Page 1

DOC023.52.03252

3798-S sc

Digital inductive conductivity sensor

User Manual

02/2013 Edition 2A

Page 2

© HACH LANGE GmbH, 2005, 2013. All rights reserved. Printed in Germany

Page 3

Table of contents

Section 1 Technical data............................................................................................................................................... 3

1.1 Technical data for the 3798-S sc conductivity sensor .............................................................................................. 3

Section 2 General information ..................................................................................................................................... 5

2.1 General handling instructions .................................................................................................................................... 5

2.2 Applications ............................................................................................................................................................... 5

2.3 Basic principles.......................................................................................................................................................... 5

2.4 Measuring principle ................................................................................................................................................... 6

Section 3 General safety instructions ......................................................................................................................... 7

3.1 Possible sources of hazards...................................................................................................................................... 7

3.2 Safety symbols .......................................................................................................................................................... 7

3.3 Electrical safety measures and fire prevention measures ......................................................................................... 8

3.4 Chemical safety measures ........................................................................................................................................ 9

3.5 Safety measures related to the flow of sample.......................................................................................................... 9

Section 4 Installation....................................................................................................................................................11

4.1 Connecting sensor cable ......................................................................................................................................... 11

4.2 Mechanical sensor installation................................................................................................................................. 12

4.2.1 Installation dimensions .................................................................................................................................. 12

Section 5 Operation..................................................................................................................................................... 15

5.1 Operating the sc controller ...................................................................................................................................... 15

5.2 Sensor setup ........................................................................................................................................................... 15

5.3 Sensor data logger .................................................................................................................................................. 15

5.4 The commands under SENSOR DIAG.................................................................................................................... 15

5.5 The commands under SENSOR SETUP ................................................................................................................ 16

5.6 Sensor calibration (conductivity) ............................................................................................................................. 17

5.6.1 Calibration in air (ZERO CAL)........................................................................................................................ 17

5.6.2 Calibration in air (ELECTRIC. SPAN) ............................................................................................................ 17

5.6.3 Calibration in the process (PROCESS SPAN)............................................................................................... 17

5.7 Adjusting the Temperature ...................................................................................................................................... 18

5.8 Calibrating two sensors simultaneously .................................................................................................................. 18

Section 6 Maintenance ................................................................................................................................................ 19

6.1 Maintenance schedule............................................................................................................................................. 19

6.2 Cleaning the sensor................................................................................................................................................. 19

Section 7 Faults, causes, rectification ...................................................................................................................... 21

7.1 Error messages ...................................................................................................................................................... 21

7.2 Warnings ................................................................................................................................................................ 21

7.3 Important service data ............................................................................................................................................. 22

Section 8 Spare parts .................................................................................................................................................. 23

Section 9 Warranty and liability ................................................................................................................................. 25

Section 10 Contact ...................................................................................................................................................... 27

Appendix A ModBUS Register Information ............................................................................................................. 29

1

Page 4

Table of contents

2

Page 5

Section 1 Technical data

1.1 Technical data for the 3798-S sc conductivity sensor

Materials Stainless steel metal housing, PEEK

Enclosure rating IP 68; stainless steel metal housing

Storage temperature

Sensor and controller

Cell constant K=2.35cm

Measuring range conductivity 250 µS/cm ... 2.5 S/

Temp. measuring range –5 °C ... 50 °C

Sensor operating temperature –20 °C ... 50 °C

Conductivity response time < 2 s; T90

Temp. response time <2min; T90

Conductivity measuring accuracy ± 1 % of the measured value displayed or ± 0.004 mS/

Temp. measuring accuracy ± 0.2 °C

Reproducibility < 0.2 %

Sensitivity ± 0.5 % of the end value of the measuring range

Sensor power < 7 W

Calibration

Max. immersion depth / pressure

for the sensor

–20 °C ... 60 °C; 95 % relative humidity, non-condensing

–1

cm

Zero value calibration in air.

Fixed value calibration with defined resistance or with standard solution

20 m / 2 bar

cm

Maximum flow speed 4 m/s

Sensor interface MODBUS

Sensor cable 10 m, hard wired, polyurethane

Sensor weight < 1 kg

Sensor dimensions (Ø × L) 43 × 370 mm

Fastening

• Immersed pipe

• Chain

Specifications are subject to change without notice.

3

Page 6

Technical data

4

Page 7

Section 2 General information

2.1 General handling instructions

Attention!

