Page 1

DOC022.98.80204

2100N IS

08/2012, Edition 2

Basic User Manual

Grundlegende Bedienungsanleitung

Manuel d'utilisation de base

Manual básico del usuario

Page 2

English...................................................................................................................................................................................................3

Deutsch...............................................................................................................................................................................................17

Français..............................................................................................................................................................................................32

Español...............................................................................................................................................................................................47

2

Page 3

Table of contents

Specifications on page 3 Standard operation on page 9

General information on page 4 Maintenance on page 14

User interface on page 7 Troubleshooting on page 14

Startup on page 8

Specifications

Specifications are subject to change without notice.

Specification Details

Measurement method Nephelometric

Regulatory Meets ISO 7027, DIN EN 27027, DIN 38404 and

Light source Light-emitting diode (LED) at 860 ± 30 nm

Measurement modes FNU and NTU

Range FNU (manual range): 0–0.999, 0–9.99, 0–99.9, 0–

Accuracy1,

Resolution Turbidity: 0.001 FNU/NTU (on lowest range)

2

NFT 9033

ASTM D7315 - Standard Test Method for

Determination of Turbidity Above 1 Turbidity Unit

(TU) in Static Mode

ASTM D6655 - Standard Test Method for

Determination of Turbidity Below 5 NTU in Static

Mode

1000

FNU (auto range): 0–1000

NTU (manual range): 0–0.999, 0–9.99, 0–99.9, 0–

1000

NTU (auto range): 0–1000

±2% of reading plus 0.01 FNU/NTU from 0–

1000 FNU/NTU

Specification Details

Repeatability ±1% of reading or 0.01 FNU, whichever is greater

Response time Signal averaging off: 6.8 seconds

Stabilization time Immediately

Reading modes Manual or auto range, signal averaging on or off

Power requirement 115–230 VAC, 50/60 Hz (automatic power selection)

Pollution

degree/installation

category

Protection Class 1

Operating conditions Temperature: 0 to 40 °C (32 to 104 °F)

Storage conditions –40 to 60 °C (–40 to 140 °F), instrument only

Interface RS232C serial interface by way of DB9 subminiature

Air purge Dry nitrogen or instrument grade air (ANSI MC 11.1,

Sample cells Round cells 95 x 25 mm (3.74 x 1 in.) borosilicate

(under reference conditions)

Signal averaging on: 14 seconds (when

10 measurements are used to calculate the average)

28 W maximum

2; II

Relative humidity: 0–90% at 25 °C, 0–75% at 40 °C,

noncondensing

Altitude: 2000 m (6560 ft) maximum

Indoor use only

D-shell connector for data output to computer or

printer, and data input (command). No handshaking.

1975)

0.1 scfm at 69 kPa (10 psig); 138 kPa (20 psig)

maximum

Hose barb connection for 1/8-inch tubing

glass with rubber-lined screw caps

Note: Smaller sample cells (less than 25 mm) can be used

when a cell adapter is used.

English 3

Page 4

Specification Details

Sample requirements 25 mm sample cell: 20 mL minimum

0 to 95 °C (32 to 203 °F)

Enclosure High-impact polycarbonate plastic

Dimensions 30.5 x 40 x 15.6 cm (12.0 x 15.7 x 6.1 in.)

Weight 3.8 kg (8.5 lb)

Certification CE, cETLus

1

Turbidity specifications identified using recently prepared formazin standard

and matched 1-inch sample cells.

2

Intermittent electromagnetic radiation of 3 volts/meter or greater may cause

slight accuracy shifts.

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

Expanded manual version

For additional information, refer to the CD for an expanded version of

this manual.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or

misuse of this product including, without limitation, direct, incidental and

consequential damages, and disclaims such damages to the full extent permitted

under applicable law. The user is solely responsible to identify critical application

risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

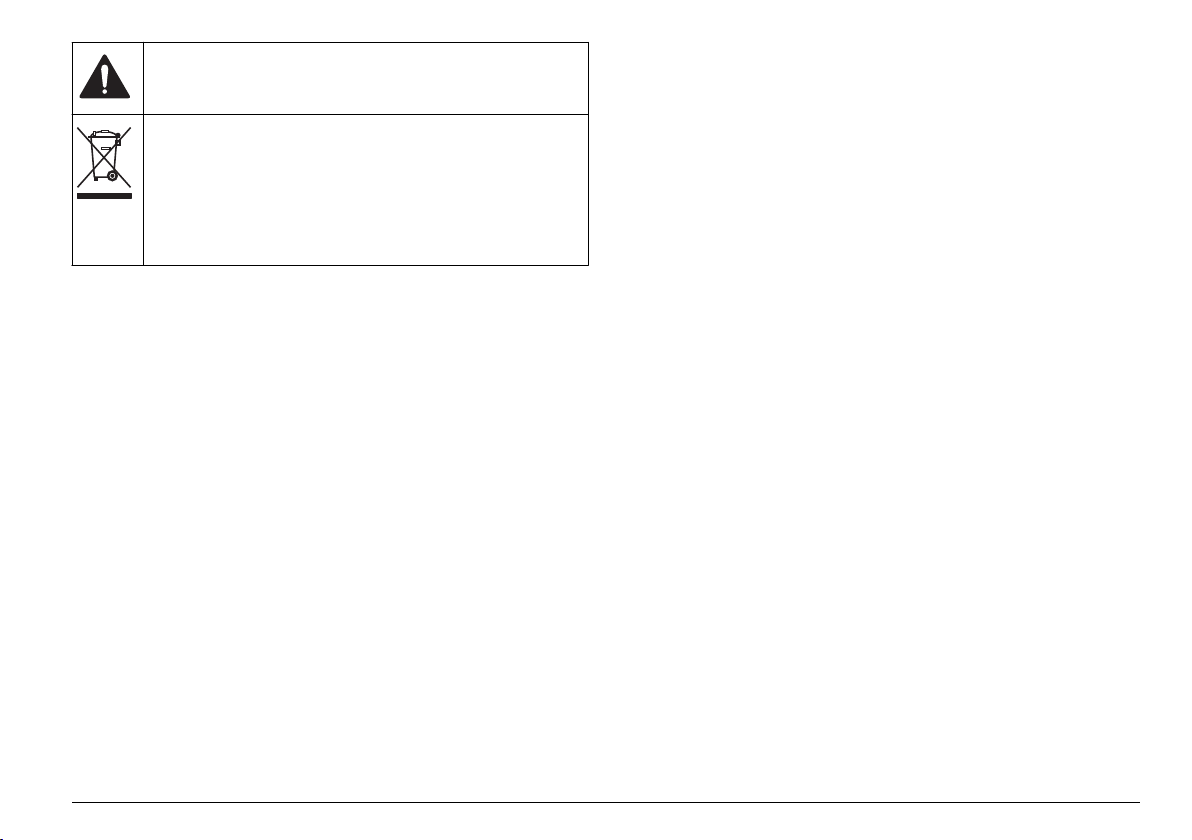

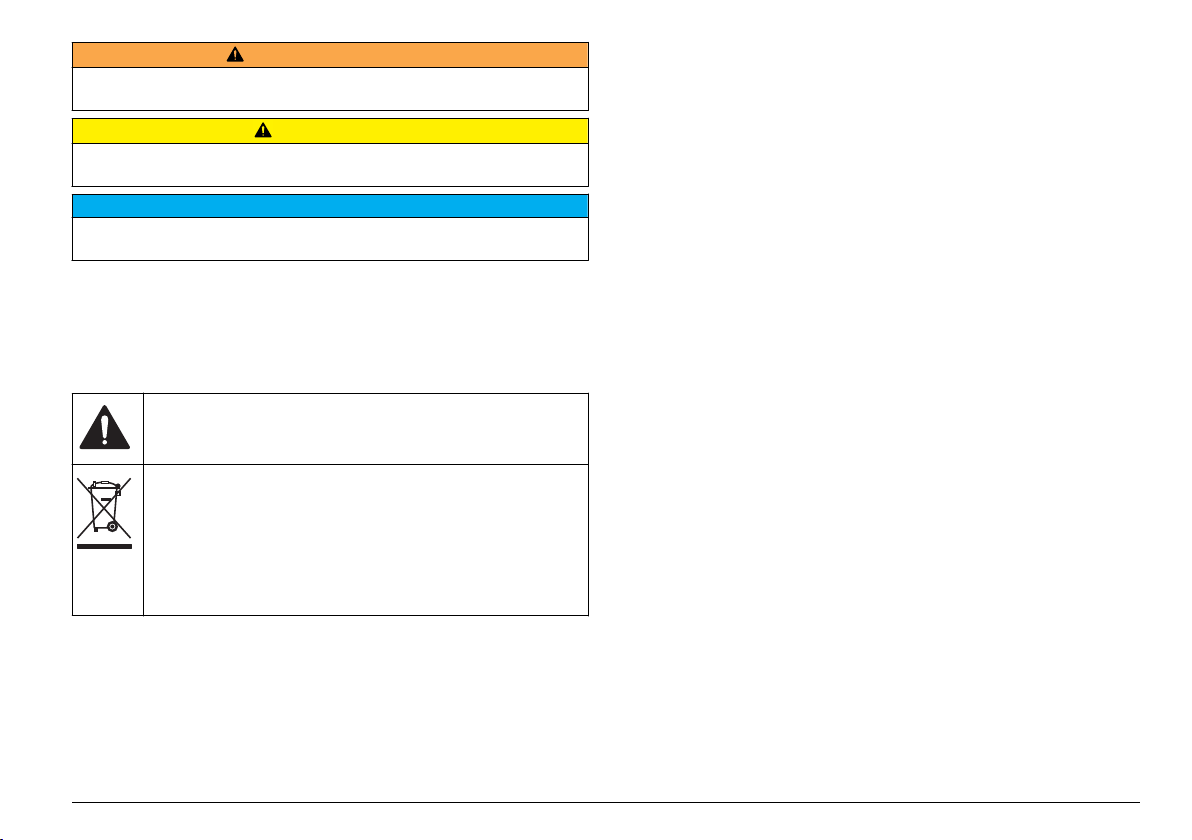

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

W A R N I N G

C A U T I O N

N O T I C E

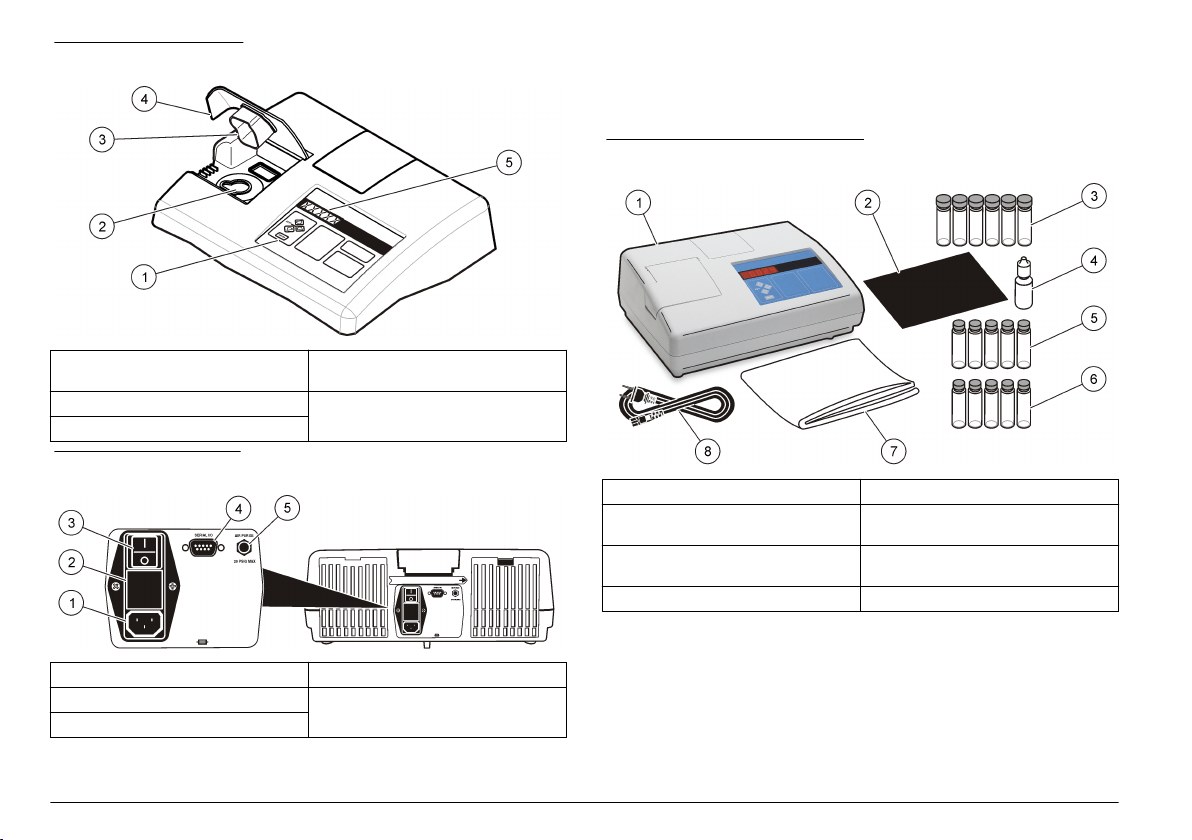

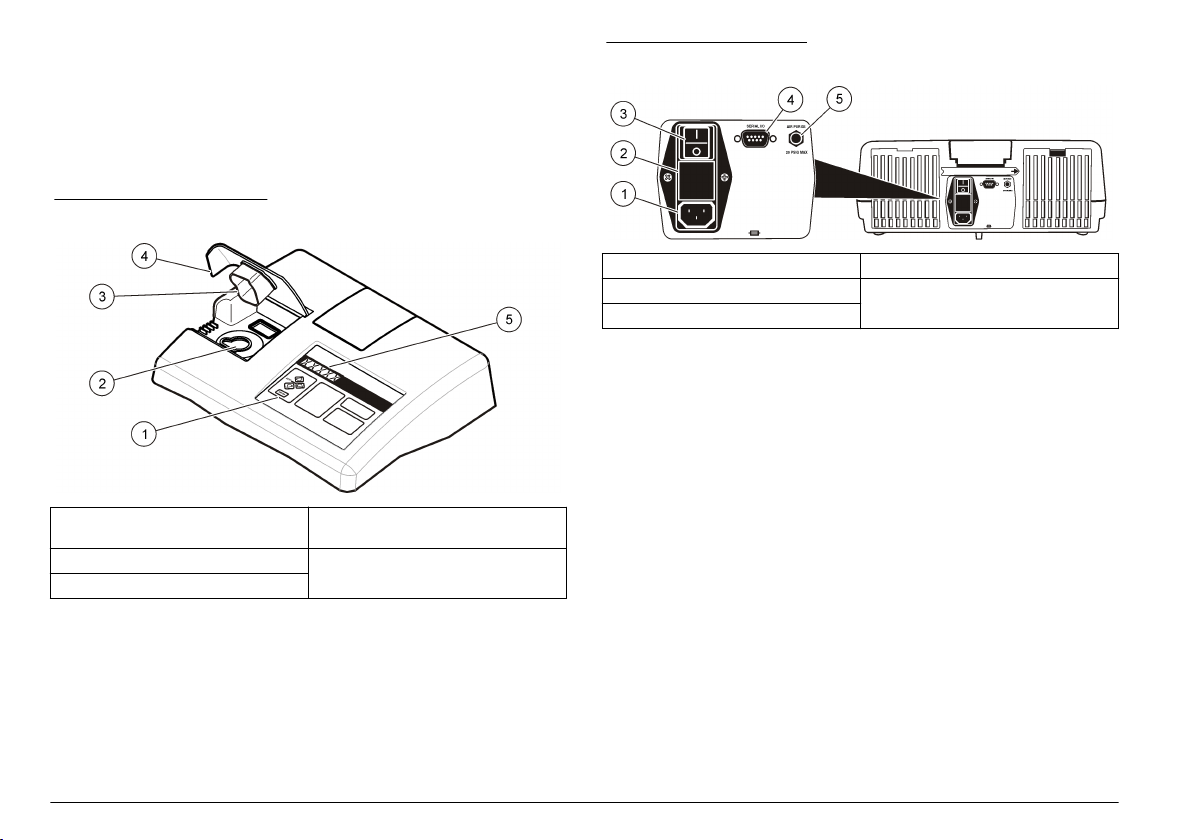

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol, if noted

on the instrument, will be included with a danger or caution statement in

the manual.

4

English

Page 5

This symbol, if noted on the instrument, references the instruction

manual for operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge

to the user.

Note: For return for recycling, please contact the equipment producer or supplier

for instructions on how to return end-of-life equipment, producer-supplied

electrical accessories, and all auxiliary items for proper disposal.

Certification

Canadian Radio Interference-Causing Equipment Regulation,

IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numèrique de la classe A respecte toutes les exigences du

Rëglement sur le matériel brouilleur du Canada.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device

complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications to this equipment not expressly approved by

the party responsible for compliance could void the user's authority to

operate the equipment. This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

Product overview

The 2100N IS laboratory turbidimeter measures turbidity in FNU

(Formazin nephelometric units) and NTU (nephelometric turbidity units).

NTUs are calculated using the conversion factors of 1.0 NTU per

1.0 FNU.

The turbidimeter has an RS232 output for connection to a printer, data

logger or computer.

English 5

Page 6

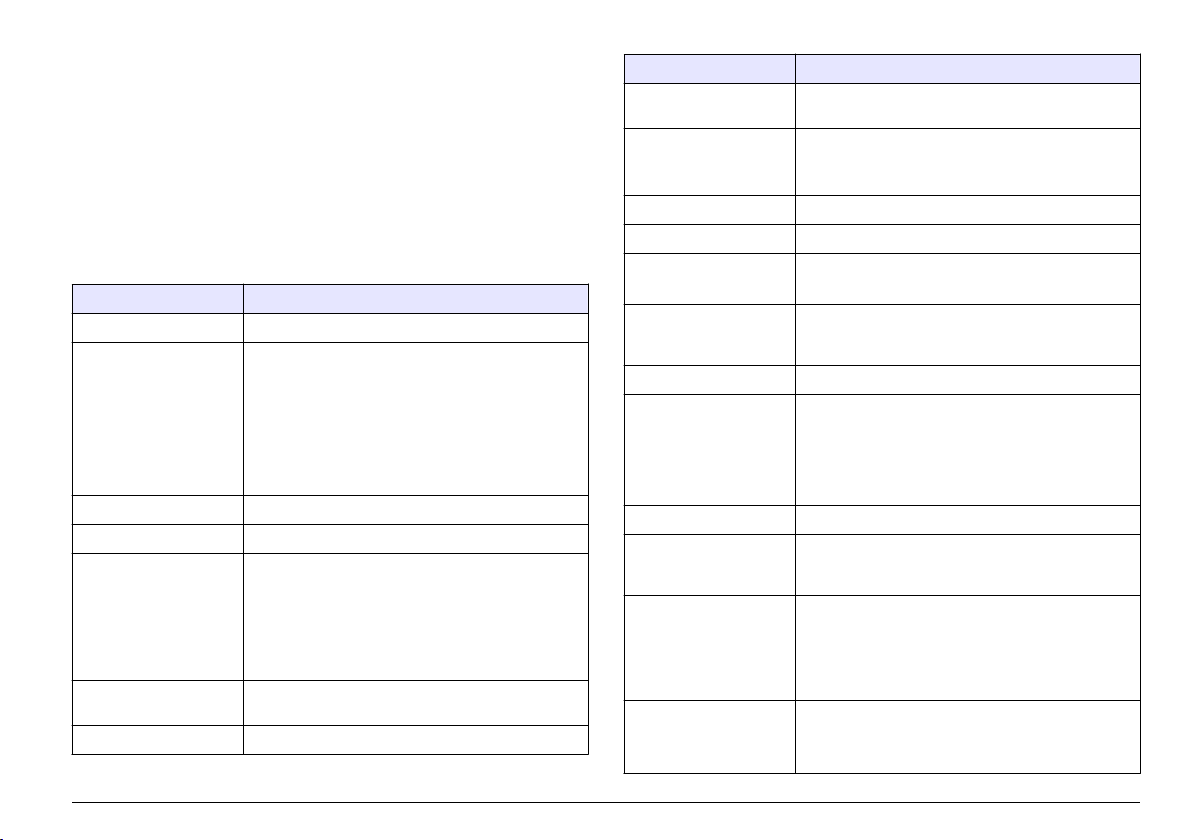

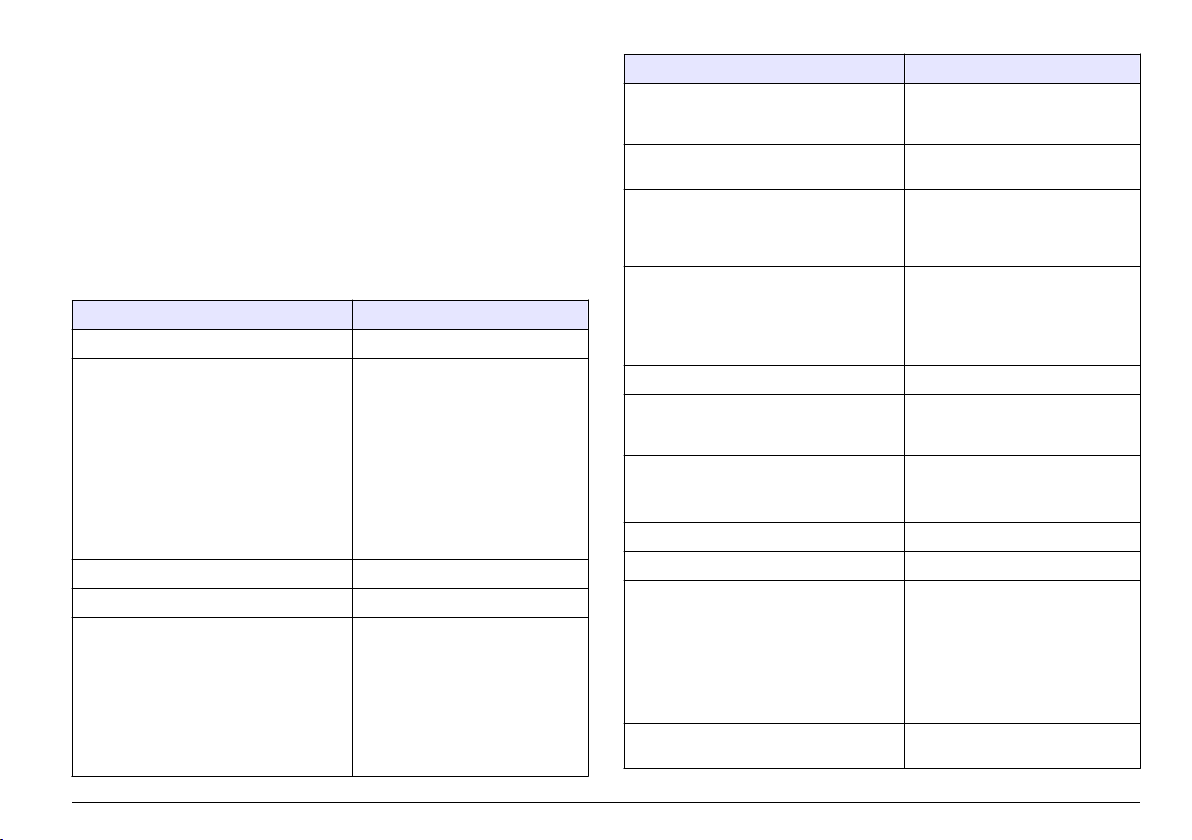

Figure 1 Front overview

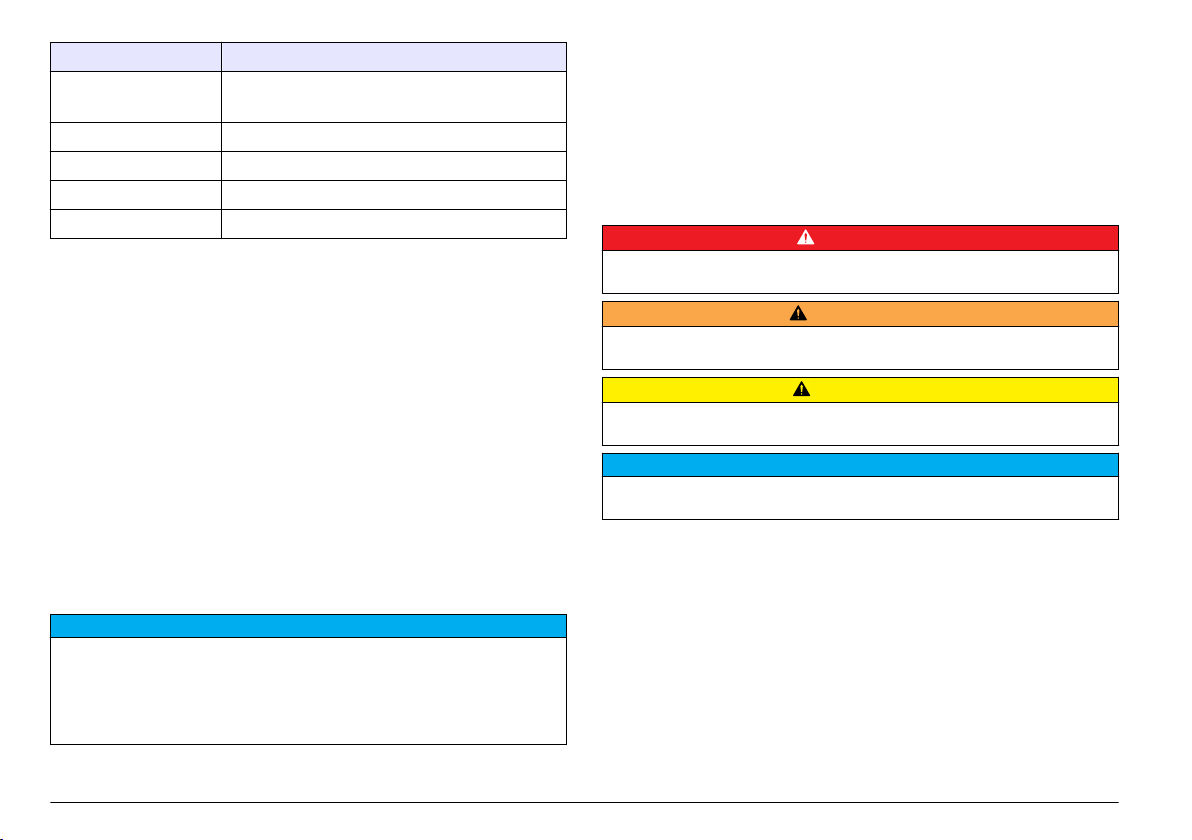

Product components

Refer to Figure 3 to make sure that all components have been received.

If any of these items are missing or damaged, contact the manufacturer

or a sales representative immediately.

