Page 1

DOC022.52.80041

2100Q and 2100Qis

04/2013

User Manual

Page 2

Page 3

Table of Contents

Specifications..................................................................................................................................................................................3

General information.....................................................................................................................................................................3

Safety information..............................................................................................................................................................................4

Use of hazard information..................................................................................................................................................................4

Precautionary labels..........................................................................................................................................................................4

Certification........................................................................................................................................................................................4

Product overview...............................................................................................................................................................................5

Product components..........................................................................................................................................................................5

Installation.........................................................................................................................................................................................6

Install the battery................................................................................................................................................................................6

User interface and navigation...............................................................................................................................................7

User interface.....................................................................................................................................................................................7

Display description.............................................................................................................................................................................8

Navigation..........................................................................................................................................................................................8

Startup.................................................................................................................................................................................................8

Turn the meter on and off..................................................................................................................................................................8

Change the language ........................................................................................................................................................................9

Change the date and time .................................................................................................................................................................9

Standard operation......................................................................................................................................................................9

Use a sample ID................................................................................................................................................................................9

Use an operator ID.............................................................................................................................................................................9

Calibrate the turbidimeter with StablCal® Standards.......................................................................................................................10

Turbidity measurement....................................................................................................................................................................10

Measurement notes..................................................................................................................................................................10

Turbidity measurement procedure............................................................................................................................................11

Data management.......................................................................................................................................................................12

About stored data.............................................................................................................................................................................12

View data log...................................................................................................................................................................................12

Delete data log.................................................................................................................................................................................12

1

Page 4

Table of Contents

Send stored data..............................................................................................................................................................................12

Advanced operation..................................................................................................................................................................12

Display contrast...............................................................................................................................................................................12

Power management.........................................................................................................................................................................13

Set the sound options......................................................................................................................................................................13

Security options...............................................................................................................................................................................13

Turn security options on...........................................................................................................................................................13

View meter information....................................................................................................................................................................13

Calibration........................................................................................................................................................................................13

Calibration options....................................................................................................................................................................14

Calibration standard overview..................................................................................................................................................14

StablCal® RapidCal™ calibration..............................................................................................................................................15

Verification options...................................................................................................................................................................16

Calibration verification (Verify Cal)...........................................................................................................................................16

Reading modes................................................................................................................................................................................17

Apply silicone oil to a sample cell....................................................................................................................................................17

Indexing a single cell........................................................................................................................................................................17

Maintenance...................................................................................................................................................................................19

Clean the meter...............................................................................................................................................................................19

Store the sample cells......................................................................................................................................................................19

Replace the battery..........................................................................................................................................................................19

Replace the lamp.............................................................................................................................................................................19

Troubleshooting..........................................................................................................................................................................22

Replacement parts and accessories...............................................................................................................................23

Replacement parts ..........................................................................................................................................................................23

Accessories .....................................................................................................................................................................................23

Index....................................................................................................................................................................................................25

2

Page 5

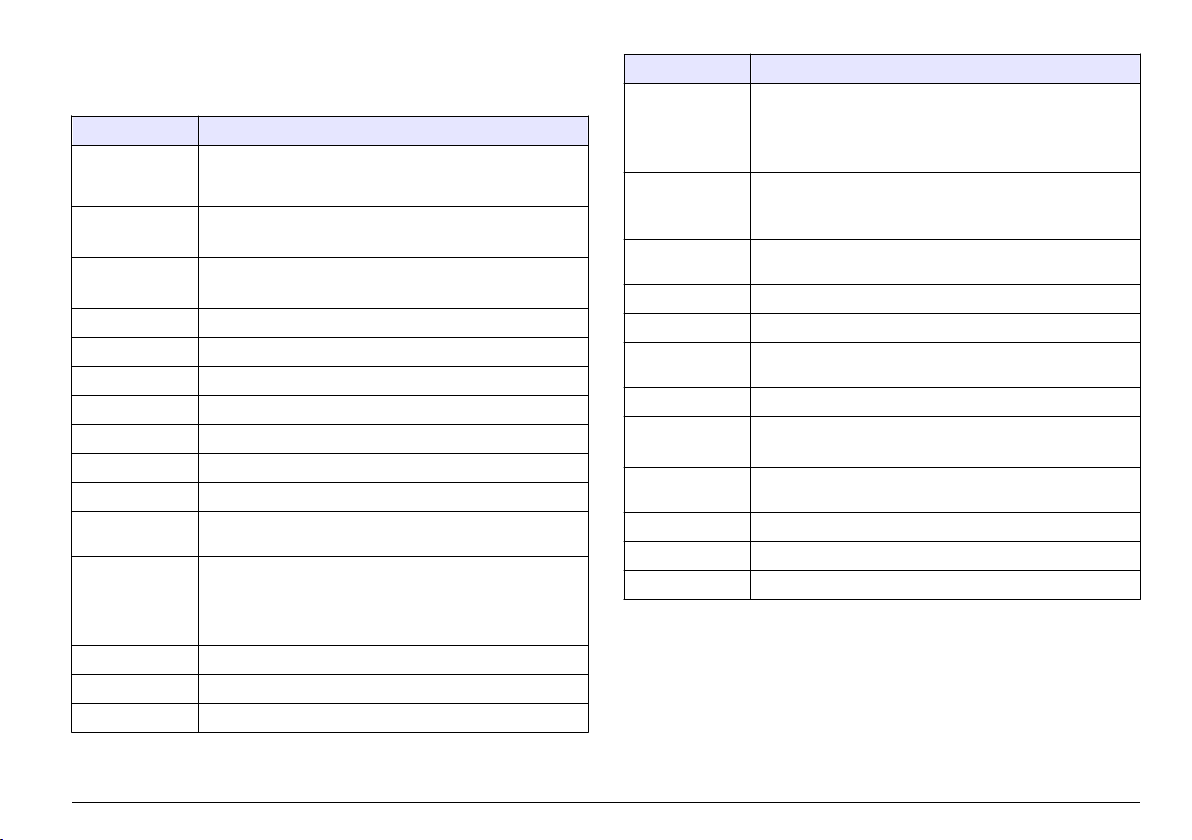

Specifications

Specifications are subject to change without notice.

