Page 1

DOC023.52.03103

SIGMATAX 2

User manual

08/2012, Edition 2A

© HACH-LANGE GmbH, 2003, 2012. All rights reserved. Printed in Germany

Page 2

Page 3

Table of Contents

Section 1 Specifications ........................................................................................................................ 5

Section 2 General Information............................................................................................................... 7

2.1 Safety information............................................................................................................................... 7

2.1.1 Use of hazard information.......................................................................................................... 7

2.1.2 Precautionary labels .................................................................................................................. 7

2.2 Application areas ................................................................................................................................8

2.3 Functional description......................................................................................................................... 8

2.4 Instrument design ............................................................................................................................... 9

Section 3 Installation............................................................................................................................ 11

3.1 Mechanical installation...................................................................................................................... 12

3.1.1 Install the sampling probe........................................................................................................ 14

3.1.2 Second mounting point and extension pipe............................................................................. 16

3.1.3 Install the open loop control unit .............................................................................................. 18

3.1.4 Prepare the connection tube.................................................................................................... 20

3.1.5 Connect the connection tube ................................................................................................... 21

3.2 Electrical installation ......................................................................................................................... 22

3.2.1 Connect the pipe trace heater and fault indication contact...................................................... 22

3.2.2 Connect the fiber optic cable ................................................................................................... 24

3.3 Internal tubing................................................................................................................................... 24

Section 4 Start Up................................................................................................................................. 27

Section 5 Operation..............................................................................................................................29

5.1 Operation.......................................................................................................................................... 29

5.2 Menu overview.................................................................................................................................. 30

5.3 Important instrument settings ........................................................................................................... 31

5.3.1 Switch on the heater ................................................................................................................ 31

5.3.2 Set the processing interval....................................................................................................... 31

5.3.3 Set the display contrast............................................................................................................ 31

5.3.4 Switch on the pressure display ................................................................................................31

5.3.5 Access service mode............................................................................................................... 32

Section 6 Maintenance ......................................................................................................................... 33

6.1 Maintenance tasks............................................................................................................................ 34

6.1.1 After 1–4 weeks (as necessary)............................................................................................... 34

6.1.2 1×/month (or as necessary) ..................................................................................................... 35

Section 7 Troubleshooting................................................................................................................... 37

Section 8 Replacement parts and accessories ............................................................................... 39

8.1 Product contents............................................................................................................................... 39

8.2 Further accessories .......................................................................................................................... 39

8.3 Replacement and wear parts............................................................................................................ 39

Section 9 Warranty and liability........................................................................................................... 41

Section 10 Contact information .......................................................................................................... 43

3

Page 4

Table of Contents

4

Page 5

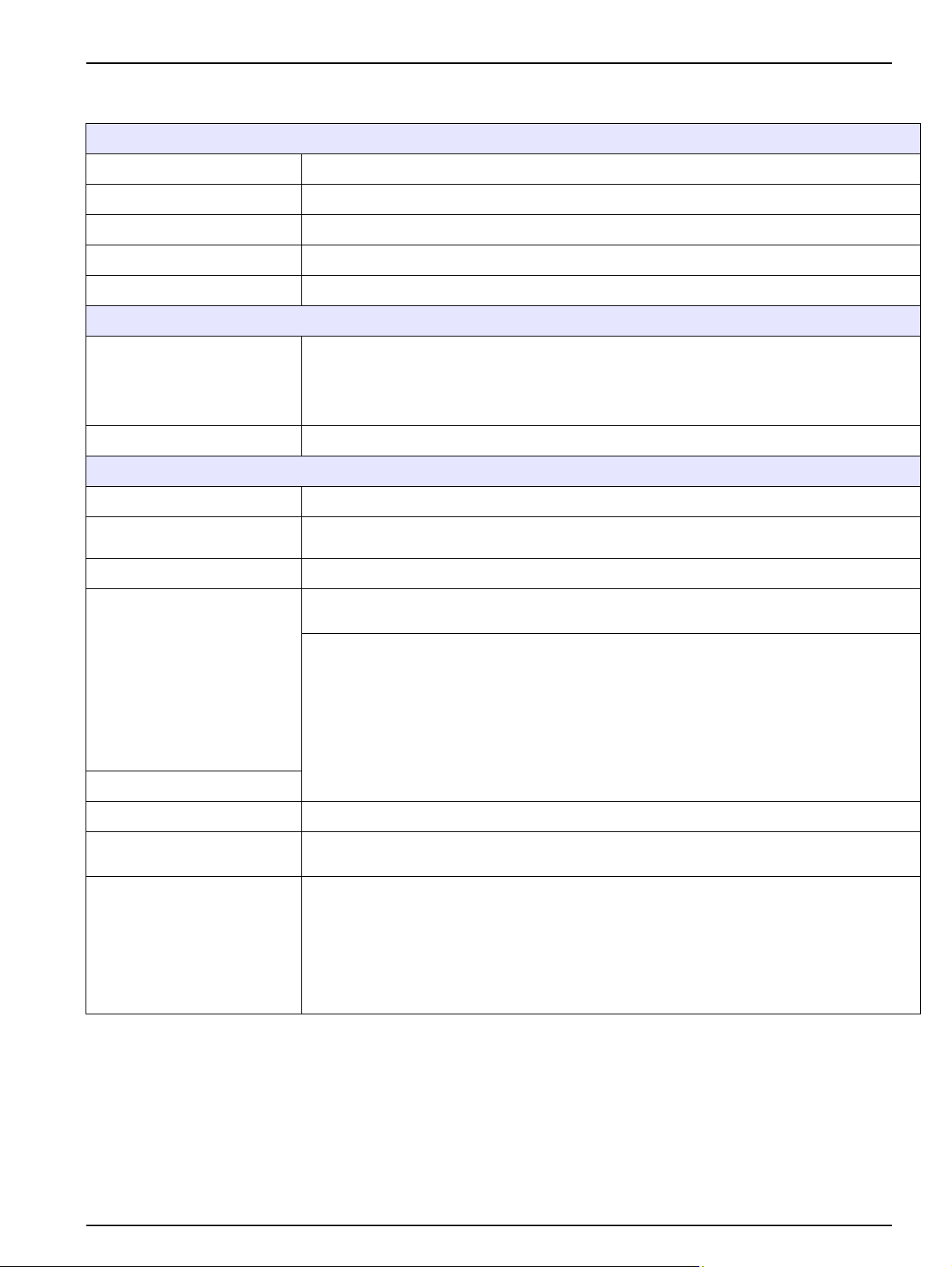

Section 1 Specifications

From software version 1.6. Subject to change.