Figure 3 Instrument components

1 Keypad 4 Cover for the sample cell

2 Sample cell holder 5 Five-digit LED display

3 Light shield

compartment

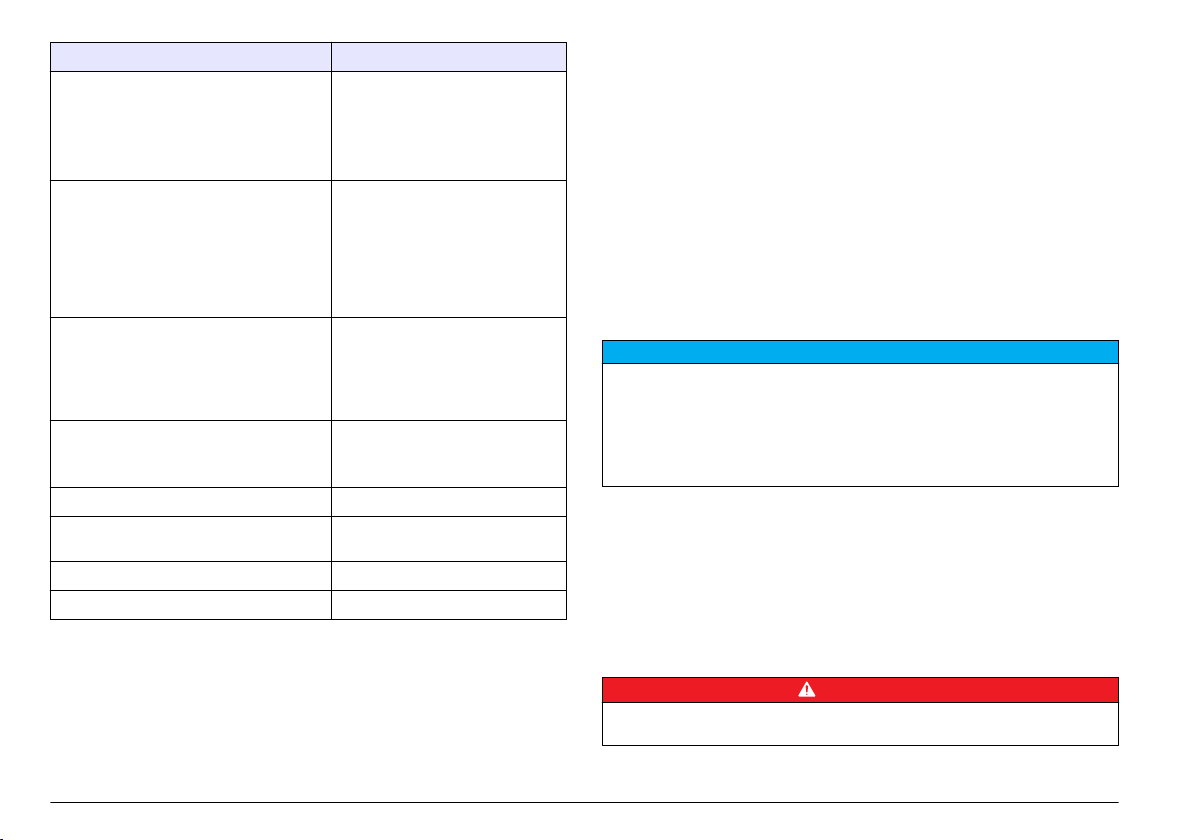

Figure 2 Back overview

1 Power cord connector 4 DB9 connector for RS232 cable

2 Fuse holder 5 Air purge fitting

3 Power switch

6

English

1 2100N IS turbidimeter 5 StablCal® Calibration kit

2 Oiling cloth 6 Gelex® secondary turbidity

3 Six 1" sample cells (30 mL) with

caps

4 Silicone oil 8 Power cord

1

Supplied with 4790000 only.

standardization kit

7 Dust cover

1

Page 7

User interface

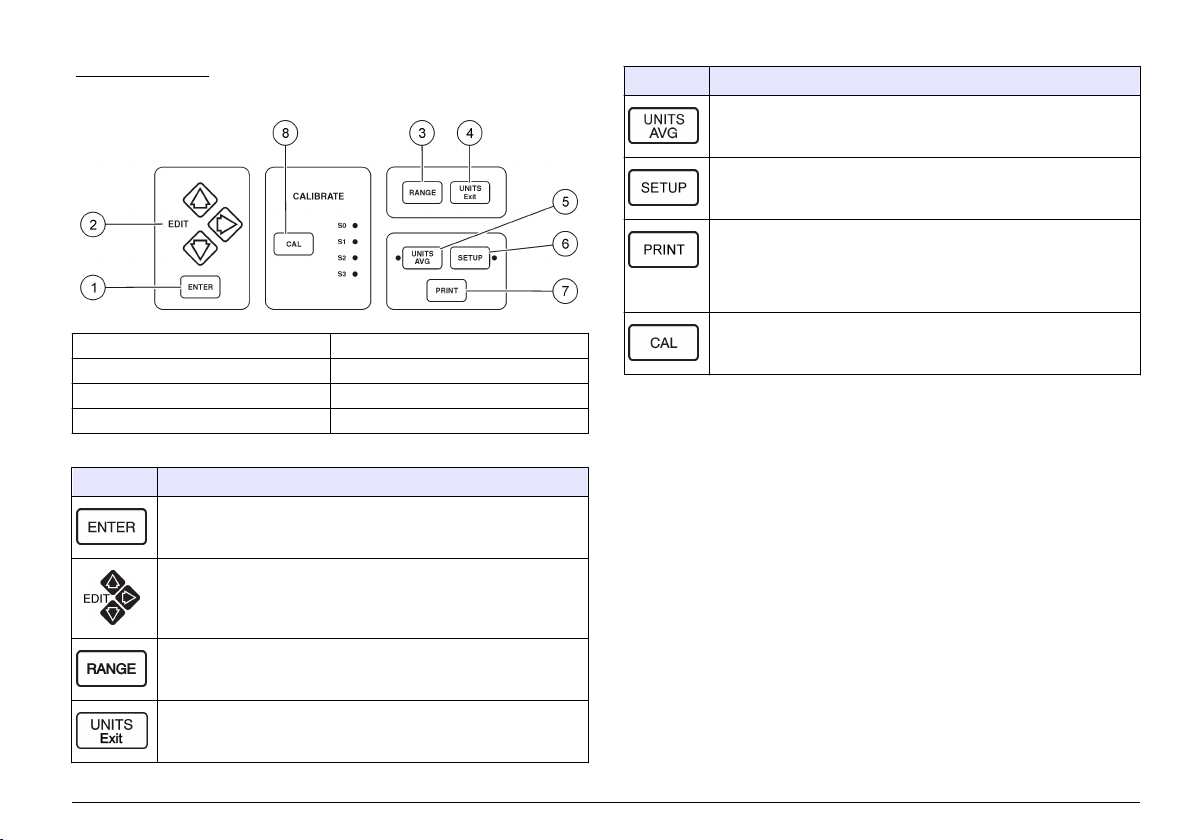

Figure 4 Keypad

1 ENTER key 5 UNITS AVG key key

2 EDIT (arrow) keys 6 SETUP key

3 RANGE key 7 PRINT key

4 UNITS/Exit key 8 CAL key

Table 1 Key descriptions

Key Description

Enters the value on the display. Starts the measurement of a

calibration standard. Clears data from the buffer.

Changes the numbers and/or letters on the display. Steps through

the calibration standards. The right arrow key moves the cursor to

the previous or next digit.

Table 1 Key descriptions (continued)

Key Description

Turns signal averaging on or off.

Turns on Setup mode and starts the selection of the setup number.

Sends the data that is on the display to a printer or computer.

Sends a calibration data report to a printer or computer when in

Calibration mode. Sends diagnostic results to a printer or computer

if held down when the instrument is turned on. Provides a print of

the setup commands when in Setup mode.

Starts or completes a calibration.

Selects automatic or manual ranging.

Selects the unit of measure. Exits Calibration or Setup mode

without saving changes.

English 7

Page 8

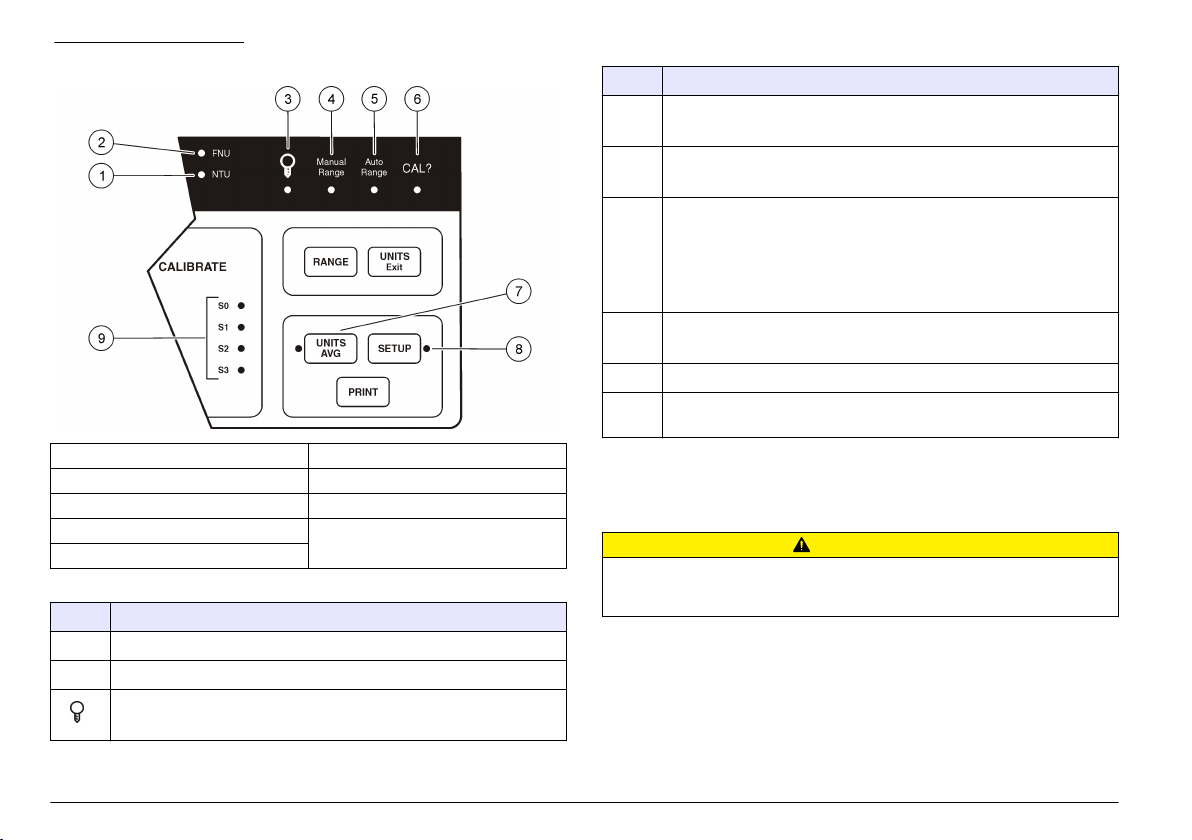

Figure 5 Indicator lights

1 NTU light 6 CAL? light

2 FNU light 7 UNITS AVG light

3 Lamp light 8 SETUP light

4 Manual Range light 9 S0–S3 lights

5 Auto Range light

Table 2 Light descriptions

Light Description

NTU Illuminated when the instrument is set for NTU unit of measure.

FNU Illuminated when the instrument is set for FNU unit of measure.

Illuminated when the instrument light source is on.

Flashes when there is not sufficient light for measurement.

Table 2 Light descriptions (continued)

Light Description

Manual

Illuminated when the instrument is in manual ranging mode.

Range

Auto

Illuminated when the instrument is in auto ranging mode.

Range

CAL? Turns on during a calibration if the calibration data is not within the

acceptable range.

Flashes when the instrument should be calibrated.

Note: The CAL? light applies when a 25-mm sample cell is used. Ignore the CAL?

light if illuminated during calibration when a smaller sample cell is used. Push

UNITS/Exit to start measurements.

UNITS

Illuminated when signal averaging is on.

AVG

SETUP Illuminated when Setup mode is selected.

S0–S3 Show the current calibration point standard that is in use during

calibration.

Startup

Turn the instrument on

C A U T I O N

Infrared Light Hazard. The infrared light produced by this instrument can cause

eye injury. The infrared light source in this instrument only receives power when

the sample cell cover is closed.

1. Put the instrument on a stable, level surface that is free of vibration.

Do not put in direct sunlight.

2. Make sure that there is air circulation around the instrument. Keep

the back and area below the instrument free of material that could

decrease air flow through the vents.

3. Connect the power cord to the power plug on the back of the

instrument.

8

English

Page 9

4. Connect the power cord to a power socket with ground contact.

5. Push the power switch on the back of the instrument to turn the

instrument on.

Turn the keypad sound off (optional)

By default, the instrument makes an audible sound when a key is

pushed. To turn the keypad sound off:

1. Push SETUP. The SETUP light turns on.

2. Use the arrow keys to select 00.

3. Push ENTER.

4. Use the arrow keys to select the sound option:

Option Description

BP An audible sound is made when a key is pushed.

BP OF No sound is made when a key is pushed.

5. Push ENTER.

6. Push SETUP.

Standard operation

Calibrate the turbidimeter with StablCal® Standards

Calibrate the turbidimeter before it is used for the first time using the

StablCal® sealed vial standards provided. As an alternative, calibration

can be done with recently prepared formazin standards.

Calibrate the turbidimeter at least every 3 months or as specified by the

regulating authority when data is used for ISO 7027 reporting.

Note: Unknown results may occur if standards other than the recommended

calibration points are used. The recommended calibration points (< 0.1, 20,

200 and 1000 NTU) provide the best calibration accuracy. Use of standards other

than StablCal, or user-prepared formazin, may result in less accurate calibrations.

The manufacturer cannot guarantee the performance of the instrument if calibrated

with co-polymer styrenedivinylbenzene beads or other suspensions.

Prepare the StablCal standards

When received and at intervals:

1. Clean the exterior surface of the StablCal vials with laboratory glass

cleaning detergent.

2. Rinse the vials with distilled or deionized water.

3. Dry the vials with a lint-free cloth.

Note: Never shake or invert the < 0.1 NTU standard. If the standard has been

mixed or shaken, do not move the vial for 15 minutes or more before using.

Note: Do not remove the caps from the sealed vials.

Make sure that the StablCal standards are at ambient instrument

temperature before use (and no greater than 40 °C (104 °F)).

Mix the standards before use:

1. Open the case lid. Remove the < 0.1 NTU standard from the plastic

case.

2. Leave the other standards in the case. Close the case lid.

3. Shake the case vigorously for at least 10 seconds.

4. Let the standards stand with no movement for 3–5 minutes before

use.

Calibration notes

• Make sure that the instrument is in the same ambient conditions as

where it is used.

• Make sure that the standards are at the same ambient temperature as

the instrument before use.

• Use only the provided silicone oil. This silicone oil has the same

refractive index as the vial glass and masks minor glass differences

and scratches.

• Store the oiling cloth in a plastic storage bag to keep the cloth clean.

• If power is lost during calibration, the new calibration data is lost and

the last calibration data is used. To exit a calibration and not save the

new values, push UNITS/Exit.

• In Calibration mode, automatic range and signal averaging on are

selected. When calibration is completed, all operational modes go

back to the last settings.

English

9

Page 10

• All nephelometric (turbidity units of measure) calibrations are done at

the same time.

• The 4000-NTU standard does not have to be measured during

calibration if FNUs will be measured. Push CAL after the 1000 NTU

standard is measured to complete the calibration procedure.

StablCal calibration procedure

• The FNU values of StablCal standards and formazin standards are

calculated using the conversion factors of 1 FNU = 1 NTU.

1. Push CAL.

The S0 light turns on.

