Page 1

HAEMONETICS

®

PCS

®

2

Service and

Maintenance Manual

Page 2

HAEMONETICS

®

PCS®2

Part Number 38855-00

Rev. D, June 2003

HAEMONETICS CORPORATION

400 Wood Road, Braintree, MA 02184

Service and Maintenance Manual

Page 3

© 1994 Haemonetics Corporation

All Rights Reserved

Printed in U.S.A.

First Printing, April 1994

PROPRIETARY MATERIAL

Information and descriptions contained herein are the property of

Haemonetics Corporation. Except where indicated, such information and

descriptions may not be copied or reproduced by any means, or

disseminated or distributed without the express prior written permission of

Haemonetics Corporation.

TRADEMARKS

HAEMONETICS®and PCS®2 are registered trademarks of Haemonetics

Corporation.

ii PCS2 Service Manual

Page 4

Chapter 1, Introduction

General..........................................................................................................................................1-1

Additional Support .......................................................................................................................1-2

Chapter 2, Machine Part Replacement Reference

Cautions........................................................................................................................................2-1

Static Discharge............................................................................................................................2-1

Notes.............................................................................................................................................2-1

Rear Panel.....................................................................................................................................2-2

Fan Assembly.........................................................................................................................2-2

Cover Stops.............................................................................................................................2-2

Cuff Connector.......................................................................................................................2-2

Front Panel....................................................................................................................................2-2

Donor Line Air Detectors 1 and 2..........................................................................................2-3

Compressor.............................................................................................................................2-3

Front Panel Distribution Board...............................................................................................2-4

Card Cage.....................................................................................................................................2-4

Centrifuge Distribution Card..................................................................................................2-4

Processor Card........................................................................................................................2-5

Main Program Chip Assembly...............................................................................................2-5

Safety Card.............................................................................................................................2-5

Driver Card.............................................................................................................................2-6

Backplane Card (Mother Board) ............................................................................................2-6

Top Deck Assembly......................................................................................................................2-6

AC Air Detector................................................................................................................2-6

Blood Line Air Detector...................................................................................................2-7

Line Sensor.............................................................................................................................2-7

Top Deck Distribution Board..................................................................................................2-7

Plasma Weigher Assembly ...........................................................................................................2-8

Weigher Arm Assembly .........................................................................................................2-8

Table of Contents

Page 5

Chapter 2, Machine Part Replacement Reference, cont.

Load Cell ................................................................................................................................2-8

Pinch Valves ...........................................................................................................................2-9

AC/Blood Pump Assembly...................................................................................................2-10

Rotor...............................................................................................................................2-10

Motor..............................................................................................................................2-11

SPM/DPM Sensor Assembly................................................................................................2-11

Centrifuge Assembly..................................................................................................................2-12

Cover Halves ..................................................................................................................2-12

Bushing Adjustment Kit.................................................................................................2-13

Cover Switch Assembly .................................................................................................2-15

Cover Latch ....................................................................................................................2-15

Fluid Sensor Assembly...................................................................................................2-16

Bowl Optics Assembly...................................................................................................2-16

Top Cover Assembly ..................................................................................................................2-17

Membrane Panel Assembly..................................................................................................2-17

Control Panel Distribution Cable....................................................................................2-18

Display Distribution Board...................................................................................................2-20

Vacuum Display....................................................................................................................2-20

Membrane Panel...................................................................................................................2-20

Power Entry Module...................................................................................................................2-21

Fuse.......................................................................................................................................2-21

Power Supply Assembly.............................................................................................................2-21

Replace Todd Power Supply with Todd Power Supply........................................................2-21

Replace Todd Power Supply with Condor Power Supply....................................................2-22

Replace Condor Power Supply with Condor Power Supply................................................2-23

Centrifuge Controller Card...................................................................................................2-24

AC and Saline Pole Holder Assembly........................................................................................2-24

Drain Tube Assembly.................................................................................................................2-24

Photoelectric Assembly..............................................................................................................2-24

Line Conditioner.........................................................................................................................2-25

Table 2-1, PCS2 Component Calibration and Diagnostic Matrix ..............................................2-26

Chapter 3, Basic Care and Preventive Maintenance

Initial Inspection...........................................................................................................................3-1

Visual Inspection ....................................................................................................................3-1

Ensure Initial Operational Integrity........................................................................................3-2

Record the Program Revision Level.......................................................................................3-2

System Cleaning...........................................................................................................................3-2

Equipment Integrity Inspection....................................................................................................3-2

Electrical Connections Inspection..........................................................................................3-2

toc-ii PCS2 Service Manual

Page 6

PCS2 Service Manual toc-iii

Chapter 3, Preventive Maintenance, cont.

Pneumatic Connections Inspection.........................................................................................3-2

Hardware Inspection...............................................................................................................3-2

Consumables Replacement...........................................................................................................3-3

Filter Inspection......................................................................................................................3-3

Calibration Testing .......................................................................................................................3-3

Power Supply Voltages Test ...................................................................................................3-3

Valves Test..............................................................................................................................3-4

Valve Occlusion Test ..............................................................................................................3-4

Weigher Test...........................................................................................................................3-5

DPM Sensor Test....................................................................................................................3-5

Cuff Test .................................................................................................................................3-6

Display Test ............................................................................................................................3-6

Keyboard Test.........................................................................................................................3-6

Centrifuge Testing ........................................................................................................................3-7

Fluid Sensor Test ....................................................................................................................3-7

Centrifuge Cover and Lock Functional Test...........................................................................3-7

Centrifuge Speed and Bowl Vibration Test............................................................................3-7

Donor Lights Test ...................................................................................................................3-7

Line Sensor Test .....................................................................................................................3-8

Bowl Optics Signal Test .........................................................................................................3-8

Air Detector Test ..................................................................................................................3-10

PCS2 Functional Test ...........................................................................................................3-10

Safety Testing .............................................................................................................................3-12

Leakage Current ...................................................................................................................3-12

Ground Continuity................................................................................................................3-12

Chapter 4, Calibration

Calibration Procedures .................................................................................................................4-1

Power Supply Voltages...........................................................................................................4-1

Todd Power Supply...........................................................................................................4-1

Condor Power Supply.......................................................................................................4-3

Bowl Optics Signal.................................................................................................................4-3

Line Sensor Signal..................................................................................................................4-6

A/D .........................................................................................................................................4-6

Cuff...................................................................................................................................4-6

Weigher.............................................................................................................................4-7

P/N 36924-00 Weigher Arm .......................................................................................4-7

P/N 52025-00 Weigher Arm .......................................................................................4-8

Weigher Calibration When Using Collection Bottles.................................................4-8

Weigher Calibration When Using Collection Bags ....................................................4-9

Page 7

Chapter 4, Calibration, cont.

Weigher Calibration When Using Collection Bottles and Bags .................................4-9

DPM ..............................................................................................................................4-9

Centrifuge.............................................................................................................................4-10

Safety System.......................................................................................................................4-11

Chapter 5, Installation and Configuration

Initial Inspection...........................................................................................................................5-1

Overall Cosmetic Check.........................................................................................................5-1

Internal Workmanship ............................................................................................................5-1

Configuration of Protocol Parameters..........................................................................................5-1

Language Configuration.........................................................................................................5-1

Protocol Selection...................................................................................................................5-2

Machine Settings ....................................................................................................................5-3

Serial Number Configuration .................................................................................................5-4

Collection Weight Configuration............................................................................................5-4

Bowl Configuration................................................................................................................5-5

Testing ..........................................................................................................................................5-6

Valves Test..............................................................................................................................5-6

Weigher Test...........................................................................................................................5-6

DPM Sensor Test....................................................................................................................5-7

Cuff Test .................................................................................................................................5-7

Display Test ............................................................................................................................5-7

Keyboard Test.........................................................................................................................5-8

Centrifuge Testing ..................................................................................................................5-8

Fluid Sensor Test ..............................................................................................................5-8

Centrifuge Cover & Lock Function Test ..........................................................................5-8

Centrifuge Speed and Bowl Vibration Test......................................................................5-8

Donor Lights Test ...................................................................................................................5-9

Line Sensor Test .....................................................................................................................5-9

Bowl Optics Signal Test .........................................................................................................5-9

Air Detector Test ..................................................................................................................5-11

PCS2 Functional Test ...........................................................................................................5-11

Leakage Current ...................................................................................................................5-13

