Page 1

DOC022.98.93082

TitraLab® KF1000 series

workstations

12/2014, Edition 1

Basic User Manual

Manuale dell'utente di base

Manuel d'utilisation de base

Manual básico del usuario

Manual básico do utilizador

Základní uživatelská příručka

Grundlæggende brugervejledning

Basisgebruikershandleiding

Podstawowa instrukcja obsługi

Grundläggande bruksanvisning

Основно ръководство за потребителя

Alapvető felhasználói kézikönyv

Manual de bază al utilizatorului

Temel Kullanıcı Kılavuzu

Základný návod na použitie

Osnovni uporabniški priročnik

Osnovni korisnički priručnik

Βασικό εγχειρίδιο χρήσης

Basishandbuch

Peruskäyttöohje

Page 2

English..............................................................................................................................3

Deutsch.......................................................................................................................... 23

Italiano............................................................................................................................ 45

Français......................................................................................................................... 67

Español.......................................................................................................................... 89

Português.................................................................................................................... 111

Čeština......................................................................................................................... 133

Dansk............................................................................................................................154

Nederlands................................................................................................................. 175

Polski............................................................................................................................ 197

Svenska....................................................................................................................... 219

Suomi............................................................................................................................240

български................................................................................................................... 260

Magyar......................................................................................................................... 282

Română....................................................................................................................... 303

Türkçe...........................................................................................................................325

Slovenský jazyk......................................................................................................... 345

Slovenski..................................................................................................................... 367

Hrvatski........................................................................................................................ 388

Ελληνικά...................................................................................................................... 408

2

Page 3

Table of contents

Specifications on page 3 Startup on page 15

General information on page 3 Standard operations on page 16

Installation on page 7 Maintenance on page 19

Keypad on page 14 Troubleshooting on page 22

Additional information

Additional information is available on the manufacturer's website.

Specifications

Specifications are subject to change without notice.

Specification Details

Dimensions (W x D x H) 22 x 40 x 36 cm (8.7 x 15.7 x 14.2 in.)

Weight 4 kg (8.8 lb)

Power requirements 100–240 VAC, 50/60 Hz

Altitude 2,000 m (6,562 ft) maximum

Operating temperature 15 to 35 °C (59 to 95 °F)

Relative humidity 20 to 80%, non-condensing

Storage temperature –5 to 40 °C (23 to 104 °F)

Installation category II

Pollution degree 2

Certifications Safety IEC/EN 61010-1; EMC IEC/EN 61326-1

Warranty 1 year (EU: 2 years)

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T IC E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

English

3

Page 4

Use of hazard information

D A N GE R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

W A R NI N G

C A U TI O N

N O T IC E

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol on the instrument is referenced in the manual with a

precautionary statement.

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety

information.

This symbol indicates that a risk of electrical shock and/or electrocution exists.

This symbol indicates the presence of devices sensitive to Electro-static Discharge (ESD) and

indicates that care must be taken to prevent damage with the equipment.

Electrical equipment marked with this symbol may not be disposed of in European public disposal

systems after 12 August of 2005. In conformity with European local and national regulations (EU

Directive 2002/96/EC), European electrical equipment users must now return old or end-of-life

equipment to the Producer for disposal at no charge to the user.

Certification

Canadian Radio Interference-Causing Equipment Regulation, IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device complies with Part 15 of the FCC

Rules. Operation is subject to the following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications to this equipment not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. This equipment has been tested

4

English

Page 5

and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at their expense. The following techniques can be used to reduce

interference problems:

1. Disconnect the equipment from its power source to verify that it is or is not the source of the

interference.

2. If the equipment is connected to the same outlet as the device experiencing interference, connect

the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

Product overview

The instrument operates with digital and analog sensors. Measurement applications are installed on

the instrument to automate the measurement process. Instructions show on the display when user

intervention is required. Refer to Figure 1 for product features.

Figure 1 Product overview

1 Keypad 6 Beaker 11 Sensor holder

2 Display 7 Syringe protection cover 12 Pump 2 input/output (waste)

3 Sensor storage tubes 8 Syringe input/output 13 Pump 1 input/output (solvent)

4 USB port 9 Tube clips 14 Pump access cover

5 Sample stopper 10 Syringe

Table 1 Instrument configuration

Model Syringes Pumps

KF1121 1 2

English 5

Page 6

Instrument connections

Figure 2 shows the connections on the rear panel of the instrument. Use the USB port on the side of

the instrument for the USB applications key supplied with the instrument. Use the USB port on the

rear of the instrument to connect to a printer, mouse, keyboard or a USB hub.

Figure 2 Instrument connections

1 24 V external power supply port 4 Not used 7 USB port

2 Sensor 1 port 5 Not used 8 Ethernet port

3 Sensor 2 port 6 Serial port

Product components

Make sure that all components have been received. Refer to the packing list in the box. If any items

are missing or damaged, contact the manufacturer or a sales representative immediately.

Figure 3 Contents of the instrument box

1 Instrument 3 Sensor storage tubes (3x) 5 Power cord

2 Sample stopper 4 Power supply

6 English

Page 7

Figure 4 Contents of the application box

1 KF standard beaker 6 Syringe holding ring

2 KF white Teflon® conical adapter 7 Syringe

3 Magnetic stir bars (10x) 8 Glass bottle

4 USB applications key 9 Bottle caps (3 x GL45)

5 Sensor 10 Desiccant cartridges (3x)

1

Installation

C A U TI O N

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

Installation guidelines

• This instrument is for indoor use only.

• The power supply connector on the rear panel must be easily accessible so the power can be

disconnected quickly in case of emergency.

• Keep the instrument away from temperature extremes, including heaters, direct sunlight and other

heat sources.

• Put the instrument on a stable and level surface in a well ventilated place.

• Make sure that there is at least 15 cm (6 in.) of space on all sides of the instrument to prevent

electrical parts from overheating.

• Do not operate or keep the instrument in dusty, damp or wet locations.

• Always keep the surface of the instrument and all accessories dry and clean.

1

2 filled with a molecular sieve, and 1 empty

English 7

Page 8

Connect to AC power

D A N GE R

Electrocution hazard. If this equipment is used outdoors or in potentially wet locations, a Ground Fault

Circuit Interrupt (GFCI/GFI) device must be used for connecting the equipment to its main power

source.

Electrical shock and fire hazards. Make sure that the supplied cord and non‐locking plug meet the

applicable country code requirements.

Fire hazard. Use only the power supply that is specified for this instrument.

1. Connect the power cord to the power supply.

2. Connect the power supply to the instrument. Refer to Figure 2 on page 6.

3. Connect the power cord to an electrical outlet.

C A U TI O N

W A R NI N G

Install the syringe

Before syringe installation, set the instrument power to on. Push the power button on the front of the

instrument. Make sure that the startup sequence shows on the display. The syringe holder lowers to

its operating position.

Note: Ignore any warning messages related to missing applications that show on the display.

The sensor holder has two positions: one over the magnetic stirrer and the second at 180° to the

right. Move the sensor holder away from the instrument to the second position.

Refer to the illustrated steps that follow.

8

English

Page 9

Install the sensor storage tubes

Put the three sensor storage tubes into the holder that is on the side of the instrument. Refer to

Figure 1 on page 5.

English

9

Page 10

Install the sensor holder accessories

Add the stir bar to the beaker, and then attach the beaker to the sensor holder. Install the desiccant

cartridge and the sample stopper. Refer to the illustrated steps that follow.

Prepare the tubes

Remove any bends in the end of the tubes. Refer to the illustrated steps that follow.

Connect the tubes

Arrow symbols identify the inlet and outlet ports for the syringe and the pump connections. The “up”

arrow is the outlet port. The “down” arrow is the inlet port. Turn the tube connectors on the inlet and

outlet ports of the syringe and pump until they click.

The suction tube that drains into the waste bottle must be installed on the bottom of the beaker for

good drainage.

N O T IC E

The diffusion tip and tube holder on the outlet tube, are pre-installed at the optimal positions. Do not change the

position of the diffusion tip or the tube holder.

Refer to the illustrated steps that follow.

10

English

Page 11

Install the sensor

Connect the sensor

Use a conical adapter to hold the sensor tightly in the sensor holder. Make sure the conical adapter

is installed correctly. This makes sure of a secure water-tight fitting in the sensor holder and the tip of

the sensor will be in the correct position in the beaker.

Connect the sensor to an available sensor port on the rear of the instrument. After the sensor is

connected, make sure that the sensor icon shows in the banner at the top of the display. Refer to the

illustrated steps that follow.

English

11

Page 12

Install the titrant and the reagent

Chemical exposure hazard. Obey laboratory safety procedures and wear all of the personal protective

equipment appropriate to the chemicals that are handled. Refer to the current safety data sheets

(MSDS/SDS) for safety protocols.

12 English

C A U TI O N

Page 13

Loosen the tube connector on the bottle cap.

Put a filled desiccant cartridge into the adapter on the titrant and solvent bottle caps. Put an empty

desiccant cartridge into the adapter on the waste bottle cap.

