Page 1

DOC023.52.03232.Dez09

SOLITAX sc

User Manual

12/2009, Edition 4A

© HACH-LANGE GmbH, 2006–2009. All rights reserved. Printed in Germany.

Page 2

Page 3

Table of Contents

Section 1 Specifications......................................................................................................................................... 5

Section 2 General Information ............................................................................................................................... 7

2.1 Safety Information............................................................................................................................................... 7

2.1.1 Use of Hazard Information......................................................................................................................... 7

2.1.2 Precautionary Labels................................................................................................................................. 7

2.2 Sensor Overview................................................................................................................................................. 8

2.3 Measuring Principle ............................................................................................................................................ 8

2.4 Handling.............................................................................................................................................................. 8

Section 3 Installation .............................................................................................................................................. 9

3.1 Unpacking the Instrument ................................................................................................................................... 9

3.1.1 Function Check.......................................................................................................................................... 9

3.2 Sensor Installation............................................................................................................................................. 10

3.3 Pipe Installation..................................................................................................................................................11

3.4 Connecting sensor cable .................................................................................................................................. 13

Section 4 Operations ............................................................................................................................................ 15

4.1 Use of an sc controller ...................................................................................................................................... 15

4.2 Sensor Setup .................................................................................................................................................... 15

4.3 Sensor Data Logging ........................................................................................................................................ 15

4.4 Sensor Diagnostics Menu for pH and ORP ...................................................................................................... 15

4.5 Sensor Setup Menu .......................................................................................................................................... 15

4.6 Calibration......................................................................................................................................................... 16

4.6.1 Setting the Outmode................................................................................................................................ 17

4.6.2 Calibration for Turbidity............................................................................................................................ 17

4.6.2.1 Calculating the Factor .................................................................................................................... 17

4.6.3 Calibration for Suspended Solids ............................................................................................................ 18

4.6.3.1 For Single Point (Factor) Calibration.............................................................................................. 18

4.6.3.2 Multi-point Calibration .................................................................................................................... 18

Section 5 Maintenance ......................................................................................................................................... 19

5.1 Maintenance Schedule ..................................................................................................................................... 19

5.2 Cleaning the Sensor Measuring Windows ........................................................................................................ 19

5.3 Replacing the Wiper.......................................................................................................................................... 20

Section 6 Troubleshooting ................................................................................................................................... 21

6.1 Error Codes....................................................................................................................................................... 21

6.2 Warnings........................................................................................................................................................... 21

Section 7 Replacement Parts and Accessories .............................................................................................. 23

7.1 Immersion Sensors ........................................................................................................................................... 23

7.2 Insertion Sensors .............................................................................................................................................. 23

7.3 Replacement Parts............................................................................................................................................ 23

Section 8 Contact Information ............................................................................................................................ 25

Section 9 Warranty and liability ........................................................................................................................... 27

Appendix A Modbus Register Information ........................................................................................................ 29