Specification Details

Measurement

method

Regulatory 2100Q: Meets EPA Method 180.1

Lamp source 2100Q: Tungsten filament lamp

Range 0–1000 NTU (FNU)

Accuracy ±2% of reading plus stray light from 0–1000 NTU (FNU)

Repeatability ±1% of reading or 0.01 NTU (FNU), whichever is greater

Resolution 0.01 NTU on lowest range

Stray light ≤ 0.02 NTU (FNU)

Signal averaging Selectable on or off

Detector Silicon Photodiode

Reading modes Normal (Push to Read), Signal Averaging or Rapidly Settling

Calibration

options

Calibration logger Records the last 25 successful calibrations

Verification logger Logs the last 250 successful verifications

Data logger 500 records

Ratio turbidimetric determination using a primary

nephelometric light scatter signal (90°) to the transmitted

light scatter signal.

2100Qis: Meets ISO 7027

2100Qis: Light-emitting diode (LED) at 860 nm

™

Turbidity

Single step RapidCal™ for Low-Level Regulatory Reporting

from 0–40 NTU (FNU)

Full range calibration from 0–1000 NTU (FNU)

Calibration to degrees of turbidity

Specification Details

Power

requirement

Operating

conditions

Storage

conditions

Interface Optional USB

Sample required 15 mL (0.5 oz.)

Sample cells Round cells 60 x 25 mm (2.36 x 1 in.) borosilicate glass with

Dimensions 22.9 x 10.7 x 7.7 cm (9.0 x 4.2 x 3.0 in.)

Weight 530 g (1.17 lb) without batteries

Meter enclosure

rating

Protection class Power supply: Class II

Certification CE certified

Warranty 1 year (EU: 2 years)

AC 100–240 V , 50/60 Hz (with power or USB/power

module)

4 AA alkaline batteries

Rechargeable NiMH (for use with USB/power module)

Temperature: 0 to 50 °C (32 to 122 °F)

Relative Humidity: 0–90% at 30 °C, 0–80% at 40 °C, 0–70%

at 50 °C, noncondensing

–40 to 60 °C (–40 to 140 °F), instrument only

screw caps

620 g (1.37 lb) with four AA alkaline batteries

IP67 (closed lid, battery and module compartment excluded)

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

English

3

Page 6

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or

misuse of this product including, without limitation, direct, incidental and

consequential damages, and disclaims such damages to the full extent permitted

under applicable law. The user is solely responsible to identify critical application

risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

W A R N I N G

C A U T I O N

N O T I C E

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol on the

instrument is referenced in the manual with a precautionary statement.

This is the safety alert symbol. Obey all safety messages that follow

this symbol to avoid potential injury. If on the instrument, refer to the

instruction manual for operation or safety information.

This symbol indicates that a risk of electrical shock and/or

electrocution exists.

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge

to the user.

Note: For return for recycling, please contact the equipment producer or supplier

for instructions on how to return end-of-life equipment, producer-supplied

electrical accessories, and all auxiliary items for proper disposal.

Certification

Canadian Radio Interference-Causing Equipment Regulation,

IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la

réglementation canadienne sur les équipements provoquant des

interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device

complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

1. The equipment may not cause harmful interference.

4

English

Page 7

2. The equipment must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications to this equipment not expressly approved by

the party responsible for compliance could void the user's authority to

operate the equipment. This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

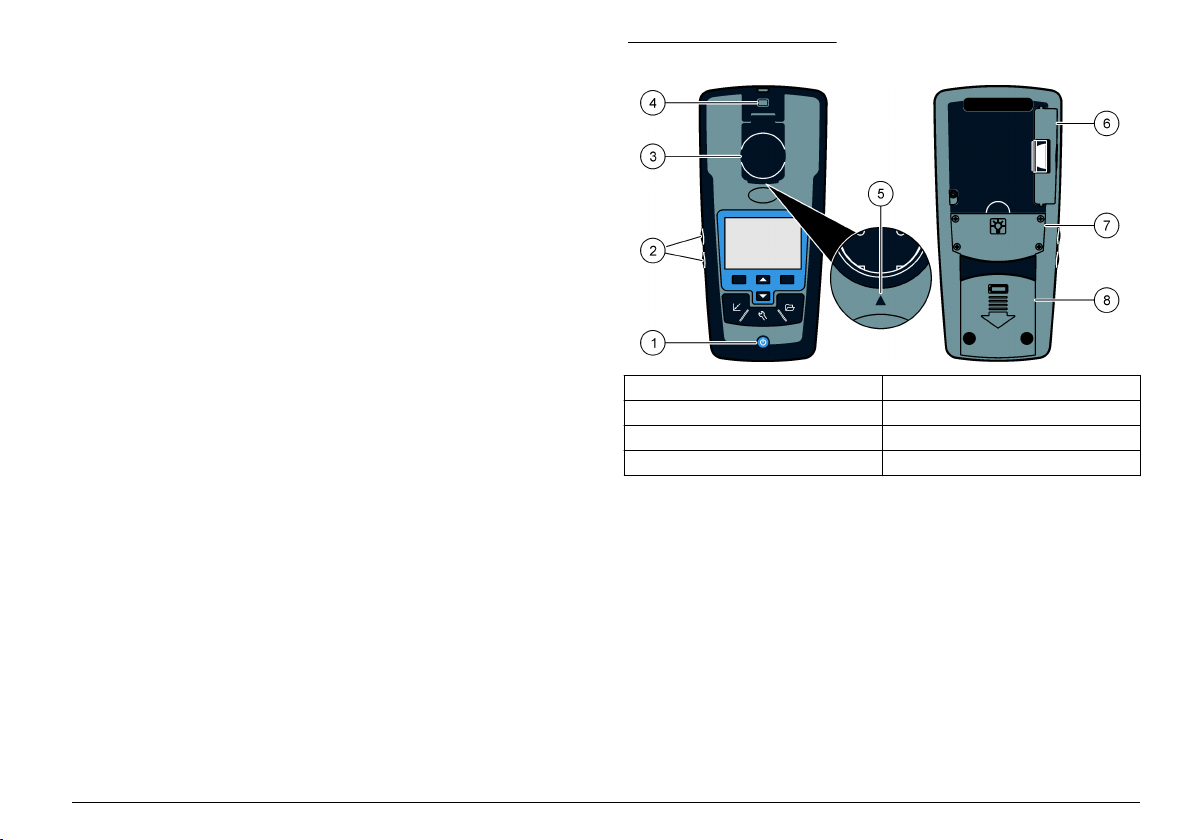

Product overview

The 2100Q and 2100Qis portable turbidimeters measure turbidity from

0 to 1000 NTU (FNU). Primarily for field use, the portable meter operates

on four AA batteries. Data can be stored and transferred to a printer,

computer or USB storage device.

