INSTRUCTION MANUAL

DIGITAL READOUT

Models

XH600-2, XH600-3

Order Code D5201, D5203

Edition no : XH600-1

datE of issuE : 03/2023

www.machineryhouse.co.nz

MACHINE DETAILS

INSTRUCTION MANUAL

XH600

MACHINE

MODEL NO.

Digital Readout

XH600

SERIAL NO.

DATE OF MANF.

distributEd by

www.machineryhouse.co.nz

NOTE:

This manual is only for your reference. At the time of the compiling of this manual ev-

ery effort to be exact with the instructions, specications, drawings, and photographs

of the machine was taken. Owing to the continuous improvement of the HAFCO

METALMASTER equipment, changes may be made at any time without obligation or

notice. Please ensure the local voltage is the same as listed on the specication plate

before operating any electric machine.

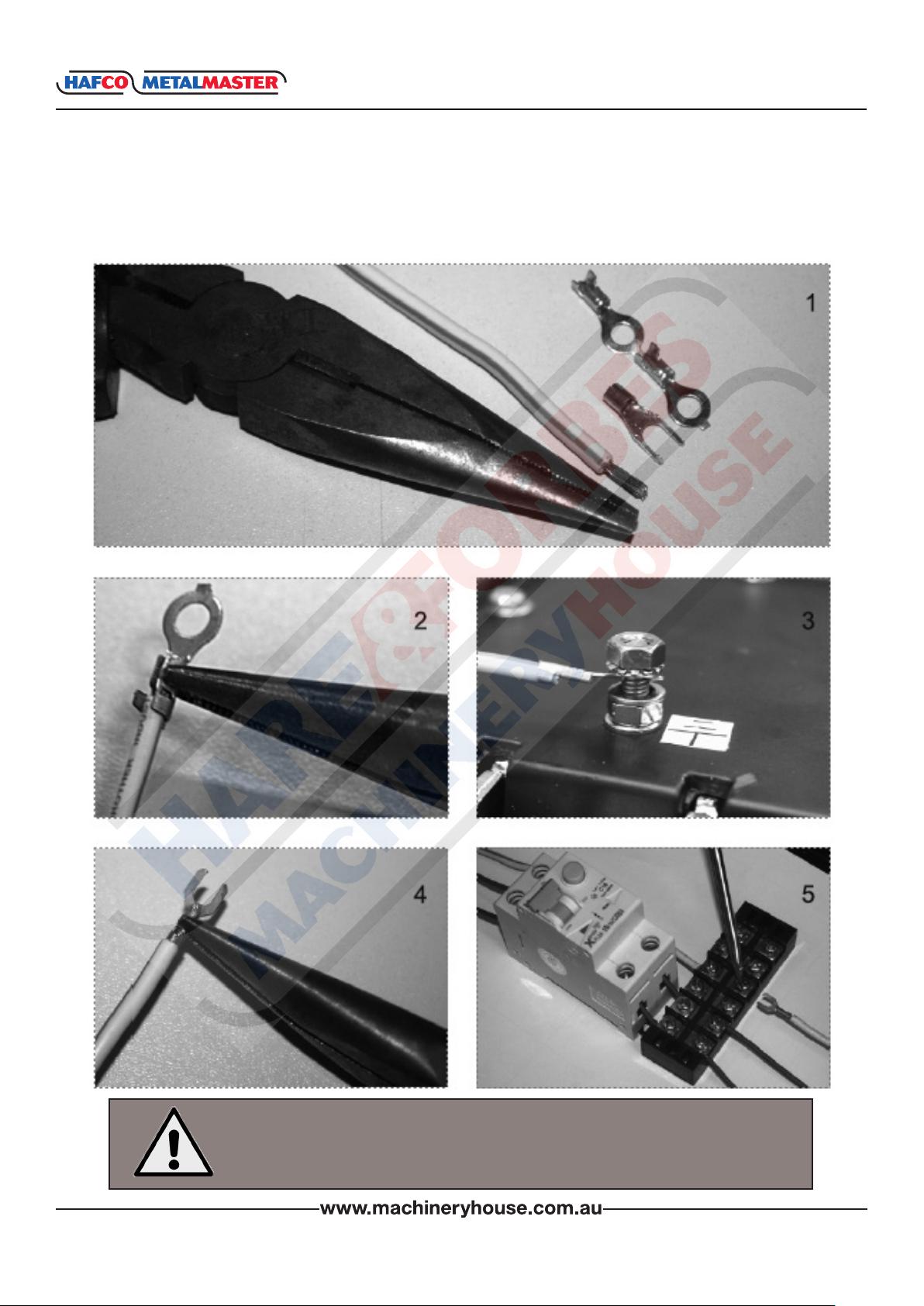

POWER SUPPLY

The PROTECTIVE EARTH CIRCUIT of the mains supply, MUST BE CONNECTED to the

protective earth terminal of the DRO through the supply cord.

The supply cord must be secured with cable ties to avoid from dropping into a hazardous

position, for example the oor or coolant tray, when disconnected from the DRO.

The supply cord must be routed away from moving parts, swarf, coolant or sources of heat.

MOUNTING

Select the location of the installation with due regard of safety and ease of operation. Keep the

DRO away of moving parts and coolant spray. To ensure correct operation of the DRO, make

sure that the DRO is correct grounding. The DRO may require grounding if different power

circuits are used. Grounding diagram can be found on page 52

www.machineryhouse.co.nz

2

INSTRUCTION MANUAL

C O N T E N T S:

XH600

Chapter 1 Identication

1.1 Front Panel 3 Axis........................ 4

Front Panel 2 Axis....................... 5

Rear Panel................................... 6

Identication Summary................ 7

1.2 Description Key Functions.......... 8

1.3 Interface....................................... 9

1.4 Coordinate System...................... 10

Chapter 2 Basic Operation

2.1 Power On..................................... 11

2.2 Zeroing The Axis.......................... 11

2.3 Inch / Metric Conversion............. 11

2.4 Enter a Dimension in an Axis....... 12

2.5 Calculating The Mid Point........... 12

2.6 Absolute/Incremental SDM Gps.. 13

2.7 Clear All SDM Datum................... 16

2.8 Lathe Function............................. 16

2.9 Vibration Filtering......................... 17

2.10 Entering/Exiting Display Settings 17

Chapter 3 SDM Coordinates

Chapter 6 Initial System Settings

6.1 Enter/Exit System Setup.............. 35

6.2 Setting DRO Type........................ 36

6.3 Setting DRO Positive Direction.... 36

6.4 Setting Error Correction Type...... 37

6.5 Toggle Between R/D Display....... 38

6.6 Setting Z Axis Dial........................ 40

6.7 Set the Scale Resolution.............. 40

6.8 Setting Input Mode in SDM Coor. 41

6.9 Setting Slope Mach. Parameter... 42

6.10 Toggle Linear Scale & Encoder.... 42

6.11 Step Mode for ARC Processing... 43

6.12 Angle Display Mode..................... 44

6.13 Angle Display Type...................... 45

6.14 Enable/Disable Error Signal......... 45

6.15 Setting Lathe Mode..................... 46

6.16 Set Display Brightness Grade...... 47

6.17 Setting Number of display Axes.. 47

6.18 Load Default Setup...................... 49

Chapter 7 Linearity Error Correction.... 50

Chapter 8 Troubleshooting.................. 51

3.1 Zeroing The Current Position....... 18

3.2 Preset Datum of SDM Coord....... 20

Chapter 4 Special Functions

4.1 Pitch Circle Hole Function........... 22

4.2 Bolt Hole Line Function............... 24

4.3 Arc Machining............................. 26

4.4 Slope Processing........................ 31

Chapter 5 Calculator Function

5.1 Enter and Exit Calculator.............. 33

5.2 Calculating Example.................... 33

5.3 Transferring Results to Axis........ 33

5.4 Transferring Display to Calculator. 34

Grounding Diagram............................. 52

www.machineryhouse.co.nz

3

INSTRUCTION MANUAL

Chaper 1 IDENTIFICATION

1.1 XH600-3 FRONT PANEL 3 AXIS

Become familiar with the names and locations of the controls and features shown below to

better understand the instructions when mentioned later in this manual.

XH600

ABS

mm

10

0.000

0.000

0.000

9

18

32

4

5

6

18

14

www.machineryhouse.co.nz

4

12

13151617

11

7

INSTRUCTION MANUAL

1.1 XH600-2 FRONT PANEL 2 AXIS

8

17

18

XH600

2

1

3

4

16

15

14

13

12

11

10

5

9

7

6

www.machineryhouse.co.nz

5

1.1 REAR PANEL

Main on / off switCH

powEr lEad soCKEt

INSTRUCTION MANUAL

sCalE ConnECtErs

grounding sCrEw

XH600

OPTIONAL ACCESSORIES

optional latHE Mounting Kit

Mounting braCKEts

optional Mill Mounting Kit

ordEr CodE d5206

ordEr CodE d5204

www.machineryhouse.co.nz

6

INSTRUCTION MANUAL

XH600

1.1 IDENTIFICATION SUMMARY

Become familiar with the names and locations of the controls and features shown on previous

pages to better understand the instructions if mentioned later in this manual.

1 Number, decimal point key

2 Calculator key

3 Reset key for calculator

4 Operation key (Add, sub, multiple and divide)

5 Key to conrm operation

6 Trigonometric function key

Four special function key (Simple R cutting function, Process a slope, Process

7

holes displayed equally on a circle, Process holes displayed equally on a line)

8 Select axis to operate

9 Zero selected axis

10 X/Y/Z Display window

11 Enter +/- sign

12 Display half value of an axis

13 Scroll up or down to select

Function shift key (in state of calculator, calculate anti-trigonometric function. In

14

display state of SDM coordinate, enter the state of input of SDM coordinate)

15 Toggle between ABS/INC coordinate

16 Toggle display unit between metric and inch

17 Indicates either metric or inch selected

18 Message window

www.machineryhouse.co.nz

7

INSTRUCTION MANUAL

1.2 DESCRIPTION OF KEY FUNCTIONS

KEY MARK KEY NAME FUNCTION

XH600

1

2

3

4

5

6 SDM Switch

7

8

9

10

11

X/Y/Z-Zero Zero selected axis.

Axis Selection Select axis to operate.

Inch/Metric Switch Toggle display unit between metric and inch

Center Finding Displays half the value of an axis.

ABS/INC Switch Toggle between ABS/INC coordinate.

Numeric Keys Enter number.

Decimal Point Enter decimal point.

+/- Sign Enter +/- sign.

Enter Conrm operation.

Clear all Cancel incorrect operation.

1. Calculate inverse trigonometric function in

calculating function.

2. Enter No. of SDM coordinate.

12

13

14

15

16

17

18 ARC Simple R cutting function

19

20

Calculator Enter or quit calculating state.

Trigonometric Function

Add: Subtract: Multi-

ple: Divide

Radical Sign Square root or square equations

BHC Process holes displayed equally on a circle.

BHL Process holes displayed equally on a line.

SLOPE Process a slope.

Item Selection Scroll up or down to select.

Calculate trigonometric or inverse trigonometric.

Operate adding: Subtracting: multiplying:

dividing.

www.machineryhouse.co.nz

8

INSTRUCTION MANUAL

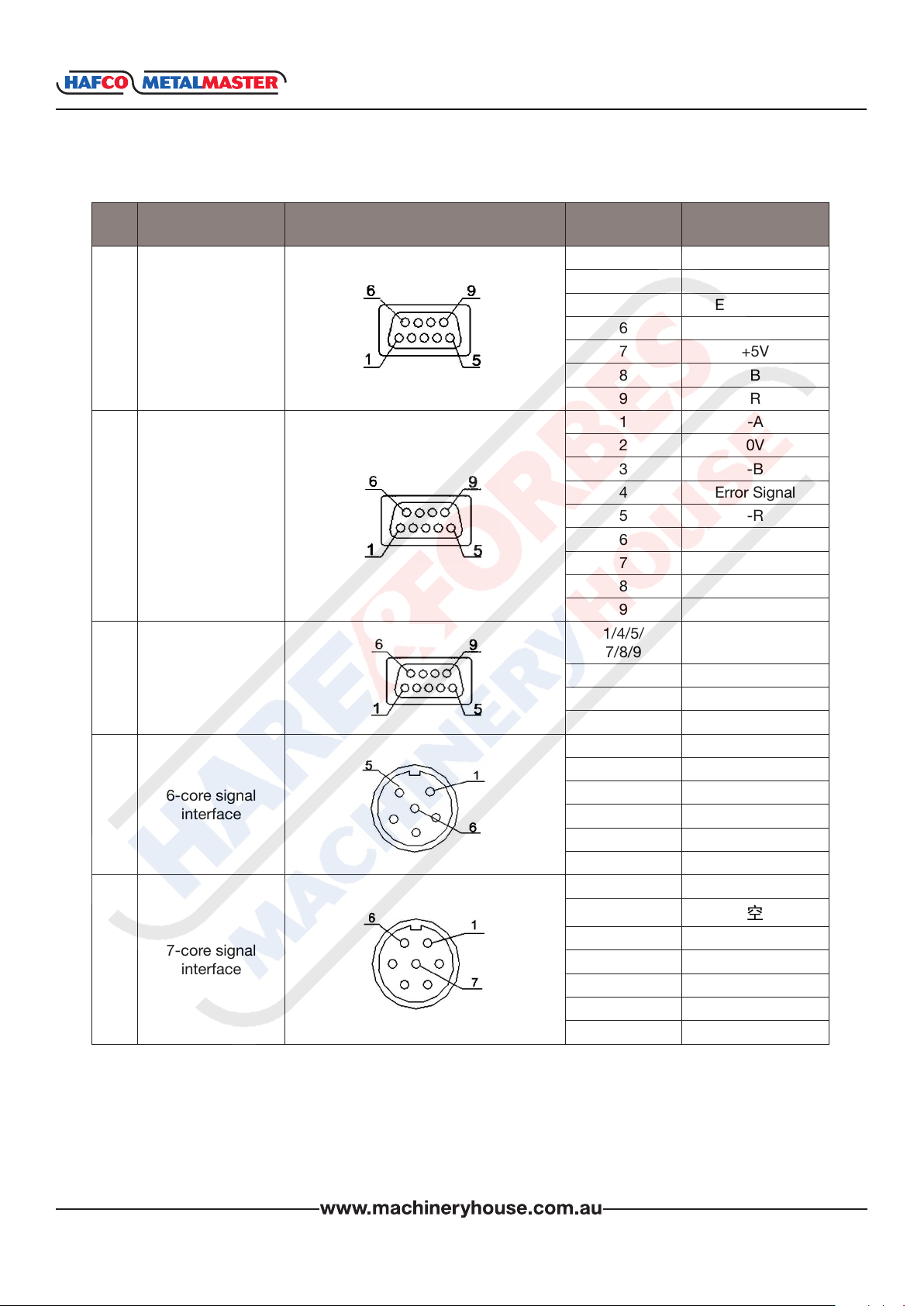

1.3 INTERFACE

No. Interface Type Schematic Diagram Pin Signal

1/3/5 Null

2 0V

1.

2.

3.

4.

5.

9-core TTL

9-core EIA-422-A

signal interface

EDM signal

6-core signal

7-core signal

Interface

interface

interface

interface

4 Error Signal

6 A

7 +5V

8 B

9 R

1 -A

2 0V

3 -B

4 Error Signal

5 -R

6 A

7 +5V

8 B

9 R

1/4/5/

7/8/9

2 Common Terminal

3 Normal Close

6 Normal Open

1 0V

2 A

3 B

4 R

5 +5V

6 PE Earth Wire

1 0V

2

3 A

4 B

5 +5V

6 R

7 PE Earth Wire

Null

XH600

www.machineryhouse.co.nz

9

INSTRUCTION MANUAL

XH600

1.4 COORDINATE SYSTEM

XH600 DRO is an instrument which can measure the position of the work piece when process-

ing. The coordinate system needs to be dened rst, for more efciency and accuracy.

On a vertical milling machine, the longitudinal travel of the table is parallel with the X axis, and

cross travel is parallel with the Y axis. Z is parallel to the spindle and is parallel to the up-anddown travel.

Origin is a point along the axis that reads zero.

Positive direction of an axis is set as the number increases as you move away from the origin.

The value of one point position is the distance relative to the origin of the coordinate.

For a work-piece as Figure A, the value of each point position is as Figure B when point O is the

origin of the coordinate.

Fig A

Fig B

www.machineryhouse.co.nz

10

INSTRUCTION MANUAL

Chapter 2. BASIC OPERATION

2.1 POWER ON

When the XH600 is Powered up it enters the normal display state, and memorizes the following

parameters.