3

Page 4

Table of Contents

4

Page 5

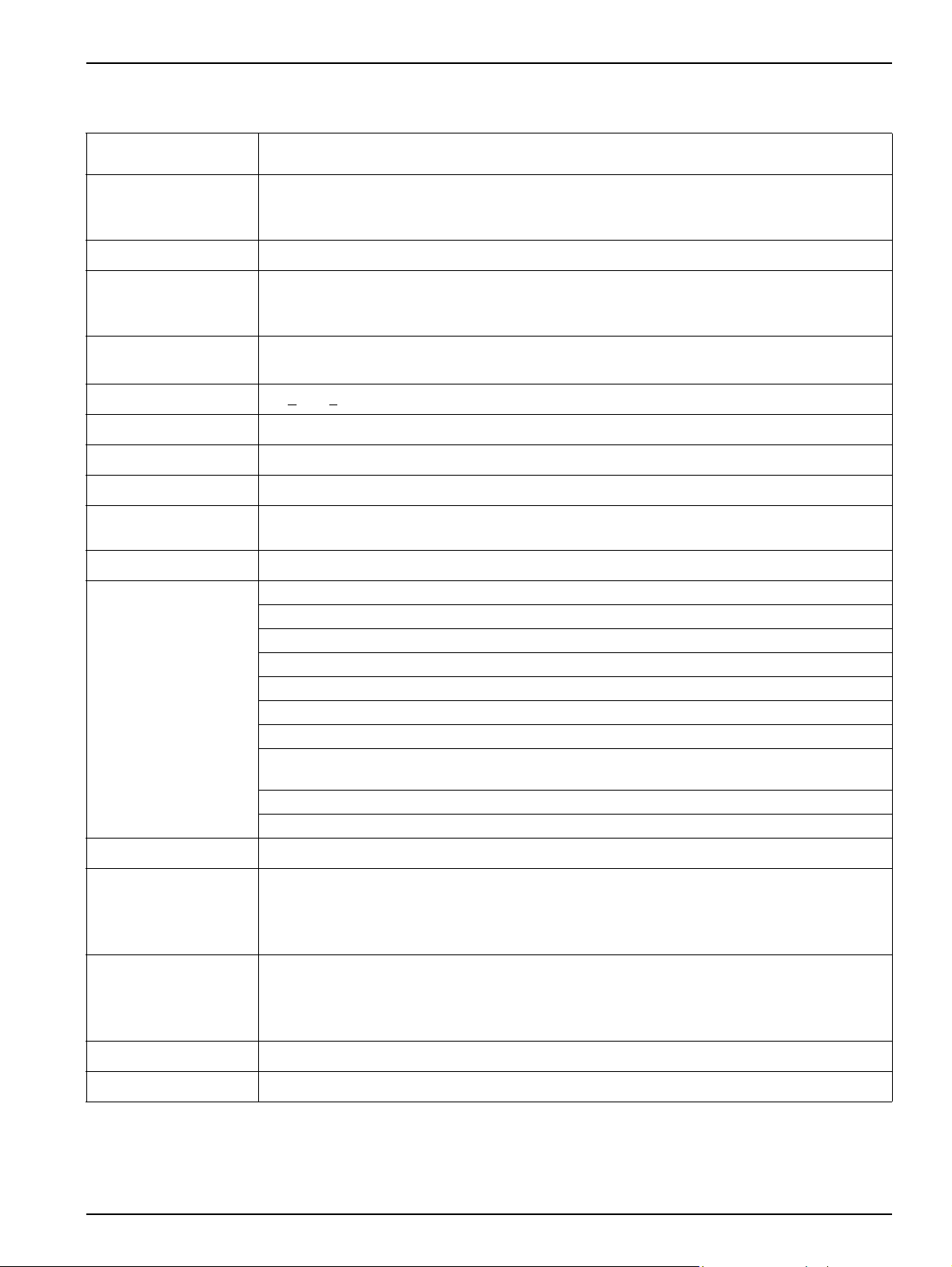

Section 1 Specifications

Specifications are subject to change without notice.

Measuring Technique

Measuring Range

Reproducibility Turbidity < 1 %, Total Suspended Solids (TSS) < 3 %

Measuring Accuracy

Technique variation

coefficient

Response Time 1s <

Calibration Zero point permanently set from the factory, gradient once for the TS content

Cable Length 10 m (33 ft), max. 100 m (328 ft) with extension cable

Ambient Temperature 0 to +40 °C (32 to 104 °F)

Pressure Range

Flow Velocity Max. 3 m/s (the presence of air bubbles affects the measurement)

Materials

Infrared Duo scattered light technique for color-independent turbidity measurement

Turbidity in accordance with DIN EN 27027 / TS equivalent DIN 38414

t-line turbidity: 0.001–4000 FNU/NTU

ts-line, inline turbidity: 0.001–4000 FNU/NTU; TSS content: 0.001 mg/L–50 g/L

hs-line, highline turbidity: 0.001–4000 FNU/NTU; TSS content: 0.001 mg/L–500 g/L TSS

Turbidity up to 1000 FNU/NTU:

without calibration < 5 % of the measured value ± 0.01 FNU/NTU

with calibration < 1 % of the measured value ± 0.01 FNU/NTU

1 % in accordance with DIN 38402

T90 < 300 s (adjustable)

Stainless steel: 6 bar or 60 m (87 psi)

PVC: 1 bar or 10 m (14,5 psi)

Optics carrier and sleeve: stainless steel 1.4571 or PVC black

Wiper shaft: stainless steel 1.4104

Wiper arm: stainless steel 1.4581

1

Wiper rubber: silicone rubber (standard) Optional: Viton

Windows and light guide: quartz glass

O-rings (optics carrier, wiper, windows): NBR (acrylonitrile butadiene rubber)

Housing seals: NBR 70

Sensor connecting cable (hard-wired): 1 cable pair AWG 22 / 12 V DC twisted, 1 cable pair AWG

24 / data twisted, common cable screen, Semoflex (PUR)

Sensor connection plug (hard-wired): type M12 enclosure rating IP 67

Threaded cable fitting: stainless steel 1.4305

(LZX578)

Inspection interval On request 1/year service contract with guarantee extension to 5 years

