DOC022.52.80206

2100AN IS

08/2012, Edition 2

User Manual

Table of Contents

Specifications..................................................................................................................................................................................5

General information.....................................................................................................................................................................6

Safety information..............................................................................................................................................................................6

Use of hazard information..................................................................................................................................................................6

Precautionary labels..........................................................................................................................................................................7

Certification........................................................................................................................................................................................7

Product overview...............................................................................................................................................................................7

Product components..........................................................................................................................................................................8

Installation.........................................................................................................................................................................................9

Put paper in the printer......................................................................................................................................................................9

User interface................................................................................................................................................................................10

Startup...............................................................................................................................................................................................12

Turn the instrument on.....................................................................................................................................................................12

Turn the keypad sound off (optional)...............................................................................................................................................12

Set the date and time.......................................................................................................................................................................12

Show the current time (optional)......................................................................................................................................................12

Standard operation....................................................................................................................................................................12

Calibrate the turbidimeter with StablCal® Standards.......................................................................................................................12

Prepare the StablCal standards................................................................................................................................................13

Calibration notes.......................................................................................................................................................................13

StablCal calibration procedure..................................................................................................................................................14

StablCal standards storage......................................................................................................................................................15

Using Gelex secondary standards...................................................................................................................................................15

Gelex notes...............................................................................................................................................................................15

Measure the Gelex stray light standard....................................................................................................................................15

Measure the Gelex secondary turbidity standards...................................................................................................................16

Calibration verification..............................................................................................................................................................17

Optical system check................................................................................................................................................................17

Prepare a sample cell......................................................................................................................................................................17

1

Table of Contents

Clean the sample cell...............................................................................................................................................................18

Indexing a single sample cell....................................................................................................................................................19

Matching sample cells..............................................................................................................................................................21

Prepare dilution water...............................................................................................................................................................23

Prepare the sample..........................................................................................................................................................................23

Prepare a representative sample..............................................................................................................................................23

Remove air bubbles from the sample.......................................................................................................................................23

Apply a vacuum.................................................................................................................................................................23

Use an ultrasonic bath.......................................................................................................................................................23

Apply heat..........................................................................................................................................................................24

Prevent condensation on a sample cell....................................................................................................................................24

Measure over-range samples...................................................................................................................................................24

Sample dilution..................................................................................................................................................................24

Turbidity measurement....................................................................................................................................................................25

Measurement notes..................................................................................................................................................................25

Turbidity measurement procedure............................................................................................................................................26

Absorbance and transmittance measurement.................................................................................................................................27

Measurement notes..................................................................................................................................................................27

Absorbance and transmittance measurement procedure.........................................................................................................27

Measurement techniques.................................................................................................................................................................28

Manual or automatic ranging....................................................................................................................................................28

Signal averaging on or off.........................................................................................................................................................28

Ratio on or off...........................................................................................................................................................................29

Using the air purge system.......................................................................................................................................................29

Using a flow cell........................................................................................................................................................................30

Install a flow cell................................................................................................................................................................30

Clean a flow cell assembly................................................................................................................................................30

Flow cell maintenance.......................................................................................................................................................31

Flow cell operation.............................................................................................................................................................31

Flow cell storage................................................................................................................................................................31

Using a manual flow cell....................................................................................................................................................31

Using an automated flow cell.............................................................................................................................................31

Measurement notes...........................................................................................................................................................32

2

Table of Contents

Static or dynamic measurement procedure.......................................................................................................................33

Use a cell adapter.....................................................................................................................................................................34

Install a cell adapter...........................................................................................................................................................35

Remove a cell adapter.......................................................................................................................................................35

Connect to a printer or computer.....................................................................................................................................................35

Configure the printer output.............................................................................................................................................................35

Configure the RS232 connection.....................................................................................................................................................36

Computer (RS232) commands........................................................................................................................................................36

Connect to a data recorder..............................................................................................................................................................36

Configure the data recorder output..................................................................................................................................................37

Advanced operation..................................................................................................................................................................37

Calibrate the turbidimeter with formazin standards..........................................................................................................................37

Prepare formazin standards.....................................................................................................................................................37

Calibration notes.......................................................................................................................................................................38

Formazin calibration procedure................................................................................................................................................39

Making 4000-NTU formazin stock solution...............................................................................................................................40

Calibrate the turbidimeter with user-selected formazin standards...................................................................................................40

Prepare formazin standards – user selected............................................................................................................................41

Change the calibration points...................................................................................................................................................41

Special research applications..........................................................................................................................................................41

Application specific methods............................................................................................................................................................41

Application specific calibration.........................................................................................................................................................41

Initial ASC entry........................................................................................................................................................................42

Program new ASC data............................................................................................................................................................42

Set the units available on the display...............................................................................................................................................42

Maintenance...................................................................................................................................................................................42

Clean the instrument........................................................................................................................................................................42

Replace the LED light source..........................................................................................................................................................42

Replace a fuse.................................................................................................................................................................................43

Troubleshooting..........................................................................................................................................................................43

Error codes .....................................................................................................................................................................................43

3

Table of Contents

Diagnostic codes..............................................................................................................................................................................44

Delete calibration data.....................................................................................................................................................................44

Flashing 9s.......................................................................................................................................................................................45

Flashing 0s.......................................................................................................................................................................................45

Replacement parts and accessories...............................................................................................................................45

4

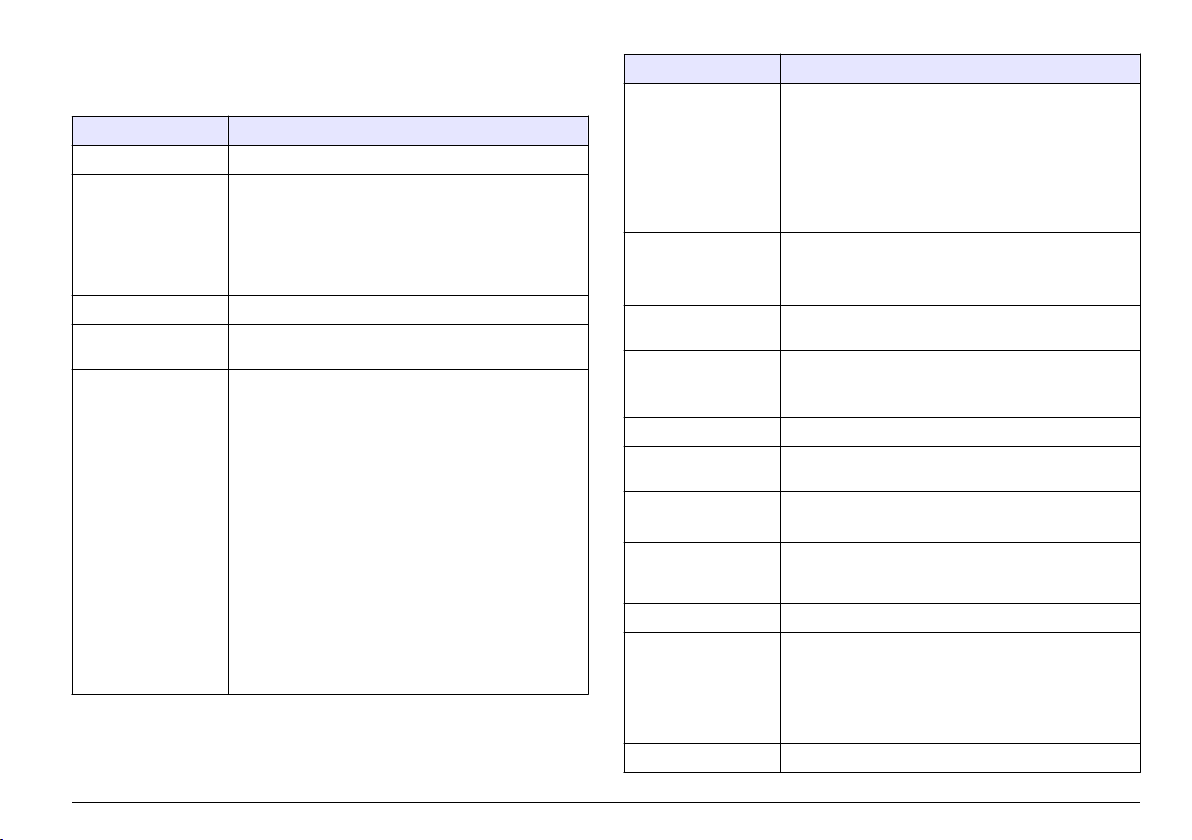

Specifications

Specifications are subject to change without notice.

Specification Details

Measurement method Nephelometric

Regulatory Meets ISO 7027, DIN EN 27027, DIN 38404 and NFT

9033

ASTM D7315 - Standard Test Method for Determination

of Turbidity Above 1 Turbidity Unit (TU) in Static Mode

ASTM D6655 - Standard Test Method for Determination

of Turbidity Below 5 NTU in Static Mode

Light source Light-emitting diode (LED) at 860 ± 30 nm

Measurement modes FNU, FAU, NTU, EBC, Abs (absorbance), %T (%

transmittance) and two user-defined units

Range FNU (manual range): 0–0.999, 0–9.99, 0–99.9, 0–1000

FNU (auto range): 0–1000

FAU (manual range): 20–99.9, 20–10,000

FAU (auto range): 20–10,000

NTU (Ratio on, manual range): 0–0.999, 0–9.99, 0–

99.9, 0–10,000

NTU (Ratio on, auto range): 0–10,000 auto decimal

NTU (Ratio off): 0–40

EBC (Ratio on, manual range): 0–0.999, 0–9.99, 0–

99.9, 0–2450

EBC (Ratio on, auto range): 0–2450 auto decimal

EBC (Ratio off): 0–9.8

Absorbance (manual range): 0–0.999, 0–2.00

Absorbance (auto range): 0–2.00

Transmittance (%): 1.0–100

Specification Details

Accuracy1, 2,

Resolution Turbidity: 0.001 FNU/NTU/EBC

Repeatability ±1% of reading or 0.01 FNU, whichever is greater

Response time Signal averaging off: 6.8 seconds

Stabilization time Immediately

Reading modes Manual or auto range, signal averaging on and

Power requirement 115–230 VAC, 50/60 Hz (automatic power selection)

Pollution

degree/installation

category

Protection Class 1

Operating conditions Temperature: 0 to 40 °C (32 to 104 °F)

Storage conditions –40 to 60 °C (–40 to 140 °F), instrument only

3

FNU4: ±2% of reading plus 0.01 FNU from 0–1000 FNU

FAU: ±10% of reading from 20–10,000 NTU

NTU4: ±2% of reading plus 0.01 NTU from 0–

1000 NTU, ±5% of reading from 1000–4000 NTU,

±10% of reading from 4000–10,000 NTU

Absorbance: ±0.005 Abs from 0–1 Abs at 860 nm

Transmittance: 0.12% T from 10–100% T at 860 nm

Absorbance: 0.001 Abs

Transmittance: 0.1% T

(under reference conditions)

Signal averaging on: 14 seconds (when

10 measurements are used to calculate the average)

adjustable or off, Ratio on or off

28 W maximum

2; II

Relative humidity: 0–90% at 25 °C, 0–75% at 40 °C,

noncondensing

Altitude: 2000 m (6560 ft) maximum

Indoor use only

English 5

Specification Details

Printer Built-in (thermal, 58-mm, up to 28 column)

Interface RS232C serial interface by way of DB9 subminiature D-

Air purge Dry nitrogen or instrument grade air (ANSI MC 11.1,

Sample cells Round cells 95 x 25 mm (3.74 x 1 in.) borosilicate glass

Sample requirements 25 mm sample cell: 20 mL minimum

Enclosure High-impact polycarbonate plastic

Dimensions 30.5 x 40 x 15.6 cm (12.0 x 15.7 x 6.1 in.)

