Page 1

DOC023.52.03221.May07

1720E Low Range Turbidimeter

USER MANUAL

May 2007, Edition 7

Page 2

© HACH LANGE GmbH, 2007. All rights reserved. Printed in Germany.

Page 3

DOC023.52.03221.May07

1720E Low Range Turbidimeter

USER MANUAL

May 2007, Edition 7

© HACH LANGE GmbH, 2007. All rights reserved. Printed in Germany.

Page 4

Page 5

Table of Contents

Section 1 Specifications......................................................................................................................................... 3

Section 2 General Information ............................................................................................................................... 5

2.1 Safety Information............................................................................................................................................... 5

2.1.1 Use of Hazard Information......................................................................................................................... 5

2.1.2 Precautionary Labels................................................................................................................................. 5

2.1.3 General Product Information ..................................................................................................................... 6

2.2 Theory of Operation ............................................................................................................................................ 7

Section 3 Installation .............................................................................................................................................. 9

3.1 Connecting/Wiring the Sensor to the sc100 Controller ....................................................................................... 9

3.1.1 Attaching a sc Sensor with a Quick-connect Fitting .................................................................................. 9

3.1.2 Hard-wiring a sc Sensor to the sc100 Controller ..................................................................................... 10

3.2 Connecting the Sensor to the sc1000 Controller .............................................................................................. 11

3.2.1 Connecting the Sensor using the Quick-connect Fittings........................................................................ 11

3.3 Turbidimeter Installation Information................................................................................................................. 11

3.3.1 Mounting the Turbidimeter Body ............................................................................................................. 13

3.3.2 Installing the Head Assembly .................................................................................................................. 13

3.4 Installing a Sample Line.................................................................................................................................... 13

3.5 Sample Connections......................................................................................................................................... 14

Section 4 System Startup..................................................................................................................................... 15

4.1 General Operation ............................................................................................................................................ 15

4.2 Starting Sample Flow........................................................................................................................................ 15

Section 5 Operation .............................................................................................................................................. 17

5.1 Sensor Setup .................................................................................................................................................... 17

5.2 Sensor Data Logging ........................................................................................................................................ 17

5.3 Sensor Diagnostics Menu ................................................................................................................................. 17

5.4 Sensor Setup Menu .......................................................................................................................................... 18

5.5 Sensor Calibration and Verification................................................................................................................... 18

5.5.1 User-prepared Calibration ....................................................................................................................... 19

5.5.2 Calibration with StablCal

5.5.3 Instrument Verification............................................................................................................................. 21

5.5.3.1 Dry Verification............................................................................................................................... 21

5.5.3.2 Wet Verification .............................................................................................................................. 21

5.6 Calibration and Verification History ................................................................................................................... 22

5.7 Offset Feature ................................................................................................................................................... 22

5.7.1 Setting the Offset..................................................................................................................................... 23

Section 6 Maintenance ......................................................................................................................................... 25

6.1 Maintenance Schedule ..................................................................................................................................... 25

6.2 Removing a Sensor from the System ............................................................................................................... 25

6.3 Reinstalling a Sensor on the System ................................................................................................................ 25

6.4 Cleaning............................................................................................................................................................ 26

6.4.1 Cleaning the Photocell Window............................................................................................................... 26

6.4.2 Cleaning the Turbidimeter Body and Bubble Trap .................................................................................. 26

6.4.3 Replacing the Lamp Assembly ................................................................................................................ 27

® .......................................................................................................................................................20

Section 7 Troubleshooting................................................................................................................................... 29

7.1 Error Codes....................................................................................................................................................... 29

7.2 Warnings........................................................................................................................................................... 29

7.3 Event Codes ..................................................................................................................................................... 31

1

Page 6

Table of Contents

Section 8 Replacement Parts and Accessories..................................................................................................33

8.1 Replacement Items............................................................................................................................................33

8.2 Optional Accessories.........................................................................................................................................33

8.3 Calibration and Verification Standards and Accessories................................................................................... 34

Section 9 Contact ................................................................................................................................................. 35

Section 10 Warranty and liability ........................................................................................................................ 37

Section 11 Compliance Information .................................................................................................................... 39

Appendix A Modbus Register Information..........................................................................................................41

Index .......................................................................................................................................................................43

2

Page 7

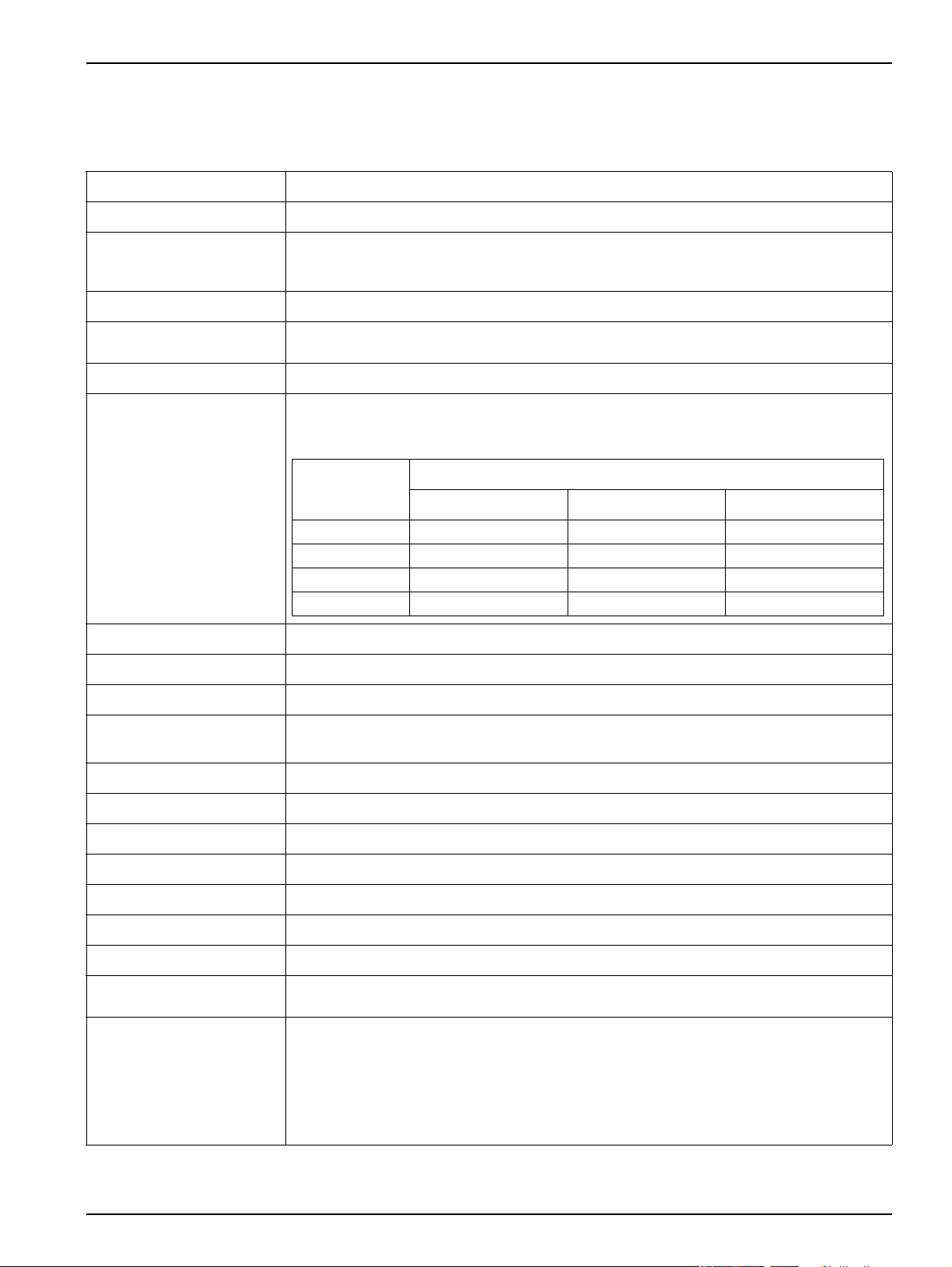

Section 1 Specifications

Specifications are subject to change without notice.

Table 1 1720E Low Range Specifications

Range 0–100 nephelometric turbidity units (NTU)

Measurement Units mg/L, NTU, TE/F, FTU, Degree

± 2% of reading or ± 0.02 NTU (whichever is greater) from 0 to 40 NTU;

± 5% of reading from 40 to 100 NTU (when calibration is performed at 20.0 NTU with the

offset turned off).

Better than 1% 0–40 NTU on formazin. Allows for accurate calibration at high turbidity values.

Accuracy

Linearity

1

1

Resolution (Displayed)

Repeatability Better than ±1.0% of reading or ±0.002 NTU, whichever is greater

Response Time

Sample Flow Required 250 to 750 mL/minute

Storage Temperature –20 to 60 °C (–4 to 140 °F)

Operating Temperature 0 to 50 °C (32–122 °F) for single sensor system, 0 to 40 °C (32–104 °F) for two sensor system

Sample Temperature

Range

Operating Humidity 5 to 95% non-condensing

0.0001 NTU up to 9.9999 NTU; 0.001 NTU from 10.000 to 99.999 NTU; 0.01 NTU at 100.00

NTU

For a full-scale step change, initial response in 1 minute, 15 seconds. Varies with flow rate,

see the table below. The response time is also dependent on the signal averaging time, which

is user selectable.

Flow Rate

% Step Change

750 500 250

10 1¼ minutes 1½ minutes 2½ minutes

50 2 minutes 2½ minutes 6 minutes

90 3½ minutes 3½ minutes 9 minutes

99 4 minutes 5 minutes 12 minutes

0 to 70 °C

Power Requirements 12 VDC ± 5%, 12.5 Watts maximum

1

Sample Inlet Fitting

Signal Average Time no averaging, 6, 30, 60, and 90 seconds, user selectable. Default is 30 seconds.

