Operator Quick Guide

ORBISPHERE 3624

Revision F - 03/10/2008

Page 2

About this Guide

The information in this guide has been carefully

checked and is believed to be accurate. However,

Hach Ultra assumes no responsibility for any

inaccuracies that may be contained in this guide.

In no event will Hach Ultra be liable for direct,

indirect, special, incidental, or consequential

damages resulting from any defect or omission in

this guide, even if advised of the possibility of

such damages. In the interest of continued

product development, Hach Ultra reserves the

right to make improvements in this guide and the

products it describes at any time, without notice or

obligation.

Instrument Controls

The front panel of the 3624 ProBrix Plus

instrument has several displays and controls.

The Power Switch and Pump Switch are used

to turn the instrument or pump on/off respectively.

The CO

2

and °brix-%diet LED displays are

driven by analog outputs from the instrument.

The Key Switch should be turned to the

horizontal unlocked position to start the

instrument in measurement mode. The function

keys are only active if the key switch is in the

unlocked position. Use the vertical locked position

to avoid accidental modifications.

The Display has a two-line liquid crystal display

(LCD) with 16 characters per line.

A Light Button, when pressed, provides

illumination to the LCD for three minutes.

Four Function Keys provide simple operator

control over the instrument functions:

• ESC jumps back a step within a program

menu.

• The × Ø keys are used to scroll through

screen displays.

• ENTER selects a highlighted item from

the menu.

Main Menu

The operator controls the instrument by menuselectable commands using the four function

keys. The main menu has three choices:

• MEASURE to start the measurement

sequence.

• OPTIONS to enable the instrument to be

customized.

• CALIBRATE to provide a choice of

sensor calibration procedures.

To select one of these commands, first press ESC

until the main menu is displayed (as illustrated

above), next press the × Ø keys until your choice

is flashing, and then press ENTER.

Entering Values

When entering numbers in any of the instrument

menus, the current numerical value is displayed

with one digit highlighted by the ^ symbol below it.

Use the × Ø keys to increase/decrease the value

of the digit (0-9 plus a decimal point) until you

reach your required target value.

Press ENTER to shift the highlight symbol one

digit to the right and repeat the process. Pressing

ENTER after the last digit saves the value.

Operating Information

Page 3

Switching on the indicating instrument first shows

the software version and date on the LCD, and

then switches to a Configuration Display

showing the gas being measured, the purge gas

required for the CO

2

sensor, and the membrane

model number for this sensor.

A configuration

screen appears

briefly, before

switching to a

Calibration

Coefficients screen for several seconds before

finally switching to an O2 Measurement Display.

This display then alternates every few seconds

with one of the CO

2

or °Brix/%Diet measurement

displays (illustrated left).

Press the × Ø keys to switch between these

three measurement displays. You may

experience a delay before the display changes,

depending on the purge/measurement cycle of

the CO

2

sensor. Press the ESC key to exit from

these displays and move to the Main Menu.

The O

2

and Brix/Diet LED displays are driven by

analog outputs from the instrument. These

displays are updated at regular time intervals but

may vary slightly from the instrument LCD's

displayed values.