Weight 3.8 kg (8.5 lb)

Certification CE, cETLus

1

Turbidity specifications identified using recently prepared formazin standard

and matched 25-mm sample cells.

2

Reference conditions: 23 ± 2 °C, 50% ± 10% RH noncondensing,

115/230 VAC, 50/60 Hz

3

Intermittent electromagnetic radiation of 3 volts/meter or greater may cause

slight accuracy shifts.

4

FNU is equivalent to NTU in the Ratio off mode.

shell connector for data output to computer or printer,

and data input (command). No handshaking.

1975)

0.1 scfm at 69 kPa (10 psig); 138 kPa (20 psig)

maximum

Hose barb connection for 1/8-inch tubing

with rubber-lined screw caps

Note: Smaller sample cells (less than 25 mm) can be used when

a cell adapter is used.

0 to 95 °C (32 to 203 °F)

Note: Refer to Use a cell adapter on page 34 for the minimum

sample size when not using a 25 mm sample cell.

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or

misuse of this product including, without limitation, direct, incidental and

consequential damages, and disclaims such damages to the full extent permitted

under applicable law. The user is solely responsible to identify critical application

risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

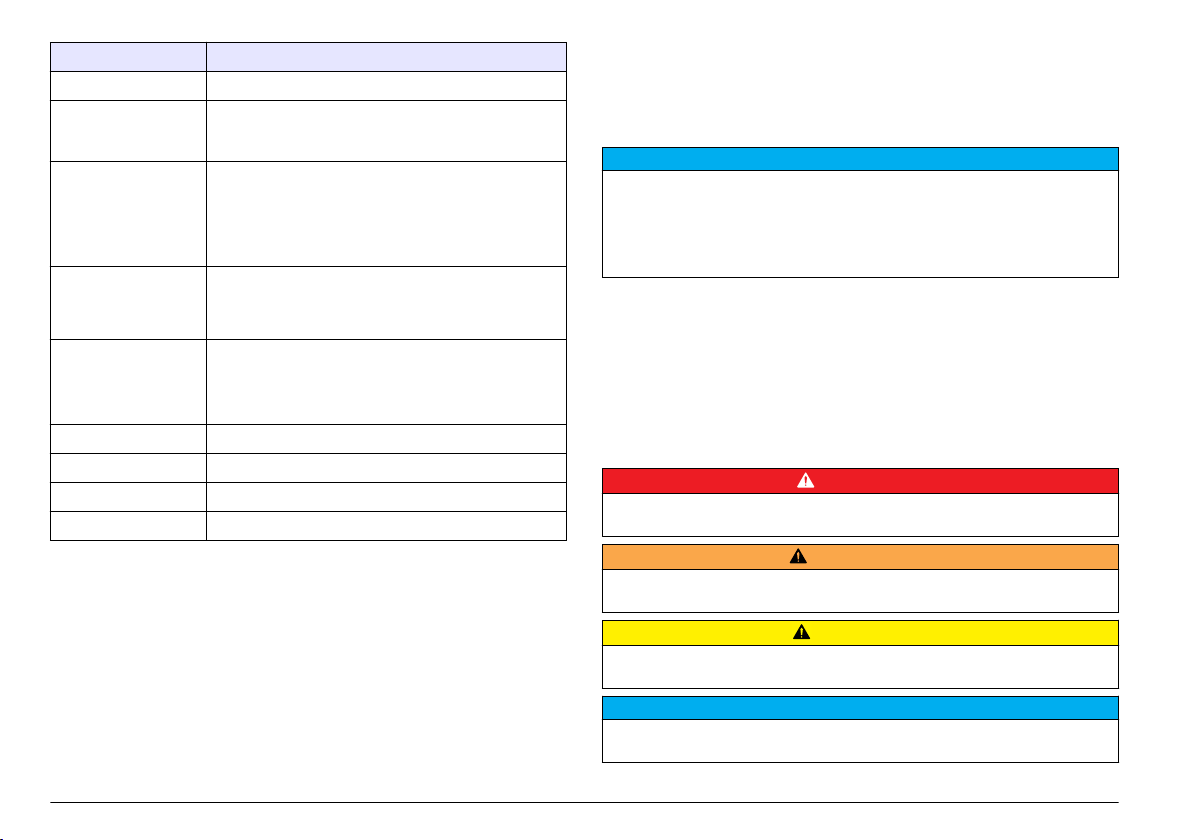

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

W A R N I N G

C A U T I O N

N O T I C E

6 English

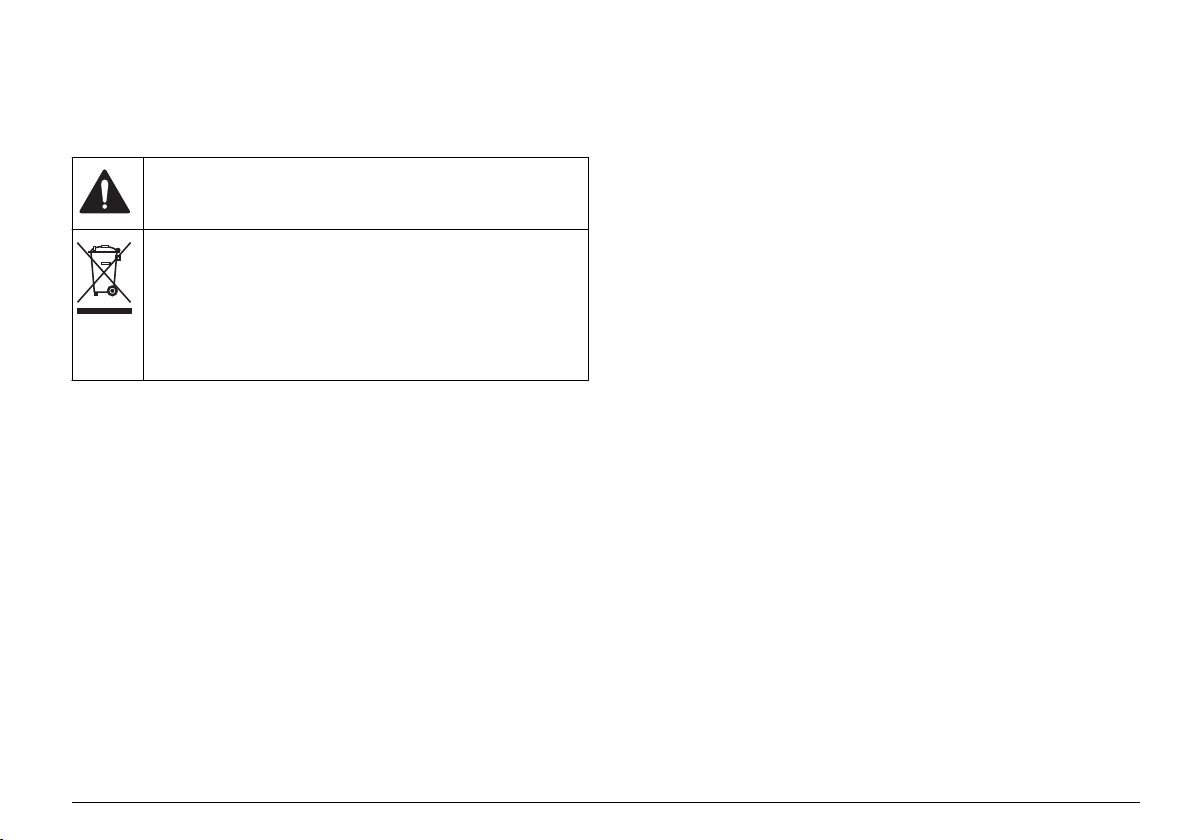

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol, if noted

on the instrument, will be included with a danger or caution statement in

the manual.

This symbol, if noted on the instrument, references the instruction

manual for operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge

to the user.

Note: For return for recycling, please contact the equipment producer or supplier

for instructions on how to return end-of-life equipment, producer-supplied

electrical accessories, and all auxiliary items for proper disposal.

Certification

Canadian Radio Interference-Causing Equipment Regulation,

IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numèrique de la classe A respecte toutes les exigences du

Rëglement sur le matériel brouilleur du Canada.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device

complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications to this equipment not expressly approved by

the party responsible for compliance could void the user's authority to

operate the equipment. This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

Product overview

The 2100AN IS laboratory turbidimeter measures turbidity in FNUs

(Formazin nephelometric units), NTUs (nephelometric turbidity units) and

EBCs (European Brewing Convention units). NTUs and EBCs are

calculated using the conversion factors of 1.0 NTU per 1.0 FNU and

0.245 EBCs per 1.0 FNU. The 2100AN IS turbidimeter also measures

attenuation (FAU), absorbance and transmittance.

In addition, two user-defined measurement units can be specified. Refer

to Application specific methods on page 41. The application specific

mode of operation uses the nephelometric optical system and the NTU

measurement mode.

The turbidimeter has a built-in printer and an RS232 output for

connection to a printer, data logger or computer and a recorder output.

English

7

The turbidimeter contains a real-time clock with battery. The clock

provides a time-date stamp on all data transmitted to the built-in printer

or to external devices by way of the RS232 interface (i.e., measurements

and calibration records).

