Page 1

Instruction Sheet

Sipper module

Safety Information

Please read this entire document before unpacking, setting up, or operating this

equipment. Pay attention to all danger and caution statements. Failure to do so could

result in serious injury to the operator or damage to the equipment.

To ensure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this document.

Use of Hazard Information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

DOC272.53.90004

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Important Note: Indicates a situation which, if not avoided, may cause damage to the

instrument. Information that requires special emphasis.

Note: Information that supplements points in the main text.

Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed. A symbol, if noted on the instrument, will be

included with a danger or caution statement in the manual.

Electrical equipment marked with this symbol may not be disposed of in European public di sposal systems after 12

August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

The Sipper Module uses a peristaltic pump to pull samples into a flow cell for readings.

After the reading is taken, the sample is either returned to the user or dumped to waste.

The Sipper Module provides improved measurement accuracy, because the sam e optical

characteristics exist for both blanking and reading, and when comparing me asurements o f

different samples. Errors resulting from optical differences between individual cells are

eliminated because every reading is taken in the same vial.

1

Page 2

Sipper module

Specifications

Specifications are subject to change without notice.

Available Path Leng ths

Wavelength Range

Rinsing Volume

Flow Rate

Storage Temperat ur e

Operating Temperature

2.42 cm (1 in.); 1 cm (0.394 in.)

190 to 1100 nm

At least 20 mL for 1-inch path length; at least 10 mL for 1-cm path length

1 mL/second (nominal)

–17 to 60 °C, 85% relative humidity, non-condensing

10 to 40 °C; 95% relative humidity, non-condensing at 25 °C; 75% relative humidity,