A. The scales position when the power was switched off.

B. The mode selection when powered off (ABS/INC/SDM)

C. The Metric/Imperial mode when switched off.

2.2 ZEROING THE AXIS

The purpose of this function is to set the current position for that axis to ZERO

Example : Setting the current X axis position to ZERO

XH600

10,000

35.000

0000

SDm

2.3 INCH / METRIC CONVERSION

The purpose of this function is to switch the display between

Inch or Metric

EXaMplE 1. inCH to MEtriC

1,000

2.000

ABS

0000

Inch

X0

J

iNCH

MM

J

ð

ð

0,000

35.000

0000

SDm

25.400

50.800

0000

ABS

mm

ABS

mm

25.400

50.800

0000

EXaMplE 2. MEtriC to inCH

iNCH

MM

J

www.machineryhouse.co.nz

11

ð

1.000

2.000

0000

ABS

Inch

INSTRUCTION MANUAL

XH600

2.4 ENTER A DIMENSION IN AN AXIS

Function: Enter a value for an axis in normal display state.

NOTE: An Axis value can not be preset while the DRO is in other states (e.g. calculating function

or special function).

Press the and the X Axis will ash “0”, press the 1 and 2 and select “+” or “-” then press

“Enter”. If the value is incorrect press to cancel and input again.

X

AC

ABS

mm

0.000

50.800

0000

X

1

Ent

ABS

=

+ _

2

J

12.000

50.800

0000

mm

2.5 CALCULATING THE MID POINT

Function: Set the center of the work piece as datum by halving the displayed value.

To set the current X axis zero position at the centre of the work piece,

Step 1. Using an edge nder locate the edge at one end of the work

piece, then zero the X axis.

0,000

35.000

X0

J

ABS

mm

30.000

35.000

0000

Step 2. Using the edge nder locate the edge at the other end

of the work piece.

60,000

35.000

1

www.machineryhouse.co.nz

X

2

Step 3. Press then to half the

“X” axis display value.

12

1

2

X

INSTRUCTION MANUAL

XH600

2.6 ABSOLUTE / INCREMENTAL / 200 GROUP SDM

An ABSOLUTE movement moves to a measurement distance from the ZERO POINT.

An INCREMENTAL movement is a measurement based on the current position. An incremental

measurement does not take the parts zero point into consideration.

During machining operations, the operator can store the work piece datum ( ZERO position ) in

ABS coordinate, then switch to INC coordinate to continue machining operations

Then the operator is free then to zero the axes or preset any dimensions into any axis in INC coordinate for any relative position machining. The work piece datum (work piece ZERO position ) is

still kept in the ABS coordinate of the DRO.

Function: The XH600 series DRO has 3 display modes, absolute mode (ABS), incremental mode

(INC) and 200 group Second Data Memory (SDM) with the range of 000 to 199.

1. Zero point of the work-piece is set at the origin point of the ABS coordinate,

2 The relative distance between datum of ABS and SDM remains unchanged when ABS

datum is changed.

3. If one point in ABS is zeroed, the point in INC is zeroed automatically, yet if one point in INC

is zeroed, the point in ABS will remain unchanged.

Example: Currently in ABS display coordinate, to switch to INC display coordinate

ABS

mm

62.000

50.800

0000

ABS

iNC

Inc

42.000

50.800

0000

mm

J

A. Toggle between ABS/INC/SDM coordinates

These three display modes can be changed only in normal display state.

ABS to INC Press

INC to ABS Press

SDM to INC Press to enter ABS or INC, If in ABS: press again.

SDM to ABS Press to enter ABS or INC, If in INC: press again.

INC to SMD Press

ABS to SDM Press

ABS

iNC

ABS

iNC

ABS

iNC

ABS

iNC

SDM

S-N

SDM

S-N

ABS

iNC

ABS

iNC

www.machineryhouse.co.nz

13

INSTRUCTION MANUAL

II Set A New SDM Number In SDM Mode

Steps:

1. Enter SDM mode;

2. Press message window ashes, waiting for a new SMD

input number.

3. Enter a new number. for example, enter

4. Conrm new SDM number, then the message window stops

ashing and the SDM number is changed to 66.

III: Increase/Decrease The SDM Number.

Return the DRO to the normal display state with the SDM display

mode, press to decrease the SDM number by 1.

Press to increase the SDM number by 1.

q

SDM

S-N

q

6

6

XH600

SDm 13

mm

SDm 66

mm

Example 1: If the current SDM number is 77, and the message window displays “SDM 77”

Press then the message window will display “SDM 76” which means the current “SDM”

number is “76”.

q

SDm 77

mm

q

ð

SDm 76

mm

J

Example 2 :If the current SDM number is 77, and the message window displays “SDM 77”

Press then the message window will displays “SDM 78” which means the current SDM

number is 78.

q

SDm 77

mm

q

ð

SDm 78

mm

J

www.machineryhouse.co.nz

14

INSTRUCTION MANUAL

XH600

SETTING SDM COORDINATES FOR A WORKPIECE

If a work-piece as the gure at the bottom of the page is

to be machined, the datum plane is E, and the coordinates

can be set as the following steps below:

1. Return to the normal display state with ABS coordinate;

2. Move the machine table until the cutting tool is aligned

with plane E, then zero X axis.

3. Move the machine table until the cutting tool is aligned

with the plane D.

Change SDM number to SDM 000, and press to

X0

zero “X” axis.

Then the Number “SDM 000” coordinate’s datum is set

at plane D.

4. Move the machine table until the cutting tool is aligned

q

with plane C, press to change SDM to SDM 001,

and then press to zero X axis, and the SDM 001

X0

with the datum plane C is set.

ABS

mm

ABS

mm

SDm 000

mm

SDm 000

mm

0,000

-90,000

0,000

-35,000

0,000

5. Move the machine table until the cutting tool touches

the plane B, the DRO will display as the right.

6. Move the machine table until the cutting tool touches

the plane A, the DRO will display as the right.

SDm 001

mm

SDm 001

mm

SDm 001

mm

10,000

-35,000

www.machineryhouse.co.nz

15

INSTRUCTION MANUAL

XH600

2.7 CLEAR ALL SDM DATUM

Function: To clear all the Datum of the SDM settings 0 – 199. After clearing, the display the value

in the SDM coordinate will be equal to the value in the ABS coordinate.

Steps:

1. Return normal display state;

2. Press simultaneously for 10 times, and the message window will display “CLR SDM”

and ashes, which means it is now clearing. After a moment, the clearing will be completed

and “CLR OK” will be displayed in message window temporary and the DRO will return to

the normal display state.

.

.

cLR SDm

mm

ð

cLR OK

mm

JX10

2.8 LATHE FUNCTION

As per the image to the right, if two scales are in-

stalled in one axis, the position of the work-piece

should be the sum of these two values (X+Y) in

this direction. It is called lathe function.

A. Lathe mode 0: normal display (the lathe

function is disabled).

B. Lathe mode 1: X window value = the value of

X axis position + the value of Y axis position.

C. Lathe mode 2: X window value = the value

of X axis position + the value of Z axis

position.

D. Lathe mode 3: Y window value = the value of

Y axis position + the value of Z axis position.

Steps:

1. Set the lathe mode in initial system settings.

2. In normal display state press to enter lathe function.

3. In lathe state, press to exit the lathe function.

A. If in normal display state: the value of the position is as the right.

B. In lathe mode 3, the DRO will display as the following,

Y window display value = value of Y axis position + value of the

Z axis position

Z+Z1

sin

Z+Z1

sin

Y

X

10,000

20.000

30.000

ABS

mm

10,000

20.000

30.000

ABS

mm

www.machineryhouse.co.nz

16

INSTRUCTION MANUAL

XH600

2.9 VIBRATION FILTERING

Vibration ltering is especially useful for old and big machines in which the machine structure is

not rigid enough to get a stable display during machining or moving, or when machining in one

axis, the other axes may vibrate and hence the DRO display numbers are jumping around which

may cause confusions and uncomfortable position visualization to the operator.

If the operator cannot see the display value clearly. The XH600 series DRO provides vibration

ltering function to stabilize the digits display,

Steps:

1. Enter display value lter function In normal display state, press to enter the display

value lter function.

2. To exit the display value lter function, press again

COS

COS

2.10 Enter/Exit Setup Display Settings

Press to enter initial system setting after DRO

powers on for 1 second, then “SETUP” displays in the

message window.

=

Ent

q

Press or to select the item you want to change.

If you want to quit initial settings, press or

until “EXIT” appears in message window and press

q

q

q

=

Ent

Setup

mm

exIt

mm

www.machineryhouse.co.nz

17

INSTRUCTION MANUAL

XH600

Chapter 3. SDM COORDINATES - 200 GROUPS

The HAFCO METALMASTER XH-600 DRO has three display modes.

1. Absolute mode (ABS),

2. Incremental mode (INC) and

3. 200 groups second data memory (SDM 0—SDM199).

ABS datum of the work-piece is set at the beginning of the processing and the 200 group SDM

is set relative to ABS coordinate.

1. INC is independent of ABS, it won’t follow any change in ABS datum ( zero point ) .

However, all SDM coordinates are relative to ABS coordinate, all SDM positions are relative

to ABS’s zero, it will shift together with ABS zero position changes.

2. All SDM coordinate’s relative distance to ABS can be entered directly into the DRO using

the keypads. No need of any calculation or actual tool positioning in the machine.

Example: The ABS datum is the center point O, the

point E, F, G, H needing processing are set as

a datum of SDM 000 — SDM 003.

Two ways to set SDM coordinates:

1. Zeroing at the current point;

2.` Presetting the datum of the SDM coordinate.

3.1 ZEROING AT THE CURRENT POINT

Set the center point of the work-piece as the origin of the

ABS, then align the lathe cutting tool with point E, F, G, H

by moving the machine table and zero them. It is the

processing position where the “0.00” appears in the X

window, Y window by moving the machine table whether

in ABS or in SDM coordinate.

Steps:

1. Set the center of rectangular point O as the datum of

ABS. Make line AB parallel with X axis: line AD parallel

with Y axis. When position lathe tool to point O

Zero X axis and Y axis in SDM 000.

Zero X axis and Y axis in SDM 001.

Zero X axis and Y axis in SDM 002.

Zero X axis and Y axis in SDM 003.

2. Set the point E as the datum of SDM 000.

SDM 000: align the cutting tool with point E and zero X

axis, and the Y axis. DRO displays as per the picture to

the right.

0,000

0.000

ABS

mm

-60,000

-45.000

SDm 000

mm

www.machineryhouse.co.nz

18

INSTRUCTION MANUAL

3.1 ZEROING AT THE CURRENT POINT Cont.

3. Set the point F as the datum of SDM 001.

In SDM 001 and align the cutting tool with point F,

then zero X axis, Y axis. DRO displays as per the right:

XH600

-60,000

-45.000

SDm 001

mm

X

Y

0

0

J

4. Set the point G as the origin of SDM 002.

In SDM 002, align the cutting tool with point G, and

zero the X axis, Y axis. DRO displays as per the right.

X

Y

0

0

J

5. Set the point H as the origin of SDM 003.

In SDM 003, align the cutting tool with point H, and

zero the X axis, Y axis. DRO displays as per the right.

X

Y

0

0

0,000

0.000

SDm 001

mm

-60,000

-45.000

SDm 002

mm

0,000

0.000

SDm 002

mm

-60,000

-45.000

SDm 003

mm

0,000

J

0.000

SDm 003

mm

6. Machine the work-piece according to the preset SDM coordinates.

7. Machine another work-piece according to the same blueprint. You only need to set the

center point as the datum of ABS. It is not necessary to set SDM coordinate again, as SDM

can be set automatically. Point E, F, G, and H are the zero points of SDM 000, SDM 001,

SDM 002, and SDM 003 respectively. Points can be machined when entering corresponding

SDM coordinate and where “0.000” appears in the screen by moving the machine table. This

function can save plenty of time where multiple pieces are to be machined

www.machineryhouse.co.nz

19

INSTRUCTION MANUAL

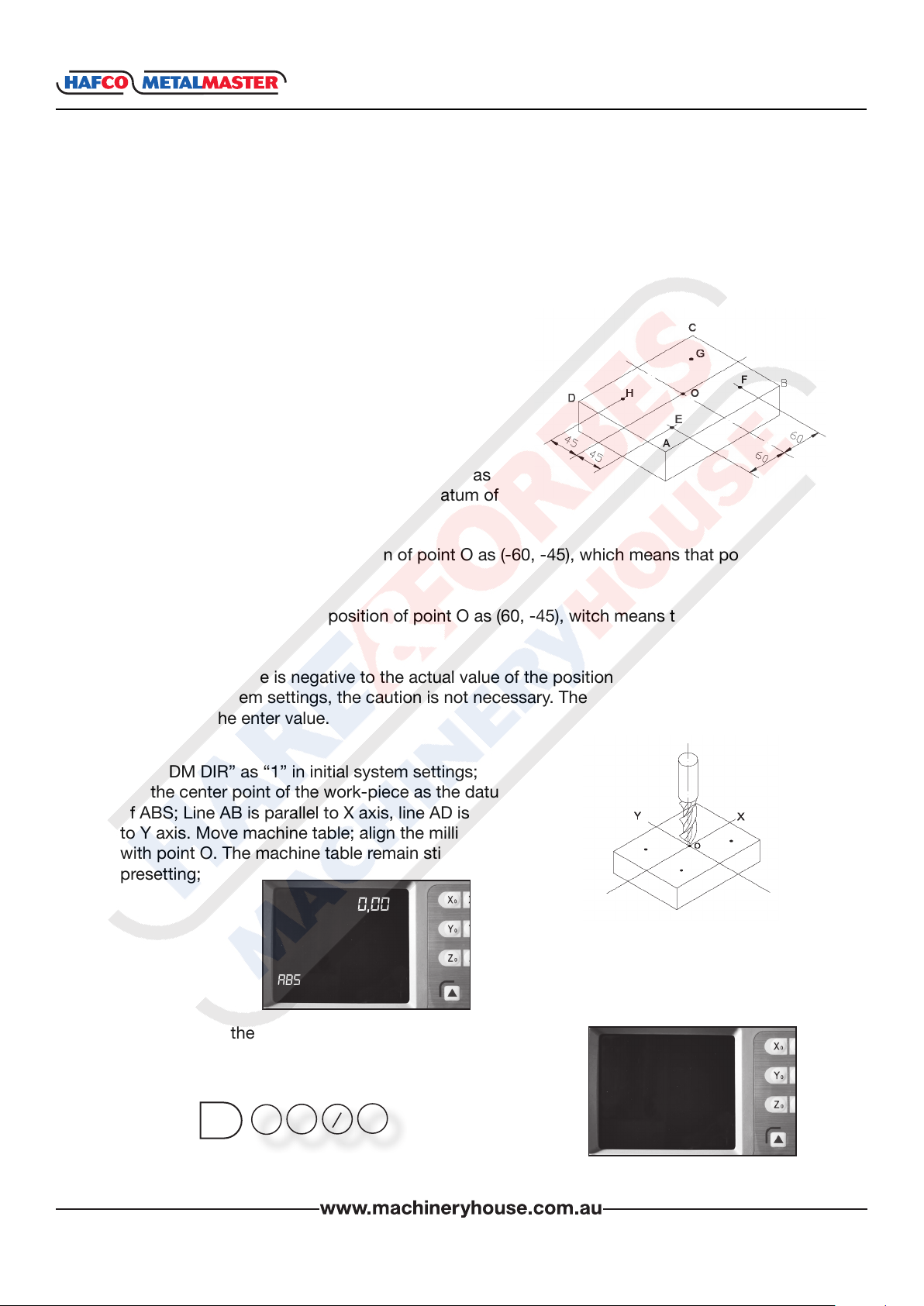

3.2 PRESET DATUM OF SDM COORDINATE

Compared with the way of zeroing at current point, another way, presetting SDM coordinate

datum, can set the zero point of the SDM more accurately and quickly without moving the

machine table.

As the gure showed right, center point is the datum of

ABS, the position points E, F, G, H are (-60, -45),

(60, -45), (60, 45), (-60, 45) in the ABS coordinate.

A. Enter SDM 000 and preset the position of point O

as (60, 45), which means the point E is the datum of

SDM 000.

B. Enter SDM 001, preset the position of point O as

(-60, 45), which means the point F is the datum of

SDM 001;

XH600

C. Enter SDM 002 and set the position of point O as (-60, -45), which means that point G is the

the datum of SDM 002.

D. Enter SDM 003, preset the position of point O as (60, -45), witch means that point H is the

datum of SDM 003.

Note: The preset value is negative to the actual value of the position in ABS. If set “SDM DIR”

as “1” in initial system settings, the caution is not necessary. The value DRO accepts, is equal to

the negative of the enter value.

1. Set “SDM DIR” as “1” in initial system settings;

2. Set the center point of the work-piece as the datum

of ABS; Line AB is parallel to X axis, line AD is parallel

to Y axis. Move machine table; align the milling cutter

with point O. The machine table remain still while

presetting;

0,000

0.000

ABS

mm

3. Set point E as the datum of SDM 000.

Enter SDM 000.