Dimensions Turbidimeter body and cap: 25.4 x 30.5 x 40.6 cm (10 x 12 x 16 inches)

Sensor Cable Length 2 m (6.6 ft); Optional 7.62 m (25 ft)

Mounting Options Turbidimeter Body and Head Assembly: Wall; floor stand

Shipping Weight

Calibration Methods

/8 barb fitting to ¼-inch NPT male adapter

1720E Series 2 Turbidimeter and Controller: 6.31 kg (13.5 lb); 1720E Turbidimeter only: 4.71

kg (10 lb)

1. StablCal

Recommended at 20.0 NTU.

2. Formazin – user-prepared primary or wet calibration of the instrument. Recommended at

20.0 NTU.

3. Multi-sensor calibration – Performed with a specialized calibration procedure for up to

eight sensors on a single set of fresh StablCal

®

(stabilized formazin) – primary or wet calibration of the instrument.

®

standards.

3

Page 8

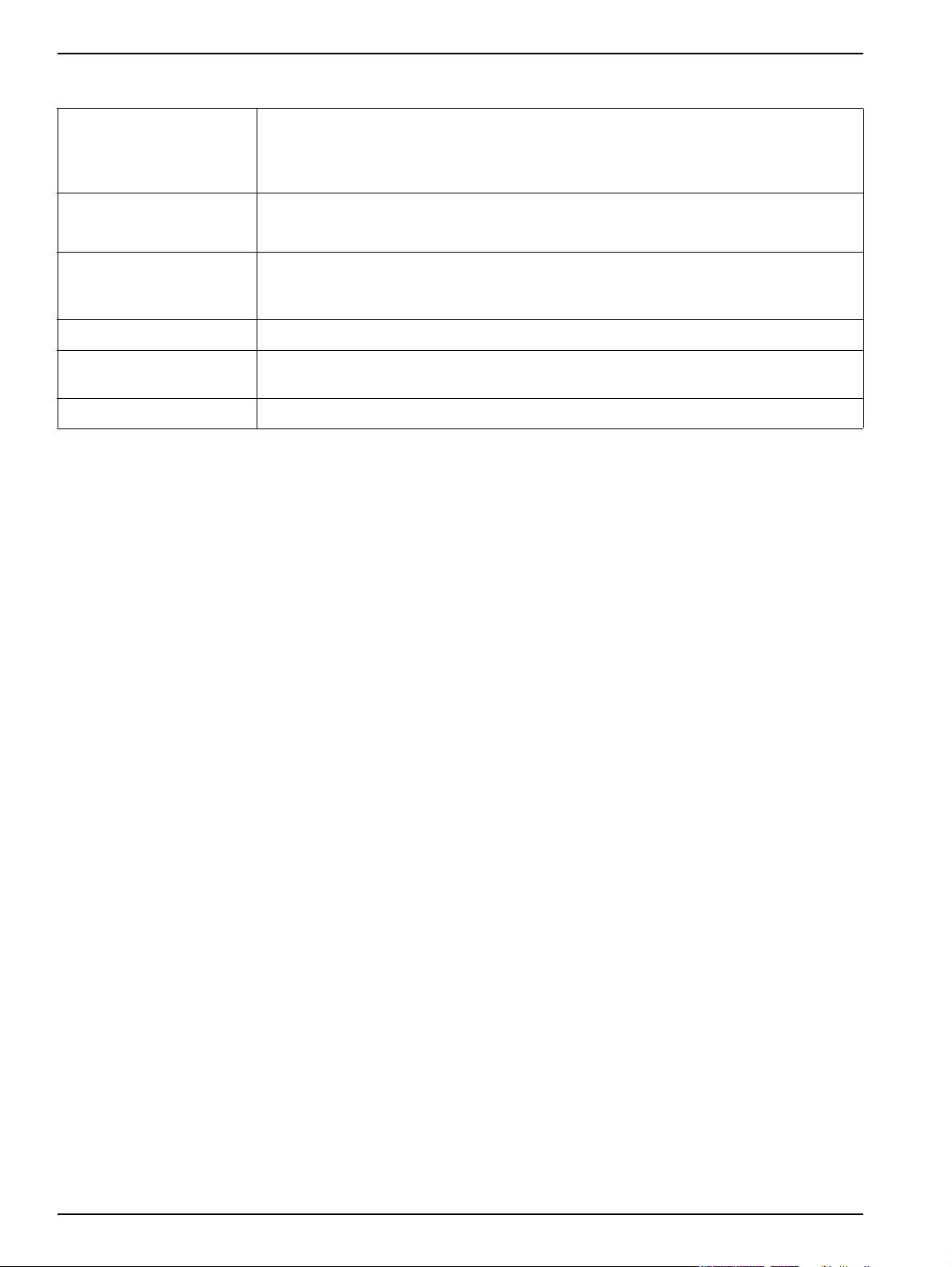

Specifications

Table 1 1720E Low Range Specifications (continued)

1. StablCal

Verification (Wet) Method

2. Formazin – fresh user-prepared standard

1. ICE-PIC™ Verification Module with factory-set values of 20.0 or 1.0 ±25%. Unique value

Verification (Dry) Method

Recommended

Maintenance

Installation Environment Indoor

1. Lamp replacement: once per year.

2. Cleaning: mandatory before calibration, optional before calibration, and mandatory upon

®

(stabilized formazin) – recommended for verification in the appropriate

application range of measurement. For regulatory verification, standards of 0.1 to 50

NTU.

is assigned when dry verification is done immediately after calibration and is used as

pass/fail criteria for subsequent verifications.

verification failure.

Primary Compliance

Method

Limit of Detection

1

All specifications are based on a calibration with 20.0 NTU formazin and with the offset turned off.

1

USEPA 180.1; Hach Method 8195; ASTM D 6698; Standard Methods 2130B

0.0032 NTU (according to criteria specified by ISO 15839)

4

Page 9

Section 2 General Information

2.1 Safety Information

Please read this entire manual before unpacking, setting up, or operating this equipment.

Pay attention to all danger and caution statements. Failure to do so could result in serious

injury to the operator or damage to the equipment.

To ensure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this manual.

2.1.1 Use of Hazard Information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Important Note: Information the requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed.

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth (ground).

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after

12 August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no charge to

the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

5

Page 10

General Information

2.1.3 General Product Information

The 1720E Turbidimeter is a continuous-reading nephelometric turbidimeter designed for

low-range turbidity monitoring. This process turbidimeter is capable of measuring turbidity

from 0.001 to 100.0 NTU. Calibration is based on formazin, the primary turbidity reference

standard adopted by the APHA Standard Methods for the Examination of Water and

Wastewater and the U.S. Environmental Protection Agency (EPA) and on StablCal

is also recognized as a primary standard.

The 1720E Turbidimeter can be operated using an sc controller. Refer to the Operation

section (Section 5 on page 17) for more information.

®

which

6

Page 11

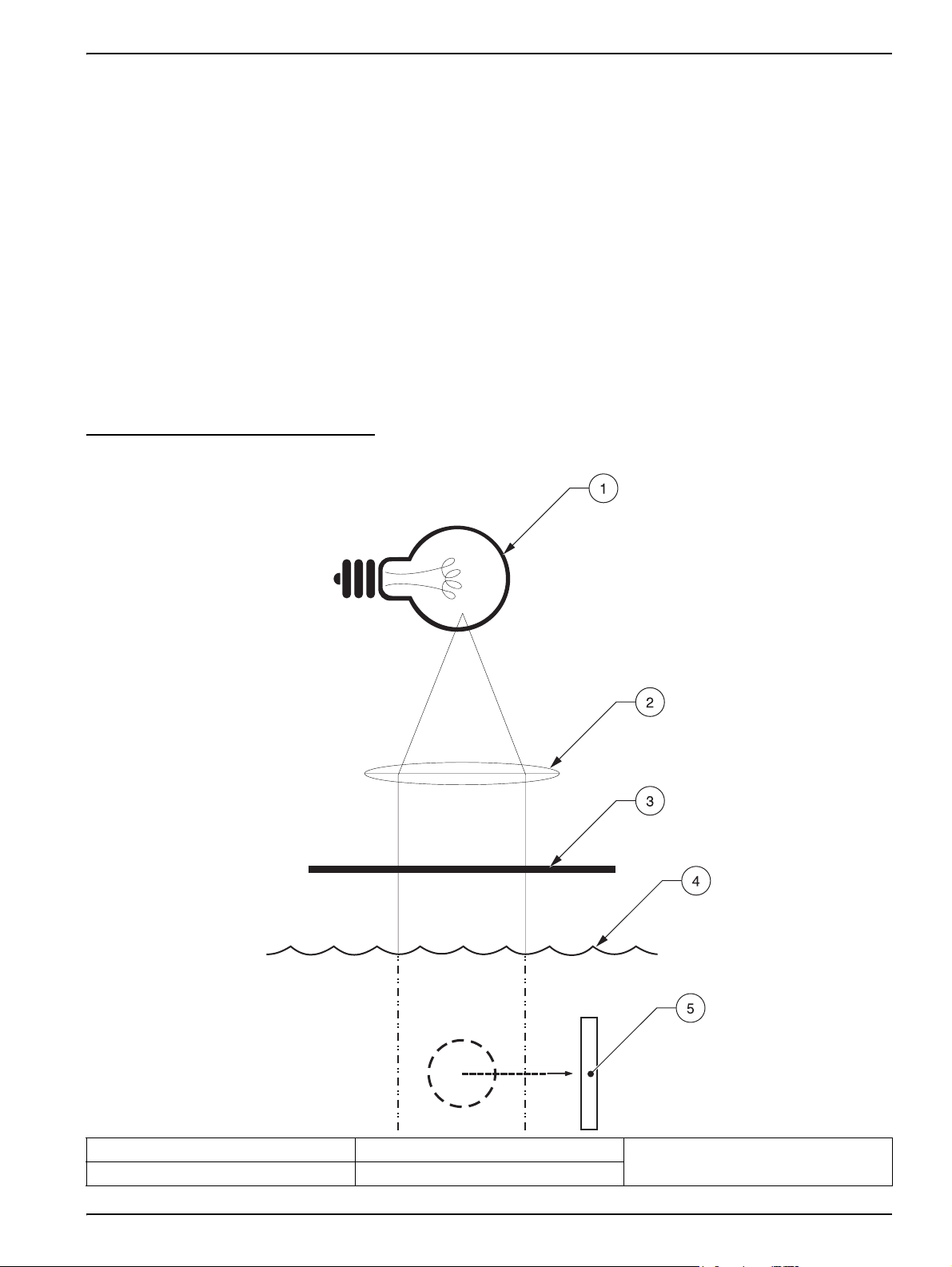

2.2 Theory of Operation

The 1720E Turbidimeter measures turbidity by directing a strong beam of collimated light

from the sensor head assembly down into the sample in the turbidimeter body. Light

scattered at 90° relative to the center line of incident light by suspended particles in the

sample is detected by the submerged photocell (Figure 1).