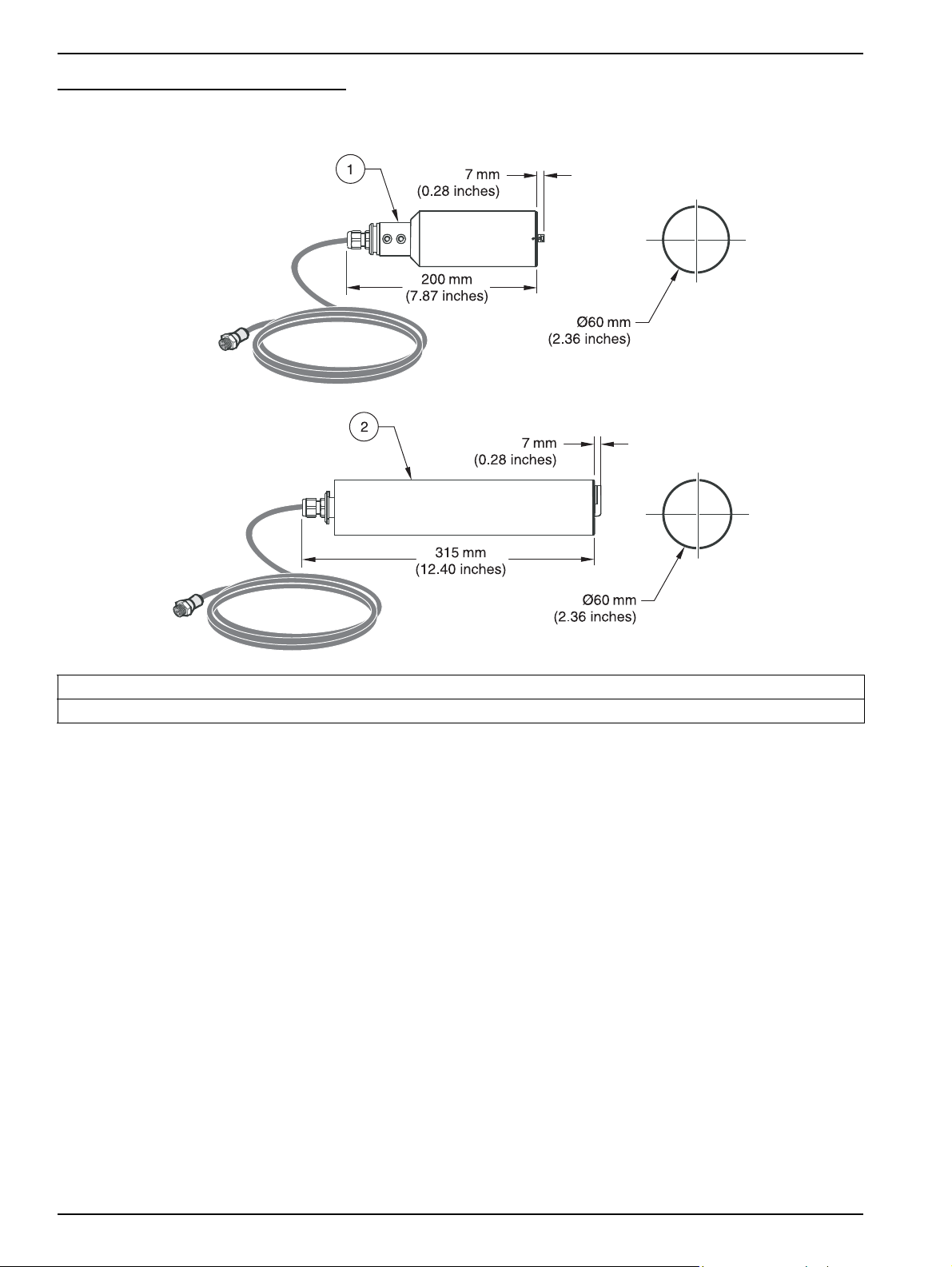

Tank probe: D x L 60 mm x 200 mm (2 x 8 in.)

Dimensions

Weight

User Maintenance 1 h / month, typical

Certifications CE

1

Viton® is a registered trademark of E.I. DuPont de Nemours + Co.

Probe for pipe installation: D x L 60 mm x 315 mm (2 x 12.4 in.)

(Pipe installation fitting: DN 65 / PN 16 DIN 2633; < 5 bar (73 psi); for pipes from DN 80)

Distance sensor - wall (floor): TS > 10 cm (4 in.), turbidity > 50 cm (20 in.)

Tank probe: approx. 1.8 kg (63 oz) (t-line: approx. 0.6 kg (21 oz))

Probe for pipe installation: approx. 2.4 kg (85 oz)

Pipe installation fitting: approx. 2.7 kg (95 oz) (without probe)

Pipe installation safety fitting:approx. 18 kg (40 lb) (without probe)

5

Page 6

Specifications

Figure 1 Sensor Dimensions

1. SOLITAX sc models t-line, ts-line, and hs-line for immersion in open tanks

2. SOLITAX sc models inline and highline sensors for insertion in pipes

6

Page 7

Section 2 General Information

2.1 Safety Information

Please read this entire manual before unpacking, setting up, or operating this equipment.

Pay attention to all danger and caution statements. Failure to do so could result in serious

injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this manual.

2.1.1 Use of Hazard Information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Important Note: Information that requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety information.

This symbol indicates that a risk of electrical shock and/or electrocution exists.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after 12

August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

7

Page 8

General Information

2.2 Sensor Overview

Note: All sensors are also available without wipers for special applications.

t-line: 0.001–4000 FNU/NTU

High-resolution turbidity probe made of plastic for the outlets of sewage treatment plants

and bodies of water.

ts-line: 0.001–4000 FNU/NTU; 0.001 mg/L–50.0 g/L

High-precision turbidity and solids probe made of stainless steel or plastic for

color-independent measurement of fine turbidities and sludges.

hs-line: 0.001–4000 FNU/NTU; 0.001 mg/L–500.0 g/L

High-precision turbidity and solids probe made of stainless steel or plastic for

color-independent measurement of highly concentrated sludges.

inline: 0.001–4000 FNU/NTU; 0.001 mg/L–50.0 g/L

High-precision pipe installation probe for turbidity and solids made of stainless steel for

color-independent measurement of fine turbidities and sludges.

highline: 0.001–4000 FNU/NTU; 0.001 mg/L–500.0 g/L

High-precision pipe installation probe for turbidity and suspended solids made of stainless

steel for color-independent measurement of highly concentrated sludges.

Figure 2 Solitax sc Sensors

2.3 Measuring Principle

The measuring principle is based on a combined infrared absorption scattered light

technique that measures the lowest turbidity values in accordance with DIN EN 27027 just

as precisely and continuously as high sludge content. Using this method, the light

scattered sideways by the turbidity particles is measured over an angle of 90°.

2.4 Handling

8

The sensor contains high-quality optical and electronic assemblies. Make sure the sensor

is not subjected to any hard mechanical knocks. There are no customer-serviceable items

inside the sensor.