Measurement - Instrument

Measurement - PC

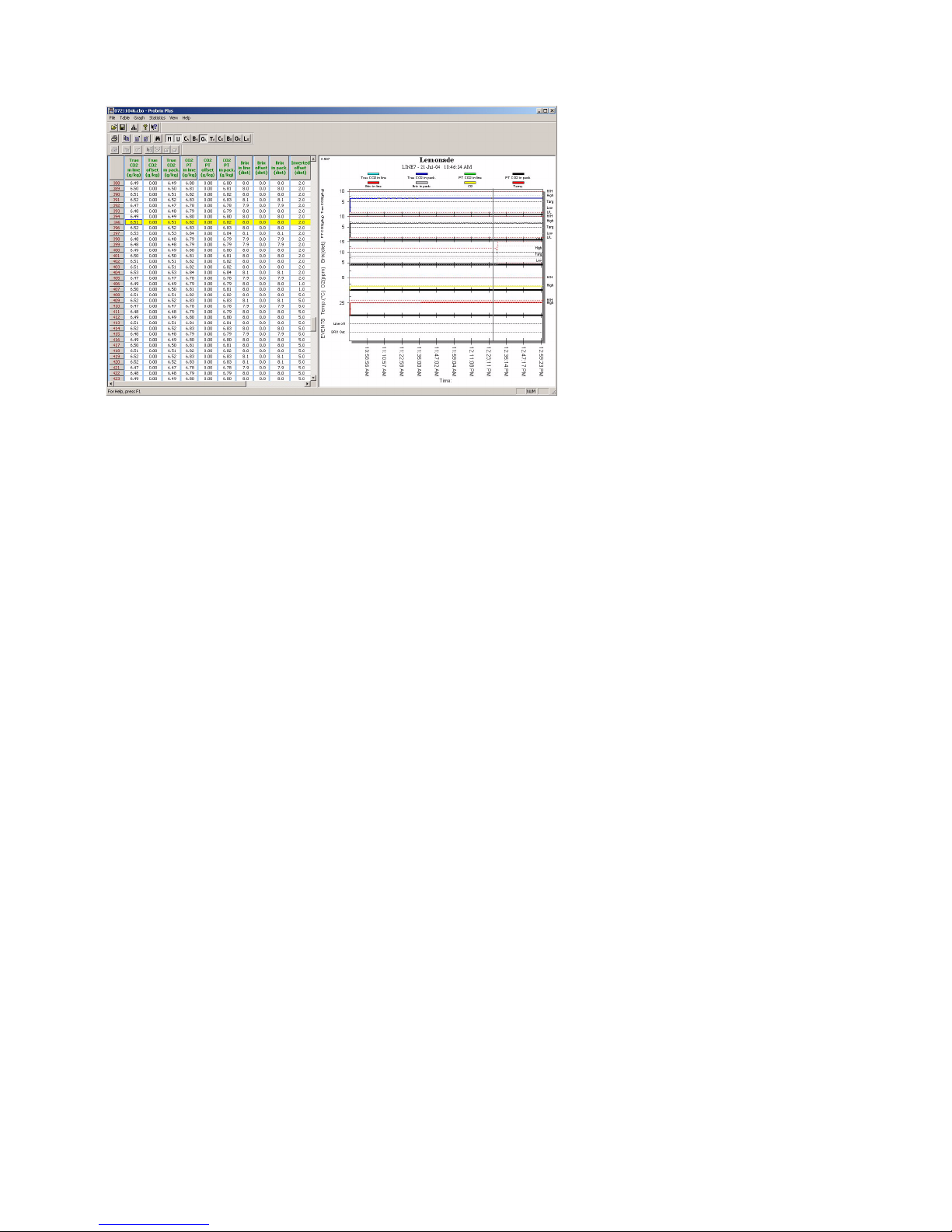

Once the ProBrix Plus PC Program software is installed on your PC, it is recommended that no screen

savers are set and that the PC is not switched off unless absolutely necessary.

The PC Program maintains a window for each active LINE, which are activated via the Start Line A/B

command in the Configuration menu, or by the A/B buttons on the toolbar at the top left of the screen.

The Numerical Indicator Panel

shows information relating to the last

measurement, and is divided into

four, containing the CO

2

data, the

Brix/Diet data, the O

2

data and the

temperature information. For each of

these, the units of measurement, the

most recent measurement value and

a vertical bar graph are shown.

The background colors show:

•GREEN measurements are within

High and Low limits

•ORANGE measurements are

outside High or Low limits, but inside

High/High and Low/Low limits

•RED measurements are outside

High/High or Low/Low limits or an

error has occurred

The Status Panel is displayed below the indicator panel and shows the status for CO

2

, Brix/Diet and O

2

indicating Standby, Measure or Fault.