The amount of light scattered is proportional to the turbidity of the sample. If the turbidity of

the sample is negligible, little light will be scattered and detected by the photocell and the

turbidity reading will be low. High turbidity, on the other hand, will cause a high level of

light scattering and result in a high reading.

Sample enters the turbidimeter body and flows through the baffle network of the bubble

trap. The flow allows bubbles to either cling to surfaces of the baffle system or rise to the

surface and vent to atmosphere. After traveling through the bubble trap, sample enters the

center column of the turbidimeter body, rises into the measuring chamber and spills over

the weir into the drain port. A reading is taken once per second.

Figure 1 90 Degree Detector

General Information

1. Lamp 3. Aperture 5. 90° Detector

2. Lens 4. Water Level

7

Page 12

General Information

8

Page 13

Section 3 Installation

DANGER

Only qualified personnel should conduct the tasks described in this section of the

manual. The 1720E/sc100 product configuration is not intended for installation in

hazardous locations.

3.1 Connecting/Wiring the Sensor to the sc100 Controller

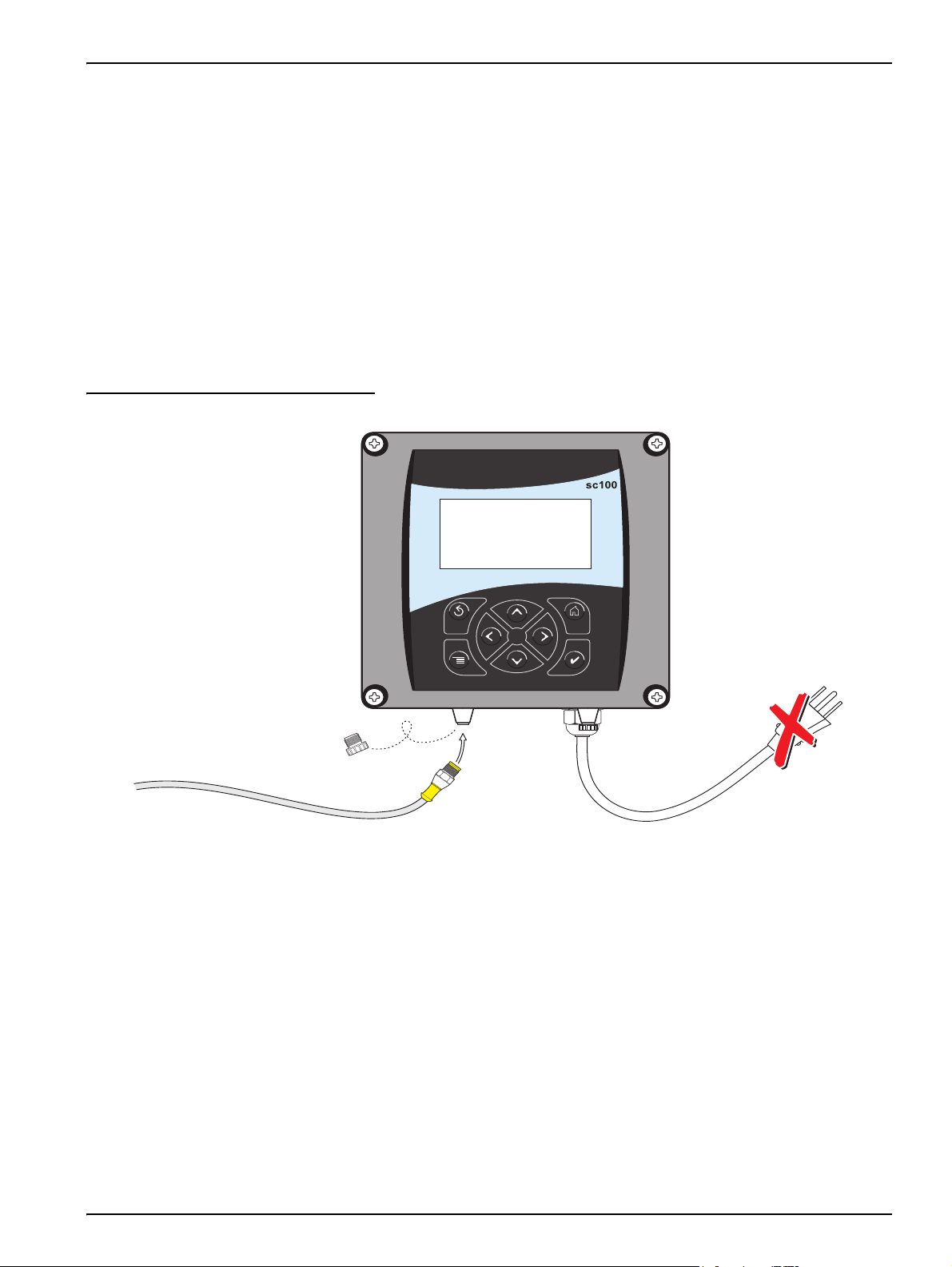

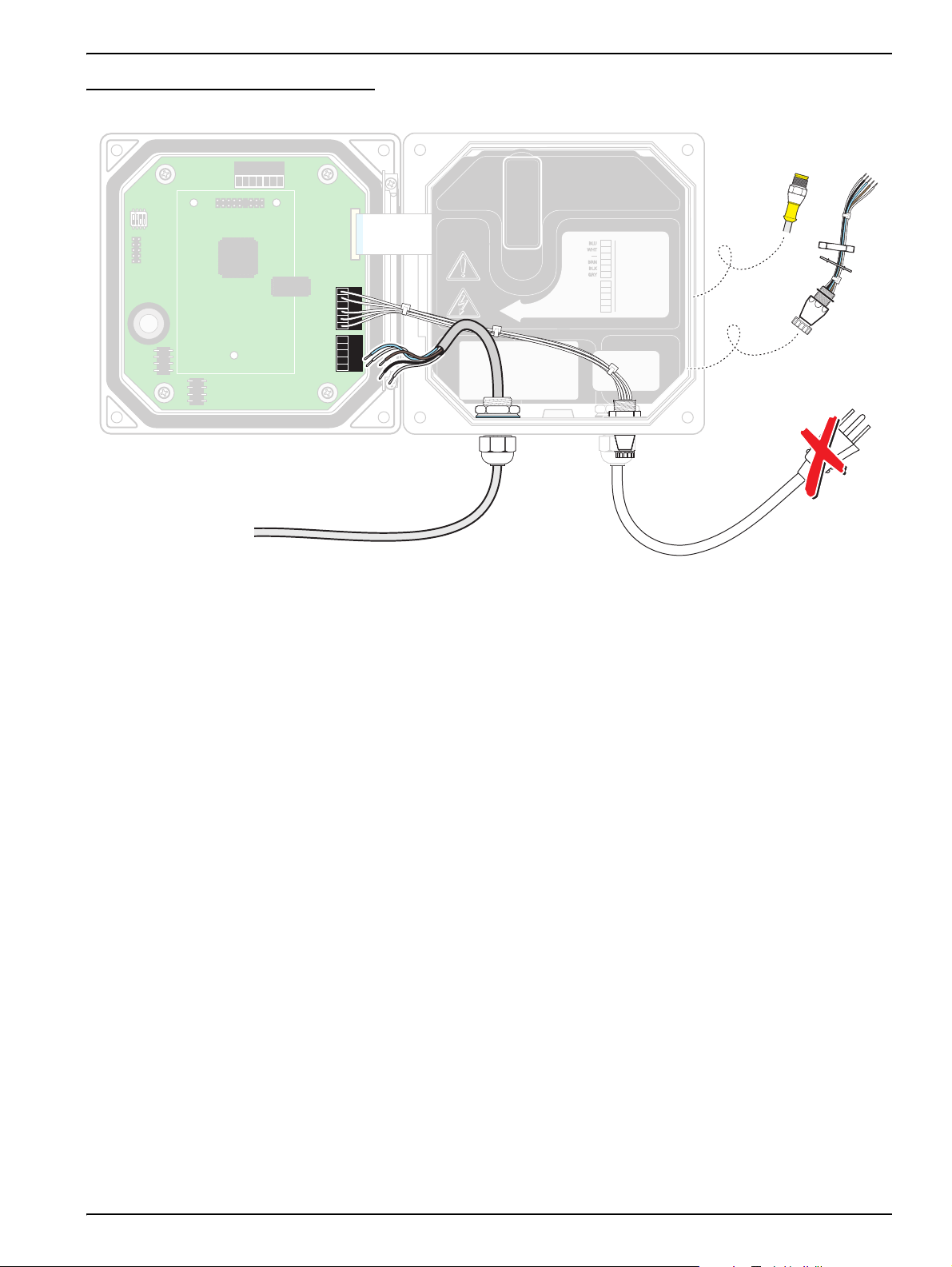

3.1.1 Attaching a sc Sensor with a Quick-connect Fitting

The sensor cable is supplied with a keyed quick-connect fitting for easy attachment to the

controller, see Figure 2. Retain the connector cap to seal the connector opening in case

the sensor must be removed. The 1720E sensor cable may be extended by a maximum of

7.62 m (25 ft), see Replacement Parts and Accessories on page 33.

