Page 1

Catalog Number DOC026.53.00742

Sigma SD900 Portable Sampler

USER MANUAL

June 2007, Edition 1

© HACH Company, 2007. All rights reserved. Printed in the U.S.A.

Page 2

Page 3

Table of Contents

Section 1 Specifications.................................................................................................................... 5

1.1 Dimensions.................................................................................................................................. 8

1.2 Bottle and retainer configurations ................................................................................................ 9

Section 2 General Information....................................................................................................... 11

2.1 Safety information...................................................................................................................... 11

2.1.1 Use of hazard information................................................................................................. 11

2.1.2 Precautionary labels ......................................................................................................... 11

2.1.3 Confined space precautions ............................................................................................. 12

2.2 Sampler overview ...................................................................................................................... 13

2.2.1 Sampler components........................................................................................................ 13

Section 3 Installation........................................................................................................................ 15

3.1 Unpack the sampler ...................................................................................................................15

3.2 Installation guidelines................................................................................................................. 17

3.2.1 Manhole installation .......................................................................................................... 19

3.3 Sampler base preparation.......................................................................................................... 19

3.3.1 Clean the sample bottles .................................................................................................. 19

3.3.2 Single bottle installation .................................................................................................... 20

3.3.2.1 Full bottle shut-off installation................................................................................... 20

3.3.3 Multiple bottle installation .................................................................................................. 21

3.3.3.1 Bottle number 1 position .......................................................................................... 21

3.3.3.2 Two or four bottle installation ................................................................................... 22

3.3.3.3 Eight bottle installation ............................................................................................. 23

3.3.3.4 24 bottle installation ................................................................................................. 24

3.3.3.5 Distributor installation............................................................................................... 26

3.4 Intake tubing and strainer installation ........................................................................................ 27

3.5 Electrical installation .................................................................................................................. 28

3.5.1 Power installation .............................................................................................................. 29

3.5.1.1 Battery installation.................................................................................................... 29

3.5.1.2 AC power installation ............................................................................................... 30

3.5.2 Flow meter installation ...................................................................................................... 31

3.5.3 Communications installation ............................................................................................. 31

Section 4 Sampler operation.......................................................................................................... 33

4.1 Power on and power off ............................................................................................................. 33

4.2 Controller overview.................................................................................................................... 33

4.2.1 Keypad description ........................................................................................................... 33

4.2.2 Navigation.........................................................................................................................34

4.2.3 Parameter selection.......................................................................................................... 34

4.3 Main menu overview.................................................................................................................. 35

4.4 Sampler programs ..................................................................................................................... 35

4.4.1 Sampler program overview............................................................................................... 36

4.4.2 Create a sampler program ................................................................................................ 37

4.4.2.1 Tips and techniques ................................................................................................. 37

4.4.3 Modify a program .............................................................................................................. 38

4.4.4 Review a program............................................................................................................. 38

4.4.5 Restore default settings .................................................................................................... 39

4.4.6 Store programs as presets................................................................................................ 39

4.4.6.1 Load a stored program............................................................................................. 39

4.5 Start or stop a program.............................................................................................................. 40

1

Page 4

Table of Contents

4.6 Manual operation........................................................................................................................40

4.6.1 Collect grab samples .........................................................................................................40

4.6.2 Move the distributor arm....................................................................................................41

4.6.3 Start or stop the pump.......................................................................................................41

4.7 View data....................................................................................................................................41

4.7.1 Status screen.....................................................................................................................41

4.7.2 Status for main program ....................................................................................................42

4.7.2.1 Ready to start ...........................................................................................................42

4.7.2.2 Running/halted .........................................................................................................42

4.7.2.3 Complete ..................................................................................................................42

4.7.3 Status for stormwater program..........................................................................................42

4.7.4 Sample history...................................................................................................................43

4.7.5 Event log............................................................................................................................43

4.7.5.1 View the event log ....................................................................................................44

4.7.5.2 Erase the event log...................................................................................................44

4.8 Volume calibration......................................................................................................................44

4.8.1 Volume calibration using the liquid sensor ........................................................................45

4.8.1.1 Reset the calibration.................................................................................................45

4.8.2 Volume calibration based on time .....................................................................................46

4.8.3 Verify sample volume........................................................................................................47

4.9 Controller settings ......................................................................................................................47

4.9.1 Liquid sensor calibration....................................................................................................48

4.9.2 Set password.....................................................................................................................48

4.9.3 Tubing life indicator ...........................................................................................................49

4.9.3.1 Enable the tubing life indicator .................................................................................49

4.9.3.2 Tubing life status ......................................................................................................49

4.9.3.3 Tubing life cycle limit ................................................................................................49

4.9.3.4 Reset tubing cycles ..................................................................................................50

Section 5 Advanced sampling........................................................................................................51

5.1 Advanced sampling overview.....................................................................................................51

5.2 Advanced sampling menu..........................................................................................................51

5.3 Advanced sampling instructions.................................................................................................51

5.3.1 Send output signal at program completion ........................................................................52

5.3.2 Send output signal with sample cycle (special output) ......................................................52

5.3.3 Operate from external signal (setpoint sample).................................................................53

5.3.4 Set multiple start and stop times .......................................................................................53

5.3.5 Collect first flush stormwater samples ...............................................................................54

5.3.6 Set variable intervals.........................................................................................................55

Section 6 Maintenance.....................................................................................................................57

6.1 Upgrades, Repairs, General Maintenance .................................................................................57

6.2 Sampler cleaning........................................................................................................................57

6.3 Pump maintenance ....................................................................................................................57

6.3.1 Pump tube life....................................................................................................................57

6.3.2 Pump tube replacement ....................................................................................................58

6.3.3 Rotor removal and cleaning...............................................................................................60

6.4 Distributor arm tubing replacement ............................................................................................62

6.5 Desiccant replacement...............................................................................................................62

Section 7 Troubleshooting ..............................................................................................................65

7.1 General troubleshooting .............................................................................................................65

7.2 Error messages and notifications ...............................................................................................66

2

Page 5

Table of Contents

7.3 Diagnostic tests.......................................................................................................................... 67

7.3.1 Distributor diagnostic ........................................................................................................ 67

7.3.2 Keypad diagnostic............................................................................................................. 68

7.3.3 LCD diagnostic.................................................................................................................. 68

7.3.4 Liquid sensor diagnostic ...................................................................................................68

Section 8 Replacement Parts and Accessories......................................................................... 69

8.1 Bottle kits ................................................................................................................................... 69

8.2 Containers and bottle sets......................................................................................................... 69

8.3 Replacement parts..................................................................................................................... 69

8.4 Accessories................................................................................................................................ 70

Section 9 Contact information....................................................................................................... 73

Appendix A Wiring for non-Sigma flow meters ......................................................................... 75

Index...................................................................................................................................................... 79

3

Page 6

Table of Contents

4

Page 7

Section 1 Specifications

Specifications are subject to change without notice.

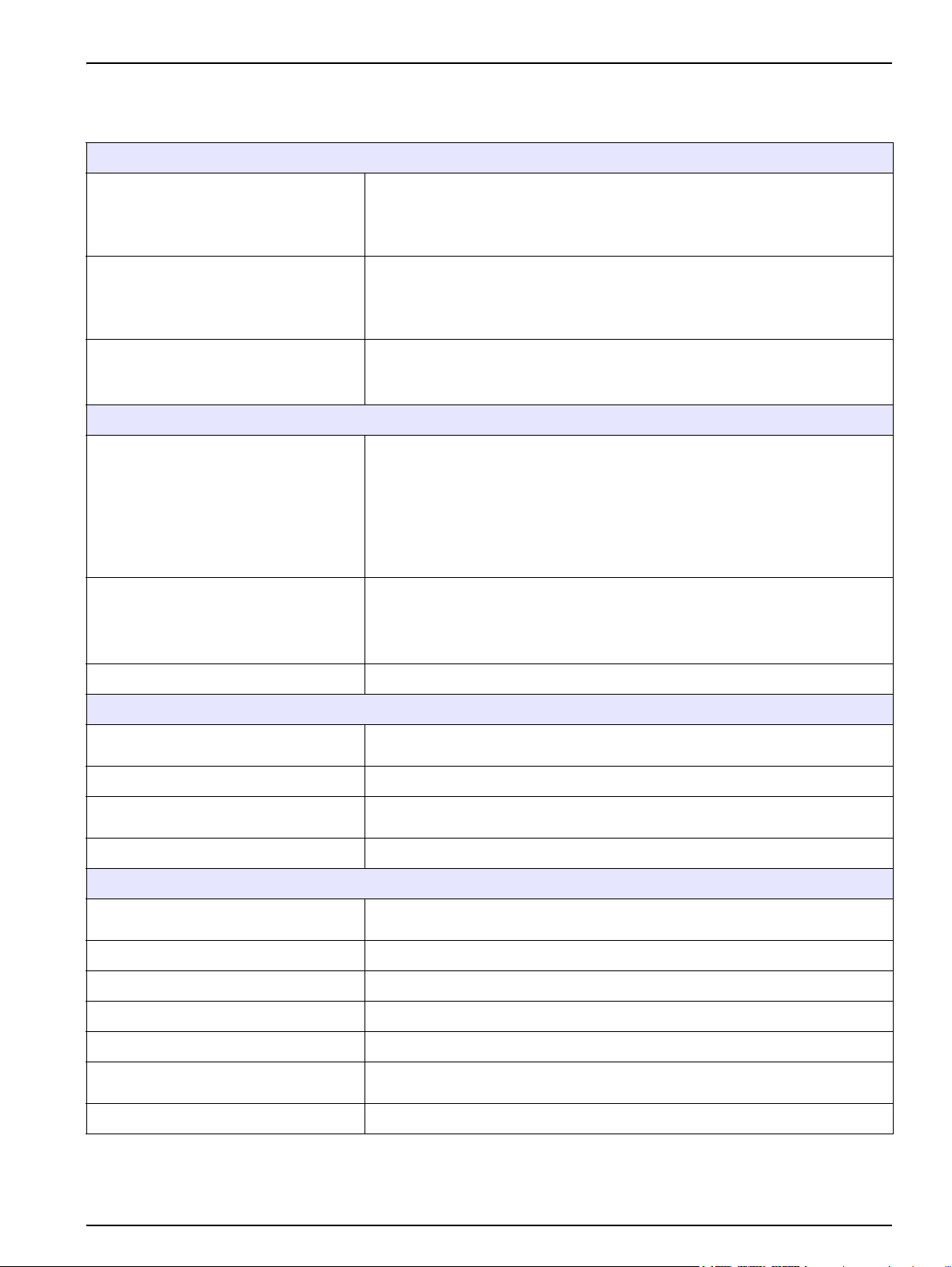

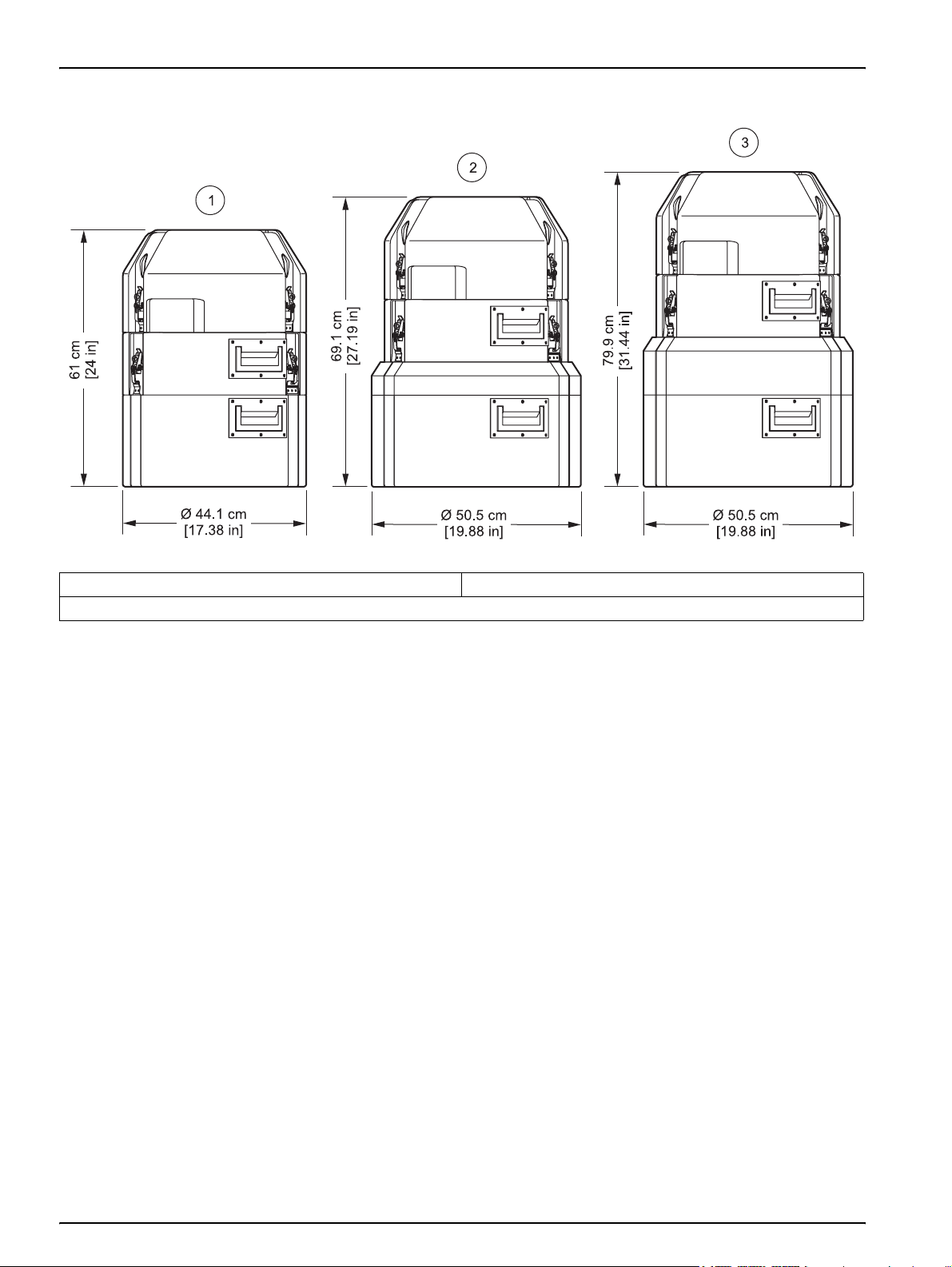

Sampler body dimensions (see Figure 1 on page 8)

Diameter: 50.5 cm (19.9 in.)

