Page 1

Haemonetics® ACP™215

Automated Cell Processing System

– Operation Manual –

0123

Printed in France

Haemonetics Corporation

400 Wood Road, Braintree, MA 02184, USA P/N 85271-30, Manual revision: C

©2003, Haemonetics International. All rights reserved. January 2003

Page 2

Page 3

Preface iii

CONSUMER INFORMATION

Proprietary rights The contents of this manual are property of the Haemonetics

Haemonetics

Corporation. Any information or descriptions contained in this manual may not

be reproduced and released to any of the general public, or used in conjunction

with any professional instruction without written consent of Haemonetics Corporation, USA. Please direct any written inquiries to the appropriate address:

International Headquarters Corporate Headquarters

Haemonetics SA Haemonetics Corporation

Signy Centre, rue des Fléchères 400 Wood Road

P.O. Box 262, 1274 Signy 2, Switzerland Braintree, MA 02184, USA

Tel. [+41 22] 363 90 11 Tel. [+1 781] 848 7100

Fax [+41 22] 363 90 54 Fax [+1 781] 848 5106

®

and ACP™215 are registered trademarks of the Haemonetics

Corporation.

Legal disclaimer This manual is intended for use as a guide, uniquely for material as supplied by

the Haemonetics Corporation. It provides the operator with necessary information to safely carry out specific procedures and satisfactorily maintain Haemonetics produced equipment. The manual is to be used in conjunction with

instruction and training as supplied by qualified Haemonetics personnel.

Haemonetics guarantees its products when correctly used by a properly trained

operator. Any failure to respect the procedures as described could result in

impaired function of the equipment, as well as in injury to the operator. Haemonetics accepts no responsibility for problems resulting from failure to comply with

prescriptions as outlined by the company. Any modifications estimated as necessary by the customer should be evaluated by a Haemonetics Clinical Specialist.

Safe utilization of Haemonetics material and equipment requires the operator to

correctly handle and dispose of blood-contaminated material. The operator of

any Haemonetics equipment is responsible for understanding and implementing

the local policies and standard operating procedures concerning the handling of

blood-contaminated material, as well as blood products.

It remains solely the responsibility of the customer to fully assess and ensure the

safety of any products obtained from Haemonetics prescribed procedures, prior

to further application or use. Haemonetics declines any responsibility for choices

made by the customer concerning the utilization of products and by-products.

P/N 85271-30, Manual revision: C

Page 4

iv Preface

Haemonetics worldwide locations

Haemonetics Asia Inc.

Taiwan Branch

26F-1, No. 102 Roosevelt Road Sec. 2

Taip ei, Taiwa n

Tel. [+886 2] 2369 0722

Fax [+886 2] 2364 3698

Haemonetics GesmbH

Handelsges.m.b.H.

Berlagasse 45/B2-02

1210 Wien, Austria

Tel. [+43 1] 294 29 00

Fax [+43 1] 294 29 05

Haemonetics Belgium NV

Leuvensesteenweg 542-BP. 14

Planet II Complex

1930 Zaventem, Belgium

Tel. [+32 2] 720 7484

Fax [+32 2] 720 7155

Haemonetics BV

Naritaweg 16

Telestone 8

1043 BW Amsterdam

The Netherlands

Tel. [+31 35] 602 3425

Fax [+31 35] 602 4198

Haemonetics Medical Devices

(Shanghai) International

Trading Co. Ltd.

Room 28032, Shanghai HSBC Tower

101 Yin Cheng East Road

Shangai 200120, PRC

Tel. [+86 21] 5066 3366

Fax [+86 21] 6841 3688

Haemonetics CZ, spol. s r.o.

Ptašínského C.8

60200 Brno, Czech Republic

Tel. [+42 05] 4121 2400

Fax [+42 05] 4121 2399

Haemonetics France S.A.R.L.

46 bis, rue Pierre Curie

Z.I. Les Gatines

78370 Plaisir, France

Tel. [+33 1] 30 81 41 41

Fax [+33 1] 30 81 41 30

Haemonetics GmbH

Rohrauerstrasse 72

81477 München, Germany

Tel. [+49 89] 785 8070

Fax [+49 89] 780 9779

Haemonetics Hong Kong Ltd.

Suite 1314, Two Pacific Place

88 Queensway, Hong Kong

Tel. [+852] 2868 9218

Fax [+852] 2801 4380

Haemonetics Italia S.R.L.

Via Donizetti 30

20020 Lainate (MI), Italy

Tel. [+39 2] 9357 0113

Fax [+39 2] 9357 2132

Haemonetics Japan K.K.

Kyodo Building 3F

16, Ichiban-cho, Chiyoda-ku

Tokyo, Japan, 102-0082

Tel. [+81 3] 3237 7260

Fax [+81 3] 3237 7330

Haemonetics Scandinavia AB

Beta Huset, Ideon

Scheelegatan 17

223 70 Lund, Sweden

Tel. [+46 46] 286 2320

Fax [+46 46] 286 2321

Haemonetics (UK) Ltd.

Beechwood House

Beechwood Estate

Elmete Lane, Roundhay

Leeds LS8 2LQ, United Kingdom

Tel. [+44 113] 273 7711

Fax [+44 113] 273 4055

Haemonetics SA

Signy Centre, rue des Fléchères

P.O. Box 262

1274 Signy 2, Switzerland

Tel. [+41 22] 363 90 11

Fax [+41 22] 363 90 54

P/N 85271-30, Manual revision: C

Page 5

Table of Contents

Chapter 1 Explaining General Information

Providing an overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What is the ACP 215 system ? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What is the purpose of this manual ? . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What is required to perform a procedure ? . . . . . . . . . . . . . . . . . . . . . . . 1-2

Understanding the use of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Symbols found in this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Symbols found on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Symbols found on disposable packaging . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Listing ACP 215 device specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Dimensions and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2 Presenting the ACP 215 Equipment

DESCRIBING THE ACP 215 CONTROL PANEL. . . . . . . . . . . . . . . . . . . . . . 2-3

Display screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

DESCRIBING THE ACP 215 CABINET COMPONENTS . . . . . . . . . . . . . . . . 2-4

Centrifuge system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Pressure monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Air detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Optical line sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Solution bag pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Power entry module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Power cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Biohazard waste bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

DESCRIBING THE SHAKER AND THE PRINTER . . . . . . . . . . . . . . . . . . . . . 2-8

Shaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

P/N 85271-30, Manual revision: C

Page 6

vi Table of Contents

Chapter 3 Maintaining the ACP 215 Equipment

CLEANING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Listing tools and cleaning supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Exterior surfaces, valves, shaker and printer . . . . . . . . . . . . . . . . . . . . . . 3-3

Pressure monitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Air detectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Optical line sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Fluid detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Centrifuge components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Filter screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

CUSTOMER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Clinical training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Field service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Returned Goods Authorization system . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Haemonetics

®

Cleaning and maintenance record . . . . . . . . . . . . . . . . . 3-8

Chapter 4 Ensuring Safety and Quality for an ACP 215

Procedure

HANDLING THE ACP 215 EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Storing the device and material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Inspecting the material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