Figure 2 Attaching the Sensor using the Quick-connect Fitting

9

Page 14

Installation

3.1.2 Hard-wiring a sc Sensor to the sc100 Controller

1. Disconnect power to the controller if powered.

2. Open the controller cover.

3. Disconnect and remove the existing wires between the quick-connect and terminal

strip J5, see Figure 3.

4. Remove the quick-connect fitting and wires and install the threaded plug on the

opening to maintain the environmental rating.

5. Cut the connector from the sensor cable.

6. Strip the insulation on the cable back 1-inch. Strip ¼-inch of each individual wire end.

7. Pass the cable through conduit and a conduit hub or a strain relief fitting

(Cat. No. 16664) and an available access hole in the controller enclosure.

Tighten the fitting.

Note: Use of strain relief fitting other than Cat. No. 16664 may result in a hazard. Use only the

recommended strain relief fitting.

8. Reinstall the plug on the sensor access opening to maintain the environmental rating.

9. Wire as shown in Table 2 and Figure 3.

10. Close and secure the cover.

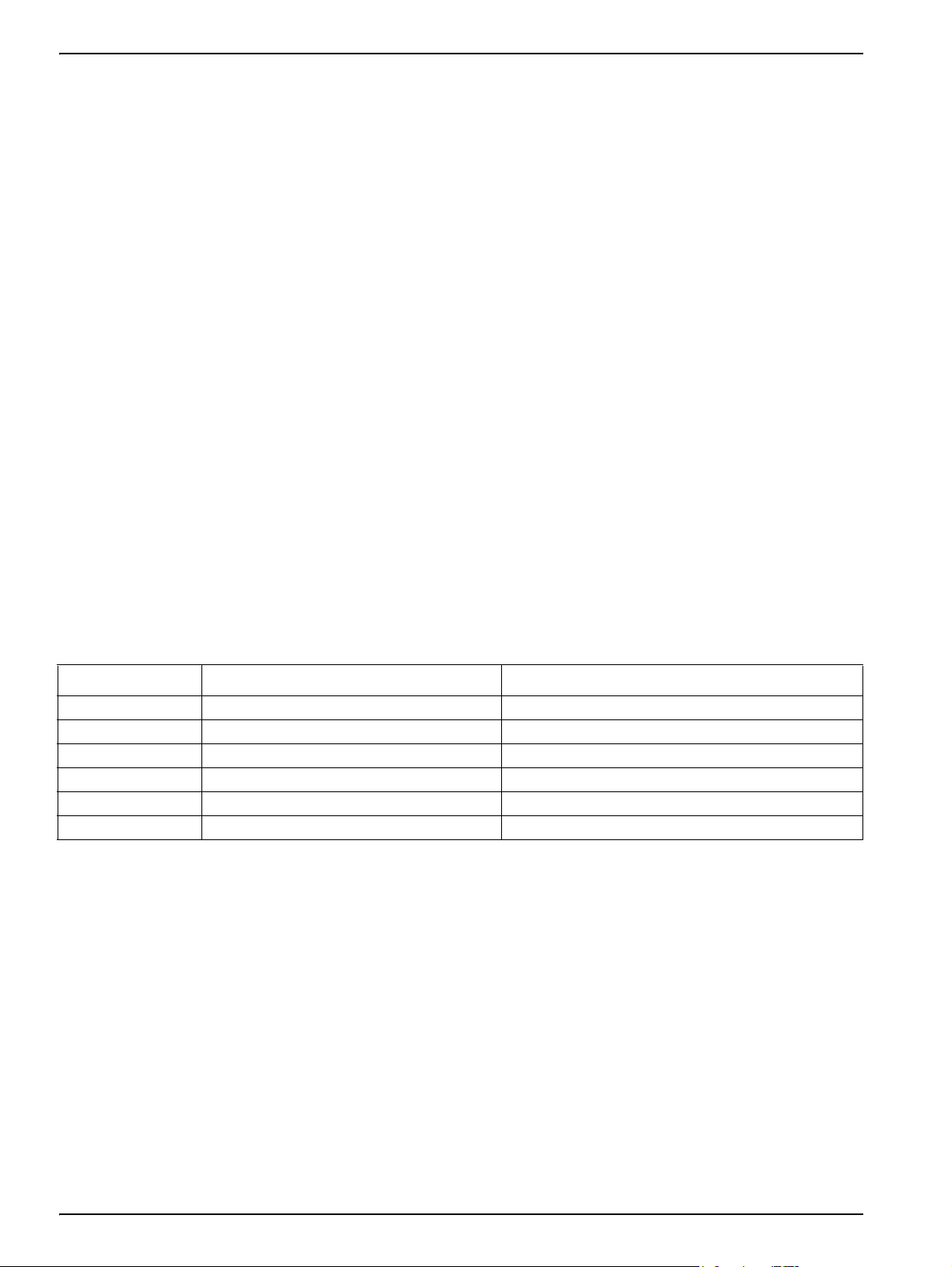

Table 2 Wiring the Sensor at Terminal Block J5

Terminal Number Terminal Designation Wire Color

1 Data (+) Blue

2 Data (–) White

3 Service Request No Connection

4 +12 V dc Brown

5 Circuit Common Black

6 Shield Shield (grey wire in existing quick disconnect fitting)

10

Page 15

Figure 3 Hard-wiring the Sensor

1

1

+

DATA

+

OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+

V

+

OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAY3RELAY2RELAY1

1

1

+

DATA

+

OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+

V

+

OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAY3RELAY2RELAY1

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

J1

J2

J4

NETWORK

INTERFACE

CARD

J3

U5

U9

S1

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

J1

S1

J2

U5

J4

U9

NETWORK

INTERFACE

CARD

J3

J5J5

J5

J5

J6

PCB

PCB

CONNECTOR

CONNECTOR

DANGER - EXPLOSION HAZARD

DANGER - EXPLOSION HAZARD

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

DANGER - RISQUE D'EXPLOSION

DANGER - RISQUE D'EXPLOSION

NE PAS DEBRANCHER TANT QUE LE EST SOUS

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

EMPLACEMENT NON-DANGEROUX

+

DATA

+

DATA

+

V

+

V

+

OUT 2

+

OUT 2

+

OUT 1

+

OUT 1

FIELD WIRING

FIELD WIRING

INSULATION MUST

INSULATION MUST

BE RATED TO

BE RATED TO

80° C MINIMUM

80° C MINIMUM

Installation

Disconnect

Power

From Probe

3.2 Connecting the Sensor to the sc1000 Controller

3.2.1 Connecting the Sensor using the Quick-connect Fittings

1. Unscrew the connector cap from the controller. Retain the connector cap to seal the

connector opening in case the sensor must be removed.

2. Push the connector into the socket.

3. Hand-tighten the union nut.

Note: Do not use the middle connection for the sensors as this is reserved for the display module.

3.3 Turbidimeter Installation Information

The turbidimeter body is designed for wall-mounting (although it may be mounted on the

optional floor stand). The turbidimeter sensor must be mounted within six feet of the

controller unless an extension cable is used. Maximum cable length is 9.6 m (31 feet).

11

Page 16

Installation

Figure 4 1720E Dimensions

12

Page 17

3.3.1 Mounting the Turbidimeter Body

Locate the turbidimeter as close to the sampling point as possible. A shorter distance for

the sample to travel results in a faster response time.

Clean the turbidimeter body and bubble trap before installation using the instructions

supplied in section 6.4.2 on page 26. Slotted mounting brackets are integral parts of the

turbidimeter body. Install customer-supplied hardware appropriate for the installation

environment using the criteria detailed below:

• Install in a location that is isolated from vibration.

• Allow at least 22 cm (approximately 10 inches) clearance for removal of the head

assembly and bubble trap cover from the top of the turbidimeter body.

• Leave enough room below the turbidimeter body to remove the bottom plug and to

place a container under the drain when calibrating or cleaning.

Note: Make sure the top of the turbidimeter body is level.

• Install two ¼-20 bolts 10-3/4 inches apart (on center). Leave at least ¼-inch of the bolt

head exposed.

• Make sure the bolts are installed level.

Installation

Slide the slotted mounting brackets of the turbidimeter body onto the bolts.

3.3.2 Installing the Head Assembly

After the turbidimeter body has been mounted, install the bubble trap cover, then place the

head assembly on the turbidimeter body with the label facing the front. Move the head

assembly back and forth slightly to ensure it is properly seated on the body of the

instrument. Failure to properly seat the head will result in light leakage and

erroneous readings.

The rear portion of the head assembly has a molded “lip” which may be used to hang the

head assembly on the turbidimeter body edge for routine maintenance.

3.4 Installing a Sample Line

DANGER

This turbidimeter is not designed for use in hazardous locations or with samples

that are flammable or explosive in nature. If any sample solution other than water is

used in this product, test the sample/product compatibility to ensure user safety

and proper product performance.

One-fourth inch OD rigid or semi-rigid tubing is recommended for sample lines. Run them

as directly as possible between the turbidimeter body and the sampling point to minimize

sample flow lag time.

Install sample line taps into larger process pipes to minimize interference from air bubbles

or pipeline bottom sediment. A tap projecting into the center of the pipe is ideal. Figure 5

shows examples of sample tap installations.

Note: When setting the flow rate, take care to avoid sweeping air “micro-bubbles” through the

internal bubble trap. Observe the sample flow inside the turbidimeter body. If small air bubbles can

be seen flowing up through the center, reduce the flow rate.

