Page 1

DOC273.52.00146.Jun06

Cleaning set LZY367

Installation instructions

Page 2

Page 3

Installation instructions

Cleaning set LZY367

Introduction

These installation instructions describe the installation and use of the cleaning set LZY367.

Items supplied, cleaning set LZY367

DOC273.52.00146Jun06

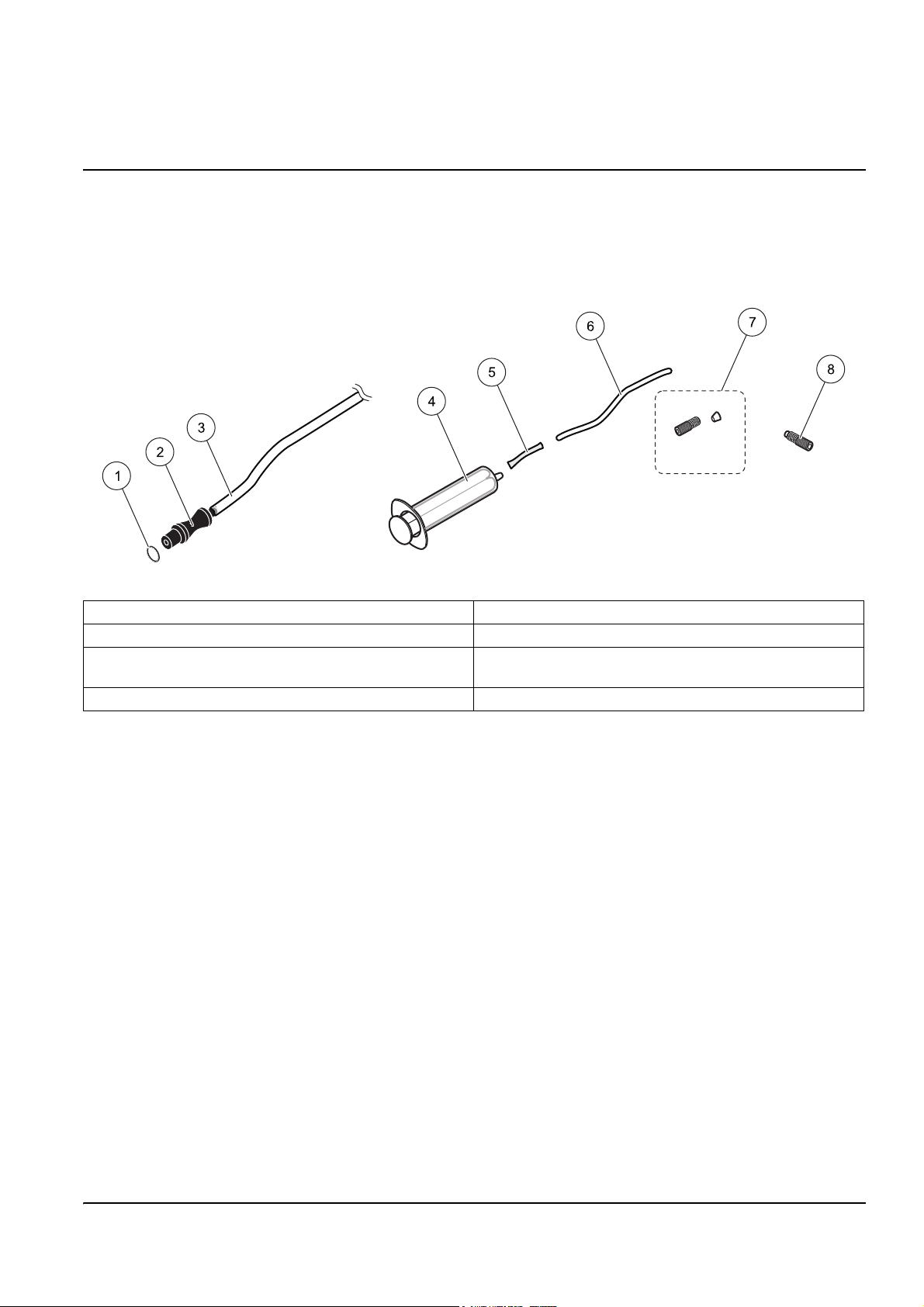

Figure 1 Items supplied, cleaning unit LZY367

1 O-ring (7.5 x 2.5 NBR), 2 pieces 5 PharMed tubing

2 Cleaning adapter for FILTRATION PROBE sc, 2 pieces 6 Tubing (2 m long, 3.2 x 0.8), LZY195

3 Tubing (4 x 1, 0.7 m), 2 pieces 7 Set of fittings (3.2 mm) LZY111

Tapered insert and union nut (2 pieces each)

4 Disposable syringe (20 mL) 8 Blind plug, 2 pieces, LZY193

Selecting the installation location

Note: Ensure you have the operating instructions

for the analysis instrument DOC023.XX.00025.YYYyy or DOC023.XX.00026.YYYyy

(xx= language, YYYyy= date) and

the FILTRATION PROBE sc DOC023.XX.00024.YYYyy

(xx= language, YYYyy= date) at hand.