Ground Continuity................................................................................................................5-13

Machine Transfers......................................................................................................................5-14

Source Plasma Customers Only ...........................................................................................5-14

PCS2 Machine Transfer Verfication Form ...........................................................................5-15

toc-iv PCS2 Service Manual

Page 8

PCS2 Service Manual toc-v

Chapter 6, Troubleshooting

Messages.......................................................................................................................................6-1

Status Messages......................................................................................................................6-2

Error Messages.......................................................................................................................6-2

CPU Error Messages ........................................................................................................6-3

Notes ..............................................................................................................................6-4

CPU Error Message List...................................................................................................6-5

Safety System Error Messages.............................................................................................6-32

Command Register.........................................................................................................6-33

Table 6-1, Error Codes of the Command Register....................................................6-33

Fault Register..................................................................................................................6-33

Table 6-2, Error Codes of the Fault Register ............................................................6-34

Critical Register..............................................................................................................6-35

Table 6-3, Error Codes of the Critical Register ........................................................6-35

Chapter 7, Repair Parts List

PCS2 Exploded View ...................................................................................................................7-2

PCS2 Exploded View with Callouts.............................................................................................7-3

PCS2 Centrifuge Exploded Views with Callouts.........................................................................7-4

PCS2 Card Cage and Air Filters Exploded Views with Callouts.................................................7-5

PCS2 Power Supply Assembly Exploded Views with Callouts...................................................7-6

PCS2 Pump Assembly Exploded View with Callouts..................................................................7-7

Parts List by Assembly.................................................................................................................7-8

Used PCS2 Parts Return Procedure............................................................................................7-12

Chapter 8, Cleaning and Maintenance

Overview.......................................................................................................................................8-1

Cleaning........................................................................................................................................8-1

Routine Cleaning Schedule ....................................................................................................8-1

Cleaning Supplies Needed......................................................................................................8-2

Cleaning the PCS2..................................................................................................................8-2

Membrane Panel and Outer Cabinet.................................................................................8-2

Donor Pressure Monitor (DPM).......................................................................................8-3

Air Detectors.....................................................................................................................8-3

Line Sensor.......................................................................................................................8-3

Centrifuge Well.................................................................................................................8-4

Fluid Sensor......................................................................................................................8-7

Bowl Optics Lens .............................................................................................................8-7

Blood and Anticoagulant Pumps......................................................................................8-8

Page 9

Chapter 8, Cleaning and Maintenance, cont.

Air Filters..........................................................................................................................8-9

Internal Chassis.................................................................................................................8-9

Leakage Current Check..............................................................................................................8-10

Return Goods Authorization (RGA)...........................................................................................8-11

RGA Procedure.....................................................................................................................8-11

Haemonetics Quality Program....................................................................................................8-12

Chapter 9, Technical Bulletins

toc-vi PCS2 Service Manual

Page 10

This Service Manual is designed to provide detailed information for the

installation and maintenance of the PCS2, which is a plasma collection

system.

The manual contains nine chapters, including:

Chapter 1, Introduction

Describes the PCS2 Service Manual.

Chapter 2, Machine Part Replacement Reference

Describes detailed steps in disassembling the PCS2 and its subsystems.

Chapter 3, Basic Care and Preventive Maintenance

Describes detailed preventive maintenance procedures.

Chapter 4, Calibration

Describes detailed calibration procedures.

Chapter 5, Installation and Configuration

Describes detailed installation procedures and configuration of protocol

parameters procedures.

Chapter 6, T

roubleshooting

Describes each of the CPU and safety system generated error messages,

and describes detailed troubleshooting steps to resolve the problems.

Chapter 7, Repair Parts List

Provides exploded views of the PCS2 and its subsystems with part

number and description call-outs. Includes parts list in assembly outline

format for each available repair part or assembly.

Chapter 1

Introduction

General

Page 11

Chapter 8, Cleaning and Maintenance

Describes routine maintenance procedures.

Chapter 9, Technical Bulletins.

Provides area to store Technical Bulletins.

Many factors affect the performance of component collection devices

including the functional integrity of the instrument, the consistency of the

disposable set, and the quality of the blood from the donor.

When the PCS2 is properly calibrated and maintained, the instrument is

very reliable and predictable and is designed to withstand substantial

abuse. There may be times, however, that a component may fail

prematurely, or damage may occur during transport or as the result of

fluid contamination.

In designing this manual, Haemonetics has attempted to address all

possible service scenarios. There may be situations which were not

predicted, and in such cases Haemonetics Product Support can be relied

upon to provide outstanding service support. Product support can be

obtained through the Haemonetics Hot Line at 800-356-3506.

1-2 PCS2 Service Manual

Additional

Support

Page 12

Chapter 2

Machine Part Replacement Reference

Extreme caution should be exercised when working inside the PCS2

cabinet to avoid electrical shock. Particularly avoid contact with AC

power connections and any electrolytic capacitors on printed circuit

boards. Whenever possible, AC power should be disconnected from the

PCS2 before opening the cabinet.

The PCS2 uses static sensitive electronics. Serious damage may occur to

the sensitive electronics if static discharge is not controlled. Internal

components should only be handled after proper precautions have been

taken to prevent static discharge.

To reassemble the PCS2, reverse the disassembly steps. In some cases,

Reassembly Notes have been added to direct your attention to any

important steps.

For brevity, a procedure often will reference another procedure. For

instance, when removing the top deck, the instructions will ask you to

remove the centrifuge. Locate the centrifuge removal procedure for

instructions on that particular step.

In most cases there is more than one way to remove a particular assembly.

These instructions provide the most logical approach to disassembling the

PCS2. With experience, you may develop a less methodical approach. You

are encouraged to use whatever method best suits your particular situation.

When replacing certain machine components, it may be necessary to

calibrate that component as well as other peripheral components.

Calibration steps are listed in each component’s replacement procedure

when needed. In addition, Table 2-1 at the end of this chapter provides a

Component Calibration and Diagnostic Matrix indicating any necessary

calibrations and diagnostic checks required for the specific component

replacement.

Cautions

Static

Discharge

Notes

Page 13

2-2 PCS2 Service Manual

1. Remove (3) Phillips head screws from the bottom edge of the rear

panel.

2. Pull bottom edge 6" away from the cabinet, then pull the rear panel

down and away from the upper lip of the cabinet.

3. Unplug the fans at P407 on the centrifuge distribution board.

4. Disconnect the cuff pneumatic line at the quick disconnect,

approximately 12 inches from the rear panel.

5. Remove the ground wire from the ground lug on the rear panel.

F

an Assembly

1. Remove the rear panel.

2. Remove (2) nuts for each fan to be removed.

Note: All four fans should be replaced at the same time, even if only one

is failing.

Cover Stops

1. Remove the rear panel.

2. Remove (2) Phillips head screws for each cover stop to be removed.

Cuff Connector

1. Remove the rear panel.

2. Remove connector nut.

3. Push connector out of panel from rear.

1. Tilt the cabinet back slightly, and remove the (3) Phillips head screws

from the bottom edge of the front panel.

2. Pull the front panel away from the cabinet, then pull the panel down

and away from the upper lip of the cabinet.

3. Disconnect the cuff pneumatic line at the quick disconnect.

4. Disconnect the ribbon cable P503/703 at P703 on the mother

backplane card.

5. Remove the ground wire from the ground lug on the front panel.

Rear Panel

Front Panel

Page 14

Chapter 2, Machine Part Replacement Reference 2-3

Donor Line Air Detectors 1 and 2

1. Remove the front panel. (See page 2-2.)

2. Disconnect air detector from P701 for DLAD1 and/or P702 for

DLAD2 on the front panel distribution board.

3. Remove (2) Phillips head screws from each air detector. Be aware of

nylon spacers between air detector mounting holes and front panel.

4. Firmly press the air detector head (from the front) through the panel.

This is normally a very tight fit, and may have been lubricated with

silicone vacuum grease when assembled.

Donor Line 1 and 2 Reassemb

ly Notes

1. Air detector connectors are keyed to ensure proper location, but the

air detectors themselves could accidentally be installed in the wrong

location. The Donor Line Air Detector #1 at P701 is located in the

upper panel location, and the Donor Line Air Detector #2 at P702 is

located in the lower panel location.

2. When installing the air detector, be sure the grommet is in place in the

panel, and lubricate the grommet inner diameter with silicone vacuum

grease to ease the installation of the air detector head.

