Page 1

W613 W614 PT-300 Planer Thicknesser. Page 1 of 4 5-05-2017

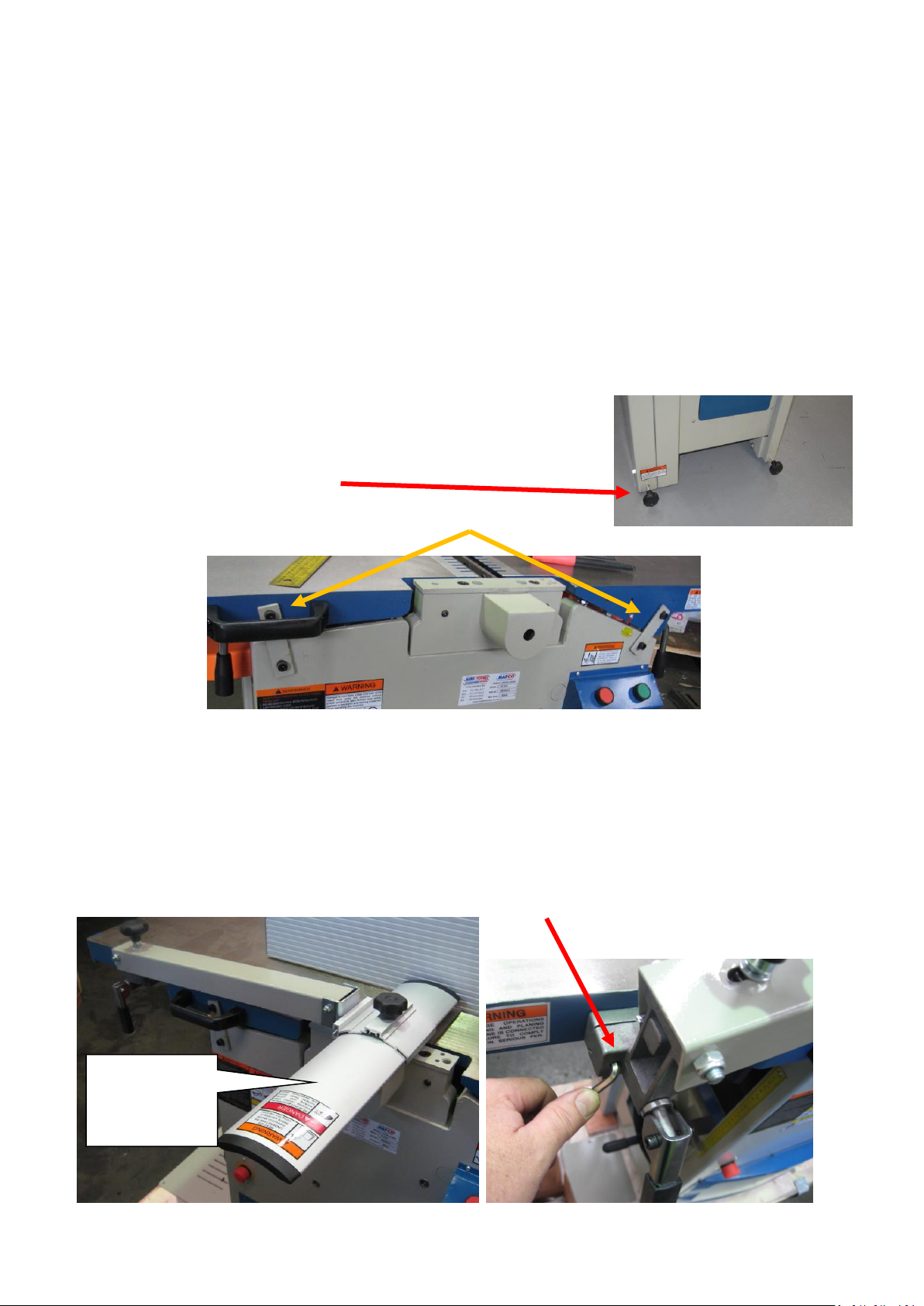

Slide in Guard

and lock in

place

EXTRA INSTRUCTIONS TO BE USED IN CONJUNCTION WITH THE FACTORY MANUAL.