Standard base

Compact base

Composite base

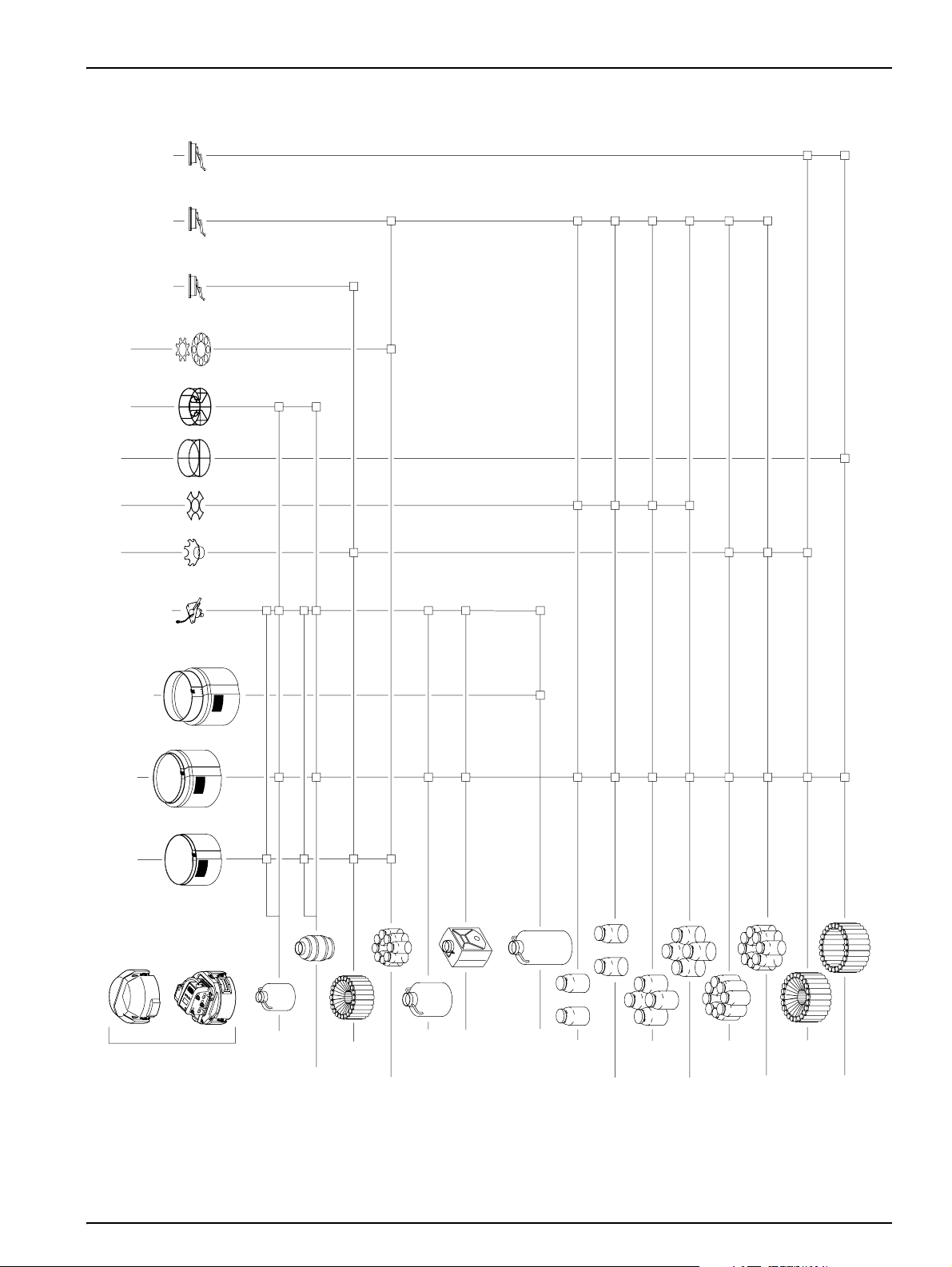

Sample bottle capacity (see Figure 2 on page 9)

Standard base

Compact base

Height: 69.4 cm (27.3 in.)

Weight: with (24) 1-L polyethylene bottles—15 kg (35.6 lb);

weight with (1) 2.5-gal polyethylene container—14.8 kg (32.6 lb)

Diameter: 44.1 cm (17.4 in.)

Height: 61 cm (24 in.)

Weight: with (24) 575-mL polyethylene bottles— 12.2 kg (27 lb);

weight with (1) 2.5-gal polyethylene container—12.9 kg (28.3 lb)

Diameter: 50.28 cm (19.8 in.)

Height: 79.75 cm (31.4 in.)

Weight: with (12) 950-mL glass bottles—15 kg (36 lb)

(24) 1 L polyethylene and/or 350-mL glass bottles

(8) 2.3 L (0.6 gal) polyethylene and/or 1.9 L (0.5 gal) glass bottles

(4) 3.8 L (1 gal) polyethylene and/or (4) 3.8 L (1 gal) glass bottles

(2) 3.8 L (1 gal) polyethylene and/or (2) 3.8 L (1 gal) glass bottles

(1) 21 L (5.5 gal) polyethylene composite container or (1) 15 L (4 gal)

polyethylene composite container or (1) 20 L (5.25 gal) polyethylene or

(1) 10 L (2.5 gal) polyethylene or (1) 10 L (2.5 gal) glass

(24) 575 mL polyethylene bottles

(8) 950 mL glass bottles

(1) 10 L (2.5 gal) polyethylene bottle

(1) 10 L (2.5 gal) glass bottle

Composite base (1) 21 L (5.5 gal) polyethylene bottle

Sampler

Sampler housing

Sample temperature range 0–60°C (32–140 °F)

Strainers

Sample intake tubing 9.5 mm (

SD900 controller

Enclosure

Power requirements 12 VDC supplied by optional AC power converter or battery

Overload protection 6 amp DC line fuse for pump

Pump Peristaltic high speed, with spring-mounted rollers

Pump rollers Nylatron,

Pump enclosure

Pump tubing 9.5 mm I.D. x 15.9 O.D. mm (3/8 in. x5/8 in.) silicone

Impact-resistant ABS, 3-section construction. Double-walled base with 2.54 cm

(1 in.) insulation—direct bottle contact with ice.

316 stainless steel in standard size, high velocity or low profile for shallow depth

applications and Teflon

3

/8 in.) I.D. vinyl or Teflon®-lined polyethylene

High-Impact, injection-molded PC/ABS blend; submersible, watertight, dust-tight,

corrosion, and ice resistant; NEMA 4X, 6, IP 67

impact/corrosion resistant

Track is injection-molded polyphenylene sulfide. Cover is polycarbonate, high

impact resistant. Pump enclosure rated IP37.

®

/316 stainless steel in standard size

5

Page 8

Specifications

20,000 sample cycles under the following conditions:

• 1 L sample volume

• 1 rinse

Pump tubing life

Tubing replacement time < 1 minute using pre-cut pump tube

Maximum vertical lift to draw sample

Pump flow rate 1.25 gpm (4.8 L/min) at 3 ft (1 m) vertical lift using

Typical sample volume repeatability

Typical sample volume accuracy

Typical transfer velocity

Liquid sensor Ultrasonic

• 6 minute pacing interval

• 16 ft of

3

/8 in. intake tube

• 15 ft of vertical lift

• 70 °F sample temperature

Minimum of 28 ft, using 29 ft of

3

/8-in. vinyl intake tube at sea level at 20–25 °C

(68–77 °F)

± 5% of 200 mL sample volume using uncalibrated liquid detect with 15 feet

vertical lift,16 feet of

3

/8-in. vinyl intake tube configured for a single bottle using full

bottle shut-off at room temperature and 5000 ft elevation

± 10% of 200 mL sample volume using uncalibrated liquid detect with 15 feet

3

vertical lift,16 feet of

/8-in. vinyl intake tube configured for a single bottle using full

bottle shut-off at room temperature and 5000 ft elevation

2.9 ft/s (0.9 m/s) with 15 ft (4.6 m) vertical lift, 16 ft of

70 °F (21 °C) and 5000 ft elevation

3

/8-in. intake tube

3

/8-in. vinyl intake tubing,

Liquid sensor body Ultem® NSF ANSI standard 51 approved, USP Class VI compliant

Internal battery Lithium

Internal clock Indicates real time and date

Storage temperature –30 to 60 °C (–22 to 140 °F)

Operating temperature 0 to 50 °C (32 to 122 °F)

Storage/operating humidity 100% condensing

Graphics display

Status display

Graphic dot matrix, 128 x 64 pixel with LED backlight. Self prompting,

menu-driven program.

Indicates the number of samples collected, the number of missed samples,

inhibit mode, bottle position, time or counts to next sample and battery voltage

Multiple bottle mode: after complete revolution of distributor arm (unless

Automatic shutdown

Continuous Mode is selected).

Composite mode: after preset number of samples have been delivered to

composite container, from 1 to 999 samples, or upon full container.

User interface

Embossed keypad with one power key, four function keys, and eight navigation

keys; LED indicator

Stores up to 255 entries for sample time stamp, bottle number and sample status

Sample history

(success, bottle full, rinse error, user abort, distributor error, pump fault, purge fail,

sample timeout, power fail and low main battery)

Records Power On, Power Fail, Firmware Updated, Pump Fault, Distributor Arm

Event log

Error, Low Memory Battery, Low Main Battery, User On, User Off, Program

Started, Program Resumed, Program Halted, Program Completed, Grab Sample,

Tube Change Required

Connections Power, auxiliary, serial communications and distributor

3

Fittings Barbed fittings for

Wetted materials

Typical materials in contact with sample: stainless steel, PE, Teflon, Ultem, Silicon

or approved materials that can be tested for leaching properties

/8-in. I.D. flexible tubing

Weight 4.2 kg (9 lb, 5 oz)

6

Page 9

Specifications

Dimensions 10-3/8 in. (26.4 cm) L x 11-½ in. (29.2 cm) W x 6-¾ in. (17.1 cm) H

Programming features

Password protection 6-character; protect changes to program and system settings

Multiple programs Stores up to three sampling programs

Cascade programs

Synchronized sampling Ability to simultaneously take two samples with input from a single flow meter

Sample volume Programmed in 10-mL increments from 100 to 10,000 mL

Air purge

Intake rinse option Option to rinse intake line with source liquid prior to each sample, 1 to 3 rinses.

Sample distribution Composite, samples per bottle or bottles per sample.

Set point sampling Ability to start and/or stop a sample program based on an external trigger.

User start/stop times Up to 12 user-defined start/stop times/dates, with option to restart at position 1.

Storm water program Ability to run time-based, first flush program in parallel with main sample program.

Two samplers used in combination. The second sampler is initiated after the first

sampler completes the program.

Air purged automatically before and after each sample; duration automatically

compensates for varying intake line lengths.

Current status Display parameters relevant to main or storm water programs.

Units of measure Volume: gallons or mL; length: feet (ft) or cm

Sample retries

Manual grab sample Ability to manually deliver a grab sample to a specific bottle location

Run modes Continuous or non-continuous with user-entered number of samples.

Time pacing Uniform or variable time intervals.

Flow pacing Uniform or variable flow intervals.

Auxiliary connector

Program delay

Communication

Firmware updates Ability to perform field upgrades using Sample View software

Serial interface

Option to repeat sample collection cycle from 1 to 3 times if sample not obtained

on initial attempt.

Power to Sigma 9XX, SD900, flow pulse input, external inhibit, special output,

bottle number output and program complete output.

Two formats: 1) 1–9,999 flow pulses (in one unit increments);

2) Programmable start time/date

RS232 compatible; allows on-site collection of stored data including event log and

sample history. Ability to configure remotely. Supports Modbus for SCADA

connectivity.