Figure 1 Product overview

1 Power on or off 5 Alignment arrow

2 Backlight keys (+ and -) 6 Module

3 Sample cell holder with lid 7 Lamp compartment

4 Attachment for lanyard 8 Battery compartment

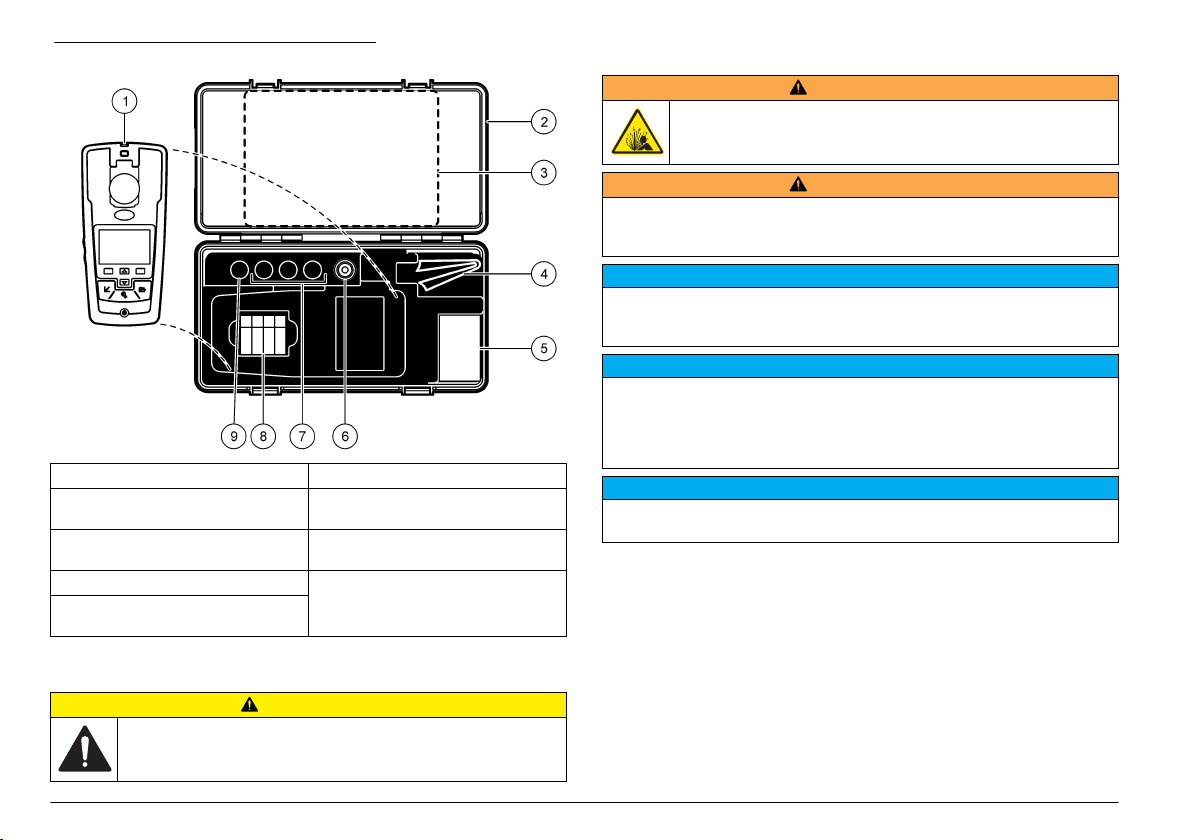

Product components

Refer to Figure 2 to make sure that all components have been received.

If any of these items are missing or damaged, contact the manufacturer

or a sales representative immediately.

English 5

Page 8

Figure 2 2100Q and 2100Qis components

1 2100Q or 2100Qis turbidimeter 6 Silicone oil

2 Carrying case 7 20, 100 and 800 NTU StablCal

3 User manual and Quick reference

guide

4 Oiling cloth 9 StablCal 10 NTU verification

5 1" sample cell (10 mL) with cap

(pk/6)

calibration standards

8 AA alkaline batteries (pk/4)

standard

Installation

Install the battery

W A R N I N G

Explosion hazard. An expired battery can cause hydrogen gas buildup

inside the instrument. Replace the battery before it expires. Do not

store the instrument for long periods with a battery installed.

Potential fire hazard. Use only alkaline or nickel metal hydride batteries (NiMH) in

the meter. Other battery types or incorrect installation can cause a fire. Never mix

battery types in the meter.

The battery compartment is not waterproof. If the battery compartment becomes

wet, remove and dry the batteries and dry the interior of the compartment. Check

the battery contacts for corrosion and clean them if necessary.

When using nickel metal hydride (NiMH) batteries, the battery icon will not

indicate a full charge after freshly charged batteries have been inserted (NiMH

batteries are 1.2 V versus 1.5 V for alkaline batteries). Even though the icon does

not indicate complete charge, 2300 mAH NiMH batteries will achieve 90% of

instrument operation lifetime (before recharge) versus new alkaline batteries.

To avoid potential damage to the meter from battery leakage, remove the meter

batteries prior to extended periods of non-use.

The meter can be powered with AA alkaline or rechargeable NiMH

batteries. To conserve battery life, the meter will power off after

10 minutes of inactivity, the backlight powers off after 30 seconds. This

time can be changed in the Power Management menu.

Note: Rechargeable batteries will only be recharged with the USB/power module.

Refer to the module documentation for further information.

For battery installation refer to Figure 3.

W A R N I N G

N O T I C E

N O T I C E

N O T I C E

6

English

C A U T I O N

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

1. Remove the battery cover.

2. Install 4 AA alkaline or 4 AA nickel metal hydride (NiMH) batteries.

Make sure that the batteries are installed in the correct orientation.