Note: The molecular sieve in the filled cartridges must be regenerated regularly depending on the humidity of the

laboratory. Refer to Regenerate the molecular sieve on page 19.

Push the inlet tube through the connector. Make sure that the end of the tube is at the bottom of the

bottle. Tighten the connector on the bottle cap.

Pump 1 is used to fill the measurement cell with solvent. Pump 2 is used to empty the measurement

cell. Refer to the illustrated steps that follow.

Tidy the work area

Attach the tubes to the instrument with the clips on the electrovalve and the sensor holder. Refer to

the illustrated steps that follow.

English

13

Page 14

User interface and navigation

Keypad

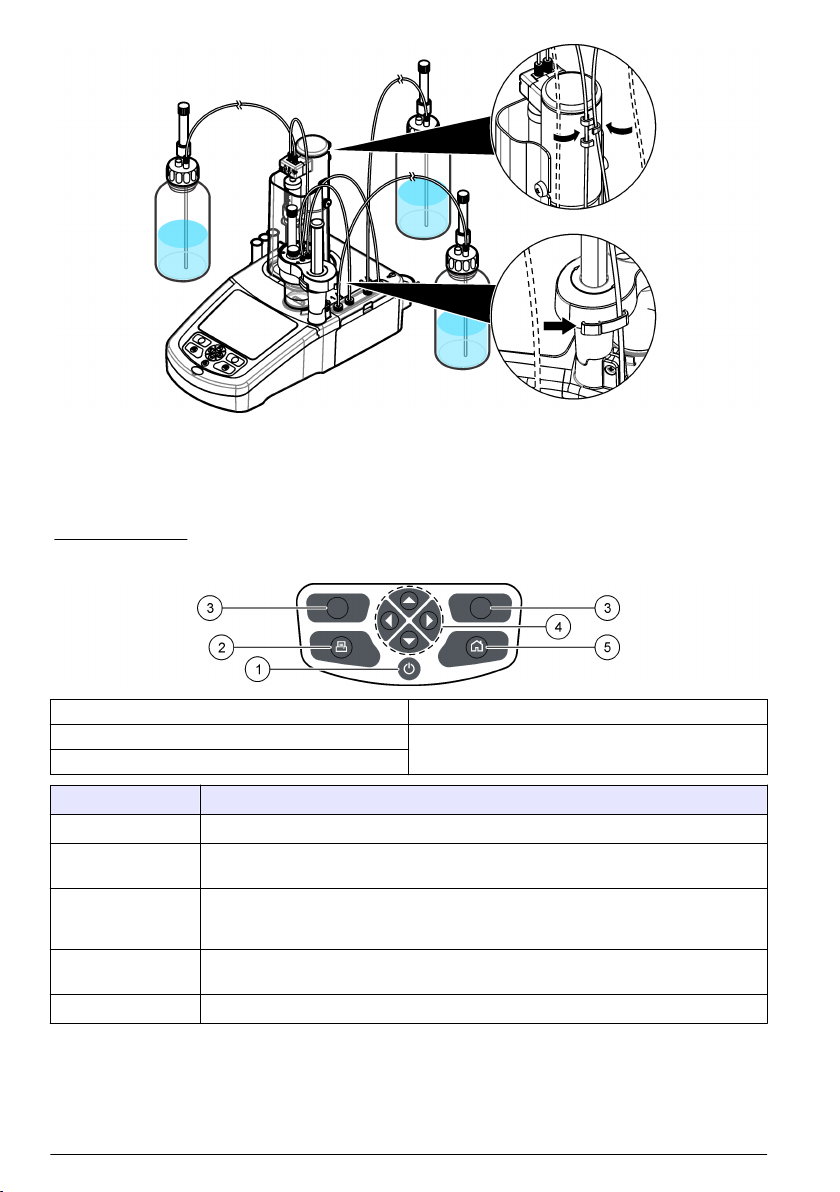

Figure 5 shows the keypad and gives the key functions.

Figure 5 Keypad

1 Power 4 Navigation keys

2 Printer 5 Home

3 Selection keys

Key Description

Power Sets the instrument power to on or off. Push the key for 2 seconds to set the power to off.

Printer Sends data to an attached printer. The printer key only operates if a printer is connected

Selection keys

(contextual)

Navigation keys Scrolls through menus and data, enter numbers and letters, enter checkbox settings and

Home Goes to the main menu.

to the instrument.

Shows the measurement options, selection and confirmation options. Use this key to exit

the current menu display or open sub-menus. Available options show on the display

above each key.

set options for the syringe and the pump.

14 English

Page 15

Startup

C A U TI O N

Chemical exposure hazard. Obey laboratory safety procedures and wear all of the personal protective

equipment appropriate to the chemicals that are handled. Refer to the current safety data sheets

(MSDS/SDS) for safety protocols.

C A U TI O N

Personal injury hazard. Never use the instrument without the syringe cover installed.

Configure the instrument

1. From the main menu, select Settings.

2. Select an option, then push Select.

Option Description

Applications Exports, changes (refer to Change the application settings on page 15), removes and

makes copies of application data. Make sure that the duplication function does not make

more than five applications.

Operators Adds, changes and removes operators.

Date + Time Sets the instrument date and time.

Brightness Sets the brightness of the display.

Sounds Sets the sound options.

Language Sets the language.

Network Give a name to the instrument. This name is used to connect the instrument to a PC.

Restart the instrument if the name is changed.

Legacy settings Specify the sensor data when the legacy adapter is used.

Info Shows information about the instrument and the attached hardware.

Restore Defaults Sets the instrument to the default configuration.

Options Sets the application parameters view to expert mode (refer to Change the application

settings on page 15). When the instrument is set to off, sets the syringe to empty into

the titrant bottle. Changes the temperature display unit. Prints the measurement curve if a

printer is connected.

3. Push Back.

Change the application settings

N O T IC E

The applications installed on the instrument have been pre-defined to optimize the measurement process.

Changing these default application parameters will have an effect on the measurement process and

measurement results. Only qualified personnel should change these parameters or use the instrument in expert

mode.

1. From the main menu, select Settings.

2. Select Applications followed by Edit.

3. Choose an application to change from the installed list and then push Edit.

English

15

Page 16

4. Push the arrow keys to scroll through the application parameters. The Edit key is only available

when a parameter can be changed.

Note: More parameters can be changed with the instrument in expert mode.

5. Push Edit to change the parameter. Enter the new details or select from a list.

Install the applications

Use the supplied USB key to install the applications. The instrument can install a maximum of five

applications. The installed applications are shown on the top line of the display. If any errors occur

during installation, refer to Troubleshooting on page 22.

1. Push Home to go to the main menu.

2. Connect the USB key to the USB port on the side of the instrument. The applications on the USB

key show on the display.

3. Push the arrow keys to highlight and select an application to install. Push the left or right arrow

key to select it. Do this step again to select additional applications to install.

4. Push Import to install the selected applications.

5. Push OK to complete the installation. The installed applications show on the main menu.

Note: To install more applications, push Home to go to the main menu, then remove the USB key and

reconnect it.

Prepare the instrument for measurement

1. From the main menu, select Purge, then push Start. All attached devices are listed.

2. Select All elements to purge all the attached devices, or select one device to purge. Push

Select. Air is removed from the device and filled with liquid from the bottle.

3. Push OK when the operation has completed.

4. Make sure that there are no air bubbles in the device. Do step 2 again if there are any air

bubbles.

5. Select the next device to purge if individual devices are being selected.

6. Push Exit when all the tubes are filled with reagent and the device has no air bubbles.

Note: If a few small air bubbles can be seen on the inner wall and/or piston of the syringe, they can be left

without effecting system performance.

Standard operations

C A U TI O N

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

C A U TI O N

Chemical exposure hazard. Obey laboratory safety procedures and wear all of the personal protective

equipment appropriate to the chemicals that are handled. Refer to the current safety data sheets

(MSDS/SDS) for safety protocols.

C A U TI O N

Personal injury hazard. Never use the instrument without the syringe protection cover in place.

Chemical exposure hazard. Never remove the stir bar from the beaker before the end of a titration.

16 English

C A U TI O N

Page 17

Get a sample measurement

Use this option to get sample measurements with one of the installed applications.

1. Make sure that the glass beaker, the sensor holder and all related parts are clean and dry. Put a

magnetic stir bar into the beaker.

2. Attach the beaker to the sensor holder. Make sure that the beaker fits tightly into the sensor

holder.

3. Read the related "Application Note" from the USB applications key for more instructions.

4. Fill the beaker with the applicable amount of solvent. Refer to Cell management on page 18.

Make sure that there is no liquid spill. Make sure that the initial level is enough so that the sensor

is correctly installed in the sample. Do not put too much solvent in the beaker.

5. From the main menu, select the measurement application, then push Start. Application

information shows on the display.

6. If necessary, select an icon for more information or to change some data.

7. Make sure that the icon at the bottom of the display is highlighted. Do the instructions that

show on the display adjacent to this icon. Make sure that the tubes and sensor are correctly

aligned.