7

Page 10

Specifications

1.1 Dimensions

Figure 1 Portable sampler dimensions

1 Portable sampler with compact base 3 Portable sampler with composite base

2 Portable sampler with standard base

8

Page 11

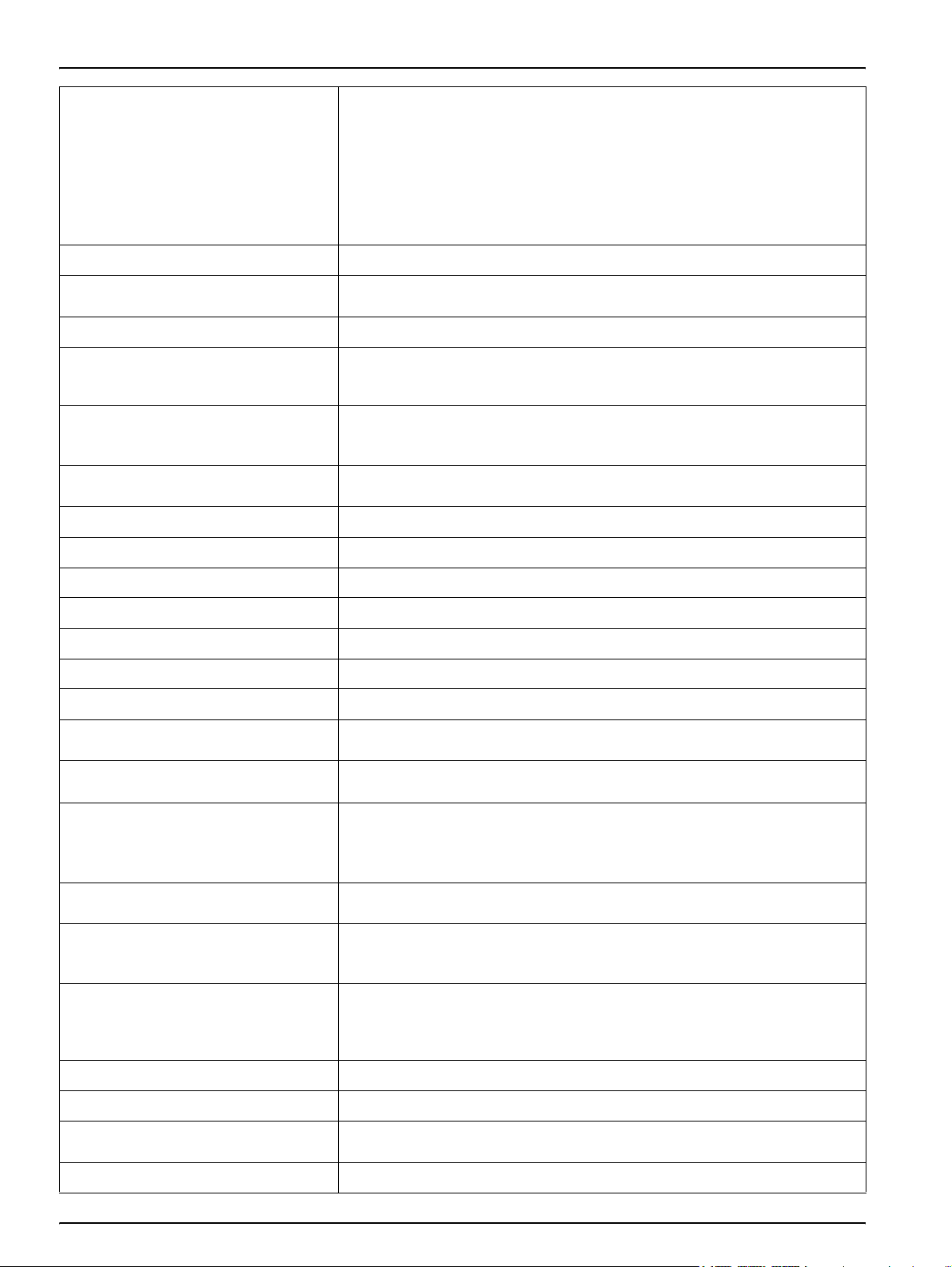

1.2 Bottle and retainer configurations

with

8582

8584

8580

2347

1502

2189

2190

[18.75 in]

ASSEMBLY

ARM (8583)

and 476.3 mm

DISTRIBUTOR

with

[16.25 in]

ASSEMBLY

ARM (8585)

and 412.8 mm

DISTRIBUTOR

with

[9.75 in]

ASSEMBLY

ARM (8581)

and 247.7 mm

DISTRIBUTOR

RETAINER

POSITIONER/

SUPPORT

CONTAINER

RETAINER

RETAINER

TUBE (8578)

TUBE (8579)

TUBE (8577)

Specifications

1422

RETAINER

8996

RETAINER\

8561

STANDARD

8976

STANDARD

8975

COMPACT

FULL

CONTAINER

FOR 5.5 GAL.

INSULATED BASE

BASE

INSULATED

BASE

INSULATED

SHUT-OFF

POLYETHYLENE

with

247.7 mm [9.75 in]

CONTAINER

TUBE (8998)

8925SD

SD900 PORTABLE

WASTEWATER SAMPLER

WITH COVER (8890)

1918 2.5 GAL.

POLYETHYLENE CONTAINER

6559 2.5 GAL.

GLASS CONTAINER

1369 (24) 575 mL

POLYETHYLENE BOTTLES

2348 (8) 950 mL

GLASS BOTTLES

1367 4 GAL.

POLYETHYLENE CONTAINER

6498 5.5 GAL.

POLYETHYLENE CONTAINER

6494 5.5 GAL.

POLYETHYLENE CONTAINER

2215 (2) 1 GAL.

Figure 2 Bottle and retainer configurations

POLYETHYLENE BOTTLES

2214 (2) 1 GAL.

GLASS BOTTLES

2217 (4) 1 GAL.

POLYETHYLENE BOTTLES

2216 (4) 1 GAL.

GLASS BOTTLES

657 (8) 2.3 LITER

POLYETHYLENE BOTTLES

1118 (8) 1.9 LITER

GLASS BOTTLES

737 (24) 1 LITER

POLYETHYLENE BOTTLES

732 (24) 350 mL

GLASS BOTTLES

9

Page 12

Specifications

10

Page 13

Section 2 General Information

2.1 Safety information

Please read this entire manual before unpacking, setting up, or

operating this equipment. Pay attention to all danger and caution

statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

To make sure that the protection provided by this equipment is not

impaired, do not use or install this equipment in any manner other

than that specified in this manual.

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in

minor or moderate injury.

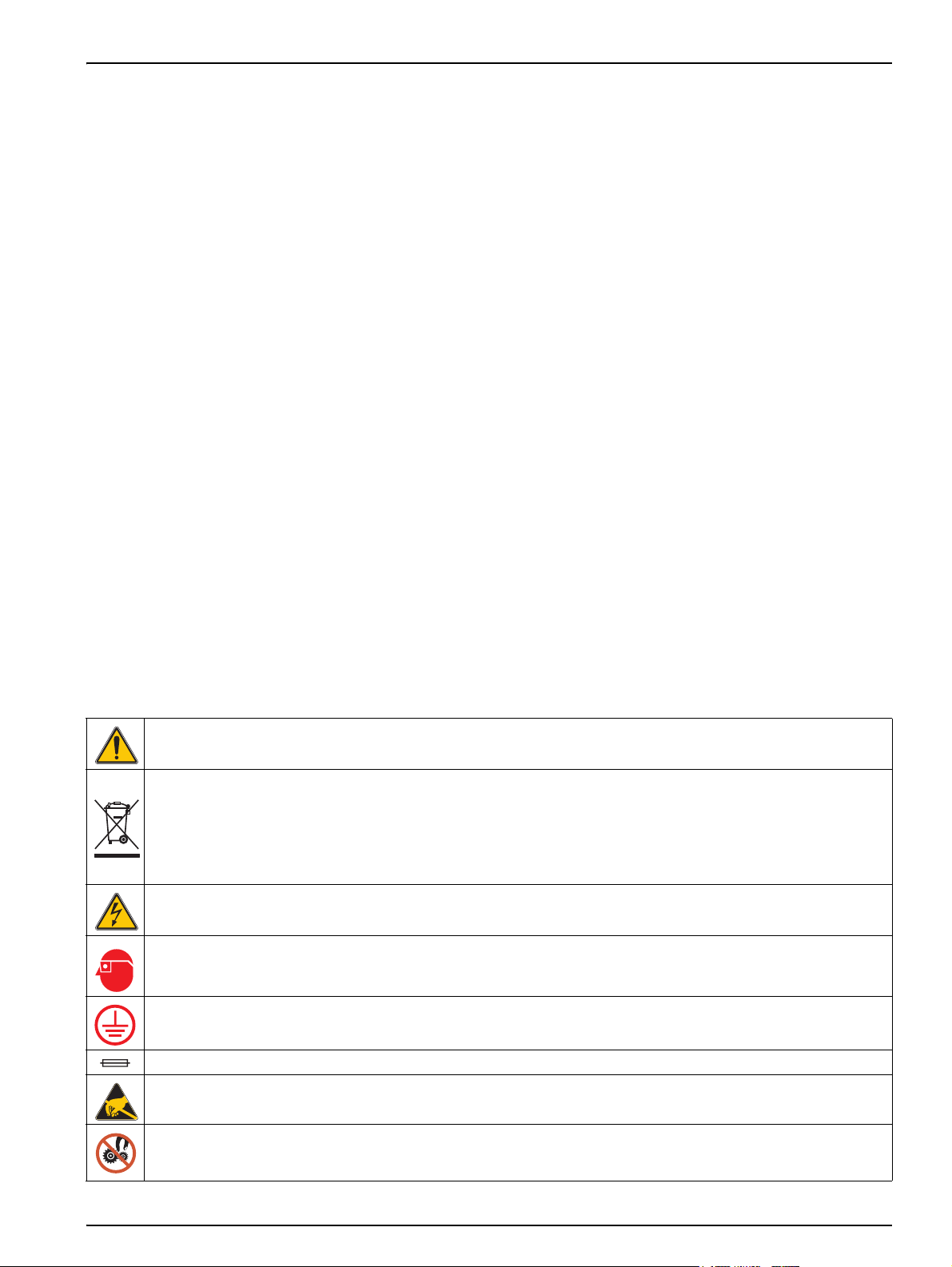

2.1.2 Precautionary labels

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after 12

August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth (ground).

Important Note: Information that requires special emphasis.

Read all labels and tags attached to the instrument. Personal injury

or damage to the instrument could occur if not observed. A symbol,

if noted on the instrument, will be included with a danger or caution

statement in the manual.

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

This symbol, when noted on the product, indicated the presence of devices sensitive to Electro-static Discharge

(ESD) and indicated that care must be taken to prevent damage with the equipment.

This symbol, if noted on the product, indicates a pinch hazard. Keep hands and fingers clear.

11

Page 14

General Information

2.1.3 Confined space precautions

Important Note: The following information is provided to guide

users of Sigma SD900 Portable Samplers on the dangers and risks

associated with entry into confined spaces.

On April 15, 1993, OSHA's final ruling on CFR 1910.146, Permit

Required Confined Spaces, became law. This new standard directly

affects more than 250,000 industrial sites in the U.S.A. and was

created to protect the health and safety of workers in confined

spaces.

Definition of a confined space

A confined space is any location or enclosure that presents or has

the immediate potential to present one or more of the following

conditions:

• An atmosphere with less than 19.5% or greater than 23.5%

oxygen and/or more than 10 ppm Hydrogen Sulfide (H

• An atmosphere that may be flammable or explosive due to

gases, vapors, mists, dusts or fibers.

• Toxic materials which upon contact or inhalation, could result in

injury, impairment of health or death.

2

S).

Confined spaces are not designed for human occupancy. They

have restricted entry and contain known or potential hazards.

Examples of confined spaces include manholes, stacks, pipes,

vats, switch vaults, and other similar locations.

Standard safety procedures must always be followed prior to entry

into confined spaces and/or locations where hazardous gases,

vapors, mists, dusts or fibers may be present. Before entering any

confined space check with your employer for procedures related to

confined space entry.