Note: When selecting the installation location, ensure the tray used and the FILTRATION PROBE sc are

securely mounted and chemicals cannot leak.

During the selection of the installation location, pay attention to

• Ease of access to the enclosure door for the analysis instrument,

• The maximum cable and tubing lengths and

• Ease of access to the display module.

1

Page 4

Cleaning set LZY367

Installation of the cleaning set LZY367

Danger!

NEVER use 3% chlorine bleach together with 5% hydrochloric acid

(Risk of the formation of chlorine gas).

The chemicals used, in particular the chlorine bleach, are not allowed to be mixed

or come into contact with other chemicals (Risk of the formation of chlorine gas).

Take suitable protective measures for the chemicals used. If necessary wear

personal safety equipment (e. g. gloves and safety glasses).

Important note: Pay attention to the applicable safety data sheets, warning instructions

on the packaging and containers, and the applicable health and safety regulations.

Observe the local regulations and protect the environment on the disposal of chemicals.

Only clean the FILTRATION PROBE sc in a suitable tray.

Pay attention to all hazard and safety instructions in the operating instructions for the

analysis instrument and the FILTRATION PROBE sc.

1. Take the FILTRATION PROBE sc out of the tank; during this process pay attention to

the installation instructions for the fastening system used.

2. Place the FILTRATION PROBE sc in the tray provided.

3. Remove the filter elements (see Figure 2 Removing the filter elements on page 5) and

store them so they remain moist.

4. Use 3% chlorine bleach (e. g: LCW811, diluted 1:3 with water) OR 5% hydrochloric

acid as the cleaning solution.

5. Fill a container with cleaning solution and place the container near the FILTRATION

PROBE sc.

6. Fit the O-rings (see Figure 1 Items supplied, cleaning unit LZY367 on page 1), grease

the O-rings lightly and connect the cleaning adapters instead of the filter elements

(see Figure 3 Fitting cleaning adapters on page 5).

7. Hang the ends of the tubes on the cleaning adapters in the container with the cleaning

solution (see Figure 4 Installation overview on page 6).

2

Page 5

Cleaning the FILTRATION PROBE sc

1. Ensure all steps in section Installation of the cleaning set LZY367 on page 2 have

been performed.

2. Open the main menu on the analysis instrument.

3. Select the menu MAINTENANCE>TEST/MAINT>PREPUMPING>PREPUMPING

PROBE and trigger a pump cycle.

4. Wait until the pump cycle is complete.

Note: Ensure the tubes are not drained!

5. Hang the ends of the tubes on the cleaning adapters in a container filled with clean

water and trigger a further pump cycle.

6. Wait until the pump cycle is complete.

7. Remove the cleaning adapters and re-fit the filter elements (see Figure 5 Installing the

filter elements on page 6).

Cleaning set LZY367

8. Replace the FILTRATION PROBE sc in the tank; during this process pay attention to

the installation instructions for the fastening system used.

3

Page 6

Cleaning set LZY367

Cleaning the analyser

1. Place the analysis instrument in the service state.

a. For this purpose open the main menu on the analysis instrument.

b. Select the menu MAINTENANCE>TEST/MAINT>SERVICE MODE and choose

2. Assemble the cleaning set as shown in the drawing Figure 6 Cleaning set assembled

on page 7.

3. Remove the tube connection on the overflow vessel at the bottom right and fit the

blind plug (see Figure 7 Fitting the blind plug and the cleaning set on page 8).

4. Fill the syringe with cleaning solution.

5. Remove the sample feed tube for the FILTRATION PROBE sc on the bottom of the

overflow vessel and fit the tube connection for the cleaning set (see Figure 7 Fitting

the blind plug and the cleaning set on page 8).

6. Inject cleaning solution into the overflow vessel until it is completely full.

START.

Note: Do not fill the overflow vessel with too much cleaning solution, as the cleaning solution can

leak through the outlet in an uncontrolled manner.

7. After 5 minutes draw off the cleaning solution and dispose of the cleaning solution

with due attention for the protection of the environment.

8. Rinse the syringe and the overflow vessel with clean water.

9. Re-fit all tubes and tube connections as before.

10. Open the MAINTENANCE menu level by pressing the back arrow.

Note: The following question appears on the display: SERV. HOLD MODE?

