ASSEMBLY INSTRUCTION

OIL

DAILY

CAUTION

10 - 16

kg

Use proper lifting techniques

CAUTION

16 - 40

kg

Use proper lifting techniques

40kg +

Use proper lifting techniques

WARNING

OVERSIZE

This product requires a mechanical lifting aid

WARNING

CAUTION

10 - 16

kg

Use proper lifting techniques

CAUTION

16 - 40

kg

Use proper lifting techniques

CAUTION

10 - 16

kg

Use proper lifting techniques

CAUTION

16 - 40

kg

Use proper lifting techniques

40kg +

Use proper lifting techniques

WARNING

WARNING

OVERSIZE

This product requires a mechanical lifting aid

ASSEMBLY INSTRUCTION

WT1D-107 WELDING TABLE

Order Code W08453

Due to the weight of the table, it is highly recommended that you have a second person to

assist during the build of the table, being made from steel it is heavy and help should be

40kg +

Use proper lifting techniques

WARNING

Suggestion of what you will need

Note - this assembly guide is merely a recommendation and should not be followed blindly, if you do not have the

equipment or the experience necessary to complete this project you should consider seeking advice from a

professional.

• 24pcs of M10 or M12mm x 75mm threaded bolts, nuts & washers.

• ‘G’ Clamps (or alternative) with an opening of at least 100mm to secure the legs in place during welding.

• Timber planks to assist in raising the table surface off the bench during assembly.

• MIG or TIG welder

• Angle grinder tted with a ne ap disc

• Soft face hammer to help assemble components

• Engineers le, spanners or shifting spanners

obtained to avoid any injuries. Always remember to wear the appropriate PPE when

working with metal and welding equipment. Refer to your welder manufacturers

recommendations for the correct settings for your welder to suit the material thickness.

NOTE: You may consider to use other methods and tools to help complete you project, the above list is

just a suggestion. read through these instructions before starting the assembly process.

Getting Started

Before starting the assembly ensure you have the correct tools & equipment to successfully assemble the table

whilst making sure you are wearing the appropriate Safety PPE.

Check for Burrs

It is normal for the components to have small burrs or minor imperfections as part of the laser cutting process. While

wearing protective gloves, check the edges of the individual pieces and visually inspect them for any small burrs.

If you do happen to nd one, use a le to remove any burrs, being careful not to remove too much excess material as

it may affect the end result.

Clean Components

The components are supplied with a thin layer rust preventative oil coating to protect it from rust, however, this lm

can affect the quality of the welds if it isn’t removed. Before you start assembling the table, ensure you wipe the

individual pieces down with an appropriate oil & grease remover.