12

Page 15

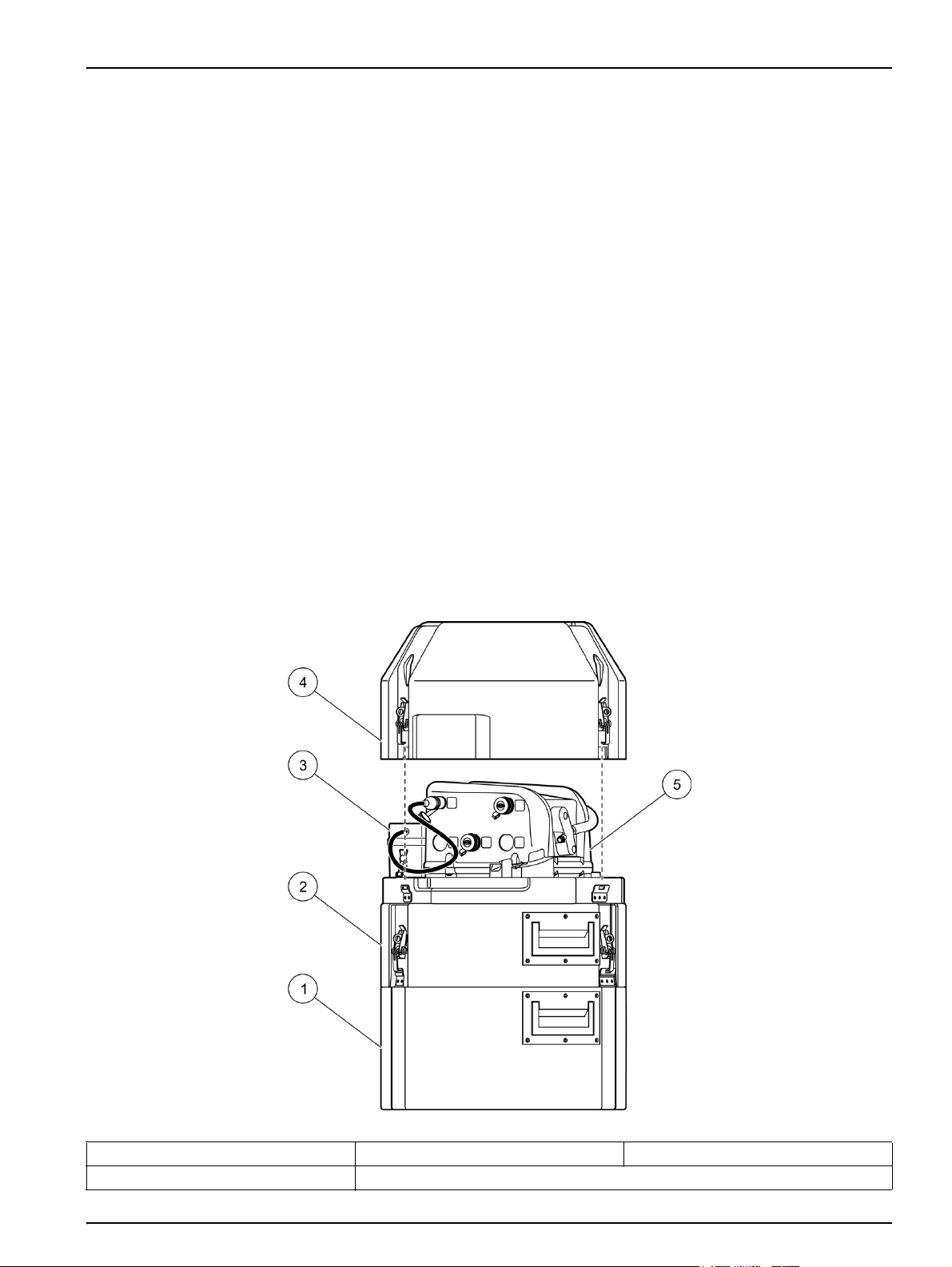

2.2 Sampler overview

2.2.1 Sampler components

General Information

DANGER

This sampler is designed for collection of aqueous samples

only. Non-aqueous samples may damage the equipment and

could result in fire and chemical hazards.

The SD900 sampler automatically collects and preserves liquid

samples. The sampler is suitable for collection of conventional and

toxic pollutants and suspended solids.

The sampler consists of three main sections (Figure 3). The center

section contains the controller. Use the controller to program the

sampler and for manual operation. The controller contains the

following components:

• Pump—operates in the forward or reverse direction to

collect a sample, rinse and purge the intake tube.

• Liquid sensor—allows the sampler to dispense accurate

sample volumes into the sample bottle(s). Can be

calibrated to specific sample conditions in the field.

• Cable connectors—for power, flow meter or

communication.

• Desiccant—absorbs internal moisture in the controller and

prevents corrosion.

Figure 3 Sampler components

1 Bottle/base section 3 Power source 5 Controller

2 Center section 4 Top cover

13

Page 16

General Information

14

Page 17

Section 3 Installation

3.1 Unpack the sampler

CAUTION

Only qualified personnel should conduct the tasks described

in this section of the manual.

WARNING

Explosion hazard. This product is not designed for hazardous

locations where combustible environments may exist.

The sampler can be set up for single-bottle or multiple-bottle

collection. The components for each configuration will vary (see

Figure 4 for single-bottle or Figure 5 on page 17 for multiple-bottle

collection).

Check the sampler packages for the following components:

• Sampler—includes cover, base and midsection with controller

and distributor or full bottle shut-off

• Bottle(s)—1, 2, 4, 8 or 24

• Power source—battery or AC power supply

• Pump tubing—replacement

• Sample intake tubing—vinyl or Teflon-lined

• Silicone grease packet—for desiccant maintenance

• Strainer—stainless steel or Teflon/stainless steel

• User documentation

15

Page 18

Installation

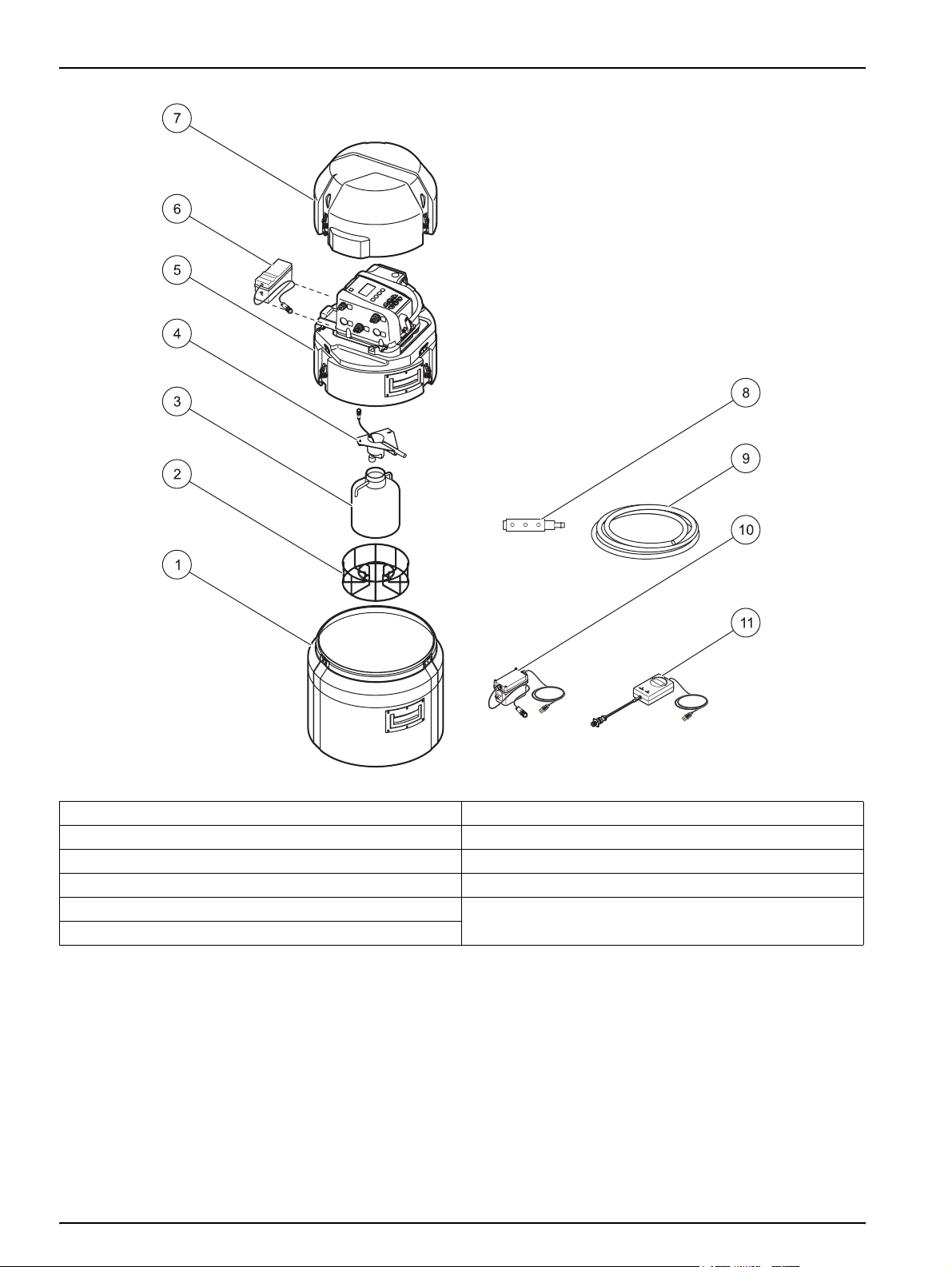

Figure 4 Sampler with single bottle

1 Sampler base 7 Top cover (Cat. No. 8890)

2 Container support (Cat. No. 1502)

3 Bottle 9 Intake tubing, vinyl or teflon-lined

4 Full bottle shut-off (Cat. No. 8996) 10 AC power supply (optional)

5 Sampler center section (Cat. No. 8922) 11 Battery recharger (optional)

6 Battery (Cat. No. 8754400, optional)

1

The container support for a 2.5-gal bottle with the standard base is shown. Other bottle sizes may not use a container support.

1

8 Strainer

16

Page 19

Installation

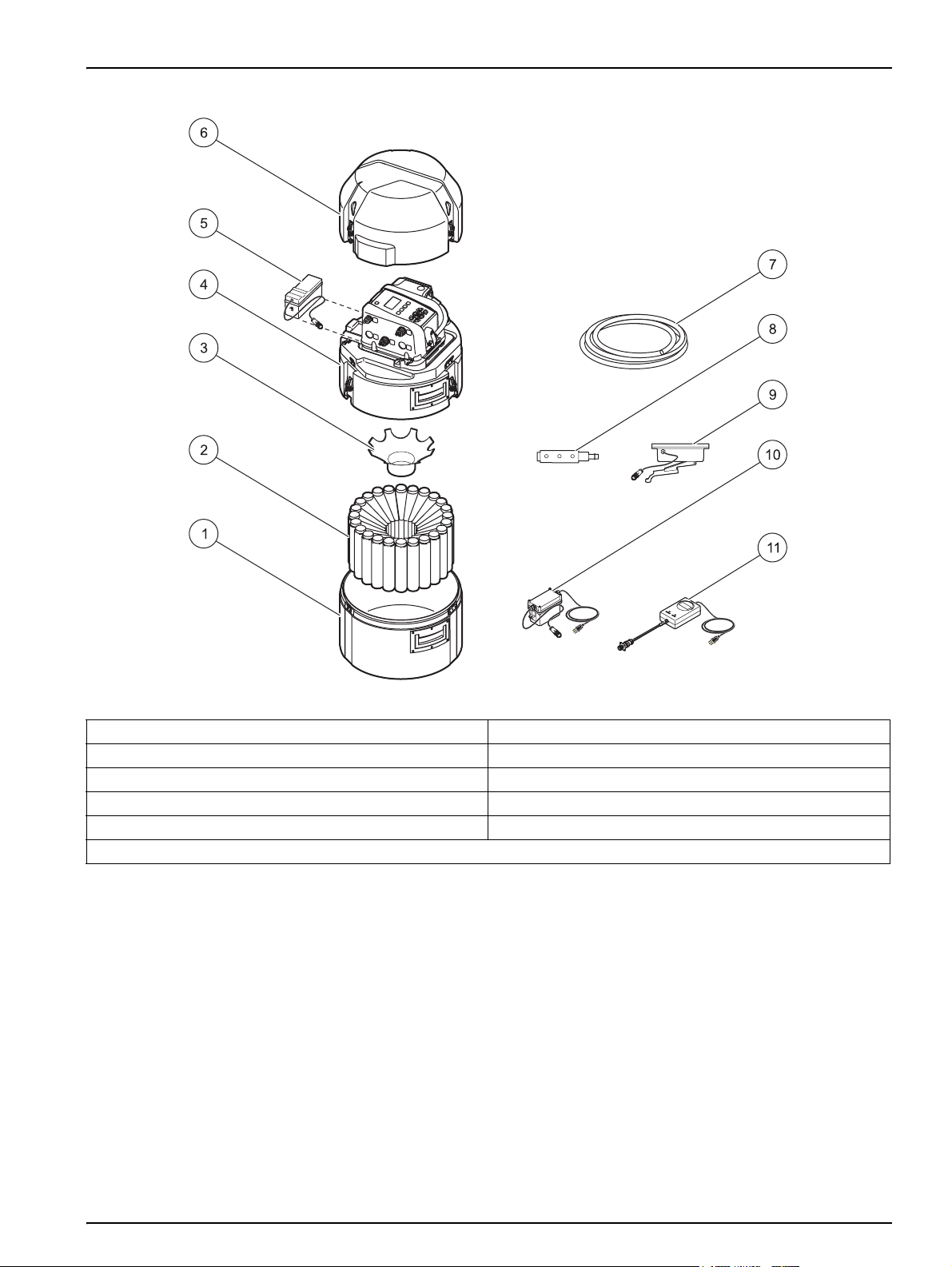

Figure 5 Sampler with multiple bottles

1 Sampler base 7 Intake tubing, vinyl or teflon-lined

2 Sample bottles 8 Strainer

3 Retainer 9 Distributor assembly

4 Sampler center section 10 AC power supply (optional)

5 Battery (Cat. No. 8754400, optional) 11 Battery recharger (optional)

6 Top cover (Cat. No. 8890)

3.2 Installation guidelines

WARNING

Explosion hazard. This product is not designed for hazardous

locations where combustible environments may exist.

Refer to the following guidelines and Figure 6 when evaluating

site location.

• If the site is located in a confined space such as a manhole,

refer to section 2.1.3 on page 12 for safety information.

• Make sure that the site has a level surface or a place to hang

the suspension harness, support bracket or spanner bar

(Figure 6).

17

Page 20

Installation

• Make sure that the temperature at the site is within the

operating temperature range that is specified for the sampler.

• Make sure that the intake tube is as short as possible.

• Maximize the vertical slope of the intake tube from the sampler

to the sample source so that the tube drains completely. This

prevents cross-contamination of samples and freezing the tube.