13

Page 18

Installation

Figure 5 Sampling Techniques

1

3

2

4

5 6 7 8

1. Sample Flow 4. Sediment (Typical) 7. Good

2. Sampling Line to Sensor 5. Poor 8. Best

3. Air (Typical) 6. Poor

3.5 Sample Connections

Sample inlet and drain connections are made on the turbidimeter body. The sample inlet

fitting installed in the body is a ¼-inch NPT

fitting supplied with the instrument is a ½-inch NPT-to-hose fitting for use with ½-inch ID

flexible plastic tubing on the drain.

x ¼-inch compression fitting. One additional

Note: For samples with high solids content (high turbidity), operate at the highest flow rate possible.

For samples with low solids content (low expected turbidity), operate at a low flow rate

(200–300 mL/min).

The required flow rate is 200 to 750 mL/min (4.0 to 11.9 gal/hour). Flow rate into the

turbidimeter may be controlled with a flow restriction device on the inlet line. Flow rates

below 200 mL/min will reduce response time and cause inaccurate readings. Flow rates

above 750 mL/min will cause the turbidimeter to overflow, indicating flow rate is too high.

Figure 6 Sample Connections

STATUS

POWER

1

2

3

1. Sample Inlet, ¼-28 NPT x ¼-inch Compression fitting 2. Drain, ½-inch NPT fitting 3. Service Drain

14

Page 19

Section 4 System Startup

4.1 General Operation

Plug the sensor into the unpowered controller by aligning the orientation tab on the cable

connector with the channel in the controller connector. Push in and turn to secure the

connection. Tug gently to check the connection.

After all plumbing and electrical connections have been completed and checked, place the

head on the body and supply power to the system. Ensure the head is seated on the body

when power is applied, since dark readings are measured at this time. If power is applied

while the sensor head is off the turbidimeter body, cycle the power with the sensor head on

the body.

The first time a controller is powered up, a language selection menu will appear. The user

must select the correct language from the displayed options.

Following language selection and upon power-up, the controller will search for connected

sensors. The display will show the main measurement screen.

4.2 Starting Sample Flow

Start sample flow through the instrument by opening the sample supply valve. Allow the

turbidimeter to run long enough for the tubing and body to become completely wetted and

the reading on the display to stabilize. One to two hours or longer may be required initially

for complete stabilization. Allow measurements to become stable through adequate

conditioning before completing instrument settings or performing calibrations.

15

Page 20

System Startup

16

Page 21

Section 5 Operation

5.1 Sensor Setup

When a sensor is initially installed, the serial number of the sensor will be displayed as the

sensor name. To change the sensor name refer to the following instructions:

1. Select Main Menu.

2. From the Main Menu, select SENSOR SETUP and confirm.

3. Highlight the appropriate sensor if more than one sensor is attached and confirm.

4. Select CONFIGURE and confirm.

5. Select EDIT NAME and edit the name. Confirm or cancel to return to the Sensor

Setup menu.

5.2 Sensor Data Logging

The sc100 provides two data logs (one for each sensor) and two event logs (one for each

sensor). The data logs store the measurement data at selected intervals. The event log

stores a variety of events that occur on the devices such as configuration changes,

alarms, and warning conditions. The data logs are stored in a packed binary format and

the event logs are stored in a CSV format. The logs can be downloaded through the digital

network port, service port, or the IrDA port. DataCom is needed for downloading logs to a

computer. If the datalogging frequency is set to 15 minute intervals, the instrument can

continue to store data for approximately six months.

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select CONFIGURE and confirm.

3. Select the datalog interval (30 seconds, 1 minute, 5 minutes, 10 minutes or

15 minutes). Confirm.

5.3 Sensor Diagnostics Menu

SELECT SENSOR

ERROR LIST See section 7.1 on page 29.

WARNING LIST See section 7.2 on page 29.

17

Page 22

Operation

5.4 Sensor Setup Menu

SELECT SENSOR (if more than one sensor is attached)

CALIBRATE

USER PREPD CAL Calibration using 4000 NTU stock solution diluted to 20.00 NTU formazin.

STABLCAL CAL Calibration using 20 NTU StablCal Stabilized Formazin Standard

VERIFICATION Perform a verification, set the pass/fail criteria, and view the verification history.

0 ELECTRONICS Zero electronics

CAL HISTORY

CONFIGURE

BUBBLE REJECT Choose Yes or No to enable/disable bubble reject. Default: Yes

SIGNAL AVG

MEAS UNITS

EDIT NAME

SET RESOLUTION Set the number of significant digits to display. Default is three significant digits.

DATALOG INTRVL

OFFSET Enter an offset between –0.05 to 0.05 NTU. Values outside this range are not accepted.

View the last 12 entered calibrations. Confirm to move to the next history entry. See section 5.6

on page 22 for more information.

Choose no averaging or specify the amount of time for signal averaging. Available options are:

no averaging, 6 sec., 30 sec., 60 sec., or 90 sec. Default is 30 seconds.

Select the appropriate measurement units to display. Choose from mg/L, NTU, TE/F, FTU and

Degree. Default: NTU

Enter up to a 12-digit name in any combination of symbols and alpha or numeric characters.

Confirm when the entry is complete. The name will be displayed on the status line above the

measurement value on the main display.

Choose the amount of time between saving data points to the data log. Default: 15 min.;

Options: 30 sec., 1 minute, 5 minutes, 10 minutes, or 15 minutes.

DIAG/TEST

SOFTWARE VERS. Displays the software version number.

SERIAL NUMBER Displays the serial number of the sensor.

INT TEMP Displays the internal temperature of the sensor electronics in °C.

DEFAULT SETUP Restores the sensor’s factory default settings and invalidates the current calibration.

POWER CHECK Displays the electrical statistics for the sensor.

SERVICE MODE Choose On or Off to enable/disable service mode. Default: Off

SERVICE DIAGS Passcode protected. Menu options only available to service personnel.

5.5 Sensor Calibration and Verification

The manufacturer offers two EPA-approved calibration methods one using user-prepared

formazin and the other using StablCal

(wet and dry) are also offered.

The 1720E Turbidimeter is factory-calibrated using StablCal

shipment. The instrument must be recalibrated before use to meet published

accuracy specifications. In addition, recalibration is recommended after any significant

maintenance or repair and at least once every three months during normal operation. The

turbidimeter body and bubble trap must be thoroughly cleaned and rinsed before

initial use and prior to each calibration.

®

Stabilized Formazin. Two verification methods

Stabilized Formazin before

18

Tips to achieve the most accurate calibrations:

• Optimum performance is achieved when calibration is performed in the turbidimeter

body. Accurately prepare the standard then add it to the turbidimeter body at the

appropriate step in the procedure. Do not prepare the standard in the body.

Page 23

Operation

• Stop sample flow, drain, and clean the turbidimeter body before beginning the

calibration procedure.

• Always clean the photocell window per the instructions in section 6.4.1 on page 26.

Rinse the photocell with deionized water and dry with a soft, lint-free cloth before

calibrating.

• Always clean the turbidimeter body or calibration cylinder per the instructions in

section 6.4.2 on page 26. Rinse with deionized water before calibrating.

• Store the calibration cylinder upside-down to minimize contamination between

calibrations.

• Pour the calibration standard into the turbidimeter body at the inflow end (left side

when facing the instrument).

• Gently invert StablCal standards for 1 minute before opening. Do not shake. This

ensures a consistent turbidity of the standard.

• If the 20.0 NTU StablCal standard is allowed to sit in the calibration cylinder or

turbidimeter body for more than 15 minutes, it must be remixed (gently swirled in the

calibration cylinder) before use to ensure a consistent turbidity.

• Discard all standards after use per the instructions on the container. Never transfer the

standard back into its original container. Contamination will result.

• Always recalibrate after restoring default settings.

5.5.1 User-prepared Calibration

The user-prepared calibration is a two-step calibration in which the difference between the

DI water and the standard value is used to determine the gain of the instrument. The water

used for the standard solution must be from the same source as that which the DI water

measurement is made. Variation in dilution of the water source could negatively impact the

accuracy of the calibration. The manufacturer does not recommend calibrating below

1.0 NTU, and instrument specifications are based on the calibration point at 20 NTU.

Before starting the calibration, read and apply the tips in section 5.5 on page 18.

Follow the procedure as written (using 1 L of deionized water and 5.0 mL of 4000 NTU

formazin) if using a calibration cylinder for calibration.

If using the turbidimeter body for the user-prepared calibration follow the procedure

below using 20.0 NTU formazin in step 12. Follow the steps below for proper

calibration:

1. Stop the sample flow, then drain and clean the body.

2. Prepare a 20.0 NTU standard by adding 5.0 mL of 4000 NTU formazin to a 1-L flask.

Dilute to the mark with deionized water and invert gently to mix.

3. Drain the deionized water and pour the prepared 20.0 NTU standard into the

turbidimeter body at step 12. Do not add additional 4000 NTU formazin.

4. From the Main Menu, select SENSOR SETUP and confirm.

5. Select the appropriate sensor if more than one is connected and confirm.

6. Select CALIBRATE and confirm.

7. Select USER PREPD CAL and confirm.

8. Select the available Output Mode (Active, Hold, or Transfer) from the list and confirm.

19

Page 24

Operation

9. Stop the sample flow. Drain and clean the body and bubble trap. Fill the cylinder with

1 L deionized water. Replace the head and confirm.

Important Note: Carefully pour the DI water in such a way that minimizes any bubble

formation that would result in a false, high reading.

10. The measured reading (based on a gain of 1.0) is displayed. Confirm.

11. Enter the standard turbidity value of the user prepared standard and confirm.

12. Drain the cylinder. Pour the prepared standard into the cylinder and confirm.

13. The measured reading (based on a gain of 1.0) is displayed. Confirm.

14. The display will read GOOD CAL! GAIN: X.XX ENTER TO CONT. Confirm. (If the

calibration was unsuccessful, the display will read BAD CAL! Confirm to redo or exit.)

15. The display will read VERIFY CAL? Confirm to verify or exit without verification.

Note: If a dry verification is performed directly after a calibration, the measured value is assigned as

the expected value for future verifications (when using the dry verification device with the same

serial number). As long as the verification exists within the verification history, the expected value will

be retained. Otherwise, the expected value will be the nominal labeled value associated with the dry

verification device.