PREVENTING PROBLEMS DURING AN ACP 215 PROCEDURE . . . . . . . . 4-3

Understanding the risk of hemolysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Avoiding the consequences of flow restriction . . . . . . . . . . . . . . . . . . . . 4-3

Avoiding bowl misalignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Avoiding overheating due to mechanical situations . . . . . . . . . . . . . . . . 4-4

WARNINGS FOR THE OPERATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Electrical shock hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Leakage current control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Mechanical hazards/rotating parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Power outlet connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Communicable disease precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Chapter 5 Troubleshooting for the ACP 215 Device

LISTING SYSTEM ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

LISTING INTERRUPT SAFETY SYSTEM MESSAGES . . . . . . . . . . . . . . . . . . . 5-5

P/N 85271-30, Manual revision: C

Page 7

Chapter 1

Explaining General Information

Providing an overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What is the ACP 215 system ?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What is the purpose of this manual ?. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

What is required to perform a procedure ? . . . . . . . . . . . . . . . . . . . . . . . 1-2

Understanding the use of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Symbols found in this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Symbols found on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Symbols found on disposable packaging. . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Listing ACP 215 device specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Dimensions and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

P/N 85271-30, Manual revision: C

Page 8

1-2 Explaining General Information

PROVIDING AN OVERVIEW

What is the ACP 215 system ?

What is the purpose of this manual ?

In the tradition of its innovative technology, Haemonetics has produced the

ACP 215 - a compact, lightweight, automated cell processing system which is

simple to operate.

The ACP 215 system can perform the following types of procedures:

! Prepare collected red blood cell products with glycerol for freezing.

! Deglycerolize thawed red blood cell products, removing extra cellular

components, and resuspend the red blood cells in an additive solution.

! Wash red blood cell units stored in commonly used AC and additive solu-

tions to remove plasma and extra cellular components.

The ability to process-control the addition and removal of cryroprotectant solution as well as wash banked blood in a closed system significantly improves the

safety and availability of blood products.

This manual is intended to supply anyone involved in using the ACP 215 equipment with information to attain:

! An awareness of the purpose of the device and the implications of its

procedures.

! An understanding of how to safely operate the system, correctly install the

appropriate disposable material, and troubleshoot any difficulties.

! An ability to consistently apply the principles behind safe operation,

What is required to perform a procedure ?

P/N 85271-30, Manual revision: C

The following material is required to perform an ACP 215 procedure:

! The ACP 215 device, to process the collected red blood cell products.

! A dedicated shaker, to properly mix the blood with procedure-specific

! A disposable set designed for the selected procedure.

! Appropriate solutions.

! A printer, to provide the operator with printed procedure data.

! A sterile connection device, to ensure proper tubing welds.

proper maintenance and correct handling, to ensure optimal results.

solutions.

Page 9

Explaining General Information 1-3

UNDERSTANDING THE USE OF SYMBOLS

Symbols found in this document

Symbols found on the device

The terms Note, Caution and Warning are used in this manual with the following

symbols to emphasize certain details for the operator.

Note: provides useful information regarding a procedure or operating technique

when using Haemonetics material.

Caution: advises the operator against initiating an action or creating a situation which could result in damage to equipment, or impair the quality of the

by-products; personal injury is unlikely.

Warning: advises the operator against initiating an action or creating a situation

which could result in serious personal injury to either the operator or the

recipient of the product.

! Text preceded by this bullet indicates an action for the operator.

" Text preceded by this bullet indicates an item on a list of information for

the operator.

The following symbols are found on the ACP 215 device.

Typ e B

Protection against electric shock, particularly regarding: allowable leakage current and reliability of the protective earth

connection.

~

Protective earth (ground)

Used to identify any terminal intended for connection to an

external conductor, for protection against electrical shock in

case of a fault.

Alternating current

Used to indicate on the rating plate that the device is suitable for

alternating current only.

Fuse symbol

Used to identify fuse boxes or the location of a fuse box.

P/N 85271-30, Manual revision: C

Page 10

1-4 Explaining General Information

Power OFF

Position of the main power switch indicating disconnection from

the mains.

Power ON

Position of the main power switch indicating connection to the

mains.

Protection against ingress of liquid

IPX1

Indicates that the enclosure of the device is designed to provide

a specified degree of protection against harmful ingress of water

or liquid into the equipment (under applicable conditions).

Attention (Consult accompanying documents)

Symbols found on

disposable packaging

The following symbols are used by Haemonetics on disposable set packaging.

REF

LOT

STERILE EO

STERILE

EO

Catalog number

Expiration date

Lot Number

Contents sterile by exposure to ethylene oxide

Fluid path sterile by exposure to ethylene oxide

STERILE R

P/N 85271-30, Manual revision: C

Contents sterile by exposure to gamma irradiation

Page 11

Explaining General Information 1-5

STERILE R

-yy˚C

yy˚C

Fluid path sterile by exposure to gamma irradiation

Do not reuse

Caution: consult operator manual for instructions

KEEP DRY [storage conditions]

