Page 1

DOC023.52.00117

SONATAX sc

User manual

04/2012, Edition 3A

© HACH-LANGE GmbH, 2006, 2010, 2012. All rights reserved. Printed in Germany

Page 2

Page 3

Table of contents

Section 1 Technical data ........................................................................................................................................ 5

Section 2 General information ............................................................................................................................... 7

2.1 Safety information .............................................................................................................................................. 7

2.1.1 Use of hazard information ........................................................................................................................ 7

2.1.2 Precautionary labels ................................................................................................................................. 7

2.2 General sensor information................................................................................................................................ 8

2.2.1 Property rights note .................................................................................................................................. 8

2.2.2 Usage areas ............................................................................................................................................. 8

2.3 Device overview................................................................................................................................................. 8

2.4 Functional principle ............................................................................................................................................ 9

Section 3 Installation ............................................................................................................................................ 11

3.1 Unpack sensor ................................................................................................................................................. 11

3.1.1 Handling of the immersed probe ............................................................................................................ 11

3.2 Connect sensor to an sc controller .................................................................................................................. 11

3.2.1 Connect sensor with quick connection ................................................................................................... 11

3.3 Function test .................................................................................................................................................... 12

3.4 Install sensor.................................................................................................................................................... 13

3.4.1 Select the measurement location and pre-set the device....................................................................... 13

3.4.1.1 Determine the distance to the tank edge ....................................................................................... 15

3.4.1.2 Determine measurement location .................................................................................................. 15

3.4.2 Installation of the sensor......................................................................................................................... 18

3.5 Advanced settings............................................................................................................................................ 18

Section 4 Operation .............................................................................................................................................. 23

4.1 Use of the sc controller .................................................................................................................................... 23

4.2 Sensor data logging ......................................................................................................................................... 23

4.3 Sensor setup.................................................................................................................................................... 23

4.3.1 Change of the sensor name ................................................................................................................... 23

4.4 SENSOR STATUS menu................................................................................................................................. 23

4.5 SENSOR SETUP menu ................................................................................................................................... 23

Section 5 Maintenance ......................................................................................................................................... 27

5.1 Maintenance tasks ........................................................................................................................................... 27

5.2 Wiper change................................................................................................................................................... 27

5.3 Cleaning tasks ................................................................................................................................................. 28

Section 6 Troubleshooting................................................................................................................................... 29

6.1 Operating state LED ........................................................................................................................................ 29

6.2 Error messages................................................................................................................................................ 29

6.3 Warnings.......................................................................................................................................................... 30

6.4 SLUDGE DOCTOR, (diagnostic software for SONATAX sc)........................................................................... 30

Section 7 Replacement parts and accessories ................................................................................................ 31

7.1 Replacement parts........................................................................................................................................... 31

7.2 Accessories...................................................................................................................................................... 31

3

Page 4

Table of contents

Section 8 Warranty and liability........................................................................................................................... 33

Section 9 Contact ................................................................................................................................................. 35

Modbus register .................................................................................................................................................. 37

4

Page 5

Section 1 Technical data

Changes reserved!

General

Measurement method Ultrasonic measurement (750–1250 kHz)

Measuring range 0.2 m–12 m (0.7 ft–40 ft) sludge level

Resolution 0.03 m (0.1 ft) sludge level

Accuracy 0.1 m (0.33 ft)

Response time 10–600 s (adjustable)

calibration One time on commissioning

Environmental conditions

Ambient temperature \> 0–50 °C (\> 0–122 °F)

Temperature compensation Automatic

Flow speed Max. 3 m/s

Pressure range

Sensor specifications

Dimensions 130 mm

Earth Approximately 3.5 kg (123.5 oz) (without struts)

Maintenance requirements < 1 hour/month, typically

Cable length 10 m (33 ft), maximum 100 m (330 ft) with extension cable

Power consumption 12 V, 2.4 W, (200 mA)

Protection type IP68 (

Compliance CE, TÜV GS, UL/CSA

Materials

Probe body Stainless steel 1.4581

Base plate and wiper POM

Wiper magnet casting compound Epoxy resin

Wiper rubber Silicone rubber

Housing seals NBR (acrylonitrile butadiene rubber)

Light guide seal Polyurethane

0.3 bar or 3 m ( 43.55 psi or 10 ft)

× 185 mm (5 in. × 7.3 in.) (H × Ø)

1 bar (14.5 psi))

Light guide LEXAN polycarbonate

Sensor connection cable

(fixed connection)

Sensor connection plug (fixed

connection)

Cable gland Stainless steel 1.4571

Cable gland insert TPE-V

Cable gland O-ring NBR, silicone

1 cable pair AWG 22 / 12 VDC twisted, 1 cable pair AWG 24 / data twisted,

common cable shield, Semoflex (PUR)

Type M12, protection type IP67

5

Page 6

Technical data

6

Page 7

Section 2 General information

The information in this manual has been carefully checked and is

believed to be accurate. However, the manufacturer assumes no

responsibility for any inaccuracies that may be contained in this

manual. In no event will the manufacturer be liable for direct,

indirect, special, incidental or consequential damages resulting

from any defect or omission in this manual, even if advised of the

possibility of such damages. In the interest of continued product

development, the manufacturer reserves the right to make

improvements in this manual and the products it describes at any

time, without notice or obligation.

Revised editions are found on the manufacturer’s web site.

2.1 Safety information

Please read this entire manual before unpacking, setting up or

operating this equipment. Pay attention to all danger, warning and

caution statements. Failure to do so could result in serious injury to

the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not

impaired, do not use or install this equipment in any manner other

than that specified in this manual.

2.1.1 Use of hazard information

2.1.2 Precautionary labels

DANGER

Indicates a potentially or imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or

moderate injury.

Notice

Indicates a situation that, if not avoided, could result in damage to the

instrument. Information that requires special emphasis.

Note: Information that supplements points in the main text.

Read all labels and tags attached to the instrument. Personal injury

or damage to the instrument could occur if not observed.

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

7

Page 8

General information

Electrical devices marked with this symbol may after August 12, 2005 no longer be disposed of in unsorted

domestic or industrial waste Europe-wide. In conformity with European local and national regulations (EU

Directive 2002/96/EC), European electrical equipment users must now return old or end-of life equipment to

the manufacturer for disposal This is free for the consumer.

Note: Obtain instructions on the correct disposal of all (marked and not marked) electrical products that were

supplied or manufactured by the manufacturer at the relevant sales office.

2.2 General sensor information

2.2.1 Property rights note

The SONATAX sc is intended for the measurement of sludge levels

in water. Use in other media without test of the materials (refer to

Section 1 Technical data on page 5) or consultation with the

manufacturer is regarded as explicitly not in accordance with

requirements.