8. Push Start to start the cell conditioning. Measurement data shows on the display.

9. If the default stirring speed needs to be adjusted, push the up and down arrow keys to increase or

decrease the speed.

Note: Changing the default stirring speed can effect the measurement result.

10. If the options are available during the measurement procedure, push Skip to ignore the current

step or push Stop to abort the measurement.

11. Weigh the sample in its container and write down the result.

12. When the cell conditioning is complete add the sample. Remove the sample stopper and put the

correct amount of sample into the beaker with an applicable utensil. Make sure that all of the

sample is put into the center of the beaker and that none of it spills onto the walls of the beaker.

13. Put the sample stopper back into the sensor holder. Make sure that the sample stopper fits tightly

into the sensor holder.

14. Weigh the empty sample container and subtract this value from the weight of the sample in its

container (refer to step 11). The result is the exact weight of the sample analyzed. Write down

this value.

15. Push Start to start the moisture content analysis. Measurement data shows on the display.

Note: The moisture content analysis will start automatically after the addition of sample if the Injection

Autodetect parameter is set to Yes.

16. If the default stirring speed needs to be adjusted, push the up and down arrow keys to increase or

decrease the speed.

Note: Changing the default stirring speed can effect the measurement result.

17. If the options are available during the measurement procedure, push Skip to ignore the current

step or push Stop to abort the measurement.

18. When the measurement is complete, enter the exact weight of the sample analyzed (refer to step

14). Push the arrow keys to see the different measurement views.

19. Push Next for the options that follow:

Option Description

Replicate sample Use this option to start the same titration on the same sample. This is used to study the

repeatability by successively analyzing several parts of the same sample. At the end of

each measurement, a window shows the average value, the standard deviation and the

relative standard deviation.

English 17

Page 18

Option Description

New sample Use this option to start the same titration on a new sample. No standard deviation or

Cell management Use this option to fill or empty the measurement cell with the pumps. Refer to Cell

relative standard deviation measurements will be done.

management on page 18.

20. Push Exit to go back to the main menu.

Cell management

Use this option to fill or empty the measurement cell with the pumps.

1. From the main menu, select Cell management.

2. Push the left and right arrow keys to make a selection.

Option Description

Fill cell (pump 1) Use this option to fill the measurement cell with reagent from pump 1. Push the up arrow

Empty cell

(pump 2)

to stop the procedure.

C A U TI O N

Chemical exposure hazard. Before selecting this option, examine the level of liquid in

the waste bottle. Make sure that there is enough space in the bottle for all of the liquid

from the measurement cell.

Use this option to empty the measurement cell with pump 2. Push the up arrow to stop

the procedure.

3. Push Exit to go back to the main menu.

Manage the data log

To select data to view, delete or export, specify data filters

1. From the main menu, select Data log.

2. Select an option, then push Select.

Option Description

View data log Views measurement data. Select individual lines of data to view more content.

Export data log Exports measurement data from the system to an external device. Preview data selection

Delete data log Removes measurement data from the system. Previews data selection before it is

before it is exported. Make sure that an external device is connected to the instrument

(e.g., a USB key, external hard drive, etc.).

removed.

3. Specify the data extraction parameters. Push the left and right arrow keys to make a selection.

Push the up and down arrow keys to select an option.

Option Description

Result type Sets the type of result available.

Application Sets the available applications.

Date Sets the date range.

Operator Sets the available operators.

18 English

Page 19

Calibration

Calibrate the titrant

1. From the main menu, select Calibration. Related information shows on the display.

2. If necessary, select an icon for more information or to change some data.

3. Do the instructions that show on the display, then push Start to start the calibration. Calibration

data shows on the display.

4. If the default stirring speed needs to be adjusted, push the up and down arrow keys to increase or

decrease the speed.

5. When the calibration is complete, push the arrow keys to see the different measurement views.

6. Push Continue to continue with the calibration.

7. When the calibration is complete, push Yes to accept the calibration or No to reject.

8. Push Exit to go back to the main menu.

Purge

Use this procedure to remove air bubbles from the system. Refer to Prepare the instrument for

measurement on page 16 for instructions.

Maintenance

C A U TI O N

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

N O T IC E

Do not disassemble the instrument for maintenance. If the internal components must be cleaned or repaired,

contact the manufacturer.

Clean the instrument

N O T IC E

Never use flammable or corrosive solvents to clean any part of the instrument. Use of these solvents can degrade

the environmental protection of the instrument and may void the warranty.

Clean the exterior surface with a moist cloth or with a mixture of water and mild detergent. Dry with a

soft cloth.

Clean the sensor

Refer to the documentation delivered with the sensor.

Regenerate the molecular sieve

It is recommended to regenerate the molecular sieve weekly, but this will vary depending on the

humidity of the laboratory. A humidity indicator, such as color changing silica gel crystal, can be used

to show when regeneration is necessary.

To regenerate the molecular sieve, dry it in an oven at a temperature of 300 °C (572 °F) for at least

4 hours. When cool, it can be kept in a glass bottle with an airtight seal.

English

19

Page 20

Maintenance menu

Select Maintenance from the main menu.

Syringe activation

Do a check of the syringe. Make sure the syringe fills and empties correctly.

1. From the maintenance menu, push Syringe activation.

Option Description

Fill Fills the syringe with titrant solution. The process stops automatically when the syringe is

Empty to bottle Discards the contents of the syringe into the titrant bottle.

Empty to beaker Discards the contents of the syringe into the beaker. Make sure that the tube from the

Stop Stops the operation.

Syringe replacement

To replace the syringe, select Syringe replacement from the maintenance menu. Obey the

instructions on the display. Refer to Install the syringe on page 8.

Pump activation

This option only applies to instruments with pumps installed. Do a check of the pump. Make sure the

pump fills and empties correctly.

1. From the maintenance menu, push Pump activation.

Option Description

Start Starts the pump. The reagent is pumped through the tubes into the beaker. Make sure that the tube

from the outlet port of the pump is in the beaker.

Stop Stops the operation.

2. Push Toggle to change to the second pump.

full.

outlet port of the syringe is inside the beaker.

Pump cassette replacement

D A N GE R

Electrocution hazard. Remove power from the instrument before this procedure is started.

This option only applies to instruments with pumps installed.

To replace the pump cassette, refer to the illustrated steps that follow and obey the instructions on

the display.

20

English

Page 21

English 21

Page 22

Other maintenance options

1. Select an option, then push Select.

Option Description

Stirring activation Do a check of the magnetic stirrer. Push the up and down arrow keys to increase or

Live measure This option is not available for all sensors. The option shows continuous

Maintenance

summary

Maintenance

schedule

Reagent

replacement

decrease the stirring speed.

measurement data with connected sensors to quickly check measurements. The

installed applications and the automatic additions to the sample are set to off.

Continuous measurements are not temperature compensated, so measurement

differences may occur in the same sample between continuous measurements and

measurements that use installed applications with temperature compensation.

See the number of days remaining for maintenance tasks. After doing a task, push

Reset to set the number of days remaining to the default value.

See the list of maintenance tasks. Push Edit to change the default value.

Use this option to replace the reagents. Obey the instructions on the display.

Troubleshooting

Refer to the following table for common problem messages or symptoms and possible causes.

Error/Warning Description

Stop requested The operator has pushed the stop button

Measurement out of range The measurement is out of range

Temperature out of range The temperature measurement is out of range

Temperature unknown The temperature measurement cannot be determined

Temperature variation too high The variation in temperature is too high

Out of range The computed result is outside accepted limits

Equation calc. error An equation variable is unknown

Titrant calibration has expired The Calibration date has expired

Maximum number of applications is reached The maximum number of applications per line has been

Requires at least one titrant that cannot be

installed

Calibration solution already used The calibration solution has already been used

No titrant information System failure. Contact technical support

No measure received System failure. Contact technical support

Burette fails to deliver The syringe cannot be emptied

Burette fails to fill The syringe cannot be filled

Burette failed to read delivered volume System failure. Contact technical support

Excess of titrant Too much titrant during cell conditioning

Excess of water Too much water during cell conditioning

reached

The application is not compatible with applications already

installed as it uses a different titration

22 English

Page 23

Inhaltsverzeichnis

Spezifikationen auf Seite 23 Inbetriebnahme auf Seite 36

Allgemeine Informationen auf Seite 23 Standardfunktionen auf Seite 38

Installation auf Seite 28 Wartung auf Seite 41

Tastenfeld auf Seite 35 Fehlerbehebung auf Seite 44

Zusätzliche Informationen

Zusätzliche Informationen finden Sie auf der Website des Herstellers.

Spezifikationen

Die Spezifikationen können ohne Vorankündigung Änderungen unterliegen.