Storage conditions, temperature level

P/N 85271-30, Manual revision: C

Page 12

1-6 Explaining General Information

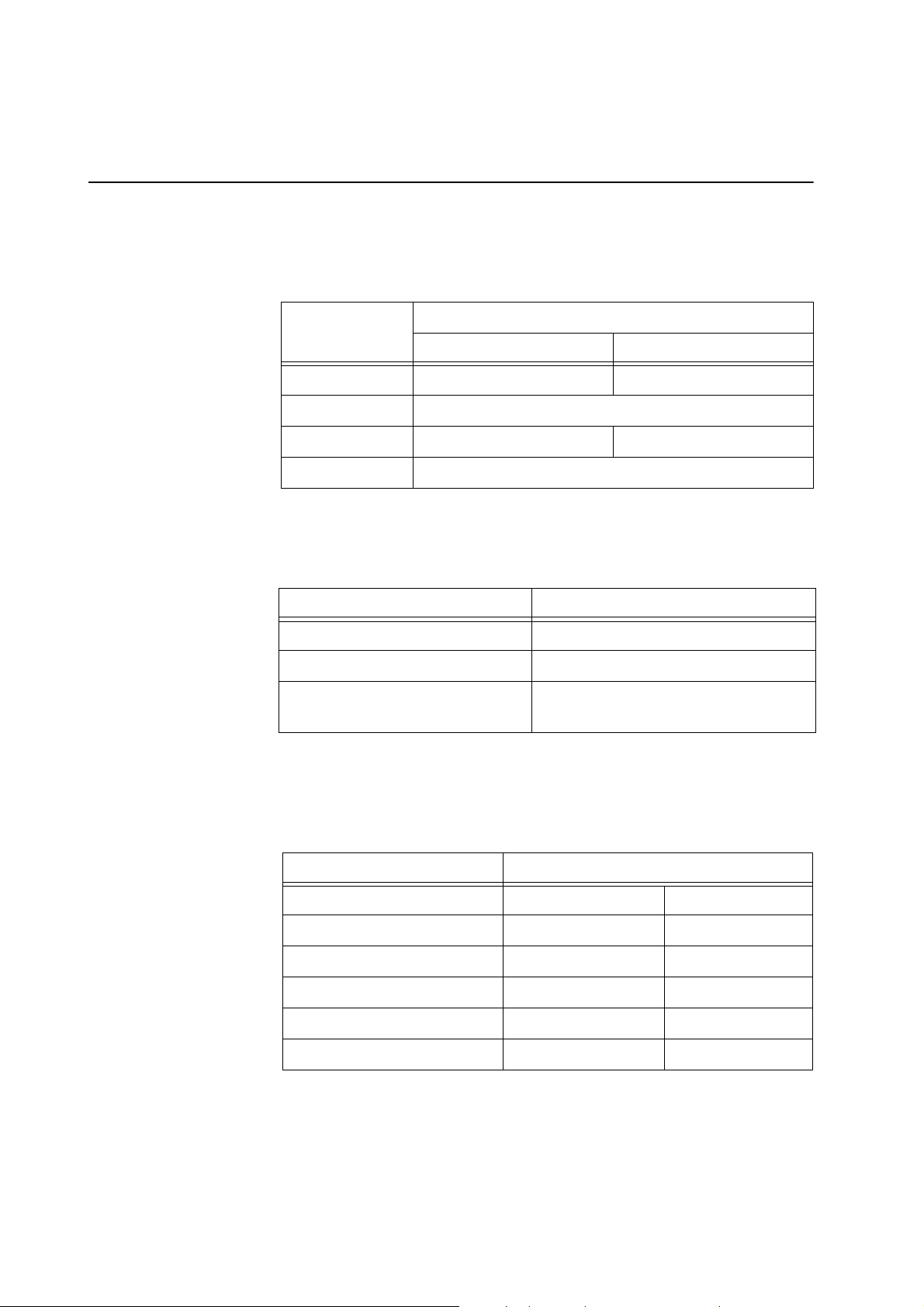

LISTING ACP 215 DEVICE SPECIFICATIONS

Dimensions and weight

Environmental conditions

The approximate weight and dimensions of the ACP 215 device are as follows:

Value (approximate)

Characteristic

Cabinet cover open Cabinet cover closed

Height 67.5 cm [26.5 inches] 43 cm [17 inches]

Width 55 cm [21.5 inches]

Depth 55 cm [21.5 inches] 30.5 cm [12 inches]

Weight 25 kg [56 lb]

The following environmental conditions should be respected pertaining to operation and storage of the ACP 215 device.

Condition Value

Operating Temperature 18° C to 35° C

Humidity 95% maximum, non-condensing

Tested storage temperature range 5° C to 45° C, non-condensing environ-

ment

Power requirements

P/N 85271-30, Manual revision: C

The power is supplied to the device from an external AC power source. The

power source must be properly grounded. Haemonetics will regulate the proper

voltage setting upon installation.

Characteristics Values (relative to input voltage)

Input voltage 230 VAC ± 10% 110 VAC ± 10%

Operating current ~1.9 A ~ 2.6 A

Maximum input current 2.5 A 5.0 A

Fuse rating F2.5 A @ 250 V F5.0 A @ 250 V

Operating frequency range 50 - 60 Hz 50 - 60 Hz

Maximum leakage current 500 µA 100 µA

Page 13

Explaining General Information 1-7

Caution: The ACP 215 device must be operated in an environment compatible to

the requirements of the IEC 60601-1-2 Standard, Electromagnetic compatibility.

Mobile RF communication equipment not approved by Haemonetics and

portable communication equipment can affect the ACP 215 device. Any accessories and cables not approved by Haemonetics used in conjunction with the

device may increase hazards and influence compatibility with EMC requirements. Therefore, non-approved accessories and cables must not be used.

In addition, the ACP 215 device and accessories must not be placed directly adjacent to, or top of other equipment, unless specifically approved by Haemonetics.

P/N 85271-30, Manual revision: C

Page 14

Page 15

Chapter 2

Presenting the ACP 215 Equipment

DESCRIBING THE ACP 215 CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . 2-3

Display screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

DESCRIBING THE ACP 215 CABINET COMPONENTS . . . . . . . . . . . . . . . . 2-4

Centrifuge system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Pressure monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Air detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Optical line sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Solution bag pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Power entry module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Biohazard waste bag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

DESCRIBING THE SHAKER AND THE PRINTER . . . . . . . . . . . . . . . . . . . . . 2-8

Shaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

P/N 85271-30, Manual revision: C

Page 16

2-2 Presenting the ACP 215 Equipment

P/N 85271-30, Manual revision: C

Figure 2-1, The ACP 215 device with the shaker

Page 17

Presenting the ACP 215 Equipment 2-3

DESCRIBING THE ACP 215 CONTROL PANEL

The control panel is located on the inside of the ACP 215 cabinet cover. It consists

of a display screen and a keypad, containing groups of keys used to operate the

device. There is a protective plastic coating on the keypad, which allows for efficient cleaning and disinfecting.

Display screen The ACP 215 display screen provides procedural information and posts the

volume of the processed solutions, pump speed, and procedure time. It is used

to guide the operator through the procedure and display warning messages.

1. Display screen

2. Start/Stop keys

3. Pump control keys

4. Programming keys

5. Shaker key

1.

2.

3.

Figure 2-2, ACP 215 control panel

Keypad START and STOP keys

These two keys are active throughout the entire procedure and will provide the

operator with the basic control of starting or interrupting the procedure.

PUMP control keys

These keys allow the operator to START, to STOP, or to increase (arrow up) or

decrease (arrow down) the speed of the pumps during a procedure. The pump

control keys are active when the pump is actually rotating.

PROGAMMING keys

The MODIFY PROGRAM, YES, NO, SAVE PROGRAM keys will allow the operator to adjust a limited set of parameters, which are presented in each relevant

procedure operation manual.

SHAKER key

This key is used only to start and stop the shaker; speed or amplitude cannot be

modified.

5.

4.

P/N 85271-30, Manual revision: C

Page 18

2-4 Presenting the ACP 215 Equipment

DESCRIBING THE ACP 215 CABINET COMPONENTS

1. Centrifuge system

2. Solution pump

3. Blood pump

4. DPM

5. SPM

6. Red valve

7. White valve

8. Green valve

9. Blue valve

10. Yellow valve

11. Orange valve

12. SLAD

13. BLAD

14. Line Sensor

15. Solution bag pole

2.

3.

4.

12.

13.

6. 7.

11.

10.

9.

1.

14.

5.

8.

Figure 2-3, ACP 215 top deck view

15.

Centrifuge system

The centrifuge chuck, seated in the centrifuge well, is designed to hold the

disposable blow molded bowl (BMB) in place during operation and spin the bowl

up to 8000 revolutions per minute (rpm).

The centrifuge lid, referred to as the cover, contains a locking knob; it will secure

the disposable bowl in the chuck while isolating the spinning bowl from the operator. The centrifuge drain tube, located at the rear of the device, must be

connected at all times to the biohazard waste bag supplied by Haemonetics.