Measurement

Principle of operation Samples delivered under pressure, homogenized using ultrasound

Interval 12 to 20 minutes

Sample quantity For up to 2 PHOSPHAX sigma or TOCTAX process photometers

Tube length 10 m, 20 m, 30 m (393.7 in, 787.4 in, 1181.1 in)

Suction height Maximum 7 m (275.6 in) (with tube of length 30 m (1181.1 in): maximum 6 m 236.2 in)

Environmental conditions

Control unit: +5 °C to +40 °C (+41 °F to +104 °F)

Ambient temperature

Medium temperature +5 °C to + 30 °C (+41 °F to +86 °F) (probe)

Equipment properties

Protection type in accordance with IP 54 (Control unit)

Outputs

Connection tube: –20 °C to +40 °C (–4 °F to +104 °F)

(Without additional insulation; in the event of low external temperatures, correct operation can

only be guaranteed with additional insulation. More information available on request)

Fault indication contact, potential-free, 24 V, maximum 1 A

Service interface: RS 232

Power connector 230 V AC / 50 Hz

Device with system components : 600 VA

Recommended fuse: 10 A, time-delay

Line Heater off Heater on (–20 °C (–4 °F))

Power consumption

10 m (393.7 in) 150 VA 250 VA 1300 VA

20 m (787.4 in) 150 VA 350 VA 2300 VA

30 m (1181.1 in) 150 VA 470 VA 3000 VA

Inspection interval: 3 months

Maintenance requirement: Approximately 0.5 h/week, typically

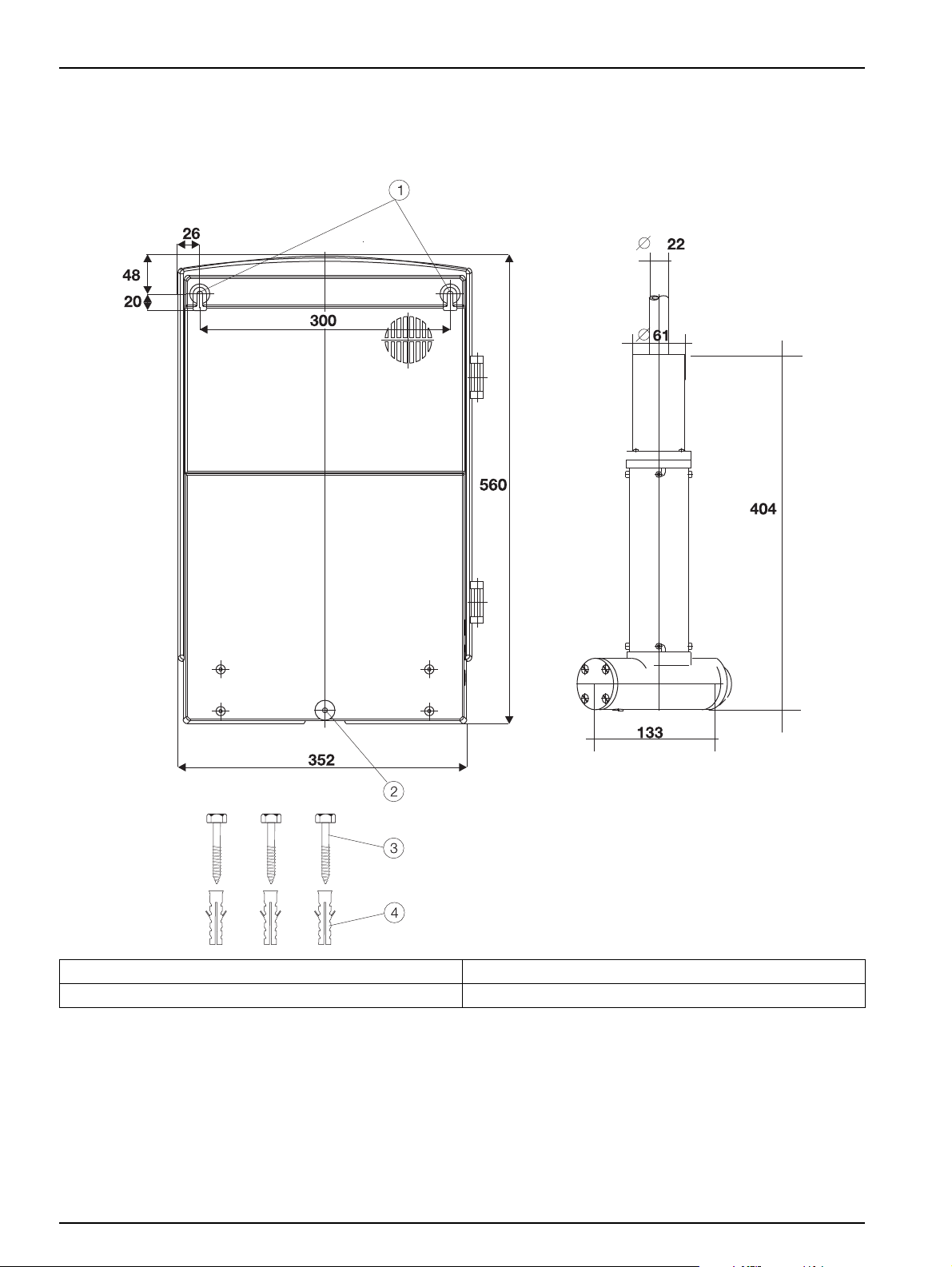

Dimensions:

Earth (approximate)

Open loop control unit: W × H × D 366 × 560 × 212 mm (14.4 × 22 × 8.3 in

Probe: Ø × L 133 × 404 mm (5.2 × 15.9 in

Control unit: 12 kg

Sampling probe 10 m (393.7 in) 7.5 kg

Sampling probe 20 m (787.4 in) 15 kg

Sampling probe 30 m

(1181.1 in)

Mounting poles: 10 kg

Continuous

operation

22 kg

At startup

5

Page 6

Specifications

6

Page 7

Section 2 General Information

2.1 Safety information

Please read this entire manual before unpacking, setting up, or operating this equipment.

Pay attention to all danger and caution statements. Failure to do so could result in serious

injury to the operator or damage to the equipment.

To prevent damage to or impairment of the device's protection equipment, the device may

only be used or installed as described in this manual.