Any use other than use in accordance with requirements defined in

the user manual leads to the loss of the warranty claims and can

lead to personal injury and property damage, for which the

manufacturer assumes no liability.

Parts of the device software are based on the work of the

Independent JPEG Group.

2.2.2 Usage areas

2.3 Device overview

The SONATAX sc can be used anywhere that the solid/liquid

separation layer must be monitored.

For example in the area of final sedimentation or in sludge

treatment (thickeners).

Figure 1 shows the device components of the SONATAX sc.

Figure 1 Device overview

1 Operating state LED (refer to Section 6.1) 3 Mount for the tank edge attachment

2 Wiper 4 Sensor head

8

Page 9

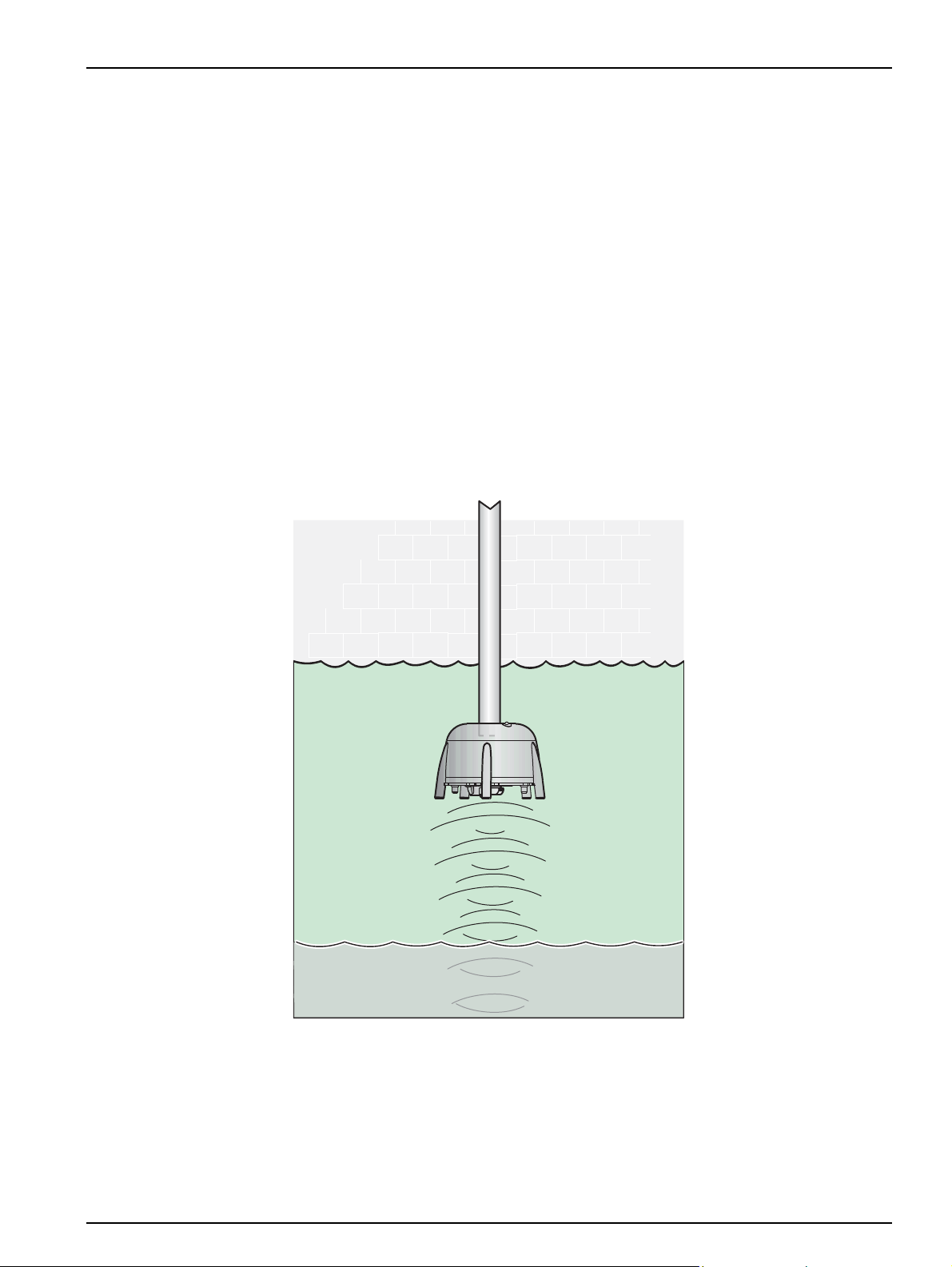

2.4 Functional principle

General information

In a tank where solid materials in water (or another fluid) can settle

to the bottom, there is a boundary between the settled solids and

the clear phase above. The distance from the water surface to the

bottom is the sludge level. The sludge height is the distance from

the tank floor.

More precisely, the sludge level (or the sludge height) indicates the

place in a tank where (viewed from the water surface) the solid

content first exceeds a defined limit. This limit value depends on the

application. It will, for example, be higher in a pre-thickener of a

wastewater treatment plant than in its final sedimentation, where

the overlying fluid should be clear water.

The SONATAX sc measures the sludge level via an echo signal

(refer to Figure 2) of an ultrasonic pulse. This echo signal is shown

in the probe menu SENSOR SETUP > TEST / MAINT > SIGNALS

in the echo list (refer to ECHO LIST on page 26). The depth and the

echo strength are specified at the ultrasonic transducer in digits

(1 digit approximately 1 µV).

Figure 2 Functional principle

Echos from layers that are further away are quieter (weaker) than

those which are closer. The SONATAX sc compensates for this

attenuation. The result is indicated on the SONATAX sc as a profile.