The Graphic Panel contains four charts showing the measurements over a one-hour period. Any onehour period within the last 7½ hours can be viewed using the horizontal scroll bar. The lines on the graph

are color-coded as per the description at the top of the panel. Placing the mouse cursor over a data point

on the graph will cause the cursor to change to a hand symbol. Clicking the mouse when the hand

symbol is visible will cause a message box to appear giving the values of the measurements, including

the time they were taken.

The Buttons Panel at the bottom of the window contains eight additional options.

Page 4

File Menu

This menu contains a standard list of File options

to allow you to open a file of historical data. When

selecting this menu, the four most recently

accessed files are listed.

Opening a file will display the initial screen

showing data in either tabular or graphical format,

or a combination of the two. You can resize these

areas by dragging the slider bar left or right with

the mouse, or alternatively using the Split

command in the View Menu.

Any changes you make can then be Saved from

this menu, as well as being saved to a different file

using the Save As option. You can also use the

Print Setup option to set up the printer you wish

to use during the process for any hard-copy

output. The Properties option allows you to view

standard information about the file and product.

Table Menu

While in the Table Window, you can right click the

mouse for quick access to some of the Table

Menu options.

A copy option lets you select table contents as a

text file and copy them to the clipboard for pasting

into other applications (e.g. Excel). The search

option allows you to search for a specified alarm

or event chosen from a drop-down list.

You can change what measurements are

displayed in the table, the formatting for the

numerical values and color options for highlighted

rows. Also, you can adjust the default and sizes of

selected rows or columns, and define the

measurements you want to view.

Graph Menu

This option gives you multiple ways of

customizing the output.

From the General window, these include the title

bars, color or black and white, the data displayed

in either or both tabular and graphical form.

Choose the styles that suit you best. Select the

Plot Style tab to define how the graphs should be

displayed (bar graph, line graph, etc.). These can

be different for each measurement.

The Subsets tab allows you to define which sets

of measurement data you wish to display. Select

the Points, Font and Color tabs and personalize

your graphical displays to suit your requirements.

Statistics

The statistics option will show the measurements

in graphical and/or tabular format depending on

how you customize the output.

Double click anywhere in the window to display

the customize menu which allows you to

customize your display. Right click the mouse to

display a list of quick access display options.

Click the hand symbol (when available) for a popup display of statistics applicable at that point.

PBViewer Program

The PBViewer Plus program allows

you to view statistical information that

has been saved by the PC Program

from the current or previous product

runs, in a graphical and tabular

format. You can start PBViewer Plus

from within the ProBrix Plus PC

Program by selecting PBViewerPlus

from the Tools menu. This will

display details for the current Product

Run.

The program can also be run on a

stand-alone basis and can be started

by double-clicking the Desktop icon.

Starting the program this way will

display an empty details screen, until you select a file to open from the File Menu.

There are three standard views available - the Table Window, the Graph Window or a combination of

both. The illustration shows the combined view.

Page 5

Your instrument is pre-set with certain default

values to anticipate your measurement

conditions, such as measurement display units,

thermal cutoff temperature, etc. You may,

however, change these using the Instrument

Modify Options Menus.

Several of these menus duplicate functions that

are more efficiently performed from the PC. For

those menus that are exclusive to the instrument,

the phrase Instrument Only has been added to

the section headings.

It is advisable to give the PC control priority over

the instrument. To do this, make sure you confirm

the Change Product mode on the instrument.

DISPLAY UNITS

This option allows you to specify your type of

measurement (CO

2

or Brix), the units of

measurement to be displayed, the display

resolution (i.e. decimal point placement), the

number of display ranges desired and the

temperature units to be displayed. Additional

choices of gas solubility are provided for CO

2

measurements.