non-condensing at 40°C

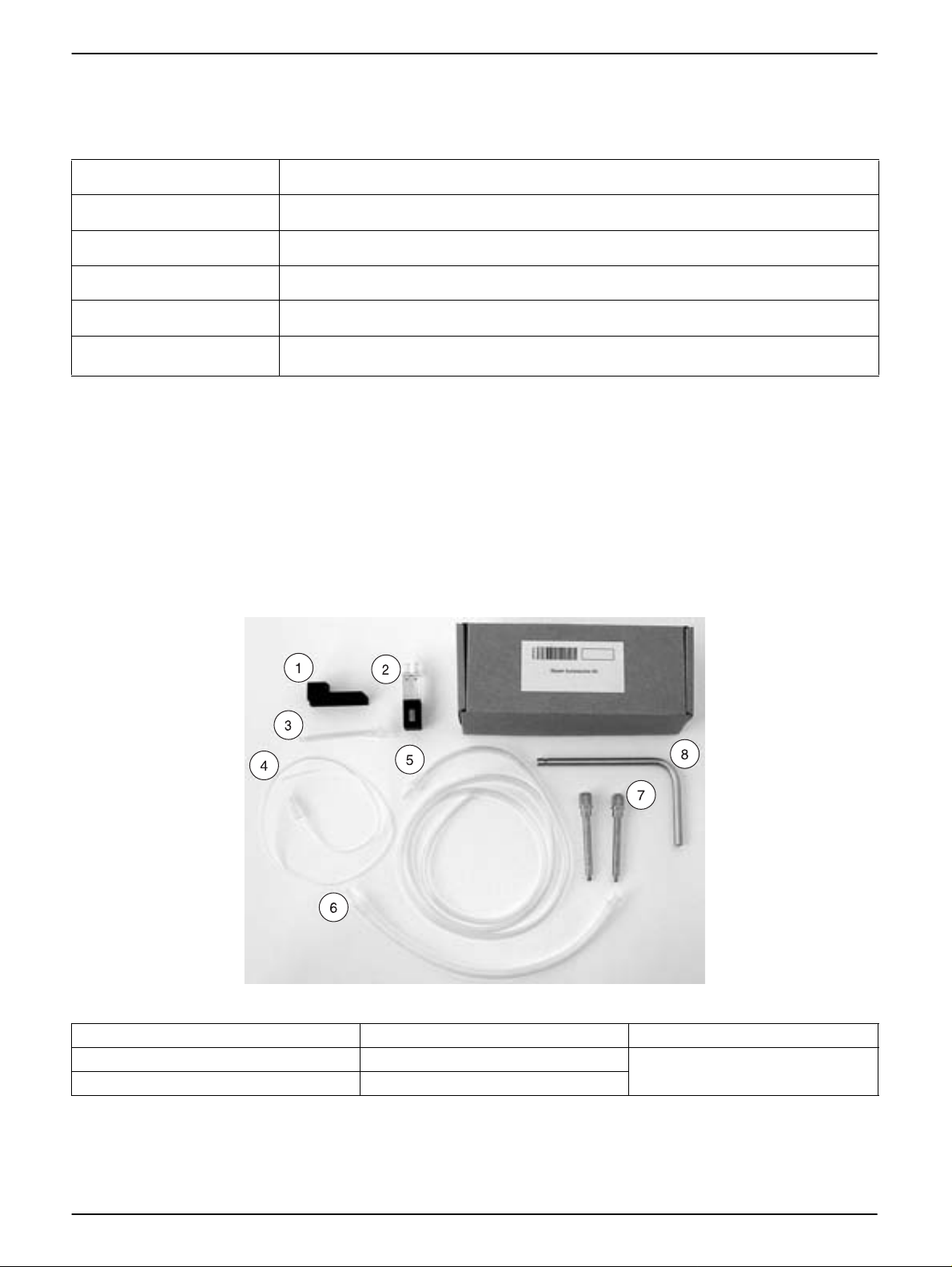

Unpacking the sipper module

Remove the Sipper Module from the shipping container and inspect it for any damage that

may have occurred during shipment. All models are shipped with

• Sipper Module

• Sipper Accessories Kit

If any of these items are missing or damaged, contact the manufacturer or a sales

representative immediately.