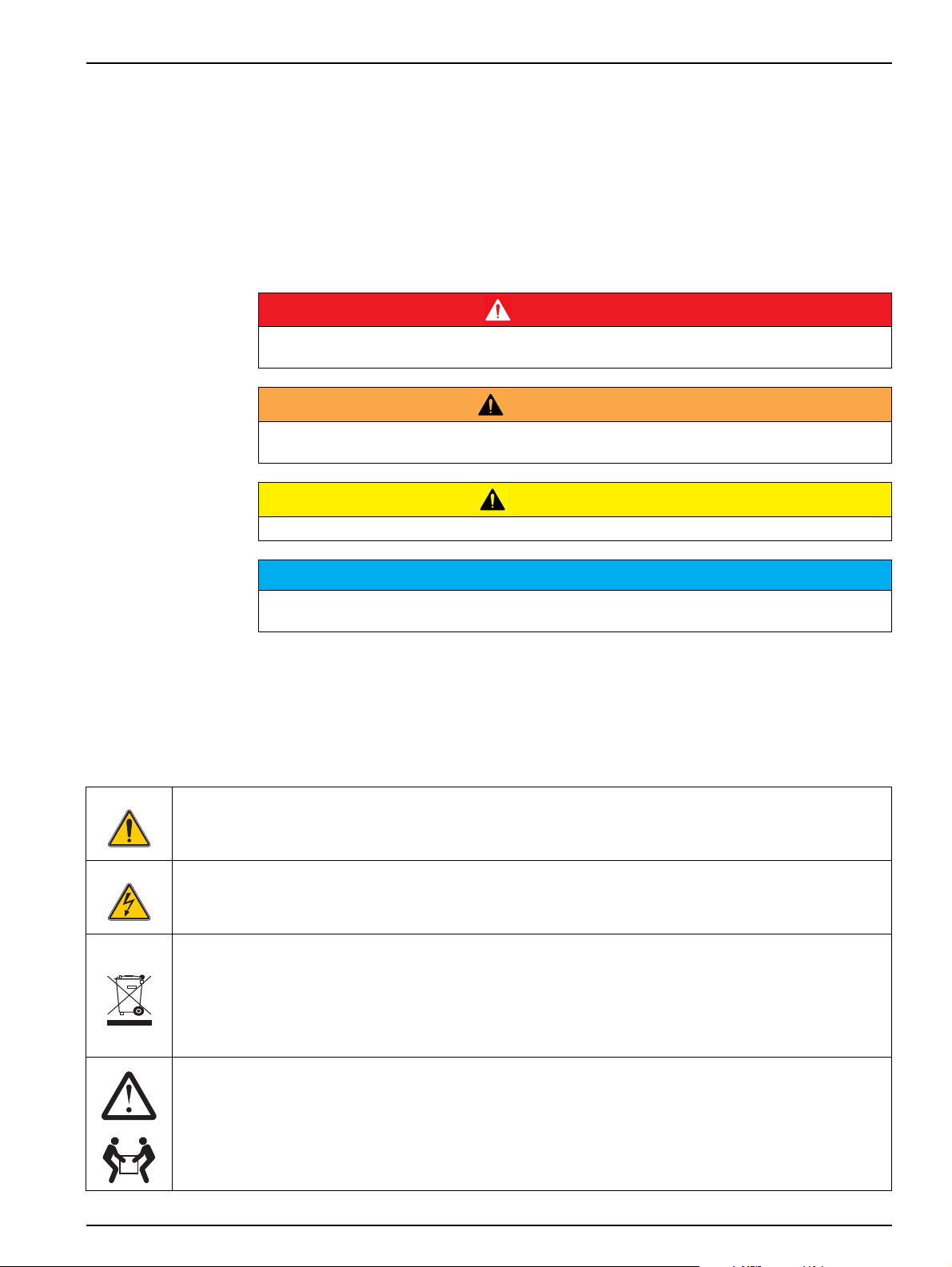

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation that, if not avoided, can result in death or

serious injury.

WARNING

Indicates a potentially or imminently dangerous situation that, if it is not avoided, can lead to

death or to serious injuries.

CAUTION

Indicates a possible dangerous situation that can have minor or moderate injuries as the result.

Indicates a situation that, if it is not avoided, can lead to damage to the device. Information that

requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary labels

Observe all labels and notices attached to the instrument and/or delivery packaging.

Personal injury or damage to the instrument could occur if not observed.

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety

information.

This symbol may be found on an enclosure or barrier within the product and indicates a risk of electric shock

and/or death by electrocution.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems after 12 August 2005. In conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the

manufacturer for disposal at no charge to the user.

Note: Y

were supplied or manufactured by Hach-Lange at your relevant Hach-Lange sales office.

ou obtain instructions on the correct disposal of all (marked and not marked) electrical products that

NOTICE

18-32 kg (39.7-70.5 lbs)

When carrying or transporting the instrument/instrument components and if the total weight is more than 18 kg,

make sure that suitable lifting equipment is used and/or that the instrument/instrument components are carried

by 2 people.

7

Page 8

General Information

2.2 Application areas

Automatic sample removal and homogenization system for supplying the PHOSPHAX S

sigma (total phosphorus), TOCTAX (total organic carbon, TOC) and astro TOC (total

organic carbon, TOC) process photometers with samples from water containing solid

particles with a diameter < 0.5 mm.

Any use other than use in accordance with requirements defined in the user manual leads to the

loss of the warranty claims and can lead to personal injury and property damage, for which the

manufacturer assumes no liability.

2.3 Functional description

A sampling probe is immersed in the water and draws only the sample volume required for

the analysis without coming into contact with pumps. The sample is conveyed into a small

storage vessel in the open loop control unit and is homogenized using an ultrasound

generator.

NOTICE

8

Page 9

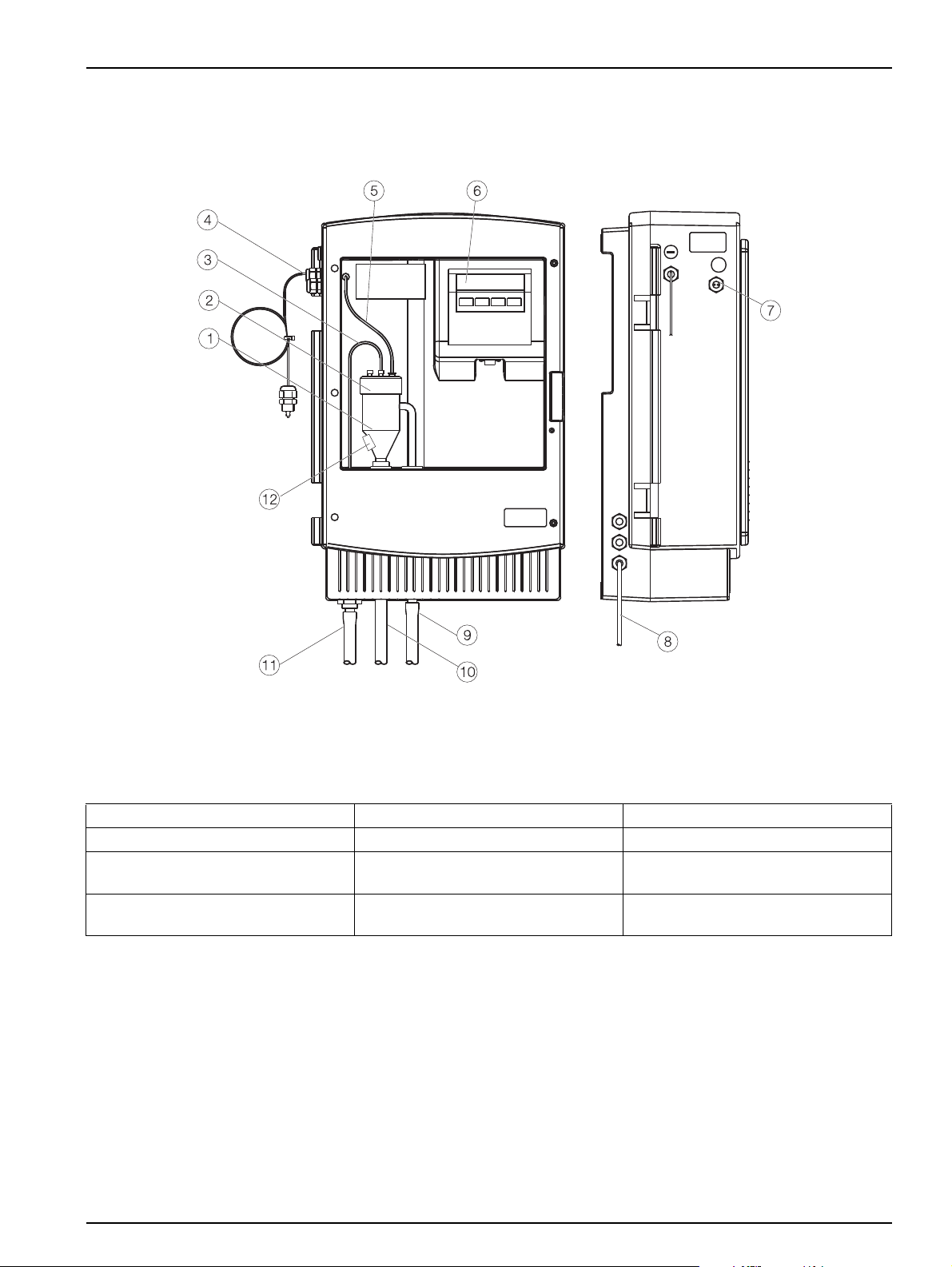

2.4 Instrument design

Figure 1 Control unit

General Information

1 Sample storage vessel 5 Pressure sensor line 9 Overflow drain tube

mple storage vessel lid 6 Display with keypad 10 Sample storage vessel drain tube