16. Select the verification type (begin at step 5 in section 5.5.3.1 on page 21 for dry

verification or section 5.5.3.2 on page 21 for wet verification) or enter initials to

complete calibration.

17. Return the sensor to measure mode and confirm.

5.5.2 Calibration with StablCal

Before starting the calibration, read and apply the tips in section 5.5 on page 18.

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select the appropriate sensor if more than one is connected and confirm.

3. Select CALIBRATE and confirm.

4. Select STABLCAL CAL and confirm. Select the available Output Mode (Active, Hold,

or Transfer) from the list and confirm.

5. Enter the standard turbidity value of the user prepared standard and confirm.

6. Drain/clean/rinse the turbidimeter body or cal cylinder. Pour the 20 NTU standard into

the cylinder body. Replace the head and confirm.

7. The measured reading (based on a gain of 1.0) is displayed. Confirm.

®

20

8. The display will read GOOD CAL! GAIN: X.XX ENTER TO CONT. Confirm. (If the

calibration was unsuccessful, the display will read BAD CAL! Confirm to redo or exit.)

9. The display will read VERIFY CAL? Confirm to verify or exit without verification.

Note: If a dry verification is performed directly after a calibration, the measured value is assigned as

the expected value for future verifications (when using the dry verification device with the same

Page 25

serial number). As long as the verification exists within the verification history, the expected value will

be retained. Otherwise, the expected value will be the nominal value associated with the dry

verification device.

10. Select the VERIFICATION type (begin at step 5 in section 5.5.3.1 on page 21 for dry

verification or section 5.5.3.2 on page 21 for wet verification) or enter initials to

complete calibration.

11. Return the sensor to measure mode and confirm.

5.5.3 Instrument Verification

Instrument verification is intended as a simple check to ensure Turbidimeter functionality

between calibrations. Two types of verifications are offered. The dry verification is

performed using a “dry” calibration device such as the ICEPIC™. A wet verification is

performed using a standard with a predetermined value such as StablCal

Formazin.

A dry verification directly after calibration is used to establish the baseline. Any verification

afterwards, until the next calibration, that uses the same dry verification standard will

reference the recorded value from the baseline verification as the “expected” value. In

order for the verification to pass, the measured value should be within the limits set by the

Pass/Fail Criteria of the baseline value.

Operation

®

Stabilized

5.5.3.1 Dry Verification

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select CALIBRATE and confirm.

3. Select VERIFICATION and confirm.

4. Select PERFORM VER and confirm. Select the available Output Mode (Active, Hold,

5. Select DRY for the verification type and confirm.

6. Select 1 NTU STD or 20 NTU STD or verify SN of previously used calibration device

7. Set the Head to Standard and confirm. Confirm again to accept the reading.

8. The display will read GOOD VER!. Confirm.

9. Enter initials and confirm.

10. Return the sensor to measure mode and confirm.

or Transfer) from the list box and confirm.

and confirm.

5.5.3.2 Wet Verification

Before starting the verification, read and apply the appropriate tips in section 5.6. For wet

verification values at or below 1.0 NTU, only use the cleaned turbidimeter body.

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select CALIBRATE and confirm.

3. Select VERIFICATION and confirm.

21

Page 26

Operation

4. Select PERFORM TEST and confirm. Select the available Output Mode (Active, Hold,

or Transfer) from the list box and confirm.

5. Select WET for the verification type and confirm.

6. Enter the Std Turbidity and confirm.

7. Drain and clean the sensor body and confirm.

8. Pour the standard into cylinder. Replace the head and confirm.

9. The reading will be displayed. Confirm to accept the verification.

10. Return the sensor to measure mode and confirm.

5.6 Calibration and Verification History

The calibration and verification history logs contain information on the last 12 calibrations

and the last 12 verifications. The calibration history log shows the gain value, the time and

date of the calibration, and the initials of the operator performing verification.

Note: Restoring default settings from the DIAG/TEST menu will return the turbidimeter to its non

calibration state (gain = 1.0) but it will not remove the previous calibration history from memory.

The calibration history log is accessed from the Calibrate menu. The verification history

log is accessed from the Verification menu (a submenu of the Calibrate menu).

Each verification history entry shows the serial number of the verification device (dry

verification) or the value of the verification standard (wet verification), the time and date of

the verification, and the initials of the operator performing the verification.

Scroll through the entries by pressing the

histories, the display will return to the calibration menu level.

When the instrument is received from the factory, default values or blank spaces will be

shown for the calibration and verification history information. Those values will be replaced

with real data as the history log is filled.

The data is retained as first in, first out. When the log is full, the newest entry is stored and

the oldest entry in the log is deleted.

5.7 Offset Feature

The offset or clean water offset (CWO) feature will allow a ± 0.05 NTU offset to the

measured value. The offset value denoted as CWO will be subtracted from the value

displayed on the sc Interface. The 0.05 NTU offset can be entered after a calibration is

complete and is based on an independent determination of the water used in the

preparation of the turbidity standards.

ENTER key. After scrolling through all 12

22

Note: The offset is a limited value. An offset outside the range of ± 0.05 mg/L, ± 0.05 NTU,

± 0.05 TE/F, ± 0.05 FTU or ± 0.05 Degree will not be accepted.

For example, if a standard is prepared with a value of 0.8 NTU, the 0.05 NTU offset would

result in a displayed value of 0.75 NTU. See the Setting the Offset section to change the

offset value. When the offset is used, the letters CWO are displayed after the turbidity

value in the upper-right corner.

Page 27

5.7.1 Setting the Offset

Follow the steps below to enter an offset:

Note: The data log for this channel will be erased if the offset is changed to anything other than zero.

1. From the Main Menu select SENSOR SETUP and confirm.

2. Select 1720E and confirm.

3. Select CONFIGURE and confirm.

Note: Offset is not used during calibration. During calibration the offset is zero.

4. Move the pointer to OFFSET and confirm.

5. The display will show an Offset screen. Use the arrow keys to enter the offset. The

value entered must be between –0.05 to 0.05 NTU, values outside this range are

not accepted.

6. Confirm to accept the offset reading.

Operation

23

Page 28

Operation

24

Page 29

Section 6 Maintenance

DANGER

Only qualified personnel should conduct the tasks described in this section of the

manual.

6.1 Maintenance Schedule

Maintenance Task Frequency

Clean the sensor

Calibrate Sensor (as required by regulatory

agency)

Scheduled periodic maintenance requirements of the 1720E are minimal and include

calibration and cleaning of the photocell window, bubble trap, and body. Check and clean

the bubble trap and turbidimeter body (as described in section 6.4.2) if visual inspection

shows that it is necessary. Perform other maintenance on a regular basis; experience will

dictate scheduling and may depend on the installation, sample type, and season.

It is very important to maintain the cleanliness of the interior and exterior of the

turbidimeter body, head assembly, the integral bubble trap, and the surrounding area.

Doing so will ensure accurate, low-level turbidity measurements.

Clean the turbidimeter body before performing any calibration or wet verification

(especially when measurements are being made at 1.0 NTU or lower).

Check and/or perform a calibration periodically (as experience dictates) using one of the

methods described in section 5.5 on page 18. A calibration history menu option is

available under Sensor Setup/Calibrate.

Before each calibration and as needed. Depends on sample

characteristics.

Per agency-dictated schedule.

6.2 Removing a Sensor from the System

Prior to physically removing a sensor from the system, record all user defined settings

such as relays, signal averaging, etc. Disconnect the sensor connector at the controller.

6.3 Reinstalling a Sensor on the System

To return the system to normal operation following a software upgrade or sensor repair

perform the following procedure:

1. Detach all sensors from the sc100 controller.

2. From the main menu, press the down arrow key to highlight TEST/MAINT.

Press ENTER.

3. Use the down arrow key to scroll to SCAN SENSORS and press ENTER.

4. Remove attached sensors by selecting the corresponding serial number or select “All”.

5. Power down the sc100 then attach the 1720E.

Note: Clean sensors before reinstallation on the system.

6. Supply power to the sc100. The system will initialize automatically.

25

Page 30

Maintenance

6.4 Cleaning

6.4.1 Cleaning the Photocell Window

Occasional cleaning of the photocell window is required. The frequency will depend on the

nature and concentration of dissolved and suspended solids in the sample. Biological

activity is a primary factor in mineral scale deposit on the window and the amount differs

with sample temperature. In general, more growth will occur in warm temperatures and

less in cold.

Note: Do not disassemble the photocell assembly. It contains liquid.

Note: Take care to not scratch the photocell window.

Inspect the photocell window often to determine cleaning needs. Remove any organic

growth or film on the photocell window before standardization or calibration. Use a cotton

swab and isopropyl alcohol or a mild detergent (such as Liqui-nox

sediment and dirt. Mineral scale buildup may require cleaning with a mild acid applied with

a cotton swab followed by a detergent wash. Do not use abrasive cleaners.

6.4.2 Cleaning the Turbidimeter Body and Bubble Trap

®

) to remove most

Sediment may collect in the turbidimeter body after extended use. Noise (fluctuation) in

the reading could indicate the need to clean the body and/or bubble trap. The 1720E

bubble trap and bottom plate may be removed to make cleaning easier. Drain and clean

the turbidimeter body before each calibration. Establish a regular schedule or perform

cleaning as determined by visual inspection.

Cleaning the Turbidimeter Body

Note: The turbidimeter body, bubble trap, and detector must be cleaned before each calibration.

1. Turn off sample flow to the turbidimeter body.

2. Remove the head assembly and bubble trap cover from the body. Remove the bubble

trap by lifting it vertically. Set it aside to be cleaned separately.

3. Drain the body by removing the plug from the bottom of the body.

4. Replace the drain plug and fill the body to the weir with cleaning solution. This

cleaning solution can consist of dilute chlorine solution (25 mL of household bleach in

3.78 liters of water) or a laboratory detergent such as Liqui-nox (1 mL detergent in

1 liter of water).