The sensor will only work correctly when the tip of the probe is completely

immersed in liquid. Ensure the tip of the probe always remains underwater

even when the water level fluctuates.

2.2 Applications

CAUTION!

Potential danger with contact with chemical/biological substances. Working

with chemical samples, standards and reagents can be dangerous. Make

yourself familiar with the necessary safety procedures and the correct

handling of the chemicals before use and read and follow all relevant safety

data sheets.

The sensor facilitates the straightforward and exact determination of the

conductivity of soiled to heavily soiled aqueous solutions. The system is specially

designed for use in municipal and industrial waste water.

2.3 Basic principles

Typical applications include

• Inlet and / or outlet of a sewage treatment plant

• Surface water if within the measuring range (> 250

Various different possible installations enable the system to be adapted to a very

wide range of conditions.

The electrolytic conductivity is the ability of a liquid to conduct an electrical current

(conductivity is the opposite of resistance). In metals, electrical currents are

passed by the movement of electrons, in liquids by the movement of ions. The

conductivity of a liquid depends on the one hand on the ionic concentration, on

the other hand on the temperature of the liquid.

To obtain the real conductivity of the liquid (in

measured

geometry of the probe and that is called the "cell constant or K" (

To be able to make a comparison between the measurements made at different

temperatures, the measurement must be converted to a reference temperature

(as a rule 25 °C).

1

/R (in S) must be multiplied by a coefficient that depends on the

C= K/R (S/cm)

S

/cm), the conductivity value

µS

/cm).

1

/

).