Note: See Specifications on page 5 for limitations on transport velocity

and maximum vertical lift.

Note: If site conditions do not permit the intake tube to have a

downward slope, or if the line is pressurized, disable the liquid sensor

and calibrate the sample volume (section 4.8.2 on page 46).

• Install the strainer in the middle of the sample stream (not near

the surface or bottom) to make sure that a representative

sample is collected.

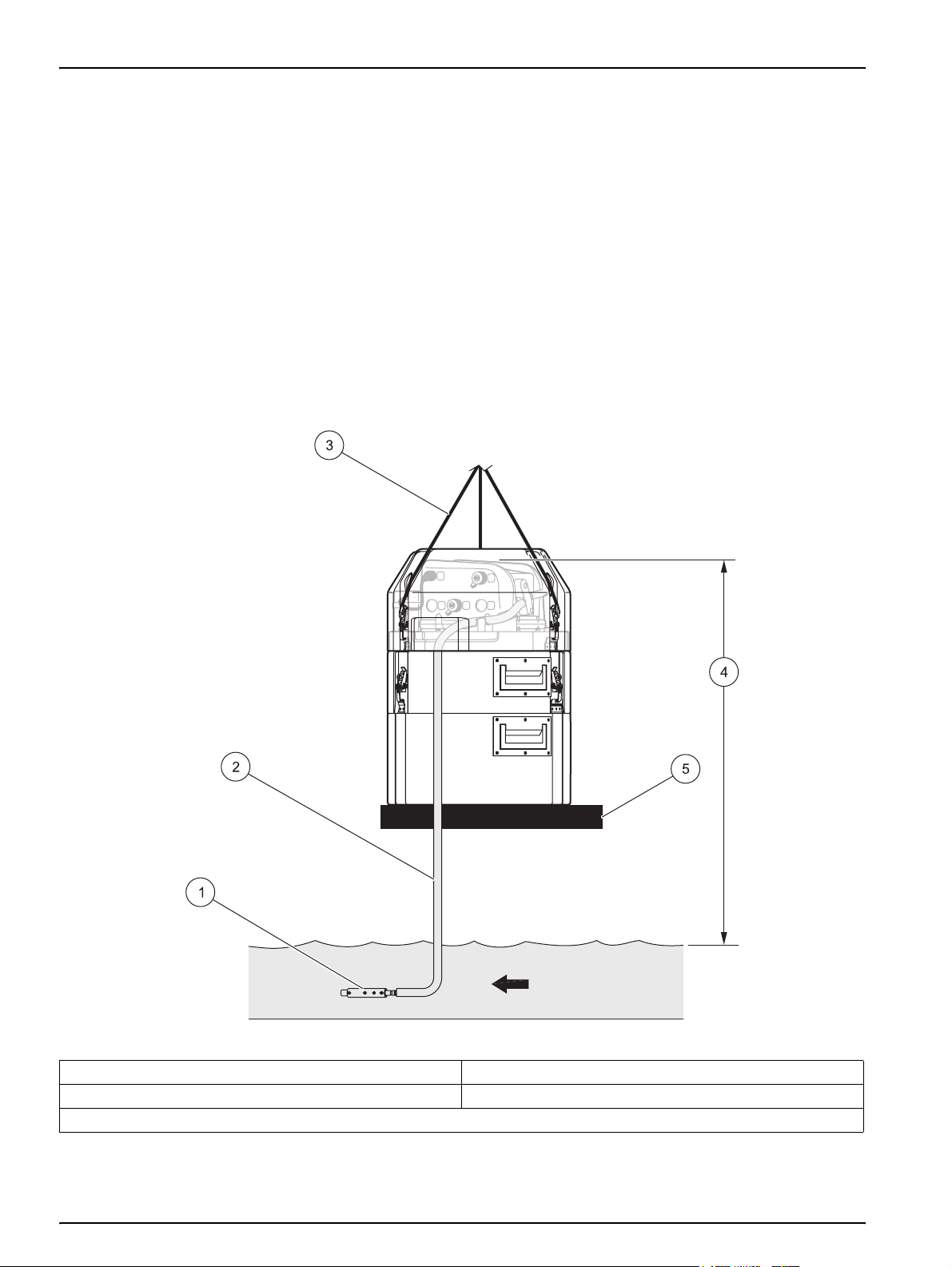

Figure 6 Mounting configuration

1 Strainer 4 Vertical lift

2 Intake tubing 5 Mounting surface

3 Suspension harness

18

Page 21

3.2.1 Manhole installation

Installation

WARNING

Explosion hazard. This product is not designed for hazardous

locations where combustible environments may exist.

Installation in a manhole requires suspending the sampler above

the sample water. Refer to section 2.1.3 on page 12 for safety

information in confined spaces.

Prerequisites:

Use the following hardware to mount the sampler in a manhole.

• Spanner bar or support bracket. A spanner bar is placed inside

the manhole and is supported by pressure against the walls. A

support bracket has the same width as the manhole cover and

is placed directly under the cover for support.

• Suspension harness

Note: See Accessories on page 70 for ordering information.

Installation procedure

Complete the following steps to mount the sampler in a manhole.

3.3 Sampler base preparation

3.3.1 Clean the sample bottles

1. Connect the suspension harness to the latches on the

sampler cover.

2. Hang the suspension harness on the spanner bar or

support bracket.

3. Mount the spanner bar or support bracket in the manhole.

CAUTION

Biological sample hazard. Follow safe handling protocols

during contact with sample bottles and sampler components.

Disconnect the sampler from power to disable the pump

before handling.

The sampler is set up at the factory with a single bottle or multiple

bottle configuration. To change the bottle configuration:

• Use Figure 2 on page 9 to determine the components that

are required for the selected configuration.

• Install the full bottle shut-off device (section 3.3.2.1 on page 20)

or distributor assembly (section 3.3.3.5 on page 26).

Clean the sample bottles and caps using a brush and water with a

mild detergent before setting up the sampler. Rinse the containers

with fresh water followed by a distilled water rinse. Glass bottles

may also be autoclaved.

19

Page 22

Installation

3.3.2 Single bottle installation

Use a single bottle when one composite sample is needed. A full

bottle shut-off signals the controller when to stop sample collection.

Refer to Figure 4 on page 16 for a diagram of required components.

Prerequisites:

• One plastic or glass bottle

• Retainer (Cat. No. 2190)

Note: Refer to Figure 2 on page 9 to make sure that the correct sample

bottle is used with the correct sampler base and retainer.

Installation procedure:

1. Clean the sample bottle as described in section 3.3.1.

2. If using a 2.5-gallon bottle with the standard base, place a

container support (Cat. No. 1502) in the sampler base.

3. Place the sample bottle in the center of the base.

4. Fill the sampler base with ice after the bottle is in place to

preserve samples.

3.3.2.1 Full bottle shut-off installation

Note: The time that it takes the ice to melt varies with the amount of

ice used, the external temperature and sample temperature.

5. Place the midsection over the base, making sure that the full

bottle shut-off is inside the neck of the bottle.

6. Program the sampler and install in the field.

The full bottle shut-off is typically installed at the factory and signals

the controller when the bottle is full. Complete the following steps to

replace or install a new full bottle shut-off.

Prerequisites:

• Full bottle shut-off device

Installation procedure:

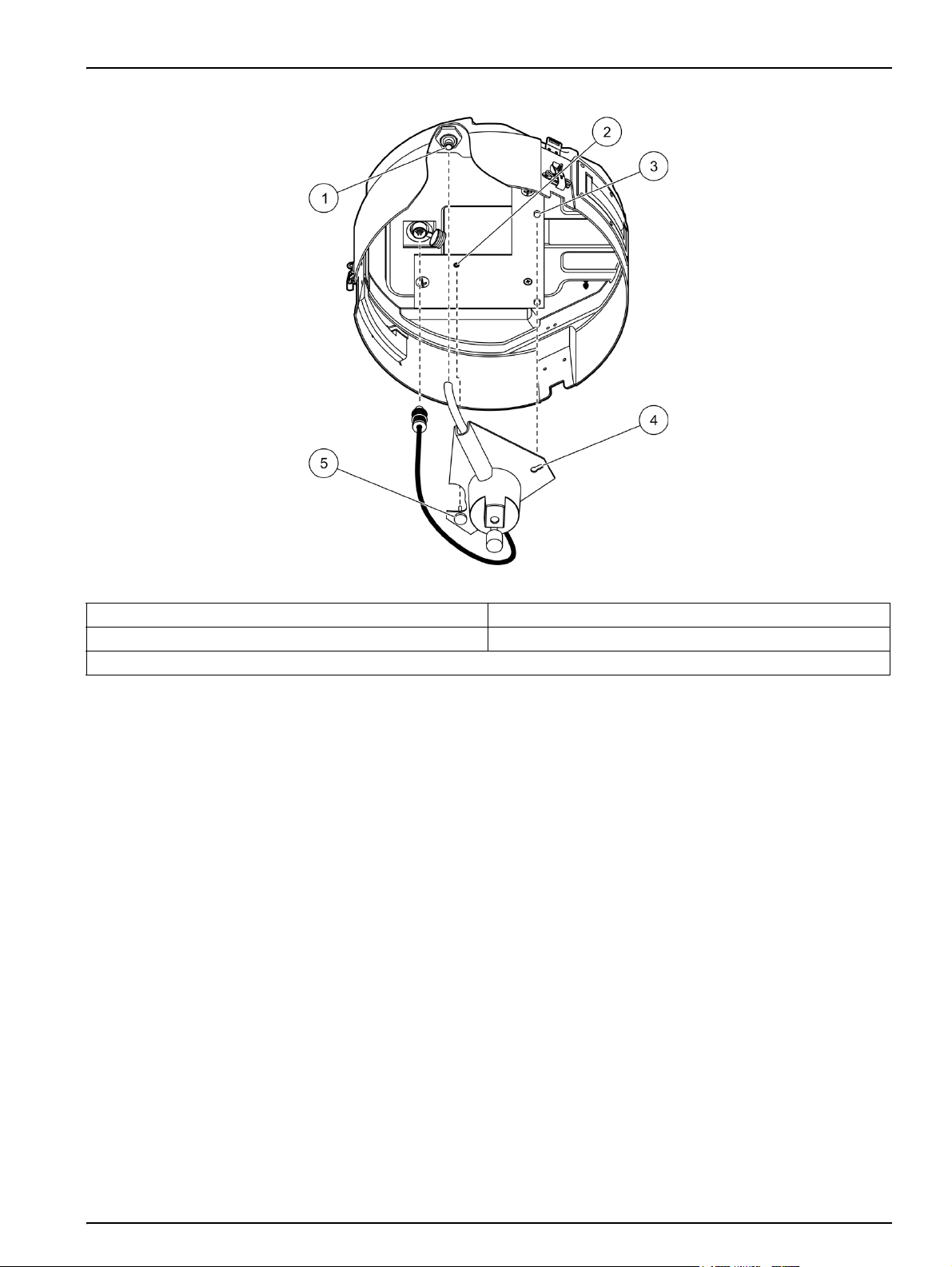

1. Slide the slot in the full bottle shut-off base plate under the

retainer pin inside the center section (Figure 7). Make sure that

the tube and cable exit through the openings in the full bottle

shut-off assembly.

2. Position the thumbscrew over the threaded hole and hand

tighten to hold the device in place.

20

3. Connect the cable on the full bottle shut-off to the bottom of the

controller (Figure 7). Turn to tighten.

4. Connect the free end of the full bottle shut-off tubing to the

inside tube fitting (Figure 7).

Page 23

Installation

Figure 7 Full bottle shut-off installation

1 Inside tube fitting 4 Slot in full bottle shut-off base plate

2 Threaded hole 5 Thumb screw on full bottle shut-off assembly

3 Retainer pin

3.3.3 Multiple bottle installation

Use multiple bottles to collect samples into separate bottles or into

more than one bottle. A distributor positions the sample tube over

each bottle. Position the bottles in the sampler base as shown in

section 3.3.3.1. Refer to Figure 5 on page 17 for a diagram of

required components.

3.3.3.1 Bottle number 1 position

Position the first sample bottle (number 1) under the label in the

sampler base (see Figure 8). Place the remaining bottles in

increasing number in the direction indicated by the label.