2 Sa

mple tube 7 Sample removal for process

3 Sa

instruments

ber optic cable for

4 Fi

PHOSPHAX sigma or TOCTAX

8 Mains connection cable 12 Ultrasound transducer

11 Connection tube from the probe

9

Page 10

General Information

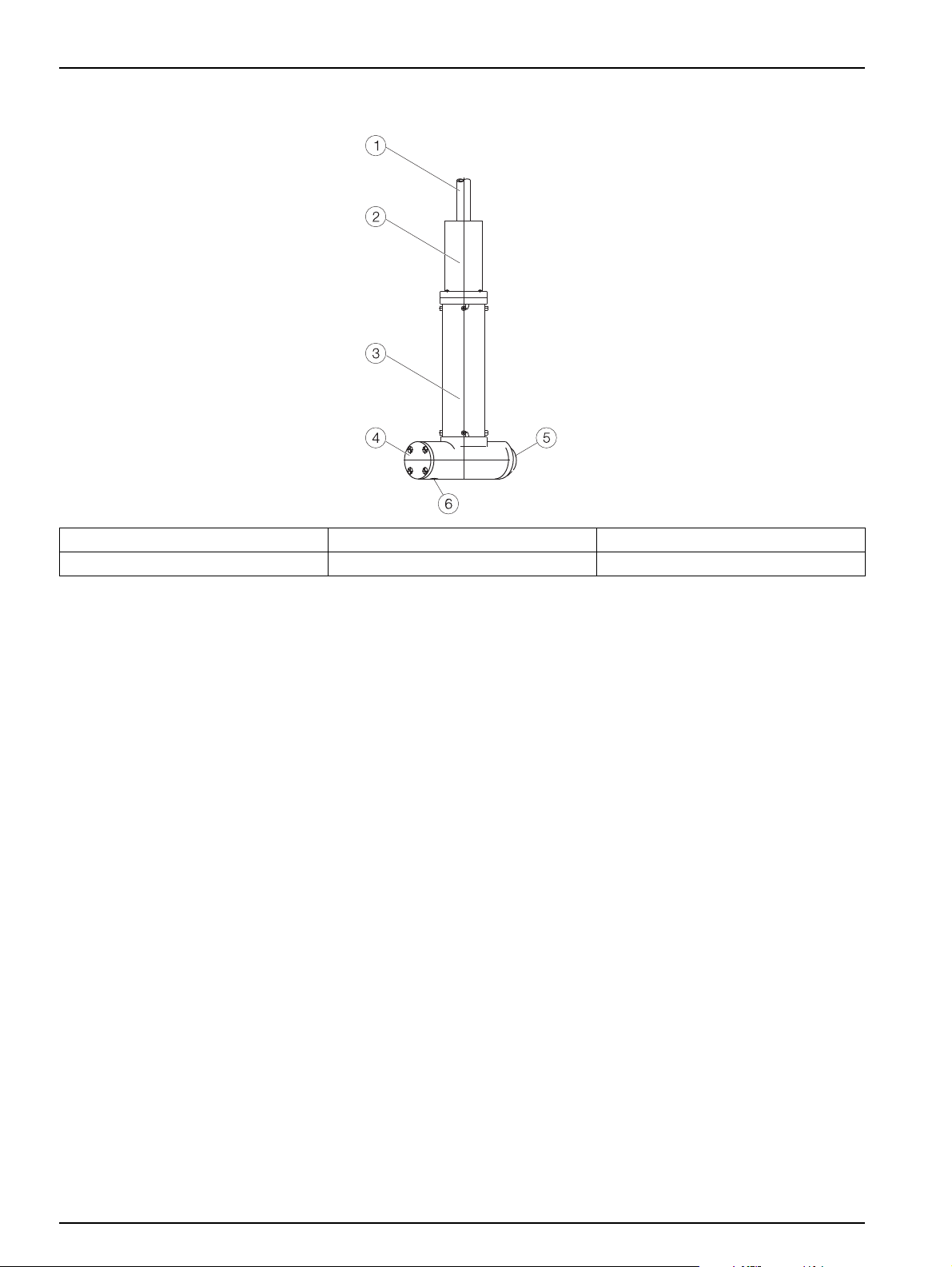

Figure 2 Sampling probe

1 Connection tube 3 Sampling vessel 5 Air outlet

2 Probe

cover 4 Valve cover 6 Drain valve

10

Page 11

Section 3 Installation

Only qualified experts may conduct the tasks described in this section.

Select a suitable attachment point for the instrument.

Plan out the mechanical mount·before po

has a sufficient bearing capacity. The dowels must be selected and authorized according to the

condition of the wall.

The manufacturer shall accept no liability if

Plan how to lay cables and tubes and their path in advance. Lay the tubes, data cables and

r cables without any bends and so they do not pose a tripping risk.

powe

Do not connect the electrical supply to the mains·u

protected against short circuits.

Sufficiently protect the electrical powe

For the external power supply, always connect a re

max.: 30 mA) between the mains and the system.

If the instrument is to be installed outdoors, conn

system.

Products intended by the manufacturer for outdoor use

the penetration of liquids and dust. If these products are connected to a mains outlet with a cable

and plug·rather than a permanently connected cable, the plug and outlet are much more

susceptible to liquid and dust penetration. The operator must sufficiently protect the plug and

outlet against liquid and dust penetration in accordance with local safety regulations. If the

instrument is to be used outdoors, it must be connected to a suitable outlet with a protection type

of at least IP44 (splash protection).

DANGER

DANGER

sitioning poles or drilling holes. Make sure the mount

the instrument is installed incorrectly.

ntil the instrument is completely wired and

r supply against short circuits.

sidual-current circuit breaker·(trip current

ect a surge arrester between the mains and the

offer a higher level of protection against

WARNING

Electrical and fire hazards. Only use the mains cable supplied. Only qualified experts may

perform the tasks described in this section of the manual, while adhering to all locally valid safety

regulations.

NOTICE

Protect the instrument from extreme temperatures from heaters, direct sunlight and other heat

sources.

CAUTION

Beware of the weight (open loop control unit: approximately 12 kg; sampling probe up to

approximately 22 kg) of the instrument and the probe. Do not

probe without assistance. Use only suitable lifting devices for the transport.

attempt to carry the instrument and

11

Page 12

Installation

3.1 Mechanical installation

Figure 3 Dimensions (in mm)

1 Suspension points 3 Wood screw, 5 x 40 (3×)

ixing point 4 Nylon plug, 8 x 40 (3×)