Please note. Manual is suited to a machine with variable type fences and guarding so some of manual will not

suit the machine you purchased

Please carefully unpack joiner ##### # BLADES ARE SHARP # #####

Before use. Being careful of sharp blades in the centre of the top table as these will be currently unguarded

Your machine is factory set and generally ready to use with minimal pre-operation adjustments although some

adjustments may move during shipping or be different when machine is placed in its final position of use

Firstly remove all accessories off and around machine and put aside out of the way

Remove machine off the packing skid and position were needed.

#1 Fit 2 x Wheel Locking knobs as shown at base of outfeed table end and

lock in place to hold machine fixed.

#2 Remove the 2 x shipping straps fitted to the tables

It is easier to remove the LH one by removing the Plastic Lifting handle first then re-installing it.

NB: The top screws have nuts on the end inside tunnel of machine and the lower screws are threaded into the

casting

#3 Clean the top of the table with an approved degreaser (WARNING Spindle Cutter blades are SHARP!)

# 4 Fit the Swinging spindle guard assemble to the front left hand side of the machine as shown

Use a 5mm Allen key provided through the holes in the bracket into encapsulated screws ready to fit

Page 2

W613 W614 PT-300 Planer Thicknesser. Page 2 of 4

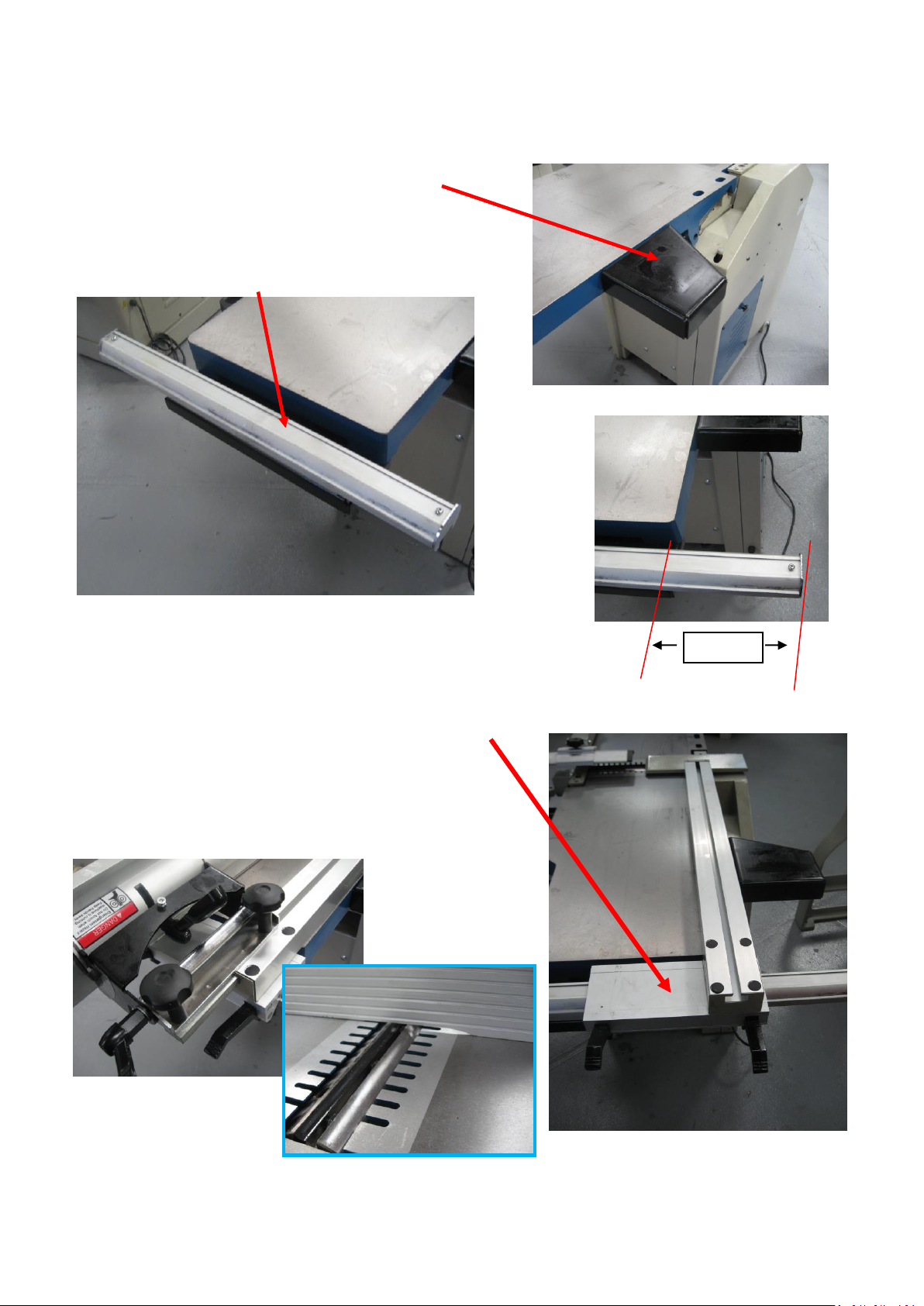

180mm

EXTRA INSTRUCTIONS TO BE USED IN CONJUNCTION WITH THE FACTORY MANUAL.

# 5 Fit the Rear LH support bracket as shown using 2 x M8 x

16mm Socket Head cap Screws supplied.

# 6 Fit the support for the Fence assemble using 2off

M8 x 20mm Socket Head cap Screws supplied to the underside

of the RH (infeed) table.

# 7 Undo the 2 screws holding the Fence rail to this support and slide

the Fence rail across to be out 180mm from side of table. Lock in place

# 8 Carefully fit the Fence support rail onto the Fence Rail and lock in place (2 front black levers)

# 9 With the 2 finger knobs loosened right off.

Slide the fence assemble onto the Fence Support

and along until cut-out in bottom of fence is 60mm from

centre of cutter head

Page 3

W613 W614 PT-300 Planer Thicknesser. Page 3 of 4

EXTRA INSTRUCTIONS TO BE USED IN CONJUNCTION WITH

THE FACTORY MANUAL.