Figure 1 Sipper accessories kit

1 Rubber Fitting 4 Sample/Inlet Tubing 7 Locking Screws (2)

2 Sipper Cell, 1-cm 5 Drain/Waste Tubing 8 Guide Tube

3 Outlet Connector (from pump to drain) 6 Pump Tubing (white)

2

Page 3

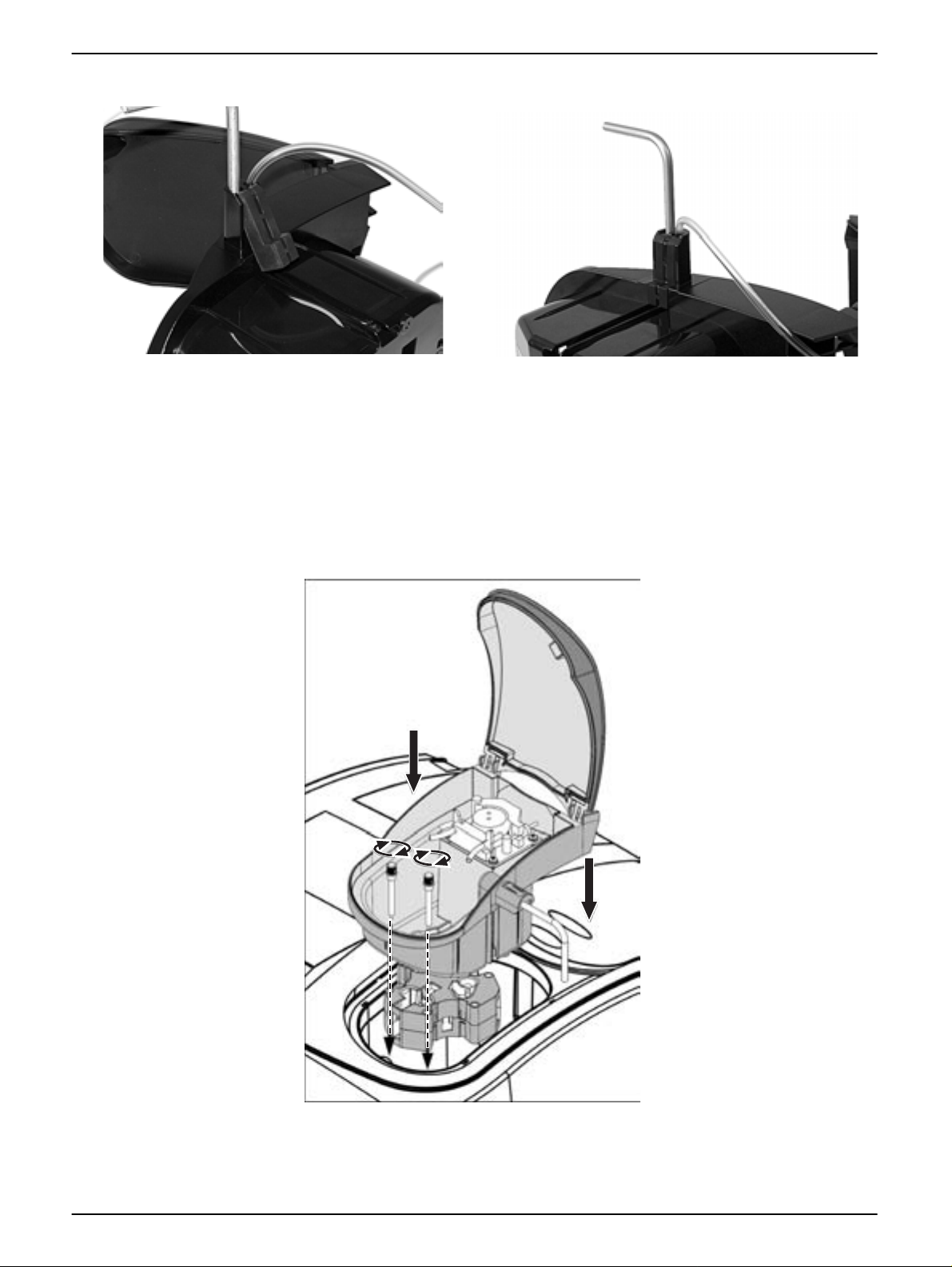

Sipper module installation

1. Pull the drain tube through the exit channel of the sipper from the inside outward s. Pull

the inlet tube through the entry channel of the sipper mod ule from the outside inwa rds.

The push-in connectors must be inside the module. Avoid kinks in the tubes.

Figure 2 Drain tube and inlet tube installation

Sipper module

2. Turn the sipper module on its side. Pull the inlet tube through the entry channel , and

the drain tube through the exit channel of the sipper. The inlet tube must be pulled

through the metal guide tube. The bottom end of the guide tube must click into the

channel. Avoid kinks in the tubes.

Figure 3 Guide tube installation

3. Hold the rubber fitting with the ridges over the grooves and push it firmly onto the

guide tube and the waste tube.The rubber fitting must firmly enclose the guide tube

and drain tube.

3

Page 4

Sipper module

Figure 4 Rubber fitting installation

4. Open the cell compartment. Without the locking screws, insert the Multi Cell Holder

into the cell compartment (refer to the user manual).

5. Place the Sipper Module on the Multi Cell Holder in such a way that the screw holes

are positioned exactly one above the other and the top of the lid of the Sipper Module,

when opended, will be facing towards the back of the instrument.

Figure 5 Place the Sipper modul

4

Page 5

Sipper module

6. Secure the Sipper Module and the Multi Cell Holder with the two locking screws

(Figure 1 on page 2).

7. Contact with instrument has now been established.

in Instrument Setup.

8. Pull the pump adjustment forward (item 1, Figure 6 on page 5) and open the pump

tubing clamp (item 2, Figure 6 ). Wrap the white pump tubing around the pump and

clamp the ends on the right and left in the two front retainers (item 3, Figure 6).The

push-in connectors of the pump tubing must be positioned as in Figure 6.

9. Clean the Sipper Cell with a lint-free cloth and insert the Sipper Cell (item 1, Figure 7

on page 6).

10. Use the outlet connector (item 2, Figure 7) to join the white pump tubing

(item 3, Figure 7) to the Sipper Cell outlet (item 1, Figure 7).