cm

5

Page 8

General information

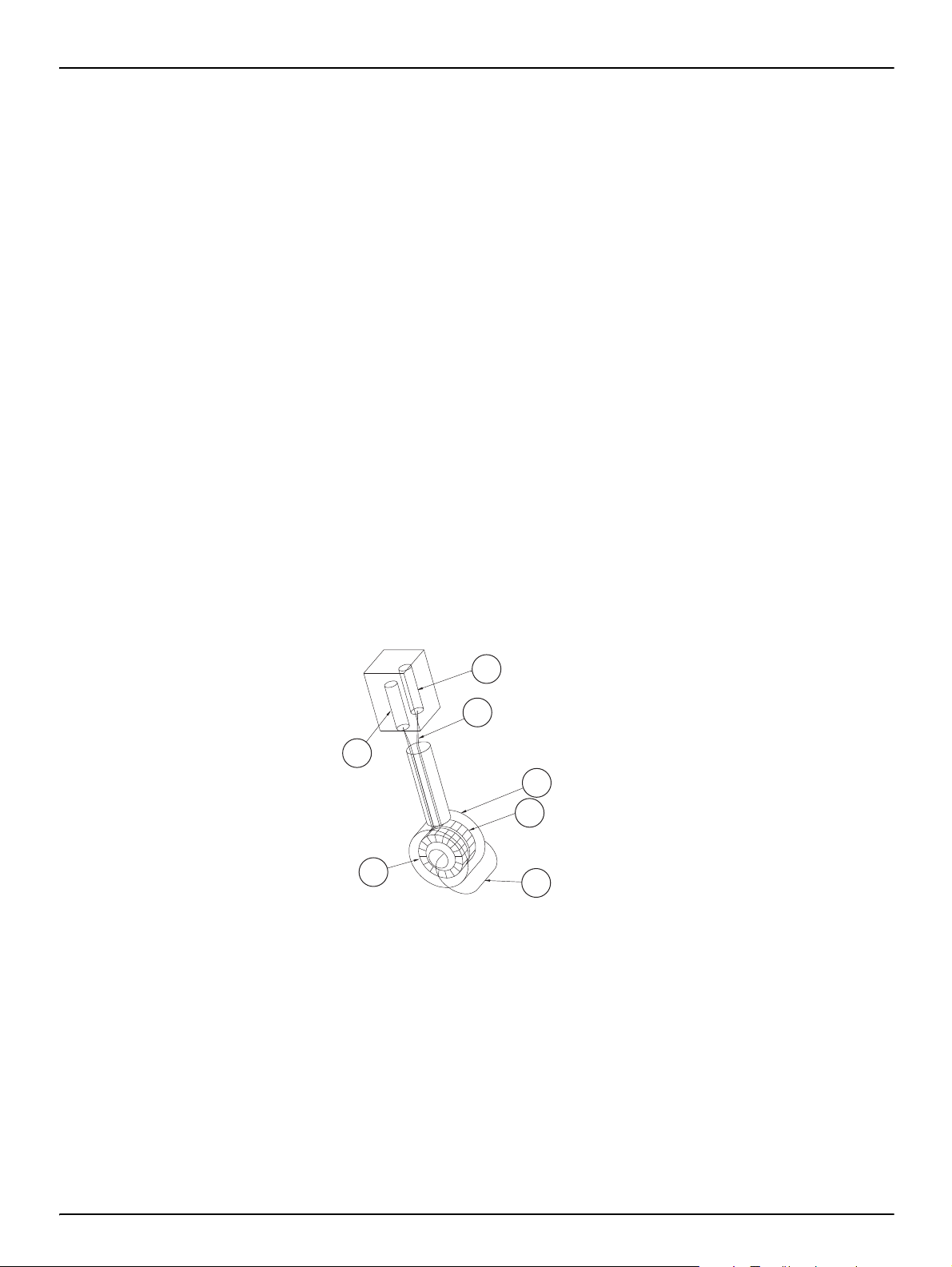

1

4

5

2

3

6

7

This temperature-dependence, expressed in [% / °C], is termed the temperature

coefficient (α).

2.4 Measuring principle

C

= CT [1 + α (T – T

Tref

C

C

T

α : coefficient of the liquid temperature (

: conductivity adjusted to the reference temperature

Tref

: conductivity measured at T

T

: reference temperature (as a rule 25 °C)

ref

ref

)]

– 1

%

/°C)

The tip of the probe comprises two coils that are completely insulated from the

surrounding medium.

Primary coil

(transmitter):

An AC voltage is applied to the primary coil and produces an

alternating electromagnetic field in the surrounding liquid. This

magnetic field generates an electrical current in the liquid.

Secondary coil

(receiver):

The secondary coil determines the current produced by the

ion movements and calculates the conductivity of the liquid

from the current.

1. Receiver

2. Oscillator

3. Cable

4. Insulation

5. Receiver coil

6. Transmitter coil

7. Field line

The electrical insulation between liquid and sensor (magnetic coupling) has

advantages compared to the conventional method of using metal electrodes:

• no polarisation, for this reason the measuring range is larger

• high mechanical and chemical resistance

• possibility of taking measurements in soiled liquids

6

Page 9

Section 3 General safety instructions

Prior to unpacking, commissioning or operating the instrument, read all of this

manual.

Please pay particular attention to all instructions on hazards and safety. Otherwise

there is a risk of serious injury to the operator or damage to the instrument, or

pollution.

The sensor is only allowed to be installed and used as per the instructions in this

manual.

3.1 Possible sources of hazards

During the operation or calibration of the sensor, there exist the following sources

of hazards if the safety instructions are not observed:

• Potentially hazardous materials (buffer solutions, flow of sample)

In all circumstance observe the safety data sheets and the applicable health and

safety instructions.

3.2 Safety symbols

This symbol, if present on the instrument, refers to information in the operating instructions on safe operation and / or

instructions that provide safety information.

This symbol, if present on a housing or a protective cover, identifies the risk of an electric shock (which may under

certain circumstances be fatal). Only personnel qualified for working on hazardous voltages are allowed to open the

enclosure or remove the protective cover.

This symbol, if present on the instrument, identifies the location of a fuse or current limit.

This symbol, if present on the instrument, identifies a part that may become hot and must not be touched without

taking precautions.

This symbol, if present on the instrument, indicates the presence of components that could be damaged by

electrostatic discharge. Appropriate precautions are to be taken.

This symbol, if present on the instrument, indicates the presence of dangerous chemical substances. Chemicals are

only allowed to be handled and maintenance on devices for supplying chemicals is only allowed to be performed by

personnel qualified and trained for working with chemicals.

All stickers and labels on the instrument are to be observed. Otherwise injuries,

pollution or damage to the instrument may occur.

7

Page 10

General safety instructions

This symbol, if present on the instrument, indicates that safety glasses must be worn.

This symbol, if present on the instrument, identifies the location of the connection for the protective earth (ground).

As of 12 August 2005, electrical appliances marked with this symbol are no longer allowed to be disposed of in

Europe in unsorted household or industrial waste. As per the applicable regulations, from this date on consumers in

the EU must return old appliances to the manufacturer for disposal. This disposal is free of charge for the consumer.