The NTU value of the

dilution water used in

the last calibration is

shown on the display.

10 English

2. Get the < 0.1 NTU

vial. Clean the vial with

a soft, lint-free cloth to

remove water spots and

fingerprints. Do not

invert the vial.

3. Apply a small bead

of silicone oil from the

top to the bottom of the

vial.

4. Use the oiling cloth

to apply the oil equally

to the surface of the

vial. Remove the

excess oil. Make sure

that the vial is almost

dry.

5. Put the vial in the

sample cell holder with

the triangle on the vial

aligned with the

reference mark on the

sample cell holder.

Close the cover.

6. Push ENTER.

The instrument display

counts down, then

measures the standard.

The next expected

standard (e.g., 20.00) is

shown. The S1 light

turns on.

Page 11

7. Remove the vial

from the sample cell

holder.

8. Do steps 5–10 for

the other StablCal vials

(from lowest to highest

NTU standard).

The S0 light turns on

after the last vial is

measured.

9. Push CAL.

The instrument saves

the new calibration data

and goes back to

Measurement mode.

StablCal standards storage

• Do not move a StablCal standard to a different container for storage.

Keep StablCal standards in the plastic case provided with the cover

closed.

• Store at 5 to 25 °C (41 to 77 °F).

• For long-term storage (more than one month between use), keep at

5 °C (41 °F).

Turbidity measurement

W A R N I N G

Potential explosion and fire hazard. This instrument is for measuring water based

samples. Do not measure solvent or combustible based samples.

For accurate turbidity readings use clean sample cells and remove air

bubbles.

Measurement notes

Proper measurement techniques are important in minimizing the effects

of instrument variation, stray light and air bubbles. For accurate and

repeatable measurements:

Instrument

• Make sure that the instrument is on a level, stationary surface that is

free of vibration during the measurement.

• Instrument stabilization is immediate. No warm-up time is necessary.

• Always close the sample compartment lid during measurement,

calibration and storage.

• Remove the sample cell from the instrument and turn off the

instrument if the instrument is stored for an extended time period

(more than a month).

• Keep the sample compartment lid closed to keep dust and dirt out.

Sample cells

• Always cap the sample cell to prevent spillage of the sample into the

instrument.

• Always use clean sample cells in good condition. Dirty, scratched or

damaged cells can result in readings that are not accurate.

• Make sure that cold samples do not “fog” the sample cell.

• Store sample cells filled with distilled or deionized water and cap

tightly.

English 11

Page 12

• For the best accuracy, use a single sample cell for every

measurement or a flow cell.

Note: As an alternative, matched sample cells may be used for measurements but

do not provide as good of accuracy or precision as a single indexed sample cell or

flow cell. When using matched sample cells, align the orientation mark on the

sample cell with the reference mark on the sample cell holder.

Measurement

Turbidity measurement procedure

• Measure samples immediately to prevent temperature changes and

settling. Before a measurement is taken, always make sure that the

sample is homogeneous throughout.

• Avoid sample dilution when possible.

• Avoid instrument operation in direct sunlight.

1. Rinse a clean,

empty sample cell two

times with the solution

to be measured and

drain to waste. Fill to

the line (about 30 mL)

with sample and

immediately put the cap

on the sample cell.

12 English

2. Clean the sample

cells with a soft, lint-free

cloth to remove water

spots and fingerprints.

3. Apply a small bead

of silicone oil from the

top to the bottom of the

sample cells.

4. Use the oiling cloth

provided to apply the oil

equally to the surface of

the sample cells.

Remove the excess oil.

Make sure that the

sample cells are almost

dry.

5. Gently and slowly

invert the sample cell to

fully mix the sample. Be

careful not to add air

bubbles.

6. Put the sample cell

in the sample cell

holder with the triangle

on the sample cell

aligned with the

reference mark on the

sample cell holder.

Close the cover.

Page 13

7. Read and record the

value when stable.

Note: To send (via

RS232) a measurement

record, push PRINT.

Measurement techniques

Measurements may be made with different operation mode settings and

optional accessories.

Calibrate the instrument whenever the sample cell pathlength is

changed.

Manual or automatic ranging

The manufacturer recommends that ranging be set to automatic for most

measurements.

The setting can be changed at any time during sample measurement.

Push RANGE repeatedly to step the instrument from automatic ranging

to manual ranging and then scroll through the manual range settings.

The Manual Range light turns on when manual ranging is selected. The

Auto Range light turns on when automatic ranging is selected.

Notes:

• When manual ranging is selected, the display flashes all 9s when the

sample being measured is greater than the selected range. The

display flashes all 0s when the sample measured is less than the

selected range.

• When automatic ranging is selected, the display flashes 9s when the

sample is greater than the maximum range of the instrument.

• When automatic ranging is selected, the display flashes all 0s when

the measurement is less than the range of the instrument or a

negative value. Calibrate the instrument.

Signal averaging on or off

Signal averaging corrects for reading fluctuations that are caused by

random drifting particles in the sample. When signal averaging is on, an

average reading is calculated every 3 seconds and shown on the

display.The last ten measurements are used to calculate the average

reading.

The manufacturer recommends that signal averaging be on for most

measurements.

Push UNITS AVG to turn signal averaging on or off. The UNITS AVG

light turns on when signal averaging is on.

Push ENTER when signal averaging is on to erase data in the signal

averaging buffer and provide an immediate update on the display as

necessary. This is especially useful when measuring samples with large

differences in turbidity.

English 13

Page 14

Maintenance

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

Clean the instrument

Keep the instrument clean to get continuous and accurate operation.

N O T I C E

Never use cleaning agents such as turpentine, acetone or similar products to

clean the instrument including the keypad.

1. Turn the instrument off and disconnect the power cord.

2. Clean the surface of the instrument with a soft, moist cloth and a

weak soap solution.

3. Dry the surface of the instrument with a lint-free cloth.

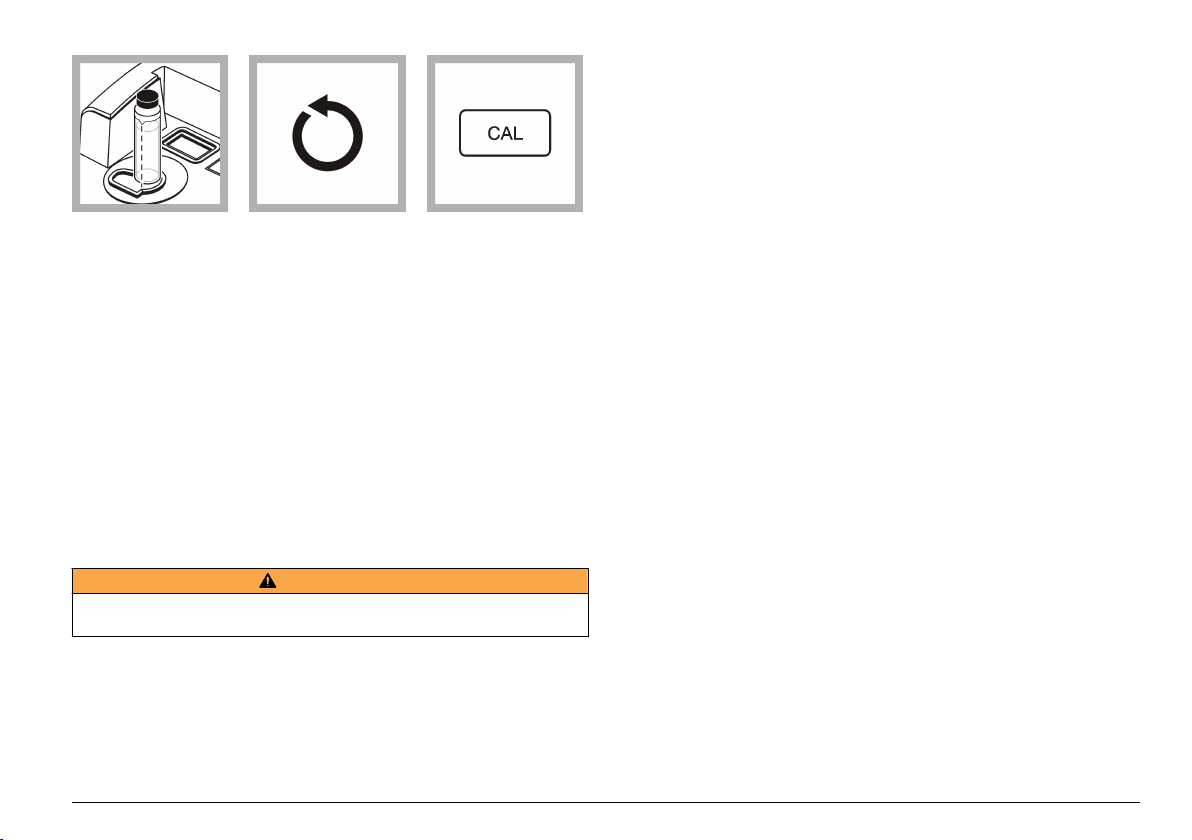

Replace the LED light source

The light source, light emitting diode (LED), is not user replaceable.

Contact Customer Service for LED replacement.

Replace a fuse

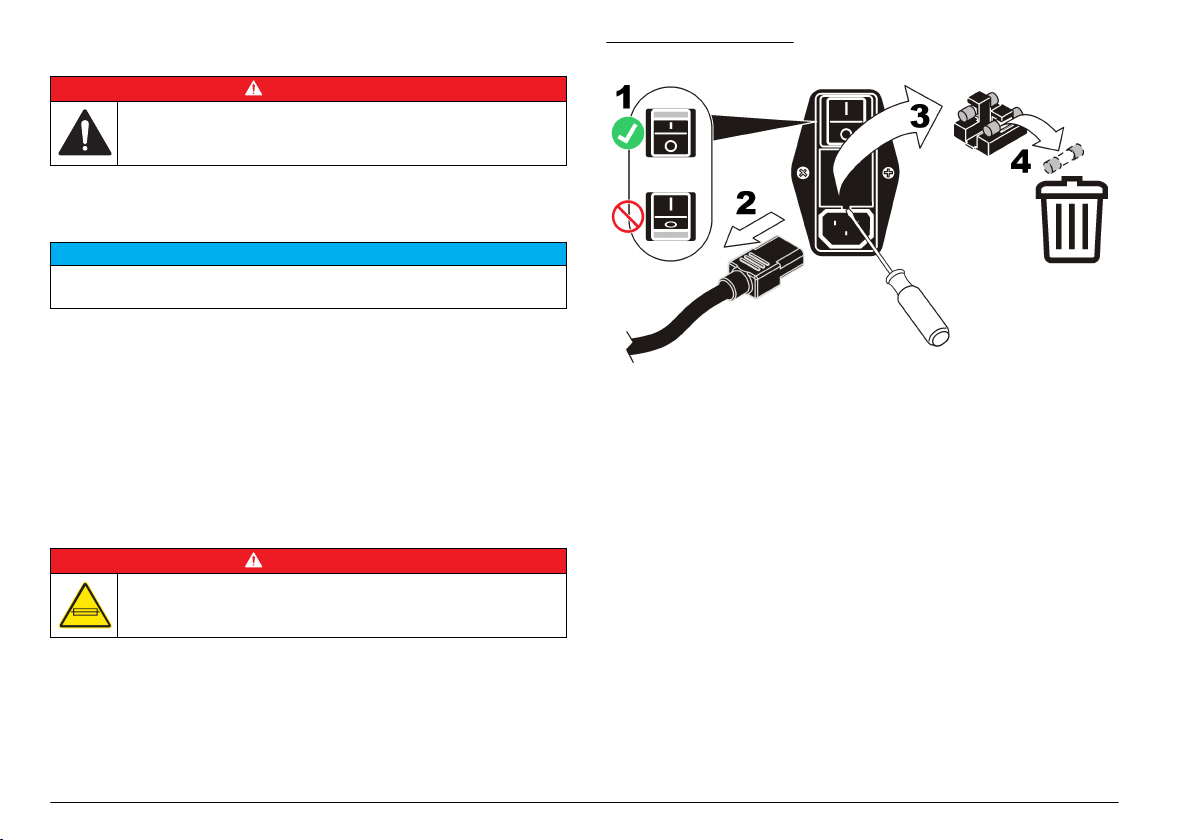

Fire hazard. Use the same type and current rating to replace fuses.

D A N G E R

Figure 6 Replace a fuse

Troubleshooting

Refer to the tables in this section for error codes, diagnostic codes,

common problem messages or symptoms, possible causes and

corrective actions.

Error codes

Table 3 lists the error codes shown for different conditions. Error codes

identify instrument malfunction or operator error.

The instrument continues operation in an error condition.

Push ENTER to clear an error code from the display.

Replacement parts:

• Fuse for 115 V operation, time-delay, 250 V, 1.6 A (3030700), or

• Fuse for 230 V operation, time-delay, 250 V, 1.6 A (3030600)

To replace a fuse, refer to the illustrated steps in Figure 6.

14

English

Page 15

Note: Any calibration being calculated when an error occurs, is discarded. The old

calibration is kept.

