Operator Quick Guide

ORBISPHERE 29981

Revision D - 16/09/2008

Page 2

About this Guide

The information in this guide has been carefully

checked and is believed to be accurate. However,

Hach Ultra assumes no responsibility for any

inaccuracies that may be contained in this guide.

In no event will Hach Ultra be liable for direct,

indirect, special, incidental, or consequential

damages resulting from any defect or omission in

this guide, even if advised of the possibility of

such damages. In the interest of continued

product development, Hach Ultra reserves the

right to make improvements in this guide and the

products it describes at any time, without notice or

obligation.

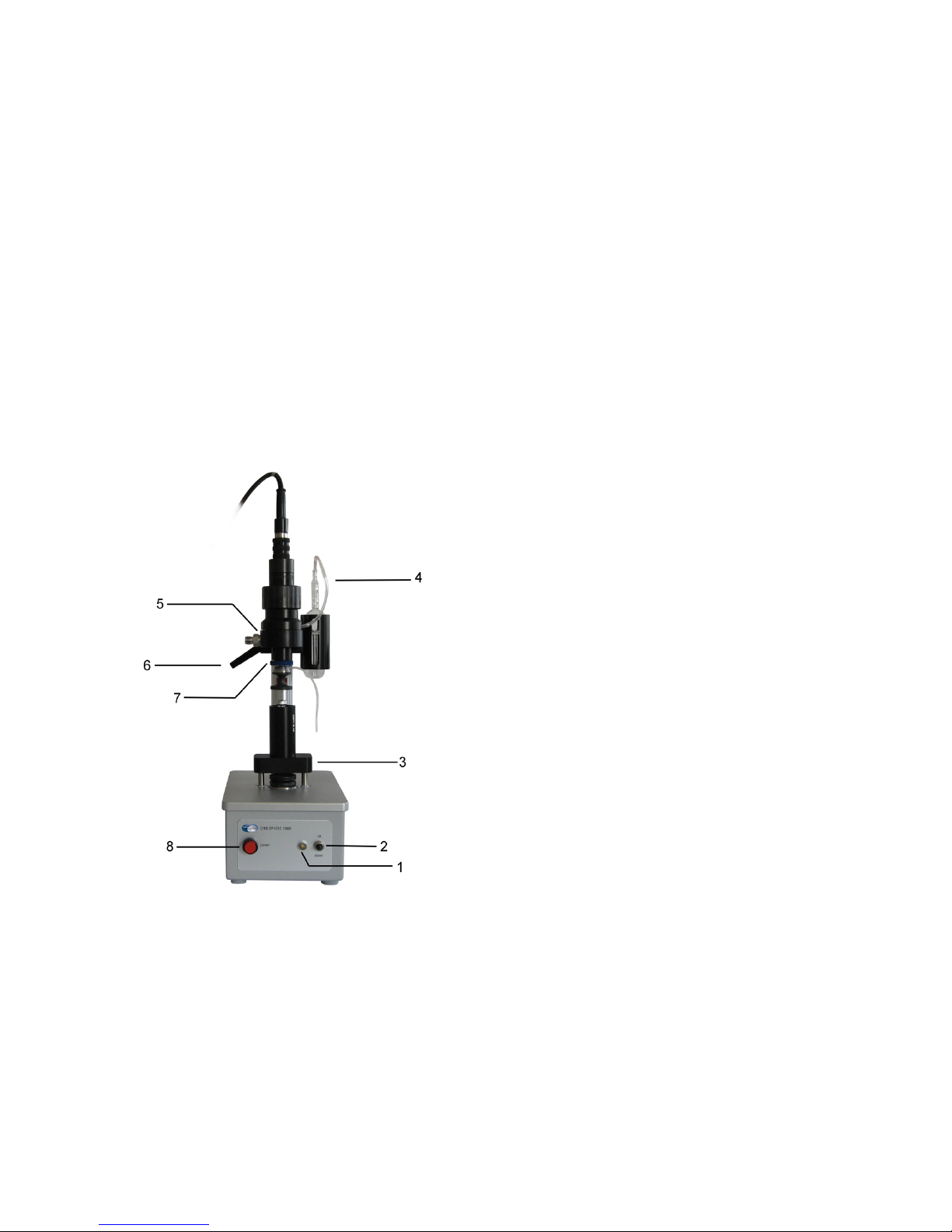

Sampler Description

The PharmaPack can analyze volumes as small

as one milliliter, in ampoules and vials. The

oxygen sensor makes headspace gas

measurements and sends them to the analyzer

for display. The package sampler is operator

controlled. Position of the sample platform

controls the flow of purge gas.