The position of point E is (-60, -45), press.

=

+ _

0

X

6

Ent

J

www.machineryhouse.co.nz

60,000

45.000

SDm 000

mm

20

INSTRUCTION MANUAL

3.2 PRESET DATUM OF SDM COORDINATE Cont.

4. Set point F as the datum of SDM 001.

Enter SDM 001.

The position of point F is (60, -45), press

XH600

X

Y

5. Set point G as the datum of SDM 002.

Enter SDM 002.

The position of point G is (60, 45), press

X

Y

6

4

6

4

Ent

=

+ _

5

0

5

=

Ent

=

Ent

Ent

=

0

ð

ð

-60,000

45.000

SDm 001

mm

-60,000

-45.000

SDm 002

mm

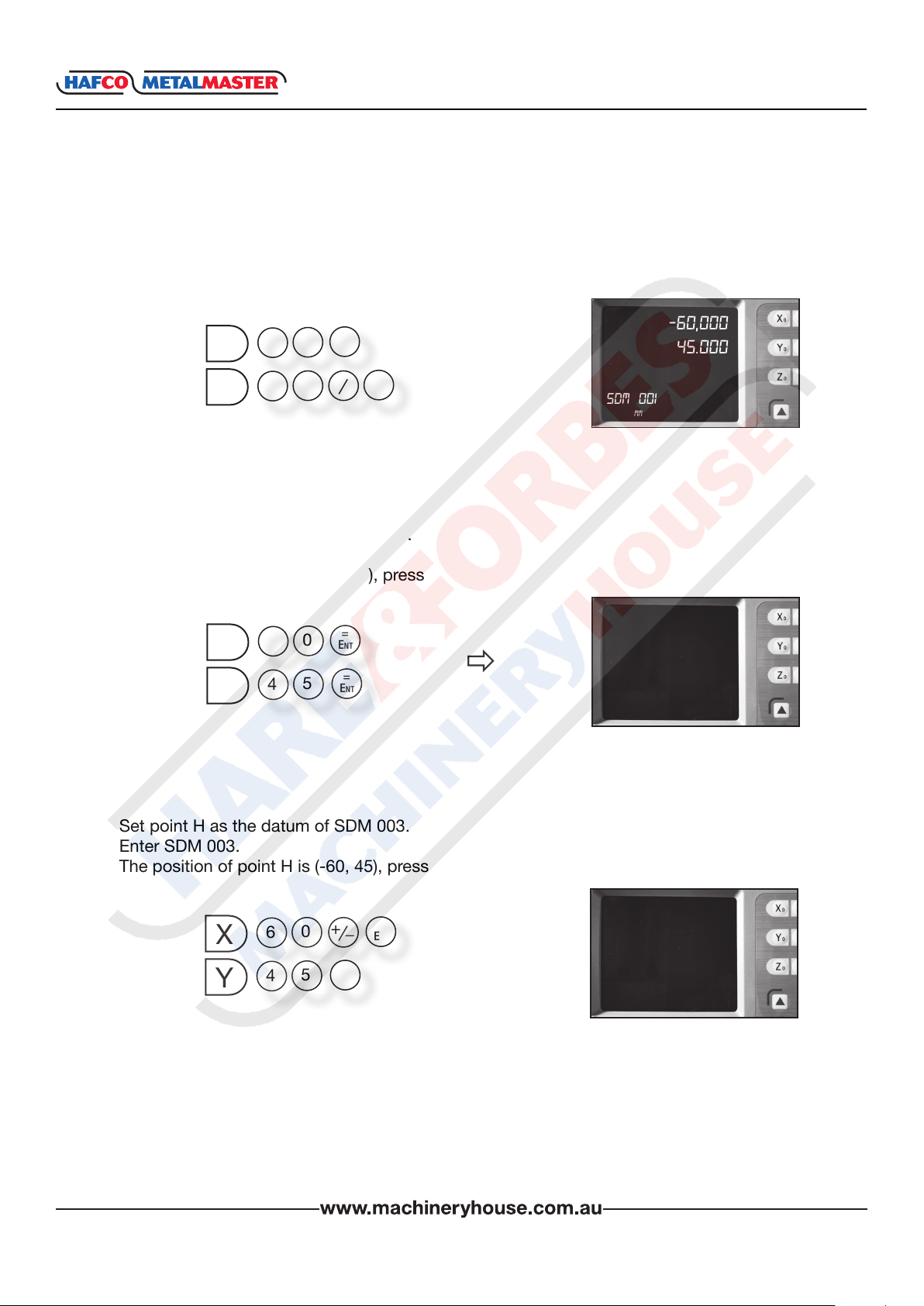

6. Set point H as the datum of SDM 003.

Enter SDM 003.

The position of point H is (-60, 45), press

=

+ _

0

X

Y

6

5

4

Ent

=

Ent

www.machineryhouse.co.nz

21

ð

60,000

-45.000

SDm 003

mm

INSTRUCTION MANUAL

XH600

Chapter 4. SPECIAL FUNCTIONS

The Hafco Metalmaster XH600 series DRO has special functions as well as measuring and

positioning.

4.1 Pitch Circle Hole Function

4.2 Bolt Hole Line Function

4.3 Arc Machining

4.4 Slope Machining Function

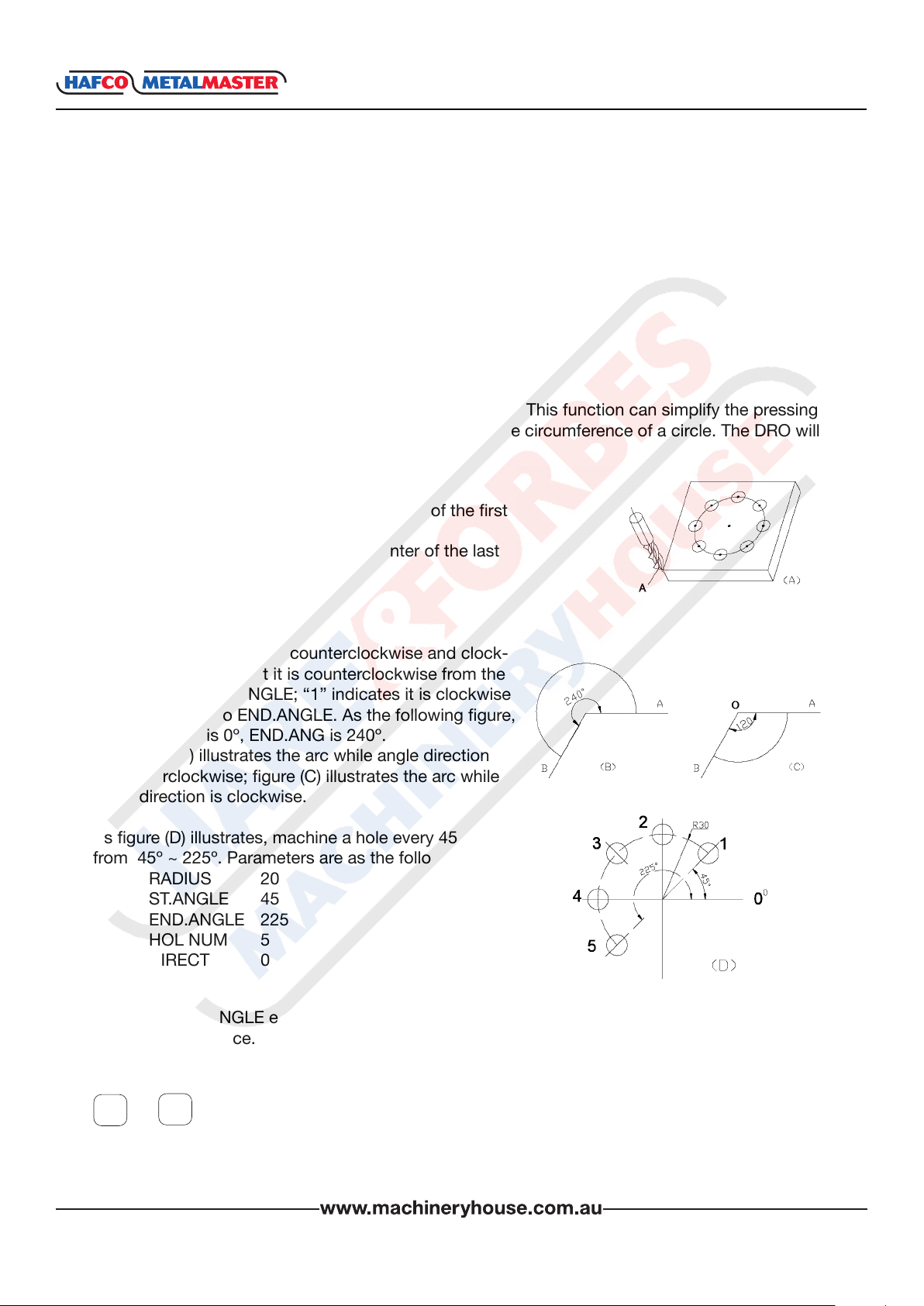

4.1 PITCH CIRCLE HOLE FUNCTION

Function description:

The XH600 series DRO has a Pitch Circle Hole Function. This function can simplify the pressing

of multiple holes which are attributed equally around the circumference of a circle. The DRO will

guide operator to enter the following parameters:

RADIUS: - Radius of circle

ST ANGLE: - Starting angle that the center of the rst

hole on the circle.

END.ANGLE:- Ending angle that the center of the last

hole on the circle.

HOLE NUM:- Number of Holes.

DIRECT:- Angle direction.

Angle has two directions: counterclockwise and clock-

wise. “0” indicates that it is counterclockwise from the

ST.ANGLE to END.ANGLE; “1” indicates it is clockwise

from ST.ANGLE to END.ANGLE. As the following gure,

the ST.ANGLE is 0º, END.ANG is 240º.

The gure (B) illustrates the arc while angle direction

is counterclockwise; gure (C) illustrates the arc while

angle direction is clockwise.

As gure (D) illustrates, machine a hole every 45 deg

from 45º ~ 225º. Parameters are as the following:

RADIUS 20

ST.ANGLE 45

END.ANGLE 225

HOL NUM 5

DIRECT 0

Note: If the ST.ANGLE equals the END.ANGLE, the holes are attributed equally around the

whole circumference.

The positions of the hole center are calculated automatically after input of all parameters. Press

q

or to choose the hole No. and move the machine table until the “0.000” appears in X

and Y windows. This is the position to process a hole.

q

www.machineryhouse.co.nz

22

INSTRUCTION MANUAL

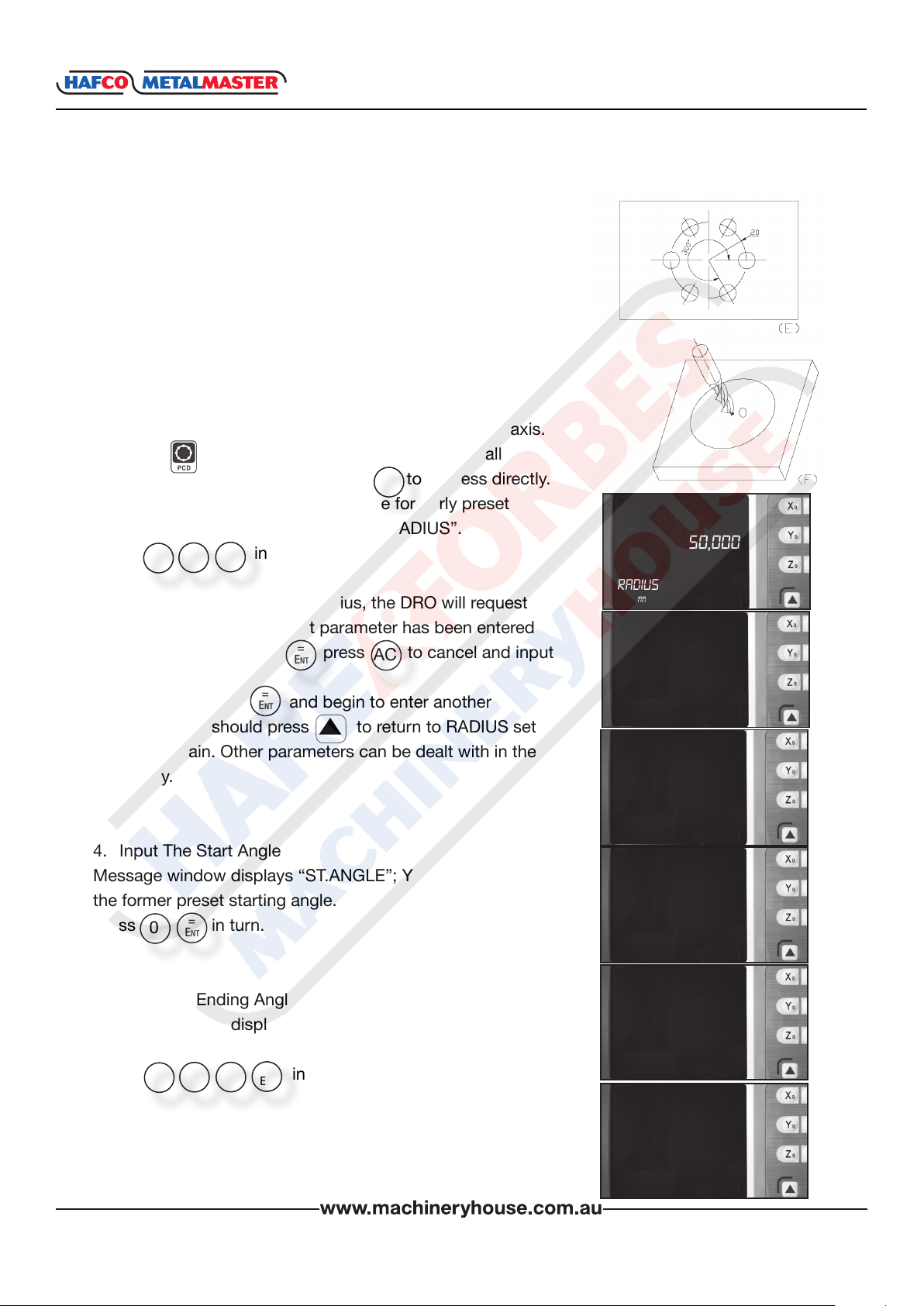

Example: Machine holes on circumference as the gure (E).

RADIUS 20MM

ST ANGLE 0°

END ANGLE 300°

HOL NUM 6

DIRECT 0

Steps:

1. Set the display unit to metric in normal state;

Move the machine table until the cutting tool is aligned

with the center of the circle, then zero X axis and Y axis.

2. Press to enter Pitch Circle Hole function. If all

q

=

Ent

AC

parameters have been set, press to process directly.

3. Input radius: Y window displays the formerly preset

radius; message window displays “RADIUS”.

Press in turn.

2

=

0

Ent

Note: If “0” is entered as the radius, the DRO will request

an input again. If an incorrect parameter has been entered

and you haven’t pressed press to cancel and input

=

Ent

again.

If you have pressed and begin to enter another

=

Ent

parameter, you should press to return to RADIUS set

and input again. Other parameters can be dealt with in the

same way.

XH600

50,000

RADIuS

mm

20

RADIuS

mm

20.000

4. Input The Start Angle

Message window displays “ST.ANGLE”; Y window displays

the former preset starting angle.

Press in turn.

=

0

Ent

5. Input The Ending Angle

Message window displays “END.ANGLE”; Y window displays

the former angle.

Press in turn

0

3

=

0

Ent

www.machineryhouse.co.nz

23

St AnGLe

mm

0

St AnGLe

mm

0

enDAnGLe

mm

300

enDAnGLe

mm

INSTRUCTION MANUAL

6. Input The Number Of Holes.

Message window displays “HOLE NUM”; Y window displays

the former number.

=

Press in turn.

Note: If “0” or “1” is entered as the number of holes, the

DRO will point out this mistake and requiure entering again.

7. Input angle direction.

Message window displays “DIRECT”, Y window displays the

former preset direction.

Press in turn.