The data is found in the probe menu SENSOR SETUP > TEST /

MAINT > SIGNALS in the profile list (refer to PROFILE LIST on

9

Page 10

General information

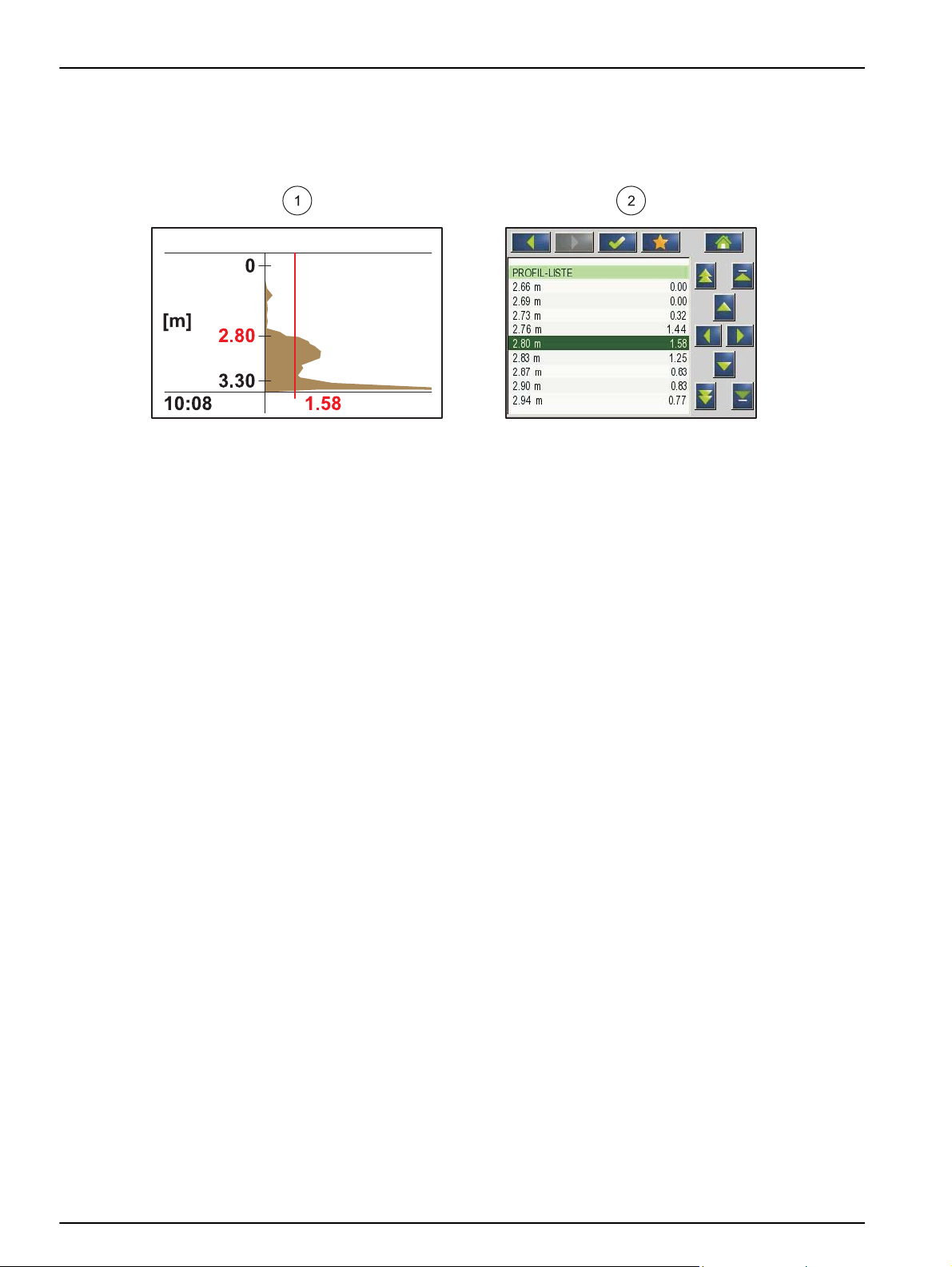

page 26) ((2) Figure 3). The graphic display (for example sc1000)

shows the profile in the measurement operation as a graphic ((1)

Figure 3).

Figure 3 Profile as graphic and list

The example shows a typical profile curve of a sludge level

measurement. The Y axis in this graphic reaches from the floor

(which can be set in the probe menu SENSOR SETUP >

CALIBRATE > TANK DEPTH on page 24) up to the water surface.

The profile strength is given on the X axis. The profile increases at

a sludge level. If the solid content below the sludge level remains

constant, the profile strength decreases again due to the absorption

of the ultrasound in the sludge. At the very bottom, the echo of the

floor is normally detected.

The vertical line represents the threshold. The sludge level is

detected by the SONATAX sc at the point at which the profile

exceeds this threshold for the first time viewed from above

(analogous to the abovementioned definition of the sludge level). In

the graphic, the detected sludge level is identified by a mark on the

Y axis.

The threshold is set automatically on the SONATAX sc (setting:

THRESHOLD AUTO = xy % in the probe menu SENSOR SETUP >

CALIBRATE > ADV.SETTINGS > THRESHOLD AUTO on

page 24). The automatic threshold function searches for the

maximum in the detected profile. Through an exact setting of the

tank depth, a faulty measurement due to the echo of the floor is

ruled out.

The background is that the echo signal of the floor in most tanks is

the strongest in the profile. With a correct setting of the tank depth,

the floor signal is not considered by the automatic threshold

function during the determination of the sludge level.

For more information on the correct determination of the tank

depth, refer to section Section 3.4.1 on page 13.

10

Page 11

Section 3 Installation

3.1 Unpack sensor

DANGER

The installation described in this section of the user manual should only

be performed by qualified and specialized personnel. The sensor is not

suitable for installation in hazardous areas.

The SONATAX sc can be used with an sc100, sc200 or with an

sc1000 controller. Installation instructions are found in the

handbook of the controller.

The SONATAX sc is supplied with the following components:

• Sensor

• User manual

• Wiper blades set (5 pieces)

If one of the parts is missing or damaged, please contact the

manufacturer or dealer.

3.1.1 Handling of the immersed probe

The immersed probe contains a sensitive ultrasound transducer.

Make sure that this is subjected to no hard mechanical impacts. Do

not install the probe hanging on the cable. Make sure before the

insertion of the probe into the medium that all functions run

undisrupted through a check of the system. Check the probe

carefully for external damage.

3.2 Connect sensor to an sc controller

3.2.1 Connect sensor with quick connection

The sensor cable is very easy to connect to the controller using a

quick connection (Figure 4). Keep the protective cap of the

connection socket in case you remove the sensor later and must

seal the socket. For longer sensor cable lengths, optional extension

cables are available.