When the package moves up, the piercing needle

assembly is pressed up against the bottom of the

flow chamber, thus blocking purge gas flow by

compressing the inner O-ring. Note the difference

in the space and the compression of the O-rings

between the flow chamber and the needle

assembly.

Subsequently, when deaerated water is

dispensed into the package, the headspace gas is

forced up the inner needle, and into the flow

chamber.

The arm (5) supports the oxygen sensor, the flow

chamber, and the piercing needle assembly. A

black handle (6), located at the rear of this arm,

allows for height adjustment to fit the package

size.

The motorized sample holding platform (3) moves

up and down, controlled by the toggle switch (2)

on the front panel. When the toggle switch is

lifted, the platform stops automatically at a preset

level. This is set by the adjustable red lever (7),

located behind the piercing needle. When the

toggle switch is lowered, the platform stops

automatically at a factory preset level.

Two indicator lights are located on the front panel.

A red light (8) illuminates when the power is

turned on (switch on the back panel). The light (1),

at the side of the toggle switch, is orange as the

sample platform is raised, turns to green when the

platform is lowered, and is off when the platform

stops.

The oxygen sensor is mounted into the top of the

flow chamber and the piercing needle assembly is

attached to the bottom of the flow chamber.

A purge gas connection is located on the flow

chamber side. An outlet tube (4) is connected to a

small glass bubbler secured in a plastic holder,

and which allows a visual check of the purge gas

flow.

A deaerated water dispenser (not shown) is used

for forcing the headspace volume into the flow

chamber for measurement. This dispenser is

connected by flexible tubing to the piercing needle

assembly.

Operating Information

Page 3

Check Deaerated Water Dispenser

Check that sufficient deaerated water

is available in the dispenser before

starting a measurement session.

For better results, make sure there

are no air bubbles trapped in the tube

attached to the PharmaPack.

Check the amount of water to be

delivered with each shot is set

correctly (the recommended quantity

is 1mL).

If you purchased the model 28300 Orbisphere

dispenser with your PharmaPack, lift the plunger

to ensure it dispenses water correctly (no air

bubbles) and returns automatically to the closed

position. You may need to do this a few times until

the plunger returns smoothly to the start position.

Adjust Package Support Ampoule Height

To adjust the ampoule

package support to the height

of the ampoule, place an

ampoule inside the package

support, with the flat end of the

ampoule in the smaller (top)

part of the support. Screw

support together, finger-tight.

To adjust height, turn the Allen

screw on the bottom of the

package support (top picture)

until the flat end of the glass

ampoule is even with the top

surface of the support (bottom

picture).

Needle Assembly Check

Check the correct needle assembly is used. The

package sampler uses two different piercing

needles, one for ampoules and one for vials. If

you use both, you must use the correct piercing

needle assembly each time.

The piercing needle assembly for ampoules has a

black knurled collar, while the piercing needle

assembly for vials has a grey knurled collar.

Adjust the Arm Height

Lower the sample platform all the way and

remove the rubber seal from the piercing needle.

Place a package support on the sample platform.

• Ampoules: Leave the ampoule support

empty, with both parts screwed tightly

together.

• Vials: Place a sample vial into the

package support.

Loosen the black handle and adjust height of arm

until the needle is 2 cm above the top of the

ampoule package support (left photo) or the vial

septum (right photo). Then, tighten the handle.

Adjust Piercing Stop Height

When the toggle

switch is raised to the

up position, the

platform is lifted and

stops automatically

at a preset height.

This level is set by

the position of the red

lever, located behind the piercing needle.

Move the toggle switch to up.

• Ampoules: When the top of the cutting

edge of the needle is level with the top of

the empty package support, stop the

platform move by switching to off.

• Vials: When the needle start to pierce

the septum of the vial, stop the platform

move by switching to off.

Loosen the Allen screw on the side of the red

lever (located on vertical post behind needle, see

photo). Adjust the red lever until it just touches the

top of the package support.

Tighten the Allen screw and reinstall the needle

rubber seal.

If proper sealing cannot be achieved with the

adjustment above, replace the needle rubber

gasket. Lower the sample platform, remove and

install a new rubber gasket around the needle.