Page 1

ASSEMBLY INSTRUCTION

9

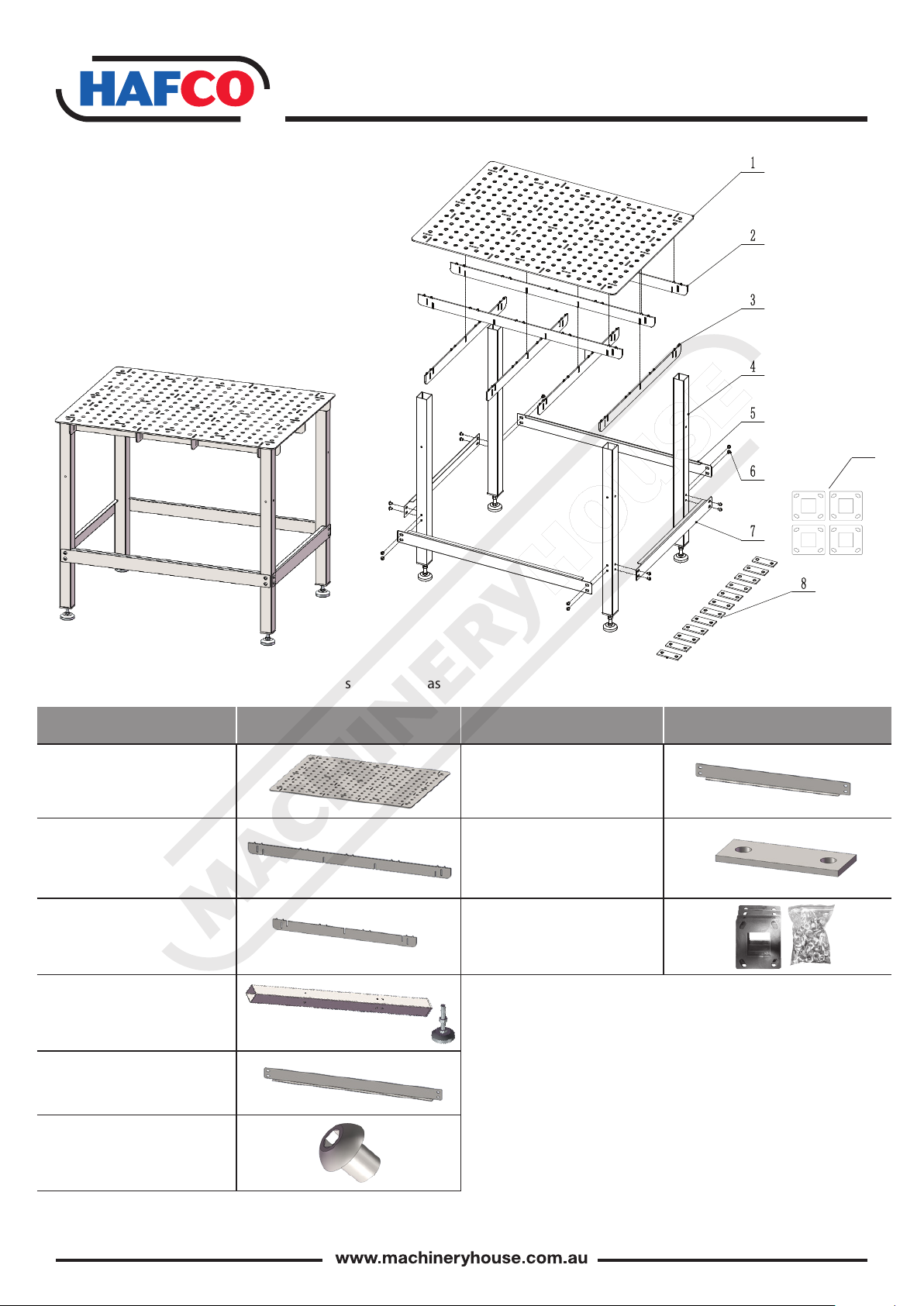

Parts list

Please check that you have all the below parts before you assemble this product

Part PartImage Image

1. Table Top

Qty:1

2. Long Ribs

Qty:3

3. Cross Ribs

Qty:4

7. Shot Leg Brace

Qty:2

8. Assembly Straps

Qty:12

9. Wheel Plate Kit

Qty:4

4. Legs with Feet

Qty:4

5. Long Leg Brace

Qty:2

6. Bolts

Qty:16

Step 1

Place the tabletop on top of timber planks or,

alternatively, sawhorses. It is best to have the

timbers spaced evenly to distribute the weight

evenly and reduce distortion during assembly.

Ensure the tabletop is level and doesn’t

rock from side to side; this will help ensure

the components t together correctly.

Step 2

Insert the ribs into the underside of the

tabletop as shown; they should t together

rmly with only a small amount of clearance

between the components. Use a soft-face

hammer to lightly tap the components into

place. If they do not t correctly the rst time,

be sure to check for any small burrs and then

try again.

ASSEMBLY INSTRUCTION

Step 3

To aid in assembly, your welding table

comes supplied with 12 pieces of pre-drilled

at bar assembly straps to span across

the webbing rib joins on the underside of

the table. Use the M10-M12 bolts and the

assembly straps to secure the ribs to the

tabletop. Ensure you do not overtighten the

bolts; otherwise, uneven forces are applied

to different parts of the table, which can

lead to twisting of the table and a less than

desirable nal result.

Page 3

ASSEMBLY INSTRUCTION

Step 4

With the assistance of a second person, carefully turn the table over so that the table surface is upright, and ensure

the welding table is placed on a at, level surface. Before doing any welding, check the atness with a builders level or straight edge. With the help of a small

ashlight, You can check if there are any gaps.

between the underside of the table

surface and the webbing ribs to ensure they

are secured correctly, there should be no

gaps between the tabletop and the ribs.

The most likely cause is a small burr,

or the bolts have not been tightened.

If this is the case, disassemble.

remove the burr and reassemble.

Once again, ensure you do not overtighten.

the bolts, otherwise uneven forces are

applied to different parts of the table, which

can lead to a twisting of the table, leading

to a less-than-desirable nal result.

Step 5

Once you are happy with the assembly and

atness, weld the areas highlighted in red

in the sequence as indicated, and weld with

a spiral motion so that the two pieces fuse

together correctly. Finish welding all the

green areas in a clockwise rotation. Less

is more when welding this table together.

More welding means more heat and higher

chances of warping the table surface.

Step 6

The 50 x 50mm steel legs come standard

with adjustable feet tted, plus we also

supply caster mounting plates. If you want

your welding table to stay on the adjustable

feet, then proceed to step 7. If you want

your welding table to be mobile, simply cut

the legs to the desired length to suit the

nished table height you require, allowing for

the height of the caster wheels. Weld on the

caster mounting plates as shown, and bolt on

your optional caster wheels.

11

2

4

8

5

7

9

3

12

6

10

1

Page 4

Step 7

Once the table has cooled, remove the

bolts and assembly straps. Again, with the

assistance of a second person, turn the table

over with the webbing ribs facing up. Clamp

the tube legs into each corner as shown,

ensuring the threaded holes are in the correct

positions to suit the leg bracing. Lightly clamp

the legs into each corner as shown, then bolt

the leg bracing into place (do not fully tighten

the bolts). Check that the legs are square and

level, then proceed to weld as shown. Once

nished welding, tighten the leg bracing.

ASSEMBLY INSTRUCTION

Step 8

The assembly is now complete. With the

assistance of the second person, carefully

turn the table over, put it in your desired

position, and adjust the levelling feet, check

all bolts are tighten and components are

secure. Your welding table is now ready for

use.

* Shown with caster mounting plates

Page 5

Loading...

Loading...