Note: You can obt ain instructions on the correct disposal of all (marked and unmarked) electrical products that have

been supplied or manufactured by Hach-Lange from your local Hach-Lange sales office.

3.3 Electrical safety measures and fire prevention measures

The following safety instructions must be observed during the installation

and repair of cables that carry electrical power:

DANGER!

Sensors and controller are designed for compliance with the U.S. and

Canadian NEC as well as the European low voltage directive. No internal

electrical or electronic parts are allowed to be modified in any way, as this

could render the CE conformity void.

WARNING!

Only qualified experts may perform the tasks described in this section of the

manual, while adhering to all locally valid safety regulations.

• Prior to maintenance or repair of the instrument, isolate it from the power

supply.

• When making electrical connections, all applicable local and national

regulations are to be met.

• The use of earth leakage trips is strongly recommended.

• The instrument must be correctly earthed for correct operation.

8

Page 11

3.4 Chemical safety measures

CAUTION!

Reference and standard solutions are used for the calibration. Some of

these compounds are toxic or caustic.

Potential danger with contact with chemical/biological substances. Working

with chemical samples, standards and reagents can be dangerous. Make

yourself familiar with the necessary safety procedures and the correct

handling of the chemicals before use and read and follow all relevant safety

data sheets.

Physical contact with a calibration solution and inhalation of vapours from a

calibration solution are to be avoided or limited to an absolute minimum.

3.5 Safety measures related to the flow of sample

The assessment of the possible hazards from the individual sample flows is the

responsibility of the user. Suitable safety measures are to be taken to avoid any

unnecessary contact with a flow of sample of unknown composition in relation to

the hazards due to traces of chemicals, radiation or biological effects.

General safety instructions

9

Page 12

General safety instructions

10

Page 13

Section 4 Installation

1

2

3

4

5

6

4.1 Connecting sensor cable

You can connect the sensor cable to the controller very easily using the plug.

Retain the protective cap for the socket in case you need to remove the sensor in

the future. Connecting cables are available in the lengths 5 m, 10 m, 15 m, 20 m,

30 m and 50 m. From a length of 100 m a bus termination box must be integrated

(see Section 8 Spare parts).

Fig. 1 Connection of the sensor plug to the controller

Fig. 2 Sensor connector pin assignment

Number Description Cable colour

1+12 VDC brown

2Ground black

3 Data (+) blue

4 Data (–) white

5 Screen Screen (grey)

6Notch

11

Page 14

Installation

180 mm

1“ NPT

75 mm

215 mm

360 mm

410 mm

65 mm

57 mm

6 mm

4.2 Mechanical sensor installation

Notice!

The sensor will only work correctly when the tip of the probe is completely

immersed in liquid. Ensure the tip of the probe always remains underwater

even when the water level fluctuates.

CAUTION!

Potential danger with contact with chemical/biological substances. Working

with chemical samples, standards and reagents can be dangerous. Make

yourself familiar with the necessary safety procedures and the correct

handling of the chemicals before use and read and follow all relevant safety

data sheets.

Requirements

• Ensure the sensor does not collide with other instruments or objects in the

tank. In this way you will avoid damaging the sensor.

• Fasten the sensor to the nearest wall with a minimum spacing of 0.5 m.

4.2.1 Installation dimensions

12

Page 15

Fig. 3 Installation examples

Installation

1. Rim mounting chain bracket, PVC or stainless steel 2. Rim mounting immersed tube, PVC or stainless steel

13

Page 16

Installation

14

Page 17

Section 5 Operation

5.1 Operating the sc controller

The sensor can be operated with all sc controllers. Prior to using the sensor,

familiarise yourself with the principle of operation of your controller. Learn how to

navigate in the menus and run appropriate functions.

5.2 Sensor setup

When you connect the sensor for the first time, the serial number of the sensor is

displayed as the sensor name. You can change the sensor name as follows:

1. Open the MAIN MENU.

2. Choose SENSOR SETUP and accept.

3. Choose the related sensor and accept.

4. Choose CONFIGURE and accept.

5. Choose EDIT NAME and accept.

6. Edit the name and accept to return to the SENSOR SETUP menu.

In the same way complete your system configuration using the commands as per

table 5.5 "The commands under SENSOR SETUP".

5.3 Sensor data logger

A data memory and event memory per sensor are available via the sc controller.