0

Ent

=

0

Ent

XH600

6

hOLe num

mm

1

DIRect

mm

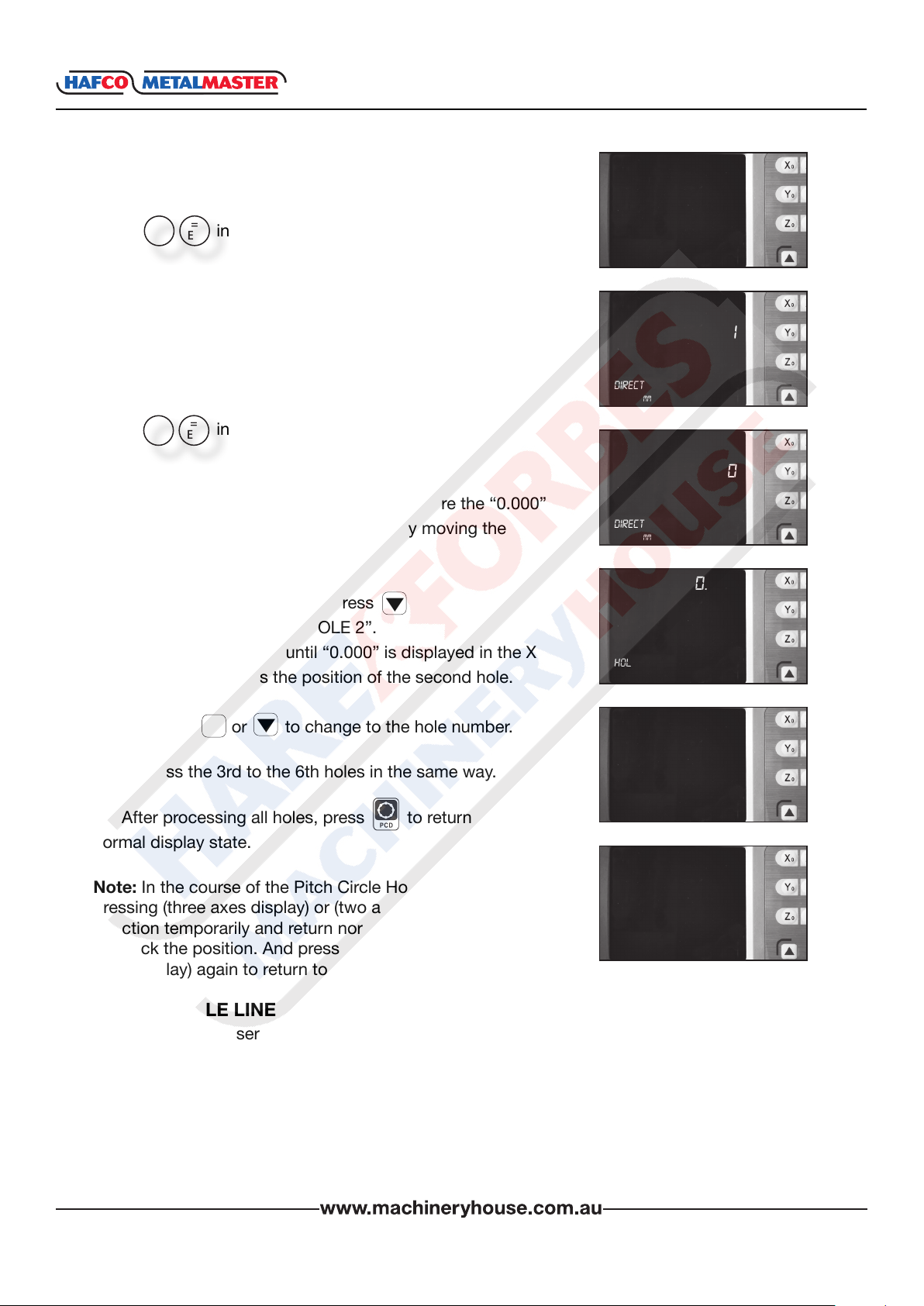

8. Message window displays “HOLE 1”.

It is the position of the rst hole to punch where the “0.000”

is displayed in X window and Y window by moving the

machine table.

9. After nishing the rst hole, press

q

Message window displays “HOLE 2”.

Move the machine table, until “0.000” is displayed in the X

and Y windows. This is the position of the second hole.

q

Note: Press or to change to the hole number.

10. Process the 3rd to the 6th holes in the same way.

11. After processing all holes, press to return to the

normal display state.

Note: In the course of the Pitch Circle Hole Function

pressing (three axes display) or (two axes) Pitch Circle Hole

Function temporarily and return normal display state in order

to check the position. And press (three axes display) or (two

axes display) again to return to the Pitch Circle Hole function.

q

0

DIRect

mm

0.000

0.000

hOLe 1

mm

0.000

0.000

hOLe 2

mm

0.000

0.000

hOLe 6

mm

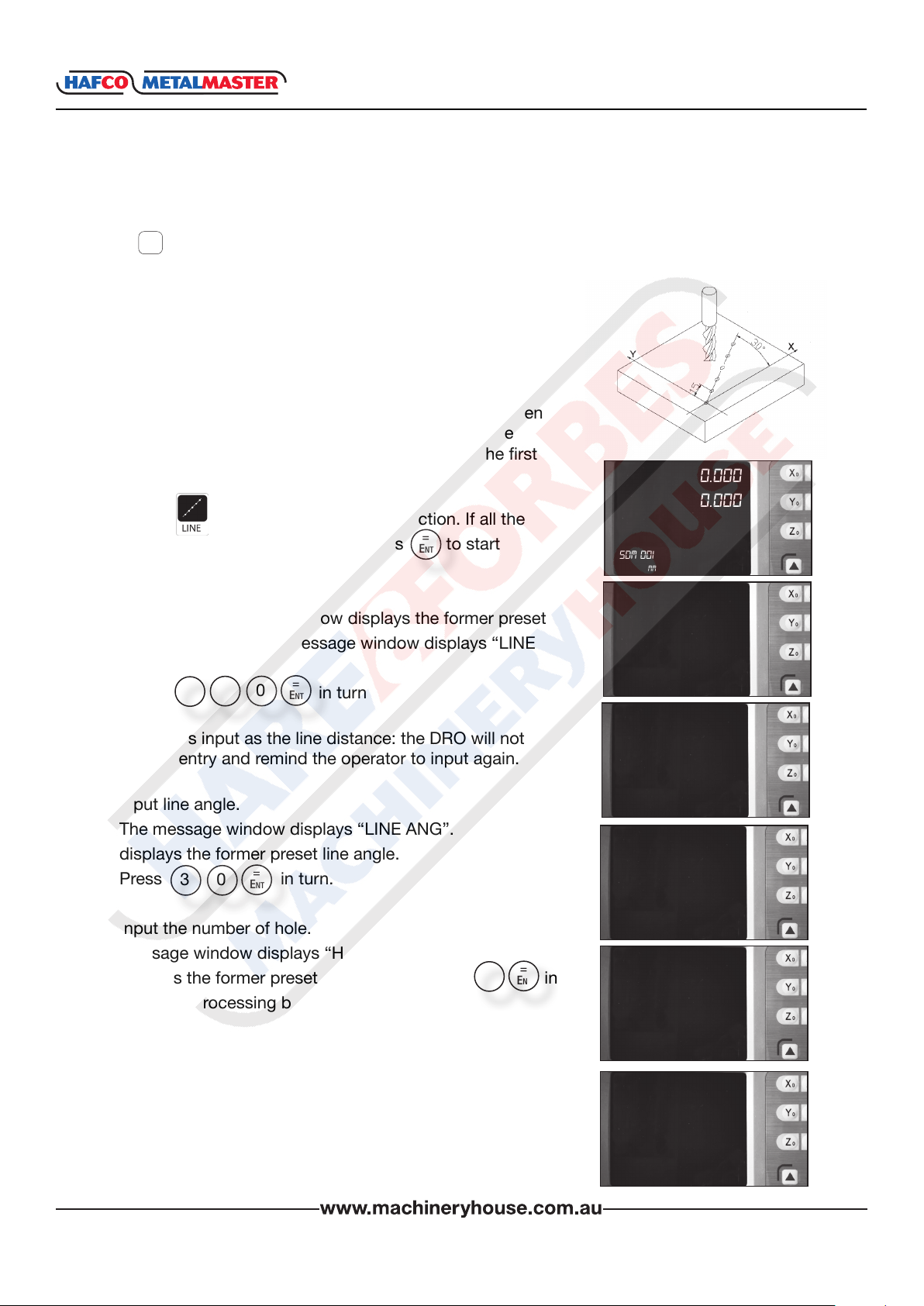

4.2 BOLT HOLE LINE FUNCTION

Function: XH-600 series DRO provides BOLT HOLE LINE (BHL) function. This function can

simplify the processing multiple holes whose centers are attributed equally on one line. The

following parameters are needed to be entered.

LINE DIS Line distance (distance between the center of rst hole and the center of

the last hole)

LINE ANG Line angle (angle between the line and the positive X axis)

HOLE NUM Number of holes

www.machineryhouse.co.nz

24

INSTRUCTION MANUAL

4.2 BOLT HOLE LINE FUNCTION Cont.

XH600

The DRO will calculate the positions of the holes after the parameters have been entered or

q

press to select the number of the hole and move the machine table is displayed in the “X”

window. This will be position of the hole.

Example:

LINE DIS 150mm

LINE ANG 30°

HOLE NUM 6

Steps

1. Set display unit to metric and the shrinkage is not taken

into consideration. Move the machine table until the

machine tool is aligned with the center point of the rst

hole, and zero the X and Y axis.

0.000

0.000

2. Press to enter Bolt Hole Line function. If all the

parameters have been entered, press to start

processing directly.

=

Ent

SDm 001

mm

3. Input line distance. Y window displays the former preset

line distance, and the message window displays “LINE

DIS”.

=

0

5

Press in turn

1

Ent

LIne DIS

20.000

mm

Note: If “0” is input as the line distance: the DRO will not

accept the entry and remind the operator to input again.

150

4. Input line angle.

The message window displays “LINE ANG”. Y window

displays the former preset line angle.

Press in turn.

3

=

0

Ent

5. Input the number of hole.

Message window displays “HOLE NUM”, Y window

=

displays the former preset hole number. Press in

6

Ent

turn, and processing begins.

Note: If “0” or “1” is entered as a hole number, the DRO will

not accept the entry and remind the user to input again.

www.machineryhouse.co.nz

25

LIne DIS

mm

35000

LIne AnG

mm

30

LIne AnG

mm

10

hOLe num

mm

INSTRUCTION MANUAL

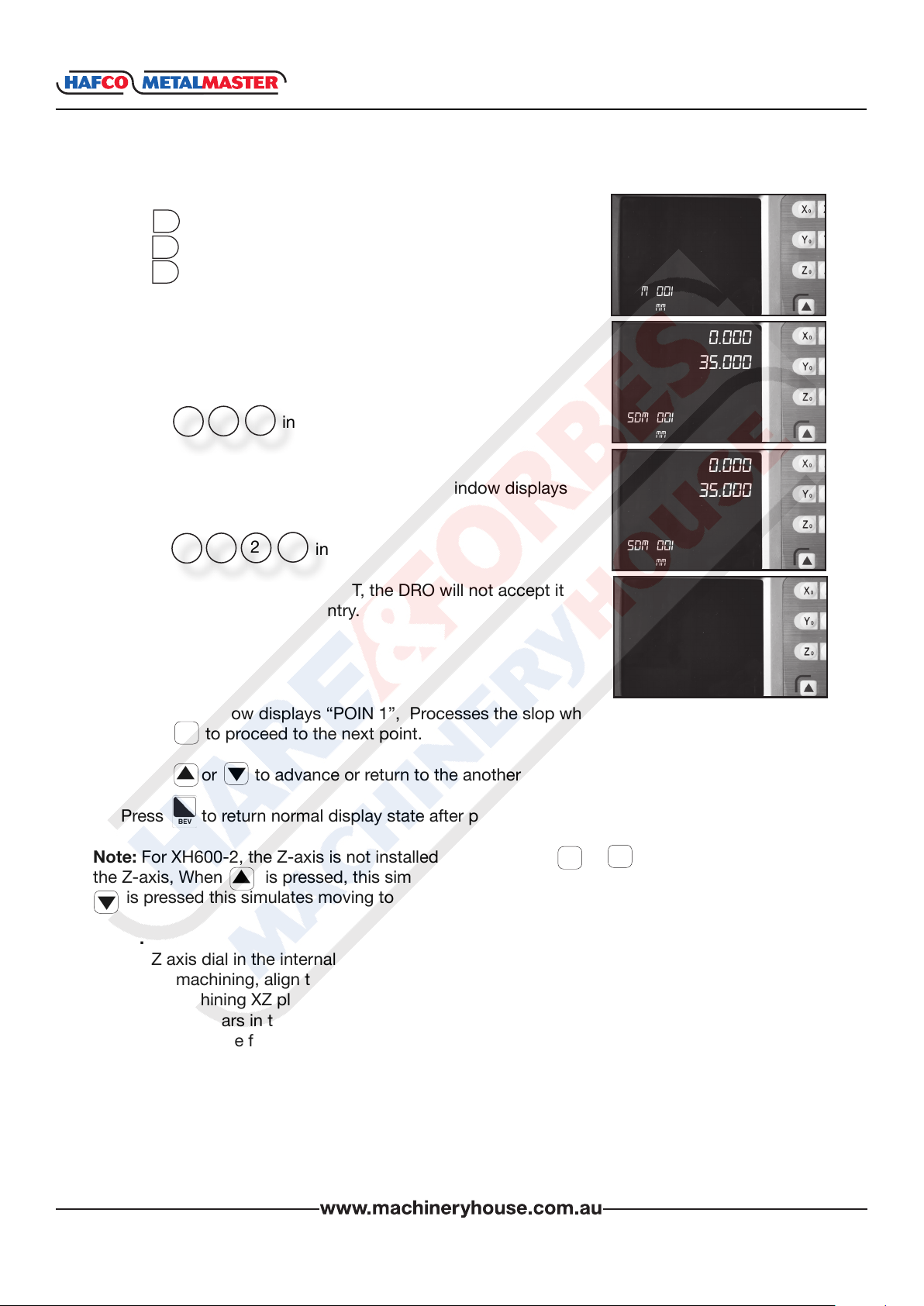

4.2 BOLT HOLE LINE FUNCTION Cont.

XH600

6. Message window displays “HOLE 1”.

Move the machine table until “0.000”appears in X window

and Y window, it is the center of the rst hole to punch.

7. After nishing the rst hole, press, and the message

q

window displays “HOLE 2”.

Move the machine table until “0.000” appears in X and Y

window, and then you can punch the second hole at this

point.

q

Note: Press or to move among the holes.

8. Process the holes 3rd – 6th in the same way.

9. Press to return to the normal display state when the

processing has nished.

q

6

hOLe num

mm

0.000

0.000

hOLe 1

mm

0.000

0.000

hOLe 2

mm

0.000

0.000

hOLe 6

mm

Note: In the course of Bolt Hole Line Function, you can press (three axes display) or (two axes

display) to leave this function temporarily and return normal display of X, Y, Z axis in order to

check the position which the DRO calculated. Then press (three axes display) or (two axes

display) again to return BHL function.

4.3 ARC MACHINING

This function is only for XH600-2, XH600-3.

It is waste of time to use a numerical control lathe to process an arc in a simple product or

small production run. This function makes it convenient to process an arc with a normal lathe.

Parameter “MAX CUT” is the arc length for each process. The smaller the MAX CUT, the more

smooth the arc plane and the longer processing time.

A. Process XZ, YZ plane

There are 8 modes as the following when processing arc in XZ or YZ plane:

www.machineryhouse.co.nz

26

4.3 ARC MACHINING Cont.

INSTRUCTION MANUAL

XH600

Milling cutter may be at-bottomed or arc-bottomed. If

at-bottomed, set the tool diameter as 0.

B. Process XY plane.

The DRO provides the 8 modes (shown at the top of the page)

in processing XY plane. The milling cutter is perpendicular to

the machine plane. The DRO has internal Arc machining and

external Arc machining for each type.

External T +TOOL.

Internal T - TOOL.

Set the tool radius according to the actual milling cutter when

process the XY plane.

TYPE 1 - 8 Mode of the Arc machining

* T+TOOL / T-TOOL Selection between T + TOOL / T - TOOL (This parameter is only for

XY plane)

RADIUS The radius of ARC that is to be processed

TOOL DIA Tool diameter

MAX CUT Feed step

Example 1:

Process an arc AB of 90° from point A to point B as the gure.

Parameters are as per the following,

Machine plane XY

ARC mode type 3

T + TOOL

RADIUS 20°

TOOL DIA 6mm

MAX CUT 0.5mm

www.machineryhouse.co.nz

27

INSTRUCTION MANUAL

XH600

4.3 ARC MACHINING Cont.

1. Set display unit is metric.

2. Move the machine table until the lathe tool is aligned with point

A, then zero X axis and Y axis.

3. Enter Arc machining state.

Press to enter Arc machining state,

If all parameters have been set, press to process directly.

4. Select machine plane,

Press to select XY.

=

X

Ent

X

Indicates XY Plane,

Note:

Indicates YZ Plane,

Indicates ZX Plane,

Y

Z

5. Select processing mode.

Message window displays “TYPE 1-8”, and Y window displays

the former processing mode.

=

Press in turn to select mode 3, and then enter ARC type.

3

Ent

6. Select T + Tool Mode.

Press to select the external Arc machining.

=

+

Ent

=

Ent

SDm 003

mm

SImR xZ

mm

SImR xY

mm

tYpe 1 - 8

mm

tYpe 1 - 8

mm

0.000

0.000

1

3

Note: indicates T + TOOL mode (external Arc machining).