Note: LED to be located toward the inside of the front panel.

3. When reassembling, assure white nylon spacers are placed between

air detectors and front panel at the mounting holes.

Compressor

1. Remove the front panel. (See page 2-2.)

2. Disconnect the compressor at P704 on the front panel distribution

board.

3. Remove O-ring around compressor clip, if present.

4. Unclasp the compressor from the front panel mounting clip.

5. Disconnect the compressor from the pneumatic harness at any

convenient junction.

6. Recalibrate compressor. Refer to Chapter 4, Calibration.

Compressor Reassemb

ly Notes

The compressor has a pressure port (P) and a vacuum port (V) that may

not be labeled. The vacuum port (V) has tubing with a filter attached to

it for drawing in air. The pressure port (P) has tubing with a filter

attached, which is then connected to the pressure transducer and cuff

pneumatic harness. If the tubing attached to the pressure and vacuum

ports are crossed, the compressor will run but there will be no pressure

output (cuff will not inflate).

Page 15

2-4 PCS2 Service Manual

Note: The filters should be replaced when a new compressor is installed.

Front Panel Distribution Board

1. Remove the front panel. (See page 2-2.)

2. Disconnect P701, 702, 703, and 704 from the front panel distribution

board.

3. Disconnect the ground wire from TS1.

4. Disconnect the compressor pneumatic line at the cuff pressure sensor.

(P2 Port)

5. Remove (4) Phillips head screws at the front panel distribution board

corners.

6. Recalibrate the compressor. Refer to Chapter 4, Calibration.

1. Remove the front and rear panels. (See page 2-2.)

2. From the front cavity, disconnect P501, P502, P503, P504, P506,

P507, and TS1 ground from the backplane card. Label cables as they

are removed.

3. Follow the directions for each of the following card cage boards. The

cage is ultimately removed along with the backplane card.

4. Remove (4) Phillips head screws securing the card cage frame to the

cabinet bases (2 in front, 2 in back).

5. Move the frame toward the rear of the cabinet, and slide out the back

cavity of the cabinet.

Car

d Cage Reassembly Notes

The (3) main cards use similar backplane connectors, but the red keys

prevent installing the card in the wrong location.

Centrifuge Distribution Card

1. Remove the front and rear panels. (See page 2-2.)

2. Disconnect P408 and P409 from the centrifuge distribution card (1/2

size board located at the far right of the card cage), then unclasp the

black card levers and partially slide the centrifuge distribution card

out of the card cage.

3. From the rear cavity, disconnect P404, P405, P406, P407, and ground

wire at TS1 from the centrifuge distribution card, then completely

remove the centrifuge distribution card from the card cage.

Card Cage

Page 16

Chapter 2, Machine Part Replacement Reference 2-5

Processor Car

d

1. Remove the rear panel. (See page 2-2.)

2. Unclasp the card levers and unplug the processor card from the

backplane card (located at far left of the card cage).

3. Slide the card out of the card cage.

4. If replacing the processor card, refer to Chapter 4 for calibration of

the bowl optics signal, line sensor signal, A/D, centrifuge, and safety

system, and Chapter 5 for configuration.

Note: Processor card MUST have Main Program IC (P/N 37008-01) chip

in position U26 prior to reassembly. Also, verify that the correct

program version for your facility is installed. If program version is

not correct contact the Haemonetics Hot Line.

Main Program Chip Assembly

1. Remove the processor card. (See above.)

2. Using an antistatic IC removal tool for a 32 pin IC, gently pull the

main program IC from chip location U26. A future program upgrade

may also utilize U23. If the IC removal tool is not available, use flat

blade screwdriver to gently pry between IC chip and IC carrier from

end to end until IC chip is out.

Note: Do NOT bend IC chip legs.

Main Pr

ogram Chip Reassembly Notes

The Main Program IC chip must be installed properly or the chip will be

destroyed. At one end of the chip there is a small notch (half circle). This

notch must align with the white notch silk-screened on the Processor card

(notch points toward the backplane connectors).

Safety Car

d

1. Remove the rear panel. (See page 2-2.)

2. Unclasp the card levers and unplug the safety card from the backplane

card (located as second card from the left in the card cage).

3. Slide the card out of the card cage.

4. If replacing the safety card, refer to Chapter 4, Calibration, for

calibration of the safety system.

Page 17

2-6 PCS2 Service Manual

Driver Card

1. Remove the rear panel. (See page 2-2.)

2. Unclasp the card levers and unplug the driver card from the backplane

card (located as third card from the left in the card cage).

3. Slide the card out of the card cage.

4. If replacing the driver card, refer to Chapter 4, Calibration, for

calibration of the safety system.

Backplane Card (Mother Boar

d)

1. See all steps to removing the card cage. (See page 2-4.)

2. Remove (7) large Phillips head screws securing the backplane card to

the card cage frame.

1. Remove the front and rear panels. (See page 2-2.)

2. Remove the centrifuge assembly. (See page 2-12.)

3. Disconnect P504 from the backplane card and thread ribbon cable

through the rear panel.

4. Disconnect P501, P502, and P506 from the backplane card.

5. Disconnect the ground wire at the top deck ground bus that connects

to the side panel ground bus.

6. Using a 3/8" wrench (or equivalent), remove the (4) #10-32 nuts that

secure the top deck to the cabinet.

7. Firmly grasp the top deck and pull away from the cabinet.

AC Air Detector

1. Remove the front and rear panels. (See page 2-2.)

2. Disconnect P605 from the top deck distribution board.

3. Remove the right handle by removing the (2) Phillips head screws

securing the inner and outer panels.

Note: It may be easier to access the screws if the AC pump is removed.

(See page 2-10.)

4. Remove the (2) Phillips head screws securing the air detector to the

top deck.

5. Firmly press the air detector head (from the top) through the top deck.

This is a very tight fit.

Note: See reassembly notes below.

Top Deck

Assembly

Page 18

Chapter 2, Machine Part Replacement Reference 2-7

Blood Line Air Detector

1. Remove the front and rear panels. (See page 2-2.)

2. Remove blood pump assembly for easier access. (See page 2-10.)

3. Disconnect P606 from the top deck distribution board.

4. Remove the (2) Phillips head screws securing the air detector to the

top deck.

5. Firmly press the air detector head (from the top) through the top deck.

This is a very tight fit.

Note: See the following reassembly notes.

A

C and Blood Line Air Detector Reassembly Notes

1. Apply a light film of silicone vacuum grease to the air detector

grommet before attempting to install the air detector.

2. If both top deck air detectors are removed, be sure to return the

correct air detectors to the correct locations. The plugs are keyed, so

use the descriptions on the top deck distribution board for

identification. P605 is for the AC and P606 is for the Blood Line Air

Detector.

3. LED is located toward the front of unit.

Line Sensor

1. Remove the rear panel. (See page 2-2.)

2. Disconnect P607 from the top deck distribution board.

3. Remove the (2) Phillips head screws securing the line sensor to the

top deck.

Note: It may be necessary to use a ratchet or stubby screwdriver to access

these screws. If you still have trouble, you may have to slide the

card cage back.

Line Sensor Reassemb

ly Notes

1. Be sure the line sensor gasket is in place between the sensor and the

top deck before securing.

2. Calibrate the line sensor. Refer to the procedure in Chapter 4, Calibration.

Top Deck Distribution Board

1. Remove the front and rear panels. (See page 2-2.)

2. Remove the centrifuge. (See page 2-12.)

3. Remove the pumps. (See page 2-10.)

4. Remove or slide back the card cage (See page 2-4.)

Page 19

2-8 PCS2 Service Manual

5. Disconnect all electrical connections on the top deck distribution

board including the ground.

6. Remove the (6) Phillips head screws securing the top deck distribution

board to the top deck.

Note: The top deck assembly may be removed as an alternative method.

(See page 2-6.)

Weigher Arm Assembly

Note: Extreme care must be used when doing this.

1. Remove the Phillips screw securing the weigher arm to the load cell

standoff.

2. Remove the arm from the load cell upper standoff.

W

eigher Arm Reassembly Notes

The weigher arm is secured to the load cell by a screw mounted to the

hexagonal shaped upper standoff assembly. The upper standoff is

permanently attached to the stainless steel stud, connecting to the lower

square standoff mounted inside the spring clip. This mounting

configuration allows the lower standoff to be rotated in one of four

positions. When securing the weigher arm to the upper standoff, ensure

the weigher arm is adjusted to be perpendicular to the machine cabinet

when the lower standoff is in one of its four positions. This may prove to

be difficult without securing the load cell upper standoff with a 1/4 inch

open wrench under the top deck while tightening the weigher arm screw.