Page 9

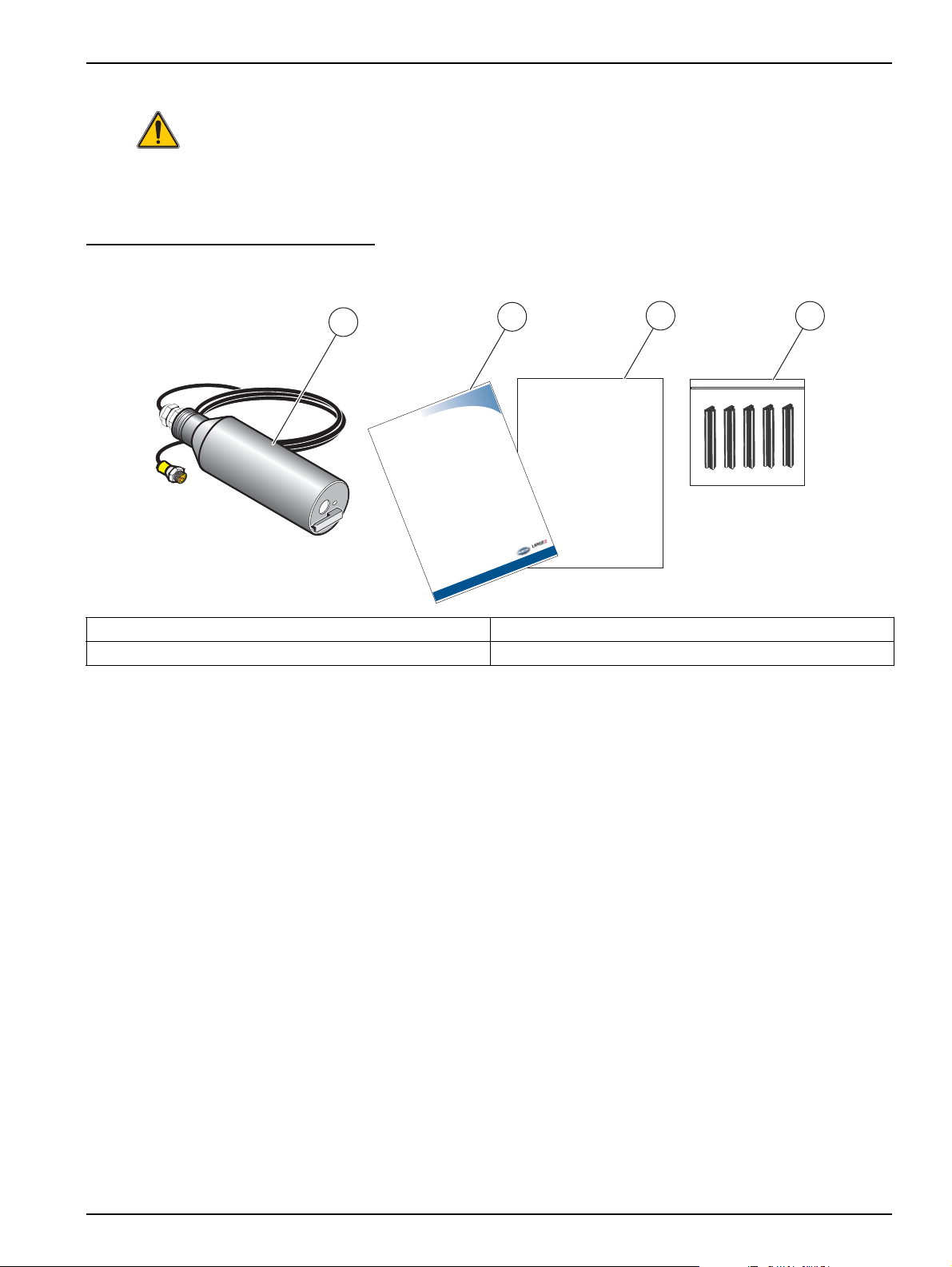

Section 3 Installation

Werksprüfzeugnis

nach DINEN10204-2.3

Sehrgeehrter Kunde,

IhrMeßgerät hatunser Werkin einwandfreiem undgeprüftem Zustandverlassen. DieGeräteprüfung erfolgte

nach einerDr.Lange Prüfanleitungdes nachDINEN ISO9001 zertifiziertenDr.LangeQualitätsmanagementsystems.

IhrMeßgerät entsprichtdenharmonisierten Normen:

-DIN EN50081-2(Störaussendung)

-DIN EN50082-2(Störfestigkeit)

-DIN EN61010-1(Sicherheitsbestimmungen)

Specific test report

accordingto EN10204-2.3

Dearcustomer,

yourinstrum enthasleft ourcompan yina perfectand inspectedcon dition.The instrumentcheck followsthe

Dr.Lange inspectionprocedureof thecertificatedDr.Lange-Qualitymanagementsystem(ISO 9001).Your

instrumentcorresponds totheharmonised standards:

-EN 50081-2(noiseemission)

-EN 50082-2(noiseimmunity)

-EN 61010-1(safetyrequirements)

Relevé de contrôle spécifique

selonla normeEN10204-2.3

Cherclient,

votreappar eilaquitt énotreusin econtrôllé estenpar faitétat deservice. Laprocédure decontrôle aété

réaliséselonle guidede Dr.Langeconformeà notresystèmede contrôledequalité (ISO9001).

L'appar eilest conformeaux normesharmon isés:

-EN 50081-2(Bruitd´emission)

-EN 50082-2(immunitéau bruit)

-EN 61010-1(Règlesde sécurités)

HDQ045

V1.0

DOC023.XX.03232.XXXyy

SOLITAX

Betriebsanleitung

1

2

3

4

DANGER

Only qualified personnel should conduct the tasks described in this section of the

manual.

3.1 Unpacking the Instrument

Figure 3 Items Supplied with SensorI

1. SOLITAX sc Sensor 3. Factory Test Certificate

2. User Manual 4. Wiper Set (for 5 changes) LZX050

3.1.1 Function Check

After unpacking, both components should be checked for any transport damage and a

short function check performed prior to installation.

To perform a function check, connect the sensor to the display unit and power the unit.

Shortly after the unit is plugged in, the display is activated and the instrument switches to

the measurement display. Measured values taken in air is meaningless.

If no messages appear in the lower part of the display, the function check is

then complete.

9

Page 10

Installation

3.2 Sensor Installation

Figure 4 on page 10 illustrates the installation overview for Solitax sc Models t-line, ts-line,

and hs-line for immersion in open tanks.

The maximum distance from the mounting surface to the sensor without the use of an

extension tube is 1.5 m (4.9 ft). When that distance exceeds 1.5 m (4.9 ft), one of the

following extension tubes is required and can be ordered separately:

• 1.0 m (3.28 ft) extension pipe LZY413

• 1.8 m (5.90 ft) extension pipe LZY414

To ensure a suitable measuring position, install the probe to the following conditions:

• The probe optical window must have a ground clearance of at least 30 cm (11.8 in.).

• Install the probe with the optical window facing (downstream) in the direction of the

flow to minimize the risk of fouling.

• Avoid installation sites where air bubbles are inconsistent. If this not possible, try

moving the probe slightly or adjusting its alignment to minimize the bubble effect.

• Protect the probe against the oncoming flow of large objects, such as branches or ice

and against flow surges.

• Avoid installing the probe with the optical window facing into direct light or facing a

highly-reflective surface.

Figure 4 Sensor Installation Overview

10

Page 11

3.3 Pipe Installation

• Install the sensor in an up-flow pipe section for best results. Do not mount the sensor

in a down-flow pipe section.