While measured data are saved in the data memory at stipulated intervals, the

event memory collects numerous events such as configuration changes, alarms

and warning conditions. Both the data memory and the event memory can be

read out in CSV format. For information on how you can download the data,

please see the controller manual.

5.4 The commands under SENSOR DIAG

SENSOR DIAG

SELECT SENSOR (for several sensors)

ERROR LIST List of all errors that have occurred (see Section 7.1 "Error messages")

WARNING LIST

List of all warnings that have occurred

(see Section 7.2 "Warnings")

15

Page 18

Operation

5.5 The commands under SENSOR SETUP

SENSOR SETUP

SELECT SENSOR (for several sensors)

CALIBRATE

ZERO CAL

ELECTRIC. SPAN

PROCESS SPAN

PROCESS TEMP

CAL CONFIG

OUTPUT_MODE

CAL REMINDER

CORR FACTORS

SET CAL DEFLT Return to the factory settings after prompt for confirmation.

CONFIGURE

EDIT NAME Enter a 10-character name.

PARAMETERS Choose a parameter.

DEGREES C-F Choose between degrees Celsius or Fahrenheit.

T-COMPENSATION Choose between LINEAR and NONE.

T-SENSOR

AUTOMATIC

MANUAL Enter a value.

FILTER Enter a value.

LOG. DELAY

LOG INTERVAL Choose between the values available or DISABLED.

TEMP INTERVAL Choose between the values available or DISABLED.

MAINS FREQ. Enter the mains frequency.

SET DEFAULTS Returns to the factory settings after a prompt for confirmation.

DIAG/TEST

PROBE INFO Provides information on driver, software and serial number

CAL DATA Provides information on GAIN, Offset (T) and GAIN CORR.

SIGNALS Provides information on raw data measured.

COUNTERS Provides information on the operating time since the last calibration

TEST/MAINT Disable OUTPUT during test or maintenance

SERVICE Reset Service Counter

Eliminates sensor offset

See 5.6.1 "Calibration in air (ZERO CAL)".

Calibration with a defined resistance.

See 5.6.2 "Calibration in air (ELECTRIC. SPAN)".

Calibration with a reference solution.

See 5.6.3 "Calibration in the process (PROCESS SPAN)".

Calibration of the temperature.

See 5.7 "Adjusting the Temperature".

Choose between:

ACTIVE, output signal follows the input signal;

HOLD, last measured value and output signal are held;

TRANSFER, fixed value is output to the peripherals; and

CHOICE

You can set when the next calibration is to be performed. The

controller then automatically indicates when the next calibration is due.

Choose between

TEMP OFFSET,

GAIN CORR and

GAIN VALUE,

16

Page 19

5.6 Sensor calibration (conductivity)

The sensor has been permanently calibrated and operates with great enough

precision and stability that calibration is rarely necessary.

Calibrate the sensor

• as required (measured value outside the permitted tolerance,

see Section 7.3 "Important service data") or

• in accordance or agreement with the authorities.

5.6.1 Calibration in air (ZERO CAL)

1. On the controller, open the menu SENSOR SETUP => CALIBRATE => ZERO

CAL and accept.

2. Remove the sensor from the tank, clean and dry.

3. Accept.

Operation

4. Wait until the controller displays CAL COMPLETE.

5. Confirm that you have replaced the sensor in the sample flow and accept.

5.6.2 Calibration in air (ELECTRIC. SPAN)

1. Remove the probe from the flow of sample, clean and dry.

2. Connect a defined resistance (in range 5 Ohms - 5 kOhms) and accept to

continue.

3. Enter the value for the resistance and accept.

4. Wait until the value has stabilised.

5. Accept the value.

6. Replace the probe in the flow of sample and accept.

5.6.3 Calibration in the process (PROCESS SPAN)

1. Hold the cleaned probe in the solution and accept to continue.

2. Accept when the measured value has stabilised.

3. Enter the value and accept.

4. Replace the probe in the flow of sample and accept.

17

Page 20

Operation

5.7 Adjusting the Temperature

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Highlight the appropriate sensor if more than one sensor is attached and

confirm.