THERMAL CUTOFF (instrument only)

If the sample temperature is liable to exceed the

compensated temperature range of the sensor,

you can set an upper temperature limit to

automatically cut off the electrical signal to the

sensor to extend the sensor's life. Once enabled,

if the sample temperature exceeds this limit, then

alarms are set and a message appears on the PC

and the instrument LCD.

ALARM

Upper and lower alarm limits are software

adjustable throughout the measurement range. If

the measured concentration is outside the

specified limits, the instrument sets an alarm.

SERIAL OUTPUT (instrument only)

The instrument serial output is normally used to

interface to the PC for analysis of measurement

data via the ProBrix Plus PC Program.

CONTINUOUS PURGE (instrument only)

Use this option to view the sensor voltages,

particularly when seeing the Prg message on

your instrument LCD.

ROLLING AVERAGE (instrument only)

The rolling average feature causes the instrument

to average measurements over successive

measurement cycles. It suppresses sharp peaks

and troughs, while retaining reasonably fast

response to real concentration changes. This

option also acts as a noise filter for Brix/Diet

measurement.

LANGUAGE (instrument only)

The instrument can display its menus in English,

French, Japanese, Spanish, German, or Italian

although the units of measurement remain the

same.

Note that this only changes the language for the

menus on the instrument. The language used on

the PC is always English.

HOLD RECOVERY (instrument only)

This option allows you to choose a longer or

shorter recovery time after a Hold condition has

ended.

OFFSET

You may wish to apply a specific offset value to

the displayed gas measurement. Be aware that

this offset value will be lost once a different

product is selected.

CORRECTIONS (instrument only)

This option is reserved for qualified Orbisphere

Service Representatives only. As such, if you feel

that corrections are required, please contact your

local Orbisphere Service Representative to

perform this operation for you.

CHANGE PRODUCT

Products can be changed either at the PC or

directly on the instrument depending on how the

change product parameter has been set.

