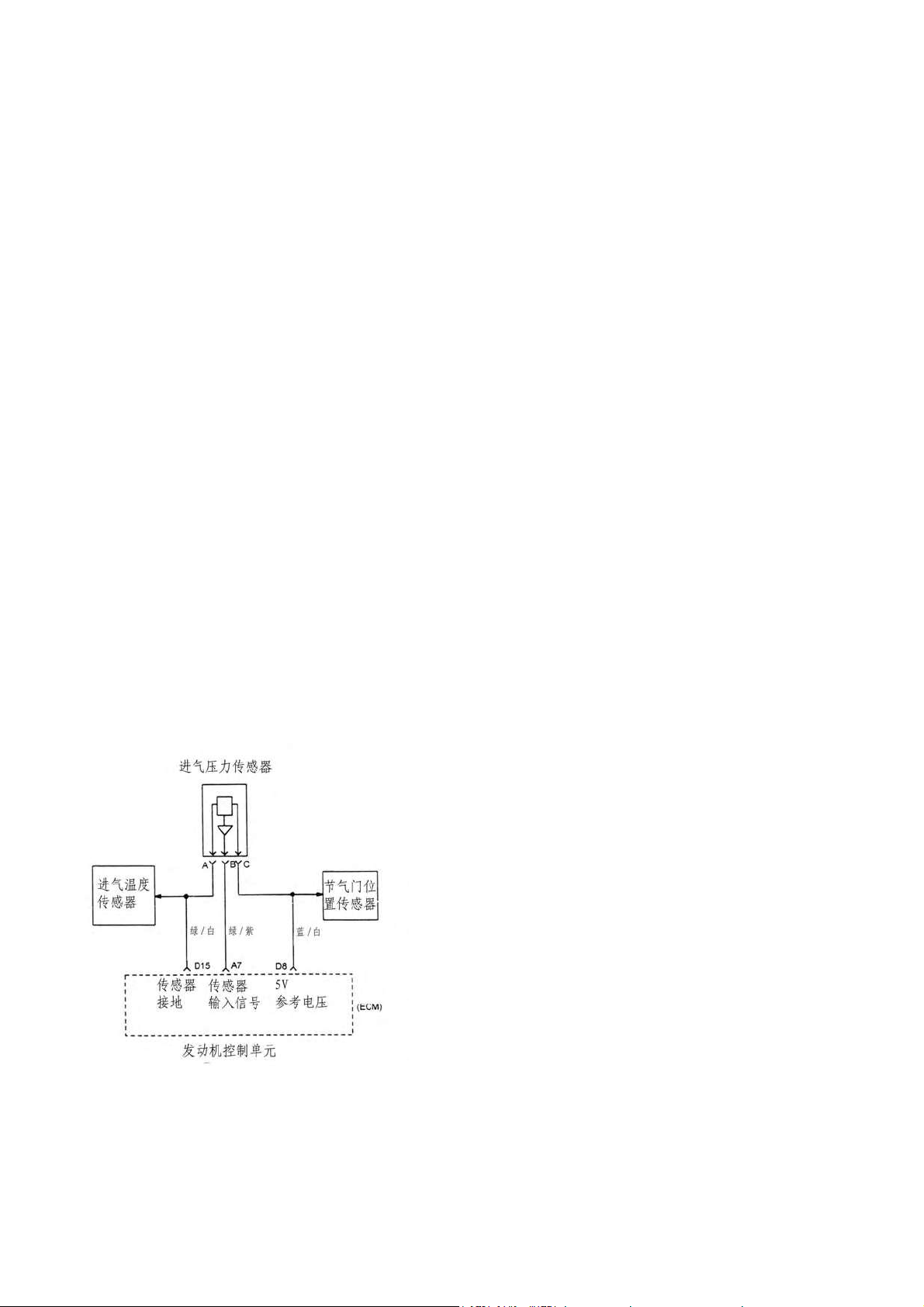

·Intake pressure sensor for DELPHI system

Be installed on the intake manifold stable pressure chamber to provide engine load information.

ECU provide 5V voltage to the sensor, the sensor responds to manifold pressure of different lode and

rotate speed which is changed to voltage single and transmitted to ECU,FIG. 4-5b),FIG.4-5c)。

Operation voltage:0.122~0.382V/15kPa

1.521~1.683V/40kPa

4.438~4.600V/94kPa

4.859~5.043V/102kPa

FIG.4-5b)

进气压力传感器: Intake pressure sensor

进气温度传感器: Intake temperature sensor

节气门位置传感器: Throttle position sensor(TPS)

传感器接地: Sensor earth

传感器输入信号: Sensor input signal

参考电压: Ref. Voltage

发动机控制单元: Engine-ECU

篮/白-LW

绿/白-GW

绿/紫-GV

FIG.4-5c)