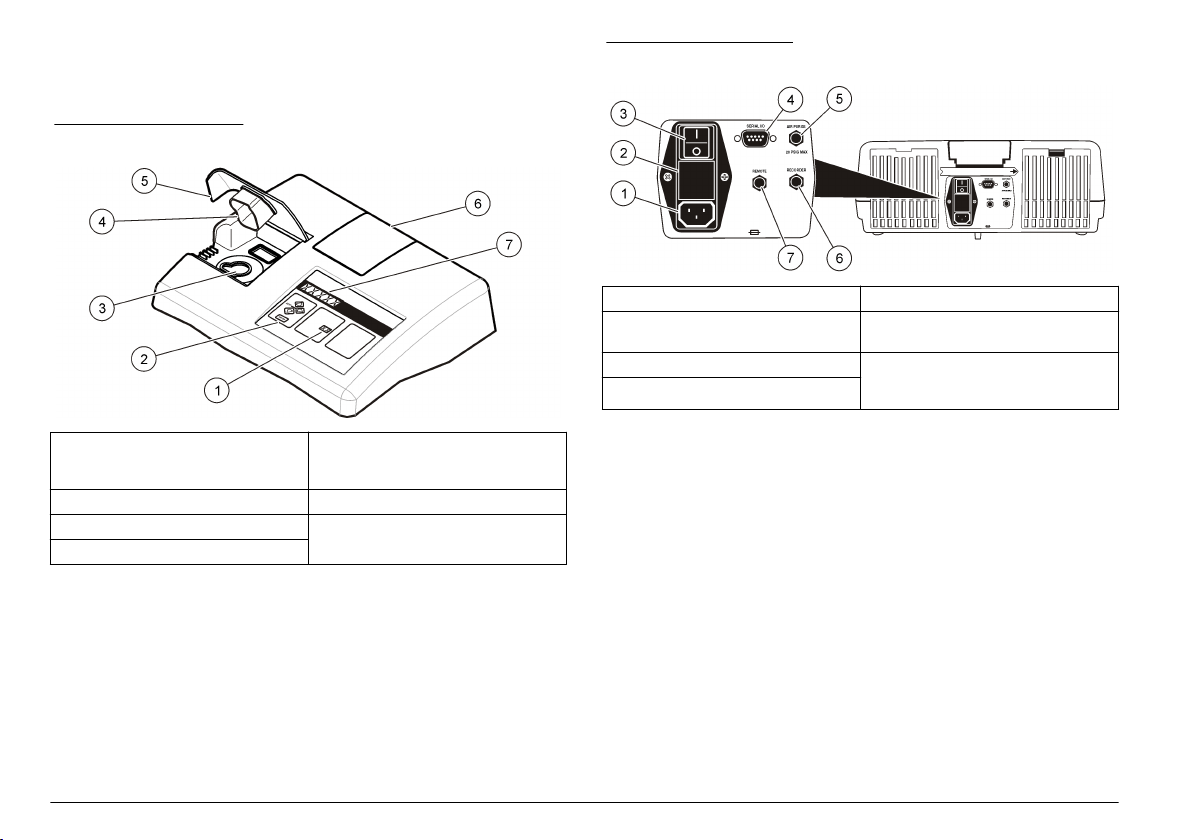

Figure 1 Front overview

Figure 2 Back overview

1 Power cord connector 5 Air purge fitting

2 Fuse holder 6 Recorder output jack for a chart

3 Power switch 7 Remote cable jack for flow valve

4 DB9 connector for RS232 cable

recorder (0 to 1 V output)

module connection to the automatic

flow cell (low pressure)

1 Mode display: shows the calibration

standard number, setup number or

sample number

2 Keypad 6 Printer cover

3 Sample cell holder 7 Eight-digit LED display

4 Light shield

5 Cover for the sample cell

compartment

8 English

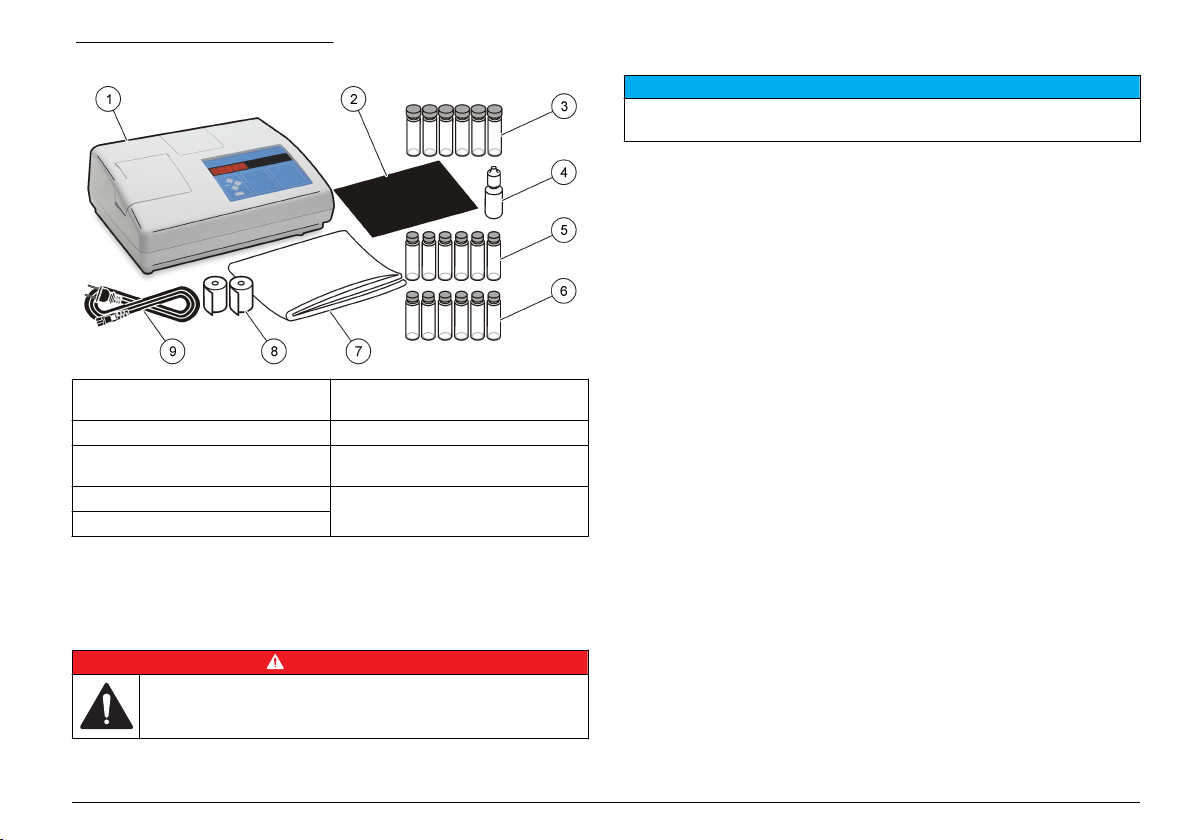

Product components

Refer to Figure 3 to make sure that all components have been received.

If any of these items are missing or damaged, contact the manufacturer

or a sales representative immediately.

Figure 3 Instrument components

1 2100AN IS turbidimeter 6 Gelex® secondary turbidity

2 Oiling cloth 7 Dust cover

3 Six 1" sample cells (30 mL) with

caps

4 Silicone oil 9 Power cord

5 StablCal® Calibration kit

1

Supplied with 4790100 only.

2

Do not remove the plastic wrapper from the paper rolls until the paper is

installed.

standardization kit

8 Printer paper roll (2x)

1

2

Installation

Put paper in the printer

N O T I C E

Use only the provided thermal paper. Use of other thermal paper may cause poor

print quality and decrease the life of the print-head.

Notes:

• Do not rub the thermal paper with a hard object.

• Do not use chemical paste on thermal paper.

• A red line on the edge of the thermal paper shows when the paper

supply is low.

1. Cut the end of the paper with scissors to make an arrow shape.

2. Open the printer cover.

3. Put the point of the thermal paper in the paper entrance slot.

4. Push the paper through until the point of the paper comes out the

exit slot.

5. Pull the paper out of the exit slot until the full width of the paper is

past the exit slot.

6. Put the paper roll in the printer.

7. Put the thermal paper through the slot in the printer cover, then close

the printer cover.

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

English 9

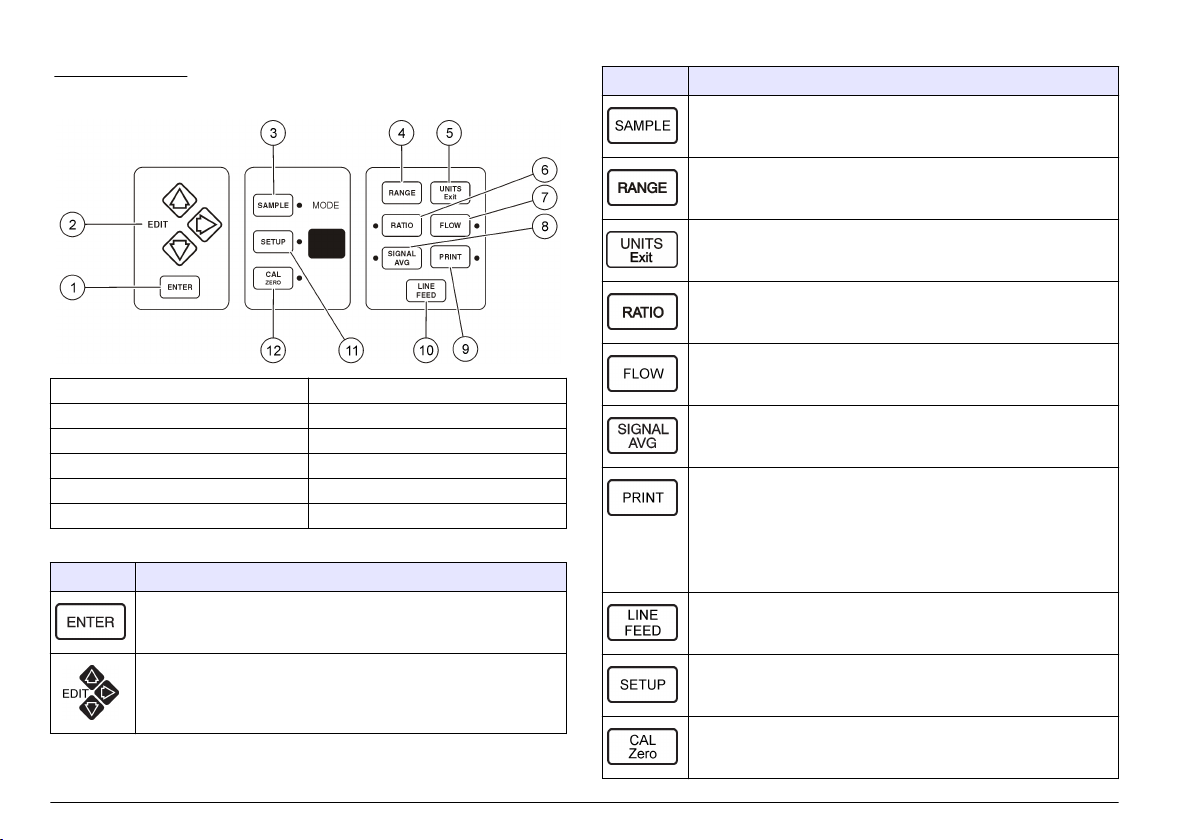

User interface

Figure 4 Keypad

1 ENTER key 7 FLOW key

2 EDIT (arrow) keys 8 SIGNAL AVG key

3 SAMPLE key 9 PRINT key

4 RANGE key 10 LINE FEED key

5 UNITS/Exit key 11 SETUP key

6 RATIO key 12 CAL/Zero key

Table 1 Key descriptions

Key Description

Enters the value on the display. Starts the measurement of a

calibration standard. Clears data from the buffer.

Table 1 Key descriptions (continued)

Key Description

Starts the changing of the sample number shown on the mode

display.

Selects automatic or manual ranging.

Selects the unit of measure. Exits Calibration or Setup mode

without saving changes.

Turns Ratio on or off.

Turns on or off the Flow mode of operation. Used only with the

automated flow cell.

Turns signal averaging on or off.

Sends the data that is on the display to a printer or computer.

Sends a calibration data report to a printer or computer when in

Calibration mode. Sends diagnostic results to a printer or computer

if held down when the instrument is turned on. Provides a print of

the setup commands when in Setup mode. Turns the print interval

feature on or off if the instrument has been configured with a printer

interval.