Setting Instrument Options

Page 6

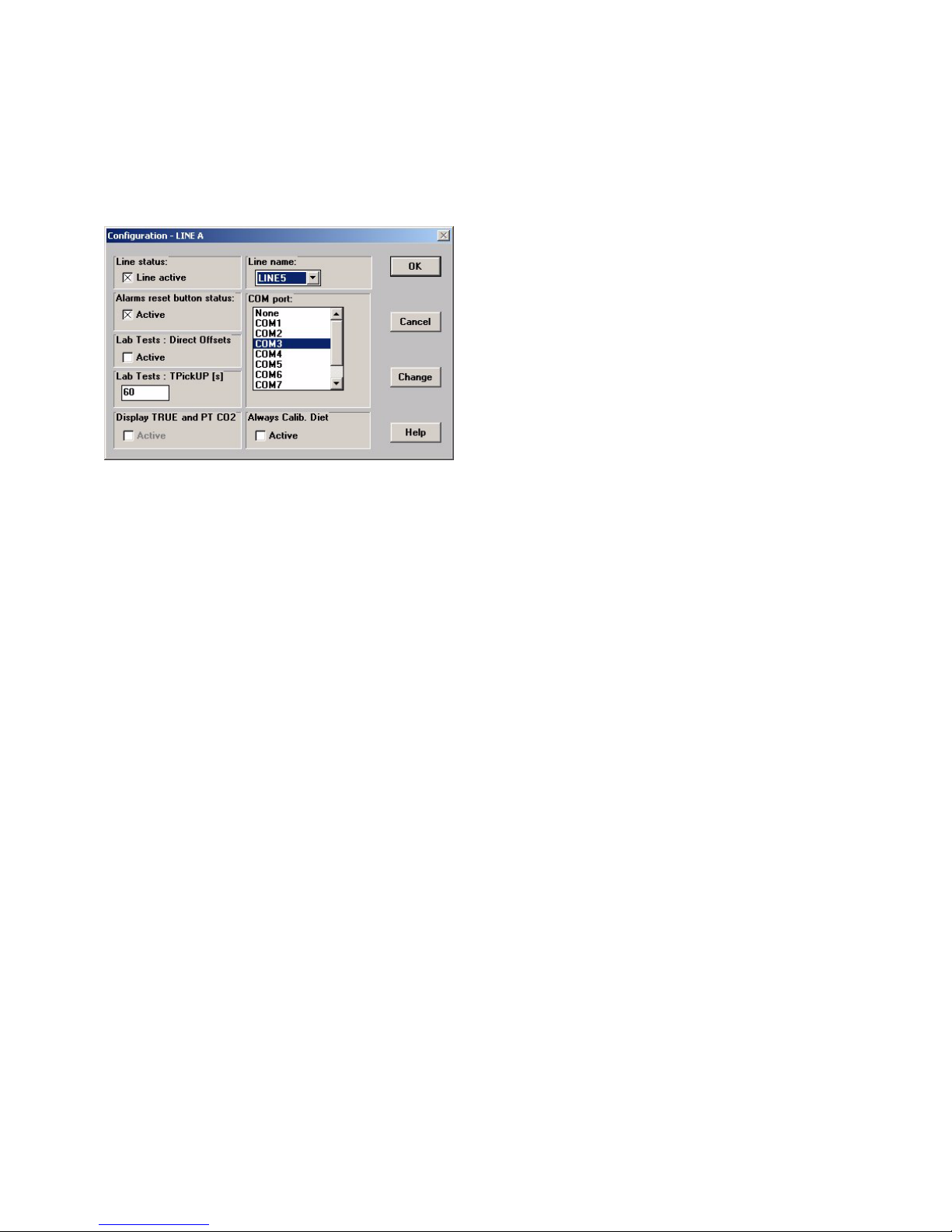

Setting a LINE Configuration

Up to two filling lines may be displayed in the

program window. Each line will be connected to a

separate PC COM port, which will have been set

up during the installation process.

Access the LINE you wish to configure, by

selecting the Line A or Line B option. Modify

parameters for that LINE by selecting the Change

button.

Products List

The Products List option allows you to set a

number of parameters for each product. There is

one product list per LINE, each with a maximum

of 9998 products. Note that product zero is

reserved for water measurement, and product

9999 is the default product used by the system

when the LINE is inactive. The default values for

both of these products are pre-set and cannot be

modified.

First select the LINE you wish to enter/modify

details for, by selecting either LINE A or LINE B in

the top left box.

Then select a product using one of the following

methods:

• By typing the product number, if known,

in the upper right-hand box

• By using the right-hand scroll bar

• By using the Search button to find a

product name

Once a product is selected, you can now enter/

modify the default parameters. Note that

modifications are only activated the next time a

run is started for this product.

Oxygen and Temperature Values

Set the units and limits for oxygen and

temperature displays and alarms. The values are

applicable to all products on both Line A and B.

Autosave

This option allows you to select the time delay for

automatically saving measurement data. Set to

None (no Autosave required), End of Run (save

only on completion) or at a time interval of 1, 2, 5,

10, 30 or 60 minutes.

As the year is not part of the filename, ensure

these measurement files (MMDDHHMM.cbo) are

backed up and deleted at the end of each year.

Water Calibration Status

For Diet measurements only, it may be desirable

to perform a water density calibration periodically.

This can be conveniently done during a long

rinse-down period. To enable this calibration,

select this option, and turn the status to On.

Alarms Delay

System alarms are disabled each time a new run

is started or when the Alarms ON/OFF button is

selected. The ProBrix Plus PC Program

automatically re-enables these after a delay

period of 5 minutes.

Selecting this option and entering a value of

between 0 and 30 will override the default to the

new value.

Sound Alarms

The ProBrix Plus PC Program can trigger audible

alarm messages. To receive these messages on

your PC, it must be equipped with speakers and

have a sound card installed.