3. Replace the battery cover.

Page 9

Figure 3 Battery installation

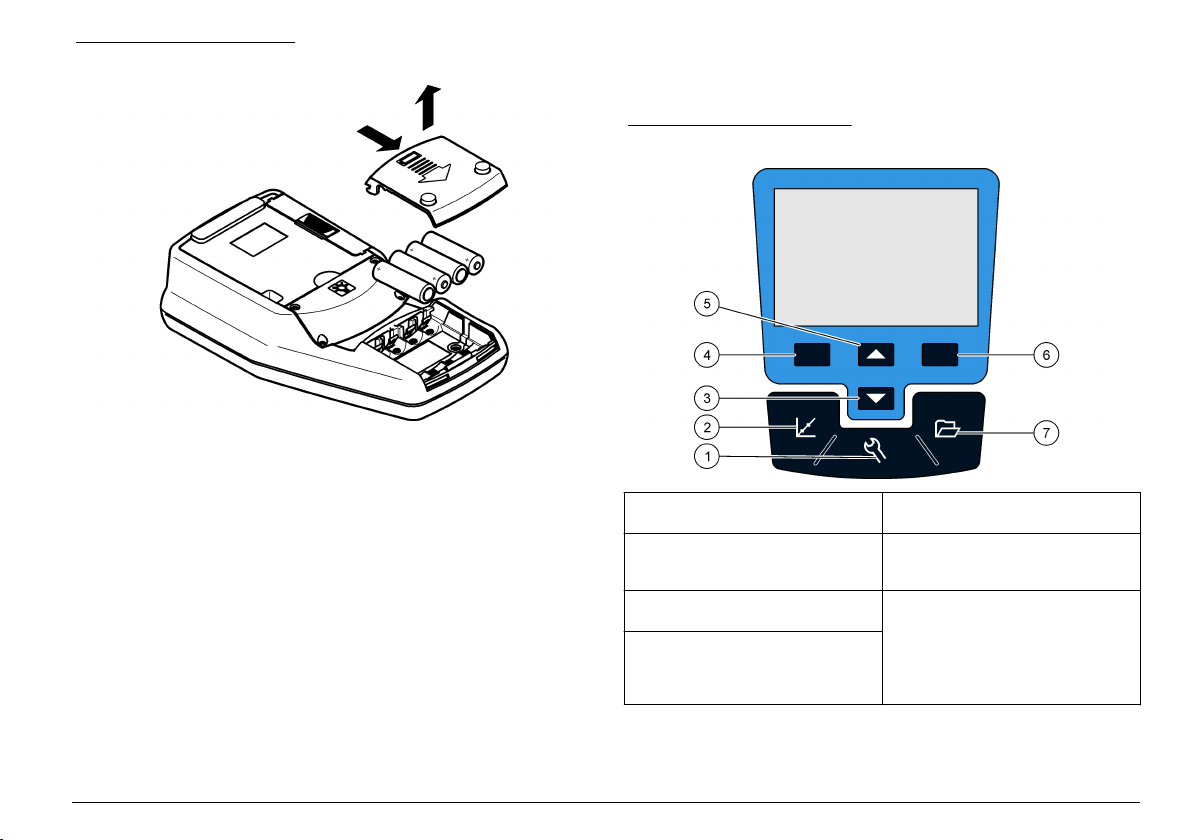

User interface and navigation

User interface

Figure 4 Keypad description

1 SETTINGS key: select menu

options for setting up the meter

2 CALIBRATION key: shows

calibration screen, start calibration,

select cal options

3 DOWN key: scroll through menus,

enter numbers and letters

4 LEFT key (contextual): access for

calibration verification, cancels or

exits the current menu screen to the

previous menu screen

5 UP key: scroll through menus, enter

numbers and letters

6 RIGHT key (contextual): read

turbidity sample, selects or confirms

options, opens/jumps to sub-menus

7 DATA MANAGEMENT key: view,

delete or transfer stored data

English 7

Page 10

Display description

The measurement screen shows the turbidity, unit, calibration status,

date and time, operator ID (if setup) and sample ID (if setup). Refer to

Figure 5.

Figure 5 Single screen display

1 Operator identification 9 NTU (Nephelometric Turbidity Unit)

2 Sample identification 10 Reading mode: Rapidly Settling

3 Stability or display lock indicator 11 Reading mode: Signal Average

4 Calibration status indicator

(Calibration OK=pass)

5 Calibration status indicator

(Calibration ?=fail)

6 Parameter title 14 Read (contextual: OK, Select)

7 AC power icon 15 Options (contextual)

8 Battery icon 16 Verification calibration

or FNU (Formazin Turbidity Unit)

Turbidity (Target icon)

(X-bar icon)

12 Time

13 Date

Navigation

The meter contains a Settings menu, Reading Options menu, Calibration

Options menu and Calibration Verification Options menu to change

various options. Use the UP and DOWN keys to highlight different

options. Push the RIGHT key to select an option. There are two ways to

change options:

1. Select an option from a list: Use the UP and DOWN keys to select an

option. If check boxes are shown, more than one option can be

selected. Push the LEFT key under Select.

Note: To deselect check boxes, push the LEFT key under Deselect.

2. Enter an option value using the arrow keys:

Push the UP and DOWN keys to enter or change a value.

3. Push the RIGHT key to advance to the next space.

4. Push the RIGHT key under OK to accept the value.

Startup

Turn the meter on and off

Push the ON/OFF key to turn on or turn off the meter. If the meter

does not turn on, make sure that the batteries, or the module, are

properly installed or that the AC power supply is properly connected to

an electrical outlet.

Note: The Auto-Shutoff option can also be used to turn off the meter. Refer to

Power management on page 13.

8 English

Page 11

Change the language

There are three options to set the language:

• The display language is selected when the meter is powered on for

the first time.

• The display language is selected when the power key is pushed and

held.

• The language can be changed from the Settings menu.

1. Select a language from the list. Confirm with OK.

2. Push Done when the update is complete.

Change the date and time

The date and time can be changed from the Date & Time menu.

Standard operation

Use a sample ID

The sample ID tag is used to associate readings with a particular sample

location. If assigned, stored data will include this ID.

1. Select Sample ID in the Settings menu.

2. Select, create or delete a sample ID:

Option Description

Current ID Select an ID from a list. The current ID will be

associated with sample data until a different ID is

selected.