Moves the printer paper forward one line.

10 English

Changes the numbers and/or letters on the display. Steps through

the calibration standards. The right arrow key moves the cursor to

the previous or next digit.

Turns on Setup mode and starts the selection of the setup number

on the mode display.

Starts a calibration when in FNU, FAU, NTU or EBC mode. Starts

analytical zeroing when in %T or Abs mode.

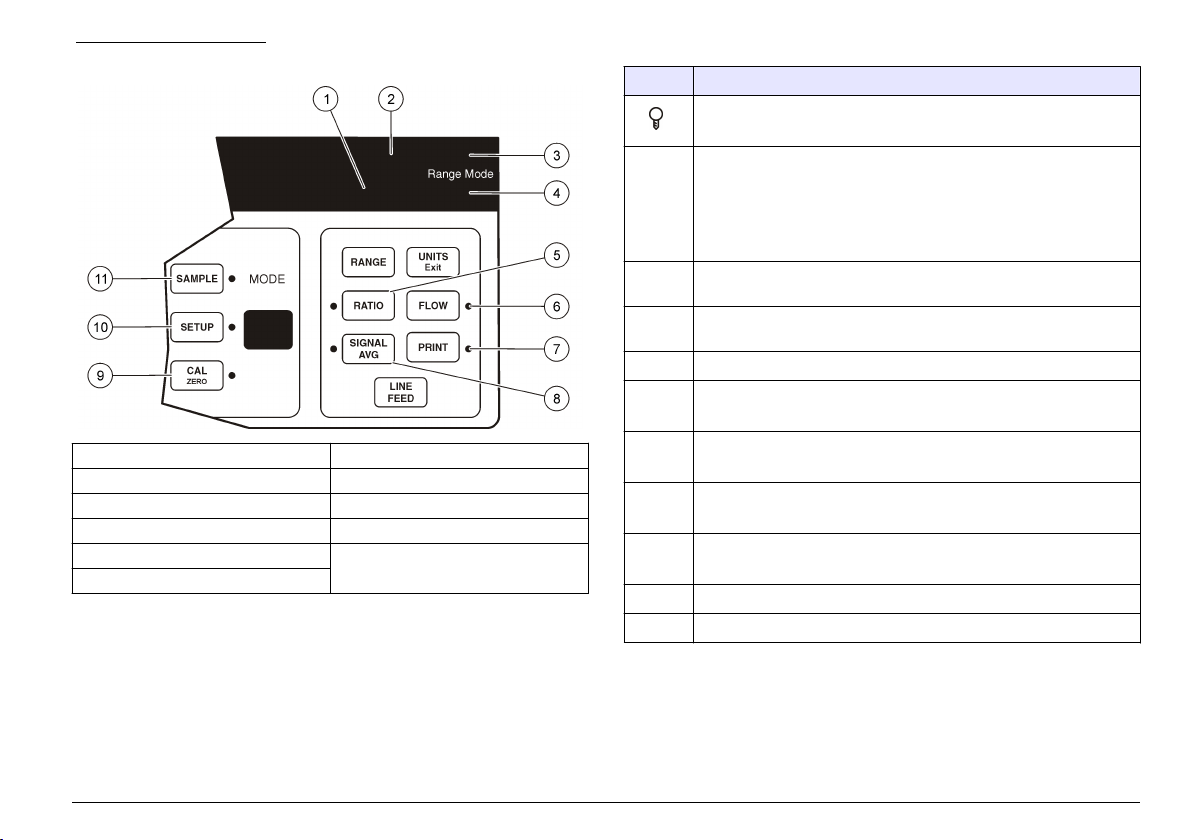

Figure 5 Indicator lights

1 Lamp icon light 7 PRINT light

2 "CAL?" light 8 SIGNAL AVG light

3 "Manual" light 9 CAL/Zero light

4 "Auto" light 10 SETUP light

5 RATIO light 11 SAMPLE light

6 FLOW light

Table 2 Light descriptions

Light Description

Illuminated when the instrument light source is on.

Flashes when there is not sufficient light for measurement.

CAL? "CAL?" is shown during a calibration if the calibration data is not

within the acceptable range.

Flashes when the instrument should be calibrated.

Note: The CAL? light applies when a 25-mm sample cell is used. Ignore the

CAL? light if illuminated during calibration when a smaller sample cell is used.

Push UNITS/Exit to start measurements.

Manual "MANUAL" is shown above the Range Mode label when the

RATIO Illuminated when Ratio is on.

FLOW Illuminated when the Flow mode of operation is selected.

PRINT Illuminated when the printer interval feature is selected.

SIGNAL

SETUP Illuminated when Setup mode is selected.

SAMPLE Illuminated when Sample mode is selected.

instrument is in manual ranging mode.

Auto "AUTO" is shown below the Range Mode label when the instrument is

in auto ranging mode.

Flashes when the flow cycle is done.

Flashes when a print interval has been selected but is not active.

Illuminated when signal averaging is on.

AVG

CAL

Illuminated when Calibration or Zeroing mode is selected.

Zero

English 11

Startup

Set the date and time

Turn the instrument on

C A U T I O N

Infrared Light Hazard. The infrared light produced by this instrument can cause

eye injury. The infrared light source in this instrument only receives power when

the sample cell cover is closed.

1. Put the instrument on a stable, level surface that is free of vibration.

Do not put in direct sunlight.

2. Make sure that there is air circulation around the instrument. Keep

the back and area below the instrument free of material that could

decrease air flow through the vents.

3. Connect the power cord to the power plug on the back of the

instrument.

4. Connect the power cord to a power socket with ground contact.

5. Push the power switch on the back of the instrument to turn the

instrument on.

Turn the keypad sound off (optional)

By default, the instrument makes an audible sound when a key is

pushed. To turn the keypad sound off:

1. Push SETUP. The SETUP light turns on.

2. Use the arrow keys to select 00.

3. Push ENTER.

4. Use the arrow keys to select the sound option:

Option Description

BEEP ON An audible sound is made when a key is pushed.

BEEP OFF No sound is made when a key is pushed.

5. Push ENTER.

6. Push SETUP.

1. Push SETUP. The SETUP light turns on.

2. Use the arrow keys to select an option:

Option Description

05 Sets the hours and minutes (HH-MM).

06 Sets the month and day (MM-DD).

07 Sets the year (YY).

3. Push ENTER.

4. Use the arrow keys to change the value.

5. Push ENTER.

6. Push SETUP.

Show the current time (optional)

1. Push SETUP. The SETUP light turns on.

2. Use the arrow keys to select 08.

3. Push ENTER. The current time is shown on the display (HH-MM-

SS).

4. Push SETUP.

Standard operation

Calibrate the turbidimeter with StablCal® Standards

Calibrate the turbidimeter before it is used for the first time using the

StablCal® sealed vial standards provided. As an alternative, calibration

can be done with recently prepared formazin standards. Refer to

Calibrate the turbidimeter with formazin standards on page 37.

Calibrate the turbidimeter at least every 3 months or as specified by the

regulating authority when data is used for ISO 7027 reporting.

Note: Unknown results may occur if standards other than the recommended

calibration points are used. The recommended calibration points (< 0.1, 20, 200,

1000, 4000 and 7500 NTU) provide the best calibration accuracy. Use of standards

12

English

other than StablCal, or user-prepared formazin, may result in less accurate

calibrations. The manufacturer cannot guarantee the performance of the instrument

if calibrated with co-polymer styrenedivinylbenzene beads or other suspensions.

Prepare the StablCal standards

When received and at intervals:

1. Clean the exterior surface of the StablCal vials with laboratory glass

cleaning detergent.

2. Rinse the vials with distilled or deionized water.

3. Dry the vials with a lint-free cloth.

Note: Never shake or invert the < 0.1 NTU standard. If the standard has been

mixed or shaken, do not move the vial for 15 minutes or more before using.

Note: Do not remove the caps from the sealed vials.

Make sure that the StablCal standards are at ambient instrument

temperature before use (and no greater than 40 °C (104 °F)).

Mix the standards before use:

1. Open the case lid. Remove the < 0.1 NTU standard from the plastic

case.

2. Leave the other standards in the case. Close the case lid.

3. Shake the case vigorously for at least 10 seconds.

4. Let the standards stand with no movement for 3–5 minutes before

use.

Calibration notes

• Make sure that the instrument is in the same ambient conditions as

where it is used.

• Make sure that the standards are at the same ambient temperature as

the instrument before use.

• Use only the provided silicone oil. This silicone oil has the same

refractive index as the vial glass and masks minor glass differences

and scratches.

• Store the oiling cloth in a plastic storage bag to keep the cloth clean.

• If power is lost during calibration, the new calibration data is lost and

the last calibration data is used. To exit a calibration and not save the

new values, push UNITS/Exit.

• In Calibration mode, automatic range and signal averaging on are

selected. When calibration is completed, all operational modes go

back to the last settings.

• All nephelometric (turbidity units of measure) calibrations are done at

the same time.

• Ratio-on and Ratio-off calibration data is measured and recorded at

the same time.

• The 4000-NTU and 7500-NTU standards do not have to be measured

during calibration if FNUs will be measured. Push CAL/Zero after the

1000 NTU standard is measured to complete the calibration

procedure.

• The 7500-NTU standard does not have to be measured during

calibration if turbidity less than 4000 NTU will be measured. Push

CAL/Zero after the 4000 NTU standard is measured to complete the

calibration procedure.

• The FNU values of StablCal standards and formazin standards are

calculated using the conversion factors of 1 FNU = 1 NTU.