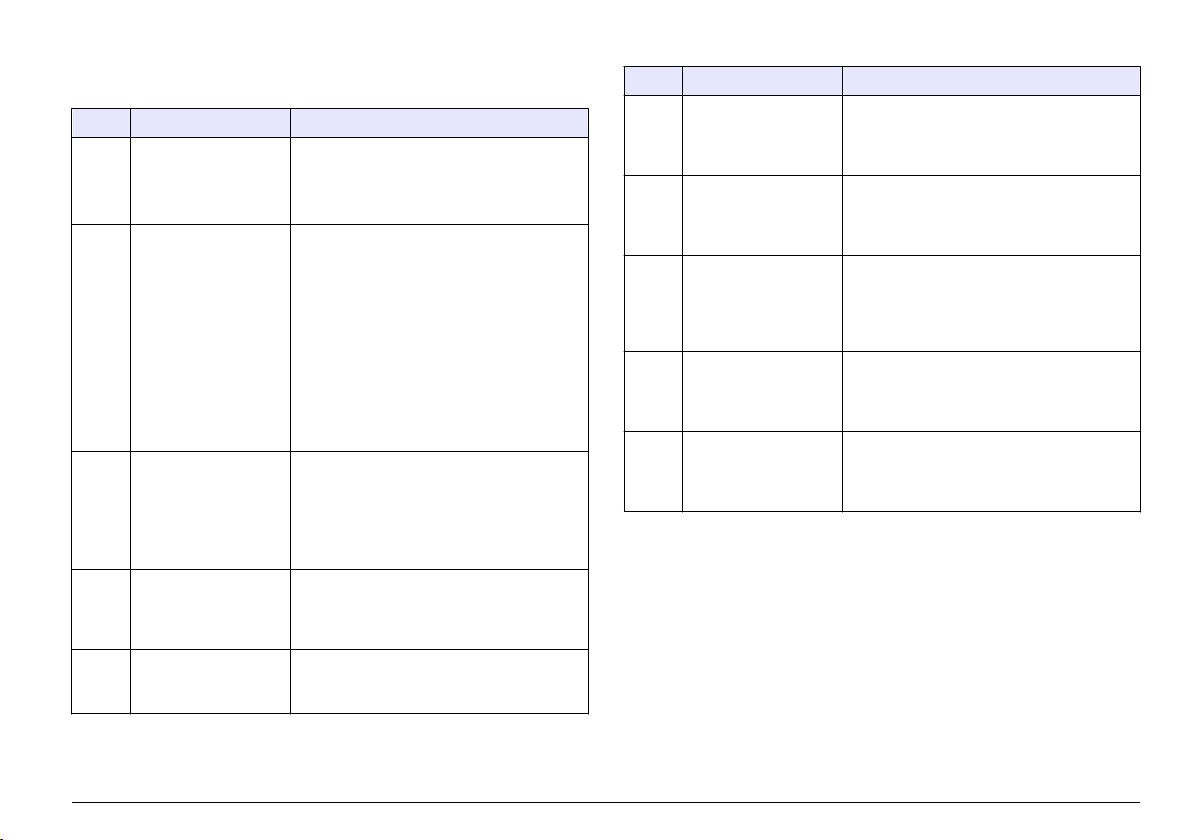

Table 3 Error codes

Error Description Solution

ERR01 The turbidity of the

dilution water is greater

than 0.5 NTU.

ERR02

• Two calibration

standards have the

same value.

• The difference

between two

calibration standards

is less than

60.0 NTU.

• The turbidity of

Standard 1 is too

low (less than

10 NTU).

ERR03 Low light error

ERR04 Memory malfunction

ERR05 A/D is over the range

Start the calibration again with lower turbidity

dilution water.

Note: Ignore ERR01 when the sample cell diameter

is less than 25 mm. Push UNITS/Exit to go back to

measurement mode.

1. Inspect the preparation of standards.

2. Do the calibration again.

Note: Ignore ERR02 when the sample cell diameter

is less than 25 mm. Push UNITS/Exit to go back to

measurement mode.

1. Put the sample in the instrument again.

2. Make sure that the lamp light is on.

3. Make sure that an object is not in the light

path.

4. Do sample dilution if necessary.

1. Turn the instrument off and then back on.

2. Contact Technical Support if the error

occurs again.

1. Make sure that the light shield is closed.

2. Contact Customer Service if necessary.

Table 3 Error codes (continued)

Error Description Solution

ERR06 A/D is under the range

ERR07 Light leak

ERR09 Printer time out error

ERR10 System voltage out of

range

ERR11 System loop test error

1. Make sure that no object is in the light

path.

2. Contact Customer Service if necessary.

1. Make sure that the cover for the sample

cell compartment is closed.

2. Turn the instrument off and then back on.

1. Make sure that the external printer is

connected correctly.

2. Make sure that the external printer is

selected (online).

1. Turn the instrument off and then back on.

2. Contact Customer Service if the error

occurs again.

1. Turn the instrument off and then back on.

2. Contact Customer Service if the error

occurs again.

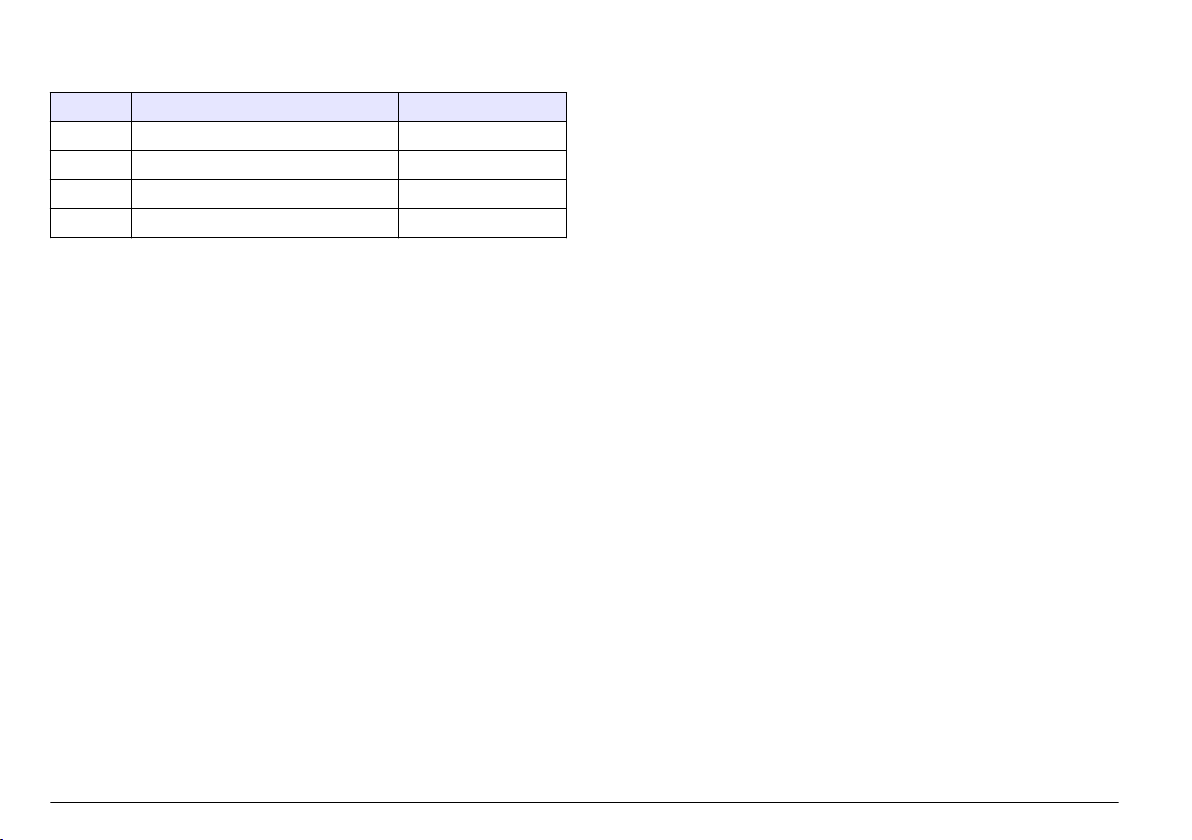

Diagnostic codes

Table 4 lists the diagnostic codes that are used to get information about

instrument operation when instrument operation is in doubt.

To do a diagnostic test:

1. Push SETUP.

2. Use the arrow keys to enter a diagnostic code.

3. Push ENTER to show the diagnostic value.

4. Push UNITS/Exit to go back to Measurement mode.

English

15

Page 16

Note: To print a diagnostic report, hold down PRINT, then turn the instrument on.

Table 4 Diagnostic codes

Code Display Description

21 Pr In Printer test

22 Test results are shown. Display test

23 Test results are shown. Keyboard test

24 Test results are shown. Memory test

Delete calibration data

To delete any calibration data entered by the user:

1. Turn off the instrument.

2. Push and hold CAL.

3. Turn on the instrument.

The CAL? light flashes. The instrument starts in Calibration mode.

4. Calibrate the instrument before use.

Flashing 9s

When manual ranging is selected, the display will flash all 9s when the

sample being measured is greater than the selected range.

When automatic ranging is selected, the display will flash 9s when the

sample is greater than the maximum range of the instrument.

Flashing 0s

When manual ranging is selected, the display will flash all 0s when the

sample measured is less than the selected range.

When automatic ranging is selected, the display will flash all 0s when the

measurement is less than the range of the instrument or a negative

value. Calibrate the instrument.

16

English

Page 17

Inhaltsverzeichnis

Technische Daten auf Seite 17 Standardbetrieb auf Seite 23

Allgemeine Informationen

auf Seite 18

Benutzeroberfläche auf Seite 21 Fehlerbehebung auf Seite 30

Inbetriebnahme auf Seite 23

Wartung auf Seite 29

Technische Daten

Änderungen vorbehalten.

Technische Daten Details

Messverfahren Nephelometrisch

Normen Erfüllt ISO 7027, DIN EN 27027,

Lichtquelle Leuchtdiode (LED) mit 860 ± 30 nm

Messmodi FNU und NTU

Messbereich FNU (manueller Messbereich): 0–

DIN 38404 und NFT 9033

ASTM D7315 –

Standardtestverfahren zur

Bestimmung der Trübung über

1 Trübungseinheit (TU) im

statischen Modus

ASTM D6655 –

Standardtestverfahren zur

Bestimmung der Trübung unter

5 NTU im statischen Modus

0.999, 0–9,99, 0–99,9, 0–1000

FNU (automatischer Messbereich):

0–1000

NTU (manueller Messbereich): 0–

0.999, 0–9,99, 0–99,9, 0–1000

NTU (automatischer Messbereich):

0–1000

Technische Daten Details

Genauigkeit1,

Auflösung Trübung: 0,001 FNU/NTU (auf

Wiederholgenauigkeit ±1 % des Ergebnisses oder

Ansprechzeit Signalmittelung aus: 6,8 Sekunden

Ansprechzeit Sofort

Messmodi Manueller oder automatischer

Spannungsversorgung 115–230 VAC, 50/60 Hz

Verschmutzungsgrad/Installationskategorie 2; II

Schutzklasse 1

Betriebsbedingungen Temperatur: 0 bis 40°C (32 bis

Lagerbedingungen – 40 bis 60 °C (– 40 bis 140 °F),

2

±2 % des Ergebnisses plus

0,01 FNU/NTU von 0–

1000 FNU/NTU

niedrigstem Bereich)

0,01 FNU, je nachdem welcher

Wert größer ist (unter

Referenzbedingungen)

Signalmittelung ein: 14 Sekunden

(wenn 10 Messungen zum

Berechnen des Durchschnitts

verwendet werden)

Messbereich, Signalmittelung ein

oder aus

(automatische Stromauswahl)

28 W Maximum

104°F)

Relative Feuchte: 0–90% bei 25 °C,

0–75 % bei 40 °C, nichtkondensierend

Höhe: maximal 2000 m (6560 ft)

Nur im Innenbereich

nur Gerät

Deutsch 17

Page 18

Technische Daten Details

Schnittstelle Serielle RS232C-Schnittstelle über

Luftspülung Trockener Stickstoff oder

Küvetten Rundküvetten 95 x 25 mm (3,74 x

Probenanvolumen 25-mm-Probenküvetten:

Gehäuse Schlagfestes Polycarbonat

Abmessungen 30,5 x 40 x 15,6 cm (12,0 x 15,7 x

Gewicht 3,8 kg (8,5 lb)

Zertifizierung CE, cETLus

1

Trübungsspezifikationen, die mit kürzlich vorbereitetem Formazinstandard

und abgeglichenen 1-Zoll-Probenküvetten identifiziert werden.

2

Zeitweilige elektromagnetische Strahlung von 3 Volt/Meter oder höher können

zu leichten Verschiebungen der Genauigkeit führen.

DB9-Subminiatur-D-ShellAnschluss für Datenausgang an

Computer oder Drucker und

Dateneingang (Befehl). Kein

Handshaking.

Instrumentenluft (ANSI MC 11.1,

1975)

0,1 scfm bei 69 kPa (10 psig);

maximal 138 kPa (20 psig)

Schlauchanschluss für 1/8-Zoll-

Schläuche

1 Zoll) Borosilikatglas mit

gummierten Schraubkappen

Hinweis: Kleinere Probenküvetten

(kleiner als 25 mm) können mit einem

Küvettenadapter verwendet werden.

mindestens 20 ml

0 bis 95 °C (32 bis 203 °F)

6,1 Zoll)

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte,

versehentliche oder Folgeschäden, die aus Fehlern oder

Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält

sich jederzeit und ohne vorherige Ankündigung oder Verpflichtung das

Recht auf Verbesserungen an diesem Handbuch und den hierin

beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedienungsanleitung sind auf der Hersteller-Webseite erhältlich.

Erweiterte Version des Handbuchs

Zusätzliche Informationen finden Sie in der erweiterten Version dieses

Handbuchs auf der CD.

Sicherheitshinweise

H I N W E I S

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung

oder Missbrauch dieses Produkts entstehen, einschließlich, aber ohne

Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür

verantwortlich, schwerwiegende Anwendungsrisiken zu erkennen und

erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von möglichen

Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät

auspacken, aufstellen oder bedienen. Beachten Sie alle Gefahren- und

Warnhinweise. Nichtbeachtung kann zu schweren Verletzungen des

Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte

Sicherheit nicht beeinträchtigt wird. Verwenden bzw. installieren Sie das

Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie

nicht vermieden wird, zum Tod oder zu schweren Verletzungen führt.

G E F A H R

18 Deutsch

Page 19

W A R N H I N W E I S

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie

nicht vermieden wird, zum Tod oder zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder

moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät

beschädigen kann. Informationen, die besonders beachtet werden müssen.

V O R S I C H T

H I N W E I S

Warnkennzeichen

Lesen Sie alle Aufkleber und Hinweisschilder, die am Gerät angebracht

sind. Nichtbeachtung kann Verletzungen oder Beschädigungen des

Geräts zur Folge haben. Für jedes auf dem Gerät angegebene Symbol

ist ein Gefahren- oder Vorsichtshinweis in der Anleitung vorhanden.

Dieses Symbol am Gerät weist auf Betriebs- und/oder

Sicherheitsinformationen im Handbuch hin.

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen ab

12. August 2005 nicht in öffentlichen europäischen Abfallsystemen

entsorgt werden. Benutzer von Elektrogeräten müssen in Europa in

Einklang mit lokalen und nationalen europäischen Regelungen (EURichtlinie 2002/96/EG) Altgeräte kostenfrei dem Hersteller zur

Entsorgung zurückgeben.

Hinweis: Mit der Wiederverwertung, der stofflichen Verwertung oder anderen

Formen der Verwertung von Altgeräten leisten Sie einen wichtigen Beitrag zum

Schutz unserer Umwelt.