Preliminary Checks and Set Up

Page 4

Operating Sequence

Page 5

The needle

assembly for

vials has a grey

knurled collar,

while the needle

assembly for

ampoules has a

black collar.

The rubber gasket used for vials is a cylindrical

gasket (above left), while the H-shaped rubber

gasket is used for glass ampoules (above right).

Procedure for Glass Ampoules

Setup

1) Switch the analyzer into Measure mode

2) Start the flow of purge gas from a

cylinder of pure nitrogen. Check the

flow rate in the glass bubbler, and verify

that 2-3 bubbles appear each second.

3) Purge the flow chamber until the

analyzer reading is very low (<0.10%)

4) Check that no air is present in the water

tube or in the piercing needle assembly.

To do this, place a beaker under the

piercing needle assembly to collect

water from the needle. Then, from the

deaerated water dispenser, send 1 ml

(one shot) through the water tube and

piercing needle into the beaker

Measurement

Wet the inside of

the two-part

package support

and place the

sample ampoule

inside.

The flat end of the

ampoule must be

flush with the flat

end of the smaller

piece of the support. To insure proper placement,

put the support on a table and insert the ampoule

carefully. Screw the support together, finger-tight.

Scribe a 3 mm circle on the exposed flat end of

the ampoule with the diamond tip pencil provided.

If you do not do this, the mechanical shock of

piercing the ampoule could introduce sufficient air

to generate a false reading.

1) Place the package support on the

sample platform with the exposed end

of the ampoule up

2) Send 1 ml of deaerated water through

the piercing needle assembly, onto the

exposed end of the ampoule in the

package support. This water removes

any air trapped between the ampoule

surface and the sampling system

3) Move the toggle switch on the front of

the sampler base to the up position.

The indicator light turns orange

4) The sampling platform moves up and

stops automatically at the correct level

after piercing the ampoule. The purge

gas shuts off automatically just before

the needle pierces the ampoule (no gas

bubbles should appear from the purge

gas exit)

5) From the dispenser, send 1 ml of

deaerated water through the piercing

needle and into the ampoule. Watch for

bubbles at the purge gas exit tubing

6) Once the signal on the analyzer display

peaks, record the value. The signal will

increase at first, then stabilize. You

should record the value at the end of

the increase slope, right at the

beginning of stabilization

7) Move the toggle switch down. The

indicator light turns green. The

sampling platform is lowered and stops

automatically

8) Remove the package support and

unscrew the two parts

9) With a pencil, carefully push the

ampoule out of the support and rinse

and wipe the support with a paper

tissue

Procedure for Vials with Rubber Septum

The package supports for vials are one piece.

Place the vial, with septum up, into the package

support. There is no setup needed, just let the

needle pierce the rubber septum of the vial. The

measurement process is then the same as for

glass ampoules.

Sampling Procedure

Page 6

Using the Test Unit

The test unit (illustrated left)

allows for a variety of tests

without having to pierce

actual vials or ampoules.

A purge gas inlet is situated at

the bottom of the unit, with the

outlet at the top.

Check for Purge Gas Leaks

To test for purge gas leaks, place a beaker of

water on the sample platform. Then raise the

platform so that the needle is immersed in the

water (but the beaker is not pressing on the

needle or gasket).

Start the purge gas and regulate the purge gas

pressure to slightly more than atmospheric

pressure.

When the purge gas is on, bubbles should be

visible in the glass bubbler, and from the needle in

the beaker. However, when the purge gas is off,

the bubbling should stop.

The analyzer display should show a change of no

more than 0.01 kPa per minute, otherwise a leak

may be present and you should check all fittings.

Unable to Purge the System

If you observe no bubbles when the purge gas is

on during the preceding test, check to see if either

the piercing needle assembly is too tight or the

sensor is improperly mounted on the flow

chamber.

Sudden Jet of Water

A sudden jet of water can come out of the purge

gas exit tubing if the purge gas pressure is too

high. Excessive purge gas pressure can cause

gas to leak into the flow chamber during the

measuring phase, thus distorting readings. Adjust

purge gas pressure and flow rate.

Check for Air Leaks

If you suspect an air leak somewhere in the flow,

first make sure that your purge gas supply is

running, and that your sensor is at baseline, that

is, showing a typically low oxygen value.