21

Page 24

Installation

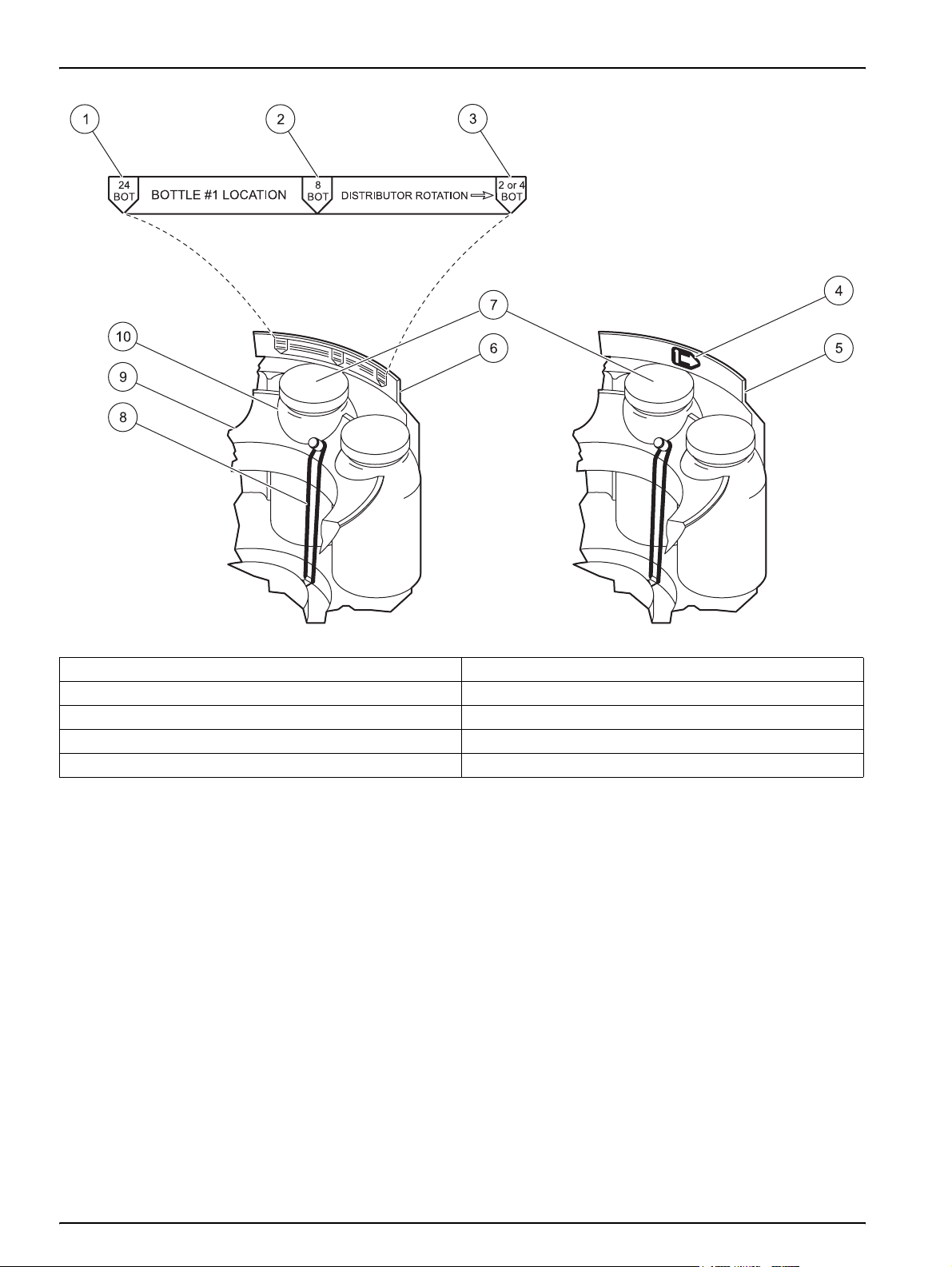

Figure 8 Bottle number 1 location

1 Bottle #1 location for 24 bottles 6 Standard base

2 Bottle #1 location for 8 bottles 7 Bottle #1

3 Bottle #1 location for 2 or 4 bottles 8 Elastic straps

4 Bottle #1 location in compact base 9 Retainer

5 Compact base 10 Sample bottle

3.3.3.2 Two or four bottle installation

Use 2 or 4 bottles to collect samples into one-gallon bottles.

Prerequisites:

• Two or four 1-gallon plastic or glass bottles

• Retainer (Cat. No. 2190)

Note: Refer to Figure 2 on page 9 to make sure that the correct sample

bottles are used with the correct sampler base and retainer.

Installation procedure:

1. Clean the sample bottles as described in section 3.3.1.

2. Place the bottles in the base as shown in Figure 9. Arrange the

bottles so that the first bottle is located under the label at the

point marked 2 or 4 BOT (Figure 8 on page 22).

22

3. Place the retainer over the bottles with the knobs pointing up.

Secure with the straps (Figure 9).

Page 25

Installation

4. To keep samples cool, fill the sampler base with ice after the

bottles are in place.

Note: The time that it takes the ice to melt varies with the amount of

ice used, the external temperature and sample temperature.

5. Place the midsection over the base, program the sampler and

install in the field.

Figure 9 Two and four bottle installation

1 Standard sampler base (Cat. No. 8976) 3 Retainer (Cat. No. 2190)

2 1-gallon plastic or glass bottles (2x) 4 1-gallon plastic or glass bottles (4x)

3.3.3.3 Eight bottle installation

Use 8 bottles to collect samples into one-liter or two-liter bottles.

Prerequisites:

• 8 plastic or glass bottles

• Retainer (see Figure 2 on page 9 for catalog number)

Note: Refer to Figure 2 on page 9 to make sure that the correct sample

bottles are used with the correct sampler base and retainer.

Installation procedure:

1. Clean the sample bottles as described in section 3.3.1.

2. Place the bottles in the base (see Figure 8 on page 22):

• Compact base first bottle position: under the arrow label.

• Standard base first bottle position: under the 8 BOT label.

3. Place the retainer over the bottles with the knobs pointing up.

Secure with the straps.

Note: The retainer for the compact base has two pieces. Place the

larger piece in the bottom of the base.

23

Page 26

Installation

4. To keep samples cool, fill the sampler base with ice after the

bottles are in place.

Note: The time that it takes the ice to melt varies with the amount of

ice used, the external temperature and sample temperature.

5. Place the midsection over the base, program the sampler and

install in the field.

Figure 10 Eight bottle installation

1 Standard sampler base (Cat. No. 8976) 5 950-mL glass bottles (8x)

2 1.9-L glass bottles or 2.3-L plastic bottles (8x) 6 Retainer bottom (Cat. No. 2347)

3 Retainer (Cat. No.1422) 7 Compact sampler base (Cat. No. 8975)

4 Retainer top (Cat. No.2347)

3.3.3.4 24 bottle installation

Use 24 bottles to collect samples into 350-mL, 575-mL or

1-liter bottles.

Prerequisites:

• 24 plastic or glass bottles

• Retainer

Note: Refer to Figure 2 on page 9 to make sure that the correct sample

bottles are used with the correct sampler base and retainer.

24

Page 27

Installation

Installation procedure:

1. Clean the sample bottles as described in section 3.3.1.

2. Place the bottles in the base:

• Compact base: arrange the bottles so that the first bottle is

located under the arrow label (Figure 8 on page 22).

• Standard base: arrange the bottles so that the first bottle is

located under the label marked 24 BOT (Figure 8 on

page 22).

3. Place the retainer over the bottles with the knobs pointing up.

Secure with the straps (Figure 11).

Note: If using 350-mL glass bottles with the standard base, place the

bottles around the outside of the retainer.

4. To keep samples cool, fill the sampler base with ice after the

bottles are in place.

Note: The time that it takes the ice to melt varies with the amount of

ice used, the external temperature and sample temperature.

5. Place the midsection over the base, program the sampler and

install in the field.

Figure 11 24 bottle installation

1 Standard sampler base (Cat. No. 8976) 5 Retainer (Cat. No. 1422)

2 350-mL glass bottles (24x) 6 Compact sampler base (Cat. No. 8975)

3 Retainer (Cat. No. 2189) 7 575-mL plastic bottles (24x)

4 1-L plastic bottles (24x)

25

Page 28

Installation

3.3.3.5 Distributor installation

CAUTION

Pinch hazard. Make sure the sampler is powered off before

removing or installing the distributor assembly.

The distributor automatically moves the sample tube over each

bottle during multiple bottle sampling. The distributor assembly is

typically installed at the factory. Complete the following steps to

install a new or different assembly.

Prerequisites:

• Distributor assembly—three assemblies are available. Refer to

Figure 2 on page 9 to make sure that the correct distributor

assembly is used.

Installation procedure:

1. Slide the two slots in the distributor assembly housing under

the retainer pins located on the top inside surface of the center

section (Figure 12).

2. When fully seated, hand tighten the thumbscrew on the

distributor assembly to hold the distributor in place.

3. Push the distributor tubing on the sampler fitting on the top

inside surface of the center section (Figure 12).

4. To make sure that the arm has sufficient freedom of movement,

hand-rotate the arm in a circle (both clockwise and

counterclockwise) until it hits the arm stop. If the arm does not

rotate freely, reposition the tubing to the other side of the arm

so that the arm can rotate.

Note: Do not force the arm past the arm stop. The arm stop prevents

the arm from rotating more than 360 degrees and pinching the tubing.

5. Install the mid section on the base.

6. To make sure that the distributor is aligned properly, run the

manual distributor diagnostic (see section 7.3 on page 67).

26

Page 29

Installation

Figure 12 Distributor assembly installation

1 Thumbscrew 3 Retainer pins

2 Arm stop 4 Slots

3.4 Intake tubing and strainer installation

Place the intake tubing and strainer directly in the sample source to

collect samples. Refer to section 3.2 on page 17 to make sure that

samples are free from contamination and are representative of the

sample source.

Prerequisites:

• Vinyl or Teflon-lined tubing

• Connection kit (Cat. No. 2186) (for Teflon-lined tubing only)

• Strainer

Note: See Accessories on page 70 for ordering information.

Installation procedure:

1. Connect one end of the tubing to the liquid sensor fitting.

Note: Use Cat. No. 2186 (connection kit) if using Teflon-lined tubing.

2. Press the tubing into the strain relief (Figure 13).

3. Route the tubing through the sampler housing so that the

tubing is not pinched when the cover is on.

4. Connect the other end of the tubing to the strainer.

Note: Use Cat. No. 2186 (connection kit) if using Teflon-lined tubing.

27

Page 30

Installation

5. Place the intake tube and strainer in the main stream of the

sample source where the water is turbulent and well-mixed.

Make sure that the intake tube does not have kinks or loops.

Figure 13 Intake tubing installation

1 Strainer 3 Strain relief

2 Intake tubing 4 Liquid sensor

3.5 Electrical installation

Connect cables to the controller as shown in Figure 14 for the

following components:

• Power (section 3.5.1)

• Flow meter or other device (section 3.5.2 on page 31)

• Communications (section 3.5.3 on page 31)

28

Page 31

Figure 14 Side view of controller—connectors

1 Power connector 3 Serial connector

2 Auxiliary connector 4 Distributor/full bottle shut-off connector

Installation

3.5.1 Power installation

3.5.1.1 Battery installation

The sampler can be powered by a battery (section 3.5.1.1) or by

AC power (section 3.5.1.2).

Prerequisites:

• 12 VDC gel electrolyte (lead acid) battery plus recharger.

Note: A 2-pin to 3-pin adaptor cable (Cat. No. 8739400) may be used with

older batteries containing a 2-pin connector to power the sampler.

Installation procedure:

1. Place the battery directly behind the controller (Figure 3 on

page 13).

2. Pull the rubber straps up and over the clips at each end of the

battery to secure it to the sampler body.

3. Connect the cable from the battery to the power connector on

the controller.

29

Page 32

Installation

3.5.1.2 AC power installation

Optional battery cable

If the external battery cable with bare leads (Cat. No. 2198) is used,

the following requirements must be met:

• The cable must not be altered to more than 3 meters long.

• The cable can only be connected to a 12 VDC battery.

• The maximum voltage cannot exceed 18 VDC.

• Failure to observe proper polarity when connecting the

clips to the battery will result in a blown fuse in the cable.

WARNING

Electric shock hazard. The temperature of the power supply

will increase when the sampler pump is operating. If the time

interval between sample cycles is too short, the power supply

can become overheated and result in a electric shock hazard

or power supply failure. Refer to the power supply instruction

sheet (DOC306.53.00801) to determine the time that the pump

must stay off between sample cycles to prevent overheating.

Prerequisites:

Important Note: Use only the AC power supply that is specified for

this sampler. The power supply connector must have three pins. An

adapter cannot be used to convert a older two-pin power supply for

use with this sampler.

• AC power supply (Cat. No. 8754500US)

Installation procedure:

1. Place the power supply directly behind the controller (Figure 3

on page 13).

2. Pull the rubber straps up and over the clips at each end of the

power supply to secure it to the sampler body.

3. Connect the cable from the power supply to the power

connector on the controller.

Electrical transients

When connected to an AC power source, the SD900 controller may

be temporarily upset by strong electrical transients caused by

sources such as lightning or large electrical motors. These upsets

can result in a missed sample, but the SD900 controller will recover

and continue with the sample program.

A missed sample will be recorded and can be viewed in the status,

event log or sample history screens. Remedial actions may involve

the use of a power line filter or connecting the controller to a

different branch circuit.

30

Page 33

3.5.2 Flow meter installation

Installation

The sampler can be connected to a flow meter to start or stop

sampling based on the flow volume.

Prerequisites:

• Multi-purpose full cable for Sigma flow meters (or 980 half

cable for the model 980 flow meter). To connect to another

brand of flow meter, use a multi-purpose half cable and follow

the wiring instructions in Appendix A on page 75.

• Optional splitter (Figure 15) to provide additional connections.

Two or more splitters may be connected in series.

Note: See Accessories on page 70 for ordering information.

Installation procedure:

1. Connect one end of the cable to the flow meter. For connection

to the model 980 flow meter, follow the instructions in the model

980 user manual.

2. Connect the other end of the cable to the controller.

Note: For connection to a flow meter with an existing 6-pin cable, use

the auxiliary adapter cable (6-pin to 7-pin adapter)

3.5.3 Communications installation

Figure 15 Splitter

The sampler can be connected to a PC or Modbus device for data

transfer or programming.

Prerequisites:

• Serial cable (Figure 16)

Note: See Accessories on page 70 for ordering information.