Figure 4 Connect sensor with quick connection

11

Page 12

Installation

1

2

3

4

5

6

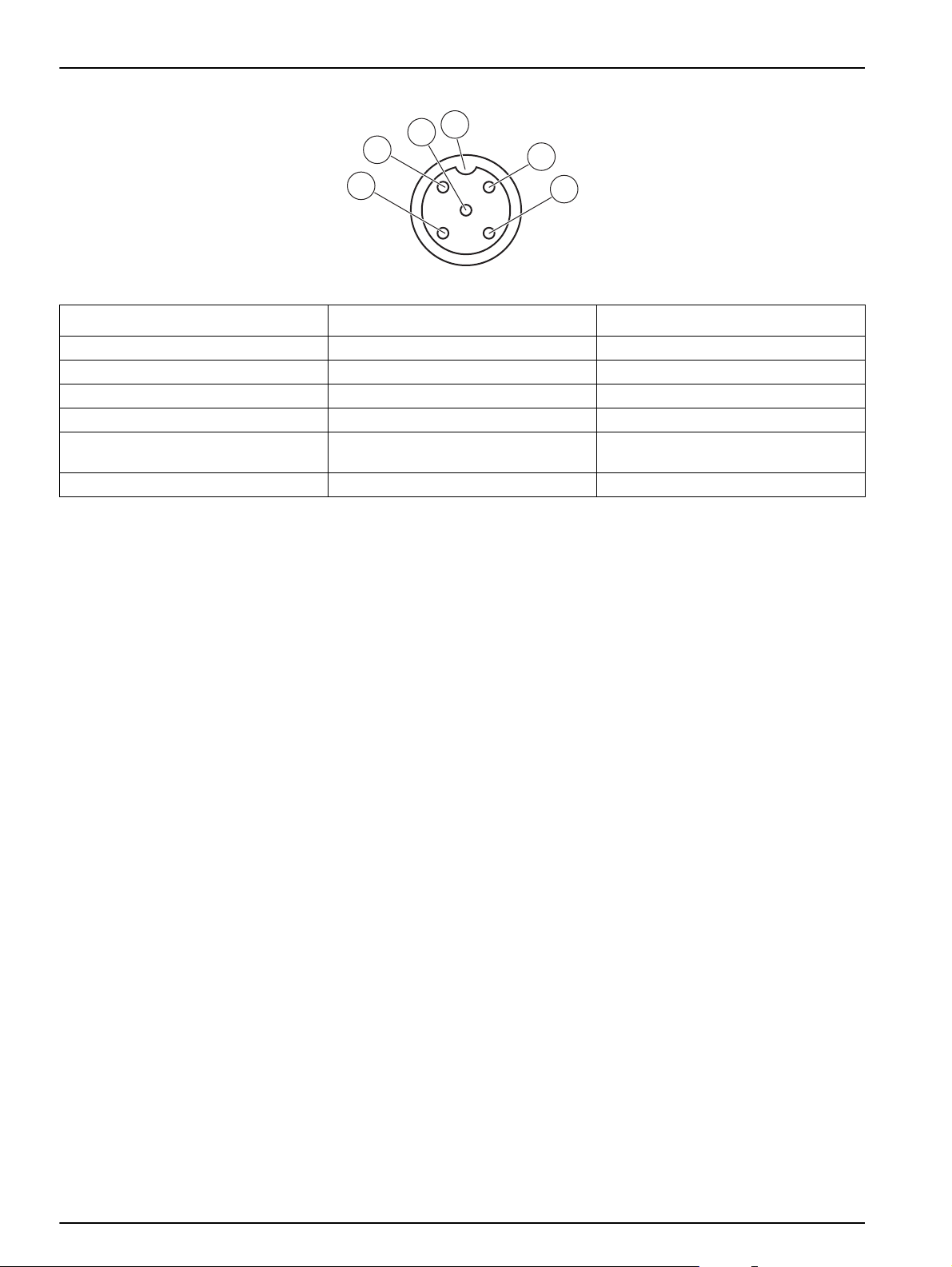

Figure 5 Pin assignment of the quick connection

Number Assignment Wire color

1 +12 V= Brown

2EarthBlack

3 Data (+) Blue

4 Data (–) White

5Shield

6 Insulator notch

Shield (gray wire for existing quick

connection)

3.3 Function test

Directly after the connection of the sensor to the controller, perform

a function check.

1. Connect the controller to the mains power.

2. If the controller does not recognize the new sensor, go to the

SCAN SENSORS menu (refer to the user manual of the

controller).

3. Confirm any prompt and wait until the new sensor is found.

If the new sensor is found, the controller switches to the

measurement operation.

A wipe process is triggered and the device switches to the

measurement operation. If no other messages appear, the sensor

is functional.

Note: Measurements in air lead to no measurement values. The error

message SENSOR MEASURE is shown. This does not show a

malfunction.

12

Page 13

3.4 Install sensor

Installation

The SONATAX sc is intended for installation with a tank edge

attachment. For more information, refer to the installation

instructions of the tank edge attachment.

Note: Do not begin with the installation of the tank edge attachment before

the installation location is determined (refer to Section 3.4.1).

Figure 6 SONATAX sc scale drawing

3.4.1 Select the measurement location and pre-set the device

In the determination of the sludge level over the duration of an

ultrasonic echo, the entire space between the probe on the water

surface and the tank bottom is required for the measurement. As

solid bodies in this area disrupt the measurements, special

attention is required in the selection of the measurement location.

In the following, it is explained how the suitability of a possible

measurement location can be tested. The tank depth should be

known here.

A suitable measurement location must be found depending on tank

type. The graphics that follow show typical examples for a round

tank and a rectangular tank. The point (1) in Figure 7 and Figure 8

is a suitable measurement location.

13

Page 14

Installation

Figure 7 Round tank graphic

Figure 8 Rectangular tank graphic

At a suitable measurement location, there should be:

• Sufficient sludge present for the measurement, and

14

• A calm, clear phase above the sludge level

In the examples shown, area (A) shows only very little or no sludge,

while in the area (C) above the sludge layer, sludge clouds may

disrupt the measurement. The measurement points (A) and (C) are

Page 15

not suitable for the installation. Suitable measurement points can be

found in between.

Note: Installation note: For round tanks with a rotating scraper bridge,

install the probe in the direction of rotation on the back of the bridge

(Figure 7).

3.4.1.1 Determine the distance to the tank edge

If the SONATAX sc is installed on the tank edge (i.e. not on a

scraper bridge), make sure there is sufficient distance from the

SONATAX sc to the tank edge.

This distance is dependent on the depth of the tank.

Use this formula to find a guideline value for this distance:

0.20 m + (0.05 x tank depth in meters) = distance to tank edge

This value can vary depending on composition of the tank. How a

possible installation location can be checked for its suitability is

described in Section 3.4.1.2 Determine measurement location.

3.4.1.2 Determine measurement location

1. Connect the probe to the sc controller and carefully immerse

the probe in the water (approximately

probe cable at the selected measurement location.

Installation

20 cm (7.9 in.)) on the

2. Select the probe menu SENSOR SETUP > CALIBRATE and do

a measurement in the REFLEXLIST menu item.

After a few seconds, the reflex list is shown (refer to REFLEXLIST

on page 24). This list usually contains the tank floor as the

strongest signal.

If strong reflections between the water surface and the tank floor

are present (for example due to pipes, plates etc.), another

measurement location must be selected. Sometimes it is sufficient

to move the probe by a few centimeters.

In the example (Table 1), there are two disruptive reflexes at a

depth of 0.87 m and 2.15 m, and the tank floor is at a depth of

3.30 m.