Zertifizierung

Kanadische Vorschriften zu Störungen verursachenden

Einrichtungen, IECS-003, Klasse A:

Entsprechende Prüfprotokolle hält der Hersteller bereit.

Dieses digitale Gerät der Klasse A erfüllt alle Vorgaben der kanadischen

Normen für Interferenz verursachende Geräte.

Cet appareil numérique de la classe A respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

FCC Teil 15, Beschränkungen der Klasse "A"

Entsprechende Prüfprotokolle hält der Hersteller bereit. Das Gerät

entspricht Teil 15 der FCC-Vorschriften. Der Betrieb unterliegt den

folgenden Bedingungen:

1. Das Gerät darf keine Störungen verursachen.

2. Das Gerät muss jegliche Störung, die es erhält, einschließlich jener

Störungen, die zu unerwünschtem Betrieb führen, annehmen.

Änderungen oder Modifizierungen an diesem Gerät, die nicht

ausdrücklich durch die für die Einhaltung der Standards verantwortliche

Stelle bestätigt wurden, können zur Aufhebung der

Nutzungsberechtigung für dieses Gerät führen. Dieses Gerät wurde

geprüft, und es wurde festgestellt, dass es die Grenzwerte für digitale

Geräte der Klasse A entsprechend Teil 15 der FCC-Vorschriften einhält.

Diese Grenzwerte sollen einen angemessenen Schutz gegen

gesundheitsschädliche Störungen gewährleisten, wenn dieses Gerät in

einer gewerblichen Umgebung betrieben wird. Dieses Gerät erzeugt und

nutzt hochfrequente Energie und kann diese auch abstrahlen, und es

kann, wenn es nicht in Übereinstimmung mit der Bedienungsanleitung

installiert und eingesetzt wird, schädliche Störungen der

Funkkommunikation verursachen. Der Betrieb dieses Geräts in

Wohngebieten kann schädliche Störungen verursachen. In diesem Fall

muss der Benutzer die Störungen auf eigene Kosten beseitigen.

Probleme mit Interferenzen lassen sich durch folgende Methoden

mindern:

1. Trennen Sie das Gerät von der Stromversorgung, um

sicherzugehen, dass dieser die Störungen nicht selbst verursacht.

2. Wenn das Gerät an die gleiche Steckdose angeschlossen ist wie das

gestörte Gerät, schließen Sie das störende Gerät an eine andere

Steckdose an.

3. Vergrößern Sie den Abstand zwischen diesem Gerät und dem

gestörten Gerät.

4. Ändern Sie die Position der Empfangsantenne des gestörten Geräts.

5. Versuchen Sie auch, die beschriebenen Maßnahmen miteinander zu

kombinieren.

Deutsch

19

Page 20

Produktübersicht

Das 2100N IS-Labor-Trübungsmessgerät misst Trübung in FNU

(Formazin Nephelometric Units) und NTU (Nephelometric Turbidity

Units). NTUs werden mit den Umrechnungsfaktors 1,0 NTU pro 1,0 FNU

berechnet.

Das Trübungsmessgerät hat einen RS232-Ausgang zum Anschluss an

einen Drucker, Daten-Logger oder Computer.

Abbildung 1 Vorderansicht

Abbildung 2 Rückansicht

1 Netzkabelanschluss 4 DB9-Anschluss für RS232-Kabel

2 Sicherungshalterung 5 Druckluftreinigungsanschluss

3 Netzschalter

Produktkomponenten

Vergewissern Sie sich anhand von Abbildung 3, dass alle Teile geliefert

wurden. Sollte eines der aufgelisteten Teile fehlen oder defekt sein,

wenden Sie sich bitte sofort an den Hersteller oder die zuständige

Vertretung.

1 Tastatur 4 Abdeckung für den

2 Küvettenschacht 5 LED-Display mit fünf Ziffern

3 Lichtschutz

Küvettenschacht

20 Deutsch

Page 21

Abbildung 3 Gerätekomponenten

1 2100N IS Trübungsmessgerät 5 StablCal® Kalibriersatz

2 Öltuch 6 Gelex®-Sekundärstandard-Kit für

3 Sechs 1 Zoll Probenküvetten

(30 ml) mit Abdeckungen

4 Silikonöl 8 Netzkabel

1

Nur im Lieferumfang des 4790000 enthalten.

7 Staubschutzhaube

Trübung

1

Benutzeroberfläche

Abbildung 4 Tastatur

1 ENTER-Taste 5 UNITS AVG-Taste

2 EDIT- (Pfeil-)Tasten 6 SETUP-Taste

3 RANGE-Taste 7 PRINT-Taste

4 UNITS/Exit-Taste 8 CAL-Taste

Tabelle 1 Tastenbeschreibungen

Taste Beschreibung

Gibt den Wert auf dem Display ein. Beginnt die Messung eines

Kalibrierstandards. Löscht Daten aus dem Puffer.

Ändert die Zahlen und/oder Buchstaben auf dem Display.

Durchläuft die Kalibrierstandards. Mit der rechten Pfeiltaste wird

der Cursor zur vorherigen oder nächsten Stelle bewegt.

Auswählen des automatischen oder manuellen Messbereichs.

Auswählen der Messeinheit. Beenden der Kalibrierung oder des

Setup-Modus ohne Speichern der Änderungen.

Deutsch 21

Page 22

Tabelle 1 Tastenbeschreibungen (fortgesetzt)

Taste Beschreibung

Ein- oder Ausschalten der Signalmittelung.

Aktiviert den Setup-Modus und beginnt die Auswahl der SetupNummer.

Sendet die Daten, die auf dem Display angezeigt werden, an einen

Drucker oder Computer. Sendet einen Kalibrierdatenbericht an

einen Drucker oder Computer, wenn im Kalibrierungsmodus.

Sendet Diagnoseergebnisse an einen Drucker oder Computer,

wenn die Taste gedrückt wird, während das Gerät eingeschaltet ist.

Stellt einen Ausdruck der Setup-Befehle im Setup-Modus bereit.

Kalibrierung starten oder beenden

Abbildung 5 Leuchten

1 NTU-Licht 6 CAL? Licht

2 FNU-Licht 7 UNITS AVG-Licht

3 Lampenlicht 8 SETUP-Licht

4 Licht für manuellen Bereich 9 S0–S3-Lichter

5 Licht für automatischen Bereich

Tabelle 2 Beschreibung der Displayleuchten

Leuchte Beschreibung

NTU Leuchtet, wenn das Gerät auf die NTU-Messeinheit eingestellt ist.

FNU Leuchtet, wenn das Gerät auf die FNU-Messeinheit eingestellt ist.

Leuchtet, wenn die Lichtquelle des Geräts eingeschaltet ist.

Blinkt, wenn nicht ausreichend Licht für die Messung vorhanden ist.

22 Deutsch

Page 23

Tabelle 2 Beschreibung der Displayleuchten (fortgesetzt)

Leuchte Beschreibung

Manual

Range

Range

UNITS

SETUP Leuchtet, wenn der Setup-Modus ausgewählt ist.

S0–S3 Zeigt den aktuellen Kalibrierungspunktstandard an, der während der

Leuchtet, wenn sich das Gerät im manuellen

Bereichsmessungsmodus befindet.

Auto

Leuchtet, wenn sich das Gerät im automatischen

Bereichsmessungsmodus befindet.

CAL? Wird wenn die Kalibrierdaten nicht innerhalb des zulässigen Bereichs

liegen.

Blinkt, wenn das Gerät kalibriert werden sollte.

Hinweis: Das CAL?-Licht leuchtet, wenn eine 25-mm-Probenküvette verwendet

wird. Ignorieren Sie das CAL?-Licht, wenn es während der Kalibrierung leuchtet,

wenn ein andere Probenküvette verwendet wird. Drücken Sie UNITS/Exit, um die

Messungen zu beginnen.

Leuchtet, wenn Signalmittelung eingeschaltet ist.

AVG

Kalibrierung verwendet wird.

Inbetriebnahme

3. Schließen Sie das Stromkabel an den Stromversorgungsanschluss

an der Geräterückseite an.

4. Schließen Sie das Stromkabel an einer Steckdose mit Massekontakt

an.

5. Drücken Sie auf den Netzschalter auf der Geräterückseite, um das

Gerät einzuschalten.

Ausschalten des Tastentons (optional)

Standardmäßig erzeugt das Gerät einen hörbaren Ton, wenn eine Taste

gedrückt wird. So schalten Sie den Tastenton aus:

1. Drücken Sie SETUP. Das SETUP-Licht leuchtet.

2. Verwenden Sie die Pfeiltasten, um 00 auszuwählen.

3. Drücken Sie ENTER.

4. Verwenden Sie die Pfeiltasten, um die Tonoption zu wählen:

Optionen Beschreibung

BP Beim Drücken einer Taste wird ein hörbarer Ton erzeugt.

BP OF Beim Drücken einer Taste wird kein hörbarer Ton erzeugt.

5. Drücken Sie ENTER.

6. Drücken Sie SETUP.

Einschalten des Geräts

V O R S I C H T

Gefahr durch Infrarotlicht. Das vom Gerät erzeugte Infrarotlicht kann Schäden am

Auge verursachen. An der Infrarotlichtquelle in diesem Gerät liegt nur dann

Strom an, wenn die Abdeckung der Probenküvette geschlossen ist.

1. Stellen Sie das Gerät auf eine stabile, ebene Fläche, die nicht

vibriert. Setzen Sie es nicht direkter Sonneneinstrahlung aus.

2. Vergewissern Sie sich, dass die Luft um das Gerät zirkulieren kann.

Halten Sie von der Rückseite und dem Bereich unter dem Gerät

Material fern, das den Luftstrom durch die Lüftungen vermindern

kann.

Standardbetrieb

Kalibrieren des Trübungsmessgeräts mit StablCal®Standards

Kalibrieren Sie das Trübungsmessgerät vor der ersten Verwendung mit

den im Lieferumfang enthaltenen versiegelten Ampullenstandards.

Alternativ kann die Kalibrierung mit den selbst hergestellten

Formazinstandards durchgeführt werden.

Kalibrieren Sie das Trübungsmessgerät mindestens alle 3 Monate oder

entsprechend den Vorgaben der Aufsichtsbehörde, wenn die Daten für

entsprechende-Berichte verwendet werden.

Deutsch

23

Page 24

Hinweis: Es kann zu ungenaueren Ergebnissen kommen, wenn andere Standards

als die empfohlenen Kalibrierpunkte verwendet werden. Die empfohlenen

Kalibrierpunkte (< 0,1; 20; 200 und 1000 NTU) bieten die optimale

Kalibriergenauigkeit. Die Verwendung anderer Standards als StablCal oder

benutzerdefiniertes Formazin können zu ungenaueren Kalibrierungen führen. Der

Hersteller kann nicht garantieren, dass das Gerät bei einer Kalibrierung mit StyrolDivinylbenzol-Copolymer oder mit anderen Suspensionen optimale Leistung zeigt.

Vorbereiten der StablCal-Standards

Bei Inbetriebnahme und danach regelmäßig:

1. Reinigen Sie die Außenseite der StablCal-Ampullen mit einem

Reinigungsmittel für Laborglas.

2. Spülen Sie die Ampullen mit destilliertem oder entionisiertem

Wasser.

3. Trocken Sie die Ampullen mit einem fusselfreien Tuch.

Hinweis: Schütteln Sie den < 0,1-NTU-Standard nicht und schwenken Sie ihn

nicht um. Falls der Standard gemischt oder geschüttelt wurde, lassen Sie die

Ampulle vor der Verwendung mindestens 15 Minuten ruhen.

Hinweis: Entfernen Sie den Deckel der verschlossenen Ampullen nicht.

Vergewissern Sie sich, dass die StablCal-Standards vor der

Verwendung die Umgebungstemperatur des Geräts haben (und nicht

wärmer als 40 °C sind).

Mischen Sie die Standards vor der Verwendung:

1. Öffnen Sie den Deckel der blauen Kunststoffbox. Entnehmen Sie

den < 0,1-NTU-Standard.

2. Lassen Sie die anderen Standards in der Kunststoffbox. Schließen

Sie den Deckel.

3. Schütteln Sie die Box mindestens 10 Sekunden stark.

4. Lassen Sie die Standards vor der Verwendung 3–5 Minuten ruhen.

Kalibrierungshinweise

• Stellen Sie sicher, dass sich das Gerät in denselben

Umgebungsbedingungen befindet, in denen es genutzt wird.

• Stellen Sie vor der Verwendung sicher, dass die Standards dieselbe

Umgebungstemperatur haben wie das Gerät.

• Verwenden Sie ausschließlich das mitgelieferte Silikonöl. Dieses

Silikonöl hat denselben Brechungsindex wie das Ampullenglas und

maskiert kleinere Glasunterschiede und Kratzer.

• Bewahren Sie das Öltuch in einem Kunststoffbeutel auf, um es sauber

zu halten.

• Wenn während der Kalibrierung die Stromverbindung getrennt wird,

gehen die neuen Kalibrierdaten verloren und die letzten Kalibrierdaten

werden verwendet. Um eine Kalibrierung zu verlassen, ohne die

neuen Werte zu speichern, drücken Sie UNITS/Exit.

• Im Kalibrierungsmodus werden automatischer Messbereich und

Signalmittelung ausgewählt. Nachdem die Kalibrierung

abgeschlossen wurde, kehren alle Bedienungsmodi zu den letzten

Einstellungen zurück.

• Alle nephelometrischen Kalibrierungen (für Trübungseinheiten)

werden gleichzeitig durchgeführt.

• Der 4000-NTU-Standard muss während der Kalibrierung nicht

gemessen werden, wenn FNUs gemessen werden. Drücken Sie CAL,

nachdem der 1000-NTU-Standard gemessen wurde, um den

Kalibriervorgang abzuschließen.

• Die FNU-Werte der StablCal-Standards und Formazinstandards

werden mit den Umrechnungsfaktoren 1 FNU = 1 NTU berechnet.

24 Deutsch

Page 25

StablCal®-Kalibrierverfahren

1. Drücken Sie CAL.

Das S0-Licht leuchtet.

Der NTU-Wert des bei

der letzten Kalibrierung

verwendeten

Verdünnungswassers

wird auf dem Display

angezeigt.

2. Nehmen Sie die <

0,1-NTU-Ampulle.