English 13

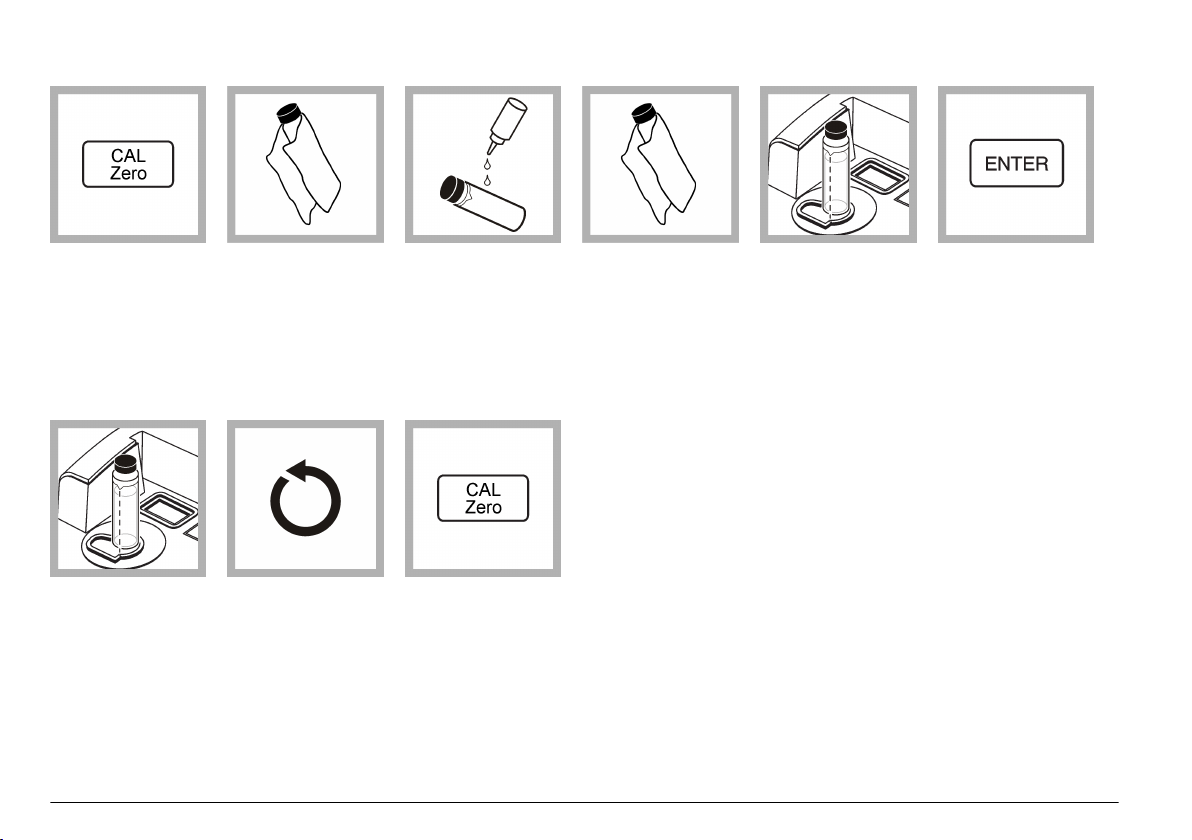

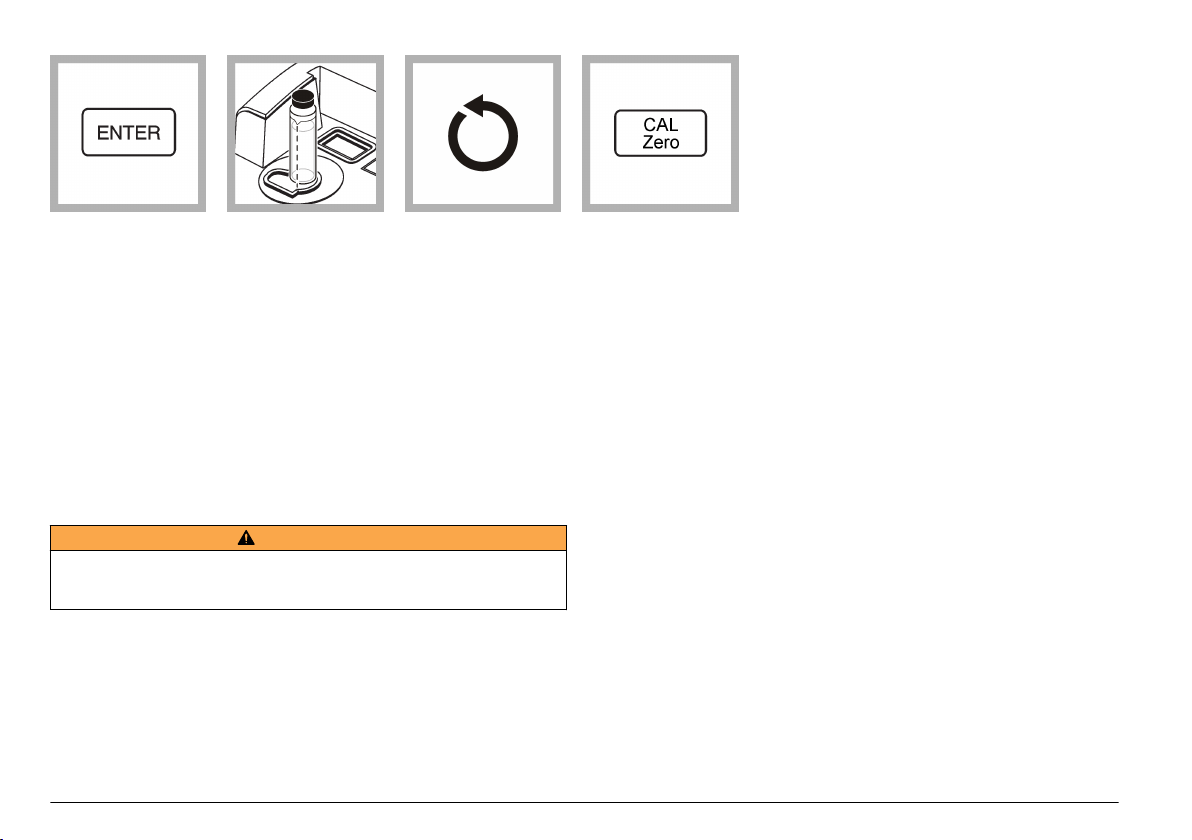

StablCal calibration procedure

1. Push CAL/Zero.

The CAL/Zero light

turns on, and the mode

display shows "00". The

NTU value of the

dilution water that was

used in the previous

calibration is shown on

the display.

7. Remove the vial

from the sample cell

holder.

14 English

2. Get the < 0.1 NTU

vial. Clean the vial with

a soft, lint-free cloth to

remove water spots and

fingerprints. Do not

invert the vial.

8. Do steps 5–10 for

the other StablCal vials

(from lowest to highest

NTU standard).

The mode display

shows "00" after the

last vial is measured.

3. Apply a small bead

of silicone oil from the

top to the bottom of the

vial.

9. Push CAL/Zero.

The instrument saves

the new calibration data

and goes back to

Measurement mode.

4. Use the oiling cloth

to apply the oil equally

to the surface of the

vial. Remove the

excess oil. Make sure

that the vial is almost

dry.

5. Put the vial in the

sample cell holder with

the triangle on the vial

aligned with the

reference mark on the

sample cell holder.

Close the cover.

6. Push ENTER.

The instrument display

counts down, then

measures the standard.

The next expected

standard (e.g., 20.00) is

shown. The mode

display shows "01".

StablCal standards storage

instrument due to small differences in glass and instrument optical

systems.

• Do not move a StablCal standard to a different container for storage.

Keep StablCal standards in the plastic case provided with the cover

closed.

• Store at 5 to 25 °C (41 to 77 °F).

• For long-term storage (more than one month between use), keep at

5 °C (41 °F).

• Do not keep a Gelex vial in the instrument for more time than is

necessary to complete measurement. The heat from the lamp can

change the turbidity value of a Gelex vial.

• Keep the Gelex standards at room temperature. Do not let Gelex

standards freeze or become warmer than 50 °C (122 °F). High

temperatures may cause Gelex suspensions to divide.

• Make sure that the Gelex standards are at ambient instrument

Using Gelex secondary standards

temperature before measurement.

The Gelex secondary standards are used when a calibration check or an

optical system check is done. Refer to Calibration verification

on page 17 and Optical system check on page 17.

Gelex notes

• Measure the Gelex secondary standards on the instrument on which

they will be used. The measured values can only be used for one

Measure the Gelex stray light standard

Measure the Gelex stray light standard when the instrument is first received. Record the value on the Gelex vial with a permanent marker one time.

1. Clean the stray light

standard with a soft,

lint-free cloth to remove

water spots and

fingerprints.

2. Apply a small bead

of silicone oil from the

top to the bottom of the

vial.

3. Use the oiling cloth

to apply the oil equally

to the surface of the

vial. Remove the

excess oil. Make sure

that the vial is almost

dry.

4. Push RANGE to

select automatic

ranging.

"AUTO" is shown below

the Range Mode label

on the instrument.

5. Push SIGNAL AVG

to turn signal averaging

off.

The SIGNAL AVG light

turns off.

6. Push UNITS/Exit to

select the NTU

measurement mode.

English 15

7. Push RATIO to turn

Ratio mode on.

8. Put the stray light

standard in the sample

cell holder with the

triangle on the vial

aligned with the

reference mark on the

sample cell holder.

Close the cover.

9. Read the value

when stable. Remove

the vial from the

instrument.

10. Record the value

on the white diamond

space on the vial using

a permanent marker.

Measure the Gelex secondary turbidity standards

Measure the Gelex secondary turbidity standards each time the instrument is calibrated and record the new values on the Gelex vials with a water

soluble marker.

1. Clean the Gelex

vials with a soft, lint-free

cloth to remove water

spots and fingerprints.

16 English

2. Apply a small bead

of silicone oil from the

top to the bottom of the

vial.

3. Use the oiling cloth

to apply the oil equally

to the surface of the

vial. Remove the

excess oil. Make sure

that the vial is almost

dry.

4. Push RANGE to

select automatic

ranging.

"AUTO" is shown below

the Range Mode label

on the instrument.

5. Push SIGNAL AVG

to turn signal averaging

off.

The SIGNAL AVG light

turns off.

6. Push UNITS/Exit to

select the NTU

measurement mode.

7. Push RATIO to

select Ratio on or off.

Ratio must be on for

Gelex standards

greater than 40 NTU.

For the 0–2 and 0–

20 NTU Gelex

standards, select the

Ratio function that the

instrument will operate

in.

8. Put the 0–2 NTU

Gelex vial in the sample

cell holder with the

triangle on the vial

aligned with the

reference mark on the

sample cell holder.

Close the cover.

9. Read the value

when stable. Remove

the vial from the

instrument.

10. Record the value

on the white diamond

space on the vial using

a water soluble marker.

Record on the vial if

Ratio was on or off

when the vial was

measured.

11. Do steps 7–10 for

the other Gelex vials

(but not the stray light

standard). Measure

from lowest to highest

NTU.

Calibration verification

At intervals, measure the Gelex secondary turbidity standard that is

closest in value to the turbidity range to be measured. Do the steps in

Measure the Gelex secondary turbidity standards on page 16, but do not

change the value that is recorded on the vial.

Turn Ratio on if the Gelex vial is greater than 40 NTU. Select the Ratio

setting recorded on the Gelex vial for vials less than 40 NTU.

If the measured value is within ±5% of the value recorded on the Gelex

vial, calibration is verified. If not, calibrate the instrument.

Note: The StablCal® primary turbidity standards can also be used to do a

calibration check. Prepare the StablCal vials before use. Refer to Prepare the

StablCal standards on page 13. Do not use the < 0.1 NTU StablCal vial as it does

not have an accurately identified NTU value. The instrument is calibrated if the

measured value is within ±5% of the StablCal value.

Optical system check

At intervals, measure the Gelex stray light standard to inspect the

integrity of the optical system. Do the steps in Measure the Gelex stray

light standard on page 15, but do not change the value that is recorded

on the vial.

If the value measured is similar to the value recorded on the Gelex stray

light standard (within ±0.02 NTU), the instrument works correctly. If not,

contact Customer Service.

Prepare a sample cell

Use a clean sample cell(s) for sample measurement.

Note: As an alternative, a flow cell can be used for sample measurement. Refer to

Using a flow cell on page 30.

English 17

Clean the sample cell

C A U T I O N

Chemical exposure hazard. Obey laboratory safety procedures and

wear all of the personal protective equipment appropriate to the

chemicals that are handled. Refer to the current material safety data

sheets (MSDS) for safety protocols.