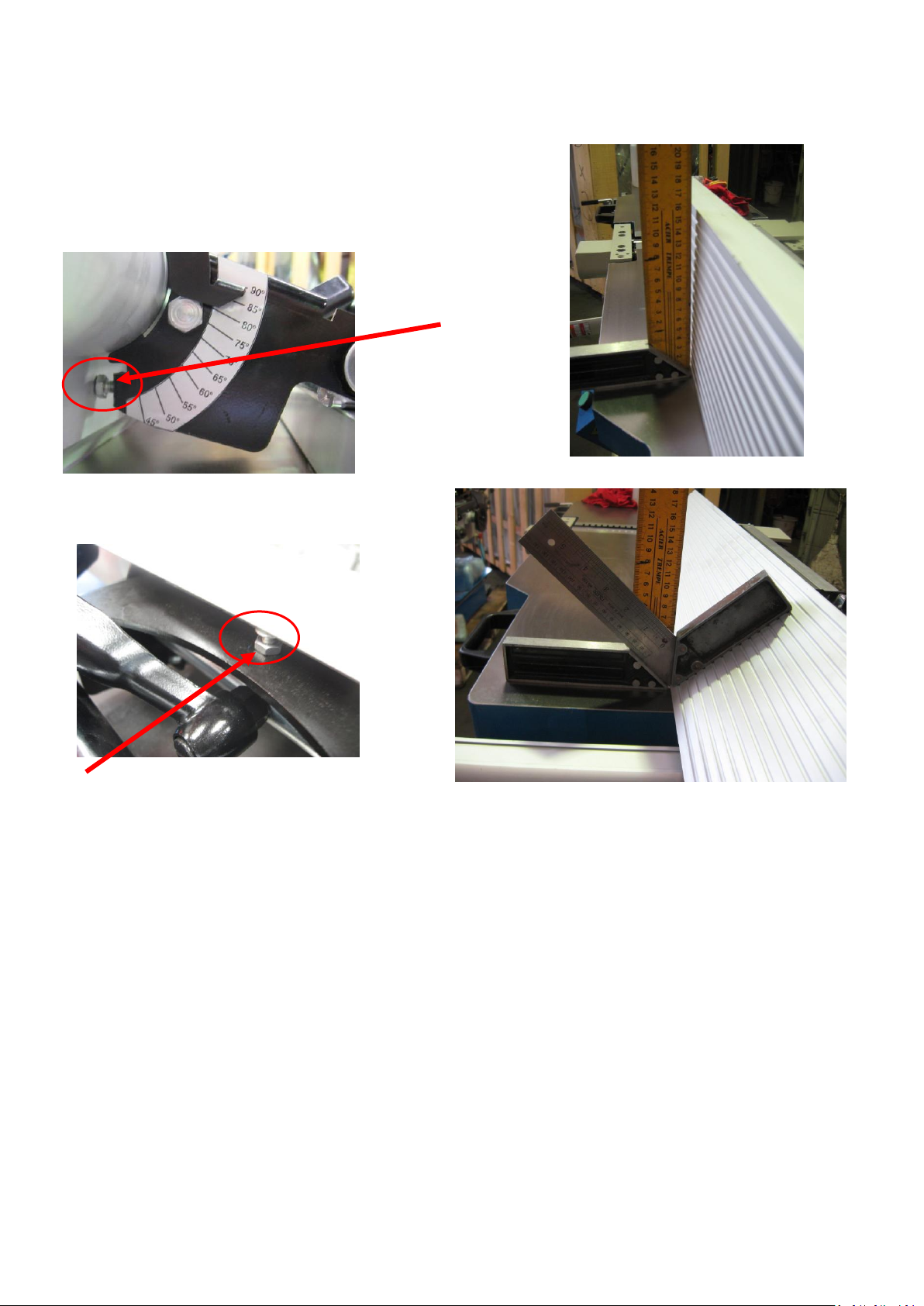

# 10 Check and adjust Fence angles if needed.

Tilt fence to 90 Degrees and put a Square or protractor up

against it.

If needed, adjust setting

screw and lock nut as

required

Tilt fence to 45 Degrees using 2 squares as

shown or a protractor up against it.

If needed, adjust setting screw and lock nut as

needed

#11 Checking/Adjusting top table Parallelism

As discussed in the factory manual this is set at factory, but because of the fine details it may need readjusting

after set up of machine. It is suggested to take a trial cut before doing this as finished product may be Ok

#12 When setting up for Planer mode, ensure for safety and Dust chip extraction, the thicknesser table is

wound all the way up to the 70mm mark before switching on

# 13 When adjusting height of Planer in feed table ensure table front table lock lever is loosened and Locking

bolt (socket head cap Screw) in end of rear adjustment shaft is loosened

Remember to lock both when height set. (See page 16 of manual Fig 16 for more detail)

#14 If after blade change height of Planer out feed table needs resetting. Ensure table front table lock lever is

loosened and Locking bolt (socket head cap Screw) in end of rear adjustment shaft is loosened

Remember to lock both when height set. (See page 16 of manual Fig 16 for more detail)

#15 Ensure the Thicknesser feed is always disengaged when not in use. Only engage when the planer is

switched on and disengage it before turning off.

Failing to do this can damaged the feed drive roller rubber coating, causing excessive wear and knocking noise.

#16 If fitting and using a Mortising Attachment (Hafco Code W615) Ensure Cutter guard is down at all times

and Thicknesser table is wound up to the 70mm mark for Safety.