When installing a bowl, the operator should exert a downward pressure on the

head of the bowl and ensure that the bowl is completely seated. The bowl will

be completely secured once the operator has locked the centrifuge lid.

To remove a bowl at the end of a procedure, the operator should open the centrifuge lid and pull upward on the bowl.

Warning: It is unlikely that a properly installed centrifuge bowl will become

unaligned as it spins. If the operator does notice anything unusual, under no

circumstances, should the operator attempt to open the centrifuge lid if the

bowl is still spinning. The bowl must come to a complete stop before attempting

to open the centrifuge for any reason.

Fluid detector

The centrifuge well is equipped with an electronic fluid detection system

designed to detect the presence of liquid. The detector is mounted on the wall of

the centrifuge well. The ACP 215 safety system will automatically stop the centrifuge and the pumps if there is contact between liquid of any sort and the fluid

detector.

P/N 85271-30, Manual revision: C

Page 19

Presenting the ACP 215 Equipment 2-5

Pumps Located on the left side of the ACP 215 top deck are two pumps which use peri-

staltic movements to displace fluids through the disposable set tubing.

Figure 2-4, ACP 215 pump rotor

Blood Pump

The blood pump will rotate during certain procedures simultaneously with the

solution pump to direct solution to the RBC bag. As the bowl is filling, the blood

pump directs the RBC product to the bowl.

Pressure monitors

At the end of certain procedures, the blood pump directs the final product from

the bowl to the final product bag.

Solution Pump

The solution pump will rotate at certain points during the procedures to transfer

solution to the RBC bag.

As the bowl is filling, or when transferring the final product from the bowl back

to the RBC bag or the final product bag, the solution pump is stopped.

There are two electronically controlled pressure monitors on the ACP 215 device,

which function with the correlating filter on the disposable set to measure pressure in the disposable tubing. The pressure monitors provide feedback to the

system about the flow of blood components.

The draw pressure monitor (DPM), located on the left side of the top deck,

measures pressure in the blood line tubing.

The system pressure monitor (SPM), located on the right side of the top deck,

measures pressure in the effluent tubing. This measurement verifies that the sterile

seal, between the head and the body of the centrifuge bowl, remains intact.

If a pressure monitor detects that pressure is outside of acceptable limits, the ACP

215 safety system will interrupt the procedure and provide an explanatory

message.

P/N 85271-30, Manual revision: C

Page 20

2-6 Presenting the ACP 215 Equipment

Valves There are six pneumatic pinch valves located on the ACP 215 top deck which

automatically control the flow of fluids through the disposable set tubing. These

valves are color-coded to facilitate accurate tubing installation.

The ACP 215 safety system will control the valves during the self-diagnostic tests.

Once the operator has selected a procedure, the appropriate valves will automatically open, in preparation for installing the disposable set tubing. In case of

power failure, the valves revert to a closed status.

Air detectors The ACP 215 device is equipped with two ultrasonic sensors designed to detect

the presence of air, bubbles or foam in the fluids flowing through the disposable

set tubing. The solution line air detector (SLAD) is located to the right of the solution pump. The blood line air detector (BLAD) is located to the right of the blood

pump.

In the case of an occlusion in the tubing, or an interruption in the fluid flow, the

pump(s) will stop and a message will be displayed with information about the

condition.

Figure 2-5, Example of an air detector

Optical line sensor

Located on the right side of the ACP 215 top deck is the optical line sensor which

monitors the blood components passing through the effluent tubing.

Caution: The line sensor will not provide accurate readings if the optical lens it

is obstructed in any way; thus the lens must be cleared of any extraneous substances to ensure proper functioning of the system.

Further information about specific functions of the line sensor is provided in each

procedure operation manual.

Solution bag pole Located on right side of the ACP 215 cabinet is a height-adjustable pole, used to

hang solution bags during the procedure. There is a knob located on the base of

the pole that permits the operator to adjust the height of the pole by pulling the

knob outward to extend or retract the pole.

P/N 85271-30, Manual revision: C

Page 21

Presenting the ACP 215 Equipment 2-7

Power entry module

1. ON/OFF power switch

2. Power input receptacle

The power entry module (PEM) is located on the left side panel of the device.

Externally, the module consists of an ON/OFF power switch and a power-input

receptacle for the power cord. In the case of an emergency, the power switch can

be used to stop all device function.

Internally, the PEM contains the fuse panel. It will interrupt power supply to the

system in the event of an electrical current surcharge. The design of the PEM also

provides a filter-effect for the device against the effects of a power surge.

1.

2.

Figure 2-6, Power entry module (PEM)

Power cord The power cord provided by Haemonetics is designed to connect the ACP 215

device with an external power source via the power-input receptacle, located on

the power entry module on the side panel.

Biohazard waste bag

The biohazard waste bag is designed to collect any biologically contaminated

material from the centrifuge well in the rare case of a spill or leak. Two biohazard

waste bags are supplied with the delivery of each ACP 215 device.

A bag must be attached at all times to the centrifuge drain tube, located at the

rear of the device. The bag must hang freely, with the clamp open, visible to the

operator.

Warning: The biohazard waste bags are not to be used to collect or store blood

products. When a bag contains evacuated waste products, it must be clamped,

removed and properly disposed of, according to the local policies concerning

biologically contaminated material. A new bag must be placed before resuming

operation.

P/N 85271-30, Manual revision: C

Page 22

2-8 Presenting the ACP 215 Equipment

DESCRIBING THE SHAKER AND THE PRINTER

1. Shaker connector port

2. Printer connector port

2

1

Figure 2-7, ACP 215 rear panel

Shaker During certain procedures, a shaker device manufactured by Haemonetics prop-

erly mixes the blood in the RBC bag with the added solutions. The ACP 215

device provides power to the shaker and controls the shaker operation. The RBC

bag is secured on the shaker platform with magnets.

The operator should connect the shaker to the rear panel of the ACP 215 device

as follows.

" Place the shaker device to the left of the ACP 215 device.

" Attach the shaker power cord to the connector port labeled SHAKER on

the rear panel of the ACP 215 device.

" Secure the connection using the two thumb screws.

Note: When ordering any additional shaker magnets from Haemonetics, the

following part number should be specified.

! ACP 215 shaker magnets, P/N 09437-00.

P/N 85271-30, Manual revision: C

Page 23

Presenting the ACP 215 Equipment 2-9

Printer The printer is a satellite unit which provides a procedure summary printout auto-

matically at the end of the procedure. Examples of a printout are provided in each

procedure operation manual. The ACP 215 device controls the printer, however

the printer has an independent power source via a wall unit adapter that converts

AC into DC.

The printer is connected to the rear panel of the device through an RS232 serial

port, using a 9 pin connector. The function of each pin is defined as follows.

Pin Number Definition

1 RS-232C Data Carrier Detect

2 RS-232C Receive Data

3 RS-232C Transmit Data

4 RS-232C Data Terminal Ready

5 RS-232C RS-232C Ground

6 RS-232C Data Set Ready

7 RS-232C Request to Send

8 RS-232C Clear to Send

9 RS-232C Ring Indicator

Connecting the printer

The operator should connect the printer to the rear panel of the device as follows.