If tightened properly the arm and lower standoff will rotate as an integral

piece. Purple Loctite must be used on the screw that attaches the weigher

arm to the upper standoff.

Load Cell

Note: The load cell is a sensitive device and should be handled with care.

1. Remove the front and rear panels. (See page 2-2.)

2. Disconnect P506 from the backplane card and thread the cable around

the side of the card cage.

3. Remove the weigher arm assembly (See above.)

4. Remove the centrifuge assembly (See page 2-12.) or slide the card

cage back (See page 2-4.) approximately six inches to allow clearance

to the weigher load cell.

5. Using a 7/32" wrench (or equivalent), remove the (2) M3 nuts,

washers, and compression springs securing the load cell to the top

deck.

Plasma

Weigher

Assembly

Page 20

Chapter 2, Machine Part Replacement Reference 2-9

Load Cell Reassembly Notes

1. When routing the P506 wire, run the wire between the front panel and

the pinch valves. Do NOT run the wire between the backplane card

and the pinch valves. This could cause the machine to short out.

2. When attaching the load cell to the top deck, the spring fits over the

securing shaft first, then the washer and then the nut. When tightening

the nuts, tighten until nut is even with the bottom of stud. Turn nut six

more complete revolutions.

3. Recalibrate the weigher assembly following the procedure in Chapter

4, Calibration.

Load Cell Lo

wer Standoff Replacement

Note: The load cell lower standoff replacement should only be performed

by Haemonetics personnel.

1. Remove the load cell assembly. (See page 2-8.)

2. Using a 1/4" wrench, secure the load cell’s upper standoff and using a

5/64" hex wrench, remove the setscrew located inside the load cell’s

lower standoff. (Save this setscrew as it will be reinstalled in the

replacement standoff.)

3. Securing the upper standoff, unscrew and remove the lower standoff

from the load cell assembly.

Note: Do not remove the upper standoff from the load cell assembly.

Load Cell Lo

wer Standoff Reassembly Notes

1. When installing the replacement standoff, ensure that the standoff is

between the spring clip.

2. When securing the standoff to the load cell assembly, tighten the

upper standoff to the lower standoff until the entire assembly is hand

tight, and then secure the standoff assembly by tightening the setscrew

in the lower standoff using the 5/64" hex wrench.

3. Ensure that the upper standoff rotates smoothly and easily with a

slight click before reinstalling the load cell assembly.

4. Recalibrate the weigher assembly, following the procedure in Chapter

4, Calibration, after the load cell and weigher arm have been

reinstalled.

Pinch Valves

1. Remove the front panel. (See page 2-2.)

2. Using 11/16" wrench (or equivalent), remove (1) #8-32 nut securing

the ground wire of the valve to be removed to the ground lug.

Page 21

2-10 PCS2 Service Manual

3. Disconnect P608 for the Saline Valve, P609 for the Plasma Valve,

and/or P611 for the Donor Valve.

4. Using 11/16" wrench (or equivalent), remove (2) #8-32 nuts securing

the valve to the cabinet top deck.

5. Pull valve down through the top deck.

Note: The pinch valves’ harnesses may be tie-wrapped together. The tie-

wraps will need to be cut if the valve is to be removed.

Pinc

h Valve Reassembl

y Notes

1. Lightly lubricate the inside surface of the pinch valve gasket with

silicone vacuum grease.

2. Install the gasket into the cabinet with the ridged lip facing up.

3. Slide the pinch valve into the gasket and mount into place.

4. Wipe excess grease from the pinch valve.

5. The three pinch valves are identical. Be sure to install the electrical

connector in the proper location on the top deck distribution board.

P608 is the Saline Valve, P609 is the Plasma Valve, and P611 is the

Donor Valve.

AC/Blood Pump Assembly

1. Remove the rear panel. (See page 2-2.)

2. Disconnect P614 and P615 for the AC Pump, or P616 and P617 for

the Blood Pump from the top deck distribution board.

3. Remove the (4) Phillips screws securing the pump assembly to the top

deck.

4. Partially pull the pump assembly out of the top deck, and remove the

(1) Phillips head screw securing the ground wire to the pump motor.

A

C/Blood Pump Reassembly Notes

1. When placing the pump back into the top deck, assure the gasket is

between the top deck and the pump.

2. Ensure that the ground wire is reattached.

Rotor

1. Using a 5/32" hex wrench, remove the (1) #10-32 socket head screw

securing the pump rotor to the pump shaft.

2. Pull the rotor out of the pump housing.

Note: If the rotor cannot be removed easily, contact the Haemonetics Hot

Line. Serious damage may occur to the pump assembly if too much

force is used.

Page 22

Chapter 2, Machine Part Replacement Reference 2-11

Rotor Reassembly Notes

When placing the rotor back into the pump housing, ensure that the slot

on the underside of the rotor is aligned with the pin on the pump motor

shaft. Do NOT overtighten the rotor screw.

Motor

1. Remove the pump assembly. (See page 2-10.)

2. Remove the pump rotor assembly. (See page 2-10.)

3. Using a 7/64" hex wrench, remove the (4) #6-32 socket head screws

securing the pump housing to the pump motor. (Mark the position of

the motor on the pump housing. This is functionally unimportant but

will keep the reassembly process consistent).

4. Gently twist the pump head and lift it from the motor.

Caution: Do not attempt to disassemble the pump motor. Serious

damage to the motor may result.

SPM/DPM Sensor Assemb

ly

Note: List number 06002-110-NA machines do not have the SPM.

Note: The SPM/DPM is not utilized by the PCS2 safety system for

Platelet Poor Plasma (PPP) collection.

Note: With a thin wall socket, and a bit of experience, you may be able to

remove these sensors without removing the top deck.

1. Remove the rear panel. Remove the top deck (page 2-6) or remove the

Blood Pump Assembly.

2. Disconnect P603 (for the SPM) or P604 (for the DPM) from the top

deck distribution board.

3. Remove the ground wire from the SPM/DPM sensor assembly.

4. Remove the (2) nuts securing the SPM/DPM sensor assembly to the

top deck.

5. Pull the SPM/DPM sensor assembly out of the top deck.

Note: The procedures in steps 6 and 7 should not be performed unless the

SPM/DPM sensor board is being replaced.

6. With or without first removing the SPM/DPM sensor assembly from

the top deck, remove the (2) Phillips head screws securing the

SPM/DPM sensor board to the SPM/DPM sensor assembly.

7. Gently twist and pull the SPM/DPM sensor board from the

SPM/DPM pressure fitting.

8. We do not advise further disassembly of the SPM/DPM sensor

assembly.

9. If replacing the DPM, recalibrate the DPM and Safety System,

referring to the procedures in Chapter 4, Calibration.

Page 23

2-12 PCS2 Service Manual

1. Remove the front and rear panels. (See page 2-2.)

2. Using a #8 hex bit, remove the (4) shoulder screws securing the

centrifuge base to the centrifuge mounting fluid drain assembly.

3. Disconnect P404 and P406 from the centrifuge distribution card.

4. Disconnect the ground braid wire clamps Phillips head screws at the

rear of the cabinet.

5. Remove the (2) optic cables from the photoelectric assembly by

unscrewing the (2) plastic thumb screw fasteners.

6. If present, you may need to remove a retaining screw located at the

front, right side of the centrifuge mounting fluid drain assembly.

7. Disconnect the ground wire located in the rear of the centrifuge.

8. Disconnect J3 from the centrifuge controller card at the front of the

cabinet.

9. Carefully lift the centrifuge up and away from the top deck of the

cabinet.

Centrifug

e Reassembly Notes

1. The centrifuge must be centered in the top deck cavity to prevent contact

of the centrifuge with the cabinet during operation. If true centering cannot

be achieved, ensure that the centrifuge is at least 1/16" from the cabinet,

measured at four points separated by 90 degrees.

2. The centrifuge location is adjusted by loosening the four centrifuge

mounting screws under the cabinet, and manipulating the centrifuge

on the centrifuge mounting fluid drain assembly.

3. Install the centrifuge on the centrifuge mount, and tighten the four

shoulder screws.

4. Adjust the centrifuge location, then tighten the four screws and

recheck location of centrifuge.