2 F

12

Page 13

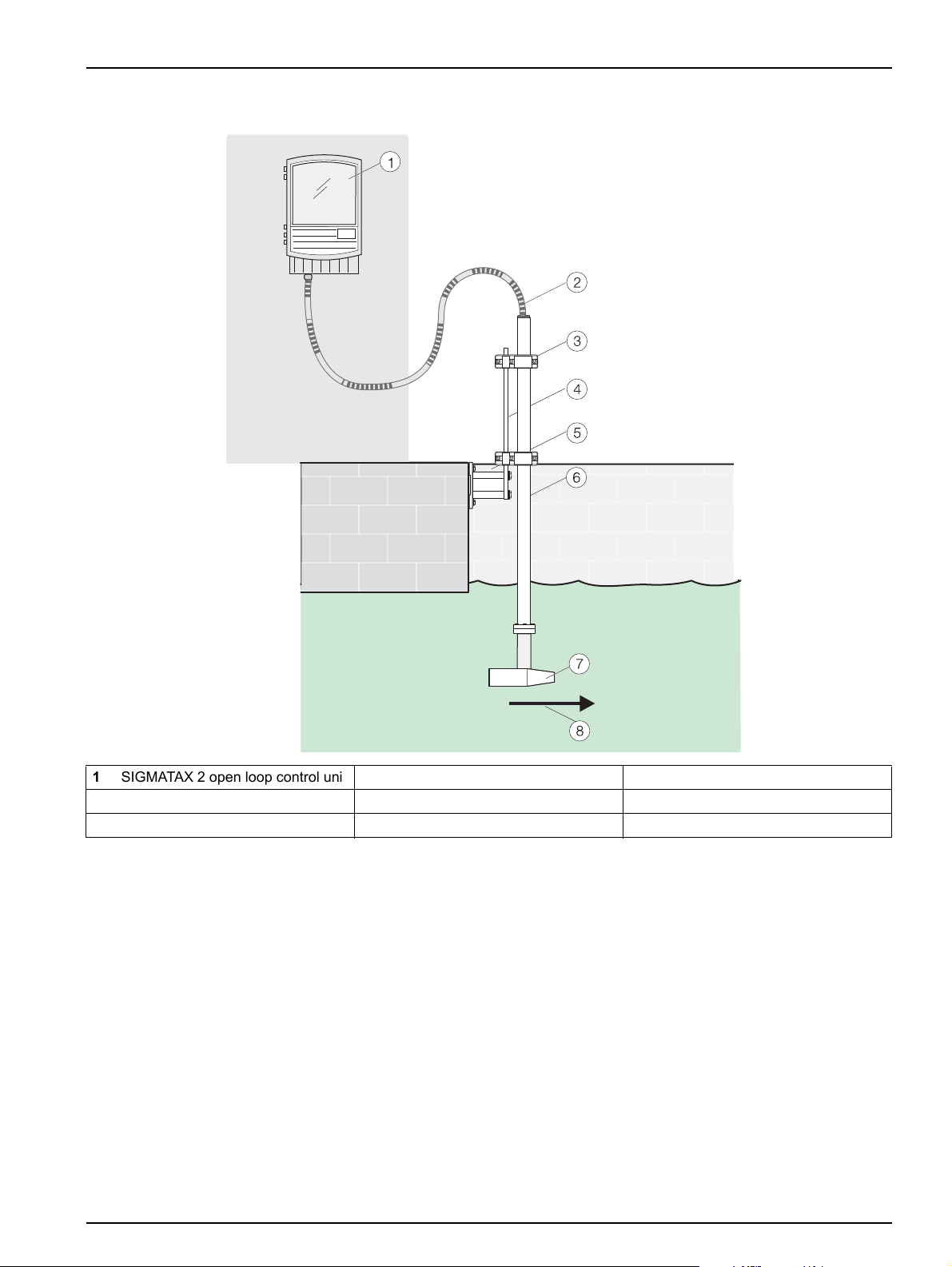

Figure 4 Installation overview

aaaaaaaa

aaaaaaaa

aaa

aaa

Installation

1 SIGMATAX 2 open loop control unit 4 Mounting attachment 7 SIGMATAX 2 sampling probe

onnection tube (10–30 m) 5 Base 8 Direction of flow

2 C

etaining clamp 6 Mounting pipe, 2 m (78.7 in)

3 R

13

Page 14

Installation

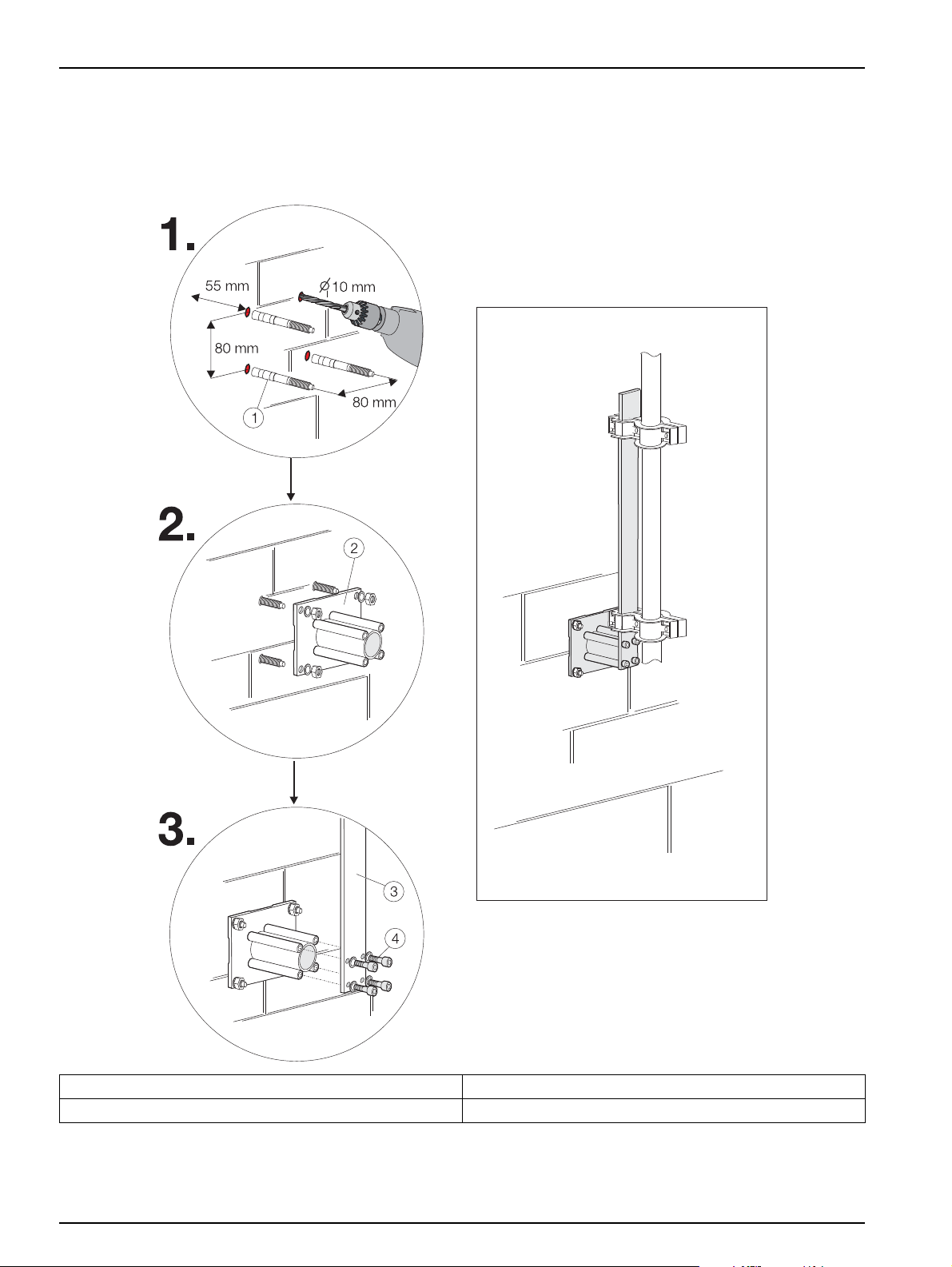

3.1.1 Install the sampling probe

Installation with rim mounting LZX414.00.00000

Figure 5

Base and mounting attachment

1 Express anchor 3 Mounting attachment

2 Base 4 Cyl

14

inder-head screw, M8 × 40 (4×)

Page 15

When carrying out an installation variant that deviates from this example, make sure that the

connection tube from the sampling probe is guided vertically upward for at least 0.5 m (19.6 in).