11. Choose the answer: NO / MEASURE START.

4

Page 7

Cleaning set LZY367

Figure 2 Removing the filter elements

Figure 3 Fitting cleaning adapters

5

Page 8

Cleaning set LZY367

Figure 4 Installation overview

Figure 5 Installing the filter elements

6

Page 9

Cleaning set LZY367

Figure 6 Cleaning set assembled

1 Disposable syringe (20 mL) 4 Union nut from set of fittings, LZY111

2 PharMed tubing 5 Tapered insert from set of fittings, LZY111

3 Tubing (2 m long, 3.2 x 0.8), LZY195

7

Page 10

Cleaning set LZY367

Figure 7 Fitting the blind plug and the cleaning set

Spare parts and accessories

Description Number Order number

Tubing (2 m long, 3.2 x 0.8) 1 LZY195

Blind plug 2 LZY193

Fittings (3.2 mm) 4 (1 set) LZY111

8

Page 11

Warranty, liability and complaints

HACH LANGE GmbH warrants that the product supplied is free of

material and manufacturing defects and undertakes the obligation

to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service

contract is taken out within 6 months of purchase, the warranty

period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for

defects including the lack of assured properties as follows: all those

parts that, within the warranty period calculated from the day of the

transfer of risk, can be demonstrated to have become unusable or

that can only be used with significant limitations due to a situation

present prior to the transfer of risk, in particular due to incorrect

design, poor materials or inadequate finish will be improved or

replaced, at the supplier's discretion. The identification of such

defects must be notified to the supplier in writing without delay,

however at the latest 7 days after the identification of the fault. If the

customer fails to notify the supplier, the product is considered

approved despite the defect. Further liability for any direct or

indirect damages is not accepted.

If instrument-specific maintenance and servicing work defined by

the supplier is to be performed within the warranty period by the

customer (maintenance) or by the supplier (servicing) and these

requirements are not met, claims for damages due to the failure to

comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages

cannot be made.

Consumables and damage caused by improper handling, poor

installation or incorrect use are excluded from this clause.

HACH LANGE GmbH process instruments are of proven reliability

in many applications and are therefore often used in automatic

control loops to provide the most economical possible operation of

the related process.

To avoid or limit consequential damage, it is therefore

recommended to design the control loop such that a malfunction in

an instrument results in an automatic change over to the backup

control system; this is the safest operating state for the environment

and the process.

9

Page 12

Contacts

HACH LANGE GMBH

Willstaetterstrasse 11

D-40549 Duesseldorf

Tel. +49 (0) 211- 52 88 - 0

Fax +49 (0) 211- 52 88 - 143

info@hach-lange.de

www.hach-lange.de

DR. BRUNO LANGE

GES. MBH

Industriestrasse 12

A-3200 Obergrafendorf

Tel. +43 (0) 2747 - 74 12

Fax +43 (0) 2747 - 42 18

info@hach-lange.at

www.hach-lange.at

HACH LANGE AB

Vinthundsvägen159A

SE-128 62 SKÖNDAL

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE LTD

Pacific Way

Salford

Manchester, M50 1DL

Tel. +44 (0)161 8 72 14 87

Fax +44 (0)161 8 48 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

DR. BRUNO LANGE AG

Juchstrasse 1

CH-8604 Hegnau

Tel. +41 (0)44 - 9 45 66 10

Fax +41 (0)44 - 9 45 66 76

info@hach-lange.ch

www.hach-lange.ch

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LTD

125 Baldoyle Industrial Estate

IRL-Dublin 13

Tel. +353(0)1 8391555

Fax +353(0)1 8063939

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0) 1541 61 20

info@hach-lange.be

www.hach-lange.be

HACH LANGE S.L.U.

C/Araba 45, Apdo. 220

E-20800 Zarautz/Guipúzcoa

Tel. +34 9 43 89 43 79

Fax +34 9 43 13 02 41

info@hach-lange.es

www.hach-lange.es

HACH LANGE

FRANCE S.A.S.

33, Rue du Ballon

F-93165 Noisy Le Grand

Tél. +33 (0)1 48 15 68 70

Fax +33 (0)1 48 15 80 00

info@hach-lange.fr

www.hach-lange.fr

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31 (0)3 44 63 11 30

Fax +31 (0)3 44 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wroclaw

Tel. +48 71 3 42 10 -83

Fax +48 71 3 42 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.L.

str. Aviator Teodor Iliescu nr.37

Sector 1

RO-011672, Bucuresti

Tel. +40 (0)21 2 08 95 78

Fax +40 (0)21 2 08 95 78

info@hach-lange.com

www.hach-lange.com

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE KFT.

Íves u. 2.

H-9027 Gy

Tel. +36 (06)96 511 400

Fax +36 (06)96 329 981

info@hach-lange.hu

www.hach-lange.hu

őr

HACH LANGE S.R.O.

Sabinovská 10

SK-821 02 Bratislava

Tel. +421 2 4820 9091

Fax +421 2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0) 2 963 19 21

Fax +359 (0)2 866 04 47

info@hach-lange.com

www.hach-lange.com

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE SU

ANALIZ SISTEMLERI

LTD.S TI.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKAR

Tel. +90 (0) 312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

Loading...

Loading...