Spezifikation Details

Abmessungen (B x T x H) 22 x 40 x 36 cm (8,7 x 15,7 x 14,2 in)

Gewicht 4 kg / 8,8 lb

Leistungsbedarf 100-240 VAC 50/60 Hz

Einsatzhöhe Maximal 2.000 m (6,562 Fuß)

Betriebstemperatur 15 bis 35 °C (59 bis 95 °F)

Relative Feuchtigkeit 20 bis 80% (nicht kondensierend)

Lagerungstemperatur -5 bis 40 °C (23 bis 104 °F)

Einbaukategorie II

Verschmutzungsgrad 2

Zertifikationen Sicherheit IEC/EN 61010-1; EMC IEC/EN 61326-1

Garantie 1 Jahr (EU: 2 Jahre)

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedienungsanleitung sind auf der Hersteller-Webseite erhältlich.

Sicherheitshinweise

H I N WE IS

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung oder Missbrauch dieses Produkts

entstehen, einschließlich, aber ohne Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür verantwortlich, schwerwiegende

Anwendungsrisiken zu erkennen und erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von

möglichen Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Deutsch

23

Page 24

Bedeutung von Gefahrenhinweisen

G E F AH R

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führt.

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

W A R NU N G

V O R SI C H T

H I N WE IS

Warnhinweise

Lesen Sie alle am Gerät angebrachten Aufkleber und Hinweise. Nichtbeachtung kann Verletzungen

oder Beschädigungen des Geräts zur Folge haben. Im Handbuch wird in Form von Warnhinweisen

auf die am Gerät angebrachten Symbole verwiesen.

Dieses Symbol am Gerät weist auf Betriebs- und/oder Sicherheitsinformationen im Handbuch hin.

Dieses Symbol weist auf die Gefahr eines elektrischen Schlages hin, der tödlich sein kann.

Dieses Symbol zeigt das Vorhandensein von Geräten an, die empfindlich auf elektrostatische

Entladung reagieren. Es müssen Vorsichtsmaßnahmen getroffen werden, um die Geräte nicht zu

beschädigen.

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen ab 12. August 2005 nicht in

öffentlichen europäischen Abfallsystemen entsorgt werden. Benutzer von Elektrogeräten müssen in

Europa in Einklang mit lokalen und nationalen europäischen Regelungen (EU-Richtlinie 2002/96/EG)

Altgeräte kostenfrei dem Hersteller zur Entsorgung zurückgeben.

Zertifizierung

Kanadische Vorschriften zu Störungen verursachenden Einrichtungen, IECS-003, Klasse A:

Entsprechende Prüfprotokolle hält der Hersteller bereit.

Dieses digitale Gerät der Klasse A erfüllt alle Vorgaben der kanadischen Normen für Interferenz

verursachende Geräte.

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Teil 15, Beschränkungen der Klasse "A"

Entsprechende Prüfprotokolle hält der Hersteller bereit. Das Gerät entspricht Teil 15 der FCCVorschriften. Der Betrieb unterliegt den folgenden Bedingungen:

1. Das Gerät darf keine Störungen verursachen.

2. Das Gerät muss jegliche Störung, die es erhält, einschließlich jener Störungen, die zu

unerwünschtem Betrieb führen, annehmen.

24

Deutsch

Page 25

Änderungen oder Modifizierungen an diesem Gerät, die nicht ausdrücklich durch die für die

Einhaltung der Standards verantwortliche Stelle bestätigt wurden, können zur Aufhebung der

Nutzungsberechtigung für dieses Gerät führen. Dieses Gerät wurde geprüft, und es wurde

festgestellt, dass es die Grenzwerte für digitale Geräte der Klasse A entsprechend Teil 15 der FCCVorschriften einhält. Diese Grenzwerte sollen einen angemessenen Schutz gegen

gesundheitsschädliche Störungen gewährleisten, wenn dieses Gerät in einer gewerblichen

Umgebung betrieben wird. Dieses Gerät erzeugt und nutzt hochfrequente Energie und kann diese

auch abstrahlen, und es kann, wenn es nicht in Übereinstimmung mit der Bedienungsanleitung

installiert und eingesetzt wird, schädliche Störungen der Funkkommunikation verursachen. Der

Betrieb dieses Geräts in Wohngebieten kann schädliche Störungen verursachen. In diesem Fall

muss der Benutzer die Störungen auf eigene Kosten beseitigen. Probleme mit Interferenzen lassen

sich durch folgende Methoden mindern:

1. Trennen Sie das Gerät von der Stromversorgung, um sicherzugehen, dass dieser die Störungen

nicht selbst verursacht.

2. Wenn das Gerät an die gleiche Steckdose angeschlossen ist wie das gestörte Gerät, schließen

Sie das störende Gerät an eine andere Steckdose an.

3. Vergrößern Sie den Abstand zwischen diesem Gerät und dem gestörten Gerät.

4. Ändern Sie die Position der Empfangsantenne des gestörten Geräts.

5. Versuchen Sie auch, die beschriebenen Maßnahmen miteinander zu kombinieren.

Produktübersicht

Das Instrument arbeitet mit digitalen und analogen Sensoren. Auf dem Instrument wurden

Messanwendungen installiert, um den Messvorgang zu automatisieren. Wenn ein Eingriff des

Benutzers erforderlich ist, erscheinen auf dem Display entsprechende Anweisungen. Für

Informationen über die Produkteigenschaften siehe Abbildung 1.

Abbildung 1 Produktübersicht

1 Tastenfeld 6 Becher 11 Sensorhalter

2 Display 7 Schutzabdeckung Spritze 12 Pumpe 2 Einlass/Auslass

3 Lagerhülsen Sensor 8 Spritze Einlass/Auslass 13 Pumpe 1 Einlass/Auslass

4 USB-Anschluss 9 Schlauchklemmen 14 Abdeckung Pumpe

5 Probenverschluss 10 Spritze

(Restflüssigk.)

(Lösungsm.)

Deutsch 25

Page 26

Tabelle 1 Instrumentenkonfiguration

Modell Spritzen Pumpen

KF1121 1 2

Anschlüsse des Instruments

Abbildung 2 zeigt die Anschlüsse auf der Rückseite des Instruments. Verwenden Sie den seitlichen

USB-Anschluss für den USB-Speicherstick mit den Anwendungen (Lieferumfang). Verwenden Sie

den USB-Anschluss auf der Rückseite des Instruments für den Anschluss von Drucker, Maus,

Tastatur oder USB-Hub.

Abbildung 2 Anschlüsse des Instruments

1 24 V Anschluss für die externe

Stromversorgung

2 Anschluss Sensor 1 5 Nicht verwendet 8 Ethernet-Anschluss

3 Anschluss Sensor 2 6 Serieller Anschluss

4 Nicht verwendet 7 USB-Anschluss

Produktkomponenten

Stellen Sie sicher, dass Sie alle Teile erhalten haben. Beziehen Sie sich dazu auf die Packliste in der

Verpackung. Wenn Komponenten fehlen oder beschädigt sind, kontaktieren Sie bitte den Hersteller

oder Händler.

26

Deutsch

Page 27

Abbildung 3 Verpackungsinhalt Instrument

1 Gerät 3 Lagerhülsen Sensor (3x) 5 Netzkabel

2 Probenverschluss 4 Stromversorgung

Deutsch 27

Page 28

Abbildung 4 Verpackungsinhalt Anwendungen

1 KF Standardbecher 6 Haltering Spritze

2 KF Konischer Adapter aus weißem Teflon

3 Magnetrührstäbe (10x) 8 Glasflasche

4 USB-Speicherstick 9 Flaschenverschlüsse (3 x GL45)

5 Sensor 10 Trocknungsmittelkartuschen (3x)

®

7 Spritze

1

Installation

V O R SI C H T

Mehrere Gefahren. Nur qualifiziertes Personal sollte die in diesem Kapitel des Dokuments

beschriebenen Aufgaben durchführen.

Anleitung für die Installation

• Dieses Instrument darf nur in Innenräumen verwendet werden.

• Die Netzteilbuchse auf der Rückseite des Geräts muss leicht zugänglich sein, damit die

Stromversorgung im Notfall schnell getrennt werden kann.

• Das Instrument vor extremen Temperaturschwankungen sowie vor Heizgeräten, direkter

Sonneneinstrahlung und sonstigen Wärmequellen schützen.

• Das Instrument in einem gut belüfteten Raum auf einer stabilen ebenen Oberfläche aufstellen.

• An allen Seiten des Gerät müssen mindestens 15 cm Freiraum gewährleistet sein, um eine

Überhitzung der elektrischen Bauteile zu vermeiden.

• Das Instrument niemals in staubigen, feuchten oder nassen Räumen aufbewahren oder betreiben.

• Die Oberfläche des Instruments und alle Zubehörgeräte müssen immer trocken und sauber sein.

1

2 mit Molekularsieb und 1 leere

28 Deutsch

Page 29

An das Stromnetz (AC) anschließen

G E F AH R

Lebensgefahr durch Stromschlag. Wenn dieses Gerät im Freien oder an potenziell feuchten Standorten

eingesetzt wird, muss eine Fehlerstrom-Schutzeinrichtung zum Anschluss an die Netzversorgung

verwendet werden.