Create a New SampleIDEnter a name for a new sample ID.

1. Push the SETTINGS key and select Date & Time.

2. Update the time and date information:

Option Description

Format Select one of the formats for the date and time:

yyyy-mm-dd 24h

yyyy-mm-dd 12h

dd-mm-yyyy 24h

dd-mm-yyyy 12h

mm/dd/yyyy 24h

mm/dd/yyyy 12h

Date Enter the current date

Time Enter the current time

The current date and time will be shown on the display.

After the date and time setup, the meter is ready to take a reading.

Delete Sample ID Delete an existing sample ID.

Use an operator ID

The operator ID tag associates readings with an individual operator. All

stored data will include this ID.

1. Select Operator ID in the Settings menu.

2. Select, create or delete an operator ID:

Option Description

Current ID Select an ID from a list. The current ID will be

Create a New

Operator ID

Delete Operator ID Delete an existing operator ID.

associated with sample data until a different ID is

selected.

Enter a name for a new operator ID (maximum

10 names can be entered).

English 9

Page 12

Calibrate the turbidimeter with StablCal® Standards

Note: For best accuracy use the same sample cell or four matched sample cells for

all readings during calibration. Insert the sample cell in the instrument cell

compartment so the diamond or orientation mark aligns with the raised orientation

mark in front of the cell compartment.

1. Push the

CALIBRATION key to

enter the Calibration

mode. Follow the

instructions on the

display.

Note: Gently invert

each standard before

inserting the standard.

2. Insert the 20 NTU

StablCal Standard and

close the lid.

Note: The standard to

be inserted is bordered.

3. Push Read. The

display shows

Stabilizing and then

shows the result.

4. Repeat Step 2 and

3 with the 100 NTU and

800 NTU StablCal

Standard.

Note: Push Done to

complete a 2 point

calibration.

5. Push Done to

review the calibration

details.

6. Push Store to save

the results.

After a calibration is

complete, the meter

automatically goes into

the Verify Cal mode.

Refer to Verification

calibration.

Turbidity measurement

W A R N I N G

Potential explosion and fire hazard. This turbidimeter is designed for water based

samples. Do not measure solvent or combustible based samples.

Readings can be taken with the Normal reading mode, Signal Average

mode or in the Rapidly Settling Turbidity mode. Refer to Reading modes

on page 17 for more information. For accurate turbidity readings use

clean sample cells and remove air bubbles (degassing).

Measurement notes

Proper measurement techniques are important in minimizing the effects

of instrument variation, stray light and air bubbles. Use the following

measurement notes for proper measurements.

Instrument

• Make sure that the meter is placed on a level, stationary surface

during the measurement.

Note: Do not hold the meter in the hand during measurement.

• Always close the sample compartment lid during measurement,

calibration and storage.

10

English

Page 13

• Remove sample cell and batteries from the instrument if the

instrument is stored for an extended time period (more than a month).

• Keep the sample compartment lid closed to prevent the entry of dust

and dirt.

Sample cells

• Always cap the sample cell to prevent spillage of the sample into the

instrument.

• Always use clean sample cells in good condition. Dirty, scratched or

damaged cells can cause inaccurate readings.

• Make sure that cold samples do not “fog” the sample cell.

• Store sample cells filled with distilled or deionized water and cap

tightly.

Measurement

• Measure samples immediately to prevent temperature changes and

settling. Before a measurement is taken, always make sure that the

sample is homogeneous throughout.

• Avoid sample dilution when possible.

• Avoid operation in direct sunlight.

Turbidity measurement procedure

Note: Before a measurement is taken, always make sure that the sample is

homogeneous throughout.

1. Collect a

representative sample

in a clean container. Fill

a sample cell to the line

(about 15 mL). Take

care to handle the

sample cell by the top.

Cap the cell.

2. Wipe the cell with a

soft, lint-free cloth to

remove water spots and

fingerprints.

3. Apply a thin film of

silicone oil. Wipe with a

soft cloth to obtain an

even film over the entire

surface (Apply silicone

oil to a sample cell).

4. Push the Power key

to turn the meter on.

Place the instrument on

a flat, sturdy surface.

Note: Do not hold the

instrument while

making measurements.

5. Gently invert and

then insert the sample

cell in the instrument

cell compartment so the

diamond or orientation

mark aligns with the

raised orientation mark

in front of the cell

compartment. Close the

lid.

6. Push Read. The

display shows

Stabilizing then the

turbidity in NTU (FNU).

The result is shown and

stored automatically.

Additional information is

available on the

manufacturer's website.

English 11

Page 14

Data management

About stored data

The following types of data are stored in the data log:

• Reading Log: stores automatically each time a sample reading is

taken (500 records).

• Calibration Log: stores only when Store is selected at the end of a

calibration (25 records).

• Verify Cal Log: stores only after Done is selected at the end of a

verification calibration (250 records).

When the data log becomes full, the oldest data point is deleted when

more data is added to the log.

View data log

The data log contains Reading Log, Calibration Log and Verify Cal log.

All logs can be sorted by date.

1. Push the DATA MANAGEMENT key.

2. Select View Data Log to view the stored data.

3. Push Select to view additional information.

Option Description

Reading Log Reading Log—shows the date, time and reading mode

and associated calibration data.

Calibration Log Calibration Log—shows the date and time of calibration

data and additional information about the calibration.

Verify Cal Log Verify Cal Log—shows the calibration verification date

and time and additional information about the verification.

All Logs by Date The most recent data and additional information is

shown. The icons show whether the data is from a

reading, calibration or calibration verification and

identifies the reading mode, if applicable.

Delete data log

There are two possibilities to delete stored readings in the Data

Management menu:

1. Push the DATA MANAGEMENT key and select Delete Data Log.

Option Description

Delete Last Reading Only the last reading stored can be deleted until a

new reading is taken and stored.

Delete All Logs The entire Reading Log can be deleted at once.

Send stored data

Data can be stored and transferred to a printer, computer or USB

storage device. The data will be formatted as an XML file. Install the

USB/power module to the meter and to AC power. Refer to the module

documentation for more information.

Advanced operation

Display contrast

1. Push the SETTINGS key and select Display Contrast.

2. Use the UP and DOWN key to adjust the contrast of the display and

push OK.