Serial Output

You can send formatted measurement and

product data to other computers on your network.

Select the serial communications port linked to

the other computer. You cannot use the same

ports that have already been configured for LINE

A and/or LINE B.

For detailed information on the format of the data

elements transmitted, please press the Help

button on this window and then select Additional

serial output help.

PC Configuration Menu

Page 7

BAROMETRIC PRESSURE SENSOR

The instrument internal barometric pressure

sensor is calibrated at the factory, and normally

requires no further attention. However, you may

wish to calibrate it against your own

instrumentation, or simply check the instrument

for accuracy.

CO

2

SENSOR

The sensor can be calibrated using either:

1) A source of 100% pure CO

2

gas at a

known elevated pressure (Partial

Pressure)

2) A known concentration of CO

2

gas at a

known pressure (Fraction)

3) A known concentration of dissolved

CO

2

(Dissolved)

The Partial Pressure method is generally

recommended when measuring at higher line

pressures, and requires a precise in-line pressure

gauge to perform.

For the Partial Pressure and Fraction methods,

shut off the sample flow to the sampling module,

then open the front panel and remove the CO

2

sensor from its flow chamber. Do not disconnect

the cables or purge gas connections from the

sensor. Before calibrating, make sure that the grill

in the front of the CO

2

sensor is clean and dry.

Insert the sensor in the flow chamber, and tighten

with its collar.

The Dissolved method requires a known

concentration of CO

2

dissolved in liquid as a

reference sample, flowing in-line through the

sample line.

For all of the three methods described above,

expose the sensor to the gas and stabilize the

reading by operating in Measurement Mode for

about 30 minutes. After this time, press ESC and

select CALIBRATE from the main menu, followed

by SENSOR CO2 and the calibration method.

Then, select your calibration measurement unit.

Enter the gas concentration of the calibration

medium. Press ENTER to start the calibration

process. The instrument starts three calibration

cycles. The gas and temperature measurements

are displayed along with the current calibration

cycle number.

On completion of the three cycles, the instrument

then shows the sensitivity of the sensor as a

percentage of the sensitivity determined when

calibration was last performed.

This percentage must be between 50% and 150%

in order to calibrate. If the percentage is outside

the limits, you will see the CALIBRATION OUT

OF BOUNDS message. You will need to press

ESC to continue. Check that the membrane does

not need to be replaced and that no leaks are

evident.

If the percentage is within the limits press ENTER

to accept and complete the calibration process

(the message CALIBRATION COMPLETE will

appear briefly) or ESC to abort.

O

2

SENSOR

The In Air method places the O

2

sensor in water-

saturated air, to provide a known oxygen

reference against which to calibrate.

Shut off the pump and turn off the sample flow to

the sampling module. Open its front panel and

remove the O

2

sensor from its flow chamber. Do

not disconnect the sensor cable.

Dry the sensor thoroughly, before placing the

sensor storage cap under tap water. Shake off

any excess water, but leave a few drops inside

the cap. Then, loosely place the storage cap back

on the sensor, holding it in place by a few turns of

its collar.

Select CALIBRATE from the main menu followed

by O2 IN AIR to start the calibration. The process

is then similar to the CO

2

sensor calibration.

The Direct method calibrates the oxygen sensor

against a liquid sample containing a known level

of dissolved O

2

, flowing through the sample line.

Select CALIBRATE from the main menu followed

by O2 DIRECT and the calibration units. Then

enter the gas concentration of the calibration

sample to start the calibration. The process is

then similar to the CO

2

sensor calibration.

Calibration - From Instrument

Page 8

DIET CALIBRATION

There are three types of diet calibration available,

depending on the type of product.

Automatic (diet-a and T.A.-a products only)

Automatic calibration performs a calibration

based on three successive stable measurement

cycles at the start of a product run, and assumes

the product is in spec when the run starts. After

three successive stable measurements, the new

Diet Calibration Coefficient is calculated based on

the target value for the product.