Installation procedure:

1. Connect one end of the cable to the PC or Modbus device.

2. Connect the other end of the cable to the controller. The pin

assignments for the serial cable are detailed in Table 1.

31

Page 34

Installation

Figure 16 Serial connector cable

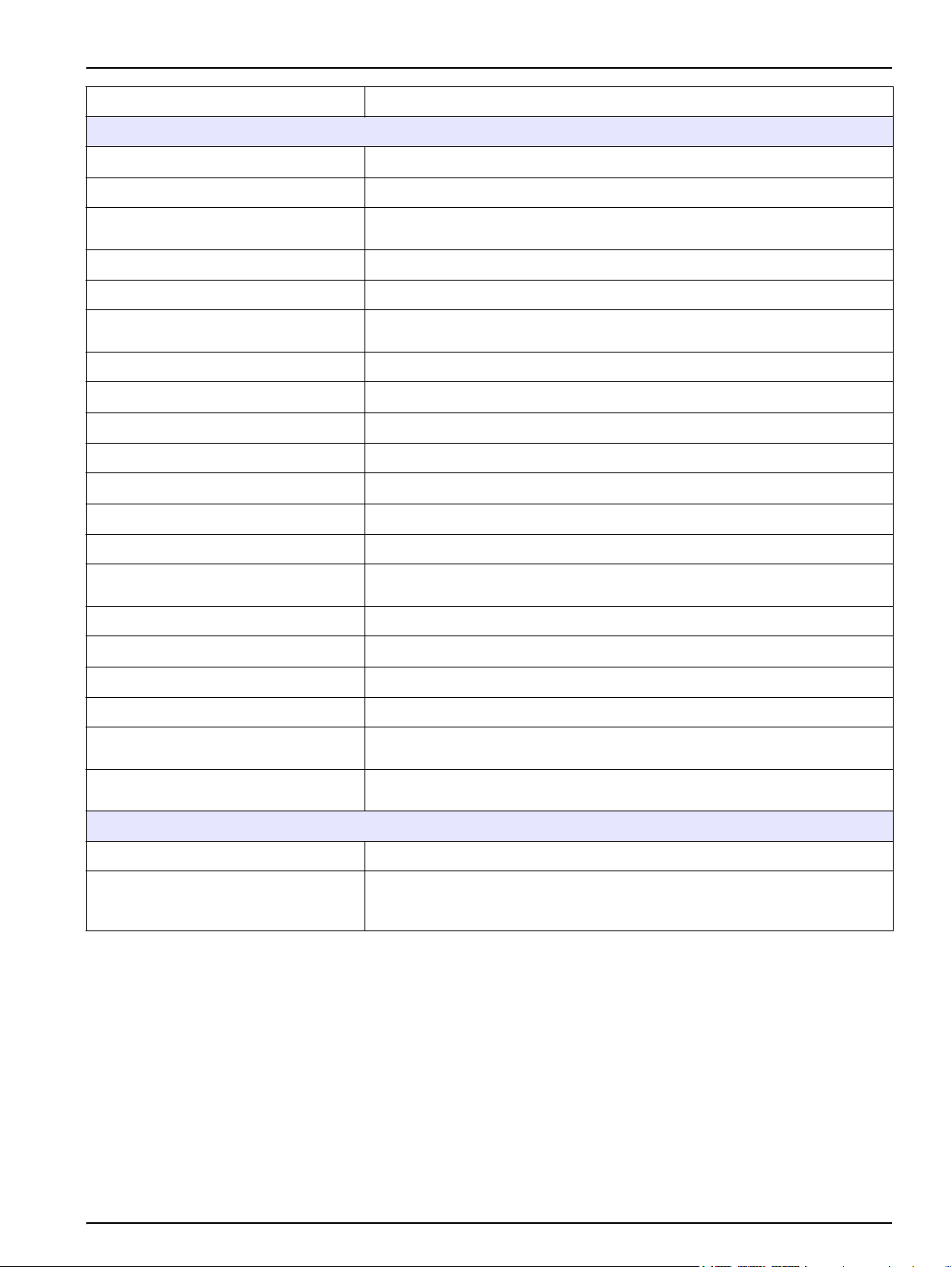

Table 1 Serial cable reference

7-pin connector assignment letter Signal description DB-9 pin assignment number

B Signal ground 5

DRCD3

FTXD2

G Earth ground —

32

Page 35

Section 4 Sampler operation

4.1 Power on and power off

Important Note: The AC power supply will become overheated if

the sampler pump is operated continuously. Refer to the power

supply instruction sheet (DOC306.53.00801) to determine the time

interval that must be allowed between sample cycles to prevent

damage to the AC power supply and/or to prevent a burn hazard.

4.2 Controller overview

4.2.1 Keypad description

Power on: press

Power off: press

POWER (Figure 17). The LED will blink.

POWER and select YES. The LED will stay off.

Sleep mode: automatic after two minutes of inactivity. The LED will

blink but the display will be blank. Press any key to restore

the display.

The keypad and description is detailed in Figure 17.

Figure 17 SD900 keypad

1 POWER: press to turn controller on or off 7 BACK: cancel or return to previous screen

VOLUME CALIBRATION: enter volume calibration menu 8 ARROW KEYS: moves cursor or scrolls through values

2

STOP: stops the pump or distributor if running 9 STATUS: displays current status of the sample program

3

LED: blinks when controller is powered on 10 RUN/HALT PROGRAM: starts or stops a sample program

4

MENU: displays the main menu 11 MANUAL OPERATION: manual operation of pump or

5

ENTER: selects the highlighted or entered value

6

distributor

33

Page 36

Sampler operation

4.2.2 Navigation

Use the controller to access all sampler operations. Use the

ARROW keys, ENTER key and BACK key to move from one screen

to another. An arrow on the display indicates that more screens are

available (Figure 18).

Example:

1. Press the

2. Press the

Press

MAIN MENU key.

DOWN ARROW key to highlight diagnostics.

ENTER. The diagnostics menu will be shown.

3. Note the down arrow on the bottom of the display (Figure 18).

Press the down arrow until additional options are shown.

4. Press the

BACK key or MAIN MENU key to return to the

main menu.

Figure 18 Screen navigation

1 Left arrow 3 Up arrow

2 Right arrow 4 Down arrow

4.2.3 Parameter selection

Parameter selection is made in one of two ways (Figure 19):

• Selection from a list

• Enter a value using the arrow keys

Figure 19 Parameter selection

1 Select item from list 2 Enter value with arrows 3 Acceptable range

34

Page 37

4.3 Main menu overview

The SD900 sampler main menu contains four options for sampler

operation, monitoring or data management. Each option is detailed

in Table 2.

Table 2 SD900 sampler menu overview

Menu option Description

Program setup Create, review, or set up a sampling program

Modify all Create or edit a sampling program

Modify selected Edit a portion of a sampling program

Review Review a sampling program

Presets Enter or select up to three program templates

Restore defaults Restore the program default selections

Status Display the status of the current program

Diagnostics Review and manage data or test the operation of components

Event log Display or delete the event log

Sample history Review the sampling history

Distrib diag

Keypad diag Test the operation of each key

LCD diag Test the operation of the LCD display screen

Liquid sensor diag Display calibration data for the liquid sensor

System setup Change controller settings or calibrate the liquid sensor

Test the ability of the distributor to detect each of the 24 bottle positions

Note: Only active when the sample program is configured for more than 1 bottle.

Sampler operation

Time/date setup Set the time (24 hour) and date

Communication

Setup base Specify whether the standard or compact base is used

Language Select one of the available languages

Liq sensor cal Calibrate the liquid sensor

Set contrast Adjust the contrast of the LCD display screen

Password setup Create or disable a password

Tubing life Enable optional alarm to indicate when pump tubing needs to be changed

Set the baud rate (19200, 38400, 57600 or 115200) and protocol (Modbus RTU or ASCII) for the

serial port

4.4 Sampler programs

Create sampler programs to operate the sampler automatically.

Once programmed, install the sampler at the sampling site. Return

to collect the samples at regular intervals or when the sampling

program is complete. Sampler programs can be stored for later

recall (4.4.6 on page 39).

35

Page 38

Sampler operation

4.4.1 Sampler program overview

Table 3 outlines the menu for creating a basic sampling program.

Table 3 Basic program setup

Menu option Description

Bottles Enter bottle information.

Bottle quantity Select the number of bottles in the sampler (1, 2, 4, 8, 12 or 24).

Bottle volume Enter the volume capacity of each bottle in milliliters or gallons (0.5–99.8 gal or 50–65000 mL).

Intake tubing Enter intake tubing information.

Tubing length

Intake tube type Select the size and type of tubing (¼ in. vinyl, 3/8 in. vinyl or 3/8 in. teflon)

Program delay

Enable/disable Select enable to use a program delay or disable to omit it.

Date and time If enabled, enter the date and time when the program will start (24 hour format).

Counts

Enter the length of the intake tube from

100–3000 cm). An accurate length is necessary to obtain accurate sample volumes.

Delay starting the sampling program until specified time and day or until specified number of

counts is reached.

If enabled, enter the counts from the flow meter when the program will start (1–9999 counts). If

counts is selected and the sample pacing is later set to time, the program delay will be disabled.

the strainer to the liquid sensor (3–99 ft or

Sample pacing/collection Specify whether to collect samples at regular time intervals or regular flow volume.

Time based Collect samples at regular time intervals.

Pacing interval Enter the time interval, in hours and minutes (0:01–999:00).

Take first sample Select whether the program will start immediately or after the first time interval has passed.

Flow based Collect samples at a specified flow volume (requires external flow meter)..

Take sample every Enter the flow interval that must expire between sample cycles, in counts (1–9999 counts).

Override time Select enable to force a sample to be collected if the flow volume is unusually low.

Time

Take first sample Select whether the program will start immediately or after the first flow interval has passed.

Sample distribution For multiple bottle sampling, specify how the samples are delivered to the bottles.

Deliver samples to all Select whether each sample will be delivered to all bottles or not.

Yes Each sample will be delivered to all bottles.

End after last Program will stop after the last sample has been collected. Enter number of samples (1–999).

Continuous Sampler will continue collecting samples until stopped manually.

No Samples will be delivered to a subset of bottles (see Figure 20 on page 38).

Samples/bottle Enter the number of samples to be collected in each bottle (1–999).

Bottles/sample Enter the number of bottles that will contain the same sample.

Liquid sensor Enable/disabled. If disabled, the sample volume must be calibrated by time.

If enabled, enter the maximum time between samples (0:01–999:00). Timer is reset each time a

sample is collected based on flow counts.

Sample volume

Intake rinses Enter the number of times the intake tube will be rinsed before each sample is collected (0–3).

Sample retries Enter the number of sample retries to perform when a failure occurs (0–3).

Site ID

Advanced sampling Access the advanced sampling menu.

Done Finished creating basic sampling program. Prompts user to start or cancel the program.

Enter the volume to be collected per sample. If bottles/sample mode is selected, each bottle

receives a full sample volume (100–10,000 mL).

Enter a name for the sampling location (enter up to 12 characters). The site ID is used as the

preset name if the program is saved.

36

Page 39

4.4.2 Create a sampler program

Sampler operation

Create a sampler program to set up the sampler for automatic

sampling routines.

Procedure:

1. Select

2. Select

PROGRAM SETUP from the main menu.

MODIFY ALL. The first parameter, bottle quantity, will be

shown.

3. Select the number of bottles in the sampler. The next

parameter, bottle volume, will be shown.

4. Enter the volume of the individual bottle(s). Use the

RIGHT

ARROW keys to move the cursor left or right. Use the UP

AND DOWN

ARROW keys to change the value. Change the

LEFT AND

units if necessary (gal or mL) with the arrow keys.

5. Continue to select or enter values for each parameter until

complete. Refer to Table 3 on page 36 for a complete list of all

available options for a basic sample program.

4.4.2.1 Tips and techniques

Refer to Table 4 and Figure 20 for help with sample programming.

Table 4 Tips and techniques for the basic sampling program

Parameter Tips and techniques

When 1 bottle is selected, the full bottle shut-off device is enabled and the distributor

Bottle quantity

Intake tubing

Program delay

Sample pacing—flow Each time a sample is collected based on flow counts, the override timer is reset.

is disabled. When more than 1 bottle is selected, the distributor diagnostic

is enabled.

The sampler uses the intake tubing information to determine sample volume. If the

intake tubing information is not accurate, the sample volume will not be accurate.

If the program delay is set to counts and sample pacing is set to time, the program

delay will be disabled.

If the bottle quantity is 1, the sample distribution option will not be available.

See Figure 20 for a description of samples per bottle vs. bottles per sample.

Sample distribution

Liquid sensor If the liquid sensor is disabled, the sample volume must be calibrated manually.

Sample volume

Bottles per sample—use bottles per sample when the sample volume is larger than

one bottle can hold.

Samples per bottle—the distributor arm will not advance to the next bottle until the

specified number of samples has been delivered to the current bottle.

The sample volume must be entered as mL (1 gal.= 3785.4 mL).

Make sure that

the sample volume does not exceed the bottle volume. Sample volumes are

rounded to the nearest 10 mL.