12 English

Page 15

Power management

Use power management to change the backlight option and the battery

saving auto-shutoff option.

Note: Power management is not active when the meter is connected to AC power.

1. Push the SETTINGS key and select Power Management.

2. Select which display option to change.

Option Description

Backlight The display is illuminated. To maximize battery life, select a

time period after which the backlight will automatically power

off if no key is pushed: 10 s, 20 s, 30 s,1 min, 2 min, 5 min

Note: The Backlight keys (Product overview) will turn the

backlight on and off.

Auto-Shutoff To maximize battery life, set a time period after which the

meter will automatically power off if no key is pushed: 1 min,

2 min, 5 min, 10 min, 30 min, 1 h

Set the sound options

The meter can make an audible sound when a key is pushed, when a

reading is complete or when the calibration reminder is due.

1. Push SETTINGS and select Sounds.

2. Select which events will produce an audible sound. Multiple items

can be selected.

Option Description

Key Press The meter will make an audible sound whenever a key

is pushed.

Reading complete The meter will make an audible sound whenever a

reading is completed.

Reminders The meter will make an audible sound when a

calibration is due.

Security options

The Security Options menu is used to protect the meter setup.

The Setup Date and Time, Delete Data Log, Restoring Factory Defaults

and Restore Factory Cal screens are not accessible without a password.

Store the password in a safe and accessible place. If the specified

password is forgotten and Security Options is turned on, the operator is

locked out of the restricted menus. Contact technical support if the

password is lost.

Turn security options on

The security options and the set password options are used together to

prevent access to restricted menus.

1. Push the SETTINGS key and select Security Options.

2. Select Edit Password and use the UP and DOWN keys to set a

password.

3. Select Security On to enable the password setting. The requirement

for the password entry is controlled by setting Security Options on or

off.

Note: Set the Security to Off to disable the password setting.

4. Push the ON/OFF key to turn off and on the meter to activate the

password settings.

View meter information

The instrument information menu shows specific information such as the

meter name, model number, software version, serial number and

available Operator and Sample IDs. 10 Operator IDs and 100 Sample

IDs are available.

1. Push the SETTINGS key and select Meter Information.

Calibration

The portable turbidimeter is calibrated with Formazin Primary Standards

at the factory. The meter should be calibrated upon receipt for best

results. The manufacturer recommends calibration with a primary

standard such as StablCal® Stabilized Standards or with formazin

standards every three months.

English

13

Page 16

Note: Set Cal Reminder Repeat in the Calibration Options menu for periodical

calibration. Verify the calibration once a week.

Calibration options

The calibration options contain Calibration History, Calibration Curves,

Cal Reminder Repeat and Restore Factory Calibration.

1. Push the CALIBRATION key and then the UPand DOWN key.

Option Description

Calibration

History

Cal.Curve Select one of the calibration curves for calibration:

Cal Reminder

Repeat

Restore Factory

Calibration

The calibration history shows a list of the times when the

meter was calibrated. Select a date and time to view a

summary of the calibration data.

StablCal® RapidCal™ (0–40 NTU)

StablCal® (0–1000 NTU)

Formazin RapidCal™ (0–40 NTU)

Formazin (0–1000 NTU)

Degrees (0–100 mg/L)

SDVB (0–1000 NTU)

Custom (0–1000 NTU)

The meter will make an audible sound when calibration is

due. Select one of the following options for time interval

and push OK: Off, 1 d, 7 d, 30 d, 60 d, 90 d

All user calibrations will be deleted. The original factory

calibration is restored.

Calibration standard overview

Refer to Calibration standard overview for the calibration standard

overview.

Table 1 Calibration overview

Type of calibration Required standards

StablCal® RapidCal

(0–40 NTU)

StablCal® (0–

1000 NTU)

Formazin RapidCal

(0–40 NTU)

Formazin (0–

1000 NTU)

Degrees (0–100 mg/L) Typically deionized or

SDVB (0–1000 NTU) Typically deionized or

Custom (0–1000 NTU) Typically deionized or

1

The water must have a turbidity <0.5 NTU to prepare the calibration

standards.

™

– 20 NTU – –

– 20 NTU 100 NTU 800 NTU

™

Typically deionized or

distilled waterFootnote

Typically deionized or

distilled waterFootnote

distilled waterFootnote

distilled waterFootnote

distilled waterFootnote

20 NTU – –

20 NTU 100 NTU 800 NTU

20 NTU 100 NTU –

20 NTU 100 NTU 800 NTU

Select values

14 English

Page 17

StablCal® RapidCal™ calibration

1. Push the

CALIBRATION key to

enter the Calibration

mode. Follow the

instructions on the

display.

Note: Gently invert

each standard before

inserting the standard.

7. Push Store to save

the results.

After a calibration is

complete, the meter

automatically goes into

the Verify Cal mode,

refer to Verification

calibration.

2. Push the UP and

DOWN key to access

Cal Options and then

select Cal.Curve.

3. Select StablCal

RapidCal™ from the list

and push OK.

®

4. Insert the 20 NTU

StablCal Standard and

close the lid.

Note: The standard to

be inserted is bordered.

5. Push Read. The

display shows

Stabilizing and then

shows the result.

6. Push Done to

review the calibration

details.

English 15

Page 18

Verification options

The Verification Options contain: Set Verification Standard, Set

Acceptance Criteria and Verification Reminder.

1. Push the Left key (Verify Cal) and then the UP and DOWN keys.

Option Description

Set Verification

Standard

Set Acceptance

Criteria

Verification

Reminder

To change the verification standard use the UP and

DOWN keys to enter a new standard value.

Range 0.50–20.0 NTU (Default setting: 10.00 NTU)

Range 0–20 NTU for RapidCal™ (0–40 NTU)

0–800 NTU for calibration curves with a range from 0–

1000 NTU

Enter the Acceptance Criteria for comparison against the

initial calibration verification reading to determine passing

or failing. Range 1–50% (Default setting: 10%)

Verification Reminder—The meter will make an audible

sound when verification is due. Select one of the following

options for time interval and push OK:Off, 30 min (Default

setting), 2 h, 4 h, 8 h, 24 h

Allow Defer—Push Allow Defer and select Yes or No to

postpone the verification due time

Calibration verification (Verify Cal)

The manufacturer recommends a calibration verification once a week.