Installation using pole mount LZX414.00.00000

Figure 6 Sampling probe and mounting pipe

Installation

NOTICE

1 Mounting pipe, 2 m (78.7 in) 3 Retaining clamp

2 EPDM flat

seal 4 Cylinder-head screw, M5 × 20 (3×)

15

Page 16

Installation

3.1.2 Second mounting point and extension pipe

Figure 7 Second mounting point LZX456

1 Mounting pipe, 2 m (78.7 in) 3 Retaining clamp

2 EPDM flat

16

seal 4 Cylinder-head screw, M5 × 20 (3×)

Page 17

When carrying out an installation variant that deviates from this example, make sure that the

connection tube from the sampling probe is guided vertically upward for at least 0.5 m (19.6 in).

Figure 8 Installation with extension pipe.

Installation

NOTICE

1 Mounting pipe, 2 m (78.7 in) 4 Retaining clamp

2 EPDM flat

3 Extensi

seal 5 Cylinder-head screw, M5 × 20 (3×)

on pipe

17

Page 18

Installation

3.1.3 Install the open loop control unit

Install the open loop control unit in a dry location out of direct sunlight.

Make sure that an area of 5 cm is kept free around the entire instrument to enable air to

circulate (distance from the wall of the building, cable channel etc.).

The Teflon sample lines must be laid without sharp bends. Shortening or extending the lines will

lead to problems when the samples are transported.

Each process instrument must have a separate drain tube!

The individual device drains may only be combined in a larger drain pipe with regular water

ghput.

throu

NOTICE

NOTICE

18

Page 19

Installation

Figure 9

Open loop control unit and process instrument

1 SIGMATAX 2 open loop control unit 5 Separate drain pipe for process

instrument

2 F

iber optic cable to the process

instruments

3 PHOSPHAX s

ared drain pipe 8 Teflon sample line

4 Sh

igma or TOCTAX 7 SIGMATAX 2 mains connection

6 SIGMATAX 2 connection tube 10 SIGMATAX 2 drain tubes

cable

9 Drain tube for process instrument

19

Page 20

Installation

3.1.4 Prepare the connection tube

The pipe trace heater in the connection tube is operated at 230 V. If any damage occurs to the

tube casing, the entire system must be taken out of operation immediately.

Figure 10 Connection tube

DANGER

1 Protective tube 3 Connection tube

eat-shrink tube 4 PG 16 screw connection

2 H

20

Page 21

3.1.5 Connect the connection tube

Installation

Figure 11

Connections for connection tube and drain tubes

1 Air hose (drain valve), Ø 3 mm

(0.11 in)

2 Air hose, Ø 5 mm (0.19 in) 5 Conn

3 Sa

mple tube 6 Drain tube for storage vessel

4 Electrical connection cable for the

pipe trace heater

ection tube from the sampling

probe

7 Overflow drain tube

8 Drain fitting

21

Page 22

Installation

3.2 Electrical installation

Protect the instrument from extreme temperatures from heaters, direct sunlight and other heat

sources.

Electrical and fire hazards. Use only the supplied power cable.

Only qualified experts may perform the tasks described

adhering to all locally valid safety regulations.

Use only earthed sockets for the connection of this device to the power supply.

If you are not sure if the sockets are earthed,

The power plug serves in addition to the power

mains where necessary.

The entire measurement system has two power plugs (

control unit).

During the disconnection from the power source it must b

is pulled (for example by labeling the sockets).

This is recommended for long-term storage and can preve

fault.

Therefore make sure that the sockets to which the de

user at all times.

NOTICE

WARNING

in this section of the manual, while

NOTICE

have this checked by a qualified electrician.

supply to isolate the device quickly from the

measurement device and open loop

e made sure that the correct power plug

nt potential dangers in the event of a

vice is connected are easy to reach by each

NOTICE

Pull out power plug before the opening of the device.

3.2.1 Connect the pipe trace heater and fault indication contact

WARNING

The electrical connection for the pipe trace heater must be carried out by a specialist electrician.

NOTICE

If the mains plug·of the power connection cable·is removed and replaced by hard wiring, then in

immediate proximity of the display unit a suitable double-pole one-way circuit breaker with clear

labeling for the power supply must be installed.

All connected signal connection lines must be shielded.

22

Page 23

Figure 12 Terminal assignment

Installation

1 Connection cable for pipe trace heater 3 Connection terminals for heater

(N, L = terminals 8 + 9 from the top)

ault indication contact (circuit diagram shows contact

2 F

during a fault indication)

Open 1/2, closed 2/3

4 Connection terminal for earth conductor

NOTICE

Route the signal lines (1, 2, 3) separated from the power cable.

23

Page 24

Installation

3.2.2 Connect the fiber optic cable

Figure 13 Fiber optic cable connection

1 Fiber optic cable for SIGMATAX 2 with PG screw

connection

2 Blin

d plug for fiber optic cable PG screw connection

(PHOSPHAX sigma or TOCTAX)

3.3 Internal tubing

1. Carefully screw the level indicator tube (1) and O-ring (2) into the cover (3) from

below.

2. Co

3. Lubricate the rubber seal of the ultrasound transducer (9) with Baysilone paste.

4. Att

5. Co

nnect the sampling line (5) to the sampling pipe (4). Then insert the sampling pipe

all the way into the cover through opening 3 or 4.

Note: Fragile glass components

ach the ultrasound transducer (9) to the sample storage vessel using the two

cross-head screws (10). Install the ultrasound transducer in line with the illustration

(cable "upward").

nnect the pressure sensor line (7) and insert the sample delivery line (8) 1 cm

(0.39 in) through the central opening in the cover.

3 Knurled-head screw for opening the front panel

4 Fiber optic cable connection

24

Page 25

Figure 14 Sample storage vessel

Installation

1 Level indicator pipe 5 Sample tube 9 Ultrasound transducer

2 O-ring 6 Conn

transducer

mple storage vessel cover with

3 Sa

O-ring compression fittings

4 Smal

l sample pipe 8 Sample tube

7 Pressure sensor line

ection cable for ultrasound

10 Cross-head screw, M4 × 16 (2×)

25

Page 26

Installation

26

Page 27

aaaaaaaa

aaaaaaaa

aaa

aaa

Section 4 Start Up

After the sampling probe and control unit have been fully installed and all lines have been

connected (connection tube, sampling and drain tubes, fiber optic cables), the mains plug

can be plugged in.

If there is a risk of freezing, switch on the pipe trace heater!

The pipe trace heater in the connection tube is operated at 230 V. If any damage occurs to the

tube casing, the entire system must be taken out of operation immediately.

Figure 15 Plug in the power plug

WARNING

27

Page 28

Start Up

28

Page 29

Section 5 Operation

5.1 Operation

All instrument functions are controlled by the software. The instrument is operated via

menus using four keys that are located below the display. From operational mode, you can

access the first menu level by pressing the function keys, F1 to F4, for 3 seconds.

The functions of the keys in the individual menus may vary, and are therefore shown

(abbreviated clearly) in the second row of the display (softkey function).