3. Select CALIBRATE and confirm.

4. Select PROCESS TEMP and confirm.

5. Press ENTER when Stable, TEMP: XX.X is displayed. confirm to continue.

6. Adjust the Reading XX.X °C with the keypad and confirm.

7. CAL COMPLETE, OFFSET: X.X °C, confirm to continue.

8. MOVE PROBE TO PROCESS is displayed. Confirm.

5.8 Calibrating two sensors simultaneously

1. Start by calibrating the first sensor and when you arrive at the point at which

you are prompted to "PRESS ENTER WHEN STABLE".

2. Press the BACK key.

3. Select EXIT and press accept. The instrument returns to the display of the

measurements. The measured value for the sensor to be calibrated starts to

flash.

4. Start the calibration of the other sensor and when you again arrive at the point

at which you are prompted to "PRESS ENTER WHEN STABLE".

5. Press the BACK key.

6. Select EXIT and press accept. The instrument returns to the display of the

measurements. The measured values for both sensors start to flash.

7. To return to the calibration menu for the individual sensors, press the Menu

key, select SENSOR SETUP and accept. Choose the required sensor and

accept.

When calibration is complete, accept.

18

Page 21

Section 6 Maintenance

6.1 Maintenance schedule

The following table reflects experience and may, depending on the sector and

application, vary significantly from actual requirements.

Maintenance task 90 days annual

Clean sensor x

Check sensor for damage x

Calibration (if necessary)

You can set the calibration interval in the sensor setup. The controller then

reminds you when calibration is due.

6.2 Cleaning the sensor

If necessary as per

agreement with the

authorities

Clean the sensor with a jet of water. If there is still soiling present, use a soft,

damp cloth.

19

Page 22

Maintenance

20

Page 23

Section 7 Faults, causes, rectification

7.1 Error messages

Possible sensor errors are displayed by the controller.

Table 1: Error messages

Error displayed Cause Rectification

*****

SENSOR MISSING

FFFFFFFFFFFFF

TEMP TOO LOW Measured temperature < –5 °C

TEMP TOO HIGH

COND TOO LOW Conductivity < 100

COND TOO HIGH Conductivity > 500 mS/

RES. TOO LOW Resistance < 2

RES. TOO HIGH Resistance > 10 k

No communication with the

controller

No communication with the

controller

Measured temperature >

+100 °C

µS

/

cm

cm

Ω Please contact service.

Ω Please contact service.

Check the connection to the controller

Check the cable to the controller

Check the connection to the controller

Check the cable to the controller

Ensure that the

medium temperature is > –5 °C.

Ensure that the

medium temperature is < +100 °C.

Ensure that the

conductivity is > 100 µS/cm.

Ensure that the

conductivity is < 500 mS/cm.

7.2 Warnings

Possible warning messages are displayed by the controller.

Table 2: Warnings

Error displayed Cause Rectification

CAL TOO OLD

HUMIDITY BAG

The last calibration was more than

180 days ago.

The desiccant bag is more than

1000 days old.

Calibrate the sensor

Please contact service.

21

Page 24

Faults, causes, rectification

7.3 Important service data

Data Minimum Maximum

Electrical gain correction 95 % 105 %

CAL DATA

Signals

Counter

MODBUS STATS Number of communication errors 0 < 1 %

Temperature offset correction – 5 °C + 5 °C

Cell constant 2.50 2.00

Output voltage

Raw measured data – 1 % + 1 %

Desiccant bag

Operating time 1000 days

Measurement of fixed

resistance 1 k

Ω

Measured value 990

Ω 1010 Ω

22

Page 25

Section 8 Spare parts

3798-S sc, inductive conductivity sensor........................................................................................ LXV428.99.00001

User Manual ..................................................................................................................................DOC023.52.03252

Accessories for the conductivity sensor

Calibration set, electrical ................................................................................................................................ LZX985

Cable extension set (0.35 m).......................................................................................................................... LZX847

Cable extension set (5 m)............................................................................................................................... LZX848

Cable extension set (10 m)............................................................................................................................. LZX849

Cable extension set (15 m)............................................................................................................................. LZX850

Cable extension set (20 m)............................................................................................................................. LZX851

Cable extension set (30 m)............................................................................................................................. LZX852

Cable extension set (50 m)............................................................................................................................. LZX853

Termination box ............................................................................................................................................. 5867000

Immersed pipe, V4A....................................................................................................................... LZX914.99.01200

Immersed pipe, PVC ...................................................................................................................... LZX914.99.02200

Chain bracket, V4A..........................................................................................................................LZX914.99.11200

Chain bracket, PVC ........................................................................................................................ LZX914.99.12200