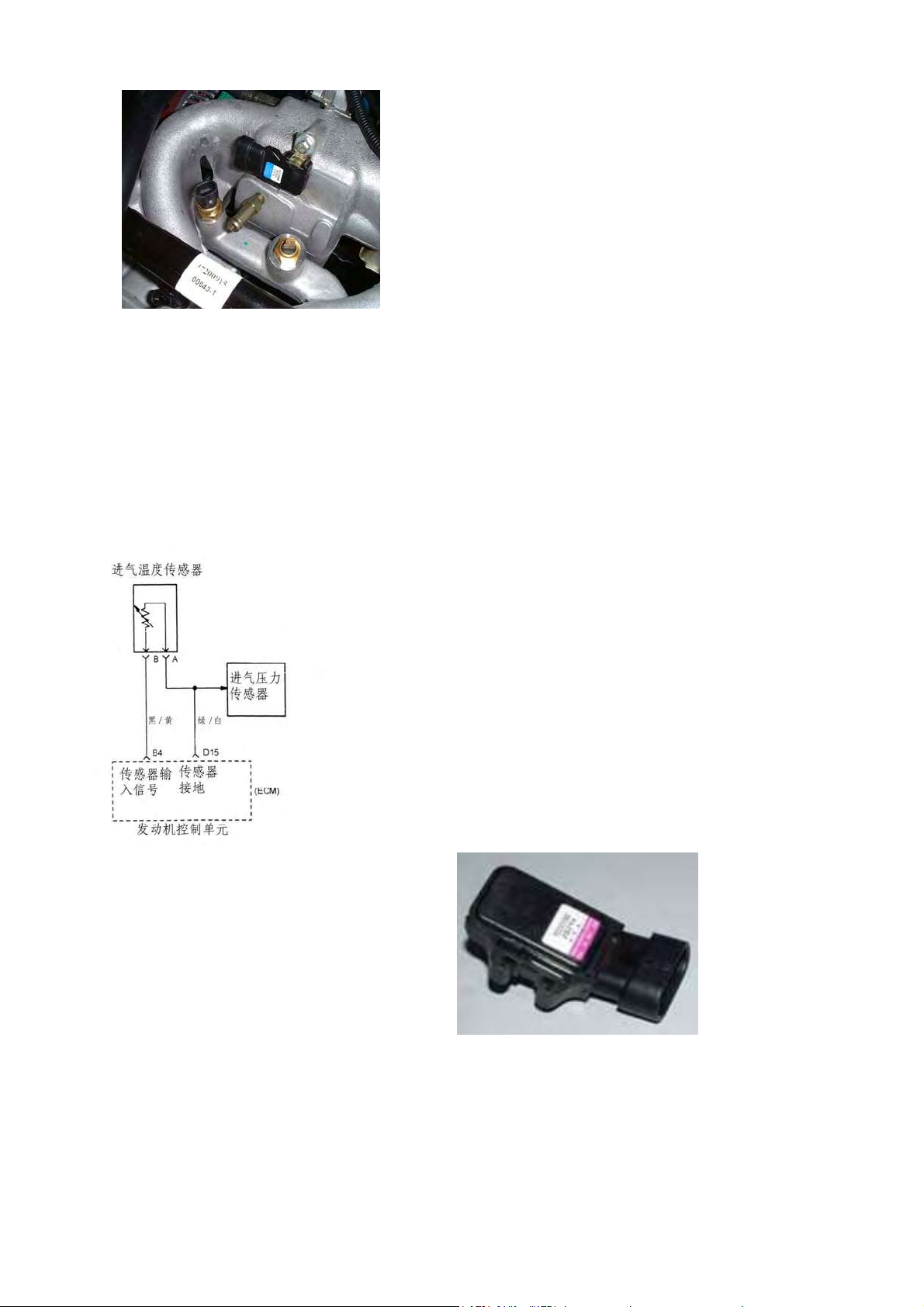

·Intake temperature sensor for DELPHI system

Installing in air fillter and provice air temperature information which is used to confirm amount

of injection and ignition timing. The end voltage is direct ratio change with resistance . Its resistance

decreases with temperature increasing.

Intake temperature sensor responds to temperature and product voltage signal which is transmitted

to ECU or ECM to control injecting quantity and ignition timing.FIG.4-5d),FIG.4-5e),MT20 see 4-5f)。

Resistance value:

178±2.3Ω/100℃ 333.8±2Ω/80℃ 3511±2.6Ω/20℃

进气压力传感器: Intake pressure sensor

进气温度传感器: Intake temperature sensor

传感器接地: Sensor earth

传感器输入信号: Sensor input signal

发动机控制单元: Engine-ECU

绿/白-GW

黑/黄-BY

FIG.4-5d)

FIG.4-5e) FIG.4-5f)

Loading...

Loading...