Indicates T - TOOL mode (internal Arc machining).

+

-

7. Set Arc Radius.

Message window displays “RADIUS”, and Y window displays the

former arc radius.

Press in turn to enter the arc radius.

2

=

0

Ent

Note: If “0” as the arc radius is entered, the DRO will display an error

message and wait for another number entry.

t - tOOL

mm

t + tOOL

mm

RADIuS

mm

RADIuS

mm

RADIuS

mm

50.000

20

20

www.machineryhouse.co.nz

28

4.3 ARC MACHINING Cont.

INSTRUCTION MANUAL

XH600

8. Set Tool Diameter.

In the message window when “TOOL DIA” is displayed the Y

window displays the former preset diameter.

=

Press in turn to enter the tool diameter.

6

Ent

9. Set The Feed Step.

Message window displays “MAX CUT”.The Y window will display

the former feed step.

Press in turn to enter the feed step.

.

0

=

5

Ent

Note: If “0” is entered as the feed step, the DRO will not accept the

and wait for a correct entry.

10. Process ARC

Message window displays “POIN 1”. Process when the “0.000”

appears in X and Y window. Then when you have nished the rst

point, then Press to switch to the second point and repeat the

same step to move through the feed points. Process in this way

until the message window displays “POIN 74”. Pressing or

q

q

q

can select any processing point.

6

tOOL DIA

mm

10

mAx cut

mm

0.5

mAx cut

mm

0.000

0.000

pOInt 1

mm

0.000

0.000

pOIn 74

mm

11. Press to exit Arc machining after machining is over.

Note:

1. In the ARC process, pressing (three axes display) or (two axes

display) allows you to leave this function temporarily. To return to

normal display of X, Y, and Z axis in order or check the position the

DRO has calculated. Press (three axes display) or (two axes display)

to return to the ARC function.

q

2. Processing or can switch amongst the parameters in the

course of the presetting parameter.

Example 2:

Process the ARC EF as the gure from point E to point F.

Parameters are set as following.

Machine plane: XZ

TYPE: 4

RADIUS: Actual radius of the arc

TOOL DIA: 0 (at-bottomed tool)

MAX CUT: Preset as per the operators input

q

www.machineryhouse.co.nz

29

INSTRUCTION MANUAL

4.3 ARC MACHINING Cont.

Example 3:

Process the ARC DE as the gure from point D to point E.

Parameters are as per the following.

Machine plane: XZ

TYPE: 6

RADIUS: Actual radius of the arc

TOOL DIA: Actual value (actual tool)

MAX CUT: Preset as per the operators

imput

Example 4:

Process the ARC DE as the gure from point D to point E.

Parameters are as per the following.

Machine plane; YZ

TYPE: 7

RADIUS: Actual radius of the arc

TOOL DIA: Actual value (actual tool)

MAX CUT: Preset as per the operators

input

XH600

Note: For XH600-2, The DRO is not installed with Z-axis, please press or to simulate

position of the Z Axis. Press to simulate moving to the former process point, and emulate

moving to the former process point, and press to simulate moving to the next process.

Steps:

1. Set “STEP MODE” as “Z STEP” in setup mode, and set Z-axis dial (default value is 2.5mm).

2. Before machining, align the tool with the beginning point Z of R, zero Z axis.

3, In the machining process, the message window displays simulate height of Z axis, which

indicates simulate height of Z axis while machining.

As per gure to the right , while machining XZ plane,

X window displays the position of the X axis, X axis

is nished when displaying “0.000” in X window.

In the Y window, the former 2 numbers indicates the

number of the dial, and the following 5 numbers

indicate the scale number of the dial, which means that machining to this scale for the

current point.

While machining YZ plane, Y window displays position of Y axis, and when this window

displays “0.000”, this indicates the machining is nished in the Y direction.

In the X window, the former 2 numbers indicate the number of the dial, and the following

5 numbers indicate the scale number of the dial, which means that machining to this scale

for the current point.

q

q

0.000

12 1.000

31.000

mm

q

12 X 2.5+1=31

q

www.machineryhouse.co.nz

30

INSTRUCTION MANUAL

4.4 Slope Processing

This function is only for XH600-2, XH600-3.

Function:

This function can calculate the position of every processing

point automatically in processing slope. Only the following

parameters need to be inputted.

INCLE: Set machine plane XY, YZ or XZ plane

INCL.ANG: The inclination angle of the slope

MAX CUT: The slope length each time processing.

Note:

Z STEP and MAX.CUT are dened as the gure.

The DRO will calculate the position of each processing on

the slope automatically when all parameters have been input.

Press or to select the processing point and process

until “0.000” appears in the window.

q

q

XH600

Example 1.

Process the slope AB as the gure. The parameters are as

following.

INCLE: XZ

INCL.ANG: 45°

MAX.CUT: 12mm

Steps:

1. Set display unit to metric

Set the SLOP.MODE 1 in initial system settings.

Note: If the third parameter isn’t Z STEP, set the

SLOP.MODE 0.

Move the machine table until the lathe tool is aligned with

the starting point A, then zero X axis and Z axis.

Press , in normal display state.

X

0

Z

0

2. Press to enter the slop processing.

Press to start processing directly if all parameter

=

Ent

have been set.

0.000

35.000

SDm 001

mm

IncL xY

mm

3. Select machine plane.

Press in turn to select the ZX plane.

Z

=

Ent

www.machineryhouse.co.nz

31

IncL Zx

mm

INSTRUCTION MANUAL

4.4 SLOPE PROCESSING Cont.

XH600

Press indicates XY plane.

Press indicates YZ plane.

Press indicates ZX plane.

4. Enter INCL.ANG.

Message window displays “INCL ANG”. Y window displays

the former INCL.ANG.

Press in turn.

5. Enter MAX.CUT.

Message window displays “MAX CUT”. Y window displays

the former MAX.CUT.

Press in turn.

Note: If “0” is entered as MAX CUT, the DRO will not accept it

and will wait for another data entry.

X

Y

Z

=

5

4

1

Ent

.

=

2

Ent

0.000

35.000

SDm 001

mm

0.000

35.000

SDm 001

mm

0.000

35.000

SDm 001

mm

0.000

35.000

SDm 001

6. Processing.

Message window displays “POIN 1”, Processes the slop when the “0.000” appears, then

press to proceed to the next point.

q

mm

q

7. Press or to advance or return to the another point.

8. Press to return normal display state after processing is over.

q

q

Note: For XH600-2, the Z-axis is not installed, please press or to simulate position of

the Z-axis, When is pressed, this simulates moving to the former process point, and when

is pressed this simulates moving to the next process point.

q

Steps.

1. Set Z axis dial in the internal system setup;

2. Before machining, align the start point Z point with cutting tool, then set Z axis as “0.000”;

3. While machining XZ plane, X window displays position of the X axis. X axis is nished when

“0.000” appears in the X window, In the Y window, the former 2 number indicates number of

the dial, and the following 5 numbers indicate scale numbers of the dial, which means that

machining to this scale for current point.

While machining YZ plane, Y window display position of Y axis, and when this window dis

plays “0.000”, which indicates the machining is nished in Y direction; In X window, the

former 2 number indicates number of dial, and the following 5 number indicates scale

number of dial, which means that machining to this scale for current point.

q

q

www.machineryhouse.co.nz

32

INSTRUCTION MANUAL

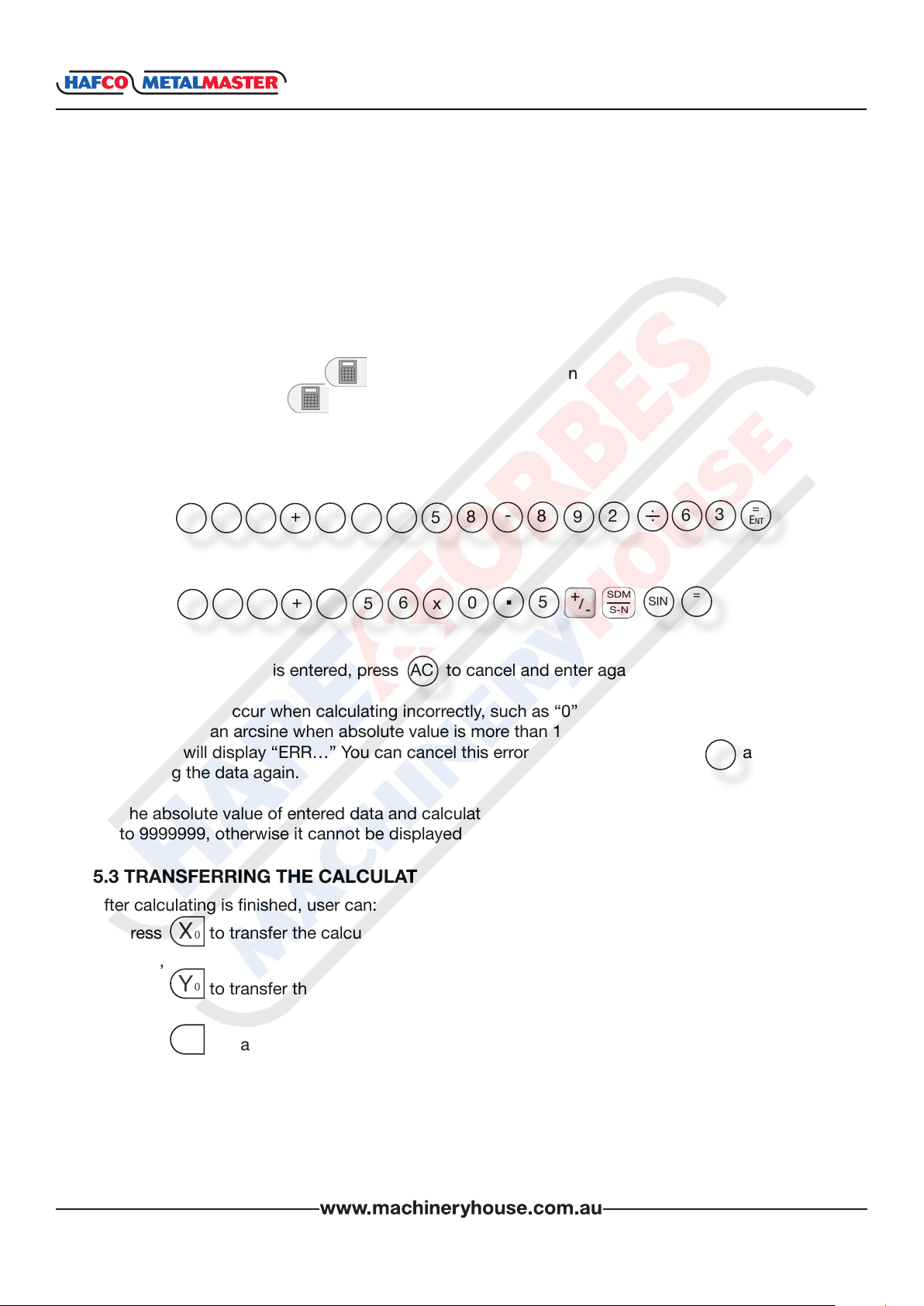

Chapter 5. CALCULATOR FUNCTION

The XH600 provides an internal calculator for operations such as plus, minus, multiply and

divide, which is convenient for the operator when processing work piece according to the

drawing.

5.1 ENTER AND EXIT CALCULATOR FUNCTION

In normal display state: press to enter calculator function

In calculator state: press to exit calculator function.

5.2 CALCULATING EXAMPLE

Example 1: 123 + 76 × 58 - 892 / 63

=

2

1

+

3

7

x

6

5

-

8

8

2

9

3

6

Ent

XH600

Example 2: 358 + 456 × sin -1(-0.5)

5

3

+

8

4

6

5

x

.

0

5

SDM

S-N

SIN

=

Ent

Note:

1. If the incorrect data is entered, press to cancel and enter again.

AC

2 An error may occur when calculating incorrectly, such as “0” being used as a divisor or

proceeding an arcsine when absolute value is more than 1. In this case, the message

window will display “ERR…” You can cancel this error message by pressing and

AC

entering the data again.

3. The absolute value of entered data and calculated result should be in the range of 0.000001

to 9999999, otherwise it cannot be displayed.

5.3 TRANSFERRING THE CALCULATED RESULTS TO SELECTED AXIS

After calculating is nished, user can:

Press to transfer the calculated result to the X axis. The X window will now display this

value,

Press to transfer the calculated result to the Y axis. The Y window will now display this

value,

Press to transfer the calculated result to the Z axis. The Z window will now display this

Y

Z

X

0

0

0

value.

Note: The calculated data can not be transfered if it is out of the displays range.

www.machineryhouse.co.nz

33

INSTRUCTION MANUAL

5.4 TRANSFERRING WINDOW DISPLAY VALUE TO CALCULATOR

While still in calculator mode:

Press to transfer the display value in X window to calculator.

Press to transfer the display value in Y window to calculator.

Press to transfer the display value in Z window to calculator.

X

Y

Z

XH600

www.machineryhouse.co.nz

34

INSTRUCTION MANUAL

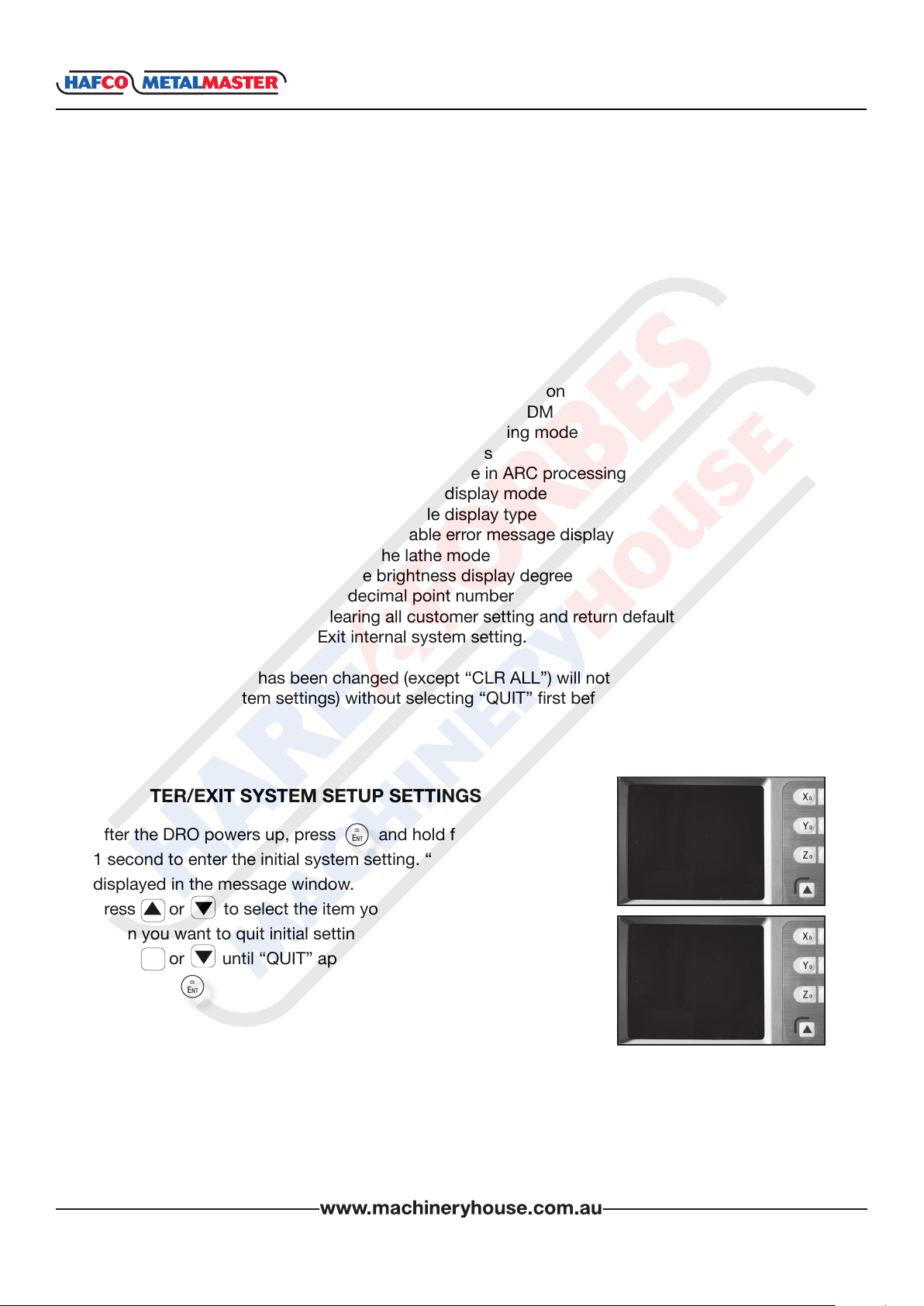

Chapter 6. INITIAL SYSTEM SETTINGS

Function:

Set various parameters according to actual operation.