" Attach one end of the printer serial cable to the serial port labeled PRINT-

ER on the rear panel of the ACP 215 device.

" Secure the printer cable to the rear panel connector using the two thumb

screws.

" Attach the other end of the printer serial cable to the serial port located on

the rear panel of the printer.

" Secure the cable in to the printer using the two thumb-screws.

" Insert the DC plug of the printer AC adaptor into the power supply jack lo-

cated at the rear of the printer.

" Plug the printer AC adaptor power cord into an electric outlet.

" Place the printer to the right of the ACP 215 device.

" Power-on the printer.

" Ensure that there is enough paper remaining in the printer.

P/N 85271-30, Manual revision: C

Page 24

2-10 Presenting the ACP 215 Equipment

To remove the printer AC adaptor, the operator should:

" Power off the printer first.

" Unplug the AC adaptor and the DC plug.

The operator should not touch the pins of the DC plugs.

Note: Further information about replacing the paper or cleaning the printer is

provided in the Operation Manual for the DPU-414 Thermal Printer, Seiko

Instruments Inc.

P/N 85271-30, Manual revision: C

Page 25

Chapter 3

Maintaining the ACP 215 Equipment

CLEANING PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Listing tools and cleaning supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Exterior surfaces, valves, shaker and printer . . . . . . . . . . . . . . . . . . . . . . 3-3

Pressure monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Air detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Optical line sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Fluid detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Centrifuge components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Filter screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

CUSTOMER SERVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Clinical training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Field service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Returned Goods Authorization system . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Haemonetics

®

Cleaning and maintenance record . . . . . . . . . . . . . . . . . 3-8

P/N 85271-30, Manual revision: C

Page 26

3-2 Maintaining the ACP 215 Equipment

CLEANING PROCEDURES

To ensure consistent performance of the device, the operator needs to primarily

perform routine cleaning of the components. A record of routine cleaning should

be kept along with any routine or preventive service maintenance performed by

a Haemonetics representative. An example of a cleaning and routine maintenance form is provided at the end of this chapter. Annual preventive maintenance should be performed by a Haemonetics service representative.

The frequency and type of cleaning each ACP 215 device will depend on the

number of procedures performed. Special cleaning needs may arise and should

be dealt with promptly. Haemonetics recommends the following routine

cleaning schedule for each device, based on an average of three procedures per

day, or approximately sixty per month. Adjustments should be made to the

cleaning schedule according to the actual number of procedures performed.

! Daily: Clean the exterior surfaces.

! Weekly: Clean the pressure monitors, air detectors, optical sensors (line

sensor and optical bowl sensor), the fluid detector and the inside of the

centrifuge well.

Listing tools and cleaning supplies

! Monthly: Clean the pump rotors and the pump wells.

! Quarterly: Clean the filter screens.

Warning: To eliminate the potential danger of electrical shock, the operator

must clean the ACP 215 device only when it is disconnected from an external

power source.

A tool kit has been included with each device containing the following articles.

! Phillips-head screwdriver, to remove the retainer plate from the air vent.

! Allen (hexagonal head) wrench, to remove the pump heads from the pump

assembly.

! A brush, to remove loose debris within the roller assembly.

! Silicon lubricant, used for the O-ring gasket of the centrifuge chuck.

The following list describes the basic material required for routine cleaning.

! Disinfectant cleaning solution, specific for blood borne pathogens.

! Clear warm water.

! 70% Isopropyl alcohol.

! Lint-free gauze or cloth for cleaning and drying.

! Cotton swabs.

! Protective gloves.

! Spray bottle, recommended for cleaning the centrifuge well.

P/N 85271-30, Manual revision: C

Page 27

Maintaining the ACP 215 Equipment 3-3

Exterior surfaces, valves, shaker and printer

Pressure monitors

The exterior cabinet, keypad, display screen, valves, shaker and printer should

be wiped daily, as well as following any spill, using an appropriate cleaning solution.

The pressure monitors (DPM/SPM) should be cleaned in the following manner.

" Depress and hold the white ring as if installing the disposable filter.

" Wipe the silver tube thoroughly, using a circular motion and warm water

only.

" Dry the tube and release the pressure on the ring.

Caution: It is very important to use only water on the pressure monitor rod.

Alcohol or cleaning solution residue could cause a reaction with the plastic

material of the corresponding disposable set filter and affect the function of the

filter.

Air detectors The air detectors (SLAD/DLAD) are designed with a groove to hold the disposable

tubing. The contents of the tubing are monitored by the sensors which are located

internally on either side of this groove. If a procedure is interrupted due to an air

detector alarm, the operator should remove the tubing and clean the groove

before continuing the procedure.

Optical line sensor

The operator should use only warm water and lint-free gauze to clean and dry

inside of the tubing grove. The groove should be kept free of any particles, such

as powder residue from disposable gloves, since this could lead to an erroneous

detection of air.

Caution: Alcohol may cause the plastic housing to degrade and must not be used

to clean the air detectors.

The line sensor contains two very small lenses which are centered on either side

of the disposable tubing groove. The lenses must be kept completely free of particles or debris which could produce inaccurate readings and influence the device

performance.

The operator should carefully pass lint-free gauze moistened with warm water

only through the groove to clean, then dry the lenses.

Caution: If cleaning solution should come into contact with the optical sensor

lenses, the lenses should be cleaned immediately with lint-free gauze and warm

water, then thoroughly dried. Dried cleaning solution can leave an opaque film

on the lens.

P/N 85271-30, Manual revision: C

Page 28

3-4 Maintaining the ACP 215 Equipment

Pumps The pump rotors should be removed from the well with the Allen/hexagonal-

head wrench. Debris should be removed from the rotors and the pump wells on

a routine basis, as well as after any spills to contribute to efficient operation.

For routine cleaning, the operator should:

" Remove the pump rotor from the housing, using the hexagonal head

wrench to remove the pump screw.

" Wipe the rotor and remove all debris from the rollers, using warm water

and lint-free cloth or gauze.

" Dry with lint free cloth (or compressed air, if available).

" Clean and dry the pump well using the same method.

" Ensure that all of the rollers spin freely and replace the pump rotor in the

well, aligning the cross pin in the rotor with the pump shaft.

" Replace and tighten the hexagonal head screw.

In the case of a fluid spill, the same cleaning method should be followed;

however, disinfectant cleaning solution should be used, followed by a clear

water rinse. The pump rotor should not be immersed in water.

Fluid detector The fluid detector is located inside of the centrifuge well. The surface of the

detector should be cleaned using a cotton swab moistened with 70% alcohol.

Centrifuge components

The centrifuge well, chuck, hinged lid and locking knob can be wiped routinely

using the cleaning solution and a lint-free cloth.

After a major cleaning, the operator should apply a small amount of the silicon

lubricant to the O-ring gasket to prevent it from cracking. It is not necessary to

remove the gasket when applying the lubricant.