• Mounting in a horizontal pipe section is acceptable if the sensor is fully immersed at all

times. Usually, mounting 90 degrees from the top of the pipe guarantees full

immersion. Do not mount on the top or bottom of a horizontal pipe section.

• Install the sensor in a pipe that is equal to or greater than 4 inches in diameter.

• Install the sensor at least 1.5 m (5 ft.) or three times the pipe diameter (whichever is

greater) downstream of pumps, valves, or pipe elbows.

• Install the sensor on the discharge side of a pump, if possible, with a dilution or flush

valve installed on the suction side of the pump.

• If the sensor is to be used to measure sludge with significant amounts of debris, install

it after a sludge grinding pump or after a pump with a grinding/comminuting unit in

front of it.

• Install the sensor within 7.8 m (25 ft.) of the controller with the standard probe cable.

Optional cable extensions can be added for a maximum combined distance of

100 meters (330 ft.).

Installation

• If the flange cannot be welded to the pipe due to incompatibility of materials between

the stud and the pipe, it is recommended that a stainless steel pipe section be

fabricated. Weld the flange onto the stainless steel pipe section and attach the

stainless steel section as a segment of the process pipe.

11

Page 12

Installation

Direction of Flow

Figure 5 Proper Positioning for Insertion into Pipe

12

Page 13

3.4 Connecting sensor cable

6

1 2

5

3

4

CAUTION

Always lay cables and hoses so they do not pose a trip hazard and are not bent.

1. Unscrew the protective cap on the controller socket and retain it.

2. Pay attention to the guide in the plug and push the plug into the socket.

3. Tighten the nuts.

Connector cables are available in various lengths (refer to Section 7 Replacement Parts

and Accessories on page 23). Maximum overall cable length: 50 m (165 ft).

Figure 6 Connection of the sensor plug to the controller

Installation

Figure 7 Sensor connector pin assignment

Number Description Cable colour (Standard-Cable)

1+12 VDC brown

2 Ground black

3Data (+) blue

4 Data (–) white

5 Screen Screen (grey)

6 Notch –

13

Page 14

Installation

14

Page 15

Section 4 Operations

4.1 Use of an sc controller

Before using the sensor in combination with an sc controller, refer to the controller user

manual for navigation information.

4.2 Sensor Setup

When a sensor is initially installed, the serial number of the sensor will be displayed as the

sensor name. To change the sensor name refer to the following instructions:

1. Select Main Menu.

2. From the Main Menu, select SENSOR SETUP and confirm.

3. Highlight the appropriate sensor if more than one sensor is attached and confirm.

4. Select CONFIGURE and confirm.

5. Select EDIT NAME and edit the name. Confirm or cancel to return to the Sensor

Setup menu.

4.3 Sensor Data Logging

A data memory and event memory per sensor are available via the sc controller. While

measured data are saved in the data memory at stipulated intervals, the event memory

collects numerous events such as configuration changes, alarms and warning conditions.

Both the data memory and the event memory can be read out in CSV format. For

information on how you can download the data, please see the controller manual.

4.4 Sensor Diagnostics Menu for pH and ORP

SELECT SENSOR (if more than one sensor is attached)

STATUS

ERROR LIST See section 6.1 on page 21.

WARNING LIST See section 6.2 on page 21..

4.5 Sensor Setup Menu

SELECT SENSOR (if more than one sensor is attached)

WIPE

Initiates a wiping action on the sensor window.

CALIBRATE

Select the behavior of the outputs during calibration for zero point setting (Hold, Active, Transfer,

SET OUTMODE

SENSOR MEASURE Displays the current, uncorrected measured value.

CONFIGURE

FACTOR/2 POINTS/

3 POINTS/4 POINTS/

5POINTS

SET CAL DEFAULT Return the instrument to the default calibration settings.

Selection). Hold maintains the last reading prior to going into the menu. Active transmits the

current level readings, corrected with previous calibration data until new data is entered. Set

Transfer transmits the value designated during the system setup

Select the calibration type and follow the calibration steps for 2 point, 3 point, 4 point, and 5 point

calibration.

Display depends on the selection in configuration.

15

Page 16

Operations

4.5 Sensor Setup Menu (continued)

CONFIGURE

EDIT NAME Enter up to a 10-digit name in any combination of symbols and alpha or numeric characters.

This setting configures the Solitax to measure turbidity or suspended solids. The Solitax cannot

SET PARAMETER

MEAS UNITS

CLEAN INTERVAL

RESPONSE TIME

LOGGER INTERVAL

SET DEFAULTS Resets all user-editable options to the factory-defaults.

TEST/MAIN

PROBE INFO

PROFILE

COUNTER Shows the number of hours or cycles left for operating hours, test/maint, gasket, and the motor.

TEST/MAIN

simultaneously measure both. Choose “TRB” for turbidity measurements, or “TS” for suspended

solids measurement. This selection determines which units may be selected in the “Meas Units”

menu.

Choose from the displayed units. TRB (FNU, EBC, TE/F, NTU); TS (mg/L, g/L, ppm, %)

Default: FNU

If TRB was selected in set parameter, select “NTU” (commonly used in the U.S.), FNU, EBC, or

TE/F. If TS was selected, choose mg/L, g/L, ppm, or %. Press enter to choose the selection. If

the units selected result in a reading that exceeds 4 digits, the display will only show dashes.

For example, if mg/L were selected, and the measurement was 10,500 mg/L, the display will

show dashes until the reading drops to 9999 or lower.

Select the cleaning interval (1, 5, 15 or 30 minutes; 1, 4, or 12 hours; 1, 3, 7 days)

Default: 12 hours

This is the interval between wiper cleaning of the sensor window. It is recommended to start with

a setting of 30 minutes. This time may be adjusted according to the application. If readings

continue to be accurate, try a longer interval. If not, shorten the interval.