Table 1 Reflex list

Meters Intensity

0.87 25 %

2.15 2 %

3.30 100 %

At an ideal measurement location, no disruptive reflections should

occur above the floor in the reflex list after multiple measurements

(Table 2).

Table 2 Reflex list

Meters Intensity

3.30 100 %

15

Page 16

Installation

If no measurement location without disruptive reflexes can be

found, select the probe menu SENSOR SETUP > CALIBRATE and

trigger a measurement in the PROFILE LIST menu item.

• If there are increased values at the depth of the disruptive

reflexes in the PROFILE LIST which influence the

measurement value, another measurement location must be

selected. Sometimes it is sufficient to move the probe by a few

centimeters (refer to

Figure 9, right).

• If the reflections do not disrupt the measurement value, this can

be a suitable measurement location (refer to

Figure 9, left).

Figure 9 Determine measurement location

3. Then assemble the tank edge attachment there and install the

probe.

Note: The probe should be installed approximately 20 cm (7.9 in.) deep

at the installation location (somewhat more than the entire probe head) to

make sure that it remains immersed during the entire measurement

operation.

4. In the CALIBRATE probe menu, enter the actual plunger depth

(Item A,

Figure 10) in the PLUNGERDEPTH menu item.

5. Trigger after approximately 2 minutes another measurement of

the reflex list (to adjust the temperature sensor to the water

temperature) (also refer to

6. In the CALIBRATE probe menu, enter the recorded value of the

tank depth (Item C,

Figure 10) in the TANK DEPTH menu item.

Important note: The shown value of the tank depth is calculated

from information shown:

Tank depth C = plunger depth A + measured distance to floor B

This calculation is performed internally and leads to incorrect

results if the plunger depth is entered incorrectly.

REFLEXLIST on page 24).

16

Page 17

Installation

Figure 10 Plunger depth–tank depth

Note: Should the reflex list not contain the tank depth (possible when there

is a lot of sludge above the floor), the tank depth must be determined in

another way (e.g. measuring).

Important note: The value entered in the TANK DEPTH menu item

must in no case be larger than the actual tank depth. This could

lead to incorrect measurement values.

In the determination of a suitable measurement location, the

optionally available SLUDGE DOCTOR diagnostic software can be

helpful (refer to 7.2 Accessories on page 31). The software enables

the representation and saving of all graphic profiles of the

SONATAX sc in a defined time interval (5 minutes–2 hours).

17

Page 18

Installation

3.4.2 Installation of the sensor

The software also shows and saves all important measurement and

configuration parameters, such as the reflex list, measurement

values, limit values and all advanced settings, such as response

time, frequency, amplitude, angle and temperature.

Take further information from the SLUDGE DOCT OR user manual

DOC013.98.90411.

Note: Take further information on the installation from the installation

instructions.

3.5 Advanced settings

18

Figure 11 Installation of the sensor

In the SENSOR SETUP > CALIBRATE > ADV. SETTINGS menu,

special probe parameters can be found.

The default settings of these parameters are selected so that no

correction is required in most applications. In exceptional cases,

these parameters must be adapted depending on the application.

The examples that follow show typical sludge profiles.

Page 19

Installation

Example 1: Pre-thickener with clear separation layer, but

sporadically empty.

The image shows a thickener with a clear profile. The signals above

the sludge level caused by turbid water do not disrupt the

measurement.

The same thickener is empty in this image. The threshold now

justs itself automatically to the signals of the turbid water. The

ad

recorded measurement value at 0.63 m is incorrect.

Recommended measure:

Increase the adjustment of the ADV. SETTINGS > LL THRESH.

AUTO setting from 0.3 to 1.0.

Note: LL THRESH. AUTO gives the smallest possible value that the

threshold can accept.

The image shows the empty thickener after the adjustment. The

result 3.18 m is correct.

Example 2: Application with c

signal.

Very low to absolutely no interference signals through turbid water

above the separation layer. Strength of the echo 0.61 is above the

LL THRESH. AUTO (pre-setting 0.3) and leads to correct

measurement value 2.28 m.

lear separation layer, but weak

19

Page 20

Installation

Very low to absolutely no interference signals through turbid water

above the separation layer. Strength of the maximum echo <0.3.

Instead of the correct measurement value, only the tank floor is

found.

Increase the adjustment of the ADV. SETTINGS > LL THRESH.

O setting from 0.3 to 0.1. The threshold 0.16 finds the correct

AUT

measurement value 2.25 m.

Example 3: Thickene

concentration up to just under the water surface; echo is absorbed

in the uppermost sludge layer:

In this application, the floor signal is no longer detected due to the

high absorption of the ultrasonic signal. The shown measurement

value 0.73 is correct. No adjustment of the ADV. SETTINGS

necessary.

If the sludge increases so far that the sludge level is above the

easurement range (the measurement range begins from 0.2 m

m

beneath the sensor), it can occur that no sludge level is detected

(SENSOR MEASURE error message). In this case, the application

must be checked.

r or other application with very high sludge

20

Page 21

Installation

Example 4: Application with large tank depth and clear separation

layer, but high absorption of the ultrasound by turbid materials

above the separation layer.

Absorption is so high that no sludge level is detected at a plunger

depth of 0.2 m and LL THRESH. AUTO 0.1 (SENSOR MEASURE

error message).

After adjustment of the plunger depth SENSOR SETUP >

CALIBRA

precisely determined at 3.30. The strength of the echo 1.41 shows

that there is a clear separation layer.

Note: After adjustment of the plunger depth, the setting of the tank floor

must be checked (SENSOR SETUP > CALIBRATE > TANK DEPTH)

TE > PLUNGERDEPTH to 3 m, the sludge level can be

Example 5: Application with clear separation layer, but interference

signal above the separation layer (for example skimmer).

Ideal profile, correct measurement value.

The same measurement point with sporadic interference of the

o in a 0.67 m tank depth. The measurement value is incorrect.

ech

21

Page 22

Installation

Fade out this disruption in SENSOR SETUP > CALIBRATE > ADV.

SETTINGS > FADE-OUT in the range of 0.5–0.8 m. The sensor

now ignores all signals in this range and finds the correct

measurement value at 2.13 m.

Example 6: Application

cloud above the separation layer.

In this application, the separation layer should be measured, the

sludge cloud should be ignored (for example pre-thickener).

No change of the default setting. The automatic threshold detects

the separation layer; the echo of the sludge cloud is lower than the

echo of the sludge cloud.

The image shows the same profile as before, but with another

reshold and measurement value.

th

In this application, the sludge cloud should be measured as an

early warning system (for example sludge drift in the final

clarification tank).

Change of the automatic threshold SENSOR SETUP >

CALIBRATE > ADV. SETTINGS > THRESHOLD AUTO to 25 %.