37

Page 40

Sampler operation

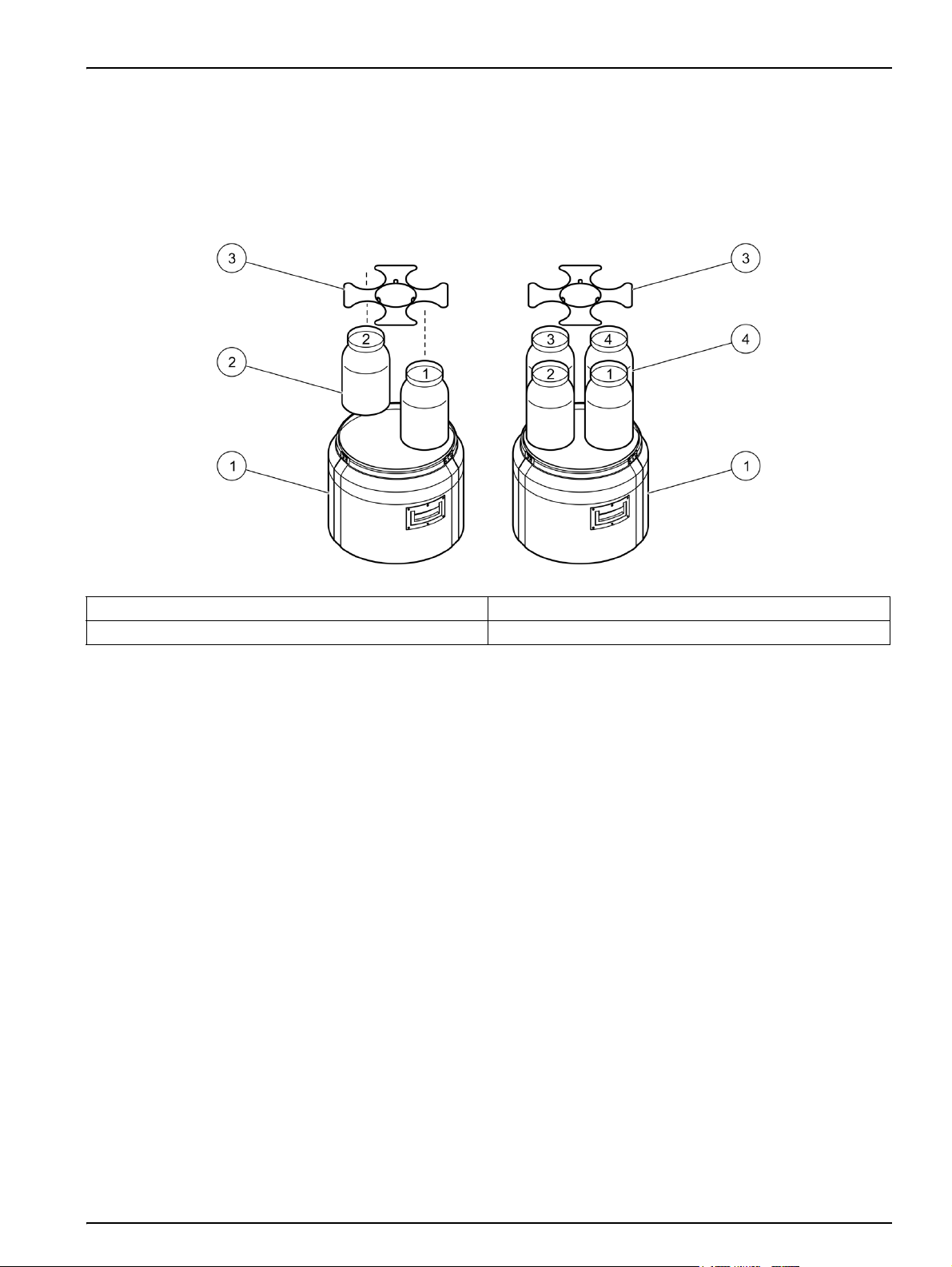

Figure 20 Two samples per bottle (left) vs. two bottles per sample (right)

4.4.3 Modify a program

Use the modify selected option to change an individual parameter

for the currently loaded program.

Procedure:

4.4.4 Review a program

1. Select

2. The selected parameters are grouped within the following

subheadings. Select one of the available subheadings using

the up and down arrow keys.

• Bottles—quantity and volume

• Intake tubing—length and type

• Program delay

• Sample pacing/collection—time or flow based

• Sample distribution—for multiple bottle sampling

• Liquid sensor—enable/disable

• Sample volume—enter volume

• Intake rinses—enter number

• Sample retries—enter number

• Site ID—enter ID

• Advanced sampling

3. Change the parameter as shown in section 4.2.3 on page 34.

PROGRAM SETUP>MODIFY SELECTED.

38

Use the review option to view the selected parameters without

making any changes to the program.

Procedure:

1. Select

2. Press

PROGRAM SETUP>REVIEW from the main menu.

ENTER to view each entry.

Page 41

4.4.5 Restore default settings

Sampler operation

Use the restore option to set all program parameters to the

default settings.

Procedure:

4.4.6 Store programs as presets

4.4.6.1 Load a stored program

1. Select

2. Select

PROGRAM SETUP>RESTORE from the main menu.

YES to restore the factory default settings.

Use the presets option to store up to three sampler programs for

later use. If any changes are made to a preset program after it is

loaded, the program must be stored again to save the changes.

Procedure:

1. Select

2. The three available presets are displayed as

PROGRAM SETUP>PRESETS from the main menu.

P1, P2 and P3.

Select one of the presets.

Note: If a program is already stored, the site ID for that program will

appear to the right of the preset number. If no preset program has

been stored, the preset field will be empty.

3. Select STORE CURRENT to store the current program as

apreset.

Use the load program option to use a preset program as the

current program.

Procedure:

1. Select

2. Select one of the presets (

3. Select

PROGRAM SETUP>PRESETS from the main menu.

P1, P2 or P3).

LOAD PROGRAM to load the selected preset as the

current program. The selected preset program will be loaded

and the display will return to the main menu. The program can

be modified or used as is.

If a preset program is loaded and then modified, the program

must be stored again (store current) to save the changes.

39

Page 42

Sampler operation

4.5 Start or stop a program

Use the RUN/HALT PROGRAM key to start or stop a program.

Procedure:

4.6 Manual operation

1. Press

2. Select one of the available options:

Note: A program must be stopped before the program setup or system

setup menus can be modified.

Use manual operation to collect a grab sample, move the distributor

arm or operate the pump.

RUN/HALT PROGRAM to run, halt, resume or end a

sampler program.

•Start: starts the currently loaded program. The status

changes to running.

•Halt: stops the program temporarily. The status changes

to halted.

•Resume: if halted, the program resumes from the point at

which it was halted. The status changes to running.

•Start over: if halted, the program starts from the beginning.

The status changes to running.

• End program: ends the currently running program. The

program status changes to complete.

4.6.1 Collect grab samples

Grab samples can be collected to verify sample volume or to collect

samples without running a sampling program.

Procedure:

1. Press the

2. Select

3. Place the intake tube into the sample water. Remove the outlet

pump tube from the fitting on the sampler and place the tube

into a sample container.

4. Enter the volume to be collected and press

Note: The grab sample volume can only be modified if the liquid

sensor is enabled. if the liquid sensor is disabled, the grab sample

volume will reflect the volume defined using timed calibration.

5. The pump will purge the intake tube and then collect the

specified volume of sample. The pump will then purge the

intake tube.

To stop the pump at any time during the sample cycle, press

the

MANUAL OPERATION key.

GRAB SAMPLE.

ENTER.

STOP key.

40

Page 43

4.6.2 Move the distributor arm

Sampler operation

When configured for multiple bottles, the distributor arm can be

moved manually to distribute a grab sample to a specific bottle.

Procedure:

4.6.3 Start or stop the pump

1. Press the

2. Select

3. The current bottle number will be displayed. Enter the bottle

number over which to position the distributor arm.

Press

4. The distributor arm will move to the selected bottle. To stop the

distributor arm at any time, press the

The pump can be operated outside of a sampling program to collect

a sample or purge the intake tubing.

Procedure:

1. Press the

2. Select

3. Select the direction to run the pump:

• Run forward: pump operates in the forward direction to

• Run backward: pump operates in the reverse direction to

MANUAL OPERATION key.

MOVE DISTRIB.

ENTER.

STOP key.

MANUAL OPERATION key.

OPERATE PUMP.

collect a sample and deposit into a sample container.

purge the intake line.

4.7 View data

4.7.1 Status screen

4. The screen will display pumping if the forward direction was

selected or purging if the reverse direction was selected.

5. The pump will operate until the

Data can be viewed from one of the status screens or from the

diagnostics menu.

The Status screen can be accessed by pressing the STATUS key or

by selecting

The status menu will be shown if the main and stormwater

programs run simultaneously. The status of either main program or

the stormwater program can be viewed by selecting

STORM from the status menu.

STATUS from the main menu.

STOP key is pressed.

MAIN or

41

Page 44

Sampler operation

4.7.2 Status for main program

4.7.2.1 Ready to start

4.7.2.2 Running/halted

The status screen for the main program gives information about the

program depending on the status of the main program. The status

information depends on whether the program is in the ready to

start, running/halted or complete mode.

The status reads READY when a program is ready to start and also

displays the power supply voltage and the current time.

The status reads RUNNING or HALTED when a program is currently

running or has been halted by the user. Use the

to access information about the program currently running.

RIGHT ARROW key

4.7.2.3 Complete

The information displayed includes:

• Power supply voltage

• Inhibit mode (none, setpoint trigger, program delay, user

start, storm trigger, full bottle, setpoint delay)

• Sample summary (number of samples tried, missed and

remaining)

• Next sample information (sample number, bottle number of

next sample)

• Time before next sample

• Program start time

The status reads COMPLETE when a program ends after all sample

cycles have been completed or when ended by the user. Use the

RIGHT ARROW key to access information about the program that

just ended. The display includes:

• Power supply voltage

• Program end time

• Sample summary (number of samples tried and missed)

4.7.3 Status for stormwater program

42

The status screen shows information about the stormwater

program similar to that shown for the main program (Ready,

Running, Halted or Complete).

Use the

the program.

RIGHT ARROW key to access additional information about

Page 45

4.7.4 Sample history

Sampler operation

Sample history displays the sample number, bottle number, result

and time/date for each sample. The following results can be shown:

• Success—the sample was drawn successfully

• Bottle full—the full bottle shut-off was activated

• Rinse error—an error occurred during the rinse cycle

• User abort—a user pressed the

• Arm faulty—the distributor arm did not move correctly

• Pump fault—a fault occurred when the pump was operating

•Purge fail—an error occurred during the purge cycle

• Sample time out—liquid not detected within the timeout period

•Power fail—a power failure occurred during sampling

If a program is running or has been halted, the sample history is

displayed for the currently running sample program. If the program

has been completed, the sample history is displayed for the most

recently completed sampling program. The sample history is

automatically erased when a new program is started.

Procedure:

1. Select

to view the sample history.

2. The sample history will list the sample numbers, bottle numbers

and brief result for each sample. Select a sample from the list

and press ENTER to view complete details.

3. The complete details for the selected sample will be shown.

DIAGNOSTICS>SAMPLE HISTORY from the main menu

STOP key to end the program

4.7.5 Event log

The event log records information on the following events:

• Power on—power was connected to the controller

•

Power fail—power was intentionally or unintentionally

disconnected from the controller without first turning power off

• Firmware update—a new version of firmware was installed

• Pump fault—a fault occurred when the pump was operating

• Arm faulty—the distributor arm did not move correctly

• Low memory battery—the internal battery should be replaced

•User on—a user turned the power on using the power key

•User off—a user turned the power off using the power key

• Program start—the sample program was started

• Program resume—a program was resumed from the halt state

• Program halt—a program was halted

• Program complete—a program was completed

•Grab sample—a grab sample was taken

• Change tube—the maximum pump cycle counts have expired

43

Page 46

Sampler operation

4.7.5.1 View the event log

View the event log to see details about the events that have

been recorded.

Procedure:

4.7.5.2 Erase the event log

1. Select

the event log.

2. Select

3. The event log will list the date and event. Select an event from

the list and press ENTER to see complete details.

The top bar will show the event number and total number of

events in the event log. For example, 01/80 will be displayed for

event number 1 and a total number of 80 events.

4. The time/date, event description and any additional data for the

selected event will be displayed.

Erase the event log after event details have been reviewed to

reduce the number of entries that are shown.

Procedure:

1. Select

the event log.

2. Select

3. Select

DIAGNOSTICS>EVENT LOG from the main menu to view

DISPLAY.

DIAGNOSTICS>EVENT LOG from the main menu to erase

ERASE.

YES to confirm the deletion.

4.8 Volume calibration

Samples can be collected with the liquid sensor enabled

(recommended) or disabled. When the liquid sensor is enabled, the

volume calibration is optional. When the liquid sensor is disabled,

the volume for samples, rinses and stormwater must be calibrated

manually.

When the liquid sensor is used for volume calibration, the sensor is

adjusted to accurately measure all programmed volumes. When

the sensor is disabled and the volume is calibrated by time, all

programmed sample volumes must be calibrated individually.

Verify calibrations by measuring the volume from a grab sample

(section 4.8.3 on page 47). If calibration using the liquid sensor

does not give accurate volumes, the sensor can be calibrated

(section 4.9.1 on page 48).

For typical applications, tap water can be used for volume

calibration. If the sample composition is significantly different from

typical water samples, calibrate the sampler using the liquid to

be collected.

Calibration cannot occur while a sample program is running. All

programs must be ended before calibration.