N O T I C E

Do not air dry the sample cells. Always store the sample cells with caps on to

prevent the cells from drying. For storage, fill the sample cell with distilled or

demineralized water.

1. Clean the internal and external surfaces of the sample cell and cap

with a laboratory glass cleaning detergent.

2. Fully rinse the sample cell many times with distilled or deionized

water.

3. Clean the internal and external surfaces of the sample cell and cap

with 1:1 hydrochloric acid.

4. Fully rinse the sample cell many times with distilled or deionized

water.

Note: If the sample cell will be used to measure low range turbidity samples or

dilution water, rinse with dilution water (not distilled or deionized water). Refer

to Prepare dilution water on page 23.

5. Dry the external surface of the sample cell with a soft, lint-free cloth.

6. Fill the sample cell with distilled or deionized water.

Note: If the sample cell will be used to measure low range turbidity samples or

dilution water, fill the sample cell with dilution water (not distilled or deionized

water).

7. Immediately put the cap on the sample cell.

Note: Hold the sample cell by the top only to minimize dirt and fingerprints.

18 English

Indexing a single sample cell

When measuring very low turbidity samples, use a single indexed sample cell or a flow cell for all measurements to get precise and repeatable

measurements. As an alternative, optically matched sample cells can be used. Refer to Matching sample cells on page 21. Matched sample cells do

not provide as good of accuracy and precision as a single indexed sample cell that is used for every measurement or a flow cell.

1. Rinse a clean,

empty sample cell two

times with dilution water

and drain to waste. Fill

the sample cell to the

line (about 30 mL) with

dilution water and

immediately put the cap

on the sample cell.

Refer to Prepare

dilution water

on page 23.

Let the sample cell sit

for at least five minutes

to degas.

2. Clean the sample

cell with a soft, lint-free

cloth to remove water

spots and fingerprints.

3. Apply a small bead

of silicone oil from the

top to the bottom of the

sample cell.

4. Use the oiling cloth

provided to apply the oil

equally to the surface of

the sample cell.

Remove the excess oil.

Make sure that the

sample cell is almost

dry.

5. Put the sample cell

in the sample cell

holder. Close the cover.

Record the value when

stable.

6. Remove the sample

cell, turn it about 1/8 of a

turn and put it in the

sample cell holder

again. Close the cover.

Record the value when

stable.

English 19

7. Repeat step 6 until

the lowest value is

shown on the display.

8. Put an orientation

mark on the marking

band near the top of the

sample cell where the

lowest value is shown.

20 English

Matching sample cells

To decrease the effects that optical differences among sample cells can have on turbidity, transmittance or absorbance measurements, measure

samples in matched sample cells. It may not be possible to match all sample cells due to the differences in glass.

1. Rinse two or more

clean, empty sample

cells two times with

dilution water and drain

to waste. Fill the

sample cells to the line

(about 30 mL) with

filtered dilution water

and immediately put the

cap on the sample cell.

Refer to Prepare

dilution water

on page 23.

Let the sample cell sit

for at least five minutes

to degas.

2. Clean the sample

cells with a soft, lint-free

cloth to remove water

spots and fingerprints.

Do not invert the

sample cell.

3. Apply a small bead

of silicone oil from the

top to the bottom of the

sample cells.

4. Use the oiling cloth

provided to apply the oil

equally to the surface of

the sample cells.

Remove the excess oil.

Make sure that the

sample cells are almost

dry.

5. Put the first sample

cell in the sample cell

holder. Close the cover.

Record the value when

stable.

6. Remove the sample

cell, turn it about 1/8 of a

turn and put it in the

sample cell holder

again. Close the cover.

Record the value when

stable.

English 21

7. Repeat step 6 until

the lowest value is

shown on the display.

13. Do steps 9–

12 again as necessary

to match the other

sample cells prepared

in steps 1–4.

8. Record the value.

Put an orientation mark

on the marking band

near the top of the

sample cell.

9. Put the second

sample cell in the

sample cell holder.

Close the cover.

Record the value when

stable.

10. Remove the

sample cell, turn it

about 1/8 of a turn and

put it in the sample cell

holder again. Close the

cover.

Record the value when

stable.

11. Repeat step

10 until the value

matches the first

sample cell value within

±0.005 FNU.

Note: Match sample

cells to within

±0.002 absorbance

units when indexing

sample cells in the

Absorbance mode for

use with transmittance

or absorbance

measurements.

12. Put an orientation

mark on the marking

band near the top of the

sample cell where the

lowest value is shown.

22 English

Prepare dilution water

Dilution water is used when indexing a sample cell or matching sample

cells and to prepare formazin standards.

1. Collect at least 1000 mL of high-quality, low-turbidity water (i.e.,

distilled, demineralized or deionized water or filtered tap water).

2. Measure the turbidity of the water using the turbidimeter. Refer to

Turbidity measurement on page 25.

3. If the turbidity of the water is greater than 0.5 NTU, filter the water

using the sample filtration and degassing kit. Refer to the user

instructions provided with the sample filtration and degassing kit.

Prepare the sample

Proper sampling techniques are important to get accurate

measurements.

Prepare a representative sample

A representative sample accurately reflects the true condition of

the water source from which the sample was taken.

To prepare a representative sample:

• Gently but fully mix every sample before collecting aliquots (sample

portions). Mix by gentle inversion only. Do not shake.

• When collecting a sample from a water tap in a distribution system or

treatment plant, turn the water on for at least five minutes, then collect

the sample.

• When collecting a sample from a body of water (e.g., a stream or

storage tank), collect at least one liter (1 quart) and fully mix before

taking an aliquot for measurement. If the quality of the sample source

is not constant, collect samples at many locations at different depths

as necessary. Then, mix the samples together to prepare one sample

for measurement.

Remove air bubbles from the sample

If readings are not stable, air bubbles may be the cause. Remove air or

other gases from the sample before measurement even if no bubbles

can be seen.

The methods typically used for degassing are:

• Let the sample stand for several minutes

• Apply a vacuum

• Use an ultrasonic bath

• Apply heat

Let the samples stand for several minutes, then gently invert two or three

times before measurement.

In some cases, more than one method may be necessary to remove

bubbles (e.g., the use of heat with an ultrasonic bath may be necessary

in some severe conditions). Use care with these methods as sample

turbidity can be changed if these methods are not used correctly.

Apply a vacuum

Apply a vacuum with any available, clean, oil-free vacuum source, such

as the sample degassing kit, or an electric or hand-operated pump

equivalent to those in Accessories on page 46. The vacuum lowers the

atmospheric pressure above the sample letting trapped gas bubbles exit.

Vacuum works well with samples that are not viscous, such as water,

and do not contain volatile components. Application of vacuum to

viscous, volatile samples (i.e., paint resins) may cause volatile

components to come out of solution, and increase the bubbles.

Use an ultrasonic bath

An ultrasonic bath removes gas bubbles from most samples, especially

viscous liquids. The time necessary to remove bubbles may be a few

seconds to a minute or more.

To identify the time necessary for ultrasonic treatment:

1. Apply ultrasound to the sample for a short period of time, then

measure turbidity. Record the value and the treatment time.

2. Do step 1 again until there is no change in the turbidity of the

sample.

Note: In some instances, the use of ultrasound may divide gas bubbles and make

them more difficult to remove.

To use an ultrasonic bath:

1. Fill a clean sample cell with sample. Do not put the cap on the

sample cell.

English

23

2. Put 1/2 to 2/3 of the sample cell into the ultrasonic bath and let it stand

until visible bubbles are removed.

3. Remove the sample cell from the ultrasonic bath and put the cap on.

4. Fully dry the sample cell.

Apply heat

C A U T I O N

Make sure that the cap on the sample cell is loose. Increasing the temperature of

a tightly-capped sample cell may cause an explosion. More caution should be

taken when increasing the temperature of volatile compounds.

If possible, do not use heat to accelerate degassing. Heat may change

the properties of the suspended particles and cause volatile components

to come out of the solution.

Gentle heat may be used to remove bubbles from very viscous samples

when used with vacuum or ultrasound. If applying heat to the sample is

necessary, do so only as much as is necessary to complete degassing.

Before measurement, decrease the temperature of the sample to the

initial temperature, then gently invert the sample.

Prevent condensation on a sample cell

Condensation may occur on the outside of the sample cell when

measuring a cold sample in a warm, humid environment. This

condensation or fogging of the sample cell interferes with turbidity

measurement.

To prevent condensation:

• Make sure that the outside of the sample cell is dry before

measurement.

• Use the air purge system as necessary. Refer to Using the air purge

system on page 29.

• If condensation occurs while using the air purge system, warm the

sample slightly. Let the sample sit at room temperature or partially put

the sample into a warm water bath for a short time. Gently invert the

sample cell before measurement.

Note: Warming may change the sample turbidity. Measure the sample without

warming when possible.

Measure over-range samples

The nephelometric method of turbidity measurement depends on light

scattering from suspended particles. If turbidity is very high, significant

amounts of light may be absorbed by the particles, and little light is

available for scattering. This results in a negative interference causing

the measured turbidity to be lower than the actual turbidity. This

condition is called “going blind”.

Methods used to prevent the instrument from going blind include:

• Turn Ratio on. Ratio on mode decreases the effects of light absorbing

particles, color, absorbance and high turbidity interferences.

• If measuring in the FNU mode, change the measurement units to NTU

by pushing UNITS/Exit. The NTU measurement mode (with Ratio on)

increases the measurement range.

• Sample dilution. Refer to Sample dilution on page 24.

When too much light is absorbed by the sample, the lamp icon on the

instrument display flashes.

Sample dilution

Use filtered sample, deionized water or distilled water for sample

dilution. Measure sample dilutions soon after they are prepared.

To prepare filtered sample, use the sample filtration and degassing kit.

Refer to the user instructions provided with the sample filtration and

degassing kit.

If the filters in the sample filtration and degassing kit plug quickly, use a

standard 47 mm filtration apparatus shown in Figure 6 with a membrane

filter or use a glass-fiber filter. Refer to Accessories on page 46.