The automatic threshold detects the sludge cloud.

with clear separation layer and a sludge

22

The optionally available SLUDGE DOCTOR diagnostic software

can be helpful for the setting of the special probe parameters (refer

to 7.2 Accessories on page 31). The software enables the

representation and saving of all graphic profiles of the SONATAX sc

in a defined time interval (5 minutes–2 hours).

The software also shows and saves all important measurement and

configuration parameters, such as the reflex list, measurement

values, limit values and all advanced settings, such as response

time, frequency, amplitude, angle and temperature.

Take further information from the SLUDGE DOCT OR user manual

DOC013.98.90411.

Page 23

Section 4 Operation

4.1 Use of the sc controller

4.2 Sensor data logging

4.3 Sensor setup

Before using the sensor with an sc controller, make yourself familiar

with the operating method of the controller. Learn to navigate

through the menu and to use the menu functions. Further

information is found in the user manual of the controller.

The sc controller provides one data log and one event log for each

sensor. The data log stores the measurement data at selectable

intervals. The event log stores a large number of events that occur

on the devices, such as configuration changes, alarms and

warnings etc. The data log and the event log can be read out in

CSV format. Refer to the controller user manual for more

information about the log download.

During initial sensor setup, select the parameter that corresponds

to the applicable instrument.

4.3.1 Change of the sensor name

When a sensor is installed for the first time, the serial number is

shown as the measurement location (or sensor name). The

measurement location can be changed as follows:

1. From the main menu, select SENSOR SETUP and confirm the

selection.

2. If more than one sensor is connected, mark the required sensor

and confirm the selection.

3. Select CONFIGURE and confirm the selection.

4. Select EDITED NAME and edit the name. Return to the Sensor

Setup menu with confirm or cancel.

4.4 SENSOR STATUS menu

Select the SONATAX sc (if several sensors are connected)

SONATAX sc

ERRORS Lists error messages; refer to 6.2 Error messages on page 29

WARNINGS Lists warnings; refer to 6.3 Warnings on page 30

4.5 SENSOR SETUP menu

Select the SONATAX sc (if several sensors are connected)

WIPE

CALIBRATE

Plunger depth of the probe underside (refer to 3.4.1.2 Determine measurement

PLUNGERDEPTH

location on page 15).

Configurable: 0.1 m to 3 m (0.3 ft to 9.8 ft)

23

Page 24

Operation

4.5 SENSOR SETUP menu (Continued)

Select the SONATAX sc (if several sensors are connected)

Shows the reflex list. A new measurement can be triggered.

A list is shown of all detected solid bodies that have clearly reflected the ultrasonic

impulse. The measurement depth is shown in m or ft and the strength of the

REFLEXLIST

TANK DEPTH

PROFILE LIST

ADV. SETTINGS

FACTOR

THRESHOLD AUTO

LL THRESH. AUTO

FADE-OUT

BEGIN

END

SET DEFAULTS

reflected signal in %, relative to the strongest signal in the list. This list mostly

contains the tank floor. If strong reflections between the water surface and the tank

floor are present (for example due to pipes, plates etc.), it should be checked

whether another installation location offers better conditions.

Entry of the floor depth (refer to 3.4.1.2 Determine measurement location on

page 15).

Configurable: 1.00 m to 12 m (3.3 ft to 39.4 ft)

A profile is calculated from the ultrasound echo and shown for the corresponding

depths respectively as profile strength. The profile is similar in its curve with the TS

profile of the tank. At an average solid content, the values are in the order of 1. A

new measurement can be triggered (refer to Figure 3 on page 10).

Correction factor for the speed of sound.

Configurable: 0.3 to 3.0, default setting 1.0

A change of the default factor is only required if the local speed of sound in the fluid

deviates from the speed of sound in water:

Factor (fluid) = speed of sound (fluid) / speed of sound (water)

Note: For applications in water, the factor should remain at 1.0.

With the automatic threshold function, the system constantly adapts the

environmental conditions and automatically changes the sensitivity in order to

guarantee maximum accuracy.

Recommendation: 75%

Configurable: 1-95%

LL THRESH. AUTO gives the smallest possible value that the threshold can accept.

Configurable: 0.1 to 1.0, recommendation 0.3

If fixed installations or other influences interfere at certain tank depths, then this

range can be faded out —·it is then completely ignored.

Configurable: ON, OFF

Upper limit of the range that should be faded out.

Only active when FADE-OUT = ON.

Lower limit of the range that should be faded out.

Only active when FADE-OUT = ON.

Reset to factory configuration for all probe-specific parameters. This occurs only

after a security prompt.

24

Page 25

4.5 SENSOR SETUP menu (Continued)

Select the SONATAX sc (if several sensors are connected)

KONFIGURIEREN (CONFIGURE)

Operation

EDIT NAME

PAR AMETER

MEAS UNITS

CLEAN. INTERVAL

RESPONSE TIME

LOGGER INTERVAL

SET DEFAULTS

TEST / MAINT

PROBE INFO

SENSOR NAME Display of the device name.

EDIT NAME

SERIAL NUMBER. Device number

MODEL NUMBER Item no. of the sensor.

HARDWARE-VERS Production status of main circuit board

SOFTWARE-VERS Sensor software version

COUNTER

WIPER COUNTER

TOTAL TIME Operating hours counter

MOTOR Forward counter for wiping processes.

TEST / MAINT Date of the last performed maintenance.

REPLACE PROFILE

Freely editable (up to 16 characters)

Factory setting: device number

The measurement result can be shown as the sludge level (as the distance of the

sludge from the water surface) or as the sludge height (as the distance from the tank

floor). To calculate the sludge height, the tank depth specified in the TANK DEPTH

menu item is used.

(Sludge height = tank depth – sludge level)

Configurable: sludge level, sludge height

Dimension of the measurement result.

Configurable: meters, feet

Wipe interval,

Recommendation: 15 minutes

Configurable: 1 minute to 1 hour

Damping of the measurement value. In the case of high measurement value

fluctuations, a high damping of for example 300 seconds is recommended.

Configurable: 10 to 1800 seconds

The interval for the internal data log.

Configurable: 1, 2, 3, 4, 5, 6, 10, 15, 30 minutes

Reset to factory configuration for all menu items listed above. This occurs only after

a security prompt.

Display of the freely selectable measurement location

(factory setting: device number).

Backward counter for wiping processes of the wiper profile.

After expiration of the counter, a warning message is shown. In the case of a wiper

change, the counter should be reset again.

For the wiper profile change, the wiper arm moves to a central position. In this

position, the wiper arm can then be removed and installed without problems.

25

Page 26

Operation

4.5 SENSOR SETUP menu (Continued)

Select the SONATAX sc (if several sensors are connected)

TEST / MAINT

SIGNALS

MOIST Indicator as to whether water is in the probe.