If there is a large difference between the new

coefficient and the last calibration, a warning

message will be displayed when you press the

Product button, showing the percentage

difference between the two values.

Manual (diet-m and T.A.-m products only)

A dialog box appears automatically. The last five

measurements are initially set to zero.

Once the measurements displayed indicate a

stable condition (at least three successive stable

measurement cycles), press OK to close the

dialog box and to calculate the new slope value

for the current product, which is based on the

value in the edit box.

The target measurement for the product is

automatically displayed in the edit box, as the

calibration value. This can be changed based on

any Lab Tests performed, as it is used in

calculating the calibration coefficient.

Absolute (diet and T.A. products only)

Before doing a calibration, it is necessary to check

your water calibration coefficient first. This can be

done during the next rinse-down period.

Make sure you have set the Water Calibration

Status to On and select water (product number 0)

as the product for measuring. As you start the

measurement process, a new dialog box appears

automatically.

The dialog box will initially display zeros in the last

five measurements column. These values are

then updated every 15 seconds, as new as

measurements are taken.

When the measurements indicate a stable

condition, press OK to close the dialog box and

apply the most recent reading (n1) as the new

water coefficient. This new coefficient will be

applied as the water correction factor for all diet

and T.A. products.

Once the water calibration is complete, you can

now go through the product calibration process.

Select the Calibration button in the Products

List window for the required product. This will

display the density of the syrup (at 20°C) and the

mixing ratio (volume of syrup to volume of water),

which can only be modified if this is a diet product

(not applicable to T.A. products).

The current Slope value is displayed, along with

the Water calibration coefficient calculated during

the water calibration run described above. These

can be changed if required.

Press Calculate, to compute a new slope value

for the product. Press OK to apply these new

parameters to future measurements of this

product.

Calibration - From PC

Page 9

The following table lists possible measurement errors, which could be caused by poor handling of the

instrument and/or identifiable installation conditions.

Measurement Troubleshooting

Symptom Probable Cause Corrective Action Expected Result

Message Out Sensor not connected

Check sensor cable

connection (at sensor and

instrument end)

Measurement should return after

approximately 20 seconds

Message Prg

(CO

2

)

Purge pressure too low or

wrong purge gas

Restore correct purge pressure and gas (refer to the TC

Sensors - Maintenance &

Installation Manual for

details). Push the small plastic tube firmly into the purge

exit and check purge flow rate

(over 3 bubbles per second.)

Check voltage in continuous

purge mode.

In continuous purge mode,

voltage should be in the range

-2.5V to +4.5V. If purge flow rate

is too small, or if voltage remains

above 4.5V, contact your

Orbisphere agent

Damaged sensing

element caused by

mishandling during

membrane replacement

For experienced service

personnel only: Remove

membrane and support.

Check for broken wires of the

thermal conductivity chip

under microscope

Contact your Orbisphere agent

System does not

start: No display

or backlight

Improper line voltage Check instrument voltage

Select proper voltage (115V or

230V) on power supply card

Blown fuse

Unplug instrument and

replace blown fuse.

Instrument should start up. If not,

or if fuse blows again, contact

your Orbisphere agent

High sample

temperature

Blockage of sample flow

causing heat buildup from

pump

Check outlet of sample flow

for blockage. If a check valve

is in use, verify proper

orientation

Temperature should decrease as

normal sample flow resumes

Voltage drift

during

measurement

(CO

2

)

Purge gas pressure too

low

Set 2 bar gauge pressure or

adjust pressure in order to get

over 3 bubbles per second

from exit tube

Measurement will return to

expected value

Low reading

(CO

2

)

Leak in purge inlet line

Check line for leaks with

soapy water

Expected reading

High reading

(CO

2

)

Erroneous calibration in

gas with a wet membrane

protection grill

Recalibrate in liquid, or,

dry out the membrane and

calibrate in gas

Expected reading

Totally erratic

readings (CO

2

)

Water condensation into

the thermal conductivity

element due to purge

failure or humid purge gas

Blow dry purge gas in "contin-

uous purge mode" overnight.