After dilution and measurement, calculate the actual turbidity as follows:

1. Calculate the total volume:

Total volume = sample + dilution water

Example: 20 mL of sample and 80 mL of dilution water

Total volume = 20 mL + 80 mL = 100 mL

2. Calculate the dilution factor:

Dilution factor = total volume ÷ sample volume

Example: Dilution factor = 100 ÷ 20 = 5

24

English

3. Calculate the actual turbidity:

Actual turbidity = measured value × dilution factor

Example: Measured value = 2450 NTU

Actual turbidity = 2450 × 5 = 12,250 NTU

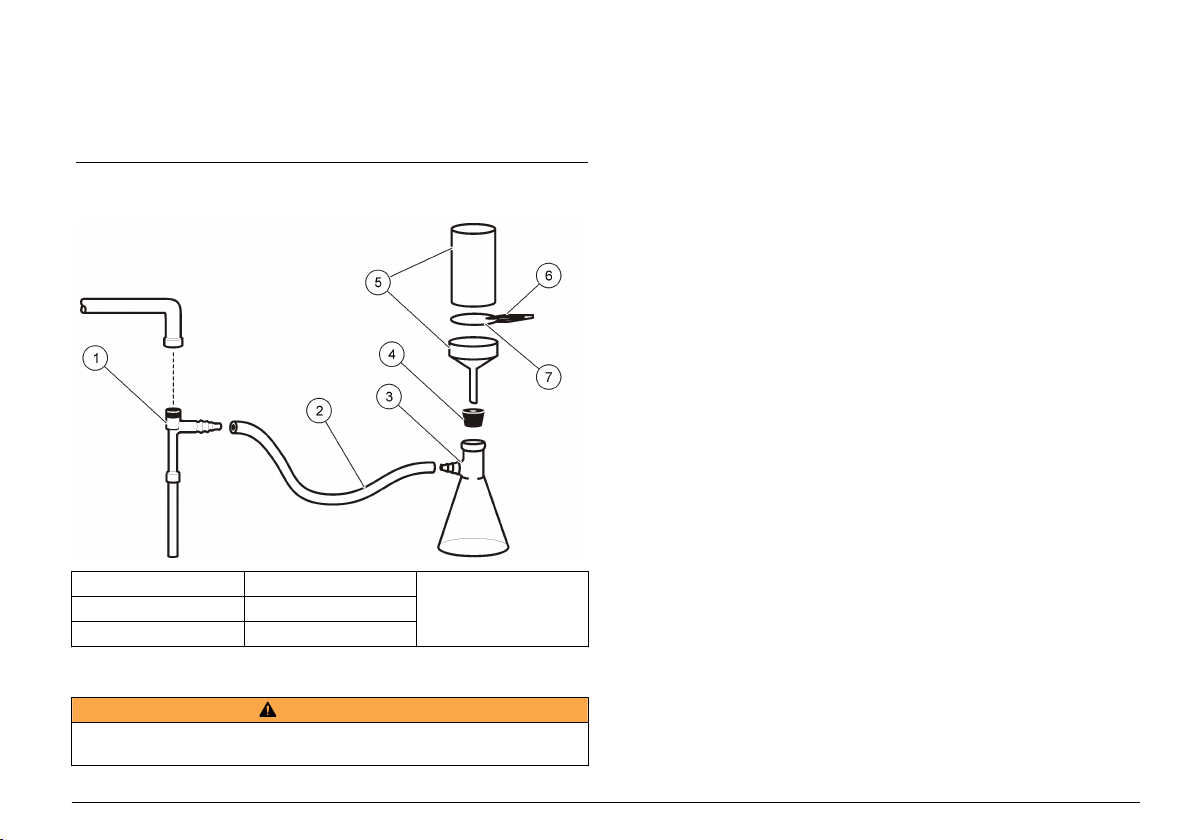

Figure 6 Prepare filtered sample using membrane or glass-fiber

filter

1 Filter pump 4 Stopper 7 Filter

2 Hose 5 Filter holder

3 Filter flask 6 Tweezers

Turbidity measurement

W A R N I N G

Potential explosion and fire hazard. This instrument is for measuring water based

samples. Do not measure solvent or combustible based samples.

For accurate turbidity readings use clean sample cells and remove air

bubbles. Refer to Clean the sample cell on page 18 and Remove air

bubbles from the sample on page 23.

Measurement notes

Proper measurement techniques are important in minimizing the effects

of instrument variation, stray light and air bubbles. For accurate and

repeatable measurements:

Instrument

• Make sure that the instrument is on a level, stationary surface that is

free of vibration during the measurement.

• Instrument stabilization is immediate. No warm-up time is necessary.

• Always close the sample compartment lid during measurement,

calibration and storage.

• Remove the sample cell from the instrument and turn off the

instrument if the instrument is stored for an extended time period

(more than a month).

• Keep the sample compartment lid closed to keep dust and dirt out.

Sample cells

• Always cap the sample cell to prevent spillage of the sample into the

instrument.

• Always use clean sample cells in good condition. Dirty, scratched or

damaged cells can result in readings that are not accurate.

• Make sure that cold samples do not “fog” the sample cell. Refer to

Prevent condensation on a sample cell on page 24.

• Store sample cells filled with distilled or deionized water and cap

tightly.

• For the best accuracy, use a single sample cell for every

measurement or a flow cell.

Note: As an alternative, matched sample cells may be used for measurements but

do not provide as good of accuracy or precision as a single indexed sample cell or

flow cell. When using matched sample cells, align the orientation mark on the

sample cell with the reference mark on the sample cell holder.

Measurement

English

25

• Measure samples immediately to prevent temperature changes and

settling. Before a measurement is taken, always make sure that the

sample is homogeneous throughout.

Turbidity measurement procedure

• Avoid sample dilution when possible.

• Avoid instrument operation in direct sunlight.

1. Rinse a clean,

empty sample cell two

times with the solution

to be measured and

drain to waste. Fill to

the line (about 30 mL)

with sample and

immediately put the cap

on the sample cell.

7. Read and record the

value when stable.

Note: To print or send

(via RS232) a

measurement record,

push PRINT.

26 English

2. Clean the sample

cells with a soft, lint-free

cloth to remove water

spots and fingerprints.

3. Apply a small bead

of silicone oil from the

top to the bottom of the

sample cells.

4. Use the oiling cloth

provided to apply the oil

equally to the surface of

the sample cells.

Remove the excess oil.

Make sure that the

sample cells are almost

dry.

5. Gently and slowly

invert the sample cell to

fully mix the sample. Be

careful not to add air

bubbles.

6. Put the sample cell

in the sample cell

holder with the triangle

on the sample cell

aligned with the

reference mark on the

sample cell holder.

Close the cover.

Absorbance and transmittance measurement

Measurement notes

For the best accuracy and reproducibility:

• Absorbance and transmittance can only be measured at 860 nm.

• Set the zero reference point before measurement. Set the zero

reference point again when a measurement is not taken for several

hours as shown in Absorbance and transmittance measurement

procedure on page 27.

• Transmittance and absorbance measurements use the same zero

single sample after setting a zero reference point in one of the two

modes.

• Use a flow cell for measurements. A flow cell is necessary to get the

accuracy and reproducibilty specifications shown in Specifications

on page 5.

If a flow cell is not used, use a single indexed sample cell or match

sample cells. Sample cells should be matched using the

Transmittance or Absorbance modes. Refer to Matching sample cells

on page 21.

• Refer to Measurement notes on page 25 for more measurement

notes.

reference point. Absorbance and transmittance can be measured on a

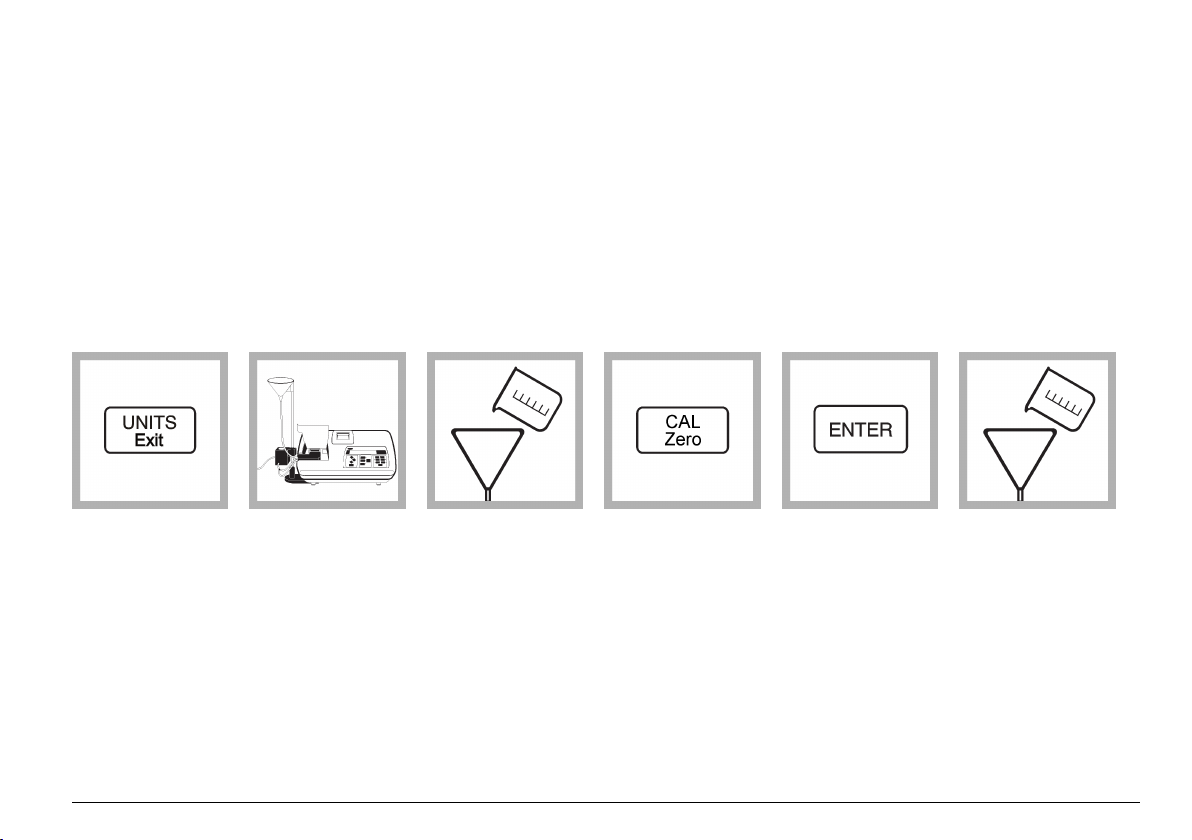

Absorbance and transmittance measurement procedure

Note: To measure samples with negative absorbance, set the analytical zero using the sample with the greatest absorbance, and measure the sample with the least

absorbance. Report the reading as negative absorbance.

1. Push UNITS/Exit

until "%T" or "ABS" is

shown on the display.

2. Using the manual

flow cell kit, install the

flow cell. Refer to Using

a flow cell

on page 30.

Note: The sample cell

cover does not close

when the flow cell is

installed.

3. Slowly put 250 mL of

100 %T or zero

absorbance reference

solution down the

interior edge of the inlet

reservoir.

Put the sample down

the interior edge of the

reservoir to prevent air

bubbles in the sample.

4. Push CAL/Zero.

The display shows

"100 %T" or zero.

Note:

The instrument starts

analytical zeroing for

transmittance, and

absorbance modes at

the same time.

5. Push ENTER.

The instrument display

counts down from 30 to

0.

Note: If the value

shown is not 100 %T,

0.000 A, or if dashes

flash, do steps 5 and

6 again.

6. Slowly put 250 mL of

the sample in the inlet

reservoir.

English 27

7. After the sample

flow stops and the

display stabilizes, read

and record the value.

Note: To print or send

(via RS232) a

measurement record,

push PRINT.

Measurement techniques

Measurements may be made with different operation mode settings and

optional accessories.

Calibrate the instrument whenever the sample cell pathlength is

changed.

Manual or automatic ranging

The manufacturer recommends that ranging be set to automatic for most

measurements.