TEMPERATURE Temperature of the surrounding water in °C or F°.

SENSOR ANGLE Deviation of the probe axis from the perpendicular in degrees.

The received echo signal in digits (units of the AD converter) is shown at the

ECHO LIST

PROFILE LIST

REFLEXLIST

FREQUENCY The resonance frequency of the ultrasound transducer is shown.

AMPL DIAG The resonance voltage of the ultrasound transducer is shown.

THRESHOLD

SHOW AMPL.

corresponding measurement depths in a list. The first element at 0 meters shows the

strength of the transmission pulse.

A new measurement can be started.

A profile is calculated from the ultrasound echo and shown for the corresponding

depths respectively as profile strength. The profile is similar in its curve with the TS

profile of the tank. At an average solid content, the values are in the order of 1.

A new measurement can be started. (See Figure 3 on page 10)

Shows the reflex list. A new measurement can be triggered. Refer to REFLEXLIST

on page 24

To determine the sludge level, a profile is first calculated from the ultrasonic echo.

This roughly returns the solid content depending on the tank depth. The sludge level

is assigned to the tank depth where the profile exceeds the threshold for the first

time.

On activation, the resonance profile of the ultrasound transducer is shown instead of

the sludge profile (PROFILE LIST) as a graphic in the measurement window (only

valid with sc1000). The resonance profile can be switched ON and OFF.

After switch-off, the sludge profile (PROFILE LIST) is shown on the measurement

window again.

26

Page 27

Section 5 Maintenance

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

No components that can be serviced by the user are in the inside of

the probe. Opening of the probe by the user leads to the loss of the

manufacturer guarantee and may cause malfunctions.

The cleanliness of the ultrasound transducer is crucial for the

accuracy of the measurement results.

The installed wiper is able to remove all impurities under normal

circumstances and if the selection of the wiper interval is not too

large (30 minutes).

If the regular check of the probe head and of the wiper (monthly)

indicates dirt, wear of the wiper rubber or a defect, then either the

probe head must be cleaned, or the wiper profile and/or the

defective part must be exchanged.

5.1 Maintenance tasks

DANGER

Take the maintenance intervals from Table 3.

Table 3 Maintenance schedule

Time interval Action

Monthly Visual inspection, if necessary, clean

Annually, at the latest after 20,000 wipe cycles Change wiper rubber

5.2 Wiper change

CAUTION

Obey the locally applicable accident prevention regulations. Wear

protective gloves where necessary during the change of the wiper

rubber.

1. Go to SENSOR SETUP > TEST / MAINT >

REPLACE

The wiper arm (refer to item 3 in Figure 12) moves for the wiper

change into a central position.

2. Remove the guide screw (refer to item 2 in Figure 12) and take

off the wiper arm.

PROFILE.

3. Pull the wiper profile (refer to item 1 in Figure 12) forward out of

the wiper arm.

4. Slide a new wiper profile with the bevel at the front into the

guide.

27

Page 28

Maintenance

5. Install the wiper arm again and tighten the guide screw again

by hand.

Note: Only tighten the screw hand-tight until the safety lugs have audibly

engaged 2–3 times.

6. Select OK and the wiper arm automatically moves back to the

initial position.

Figure 12 Wiper unit

1 Wiper profile 3 Wiper arm

2 Guide screw

5.3 Cleaning tasks

Use water and a suitable brush to remove heavy contamination on

the probe or on the strut as necessary.

Clean the ultrasound transducer carefully with water and a lint-free

cloth.

28

Page 29

Section 6 Troubleshooting

6.1 Operating state LED

The sensor is equipped on the top side with an LED that provides

information on the operating state.

Figure 13 Operating state LED

1 Operating state LED

Table 4 Sensor status

Green LED No errors or warnings

Green/red flashing LED

Red LED Error

LED off No device function

Probe in operation, probe position deviates strongly from the perpendicular, the

measurement value is retained, there is no error

6.2 Error messages

In the case of an error, an error message is shown on the controller.

Find error messages and notes on the resolution of the errors in

Table 5.

Table 5 Error messages

Error message Reason Resolution

The PROFILE LIST and graphic on the sc1000

is less than the programmed value for

SENSOR MEASURE

POS. UNKNOWN

AMPL DIAG Internal error Call service

MOIST Moisture value \> 10 Call service

SENSOR ANGLE

SYSTEM ERROR Faulty RAM Call service

LL THRESH.AUTO. over the entire tank depth,

or the ultrasound transducer is contaminated or

not immersed.

The wiper position is not detected. The wiper is

in the central position (after a wiper change).

Defective light barrier plate Call service

Application with particles that block the wiper.

The probe is more than 20° from perpendicular

and for longer than 180 seconds.

Incorrectly calibrated position sensor Call service

Check device data, also the plunger depth,

floor depth and advanced settings, check

installation and remove contamination.

Start a wiping process

Cleaning of the ultrasound transducer and of

the wiper system.

Check installation

29

Page 30

Troubleshooting

6.3 Warnings

In the case of a warning, a warning message is shown on the

controller. Find warnings and notes on the resolution of the warning

in Table 6.

Table 6 Warnings

Warning message Reason Resolution

REPLACE PROFILE The counter for the wiper profile has expired Change wiper profile

6.4 SLUDGE DOCTOR, (diagnostic software for SONATAX sc)

SLUDGE DOCTOR is an optionally available diagnostic software

for the SONATAX sc probe in connection with the controllers sc100,

sc200 or sc1000. The software enables the representation and

saving of all graphic profiles of the SONATAX sc in a defined time

interval (5 minutes–2 hours).

The software also shows and saves all important measurement and

configuration parameters, such as the reflex list, measurement

values, limit values and all advanced settings, such as response

time, frequency, amplitude, angle and temperature.

Take further information from the SLUDGE DOCT OR user manual

DOC013.98.90411.

30

Page 31

Section 7 Replacement parts and accessories

7.1 Replacement parts

Description Number Order number

SONATAX sc 1 LXV431.99.00001

1 set of replacement wiper blades out of silicone

for SONATAX/SONATAX sc probes (5 pieces)

Wiper arm 1 LZY344

Guide screw

(for stopping the wiper arm)

User manual (xx=language code) 1 DOC023.xx.00117

7.2 Accessories

Description Order number

Pivot attachment set, 0.35 m (1.15 ft) LZX414.00.72000

Pivot attachment set, 1 m (3.3 ft) LZX414.00.71000

Rail assembly attachment set LZX414.00.73000

Tank edge attachment set LZX414.00.70000

Scraper bridge attachment set LZX414.00.74000

SONATAX sc chain stay LZX914.99.11300

SLUDGE DOCTOR, diagnostic software without interface cable LZY801.99.00000

SLUDGE DOCTOR, diagnostic software with sc200 interface cable LZY801.99.00010

SLUDGE DOCTOR, diagnostic software with sc1000 interface cable LZY801.99.00020

1LZX328

1LZY345

31

Page 32

Replacement parts and accessories

32

Page 33

Section 8 Warranty and liability

The manufacturer warrants that the supplied product is free of

material and manufacturing defects, and undertakes to repair or to

replace any defective parts without charge.