11. Connect the drain tube (item 5, Figure 7) to the right end of the white pump tubing.

12. Connect the inlet tube to the inlet of the Sipper Cell (item 4, Figure 7).

SIPPER OPTIONS is now available

Figure 6 Pump Adjustment

1 Pump Adjust Forward 2 Pump Tubing Clamp 3 Front Retainers

5

Page 6

Sipper module

Figure 7 Sipper module with tubes in place

1 Pump Tubing (white) 4 Sample/Inlet Tubing

2 Drain/Waste Tubing 5 Pour-Thru Cell

3 Guide tube 6 Outlet Connector (from pump to drain)

Sipper Module Setup

When a Sipper Module is installed, SIPPER OPTIONS icon is available in Instrument Setup.

1. From Instrument Setup, press

2. Enter the times for the listed parameters.

SIPPER OPTIONS.

6

Page 7

Sipper module

Automatic Mode

The characteristics of the three basic sipper cycles can be defined in the automatic mode:

Sip Time, Settle Time, and Purge Time.

• Sip Time: The sip time and the pump setting determin e the sample volume that can

be pumped into the cell.

• Settle Time: The settle time is the interval that must be allowed before the

measurement is performed. During this time, air bubbles that may have formed during

pumping can be eliminated, and any turbulence in the sample can settle.

• Purge Time: The purge time determines the volume of air or purging solution that is

pumped through the cell after the measurement.

Note: If the Sipper Module is not in automatic mode, press the PURGE START: MANUAL key to

change the mode to Auto.

Press ZERO or READ to run the programs through the sipper cycles automatically. Press

READ to run the program through the Sipper Module.

Manual Mode

In the manual Sipper mode, the purge cycles can be activated manually. This mode can

be useful during the input of the basic parameters, as an aid to determining which

parameter values to work with in the automatic mode.

7

Page 8

Sipper module

Performing a Single or Multi-Wavelength Measurement

1. Load and insert the Sipper Module. The SIPPER OPTIONS key will appear on the

Instrument Setup screen.

2. Press

SIPPER OPTIONS to select the Sipper Settings. Select the sipper settings and

press OK.

3. Press

OPTIONS on the Single or Multi-Wavelength menu to configure the parameters.

4. Route the drain tube to an appropriate drain or collection vessel.

5. Place the Sample Inlet Tube into th e blank and press

ZERO. Leave the inlet tube in the

sample until the Sipper Pump stops and the settling cycle begins.

Note: The remaining time in seconds is shown instead of the date on the display. Press

CANCEL to stop the sip cycle.

6. When the settling cycle is complete, the blank is displayed. In the automatic mode, the

purge begins immediately after the reading without operator intervention. If the purge

is set up for a manual start, the instrument will wait for the operator to press

Note: Distilled water or the sample can be used as the rinsing liquid.

PURGE.

7. Rather than wasting the sample, a distilled water purge can be placed at the sample

inlet to rinse the sample cell between readings.

8

Page 9

Sipper module

8. Leave the inlet tube in the purge solution until the Sipper pump stops.

Note: The remaining time in seconds is shown instead of the date on the display. Press

CANCEL during the purge interval to stop the purge cycle.

9. When the sample purge is complete the instrument is ready for the next sample.

Note: After starting the Reading sequence the ZERO/READ keys turn into a CANCEL key . P ress

CANCEL at any time to start over and to erase all readings from the current set of

measurements.

Performing a Wavelength Scan

1. Load and insert the Sipper Module. The SIPPER OPTIONS key will appear on the

Instrument Setup screen.

2. Press

3. Press

4. After the scanning parameters have been sele cted, the baseline must be scanned.

SIPPER OPTIONS to select the Sipper Settings. Select the sipper settings and

press OK.

OPTIONS on the Wavelength Scan menu to configure scanning parameters

Changing any of the scanning parameters requires a new baseline scan. When the

baseline has been scanned, the instrument is ready to scan the samples.

5. Route the drain tube to an appropriate drain or collection vessel.

6. Place the sample inlet tube into the blank and press

ZERO. Leave the inlet tube in the

sample until the Sipper pump stops and the settling cycle begins. The remaining time

in seconds is shown instead of the date on the display. Press

CANCEL to stop the sip

cycle.