After a calibration is complete, the meter automatically goes into the

Verify Cal mode.

Make sure that the sample cell is clean. Oil the sample cell with silicone

oil, refer to Apply silicone oil to a sample cell. Check the standard

solution. Prepare a formazin standard at the same value and read the

value.

1. Push Verify Cal to

enter the Verify menu.

4. Push Done to return

to the reading display.

Repeat the calibration

verification if the

verification failed.

2. Gently invert the

standard. Insert the

10.0 NTU (or other

defined value)

Verification Standard

and close the lid.

3. Push Read. The

display shows

Stabilizing and then

shows the result and

tolerance range.

16 English

Page 19

Reading modes

1. Push the UP or DOWN key to enter the Reading Options menu.

2. Select Reading Mode to select one of the following options:

Option Description

Normal

(Default

setting)

Signal

Average

Rapidly

Settling

Turbidity

(RST)

The normal mode reads and averages three readings. The

result is shown after the reading.

The Signal Average mode compensates for reading

fluctuations caused by drifting of sample particles through

the light path.

The X-bar icon is shown on the display when signal

averaging is on.

The Signal Average mode measures 12 times and starts to

show the average after three readings. The final result is

the average of all 12 readings.

The Rapidly Settling Turbidity (RST) mode calculates and

continuously updates the turbidity reading of the sample to

™

a confidence of 95%, based on the accumulated trend of

the real time measured values.

The RST mode is best used on samples that settle rapidly

and continuously change in value. The reading is based on

a correctly prepared sample that is homogeneous at the

beginning of the reading. It is best applied to samples that

are greater than 20 NTU. The sample must be mixed

thoroughly by inversion immediately before inserting it into

the meter.

The target icon is shown on the display when the Rapidly

Settling Turbidity is on.

The Rapidly Settling Turbidity reads and calculates five

readings while showing intermediate results.

Apply silicone oil to a sample cell

Sample cells and caps must be extremely clean and free from significant

scratches. Apply a thin coating of silicone oil on the outside of the

sample cells to mask minor imperfections and scratches that may

contribute to light scattering.

Note: Use only the provided silicone oil. This silicone oil has the same refractive

index as the sample cell glass.

1. Clean the inside and

outside of the cells and

caps by washing with a

laboratory glass

cleaning detergent.

Follow with multiple

rinses with distilled or

demineralized water.

2. Apply a small bead

of silicone oil from the

top to the bottom of the

cell.

3. Use the provided

oiling cloth to spread

the oil uniformly. Wipe

off the excess so that

only a thin coat of oil is

left. Make sure that the

sample cell is almost

dry with little or no

visible oil.

Note: Store the oiling

cloth in a plastic

storage bag to keep the

cloth clean.

Indexing a single cell

Precise measurements for very low turbidity samples require the use of

a single cell for all measurements or optically matching the cells. Use

one cell to provide the best precision and repeatability. When one cell is

used, an index or orientation mark (other than the factory-placed

diamond) can be placed on the cell so it is inserted into the instrument

with the same orientation each time.

When using a single cell, make an index or orientation mark on the cell

as follows:

English

17

Page 20

1. Fill the clean sample

cell to the line with high

quality water (<

0.5 NTU) and cap

immediately. Let the

sample cell degas for at

least five minutes.

2. Wipe with lint-free

cloth. Apply a thin film

of silicone oil (Apply

silicone oil to a sample

cell).

3. Push the POWER

key to turn the meter

on. Place the

instrument on a flat,

sturdy surface.

Note: Do not hold the

instrument while

making measurements.

4. Insert the sample

cell in the instrument

cell compartment so the

diamond or orientation

mark always aligns with

the raised orientation

mark in front of the cell

compartment. Close the

lid.

5. Push the UP and

DOWN key to access

the Reading Options

and then select

Indexing Sample Cell.

Note: The instruments

always stays in the last

selected reading mode.

6. Push Read. The

display shows

Stabilizing then the

turbidity in NTU. Record

the cell position in the

cell compartment and

the reading result.

7. Remove the cell,

rotate it slightly

approximately ⅛ of a

turn and insert it again

into the cell

compartment. Close the

lid.

18 English

8. Push Read. Record

the cell position in the

cell compartment and

the reading result.

9. Repeat step 6 until

the lowest reading is

shown. Place an

orientation mark on the

cell marking band near

the top of the cell so the

cell can be consistently

inserted in the position

that yields the lowest

reading.

Page 21

Maintenance

Replace the battery

C A U T I O N

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

Clean the meter

The meter is designed to be maintenance-free and does not require

regular cleaning for normal operation. Exterior surfaces of the meter may

be cleaned as necessary.

Note: Do not clean the meter with solvents to avoid damaging the material.

1. Clean the meter with a dust- and lint-free dry or slightly damp cloth. A

mild soap solution can also be used for liposoluble contamination.

Store the sample cells

N O T I C E

Do not air dry the sample cells.

Note: Always store the sample cells with caps on to prevent the cells from drying.

1. Fill the sample cells with distilled or demineralized water.

2. Cap and store the sample cells.

3. Wipe the outside of the sample cells dry with the a soft cloth.

W A R N I N G

Explosion hazard. An expired battery can cause hydrogen gas buildup

inside the instrument. Replace the battery before it expires. Do not

store the instrument for long periods with a battery installed.

Potential fire hazard. Use only alkaline or nickel metal hydride batteries (NiMH) in

the meter. Other battery types or incorrect installation can cause a fire. Never mix

battery types in the meter.

For battery replacement refer to Install the battery on page 6.

1. Remove the battery cover.

2. Remove the batteries.

3. Install 4 AA alkaline or 4 AA nickel metal hydride (NiMH) batteries.

Make sure that the batteries are installed in the correct orientation.

4. Replace the battery cover.

W A R N I N G

Replace the lamp

C A U T I O N

Burn Hazard. Wait until lamp cools down. Contact with the hot lamp can cause

burns.

English 19

Page 22

1 2

3 4

20 English

Page 23

5 6

7 8

English 21

Page 24

Troubleshooting

Refer to the following table for common problem messages or

symptoms, possible causes and corrective actions.

Error/Warning Description Solution

Close lid and push

Read.