This is a damping function. While the Solitax takes readings continually, it will average them

together over the period of the response time. Once the response time has elapsed, the

displayed reading, 4-20 outputs, and alarm status are updated. (0 to 300 seconds)

Default: 3 seconds

This is the datalog interval, with options from 1–15 minutes. Values logged are the average of

the all readings during the previous logging interval. The controller will hold approximately

360 days of readings for one sensor at 15 minute intervals, or 24 days at 1 minute intervals (and

proportional in between). Default:10 minutes

Displays the sensor type, entered name of the sensor (Default: sensor serial number), the sensor

serial number, the software version number, and the sensor driver version number.

Select Profile Counter to display the number of wipes made (from 20000 backwards). Select

Reset Config to manually reset the profile counter.

WIPE—Initiates the wiping action of the wiper.

SIGNALS—displays the signal outputs for the device.

OUTPUT MODE—Select the behavior of the instrument outputs (Hold, Active, Transfer,

Selection)

DEFAULT SETUP—Resets all user-editable options to the factory defaults.

4.6 Calibration

16

There are two calibration techniques; depending on whether turbidity or suspended solid

is required (refer to section 4.6.2 or section 4.6.3 on page 18). Before calibration,

determine the behavior of the 4–20 outputs and alarm relays while the user is in the

CALIBRATE menu (refer to section 4.6.1).

Page 17

4.6.1 Setting the Outmode

1. From the Main Menu, select SENSOR SETUP and press confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and press confirm.

4. Select SET OUTMODE. Select the available Out Mode (Active, Hold, Transfer) and

confirm.

4.6.2 Calibration for Turbidity

Turbidity calibration requires the use of a Turbidity Standard Solution. The manufacturer

recommends the 800 NTU Turbidity Standard Solution (part of the calibration kit No.

57330-00). A zero-point calibration using deionized water is also recommended.

1. From the Main Menu, select SENSOR SETUP and press confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and press confirm.

4. Select SENSOR MEASURE and confirm.

5. Place the sensor in the calibration cylinder with deionized water, mounting it with the

supplied clamp. The tip of the probe should be approximately 1-inch below the surface

of the water. Record the reading from the sensor measure display.

Operations

6. Select OFFSET. Multiply the reading obtained in step 5 and enter the value.

7. Select SENSOR MEASURE.

8. Rinse the outside of the StablCal

or debris adhering to the surface of the bottle. Gently invert both StablCal standard

bottles a minimum of 50 times. Remove the lid and seal from each bottle. Slowly (to

avoid creating bubbles) pour the contents of the bottles into the calibration cylinder.

Immediately place the tip of the probe into the positioning bracket in the calibration

cylinder. The tip of the probe should be approximately 1-inch below the surface

standard. Allow the reading to become stable on the SENSOR MEASURE screen.

Record the value (measured value). Calculate the factor. Refer to section 4.6.2.1.

9. Select FACTOR to display the corrected measurement.

4.6.2.1 Calculating the Factor

New Factor =

For example, if a sample measures 750 NTU using the sensor and the standard is

800 NTU, the new factor would be calculated as follows:

800 NTU Standard

measured value

®

800 NTU standard with water to remove any dust

New Factor =

800 NTU

750 NTU

= 1.07

17

Page 18

Operations

4.6.3 Calibration for Suspended Solids

Suspended solids calibration requires calibration to the actual sample. This optimizes the

compensation for the particle size and shape typical at a measuring site. It is best

performed by mounting the sensor as usual for normal measurement, and then grab

samples collected and evaluated by laboratory methods. While a single point calibration is

usually sufficient to provide accuracy, the SOLITAX does offer the ability to calibrate with

up to 5 calibration points.

1. From the Main Menu, select SENSOR SETUP and press confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and press confirm.

4. Select CONFIGURE and confirm.

5. Select the number of points desired for calibration (the unit with linearly interpolate

values between calibration points). Select Factor for a single point calibration.

6. Mount the sensor as is during normal operation. Alternatively, place the sensor in the

calibration cylinder (or a container with dark, non-reflective walls) 2 inches of

clearance from the probe face with the probe face submerged by 1 inch or more.

7. Select SENSOR MEASURE and record the reading.

8. Immediately take a grab sample. Determine the total suspended solids using a

gravimetric method such as Method 2540 D in Standards Methods for the

Examination of Water and WasteWater.

9. Calculate the new factor. Refer to section 4.6.3.1 for single point (Factor) calibration.

Refer section 4.6.3.2 on page 18 for multiple point calibrations.

10. Select FACTOR and press confirm. The corrected measurement should be displayed.

4.6.3.1 For Single Point (Factor) Calibration

Calculate the new factor:

New Factor =

For example, if a sample measures 2.3 g/L using the SS sensor and the gravimetric value

was 2.0 g/L, the new factor would be calculated as follows:

New Factor =

Determined gravimetric value

measured value

2.0 g/L

2.3 g/L

= 0.87

4.6.3.2 Multi-point Calibration

1. Repeat steps 6–8 in section 4.6.3 on page 18 at different times to obtain different

measurements.

2. From the CONFIGURE menu, select the appropriate calibration point menu.

3. Enter the pairs of values for each reading, the target value being the laboratory

determined value, and the actual value being the reading that the SOLITAX produced

in step 5. The pairs should be entered in order from lowest values to highest.

18

Page 19

Section 5 Maintenance

DANGER

Only qualified personnel should conduct the tasks described in this section of the

manual.

Proper maintenance of the measuring windows in the sensor is critical for accurate

measurements. The measuring windows should be checked monthly for soiling and the

wiper checked for wear.

Important Note: The seals must be replaced every 2 years by the Service Department. If

the seals are not changed regularly, water may enter the probe head and seriously

damage the instrument.

5.1 Maintenance Schedule

Maintenance Task Duration

Visual inspection monthly

Check calibration

Inspection six months (counter)

Seal change every 2 years (counter)

Change wiper and reset counter as per counter (20000 cycles)

monthly

(depending on the ambient conditions)

5.2 Cleaning the Sensor Measuring Windows

CAUTION

Always were

Safety glasses,

Gloves and

Overal

handling hydrochloric acid and observe safety regulations.