The warranty period is 24 months. If a maintenance contract is

taken out within 6 months of purchase, the warranty period is

extended to 60 months.

With the exclusion of further claims, the supplier is liable for

defects, including the lack of assured properties, as follows: all

parts that, within the warranty period calculated from the day of the

transfer of risk, can be demonstrated to have become unusable or

that can only be used with significant limitations owing to

circumstances prior to transfer of risk, in particular due to incorrect

design, substandard materials or inadequate finish, shall be

repaired or replaced at the supplier's discretion. The identification

of such defects must be reported to the supplier in writing as soon

as possible, but no later than 7 days after the discovery of the fault.

If the customer omits this notification, the product is considered

approved despite the defect. Further liability for indirect or direct

damages is not accepted.

If device-specific maintenance- or inspection work prescribed by

the supplier is to be performed within the guarantee period by the

customer (maintenance) or by the supplier (inspection) and these

requirements are not met, claims for damages that result from

non-observance of these requirements are void.

Further claims, in particular for consequential damages, cannot be

made valid.

Wear and damage caused by improper handling, incorrect

installation or non-designated use are excluded from this clause.

The process instruments of the manufacturer are of proven

reliability in many applications and are therefore often used in

automatic control loops to enable the most economical and efficient

operation of the relevant process.

To avoid or limit consequential damage, it is therefore

recommended that the control loop be designed such that an

instrument malfunction results in an automatic changeover to the

backup control system. This guarantees the safest operating

condition both for the environment and the process.

33

Page 34

Warranty and liability

34

Page 35

Section 9 Contact

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP. ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Zamówienia: +48 717 177 707

Doradztwo: +48 717 177 777

Fax +48 717 177 778

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Rossini, 1/A

I-20020 Lainate (MI)

Tel. +39 02 93 575 400

Fax +39 02 93 575 401

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 - Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edificio Seminario

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD.ŞTİ.

Ilkbahar mah. Galip Erdem

Cad. 616 Sok. No:9

TR-Oran-Çankaya/ANKARA

Tel. +90312 490 83 00

Fax +90312 491 99 03

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

35

Page 36

Contact

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE OOO

Finlyandsky prospekt, 4A

Business Zentrum “Petrovsky

fort”, R.803

RU-194044, Sankt-Petersburg

Tel. +7 (812) 458 56 00

Fax. +7 (812) 458 56 00

info.russia@hach-lange.com

www.hach-lange.com

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

36

Page 37

Appendix A Modbus register

Table 7 Sensor Modbus register

Tag name Register # Data type Length R/W Description

SLUDGELEVEL m 40001 Float 2 R Measured sludge level in m

SLUDGELEVEL ft 40003 Float 2 R Measured sludge level in ft

SLUDGEHEIGHT m 40005 Float 2 R Measured sludge height in m

SLUDGEHEIGHT ft 40007 Float 2 R Measured sludge height in ft

PLUNGERDEPTH m 40009 Float 2 R/W Plunger depth in m

PLUNGERDEPTH ft 40011 Float 2 R/W Plunger depth in ft

BOTTOM m 40013 Float 2 R/W Tank depth in m

BOTTOM ft 40015 Float 2 R/W Tank depth in ft

SET PARAMETER 40017 Unsigned integer 1 R/W

MEAS UNITS 40018 Unsigned integer 1 R/W Dimension set: meters, feet

FACTOR 40019 Float 2 R/W

WIPE 40021 Unsigned integer 1 R/W Wiper status

ERROR 40022 String 8 R Error shown

EDITED NAME 40022 String 8 R/W Name of the measuring location

CLEAN. INTERVAL 40030 Unsigned integer 1 R/W Wiper interval

RESPONSE TIME 40031 Unsigned integer 1 R/W Response time: 10–600 seconds

FADE-OUT 40032 Unsigned integer 1 R/W Blanking: ON/OFF

BEGIN m 40033 Float 2 R/W Blanking start in m

BEGIN ft 40035 Float 2 R/W Blanking start in ft

END m 40037 Float 2 R/W Blanking end in m

END ft 40039 Float 2 R/W Blanking end in ft

LOGGER INTERVAL 40041 Unsigned integer 1 R/W Logger interval

THRESHOLD AUTO 40042 Unsigned integer 1 R/W Automatic threshold function: ON/OFF

THRESHOLD 40043 Float 2 R/W Threshold value (manual): 0.1–50

WINDOW 40045 Unsigned integer 1 R/W Window

PROFILE COUNTER 40046 Unsigned integer 1 R/W Wiper profile counter

SERIAL NUMBER 40047 String 6 R Serial number

TEST / MAINT 40053 Time2 2 R/W Date of the last maintenance

PROGRAM 40055 Float 2 R Application version

BOOTPROG. 40057 Float 2 R Boot loader version

STRUCTURE 40059 Unsigned integer 1 R Structure driver version

FIRMWARE 40060 Unsigned integer 1 R Firmware driver version

CONTENT 40061 Unsigned integer 1 R Register driver version

FormatMinSL m 40062 Float 2 R Lower sludge level limit in m

FormatMaxSL m 40064 Float 2 R Upper sludge level limit in m

FormatMinSL ft 40066 Float 2 R Lower sludge level limit in ft

FormatMaxSL ft 40068 Float 2 R Upper sludge level limit in ft

FormatMinSH m 40070 Float 2 R Lower sludge height limit in m

FormatMaxSH m 40072 Float 2 R Upper sludge height limit in m

FormatMinSH ft 40074 Float 2 R Lower sludge height limit in ft

FormatMaxSH ft 40076 Float 2 R Upper sludge height limit in ft

MOIST 40078 Unsigned integer 1 R Moisture signal

Type of measurement: sludge level,

sludge height

Correction factor for the measured value:

0.9–1.1

37

Page 38

Table 7 Sensor Modbus register

Tag name Register # Data type Length R/W Description

TEMPERATURE 40079 Integer 1 R Temperature signal in °C

SENSOR ANGLE 40080 Unsigned integer 1 R Probe position signal in degrees

FREQUENCY 40081 Integer 1 R Resonance frequency signal in hertz

AMPL DIAG 40082 Integer 1 R Resonance voltage signal in volts

38

Loading...

Loading...