5. Recalibrate the centrifuge and bowl optics, referring to the procedures

in Chapter 4, Calibration.

Co

ver Halves

1. Open the centrifuge cover halves.

2. Using a #8 hex bit, remove the (1) shoulder screw securing each cover

half and pull the cover away from the cover hinge.

3. The centrifuge cover halves are a matched pair. It is very important

that the components of each cover half are kept together if the cover

halves are to be disassembled further.

Centrifuge

Assembly

Page 24

Chapter 2, Machine Part Replacement Reference 2-13

Bushing Adjustment Kit

Note: For this procedure you should have the following equipment:

Screwdriver

1/8" L-hex wrench or equivalent

1/2" box wrench or equivalent

Primer “T” P/N 10425-01

Loctite #222 (purple) P/N 10422-00

Hinge Bushing Adjustment Kit P/N 38064-00

Torque wrench (set to 15/16 in./lb) with a regular 6-point 1/2" socket

Warning!

Primer “T” activator is flammable and may be harmful if it comes

in contact with skin or eyes. It is recommended that eye protection

and rubber gloves be worn when using Primer “T.” Do not use

near heat or an open flame.

1. Ensure the centrifuge cover is in the “unlocked” (or up) position.

2. Using the screwdriver, remove the two (2) headless shoulder screws at

the centrifuge cover hinge area. These are the screws that are set

inside the brass bushings. Apply the Primer “T” activator to the

screws and set them aside.

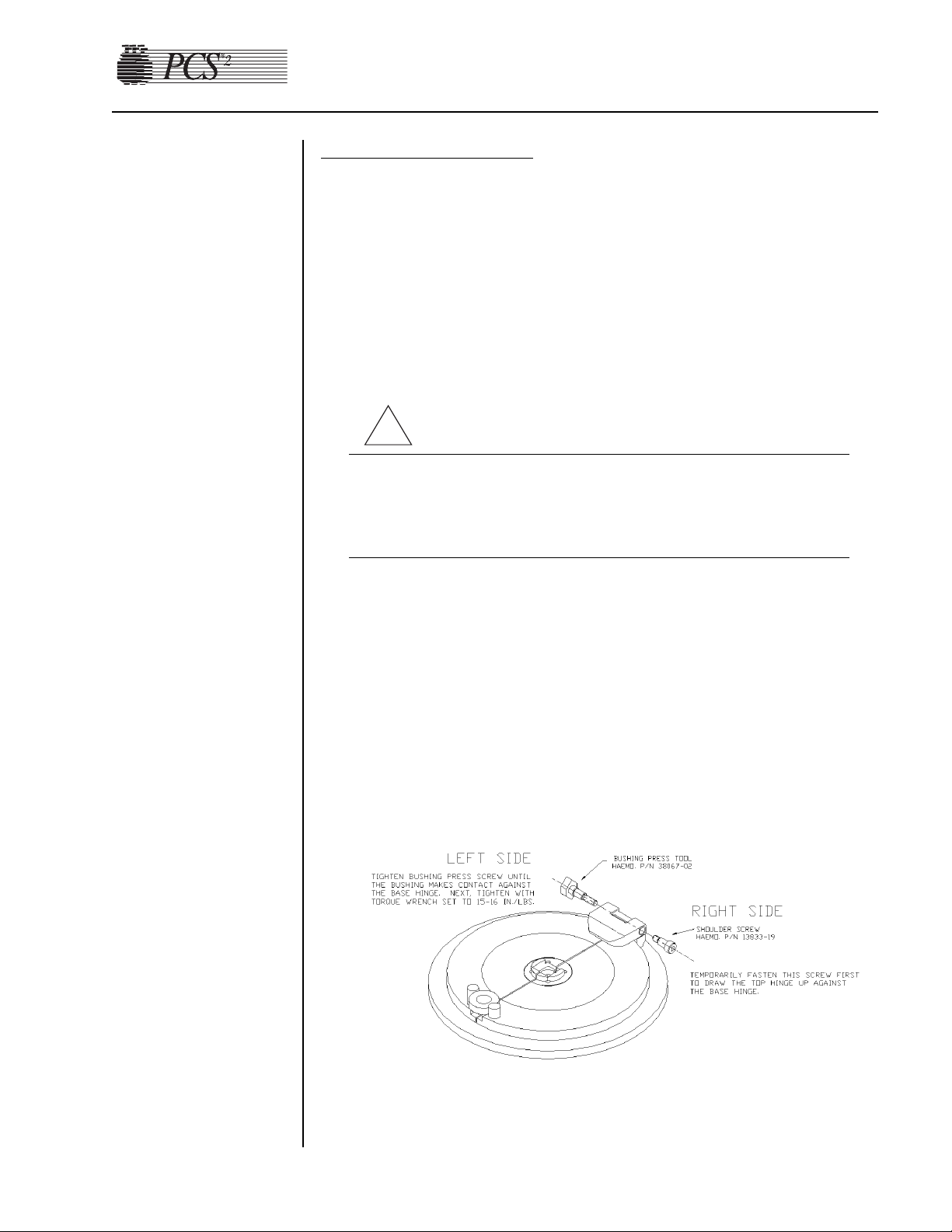

3. Using the L-Hex wrench, temporarily fasten the centrifuge cover

hinge on the right side with hex head shoulder screw, P/N 13833-19.

Tighten the screw until the top hinge is drawn up against the base

hinge. (See illustration below.)

!

Page 25

2-14 PCS2 Service Manual

4. Using the 1/2" box wrench, fasten the left side of the cover hinge

using the Bushing Press Tool, P/N 38067-02, and tighten until the

bushing makes contact against the base hinge. (This tool will

physically push the bushing into the cover hinge.) Next, tighten the

Bushing Press Tool with a torque wrench set to 15/16 in./lb., until the

click of the torque wrench is heard. This will ensure a firm press of

the bushing against the base hinge. (See illustration below.)

Warning!

Failure to use a torque wrench set to the correct torque could cause

damage to the bushings and render the centrifuge cover inoperable.

5. Check to make sure there is no side to side movement between the

centrifuge cover hinge and the base hinge.

6. Remove the Bushing Press Tool from the left side of the centrifuge

cover. Apply a couple of drops of purple Loctite to one of the

previously removed headless shoulder screws and install in the cover.

7. Remove the shoulder screw from the right side of the centrifuge cover.

Apply a couple of drops of purple Loctite to the previously removed

headless shoulder screws and install in the cover.

Centrifug

e Cover Reassembly Notes

1. The hex shoulder screws are designed to be completely tightened and

a nylon washer is fitted to provide a moderate amount of rotational

resistance for each cover half. In some cases, completely tightening

the shoulder screw may result in an immobile cover half due to an

oversized nylon washer. In either case, it is extremely important that

the shoulder screw is secured to the cover hinge with Loctite.

Otherwise the shoulder screw may loosen and cause the cover half to

vibrate.

2. Also, since the cover halves are hinged, they must be aligned so they

simultaneously touch the cover latch when closed.

3. First mount one cover half completely.

4. Lower the cover half and slide it closed against the cover latch.

5. Position the second cover half, with the nylon washer installed, along

the cover latch and the cover hinge.

6. Carefully slide the cover halves open (they are now geared), while

maintaining the proper cover hinge position, then raise the cover

halves.

7. Loctite and install the shoulder screw into the second cover half.

!

Page 26

Chapter 2, Machine Part Replacement Reference 2-15

8. Test the position of the two cover halves when closed against the

cover latch.

Cover Switch Assembl

y

1. Remove the centrifuge from the cabinet.

2. Remove the (2) #4 socket head screws or Phillips head screws

securing the cover switch assembly to the centrifuge well.

3. Pull the cover switch assembly away from the centrifuge well.

Co

ver Switch Reassembly Notes

1. The cover switch assembly mounting position is a calibration step.

2. Set switch engagement of cover switch assembly to the bottom of the

shaft so that there is 3/8 to 5/8 clockwise turn of the centrifuge knob

after both switches have been disengaged.

Cover Latch

Note: The cover latch is not designed for disassembly. These instructions

are provided in case the cover latch requires replacement.

1. Remove the knob disk. This can be accomplished by placing a thin

flat screwdriver in the gap between the knob disk and the knob and

tapping on the back of the handle of the screwdriver until the cap

detaches from the knob.