The measuring windows are made of quartz glass. If necessary, they can be cleaned with

a cleaning agent and a cloth.

19

Page 20

Maintenance

1

4

2

3

5.3 Replacing the Wiper

The life of the wiper is dependent on the number of cleaning actions performed and the

type of deposits to be removed. The life of the wiper varies. The wipers supplied with the

instrument should last for approximately one year.

1. From the Main Menu, select SENSOR SETUP and press confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select TEST/MAINT and press confirm.

4. Select PROFILE and confirm. Change the wiper, see section 5.3 on page 20.

5. Select RESET CONFIG and confirm.

6. Select MAN. RESET ARE YOU SURE? and confirm.

Figure 8 Wiper Replacement

1. Wiper arm 3. Wiper

2. M4 hex socket head bolt 4. Wiper axle

20

Page 21

Section 6 Troubleshooting

6.1 Error Codes

In the case of an error, the indication of the measured value flashes on the display and all

the contacts and current outputs allocated to this sensor are placed on hold. The following

conditions will result in flashing measured values:

• Data transmission between controller and sensor interrupted

On the Main menu open the SENSOR DIAG menu using ENTER and determine the

cause of the fault.

Table 1 Error Messages

Error Displayed Cause Solution

POS. UNKNOWN Wiper position unknown

LED FAULTY Faulty LED Contact customer service

MOIST Moisture value > 10

CAL. DATA Factory calibration data lost Contact customer service

6.2 Warnings

Open the TEST/MAINT menu and trigger the ”WIPE” function, if the

problem persists contact the manufacturer's customer service

Remove the sensor immediately and store in a dry place, contact

customer service

A warning results in a flashing warning icon on the right of the display, all menus, contacts

and outputs remain unaffected and continue to work normally. On the Main menu open the

SENSOR DIAG menu using ENTER and determine the cause of the warning.

A warning may be used to trigger a relay and users can set warning levels to define the

severity of the warning.

Table 2 Warnings

Warning Displayed Cause Solution

WARNING Cause Action

REPLACE WIPER Counter elapsed Replace wiper, reset counter

TEST/MAINT Counter elapsed Contact customer service

GASKET Counter elapsed Contact customer service

21

Page 22

Troubleshooting

22

Page 23

Section 7 Replacement Parts and Accessories

7.1 Immersion Sensors

Description Catalog Number

Turbidity, t-line sc, PVC with wiper (0.001 to 4000 NTU) LXV423.99.10000

Turbidity, t-line sc, PVC without wiper (0.001 to 4000 NTU) LXV423.99.12000

Turbidity and Suspended Solids, ts-line sc,

PVC with wiper (0.001 to 4000 NTU, 0.001 mg/L to 50 g/L)

Turbidity and Suspended Solids, ts-line sc,

PVC without wiper (0.001 to 4000 NTU, 0.001 mg/L to 50 g/L)

Turbidity and Suspended Solids, ts-line sc, stainless steel with wiper

(0.001 to 4000 NTU, 0.001 mg/L to 50 g/L)

Turbidity and Suspended Solids, ts-line sc, stainless steel without wiper

(0.001 to 4000 NTU, 0.001 mg/L to 50 g/L)

Turbidity and Suspended Solids, hs-line sc, PVC with wiper

(0.001 to 4000 NTU, 0.001 mg/L to 500 g/L)

Turbidity and Suspended Solids, hs-line sc, PVC without wiper

(0.001 to 4000 NTU, 0.001 mg/L to 500 g/L)

Turbidity and Suspended Solids, hs-line sc, stainless steel with wiper

(0.001 to 4000 NTU, 0.001 mg/L to 500 g/L)

Turbidity and Suspended Solids, hs-line sc, stainless steel without wiper

(0.001 to 4000 NTU, 0.001 mg/L to 500 g/L)

1

All sensors come with the sensor, replacement wipers, and manual.

1

LXV423.99.10100

LXV423.99.12100

LXV423.99.00100

LXV423.99.02100

LXV423.99.10200

LXV423.99.12200

LXV423.99.00200

LXV423.99.02200

7.2 Insertion Sensors

Description Catalog Number

Turbidity and Suspended Solids, inline sc, stainless steel with wiper

(0.001 to 4000 NTU, 0.001 mg/L to 50 g/L)

Turbidity and Suspended Solids, inline sc, stainless steel without wiper

(0.001 to 4000 NTU, 0.001 mg/L to 50 g/L)

Turbidity and Suspended Solids, highline sc, stainless steel with wiper

(0.001 to 4000 NTU, 0.001 mg/L to 500 g/L)

Turbidity and Suspended Solids, highline sc, stainless steel without wiper

(0.001 to 4000 NTU, 0.001 mg/L to 500 g/L)

1

All sensors come with the sensor, replacement wipers, and manual.

1

LXV424.99.00100

LXV424.99.02100

LXV424.99.00200

LXV424.99.02200

7.3 Replacement Parts

Description Catalog Number

Set of wipers (for 5 changes) made of silicone for normal applications LZX050

Set of wipers (for 5 changes) made of Viton for e. g. media containing oil LZX578

SOLITAX sc User Manual, english DOC023.52.03232

Extension cable, 5 m (16.4 ft) LZX848

Extension cable, 10 m (33 ft) LZX849

Extension cable, 15 m (50 ft) LZX850

Extension cable, 20 m (65 ft) LZX851

Extension cable, 30 m (100 ft) LZX852

Extension cable, 50 m (165 ft) LZX853

23

Page 24

Replacement Parts and Accessories

7.3 Replacement Parts (continued)

Description Catalog Number

Extension pipe, 1,0 m (3.28 ft) LZY413

Extension pipe, 1,8 m (5.90 ft) LZY414

Installation kit, fixed-point (for t-line, ts-line, and hs-line immersion sensors) LZX414.00.10000