Fill the test unit with deaerated water, full enough

to form a protruding meniscus at the test unit's

opening. Place the test unit on the sample

platform and raise the test unit. When the rubber

gasket forms a seal with the test unit, stop the

platform.

After five minutes, check the instrument

measurement. The oxygen value should remain

constant, rising no more than 0.05% (kPa) during

that delay. If the value increases significantly,

then you may assume that the system is leaking.

Check all appropriate fittings and try this test

again.

Alternate Check for Purge Gas Leaks

The display value could also decrease in the

preceding test if there is leakage of purge gas into

the flow chamber. First, verify the presence of

bubbles in the glass bubbler.

Then, place the test unit on the sample platform

and raise the platform until the rubber gasket

forms a seal with the test unit. Check to see that

the bubbling stops.

If the bubbling does not stop, the leak is

continuous. Disassemble the piercing needle

assembly, and replace the small O-ring. (Do not

forget to place a thin film of silicone grease

around the O-rings before reassembling the

piercing needle assembly.)

If the purge gas tubing "burps", the leak probably

is due to purge gas pressure that is too high.

Adjust purge gas pressure and flow rate.

Troubleshooting

Page 7

Check for Water Leaks

Connect a source of high purity N2 with a known

concentration of O

2

to a needle to pierce the test

units rubber septum. (Use N

2

with a concentration

of O

2

close to the concentration that you will want

to measure).

Insert the needle into the rubber septum, which is

located near the bottom of the test unit.

Place the test unit on the sample platform and

raise the platform until the rubber gasket forms a

seal with the test unit. Check if the instrument

measurement corresponds with the known

concentration of O

2

in the gas.

Then, remove the needle from the test unit and

check the measurement display. If the reading

decreases with the removal of the needle, water is

probably trapped in the flow chamber.

Purge the system with more N

2

and repeat the

reading. If the decreasing reading persists,

indicating that the flow chamber has not dried out,

remove the sensor from the flow chamber and

carefully dry the sensor face with a clean cloth.

Check Oxygen Values

Connect an oxygen supply to a regulator and a

needle to pierce the test unit's rubber septum.

Use a supply of known O

2

content, preferably of a

value that closely matches your expected sample

oxygen level, for example, 97% N

2

, 3% O2, to

match a 3% expected sample value. You also

may wish to install a three way valve ahead of the

regulator to allow for alternate gas sources.

Insert the needle into the rubber septum located

near the bottom of the test unit. Place the test unit

on the sample platform, and run enough gas to

purge the test unit cavity.

Then, raise the sample platform. As the test unit

approaches the rubber gasket, drop the flow of

gas to a trickle (0.01 to 0.03 bar) just before it

makes contact. After the rubber gasket forms a

seal with the test unit, the glass bubbler should

show a few bubbles per second. Check if the

analyzer measurement value matches the gas

sample.

Check for Clogged Needle

Fill a small

container with

soapy water and

place on top of the

test unit.

With the purge gas

running, place the

test unit (with the

container on top) on the sample platform.

Raise the test unit so that the needle is immersed

in the soapy water but ensuring that the container

does not come into contact with the needle

assembly. Check for bubbles at the needle (as

illustrated above). If bubbles show in the glass

bubbler but not from the needle in the container,

then the needle may be clogged.

Unable to Obtain Low Residual Value

If you have performed all the checks above and

there are no air or water leaks, and you are still

having problems in obtaining a low residual value,

your sensor may need servicing.

Check Purge Gas Shutoff for Vials

Vial have different piercing characteristics,

because of the septum shape and its material.

These differences may require adjustment to the

rubber gasket surrounding the piercing needle.

When a sample vial is raised by the platform, two

actions occur:

1) The vial is applied against the rubber

gasket that surrounds the needle. This

action pushes up the piercing needle

assembly against the flow chamber.

This stops the flow of purge gas to the

flow chamber by compressing the inner

O-ring. Purge gas flow is indicated by

bubbles flowing from the exit tubing into

a beaker of water. When the purge gas

stops, there are no more bubbles.

2) The needle starts piercing the rubber

septum of the vial.

For proper headspace gas measurements, the

purge gas must stop flowing before the needle

pierces the septum of the vial. You may need to

adjust the height of the rubber gasket (shorten or

lengthen it) to ensure that the purge gas flow

stops right before the septum is pierced.

Troubleshooting (cont)

Loading...

Loading...