5. Use a soft brush to clean the inside surfaces of the body.

6. Remove the drain plug again and thoroughly flush the turbidimeter body with

ultra-filtered deionized water. Clean and replace the plug.

26

Cleaning the Bubble Trap

1. Prepare a cleaning solution (as in step 4 above) in a container large enough to

submerge the entire bubble trap.

2. Using a test tube brush such as Cat. No. 690-00, clean each surface.

3. Rinse the bubble trap thoroughly with ultra-filtered deionized water and reinstall it in

the turbidimeter body.

Page 31

Maintenance

4. Replace the bubble trap cover and head assembly on the top of the body.

5. Restore sample flow to the instrument.

6. Calibrate the instrument using one of the methods in section 5.5 on page 18.

If the above cleaning procedures have been performed and the turbidimeter readings are

still noisy, the bottom plate and gasket may need to be removed and cleaned. Carefully

perform the following procedure to ensure the turbidimeter body integrity is maintained.

1. Turn off sample flow to the turbidimeter body.

2. Remove the head assembly, bubble trap cover, and bubble trap (by lifting it vertically)

from the body.

3. Drain the body by removing the plug from the bottom of the body.

4. Lift the body off of its mounting screws.

5. With the body turned upside-down, remove the two Phillips-head screws holding the

bottom plate.

6. Lift the bottom plate off the body; set the gasket aside for use in reassembly.

7. Use a soft brush and a dilute cleaning solution (as prepared above) to clean the

bottom plate and inside surfaces of the turbidimeter body. Rinse the entire body and

bottom plate with ultra-filtered deionized water.

8. Reassemble by inserting the gasket into the molded channel in the bottom plate.

9. Fit the bottom plate onto the turbidimeter body.

10. Reinstall both screws and carefully tighten to 15 inch-lb maximum.

11. Reinstall the turbidimeter onto the wall mounting screws.

12. Replace the bubble trap, bubble trap cover, and head assembly on the top of the body.

13. Restore sample flow to the instrument.

6.4.3 Replacing the Lamp Assembly

The Lamp Assembly is located on the head assembly. Under normal use, Hach

recommends replacing the lamp once a year to maintain peak performance. Replacement

bulbs have been “burned-in” at the factory and are ready for installation and use.

To change the lamp, refer to Figure 7 on page 28 and perform the following steps:

1. Disconnect power to the controller to remove all power to the turbidimeter.

2. Disconnect the lamp leads by unplugging the connector.

27

Page 32

Maintenance

3. After the bulb has cooled, remove as follows:

a. Wear cotton gloves to protect your hands and to avoid fingerprints on the bulb.

b. Grasp the bulb.

c. Twist the bulb in a counterclockwise direction, pulling out slightly, until it is

released from the housing.

d. Pull the lamp leads and connector through the hole in the lamp housing.

Do not touch the new bulb with bare hands. Etched glass and reduced lamp life will result.

Wear cotton gloves or grasp the lamp assembly with a tissue to avoid contamination. If

contamination occurs, clean the glass bulb portion with isopropyl alcohol.

Replace the bulb by reversing the above instructions. The bulb base only fits one way;

align the notch in the metal bulb flange with the hole in the lamp holder.

Figure 7 Lamp Replacement

1

1. Lamp Housing 2. Lamp Assembly 3. Photo Detector

2

3

28

Page 33

Section 7 Troubleshooting

7.1 Error Codes

When a sensor is experiencing an error condition, the sensor reading on the

measurement screen will flash and all relays and analog outputs associated with the

sensor will be held.

7.2 Warnings

Highlight the Probe Diag menu and press

ENTER. Highlight Errors and press ENTER to

determine the case of the error. Errors are defined in Table 3.

Table 3 Error Codes

Displayed Error Definition

A/D Fail Failed A/D converter. Call the Service Department.

Lamp Fail

Flash Fail Datalog and event log will not work.

The light source has failed. See section 6.4.3 on page 27 for instructions for

replacing it.

A sensor warning will leave all menus, relays, and outputs functioning normally, but will

cause a warning icon to flash on the right side of the display. Highlight the Probe Diag

menu and press

ENTER to determine the cause of the error. Warnings are defined in

Table 4.

A warning may be used to trigger a relay and users with the sc100 controller can set

warning levels to define the severity of the warning (see the sc100 controller user manual

for more information about warning levels). Errors are defined in Table 4.

Table 4 Warning Codes

Warning

Number

1 Dark Reading Warning Dark reading detects too much light. (> 0.05 NTU)

2 Temp Warning

3 Data Log Full

4 Event Log Full

5 5 Volt Warn Monitored voltage is outside the range of 4.5–5.5 V.

6 Inp V Warn Monitored voltage is outside the range of 9.08–14.13 V.

7 Lamp Volt Warn Monitored voltage is outside the range of 3.96–4.48 V.

8 Lamp Curr Warn Monitored current is outside the range of 1.67–2.75 Amps.

9 Output Mode Warn

Displayed Warning Definition/Resolution

Sensor head internal temperature is higher than specified. Contact the Service

Department. (> 70 °C)

Sensor data log is full. No additional data will be logged until sensor log is

downloaded into controller memory.

Sensor data log is full. No additional data will be logged until sensor log is

downloaded into controller memory.

Activated when the sensor is not in normal measurement mode (such as when

in calibration or verification mode).

29

Page 34

Troubleshooting

Table 5 presents sensor warnings displayed in the Event Log, possible causes, and

corrective actions.

Table 5 General Troubleshooting

Sensor Warning Possible Cause Corrective Action

Lamp burned out Replace the lamp. See section 6.4.3 on page 27.

Lamp unplugged Restore connection

Bad Lamp

Low Signal

Bad System Voltage

A/D Converter Timeout

High Dark Counts

+12 V connection loose at controller Restore connection

Dislodged lamp Reinstall lamp

Bad circuit board in turbidimeter head Contact the Customer Service Department.

Photocell coated/dirty

Photocell wires disconnected Reconnect wires

Photocell broken/cracked

Lens coated/dirty Clean the lens using isopropyl alcohol and a cotton swab.

Obstructed light path Remove obstruction

See Bad Lamp causes above See Bad Lamp corrective actions above

Improper wiring at controller Refer to section 3.1 on page 9.

Turbidimeter head cable shortened to

improper length

Fluctuation in voltage Turn instrument power off and back on.

Bad circuit board in turbidimeter head Contact the Service Department

Fluctuation in voltage Turn instrument power off and back on.

Bad circuit board in turbidimeter head Contact the Customer Service Department.

Light Leak—Turbidimeter head not on

turbidimeter body or calibration

cylinder during Power Up or Zero

Electronics

Light Leak—Turbidimeter head not

properly aligned on the turbidimeter

body or calibration cylinder during

Power Up or

Zero Electronics

Photocell broken/cracked Contact the Customer Service Department.

See section 6.4.1 on page 26.

Contact the Customer Service Department.

Replace photocell

Contact the Customer Service Department.

Contact the Customer Service Department.

Make sure the turbidimeter head is on the turbidimeter

body and properly aligned and repower instrument or

perform ZERO ELECTRONICS in the CALIBRATION

MENU.

Make sure the turbidimeter head is properly aligned and

repower instrument or perform ZERO ELECTRONICS in

the CALIBRATION MENU.

Table 6 presents additional malfunctions which may not be recorded in the Event Log.

Table 6 Additional Malfunctions Not Recorded in the Event Log

Symptom Possible Cause Corrective Action

Continuous Underrange The calibration standard was either

improperly prepared or was unstable at

the time the calibration was accepted.

Continuous Overrange

(100 NTU)

Erratic Readings Inadequate bubble removal from sample Verify the accuracy of calibration standards and

The calibration standard was either

improperly prepared or was unstable at

the time the calibration was accepted.

Verify the accuracy of calibration standards and

recalibrate the instrument. See Low Signal in Table 5.

Verify the accuracy of calibration standards and

recalibrate the instrument.

recalibrate the instrument.

Increase the signal averaging time to a longer interval.

Make sure the Bubble Reject feature is turned on.

Slow the flow of sample into the instrument.

30

Page 35

Troubleshooting

Table 6 Additional Malfunctions Not Recorded in the Event Log (continued)

Symptom Possible Cause Corrective Action

High Readings Deionized water turbidity is greater than

0.5 NTU

Clean the instrument.

Access Calibration History for turbidity value of

ultra-filtered water.

Verify the flow is between 200–750 mL/min.

Recalibrate the instrument.

7.3 Event Codes

Event codes are not displayed on controller and must be downloaded from the event log to

be viewed. Troubleshooting actions are provided in Table 5 on page 30.