Elektrische Gefahren und Brandgefahr Stellen Sie sicher, dass das mitgelieferte Kabel und der

nichtverriegelnde Stecker den Vorschriften des jeweiligen Landes entsprechen.

Brandgefahr. Verwenden Sie nur die für dieses Gerät spezifizierte Stromversorgung.

1. Netzkabel an das Netzteil anschließen.

2. Netzteil an das Instrument anschließen. Siehe Abbildung 2 auf Seite 26.

3. Netzkabel an eine Steckdose anschließen.

V O R SI C H T

W A R NU N G

Spritze installieren

Vor der Installation der Spritze das Instrument einschalten. Drücken Sie dazu die Ein-/Aus-Taste auf

der Vorderseite des Instruments. Achten Sie darauf, dass die Startupsequenz auf dem Display

angezeigt wird. Der Spritzenhalter senkt sich in seine Arbeitsstellung.

Hinweis: Eventuelle auf dem Display angezeigte Warnmeldungen bezüglich fehlender Anwendungen können

ignoriert werden.

Der Sensorhalter verfügt über zwei Positionen, die erste über dem Magnetrührwerk und die zweite

180° rechts. Bewegen Sie den Sensorhalter von dem Instrument weg in die zweite Position.

Siehe die folgenden bebilderten Schritte.

Deutsch

29

Page 30

Lagerhülsen der Sensoren installieren

Setzen Sie die drei Lagerhülsen der Sensoren in den seitlichen Halter. Siehe Abbildung 1

auf Seite 25.

30

Deutsch

Page 31

Haltevorrichtung für den Sensor installieren

Legen Sie den Rührstab in den Becher. Befestigen Sie den Becher anschließend an dem

Sensorhalter. Trocknungsmittekartusche und Probenverschluss montieren. Siehe die folgenden

bebilderten Schritte.

Schlauchleitungen vorbereiten

Eventuelle Krümmungen am Schlauchende entfernen. Siehe die folgenden bebilderten Schritte.

Schlauchleitungen anschließen

Die Einlass- und Auslassanschlüsse für die Spritze und die Pumpe sind durch Pfeile gekennzeichnet.

Der Aufwärtspfeil kennzeichnet den Auslassanschluss. Der Abwärtspfeil kennzeichnet den

Einlassanschluss. Drehen Sie die Schlauchverbinder bis zum Einrasten auf die Ein- und

Auslassanschlüsse der Spritze und der Pumpe.

Die Ansaugleitung, die in die Flasche für die Restflüssigkeit abläuft, muss auf dem Becherboden

installiert werden, um den ungehinderten Abfluss zu gewährleisten.

H I N WE IS

Die Diffusionsspitze und der Schlauchhalter auf dem Auslass wurden werkseitig optimal installiert. Verändern Sie

die Position der Diffusionsspitze oder des Schlauchhalters nicht.

Siehe die folgenden bebilderten Schritte.

Deutsch

31

Page 32

Sensor anschliessen

Schließen Sie den Sensor an.

Verwenden Sie einen konischen Adapter, damit der Sensor fest im Sensorhalter sitzt. Prüfen Sie die

korrekte Installation des konischen Adapters, d. h., der Anschluss in dem Sensorhalter ist sicher und

wasserdicht und die Sensorspitze sitzt korrekt in dem Becher.

Schließen Sie den Sensor an einen freien Sensoranschluss auf der Rückseite des Instruments an.

Prüfen Sie, ob das Sensorsymbol in der oberen Leiste des Displays erscheint, nachdem der Sensor

angeschlossen wurde. Siehe die folgenden bebilderten Schritte.

32

Deutsch

Page 33

Montieren Sie das Titrationsmittel und das Reagenz.

V O R SI C H T

Gefahr von Kontakt mit Chemikalien. Halten Sie sich an die Sicherheitsmaßnahmen im Labor, und

tragen Sie Schutzkleidung entsprechend den Chemikalien, mit denen Sie arbeiten. Beachten Sie die

Sicherheitsprotokolle in den aktuellen Materialsicherheitsdatenblättern (MSDS/SDB).

Deutsch 33

Page 34

Lösen Sie den Schlauchverbinder auf dem Flaschendeckel.

Setzen Sie eine volle Trocknungsmittekartusche in den Adapter auf dem Flaschendeckel. Setzen Sie

eine leere Trocknungsmittekartusche in den Adapter auf dem Deckel der Flasche für die

Restflüssigkeit.

Hinweis: Das Molekularsieb in den vollen Kartuschen muss regelmäßig regeneriert werden. Die Häufigkeit hängt

von der Luftfeuchtigkeit im Labor ab. Siehe Molekularsieb regenerieren auf Seite 41.

Schieben Sie den Einlassschlauch durch den Schlauchverbinder. Achten Sie darauf, dass das

Schlauchende den Boden der Flasche berührt. Ziehen Sie den Schlauchverbinder auf dem

Flaschendeckel an.

Pumpe 1 wird für die Befüllung der Messzelle mit Lösungsmittel verwendet. Pumpe 2 wird für die

Entleerung der Messzelle verwendet. Siehe die folgenden bebilderten Schritte.

Arbeitsbereich aufräumen

Schließen Sie die Schläuche mit den Klemmen auf dem Elektroventil und dem Sensorhalter an das

Instrument an. Siehe die folgenden bebilderten Schritte.

34

Deutsch

Page 35

Benutzerschnittstelle und Navigation

Tastenfeld

Abbildung 5 zeigt das Tastenfeld und gibt die Tastenfunktionen an.

Abbildung 5 Tastenfeld

1 Ein-/Aus-Taste 4 Navigationstasten

2 Drucker 5 Startseite

3 Auswahltasten

Taste Beschreibung

Ein-/Aus-Taste Schaltet das Gerät ein bzw. aus. Halten Sie die Taste 2 Sekunden gedrückt, um das

Drucker Sendet Daten an einen angeschlossenen Drucker. Die Druckertaste funktioniert nur,

Auswahltasten

(kontextabhängig)

Navigationstasten Mit dieser Taste können Sie durch Menüs und Daten scrollen, Kontrollkästchen

Startseite Ruft das Hauptmenü auf.

Gerät auszuschalten.

wenn ein Drucker an das Instrument angeschlossen wurde.

Zeigt die Optionen für die Messung und die Optionen für die Auswahl und die

Bestätigung an. Verwenden Sie diese Taste, um die Anzeige des aktuellen Menüs zu

verlassen oder Untermenüs aufzurufen. Die verfügbaren Optionen werden über jeder

Taste angezeigt.

aktivieren bzw. deaktivieren und Optionen für die Spritze und die Pumpe einstellen.

Deutsch 35

Page 36

Inbetriebnahme

V O R SI C H T

Gefahr von Kontakt mit Chemikalien. Halten Sie sich an die Sicherheitsmaßnahmen im Labor, und

tragen Sie Schutzkleidung entsprechend den Chemikalien, mit denen Sie arbeiten. Beachten Sie die

Sicherheitsprotokolle in den aktuellen Materialsicherheitsdatenblättern (MSDS/SDB).

V O R SI C H T

Verletzungsgefahr. Verwenden Sie das Gerät niemals ohne die korrekt montierte Schutzabdeckung der Spritze.

Instrument konfigurieren

1. Wählen Sie im Hauptmenü Settings (Einstellungen).

2. Wählen Sie eine Option und drücken Sie dann Select (Auswählen).

Option Beschreibung

Applications (Anwendungen) Exportiert, ändert (siehe Anwendungseinstellungen ändern

Operators (Benutzer) Fügt neue Benutzer hinzu und ändert oder löscht Benutzer.

Date + Time (Datum + Uhrzeit) Stellt den Tag und die Uhrzeit ein.

Brightness (Helligkeit) Stellt die Helligkeit des Displays ein.

Sounds (Töne) Stellt die Optionen für die Töne ein.

Language (Sprache) Stellt die Sprache ein.

Network (Netzwerk) Geben Sie dem Instrument einen Namen. Dieser Name wird für den

Legacy settings (LegacyEinstellungen)

Info (Systeminformationen) Zeigt Informationen über das Instrument und die angeschlossene

Restore Defaults (Standardwerte

wiederherstellen)

Options (Optionen) Setzen Sie die Ansicht der Anwendungsparameter auf Expertenmodus

3. Drücken Sie Back (Zurück).

auf Seite 37), löscht und kopiert Anwendungsdaten. Achten Sie

darauf, dass die Kopierfunktion nicht mehr als fünf Anwendungen

erstellt.

Anschluss des Instruments an einen PC verwendet. Starten Sie das

Instrument neu, wenn der Name geändert wurde.

Geben Sie bei der Verwendung des Legacy-Adapters die Sensordaten

ein.

Hardware an.

Setzt das Instrument auf die Standardeinstellungen zurück.