Resume measurement mode.

In most cases, sensor operates

properly. But condensation may

result in serious damage,

requiring service

Page 10

Measurement Troubleshooting (cont)

Symptom Probable Cause Corrective Action Expected Result

Noisy reading

during gas

calibration

Calibrating gas flow

restricted generating

pressure pulses

Make sure calibration gas

flows freely

Stabilized reading

Noisy readings

during

measurement

Improperly mounted

protection cap or

membrane on CO

2

or O2

sensor

Turn off purge gas and check

membrane and protection

cap mounting procedure.

Restart purge

Stabilized reading

Leaking solenoid valve in

CO

2

sensor

Check purge outlet. No gas

bubble should evolve during

the measurement ramp

If solenoid leaks (more than 1

bubble in 15 seconds), return

sensor to Orbisphere

Grounding mismatch

between Orbisphere

instrument and electronic

accessories (plotter,

terminal)

Plug all accessories and

instrument into same mains

terminal

Stabilized reading

Calibration out of

bounds

Wrong membrane model;

pierced/torn membrane;

or two membranes

superimposed

Replace membrane

Calibration constant should be

±50% of default value

Wet protection cap

Blow grill with compressed air

and let dry, carefully, in dry

gas flow for one hour

Wrong calibration values

entered against actual

calibration fluid or

pressure

Check that gas concentration

or pressure fit the entered

numerical data and units

Page 11

The following table lists sensor warning messages, where #n is defined as follows:

• #0 refers to the CO

2

sensor

• #1 refers to the Brix/Diet sensor

• #2 refers to the O

2

sensor

The last three messages in the table apply to the Brix/Diet sensor only.

Sensor Warning Messages

Message on

Instrument LCD

LCD

Code

PC

Event

List

High/

Low

Relay

Hi-Hi/

Lo-Lo

Relay

Reason Action

#n CHECK

THE SENSOR

Out

Sensor

out

On On Sensor disconnected Connect sensor

#n WARNING

THERMAL

CUTOFF

Hot

Sensor

too hot

On On Sensor Thermal cutoff Check process

#0 SENSOR

PURGE

FAILURE

Prg Overflow On On

At the beginning of a

measurement cycle if

V3beg< -2500mV or

V3beg> +4450mV

Restore purge gas

#0 RAMP LIMIT

VIOLATED

Lmt Overflow On On

At the end of a

measurement cycle if

V3end< -2500mV or

V3end> +4450mV

Check membrane

#0 PURGE

VOLTAGE

DRIFTING

Chk N/A Off Off

At the beginning of a

measurement cycle if

V3beg< -2000mV or

V3beg> +3950mV OR

at the end of a measurement cycle if

V3end< -2000mV or

V3end> +3950mV

Check purge gas

#n ATTENTION

LOW LIMIT

LoL Low limit On Off Low limit alarm Check process

#n ATTENTION

HIGH LIMIT

HiL

High

Limit

On Off High limit alarm Check process

#n ATTENTION

LOWLOW LIMIT

LLL

Lo/Lo

limit

On On LowLow limit alarm Check process

#n ATTENTION

HIGHHIGH LIMIT

HHL

Hi/Hi

limit

On On HighHigh limit alarm Check process

OSCILLATOR

STOPPED

Osc Overflow On On

Brix/Diet sensor

malfunction

Check sensor

connections

U-TUBE EMPTY Emp Overflow On On

Brix/Diet sensor

U-tube empty

Restore sample

DEGASSING IN

U-TUBE

Deg Overflow On On

Sample drop-off in

U-tube

Restore sample

Loading...

Loading...