Immersed pipe set, V4A ................................................................................................................. LZX914.99.31200

Immersed pipe set, PVC................................................................................................................. LZX914.99.32200

U-bolt.............................................................................................................................................................. LZX959

Calibration set................................................................................................................................................. LZX985

Reference solutions

100 - 1000 µS/cm, 1l ........................................................................................................................25M3A2000-119

1000 - 2000 µS/cm, 1l ......................................................................................................................25M3A2050-119

2000 - 150,000 µS/cm, 1l .................................................................................................................25M3A2100-119

200000 - 300000 µS/cm, 1l ..............................................................................................................25M3A2200-119

23

Page 26

Spare parts

24

Page 27

Section 9 Warranty and liability

HACH LANGE GmbH warrants that the product supplied is free of material and

manufacturing defects and undertakes the obligation to repair or replace any

defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out

within 6 months of purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including

the lack of assured properties as follows: all those parts that, within the warranty

period calculated from the day of the transfer of risk, can be demonstrated to have

become unusable or that can only be used with significant limitations due to a

situation present prior to the transfer of risk, in particular due to incorrect design,

poor materials or inadequate finish will be improved or replaced, at the supplier's

discretion. The identification of such defects must be notified to the supplier in

writing without delay, however at the latest 7 days after the identification of the

fault. If the customer fails to notify the supplier, the product is considered

approved despite the defect. Further liability for any direct or indirect damages is

not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to

be performed within the warranty period by the customer (maintenance) or by the

supplier (servicing) and these requirements are not met, claims for damages due

to the failure to comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages cannot be

made.

Consumables and damage caused by improper handling, poor installation or

incorrect use are excluded from this clause.

HACH LANGE GmbH process instruments are of proven reliability in many

applications and are therefore often used in automatic control loops to provide the

most economical possible operation of the related process.

To avoid or limit consequential damage, it is therefore recommended to design the

control loop such that a malfunction in an instrument results in an automatic

change over to the backup control system; this is the safest operating state for the

environment and the process.

25

Page 28

Warranty and liability

26

Page 29

Section 10 Contact

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP. ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Zamówienia: +48 717 177 707

Doradztwo: +48 717 177 777

Fax +48 717 177 778

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Rossini, 1/A

I-20020 Lainate (MI)

Tel. +39 02 93 575 400

Fax +39 02 93 575 401

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 - Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edificio Seminario

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD.ŞTİ.

Ilkbahar mah. Galip Erdem

Cad. 616 Sok. No:9

TR-Oran-Çankaya/ANKARA

Tel. +90312 490 83 00

Fax +90312 491 99 03

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

27

Page 30

Contact

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE OOO

Finlyandsky prospekt, 4A

Business Zentrum “Petrovsky

fort”, R.803

RU-194044, Sankt-Petersburg

Tel. +7 (812) 458 56 00

Fax. +7 (812) 458 56 00

info.russia@hach-lange.com

www.hach-lange.com

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

28

Page 31

Appendix A ModBUS Register Information

Table A-3 Sensor Modbus Registers

Tag Name Register # Data Type

Measurement mS/cm 40001 Float 2 R Conductivity in mS/cm

Measurement Ohm.cm 40003 Float 2 R Resistivity Ohm.cm

Measurement temperature 40005 Float 2 R Temperature

Measurement uScm 40007 Float 2 R Conductivity in uS/cm

Measurement S/m 40009 Float 2 R Conductivity in S/m

Measurement mS/m 40011 Float 2 R Conductivity in mS/m

Measurement KOhm.cm 40013 Float 2 R Resistivity KOhm.cm

Measurement Ohm.m 40015 Float 2 R Resistivity Ohm.m

Measurement Ohm.m (2) 40017 Float 2 R Resistivity Ohm.m2

AutoRange S/cm 40019 Integer 1 R Auto Ranging redirection

AutoRange S/m 40020 Integer 1 R Auto Ranging redirection of Sm

AutoRange Ohm.cm 40021 Integer 1 R Auto Ranging redirection of Ohm.cm

AutoRange Ohm.m 40022 Integer 1 R Auto Ranging of Ohm.m

measurement raw temperature 40023 Float 2 R Raw Temperature

Conductivity unit 40025 Integer 1 R Conductivity unit

Temperature unit 40026 Bit 1 R/W Temperature unit

Output Mode 40027 Integer 1 R/W OutputMode

Sensorname[0] 40028 Integer 1 R/W sensorname[0]