(siehe Anwendungseinstellungen ändern auf Seite 37). Wenn das

Instrument ausgeschaltet ist, wird die Spritze in die Titrationsflasche

entleert. Wählen Sie eine andere Einheit für die Temperaturanzeige.

Druckt die Messkurve aus, wenn ein Drucker angeschlossen wurde.

36

Deutsch

Page 37

Anwendungseinstellungen ändern

H I N WE IS

Die in dem Instrument installierten Anwendungen wurden werkseitig so eingestellt, dass ein optimale

Messvorgang gewährleistet ist. Eine Veränderung der Standardparameter der Anwendungen wirkt sich auf den

Messvorgang und die Messergebnisse aus. Nur qualifiziertes Personal darf diese Einstellungen ändern bzw. das

Instrument im Expertenmodus verwenden.

1. Wählen Sie im Hauptmenü Settings (Einstellungen).

2. Wählen Sie Applications (Anwendungen) und anschließend Edit (Bearbeiten).

3. Wählen Sie aus der Liste die Anwendung, die geändert werden soll und drücken Sie dann Edit

(Bearbeiten).

4. Verwenden Sie zum Scrollen der Anwendungsparameter die Pfeiltasten. Die Taste Edit

(Bearbeiten) ist nur dann verfügbar, wenn ein Parameter geändert werden kann.

Hinweis: Weitere Parameter können geändert werden, wenn das Instrument in den Expertenmodus gesetzt

wird.

5. Drücken Sie Edit (Bearbeiten), um den Parameter zu ändern. Geben Sie die neuen Details ein

oder wählen Sie diese aus der Liste aus.

Anwendungen installieren

Verwenden Sie den beiliegenden USB-Speicherstick für die Installation der Anwendungen. Das

Instrument kann maximal fünf Anwendungen installieren. Die installierten Anwendungen werden in

der ersten Displayzeile angezeigt. Beziehen Sie sich auf den Abschnitt Fehlerbehebung

auf Seite 44, wenn Fehler auftreten.

1. Wählen Sie Home (Startseite), um zum Hauptmenü zurückzukehren.

2. Schließen Sie den USB-Speicherstick an den seitlichen USB-Anschluss des Instruments an. Die

auf dem USB-Speicherstick gespeicherten Anwendungen werden jetzt angezeigt.

3. Wählen Sie mit den Pfeiltasten die Anwendung aus, die installiert werden soll. Verwenden Sie für

die Auswahl die rechte oder linke Pfeiltaste. Wiederholen Sie diesen Schritt, um eine weitere

Anwendung auszuwählen.

4. Drücken Sie anschließen Import (Importieren), um die ausgewählten Anwendungen zu

installieren.

5. Drücken Sie OK, um die Installation abzuschließen. Die installierten Anwendungen werden jetzt

im Hauptmenü angezeigt.

Hinweis: Für die Installation weiterer Anwendungen drücken Sie Home (Startseite), um das Hauptmenü

aufzurufen. Anschließend entfernen Sie den USB-Speicherstick kurz und schließen ihn dann wieder an.

Instrument für die Messung vorbereiten

1. Wählen Sie im Hauptmenü Purge (Spülen). Drücken Sie anschließend Start. Alle

angeschlossenen Dosiereinheiten werden angezeigt.

2. Wählen Sie All elements (Alle Elemente), damit alle angeschlossenen Geräte gespült werden,

oder wählen Sie eine Dosiereinheiten für die Spülung aus. Drücken Sie Select (Auswählen). Die

Luft wird aus der Dosiereinheiten entfernt und es wird mit der Flüssigkeit aus der Flasche befüllt.

3. Drücken Sie nach Abschluss des Vorgangs OK.

4. Die Dosiereinheiten muss frei von Luftblasen sein. Wiederholen Sie Schritt 2, wenn noch

Luftblasen in der Dosiereinheiten sind.

5. Wählen Sie die nächste Dosiereinheit für die Spülung aus, wenn zuvor einzelne Dosiereinheiten

ausgewählt wurden.

6. Drücken Sie Exit (Verlassen), wenn alle Schläuche mit Reagenz befüllt wurden und die

Dosiereinheit luftblasenfrei ist.

Hinweis: Wenige kleine Luftblasen auf der Innenseite oder auf dem Kolben der Spritze haben keinen Einfluss

auf die Leistungen des Instruments und müssen deshalb nicht entfernt werden.

Deutsch

37

Page 38

Standardfunktionen

V O R SI C H T

Mehrere Gefahren. Nur qualifiziertes Personal sollte die in diesem Kapitel des Dokuments

beschriebenen Aufgaben durchführen.

V O R SI C H T

Gefahr von Kontakt mit Chemikalien. Halten Sie sich an die Sicherheitsmaßnahmen im Labor, und

tragen Sie Schutzkleidung entsprechend den Chemikalien, mit denen Sie arbeiten. Beachten Sie die

Sicherheitsprotokolle in den aktuellen Materialsicherheitsdatenblättern (MSDS/SDB).

V O R SI C H T

Verletzungsgefahr. Verwenden Sie das Gerät niemals ohne die korrekt montierte Schutzabdeckung der Spritze.

Gefahr von Kontakt mit Chemikalien. Den Rührstab niemals vor Abschluss der Titration aus dem Becher

entfernen.

Führen Sie eine Probenmessung durch.

Verwenden Sie diese Option, um Probenmessungen mit einer der installierten Anwendungen

durchzuführen.

1. Achten Sie darauf, dass der Glasbecher, der Sensorhalter und alle damit verbundenen Teile

sauber und trocken sind. Legen Sie jetzt einen Rührmagneten in den Becher.

2. Befestigen Sie den Becher an dem Sensorhalter. Der Becher muss fest in dem Sensorhalter

sitzen.

3. Weitere Anweisungen lesen Sie bitte in dem jeweiligen "Anwendungshinweis" auf dem USB-

Speicherstick.

4. Den Becher mit einer zulässigen Menge Lösungsmittel befüllen. Siehe Cell management

(Messzellen verwalten) auf Seite 39. Achten Sie darauf, dass keine Flüssigkeit verschüttet wird.

Der anfängliche Füllstand muss ausreichend sein, damit der Sensor korrekt in die Probe taucht.

Nicht zu viel Lösungsmittel in den Becher füllen.

5. Wählen Sie im Hauptmenü die Anwendung für die Messung. Drücken Sie anschließend Start.

Auf dem Display werden die Informationen über die Anwendung angezeigt.

6. Wählen Sie das entsprechende Symbol, um mehr Informationen abzufragen oder einen Wert zu

ändern.

7. Achten Sie darauf, dass das Symbol am unteren Rand des Displays markiert ist. Folgen Sie

den Anweisungen, die neben dem Symbol angezeigt werden. Achten Sie darauf, dass die

Schläuche und der Sensor korrekt angeschlossen wurden.

8. Drücken Sie Start, um die Konditionierung der Messzelle zu starten. Auf dem Display werden

jetzt die Messdaten angezeigt.

9. Die Standard-Rührgeschwindigkeit kann mit den Auf- und Abwärtspfeiltasten erhöht bzw.

reduziert werden.

Hinweis: Eine Veränderung der Standardrührgeschwindigkeit kann das Messergebnis beeinflussen.

10. Wenn diese Optionen während des Messverfahrens zur Verfügung stehen, drücken Sie Skip

(Überspringen), um den nachfolgenden Schritt zu überspringen, oder Stop, um die Messung

abzubrechen.

11. Wiegen Sie die Probe in ihrem Behälter und notieren Sie das Gewicht.

12. Nach Abschluss der Messzellenkonditionierung füllen Sie die Probe ein. Entfernen Sie den

Probenverschluss und füllen Sie die erforderliche Probenmenge mit einem zulässigen Gerät in

V O R SI C H T

38

Deutsch

Page 39

den Becher. Die Probe muss vollständig in die Mitte des Bechers laufen und darf nicht an die

Becherwände spritzen.

13. Anschließend den Probenverschluss wieder auf den Sensorhalter setzen. Achten Sie darauf,

dass der Probenverschluss fest auf dem Sensorhalter sitzt.

14. Wiegen Sie den leeren Probenbehälter und subtrahieren Sie diesen Wert von dem Gewicht der

Probe in dem Behälter (siehe Schritt 11). Das Ergebnis ist das genaue Gewicht der analysierten

Probe. Notieren Sie diesen Wert.

15. Drücken Sie Start, um die Analyse des Feuchtigkeitsgehalts zu starten. Auf dem Display werden

jetzt die Messdaten angezeigt.

Hinweis: Die Analyse des Feuchtigkeitsgehalts startet nach Zugabe der Probe automatisch, wenn für den

Parameter Injection Autodetect (Einspritzung automatisch erkennen) die Option Yes (Ja) eingestellt wurde.

16. Die Standard-Rührgeschwindigkeit kann mit den Auf- und Abwärtspfeiltasten erhöht bzw.

reduziert werden.

Hinweis: Eine Veränderung der Standardrührgeschwindigkeit kann das Messergebnis beeinflussen.