Figure 16 Display and keypad

1 Time remaining for current process 4 Operational status of heater

("H" visible = heater active)

2 C

urrent status message 5 Cancel 8 Go to next menu item

3 Ope

rational status of ultrasound

("U" visible = ultrasound active)

6 Setting change

7 Go back to previous menu item

29

Page 30

Operation

5.2

+SETTINGS

for parameterizing the

instrument

+OUTPUT TEST

for testing

connected

data cables

Menu overview

Menu level 1 Menu level 2 Menu level 3 Description

Language Option to select the language for the menus

HEATER Self-adjusting pipe trace heater —

turn on if there is a risk of freezing!

Interval

Probe type

Contrast

press. indic.

Version Instrument type and program version

error indication

fiber optic 1

Time interval (6–60 minutes) between

2 samples.

An interval > 12 minutes is only necessary for

onger analysis periods

l

Length of connection tube (10–30 m

(393.7–1181.1 in)

Reading angle (0–30) of the display;

tempe

rature dependent

Pressure display on the screen; can be

switched off

Switches on the potential-free fault indication

contact for 2 seconds

The fault indication contact

the previous position for as long as the

user activates it for testing purposes.

Blanks fiber optic cable 1 for 1 second

is only held in

OF output 2

ERVICEMENU

+S

for maintenance tasks

d functional tests

an

fiber optic 2

+INSPECTION:

SIGMATAX switches to

service mode

+FUNCTIONSTEST

SIGMATAX switches

to service

mode

+ERROR STATUS

Blanks fiber optic cable 2 for 1 second

clean.samp. tube

cleaning probe

blowing probe

blowing valve Automatically cleans the drain valve with air

compressor Activates compressor for 30 seconds

probe valve

ultrasonic

drain valve

filling error Counter for filling errors that have occurred

delivery error Counter for delivery errors that have occurred

error reset Reset the counters to "0"

Cleans the sample tube (assisted by the

ogram)

pr

Cleans the sampling probe (assisted by the

ogram)

pr

Automatically cleans the sampling probe with

ai

r

Automatically open and close the

probe valve

Takes a new sample and

ultrasound for 30 seconds

Automatically opens and closes the drain

valve

activates

30

Page 31

5.3 Important instrument settings

5.3.1 Switch on the heater

1. Press one of the function keys, F1 to F4, for 3 seconds.

Operation

2. Open

3. Pr

4. Se

5. Swit

6. Con

the +SETTINGS menu by pressing F2.

ess F4 to scroll to the [heating] menu item

lect this menu item by pressing F2.

ch the heater on or off by pressing F3 or F4.

firm by pressing F2 and exit this menu level by pressing F1.

5.3.2 Set the processing interval

1. Press one of the function keys, F1 to F4, for 3 seconds.

2. Open

3. Press

4. Se

5. Set th

6. Con

the +SETTINGS menu by pressing F2.

F4 twice to scroll to the [interval] menu item.

lect this menu item by pressing F2.

e desired interval by pressing F3 and F4.

firm by pressing F2 and exit this menu level by pressing F1.

5.3.3 Set the display contrast

1. Press one of the function keys, F1 to F4, for 3 seconds.

2. Open

3. Press

the +SETTINGS menu by pressing F2.

F4 four times to scroll to the [contrast] menu item.

4. Se

5. Set th

6. Con

lect this menu item by pressing F2.

e desired contrast by pressing F3 and F4.

firm by pressing F2 and exit this menu level by pressing F1.

5.3.4 Switch on the pressure display

1. Press one of the function keys, F1 to F4, for 3 seconds.

2. Open

3. Press

4. Se

5. Swit

6. Con

STATUS U O

Open the probe 0 to minimum –0.5 bar –

Close the probe 0 to minimum 1.3 bar –

Deliver the sample > 1.6 bar 10–16

Empty the probe 0.1–0.5 bar –

the +SETTINGS menu by pressing F2.

F4 five times to scroll to the [press indic.] menu item.

lect this menu item by pressing F2.

ch the pressure indicator on or off by pressing F3 or F4.

firm by pressing F2 and exit this menu level by pressing F1.

31

Page 32

Operation

5.3.5 Access service mode

1. Press one of the function keys, F1 to F4, for 3 seconds.

2. Press F4 twice to scroll to the [+SERVICEMENU] menu.

3. Press F2 to open this menu.

4. When the [+INSPECTION] or [+FUNCTION TEST] menus are selected, the system

automatically switches to service mode.

Service mode means that:

• The instrument is no longer in operational mode

• The sampling probe and sample storage vessel are empty

• The system is depressurized

• The sampling probe is closed

• The fault indication contact remains in the last valid position

• The instrument will not switch back automatically to operational mode

32

Page 33

Section 6 Maintenance

The manufacturer recommends that an inspection contract be concluded. This contract

extends the warranty period to 5 years and makes sure that all inspection and

maintenance tasks are carried out by qualified experts.

Maintenance tasks for users are limited to regular visual inspections and, if necessary,

cleaning procedures.

Maintenance schedule DOC273.72.04008.MRZ03

Type of

device:

Commissioning on: by:

◦ 10 m ◦ 20 m ◦ 30 m Instrument number:

Annually:

Seal membrane on relief valve

Every 1.5 years:

Replace compressor

Every 3 months:

Clean supply lines and

ng probe (interior)

sampli

Test pressure

Every 6 months:

Replace valve piston with seal

kit

Heat if there is a risk of

freezing!

Weekly:

Clean sample storage vessel

Visually inspect sample quality

Every 1–4 weeks:

Check/clean sampling probe

Clean sample tube

(semi-au

tomatic)

33

Page 34

Maintenance

6.1 Maintenance tasks

6.1.1 After 1–4 weeks (as necessary)

Potential dangers with contact with chemical/biological substances.

Working with chemical samples, standards and reagents is linked with dangers.

Make yourself familiar with the necessary safe

chemicals before the work and read and follow all relevant safety data sheets.

Before handling these substances observe all danger notes and safety information printed on the

containers of the original solutions and in the safety data sheet.

Dispose of all consumed solutions in accordan

Select the type of protective equipment suitable to the concentration and quantity of the

dangerous material being used.

Clean the sample tube

DANGER

ty procedures and the correct handling of the

WARNING

ce with the national regulations and laws.

1. In the [+SER

VICEMENU] menu, open the [+INSPECTION] submenu and the

[clean.samp. tube]menu item.

2. The

individual steps are specified here and carried out with the support of the

program (see table).

Display text Description/action

clean. samp. tube Begin the cleaning tasks supported by the

by pressing F4

clean. samp. tube Confirmation prompt; confirm by pressing F4

cleaning glass inserted? Replace the sample storage vessel with the

chlorine bleach (sodium hypochlorite), and confirm by pressing F4.

sample tube advanced? Feed the sample tube through to the base of the cleaning vessel and confirm

ressing F4.

by p

opening probe cleaning

emptying probe cleaning

affecting

tube xx sec

please wait xx sec

sample glass inserted? Insert the sample storage vessel again and confirm by pressing F4

sample tube retracted Retract the sample tube and confirm by pressing F4

from cleaning to At this point, it is possible to choose whether SIGMATAX calls up the

Test/maint Operation

opening probe cleaning

emptying probe cleaning

filling probe cleaning

closing probe cleaning

deliv. sample cleaning

emptying sample tube cleaning

[+SERVICEMENU] or op

eration Status after rinsing is complete

The cleaning solution is automatically sucked in

meantime, the sample storage vessel can be cleaned using a paper towel

and, if necessary, a little window cleaning solution or diluted hydrochloric

acid.

SERVICEMENU] menu and remains in SERVICE mode, or whether it

[+

switches to operational mode.