The setting can be changed at any time during sample measurement.

Push RANGE repeatedly to step the instrument from automatic ranging

to manual ranging and then scroll through the manual range settings.

"MANUAL" is shown above the Range Mode label on the instrument

when manual ranging is selected. "AUTO" is shown below the Range

Mode label on the instrument when automatic ranging is selected.

Notes:

• When manual ranging is selected, the display flashes all 9s when the

sample being measured is greater than the selected range. The

28 English

display flashes all 0s when the sample measured is less than the

selected range.

• When automatic ranging is selected, the display flashes 9s when the

sample is greater than the maximum range of the instrument. The

display flashes 9s when Ratio is off and the measurement is greater

than 40 NTUs (1000 FNUs or 9.8 EBCs). Turn Ratio on to increase

the range. Refer to Measure over-range samples on page 24.

• When automatic ranging is selected, the display flashes all 0s when

the measurement is less than the range of the instrument (i.e., less

than 20 FAU) or a negative value. Calibrate the instrument. When

measuring absorbance or transmittance, set the zero reference point

again.

Signal averaging on or off

Signal averaging corrects for reading fluctuations that are caused by

random drifting particles in the sample. When signal averaging is on, an

average reading is calculated every 3 seconds and shown on the

display.

The manufacturer recommends that signal averaging be on for most

measurements.

Push SIGNAL AVG to turn signal averaging on or off. The SIGNAL AVG

light turns on when signal averaging is on.

Push ENTER when signal averaging is on to erase data in the signal

averaging buffer and provide an immediate update on the display as

necessary. This is especially useful when measuring samples with large

differences in turbidity.

To change the number of measurements that are used to calculate the

average reading (default=10):

1. Push SETUP. The SETUP light turns on.

2. Select 09 using the arrow keys.

3. Push ENTER.

4. Use the arrow keys to select the number of measurements—1 to 15.

Note: If a number greater than 15 is selected, 15 measurements will be used.

5. Push ENTER.

6. Push SETUP.

Ratio on or off

Ratio on provides very good linearity, calibration stability and a wide

measurement range. Ratio on helps correct for interference when color

is present in the sample that absorbs at the wavelength of incident light.

The manufacturer recommends that Ratio on be used for most

measurements. Ratio must be on to measure samples greater than

40 NTUs (9.8 EBCs).

Ratio can be turned on for NTU, EBC and ASC -1- and -2measurements.

Push RATIO to turn Ratio on or off. The Ratio light is on when Ratio is

on.

Notes:

• If the sample being measured is greater than 40 NTU (or equivalent)

and Ratio is off, the display will show 9s and the RATIO light will flash.

Push RATIO to turn Ratio on and remove the over-range condition.

• Measurements with Ratio on and measurements with Ratio off are

almost the same for turbidity measurements that are less than 40 NTU

if interferences caused by color or light absorbing particles are not

present.

Using the air purge system

The air purge system is used to keep condensation off the external

surface of the sample cell when cold samples are measured.

The air purge system pushes dry air through the optical compartment to

keep the outside the sample cell dry. The connection is made at the air

purge fitting on the back of the instrument Figure 2 on page 8.

Use dry nitrogen or instrument grade air (ANSI MC 11.1, 1975) at no

greater than 138 kPa (20 psig). The manufacturer recommends an air

consumption rate of 3 to 10 SCFH (standard cubic feet/hour).

When the sample temperature is about or less than 2 °C (35 °F), use a

desiccant dryer and particle filter to make sure that the dew point of the

air purge is less than the sample temperature. The air dryer contains

silica gel desiccant that turns pink. Replace the desiccant when it turns

pink.

If only shop air is available, use a coalescing filter with an automatic

drain and a dryer and particle filter to get instrument quality air. Use a

coalescing filter that typically operates for greater than 2000 hours.

Replace the particle filter when the air dryer is replaced.

Figure 7 and Figure 8 show the methods for connecting the two types of

air supply to the instrument.

Note: The dryer and filter are not necessary if dry nitrogen is used.

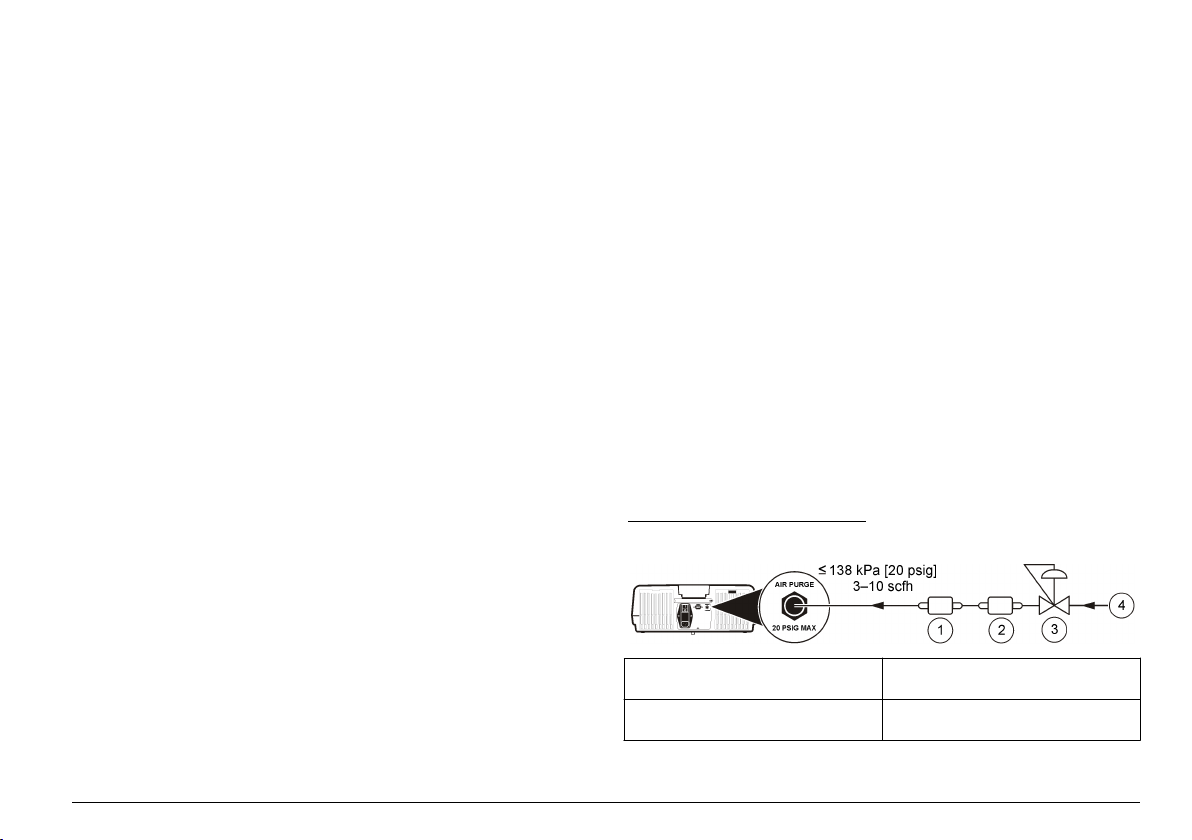

Figure 7 Instrument quality air

1 Particle filter (Balston DFU 9933-

05-BQ or equivalent)

2 Air dryer (Balston DAU 9933-

05-101 or equivalent)

3 Pressure regulator

4 Instrument air

English 29

Figure 8 Standard shop air

1 Particle filter 5 Filter (Balston 100-12-BX or

2 Air dryer 6 Auto drain (Balston 20-105 or

3 Coalescing filter/regulator (0–

30 psig)

4 Shop air

equivalent)

equivalent)

7 Filter housing (Balston

FR-920-30 or equivalent)

Using a flow cell

C A U T I O N

Do not use a flow cell with flammable samples or those that contain

hydrocarbons, solvents, concentrated acids or concentrated bases that may

damage wetted parts of the cells. Conduct tests before use of flow cells if sample

compatibility is not known.

Note: Do not use a high pressure flow cell kit with this instrument.

Use a flow cell to increase the speed, accuracy and reproducibility of

measurement. The manufacturer especially recommends using a flow

cell for low turbidity measurements.

A flow cell must be used to get the accuracy and reproducibility values in

Specifications on page 5 for absorbance or transmittance.

Install a flow cell

1. Fully clean and assemble the flow cell, tubing and stand. Refer to

Clean a flow cell assembly on page 30 and the user instructions

provided with the flow cell.

2. Fill the flow cell and tubing with water and make sure that there are

no leaks or air bubbles.

Note: Air bubbles collect in areas that are not cleaned fully.

3. Clean the exterior surface of the flow cell with a soft, lint-free cloth to

remove water spots and fingerprints.

4. Apply a small bead of silicone oil from the top to the bottom of the

flow cell.

Note: Use only the provided silicone oil. This silicone oil has the same

refractive index as the flow cell glass and masks minor glass scratches.

5. Use the oiling cloth provided to apply the oil equally to the surface of

the flow cell. Remove the excess oil. Make sure that the flow cell is

almost dry.

Note: Put the oiling cloth in a plastic storage bag to keep the cloth clean.

6. Install the flow cell in the sample cell compartment.

7. Push the inlet and outlet tubes in the slots on the top of the

instrument enclosure so the sample cell cover can be installed. Refer

to the user instructions.

8. Put the flow-cell light cover over the flow cell.

Note: The standard sample cell cover of the instrument does not close when

the flow cell is installed.

Clean a flow cell assembly

1. Disassemble the flow cell assembly.

2. Clean the inside and outside of the glass parts with a laboratory

glass cleaning detergent. Follow with multiple rinses with distilled or

demineralized water.

Note: All tubing, flow cells, and caps in the flow cell assembly can also be

steam sterilized.

3. If measuring low turbidity samples, clean the inside and outside of

the glass parts with 1:1 hydrochloric acid and rinse multiple times

with dilution water.

4. Fill the sample cell with distilled or demineralized water and

immediately put the caps on the sample cell.

5. Clean the inside and outside of the plastic parts and tubing with

laboratory detergent and warm water.

30

English

Note: At intervals, replace the tubing as contaminants, including

microbiological growths, are difficult to remove from the inside surface of the

tubing.

6. Air dry the parts after cleaning.

Flow cell maintenance

• Keep all parts of the flow cell assembly clean.

• At intervals, replace all the tubing to make sure that the system is

clean. Keep the tubing as short as possible to minimize air locking and

lag time of sample flow. Locate the instrument as close to the drain as

possible.

Flow cell operation

• Do not use the flow cell for samples that contain large particles that

may collect and stop the sample from flowing.

• Slowly put the sample down the interior edge of the inlet reservoir to

prevent mixing of the sample, which can cause air bubbles. Air

bubbles create a false positive interference in a turbidity

measurement.

• If bubbles collect in the flow cell, gently tap the flow cell on a soft

surface to remove the bubbles. If bubbles continue to collect in the

flow cell, put the glass flow cell in liquid detergent for 24 hours and

then rinse fully.

• When measuring many samples of different turbidity, measure the

samples in order of the cleanest (lowest turbidity) to the dirtiest