17. Wenn diese Optionen während des Messverfahrens zur Verfügung stehen, drücken Sie Skip

(Überspringen), um den nachfolgenden Schritt zu überspringen, oder Stop, um die Messung

abzubrechen.

18. Nach Abschluss der Messung geben Sie das genaue Gewicht der analysierten Probe ein (siehe

Schritt 14). Wählen Sie mit den Pfeiltasten die verschiedenen Ansichtsmodi für die Messungen.

19. Drücken Sie Next (Weiter) für die nachfolgenden Optionen:

Option Beschreibung

Replicate sample

(Probe wiederholen)

New sample (Neue

Probe)

Cell management (Messzellen verwalten)

Wählen Sie diese Option, um die gleiche Titration mit derselben Probe

durchzuführen. Die Option wird verwendet, um die Reproduzierbarkeit durch die

nachfolgende Analyse mehrerer Teile derselben Probe zu prüfen. Am Ende jeder

Messung wird in einem Fenster der Durchschnittswert, die Standardabweichung

und die relative Standardabweichung angezeigt.

Wählen Sie diese Option, um die gleiche Titration mit einer neuen Probe

durchzuführen. Jetzt werden Messungen für die Standardabweichung oder die

relative Standardabweichung durchgeführt.

Verwenden Sie diese Option, um die Messzelle mithilfe der Pumpe zu befüllen

bzw. zu entleeren. Siehe Cell management (Messzellen verwalten) auf Seite 39.

20. Wählen Sie Exit (Verlassen), um zum Hauptmenü zurückzukehren.

Cell management (Messzellen verwalten)

Verwenden Sie diese Option, um die Messzelle mithilfe der Pumpe zu befüllen bzw. zu entleeren.

1. Wählen Sie im Hauptmenü Cell management (Messzellen verwalten).

2. Drücken Sie für die Auswahl die rechte oder linke Pfeiltaste.

Option Beschreibung

Fill cell (pump1)Verwenden Sie diese Funktion, um die Messzelle mit Reagenz aus Pumpe 1 zu befüllen.

Empty cell

(pump 2)

3. Wählen Sie Exit (Verlassen), um zum Hauptmenü zurückzukehren.

Drücken Sie die Pfeiltaste, um den Vorgang zu unterbrechen.

V O R SI C H T

Gefahr von Kontakt mit Chemikalien. Bevor Sie diese Option auswählen, müssen Sie

den Füllstand in der Flasche für die zu entsorgenden Flüssigkeiten prüfen. Die Flasche

muss die Flüssigkeit aus der Messzelle vollständig aufnehmen können.

Verwenden Sie diese Funktion, um die Messzelle mit Pumpe 2 zu entleeren. Drücken Sie

die Pfeiltaste, um den Vorgang zu unterbrechen.

Deutsch

39

Page 40

Datenaufzeichnung verwalten

Definieren Sie für die Anzeige, das Löschen und den Export von Daten einen Datenfilter.

1. Wählen Sie im Hauptmenü Data log (Datenaufzeichnung).

2. Wählen Sie eine Option und drücken Sie dann Select (Auswählen).

Option Beschreibung

View data log (Erfasste Messwerte

anzeigen)

Export data log (Messwerte

exportieren)

Delete data log

(Messwerterfassung löschen)

Zeigt Messdaten an. Wählen Sie einzelne Datenzeilen aus, um sich

mehr Informationen anzeigen zu lassen.

Exportiert Messdaten aus dem System in ein externes Gerät. Die

ausgewählten Daten werden vor dem Export angezeigt. Stellen Sie

vor dem Export sicher, dass ein externes Gerät (z. B. USBSpeicherstick, externe Festplatte usw.) an das Gerät angeschlossen

wurde.

Löscht Messdaten aus dem System. Die ausgewählten Daten werden

vor dem Löschen angezeigt.

3. Definieren Sie die Parameter für den Datenexport. Drücken Sie für die Auswahl die rechte oder

linke Pfeiltaste. Drücken Sie für die Auswahl der Optionen die Auf- oder Abwärtspfeiltaste.

Option Beschreibung

Result type (Ergebnistyp) Bestimmt den verfügbaren Ergebnistyp.

Application (Anwendung) Bestimmt die verfügbaren Anwendungen.

Date (Datum) Bestimmt den Datumsbereich.

Operator (Benutzer) Bestimmt die verfügbaren Benutzer.

Kalibrierung

Titrationsmittel kalibrieren

1. Wählen Sie im Hauptmenü Calibration (Kalibrierung). Auf dem Display werden die

entsprechenden Informationen angezeigt.

2. Wählen Sie das entsprechende Symbol, um mehr Informationen abzufragen oder einen Wert zu

ändern.

3. Folgen Sie den Anweisungen, die auf dem Display angezeigt werden. Drücken Sie anschließend

Start, um die Kalibrierung zu starten. Auf dem Display werden Kalibrierungsdaten angezeigt.

4. Die Standard-Rührgeschwindigkeit kann mit den Auf- und Abwärtspfeiltasten erhöht bzw.

reduziert werden.

5. Wählen Sie nach Abschluss der Kalibrierung mit den Pfeiltasten die verschiedenen Ansichtsmodi

für die Messungen.

6. Drücken Sie die Taste Continue (Fortsetzen), um die Kalibrierung fortzusetzen.

7. Drücken Sie nach Abschluss der Kalibrierung entweder Yes, um die Kalibrierung zu bestätigen,

oder No, um sie abzulehnen.

8. Wählen Sie Exit (Verlassen), um zum Hauptmenü zurückzukehren.

40

Deutsch

Page 41

Spülen

Verwenden Sie dieses Verfahren, um Luftblasen aus dem System zu entfernen. Entsprechende

Anweisungen finden Sie unter Instrument für die Messung vorbereiten auf Seite 37.

Wartung

V O R SI C H T

Mehrere Gefahren. Nur qualifiziertes Personal sollte die in diesem Kapitel des Dokuments

beschriebenen Aufgaben durchführen.

H I N WE IS

Nehmen Sie das Gerät nicht zur Wartung auseinander. Falls eine Reinigung oder Instandsetzung von externen

Bauteilen erforderlich ist, wenden Sie sich an den Hersteller.

Instrument reinigen

Keine entzündlichen oder ätzenden Lösungsmittel für die Reinigung des Instruments verwenden. Die

Verwendung dieser Lösungsmittel kann Schäden am Gehäuse des Instruments verursachen und zu dem Verfall

der Garantie führen.

Die Oberflächen mit einem feuchten Tuch und einer Mischung aus Wasser und einem milden

Reinigungsmittel reinigen. Mit einem weichen Tuch trocken reiben.

Sensor reinigen

Beziehen Sie sich auf die Dokumentation, die mit dem Sensor geliefert wurde.

Molekularsieb regenerieren

Das Molekularsieb sollte einmal pro Woche regeneriert werden. Die Häufigkeit hängt jedoch von der

Luftfeuchtigkeit im Labor ab. Verwenden Sie eventuell einen Feuchtigkeitsindikator (Silikagelkristalle,

die ihre Farbe verändern), der anzeigt, wann eine Regenerierung erforderlich ist.

Für die Regenerierung das Molekularsieb mindestens 4 Stunden in einem Ofen bei einer Temperatur

von 300 °C (572 °F) trocknen. Das erkaltete Sieb kann in einer Glasflasche mit luftdichtem

Verschluss aufbewahrt werden.

H I N WE IS

Wartungsmenü

Wählen Sie im Hauptmenü die Option Maintenance (Wartung) aus.

Spritze einschalten

Testen Sie die Spritze. Prüfen Sie, ob sich die Spritze korrekt befüllt bzw. entleert.

1. Drücken Sie im Wartungsmenü Syringe activation (Spritze einschalten).

Option Beschreibung

Fill (Befüllen) Befüllt die Spritze mit Titrationslösung. Der Vorgang wird automatisch

Empty to bottle (In Flasche

entleeren)

unterbrochen,wenn die Spritze voll ist.

Entleert den Inhalt der Spritze in die Titrationsflasche.

Deutsch 41

Page 42

Option Beschreibung

Empty to beaker (In Becher

entleeren)

Stop Unterbricht den Vorgang.

Entleert den Inhalt der Spritze in den Becher. Achten Sie darauf, dass sich

der Schlauch des Auslassanschlusses der Spritze im Becher befindet.

Spritze austauschen

Wählen Sie im Wartungsmenü Syringe replacement (Spritze austauschen) Folgen Sie den

Anweisungen auf dem Display. Siehe Spritze installieren auf Seite 29.

Pump activation (Pumpe einschalten)

Diese Option ist nur bei Instrumenten mit installierten Pumpen verfügbar. Prüfen Sie die Pumpe.

Prüfen Sie, ob die Pumpe korrekt befüllt bzw. entleert.

1. Drücken Sie im Wartungsmenü Pump activation (Pumpe einschalten).

Option Beschreibung

Start Schaltet die Pumpe ein. Das Reagenz wird durch die Schläuche in den Becher gepumpt. Achten Sie

darauf, dass sich der Schlauch, der mit dem Auslassanschluss verbunden ist, im Becher befindet.