Reinigen Sie die

Ampulle mit einem

weichen, fusselfreien

Tuch, um

Wasserflecken und

Fingerabdrücke zu

entfernen. Schwenken

Sie die Ampulle nicht

um.

3. Tragen Sie von der

Oberkante der Ampulle

zur Unterseite hin

wenig Silikonöl auf.

4. Verwenden Sie das

Kalibrierdatensätze, um

das Öl gleichmäßig auf

die Oberfläche der

Ampullen aufzutragen.

Entfernen Sie

überschüssiges Öl.

Stellen Sie sicher, dass

die Ampulle nahezu

trocken ist.

5. Setzen Sie die

Ampulle so in den

Küvettenschacht, dass

das Dreieck an der

Ampulle mit der

Referenzmarkierung

am Küvettenschacht

übereinstimmt.

Schließen Sie die

Abdeckung.

6. Drücken Sie

ENTER.

Auf dem Display des

Geräts wird ein

Countdown angezeigt,

dann wird der Standard

gemessen.

Der nächste akzeptierte

Standard (z. B. 20,00)

wird angezeigt. Das S1Licht leuchtet.

Deutsch 25

Page 26

7. Entnehmen Sie die

Ampulle aus dem

Küvettenschacht.

8. Führen Sie die

Schritte 5–10 für die

anderen StablCalAmpullen durch (vom

niedrigsten zum

höchsten NTUStandard).

Das S0-Licht leuchtet,

nachdem die letzte

Ampulle gemessen

wurde.

9. Drücken Sie CAL.

Das Gerät speichert die

neuen Kalibrierdaten

und kehrt zum

Messmodus zurück.

Lagerung der StablCal-Standards

• Lagern Sie die StablCal-Standards nur in dem dafür vorgesehenen

Behälter und die StablCal-Standards in der geschlossenen Box auf.

• Bei 5 bis 25 °C (41 to 77–°F) lagern.

• Bei langfristiger Lagerung (mehr als einen Monat zwischen der

Verwendung) bei 5 °C (41–°F) lagern.

Trübungsmessung

W A R N H I N W E I S

Explosions- und Feuergefahr. Dieses Gerät dient zur Messung wasserbasierter

Proben. Messen Sie damit keine Proben, die Lösemittel oder brennbare Stoffe

enthalten.

Verwenden Sie für genaue Trübungsmessungen ausschließlich saubere

Küvetten und entfernen Sie Luftblasen.

26 Deutsch

Hinweise zur Messung

Um die Einflüsse von gerätebedingten Streuungen, Streulicht und

Luftblasen zu minimieren, müssen immer die geeigneten Messverfahren

angewendet werden. Für genaue und wiederholbare Messungen:

Messgerät

• Vergewissern Sie sich, dass das Gerät auf einer ebenen, festen

Fläche steht, die während der Messung nicht vibriert.

• Das Gerät stabilisiert sich sofort. Es ist keine Aufwärmzeit erforderlich.

• Halten Sie den Messschacht-Deckel während Messung, Kalibrierung

und Lagerung immer geschlossen.

• Entnehmen Sie Probenküvetten aus dem Gerät und schalten Sie es

aus, wenn Sie das Gerät über einen längeren Zeitraum (mehr als

einen Monat) nicht benötigen.

• Schließen Sie das Probenfach, damit kein Staub oder Schmutz

eindringt.

Küvetten

Page 27

• Schrauben Sie immer die Kappen auf die Küvetten auf, um Austreten

der Probe in das Gerät zu verhindern.

• Verwenden Sie nur saubere Küvetten, die sich in einem guten

Zustand befinden. Schmutzige, zerkratzte oder beschädigte Küvetten

können zu fehlerhaften Ergebnissen führen.

• Stellen Sie sicher, dass kalte Proben nicht zum Beschlagen der

Küvette führen.

• Füllen Sie die Küvetten zur Aufbewahrung mit destilliertem oder

entionisiertem Wasser und schrauben Sie die Kappe fest auf.

• Verwenden Sie für optimale Genauigkeit für jede Messung eine

einzelne Probenküvette oder eine Fließzelle.

Hinweis: Alternativ kann eine abgeglichene Probenküvette für die Messung

verwendet werden. Diese bietet jedoch nicht dieselbe Genauigkeit oder Präzision

Vorgehensweise zur Trübungsmessung

einer einzelnen indexierten Probenküvette oder Fließzelle. Bei der Verwendung

abgeglichener Probenküvetten richten Sie die Markierung an der Probenküvette an

der Referenzmarkierung am Probenküvettenhalter aus.

Messdaten

• Messen Sie die Proben sofort, um Temperaturänderungen und

Absetzen zu verhindern. Stellen Sie vor einer Messung immer sicher,

dass die Probe homogen ist.

• Wenn möglich, vermeiden Sie es, die Probe zu verdünnen.

• Meiden Sie direkte Sonneneinstrahlung auf das Gerät.

1. Spülen Sie eine

saubere, leere

Probenküvette zweimal

mit der zu messenden

Lösung und leeren Sie

sie dann vollständig

aus. Füllen Sie sie bis

zur Linie (etwa 30 ml)

mit der Probe und

schrauben Sie sofort

die Kappe auf die

Probenküvette.

2. Reinigen Sie die

Probenküvetten mit

einem weichen,

fusselfreien Tuch, um

Wasserflecken und

Fingerabdrücke zu

entfernen.

3. Tragen Sie von der

Oberkante der

Probenküvetten zur

Unterseite hin wenig

Silikonöl auf.

4. Verwenden Sie das

im Lieferumfang

enthaltene

Kalibrierdatensätze, um

das Öl gleichmäßig auf

die Oberfläche der

Probenküvetten

aufzutragen. Entfernen

Sie überschüssiges Öl.

Stellen Sie sicher, dass

die Probenküvetten

nahezu trocken sind.

5. Schwenken Sie die

Probenküvette

vorsichtig und langsam

um, um die Probe

vollständig zu mischen.

Achten Sie darauf, dass

keine Blasen entstehen.

6. Setzen Sie die

Probenküvette so in

den Küvettenschacht,

dass das Dreieck an

der Probenküvette mit

der

Referenzmarkierung

am Küvettenschacht

übereinstimmt.

Schließen Sie die

Abdeckung.

Deutsch 27

Page 28

7. Lesen Sie den Wert

ab, wenn er stabil ist,

und notieren Sie ihn.

Hinweis: Drücken Sie

zumSenden (über

RS232) des Messwerts

auf PRINT.

Messtechniken

Messungen können mit unterschiedlichen Geräteeinstellungen und mit

optionalem Zubehör durchgeführt werden.

Kalibrieren Sie das Gerät immer dann, wenn die Schichtdicke der

Probenküvette verändert wird.

Manuelle oder automatische Bereichsmessung

Der Hersteller empfiehlt für die meisten Messungen, die

Messbereichswahl auf automatisch zu setzen.

Die Einstellung kann während der Probenmessung jederzeit geändert

werden.

Drücken Sie RANGE wiederholt, um das Gerät von automatischer

Messbereichswahl auf manuelle Messbereichswahl zu setzen, und

blättern Sie dann durch die manuellen Messbereichsseinstellungen.

Das Licht für den manuellen Bereich leuchtet, wenn manueller

Messbereich ausgewählt ist. Das Licht für den automatischen

Messbereich leuchtet, wenn automatischer Messbereich ausgewählt ist.

Hinweise:

28 Deutsch

• Wenn manuelle Messbereichswahl ausgewählt ist, blinken auf dem

Display Neunen, wenn die Probe größer als der ausgewählte

Messereich ist. Auf dem Display blinken alle Nullen, wenn die

gemessene Probe geringer als der ausgewählte Messbereich ist.

• Wenn automatische Messbereichswahl ausgewählt ist, blinken auf

dem Display Neunen, wenn die Probe größer ist als der

Maximalbereich des Geräts.

• Wenn automatische Messbereichswahl ausgewählt ist, blinken auf

dem Display Nullen, wenn der Messwert geringer als der Bereich des

Geräts oder ein negativer Wert ist. Kalibrieren Sie das Gerät.

Signalmittelung ein oder aus

Signalmittelung korrigiert Ergebnisfluktuationen, die durch zufällig

schwebende Partikel in der Probe verursacht werden. Wenn

Signalmittelung eingeschaltet ist, wird alle 3 Sekunden ein

Durchschnittsergebnis berechnet und auf dem Display

angezeigt.Anhand der letzten zehn Messungen wird der

Durchschnittswert berechnet.

Der Hersteller empfiehlt, die Signalmittelung für die meisten Messungen

einzuschalten.

Page 29

Drücken Sie SIGNAL AVG UNITS AVG, um Signalmittelung ein- oder

auszuschalten. Das Licht für UNITS AVG leuchtet, wenn Signalmittelung

eingeschaltet ist.

Drücken Sie ENTER, wenn Signalmittelung eingeschaltet ist, um die

Daten im Signalmittelungspuffer zu löschen und ggf. eine direkte

Aktualisierung auf dem Display anzuzeigen. Das ist auch hilfreich, wenn

Proben mit großen Trübungsunterschieden gemessen werden.

Wartung

G E F A H R

Mehrere Gefahren. Nur qualifiziertes Personal sollte die in diesem

Kapitel des Dokuments beschriebenen Aufgaben durchführen.

Reinigen des Geräts

Für kontinuierlichen und akkuraten Betrieb sollte das Gerät regelmäßig

gereinigt werden.

H I N W E I S

Verwenden Sie zum Reinigen des Geräts, einschließlich der Tastatur, keine

Reinigungsmittel wie Terpentin, Azeton oder ähnliche Produkte.

1. Schalten Sie das Gerät aus und trennen Sie das Netzkabel.

2. Reinigen Sie das Gerät mit einer milden Seifenlösung und einem

weichen, feuchten Tuch.

3. Trocknen Sie das Gerät mit einem fusselfreien Tuch.

Ersetzen der LED-Lichtquelle

Die Lichtquelle, eine LED, darf nicht vom Benutzer ausgetauscht

werden. Wenden Sie sich dazu an den Kundendienst.

Austauschen einer Sicherung

G E F A H R

Brandgefahr. Ersetzen Sie Sicherungen mit dem gleichem Typ und

Nennstrom.

Ersatzteile:

• Sicherung für 115-V-Betrieb, zeitverzögert, 250 V, 1,6 A (3030700),

oder

• Sicherung für 230-V-Betrieb, zeitverzögert, 250 V, 1,6 A (3030600)

Zum Austauschen einer Sicherung siehe die illustrierten Schritte in

Abbildung 6.

Abbildung 6 Austauschen einer Sicherung

Deutsch 29

Page 30

Fehlerbehebung

Beachten Sie die Tabellen mit Fehlercodes, Diagnosecodes, häufigen

Problemmeldungen, möglichen Ursachen und Abhilfemaßnahmen in

diesem Abschnitt.

Fehlercodes

Tabelle 3 listet die Fehlercodes für unterschiedliche Ursachen auf.

Fehlercodes zeigen Gerätestörungen oder Bedienfehler an.

Das Gerät arbeitet im Fall eines Fehlers weiter.

Drücken Sie ENTER um den Fehlercode vom Bildschirm zu löschen.

Hinweis: Tritt ein Fehler während einer Kalibrierung auf, werden die Daten der

Kalibrierung verworfen. Die alte Kalibrierung wird beibehalten.

Tabelle 3 Fehlercodes

Fehler Beschreibung Lösung

ERR 01 Die Trübung des

ERR 02

Verdünnungswassers beträgt mehr

als 0,5 NTU.

• Zwei Kalibrierstandards haben

den selben Wert.

• Der Unterschied zwischen zwei

Standards beträgt weniger als

60,0 NTU.

• Die Trübung von Standard 1 ist

zu gering (weniger als 10 NTU)

Beginnen Sie die Kalibrierung

erneut mit weniger trübem

Verdünnungswasser.

Hinweis: Ignorieren Sie ERR 01 wenn

der Durchmesser der Probe-Küvette

weniger als 25 mm beträgt. Drücken

Sie UNITS/Exit, um zum Messmodus

zurückzukehren.

1. Überprüfen Sie die

Herstellung der Standards.

2. Kalibrieren Sie neu.

Hinweis: Ignorieren Sie ERR 02 wenn

der Durchmesser der Probe-Küvette

weniger als 25 mm beträgt. Drücken

Sie UNITS/Exit, um zum Messmodus

zurückzukehren.

Tabelle 3 Fehlercodes (fortgesetzt)

Fehler Beschreibung Lösung

ERR 03 Fehler durch schwaches Licht

ERR 04 Speicherfehler

ERR 05 A/D liegt über dem Bereich

ERR 06 A/D-Bereichsunterschreitung

ERR 07 Lichtverlust

1. Setzen Sie die Probe neu

ein.

2. Prüfen Sie, ob die Licht

brennt.

3. Stellen Sie sicher, dass der

Strahlengang frei ist.

4. Möglicherweise ist eine

Verdünnung der Probe

notwendig.

1. Schalten Sie das Gerät aus

und wieder ein.

2. Wenden Sie sich an den

technischen Support, falls

der Fehler erneut auftritt.

1. Prüfen Sie, ob der

Lichtschutz geschlossen ist.

2. Wenden Sie sich wenn nötig

an den Kundenservice.

1. Überprüfen Sie den

Strahlengang auf Blockaden.

2. Wenden Sie sich wenn nötig

an den Kundenservice.

1. Prüfen Sie, ob der Deckel

des Küvettenschachts

geschlossen ist.

2. Schalten Sie das Gerät aus

und wieder ein.

30 Deutsch

Page 31

Tabelle 3 Fehlercodes (fortgesetzt)

Fehler Beschreibung Lösung

ERR 09 Drucker Timeout-Fehler

ERR 10 Systemspannung außerhalb des

Bereichs

ERR 11 Systemschleifenmessungsfehler

1. Überprüfen Sie, ob der

externe Drucker korrekt

angeschlossen ist.

2. Überprüfen Sie, ob der

externe Drucker ausgewählt

ist (online).

1. Schalten Sie das Gerät aus

und wieder ein.

2. Wenden Sie sich an den

Kundenservice falls der

Fehler erneut auftritt.

1. Schalten Sie das Gerät aus

und wieder ein.

2. Wenden Sie sich an den

Kundenservice falls der

Fehler erneut auftritt.