Note: The knob disk is loctited to the knob. It may be difficult to detach

and require more force to separate it from the knob. Do not worry

about damaging these components as they are going to be replaced.

2. Remove the centrifuge from the cabinet.

3. Remove the cover switch assembly from the centrifuge.

4. Remove the knob by unscrewing the retaining screw and unscrewing

the knob from the centrifuge lock shaft.

5. Twist the centrifuge shaft spacer counterclockwise using vice grips or

locking pliers. As the centrifuge shaft spacer is removed, the

centrifuge lock shaft will drop out from the bottom of the centrifuge

cap assembly. Save the spring for reuse with replacement parts.

6. Place the compression spring on the replacement lock shaft and insert

it into the centrifuge cap assembly.

7. Prime and loctite the lock shaft threads at the base only, and then

screw the centrifuge shaft spacer (threads up) on the lock shaft until

the spacer bottoms out. Be sure that no loctite is touching the

centrifuge cap assembly where the shaft and the spacer come into

contact with the centrifuge cap assembly.

Page 27

2-16 PCS2 Service Manual

8. Thread the large knurled centrifuge knob (flat side up) onto the lock

shaft.

9. Install the o-ring into the channel of the centrifuge knob cap. Apply a

light coating of vacuum grease or o-ring lubricant.

10. Apply a small amount of purple loctite onto the top of the lock shaft

and thread the knob cap onto the shaft. Tighten the cap down using a

small set of needle-nose or snap-ring pliers.

11. Close centrifuge cover halves to check the general operation of the

assembly.

12. Apply a small amount of green loctite to the underside edge of the

knob disk and set it onto the knob cap. Wipe off any excess loctite.

13. Install the cover switch assembly and calibrate the switch position.

14. Install the centrifuge into the cabinet.

Fluid Sensor Assembly

1. Remove the (1) center Phillips head screw from the fluid sensor

assembly pcb.

2. Gently twist the fluid sensor assembly out of the centrifuge well.

3. When reinstalling, place a bead of rtv around sensor housing to seal.

Note: Ensure that the rtv does not cover the face of the detector.

Bo

wl Optics Assembly

Note: Do not perform this procedure unless you have the necessary test

fixtures to realign after reassembly. (This includes the optical alignment

fixture and photographic gray card. See Chapter 4, Calibration.)

1. Remove the (1) Phillips head screw securing the ground to the optics

assembly.

2. Using a 1/4" wrench (or equivalent), remove the (4) #4-40 hex nuts

securing the optics assembly to the centrifuge well and pull off the (2)

wedge-shaped spacers.

3. Gently push the top of the optics assembly into the centrifuge well,

and guide the optics pipe through the cavity.

4. To remove the optics cable, firmly hold the optics assembly and, using

a locking plier, grip the brass threaded coupler and unscrew the optics

cable from the optics assembly.

5. Very carefully, remove any debris in the optics assembly (cable)

threaded hole. Any dried primer/Loctite could interfere with the

transmission of light.

Page 28

Chapter 2, Machine Part Replacement Reference 2-17

Bowl Optics Reassemb

ly Notes

Refer to Chapter 4, Calibration, to properly adjust and calibrate the optics

after reassembly.

1. Remove the front and rear panels. (See page 2-2.)

2. Disconnect P504 from the backplane card (located in the lower right

hand corner).

3. Disconnect the display ground wire from the ground bus on the

cabinet side (located on the left side when looking from the front of

the cabinet).

4. Remove the (2) lower Phillips head screws securing the membrane

panel ribbon cable to the upper deck (located above the card cage at

the rear of the cabinet).

5. Using a #10 hex bit, remove the (2) shoulder screws securing the top

cover assembly to the top deck while supporting the top cover assembly.

Membrane P

anel Assembly

1. Remove the (2) Phillips head screws securing the fiberglass decorative

panel to the top cover assembly (inside hinge area).

2. Remove the (3) Phillips head screws securing the membrane panel to

the top cover assembly.

3. Simultaneously pull the base of the membrane panel down and away

from the top cover assembly to disengage the top panel catches from

the catch plate.

4. Carefully pull the top of the membrane panel down to expose the

inner wiring of the membrane panel.

5. Remove the (1) Phillips head screw on the top cover, securing the

ground wire from the membrane panel to the top cover ground

surface.

6. Disconnect the ribbon cable from the card cage assembly by

following steps 1-4 of the disassembly instructions for the top cover

assembly or go to step 7.

7. Using a 1/4" wrench (or equivalent), remove the (2) #4-40 nuts

securing the ground from the ribbon cable to the top cover mounting

plate.

8. Using a 1/4" wrench (or equivalent), remove the (2) #4-40 nuts

securing the ribbon cable strain relief.

9. Disconnect P804 from the display distribution board.

Top Cover

Assembly

Page 29

2-18 PCS2 Service Manual

Control Panel Distribution Cable

Note: The old-style cable is a multicolored ribbon cable and the new-style

cable is a solid blue ribbon cable.

Remo

v

al of the old cable.

1. Remove front and rear panel assembly.

2. Remove decorative and membrane panel assembly.

3. Remove the old cable assembly and the two brackets, discard all three

components and retain the screws for use later.

4. Remove the retainer pad in the cover that the cable lay across and

discard.

5. Remove the two Allen shoulder screws that secure the top cover to the

deck.

6. Remove the two Phillips head screws holding the third cable bracket

attached to the top deck (above card cage), discard bracket and retain

screws for use later.

Installation of ne

w cable and parts.

1. Mount the body clamp (P/N 47132-02) to the deck using the two #632 x 3/8" long Phillips flat head screws (removed above) with a drop

of purple Loctite. (Orient so that the long step is toward the centrifuge

cut-out.)

2. Reinstall the top cover onto the top deck assembly, using the two

Allen head shoulder screws removed above.

Note: Reinstall all ground wires that may have been removed when

removing the old cable, except the ground wire with the old cable.

This ground wire and old cable are to be discarded.

3. On the membrane panel assembly, connect one end of the new

distribution cable assembly (35231-00) to the display dist. PCB

connector (P804). Secure the copper tape under the strain relief block

and secure with the two #6-32 small pattern keps nuts (removed

previously).

Note IMPORTANT: The strain relief block must be in the center of the

copper tape.

4. Install the new retainer pad (P/N 13549-02) onto the back of the

decorative panel, centered on the radius and aligned with the edge.

5. Cut the EMI shielding tape (P/N 47015-00) into two 2" ± ¼" pieces,

remove the protective paper from one piece and attach it lengthwise to

the top cover, gray portion at the bottom, align with the center of the

hinge nut plate and then affix onto the hinge nut plate about halfway

up the hinge.

Note: Make sure that the hole for the decorative panel is not covered.

Page 30

Chapter 2, Machine Part Replacement Reference 2-19

Remove the protective paper from the other piece of tape and attach it

in the same manner inline with the other hinge nut plate.

6. Reinstall the membrane panel onto the top cover.

7. Reinstall the decorative panel onto the top cover.

8. Cut double-sided tape (P/N 18142-00) to a length of 1½" ± ¼".

Adhere the tape to the underside of one of the EMI ferrite attenuators

(P/N 39475-00).

9. Sandwich the ribbon cable from the top cover assembly between the

attenuator with the tape and the attenuator (P/N 39475-00) without the

tape at approximately 4" ± ¼" from the end of the cable jacket.

Note: The attenuator with the tape must be toward the card cage.