SEL TYPE Setting the number of linear scale

DIRECT Setting positive direction for the counter

COM TYPE Set the error correction type

R-D MODE Radius/Diameter Mode

Z DIAL Setting Z axis Dial

RESOLUTE Set the grating ruler’ s resolution

SDM DIR Setting the input mode of SDM

SLOP.MODE Setting the slope machining mode

AXIS.TYPE Setting the type of axis

STEP.MODE Select the step mode in ARC processing

ANGE.MODE Select the angle display mode

ANGE.TYPE Select the angle display type

ERROR Enable / Disable error message display

LATH.MODE Setting the lathe mode

DIS LEVE Set the brightness display degree

DISP BIT Set decimal point number

CLR ALL Clearing all customer setting and return default setting.

QUIT Exit internal system setting.

XH600

Note: Any entry that has been changed (except “CLR ALL”) will not been saved if you quit

“SETUP” (initial system settings) without selecting “QUIT” rst before exiting.

6.1 ENTER/EXIT SYSTEM SETUP SETTINGS

After the DRO powers up, press and hold for approximately

Ent

=

1 second to enter the initial system setting. “SETUP” will then be

displayed in the message window.

Press or to select the item you want to change.

When you want to quit initial settings.

Press or until “QUIT” appears in the message window and

then press

q

q

Ent

q

q

=

Setup

mm

QuIt

mm

www.machineryhouse.co.nz

35

INSTRUCTION MANUAL

XH600

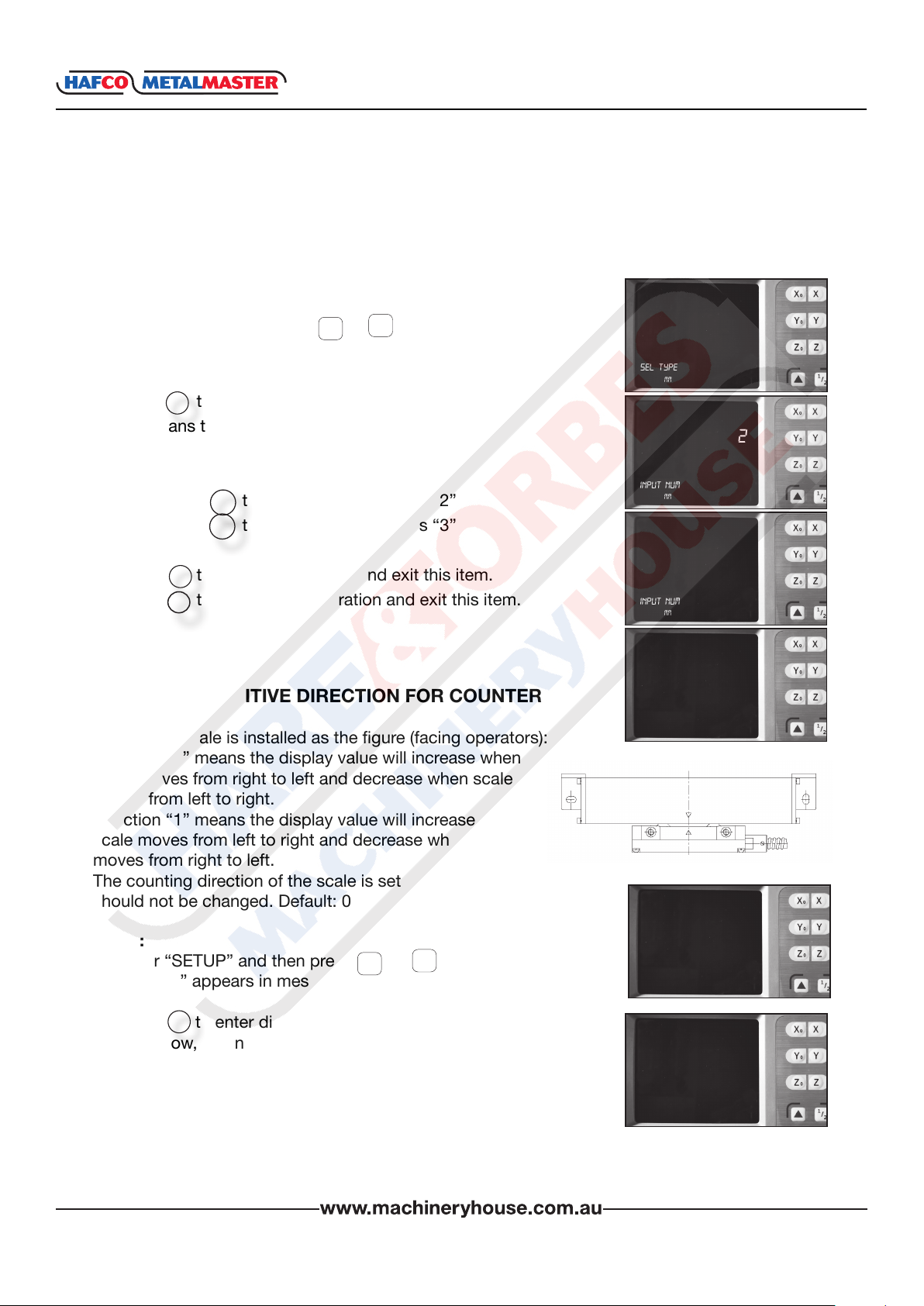

6.2 SETTING THE TYPE OF DRO

Because XH600 series DROs (two axes or three axes DRO) share the same software and their

functions have some differences, the DRO type must be set before use. CLR ALL has no effect

on type of DRO.

1. Enter “SETUP” and press or until “SEL TYPE”

appears in the message window.

2. Press then Y window displays “2” or “3”.

Ent

=

“2” means the DRO type is XH-600-2 two axis

“3” means the DRO type is XH-600-3 three axis.

3. If you press the “Y” window displays “2”

If you press the “Y” window displays “3”

4. Press to save the selection and exit this item.

Press to cancel your operation and exit this item.

AC

Ent

2

3

=

q

6.3 SETTING POSITIVE DIRECTION FOR COUNTER

If the linear scale is installed as the gure (facing operators):

Direction “0” means the display value will increase when

scale moves from right to left and decrease when scale

moves from left to right.

Direction “1” means the display value will increase when

scale moves from left to right and decrease when scale

moves from right to left.

The counting direction of the scale is set by the DRO and

should not be changed. Default: 0

q

SeL tYpe

mm

Input num

mm

Input num

mm

SeL tYpe

mm

2

3

Steps:

1. Enter “SETUP” and then press or until

q

q

DIRECT” appears in message window.

2. Press to enter direction setup.

Ent

=

X window, Y window and Z window display “0” or

“1” separately. “0” means the opposite counter

direction for “1” , in other words, “0” means A signal

exceed B signal and the counts increase during

counting. Vice versa.

Message window displays “SEL AXIS”, which means the

next step is to select axis.

www.machineryhouse.co.nz

36

DIRect

SeL AxIS

mm

mm

INSTRUCTION MANUAL

6.3 SETTING POSITIVE DIRECTION FOR COUNTER Cont.

XH600

3. Select axis

Press to change X axis counting direction.

Press to change Y axis counting direction.

Press to change Z axis counting direction.

4. Press to conrm your selection and exit.

Press to cancel your change and exit.

=

Ent

AC

X

Y

Z

SeL AxIS

DIRect

mm

mm

1

1

1

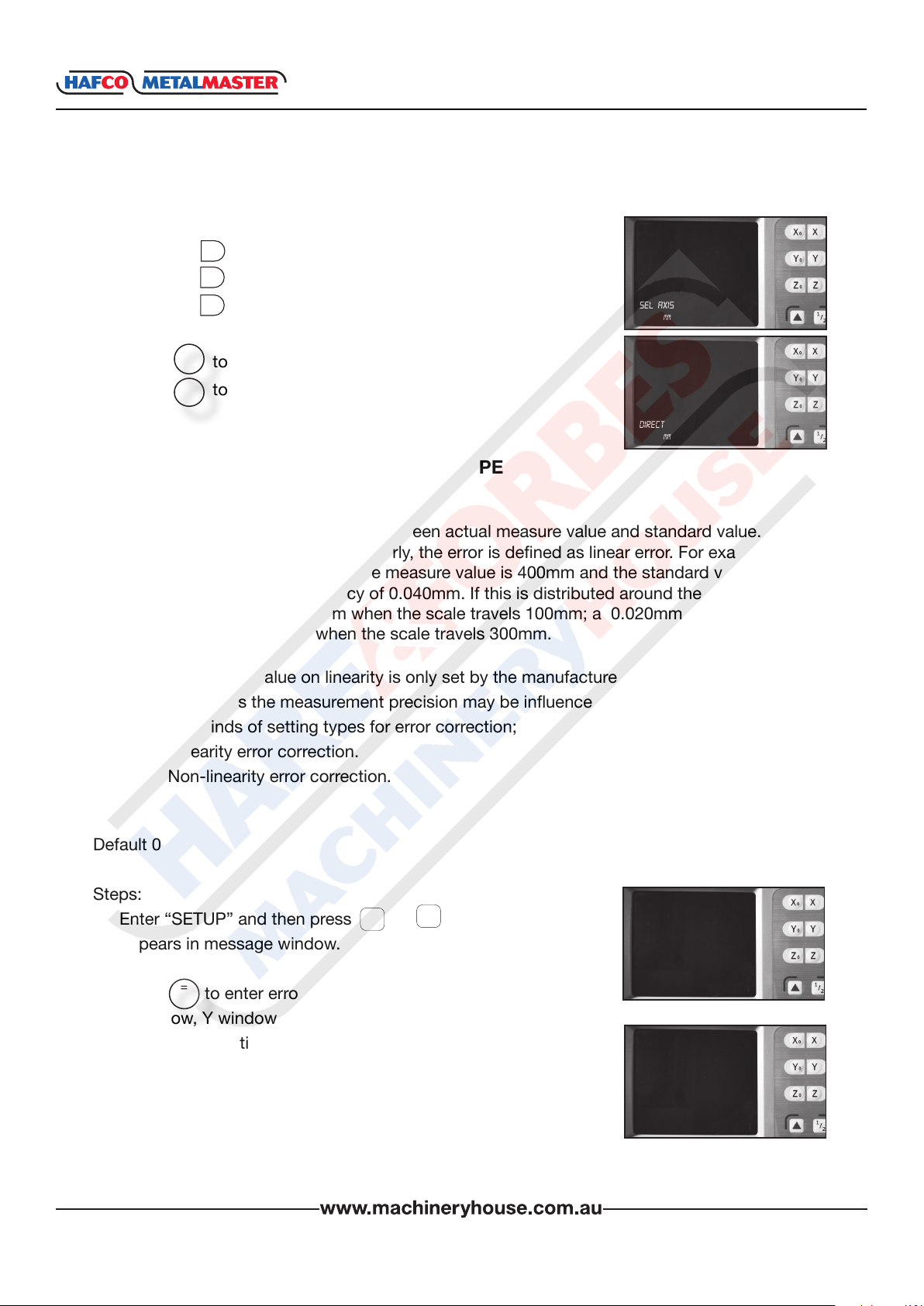

6.4 SETTING THE ERROR CORRECTION TYPE

Denition:

Linear error: There is always an error between actual measure value and standard value. If it is

distributed around the scale travel linearly, the error is dened as linear error. For example

the scale valid length is 400mm. If the measure value is 400mm and the standard value is

400.040mm: There is a discrepancy of 0.040mm. If this is distributed around the scale linearly,

there is a discrepancy of 0.10mm when the scale travels 100mm; a 0.020mm when the scale

travels 200mm, and 0.03mm when the scale travels 300mm.

Note: The correction value on linearity is only set by the manufacturer, and the user should not

modify randomly, as the measurement precision may be inuenced.

There are two kinds of setting types for error correction;

1. Linearity error correction.

2. Non-linearity error correction.

Default 0

Steps:

1. Enter “SETUP” and then press or until “COMP.TYPE”

q

q

appears in message window.

cOmptYpe

2. Press to enter error correction type setup.

=

Ent

mm

X window, Y window, and Z window displays the former linear

error compensation coefcient separately.

Message window displays “SEL AXIS” which indicates that the

next step is to select axis.

SeL AxIS

mm

0

0

0

www.machineryhouse.co.nz

37

INSTRUCTION MANUAL

6.4 SETTING THE ERROR CORRECTION TYPE Cont.

3. Select axis

Press to change X axis error correction type.

Press to change Y axis error correction type.

Press to change Z axis error correction type.

4. Press to conrm your selection and exit.

Press to cancel your change and exit.

X

Y

Z

=

Ent

AC

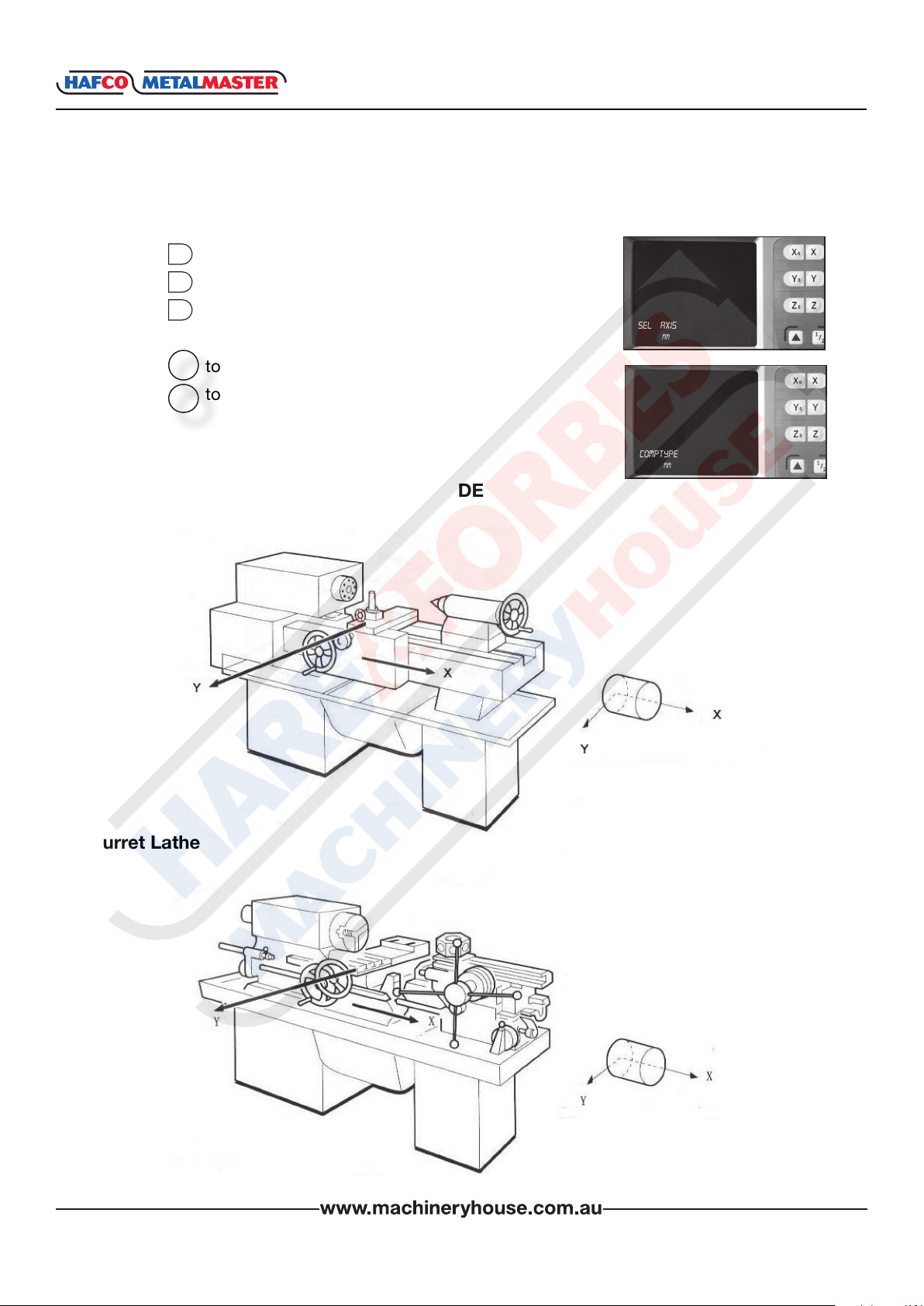

6.5 TOGGLE BETWEEN R/D DISPLAY MODE

Centre Lathe

SeL AxIS

mm

cOmptYpe

mm

XH600

1

1

1

Turret Lathe

www.machineryhouse.co.nz

38

INSTRUCTION MANUAL

XH600

6.5 TOGGLE BETWEEN R/D DISPLAY MODE Cont.

Face Plate Lathe

The machining process of a lathe is very different from the common vertical or horizontal

machines like milling, boring or drilling machines.