Hinweis: Um einen Diagnosebericht zu drucken, halten Sie PRINT gedrückt und

schalten Sie das Gerät ein.

Tabelle 4 Diagnosecodes

Code Display Beschreibung

21 Pr In Druckertest

22 Die Testergebnisse werden angezeigt. Test des Displays

23 Die Testergebnisse werden angezeigt. Test der Tastatur

24 Die Testergebnisse werden angezeigt. Test des Arbeitsspeichers

Löschen von Kalibrierdaten

So löschen Sie Kalibrierdaten, die vom Benutzer eingegeben wurden:

1. Schalten Sie das Instrument aus.

2. Halten Sie CAL gedrückt.

3. Schalten Sie das Instrument ein.

Das CAL?-Licht blinkt. Das Gerät startet im Kalibrierungsmodus.

4. Kalibrieren Sie das Gerät vor der Verwendung.

Diagnosecodes

Tabelle 4 listet die Diagnosecodes auf, die zum Abrufen von

Informationen zur Gerätebedienung verwendet werden, falls Sie sich

diesbezüglich nicht sicher sind.

So führen Sie einen Diagnosetest durch:

1. Drücken Sie SETUP.

2. Verwenden Sie die Pfeiltasten, um einen Diagnosecode einzugeben.

3. Drücken Sie ENTER, um den Diagnosewert anzuzeigen.

4. Drücken Sie UNITS/Exit, um zum Messmodus zurückzukehren.

Blinkende Neunen

Wenn manuelle Messbereichswahl ausgewählt ist, blinken auf dem

Display Neunen, wenn die Probe größer als der ausgewählte

Messbereich ist.

Wenn automatische Messbereichswahl ausgewählt ist, blinken auf dem

Display Neunen, wenn die Probe größer ist als der Maximalbereich des

Geräts.

Blinkende Nullen

Wenn manuelle Messbereichswahl ausgewählt ist, blinken auf dem

Display Nullen, wenn die gemessene Probe geringer als der

ausgewählte Bereich ist.

Wenn automatische Bereichsmessung ausgewählt ist, blinken auf dem

Display Nullen, wenn die Messung geringer als der Bereich des Geräts

oder ein negativer Wert ist. Kalibrieren Sie das Gerät.

Deutsch

31

Page 32

Table des matières

Caractéristiques à la page 32 Fonctionnement standard

Généralités à la page 33 Maintenance à la page 43

Interface utilisateur à la page 36 Dépannage à la page 44

Mise en marche à la page 38

à la page 38

Caractéristiques

Les caractéristiques techniques peuvent être modifiées sans préavis.

Caractéristique Détails

Méthode de mesure Néphélométrique

Réglementation Conforme aux normes ISO 7027, DIN EN 27027,

Source de lumière Diode électroluminescente (LED) à 860 ± 30 nm

Modes de mesure FNU et NTU

Plage de mesures FNU (plage manuelle) : 0–0,999, 0–9,99, 0–99,9, 0–

Précision1,

Résolution Turbidité : 0,001 FNU/NTU (sur la plage la plus

2

DIN 38404 et NFT 9033

ASTM D7315 - Méthode de test standard pour

déterminer la turbidité au-dessus d'une unité de

turbidité (TU) en mode statique

ASTM D6655 - Méthode de test standard pour

déterminer la turbidité en-dessous de 5 NTU en

mode statique

1 000

FNU (plage auto) : 0–1 000

NTU (plage manuelle) : 0–0,999, 0–9,99, 0–99,9, 0–

1 000

NTU (plage auto) : 0–1 000

±2 % du relevé plus 0,01 FNU/NTU de 0 à

1 000 FNU/NTU

basse)

Caractéristique Détails

Répétabilité ±1 % du relevé ou 0,01 FNU, selon l'écart le plus

Temps de réponse Moyenne pondérée du signal désactivée :

Temps de stabilisation Immédiatement

Modes de mesure Plage manuelle ou auto, moyenne pondérée du

Exigences électriques 115–230 VCA, 50/60 Hz (sélection d'alimentation

Degré de

pollution/catégorie de

l'installation

Classe de protection 1

Conditions de

fonctionnement

Conditions de stockage –40 à 60 °C (–40 à 140 °F), instrument seulement

Interface Interface série RS232C via un connecteur à

important (dans les conditions de référence)

6,8 secondes

Moyenne pondérée du signal activée : 14 secondes

(lorsque 10 mesures sont utilisées pour calculer la

moyenne)

signal activée ou désactivée

automatique)

28 W maximum

2 ; II

Température : 0 à 40 °C (32 à 104 °F)

Humidité relative : 0–90 % à 25 °C, 0–75 % à 40 °C,

sans condensation

Altitude : 2 000 m maximum

Utilisation intérieure seulement

enveloppe D sous-miniature DB9 pour la

transmission des données vers un ordinateur ou une

imprimante, et entrée de données (commande). Pas

de secouage manuel.

32 Français

Page 33

Caractéristique Détails

Purge d'air Azote sec ou air pour instruments (ANSI MC 11.1,

Cuves d'échantillon Cuves rondes 95 x 25 cm (3.74 x 1 po) verre au

Exigences relatives à

l'échantillon

Boîtier Plastique polycarbonate très résistant aux chocs

Dimensions 30.5 x 40 x 15.6 cm (12.0 x 15.7 x 6.1 po)

Poids 3.8 kg (8.5 lb)

Certification CE, cETLus

1

Spécifications de turbidité identifiées à l'aide d'un étalon de formazine

récemment préparé et de cuves pour échantillon d'un pouce correspondantes.

2

Un rayonnement électromagnétique intermittent de 3 volts/mètre ou plus peut

causer de légères imprécisions.

1975)

0,1 scfm à 69 kPa (10 psig) ; 138 kPa (20 psig)

maximum

Raccord de flexible à crans pour tube de 1/8e de

pouce

borosilicate avec bouchons à vis revêtus de

caoutchouc

Remarque : Des cuves pour échantillon plus petites (moins

de 25 mm) peuvent être utilisées lorsqu'un adaptateur pour

cuves est utilisé.

cuve pour échantillon de 25 mm : 20 ml minimum

0 à 95 °C (32 à 203 °F)

Généralités

En aucun cas le constructeur ne saurait être responsable des

dommages directs, indirects, spéciaux, accessoires ou consécutifs

résultant d'un défaut ou d'une omission dans ce manuel. Le constructeur

se réserve le droit d'apporter des modifications à ce manuel et aux

produits décrits à tout moment, sans avertissement ni obligation. Les

éditions révisées se trouvent sur le site Internet du fabricant.

Version enrichie de ce manuel

Pour plus d'informations, reportez-vous au CD qui contient la version

enrichie de ce manuel.

Consignes de sécurité

A V I S

Le fabricant décline toute responsabilité quant aux dégâts liés à une application

ou un usage inappropriés de ce produit, y compris, sans toutefois s'y limiter, des

dommages directs ou indirects, ainsi que des dommages consécutifs, et rejette

toute responsabilité quant à ces dommages dans la mesure où la loi applicable le

permet. L'utilisateur est seul responsable de la vérification des risques

d'application critiques et de la mise en place de mécanismes de protection des

processus en cas de défaillance de l'équipement.

Veuillez lire l'ensemble du manuel avant le déballage, la configuration ou

la mise en fonctionnement de cet appareil. Respectez toutes les

déclarations de prudence et d'attention. Le non-respect de cette

procédure peut conduire à des blessures graves de l'opérateur ou à des

dégâts sur le matériel.

Assurez-vous que la protection fournie avec cet appareil n'est pas

défaillante. N'utilisez ni n'installez cet appareil d'une façon différente de

celle décrite dans ce manuel.

Interprétation des indications de risques

D A N G E R

Indique une situation de danger potentiel ou imminent qui, si elle n'est pas évitée,

entraîne des blessures graves, voire mortelles.

A V E R T I S S E M E N T

Indique une situation de danger potentiel ou imminent qui, si elle n'est pas évitée,

peut entraîner des blessures graves, voire mortelles.

Indique une situation de danger potentiel qui peut entraîner des blessures

mineures ou légères.

A T T E N T I O N

Français 33

Page 34

A V I S

Indique une situation qui, si elle n'est pas évitée, peut occasionner

l'endommagement du matériel. Informations nécessitant une attention

particulière.

Etiquettes de mise en garde

Lire toutes les informations et toutes les étiquettes apposées sur

l’appareil. Des personnes peuvent se blesser et le matériel peut être

endommagé si ces instructions ne sont pas respectées. Si un symbole

‘danger’ ou ‘attention’ se trouve sur l’instrument, une explication est

indiquée dans le manuel.

Si l'appareil comporte ce symbole, reportez-vous au manuel

d'utilisation pour consulter les informations de fonctionnement et de

sécurité.

En Europe, depuis le 12 août 2005, les appareils électriques

comportant ce symbole ne doivent pas être jetés avec les autres

déchets. Conformément à la réglementation nationale et européenne

(Directive 2002/96/CE), les appareils électriques doivent désormais

être, à la fin de leur service, renvoyés par les utilisateurs au fabricant,

qui se chargera de les éliminer à ses frais.

Remarque : Pour le retour à des fins de recyclage, veuillez contacter le fabricant

ou le fournisseur d'équipement pour obtenir les instructions sur la façon de

renvoyer l'équipement usagé, les accessoires électriques fournis par le fabricant,

et tous les articles auxiliaires pour une mise au rebut appropriée.

Certification

Règlement canadien sur les équipements causant des

interférences radio, IECS-003, Classe A:

Les données d'essai correspondantes sont conservées chez le

constructeur.

Cet appareil numérique de classe A respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

Cet appareil numérique de classe A respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

FCC part 15, limites de classe A :

Les données d'essai correspondantes sont conservées chez le

constructeur. L'appareil est conforme à la partie 15 de la règlementation

FCC. Le fonctionnement est soumis aux conditions suivantes :

1. Cet équipement ne peut pas causer d'interférence nuisible.

2. Cet équipement doit accepter toutes les interférences reçues, y

compris celles qui pourraient entraîner un fonctionnement inattendu.

Les modifications de cet équipement qui n’ont pas été expressément

approuvées par le responsable de la conformité aux limites pourraient

annuler l’autorité dont l’utilisateur dispose pour utiliser cet équipement.

Cet équipement a été testé et déclaré conforme aux limites définies pour

les appareils numériques de classe A, conformément à la section 15 de

la réglementation FCC. Ces limites ont pour but de fournir une protection

raisonnable contre les interférences néfastes lorsque l’équipement

fonctionne dans un environnement commercial. Cet équipement génère,

utilise et peut irradier l'énergie des fréquences radio et, s'il n'est pas

installé ou utilisé conformément au mode d'emploi, il peut entraîner des

interférences dangereuses pour les communications radio. Le

fonctionnement de cet équipement dans une zone résidentielle risque de

causer des interférences nuisibles, dans ce cas l'utilisateur doit corriger

les interférences à ses frais Les techniques ci-dessous peuvent

permettre de réduire les problèmes d'interférences :

1. Débrancher l'équipement de la prise de courant pour vérifier s'il est

ou non la source des perturbations

2. Si l'équipement est branché sur le même circuit de prises que

l'appareil qui subit des interférences, branchez l'équipement sur un

circuit différent.

3. Éloigner l'équipement du dispositif qui reçoit l'interférence.

4. Repositionner l’antenne de réception du périphérique qui reçoit les

interférences.

5. Essayer plusieurs des techniques ci-dessus à la fois.

Présentation du produit

Le turbidimètre de laboratoire 2100N IS mesure la turbidité en FNU

(unités néphélométriques de formazine) et en NTU (unités de turbidité

néphélométriques). Les NTU sont calculées à l'aide des facteurs de

conversion de 1 NTU pour 1 FNU.

34

Français

Page 35

Le turbidimètre est doté d'une d'une sortie RS232 pour se connecter à

une imprimante, un enregistreur de données ou un ordinateur.

Figure 1 Vue de face

Composants du produit

Consultez la Figure 3 pour vous assurer que tous les éléments ont bien

été reçus. Si un élément est manquant ou endommagé, contactez

immédiatement le fabricant ou un représentant.

Figure 3 Composants de l'instrument

1 Clavier 4 Couvercle du compartiment pour

2 Porte-cuve 5 Affichage LED à cinq chiffres

3 Ecran protecteur de la lumière

cuves pour échantillon

Figure 2 Vue de dos

1 Connecteur du cordon

d'alimentation

2 Porte-fusible 5 Raccord de la purge d'air

3 Interrupteur marche/arrêt

4 Connecteur DB9 pour le câble

RS232

1 Turbidimètre 2100N IS 5 Kit d'étalonnage StablCal

2 Chiffon de huilage 6 Kit de standardisation de turbidité

3 Six cuves pour échantillon d'1"

(30 ml) avec bouchons

4 Huile de silicone 8 Cordon d'alimentation

1

Fourni avec 4790000 uniquement.

secondaire Gelex

7 Cache anti-poussière

®

1

®

Français

35

Page 36

Interface utilisateur

Figure 4 Clavier

1 Touche ENTER (entrée) 5 Touche UNITS AVG (moyenne des

unités)

2 Touches (fléchées) EDIT (modifier) 6 Touche SETUP (configuration)

3 Touche RANGE (plage) 7 Touche PRINT (imprimer)

4 Touche UNITS/Exit (unités/quitter) 8 Touche CAL (étalonnage)

Tableau 1 Description des touches

Touche Description

Entre la valeur sur l'écran. Démarre la mesure d'un étalon

d'étalonnage. Efface les données de la mémoire tampon.

Modifie les chiffres et/ou les lettres sur l'écran. Fait défiler les

étalons d'étalonnage. La touche fléchée vers la droite déplace le

curseur vers le chiffre précédent ou suivant.

Tableau 1 Description des touches (suite)

Touche Description

Active ou désactive la moyenne pondérée du signal.

Active le mode Configuration et démarre la sélection du numéro de

configuration.

Envoie les données affichées sur l'écran à une imprimante ou un

ordinateur. Envoie un rapport de données d'étalonnage à une

imprimante ou un ordinateur en mode étalonnage. Envoie les

résultats du diagnostic à une imprimante ou un ordinateur si le

bouton est enfoncé lorsque l'instrument est mis en marche. Fournit

une impression des commandes de configuration en mode

Configuration.

Démarre ou termine un étalonnage.

36 Français