Cleaning after a blood spill

In the case of a blood spill, the operator should:

" Power off the device and disconnect it from the external power source

before cleaning.

" Ensure that the equipment waste bag is attached to the drain tube and

hangs freely.

" Wipe the centrifuge lid with cleaning solution.

" Clean the centrifuge chuck and well using the disinfectant solution and a

lint-free cloth until all traces of blood components are removed.

" Lubricate the O-ring gasket with a small amount of the silicon lubricant.

Haemonetics recommends that the operator wear protective gloves to avoid

direct contact with the cleaning solution and/or any spilled blood which may be

present.

P/N 85271-30, Manual revision: C

Page 29

Maintaining the ACP 215 Equipment 3-5

In the case of a larger spill, fluid and/or blood may be evacuated into the

biohazard waste bag. The operator should complete the following additional

steps and contact the local Haemonetics representative for further instructions

before using the device.

" Wipe away as much blood as possible with gauze pads.

" Irrigate the centrifuge drain holes with cleaning solution, until the drain

tube is rinsed clear of the spilled material.

" Remove the bag and replace it with a new bag.

" Dispose of the used waste bag according to local established policies

concerning the disposal of biohazard waste.

Note: A 50 ml syringe attached to a 20 cm section of disposable tubing placed in

the drain holes can be used for irrigation. The biohazard waste bag should be

monitored to avoid overfilling.

Warning: An authorized Haemonetics technician should perform a leakage

current control after any major fluid spill involving the ACP 215 device. Leakage

current represents a primary indication of electrical shock hazard and should

be checked according to guidelines as described in local standard operating

procedures.

Filter screens The ACP 215 device is equipped with filter screens on the bottom of the cabinet,

which eliminate dust from incoming cool air. The filters should be cleaned

routinely, especially if dust becomes visible on the screens.

To clean the filters, the operator should:

" Remove the retainer plates using a Phillips-head screwdriver.

" Remove the filter screens from the panel.

" Rinse the screens under running water - DO NOT use any cleaning agents.

" Gently squeeze the screens to remove excess water.

" Place the screens on a clean, dry cloth and allow to dry completely.

" Reinsert the screens into the panel, ensuring that all openings are

completely covered by the filter.

" Replace the retainer plates and tighten the screws.

Warning: To avoid electrical shock, the filter screen should be completely dry

before it is reinstalled on the ACP 215 cabinet.

P/N 85271-30, Manual revision: C

Page 30

3-6 Maintaining the ACP 215 Equipment

CUSTOMER SERVICE

Clinical training Haemonetics employs a staff of Clinical Specialists to provide training in the use

of the ACP 215 equipment. The local Haemonetics representative will schedule

staff training upon delivery of the ACP 215 equipment and should be contacted

to organize further instruction when needed.

Field service Haemonetics maintains a worldwide network of company-trained service repre-

sentatives responsible for responding to technical needs concerning equipment.

These technical specialists are available to diagnose and repair any malfunctions,

as well as provide routine annual or semi-annual maintenance of the equipment,

including leakage current tests. If service beyond the routine maintenance and

cleaning described in this manual is required, the local Haemonetics representative should be contacted to provide specific instruction.

Returned Goods Authorization system

Haemonetics seeks to provide its customers with equipment and material which

respects the highest established standards of quality in design and manufacturing.

If for any reason merchandise must be returned to the company, the customer

should refer to the Haemonetics Returned Goods Authorization (RGA) system

procedure to ensure proper handling and subsequent analysis of the material.

The customer should contact the local Haemonetics Representative (or the

Haemonetics Customer Service Department) and provide the following information:

! Product list number, lot number and manufacture date.

! Number of articles to be returned.

! Description of defect.

! Number of parcels being shipped.

The Haemonetics Representative may ask for additional details, depending on

the nature of the problem. The customer should be prepared to provide a thorough description of the problem encountered, as well as the product information

listed above.

If a contaminated disposable set must be returned by courier services, the

Haemonetics Representative may provide specific instructions concerning preparation for shipping blood-contaminated products. In addition to the Haemonetics guidelines, the consumer should strictly follow the local standard operating

procedure related to the shipment of blood-contaminated materials and thus

minimize any potential health hazards involved.

P/N 85271-30, Manual revision: C

Page 31

Maintaining the ACP 215 Equipment 3-7

In some cases, it may be necessary to dispose of the contaminated goods after

reporting the problem to the Haemonetics representative. This should be done

according to the locally established guidelines pertaining to the disposal of

biologically contaminated material.

Warning: Haemonetics products must be properly cleaned and packed prior to

their return. It remains an important responsibility of the customer to reduce

this serious potential health hazard, by being aware of the risks involved in the

shipping, handling and testing of this material.

P/N 85271-30, Manual revision: C

Page 32

Cleaning and maintenance record

®

Action January Febr. March April May June July August Sept. Oct. Nov. Dec.

Clean cabinet, control panel, valves, shaker and

printer

Clean air detectors

Clean pump rotors

Clean centrifuge cover and well

Haemonetics

Device serial number: ................................................................................. Year: .....................................................................................

Clean optical bowl sensor

Clean optical line sensor

Clean air filters

Inspect O-ring: apply silicon lubricant

Clean DPM and SPM

Verify biohazard waste bag

Maintenance performed by:

(date and initials)

Reviewed by:

(date and initials)

Annual preventive maintenance should be scheduled by a supervisor when appropriate and performed by a Haemonetics service representative or a qualified engineer.

Annual maintenance performed by: ................................................................................................ Date performed: ................................................................................................

Reviewed by: .................................................................................................................................. Date/initials: ......................................................................................................

Page 33

Chapter 4

Ensuring Safety and Quality for an ACP 215 Procedure

HANDLING THE ACP 215 EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Storing the device and material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Inspecting the material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

PREVENTING PROBLEMS DURING AN ACP 215 PROCEDURE . . . . . . . . . 4-3

Understanding the risk of hemolysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Avoiding the consequences of flow restriction. . . . . . . . . . . . . . . . . . . . . 4-3

Avoiding bowl misalignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Avoiding overheating due to mechanical situations. . . . . . . . . . . . . . . . . 4-4

WARNINGS FOR THE OPERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Electrical shock hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Leakage current control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Mechanical hazards/rotating parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Power outlet connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Communicable disease precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

P/N 85271-30, Manual revision: C

Page 34

4-2 Ensuring Safety and Quality for an ACP 215 Procedure

HANDLING THE ACP 215 EQUIPMENT

Safe and successful ACP 215 operation will depend in part on the proper routine

handling of the ACP 215 equipment. The operator should be aware of the problems which could result if the device or disposable material is stored, installed or

used incorrectly.

Storing the device and material

Inspecting the material

The ACP 215 device must not be operated or stored in an area where flammable

gases or vapors are present. The ACP 215 disposable set material should be kept

in a dry, well-ventilated area and isolated from any chemical vapors. The operator

should handle the disposable set elements with clean, dry hands or gloves.

Prior to installation, the operator should complete a visual inspection of the

disposable set elements and control for twisted or flattened sections.