Table 7 Event Log List

Event Event # Data1 Data2 Data3

Bubble Reject Change 0

Filter Size Change 1

Data Log Interval Change 2

Power On 3 1 — —

Calibration 4 Cal Gain Initials —

Verification 5 Expected Value Meas Value Initials

Dark Reading Warning 6 Measured Value — —

Temperature Warning 7 Temperature Value — —

Voltage Warning 8

Lamp Warning 9

A/D Fail 10 1 — —

Lamp Fail 11 2 — —

Flash Fail 12 4 — —

Output Mode Change 13

0 = OFF

1= ON

0 = No avg, 1 = 6 sec

2 = 30 sec, 3 = 60 sec

4 = 90 sec

0 = 30 sec, 1 = 1min

2 = 5 min, 3 = 10 min

4 = 15 min

16 = +5V high

32 = +5V low

64 = V in high

128 = V in low

1 = lamp V high

2 = lamp V low

4 = lamp I high

8 = lamp I low

0 = Active, 1 = Hold

2 = Transfer, 4 = Normal

——

——

——

——

——

——

31

Page 36

Troubleshooting

32

Page 37

Section 8 Replacement Parts and Accessories

8.1 Replacement Items

Description QTY Catalog Number

Lamp Assembly each 18950-00

Instruction Manual, 1720E Turbidimeter System, English each 60100-18

8.2 Optional Accessories

Description QTY Catalog Number

Cable, sensor extension, 7.7 m (25 ft) each 57960-00

Cap, Connector Receptacle each 52100-00

Deionized (demineralized) water 1 L 272-56

Drain plug for the 1720E body each 44116-00

Filter, 0.45 µm, to produce ultra-filtered water for cleaning and calibration each 26705-00

Filter, 0.2 µm, to produce ultra-filtered water for calibration standard preparation each 23238-10

Formazin Calibration Kit includes: Calibration Cylinder, TenSette® Pipet, 4000 NTU

Formazin Primary Standard (500 mL)

Floor Stand each 57432-00

Flow meter, 500–700 mL/min each 40282-00

ICE-PIC Module for Calibration and Calibration Verification, 20 NTU each 52250-00

ICE-PIC Module for Calibration and Calibration Verification, 1 NTU each 52215-00

Lid, Bubble Trap, 1720E each 52012-00

LonWorks Card each 59200-02

Photocell Replacement Kit for the 1720E each 52180-00

Pipet tips for 19700-01 TenSette Pipet 50/pkg 21856-96

Pipet tips for 19700-10 TenSette Pipet 50/pkg 21997-96

StablCal Calibration Set for the 1720 Series Turbidimeter

Includes: StablCal Standards, < 0.1 NTU, 20.0 NTU 1 L/each 26596-00

StablCal Standard, 0.1 NTU 1 L 27233-53

StablCal Standard, 0.3 NTU 1 L 26979-53

StablCal Standard, 0.5 NTU 1 L 26980-53

StablCal Standard, 1.0 NTU 1 L 26598-53

Strain relief, Heyco each 16664

Swabs, Cotton, presterilized for cleaning the photodetector 100/pkg 25543-00

TenSette Pipet, 0.1 to 1.0 mL each 19700-01

TenSette Pipet, 1.0 to 10.0 mL each 19700-10

Tubing, Inlet, ¼-inch OD, Polyethylene per foot 51322-00

Tubing, Outlet, ½-inch ID, ¾ inch OD, Tygon R3603 per foot 51263-00

each 44156-00

33

Page 38

Replacement Parts and Accessories

8.3 Calibration and Verification Standards and Accessories

Description QTY Catalog Number

Calibration Cylinder each 44153-00

Formazin Calibration Standards, Formazin, 4000 NTU Stock Solution 500 mL 2461-49

Calibration/Verification Modules

ICE-PIC™ Module, 1 NTU 1 each 52215-00

ICE-PIC™ Module, 20 NTU 1 each 52250-00

®

StablCal

Calibration Standards

StablCal® Stabilized Formazin Standard, 1 NTU 1 L 26598-53

®

StablCal

StablCal® Stabilized Formazin Standard, <0.1 NTU 1 L 26597-53

StablCal

<0.1 NTU

StablCal® Stabilized Formazin Standard, 40 NTU 1 gallon (3.78 L) 27463-56

StablCal

Stabilized Formazin Standard, 20 NTU 1 L 26601-53

®

Stabilized Formazin Set, four 1-L bottles 20-NTU and four 1-L bottles

®

Stabilized Formazin Standard, 0.1 NTU 1 gallon (3.78 L) 27233-56

1 L each 26596-00

34

Page 39

Section 9 Contact

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-0

Fax +49 (0)2 11 52 88-143

info@hach-lange.de

www.hach-lange.com

DR. BRUNO LANGE GES. MBH

Industriestraße 12

A-3200 Obergrafendorf

Tel. +43 (0)27 47 74 12

Fax +43 (0)27 47 42 18

info@hach-lange.at

www.hach-lange.at

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

DR. BRUNO LANGE AG

Juchstrasse 1

CH-8604 Hegnau

Tel. +41(0)44 9 45 66 10

Fax +41(0)44 9 45 66 76

info@hach-lange.ch

www.hach-lange.ch

DR. LANGE NEDERLAND B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE FRANCE S.A.S.

33, Rue du Ballon

F-93165 Noisy Le Grand

Tél. +33 (0)1 48 15 68 70

Fax +33 (0)1 48 15 80 00

info@hach-lange.fr

www.hach-lange.fr

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava – Vajnory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wrocław

Tel. +48 (0)71 342 10-83

Fax +48 (0)71 342 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE KFT.

Hegyalja u. 7-13.

H-1016 Budapest

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE S.R.L.

str. Aviator Teodor Iliescu nr.37,

Sector 1

RO-011672, Bucuresti

Tel. +40 (0)21 2 08 95 78

Fax +40 (0)21 2 08 95 78

info@hach-lange.ro

www.hach-lange.ro

35

Page 40

Contact

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 04 47

info@hach-lange.bg

www.hach-lange.bg

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE SU

ANALİZ SİSTEMLERİ LTD. ŞTİ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

36

Page 41

Section 10 Warranty and liability

The manufacturer warrants that the product supplied is free of

material and manufacturing defects and undertakes the obligation

to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service

contract is taken out within 6 months of purchase, the warranty

period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for

defects including the lack of assured properties as follows: all those

parts that, within the warranty period calculated from the day of the

transfer of risk, can be demonstrated to have become unusable or

that can only be used with significant limitations due to a situation

present prior to the transfer of risk, in particular due to incorrect

design, poor materials or inadequate finish will be improved or

replaced, at the supplier's discretion. The identification of such

defects must be notified to the supplier in writing without delay,

however at the latest 7 days after the identification of the fault. If the

customer fails to notify the supplier, the product is considered

approved despite the defect. Further liability for any direct or

indirect damages is not accepted.

If instrument-specific maintenance and servicing work defined by

the supplier is to be performed within the warranty period by the

customer (maintenance) or by the supplier (servicing) and these

requirements are not met, claims for damages due to the failure to

comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages

cannot be made.

Consumables and damage caused by improper handling, poor

installation or incorrect use are excluded from this clause.

The manufacturer process instruments are of proven reliability in

many applications and are therefore often used in automatic control

loops to provide the most economical possible operation of the

related process.

To avoid or limit consequential damage, it is therefore

recommended to design the control loop such that a malfunction in

an instrument results in an automatic change over to the backup

control system; this is the safest operating state for the environment

and the process.

37

Page 42

Warranty and liability

38

Page 43

Section 11 Compliance Information

Hach Co. certifies this instrument was tested thoroughly, inspected and found to meet its

published specifications when it was shipped from the factory.

The Model sc100/sc1000 with 1720E Sensor has been tested and is certified as

indicated to the following instrumentation standards:

Product Safety

UL 61010A-1 (ETL Listing # 65454)

CSA C22.2 No. 1010.1 (ETLc Certification # 65454)

Certified by Hach Co. to EN 61010-1 Amds. 1 & 2 (IEC1010-1) per 73/23/EEC,

supporting test records by Intertek Testing Services.

Immunity

This equipment was tested for Industrial level EMC per:

EN 61326 (EMC Requirements for Electrical Equipment for Measurement, Control and

Laboratory Use)

certified compliance by Hach Company.

per 89/336/EEC EMC: Supporting test records by Hach Company,

Emissions

Standards include:

IEC 1000-4-2:1995 (EN 61000-4-2:1995) Electro-Static Discharge Immunity (Criteria

B)

IEC 1000-4-3:1995 (EN 61000-4-3:1996) Radiated RF Electro-Magnetic Field

Immunity (Criteria A)

IEC 1000-4-4:1995 (EN 61000-4-4:1995) Electrical Fast Transients/Burst (Criteria B)

IEC 1000-4-5:1995 (EN 61000-4-5:1995) Surge (Criteria B)

IEC 1000-4-6:1996 (EN 61000-4-6:1996) Conducted Disturbances Induced by RF

Fields (Criteria A)

IEC 1000-4-11:1994 (EN 61000-4-11:1994) Voltage Dip/Short Interruptions (Criteria

B)

Additional immunity Standard/s include:

ENV 50204:1996 Radiated Electro-Magnetic Field from Digital Telephones (Criteria A)

This equipment was tested for Radio Frequency Emissions as follows:

Per 89/336/EEC EMC: EN 61326:1998 (Electrical Equipment for measurement, control

and laboratory use—EMC requirements) Class “A” emission limits. Supporting test

records by Hewlett Packard, Fort Collins, Colorado Hardware Test Center (A2LA #

0905-01) and certified compliance by Hach Company.

Standards include:

EN 61000-3-2 Harmonic Disturbances Caused by Electrical Equipment

EN 61000-3-3 Voltage Fluctuation (Flicker) Disturbances Caused by

Electrical Equipment

Additional Emissions Standard/s include:

EN 55011 (CISPR 11) Class “A” emission limits

39

Page 44

Compliance Information

Canadian Interference-causing Equipment Regulation, IECS-003, Class A

Supporting test records by Hewlett Packard, Fort Collins, Colorado Hardware Test Center

(A2LA # 0905-01) and certified compliance by Hach Company.

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet appareil numÈrique de la classe A respecte toutes les exigences du RËglement sur le

matÈriel brouilleur du Canada.

FCC PART 15, Class “A” Limits

Supporting test records by Hewlett Packard, Fort Collins, Colorado Hardware Test Center

(A2LA # 0905-01) and certified compliance by Hach Company.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at his own expense. The following techniques of

reducing the interference problems are applied easily.

1. Disconnect the Controller from its power source to verify that it is or is not the source

of the interference.

2. If the Controller is connected into the same outlet as the device with which it is

interfering, try another outlet.

3. Move the Controller and 1720E sensor away from the device receiving the

interference.

4. Reposition the device receiving the interference.

5. Try combinations of the above.

40

Page 45

Appendix A Modbus Register Information

Table 8 Sensor Modbus Registers

Group Name Tag Name

Measurements Cal Gain 40013 float 2 R none 0.5 to 2.0

Verification PF Criteria 40062 Integer 1 R/W % 5 to 10