The program runs through an automatic rinsing function to remove the

esidual cleaning solution by repeatedly filling and emptying the system.

r

program for the sample tube; start

cleaning vessel, which contains

for 60 seconds. In the

34

Page 35

6.1.2 1×/month (or as necessary)

Potential dangers with contact with chemical/biological substances.

Working with chemical samples, standards and rea

Make yourself familiar with the necessary safety procedures and the correct handling of the

chemicals before the work and read and follow all relevant safety data sheets.

Before handling these substances observe all danger notes and safety information printed on the

containers of the original solutions and in the safety data sheet.

Dispose of all consumed solutions in accordance with the national regulations and laws.

Select the type of protective equipment suitabl

dangerous material being used.

Clean the sampling probe

Maintenance

DANGER

gents is linked with dangers.

WARNING

e to the concentration and quantity of the

1. In the [+SER

VICEMENU] menu, open the [+INSPECTION] submenu and the

[cleaning probe] menu item.

2. Th

e individual steps are specified here and carried out with the support of the

program (see table).

Display text Description/action

cleaning probe Begin the cleaning tasks supported by the program

start by pressing F4

cleaning probe Confirmation prompt; confirm by pressing F4

probe in clean.solution? Immerse the sampling probe in a bucket containing cleaning solution (rinsing

ent) and confirm by pressing F4

ag

pressure comp.

opening probe cleaning

emptying probe cleaning

filling probe cleaning

closing probe cleaning

was probe shaken?

opening probe cleaning

emptying probe cleaning

closing probe cleaning

probe back in basin? Immerse the sampling probe again at the sampling location and confirm by

from cleaning to At this point, it is possible to choo

Test/maint Operation

opening probe cleaning

emptying probe cleaning

filling probe cleaning

closing probe cleaning

[+SERVICEMENU] or

operation Status after rinsing is completed

The sampling probe is automatically filled with cleaning solution.

You can assist the cleaning process mechanically. To do this, simply shake

the prob

The sampling probe empties automatically and rinses the removed solids out

in

pressin

[+SERVICEMENU] menu and remains in SERVICE mode, or whether it

switches to operational mode.

The program runs through an automatic rinsin

the system to remove the residual cleaning solution.

e and confirm by pressing F4

to the bucket with the cleaning solution.

g F4

se whether SIGMATAX calls up the

for the sampling probe;

g function, filling and emptying

35

Page 36

Maintenance

36

Page 37

Section 7 Troubleshooting

As soon as a fault leads to an interruption in operation, SIGMATAX 2 immediately

switches to service mode. Corresponding error messages are shown both on the

SIGMATAX 2 display and on the displays of the connected process photometers.

Service mode means that:

• Th

• Th

• Th

• Th

• Th

• The instrument will

Error message Possible cause Measures

delivery error Sample line clogged

filling error Probe valve clogged

Sensor error Internal electrical cause Call customer service.

e instrument is no longer in operational mode

e sampling probe and sample storage vessel are empty

e system is depressurized

e sampling probe is closed

e fault indication contact is held in the last valid position

not return automatically to operational mode

Select [clean.samp. tube]and carry

necessary, blow air through the sample line using the

compressor. Inspect the upper level indication sensor.

Check the compressor in the [

menu

Remove probe, extract blockages and inspect the

valve and drain valve.

probe

out a full clean; if

+FUNCTIONTEST]

37

Page 38

Troubleshooting

38

Page 39

Section 8 Replacement parts and accessories

8.1 Product contents

Description Cat. No

Control unit LXV215

10 m (393.7 in) connection tube + sampling probe

20 m (787.4 in) connection tube + sampling probe LXV232

30 m (1181.1 in) connection tube + sampling probe

Storage vessel LZX394

Drain fitting

Maintenance schedule HDF 167

Cleaning vessel

2× drain tube 2 m (78.7 in) LZX278

Screw set

Lid for sample storage vessel with level indicator pipe

Sampling pipe

PG 16 screw connection

Works test certificate

User manual

LXV231

LXV282

LZX389

LZX397

LZX355

8.2 Further accessories

Description Cat. No

Pole mount for the probe LZX414.00.00000

User manual

Second mounting point (for vibrations) LZX456

BDA361

8.3 Replacement and wear parts

Description Cat. No

230 V membrane compressor (for approximately 1,5 years) LZX376

Sample storage vessel

Valve piston LZX267

Wear part set for probe valve (for approximately 6 months)

Complete drain valve LZX266

Complete air filter

Air filter without fittings (for approximately 12 months) LZX299

Sample storage vessel lid

Accessory set for lid of sample container vessel LZX385

Maintenance schedule

Sampling nozzle (inside the probe) LZX271

Filter for air outlet

Level indicator pipe with O-ring LZX386

Complete probe valve

Straight sampling pipe LZX305

Bent sampling pipe

Sampling vessel (probe body) LZX294

Sample tubes 1.5 m (59 in) and 2 m (78.7 in)

Cleaning vessel LZX397

LZX394

LZX306

LZX300

LZX381

HDF167

LZX295

LZX269

LZX293

LZX275

39

Page 40

Replacement parts and accessories

8.3 Replacement and wear parts

Description Cat. No

Probe line 10 m (393.7 in) LZX393

Probe line 20 m (787.4 in) LZX398

Probe line 30 m (1181.1 in) LZX411

Bottom overflow fitting LZX388

Complete ultrasound transducer LZX284

40

Page 41

Section 9 Warranty and liability

The manufacturer warrants that the product supplied is free of material and manufacturing

defects and undertakes the obligation to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out within

6 months of purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including the lack

of assured properties as follows: all those parts that, within the warranty period calculated

from the day of the transfer of risk, can be demonstrated to have become unusable or that

can only be used with significant limitations due to a situation present prior to the transfer

of risk, in particular due to incorrect design, poor materials or inadequate finish will be

improved or replaced, at the supplier's discretion. The identification of such defects must

be notified to the supplier in writing without delay, however at the latest 7 days after the

identification of the fault. If the customer fails to notify the supplier, the product is

considered approved despite the defect. Further liability for any direct or indirect damages

is not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to be

performed within the warranty period by the customer (maintenance) or by the supplier

(servicing) and these requirements are not met, claims for damages due to the failure to

comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages cannot be made.

Consumables and damage caused by improper handling, poor installation or incorrect use

are excluded from this clause.

The manufacturer process instruments are of proven reliability in many applications and

are therefore often used in automatic control loops to provide the most economical

possible operation of the related process.

To avoid or limit consequential damage, it is therefore recommended to design the control

loop such that a malfunction in an instrument results in an automatic change over to the

backup control system; this is the safest operating state for the environment and the

process.

41

Page 42

Warranty and liability

42

Page 43

Section 10 Contact information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP. ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Zamówienia: +48 717 177 707

Doradztwo: +48 717 177 777

Fax +48 717 177 778

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Rossini, 1/A

I-20020 Lainate (MI)

Tel. +39 02 93 575 400

Fax +39 02 93 575 401

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 - Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edificio Seminario

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD. ŞTİ.

Ilkbahar mah. Galip Erdem

Cad. 616 Sok. No:9

TR-Oran-Çankaya/ANKARA

Tel. +90312 490 83 00

Fax +90312 491 99 03

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

43

Page 44

Contact information

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE OOO

Finlyandsky prospekt, 4A

Business Zentrum “Petrovsky

fort”, R.803

RU-194044, Sankt-Petersburg

Tel. +7 (812) 458 56 00

Fax. +7 (812) 458 56 00

info.russia@hach-lange.com

www.hach-lange.com

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

44

Loading...

Loading...