9

Page 10

Sipper module

7. When the settling cycle is complete, the blank is displayed. In automatic mode, the

purge begins immediately after the reading. If the purge is set up for a manual start

the instrument will wait for the operator to press

Note: Distilled water or the sample can be used as the rinsing liquid.

8. Leave the inlet tube in the purge solution until the Sipper pump stops. The remaining

time in seconds is shown instead of the date on the display. Pre ss

purge interval to stop the purge cycle.

9. When the sample purge is complete the instrument is ready for the next sample.

Note: After starting the Reading sequence the ZERO/READ keys turn into a CANCEL key. Press

CANCEL at any time to start over and to erase all readings from the current set of

measurements.

Performing a Time Scan

1. Load and insert the Sipper Module. The SIPPER OPTIONS key will appear on the

Instrument Setup screen.

PURGE.

CANCEL during the

2. Press

SIPPER OPTIONS to select the Sipper Settings. Select the sipper settings and

press OK.

3. Press

OPTIONS on the Time Course menu to configure scanning p arameters. After th e

parameters have been selected, the instrument must be bla nked.

4. Route the drain tube to an appropriate drain or collection vessel.

5. Place the sample inlet tube into the blank and press

ZERO. Leave the inlet tube in the

sample until the Sipper pump stops and the settling cycle begins. The Remaining time

in seconds is shown instead of the date on the display. Press

CANCEL to stop the sip

cycle.

6. When the settling cycle is complete, the blank is displayed. In the automatic mode, the

purge begins immediately after the reading without operator intervention. If the purge

is set up for a manual start the instrument will wait for the operator to press

Note: Distilled water or the sample can be used as the rinsing liquid.

PURGE.

7. Leave the inlet tube in the purge solution until the Sipper pump stops. The remaining

time in seconds is shown instead of the date on the display. Pre ss

CANCEL during the

purge interval to stop the purge cycle.

10

Page 11

8. When the sample purge is complete the instrument is ready for the next sample.

Note: After starting the Reading sequence the ZERO/READ keys turn into a MARK/STOP key.

Press STOP at any time to start over.

Cleaning the Sipper Module

Sample Cell

Purge the cell with deionized water before and after each test session. If the cell is

unusually dirty, repeat the sip and purge cycles several times with deionized water, or

temporarily set the purge cycle to a higher setting befor e a djusting th e timing p a ra meters .

Occasionally inspect the sample cell windows. If the windows appear dirty or hazy,

remove the sample cell and soak it in a soap solution or dilute acid and rinse thoroughly

with deionized water.

Module

If the module becomes dirty, wipe it clean with soap, water, and a soft cloth. DO NOT

immerse the module or use solvents (e.g. acetone) to clean the module.

Cleaning the Tubes

The tubes should always be cleaned with deionized or distilled water after a measurement

series has been completed.

Sipper module

The discharge tube in the pump zone and the sipper tube are subject to mechanical and

chemical stresses and must be replaced. The number of op erating hours for th e tube set s

depends on the type of pumped solutions.

11

Page 12

Contact Information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

DR. BRUNO LANGE AG

Juchstrasse 1

CH-8604 Hegnau

Tel. +41(0)44 9 45 66 10

Fax +41(0)44 9 45 66 76

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

33, Rue du Ballon

F-93165 Noisy Le Grand

Tél. +33 (0)1 48 15 68 70

Fax +33 (0)1 48 15 80 00

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorferstr. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 9 12 16 92

Fax +43 (0)1 9 12 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 1 1

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Hegyalja út 7-13.

H-1016 Budapest

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wrocław

Tel. +48 (0)71 342 10-83

Fax +48 (0)71 342 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Leonida, nr. 13

Sector 2

RO-020555 Bucuresti

Tel. +40 (0) 21 201 92 43

Fax +40 (0) 21 201 92 43

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 04 47

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vajnory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD.ŞTİ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

© Hach Company, 2008 Edition 1 June 2008 as/sk

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

Loading...

Loading...