Page 4

W613 W614 PT-300 Planer Thicknesser. Page 4 of 4

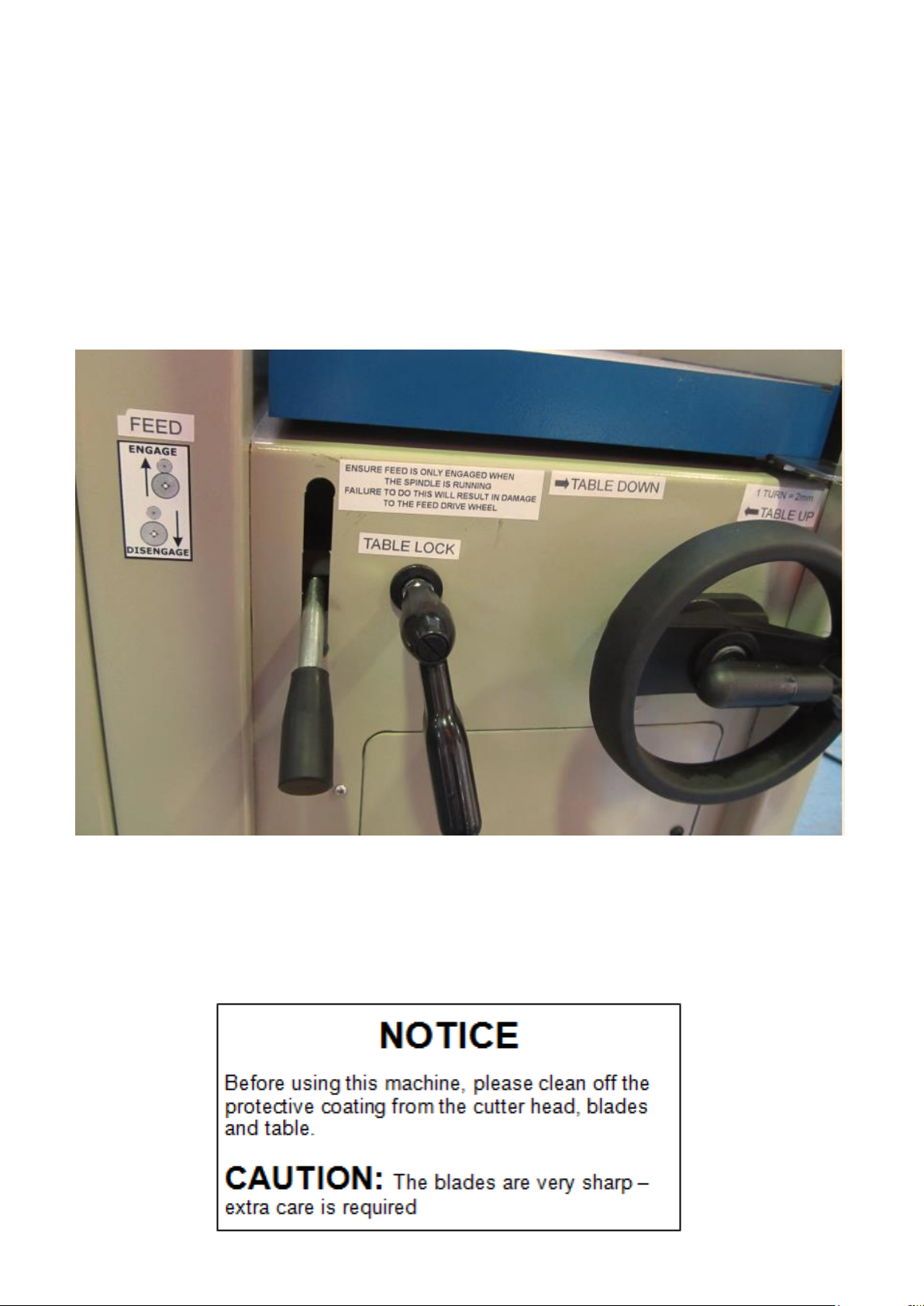

Please also note the following operational information

As per stickers for reference shown on below picture

# Thicknesser table

. 1 turn of Handwheel = 2mm movement

. Turning hand wheel anti clockwise moves table UP! (Makes thinner work piece!)

Ensure feed is only engaged when

the spindle is running.

Failure to do this will result in damage

to the feed drive wheel ”’

!

WARNING

Before using Morticer or top planer mode

Ensure for safety and efficient Dust chip extraction

That the lower Thicknesser table is wound up to the 70mm mark

and Planer guards are fitted before switching machine on.

Loading...

Loading...