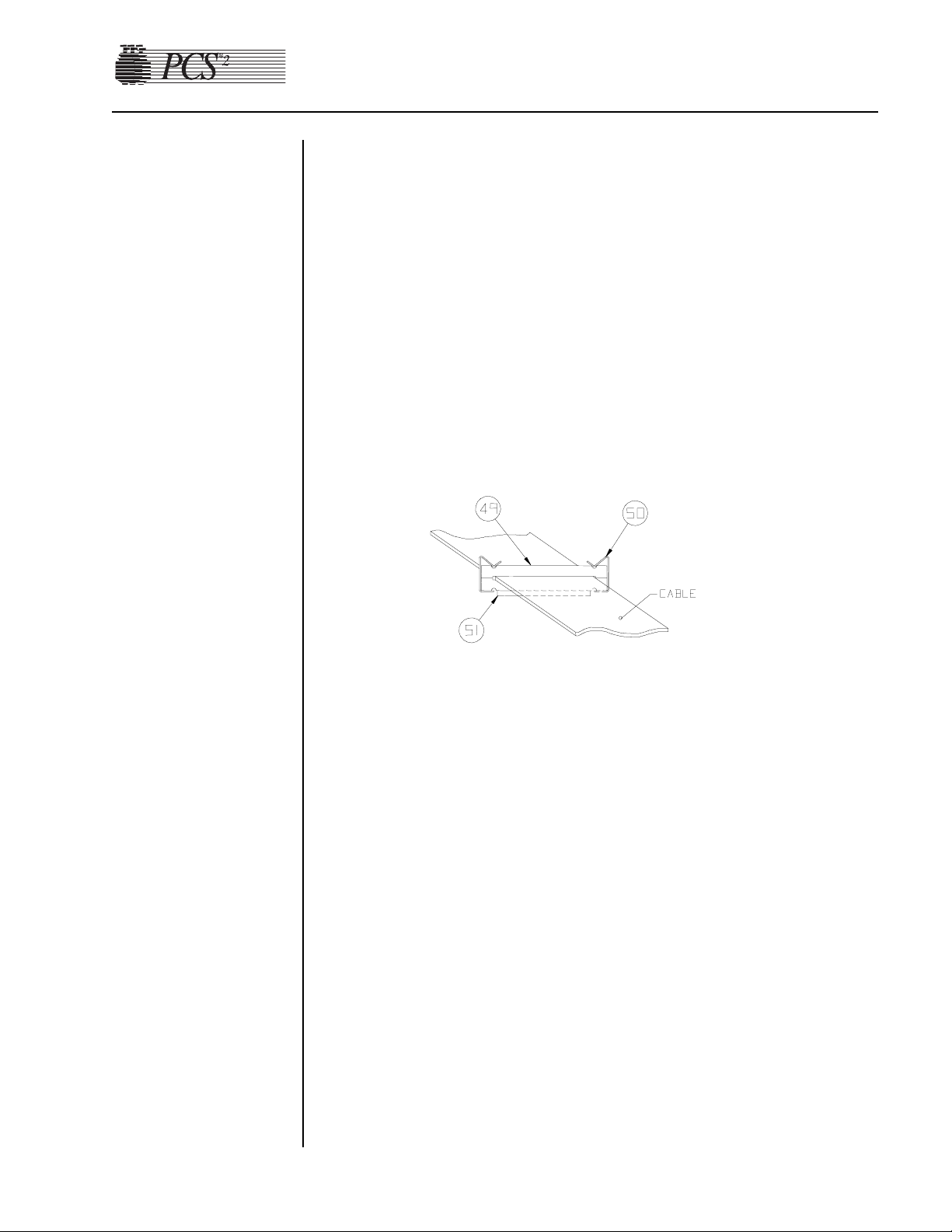

10. Install the two spring clips (P/N 47241-00) over each end as shown,

reference balloon #50.

Note: The flat end of the spring clip must be toward the card cage.

11. Remove the protective paper from the tape on the attenuator and

adhere the attenuator assembly with the ribbon cable to the top of the

card cage.

Note: Do not cover slots in top of card cage.

12. Apply purple Loctite to the threads of the two #6-32 x 3/8" Phillips

flat head screws (removed previously). Make sure the ribbon cable

from the cover assembly is centered in the deck body clamp and

secure the copper tape of the cable assembly under the strap clamp

(P/N 47133-02) and secure in place with the Loctited screws.

Note IMPORTANT: The copper tape must be centered in the strap

clamp.

13. Reinstall cable connector into the backplane card.

14. Complete a Diagnostic and Functional Test according to the

procedure outlined in Chapter 3.

Page 31

2-20 PCS2 Service Manual

Display Distribution Board

1. Remove the membrane panel assembly from the top cover assembly.

(See page 2-17.)

2. Disconnect P801 and P804 from the display distribution board.

3. Place the membrane panel on a flat level surface and remove the (4)

Phillips head screws securing the display distribution board to the top

cover mounting plate.

4. Carefully pry the display distribution board up to disconnect the

display distribution board from the membrane panel at P803.

Vacuum Display

1. Remove the membrane panel assembly from the top cover assembly.

(See page 2-17.)

2. Disconnect CN1 and CN2 from the vacuum display.

3. Place the membrane panel on a flat level surface and remove the (4)

Phillips head screws securing the vacuum display to the top cover

mounting plate.

4. Carefully lift the vacuum display up and away from the top cover

mounting plate.

Membrane Panel

1. Remove the membrane panel assembly from the top cover assembly,

and remove the display distribution board from the top cover

mounting plate.

2. Using a 1/4" wrench (or equivalent), remove the (6) perimeter #6-32

small pattern nuts securing the top cover mounting plate to the top

cover panel fascia.

3. Using a 1/4" wrench (or equivalent), remove the (1) #6-32 small

pattern nut securing the membrane panel ground strap to the

membrane panel mounting lug and pull the ground strap off the lug.

4. Using a 5/16" wrench (or equivalent), remove the (7) perimeter and

(1) central #6-32 small pattern nuts, and the (1) #6-32 nut securing the

membrane panel to the top cover mounting plate.

5. Pull the top cover mounting plate away from the top cover panel

fascia.

6. Remove the nylon spacer and washer from the central membrane

panel mounting lug. Save the nylon spacer and washer for reuse with

the replacement membrane panel.

7. Using considerable force, peel the membrane panel edges away from

the top cover panel fascia and push the membrane panel through the

top cover panel fascia. The membrane panel cannot be reused.

Page 32

Chapter 2, Machine Part Replacement Reference 2-21

Power Supply

Assembly

1. Remove the rear panel. (See page 2-2.)

2. Using a 1/4" wrench (or equivalent), remove (2) #4-40 nuts on either

side of the power input module.

3. Disconnect the left top (blue) and bottom (brown) AC power lines

from the power input module and disconnect the ground lug from the

ground bus on the cabinet.

Fuse

1. Pry above the power switch on the power entry module to open the

fuse cover.

2. Pry out each fuse holder.

3. Replace with same size and rating fuse (5a 250V).

Fuse Holder Reassembly Notes

When replacing fuse holders, be sure arrows on fuse holder and power

input module face the same direction.