The display value is the distance between lathe tool and the workpiece origin. This display mode

is called “MODE R”. When turning a cylinder the given diameter measurement, is double the

distance between the lathe tool and the workpiece datum. To use the DRO with the display

showing the diameter, the DRO needs to be in “MODE D”.

The default mode of the DRO is “MODE R”.

Steps.

1. Enter “SETUP” and press or until the message

window displays “R-D MODE”.

q

q

2. Press

=

Ent

X window, Y window and Z window displays “0” or 1” separately.

“0” is mode R, which means the display value equals the actual

measurement. “1” is mode D where the display value equals

double the actual measurement.

Message window displays “SEL AXIS”, which indicates the next

step is to select the axis.

3. Select axis

In most cases the “Y” axis will be the axis that changes

Press to change the R/D mode of X axis.

Press to change the R/D mode of Y axis.

Press to change the R/D mode of Z axis.

4. Press to save the change and exit.

Press to cancel the change and exit.

X

Y

Z

=

Ent

AC

R-D mODe

mm

SeL AxIS

mm

SeL AxIS

mm

R-D mODe

mm

0

0

0

0

1

0

www.machineryhouse.co.nz

39

INSTRUCTION MANUAL

XH600

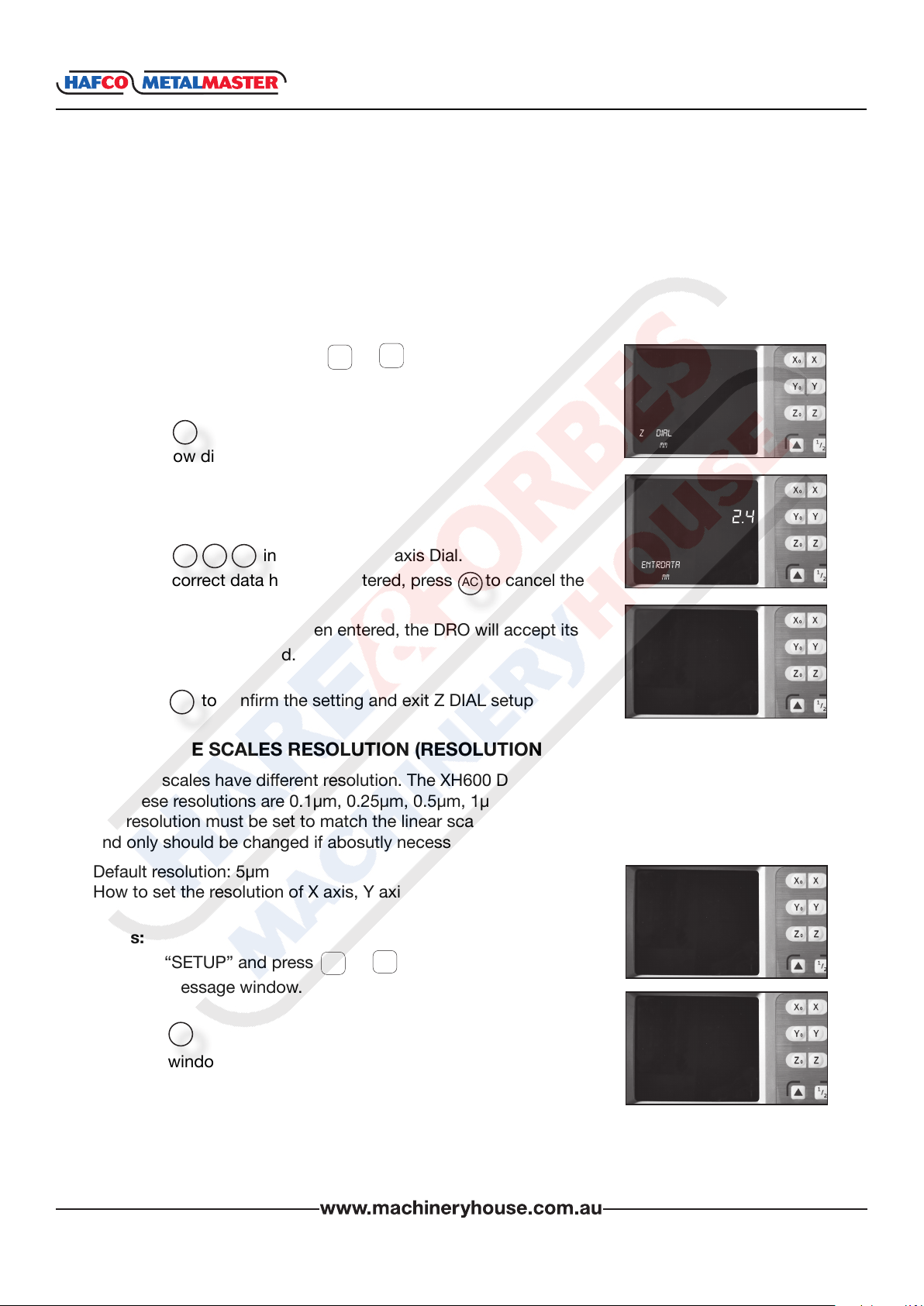

6.6 SETTING Z AXIS DIAL

The Z axis Dial should be set if the Z axis is emulated for XH600-2 and only X and the Y linear

scales have been install. Z axis Dial means the distance the Z axis travels when the screw is

rotated one revolution.

Default value: 2.5mm

How to set Z axis Dial to 2.4 mm.

q

1. Enter “SETUP”, then press or until the message

window displays “Z DIAL”.

q

2. Press

=

Ent

Z DIAL

mm

Y window displays the former Z axis Dial.

Message window displays “Z DIAL”.

2.4

3. Input the Z axis Dial.

Press in turn to input Z axis Dial.

If an incorrect data has been entered, press to cancel the

.

2

4

AC

entRDAtA

mm

entry and input again.

If a minus number has been entered, the DRO will accept its

absolute value instead.

4. Press to conrm the setting and exit Z DIAL setup

=

Ent

Z DIAL

mm

6.7 SET THE SCALES RESOLUTION (RESOLUTION)

Different scales have different resolution. The XH600 DRO can connect with 10 kinds of scales,

and these resolutions are 0.1µm, 0.25µm, 0.5µm, 1µm, 2µm, 5µm, 10µm, 20µm, 50µm, 100µm.

The resolution must be set to match the linear scale. This parameter is set by the manufacturer

and only should be changed if abosutly necessary.

Default resolution: 5µm

How to set the resolution of X axis, Y axis, Z axis to 1um.

Steps:

1. Enter “SETUP” and press or until “RESOLUTE” appears

q

q

in the message window.

2. Press

=

Ent

The X window, Y window and Z window will display the former

resolution of each axis separately. The message window displays

“SEL AXIS”, which indicates the next step is to select the axis.

www.machineryhouse.co.nz

40

ReSOLute

mm

SeL ReS

mm

5.00

5.00

5.00

INSTRUCTION MANUAL

6.7 SET THE SCALES RESOLUTION(RESOLUTION) Cont.

XH600

3. Select Axis

Press to change the resolution of the X axis, then the data

X

in the X window will ash.

Press to change the resolution of the Y axis, then the data

Y

in the Y window will ash.

Press to change the resolution of the Z axis, then the data

Z

in the Z window will ash.

q

4. Press or to scroll through 0.10, 0.20, 0.50, 1.00, 2.00,

5.00, 10.00, 20.00, 5 0.00, or 100.00.

Press to select “1.00” when it appears and return to

Ent

“SEL.RXIS” state.

Press to cancel your selection.

AC

5. Set the resolution of Y axis: Z axis by repeating step 3-4.

6. Press to exit the “RESOLUTE” setup.

q

=

SeL ReS

mm

SeL AxIS

mm

ReSOLute

mm

1.00

5.00

5.00

1.00

1.00

1.00

6.8 SETTING THE INPUT MODE IN SDM COORDINATE

The XH600 series DRO provides two data entry modes in trhe SDM coordinate:

MODE 0 (Normal entry mode): the data the DRO accepts equals the inputted data;

MODE 1 (Special entry mode): the data the DRO accepts equals the negative of the entered

number

Example: Set SDM mode 1.

q

1. Enter “SETUP”, then press or until the message

window displays “SDM DIR”.

2. Press

=

Ent

Y window displays the former SDM direction.

3. Press to set the SDM direction 1.

Note: Press to set the SDM direction 0.

1

0

q

SDm DIR

mm

SDm DIR

mm

0

1

SDm DIR

mm

www.machineryhouse.co.nz

41

INSTRUCTION MANUAL

6.8 SETTING THE INPUT MODE IN SDM COORDINATE Cont.

=

4. Press to conrm the setting and exit “SDM DIR”

Press to cancel the change and exit “SDM DIR”.

Ent

AC

SDm DIR

mm

6.9 SETTING THE SLOPE MACHINING PARAMETER

Parameters can be set in two ways for slope machining.

A. Set the steps of the second axis (Z STEP) in one plane, for XY plane.

set the steps of the Y axis, for YZ plane and set the steps of Z axis XZ plane set.

B. Set MAX CUT

Default setting: the step of the second axis (Z STEP).

Set the slope machining parameter MAX CUT. STEPS:

q

1. Enter “SETUP” and press or window displays

“SLOP.MODE”.

q

SLOp mODe

mm

2. Press

=

Ent

The Y window displays the former parameter mode.

Press to select MAX CUT parameter mode.

1

SLOp mODe

mm

0

XH600

Note. Press to select Z STEP parameter mode.

0

1

4. Press to save the change and exit this item.

Press to cancel your change and exit this item.

=

Ent

AC

SLOp mODe

mm

SLOp mODe

mm

6.10 TOGGLE BETWEEN LINEAR SCALE AND ROTARY ENCODER

Both linear scales or a rotary encoder can be installed in any axis. The linear scale is used to

measure distance; the rotary encoder is used to measure angles.

Default: linear scale.

Set rotary encoder in Z axis.

Steps:

q

1. Enter “SETUP” and press or until the message

window displays “AXIS.TYPE”;

q

AxIS tYpe

mm

www.machineryhouse.co.nz

42

INSTRUCTION MANUAL

6.10 TOGGLE BETWEEN LINEAR SCALE AND ROTARY ENCODER Cont.

XH600

2. Press

=

Ent

X, Y, Z windows will display the former type.

“LINEAR” means linear scale.

“ENCODE” means rotary encoder.

Message window displays “SEL AXIS”, which means the next

step is to select axis.

3. In this example the Z axis has been installed with a rotary

encoder.

Press until “ENCODE” is displayed in the Z window.

Note: Press to change the X axis.

Press to change the Y axis.

Press to change the Z axis.

4. Press to save the change and exit this item.

Z

Ent

X

Y

Z

=

SeL AxIS

mm

SeL AxIS

mm

LIneR

LIneR

LIneR

LIneR

LIneR

encODe

Press to cancel your change and exit this item.

AC

6.11 STEP MODE FOR ARC PROCESSING

In the ARC function, if the axis is not XY, you can setup the step mode. There are two modes.

Mode 0 is Z STEP mode and Mode 1 is MAX CUT mode.

Default setting: Z STEP

Example: setting the mode as the STEP mode.

Steps:

q

1. Enter “SETUP” and press or until the message

window displays “STEP.MODE”.

=

2. Press

Ent

The Y window displays the former setting. “0” means Z STEP.

“1” means MAX CUT.

The message window displays “SEL MODE”, which means

selecting the step mode for ARC next step.

q

Step mODe

mm

Step mODe

mm

0

www.machineryhouse.co.nz

43

INSTRUCTION MANUAL

6.11 STEP MODE FOR ARC PROCESSING Cont.

XH600

3. Setting the mode as STEP mode.

Press then the Y window displays the changed mode.

4. Press to save the change and exit this item.

Press to cancel your change and exit this item.

1

=

Ent

AC

Step mODe

mm

1

Step mODe

mm

6.12 ANGLE DISPLAY MODE

XH600 provides 3 angle display modes. In Mode 1, the angle is in the range of 0° to 360°.

In mode 2, the angle is in the range of -360°to 360°.

In mode 3, the angle is in the range of -180° to 180°.

Default mode: MODE 1.

Example: Setting the Angle display mode to mode 3.

Steps:

q

1. Enter “SETUP” and press or until the message

window displays “ANGL.MODE”.

q

AnGL mODe

mm

1

0 - 360

=

2. Press then the Y window displays the changed mode.

The message window will display “SEL MODE”, which means

Ent

SeL mODe

mm

the next step is to select the angle display mode.

3. Set the angle display mode as mode 3.

Press then the X window displays the changed mode.

3

The Y window will display the angle mode.

4. Press to save the change and exit “ANGL.MODE” setup.

Press to cancel your change and exit “ANGL.MODE” setup

=

Ent

AC

www.machineryhouse.co.nz

44

SeL mODe

mm

AnGL mODe

mm

3

-180 - 180

6.13 ANGLE DISPLAY TYPE

INSTRUCTION MANUAL

XH600

There are two angle display types for XH-600.

TYPE 0: indicate angle display is DD.

TYPE 1: indicate angle display is DMS.

Default value: TYPE 0°

Setting the angle display type to DMS.

Steps:

q

1. Enter “SETUP” and press or until the message

window displays “ANGL.TYPE”.

2. Press then the X window displays the former setup.

=

Ent

The Y window displays the former angle mode is DD°.

3. Set the angle display mode as MODE 1.

Press then the X window displays the changed mode.

1

The Y window will display the current mode as DMS.

q

AnGL tYpe

mm

SeL mODe

mm

SeL mODe

mm

0

360.00

1

35959.59

=

4. Press to save the change and exit “ANGL.TYPE” setup.

Press to cancel your change and exit “ANGL.TYPE” setup

Ent

AC

AnGL tYpe

mm

6.14 ENABLE / DISABLE ERROR SIGNAL

XH-600 serial DRO provides the function of checking whether the counting signal is normal or

not. It can display the ERROR information if some error occurs in counting the signal. The user

can enable or disable this function.

“0” means no error information will be displayed and the DRO continue to work when there is

some error with linear scale or encoder:

“1” means error information will be displayed when error occurs.

Default setting: 0 (disable display error message).

Example: Enable display ERROR message.

Steps:

q

1. Enter “SETUP” and press or until the message

window displays “ERROR”.

2. Press the Y window displays the former “0” setup.

=

Ent

q

eRROR

mm

0

www.machineryhouse.co.nz

45

eRROR

mm

INSTRUCTION MANUAL

6.14 ENABLE / DISABLE ERROR SIGNAL Cont.

XH600

3. Press to change it to enable error message.

Press to change to disable error message.

4. Press to save the change and exit “ERROR” setup.

Press to cancel your change and exit “ERROR” setup.

1

0

=

Ent

AC

eRROR

mm

eRROR

mm

6.15 SETTING LATHE MODE

Lathe mode 0: Disable lathe function;

Lathe mode 1: X window display value = the position of X axis + the position of Y axis;

Lathe mode 2: X window display value = the position of X axis + the position of Z axis;

Lathe mode 3: Y window display value = the position of Y axis + the position of Z axis;

Default mode: disable lathe mode.

Setting the lathe to mode 3.

Steps:

q

1. Enter “SETUP” and press or until the message

window displays “LATH.MODE”.

q

LAth mODe

mm

1

2. Press then the Y window displays the former setup.

=

Ent

3. Set the new lathe mode.

Press

Note: Press or 2 or or to change the lathe mode.

4. Press to save the change and exit “LATH.MODE” setup.

Press to cancel your change and exit “LATH.MODE” setup.

3

3 1 0

=

Ent

AC

www.machineryhouse.co.nz

46

nOne

mm

Z=Z+Z 1

mm

LAth mODe

mm

0

3

INSTRUCTION MANUAL

6.16 SET THE DISPLAY BRIGHTNESS GRADE

XH600

Function: The brightness displayed by the digital tube may be

regulated based on the environment on user’s site

environment, Grade 0~7 is divided totally.

Default grade: 5

Setting the display brightness grade 3.

Steps:

q

1. Enter “SETUP” and press or until the message

window displays “DSP.LEVE”.

2. Press then the Y window displays the former setup.

=

Ent

3. Press

Note: Press to 1 to change the brightness grade.

4. Press to save the change and exit “DSP.LEVE” setup.

Press to cancel your change and exit “DSP.LEVE” setup.

3

=

Ent

AC

7

q

DSp Leve

mm

LeD 5

mm

LeD 3

mm

DSp Leve

mm

6.17 SETTING THE NUMBER OF DISPLAY AXES

Function: The display is capable of setting the number of display axes on the coordinate

interface based on the users needs, from 1 to 6.

Default number of display axes: 3.

Setting the number of X display axis to 4.

Steps:

1. Enter “SETUP” and press or until the message

window displays “DSP.BITS”.

2. Press number of X display axis to 4, then the Y window

=

Ent

displays the former setup.

q

q

DSp BItS

mm

0.001

0.001

0.001

www.machineryhouse.co.nz

47

SeL AxIS

mm

INSTRUCTION MANUAL

6.17 SETTING THE NUMBER OF DISPLAY AXES

XH600

3. Select axis

Press to change the number of display X axis, then data in

X

X window ashes.