Consisting of:

Base ATS010

Mounting plate HPL061

Holding clamp (2×) LZX200

Assembly pipe 2 m BRO075

HS small parts set LZX416

Installation kit with straight adapter LZX414.00.20000

Kit, screws and seals for sensor adapters LZX417

Miscellaneous hardware for probe installation kit LZX416

Second fastening point, includes: bracket, sensor pipe stand, sensor pipe stand bracket, screws,

and grommet)

Sensor fixed-point mounting kit: Sensor pipe bracket ATS010

Sensor pipe stand bracket LZX200

L-bracket ATS 011

Adapter, Sensor 90° elbow AHA034

Ball valve for insertion probes without adapting flange LZX337

Welded flange made of C-steel for the pipe installation fitting LZX703

Welded flange made of stainless steel for pipe installation safety fitting LZX660

LZX456

24

Page 25

Section 8 Contact Information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE

Rorschacherstrasse 30 a

CH-9424 Rheineck

Tel. +41 (0)71 886 91 11

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0)8 20 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorferstr. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 9 12 16 92

Fax +43 (0)1 9 12 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wrocław

Tel. +48 (0)71 342 10-83

Fax +48 (0)71 342 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3

Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD. ŞTİ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

25

Page 26

Contact Information

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

26

Page 27

Section 9 Warranty and liability

The manufacturer warrants that the product supplied is free of material and manufacturing

defects and undertakes the obligation to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out within

6 months of purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including the lack

of assured properties as follows: all those parts that, within the warranty period calculated

from the day of the transfer of risk, can be demonstrated to have become unusable or that

can only be used with significant limitations due to a situation present prior to the transfer

of risk, in particular due to incorrect design, poor materials or inadequate finish will be

improved or replaced, at the supplier's discretion. The identification of such defects must

be notified to the supplier in writing without delay, however at the latest 7 days after the

identification of the fault. If the customer fails to notify the supplier, the product is

considered approved despite the defect. Further liability for any direct or indirect damages

is not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to be

performed within the warranty period by the customer (maintenance) or by the supplier

(servicing) and these requirements are not met, claims for damages due to the failure to

comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages cannot be made.

Consumables and damage caused by improper handling, poor installation or incorrect use

are excluded from this clause.

The manufacturer process instruments are of proven reliability in many applications and

are therefore often used in automatic control loops to provide the most economical

possible operation of the related process.

To avoid or limit consequential damage, it is therefore recommended to design the control

loop such that a malfunction in an instrument results in an automatic change over to the

backup control system; this is the safest operating state for the environment and the

process.

27

Page 28

Warranty and liability

28

Page 29

Appendix A Modbus Register Information

Table 3 Sensor Modbus Registers

Group Name Tag Name Register Data Type# Length R/W Description

Measurements TurbidityFNU 40001 Float 2 R Turbidity FNU

Measurements TurbidityEBC 40003 Float 2 R Turbidity EBC

Measurements SolidsMGL 40005 Float 2 R Solids mg/L

Measurements SolidsGL 40007 Float 2 R Solids g/L

Measurements SolidsPR 40009 Float 2 R Solids %

— Reserved 40011 Unsigned Integer 1 R Reserved

Base Parameter 40012 Unsigned Integer 1 R/W Parameter

Base UnitTRB 40013 Unsigned Integer 1 R/W Unit Turbidity

Base UnitTS 40014 Unsigned Integer 1 R/W Units Solids

Calibration OffsetTRB 40015 Float 2 R/W Turbdity Offset

Calibration FactorTRB 40017 Float 2 R/W Turbidity Factor

Calibration FactorTS 40019 Float 2 R/W Solids Factor

Data Wiperstate 40021 Unsigned Integer 1 R/W Wiper register

Setup ResponseInterval 40022 Unsigned Integer 1 R/W Response time

Setup CleaningInterval 40023 Unsigned Integer 1 R/W Wiper interval

Setup LogInterval 40024 Unsigned Integer 1 R/W Logger interval

Setup Outputmodekal 40025 Unsigned Integer 1 R/W Output when calibrate

Setup Outputmodesrv 40026 Unsigned Integer 1 R/W Output when service

Setup Location 40027 String 8 R/W Edited name

Setup ProfilCounter 40035 Unsigned Integer 1 R/W Profi counter

Data SerienNummer 40036 String 6 R Serial number

Calibration DateUserCal 40042 Date 2 R

Calibration DateUserCalTURB 40044 Date 2 R Date of calibration turbidity

Calibration DateUserCalSOLID 40046 Date 2 R Date of calibration solid

Data VersionAppl 40048 Float 2 R Version application

Data VersionBoot 40050 Float 2 R Version Bootlader

Data VersionStruct 40052 Unsigned Integer 1 R Version structure probedriver

Data VersionContent 40053 Unsigned Integer 1 R Version register probedriver

Data VersionFirmware 40054 Unsigned Integer 1 R Version firmware probedriver

Data FormatMinFNU 40055 Float 2 R Minimum turbidity FNU

Data FormatMaxFNU 40057 Float 2 R Maximum turbidity FNU

Data FormatMinEBC 40059 Float 2 R Minimum turbidity EBC

Data FormatMaxEBC 40061 Float 2 R Maximum turbidity EBC

Data FormatMinGL 40063 Float 2 R Minimum solids g/L

Data FormatMaxGL 40065 Float 2 R Maximum solids g/L

Data FormatMinMGL 40067 Float 2 R Minimum solids mg/L

Data FormatMaxMGL 40069 Float 2 R Maximum mg/L

Data FormatMinPR 40071 Float 2 R Minimum solids %

Data FormatMaxPR 40073 Float 2 R Maximum solids %

Data SignalsLED 40075 Unsigned Integer 1 R Signal LED

Data SignalsMoist 40076 Unsigned Integer 1 R Signal moist

Date of manufacturing

calibration

29

Page 30

Modbus Register Information

30

Loading...

Loading...