After installing the disposable set, the operator should verify the correct placement of the individual elements, prior to initiating a procedure. It is important that

the tubing remain free of any twists or occlusions which could cause a flow

obstruction.

Warning: Upon completion of any procedure, the used disposable should be

considered as biologically contaminated. It must be disposed of according to

local standard operating procedure for the removal of such material and should

not be mixed with non-biologically contaminated waste.

Installation Installation of the disposable set is explained in detail in each procedure opera-

tion manual.

P/N 85271-30, Manual revision: C

Page 35

Ensuring Safety and Quality for an ACP 215 Procedure 4-3

PREVENTING PROBLEMS DURING AN ACP 215 PROCEDURE

Understanding the risk of hemolysis

Avoiding the consequences of flow restriction

Hemolysis involves the destruction of red blood cell membranes, with the release

of free hemoglobin into the plasma portion of the blood. Free hemoglobin does

not have the capacity to transport oxygen and can produce serious problems. The

remnants of the red cell can stimulate clot formation and damage the vascular

nature of the lungs and the kidneys. This could lead to respiratory complications

and/or renal failure.

Hemolysis of red cells can occur during a procedure in the rare event of a

mechanically induced situation, such as overheating or excessive pressure.

Warning: Forcing a pump to work against a severe flow restriction can lead to

hemolysis, and thus, consequently high levels of free hemoglobin. It is important

that the operator remain attentive to this fact in the case of any “high pressure”

alarms during operation.

If there is any suspicion that hemolysis has occurred, the operator should follow

the local SOP applicable in this type of situation. The operator should also

contact the local Haemonetics representative if there is any suspicion of a

mechanically induced problem.

As the bowl is filling, a flow restriction in the effluent tubing can create pressure

on the outlet port of the disposable bowl. This unrelieved pressure can deform

the rotary seal of the disposable bowl. If the functional characteristics of the

rotary seal are altered, the increased friction and excessive heat can make the

contents of the bowl unsuitable for further use.

As the bowl is emptying, a flow restriction in the effluent tubing can cause the

pressure in the centrifuge bowl to drop severely. This sudden drop in pressure

could potentially produce hemolysis.

To eliminate these potential problems, the operator should not clamp the effluent

tubing.

P/N 85271-30, Manual revision: C

Page 36

4-4 Ensuring Safety and Quality for an ACP 215 Procedure

Avoiding bowl misalignment

Avoiding overheating due to mechanical situations

An improperly installed disposable bowl can become misaligned as it spins. This

can create excessive friction, and consequently overheat the bowl contents. The

operator should follow the bowl seating procedure to ensure proper placement

of the bowl in the centrifuge.

Warning: The operator must not use any bowl which cannot be properly seated

in the centrifuge chuck. Overheating can occur, subsequently lead to hemolysis

and make any blood being processed unsafe for reinfusion. During operation

the operator should interrupt the ACP 215 procedure if an abnormality or noise

appears, related to the spinning bowl.

Overheating could also result from a mechanical or maintenance-related

problem, such as a defective bearing or seal within the centrifuge well. In this

case, the operator should contact the local Haemonetics representative and

discontinue use of the device until it is serviced.

Warning: If any component of the ACP 215 device has become overheated

during a procedure, and thus overheats the blood being processed, the blood

components cannot be considered safe for re-infusion.

P/N 85271-30, Manual revision: C

Page 37

Ensuring Safety and Quality for an ACP 215 Procedure 4-5

WARNINGS FOR THE OPERATOR

Electrical shock hazards

Leakage current control

The operator should always use the ACP 215 device with clean, dry hands, or

gloves. The internal parts of the device contain various electrical components.

Contact with any of these components, when the device is connected to an

external powered source, could result in an electrical shock to the operator.

The operator should never remove any of the ACP 215 cabinet panels. Maintenance requiring access to the inner cabinet remains the responsibility of a

Haemonetics-trained technician.

Each ACP 215 device receives a careful inspection for leakage current prior to

leaving the factory. Haemonetics recommends that a control be performed for

leakage current by an authorized representative as part of the annual preventative

maintenance. It remains the responsibility of the facility to ensure that this control

is performed.

In the event of any major spill in which fluid may enter the cabinet, or an important voltage surge, the operator is responsible to ensure that a leakage current test

is performed before re-using the device. The control is necessary to avoid the risk

of electrical shock and should be conducted by an authorized Haemonetics

representative.

Mechanical hazards/rotating parts

Power outlet connection

As with any equipment containing rapidly rotating parts, the potential for severe

injury exists if contact is made, or if clothing becomes entangled with the moving

parts. The ACP 215 device contains a safety feature, designed to prevent the

centrifuge from spinning if the system has not been properly secured. However,

the operator should respect the usual precautions taken when working with

equipment containing rotating mechanical parts.

It is not permitted to power the device using a power cord not supplied by

Haemonetics, a multiple portable socket outlet or an extension cord.

P/N 85271-30, Manual revision: C

Page 38

4-6 Ensuring Safety and Quality for an ACP 215 Procedure

Communicable disease precautions

Despite testing and screening to detect communicable diseases such as hepatitis,

syphilis or HIV, the risk remains that the blood being processed may be infected.

The operator must take the appropriate precautions when handling blood products and disposing of blood-contaminated material, to ensure personal safety as

well as the safety of others who may come in contact with the material.

Proper handling of blood contaminated material

If a leak or blood spill should occur, it should be cleaned immediately. The operator should follow the local standard operating procedure outlining the steps to

follow and product(s) to be used for the disinfection of blood-contaminated material.

If any blood-contaminated material must be returned to Haemonetics for further

inspection, the operator should consult the RGA Procedure as described in the

chapter Maintaining the ACP 215 Equipment.

Proper disposal of biologically contaminated materials

Any disposable material used during an ACP 215 procedure is considered as

biologically contaminated. It must be disposed of according to local standard

operating procedure for the removal of such material and should not be mixed

with non-biologically contaminated waste.

P/N 85271-30, Manual revision: C

Page 39

Chapter 5

Troubleshooting for the ACP 215 Device

LISTING SYSTEM ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

LISTING INTERRUPT SAFETY SYSTEM MESSAGES . . . . . . . . . . . . . . . . . . . 5-5

P/N 85271-30, Manual revision: C

Page 40

5-2 Troubleshooting for the ACP 215 Device

LISTING SYSTEM ERROR MESSAGES

When the ACP 215 device is powered-on, several internal tests are performed.

Any test failure will interrupt the test sequence and a system error message will

be displayed. If a message of this type is displayed, the operator should record the

message, power off the device and contact Haemonetics Field Service.

If for any reason the system has been powered off, or an unexpected power

failure has occurred during a procedure, there is no automatic recovery procedure. The operator should follow the local SOP applicable in this type of situation.

The following table lists the system error messages with a corresponding code

number and relevant operator actions.