Low Battery! Battery is low.

ADC Failure! Hardware error causing

Detector signal too low! Insufficient light on the

Overrange! Turbidity too high-

Underrange! The measured

Please check the lamp! Signals are too low on

The lid is open or lid

detection failed.

reading to fail.

180° detector.

caused probably by

calibrating with

RapidCal™ only.

absorbance is below the

calibration range.

the 90° and 180°

detector.

Make sure that the lid is

closed during reading

and re-read.

• Insert new batteries

• Connect USB/power

module if

rechargeable batteries

are used

Repeat the reading.

• Check for obstructed

light path.

• Check the lamp.

• Calibrate the upper

range.

• Dilute the sample.

Repeat calibration

2100Q: The lamp is

defective. Change the

lamp (refer to Replace

the lamp on page 19).

2100Qis: Contact

technical support.

Error/Warning Description Solution

Temperature too high!

Switch off instrument.

RST: Average value! Solids are settling too

Confidence level is <

95%

Standard value out of

range. Insert standard

and push Read

ID already in use. Enter

new ID

Error - Security Please

set password before

activating security

Please enter at least

one character.

Password incorrect.

Please retry.

Temperature has

exceeded the meter

limits (>60 °C or

>140 °F).

slowly. The reading

mode is not suitable for

this sample.

The reading mode

Rapidly Settling Turbidity

did not meet the range of

≥ 95% confidence.

Used incorrect standard

value for the reading.

The Operator or Sample

ID is unavailable as it is

already assigned.

No password is created. Create a new password.

Password must contain

minimum of one

character.

Incorrect password was

entered.

Turn off the meter and let

it cool down.

Select Normal or Signal

Average reading mode.

• Invert the sample

several times so that

the solids allocate.

Repeat the reading

again.

• Switch to the Normal

reading mode if the

sample is stable and

does not have settable

solids.

Insert the appropriate

standard and read again.

Create a new ID.

Create a password of at

least one character.

Enter the appropriate

password.

22 English

Page 25

Error/Warning Description Solution

Please disconnect the

USB cable from your

computer.

USB module memory

full. Delete data and try

again.

Delete Last Reading

Failed!

Delete Data Log failed!

Can't read data set!

Can't store data!

Can't store to the

Reading Log!

Can't store to the Verify

Cal Log!

Error storing data!

Error reading data!

Data storage does not

respond while connected

to the meter and the

computer.

Data storage is full. 1. Connect USB/power

Error in the data storage. Turn the meter off and

Disconnect the USB

cable from the meter and

try sending data again.

module to the computer.

2. Download the stored

data to the computer.

3. Delete Data Log on

the module.

on. If the error message

still occurs, contact

technical support.

Replacement parts (continued)

Description Quantity Item no.

Insert, molded bottom 1 2971507

Sample cell oiling cloth 1 4707600

1" glass sample cell (10 ml ) w/cap (Turb) pkg/6 2434706

Carrying case (includes insert) 1 2971500

Battery set, AA alkaline batteries pkg/4 1938004

Lamp assy 1 4653900

Blank module 1 LZV797

Rubber foot set 1 LZV821

Lamp cover (includes screws) 1 LZV822

Battery cover (includes 2 feet) 1 LZV823

Module cover 1 LZV824

Connector cover for USB/power module 1 LZV825

Connector cover for power module 1 LZV826

Lid (includes magnet) 1 LZV827

Accessories

Replacement parts and accessories

Replacement parts

Description Quantity Item no.

StablCal ampule calibration kit 1 2971205

10 NTU verification standard 100 mL 2961701

Silicone Oil 15 mL 126936

Description Quantity Item no.

USB/power module (includes: universal

power supply, USB cable, instruction

sheet)

Power module (includes: universal power

supply, instruction sheet)

USB module with USB cable (2x) 1 LZV949.99.00001

StablCal 0.1 NTU Standard 100 mL 2723342

1 LZV813.99.00001

1 LZV804.99.00001

English 23

1

1

1

Page 26

Accessories (continued)

Description Quantity Item no.

StablCal 0.3 NTU Standard 100 mL 2697943

StablCal 0.5 NTU Standard 100 mL 2698042

StablCal calibration kit 100 mL 2971210

StablCal calibration kit 500 mL 2971200

Gelex secondary standards set 1 2464105

Deionized water 4 vials 27217

Filter 0.2 micron 2323810

Formazin 500 ml 246149

Formazin 1000 ml 246142

Sample degassing kit 1 4397500

Sample degassing and filtration kit 1 4397510

Battery, NiMH AA pk/4 2971304

1

Not available in all regions

24 English

Page 27

A

auto-shutoff ............................................................................................13

B

backlight .................................................................................................13

battery installation ..............................................................................6, 19

Index

M

menu navigation .......................................................................................8

meter components ...................................................................................5

meter specifications .................................................................................3

meters

troubleshooting .................................................................................. 22

C

calibration ...............................................................................................13

contrast, display .....................................................................................12

D

data, calibration log ................................................................................12

data, data log .........................................................................................12

data, reading log ....................................................................................12

data, stored data ....................................................................................12

data, verification log ...............................................................................12

date and time ...........................................................................................9

display ......................................................................................................8

I

Indexing a sample cell ...........................................................................17

K

keypad .....................................................................................................7

L

language ..................................................................................................9

N

normal reading .......................................................................................17

O

operator ID ...............................................................................................9

orientation mark .....................................................................................17

P

parts list ............................................................................................23, 24

power

battery installation .........................................................................6, 19

R

rapidly settling turbidity (RST) ................................................................17

reading mode .........................................................................................17

S

sample ID .................................................................................................9

security options ......................................................................................13

signal average reading ...........................................................................17

25

Page 28

Index

silicone oil ..............................................................................................17

sound options .........................................................................................13

stored data, send ...................................................................................12

V

verification ..............................................................................................16

26

Page 29

Page 30

HACH COMPANY World Headquarters

P.O. Box 389, Loveland, CO 80539-0389 U.S.A.

Tel. (970) 669-3050

(800) 227-4224 (U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

©

Hach Company, 2009, 2013. All rights reserved. Printed in the U.S.A.

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf, Germany

Tel. +49 (0) 2 11 52 88-320

Fax +49 (0) 2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

Loading...

Loading...