Press to change the number of display Y axis, then data in

Y

Y window ashes.

Press to change the number of display Z axis, then data in

Z

Z window ashes.

q

4. Press or to scroll through 0.1, 0.01, 0.001, 0.0001,

0.00001, 0.000001.

Press to select “0.0001” when it appears and return to

Ent

“SEL.AXIS” state. Press to cancel your selection.

5. Set the number of display Y axis: Z axis by repeating step 3-4.

6. Press to conrm the new set and exit.

Press to cancel the new set and exit.

Ent

AC

q

=

AC

=

SeL AxIS

mm

SeL AxIS

mm

DSp BItS

mm

0.0001

0.001

0.001

0.0001

0.001

0.001

6.18 LOAD DEFAULT SETUP

Function: Clear all data except the linear compensation and DRO type. DRO will load default

setup for all parameters. After loading default setup, user must search RI once to

enable resuming ABS datum function; otherwise to resume the datum by RI is unable.

Steps:

1. Enter “SETUP” and press or until the message

q

q

window displays “CLR.ALL”.

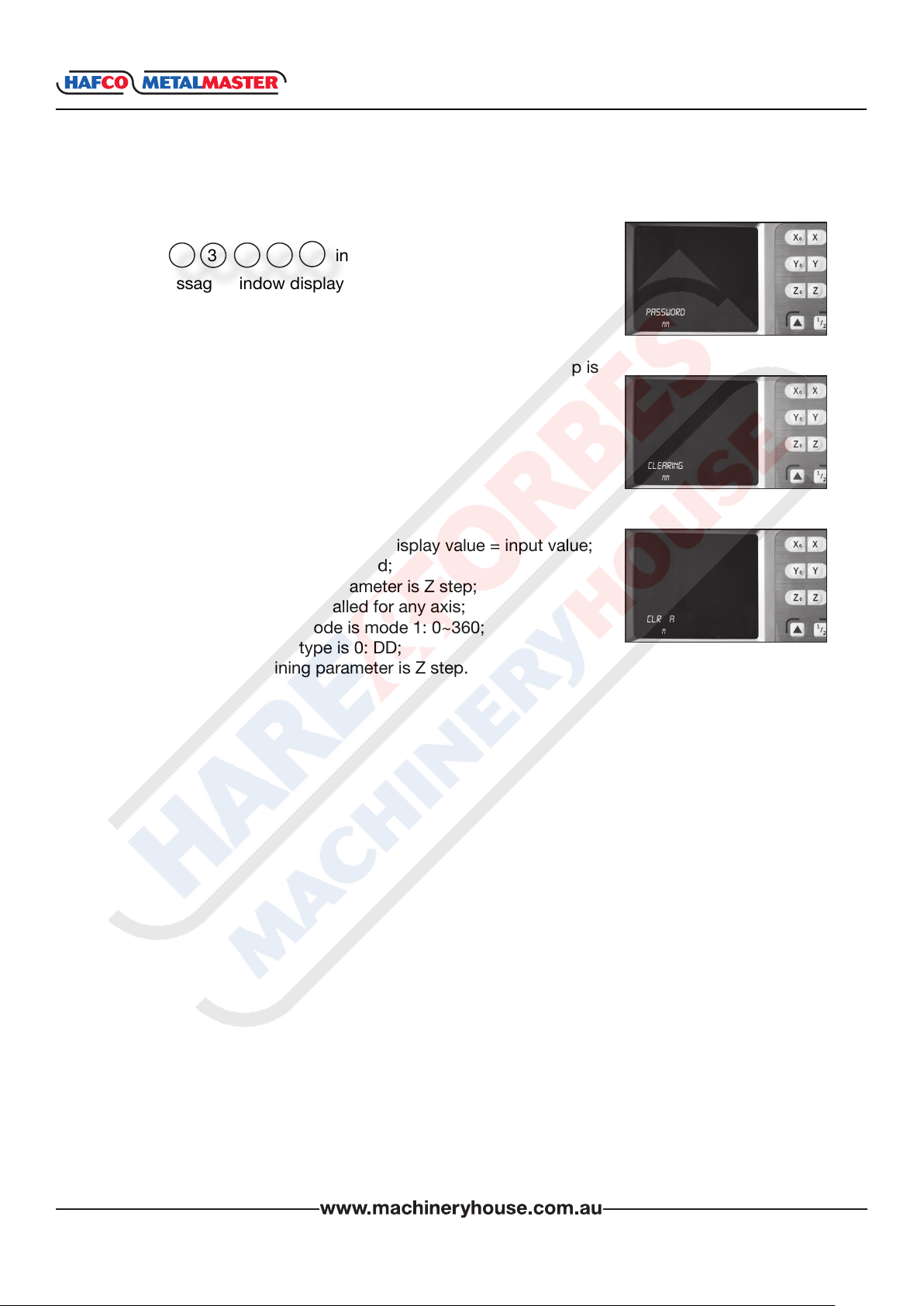

2. Press and message windows display “PASSWORD”

=

Ent

cLR ALL

mm

indicating the operator to input password. At this moment,

there are two selections:

____

A. Press to quit “CLR ALL”.

B. Enter the correct password to clear all parameters and load

default setup.

AC

pASSwORD

mm

www.machineryhouse.co.nz

48

INSTRUCTION MANUAL

6.18 LOAD DEFAULT SETUP Cont.

XH600

3. Input the password.

Press 3 in turn to load default value.

4 2 1

=

Ent

The message window displays “CLEARING”, which means the

data is clearing.

4. Return to the normal display state after loading default setup is

nished.

The default setup for all parameters is as follows.

w Counting direction is mode 0;

w The R/D is mode R ;

w Z DIAL = 2.5mm;

w Resolution = 5μm;

w Input mode in SDM as 0, display value = input value;

w Lathe function is disabled;

w Slope machining parameter is Z step;

w Linear scale is installed for any axis;

w Angle display mode is mode 1: 0~360;

w Angle display type is 0: DD;

w ARC machining parameter is Z step.

pASSwORD

mm

cLeARInG

mm

cLR ALL

mm

0000

www.machineryhouse.co.nz

49

INSTRUCTION MANUAL

XH600

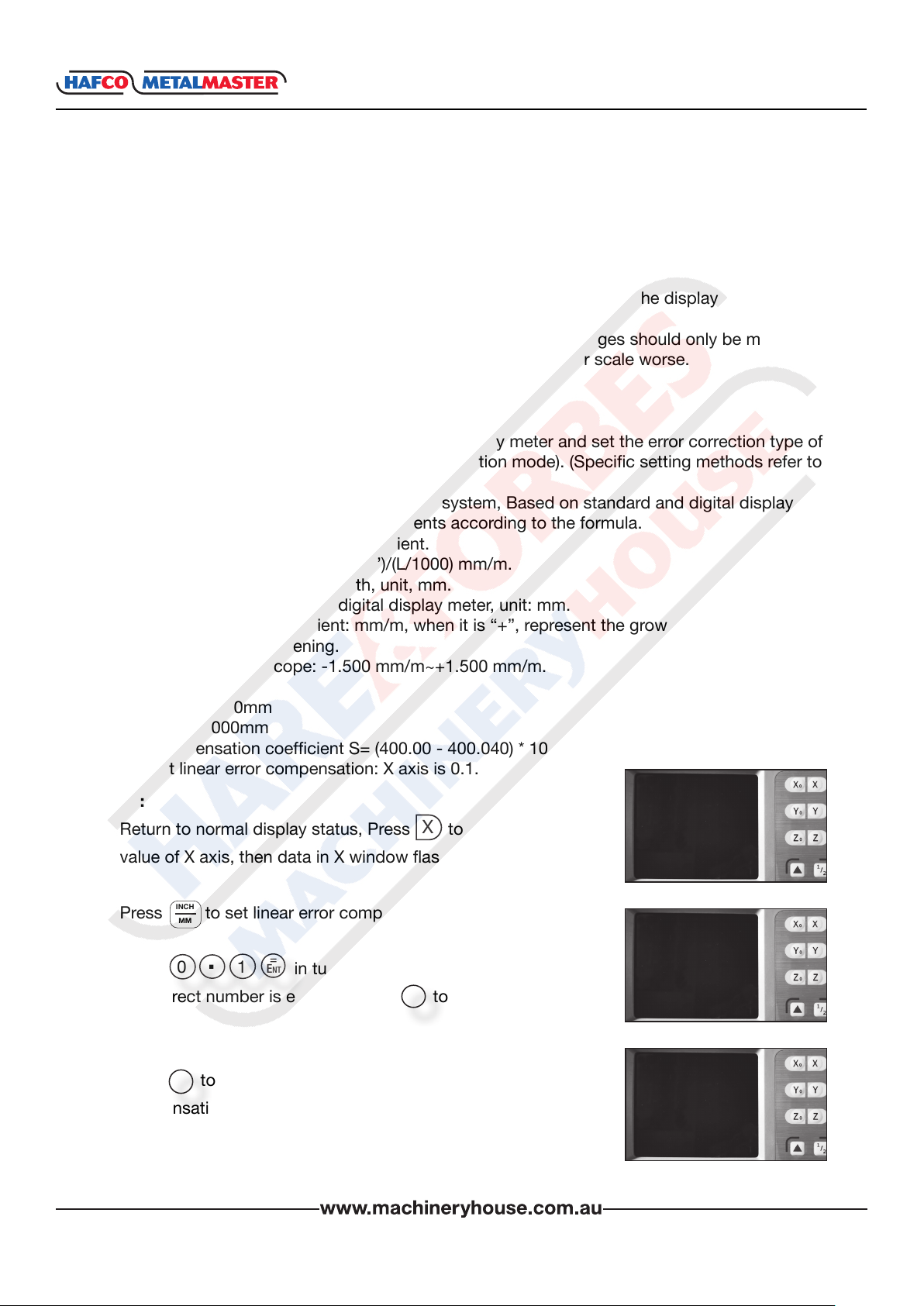

Chapter 7 LINEARITY ERROR CORRECTION

Function:

There is a error between the grating ruler’s measuring value and standard value, if it is assumed

that the shape of two measuring curves within grating ruler’s travel range is consistent completely but isn’t coincide, which is called as linearity error.

Linearity correction: compensate the linearity error so as to enable that the display value is equal

to standard value.

NOTES: The linear compensation is set by the manufacturer. Changes should only be made

after careful consideration as it could make the accuracy of linear scale worse.

Default coefcient: 0

Step 1: Enter into the parameters inside digital display meter and set the error correction type of

corresponding axle is 0 (linearity compensation mode). (Specic setting methods refer to

Chapter 6.4)

Step 2: Input the linearity error compensation system, Based on standard and digital display

value, calculate the correct coefcients according to the formula.

The calculation of compensation coefcient.

Correction coefcient: S =(L-L’)/(L/1000) mm/m.

L---actually-measured length, unit, mm.

L’---display value on the digital display meter, unit: mm.

S--- correction coefcient: mm/m, when it is “+”, represent the growth; when it is “-”,

represent the shortening.

Compensation scope: -1.500 mm/m~+1.500 mm/m.

Example:

L’ = 400.040mm

L = 400.000mm

Compensation coefcient S= (400.00 - 400.040) * 1000 / 400 = 0.1 Unit: mm/m.

Set linear error compensation: X axis is 0.1.

0

Steps:

1. Return to normal display status, Press to preset display

X

value of X axis, then data in X window ashes.

ABS

mm

0.000

0.000

2. Press to set linear error compensation.

3. Press in turn.

If incorrect number is entered, press to cancel and enter

INCH

MM

0

.

=

1

Ent

AC

again.

4. Press to conrm your setting and exit the linear error

=

Ent

compensation setup.

www.machineryhouse.co.nz

50

cOmpen x

mm

cOmpen x

mm

0

0.000

0.000

0.1

0.000

0.000

INSTRUCTION MANUAL

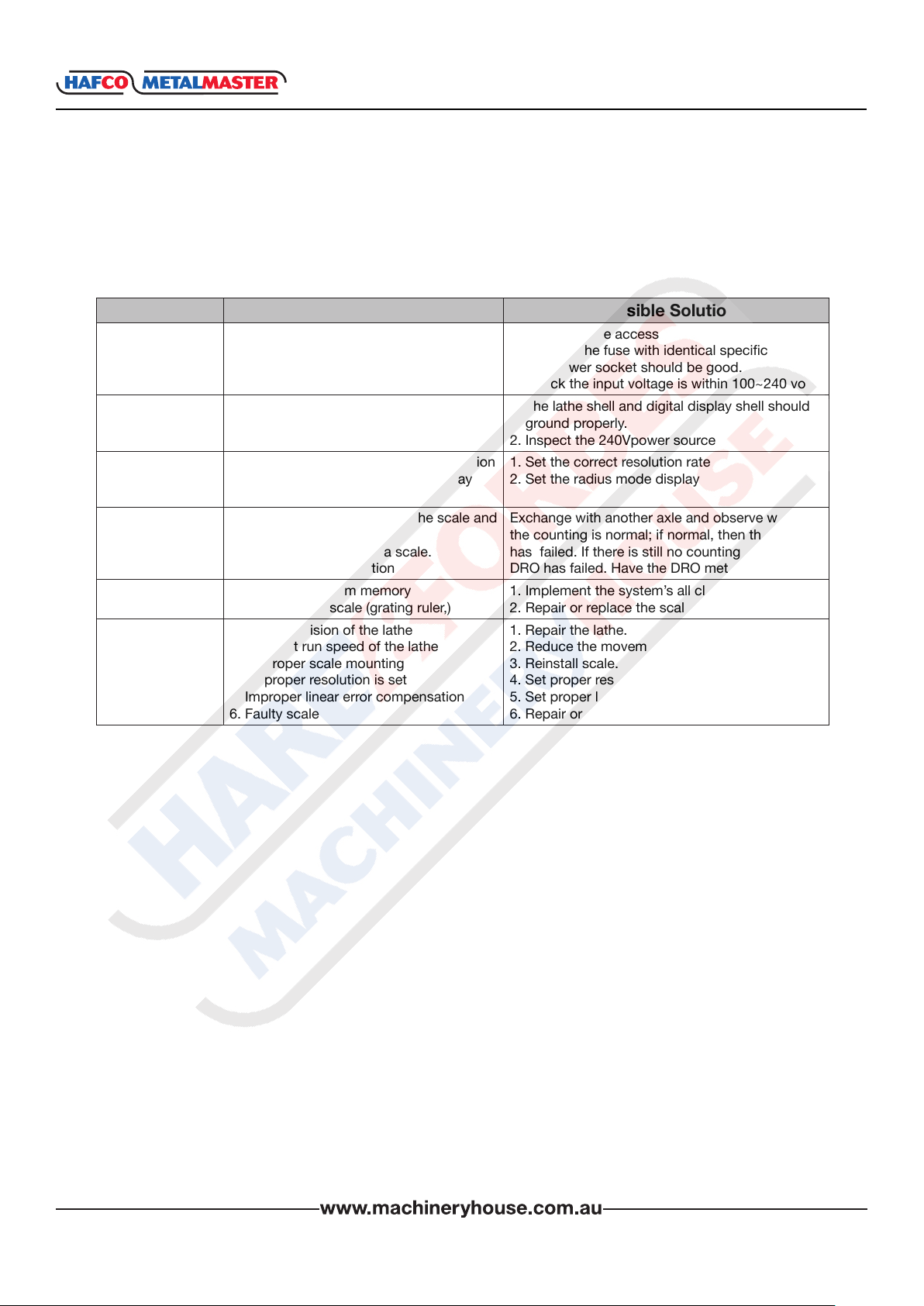

Chapter 8 TROUBLE SHOOTING

Review the troubleshooting and procedures in this section if a problem develops with your

equipment. If additional help with a procedure is required, then contact you distributor.

Note: Make sure you have the model number, before calling.

Symptoms Possible Cause Possible Solution

No display

DRO Cover is

charged

Display value is

double

No counting

Display value is in

disorder

Incorrect

counting

1. Power source failure

2. Damage of fuse

3. Poor 220V power source wiring

4. Inappropriate power voltage.

1. Improper grounding between lathe and

digital display.

2. Leakage of Electricity

1. Improper setting of the scales resolution

2. Some axle is set as diameter display

mode

1. Improper contact between the scale and

the reader head.

2. No signal output from a scale.

3. Failed counting function

1: Disorderly system memory

2. Failure of the scale (grating ruler,)

1. Poor precision of the lathe

2. Too fast run speed of the lathe

3. Improper scale mounting

4. Improper resolution is set

5. Improper linear error compensation

6. Faulty scale

1. Power source access

2. Replace the fuse with identical specication

3. The power socket should be good.

4. Check the input voltage is within 100~240 volts

1. The lathe shell and digital display shell should