Sensorname[1] 40029 Integer 1 R/W sensorname[1]

Sensorname[2] 40030 Integer 1 R/W sensorname[2]

Sensorname[3] 40031 Integer 1 R/W sensorname[3]

Sensorname[4] 40032 Integer 1 R/W sensorname[4]

Sensorname[5] 40033 Integer 1 R/W sensorname[5]

Software Version (float) 40034 Float 2 R/W Software version

Driver Version (float) 40036 Float 2 R/W Driver version

Mains Frequency 50Hz 40038 Bit 1 R/W Main Frequency

Function code 40039 Integer 1 R/W Function Code

Next state 40040 Integer 1 R/W Next Step

Password 40041 Password 1 R/W Password

Serial number[1] 40042 Integer 1 R/W Serial number[0]

Serial number[2] 40043 Integer 1 R/W Serial number[1]

Serial number[3] 40044 Integer 1 R/W Serial number[2]

Conductivity parameter 40045 Bit 1 R/W &CMD_kunit

Temperature unit 40046 Bit 1 R/W &CMD_tunit

Offset correction 40047 Float 2 R/W Resistivity Offset

Electrical Calibration Resistance 40049 Float 2 R/W Resistivity Adjust vaue

Electrical Slope 40051 Float 2 R/W Electrical slope

Process Slope 40053 Float 2 R/W Process slope

Main Calibration Adjust Value 40055 Float 2 R/W Cal Conductivity Adjust Value

Second. Calibration Adjust Value 40057 Float 2 R/W Cal Temperature Adjust Value

Temporary Meas.[0] 40059 Float 2 R/W Temporary Measurement[0]

Temporary Meas.[1] 40061 Float 2 R/W Temporary Measurement[1]

Lengt

h

R/W Description

29

Page 32

ModBUS Register Information

Table A-3 Sensor Modbus Registers

Constant cell 40063 Float 2 R/W Constant cell

Temperature Compensation 40065 Bit 1 R/W Temperature Compensation

Coefficient Compensation 40066 Float 2 R/W Compensation Coefficient

Temperature Reference 40068 Float 2 R/W Temperature Reference

AutomaticTemperature 40070 Bit 1 R/W AutomaticTemperature

Manual Temperature 40071 Float 2 R/W Manual Temperature

Temperature Offset 40073 Float 2 R/W Temperature Offset

--- 40075 Integer 1 R/W &RS_tgMainMeas

--- 40076 Integer 1 R/W &RS_tgSecondMeas

--- 40077 Integer 1 R/W &RS_tgCalMainMeas

--- 40078 Integer 1 R/W &RS_tgCalSecondMeas

--- 40079 Integer 1 R/W &RS_tgCalMainAdjValue

--- 40080 Integer 1 R/W &RS_tgCalSecondAdjValue

--- 40081 Integer 1 R/W &RS_tgTemporary0

--- 40082 Integer 1 R/W &RS_tgTemporary1

--- 40083 Integer 1 R/W &RS_tgTempOffsetCorr

--- 40084 Integer 1 R/W &RS_tgTempRef

--- 40085 Integer 1 R/W &RS_tgTempManual

--- 40086 Integer 1 R/W Analogue Output Command

Serial Number String[0] 40087 Integer 1 R/W &RS_sn_string[0]

Serial Number String[2] 40088 Integer 1 R/W &RS_sn_string[2]

Serial Number String[4] 40089 Integer 1 R/W &RS_sn_string[4]

Serial Number String[6] 40090 Integer 1 R/W &RS_sn_string[6]

Serial Number String[8] 40091 Integer 1 R/W &RS_sn_string[8]

Serial Number String[8] 40092 Integer 1 R/W &RS_sn_string[10]

--- 40093 Float 2 R/W &MESS_OutputVoltage

Averaging 40095 Integer 1 R/W Averaging

--- 40096 Integer 1 R/W &MESS_cal_code

Delay from last Calibration 40097 Integer 1 R Delay from last Calibration

Time from Start up 40098 Integer 1 R Time from Start up

Time of Humidity Bag 40099 Integer 1 R Time of Humidity Bag

Conductivity Log Interval 40100 Integer 1 R Conductivity Log Interval

Temperature Log Interval 40101 Integer 1 R Temperature Log Interval

30

Loading...

Loading...