Stop Unterbricht den Vorgang.

2. Drücken Sie Toggle, um auf die zweite Pumpe umzuschalten.

Pumpenkassette austauschen

G E F AH R

Lebensgefahr durch Stromschlag. Trennen Sie das Gerät von der Spannungsversorgung, bevor Sie

diesen Vorgang starten.

Diese Option ist nur bei Instrumenten mit installierten Pumpen verfügbar.

Für den Austausch der Pumpenkassette beziehen Sie sich bitte auf die nachfolgenden bebilderten

Schritte. Folgen Sie auch den Anweisungen auf dem Display.

42

Deutsch

Page 43

Weitere Optionen für die Wartung

1. Wählen Sie eine Option und drücken Sie dann Select (Auswählen).

Option Beschreibung

Stirring activation

(Rührwerk aktivieren)

Live measure

(Direktmessung)

Maintenance summary

(Wartungsübersicht)

Prüfen Sie das Magnetrührwerk. Drücken Sie den Aufwärts- oder

Abwärtspfeil, um die Rührgeschwindigkeit zu erhöhen bzw. zu senken.

Diese Option ist nicht für alle Sensoren verfügbar. Bei angeschlossenen

Sensoren zeigt die Option kontinuierlich Messdaten an und ermöglicht so

eine schnelle Kontrolle der Messungen. Die installierten Anwendungen und

die automatischen Zugaben zu der Probe sind ausgeschaltet. Bei

kontinuierlichen Messungen erfolgt keine Temperaturkompensierung.

Deshalb können in der gleichen Probe Differenzen zwischen kontinuierlichen

Messungen und Messungen, die installierte Anwendungen mit

Temperaturkompensierung verwenden, auftreten.

Prüfen Sie, wie viele Tage noch bis zur Durchführung der

Wartungsmaßnahmen verbleiben. Nach Ausführung einer

Wartungsmaßnahme drücken Sie die Taste Reset (Zurücksetzen), um die

Anzahl der verbliebenen Tage auf den Standardwert zurückzusetzen.

Deutsch 43

Page 44

Option Beschreibung

Maintenance schedule

(Wartungsplan)

Reagent replacement

(Reagenz austauschen)

Prüfen Sie die Liste der Wartungsmaßnahmen. Drücken Sie Edit

(Bearbeiten), um den Standardwert zu ändern.

Mit dieser Option tauschen Sie die Reagenzien aus. Folgen Sie den

Anweisungen auf dem Display.

Fehlerbehebung

In der folgenden Tabelle werden allgemeine Fehlermeldungen, Störungssymptome und mögliche

Ursachen beschrieben.

Fehler/Warnung Beschreibung

Stop requested (Stopp erforderlich) Der Bediener hat die Stopptaste gedrückt.

Measurement out of range (Messung außerhalb des

zulässigen Bereichs)

Temperature out of range (Temperatur außerhalb des

zulässigen Bereichs)

Temperature unknown (Temperatur unbekannt) Die Temperatur kann nicht erfasst werden.

Temperaturschwankung zu hoch Die Temperaturschwankungen sind zu hoch.

Out of range (außerhalb Bereich) Das ermittelte Ergebnis liegt außerhalb der zulässigen

Equation calc. error (Berechnungsfehler Gleichung) Eine Gleichungsvariable ist unbekannt

Titrant calibration has expired (Titriermittelkalibrierung

ist abgelaufen)

Maximum number of applications is reached (Max.

Anwendungszahl erreicht)

Requires at least one titrant that cannot be installed

(Benötigt mindestens ein Titriermittel, das nicht

installiert werden kann.)

Calibration solution already used (Kalibrierungslösung

wurde schon verwendet)

No titrant information (Keine Information über

Titriermittel)

No measure received (Keine Messungen erhalten) Systemfehler Kontaktieren Sie den Kundendienst.

Burette fails to deliver (Bürette kann nicht übertragen) Die Spritze kann nicht geleert werden.

Burette fails to fill (Bürette kann nicht befüllen) Die Spritze kann nicht befüllt werden.

Burette failed to read (Bürette konnte das übertragene

Volumen nicht lesen)

Excess of titrant (Titriermittelüberschuss) Zu viel Titrationsmittel während der Konditionierung

Excess of water (Wasserüberschuss) Zu viel Wasser während der Konditionierung der

Messung liegt außerhalb des zulässigen Bereichs.

Temperatur liegt außerhalb des zulässigen Bereichs.

Grenzwerte.

Datum der Kalibrierung ist abgelaufen.

Maximale Anwendungszahl pro Leitung wurde erreicht.

Anwendung ist nicht mit der installierten Anwendung

kompatibel, denn sie verwendet eine andere Titration.

Die Kalibrierungslösung wurde schon verwendet.

Systemfehler Kontaktieren Sie den Kundendienst.

Systemfehler Kontaktieren Sie den Kundendienst.

der Messzelle

Messzelle

44 Deutsch

Page 45

Sommario

Specifiche a pagina 45 Avviamento a pagina 58

Informazioni generali a pagina 45 Operazioni standard a pagina 60

Installazione a pagina 50 Manutenzione a pagina 63

Tastiera a pagina 57 Risoluzione dei problemi a pagina 66

Ulteriori informazioni

Ulteriori informazioni sono disponibili sul sito Web del produttore.

Specifiche

Le specifiche sono soggette a modifica senza preavviso.

Specifiche Dettagli

Dimensioni (L x P x A) 22 x 40 x 36 cm (8,7 x 15,7 x 14,2 poll.)

Peso 4 kg (8,8 libbre)

Requisiti di alimentazione 100-240 V CA, 50/60 Hz

Altitudine 2.000 m (6.562 ft) massimo

Temperatura operativa Da 15 a 35°C (da 59 a 95°F)

Umidità relativa 20 - 80%, senza condensa

Temperatura di stoccaggio Da -5 a 40°C (da 23 a 104°F)

Categoria di installazione II

Grado di inquinamento 2

Certificazioni Norme di sicurezza CEI/EN 61010-1; EMC CEI/EN

Garanzia 1 anno (EU: 2 anni)

61326-1

Informazioni generali

In nessun caso, il produttore potrà essere ritenuto responsabile per danni diretti, indiretti o accidentali

per qualsiasi difetto o omissione relativa al presente manuale. Il produttore si riserva il diritto di

apportare eventuali modifiche al presente manuale e ai prodotti ivi descritti in qualsiasi momento

senza alcuna notifica o obbligo preventivi. Le edizioni riviste sono presenti nel sito Web del

produttore.

Informazioni sulla sicurezza

A V V IS O

Il produttore non sarà da ritenersi responsabile in caso di danni causati dall'applicazione errata o dall'uso errato di

questo prodotto inclusi, a puro titolo esemplificativo e non limitativo, i danni incidentali e consequenziali; inoltre

declina qualsiasi responsabilità per tali danni entro i limiti previsti dalle leggi vigenti. La responsabilità relativa

all'identificazione dei rischi critici dell'applicazione e all'installazione di meccanismi appropriati per proteggere le

attività in caso di eventuale malfunzionamento dell'apparecchiatura compete unicamente all'utilizzatore.

Prima di disimballare, installare o utilizzare l’apparecchio, si prega di leggere l’intero manuale. Si

raccomanda di leggere con attenzione e rispettare le istruzioni riguardanti note di pericolosità. La non

osservanza di tali indicazioni potrebbe comportare lesioni gravi all'operatore o danni all'apparecchio.

Italiano

45

Page 46

Assicurarsi che i dispositivi di sicurezza insiti nell'apparecchio siano efficaci all'atto della messa in

servizio e durante l'utilizzo dello stesso. Non utilizzare o installare questa apparecchiatura in modo

diverso da quanto specificato nel presente manuale.

Indicazioni e significato dei segnali di pericolo

P E R IC O L O

Indica una situazione di pericolo potenziale o imminente che, se non evitata, causa lesioni gravi anche mortali.

A V V ER T E N Z A

Indica una situazione di pericolo potenziale o imminente che, se non evitata, potrebbe comportare lesioni gravi,

anche mortali.

A T T EN ZI O N E

Indica una situazione di pericolo potenziale che potrebbe comportare lesioni lievi o moderate.

Indica una situazione che, se non evitata, può danneggiare lo strumento. Informazioni che richiedono particolare

attenzione da parte dell'utente.

A V V IS O

Etichette di avvertimento

Leggere tutte le etichette e i contrassegni presenti sullo strumento. La mancata osservanza di questi

avvertimenti può causare lesioni personali o danni allo strumento. Un simbolo sullo strumento è

indicato nel manuale unitamente a una frase di avvertenza.

Tale simbolo, se apposto sullo strumento, fa riferimento al manuale delle istruzioni per il

funzionamento e/o informazioni sulla sicurezza.

Questo simbolo indica un rischio di scosse elettriche e/o elettrocuzione.