System Error Message Corrective Action

CPU OPERATION ERROR

CODE = 4

Please POWER OFF

ROM TEST FAILURE

CODE = 5

Please POWER OFF

CALIBRATION CRC FAILURE

CODE = 7

Please POWER OFF

DPM FAILED 20% ANALOG TEST

CODE = 10

Please POWER OFF

DPM FAILED 50% ANALOG TEST

CODE = 10

Please POWER OFF

DPM FAILED 80% ANALOG TEST

CODE = 10

Please POWER OFF.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

SPM FAILED 20% ANALOG TEST

CODE = 11

Please POWER OFF

SPM FAILED 50% ANALOG TEST

CODE = 11

Please POWER OFF

P/N 85271-30, Manual revision: C

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

Page 41

Troubleshooting for the ACP 215 Device 5-3

System Error Message Corrective Action

SPM FAILED 80% ANALOG TEST

CODE = 11

Please POWER OFF

XXX* VALVE POSITION FAULT

CODE = 12

PLEASE POWER OFF

* XXX DENOTES THE COLOR OF THE VALVE

WATCHDOG ERROR

CODE = 14

Please POWER OFF

WATCHDOG ERROR

CODE = 15

Please POWER OFF

LINE SENSOR VOLTAGE TOO LOW

CODE = 50

Please POWER OFF

LINE SENSOR VOLTAGE TOO HIGH

CODE = 51

Please POWER OFF

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

CONFIGURATION CRC FAILURE

CODE = 52

Please POWER OFF

SPM FILTER INTERLOCK FAILURE

CODE = 502

Please POWER OFF

DPM FILTER INTERLOCK FAILURE

SPM FILTER INTERLOCK FAILURE

CODE = 504

Please POWER OFF

DPM FILTER INTERLOCK FAILURE

CODE = 507

Please POWER OFF

AIR DETECTOR FAULT: [SLAD]

CODE = 509

Please POWER OFF

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

P/N 85271-30, Manual revision: C

Page 42

5-4 Troubleshooting for the ACP 215 Device

System Error Message Corrective Action

AIR DETECTOR FAULT: [BLAD]

CODE = 510

Please POWER OFF

DPM OUT OF TOLERANCE

CODE = 514

Please POWER OFF

SPM OUT OF TOLERANCE

CODE = 515

Please POWER OFF

CPU RELAY CLOSING FAILURE

CODE = 701

Please POWER OFF

CPU RELAY OPENING FAILURE

CODE = 702

Please POWER OFF

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

P/N 85271-30, Manual revision: C

Page 43

Troubleshooting for the ACP 215 Device 5-5

LISTING INTERRUPT SAFETY SYSTEM MESSAGES

Specific inputs are checked at 50 ms intervals during an ACP 215 procedure. If

an error is detected, all peripherals are shut down, and an error message is

displayed.

For most these of situations, the procedure can be automatically recovered.

However, in some of these situations, the operator will be required to power off

the device and the procedure cannot be recovered.

The following table list these messages which may be displayed during a procedure and the relevant operator actions.

Interrupt Safety System Message Corrective Action

CENTRIFUGE OVERSPEED

PRESS YES TO CONTINUE

CENTRIFUGE UNDERSPEED

PRESS YES TO CONTINUE

CENTRIFUGE COVER UNLOCKED

PRESS YES TO CONTINUE

DPM FILTER NOT INSTALLED

PRESS YES TO CONTINUE

SPM FILTER NOT INSTALLED

PRESS YES TO CONTINUE

1. Press the YES key to continue.

2. If the message persists, stop the procedure and contact

Haemonetics Field Service.

1. Press the YES key to continue.

2. If the message persists, stop the procedure and contact

Haemonetics Field Service.

1. Verify the position of the cover lock and ensure that it is in

the locked position.

2. Press the YES key to resume the procedure.

3. If the message persists, stop the procedure and contact

Haemonetics Field Service

1. Ensure that the DPM filter is correctly installed on the draw

pressure monitor and reinstall if necessary.

2. Press the YES key to resume the procedure.

3. If the message persists, stop the procedure and contact

Haemonetics Field Service.

1. Ensure that the SPM filter is correctly installed on the

system pressure monitor and reinstall if necessary.

2. Press the YES key to resume the procedure.

3. If the message persists, stop the procedure and contact

Haemonetics Field Service

XXX* VALVE POSITION FAULT

PRESS YES TO CONTINUE

* XXX DENOTES THE COLOR OF THE VALVE

BLOOD PUMP POSITION FAULT

PRESS YES TO CONTINUE

1. Press the YES key to continue.

2. If the message persists, stop the procedure and contact

Haemonetics Field Service.

1. Ensure that the tubing is properly installed in the blood

pump and reinstall if necessary.

2. Press the YES key to resume the procedure.

3. If the message persists, stop the procedure and contact

Haemonetics Field Service

P/N 85271-30, Manual revision: C

Page 44

5-6 Troubleshooting for the ACP 215 Device

Interrupt Safety System Message Corrective Action

SOLUTION PUMP POSITION FAULT

PRESS YES TO CONTINUE

BLOOD PUMP WRONG DIRECTION

PRESS YES TO CONTINUE

SOLUTION PUMP WRONG DIRECTION

PRESS YES TO CONTINUE

CHECK SHAKER CONNECTION

PRESS YES TO CONTINUE

FLUID IN CENTRIFUGE DETECTED

Please POWER OFF

1. Ensure that the tubing is properly installed in the solution

pump and reinstall if necessary.

2. Press the YES key to resume the procedure.

3. If the message persists, stop the procedure and contact

Haemonetics Field Service

1. Press the YES key to continue.

2. If the message persists, stop the procedure and contact

Haemonetics Field Service.

1. Press the YES key to continue.

2. If the message persists, stop the procedure and contact

Haemonetics Field Service.

1. Ensure that the shaker connector is attached to the rear panel of the ACP 215 device.

2. Press the YES key to resume the procedure

3. If the message persists, stop the procedure and contact

Haemonetics Field Service.

If there is a spill in the centrifuge, the centrifuge and pump(s)

will stop.

1. Power off the ACP 215 device.

2. Refer to the appropriate section of the manual for guidance

on handling a blood spill.

3. Contact Haemonetics Field Service.

WATCHDOG ERROR

Please POWER OFF

SOFTWARE WATCHDOG FAULT

INVALID STATE

CODE = 802

Please POWER OFF

SOFTWARE WATCHDOG FAULT

CURRENT MODULE ID = XXX*

EXPECTED MODULE ID = XXX

CURRENT STATE = XXX

CODE = 800

Please POWER OFF

* XXX DENOTES THE VALUE DISPLAYED

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

P/N 85271-30, Manual revision: C

Page 45

Troubleshooting for the ACP 215 Device 5-7

Interrupt Safety System Message Corrective Action

=============================

INTERNAL SOFTWARE ERROR

MODULE: XXX*

LINE: XXX

STATE: XXX

PARAM: XXX

=============================

* XXX DENOTES THE VALUE DISPLAYED

INTERNAL SOFTWARE ERROR

CALL HAEMONETICS FIELD SERVICE

1. Power off the ACP 215 device.

2. Contact Haemonetics Field Service.

1. Power off the ACP 212 device.

2. Contact Haemonetics Field Service.

P/N 85271-30, Manual revision: C

Loading...

Loading...