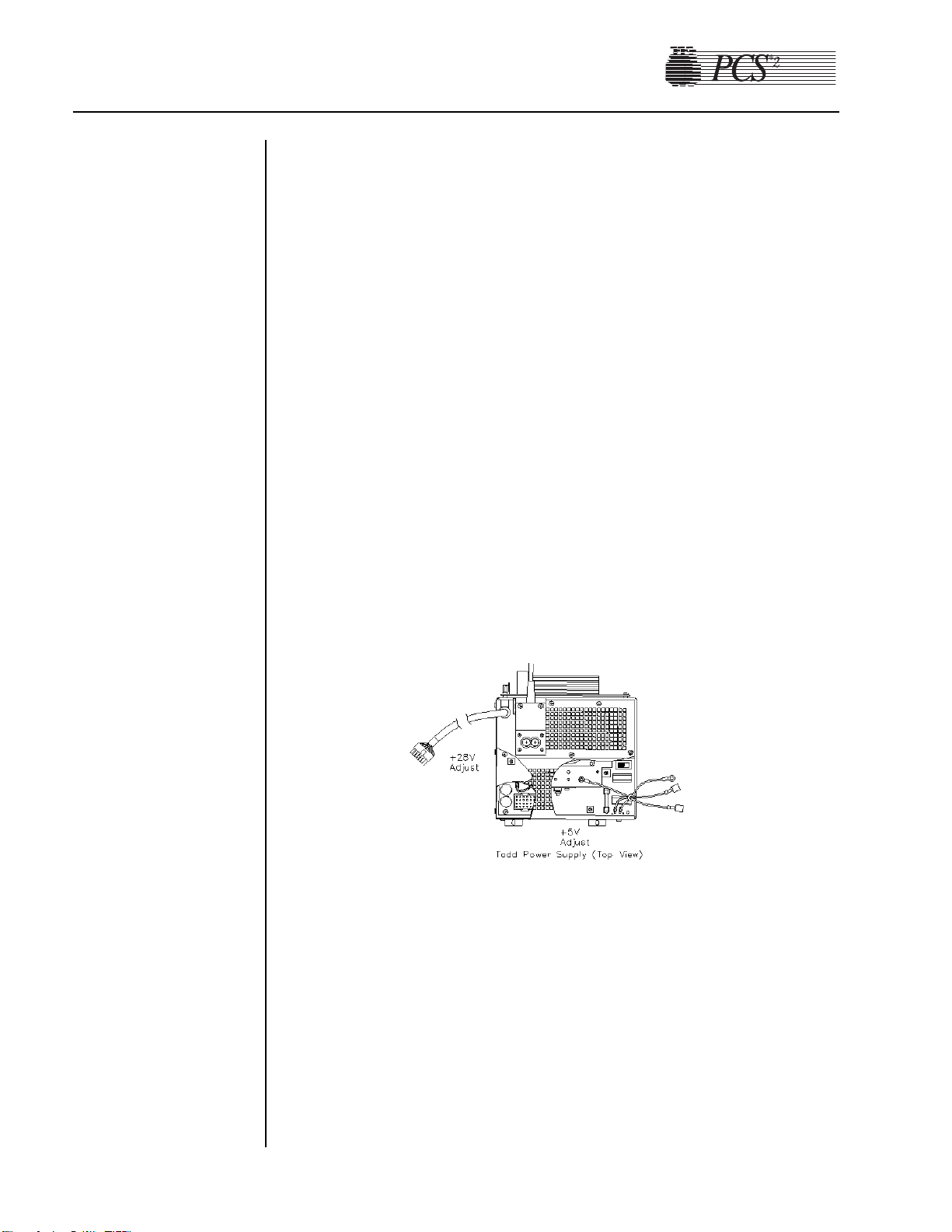

Replace T

odd Po

wer Supply with Todd Power Supply

Note: Use the following directions if replacing a Todd power supply (P/N

18878-00) with another Todd power supply.

1. Remove the front and rear panels. (See page 2-2.)

2. Disconnect P1, P2, and P3 from the centrifuge controller card.

3. Disconnect P405 from the centrifuge distribution card and thread the

cable through the cabinet to the photoelectric assembly.

4. Disconnect P507 from the backplane card.

5. Remove the (4) Phillips head screws securing the power supply cage

access panel, and remove the panel (located at the rear of the cabinet).

6. Using a 11/32" wrench, remove the (2) #8-32 hex nuts securing the

line conditioner to the cabinet, and pull the line conditioner away

from the cabinet.

7. Unplug the L (brown, located on the left) and N (blue, located on the

right) AC power lines from the power supply.

8. Using a 5/16" wrench, disconnect the (1) #6-32 nut and ground from

the power supply fan.

9. Remove the (2) optic cables from the photoelectric assembly by

unscrewing the (2) plastic thumb screw fasteners.

10. Remove the (2) Phillips head screws securing the power supply cage

to the cabinet.

11. Pull the power supply cage out the rear cabinet cavity by lifting the

rear edge and pulling the front edge away from the plastic edge clips

on the cabinet base.

Power Entry

Module

Page 33

2-22 PCS2 Service Manual

12. Remove the (6) Phillips head screws securing the power supply top

cage to the power supply frame.

13. Disconnect P1 on the power supply. This is not an easy job. Take great

care not to dislodge any cables from the P1 connector.

14. Remove the (4) Phillips head screws securing the power supply to the

power supply frame.

15. Lift the power supply away from the power supply frame. Do not

remove the fan. It cannot be replaced separately from the power

supply.

16. Recalibrate the Todd Power Supply, referring to the procedure in

Chapter 4, Calibration.

T

odd Po

wer Supply Reassembly Notes

1. Partially insert the power supply cage into the cabinet from the rear

cavity, and then align the frame with the plastic edge clips from the

front cavity.

2. Be sure to insert the AC wires from the line filter into the rubber

grommet, and insert the grommet into the power supply cage.

Replace Todd Power Supply with Condor Power Supply

Note: Use the following directions if replacing a Todd power supply

assembly (P/N 37121-00) with a Condor power supply assembly

(48895-00).

1. Remove front and rear panels. (See page 2-2.)

2. Remove the Todd power supply. (See page 2-21, steps 2 through 11.)

Note: Removal of the power supply board from the power supply cage is

not necessary. The Condor power supply assembly replaces the

power supply board and the cage. However, the AC lines (L and N

wires) need to be removed from the line conditioner and the power

supply ground wire needs to be removed from the GND terminal

block of the PCS2 cabinet.

3. Remove the centrifuge controller card from the power supply cage.

(See page 2-24.)

4. Remove the photoelectric assembly from the power supply cage. (See

page 2-24.)

5. Attach the centrifuge controller card on the (4) standoffs located on

the right hand bracket of the Condor power supply assembly using the

same (4) Phillips head screws.

Note: The heatsink, the long, rectangular black component, on the

centrifuge controller card is located toward the bottom of the frame

Page 34

Chapter 2, Machine Part Replacement Reference 2-23

when the card is mounted. If the heatsink is located toward the top

of the frame, there will not be enough slack in the harnesses to reconnect P1, P2, and P3.

6. Mount the photoelectric assembly to the power supply plate of the

Condor power supply assembly using the same (2) Phillips head

screws.

Note: Mount the photoelectric assembly with the harness, P405, facing

the same direction as the Condor power supply harness, P507.

7. Remove the protective label on the back of the cord clip and affix the

cord clip to the side of the cabinet above the line conditioner.

8. Partially insert the power supply assembly into the cabinet from the

rear cavity, and then align the frame with the plastic edge from the

front cavity. Align the rear brackets of the power supply with the two

threaded holes of the cabinet’s bottom panel and secure the power

supply assembly to the cabinet by using the (2) Phillips head screws.

9. Connect the 3 wire harness assembly (AC lines) on the power supply

as follows: Quickslide (blue wire) to N terminal of the line

conditioner, Quickslide (brown wire) to L terminal of the line

conditioner and attach the green wire to the GND terminal block of

the PCS2 cabinet using (1) Phillips head screw and star washer.

10. Reattach P1, P2, and P3 to the centrifuge controller card.

11. Reattach the fiber-optic cables to the photoelectric assembly by

unwrapping the cables around the centrifuge and running them

through the cord clip to the photoelectric assembly.

12 Reattach P405 to the centrifuge distribution card.

13. Reattach P507 to the backplane board.

14. Recalibrate the Condor power supply referring to the procedure in

Chapter 4, Calibration.

Replace Condor Power Supply with Condor Power Supply

Note: Use the following directions if removing a Condor power supply

(P/N 48102-00).

1. Remove front and rear panels. (See page 2-2.)

2. Disconnect P1, P2, and P3 from the centrifuge controller card.

3. Disconnect P405 from the centrifuge distribution card and thread the

cable through the cabinet to the photoelectric assembly.

4. Disconnect P507 from the backplane card.

5. Unplug the L (brown) and N (blue) AC power lines and the Ground

wire from the back of the power supply.

6. Remove the two (2) optic cables from the photoelectric assembly by

unscrewing the two (2) plastic thumb screw fasteners.

Page 35

2-24 PCS2 Service Manual

7. Remove the (2) Phillips head screws securing the power supply

assembly to the cabinet.

8. Pull the power supply assembly out the rear cabinet cavity by lifting

the rear edge and pulling the front edge away from the plastic edge

clips on the cabinet base.

9. Remove the two (2) Phillips head screws securing the left hand

bracket to the power supply.

10. Remove the four (4) Phillips head screws securing the right hand

bracket to the power supply.

11. Slide the power supply away from the power supply mounting frame.

12. Recalibrate the Condor power supply referring to the procedure in

Chapter 4, Calibration.

Centrifuge Controller Card

1. Remove front and rear panels. (See page 2-2.)

2. Disconnect P1, P2, and P3 from the centrifuge controller card.

3. Remove the (4) Phillips head screws securing the centrifuge controller

card to the power supply assembly cage.

4. Recalibrate the centrifuge referring to the procedure in Chapter 4,

Calibration.

1. Remove the rear panel. (See page 2-2.)

2. Remove the (2) Phillips head screws securing the AC or saline pole

holder assembly to the cabinet.

1. Tilt the cabinet and remove the (4) Phillips head screws securing the

spill bag plate to the base of the cabinet.

2. Carefully cut the tubing from the drain tube.

3. Replace with new drain tube assembly.

1. Remove the rear panel. (See page 2-2.)

2. Disconnect P405 from the centrifuge distribution card.

3. Remove the (2) fiber-optic cable ends from the photoelectric assembly

by unscrewing the (2) plastic thumb screw fasteners.